Snyder Civil, headquartered in Portland, Conn, is an engineering/construction firm that provides a full range of services from the initial planning and design to the successful construction completion since its founding in 2011.

Snyder prides itself on working with clients to provide clean water, create safe communities and build and maintain sustainable infrastructure. Under the leadership of Donald R. Snyder Jr., a licensed professional engineer, the company has a record of success overseeing all phases of civil engineering projects for municipalities, government and private sector clients. The company boasts years of experience in water distribution systems, water mains, water storage tanks, pump stations, dams and operation assistance.

Snyder Civil is essentially two companies under one roof: Snyder Civil Engineering for design and planning of projects as well as land surveying; and Snyder Civil Construction, under the

Robert H. Finke & Sons held an open house Sept. 12, 2024, at its new facility at 429 Troy Avenue in Colchester, Vt., just north of Burlington.

The event included lunch, refreshments, displays from equipment manufacturers and facility tours.

“The decision to open a facility in Vermont had several determining factors,” said Don Fiacco, general manager of Robert H. Finke & Sons. “Several of the manufacturers that we represent were looking to find representation in the Vermont market and with

SENNEBOGEN, in kee philosophy to maxim created UPTIME Kits

eping with their mize uptime, has Whether you are a service technician i road, these kits have need for every service and PM task in one p created to save you t Managing hundreds o parts, from belts and and special tools bec single part number to n-house or on the everything you e, maintenance place. They were ime and money. of related service d nuts to O-Rings omes easy with a o order and stock

They are:

• Easy to order and ea t d t stock asy to s l

components and too

• Ideal for stocking se and trucks

Choose from the follo

• Central lubrication

• Preventive mainte

• O-Ring kits

• Electrical service k

• Hydraulic service k And the best thing is in stock and ready to built to match your m and series. Count on in-house. For more in UPTIME Kits, scan th s that these kits, go, are custommachine model SENNEBOGEN nformation on he QR code.

Hydraulic service k :kits shops ols ervice owing kits system kits nance service kits its kits

NO North our in parts com with customers maxim commitment h about more Read ontract Demolition C st in parts repair the have virtu and I machine another in If back. to front every come t a have They echnician machine, wntim warehouse. American ready-to-ship of inventories plete for uptime izes aftersale Machine” he “Beyond our ow , Bloomfield Hills, MI or quickly. back unit the g I k they Since do no lose ally bring just [they] situation, a have I over go to month a once through wntime… ock. get theSENNEBOGEN

EVENT from page 1

Finke’s Selkirk, N.Y., headquarters being in proximity to Vermont, we had already established a customer base in Vermont.”

In Vermont, Finke is representing Kobelco, BOMAG, StewartAmos, Superior Brooms, Indeco, Geith and Engcon.

Robert H. Finke & Sons also recently announced that it is now the exclusive distributor of Gradall in Vermont. From the Colchester, Vt., location, Finke is offering sales, service, parts and rentals for all of the products it represents. With five service bays and plenty of space in the parts department, the Colchester store is well positioned for future growth. CEG

(All photographs in this article are Copyright 2024 Construction Equipment Guide. All Rights Reserved.)

see EVENT page

Equipment East has = job the compact machine to ell do w one.

ork modes pl and w us one of the highest

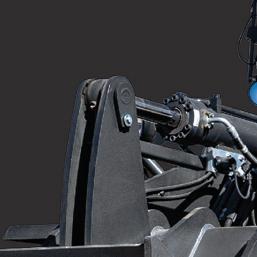

Engcon is changing how contractors excavate with their tiltrotators. Nick Bacon, Engcon area sales manager, was eager to discuss it with customers.

EVENT from page 4

Jim Berryman has been representing Eager Beaver for decades.

direction of Mike Archer, who executes the construction phases of the projects that are designed and engineered by Snyder Civil Engineering.

Snyder and Archer have a long history together. According to Snyder, “Mike and I grew up together in Portland, Conn., attended and graduated high school together, after which I went on to attend Roger Williams University to obtain my Bachelor Degree of Science and Civil Engineering and Mike attended the University of Maine in Orono, Maine, to study construction management.

