By Ken Liebeskind CEG CORRESPONDENT

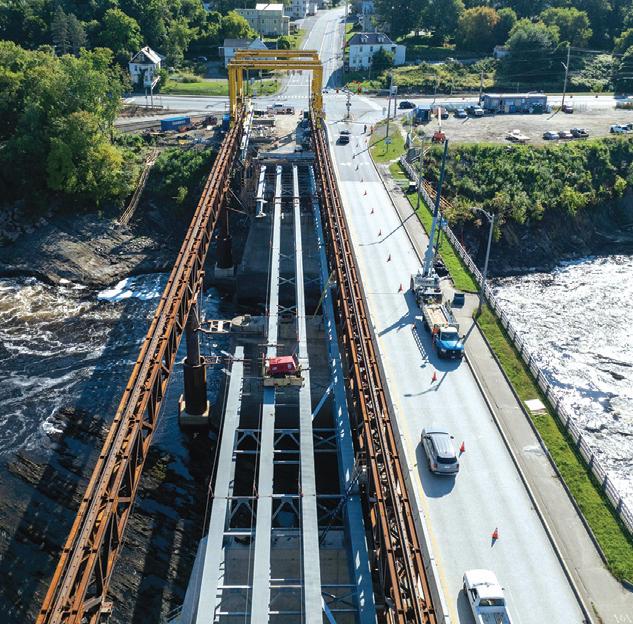

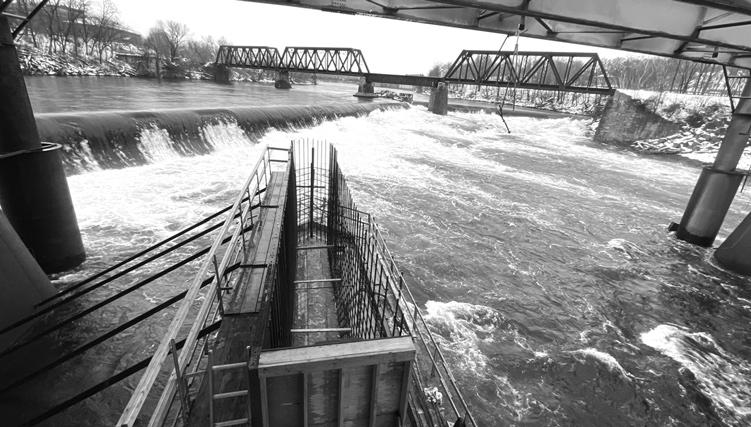

The replacement of the Ticonic Bridge, which carries Bridge Street (Routes 137 and 201) over the Kennebec River between Waterville and Winslow, Maine, is under way.

The $52.85 million project, which received a $25 million BUILD grant from the U.S. Department of Transportation, is being constructed by Cianbro of Pittsfield, Maine.

Construction began in March 2023 with a completion date that has been set at May 2027.

Maine DOT said the project team determined construction will be completed in two stages that will allow the contractor to complete construction activities while accommodating traffic operations and remove and replace the old bridge one half at a time.

The Ticonic Bridge will be replaced on alignment with a new two-span, steel girder with concrete bridge deck structure. A single concrete pier will be built in the river to support the new bridge.

These girders, up to 150 ft. in length and weighing up to 140,000 lbs. each, will support the new utilities and concrete bridge deck.

The work has included leaving the concrete arch as it was, removing the failed truss, reconstructing the piers and building a new riveted steel girder structure to replace the truss, creating the first sizable roadway for vehicular traffic

Powerscreen New England announced it will be offering Continental Biomass Industries (CBI)

SENNEBOGEN, in kee philosophy to maxim created UPTIME Kits

eping with their mize uptime, has Whether you are a service technician i road, these kits have need for every service and PM task in one p created to save you t Managing hundreds o parts, from belts and and special tools bec single part number to n-house or on the everything you e, maintenance place. They were ime and money. of related service d nuts to O-Rings omes easy with a o order and stock

They are:

• Easy to order and ea t d t stock asy to s l

components and too

• Ideal for stocking se and trucks

Choose from the follo

• Central lubrication

• Preventive mainte

• O-Ring kits

• Electrical service k

• Hydraulic service k And the best thing is in stock and ready to built to match your m and series. Count on in-house. For more in UPTIME Kits, scan th s that these kits, go, are custommachine model SENNEBOGEN nformation on he QR code.

