By Eric Olson CEG CONTRIBUTING EDITOR

A relatively short but critical bypass of U.S. Highway 70 around the small community of Havelock, in southeastern North Carolina, is now in its last year of construction after the state’s Department of Transportation (NCDOT) commissioned the project in 2019. When complete, the new freeway will be designated as a section of the state’s future Interstate 42.

That was the word from Brad McMannen, NCDOT’s resident engineer on the U.S. 70/Havelock Bypass, in late September when he was asked to give an update on the project.

He said the new 10.3-mi., four-lane divided highway, designed to divert

By Lucy Perry CEG CORRESPONDENT

FHWA and the road construction industry agree on one thing: The safety of crews in work zones is a priority. Ramped-up construction means the risk to highway workers is as great or greater this year than last. FHWA has proposed rule changes to meet broader impacts of work zones on both driver mobility and worker safety. AGC and ARTBA believe road workers should be the priority.

In September, FHWA announced proposed rulemaking amending its traffic safety and mobility regulations. The agency said it recognizes increasing road construcsee RULE page 32

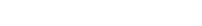

The North Charleston, S.C., city council approved contract agreements Dec. 14 for a 50-acre development known as Battery Park along the west bank of the Cooper River.

The Louisiana DOTD is closing the Harvey Tunnel — one of only three highway tunnels in the state — for the better part of two years to perform tile, road, electrical, ventilation and drainage improvements at a cost of $53.7 million.

Duane and Jennifer Lopez moved to Ft. Myers, Fla., from Chicago in 2003, when Jennifer had an opportunity to transfer within her company. Duane left his small remodeling business where he was finishing basements and doing roofing work.

18

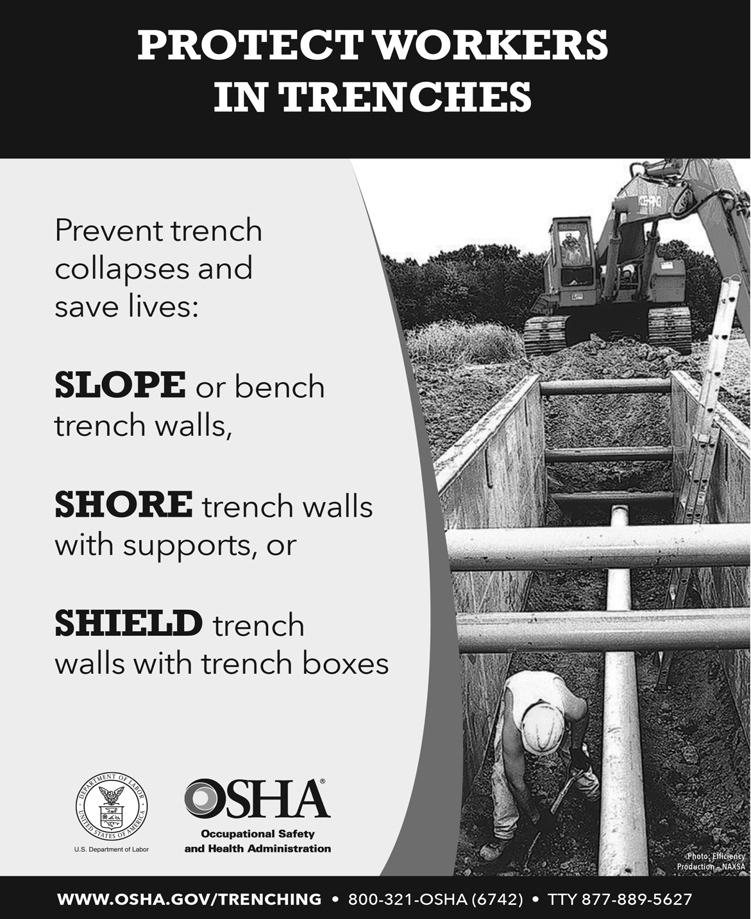

The U.S. Department of Labor’s OSHA announced that the agency is replacing traditional hard hats used by its employees with more modern safety helmets to protect them better when they are on inspection sites.

HD Hyundai announced that it will present its innovative vision to create and encourage sustainability on land under the name Xite Transformation at CES 2024, the world’s largest electronics trade show.

Kubota announced it is returning as the presenting sponsor for another round of country music superstar Blake Shelton’s “Back To The Honky Tonk” Tour, which kicks off Feb. 22, 2024, in Hershey, Pa.

AEM’s new report, Benefits of Construction Technologies and their Impact on Society, details how four key innovations are helping construction sites become safer and more productive, while also reducing their environmental footprint.

40 JCB UNVEILS PLATINUM EDITIONS OF BACKHOES TO CELEBRATE 70 YEARS

JCB is celebrating 70 years of manufacturing its iconic backhoe loader with the unveiling of Platinum Editions of the 3CX and 4CX models. Company founder Joseph Cyril Bamford CBE invented the backhoe concept.

59

Bobcat Company continued to expand its attachment offerings in 2023, empowering customers to accomplish more in landscaping, construction, forestry, agriculture and other industry applications.

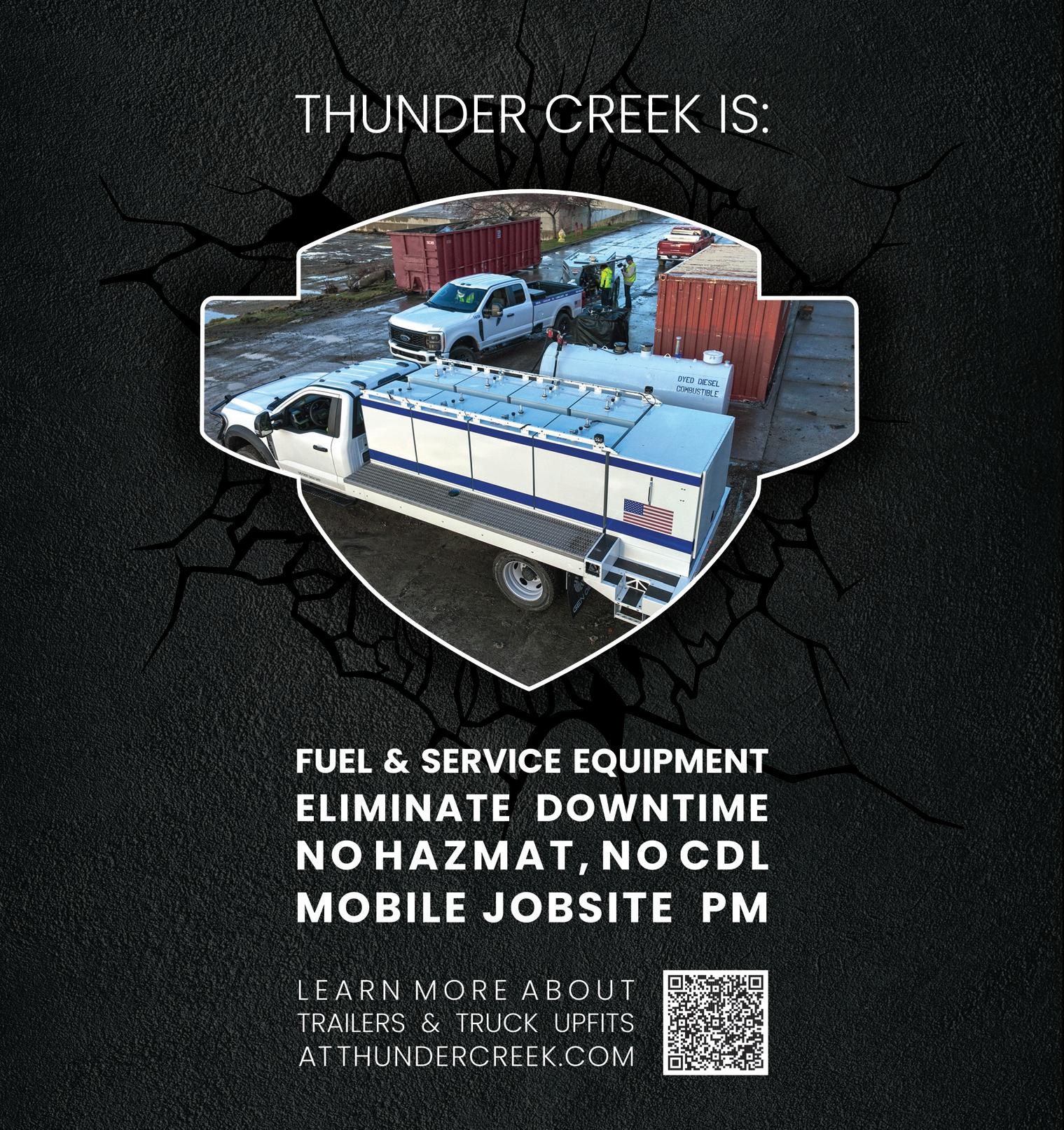

Hart Fueling Service has added Thunder Creek Equipment’s lineup of fuel and service trucks and trailers to its expansive fuel equipment sales lineup.It will now rent, sell and support the full lineup.

68 AIR BURNERS COLLABORATES WITH VOLVO CONSTRUCTION, ROLLS-ROYCE

Air Burners, a manufacturer of air curtain burner systems, collaborated with Rolls-Royce and Volvo Construction Equipment to develop and test the BioCharger — a portable machine that turns biomass waste into energy.

