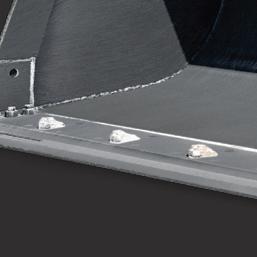

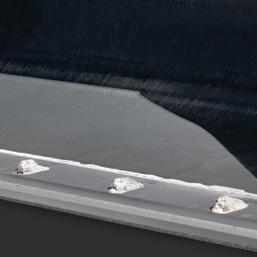

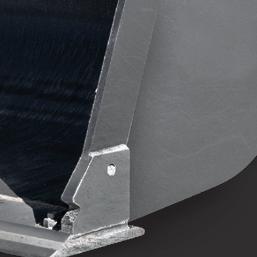

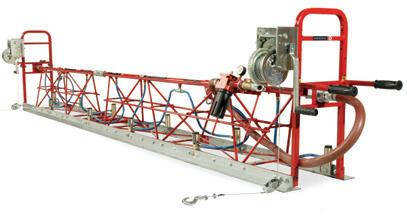

XBroom Sweepers’ special edition Raised On Blacktop sweeper.

Promoting the brand American Pavement Specialists has always been a high priority for Bill Stanley, the company’s owner. Thirty years ago, when he started the company, the name American Pavement Specialists came about partially as a result of the fact that the “A” in the American Pavement Specialists name would put them at the top of the list of the

Paving Category in the Yellow Pages.

But that was 30 years ago, and the Yellow Pages have all but disappeared. In the early 2000s, Stanley saw that the trends had shifted, and it was time to put more emphasis on Web-based marketing.

For five generations, Chappell Tractor has been serving northern New England contractors with some of the most sought-after construction equipment products in the industry. Founded 69 years ago in Milford, N.H., the company expanded in the 90s and 2000s with locations in Brentwood and Concord, N.H.

“With a reputation for a commitment to customer satisfaction and product support second to none, the Chappell family has developed a great following,” said Brad Chappell, partner of Chappell Tractor.

Chappell Tractor has now

SENNEBOGEN, in kee philosophy to maxim created UPTIME Kits

eping with their mize uptime, has Whether you are a service technician i road, these kits have need for every service and PM task in one p created to save you t Managing hundreds o parts, from belts and and special tools bec single part number to n-house or on the everything you e, maintenance place. They were ime and money. of related service d nuts to O-Rings omes easy with a o order and stock

They are:

• Easy to order and ea t d t stock asy to s l

components and too

• Ideal for stocking se and trucks

Choose from the follo

• Central lubrication

• Preventive mainte

• O-Ring kits

• Electrical service k

• Hydraulic service k And the best thing is in stock and ready to built to match your m and series. Count on in-house. For more in UPTIME Kits, scan th s that these kits, go, are custommachine model SENNEBOGEN nformation on he QR code.

Hydraulic service k :kits shops ols ervice owing kits system kits nance service kits its kits

NO North our in parts com with customers maxim commitment h about more Read ontract Demolition C st in parts repair the have virtu and I machine another in If back. to front every come t a have They echnician machine, wntim warehouse. American ready-to-ship of inventories plete for uptime izes aftersale Machine” he “Beyond our ow , Bloomfield Hills, MI or quickly. back unit the g I k they Since do no lose ally bring just [they] situation, a have I over go to month a once through wntime… ock. get theSENNEBOGEN

This summer, workers are building a missing link along Massachusetts’s Mystic River greenways that will bring the network of riverfront paths into downtown Medford, located north of Boston.

The Clippership Connector path is relatively short — only about a halfmile long — but it will give Medford a safe, relatively scenic way to get across Interstate 93, a major barrier in the city for pedestrians, and connect the downtown area with its riverfront parks and schools in the fast-growing districts near the Wellington Orange Line transit station.

Since the project began in 2018, DCR has invested nearly $750,000 in the design and permitting of the Clippership Connector Greenway project.

The path will follow the northern bank of the Mystic River from Medford’s Clippership Park before crossing under the freeway and connecting to the existing Riverbend Park path network behind Madeleine Dugger Andrews Middle School.