Hydraulic service k :kits shops ols ervice owing kits system kits nance service kits its kits

NO North our in parts com with customers maxim commitment h about more Read ontract Demolition C st in parts repair the have virtu and I machine another in If back. to front every come t a have They echnician machine, wntim warehouse. American ready-to-ship of inventories plete for uptime izes aftersale Machine” he “Beyond our ow , Bloomfield Hills, MI or quickly. back unit the g I k they Since do no lose ally bring just [they] situation, a have I over go to month a once through wntime… ock. get theSENNEBOGEN

The Massachusetts Bay Transportation Authority (MBTA) will receive $472.3 million in federal funding to replace a Depression-era drawbridge over the Charles River, the agency announced Sept. 23

The North Station Draw One Bridge connects Boston and Cambridge, carrying more than 11 million passengers per year on the Commuter Rail and Amtrak trains. Replacing the structure is a high-priority project for the MBTA, according to state authorities.

The U.S. Department of Transportation (USDOT) funding, which represents the largest federal grant ever received by the Massachusetts agency, will not only help fully rebuild the existing drawbridge, but also renovate portions of North Station, and conduct other work to upgrade the train infrastructure in the area.

U.S. Sen. Elizabeth Warren, D-Mass., said in a statement that the investment is “a game-changer for the thousands of passengers who pass through North Station every day — and will build a safer, more reliable public transit system for the Commonwealth.”

Additionally, the project will allow for more train capacity, faster and more reliable rides, and increased safety on MBTA commuter rail and Amtrak trains, noted Gov. Maura Healy’s office, as well as make the bridge more resilient to climate change and rising sea levels.

“We know that improving our transportation infrastructure is critical for improving quality of life and making sure Massachusetts remains the best place to live, work, raise a family and build a future,”

Healey said in a statement. “That’s why our administration is competing so aggressively to win federal funding that can be put toward our roads, bridges and public transportation.”

The federal grant came from the National Infrastructure Project Assistance program as part of the Multimodal Project Discretionary Grant program.

According to MBTA, the program “supports large, complex projects that are difficult to fund by other means and likely to generate national or regional economic, mobility or safety benefits.”

The Draw One bridge carries both MBTA commuter and Amtrak passenger trains. The MBTA lines that utilize the drawbridge are the Haverhill, Lowell, Newburyport/Rockport and Fitchburg commuter rail lines.

The project’s features include replacing and modernizing the existing drawbridge, building a new control tower, extending the bridge platform, connecting tracks 11 and 12 to the existing network, making station improvements and working to upgrade tracks, signals, communications and infrastructure.

In addition, MBTA said the effort also will support more than 14,500 jobs, make the bridge more climate resilient by bringing it above projected sea-level rises, and lower emissions.

Massachusetts’ political leaders stressed the vital importance of the span to transporting residents between Boston and communi-

ties to the North.

“As someone who often commutes from north of Boston, I know firsthand what a difference this bridge replacement will make,” said Massachusetts Lt. Gov. Kim Driscoll.

U.S. Rep. Ayanna Pressley, D-7th District, added, “Transit justice is a racial and economic justice issue, and a matter of public safety. This massive federal investment helps make the Commonwealth more connected.

“I’m glad that families in the Massachusetts 7th who depend on the commuter rail will be better able to access jobs, healthcare, education and essential services in other parts of the state, and we won’t stop fighting to build the more just, equitable, and accessible transit system our communities deserve,” she continued. “I thank my delegation colleagues and the Healey-Driscoll Administration for their partnership, and the Biden-Harris Administration for continuing to invest in Massachusetts.”

MBTA noted in a news release that Healey and Driscoll have put a priority on being aggressive in competing for federal funding since they were sworn in last January.

“Since Governor Healey took office, the state has pulled in almost $8 billion in federal funding, including over $4 billion allotted by formula and more than $3.5 billion in discretionary grant awards. The funds have successfully supported projects across the state related to transportation, climate resiliency, job creation and economic development.”

The North Station Draw One Bridge funding is just the latest in a string of federal

grants awarded to the MBTA, which has successfully secured an award from every grant program it has applied for since the beginning of the year, signaling a growth in confidence in its ability to efficiently deliver productive results.

Massachusetts also has been the recipient of several large transportation awards, such as the $1.2 billion it received to replace the Sagamore and Bourne bridges on Cape Cod, $335 million to reconnect communities and increase mobility through the Allston I-90 Multimodal Project, $108 million for WestEast Rail, $75 million for schools to electrify their bus fleets, $60 million for transit agencies to acquire zero- and low-emission buses, and $24 million to rehabilitate Leonard’s Wharf in New Bedford.