70 WORLD OF CONCRETE 2024 TO FEATURE DEVELON EXCAVATOR TRIO

DEVELON will showcase three excavators at World of Concrete in Las Vegas, Jan. 23 to 25, 2024. The DX42-7 mini-excavator, DX225LC-7X crawler excavator and DX140W-7 wheel excavator will be on display.

74 FRECKMANN OF ALL CRANE’S DAWES RIGGING & CRANE RENTAL RETIRES

The new year will bring big changes to Dawes Rigging & Crane Rental, a member of the ALL Family of Companies, as it will be the first time in more than three decades that Steve Freckmann isn’t its general manager.

45 CL

INVESTS IN NEW

The North Charleston, S.C., city council approved contract agreements Dec. 14 for a 50-acre development known as Battery Park along the west bank of the Cooper River.

A partnership made up of Jamestown L.P. and Weaver Capital Partners, each of which is based in Atlanta, and Charleston’s WECCO Development, will assist the city in transforming the former Charleston Naval Complex into a vibrant, mixed-use district and regional destination, according to a news release from the city of North Charleston.

The project, which is aligned to North Charleston’s “Battery Park Master Plan,” will include more than 1,400 residential units and a mix of commercial uses that support local and regional economic growth noted the release. It is designed to improve quality of life of area residents, foster more equitable and sustainable economic development, advance community health and wellness, encourage social cohesion and build community.

Battery Park’s development plans will establish a series of residential, retail, office, entertainment spaces and parks along the Cooper River waterfront and include the construction of a new pavilion with a market hall, event space and an active green fronting the river.

Within the 50-acre site, approximately 23 acres will become public spaces, parks and streets.

“Battery Park is an investment in — and commitment to — the future of North Charleston,” said Jay Weaver, founder and president of Weaver Capital Partners. “The project will be a catalyst

for community, providing access to the waterfront and greenspaces while creating opportunities for area residents, businesses, artists and restaurants. This is a vision many years in the making, and we are honored to partner with the city to bring it to life.”

As part of the agreement, the development team will target 15 percent Minority and Women Owned Business Enterprises contractor participation during the construction phase, establish a local apprenticeship program and reserve 17 percent of the residential units as workforce housing for people earning less than 120 percent of the area’s median income.

“Our promise to the people of North Charleston is simple: Battery Park will embrace the rich culture and history of the city while creating a Central Business District that will be a focal point of new possibilities,” explained Lucile Cogswell, president of WECCO Development. “Battery Park will be a defining destination offering experiences rooted in and inspired by the best that the Lowcountry has to offer.”

The vision for the redevelopment was outlined in North Charleston’s project plan, a culmination of decades of planning and community engagement, according to the city. Municipal officials issued a Request for Qualifications for a primary developer for the site in January 2023.

In total, seven development teams responded to the request before the city decided in May that the partnership of Jamestown, Weaver Capital Partners and WECCO Development would be the most qualified, experienced and capable of fulfilling its vision.

The development agreement was finalized in December by way of the city council vote.

Battery Park’s trio of developers also is developing a nearby site known as Navy Yard Charleston, which is projected to encompass approximately 3.5 million sq. ft. of commercial and residential space — including over 2,600 housing units — across 85 acres. Adaptive reuse of the historic brick “storehouse row” buildings, the base’s former power plant, and the former Naval Hospital will also be incorporated into Battery Park’s redevelopment.

Louisiana’s Harvey Tunnel opened nine governors ago, during Earl Long’s administration, and for much of its 66-year history has been maintained and repaired on a piecemeal basis: Close one or both lanes in one direction to traffic, work for a week or so, then repeat on the other side.

Now, in a break with that practice, the state Department of Transportation and Development (DOTD) is closing the entire underwater shaft — one of only three highway tunnels in the state — for the better part of two years to perform tile, road, electrical, ventilation and drainage improvements at a cost of $53.7 million.

The tunnel is located just south of the Mississippi River opposite downtown New Orleans in Jefferson Parish and allows eastwest traffic on U.S. Highway 90 Business to pass under the Harvey Canal.

“They’re going to redo it from top to bottom,” state Sen. Patrick Connick, R-Marrero, told the New Orleans Times-Picayune.

A Louisiana DOTD contractor began blocking westbound access to the four-lane tunnel beneath the canal in early October, and closed the eastbound side Nov. 27, a move that quickly generated complaints about congestion on the only nearby ground-level alternative: the two-lane Fourth Street drawbridge, which motorists have said is raised just about any time a tugboat approaches in the canal, backing up car traffic as far as 10 blocks.

Connick said he hopes to speed the tunnel work and to find some relief for Fourth Street motorists.

The traffic complaints would have been scarcely imaginable in 1839, when the West Bank was largely agrarian, and Nicholas Noël Destrehan secured laborers to excavate a canal connecting Bayou Barataria with the commercial land close to the river, the New Orleans newspaper noted.

“Completed by 1844, Destrehan’s canal soon became

busy with barges, luggers and schooners hauling timber, moss, finfish, shellfish and game in from swamps, marshes and bays,” historic geographer Richard Campanella wrote for Preservation in Print in 2021. “In [a] short time, Destrehan earned a fortune by charging tolls for vessels to sail there from the Mississippi River.”

In the 20th century, with oil and gas exploration under way in south Louisiana, the Harvey Canal became a locus for oilfield supply, fabrication and repair businesses. And the West Bank population grew along with it.

Still, the only one way to drive across the canal was at Fourth Street.

That was until 1957, when the tunnel opened after a four-year building effort costing $5 million, according to DOTD. Now a passageway for the West Bank Expressway/U.S. 90 Business, the four-lane tube is 1,079 ft. long.

Farther south, the Lapalco Boulevard bridge over the canal opened in 1972, and directly over

the Harvey Tunnel, the West Bank Expressway bridge opened in 1984. Combined, the expressway bridge and tunnel carry about 58,500 vehicles per day, the TimesPicayune noted. The state transportation agency ascribes about one quarter of that volume, or 15,000 vehicles, to the tunnel, and much of that comes from local motorists in the 2-mi.-wide corridor bounded by Manhattan and Barataria boulevards.

The Houma Tunnel is now the only highway tube in use in the Bayou State after the tunnel in Belle Chasse closed permanently Dec. 20 following completion of the new Louisiana Highway 23 bridge over the Gulf Intracoastal Waterway.

The federal government is paying for 80 percent of the rehabilitation to the Harvey Tunnel with the rest of the money coming from the state budget and from leftover toll revenue from the Crescent City

Connection Bridge in New Orleans. DOTD contracted with CEC Inc. to perform the renovation project.

The Lafayette-based contractor will remove and replace the tile in the tunnel’s walls and ceiling, rebuild the roadway and improve the electrical, ventilation and drainage infrastructure.

Both sides of the Harvey Tunnel reopened to traffic Dec. 22 for the winter holidays but will close again in January. The construction schedule runs through December 2025, according to the state agency, and noted that there might be brief periods where two of the four lanes are opened to traffic.

Connick told the TimesPicayune that he is trying to get the U.S. Coast Guard to reduce the number of times the Fourth Street bridge is raised for marine traffic so motorists can cross the canal there without a long wait.

“Like all major projects, you’re going to have to sacrifice some. It’s going to be a pain,” he explained. “But in the long run it’s going to be worth it.”

You will find the parts you need at MOBRO Marine, Inc. We purchase in bulk directly from the manufacturers to maintain our large inventory. We also have a large inventory of long-lead time parts for cranes that can’t be found anywhere else. Not only does this mean we have the part you need in stock, it also saves you money. Because we buy in volume, we can buy for less and pass the savings on to you.

Our large inventory keeps construction equipment performing at optimum levels. We offer same-day shipping on most partsyou’ll experience minimal downtime. We are a full-service company. We not only supply parts, but we also service and repair construction equipment and cranes of any type.

Duane and Jennifer Lopez moved to Ft. Myers, Fla., from Chicago in 2003, when Jennifer had an opportunity to transfer within her company. Duane left his small remodeling business where he was finishing basements and doing roofing work in the Chicago area.

After arrival in south Florida, Duane picked up right where he left off in Illinois and started a general contracting company with a partner. He later left the company to move on to bigger things, establishing Extreme Painting & Contracting in 2016, which performed general contracting work such as painting, stucco, drywall and metal framing.

The work of this company spawned another company in 2018 called Extreme Disposal, which consisted of one roll-off truck and 50 dumpsters. Growth continued with the company expanding to include three Florida locations: Ft. Myers, Panama City and Tampa.

After more than a year to get permitting, Lopez opened a recycling transfer station in 2021 for construction debris. One week after the business finally got permitted, one of the “bigs” came in and bought it. With that additional capital, Lopez was able to go from one truck to 20 trucks and approximately 2,000 dumpsters.

“While we were running Extreme Disposal, we started doing demolition and land clearing,” he said. “After we sold Extreme Disposal, we continued with a few pieces of equipment and a couple trucks and in 2021 begun operating under the name Extreme Demolition & Land Clearing.”

Born from a dream and raised by industry demand, Extreme Demolition & Land Clearing has quickly become a force to be reckoned with in southwest Florida. Lopez said, “I’d say we’re probably the largest demolition contractor in southwest Florida.”

Extreme operates under a portfolio of four unique companies: Extreme Florida Roofing; Extreme Painting & Contracting — a full-service general contractor; Extreme

Demolition & Land Clearing; and Extreme Florida Metals — a 12,000-sq.-ft. metal shop for machining roofing products, including gutters, downspouts, drip edge, soffit, fascia gutters and more.