“Upon graduation, Mike went to work for a Conn.-based heavy civil construction firm and I got a position in Fairfield County, Conn., working for a firm that specialized in water utilities. Over the years, we stayed in contact and maintained our relationship.”

In 2011, Snyder went out on his own and started Snyder Civil Engineering, where he focused primarily on engineering and design work for water utilities, which includes water main pipelines, pump stations, tank work and water treatment plants. Over time, Snyder and Archer saw the logic in expanding Snyder Civil Engineering to include Snyder Civil Construction and have the ability to offer clients a turn-key operation that includes design, engineering, as well as construction and completion of a given project.

“There are a couple of different approaches that are taken,” Snyder said. “One being the two companies partnering and preparing a design/build proposal where Snyder bids the project from start to finish. In other cases, Snyder Civil Engineering. performs the engineering and design of a project and puts it out to bid with the prospect of Snyder Civil Construction winning the bid to execute the project. Approximately 75 percent of the time, Snyder Civil Construction is able to win the construction phase bid.”

Most of the work designed and built by Snyder is in Fairfield County, a prosperous and affluent area of Connecticut. However, the company does not exclusively work in Fairfield County; it has tackled projects all across the state.

Snyder believes that there is a definite benefit to the client when Snyder Civil Engineering and Snyder Civil Construction are working together to execute a project.

“When we work together, the customer benefits with cost and value,” he said. “We can assure the customer that there will be high levels of quality control, cooperation and performance that may not necessarily be the case when the construction firm and the engineering firm are separate parties.

“We are also typically able to accelerate the construction schedule when our two teams are working together,” he added. “As one firm prepares the drawings and the plans, they are able to review the design phase of the project with their construction team to assure the feasibility and cost of the project.

“We know from experience that what a team of engineers

designs cannot always be executed in the real world once the contractor starts the project. By working together with our construction team, Snyder Civil Engineering is able to avoid difficult challenges once a plan goes into the build phase. We can also work through some economical approaches to make design revisions that will deliver a more affordable project for the water utility.”

Currently, Snyder Civil Engineering and Snyder Civil Construction are working together on the construction of the Dorwin Hill booster station in New Milford, Conn., a $1.6 million project. The purpose of the project is to supply municipal water to an area of New Milford, Conn., that previously had no municipal water access. Snyder Civil Engineering designed the water mains for the street area, in addition to designing the two booster stations that will make the water supply accessible.

The Dorwin Hill booster station is the final booster station and storage facility so that the water gets pumped to the new service area.

“New Milford has a main system that is referred to as the New Milford Main System,” Snyder said. “That is the whole water system of the developed corridor of New Milford, which is essentially Route 7 as it flows along the Housatonic River. That system determines the base water level.

“The owner of the system is the Aquarion Water Company of Connecticut,” he added. “They are the largest water utility in the state and the New Milford main system is

Besides the need for more public financing, construction of a proposed minor league soccer stadium on the lower East Side of Bridgeport, Conn., faces another wrinkle in the form of possible interference from a nearby state infrastructure project.

The Connecticut Department of Transportation (CTDOT) and Bridgeport Mayor Joe Ganim’s administration confirmed that a vacant municipal parcel that would serve as a public park and gateway into the future sports venue will for two years be a staging area for a nearby $30 million bridge replacement effort.

“Connecticut DOT will

be using a portion of the property for the upcoming Stratford Avenue Bridge replacement project,” Josh Morgan, that agency’s director of communications, said in an email to CTPost. “The location will provide staging of equipment and material, as well as provide access to the bridge.”

Morgan added that CTDOT has obtained a temporary property easement for access to the acreage, formerly the home of the now-demolished AGI rubber factory, and the land will revert back to Bridgeport at the bridge project’s conclusion.

However, the challenge that awaits tech entrepreneur and stadium developer Andre Swanston, his Connecticut Sports Group and the city is figuring out how to schedule the construction of both the soccer venue and the bridge so that they do not conflict with one another.

CTPost reported Sept. 8 that the bridge work is set to begin next spring and conclude by the end of 2026, while Swanston’s development group had hoped to open the stadium in time for that year’s soccer season.

If and how that latter goal can still be met is the question as AGI’s land needs to be cleared of environmental contaminants before being redeveloped as a sports stadium.