It also threads its way between several densely-packed and privately-owned properties, which created some challenging design constraints. At several points, the pathway will run along elevated boardwalks, like the one currently being constructed around the edge of the Medford Housing Authority’s property just west of I-93, to minimize impacts to the riverbanks.

While it is common for people to start using new trails while they are still under construction, that is not really an option in Medford — at least for the time being. Contractors have lined the future trail with

fencing, making it impossible to access while work is ongoing, according to StreetsblogMASS.

For those looking to walk or bike between Medford Square and the other existing Mystic River paths to the southeast, their best option is to take Riverside Avenue from Medford Square, then cut south on Freedom Way to access the riverfront behind the middle school.

In October 2020, the Massachusetts Department of Conservation and Recreation (DCR) presented its final plans for the Clippership Connector, but it was not until last fall that the agency and the city of Medford were finally able to celebrate the beginning of construction on the greenway.

The new trail is nearly a decade in the

making and represents a partnership between the state, the city, local advocacy groups and private organizations.

When the link is completed, it will connect 10 mi. of contiguous greenways through the Mystic River Reservation, one of the original five reservations delineated by the Metropolitan Park Commission in 1893.

Located in five communities — Boston, Arlington, Medford, Everett and Somerville — the reservation has undergone many initiatives to protect open space and to provide contiguous greenspaces, pedestrian and bicycle connections, and active recreation facilities. DCR has been working to implement the most recent master plan that was published in 2009.

Needless to say, the Connector project has been one of the more challenging aspects of the plan and the construction marks a milestone in its completion, the department noted in a news release.

“DCR manages a vast trail network across the Commonwealth that provides communities with critical connections for economic opportunity, recreation and environmentally friendly commuting,” said Brian Arrigo, the state agency’s commissioner at 2023’s groundbreaking event. “The Clippership Connector Greenway will build healthy communities by allowing them to walk,

bike, and run along a section of the Mystic River that, to date, has been blocked from public access.”

Since the project began in 2018, DCR has invested nearly $750,000 in the design and permitting of the Clippership Connector Greenway project. The construction is an additional $4 million investment funded through the American Rescue Plan Act (ARPA).

The project is a collaboration between DCR, the city of Medford, the Mystic River Watershed Association, WalkMedford and the Solomon Foundation through the DCR Partnership Grant Program.

“The Clippership Connector truly connects our community, from Medford Square and the Senior Center to the Mystic River, to schools and parks, and, importantly, a whole bike network,” noted state Rep. Christine P. Barber, D-34th Middlesex. “The result of a partnership between city and state partners, along with local advocates at Mystic River Watershed Association and WalkMedford, is this multi-use path will help to address climate change and improve mobility and quality of life for people in Medford and beyond.”

In addition to maximizing opportunities for riverfront views for the community and increasing accessibility for people of all ages and abilities, DCR noted that the trail also improves the habitat and ecology of the riverbank.

The state agency anticipates construction on the greenway to be completed by 2025.

After the abrupt halt of work last fall on the multi-million dollar and multi-year construction project for the Massachusetts Highway 24/140 interchange in Taunton, crews were back on the site last winter with a new contractor.

Manafort Brothers Inc., with offices in Worcester, Mass., and Cumberland, R.I., took over the project on Jan. 5 after the original contractor walked off the job, according to Massachusetts Department of Transportation (MassDOT) spokesperson John Goggin.

Manafort provides specialty construction and demolition services as well as general contracting services primarily in the northeastern United States. The firm is a prequalified MassDOT contractor, Goggin added, meaning no vetting is needed as it has done work for the state agency before.

With crews working again at the interchange southeast of downtown Taunton, the project includes:

• Construction of a new Mass. 24 southbound ramp to northbound Mass. 140 northbound.

• Widening Mass. 24 to three travel lanes on both sides, plus acceleration and deceleration lanes at interchange ramps.

• Replacing several bridges, including the Mass. 24 span across Mass. 140, in addition to a pair of bridges on Mass. 24 above several railroad tracks to be used as train lines for South Coast Rail.

• Reconstructing the interchange ramps between the two highways, including two lane entrance ramps from Mass. 140.