The big investment for the company was recently opening a recycling yard providing it the capability of recycling its own wood waste, horticulture debris and green waste for processing into a reusable product. Lopez said it also allows other companies to dump clean concrete, clay roofing tiles and other recyclables for processing.

Extreme sells the crushed and sized aggregate directly from the yard and ships the processed wood products to mulch bagging and coloring facilities for their resale.

The 15-acre processing yard is in Cape Coral, Fla., and saves Extreme a lot of money on its own recycling needs: “We charge other vendors to dump and then make

money on the finished product,” Lopez said.

“Much of the land clearing and demolition products received in the yard come from our own projects and job sites throughout southwest Florida. Now we make money on the project itself and the wood waste and concrete processing proceeds.”

Extreme started out with the purchase of two Case machines: a pair of Case CX 250 excavators; the rolling stock at the processing yard is now exclusively Case excavator and wheel loader products.

“Regular staffing on the recycling yard is six to eight operators on Case machines working five days a week. As we finish up other offsite jobs, we’ll haul the Case machines to the processing yard and utilize those operators with their machine to help catch up or get ahead on our needs here on

the recycling yard.”

Non-rolling stock products on the processing yard include products from Diamond Z, Morbark and Powerscreen. For the excavators, manual sheers and concrete densifiers have been added to assist in separating concrete and metal/rebar.

When Hurricane Ian hit in September of 2022 as a Category 5 Hurricane in Ft. Myers, Fla., Extreme Demolition & Land Clearing began buying more-and-more Case machines to keep up with the intense work required for cleanup and debris processing.

To simply say Extreme is “hooked on Case machines” is a bit of an understatement. In a mere two-year span of time, the company has purchased 17 new and four used Case machines with a vast array of attachments of buckets, grapples, thumbs, shears and densifiers, with most of the spe-

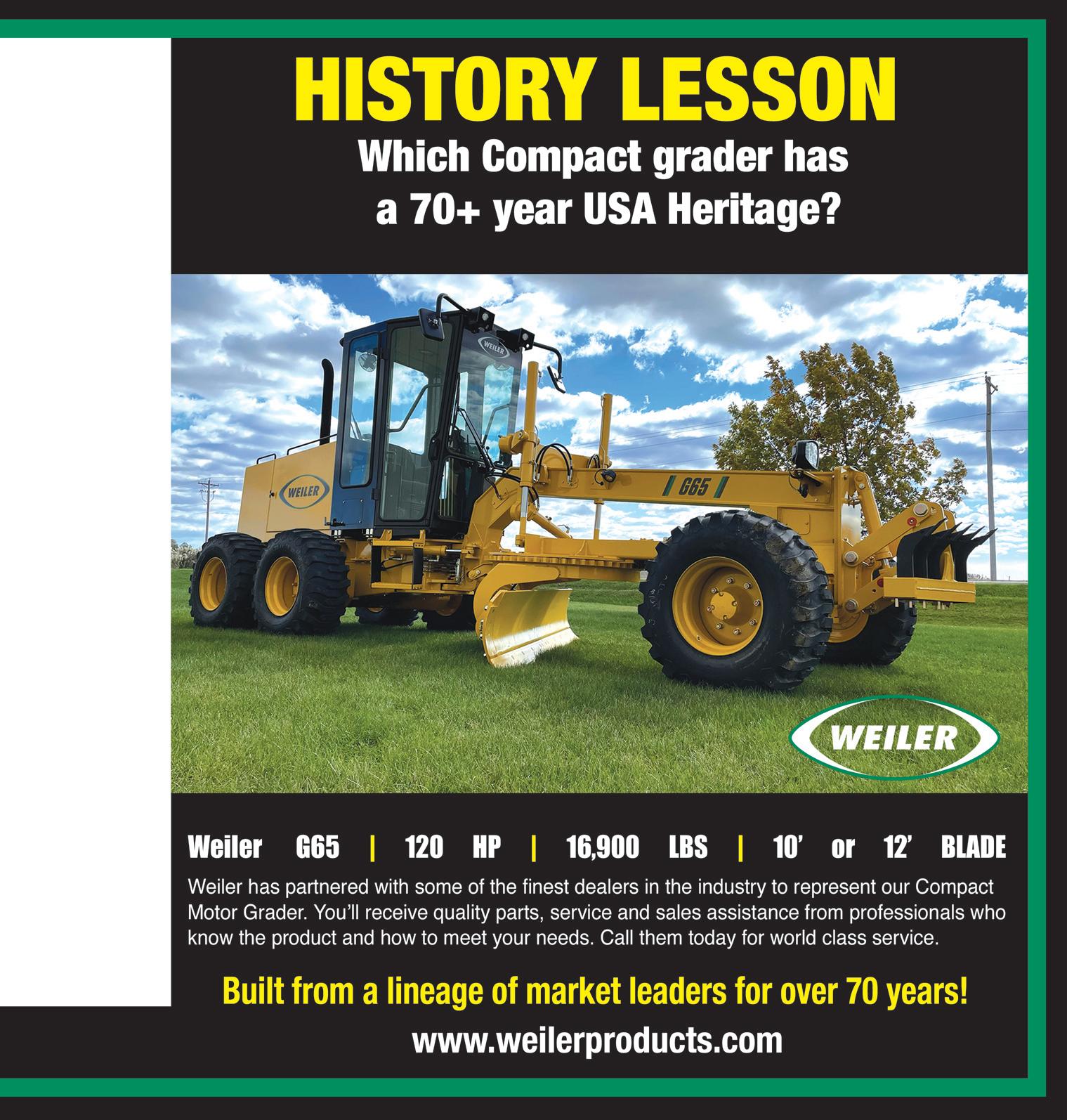

Border Rents borderequipment.com

Augusta, GA 706-737-7253

Norcross, GA 770-609-8299

Don Allison Equipment, Inc. (Compact Excavator Only) donallisonequipment.com

Arley, AL 800-669-6450

First Choice Farm and Lawn firstchoicekubota.com

Brookland, AR 870-790-2301

Dyersburg, TN 731-882-1855

Eads, TN 901-616-5129

Mayfield, KY 270-856-4355

Savannah, TN 731-925-2141

Union City, TN 731-885-1315

Forsythe Tractor

(Compact Excavator Only) forsythetractor.com

Shreveport, LA 318-687-1341

Hi-Low Equipment of Florida (Compact Excavator Only) hilowequipment.com

Ocala, FL 352-820-4200

Larry Stovesand Equipment (Compact Excavator Only) lsetractor.com

Murfreesboro, TN 615-442-6738

Mid South Machinery

gomidsouth.com

Jackson, MS 601-948-6740

National Equipment Dealers

Carolinas

nedealers.com

Charlotte, NC 704-228-0455

Clayton, NC 886-629-3784

Grimesland, NC 252-752-1500

Lexington, NC 866-629-3784

Columbia, SC 888-865-1002

Conway, SC 800-968-0754

Piedmont, SC 864-434-1154

Summerville, SC 843-501-0566

National Equipment Dealers

Florida nedealers.com

Apopka, FL 407-401-8956

Fort Pierce, FL 772-212-4043 Tampa, FL 813-940-4405

National Equipment Dealers

Georgia nedealers.com Dallas, GA 770-445-9019

Douglas, GA 912-384-4664

Macon, GA 478-257-8300

Richmond Hill, GA 912-756-7854

Southern Lift Trucks

southernlift.com

Mobile, AL 251-278-2247

Springdale Tractor

Springdale, AR 479-361-2513

State Machinery

statemachineryeq.com

Kenner, LA 504-464-0431

Stone Equipment Co., Inc. stoneequipmentco.net

Alabaster, AL 844-786-6373 Montgomery, AL 844-786-6373

Taylor Construction Equipment taylorconstructionequipment.com Louisville, MS 833-773-3421 Philadelphia, MS 833-733-3421

Maryville, TN 662-773-3421

White House, TN 615-392-4803

Van Keppel vankeppel.com

North Little Rock, AR 501-945-4594

The U.S. Department of Labor’s Occupational Safety and Health Administration announced that the agency is replacing traditional hard hats used by its employees with more modern safety helmets to protect them better when they are on inspection sites.

In 2020, the Bureau of Labor Statistics reported head injuries accounted for nearly 6 percent of non-fatal occupational injuries involving days away from work. Almost half of those injuries occurred when workers came in contact with an object or equipment while about 20 percent were caused by slips, trips and falls.

Dating back to the 1960s, traditional hard hats protect the top of a worker’s head but have minimal side impact protection and also lack chin straps. Without the straps, tradition hard hats can fall off a worker’s head if they slip or trip, leaving them unprotected. In addition, traditional hard hats lacked vents and trapped heat inside.

On Nov. 22, 2023, OSHA published a

Safety and Health Information Bulletin detailing key differences between traditional hard hats and more modern safety helmets and the advancements in design, materials and other features that help protect workers’ entire heads better. Today’s safety helmets also may offer face shields or goggles to protect against projectiles, dust and chemical splashes. Others offer built-in hearing protection and/or communication systems to enable clear communication in noisy environments.

The agency recommends safety helmets be used by people working at construction industry and the oil and gas industry; in high-temperature, specialized work and low-risk environments; performing tasks involving electrical work and working from heights; and when required by regulations or industry standards.

OSHA wants employers to make safety and health a core value in their workplaces and is committed to doing the same by leading by example and embracing the evolution of head protection.

cialty attachments coming from Floridabased Pemberton Attachments.