“At this point we’re just in a question of logistics,” said Thomas Gaudett, Ganim’s chief administrative officer.

He noted the bridge work has been in the works for some time and is not “out of the blue.”

“Does [the bridge project]

complicate things? Sure,” Gaudett acknowledged, “but we’ve had this conversation. Everyone knows it’s an issue. And we’re all hoping to play nice to get everything accomplished.”

Announced in 2023, Swanston’s vision is to launch a minor league soccer team, Connecticut United, and build its 7,500seat stadium on Bridgeport’s waterfront, followed by a major league venue and other attractions. Its design was done to make it accessible and centrally located.

The main soccer facility construction would occur on privately-owned land along the banks of the Pequonnock River on Kossuth Street where the now-shuttered Shoreline Star off-track betting facility operated. The city offered the adjacent AGI property as an important complement to the development.

Swanston initially set his sights on having the stadium open by next year, but Connecticut Sports Group noted on Aug. 30 that those plans had been delayed until 2026.

Public financing totaling $16 million, in the form of combined grants for environmental remediation and site preparation, were awarded to Swanston for the Bridgeport development, but CTPost noted that the project still needs additional substantial public investment.

For that reason, and because the parties are still working out the details necessary for the release of the initial $16 million, the move

from 2025 to 2026 was not surprising.

In its Aug. 30 statement, Connecticut Sports Group said the delay will “enable us to complete much-needed infrastructure work around the stadium site and continue to build out our talented staff.”

Swanston got more specific in a social media post from early September when he cited the CTDOT bridge project as one of the main reasons for the timetable change but was not critical of it.

“This much-needed infrastructure investment will make the bridge safer for all auto, boat, and pedestrian traffic,” he wrote. “We’re working with the DOT and city of Bridgeport to mitigate the effect their work will have on stadium construction logistics and timeline.”

Gaudett similarly described the Stratford Avenue Bridge replacement as an overall positive for the city and the soccer plan, noting that the new infrastructure will better accommodate the current and anticipated increased traffic to Bridgeport’s lower East Side.

More people are visiting that area of town due to the Steelpointe redevelopment, across Interstate 95 from where the soccer stadium is proposed, CTPost noted.

The multipurpose shopping and restaurant destination currently includes a Bass Pro Shop, a Starbucks coffee shop and a new marina with a Boca Seafood restaurant. In addition, ground has been broken in the development for the construction of as many as 1,500 new apartments.

interconnected with other larger systems, therefore there is a lot of redundancy. New Milford also has a lot of hills based on its topography. The elevation across the town can change by hundreds of feet.

“As a general rule of thumb, anytime you have more than 150 feet of elevation change, there is a need for a pumping station if you are going uphill or a pressure reducing facility if you are moving the water downhill. On this project, we have a need for four different tiers, which starts with the water level at the New Milford main system, which then feeds the Prospect Hill booster station. The Prospect Hill booster station involves an elevation gradient change, which then feeds the Dorwin Hill booster station. The Dorwin Hill booster station also involves another elevation change.

“In addition to water storage, the Dorwin Hill booster station is also feeding upper water levels at higher elevations. In total, the water from the main is being pushed about 300 feet.”

When completed, water will be pumped into the booster station statically. The water then fills the tanks, which is then pumped out of the tanks, which provides enough pressure to push the water up the hill to the next level, Snyder said.

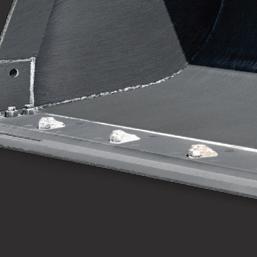

The mass excavation for this project is approximately 1,200 cu. yds. to balance the earth materials. There was an additional 1,100 cu. yds. of mass rock that had to be drilled and blasted. Approximately 600 linear ft. of 12-in. ductile piping for the suction and discharge mains and approximately 240 linear ft. of 12-in. HDPE drainage. There also is

Equipment East, LLC

61 Silva Lane Dracut, MA 01826 978-454-3320

196 Manley Street Brockton, MA 02301 508-484-5567 1474 Route 3A Bow, NH 03304 603-410-5540

www.equipmenteast.com

30 Birch Island Road Webster, MA 01570 508-949-0005

7 Harry’s Way Webster, MA 01570 508-949-0005

1608 John Fitch Blvd South Windsor, CT 06074 860-288-4600

www.barryequipment.com

164 Boston Post Road Orange, CT 06477 203-795-0591 www.fwequip.com

45 Dempsey-Greaves Lane Stillwater, ME 04489

207-827-6193

www.centralequipmentco.com

SNYDER from page 16

approximately 300 ft. of duct bank that is installed for communication and power supply and approximately an acre of topsoil and turf establishment for the completed site. There also will be approximately 75 tons of driveway paving.

