By Brenda Ruggiero CEG CORRESPONDENT

Fay, a subsidiary of S&B USA Construction, is currently acting as a subcontractor to Bridging Pennsylvania Constructors (BPC), a joint venture between S&B USA Construction and FCC

Construction on the I-80 North Fork bridges project in Brookville, Pa.

This project is a part of the PennDOT Major Bridge P3 (MBP3), a mega project with a total construction value of $1.5 billion. It involves the financing, design, construction and future maintenance of a total of 23 structures and 21.27 mi.

of roadway across six critical major highway locations in Pennsylvania. BPC is the general contractor for the entirety of this project. Fay reported that the I-80 North Fork bridges, built in 1962, were selected for the MBP3 due to the importance of the bridges in Pennsylvania’s

see BRIDGES page 90

By Lucy Perry CEG CORRESPONDENT

Data-driven decisions are key to the success of any contractor’s business. When it comes to heavy transport, the metrics you value indicate more than just a successful delivery. Analyzing the right data can help you fine-tune your operations for efficient transport management. Deciding which key performance indicators (KPI) to focus on can be tricky, but it comes down to how you want to run your transport business.

“The global trucking industry runs on fuel, but see TELEMATICS page 94

Outback Parts is linked nationwide with three used parts networks, so finding dependable parts fast and conveniently is never a

Outback Parts also supplies replacement parts for Non-Cat® machines. So when you’re needing parts, call or visit us on-line.

Although construction will not begin until 2027 on Northern Virginia’s $937 million Richmond Highway Bus Rapid Transit (BRT) mega project, the effort is already making significant progress, Fairfax County officials said.

Each year, Eagle Power & Equipment always makes its “Case” for a great holiday light display at its Montgomeryville, Pa., headquarters. This year, the equipment dealer went with a charming campfire theme.

Caterpillar Inc. launched its third Global Operator Challenge, inviting thousands of machine operators worldwide to put their agility, resilience and versatility to the test on a wide range of construction equipment and technology.

Traffic signals at two intersections on U.S. Highway 119 in southwest Pennsylvania are slated to be removed as state transportation officials hope to improve safety on a section of the highway just south of Westmoreland County.

On Nov. 20, Hitachi Construction Machinery Co. Ltd. and Hitachi Construction Machinery Americas Inc. hosted the inaugural Hitachi Construction Machinery Challenge 2024 pitch event at the Americas regional headquarters.

In addition to celebrating Merit Award winners from each category, DBIA revealed the recipients of this year’s Excellence Awards, several Best-In honors and the coveted Project of the Year.

SISO Air, a Smyrna, Ga.-based national dealer for commercial drones, recently conducted a comprehensive drone and technology demo at the SSG Anthony Davis Memorial Model Airfield in Savannah, Ga.

Founder Emeritus

109 ABC NAMES PUGH AS 2025 NATIONAL CHAIR, EXECUTIVE COMMITTEE

Associated Builders and Contractors announced that David Pugh was elected 2025 chair of ABC National Board of Directors during its meeting at the association’s annual Leadership Institute in Scottsdale, Ariz.

110

Equipment Corporation of America (ECA) announced three strategic promotions that reflect its continued commitment to excellence in the foundation and construction industry.

Would-be buyers bid on more than 500 items including crawler cranes, construction and paving equipment, asphalt equipment, equipment trailers and crash, cone, bucket and pickup trucks.

• Western Pennsylvania

Cell 260/760-0521 e-mail nspain@cegltd.com

Teddy McKeon

• Delaware • Maryland 215/885-2900

Cell 215-260-8709 e-mail tmckeonjr@cegltd.com

BACKHOES:

2019 NEW HOLLAND B110SPC, 747 HRS, CAB HVAC, QUICK TACH FRONT BKT, EXTENDAHOE, FRONT HYDRAULICS..$88,995

2008 NEW HOLLAND B95B, 5805 HRS, CAB, HVAC, 4WD, EXTENDAHOE, TOOL CARRIER....................................................$32,995

2021 NEW HOLLAND B95C TLB, 139 HRS, CAB, HVAC, 4 IN 1, EXT HOE..........................................................................$107,995

CHIPPERS:

2013 BANDIT 1390XP CHIPPER, 15” CAPACITY, 142 HP PERKINS DIESEL ENGINE, 2511 HRS, AUTOFEED, WINCH..............$29,995

2017 BANDIT 250XP 12” CHIPPER, CAT 120HP DIESEL ENGINE, 2305 HRS, AUTO FEED, WINCH........................................$41,995

2017 BANDIT 2550XP STUMP GRINDER W/TRAILER, 1123 HRS.. $29,995

2022 BANDIT 250XP CHIPPER, 400 HRS, WINCH, 12" CAPACITY, CAT 120 HP........................................................................$64,995

WHEEL LOADERS:

2002 DAEWOO MEGA200V, 2YD 4IN1 BKT, 2283 HRS, HYD COUPLER..................................................................................$39,995

2000 NEW HOLLAND LW80, CAB W/HEAT, 10,000 HRS, COUPLER BKT AND FORKS, PERKINS DIESEL ENGINE, WAS NURSERY MACHINE............................................................................$24,995

EXCAVATORS:

2017 HITACHI ZX135-6, 3900 HRS, HYD THUMB, FRONT BLADE, COUPLER, PATTERN CHANGER......................................$105,000

2019 KOBELCO SK75SR, 2447 HRS, RUBBER TRACKS....$69,995

2021 KOBELCO SK75, 793 HRS, CAB, HVAC......................$89,995

2012 KUBOTA KX080-3, 2480 HRS, CAB, HVAC, 36" & 24" BUCKETS, COMES WITH HYDRAULIC BREAKER........................$78,000

2016 KUBOTA KX057, 1393 HRS, HYD THUMB, CAB, HVAC..........

$54,995

2005 KUBOTA KX080-3, 5246 HRS, THUMB, CAB, HVAC..$29,995

MINI EXCAVATORS:

2003 KUBOTA KX91-3, 3896 HRS (200 HRS ON NEW ENGINE), CAB/HEAT, MECHANICAL THUMB, PLUMBED RUBBER TRACKS $26,000

SCREENERS:

2021 VIBROSCREEN SCM40

$79,995

2021 VIBROSCREEN SCM27 $62,995

NEW VIBROSCREEN SCM75C BOX SCREEN W/CONVEYOR, TIER

3 ENGINE..........................................................................

$195,000

NEW VIBROSCREEN SCM115T TROMMEL, NO DPF, NO DEF........

$179,995

SKID STEER LOADERS:

2021 KUBOTA SVL97-2 TRACK SKID STEER, CAB, HVAC, 905 HRS, STD FLOW HYD, HYD COUPLER, 78” BKT, BACKUP CAMERA....................................................................................$78,995

2017 NEW HOLLAND L228, 560 HRS, CAB HVAC, PILOT CONTROLS, HIGH FLOW, 2 SPEED RADIO..............................$36,995

2012 KUBOTA SVL90-2 TRACK SKID STEER, 1446 HRS, CAB HVAC, HIGH FLOW, LEXAN DOOR, COMES W/BKT, FORKS & AFE ROTARY FORESTRY HEAD................................................$78,995

KUBOTA KX080 EXCAVATOR TO SKID STEER COUPLER ADAPTOR $3,199

2011 M-B MULTI-SERVICE VEHICLE, 595 HRS, 110HP CUMMINS, AIR RIDE SEAT, HEAT & AC, SNOWBLOWER W/CHUTE EXTENSION, V-PLOW, ALL BOOKS & MANUALS........................

Although construction will not begin until 2027 on Northern Virginia’s $937 million Richmond Highway Bus Rapid Transit (BRT) mega project, the effort is already making significant progress, Fairfax County officials said.

The county’s Department of Transportation (FCDOT) received approval earlier this summer from the Federal Transit Administration (FTA) to commence the project’s engineering phase, marking a major design milestone that will lead directly to final design and construction.

The 7.4-mi. BRT system, named “The One,” is intended to revitalize the Richmond Highway/U.S. Highway 1 corridor with a dedicated bus lane and mixed traffic.

Nine new transit station areas between the Huntington Metro station near Alexandria and the Fort Belvoir Military Reservation to the southwest also are included within the BRT project, along with pedestrian and bicycle facilities, and safety enhancements.

FCDOT’s aim is to improve transit frequency and reliability, as well as reduce traffic congestion and support economic growth in the southeastern portion of the county near the Potomac River.

The existing transit service in the corridor does not meet the needs of current or future residents, according to FCDOT, with challenges such as long travel times, infrequent service, and delays during rush hour. The new BRT system is expected to improve transit frequency, reliability, comfort and attractiveness.

“This milestone approval propels us towards a transformative era in Fairfax County’s transportation landscape,” said Jeffrey McKay, chair of the Fairfax County board of supervisors. “The Richmond Highway BRT project is not just about enhancing transit; it’s about fostering economic growth, improving the quality of life for our residents; and building a sustainable future. As we move into the engineering phase, we reaffirm our dedication to creating a modern, efficient, and reliable transit system that meets the evolving needs of our vibrant community.”

If all goes well with the construction, FCDOT plans to have the BRT fully operational by 2031.

The FTA approval aligns with Embark Richmond Highway, a Fairfax County project designed to improve the Richmond Highway area with better transportation options and economic growth. The county is working with the Virginia Department of Transportation (VDOT) to widen the highway to include more lanes and facilities for pedestrians and cyclists.