• Building a bypass lane on southbound Mass. 140, between the Mass. 24 north and south ramps.

• Widening Mass. 140 for additional turning lanes and a bypass lane.

• Drainage work, including an extension of the culvert on the Cotley River.

When asked by the Taunton news source, Goggin did not specify how much of this work had already been completed

by the former contractor.

The construction is currently listed as 20 percent complete, according to MassDOT’s listing of highway division projects.

After previously estimated to be finished by summer 2027, last year’s delays have pushed the new completion date to the fall of 2027, Goggin told the Gazette.

Last November, Goggin told the Gazette that whoever was the replacement contractor would be doing it under the original terms and agreed upon costs of the project. The previous builder had initially won the construction bid in late 2020 for $116.5 million.

The current $139.2 total project price tag includes a contingency fund, construction engineering and traffic police details.

The original builder on the Mass. 24/140 interchange started work at the site in May

2021 before officially suspended operations in October 2023. It had been dealing with financial troubles and went out of business at the end of the year, according to the Providence Journal.

Manafort’s portfolio of work in the two New England states has included rehabilitation and demolition of at-grade railroad crossings associated with South Coast Rail, structural concrete work for New Bedford’s Marine Commerce Terminal, foundation and concrete work for a residence hall at the University of Massachusetts at Boston, all the concrete and steel work for Worcester’s Polar Park, massive renovation work for St. Mary’s Hall at Boston College, and civil engineering, utility and excavation work associated with new office, housing. and retail buildings in Somerville’s Union Square.

Additionally, Manafort is the main contractor for the 1,295-ft.-long Providence Viaduct Bridge project on Interstate 95 in Rhode Island.

With its construction recently completed, Maine Medical Center (MMC) in Portland is scheduled to begin admitting patients June 9 to its new 300,000-sq.-ft. Malone Family Tower, located on Congress Street.

The new $378 million facility, which will primarily serve cardiac and cardiovascular patients, is the final piece of the medical center’s multi-year expansion and modernization effort to enhance patient access to hospital-based care, create more private rooms and help facilitate better patient outcomes.

At eight stories tall, the Malone Family Tower increases MMC’s capacity to care for patients and represents a significant modernization of its facilities. The building includes 96 private patient rooms, 10 operating rooms, nine procedure rooms, and 40 pre- and post-procedure beds.

Sitting atop the tower will be a new 20,000-sq.-ft. sterile processing department (SPD) that will serve all of the operating and procedure rooms at MMC. The building also features ample space for patients and visitors as well as multi-disciplinary collaboration and learning for care team members.

The Malone Family Tower’s glass exterior is designed to bring in natural light and transform a major gateway into the city of Portland.

Visitors to the facility will be able to drive up and drop off patients before directly accessing MMC’s patient and visitor garage on Congress Street; valet parking also will be available at the tower’s entrance. In addition, the Congress Street entrance will supplement the hospital’s main entrance on Bramhall Street.

“The Malone Family Tower is a muchneeded investment in our patients, our care team, and our entire region,” explained MaineHealth Southern Region President Britt Crewse. “Without a doubt, the modern clinical care space in this facility will improve our ability to serve our state’s most acutely ill patients with the highest-quality care.”

It also was developed to meet a growing need for cardiac and cardiovascular care in the region with flexible spaces that promote collaboration and innovation among members of MMC’s nationally recognized cardiovascular care team. By adding 32 intensive care unit (ICU)-level beds to the hospital, MMC’s total number of ICU beds will increase to more than 100.

“[The hospital’s] cardiovascular team provides extraordinary care, and with the Malone Family Tower we have a facility that matches that high bar,” said Joel Botler, MaineHealth Southern Region’s chief medical officer. “Today, we cannot serve all of the patients who require this type of care at Maine Medical Center. This tower allows us

The new $378 million facility, which will primarily serve cardiac and cardiovascular patients, is the final piece of the medical center’s multi-year expansion and modernization effort to enhance patient access to hospital-based care, create more private rooms and help facilitate better patient outcomes.

to [do so] both today and for tomorrow.”