In addition to full-sized excavators and wheel loaders, the overall fleet now includes a Case TV450B compact track loader and Case’s largest built compact track loader, the TV620 with a land clearing mulching head. Extreme even purchased the first Case CX220E ever sold in the state of Florida.

The overall machine fleet for Extreme Demolition totals 30 machines, including some forestry machines like skidders and harvesters and a couple other excavators with hammers. The company owns and operates a fleet of approximately 30 trucks — mostly big tractor-trailers with 75-yard dump trailers.

The Extreme group of companies did not obtain the level of success it is experiencing by simply “going with the flow.”

“Our fleet was aging, we were having issues with them, and we weren’t getting quite the service timeliness that we needed. So, we tried Case.

“The service is great. Whenever we needed something fixed, [CASE Power & Equipment of Florida] was there within a couple of hours. We were back and forth

with Case for several months on what they were able to do for us and what we could get for our other machines without it hurting us too badly. They were able to make it work and after three months we struck a deal and here we are with all Case machines.

“These guys have been really good. Best service I’ve ever seen. They really stepped up to the plate and made it happen and we consider them a partner in our operation.

“Our sales rep, Todd Kundinger, has been great. He’s ‘Johnny on the spot’ when needed and will answer his phone at midnight if we have a need.”

In addition to reliability, Lopez said his Case machines are user friendly and the operators like them.

“In our business, we beat the Hell out of machines. Our first Case purchases from a year and a half ago are still running strong. What we do is far more damaging to a machine than the average contractor digging in the dirt. And these machines have held up great. They’re what I call EXTREME.” CEG

(All photographs in this article are Copyright 2024 Construction Equipment Guide. All Rights Reserved.)

HD Hyundai announced that it will present its innovative vision to create and encourage sustainability on land under the name Xite Transformation at CES 2024, the world’s largest electronics trade show.

HD Hyundai will share details about Xite Transformation at CES during a keynote speech by Vice Chairman and CEO of HD Hyundai Kisun Chung. The keynote will focus on the company’s comprehensive strategy and vision to create innovation in infrastructure construction.

Xite Transformation is HD Hyundai’s vision to solve pressing challenges humanity is facing such as safety, security, supply chain issues, climate change and more. The company is eager to embrace its role as a “Future Builder” by expanding its sustainability focus beyond ocean infrastructure to also include land infrastructure.

At CES 2023, HD Hyundai shared its Ocean Transformation strategy, which aims to fundamentally change the way the ocean is

utilized and to explore the infinite potential of the marine ecosystem. This year marks the third consecutive year for HD Hyundai to participate in CES as it spreads its influence as a keynote speaker. Now, the company plans to expand on its

previous vision to include transformative land infrastructure ideas.

HD Hyundai’s exhibit at CES 2024 will consist of three main themes: Future Xite, Twin Xite and Zero Xite.

Future Xite will present what

the future of next-generation construction machines will look like when utilizing advanced unmanned and automation technologies. Twin Xite will introduce site control solutions and remote control technologies based on dig-

ital twins. Zero Xite will focus on exhibiting the company’s wide experience and technological capabilities for green energy value chains.

According to HD Hyundai, “We are committed to being a Future Builder as we continue to design a brighter world for humanity, from ocean to Xite. We are excited to share our plans for how we are creating a sustainable future through a shift in the industry’s paradigm with those attending the show.”

Chung’s keynote speech will take place on Jan. 10. Representing the third Korean and third nonconsumer electronics company, Chung will showcase how comprehensive innovation in building smart infrastructure will shape a more sustainable future. The keynote will be given at the Venetian hotel in the Palazzo Ballroom on Level 5. In addition to HD Hyundai, other global top-tier companies, including Siemens, Walmart, L’Oreal, Nasdaq, Qualcomm and Elevance Health also will be delivering a keynote at CES 2024.

Kubota Tractor Corporation announced that it is returning as the presenting sponsor for another round of country music superstar Blake Shelton’s “Back To The Honky Tonk” Tour, which kicks off Feb. 22, 2024, in Hershey, Pa., and ends March 29, 2024, in Wichita, Kan.

Along with the tour sponsorship, Kubota also is launching the Kubota Blake Shelton VIP Concert Sweepstakes to provide customers and fans a chance to win tickets to see Blake Shelton perform at one of five tour venues.

“Wherever I am, when I’m on my Kubota, I know I’m in ‘God’s Country,’” said Blake Shelton. “Whether you’re at work or play, Kubota has equipment that’s just right for you. I’m thrilled they’re joining us for another round of my ‘Back To The Honky Tonk Tour.’”

The 17-date tour includes three stops in Canada and features platinum-selling, eight-time chart-topping recording artist Dustin Lynch and rising country artist Emily Ann Roberts, who was a member of Team Blake on the ninth season of NBC’s “The Voice.”

The Kubota Blake Shelton VIP Concert Sweepstakes, which launched Dec. 1 and ends Jan. 19, 2024, offers customers and fans the chance to win one of five VIP packages for an exclusive concert experience, including two VIP tickets, roundtrip flights for two, hotel accommodations for two nights, and a $500 gift card.

Tour stops for the Kubota Blake Shelton VIP Concert Sweepstakes include Austin, Texas, on March 1; Edmonton, Alberta, on March 8; Tacoma, Wash., on March 15; Palm Springs, Calif., on March 22; and Glendale, Ariz., on March 23.

“Blake counts on Kubota equipment at home on his farm and now he can count on Kubota to be with him on the road as he heads ‘Back To The Honky Tonk,’” said Todd Stucke, Kubota Tractor Corporation senior vice president of marketing, product support and special projects.

“We’re all about finishing what we started and doing things right in Kubota Country, so we’re looking forward to joining Blake for the second leg of his tour and connecting with fans and our dealers across the U.S. and Canada.”

To enter the Kubota Blake Shelton VIP Concert Sweepstakes, visit info.kubotausa.com/honkytonktour. For more information and a full list of tour dates for the “Back To The Honky Tonk” Tour presented by Kubota, visit www.BlakeShelton.com.

No purchase necessary to enter or win. A purchase will not increase your chances of winning. Open only to legal residents of the 50 United States (D.C.) or Canada (excl. QC), 21 years or older. Void in QC and where prohibited by law. Sweepstakes begins at 9:00:00 am CT on 12/1/23 and ends at 11:59:59 pm CT on 1/19/24. One GP Trip/Concert prize available for Canada participants (ARV $3,105.95 USD approx. $4,265.03 CAD based on a hypothetical Toronto, ON departure) and Four GP Trips/Concerts prizes available for US ($3,205.95 USD). Odds of winning depend on the total number of entries received per country. Skill-test question required for Canadian winner. Subject to full Official Rules. Sponsor: Kubota Tractor Corporation, 1000 Kubota Drive, Grapevine, TX 76051.

The largest annual display of construction equipment in the Carolinas and Virginia

HYUNDAI • JCB • KOBELCO • NEW HOLLAND

KUBOTA • JOHN DEERE • HITACHI • VOLVO

KOMATSU • BOBCAT • ASV • KIOTI

MANITOU • YANMAR • LIUGONG • GEHL

TAKEUCHI • FAE • FECON • VERMEER

PRINOTH • BLUE DIAMOND • BAUMALIGHT

SEPPI • DENIS CIMAF • AUSA • LOFTNESS

SHOULE and more

Plus a great selection of construction attachments, forestry equipment, and trailers.

January 31 – February 2 NC STATE FAIRGROUNDS •RALEIGH, NC Free Admission | 9am to 4pm Wed and Thurs, 9am to 3pm

AEM’s new report, Benefits of Construction Technologies and their Impact on Society, details how four key innovations are helping construction sites become safer and more productive, while also reducing their environmental footprint.

One of those technologies, machine control, is changing the way earthmoving and paving tasks are completed. Previously unimaginable levels of accuracy and efficiency are being achieved, resulting in job sites that are safer and more productive, and projects that are completed faster and with less waste.

“Machine control is a technology system that calculates the position of machinery,” said Brad Viernow, OEM director of North America Heavy Construction at Leica Geosystems, a supplier of sensors, software and services for geospatial data intelligence.

“To determine precise location, machine control uses measurement data from either satellites [i.e. GNSS] or an onsite surveying instrument called a total station. Then machine control is able to compare that positioning data to a project design.”

Armed with all of that information, machine control is then able to guide and assist the person operating a piece of equipment. It’s pretty simple: Better information leads to better results.

“On average, 52 percent of all rework globally is caused by poor data and missed communication,” said Viernow. “Sharing up-to-date data via cloud connectivity allows the equipment operator to see all of the design information on the panel in the cab while they are working. Going one step further, machine automation can also come into play. Machine control can actually take some of the work out of the operator’s hands while achieving the desired accuracy even more easily.”

Earthmoving and paving applications lend themselves well to machine control. Equipment operators must work within tight tolerances with respect to things like material placement, grade, cross slope and compaction density. That is why motor graders, dozers, excavators and pavers are among the most common pieces of equipment utilizing machine control today. However, the potential for machine control spans much further.

“There is no piece of machinery within the construction industry that isn’t seeing this type of technology being used in some way,” said Adam Woods, general manager of innovation and product portfolio Strategies at LBX Company, manufacturer of Link-Belt excavation equipment.

“Even something like a compactor, which seems like a relatively simple product that just rolls back and forth, will benefit from machine control. Machine control helps determine how much compaction has taken

place, and if any further compaction is needed to meet the desired specs. Automation is even allowing machines to do that all on their own. It’s all in the aim of making job sites more efficient.”