Endorsed by the county board of supervisors in 2015, the new BRT system was always seen as a key part of the plan. The improvements will support federal investments, including upgrades to Fort Belvoir.

Now, engineers working on the BRT mega project can begin detailed planning and design, FCDOT noted, as well as secure additional funding and prepare for its construction.

Additionally, each of Fairfax County’s HRT transit stations will support compact, medium-density, mixed-use and pedestrian-oriented redevelopment efforts, also known as transit-oriented development (TOD), according to Holland & Knight, a law practice that has land-use teams focused on the Richmond Highway corridor.

The firm noted that the new urban nodes are designed to catalyze smart growth and economic development along Richmond Highway, transforming the auto-dominated high-

way into distinct new districts that are transit-oriented, pedestrian-friendly, and mixed-use. Additionally, the BRT will pave the way for a proposed future Metro extension from Huntington Station to Hybla Valley.

Given the nearly $1 billion future investment, the benefits of being designated as a commercial revitalization district, along with the current cost of land, makes the Richmond Highway corridor a prime area for redevelopment.

And, with the corridor already serving as a connection between Fort Belvoir, Fairfax County’s largest employer,

and Amazon HQ2/Washington, D.C., both the highway and the new transit infrastructure are likely to further bolster additional improvements to the area.

During his time working for Fairfax County, Holland & Knight’s Washington D.C. and Northern Virginia Land Use Planner Anthony DeLorenzo served as the lead urban designer for the HRT project, where he oversaw the development of urban concepts that transformed current land use and transportation conditions into distinct multimodal transit-oriented districts.

fairfaxcounty.gov

ROKBAK MODEL RA30 OFF ROAD TRUCK: 30 TON CAPACITY WITH TAIL GATE, 276HP SCANIA ENGINE. AVAILABLE FOR SALE OR RENT! +N5027........................................................................ OFF RENT - CALL FOR SPECIAL YEAR-END DEAL!

NEW ASV RS75 WHEEL SKID STEER: OPEN ROPS, SUSPENSION SEAT, 74" BUCKET, 21.3 GPM, ELECTRIC PLUG ON BOOM FOR ATTACHMENTS, MAX CAB, UNIT# N4200......CALL FOR PRICE

ANACONDA DF410 SCALPING SCREEN: 2 DECK TRACKED SCREENING PLANT WITH LOW HOURS, UNIT# AG1381........................................................................................CALL FOR PRICE

ANACONDA TR75 TRACKED CONVEYOR: 42” X 75’ CONVEYOR, IT ALLOWS FOR STOCKPILING OR FEEDING OF A RANGE OF APPLICATIONS. THE TR75 HAS A VARIABLE SPEED CONVEYOR IN ORDER TO FACILITATE FOR DIFFERENT APPLICATIONS SUCH AS SAND, GRAVEL, AGGREGATES, COMPOST, COAL AND WOOD CHIP. WE STOCK A FULL RANGE OF SPARE PARTS AS A DISPLAY OF OUR COMMITMENT TO PROVIDE A DEDICATED AND RESPONSIVE SERVICE TO ALL OUR CUSTOMERS, 12 CONVEYORS IN STOCK! CALL FOR PRICE

ANACONDA FTR150 UNIT AG1353: MID SIZE FEED LOADER RANGE. FULLY EQUIPPED WITH 50' STOCKPILING CONVEYORALLOWS DFOR STOCKPILING OR FEEDINGA WIDE RANGE OF APPLICATIONS. INCLUDES OPTIONAL 2 DECK VIBRATING GRID..................................$187,000

ASV MODEL RT50, ENCLOSED CAB WITH HEAT & AC, 15” RUBBER TRACKS, VERY LOW GROUND PRESSURE, AUXILIARY HYDRAULICS................................................CALL FOR PRICE

ASV MODEL RT50: ALL WEATHER CAB WITH HEAT AND AC, SUSPENSION SEAT, 15” RUBBER TRACKS, 60” BUCKET WITH BOLT ON EDGE, UNIVERSAL SKID STEER COUPLER, YANMAR TURBO DIESEL ENGINE, BLOCK HEATER, ATTACHMENT CONTROL KIT, REAR VIEW CAMERA, APPROXIMATELY 168 HRS, UNIT# 4310............................................................CALL FOR PRICE

SIMEX PLC-24 24" WIDE COLD PLANER WITH REVERSIBLE DISCHARGE CONVEYOR: CUTTS UP TO 7" DEEP, 16 DEGREE TILT, 27-40GPM DISSCHARGE CONVEYOR HELPS LEAVE A CLEANER CUT, WINDROWS MATERIAL BEYOND THE CARRIER FOR EASIER CLEAN UP, UNIT# AT4540......

$25,400

2020 BOBCAT T740: WITH CAB, HEAT & AIR EXCELLENT CONDITION, 1600 HOURS, HYDRAULIC COUPLER, 2 SPEED......................................................................................

$45,500

KOBELCO SK350LC-11, APPPROXIMATELY 2400 HOURS, 31.5” TRACK SHOES, 10’10” ARM, 2 WAY AUXILLIARY HYDRAULICS, HAND CONTROL PATTERN CHANGER, HEATED AIR RIDE SEAT, VERY GOOD CONDITION........................................................................................

$188,000

AG1359, ANACONDA J12 JAW CRUSHER: IS AN AGGRESSIVE & POWERFUL MOBILE JAW CRUSHER. WITH THE PROVEN ABILITY OF THE UNIVERSAL CRUSHERS JAW CHAMBER 28" X 44" WITHIN AN INNOVATIVE ANACONDA TRACKED SOLUTION......................................

X 33’ FINE MATERIALS WASHER: IN STOCK & READY FOR IMMEDIATE DELIVERY, UNIT# AG1402....................................................................$94,500

$569,500

BOMAG BW120SL-5: FOLDING ROPS, 47.2” WIDE DRUMS, 5511LBS. OPERATING WEIGHT, KUBOTA 24.8HP DIESEL, FRONT & REAR VIBRATORY, 4320 VPM, .020 IN AMPLITUDE, UNIT# N4538..$47,900

BOMAG BW120AD-5: FOLDING ROPS, 47.2” WIDE DRUMS, 6063LBS. OPERATING WEIGHT, KUBOTA 33HP DIESEL, FRONT & REAR VIBRATORY, 3780 VPM, .020 IN AMPLITUDE, UNIT# N4537....................................$51,900

SCHIBECI MODEL ST1000 COLD PLANER/SOIL MIXER: 40” MILLING WIDTH, 9” MILLING & MIXING DEPTH. REQUIRES HIGH FLOW MINIMUM 33GPM. THREE LINE SYSTEM W/REMOTE. HYD. SIDE SHIFT & TILT, STABILIZATION FLUID/BINDING INJECTION PORTS.

Ted McKeon

Joe McKeon

Richard McKeon

Barry McKeon

Teddy McKeon

Kent Hogeboom

Rich Olivier

Patrick Kiel

Dennis Hogeboom

Sharon Swanson

Natalie Spain

Jacob Estrello

Amanda Guilfoyle

Judy Nixon

Theresa Vickers

Jill DePoy

Deby Hogeboom

Denise Giaccio

Mary DeRosa

John Pinkerton

Matt Seslow

Jennifer Hood

Craig Mongeau

Andy Gotlieb

Katherine Petrik

Mia Klimp

Sondra Rossi

Cathy Printz

Caitlin Murphy

Maria McKeon

Donna Prendergast

Kathy McDonnell

Kathy Miller

Terry Mazza

Andrea Pinkerton

Stephen Collins

Rob Tredinnick

AIR LIFT 3RD & 4TH

Rogers 40 ton Tandem, No-Foot Neck, 24' deck, adjustable width ramps, bucket pocket, 275's, aluminum outers, night lights, work lights, strobes. Rogers Black............ IN STOCK!

RATCHET RIDE HEIGHT

Rogers 35 Ton Gentle Riser, 24' deck, adjustable width bi-fold ramps, 275's on Aluminum, Extra lights and strobes, Rogers Green......IN STOCK!

Rogers 55 Ton CobraNeck, Severe Service Design. 2-position pin, ratchet ride height, adjustable width bi-fold steel ramps, 26' clear deck, deep well pocket, chain bins, tool boxes, 275's, alum. outers, side reinforcing, extra lights, strobes, night light pkg. 3-axles air lift 3rd, 4-axles air lift 3rd & 4th, Black....................IN STOCK!

Rogers 55 Ton, No-Foot, 25' deck, deep well pocket, depressed cross members, adjustable width bi-fold ramps. reinforced wheel covers, reinforced front slope & side rails. Safety Lighting Package, Strobes, 275's on Alum. outers, Air Lift 3rd. All Wheel ABS. Rogers Red and Black........ IN STOCK

Rogers TAG25XXL, 25 Ton Capacity, Premium Specs, Superior Quality, 235’s Aluminum, 7-Year Warranty, Black or Red Paint, 24’ deck + 6’ tail, 8’ Air Ramps.................. IN STOCK!

Strobes, In Production for Custom Colors. Rogers Red................ IN STOCK!

Each year, Eagle Power & Equipment always makes its “Case” for a great holiday light display at its Montgomeryville, Pa., headquarters. This year, the equipment dealer went with a charming campfire theme. Thanks to our friends at Eagle Power for sharing this wonderful holiday photo.