MMC performs the most cardiac and cardiovascular procedures in Maine, including more than 1,200 open heart surgeries, approximately 5,000 catheter-based procedures and about 600 ablations a year.

The Malone Family Tower was created with sustainability in mind, according to a news release from MMC. The facility is designed to be Leadership in Energy and Environmental Design (LEED) Silver Certified and its construction materials are recycled whenever possible. The tower also has a “green roof” to reduce water runoff, minimize any “heat island” effect, and offer a calming space for patients and care team members.

Additionally, the tower provides a muchneeded enhancement to MMC’s campus infrastructure, which was built out over several decades. The new building was completed on time and on budget, despite facing numerous construction challenges during the pandemic and a period of significant inflation. Its architects designed it to minimize operating costs by stressing flexibility, utility and efficiency.

“Health care excellence requires strategic,

fiscally responsible investment,” noted Crewse. “The Malone Family Tower was built with an eye toward Maine’s future, in keeping with the MaineHealth vision of working together so our communities are the healthiest in America. Many people — from city, state and federal officials to clinical experts to construction and trades professionals — kept us on track and we are so grateful to them all.”

The completion of the Malone Family Tower marks the end of MMC’s expansion and modernization project that began construction in 2018, which also included:

• An expansion of the hospital’s patient and visitor parking garage, completed in 2019.

• The addition of two additional floors containing a total of 64 private rooms as well as the Linda and Diana Bean Sisters Heliport atop MMC’s Coulombe Family Tower, also finished in 2019.

• The 2020 completion of a new parking garage for the MMC care team.

• A new medical office building opened in 2021 and dedicated to specialty care on MMC’s Scarborough campus.

Funding for the multi-million-dollar Malone Family Tower comes from reserves, operating revenues, grants, bonds, and, most importantly, generous donations from the

community, the hospital noted.

The tower is named in recognition and appreciation of John and Leslie Malone, whose $25 million donation to The NEXT 150|The Campaign for Maine Medical Center in 2021 was the largest single philanthropic gift in MMC’s history.

The Malones joined more than 2,600 benefactors in supporting the capital campaign between 2017 and 2023, which raised $179 million in designated funds to support MMC’s mission through facility expansion and modernization, workforce development and innovation and clinical research.

Maine Medical Center, recognized as a Best Regional Hospital by U.S. News and World Report for 2023-2024, is a complete health care resource for the people of Greater Portland and the entire state, in addition to northern New England.

Incorporated in 1868, MMC is the state’s largest medical center, licensed for 700 beds and employing more than 9,600 people. The facility’s role as both a community hospital and a referral center require an unparalleled depth and breadth of services, including an active educational program and a worldclass biomedical research center.

As a nonprofit institution, MMC also provides nearly 23 percent of all the charity care delivered in Maine.

“My vision was a website that would help customers understand what we offer and what various aspects of their project would look like,” he said. “I envisioned a website that would have a ‘Paving’ tab and give a video of what paving looks like. The same idea with ‘Milling,’ ‘Striping,’ and any of the services that we offer.

“Unfortunately, Web development at that time was very expensive and it was difficult to accomplish exactly what I was looking for,” he added. “It didn’t really have a name at the time, but we were one of the first companies to use social media to promote ourselves. There was no Instagram, Tik Tok or YouTube, but what was out there was a site called Facebook that was wildly popular with young people, and that’s where our social media presence started.

“We made up our own Facebook business page account and we started by taking pictures of trucks, primarily because my kids were at an age when they thought trucks were really cool and would get a lot of attention. We then started to put pictures of projects that were completed or in the process of being worked on. In no amount of time at all our Facebook became wildly popular. The

best part was it was free.

“Over time we loaded Facebook with pictures and videos of everything we do. If we were quoting a milling job and the customer asked about the milling process or what equipment we use, we could send them straight to Facebook. When Instagram came along, we immediately got involved with project pictures and in no time at all we had

10,000 followers. Instagram, with its heavy emphasis on photographs, turned into an overnight sensation for us. We currently have 143,000 followers on Instagram.