That goes for smaller job sites and equipment, too.

“The utility of something like a compact track loader, paired with the benefits of a technology like grade control, is really a winning combination,” said Sean Mairet, group product manager of Grade Control at John Deere.

Everything starts with the accuracy a machine control system helps deliver. Take grade control, for instance. The most advanced system, 3D grade control, deservedly receives a lot of praise. But even a more entry-level 2D system produces meaningful results.

A 2D grade control system helps eliminate inaccurate digging by guiding the operator as they dig. The operator specifies key parameters such as depth and slope in the software. A sensory system on the machine then measures those datapoints as the machine digs, providing visual and/or audible coaching to the operator via a display screen in the cab.

“This level of machine control is based on plane and slope,” Mairet explained. “It’s an ideal solution on projects that don’t require a complex site design, such as sloping terrain away from a house. The operator tells the machine they want to maintain a 2 percent slope, for example, and the 2D grade control system controls the blade or bucket to achieve that. From this standpoint, even a 2D system can help save a lot of time and material by not over-cutting or over-digging.”

Modern 3D grade management takes accuracy to another level. In fact, certain systems can help equipment operators achieve accuracy up to a millimeter. 3D systems also are more sophisticated.

3D systems tie into position information and a site design to pinpoint where a machine is located at all times. The position information is provided by either satellites (i.e. GNSS) or an onsite surveying instrument called a total station. Each has its own advantages. Regardless, the precision accuracy of 3D grade control can lead to even greater gains in efficiency and resource optimization.

Case in point, industry estimates suggest that construction projects see a 10 to 20 percent reduction in material use when grade control is deployed. That means the amount of asphalt and concrete saved on public road construction projects each year is enough to pave a two-lane highway from Chicago to

Phoenix. That has a direct financial implication for not only construction companies, but also everyday citizens. By increasing accuracy and reducing waste, taxpayers saved approximately $3.6 billion in material costs on public road construction projects in 2022 alone.

Grade control also can have a positive impact on project scheduling. Time is money on construction projects. When operating equipment with machine control, Woods has seen some construction companies improve productivity by 30 to 50 percent.

“Think about a project like an irrigation canal,” Woods said. “If that canal is 1,000feet-long with a 0.3 percent slope, that slope isn’t changing much from spot to spot. Machine control is able to constantly check

“On average, 52 percent of all rework globally is caused by poor data and missed communication.”

Brad Viernow Leica Geosystems

that slope so it’s accurate. That’s where productivity can really climb, because the operator isn’t having to repeatedly stop and check grade. It’s almost unheard of anymore, but some contractors are even finishing projects ahead of schedule when using this technology.”

“We’ve found that 35 percent of working time on a job site is spent on non-valueadding activities,” Viernow added. “Additionally, rework can create an average of 10 percent schedule growth. Machine control helps reduce a lot of this waste throughout the construction process. By simply moving the right dirt the first time, you can really reduce a lot of waste on a job site.”

Machine control technologies like grade control can also help reduce safety-related incidents on a job site.

“Without technology like this, you need surveyors, civil engineers and other people on a job site to be constantly checking grade,” Woods said. “They are constantly walking up to and around the machine. They are oftentimes working within a trench. With grade control technology, you reduce the need for these people to place themselves in these potentially unsafe environments.”

There also are safety-specific machine control features that are helping enhance job

sites. A camera system is the first thing that comes to mind. Cameras give equipment operators enhanced visibility all around a machine, oftentimes calling attention to people and objects that are getting dangerously close to that machine.

As important as that type of operator guidance system is, machine control has the ability to do much more. Technology is capable of actually stopping a machine when a potential collision is detected. Additionally, Viernow said 3D avoidance zones can be created by leveraging another key construction technology, geofencing.

“Let’s say a person is operating an excavator in an area with a powerline right above them,” Viernow related. “Through locationbased geofencing, the operator could set up an automatic stop so the excavator arm couldn’t extend beyond a certain point.”

That makes things much safer and less stressful for the operator, which is one of the core objectives of machine control.

In addition to making equipment safer and more productive, machine control also makes equipment easier to operate. By improving accuracy and taking over certain functions, machine control can help operators become proficient in less time and fatigued far less often.

“It isn’t easy to hop into a piece of construction equipment and start doing what these operators are asked to do,” Mairet said. “Technology like grade control can help operators get comfortable and productive a lot faster. Even people who’ve been operating equipment for many years will benefit from technology that lightens their workload. That leads to happier and more productive operators.”

“With machine guidance, you can take a proficient operator and make them distinguished,” Woods added. “With machine control, a novice operator could learn to cut grade within a day or so of using the equipment. Without this type of technology, the necessary training could take months, if not years.”

To that point, machine control is one solution to the growing skilled labor shortage the construction industry is facing. Machine control allows equipment operators to rely on real-time data and semiautonomous operation, as opposed to intuition and decades of skill refinement.

“Machine control technologies are really modernizing the workflow,” Mairet said. “Good operators and surveyors have always been able to maintain grade. Machine control is just making that process much safer and more efficient. Machine control is really a modern approach to how we shape our world.”

tion activity can lead to traffic disruptions resulting in congestion and crashes. Loss of productivity and public frustration with work zones also were cited in the proposed rulemaking.

The goal is a “more coordinated and comprehensive” approach to safety and mobility issues across project stages, said FHWA.

AGC responded with a letter outlining the association’s emphasis on worker safety.

“Work zone safety continues to be one of the biggest concerns among highway contractors,” said AGC.

Last spring, the association released results of a highway work zone study conducted among its members.

“In fact, 97 percent of contractors report that highway work zones are either as dangerous or more dangerous than they were a year ago.”

Tracking a “concerning rise in crashes, injuries and fatalities,” the association said it hopes to see a reversal in “this disturbing trend.”

The AGC safety survey found that many motorists are in even greater danger from highway work zone crashes than construction workers.

Ken Simonson, association chief economist, said 28 percent of responding contractors experienced crashes that resulted in injury to construction workers.

“But more than twice as many firms — 59 percent — reported experiencing a crash in which drivers or passengers were injured.”

The survey noted that work zone crashes are twice as likely to result in fatalities to drivers or passengers as construction workers. In fact, 8 percent of contractors in the survey reported workers killed in crashes, and 16 percent noted drivers or passengers killed.

“In many cases, vehicle speeding contributes to these crashes in work zones,” said Steve McGough, president of HCSS, survey partner with AGC.

“Utilizing speed cameras with a zero-tolerance policy would go a long way to protect the traveling public and our workforce.”

Concerning was Simonson’s revelation that 97 percent of contractors believe work zones are either as dangerous, or more dangerous, than a year ago. More than half of respondents want automatic ticketing for speeding in work zones, noted the economist. Understandably, 79 percent want a greater police presence and 65 percent want stricter enforcement.

AGC pressed states to prioritize education and enforcement in order to make work zones safer.

The association said it wants every state to

implement a driver work zone safety course and deploy more police to work zones. AGC also urged states to authorize speed cameras in work zones and set tougher penalties for unsafe work zone driving.

“Nobody should die because our laws fail to penalize unsafe operations in work zones in the same way they punish drunk driving and stigmatize not using a seat belt,” said Simonson.

The association also urged motorists to be careful when passing through highway work zones. Simonson said AGC is releasing a new video featuring highway workers pleading with motorists to be more careful when passing through work zones.

In its proposal, DOT said its “principal mission is to ensure America is the safest, most efficient and modern transportation

system in the world.”

The proposed changes affect work zone safety and mobility and temporary traffic control devices. The changes would “clarify and correct certain aspects of the regulations that were last modified in 2004 and 2006, respectively,” said FHWA.

Work zones are a “necessary part of meeting the need to maintain and upgrade our aging roadway infrastructure,” the agency said. “Work zone activities are expected to increase significantly with the passage of the Bipartisan Infrastructure Law [BIL].”

The BIL earmarks some $350 billion for highway programs from 2022 through 2026, FHWA noted.

“This represents a 55 percent increase in highway and bridge program funding over the Fixing America’s Surface Transportation [FAST] Act” of 2015.

Regardless of increased funding, work

zones already result in significant safety and mobility impacts, FHWA said adding that 857 people died in 774 crashes.

In 2020, the NHTSA said 117 road construction workers suffered fatal occupational injuries. And 62 of those were workers hit by a motor vehicle.

And while FHWA offers resources to assist states in implementing the revisions safety and mobility rule, implementation is varied across the country. The agency said many states have developed and implemented systematic procedures to assess anticipated work zone impacts in project development. But only a few have procedures to manage impacts during project implementation or to perform post-project evaluations.

And that’s despite increased availability of data sources and methodologies available to do so.

Further, many states have not embraced data-driven performance-based process reviews that these resources offer, said FHWA, even with encouragement.

“The FHWA acknowledges that a lack of clarity in what is required by certain parts of the regulation may partially explain the uneven adoption.”

The existing regulation has language considered necessary at the time to ensure state understanding but now superfluous to implementation, the agency added.

FHWA said it also recognizes the frequency of agency process reviews may hamper some states from more in-depth assessments.

BIL calls for revisions to ensure that the work zone process review is required not more frequently than once every five years. Plus, urged revisions would ensure only a project with a lane closure for three or more days shall be considered significant. And a state shall not be required to develop or implement a transportation management plan for a highway project not on the Interstate System.

This, “if the project requires not more than three consecutive days of lane closures,” said FHWA.