Other recent awards include:

• A $67.6 million grant to advance accessibility at MBTA Green Line stations.

• Nearly $40 million in support of the Battery-Electric Bus Transition Phase 1B Project to replace the diesel-fueled buses at the Quincy Bus Maintenance Facility with battery-electric buses (BEBs).

• Another $22 million to construct hybrid center-running bus lanes and make bike and pedestrian improvements through the Lower Broadway Everett Transit Priority Corridor Project.

• Transit security funds totaling $3.8 million.

• A total of $2.1 million to pilot technology upgrades on 175 buses to assist with “blind spot” challenges.

• A $1.2 million grant to advance the Alewife Station and Garage Technical Assistance Program.

Construction has gotten under way on a $10.6 million boardwalk and bulkhead project at Rhode Island’s Roger Wheeler State Park in Narragansett.

The state’s Department of Environmental Management (DEM) in Providence announced Sept. 24 that plans call for a new concrete boardwalk to provide access from the beach’s parking area. Additionally, the boardwalk will feature new shade structures, sidewalks, foot washing stations, American Disabilities Act (ADA)-compliant access ramps and concrete benches.

In a news release, the state agency noted that its Division of Parks and Recreation “is committed to accessibility and aims to make each state park and beach location as barrierfree as possible for the convenience of those with limited mobility. The new boardwalk and shade structures will enhance accessibility to the beach area while providing an increasingly important respite from the sun.”

The current steel bulkhead at Roger Wheeler State Park, originally installed in the 1950s to separate the beach and parking lot areas, has shown signs of deterioration and will be replaced, according to DEM. That degradation, the department noted, is due to several challenges that the state’s

coastal communities are increasingly contending with due to the impacts of climate change, including sea level rise, flooding and erosion.

Ferreira Construction in Branchburg, N.J., was hired to perform the work, and its design was developed by Lincoln, R.I.-based Pare Corp.

The existing steel sheet piles will be cut and removed, and a new concrete retaining wall will be installed spanning 1,200 ft. across both sides of the pavilion, strengthening the resilience of the beach facility’s infrastructure to the growing impacts of climate change. In addition, the project includes the relocation of a short section of Narragansett’s existing water main, which travels through a portion of the site.

The original roadway and waterline, also constructed in the 1950s, ran along the length of the existing bulkhead and pavilion. Since then, the roadway has been relocated and a parking lot has been added so that beachgoers would not need to cross the busy street to access the shore. To construct the new boardwalk and bulkhead, the waterline will be relocated roughly 100 ft. to the north in the beach parking lot.

DEM generally plans major construction

and maintenance projects outside of the busy summer season to avoid potential disruptions to visitor experiences. The state agency said that Roger Wheeler State Park will be fully open to the public during the 2025 beach season, but portions of the site will be closed to the public during the off-season periods to allow construction to take place.

It will, however, prevent the annual early opening of the beach two weeks ahead of Memorial Day, when Rhode Island’s beach season official starts. If necessary, the agency noted, the work will continue during the off-season until spring 2026.

Roger Wheeler State Park is a location where the federally protected Piping Plover shorebirds are known to nest, and Rhode Island DEM has been working closely with the U.S. Fish and Wildlife Service (USFWS) to ensure the protection of birds and nests throughout the construction process.

The state agency received more than $3.1 million for the project from a portion of banked Land and Water Conservation Fund (LWCF) formula funding that Rhode Island has accumulated in recent years. Each year,

the state receives a formula allotment of LWCF funding from the National Park Service (NPS), and DEM applied to get monies from that allotment for this project.

The portions of the construction work not funded by LWCF will be paid for through the voter-approved 2021 Rhode Island Beach, Clean Water, and Green Economy Bond.

“Roger Wheeler is a popular family-oriented beach due to its gentle surf and beach pavilion featuring a child-friendly environmental education area,” said DEM Director Terry Gray. “This project … will help modernize and protect this facility and is an example of the importance of the investments that the state of Rhode Island can make in public assets thanks to green bonds.”

With state residents set to decide on the passage of the 2024 Green Bond in the November elections, Gray appealed to them to approve the measure once again.