“YouTube has been another big success for us. We just keep feeding it videos of our projects. The YouTube channel has been a big hit within the industry. I am constantly amazed by how

American Pavement Specialists is one of the leading paving and milling contractors in the state of Connecticut and the company’s owner, Bill Stanley, is a well-known media influencer for the asphalt equipment industry. The company recently purchased its third Bagela asphalt recycler, following the purchase of two recycling machines in 2012.

The general purpose of the Bagela is to turn pavement waste (ground millings, etc.) into a hot mix asphalt that can be produced year-round. A significant percentage of the asphalt is used in the off season to repair damaged areas such as potholes.

According to Stanley, “We purchased our first Bagela in 2012 and have worked closely ever since with Greg Harla, our representative with Bagela. If you look at the typical paving contractor in the United States, it’s almost always family run. It might be brothers, it might be father and son, but there is always that family connection.

“To a company like ours, relationship and support is everything,” he added. “When we started working with Greg, he was a tremendous source of information on how to recycle and turn into cash asphalt that we had previously been unable to find other applications for. But, more than just his knowledge, he also supports our company. Greg has been instrumental in promoting our

Raised on Blacktop social media presence and introducing it to other contractors and equipment manufacturers.

“But more than just lip service, he has also come to the table with a special Raised on Asphalt Bagela recycler. That’s the kind of support that keeps us coming back to Bagela.”

To accommodate the new Bagela recycler, American Pavement Specialists has built a loading area so that the millings can be delivered and stockpiled effortlessly. The machine has been raised off the ground to accommodate better loading with mafia blocks and with a shed enclosure built around the Bagela recycler so that approximately 20 tons of material can be kept dry and the operator is given an opportunity to get out of the weather.

many of our fellow contractors and people involved in paving equipment manufacturing are tracking our posts on YouTube.” Stanley’s sons have been involved in the business since a very young age, and they take a lot of pride and an active role in the company’s Web marketing — they developed the idea of becoming social media influencers within the paving industry. They also developed the phrase “Raised on

Because most of product being made is for winter road repair, most of the production for the Bagela recycler is done in cold weather. Most of that product is sold to customers, typically municipalities or contractors focusing on municipal work. It’s a great market for American Pavement Specialists: cold patch repair has been determined to be ineffective and costly. Filling holes with recycled hot asphalt has become the new normal in winter repair work.

The product also is used by utility contractors who are patching their road cuts. The asphalt plants are typically closed for the winter so if contractors are producing hot recycled asphalt, they can effectively capture that winter market.

The market for the recycling asphalt is not just limited to road repair. If someone is looking for a basic paved pad or yard where the quality of the finish is not critical, the Bagela recycler is producing an affordable alternative to using virgin asphalt, Stanley said.

“We produce a product called Contractors Mix.

CHAPPELL from page 1

customers,” said Corey Chappell, president of Chappell Tractor.

When Hitachi expanded its product offering to include excavators, Chappell Tractor was named the exclusive dealer of Vermont, New Hampshire, Massachusetts, Rhode Island and parts of Connecticut.

“With 26 in-house technicians, nine mobile technicians, 16 parts reps and nine sales representatives, we are well prepared to support the 7,500-square-foot facility that we have opened in Hopedale, Mass.,” Chappell said.

Chappell Tractor’s new facility has been recently remodeled and offers four service bays, a wellinventoried parts department and a great selection of Hitachi machines available for sale or rent. The Hitachi product offering includes 12 models of compact excavators, along with five models of compact wheel loaders, 28 mid-sized to large excavators, 18 mid-sized to large wheel loaders. Hitachi’s mining equipment division offers 17 quarry sized excavators and six haul trucks.

Mark Westberg will be the general manager of the Massachusetts facility, and Chris Lajoie and Josh Stack are the newest members of the equipment sales team at the Massachusetts store.

For more information, visit www.chappelltractor.com. CEG

(All photographs in this article are Copyright 2024 Construction Equipment Guide. All Rights Reserved.)

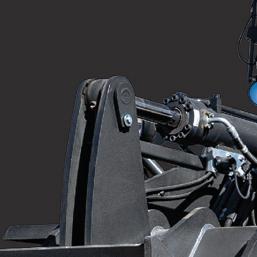

A special auger system that allows for direct asphalt placement was jointly engineered between Trout River and American Pavement Specialists.