Caterpillar Inc. launched its third Global Operator Challenge, inviting thousands of machine operators worldwide to put their agility, resilience and versatility to the test on a wide range of construction equipment and technology.

“For nearly 100 years, our customers have been pushing the limits with our machines,” said Caterpillar Construction Industries Group President Tony Fassino. “This challenge helps showcase and celebrate the exceptional skills of the expert men and women in this important profession as they forge their legacies of being the best operators in the world.”

More than 140 Cat dealer competitions were held during the 2022-2023 challenge, which attracted more than 10,000 operators from 32 countries. The 2025-2026 challenge aims to include more events, countries and operators than previous programs.

Operators are invited to compete in local challenges facilitated by Cat dealers around the globe during the first round, being held from January to September 2025. The competitions will feature at least three different

challenges on at least three separate pieces of equipment.

Scoring is based on the operator’s skills, safety, efficiency and competence in using integrated technology such as payload, grade control and operator ease-of-use features to enhance the machine’s performance.

Winners from local dealer events will advance to regional semifinal competitions during the fall of 2025. Nine finalists will emerge from the regional semifinals and participate in the final competition in March 2026 at Caterpillar’s outdoor Festival

Grounds exhibit during ConExpoCon/AGG in Las Vegas. The winner receives either a $10,000 cash prize or an equal value trip for two where Caterpillar has a location worldwide.

For more information and official rules about the Global Operator Challenge, including how to participate, visit www.cat.com/operatorchallenge. (Photos courtesy of Caterpillar.)

Traffic signals at two intersections on U.S. Highway 119 in southwest Pennsylvania are slated to be removed as state transportation officials hope to improve safety on a section of the highway just south of Westmoreland County.

“It all started with a desire to reduce crashes at these intersections,” said Jeremy M. Hughes, the District 12 assistant executive for design at the Pennsylvania Department of Transportation (PennDOT).

TribLIVE.com, an online news source in the western part of the state, noted Nov. 29 that the work area is between the Mt. Pleasant-Scottdale and Everson exits on U.S. 119. PennDOT is focusing on the McClure Road and Kingview Road intersections in Fayette County’s Upper Tyrone and Bullskin townships, just over the border from Westmoreland.

Bids could be sought next spring with construction starting later in 2025, though PennDOT Project Manager Joshua Zakovitch said impacts for U.S. 119 motorists likely will not occur until 2026.

The $50 million Route 119-McClure, Kingview Interchange Project is advertised as a safety and roadway effort that will include resurfacing and reconstruction of the main highway, in addition to six other nearby roadways: Kingview, Crossroads, Mount Pleasant, McClure, Wedding and Kendi.

According to PennDOT, crews also will work to:

• Extend Kendi Road to connect with Kingview Road and make other improvements to that stretch of the corridor.

• Construct new turn lanes, a roundabout, and a new bridge and roadway (Connector Road), the latter of which will link Mt. Pleasant Road on the northbound side of the highway and Kendi Road on the southbound side.

• Remove two signals on U.S. 119 and build acceleration/deceleration lanes on the four-lane highway.

The $50 million Route 119-McClure, Kingview Interchange Project is advertised as a safety and roadway effort that will include resurfacing and reconstruction of the main highway and more.

District 12 office, said the bridge will undergo evaluations every six months through the end of 2027 to determine if safety-related repairs need done.

“Typically, it’s two years or more, but this bridge is on a [six month] frequency because of the condition of it,” he explained. “Now, every six months we go out and we inspect it, and if we find anything that needs to be addressed, we do it immediately in an attempt to try to keep it open for the public.”

Construction on a new bridge was delayed so that studies about nearby habitats of endangered bats could be done, the transportation department noted.

the Kingview Road intersection between 2019 and 2023, according to PennDOT, in addition to a handful of other crashes there and at the McClure Road interchange.

Included among those accidents was one where a woman was killed near U.S. 119 and McClure Road in 2020 after hitting a deer. Just last March, a motorcyclist died near the Kingview Road intersection, and, in 2015, four people were hurt in a fiery threevehicle collision at the same crossing.

truss design, and stretches 911 ft. across the Youghiogheny River just to the east of Perryopolis.

The effort to maintain the current superstructure began in June and will continue until the new, separate bridge is completed. It is part of a preservation project provided for the adjoining Layton Tunnel, a 208-ft.long former rail passageway that lies on the west bank of the river.

Both the bridge and tunnel were converted to single-lane automobile use in 1933 and are still used for that purpose today.

“Hopefully we’ll have the environmental clearances by the end of [2024], and we’ll be able to move to the next phases…”

Zakovitch told TribLIVE.com that once the phased construction starts on U.S. 119, there may be some lane restrictions and other impacts, but motorists will still be able to freely travel north and south. The daily average of motorists using the highway is approximately 23,000, according to PennDOT traffic maps.

Construction of the road project is expected to be complete during the autumn of 2027.

Hughes said that he expects to see a reduction in crashes along U.S. 119 in that area of Fayette County once the work is done. There were five rear-end collisions at

Troy Pritts PennDOT

After being closed for most of the summer for repairs, the Layton Bridge near the Fayette County town of Perryopolis is once again open for travel.

It is unlikely to be the last time the 125year-old structure undergoes repairs as it will remain a placeholder until a new bridge is constructed and hopefully opened by 2028, the Uniontown Herald-Standard reported earlier this fall.

The Layton Bridge, listed on the National Register of Historic Places, utilizes a Pratt

The preservation project consists of repairing masonry elements at both portals of the tunnel, installing additional riser beams on the bridge floor system, mitigating deficiencies to the bridge timber sidewalk, and repairing or replacing bridge joints.

PennDOT noted that specific concrete and structural steel repairs to the bridge’s superstructure, substructure, curb and barriers are scheduled to be finished by the end of the year. The extent of potential as-needed repairs is subject to future inspections and analyses.

The contractor completed bridge work on Spans 2 and 3 on Sept. 16, and the roadway was reopened the next day. Additionally, crews placed a barrier that created a one-lane road across the entire length of the span. Work then shifted to Span 1 and to the substructure on Spans 4 through 17.

PennDOT’s proposed replacement of the Layton Bridge, means to incorporate:

• Replacement of the single-span, singlelane bridge carrying Layton Road over Washington Run.

• Improvements to the associated roadway connecting the two structures, as both the tunnel and bridge were originally designed and utilized by a railroad.

William Beaumariage, assistant district executive of construction in PennDOT’s

PennDOT project manager Troy Pritts said after a series of reports were submitted to the U.S. Fish and Wildlife Service and the state Game Commission, those agencies provided a number of conditions for construction to proceed.

“We agreed to a timbering restriction during the winter when the bats are in their caves,” he told the Uniontown news source. “Similarly, to not disturb the bats that are hibernating over winter, we will do our blasting in the summer.”

Pritts noted that PennDOT also has agreed to create bat boxes and rock piles for the animals during the building of the new bridge.

As for when that construction will begin, he said a “conservative estimate” would be by the end of next year, and the new bridge would be open to the public by 2028.

“Hopefully we’ll have the environmental clearances by the end of [2024], and we’ll be able to move to the next phases, which [include] final design, right-of-way acquisitions, and getting our permits submitted to the DEP,” explained Pritts.

Pennsylvania State Rep. Ryan Warner, R52nd District, who has been critical of what he calls “ridiculous bureaucratic red tape,” said that while he respects the historical and environmental protections, the delay in construction of the new bridge comes with a risk.

Every time the Layton Bridge is shut down, he said, emergency responders must take a longer route to get to their destination. He referenced a fire that took place over the summer in Perryopolis near the bridge when he added, “Thankfully no one’s lives were at risk but you’re looking at a major delay to get fire and medical services there.”

However, Beaumariage said PennDOT has made safety a priority at the bridge site.

“We are dedicated to the local citizens and keeping this existing bridge open, getting the new bridge built, improving the area, and bringing funds into the area,” he told the Herald-Standard. “I just hope the locals know that we are doing everything we can to get this project to the finish line. And that’s heartfelt.”

MANASSAS, VA 6918 Wellington Rd. Manassas, VA 20109 703/257-2381 JESSUP, MD 10421 Guilford Road, Jessup, MD 20794 410/792-9134 from Washington D.C. 301/725-7394

38420 Sussex Highway Delmar, DE 19940 302/846-3033

When you’ve got job that requires a site to be prepped or cleared, you need attachments you can trust to get the job done right the first time. At Blue Diamond Attachments, we’ve got your back.

Our family of brush cutters are purpose built to provide optimal performance on your skid and compact track loaders, mini loaders and full line of excavators. Providing you exactly what you need to get to the next phase of your project on – or even ahead of schedule.

So, whether the job is large, small or somewhere in between, Blue Diamond brush cutters are designed to handle it. Choose Blue Diamond – where all we do is elevate everything you do.

Clear your way to increased productivity by scanning the QR code or visit us at www.BDACutters.com! ATTACHMENTS - IT’S ALL WE DO

(L-R) are Sonny Ishii, chairman, HCMA; Craig Hannam, Veristart; Ralf Pfefferkorn, Sodex Innovations; Mark Piotto, Teleo; and Masahiro Yamada, VP, New Business Creation Unit.