Where temporary traffic control devices are concerned, FHWA proposes adding a new subpart on appropriate use of and expenditure of funds. This would include uniformed law enforcement and protective measures between workers and traffic. It would also cover installation and maintenance of temporary devices during construction, utility and maintenance operations.

“The intent of the regulation was to reduce both worker and motorist fatalities and injuries in work zones,” said the agency. “Overall, work zone fatalities did decrease significantly from a high of 1,068 work zone fatalities in 2004 to 590 fatalities in 2011.

THE CAT RENTAL STORE AT THOMPSON MACHINERY TMRents.com

Columbus, MS 622-244-4610 Greenwood, MS 662-459-7210 Belden, MS 622-842-4322 Nashville, TN 615-291-5444 Memphis, TN 901-362-8883 Clarksville, TN 931-905-3902 Jackson, TN 731-988-4259

LOUISIANA CAT www.louisianacat.com

Alexandria, LA 318-443-2577

Baton Rouge, LA 225-296-0020 Belle Chase, LA 504-433-1350 Bossier City, LA 318-746-2341 Hammond, LA 985-340-2820 Lafayette, LA 337-837-2476 Lake Charles, LA 337-439-3601 Monroe, LA 318-323-1345 Praireville, LA 225-673-3480 Reserve, LA 985-536-1121 St. Rose, LA 504-904-7421

RING POWER ringpower.com/paving St. Augustine, FL 904-737-7730

Brooksville, FL 352-796-4978 Daytona Beach, FL 386-947-3363 Gainesville, FL 352-371-9983 Jacksonville, FL 904-714-2600 Lake City, FL 386-755-3997 Lakeland, FL 863-606-0512 Ocala, FL 352-732-2800 Orlando, FL

407-855-6195 Palm Bay, FL 321-952-3001 Sarasota, FL 941-359-6000 Tallahassee, FL 850-562-2121 Tampa, FL 813-671-3700

KELLY TRACTOR www.kellytractor.com Miami, FL 305-592-5360 Davie, FL 954-581-8181 West Palm Beach, FL 561-683-1231 Clewiston, FL 863-983-8177 Ft. Myers, FL 239-693-9233

YANCEY BROS. CO.

www.yanceybros.com

Austell, GA

800-282-1562

Albany, GA

800-768-2892

Augusta, GA

800-446-5131

Bloomingdale, GA

800-482-1144

Brunswick, GA

800-299-5010

Calhoun, GA

800-752-9804

Columbus, GA

800-633-5240

Dacula, GA

800-545-2945

Macon, GA

800-633-5180

McDonough, GA

888-926-2392

Savannah, GA

800-755-8382

Statesboro, GA

888-764-6506

Valdosta, GA

800-755-6841

Washington, GA

888-678-3211

Waycross, GA

888-948-2443

traffic to the west side of the small town and encompass parts of Craven and Carteret counties, has progressed to the point that he felt confident in saying construction crews are likely to have the job finished late next summer — only a few months longer than his agency anticipated in 2014.

“A lot of that delay is because of the interchange at the north end of Havelock where U.S. 70 meets U.S. 70 Business,” he explained. “We had to hold up the construction until we got a redesign on that part of the project.”

Originally, the interchange was planned so that traffic would travel at 60 mph, but an upcoming project that ties into the bypass has a speed limit of 70 mph.

“With the bypass and that new project each having higher speed limits than the interchange, we needed a redesign to make it 70 mph throughout, meaning we also had to change some walls, and do a little bit of structure and field work,” McMannen said.

The change also boosted the overall price tag of the bypass. McMannen declined to name a cost figure for the redesign, but NCDOT currently lists the construction at $167.2 million.

Factoring in the costs for the project’s development, design, right-of-way acquisition and utility relocation, the grand total to build the Havelock Bypass is $221.25 million, the agency noted on its website.

Balfour Beatty Infrastructure in Wilmington, N.C., has managed crews to build the project since the effort began at Havelock nine years ago.

The Havelock Bypass is one component of NCDOT’s plan to upgrade the high priority U.S. 70 corridor to eventually become I-42 in eastern North Carolina between Raleigh and the Port of Morehead City on the Atlantic coast, a drive that currently takes a little less than three hours. Most of the roadway already accommodates four lanes of traffic.

Nine different projects make up the transportation agency’s plan to improve the route, most of which are either under construction or still in development. They include additional bypasses around the cities of Goldsboro and Kinston, and upgrades to the highway through the town of James City, just south of New Bern.

Connecting with the Havelock Bypass on its north end is a $242 million U.S. 70 upgrade that will start construction next year and continue northwest for 6.4 mi. to near Thurmond Road, where it will join the James City portion of the corridor. NCDOT projects that building effort to last about four years.

“Balfour Beatty Infrastructure will work on that part of the roadway as a design-build,” McMannen said. “They are continuing to work out the rights of way, the utilities and finalize the plans. Also, the Kinston Bypass west of here is one that is still in the design phase, while the Goldsboro Bypass has been completed, so there are different legs still being built and others undergoing their initial designs.”

Although much of the area is rural and more sparsely populated compared to points west and north, U.S. 70 in the Tarheel State’s eastern third is a key route for moving freight to and from the Port of Morehead City and plays an important role in evacuating people from the state’s beaches ahead of summertime hurricanes.

Additionally, two key East Coast military bases are just off U.S. 70 — the Marine Corps Air Station Cherry Point on Havelock’s east side, and Seymour Johnson Air Force base in Goldsboro.

At the Havelock Bypass, Balfour Beatty has so far constructed 16 new bridges, and raised two existing overpasses across the new highway. No bridge or structure demolition was needed on the job, according to McMannen.

In addition, Balfour Beatty is overseeing the work of a number of key subcontractors on the U.S. 70 bypass, including Barnhill Contracting Co., to handle asphalt work; Bullington Construction Inc., in charge of installing guardrails; Gosalia Concrete Constructors, builders of the concrete barrier rails; National Erectors, rebar and steel professionals; and four companies that hauled in stone, riprap, aggregate base stone (ABC), and asphalt to the job site: Military Federal Construction, More Tons LLC, M&J Trucking Inc., and RL Thompson Inc.

McMannen said that most of the borrowed hauling on the bypass has been done by Balfour Beatty with off-road trucks. He added that all but one pit is on the new road alignment where the subs used on-road trucks – the other pits

required off-road vehicles.

With much of the Havelock construction site being in a part of the state where wetlands are prevalent, excavation was required to remove less desirable undercut material to allow for aggregates to be trucked in to give the new roadway a more stable base, he added.

“We have had 95,000 cubic yards of undercut excavated, then replaced by borrow from the pits that totaled 4.9 million cubic yards, and we still have some left to bring in for various tie-ins,” said McMannen. “We are still scheduled to get close to 5.8 million cubic yards of material before the work is done.”

The result will provide the Havelock Bypass better drainage and a more solid support for the highway’s pavement.

Although the construction’s completion late next summer is in sight, McMannen said much work still needs to be accomplished to build a bypass that meets federal interstate standards.

“We are working on the interchanges — the bridges on both ends of the project,” he said. “The next step is to detour traffic onto the bypass at the interchange with U.S. 70 that continues into Havelock on the north end of town. We also will continue to build the tie-ins and construct bridges and road surfaces, even though a lot of the work is completed.

“In addition, the contractors are still bringing in a lot of ABC stone to get the roadway covered up and get it paved to help with drainage and erosion control measures, and we have most of our pipe work completed too. At this point in the project, there are just a variety of things that still need to be done.”

McMannen could not think of too many days since the effort began when the work has slowed down at the Havelock site.

“It has been fairly busy from the get-go and stayed consistent throughout most of the project,” he said. “It is a great operation because we are still hauling, as I said, and the structural crews will work on a couple bridges at a time and then move on to another one. Plus, when we have one subcontractor finish a component of the job, another sub comes in to perform their task. That keeps things buzzing on site. In a single month, we will have 125 to 150 different people out

see NCDOT page 80

JCB is celebrating 70 years of manufacturing its iconic backhoe loader with the unveiling of Platinum Editions of the 3CX and 4CX models.

Company founder Joseph Cyril Bamford CBE invented the backhoe concept, and the first JCB model was manufactured in 1953 after he combined a lightweight backhoe with a Major Loadall tractor loader. It created, for the first time, a single machine which combined a front shovel and rear excavator arm.

While it took 20 years for JCB to build 50,000 backhoes, under the leadership of JCB Chairman Anthony Bamford, more than 900,000 have now been made.

JCB has been world market leader for backhoes for almost 25 years and today manufactures the iconic machine in the UK, India and Brazil. A total of 70 limited-edition 70th birthday 3CX PRO and 4 CX PRO machines will be manufactured.

Bamford said, “The backhoe loader is an incredibly versatile machine, and thanks to continued innovation and evolution, it remains just as relevant today as the day it was first invented. The JCB backhoe loader remains one of the most popular pieces of construction equipment in the world, and it has a very exciting future ahead of it.”

The Platinum Edition models will have servo excavator controls, Powerslide, air conditioning and bidirectional auxiliary flow hydraulics. The machines also will have limited edition platinum decals and grill badge and platinum-colored wheels. The cab will have an embroidered graphic in the carpet and upgraded seat material with 70th anniversary branding, along with a steering wheel center cap featuring the 70th logo.

Each machine also will have a special plaque, and customers will receive a special platinum gift pack with the backhoe loader.