“Passage of the 2024 Green Bond will help fund projects that will increase Rhode Island’s resilience against climate change, protect clean water, revitalize brownfield sites and conserve open space,” he explained.

More than 750 affordable apartments will soon be added to Connecticut’s rental supply, largely through state funding.

Connecticut Public Radio (WNPR) reported Sept. 10 that six projects will be funded within five communities. Fairfield County will receive the majority of the new housing, with nearly 400 new apartments to be built in Norwalk, Stamford and Westport near the shoreline of Long Island Sound.

The approximately $118 million investment comes from the state Department of Housing (DOH) and the Connecticut Housing Finance Authority (CHFA).

While DOH supplied $25 million in loans and grants, CHFA provided Low-Income Housing Tax Credits (LIHTCs) generating $93 million in private investments.

Pat Guliano, CHFA’s managing director of multifamily operations, told WNPR the projects also involve rehabilitating existing housing and lessening the pressure on the market for all renters, which can impact other aspects of residents’ lives.

“That bleeds into everything, that bleeds into people’s lives and jobs, and it all starts

with a stable, safe and comfortable home, place to live,” Guliano added.

All of the apartments will be reserved for renters earning below their community’s average median income (AMI), ranging in affordability from those earning 20 percent AMI to residents earning up to 80 percent AMI.

Monterey Village and Wall Street Place, both located in Norwalk, were among the projects to have received funding.

The Monterey Village development, in South Norwalk, will include 161 apartments reserved for residents earning below 60 percent AMI.

Wall Street Place is planned to include 155 apartments with a range of affordability for families earning between 20 percent and 80 percent AMI.

To the southeast in Stamford, DOH and CHFA funds will go toward the first of a three-phrase redevelopment of Oak Park, which was built in the 1940s under the State Moderate Rental Program. It includes a total of 61 units, 19 of which will use vouchers for very low-income households. All of its

apartments will be affordable to households earning below 60 percent AMI.

Funding also will be provided to a 19unit complex of two- and three-bedroom apartments in Westport, according to WNPR.

Guliano said the funding provided by the state and CHFA is vital to the growth of the housing market.

“If we’re not doing this, then not only are we not putting new units out, but a lot of the work we do preserves the existing housing stock in the state, so we would also be losing ground on that,” explained Guliano.

LIHTCs are administered in two forms: 4 percent and 9 percent tax credits, Guliano added.

At 9 percent, those tax credits are more valuable and are determined in a competitive application process early each year. The 4 percent tax credits are administered on a rolling basis and are taken from the state’s

annual tax-exempt bond allocation.

However, in recent years, Connecticut has struggled to stretch the $500 million in tax exempt bond funding as far, WNPR reported.

“When that runs out, we can’t do any more deals, and we’re actually starting to bump up against our cap because these deals are getting so expensive,” Guliano said. “A lot of states have bumped up against their volume cap, primarily based on probably the last four or five years where we’ve seen drastically increased development costs and fewer and fewer resources to go into them.”

More than 360 of the apartments being built are part of CHFA and DOH’s Build for CT program, which targets affordable housing options for middle-income renters, CHFA Executive Director Nandini Natarajan said.

“By leveraging programs like Build For CT and LIHTC, we’re not only providing quality, affordable housing for a wide range of income levels but also driving significant private investment into Connecticut’s neighborhoods,” Natarajan said.

Chadwick-BaRoss Inc. and Thompsonrolec Enterprises LLC (Thompson Equipment), leading equipment dealers in New England, announced the appointment of Jeremy Jordan as president of both companies, effective July 7th.

“Jeremy’s appointment marks an important chapter in the history of both companies,” said Yedidia Koschitzky, chairman of Chadwick-BaRoss and Thompson Equipment. “His leadership, and deep long-tenured knowledge of the companies for over 30 years, positions us to meet the growing needs of our markets, strengthen our regional focus, and continue the legacy of nearly a century of excellence. We are confident that Jeremy will take these companies to new heights.”

As Jordan steps into his new role, he aims to uphold ChadwickBaRoss’ “Be Unstoppable” mantra and Thompson Equipment’s principle of “The more you make, the more you make.”

With a focus on expanding their

presence in the eastern Massachusetts and Rhode Island territories, while maintaining their strong footprint in northern New England. Jordan underscores the importance of attracting and retaining top-tier talent to drive growth.

“By aligning with market needs, current customers and equipment manufacturer partners, our vision extends beyond merely expanding our market presence and full-scale product offerings.