On Nov. 20, Hitachi Construction Machinery Co. Ltd. and Hitachi Construction Machinery Americas Inc. hosted the inaugural Hitachi Construction Machinery Challenge 2024 pitch event at the Americas regional headquarters.

The winners, Sodex Innovations, Teleo and Veristart Technologies, will join the Hitachi Construction Machinery exhibition area at bauma 2025 (April 7-13, 2025) and explore the possibility of collaboration with the Hitachi Construction Machinery Group.

Traditionally, the development of construction machinery has focused on the machine itself, and development was carried out to produce high-performance and high-quality machinery. In recent years, the focus has shifted to improving safety and productivity at construction sites, reducing life cycle costs and responding to ESG concerns.

The demand for “connected construction machinery” that uses digital technology to link data acquired from workers, machines and construction sites to external systems has grown. To develop solutions that improve user connectivity to machines, Hitachi Construction Machinery believes it is important to incorporate the innovations created by start-ups into the machinery and products of the future.

The Hitachi Construction Machinery Challenge 2024 solicited ideas from start-ups

The company behind the design of the battery packs, the motor, the circuitry and all components that operate the hydraulics of the Zaxis 17U electric excavator is DIMAAG AI. Representing the company is Shankar Radhakrishnan (L), COO, and Satish Padmanabhan, CEO.

selecting

Hamm 3412P, 2012, 84” vibratory padfoot compactor, EROPS w/ heat & A/C, 1,200HMR .

$82,500

Cat 815F, 2006, EROPS cab, 12’4” S-Blade w/ tilt, new paint job, very good condition, 9,400 HMR . .$195,000

Hamm GRW-5 Pneumatic Roller, 1994, Deutz Diesel, ROPS Canopy, (9) Ea. 7.50-15C1 Tires

$15,500

(4) Cat 825C’s, 1981-1990, EROPS, S-blade w/tilt, all work ready

From $79,500

Rammax Walk Behind Rollers, over 25 in stock, lever & remote

$4,000 to $10,000 (8) Sheepsfoot, 48" and 60", double drum & single drum, tow type

$4,000 - $6,500

Volvo A40, 1998, 40 tons, 10991 hrs, 395 hp, 8WD, 29.5R25, A/C, 29 cy cap. sideboards, tailgate (currently off work), work ready

$127,500

Volvo A40, 1996, 40 tons, 395 hp, 6WD, A/C, 29.5R25, working everyday

$145,000

Volvo A40, 1996, 40 tons, 11,000 hrs, 6WD, 20.5R25, A/C, P/S trans, 29 cy cap., 6/06 hitch rebuilt .$115,000

Volvo A40, 1995, 40 tons, 395 hp, 8WD, 29.5R25, A/C, P/S trans, tailgate, work ready

$115,000

Volvo A35C, 1998, 35 tons, 6WD, 26.5R25 tires, approx 7,000 hrs, good condition

$147,500

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5x25, A/C, P/S trans, working everyday on jobsites

$87,500

Broderson IC80-2E, 1997, 8.5 ton, 24’ boom, dual fuel, 10.00R15 tires, 3,400 hrs .

$21,500

Grove RT58C, 1981, down cab, 18 ton r.t., 70' boom anti-two block, GM dsl, clean

185’s, JD diesels

CALL

(12) Allmand Light Plants, 2008-2010, diesel, s/a towtype, (4) MH lights, excellent

Cat 336EL, 2012, 33.5” TBG pads, Q/C, aux hyd, 6,700 HMR, work ready

$162,500

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5R25, A/C, P/S trans, 26 cy, working everyday on jobsites

$89,000

$224,500

Cat 336FL, 2015, 33.5” TBG Pads, Q/C, aux hyd, 4,300 HMR, work ready

Komatsu PC220LC-8 Longreach, 2011, Young Boom/Stick 60’ reach, 3,500 HMR

Volvo A30C, 1996, 30 tons, 11,000 hrs, 296 hp, 6WD, 23.5R25, 21 cy cap, A/C, P/S trans, works everyday

$179,000

$122,500

$72,500

Kobelco SK210LC, 2007, Q/C, aux hyd, 31.5” TBG Pads, 3,900 HMR

Cat D5NXL, 2006, 10’ PAT Blade, Paccar PA55 winch, 22” Pads, 4,100 HMR

$82,000

$49,500

Cat 613C Water Wagon, 1994, 5000 gal drop tank, ROPS, spray heads

Cat 621F, 1996, Scraper, OROPS, 33.25x2, very good condition

Cat 621E, 1989, Scraper, OROPS, 33.25x29, very nice CALL

Cat D6NLGP, 2008, VPAT Blade, Drawbar, 33” Pads, 9,900 HMR

$87,500

Cat D6NLGP, 2014, Foldable VPAT Blade, Paccar PA55 winch, 7,200 HMR

$142,500

100 Excavator, Loader, Specialized & Grapple Buckets in Stock -Call For Your Needs FORKS (8) IT28F/G Forks, Balderson qc, 48"-60" pallet style, excellent

$229,500

Komatsu D155AX-6, 2007, Sigma S-U Blade, 4-bbl Single Shank Ripper, 8,400 HMR

Cat D6TXW, 2013, 13’6” VPAT Blade, Carco 70APS winch, 28” pads, 7,300 HMR

lbs, stk#XC556........................................................$47,500

2017 John Deere 544K-II, 2,903 hours, 3 yard, cab w/ a/c, ride control, backup camera, 6 cyl John Deere turbo, 32k lbs, stk#LO464........................................................$93,500

2019 John Deere 35G, 2,099 hours, 17" digging bkt & 34" cleanup bkt, cab w/ a/c, hyd thumb, 68" blade, manual coupler, 2 spd, swing boom, 8.2k lbs, stk#MX907 $39,500

2017 Doosan DX140LCR-5, 4,288 hours, 32" bucket, hydraulic thumb, a/c, 4 cyl Perkins turbo, 2 speed, backup camera, 33k lbs, stk#XC730....................................$77,500

2000 JCB 508C, 3,838 hours, 8k lb lifft, cab, 41 ft lift height, 27 ft horizontal reach, 4x4, 4 ft rotate forks, tilt body, 4 cyl JCB, 91 hp, stk#FL487..........................$24,500

2017 Vermeer RTX250, 738 hours, walk-behind trencher, 4 ft blade, 6" trencher width, crumber, 2 cyl Kohler gas, good rubber tracks, stk#TH977..........................................$7,500

2005 Caterpillar D8T, 17,631 hours, 12'9" semi-u blade w/ tilt, cab w/ a/c, diff steer, 6 cyl Cat C15 Acert turbo, 87k lbs, stk#DZ577..................................................................$129,500

DBIA recognized nearly 50 project and team awards during a special Awards Dinner at the 2024 Design-Build Conference & Expo.

In addition to celebrating Merit Award winners from each category, DBIA revealed the recipients of this year’s Excellence Awards, several Best-In honors and the coveted Project of the Year.

Chosen by the Chair of DBIA’s National Board of Directors, the Chair’s Award is a special honor recognizing design-build teams that have shown extraordinary commitment to triple bottom line success.

• 2024 Project of the Year: University of Arizona Applied Research Building (Ariz.)

• 2024 Chair’s Award: Holt Watters Field Camp (Livingston Island, Antarctica)

• Best in Process — Best Value: National Renewable Energy Laboratory (NREL) Research and Innovation Laboratory (RAIL) (Colo.)

• Best in Process — Progressive DesignBuild: Wake Technical Community College, Central Energy Plant (N.C.)

• Best in Design — Architecture: University of Arizona Applied Research Building (Ariz.)

• Best in Design — Engineering: Central

70 Design-Build-Finance-Operate-Maintain

(Colo.)

• Best in Virtual Design and Construction: Nashville International Airport Terminal Lobby and International Arrivals Facility (Tenn.)

• Best in Small Projects — Horizontal: Fern Hollow Bridge Emergency Replacement Project (Pa.)

• Best in Small Projects — Vertical: Holt Watters Field Camp (Livingston Island, Antarctica)

• Best in Teaming: Millbrae Recreation Center (Calif.)

• Meaningful Diversity, Equity and Inclusion: I-270 North Design-Build (Mo.)

• Enlightened Owner: NREL Research and Innovation Laboratory (RAIL) (Colo.)

• INSPIRED Owner: Queens Borough Hall Municipal Garage and Community Space (N.Y.)

The jury also chose National Award of Excellence winners, representing the best of their category. The 2024 Excellence Awards winners are:

• Aviation: Nashville International Airport Terminal Lobby and International Arrivals Facility (Tenn.): This 780,000 sq. ft. renovation transformed a 35-year-old terminal into a modern, efficient facility that enhances passenger experience and reflects

Nashville’s musical heritage through innovative design elements.

• Civic/Assembly: Millbrae Recreation Center (Calif.): Rebuilt after arson destroyed the original structure, this recreation center features sustainable design and net-zero emissions standards and is a flexible community hub in Millbrae, Calif.

• Commercial/Office Buildings: Wake Technical Community College, Central Energy Plant (N.C.): This cutting-edge facility in Wendell, N.C., features one of the largest geothermal well installations in the southeast and serves as a living classroom showcasing sustainable energy solutions.

• Educational Facilities: University of Arizona Applied Research Building (Ariz.): This research facility at the University of Arizona supports diverse atmospheric and space exploration research activities. It features the world’s largest university-based Thermal Vacuum chamber.