Over the last seven decades JCB has continued to develop and enhance the backhoe loader concept, with turbocharged engines, powershift transmissions, all-wheel drive and extending dipper arms. The machine has broadened in appeal, with the launch of the skid steer based 1CX, the all-wheel steer 3CX Compact and the larger 4CX and 5CX equal-sized wheel machines.

For more information, visit www.jcb.com.

(All photos courtesy of JCB)

EQUIPMENTSHARE www.equipmentshare.com

10179 US-78 Ladson, SC 29456 843-709-2458

145 Thunderbird Dr. Richmond Hill, GA 31324 912-400-0752

2919 E. Napolean St. Sulphur, LA 70663 337-284-9804

HEAVY MACHINES, INC. www.heavymachinesinc.com

3930 East Raines Road Memphis, TN 38118 800-432-8902

2115 N. Thompson Lane Murfreesboro, TN 37129 877-200-5654

5200 Hollywood Ave. Shreveport, LA 71109 800-548-3458

364 Bob Jobe Rd. Gray, TN 37615 855-201-7453

10110 Roberts Way Covington, GA 30014 770-788-0888

7651 Theodore Dawes Rd. Theodore, AL 36582 251-653-5955

825 31st Street North Birmingham, AL 35203 205-323-6108

Ashland, VA 866-955-6071 Chesapeake, VA 800-342-3248 Frederick, MD 833-546-5235

PARMAN TRACTOR & EQUIPMENT www.parmantractor.com

3570 Dickerson Pike Nashville, TN 37207 615-865-7800

MID SOUTH MACHINERY, INC. www.gomidsouth.com

3233 Highway 80 West Jackson, MS 39204 601-948-6740

3145 Cliff Gookin Blvd. Tupelo, MS 38801 662-690-6553

14336 Seaway Road Gulfport, MS 39503 228-867-1555

www.gsequipment.net Tampa, FL 866-586-8956 Pompano Beach, FL 954-327-8808 Ft. Myers, FL 239-334-6063 Tallahassee, FL 850-574-0892 Orlando, FL 407-859-9160 Jacksonville, FL 904-268-4400

In the woods of Roxboro, N.C, Chase Allen recently channeled his farming roots into a new venture. Founded in June 2020, during the thick of the COVID-19 pandemic, CL Allen Land Management was Allen’s answer to an unexpected halt in everyday activities.

“People had projects they wanted done around their house, but not everybody has the equipment to do it,” said Allen, whose company zeroes in on forestry mulching, armed with a new Fecon FTX150-2 mulching tractor. “We’ve got a range of Fecon equipment — from excavator and skid-steer mounts to a specialized machine. They aren’t just machines; they’re fun to run.”

Allen’s passion for running equipment was cultivated from days on his family’s tobacco farm.

“Growing up, it was all tractors and equipment,” said Allen. “One night, a mulching YouTube video caught my interest. Having an excavator on hand, I thought I could do a lot of the mulching they were doing on the video. The interest only grew from there.”

His upbringing not only sparked the interest but also provided him with the right skill set.

“Growing up on a farm, you turn into a driver, operator, mechanic, everything,” commented Allen. “I always aimed for something beyond just tractors. My background and the timing worked out just right.”

Despite CL Allen Land Management’s growth, Allen stays close to home, focusing on areas around Roxboro like Person, Caswell and Orange counties. He relies on word-ofmouth advertising to find new clients and has built a strong reputation in the area.

For Allen, every piece of equipment has its place and purpose. Forestry mulching offers a distinct advantage for clients who don’t want the hassle of hauling away debris or dealing with grading issues.

“A recent customer wanted their land cleared without creating huge piles,” Allen noted. “There was a lot of underbrush and pine trees roughly 8 inches in diameter. When you consider the added cost of hauling debris away, grinding it into a fine mulch made sense. That’s a typical job, and what’s nice is our Fecon machine didn’t bog down; it goes as fast as you can run it.”

The Fecon FTX150-2 mulching tractor helps Allen complete jobs efficiently, and he doesn’t shy away from taking pride in the equipment.

“This machine’s only job is to mulch and grind trees,” said Allen. “From my experience, it’s just a better option than a skid-steer. It’s heavier, stronger and more efficient. Time is money at the end of the day, and this machine saves both.”

Allen also spoke about the innovative features of the machine and their practical applications.

Chase Allen, owner

“One of the features I love is the increased ground clearance,” said Allen. “With 21 inches of ground clearance, I can drive over the whole tree, which increases efficiency compared to the 8 inches of ground clearance on some other equipment.”

Beyond efficiency, the Fecon FTX150-2 is an environmentally friendly machine.

“The environmentally friendly hydraulic fluid is what the machine is designed to run, ensuring that if a breakdown happens, we won’t harm the environment,” explained Allen. “You’re also reducing ground disturbance and preventing erosion by mulching the brush instead of ripping it out of the

ground and creating holes or runoff issues. It’s reassuring to know that the machine and process are working together to limit their environmental impact.”

The machinery Allen uses also reflects a keen awareness of technological advancements and their benefits.

“The joystick control on the machine was something new for me, but I quickly adapted,” Allen said. “It’s electric instead of hydraulic, and the sensitivity is a bit different, but it didn’t take long to learn. I think anyone could learn how to do it.”

Choosing the right brand isn’t just about the machine’s performance on the job. It’s also about the support that comes after the purchase. For Allen, Fecon’s customer service played a significant role in his choice.

“I’ve talked with multiple salesmen for Fecon,” stated Allen. “I really like their service department because if it’s something I can’t figure out, I pick up the phone, talk to a person, and nine times out of ten they tell you right then what the problem is.”

When working with Linder Industrial Machinery

Rock breaking projects on land are tough, but nothing Atlas Copco handheld breakers can’t handle. Fracturing rocks underwater, on the other hand... now there’s a challenge

of a much higher order. Just ask Pina Dalgıçlık naat San and Trade (PDIST), a specialist underwater contractor based in Bakırköy, one of the oldest districts in Istanbul, Turkey.

The company is currently using Atlas Copco’s robust LH 390 pneumatic breaker for an intensive eight-month underwater electrical infrastructure project, as part of a wider effort to energize cruise liners and cargo ships across Turkey and Malta.

The “Malta Medium Voltage Underwater Cable Laying” project will enable vessels to plug into shoreside electricity to charge onboard systems while berthed at port, swapping out the need for fuel-dependency in place of clean electric.

Coupled with Atlas Copco’s LP 18-40PE Hydraulic Power Pack, the LH 390 handheld hydraulic breaker is being used to crush rocks beneath the water’s surface in order to prepare the area for underwater electric cables. On land, the LP 18-40PE Hydraulic Power Pack transmits power to drive the submerged LH 390 breaker unit, which is tasked with the demanding job of fragmenting rocks and dislodging them from the ground to forge a clear path for the cables, which will transmit electricity to allotted onland charging ports.

While such a demanding application may land other air units in troubled waters, Atlas Copco’s LH 390 hydraulic unit has proven itself to be tough enough to take such a challenge in its stride. As one of the most powerful handheld breakers in the world, the titan LH 390 is designed to break anything, anywhere.

Weighing 73 lbs. and offering 125 bar of pressure, its high pressure-to-weight ratio also means users can achieve optimal performance without compromising on portability, the manufacturer said.

The LH 390 handheld breaker is coated with premium water resistant, anti-corrosion and anti-rust paint, meaning it can be plunged in saline ocean water and remerge unscathed. Before use, the machine’s robust design and high-quality components also are rigorously tested at Atlas Copco’s in-house testing facility, ensuring it is suitable to weather any storm.

The PDIST team is required to physically dive underwater to power their tools, which is why it is important to not only have a breaker unit that is tough enough to crack rocks underwater, but also easy to maneuver

and work with. Fortunately, Atlas Copco’s LH 390 handheld breaker’s slim design and lightweight design offers a smooth user experience.

“Mobility is one factor that is really critical to this operation,” said Serdar Yaygili, PDIST general manager. “We are routinely diving into the water to remove rocks and debris from the seabed, then swimming back up to the surface again — all while operating and carrying our handheld breaker.

“The LH 390’s high power to weight ratio means we can get plenty done in a short space of time, improving our team’s productivity and enabling us to ‘crack’ on with our project with ease — pun intended.”

The LH 390’s vibration reduction technology and low noise also means that PDIST can work comfortably for a full workday, without risking injury.

Once finalized, the project is predicted to reduce the emissions of visiting cruise liners and cargo ships significantly supporting the region’s electric and net zero transformation. PDIST is spending two months completing rock breaking work in Bandirma, Turkey, and another six months in Malta.

For more information, visit www.atlascopcogroup.com.

Metso is launching the Reactorwell upgrade — a new generation feedwell upgrade — for maximizing thickener and clarifier performance while minimizing flocculant consumption and bringing significant operational cost efficiencies.

The first-class feed system upgrade features high solids retention and mixing efficiency. It eliminates feed short-circuiting and offers low shear for ideal floccule growth and even discharge symmetry. The new feed system upgrade provides optimum feed conditioning for thickeners and clarifiers.

Due to its many benefits in addition to low flocculant usage, the Reactorwell upgrade is part of Metso’s sustainable Planet Positive portfolio.

The Reactorwell upgrade enables a big leap forward in thickener and clarifier performance as it utilizes maximum settling area due to its high exit symmetry. It also provides improved overflow clarity as well

as higher underflow density. Additionally, the Reactorwell upgrade allows better thickener operability with an improved response to process changes.