In fact, the recycling area of American Pavement Specialists yard was produced using recycled asphalt. Another application that has created significant savings is preserving for later use excess virgin asphalt from a project.

PAVEMENT from page 8

Blacktop.”

The idea was to create a forum that promotes the asphalt and paving industries as well as giving information on how paving contractors can improve their businesses. Once again, it became nearly an overnight sensation, Stanley said.

Today “Raised On Blacktop” has 75,000 Instagram followers as well as several thousand followers on Facebook. In fact, the “Raised on Blacktop” concept has become so popular it now has its own apparel line. There is a daily stream of orders for branded hats, t-shirts and hoodies. In 2023, they had hundreds of thousands in just t-shirt sales. Orders come from across the world, including Paraguay, Australia and Saudi Arabia.

The company is even currently working on a deal to create “Raised on Blacktop” work shoes.

According to Stanley, the Raised on Blacktop theme has become so

“It is not unusual to overestimate the amount of asphalt to be used on a project, which has been a real problem. What do you do with it? Once it cools, it’s useless to you and you can’t just stockpile hot asphalt and use it the next day. We are stockpiling our excess asphalt, reheating it and running it through the Bagela recycler, and we are able to use the excess product on our next project.

“What’s really surprising is how long a pile of hot asphalt will maintain its temperature. A load that is left in our yard at the end of the day will typically hold much of its temperature beneath the surface of the crusted over pile, so it’s really not a big jump to get the entire pile back up to the required temperature when you start out the next day. It’s just like throwing the asphalt in a microwave and reheating it. It’s just as good a product as it was the day before.

“Essentially, I’m taking a 1 percent waste factor and turning this into savings. Which at the end of the year becomes very substantial for APS. An

additional benefit is not having to extend your workday into the evening because too much asphalt was delivered for that day’s project. If it’s a multiple-day project, we would typically end up working into the night to lay the extra load of asphalt, which does not make for a happy employee. Now we can just resend that load back to our yard and heat it back up the next morning. This also helps control unplanned overtime.”

The Bagela recycler is a significant revenue enhancer for American Pavement Specialists.

“Wintertime, we typically wouldn’t have much else to do besides maintain equipment. The Bagela recycler keeps the crew busy and cashflow coming

in, which is good for everybody.”

Greg Harla of Bagela mentioned some benefits that he is seeing by doing cross promotion with Raised on Blacktop.

“Bill and his family have used multiple videos of the Bagela at work through their social media platform,” he said. “We now have potential customers come to us that don’t need an education process because they are already up to speed on what the Bagela does.”

“It’s an extremely reliable machine,” Stanley added from his experience of more than 12 years of using the Bagela product. “It’s built with a double jacket concept and the flame never touches the material, so you don’t ever have to worry about a burn factor. We’ve only had one machine failure in the past 12 years, which we repaired, but it was an issue with our own operation of the machine. It was not the fault of the Bagela.

For more information, visit www.bagelausa.com.

from page 14

popular that companies like LeeBoy, Mauldin, John Deere, Bagela, Wirtgen, Trout River Trailers, XBroom Sweepers and Shoulder Master sweepers have released special “Raised on Blacktop” editions of their equipment.

“They pay us to operate their equipment and then promote it on our social media platforms,” Stanley said. “As an example, Mauldin released a Raised on Blacktop motor grader that includes the Raised on Blacktop logo prominently displayed on the machine and a number of upgrades to the machine that we worked with Mauldin to develop, including a special lighting package, a more comfortable seat and a special paint job.

“Trout River Trailers worked closely with us to develop an auger truck for an asphalt transfer trailer. It features an 8foot auger for unloading in specific spots, particularly in hard-to-reach areas, and the auger is completely operated by a remote control to give very precise delivery and allowing your worker to see exactly what is going on. The end result is something that looks a little bit like a hybrid of an asphalt trailer and stone slinger. “Trout River was amazing to work with. We had a concept of what we wanted but did not have the capacity to create it and their engineers worked very closely with us to create a new product to help us specifically meet some of our needs.”