• Federal, State, County, Municipal: Queens Borough Hall Municipal Garage and Community Space (N.Y.): New York City’s first design-build project under new legislation, this Parksmart Bronze-certified garage and community space exemplifies urban sustainability and civic integration.

•Industrial/Process/Research Facilities:

NREL Research and Innovation Laboratory (RAIL) (Colo.): This flexible, cross-disciplinary research facility at NREL in Golden, Colo., sets a new standard for sustainable and collaborative laboratory spaces. It focuses on advanced energy materials and nextgeneration batteries.

• Rehab/Reno/Restoration: Large Diameter Sewer Rehabilitation Project (Ky.): This project successfully rehabilitated critical sewer infrastructure using innovative techniques and strong community engagement, ensuring long-term environmental sustainability.

• Transportation: Central 70 DesignBuild-Finance-Operate-Maintain (Colo.): This transformative project modernized an 11-mile stretch of one of Denver’s busiest highways, replacing an aging viaduct with a below-grade highway topped by a park, reconnecting divided communities.

• Water/Wastewater: Headworks Facility at the San José-Santa Clara Regional Wastewater Facility (Calif.): As part of a major capital improvement program, this project modernized one of the largest wastewater treatment facilities in

For more information, visit dbia.org.

Erich Omans of Phoenix LiDAR Systems, based in Austin, Texas, assembles a drone with his company’s Miniranger 3-UAV LIDAR Solution scanner for a high accuracy mapping demo.

SISO Air, a Smyrna, Ga.-based national dealer for commercial drones, recently conducted a comprehensive drone and technology demo at the SSG Anthony Davis Memorial Model Airfield in Savannah, Ga.

Manufacturers from across the country traveled to the event to present their products and technology to attendees. The weather wasn’t ideal, but flights took place between showers and overcast conditions.

SISO Air provides coast-tocoast drone technology sales, service and support for use in engineering, construction and military and more. SISO Air is an authorized distributor for top drone manufacturers, including DJI, Harris Aerial, Skydio, Wingtra, WISPR and others and for leading hardware, software and accessory

manufacturers, including Pix4D, Propeller, GNext Labs, Trimble, InTerra, and others to provide customers with a total technology solution. CEG (All photographs in this article are Copyright 2024 Construction Equipment Guide. All Rights Reserved.)

Gabriel Allit (L), senior commercial UAS pilot of MasTec Clean Energy & Infrastructure, gets a briefing of all the products that will be demonstrated throughout the day from SISO Air’s UAS Support Manager Joseph Johnson.

(L-R): Staffers of SISO Air and their parent company SITECH South assemble early morning to set up for the event including Joseph Johnson, Rob Angel, Jamie Reinholt, Kyle Byrd and Omar Maldonado.

Omar Maldonado, SISO Air UAS support specialist, provides a comprehensive presentation on the uses and capabilities of drones, payloads and software.

Erie 40H Excavator, 1:50 scale - $135

Allis Chalmers Forty-Five Motor Grader,1:50 scale..............................

Allis Chalmers TS300 Motor Scraper, 1:50 scale................................

Bantam Lattice Truck Crane on White WC Carrier,1:50 scale..............

Bobcat 743 Skid Steer Loader,1:25 scale................................................

Bucyrus Erie 22B Dragline,1:50 scale....................................................

Bucyrus Erie 22B Cable Shovel,1:50 scale............................................

Bucyrus Erie 22B Cable Backhoe,1:50 scale..........................................$225

Bucyrus Erie 40H Excavator,1:50 scale..................................................$135

Case 580SR Backhoe/Loader,1:50 scale................................................$160

Case 590 Super L Backhoe/Loader,1:50 scale........................................$50

Case 621C Wheel Loader,1:50 scale........................................................$50

Case 850B Angle/Tilt Dozer,1:35 scale..................................................$100

Case 1845 Skid Steer Loader $45

Case DH4B Trencher,1:35 scale..............................................................$90

Case 9030B Excavator,1:50 scale............................................................$65

Caterpillar D6H Track-Type Tractor,1:50 scale........................................$90

Caterpillar 988F Wheel Loader,1:50 scale............................................$110

Caterpillar D9N Track-Type Tractor w/black Tracks 1:50 scale............$110

Caterpillar D9N Track-Type Tractor w/yellow Tracks 1:50 scale..........$110

Caterpillar D8L Track-Type Tractor,1:50 scale......................................$125

Caterpillar D7C Track-Type Tractor,1:50 scale......................................$110

Caterpillar D10 Track-Type Tractor,1:50 scale......................................$120

Caterpillar D11R Track-Type Tractor,1:50 scale......................................$90

Caterpillar D4E Track-Type Tractor,new color,1:50 scale........................$75

Caterpillar D4E Track-Type Tractor,old color,1:50 scale........................$75

Caterpillar AP-1000 Asphalt Paver,1:50 scale......................................$110

Caterpillar M318 Wheel Excavator,1:50 scale......................................$100

Caterpillar 936 Wheel Loader,1:50 scale................................................$75

Caterpillar 920 Wheel Loader, 1:50 scale..............................................

Caterpillar 428 Silver Backhoe/Loader,1:50 scale..................................

Caterpillar 416 Silver Backhoe/Loader,1:50 scale..................................

Caterpillar 438C Backhoe/Loader,1:50 scale..........................................

Caterpillar 225 Crane w/clamshell bucket,1:50 scale............................

Caterpillar 12G Motor Grader,1:50 scale................................................

Caterpillar PR-450 Profiler,1:50 scale..................................................

Caterpillar CB534 Double Drum Roller, 1:50 scale................................

Caterpillar 225 Excavator,1;70 scale........................................................

Caterpillar 773B Off-Highway Truck, 1:70 scale......................................

Caterpillar 631 Tilting Dumper,1:70 scale..............................................

631D Motor Scraper,1:70 scale..............................................

825B Landfill Compactor,1:50 scale......................................

that fit within three themes; “Construction Planning,” “Revolutionize Equipment: Information, Interface & Autonomy” and “Transform Fleet Management.” One hundred and twenty seven start-ups submitted proposals, and nine start-ups pitched their ideas to a panel of judges in front of an audience made up of start-up CEOs, venture capitalists and executives of construction companies.

Sodex, Teleo and Veristart Technologies pitched the ideas that impressed the judges the most.

Guest judges included Cutler Knupp, Haskell (Dysruptek) vice president of strategy & technology investment (managing director); Kaustubh Pandya, Brick & Mortar Ventures Partner; and Satish Padmanabhan, DIMAAG-AI CEO.

“Hitachi Construction Machinery is traditionally known as a company that provides mechanical items, but we are pivoting to also being a true technological solutions provider. For us, that means collaborating with innovative startups,” said Masahiro Yamada, Hitachi Construction Machinery vice president of the new business creation unit.

“This event is very important to us because it will show the world that Hitachi Construction Machinery is more than just excavators, wheel loaders and mining trucks. We are also a technology company that listens to their customers’ needs and provides wholistic solutions.”

Sodex Innovations won under the “Construction Planning” theme. Its product equips machines with a system that enables capturing terrain in real time. This allows job sites to keep track of their progress and report on it without the need to pause the job

site for a survey. Essentially, it creates digital twins of construction sites by equipping machines with laser scanners and cameras, giving construction machinery digital eyes.

With Sodex Innovation’s winning solution, any machine operator can become a surveyor while getting the job done.

“The ability to move on with Hitachi Construction Machinery means a lot for us because the possibility of giving Hitachi machinery more eyes will make them more attractive,” said Ralf Pfefferkorn, Sodex Innovations CEO and co-founder. “At bauma 2025 we are hoping to show attendees a great solution that they have never seen before on a construction machine. We are from Austria so we are excited to show our German neighbors some really cool technology on amazing machinery.”

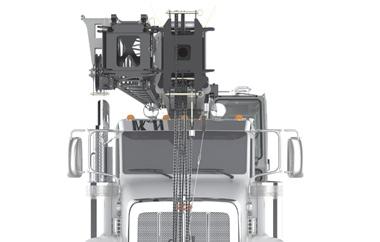

Teleo won under the “Revolutionize Equipment: Information, Interface & Autonomy” theme. Its supervised autonomous machine is a brand-agnostic solution that allows operators to operate multiple machines simultaneously from an office-like environment.

“This is a tremendous opportunity for us to work with a global leader like Hitachi Construction Machinery. We hope to work together to develop products and solutions that are going to innovate the construction and mining industries,” said Mark Piotto,

Teleo vice president of sales.

“We want to focus on the operator experience and what the next generation of operators will be. Artificial intelligence and Large Language Models have made an impact in the world and we are excited to leverage that

The design of the

electric excavator allows it to run on two to six batteries, depending on how much operating time is required. Batteries can be charged internally or removed and charged elsewhere or swapped out on site for other charged batteries. At only 48 pounds per battery, DIMAAG-AI COO Shankar Radhakrishnan shows how easy the battery is to extract from the battery bank.

technology to help operators do their job.”

Veristart Technologies won under the “Transform Fleet Management” theme. Its solution is targeted at preventing machinery theft by providing fleet managers with better control of its machines. It presented a product that is a cloud application, a mobile application, and a hardware device that works together to give fleet managers precise control over who can operate their fleet.

With this product, machine operators will receive an electronic key on their smartphone that allows them to start the vehicle.