It’s about cultivating a company culture that values people, excep-

tional local service, and innovation,” said Jordan.

Jordan’s journey with Chadwick-BaRoss started in 1992 as an apprentice in the track shop. Since then, he has risen through the ranks, holding various roles, including shop technician, field

service technician, used/rental fleet manager, general manager, sales territory manager and, most recently, vice president of Chadwick BaRoss. His hands-on experience in both technical and managerial positions has equipped him with a unique perspective on the challenges and opportunities within the industry.

Chadwick-BaRoss and Thompson Equipment are positioned to take advantage of new market opportunities while continuing to build on their longstanding reputations for quality and customer service. Under Jordan’s leadership, the companies will maintain a strong focus on personnel development and innovation, ensuring they remain agile in a rapidly evolving industry. Thompson Equipment will maintain its independent focus, with Steve Ferris continuing his established role as vice president, providing stability and continuity in its operations.

For more information, visit www.chadwick-baross.com and www.thompson-equip.com.

Construction began in March 2023 with a completion date that has been set at May 2027.

in a four-span configuration.

According to MaineDOT, the following construction work has been completed:

Early in 2024, Cianbro continued with gantry crane erection, including installing crane track and truss sections. Divers on site worked at a gantry foundation location. Bridge rail was removed from the Waterville side of the bridge, access to the newly placed pier seal was reinstalled, crews began drilling for footing dowels and started work on the pier seal, prepping for next phase of the pier placement.

Cianbro continued work on the gantry truss. Crews finished assembling gantry crane 1 and started installing gantry crane 2. The high spots in the seal were leveled, then drilled and installed dowels on pier seal for footing. Workers continued installing form work for the pier footing.

Concrete placement was completed on the pier footing. Cianbro continued with gantry truss erection and prepped for gantry foundation installation. Crews began bridge deck demolition.

By mid 2024, crews made significant progress by completing the gantry crane setup along the entire length of the bridge. Demolition was completed on span three and began on span four. Crews also worked on the center pier, installing rebar for the first section of the pier stem and installed forms for the same.

Crews continued saw cutting operations from abutment one and into span two and completed phase one of the deck removal. The gantry crane facilitated the removal of girders and structural steel, while workers continued to install rebar, formwork and armor for the next lift of the pier stem. Demolition and structural earthwork efforts occurred at abutment one.

Workers completed concrete placement for the phase one pedestals. Forms on the first lift of the pier seal were removed, along with steel girders. Crews continued with the abutment one demo and structural earth excavation. Steel girders were removed on the westbound spans along with pier stems. Crews excavated to bedrock and cleaned it in preparation for abutment two work. Tree

clearing on the Waterville side was completed and began on the Winslow side. Abutment one demolition was completed. Forms and rebar were installed for abutments one and two sub-footings. When completed, the new bridge will introduce streetscape features to promote walking and bicycling and improve the attractiveness and quality of life downtown. The new bridge will feature 5ft. shoulders to accommodate bicycles, as well as 6-ft. sidewalks for pedestrians. It will have modern bridge rails that are safer and meet crashworthy standards, will include architectural lighting and feature corrosion resistant construction materials that will stand the test of time. CEG

(All photos courtesy of MaineDOT.)

When you need to move dirt and rock quickly, you need our R 936 crawler excavator. Advanced electronics let drive components work together efficiently to save fuel. Sensor-guided controls give you speed, precision and power. And robust cast steel components stand up to the toughest environments. It's all built to last with exclusive Liebherr components.

Skanska, a leading global construction and development firm, has appointed Cassandra Campbell as supplier diversity manager.

Campbell brings a robust track-record in compliance, contractual analysis and business administration along with a deep commitment to furthering diversity and inclusion across organizations.

Based out of Skanska’s Boston office, Campbell will be responsible for developing and managing regional offices’ supplier diversity strategy and collaborating with internal stakeholders including operations, preconstruction, marketing and business development to maximize opportunities for the diverse subcontractors Skanska partners within the New England region. She also will take the lead in organizing Diverse Business events, representing Skanska in the Diverse Business community, and overseeing the education of Skanska’s Supplier Diversity program to employees who

engage with Diverse Business firms.

“We’re incredibly excited to have Cassandra join our team as supplier diversity manager,” said Bryan Northrop, executive vice president of Skanska USA Building’s New England region. “Her dedication to advancing initiatives across the diverse business landscape is in complete alignment with Skanska’s own mission to maximize opportunities for minority and womenowned, as well as disadvantaged businesses in our industry. In addition, her experience at Massport will prove invaluable as we continue to strengthen community relationships and develop inclusive practices that bolster the small businesses we support across New England.”