“The Reactorwell’s design allows it to be integrated into existing mining operations as an upgrade that is compatible with most makes of thickeners. We offer expertise and support to retrofit existing infrastructure without major modifications. The Reactorwell can also be upgraded to a new channel configuration if process conditions significantly change,” said Andrew Mcintosh, senior product manager, thickening at Metso.

The Reactorwell upgrade is easy to maintain due to its intelligent design and modularity. It consistently achieves high unit area throughput and the improved Autodil performance minimizes the need for pumped dilution, leading to lower total cost of ownership.

For more information, visit

Luck Stone, one of the United States’ largest family-owned producers of crushed stone, sand and gravel, has invested in a 110 tph sand wash system to replace its sand screw equipment.

Luck Stone, which is celebrating its 100th year in business this year, is headquartered in Richmond, Va.

Starting with a single quarry in Richmond, the organization now has 30 locations across the United States to provide aggregate materials and services for the construction of roads, bridges and buildings.

The firm recently invested in a 110 tph EvoWash sand washing system from industry experts CDE in a bid to optimize output and reduce wastage at its site in Atlanta, Ga.

Previously, the company produced a washed sand using a traditional sand screw however Luck Stone found that the technology was not optimal in getting the desired specification.

Luck Stone sought out expertise from wet processing experts at CDE to help optimize their sand processing, reduce waste and ensure their products provided the best quality for concrete customers.

Luck Stone has many years’ experience producing sand and gravel, and this project benefited from its strong technical understanding and clear goals.

Through various sand gradations and test analysis, CDE found that if Luck Stone want-

ed to produce an in spec concrete sand, the removal of the 30-50# sand was essential, which had to be done in an optimized environment.

In order to optimize output, CDE replaced the existing sand screw equipment with its EvoWash technology, processing at a rate of 110 tph.

Commenting on the installation process, Brent Junior, senior process specialist at Luck Stone said: “We did a lot of work ahead of installation with gradations analysis, having CDE run simulations along with our own simulations so that we really knew what we needed to do to have the right controls when the plant was installed.

“The installation was really great. On a Thursday morning, we started disassembling the sand screw. The team worked through the weekend and by Monday morning we were operating and producing in spec sand. It was great to minimize downtime and start making product right away to meet customer needs.”

Joe Teague, vice president of sales of CDE added: “This project is a great accomplishment. Thanks to all the collaboration and preplanning with both companies the install went smoothly on site.”

A compact, modular sand washing system, the EvoWash separates the smaller sand and gravel fractions through an integrated highfrequency dewatering screen, sump and hydrocyclones which provide unrivalled con-

trol of silt cut points and eliminates the loss of quality fines with significant commercial value, the manufacturer said.

Incorporating CDE’s Infinity Screen technology, the EvoWash offers optimal dewatering results, which enables operators to produce a range of high-quality sands that are market-ready straight from the belt.

Protecting revenue by eliminating the need for maintaining settling ponds, the EvoWash can integrate seamlessly into existing operations to reduce site footprint. The technology minimizes downtime and, with an increased number of parameters to ensure improved accuracy on the material cut point, removes the double-handling of materials, as highvalue fines can often be lost and trapped at the bottom of ponds when processed with traditional sand screw equipment.

The CDE EvoWash allows the operator to make adjustments to the blending of final products as they discharge off the dewatering screen. It also allows adjustment in the feedbox, prior to material entering the dewatering screen leaving a complete adjustable cut point in real-time, which is essential for a potentially fluctuating feed. This enables the operator to perform a consistent and optimized concrete sand product

With CDE’s technology, Luck Stone is producing three sand products: concrete sand, asphalt sand and masonry sand to be used in construction projects across Georgia.

Since its installation, CDE’s CustomCare support has been at the heart of the relationship as Plant Manager for Luck Stone Mike Maldonado said: “Customer support is very important and the partnership with CDE is very important. Having that support and customer service has always been key for me. As busy as we are here with everything that’s going on, it’s important to have that person who you can contact to get you the information or help that you need to help solve the problem. With CDE, we know we have this support.”

Teague concluded: “The EvoWash is one of our core products and is much more efficient than the sand screw technology. It also helps produce a much drier product than a screw would so you’re able to sell straight off the belt. Operators can also make quick adjustments to be able to blend different sands.

“This is our first project with Luck Stone, it’s been a great experience for CDE, the professionalism and the collaboration that we experienced from our team working with their team early on was great and we look forward to continuing our partnership.”

CDE currently has a trade in deal where producers can trade in their sand screw for CDE’s EvoWash.

For more information about the new trade in deal, which is only available for a limited time, visit cdegroup.com/swapyourscrew.

The icy grip of the winter season presents a unique set of challenges for wash plant operators, but with effective planning materials producers can protect their investment and ensure their operations are ready for an efficient return to production in spring.

When it comes to plant maintenance, it is essential that any potential complication is identified and remedied quickly to protect an operator’s investment and ensure optimal performance, particularly during the coldest months of the year when washing and classifying equipment is especially susceptible to the elements.

“In this business, time is money,” said Mike Matusik, a customer relationship manager at CDE.

“Implementing a robust maintenance program year-round will safeguard equipment from the taxing cold weather, helping to minimize downtime for unscheduled maintenance and maximize product output.

“With planning and preparedness, operators can ensure the safe and efficient shutdown of a wash plant in winter and facilitate an efficient restart of operations in the spring. While there is no one-size-fits-all approach, there are some basic steps operators can take to protect their investment.”

CDE photo

When it comes to plant maintenance, it is essential that any potential complication is identified and remedied quickly to protect an operator’s investment and ensure optimal performance, particularly during the coldest months of the year when washing and classifying equipment is especially susceptible to the elements.

• Water Management: Effective water management as the cold weather sets in should be paramount for operators. It’s advisable to drain all standing water from tanks and pumps when plants are mothballed for the winter season otherwise you risk lines freezing, cracking, and leading to a delayed and costly restart in the spring.

• Insulate: The winter months can bring unforgiving conditions, so consider insulation to protect pipes, valves and pumps. Ensure your control cabin has been closed and, if possible, keep the internal heating on to protect the beating heart of your plant from plummeting temperatures.

• Open Valves: In addition to draining the system and, where possible, insulating pipes valves and pumps, it’s also advisable to keep valves open during winter shutdown as this will prevent any residual water accumulating in the system.

• Spray Bars: Clean out spray bar nozzle heads and ensure smaller pipework is free of debris such as silt and sands. Ensure your spray bars are receiving adequate water pressure, and the spray from the nozzles are fanning at the correct angle. This will allow you to get more water on to the screen to ensure the product is getting the best washing treatment.

• Safety Protocols: Winter also poses additional safety concerns for plant operators. Consider refreshing and rehearsing your training procedures to ensure your teams are well versed in the appropriate safety protocols when working in the vicinity of a wash plant to avoid slips, trips and falls.

Proactive and preventative approaches to plant maintenance during winter months are essential for long-term efficiency and profitability, but unforeseen challenges can still arise despite best laid plans, explained fellow CDE customer relationship manager Andrew Bunting.

“A responsive service is key when the unexpected occurs.

For the CDE CustomCare team, the name of the game is minimizing and, where possible, wholly eliminating any unexpected downtime by supporting customers to get up, running and processing material again as fast as possible, whether that’s during the normal production season or when starting up production again once winter is behind us.”

In order to respond in a timely manner, CDE holds stock of parts locally, from screen media and cyclone parts to marsh mellow springs, motors, and gearboxes. These are all available for immediate dispatch to customers from CDE’s North American headquarters in Fort Worth, Texas.

“Our CustomCare team holds a complete order history detailing critical plant components and spare parts for each of our customers’ wash plants. This helps ensure straightforward re-ordering and allows our service engineers to maintain a comprehensive overview of how a plant is performing.”

Prevention is always the number one focus, Bunting added.

“We work closely with our customers to deliver regular preventative maintenance inspections which are highly effective at identifying potential issues before they arise and adversely impact production. Our plant health checks are just one part of our commitment to providing a lifetime of care to customers and ensuring their long-term success.”

As part of its free plant health check initiative, CDE’s expert service engineers will analyze the plant’s condition, highlight signs of wear or irregular noises, identify parts in need of replacing, schedule regular maintenance, support and advise operators, and recommend fast-moving parts ideal for storage on site.

For more information about CDE CustomCare and to order parts, contact: customcare@cdeusa.com.

(Brush Chippers, Stump Grinders, Skid Steer Attachments) Mason Tractor Company www.masontractor.com

5038 Buford Hwy. Norcross, GA 30071 770-582-0377

Blue Ridge, GA 706-632-3777

Cumming, GA 770-887-6119

Hiawassee, GA 706-970-3077

McDonough, GA 770-957-3370

Villa Rica, GA 678-952-2037

Perry, GA 478-987-1173

Stowers Machinery Corporation

stowerscat.com

6301 Old Rutledge Pike Knoxville, TN 37924 865-546-1414

10644 Lexington Drive Knoxville, TN 37932 865-218-8800

1825 Veterans Boulevard Sevierville, TN 37862 865-595-3750

9960 Airport Parkway Kingsport, TN 37663 423-323-0400

4066 South Access Road Chattanooga, TN 37406 423-698-6943

215 Interchange Drive Crossville, TN 38571 931-456-6543

BS,AND STUMPS NDIT®

ways, lot clearing ork done faster and efore with Bandit® ferent styles and l today to reserve nstration