“We are adding control to heavy machinery equipment. We want to make sure that when an operator is operating a machine they are both authorized and properly trained to use the machine,” said Craig Hannam, Veristart Technologies CEO and co-founder.

“This win is huge for us. To have a partner like Hitachi Construction Machinery at this early stage in our start-up is amazing. At bauma 2025 we are excited to show attendees our prototype and the evolution of the solution.”

Hitachi Construction Machinery will continue to engage in open innovation with start-ups and aims to incorporate these innovations into their solutions at all points of contact with their customers. In addition to this, Hitachi Construction Machinery has been working on open technology and product development through investments and collaboration in venture capital funds and start-ups.

(All photography in this article are Copyright 2024 Construction Equipment Guide. All Rights Reserved.)

An online web platform, VisionLink Productivity for cold planers delivers near real-time machine and jobsite data designed to improve the contractor’s productivity.

Available for Cat PM620, PM622, PM820, PM822 and PM825 cold planers, VisionLink Productivity gathers, analyzes and summarizes detailed data such as time spent waiting for trucks, cutting and travel at the jobsite as well as distance cut, fuel burn, location and cycle mapping.

This gives contractors insights into jobsite productivity and equipment utilization.

VisionLink Productivity segments data into easy-to-navigate dashboards, providing multiple ways to view more detailed data and key product indicators (KPIs). Contractors can quickly track the hours and distance milled each day and visualize excess travel, slow milling speeds and stoppage.

Eliminating manual data gathering, detailed reports are available in PDF, Excel and CVS formats and can be scheduled for email inbox delivery.

This powerful reporting technology enables contractors to measure performance of cycle segments; track and eliminate unnecessary fuel consumption; and compare operations between shifts, machines and projects. Allowing for the identification and reduction of unnecessary waiting, companies can achieve longer, more productive milling cycles, improve estimating for future projects, and

optimize profitability by increasing efficiency and reducing costs, according to the manufacturer.

A cloud-based platform, VisionLink Productivity gathers and summarizes machine telematics and jobsite data from all equipment at the job site, regardless of the brand, and can be accessed anywhere via a mobile, tablet or desktop device. Fleets with mixed OEM equipment brands can all be incorporated into VisionLink Productivity.

For more information, visit www.cat.com.

ALL ISLAND EQUIPMENT

39 Jersey Street West Babylon, NY 11704

631/643-2605

allislandequipment.com

AMBROSE EQUIPMENT / ALTA EQUIPMENT

1401 Hooksett Rd. Hooksett, NH 03106

603/644-8787 ambroseequipment.com

HOFFMAN EQUIPMENT COMPANY

1440 Route 9W Marlboro, NY 12542

845/236-3000 www.hoffmanequip.com

JESCO, Inc.

1275 Bloomfield Ave. Fairfield, NJ 07004

973/227-2221

800/321-8080

118 St. Nicholas Ave. S. Plainfield, NJ 07080

908/753-8080

800/241-7070

1790 Route 38 Lumberton, NJ 08048

609/267-2020 www.jesco.us

MONROE TRACTOR

1001 Lehigh Station Rd. Henrietta, NY 14467

585/334-3867

5035 Genesee Street Buffalo, NY 14225

716/681-7100

8194 State Route 415 Campbell, NY 14821

607/739-8741

www.monroetractor.com

RICHMOND MACHINERY

2350 Greystone Ct. Rockville, VA 23146

804/359-4048 www.richmondmachinery.com

W.I. CLARK COMPANY

30 Barnes Ind. Pk. Rd. Wallingford, CT 06492

203/265-6781 17 Eagle Road Danbury, CT 06810

203/775-1203

80 Pratt Rd. Plainfield, CT 06374

860/546-4808 www.wiclark.com

Harrisburg, PA 7201 Paxton Street Harrisburg, PA 17111 800/325-6455

Wilkes-Barre, PA

600 Sathers Drive Pittston, PA 18640 866/667-6756

Butler, PA

796 Unionville Road Prospect, PA 16052 724/865-9221

Philadelphia, PA

135 Lincoln Avenue Prospect Park, PA 19076 800/220-4033

Pittsburgh, PA 8181 Noblestown Road McDonald, PA 15057

800/692-7600

Ebensburg, PA

2350 Munster Road Lilly, PA 15946 814/886-5191

Albany, NY

3 Industry Drive Waterford, NY 12188 518/357-2200

Syracuse, NY

6018 Drott Drive

East Syracuse, NY 13057

800/368-6455

Northern, VA (DC)

8192 Euclid Court Manassas Park, VA 20111

703/330-5579

Hagerstown, MD 20332 Leitersburg Pike Hagerstown, MD 21742

301/733-7414

Baltimore, MD

1109 Middle River Rd Middle River, MD 21220 800/633-5077

www.traceyroad.com

AdClosingDate January2,2025

PublishingDate January15,2025

AdClosingDate January30,2025

PublishingDate February12,2025

AdClosingDate February27,2025

PublishingDate March12,2025

AdClosingDate March27,2025

PublishingDate April9,2025

AdClosingDate April24,2025

PublishingDate May7,2025

Twiceme Technology, a Swedish company dedicated to safety solutions, revealed the findings of its 2024 Construction Safety Survey.

In the industrial market survey of 500 construction contractors and 390 safety managers/directors, the data revealed that while 79 percent of safety managers have digital systems to track critical safety information and personal protective equipment (PPE) health, only 40 percent of contractors surveyed noted they have digital access to this information, too.

Digital safety technologies have served a vital role in the outdoor sports industry for quite some time, and the construction industry is now beginning to follow suit. Digital technologies embedded within PPE can increase efficiency, decrease deficiencies in information, and empower the wearer and issuer to make the workplace safer by more quickly alerting, locating, and identifying injured persons. It is critical to have information about workplace certifications, PPE equipment health and emergency information about a contractor available at the fingertips of those at a job site.

“Safety managers are doing a great job with digital safety processes, but there is a critical gap when this information does not reach the workers.”

Christian Connolly Twiceme Technology

Digital technologies can make an immense difference in response times when an incident occurs.

Construction sites can be dangerous, and 69 percent of contractors surveyed noted that they or a coworker had experienced a serious accident at a job site. Of this group, 54 percent said that the first person to respond on site did not have relevant health information about the injured person, which could help accelerate and improve the first-aid process. Also, 45 percent of this group were not adequately trained to provide preliminary help to an injured worker in the moments before first responders were on the scene.

“Safety managers are doing a great job with digital safety processes, but there is a critical gap when this information does not reach the workers,” said Christian Connolly, CEO, Twiceme. “Distributing smart PPE can help solve this issue. Investing in PPE like safety helmets and harnesses that have Twiceme-enabled NFC chips embedded within revolutionizes how information is shared and accessed, thus having a positive impact on how management and contractors can respond and act in emergency scenarios.”

When safety managers were prompted to rank features of an ideal safety management

system, the large majority marked the following components to be valuable to extremely valuable:

• Get alerts for overdue inspections and maintenance tasks for PPE (96 percent).

• Get real-time reports on safety compliance issues and incidents (96 percent).

• Access to real-time insights into worker attendance and location at job sites (96 percent).

• Inspect and receive automatic reminders when workers’ certifications near expiration (91 percent).

• Keep track of their workers’ PPE to reduce missing or lost equipment (90 percent).

• Access to paperless inspection and filing of required inspections per OSHA guidelines (88 percent).

The value of such features is clear: more than 88 percent of survey managers said they would be willing to pay $15 or more for helmets or other PPE gear for their organization if they included a safety management system that tracks work-related documents, equipment expiration dates, emergency response and reporting tools.

“As general contractors and other industrial organizations across the U.S. transition from hard hats to safety helmets or plan to invest in other job site PPE, such as fall protection, they should also look at embedded digital technologies as a top priority,” added Connolly.

For more information,

The CP100II sets the standard for versatility, component lifecycle and mat quality. With a powerful 100 horsepower engine, an array of configurations and the class-leading Carlson EZCSS single slide screed, it’s easy to see why the CP100II is the ideal choice for heavy-duty commercial paving.