“Cassandra is a dynamic addition to the team who brings a passion and expertise for promoting and engaging with the diverse business community,” said Joycelyn Yue, national director of supplier diversity for Skanska USA Building. “She will play a

pivotal role in advancing Skanska’s supplier diversity program strategies and will expand our community outreach initiatives in the New England region.”

Campbell joins Skanska from the Massachusetts Port Authority (Massport), where she held numerous roles throughout her 27year tenure at the company including senior accounts receivable specialist, accountant, internal audit staff, compliance contractual analyst, and most recently, senior program administrator for M/WBE & DBE Construction. In her latter role, she honed her expertise in promoting the success of small diverse businesses and pioneering data analysis methods to enhance business diversity initiatives. She

also was responsible for all aspects of M/W/DBE compliance, coordinating relevant programs and initiatives with third party partners, and served as an advisor on M/W/DBE matters for key Massport stakeholders.

“I’m thrilled to be joining Skanska and contribute my expertise and experience to what Skanska is already doing towards supplier diversity,” said Campbell. “Skanska is known across the industry as a trailblazer in creating unique opportunities for small diverse businesses, and I’m looking forward to advancing these efforts across New England.”

For more information, visit www.skanska.com.

industry-leading solutions from CBI and

Continental Biomass Industries provides a comprehensive range of portable and stationary equipment, including horizontal

grinders, shredders, industrial wood chippers and flail debarkers.

Terex Ecotec offers a diverse portfolio featuring slow, medium, and high-speed shredders, hybrid chippers, recycling screens, trommel screens, waste handlers and tracked conveyors.

With this collaboration, Powerscreen New England strengthens its position

With this collaboration, Powerscreen New England strengthens its position as a trusted partner for environmental equipment solutions, empowering customers across the region to achieve their operational goals while prioritizing sustainability and resource efficiency, the company said.

as a trusted partner for environmental equipment solutions, empowering customers across the region to achieve their operational goals while prioritizing sustainability and resource efficiency, the company said.

For more information, visit www.powerscreen-ne.com. (Photos courtesy of Powerscreen.)

Push

... more material with the new Hyundai HD100 crawler dozer's best-inclass power-to-weight ratio.

See ...more than ever with the unobstructed view to the blade.

Engage

...more accurately and more productively with standard 2D or optional 3D machine guidance.

Doze

...with confidence, knowing your new 115 hp Hyundai crawler dozer delivers the quality and value you expect from Hyundai, with the peace of mind that comes with our industry-leading warranty.

wonder so many first-time Hyundai users become longtime fans. See the Hyundai difference yourself at your local dealer, na.hd-hyundaice.com

Skanska, a leading global construction and development firm, announced that its program management and consulting group, Skanska Integrated Solutions (SIS), is serving as the program manager for the construction of the Williams College Museum of Art.

Situated on a 6.75-acre site, the new museum will be 76,800 sq. ft. and house exhibits, gatherings, teaching spaces, and administrative and support spaces.

“We’re incredibly excited to continue working with Williams College to enhance its campus and bring a vibrant museum space for the school and local community,” said John Benzinger, program executive, Skanska USA Building. “The Williams College Museum of Art has particularly ambitious sustainability goals to meet, and I’m confident that our team’s extensive experience leveraging sustainable design and construction will ensure these goals are met upon the project’s completion.”

Located at the western entrance of Williams College, the museum will serve students and faculty, the local community

and visitors to the Berkshires through a cluster of four program areas that are unified through their materials, open atmosphere, a centralized gathering place and an overarching roof sheltering the entire space.

Skanska will apply sustainable design and construction principles throughout the project, including the incorporation of Passive House design and additional sustainable elements in order to track towards a Living Building Challenge certification, a program defining today’s most advanced measure of sustainability in the built environment.

SIS has previously provided program management services to Williams College, including the 177,200-sq.-ft. addition and renovation of Stetson Hall and Sawyer Library, which was part of the adaptive reuse of a four-story 1923 Georgian Revival building that had formerly been the college’s primary library. The project included the demolition and replacement of two additions dating from 1956 and 1962 with a 130,000gross-sq.-ft. concrete framed structure. Construction on the project began in September 2024.