XBroom, a sweeper company, also has gotten onboard with a Raised on Blacktop special edition. Like the others, it features the Raised on Blacktop logo and then some added features that aren’t included in its standard lineup.

“The LeeBoy special edition model is a LeeBoy 8520 paver, again with the Raised on Blacktop logo and some extra features that we worked with LeeBoy on. For instance, we made a tool carrying kit that holds shovels, rakes, etc. It has a special color scheme, additional LED lighting and strobe lights for visibility. More than 250 machines have been sold thus far.

“This machine is so popular that LeeBoy has them on backorder. LeeBoy was the first company to work with us on special edition machines. We have a great history with LeeBoy; we’ve done business with them since we opened our doors and I’ve probably bought 20 LeeBoy machines in the past 25 years. We’ve stayed very loyal to the LeeBoy brand. They demonstrate a huge commitment to the paving industry, and they are leaders in innovation. Just about every year there are improvements to the machines that were close to perfect to begin with.

“Raised on Blacktop is designed to accomplish that, but also to help encourage a new generation of people coming into this industry and make sure that they are well suited to do excellent work.

“We consider ourselves a premium contractor. We do extremely good work and as a result we get paid a premium price. We are showing other contractors how to achieve getting themselves into this premium contractor position. It is to our advantage at American Pavement Specialists to have as many paving contractors as possible doing premium work. The reason, if everyone is doing premium work, the industry can maintain work at healthier pricing levels because they’re not competing with competitors that do inferior work.

“I have been in this business for 45 years,

We don’t find ourselves in the polarizing position of not being able to find help.

“Through things like putting cabs on rollers, we make our employees’ working environment as pleasant as possible. The machines in our fleet are new or like-new, which is a pleasure for an employee to operate. After every job, we clean and service every piece that’s been used so that our employees have good and reliable equipment to go out and work with. American Pavement Specialists has built a brand that people want to work for.”

where I started with a pick and a shovel. We have a lot of experiences to share. We are always looking for ways to do a better job and when we find them, we use Raised on Blacktop and its social media presence to share that information.

“We try to instill in all of our followers the importance of giving your employees as good a working environment as you can possibly have, considering the extreme conditions we work in. For instance, we have started ordering our asphalt rollers with a heated and air-conditioned cab. It’s critical these days to keep your employees as happy as possible.

The service and maintenance of the equipment fleet does a lot more than just keep employees happy. The equipment in the fleet is typically worth hundreds of thousands of dollars. Keeping machines in peak working order is a part of the company’s philosophy that pays off with significantly longer life of the machines, which in turn pays big dividends. Stanley’s heavy emphasis on marketing his company, producing excellent quality work and taking good care of his equipment has all paid off. In Connecticut, Stanley said, he is known as the guy you want doing your job. It’s not unusual for potential customers to immediately say, “yes, I’ve heard about you guys, you do really good work.”

American Pavement Specialists is a marketing-driven company, and it does far more than market its website and its social media platforms. For example, at one time it sponsored a car in the NASCAR truck series that was driven by Spencer Boyd. Another aspect of its marketing vision is having every machine in the fleet carefully detailed with the company’s logo, and then making sure that every machine looks as shiny and clean as the day it was purchased when it is delivered at the job site, further enhancing American Pavement Specialists’ image.

For more information, visit www.americanpavement.com. CEG

(All photographs in this article are Copyright 2024 Construction Equipment Guide. All Rights Reserved.)

Equipment East, LLC

61 Silva Lane Dracut, MA 01826 978-454-3320

196 Manley Street Brockton, MA 02301 508-484-5567 1474 Route 3A Bow, NH 03304 603-410-5540

www.equipmenteast.com

30 Birch Island Road Webster, MA 01570 508-949-0005

7 Harry’s Way Webster, MA 01570 508-949-0005

1608 John Fitch Blvd South Windsor, CT 06074 860-288-4600

www.barryequipment.com

164 Boston Post Road Orange, CT 06477 203-795-0591 www.fwequip.com

45 Dempsey-Greaves Lane Stillwater, ME 04489

207-827-6193

www.centralequipmentco.com

New Hampshire officials and area residents remain at odds over plans to fix the 94-yearold Cheshire Bridge, which spans the Connecticut River between Charlestown, N.H., and Springfield, Vt.