The Carlson CP100 II sets the standard for versatility, component lifecycle and mat quality. With a powerful 100hp engine, an array of configurations and the class-leading EZCSS single slide screed, it’s time to see why the CP100 II has fast become the contractor’s choice for heavy-duty commercial paver platforms.

www.traceyroad.com

Albany, NY

518-438-1100

866-740-8853

Kirkwood, NY

607-775-5010 800-370-9488

Queensbury, NY 518-793-9688 833-817-2917

Henrietta, NY 585-334-5120 866-950-6210

Utica, NY 315-765-8746 800-872-2390 Adams Center, NY 315-788-0200 888-335-0200

www.GTMidAtlantic.com

Vineland, NJ 856-697-1414

Totowa, NJ 973-785-4900

Freehold, NJ 732-780-4600

r No for ctedPerfe

caAmeri th r e p x E f o deliveringthe -our machines are ing and milling, ground, in every NSTRUCTION smartsafeandsu to paving, compac climate, condition, , th TECHNOLOGY AS THE GLOBAL L stainableconsistently ction and rehabilitation and terrain. From min e world is our proving EADER IN ROAD CO highest quality and lowest total cost of ownership.

smart, safe, and sustainable, consistently delivering the

39 Jersey Street West Babylon, NY 11704

631/643-2605 www.allislandequipment.com

1275 Bloomfield Ave. Fairfield, NJ 07004

973/227-2221

800/321-8080

118 St. Nicholas Ave.

S. Plainfield, NJ 07080

908/753-8080

800/241-7070

1790 Route 38

Lumberton, NJ 08048

609/267-2020 www.jesco.us

1401 Hookset Rd. Hooksett, NH 03106 603/644-8787 ambroseequipment.com

1440 Route 9W Marlboro, NY 12542

845/236-3000 www.hoffmanequip.com

30 Barnes Ind. Pk. Rd. Wallingford, CT 06492 203/265-6781

17 Eagle Road Danbury, CT 06810 203/775-1203

80 Pratt Rd. Plainfield, CT 06374 860/546-4808 www.wiclark.com

2350 Greystone Ct. Rockville, VA 23146 804/359-4048 www.richmondmachinery.com

1001 Lehigh Station Road Henrietta, NY 14467 585/334-3867

5035 Genesee Street Buffalo, NY 14225 716/681-7100

8194 State Route 415 Campbell, NY 14821 607/739-8741 monroetractor.com

Harrisburg, PA 7201 Paxton Street Harrisburg, PA 17111 800/325-6455

Wilkes-Barre, PA 600 Sathers Drive Pittston, PA 18640 866/667-6756

Butler, PA

796 Unionville Road Prospect, PA 16052 724/865-9221

Philadelphia, PA 135 Lincoln Avenue Prospect Park, PA 19076 800/220-4033

Pittsburgh, PA 8181 Noblestown Road McDonald, PA 15057 800/692-7600

Ebensburg, PA 2350 Munster Road Lilly, PA 15946 814/886-5191

Albany, NY 3 Industry Drive Waterford, NY 12188 518/357-2200

Syracuse, NY 6018 Drott Drive East Syracuse, NY 13057 800/368-6455

www.stephensonequipment.com

Northern, VA (DC) 8192 Euclid Court Manassas Park, VA 20111 703/330-5579

Hagerstown, MD 20332 Leitersburg Pike Hagerstown, MD 21742 301/733-7414

Baltimore, MD

1109 Middle River Rd Middle River, MD 21220 800/633-5077

Engineered and built to exceed the demands of commercial paving, the Weiler pavers incorporate proven designs with new innovations to provide performance, reliability and outstanding mat quality in a wide range of applications. clevelandbrothers.com

Murrysville, PA

724-327-1300

Erie, PA

814-898-3388

Somerset, PA

814-445-7915

Clearfield, PA

814-765-1611

Mansfield, PA

570-662-7171

Kane, PA

814-778-5250

Mt. Pleasant, PA

724-696-4080

Watsontown, PA 570-538-2551

Ephrata, PA 717-859-4905 State College, PA 814-237-8338

Harrisburg, PA 717-564-2121 Pittston, PA 800-922-8630

Bridgeport, WV 304-842-2222

Shinnston, WV 304-592-5855

Bellefonte, PA 814-353-2800 Blawnox, PA 412-828-7810 Camp Hill, PA 717-730-7435 Cranberry Twp, PA

724-776-7660

Ebensburg, PA 814-471-1710 Indiana, PA 724-463-8743

Barnesville, PA 570-773-1720 Howard, PA 814-355-3500

Blawnox, PA 412-828-7810

Howard, PA 814-355-3500

Hunker, PA

724-861-6080

foleyinc.com

Piscataway, NJ 732-885-5555 Hammonton, NJ 609-561-0308

Bensalem, PA 215-639-4300

Whitehall, PA 610-261-4887 Bear, DE 302-328-4131 hopenn.com

Poughkeepsie, NY 845-452-1200 Bronx, NY 718-863-3800

Bloomingburg, NY 845-733-6400

Holtsville, NY 631-758-7500 Newington, CT 860-666-8401

Eighty Four, PA 724-325-9297 miltoncat.com

Milford, MA 508-634-3400 North Reading, MA 978-276-2400 Wareham, MA 508-291-1200

Cranston, RI 401-946-6350 Richmond, VT 802-434-4228

Londonderry, NH 603-665-4500

Brewer, ME 207-989-1890

Scarborough, ME

207-883-9586

Batavia, NY

585-815-6200

Binghamton, NY

607-772-6500

Clifton Park, NY

518-877-8000 Syracuse, NY

315-476-9981

Tonawanda, NY 716-799-1320 N. Syracuse, NY 315-703-7000

Join the commercial vehicle industry data revolution at Work Truck Week 2025.

NTEA – The Work Truck Association introduces Commercial Vehicle Data Exchange & Reception, a half-day special session on March 6 showcasing new possibilities for obtaining, analyzing and using data; understanding market trends; and improving business processes.

Work Truck Week 2025 runs March 4–7, 2025, at Indiana Convention Center in Indianapolis. It encompasses Green Truck Summit, The Work Truck Show, NTEA Annual Meeting, Ride & Drive, educational program and more.

Green Truck Summit is March 4, educational sessions run March 4–6, Work Truck Show exhibits are open March 5–7 and Ride & Drive runs March 5–6.

Work Truck Week, North America’s largest work truck event, is produced by NTEA. Register at worktruckweek.com.

“We are on the cusp of a data revolution in the commercial vehicle industry,” said Kevin Koester, NTEA managing director.

“Software-defined vehicles, telematics, artificial intelligence and other technologies are generating data and providing resources that can help businesses plan and progress in new ways. The time is right to come together to

explore the tools to leverage existing data and lead the development of the next wave of data-driven decision-making.”

Commercial Vehicle Data Exchange is designed for industry professionals looking for new data sources, interested in leveraging their company’s own data and/or collaborating with others who want to move the industry forward.

The four-hour event kicks off with a review of the current state of data availability and use in the commercial vehicle industry led by Andrew Wrobel, NTEA commercial vehicle insight strategist. This is followed by three breakouts:

• Best practices for using data in business decisions

• Evolution through telematics

mercial vehicles through the lens of telematics. He’ll provide an overview of the macro trends that have influenced the industry over

“Success in the work truck industry goes beyond hardware and software.”

It also will examine best practices for securing data.

Koester will wrap up the conference with a look to the future of data acquisition and analysis within the commercial vehicle industry. The conference is followed by a reception to give participants the opportunity to discuss what they’ve learned and exchange ideas.

Kevin Koester NTEA

• Leveraging artificial intelligence (AI) for data analysis and protection.

In the first session, Joe Langley, associate director, North American light vehicle production for S&P Global Mobility, will identify best practices for vehicle analysis to make better-informed business decisions.

Steven Berube, vice president of sales for GEOTAB, will then explore the evolution of Class 3–7 multi-stage manufactured com-

the last two decades and the role that telematics has played in supporting these transitions — as well as how changes in telematics will help drive the industry into the future.

Finally, Bucky Dodd, CEO and principal consultant at ClearKinetic, will discuss how AI is transforming data analysis, making it easier than ever to turn complex information into clear, actionable insights. The session will uncover how AI-driven analysis makes it easier to identify trends, refine strategies and make data-backed decisions in real time.

“Success in the work truck industry goes beyond hardware and software,” Koester said. “It increasingly depends on data and the people who are willing to create, leverage and collaborate on it. Attending the Commercial Vehicle Data Exchange is an important step in understanding how to transform data into strategic actions to move operations — and the work truck industry — forward.”

The Commercial Vehicle Data Exchange & Reception Special Session runs 1:30–5:30 p.m. on March 6, at Indiana Convention Center. It is not included in any Work Truck Week registration package — it is available for purchase separately.

For more information, visit worktruckweek.com or contact NTEA (info@ntea.com or 248/489-7090).

Cemen Tech, a manufacturer of volumetric concrete mixers and concrete production equipment, announced Fred Vincent as the new national used & rental equipment manager. With more than 25 years of experience in heavy truck dealer operations, Vincent will drive growth in Cemen Tech’s rental and used equipment divisions.

In this new role, Vincent will oversee rental fleet management, used equipment sales and business development strategies to further strengthen Cemen Tech’s market position. With a focus on customer relationships and operational excellence, he will help customers maximize profitability through flexible fleet solutions, including rentals, trade-ins and buyback programs.

Vincent’s career has spanned roles from diesel technician to dealer principal, giving him a broad and comprehensive understanding of the industry. His background includes building cross-functional teams, leading mergers and acquisitions, and holding executive leadership and board positions. His experience has consistently driven business growth and operational success throughout his career.

“We are pleased to welcome Fred to Cemen Tech,” said Connor Deering, CEO and president of Cemen Tech. “His extensive experience in heavy equipment operations and strategic leadership will play a key role in expanding our rental and used equipment business, helping construction companies and fleet operators meet their equipment needs.”

height.

Liebherr will participate at World of Concrete 2025 showcasing the 38Z4 XXT truck-mounted concrete pump equipped with the latest drive technology as well as the THS THS 110 D-K crawler pump at booth #C6149.

“We are thrilled to announce our participation at World of Concrete 2025. We look forward to showcasing our cuttingedge 38 XXT pump, which offers enhanced performance and top-tier operational support solutions, including powerbloc and the XXA stability support system,” said Guilherme Zurita, director of concrete technology.

The THS 110 D-K crawler concrete pump pairs well with bored pile foundations to supply concrete.

it easy to handle with a low

“Liebherr USA’s involvement highlights its continuous dedication to advancing the concrete industry. Our booth staff eagerly anticipate meeting customers and their future goals.”