According to Archer, “The biggest challenge we have run into in this particular job is rock. We knew there was rock here, but we did not know the magnitude of it. We got the site cleared and we were able to strip the overburden and actually start some layout and open up the site.

“The site was heavily wooded and had a significant slope, which complicated the excavation we needed to do to remove the rock,” he added. “It was necessary to do some blasting and some hammer work to be able to manage the rock and ultimately, we brought in a jaw crusher and reduced the size of the rock to three-inch minus. We produced about 1,000 yards of three-inch minus material, which we ultimately used on site.”

The structure being built on site is 20 by 38 and has a cast-in-place foundation. It will have masonry walls and a traditional truss framed roof. The exterior is covered with hardie plank siding and Azek composite lumber for the trim.

The two storage tanks that are going into this site are constructed of steel and each has a 15,000-gal. storage capacity. The tanks produce the pressure to push the water up hill.

Snyder Civil Construction currently has 14 employees, three who are on the administrative side and 11 employees that are trade workers. The trade employees are broken into three categories: mechanical crew, site and civil workers and a building crew. Snyder Civil Engineering has approximately 70 employees.

Snyder Civil Construction owns its own fleet of equipment consisting of approximately 12 pieces, primarily Caterpillar, with the exception of compaction equipment, which is Wacker Neuson purchased from Able Tool and Equipment.

“We use Able Tool and Equipment for a lot of our compaction equipment and attachments,” Archer said. “We consider them a key supplier. We also use them for specialized equipment such as pumps, generators, drill bits, cut-off saws and tooling, etc. In addition to our small hand compaction equipment, we purchased a Wacker Neuson RC50 dirt roller. We purchased a water trailer from Able Tool and Equipment, which we use more often than you would think.”

When asked why Able Tool and

Equipment, Archer said, “The biggest attraction is their customer service. Like Snyder Civil, they are a very nimble company. When you call them, the person you need picks up the phone or calls you back immediately and their people are highly trained and know exactly what they are doing.

“They know the equipment they sell, and they actually service the products themselves. You are talking directly to the person who can give you the answers and you do not have to navigate your way from two or three levels of employees to get what you need, and they almost always have what you need when you need it. I first started working with Derek [Bauer] at Able Tool and Equipment and his staff in 2011, and the experience was so good I made a commitment to stick with them.

“There are several things that Able Tool and Equipment brings to the table that make them a valuable partner,” he added. “For instance, their ability to balance the tool and equipment. Many other vendors can provide the equipment that Able Tool and Equipment does, but no one else marries the tool and the equipment to meet the equipment as well as they do.

“They are bringing us real value, from the ownership to the field staff. They are true professionals. They study the site and the project and match us up with the applicable tools. They are certainly compaction equipment specialists with equipment that meets our full range of needs from a jumping jack to our Wacker Neuson dirt roller.

“We have also purchased Atlas Copco hammers to work on our Cat excavators. We purchased a broom to fit our Cat 908 loader, which we use to clean up the road at the end of each day. Able Tool and Equipment also helps us work the equation of ownership versus rental and which is more economic for us. They evaluate how much utilization we will have and steer us in the right direction. The equipment we receive from them is always well maintained, eliminating the concern over equipment failure. When emissions are an issue, Able Tool and Equipment has electric powered machines that are available to us. Many of our clients put a high value on being a good steward for the environment and Able Tool and Equipment gives us the equipment we need to satisfy our customers.”

For more information, visit www.abletool.net and www.snydercivil.com. CEG

(All photographs in this article are Copyright 2024 Construction Equipment Guide. All Rights Reserved.)