The state’s Department of Transportation (NHDOT) had planned to advertise the project to contractors in the fall and begin work next spring that would require closing the bridge for 34 weeks, according to Valley News, a daily news source for the Upper Valley region of New Hampshire and Vermont.

That plan has been delayed until at least 2026; in the meantime, though, business owners and others remain concerned about the impact of the project.

The three-span Pennsylvania truss Cheshire Bridge carries traffic from N.H. Highway 11 to U.S. Highway 5 in Vermont.

On May 15, with about 40 people in attendance inside Charlestown’s old town hall, David Scott, NHDOT’s in-house design chief, presented a pair of options for fixing the structure. The first would close the bridge for eight weeks for overhead painting, while the second called for a one-lane traffic restriction on the span lasting almost eight months.

He added that the bridge rehabilitation would take place over two construction seasons.

While eight weeks of complete closure was an improvement over 34 weeks, those who spoke at the meeting said it was still too long.

“It is better, but it does not sound all that great,” said Charlestown resident Phil Turner.

Under the second alternative presented by Scott, large trucks could not fit in the single lane and would need to detour to other crossings. If that option were approved, one lane would be widened from 8 ft. to 12 ft. to allow for truck traffic.

Additionally, expanding the one-lane width would mean equipment for painting the structure would be placed on a barge in the river instead of on the bridge deck.

But, Scott added, using a barge would make the Cheshire Bridge project more complex and increase the environmental impact to wetlands and endangered species. In addition, because the Connecticut River is shallow, a bulkhead would have to be constructed on the water’s edge to load the barge with the needed equipment.

Without the longer full closure, the original price to repair the bridge of $6.3 million would increase to $9 million with the barge, Scott said.

Valley News reported that a number of residents at the meeting felt that an entirely new bridge would be a better long-term solution than repairing and repainting the existing 489ft-long, 21-ft.-wide structure, first constructed

in 1930.

The last time the Cheshire Bridge saw a paint job was in 1992, which required it to be closed to traffic for about four weeks. Additional repairs were completed in 2015, according to the news source.

Turner and others contend the bridge is too narrow for today’s vehicles and because of its age, will require more costly maintenance in the years ahead. Many suggested it should be used for pedestrian and bike traffic once a new bridge is constructed.

Among those arguing for a new structure over the river were Charlestown business owners Matt Blanc of Blanc and Bailey Construction, and Albert St. Pierre of St. Pierre Sand and Gravel.

St. Pierre noted the $20 million that NHDOT has budgeted for permanent repairs to a section of N.H. 12 in South Charlestown, damaged by heavy rains three years ago, could be better spent on a new replacement for the Cheshire Bridge.

“Give it to us for a new bridge, please,” implored St. Pierre.

Fellow Charlestown resident Vincent Jordan said a bridge closure would burden many people with longer, more expensive commutes. The closest crossings on the Connecticut River are 10 mi. north of town and 9 mi. to the south.

Jordan referred to the river crossing at Brattleboro, Vt., where a second bridge was constructed in 2003 next to a 1930s-era span, the latter of which has been converted for use by pedestrians and bicyclists, as something he would like to see in his town.

“Why can’t you do it here?” he asked Scott. “In 10 years, you will be back here [to make repairs]. Do the right thing. Build a new bridge.”

If approved, Scott said a new span connecting Charlestown and Springfield, Vt., would be moved to the end of NHDOT’s next 10year plan and would not be constructed for at least another decade.

At the very least, residents called for a temporary bridge to be put in place before repairs to avoid a complete closure and suggested the state transportation agency work with the U.S. Army Corp of Engineers.

However, Scott explained that a temporary bridge would add years to the project and another $5 million to $6 million in costs, raising the entire construction effort to approximately $14 million.

At the conclusion of the May 16 meeting, NHDOT Commissioner William Cass assured everyone that his agency will continue to research the best path forward for the Cheshire Bridge, even if that takes another two or three years.

“We want to make sure whatever project comes out of this it is not rushed,” he said. “If we have to take more time to develop a consensus, we will do that.”