The 38 XXT features a four-part distribution boom in a convenient Z-fold making it easy to handle and offers an impressive reach for the 30 m class.

This model comes standard with XXT-outriggers and an XXA stability assistance system. The pivoting XXT support ensures stability when supporting in tight spaces, and the XXA stability assistance system allows partially supported areas to be electronically monitored. The concrete pump also is equipped with the latest drive unit, powerbloc. This unit does not require a separate control block.

Offering an extensive accessories catalogue, the 38 also can be equipped with LED lighting designs for optimal work in the dark, various storage boxes for materials and tools as well as shelves for extension hoses.

The THS 110 D-K crawler concrete pump is ideal for bored pile foundations to supply concrete to any foundation machine. This work involves deep drilling holes to prepare the ground for construction. When the drill is pulled out, these holes are filled with concrete. In the process, the concrete is conveyed down via a tube in the middle of the drill.

The crawler concrete pump travels in parallel with the drilling rig to the various pile locations, with the concrete hose remaining connected to the drilling rig.

The Liebherr crawler concrete pump also is suitable for various other types of pumping applications.

(Photos courtesy of Liebherr.)

LESLIE EQUIPMENT COMPANY www.lec1.com

6248 Webster Road Cowen, WV 26206 304/226-3299

2098 Lillian Lane Pleasant Valley, WV 26554 304/534-5454

19 Goff Crossing Drive Cross Lanes, WV 25313 304/204-1818

80 John Deere Lane Norton, WV 26285 304/636-6421

136 Clifftop Drive Beaver, WV 25813-1525 304/255-1525

www.monroetractor.com

1001 Lehigh Station Road Henrietta, NY 14467 585/334-3867

5035 Genesee Street Buffalo, NY 14225 716/681-7100

7300 Eastman Road N. Syracuse, NY 13212 315/452-0000

8194 State Route 415 Campbell, NY 14821 607/739-8741

6 Equipment Drive Binghamton, NY 13904 607/754-6570

GROFF TRACTOR & EQUIPMENT www.grofftractor.com 800-33-GROFF 800-33-(47633)

6779 Carlisle Pike Mechanicsburg, PA 17050

20 Stauffer Lane Ephrata, PA 17522

210 Rolling Ridge Drive Bellefonte, PA 16823

963 South Center Ave New Stanton, PA 15672

179 Perry HWY Hamony, PA 16037

2550 East Cumberland St. Lebanon, PA 17042 640 Lowther Rd. Lewisberry, PA 17339

UNITED CONSTRUCTION & FORESTRY

www.unitedequip.com

80 Southbridge Rd. • Route 20 North Oxford, MA 01537

508/987-8786

2397 GAR Highway • Rte 6 & 136 North Swansea, MA 02777 508/379-9810

88 Camelot Drive • Unit 42 Plymouth, MA 02360 508/830-9997

1620 Page Blvd Springfield, MA 01104 413/543-5595

4 Sterling Road North Billerica, MA 01862 978/667-4345

34 Page Road West Hermon, ME 04401 207/947-6786

106 North Street Houlton, ME 04730

207/532-6517

1505 Caribou Road New Canada, ME 04743 207/834-6701

396 County Road Westbrook, ME 04092 207/773-3777

98 Sheep Davis Road Pembroke, NH 03275 603/225-2769

300 Clinton Street Springfield, VT 05156 802/885-6840

Mecalac, a global designer, manufacturer and distributor of compact construction equipment, offers a foldable-canopy version of the MCL2, MCL4, MCL6 and MCL8 — part of its MCL compact loader line.

The foldable-canopy MCL loaders offer an ideal solution in landscaping and especially agriculture applications, according to the manufacturer.

The quick-folding canopy allows operators to leverage the loaders’ benefits in areas with limited overhead clearance, making a spot once inaccessible to machines now a reality. This compactness is especially valuable on a farm where operators are completing work in areas such as livestock stalls and milk parlors.

“Space can come at a premium in some work sites, but that doesn’t mean productivity must be sacrificed,” said Peter Bigwood, general manager of Mecalac North America. “Engineering compact loaders with a folding canopy gives our customers an efficient option to thrive in areas not previously reachable with similar equipment.”

The MCL loaders are compact but robust machines providing features and functionality not found in other machines their size. A folding canopy allows users to work in areas inaccessible by traditional, larger loaders. The loaders are equipped with hydraulic and maneuverability options, M-Drive and Speed Control. With M-Drive, the engine speed can be controlled independently of travel speed, allowing power and hydraulic flow to be adapted to best suit the job at hand. Speed Control allows operators to set the maximum travel speed from 1 mph to the max speed of 19 mph (MCL6 & MCL8 only).

Operators can reduce the machine’s height to less than 6.6 ft., allowing them to drive in areas with limited clearance, operate seamlessly indoors and navigate under carports and garage doors with swift, agile performance.

Operators can easily fold down the canopy in seconds by removing a pin on each column and simply pushing the roof back. This reduces the machine’s height by as much as 1 ft. to less than 6.6 ft., allowing them to drive in areas with limited clearance, operate seamlessly indoors and navigate under carports and garage doors with swift, agile performance.

With exceptional balance between compactness and lifting capacity, MCL loaders can accommodate a range of attachments, including buckets, grapple forks, pallet forks and shredders. An extended boom enhances material handling productivity, making tasks such as stacking bales, managing fodder and cleaning stables simple and efficient.

The MCL series’ optimum height-towidth-to-length ratio ensures agility on any

job site. Each machine has a 45-degree articulation that keeps the front wheels traveling in the same path as the rear wheels while driving. A 10-degree oscillation allows for a strong follow-up and maximum traction wherever the machine might travel, including on uneven ground.

For more information, visit www.mecalac.com.

(All photos courtesy of Mecalac.)

Ahearn Equipment Inc.

www.ahearnequipment.com

Spencer, MA 01562 877/624-3276

Erb & Henry Equip., Inc.

www.erbhenry.com

New Berlinville, PA 19545 610/367-2169

ADMAR Construction Equipment & Supplies

www.admarsupply.com

Vestal, NY 13850 607/798-0333

Tonawanda, NY 14217 716/873-8000

Canandaigua, NY 14424 585/396-0031

Rochester, NY 14623 585/272-9390

Cicero, NY 13039 315/433-5000

Eagle Power Kubota

www.eaglepowerkubota.com

West Chester, PA 19380 610/458-7054

Doylestown, PA 18901 215/348-9041

Pennington, NJ 08534 609/737-7400

Reading Tractor and Equipment

www.readingtractor.com

5538 Pottsville Pike Leesport, PA 19533 610/926-2441

Marshall Machinery, Inc.

www.marshall-machinery.com

Honesdale, PA 18431 570/729-7117

Middletown, NY 10940 845/343-6683

South Abington Township, PA 18411 570/489-3642

Tannersville, PA 18372 570/895-4884

Belvidere, NJ 07823 908/475-8111

Westchester Tractor Inc.

www.wtractor.com

Brewster, NY 10509 845/278-7766

Chappell Tractor

www.chappelltractor.com

454 Route 13 South Milford, NH 03055

603/673-2640

Your hometown Kubota dealers of choice.

Kubota Tractor Corporation announced the launch of the new SVL50x compact track loader from the showroom floor at Equip Exposition, marking its entry into the smallest cabbed compact track loader category on the market.

Featuring a 48-in.-wide frame, the new SVL50x is the smallest compact track loader in Kubota’s lineup and will be available at dealerships beginning in the first quarter of 2025.

“With the trend of putting more houses on less land, and the space between lots getting tighter and tighter, Kubota is filling a need in the market for a narrow, cabbed track loader among construction and landscaping professionals,” said Jerry Corder, Kubota product manager, construction equipment.

lineup and will be available at dealerships beginning in the first quarter of 2025.

“The new SVL50x gives operators a smaller, feature-packed machine, some of which have never been seen on a Kubota compact track loader.”

Available in four models ranging from an open (ROPS) station to a deluxe cab, the new SVL50x is powered by a 49.6 hp (SAE J1995 gross) Kubota diesel engine and features a working range that includes a rated operating capacity of 1,176 lbs. at 35 percent of the tipping load, 4,900 lbs. of bucket breakout force, and a hinge pin height of 101.6 in.

Built for job sites that require a tracked machine that can easily fit through narrow passageways and operate in confined spaces, the SVL50x is just 48 in. wide, and measures 76.5 in. in height and 92.8 in. in length, with an operating weight of 5,620 lbs.

The “x” in SVL50x stands for “extra” due to the number of additional features included in the new model. Similar to Kubota’s larger SVL75-3 compact track loader, the SVL50x is available with a one-piece sealed cab that helps prevent dirt, dust, rain and debris from entering the operator space while providing a quiet operating environment. Another similarity to the SVL75-3 is a 7-in. color LCD touch panel that comes standard on the SVL50x. This gives operators access to a wide range of functions and information at their fingertips, like battery charge, hydraulic oil and coolant temperature, auxiliary mode and fuel level, and also is where the standard rear-view camera is displayed.

Built for job sites that require a tracked machine that can easily fit through narrow passageways and operate in confined spaces, the SVL50x is just 48 in. wide, and measures 76.5 in. in height and 92.8 in. in length, with an operating weight of 5,620 lbs.