A stretch of Tennessee highway — in a place perhaps best known for the famous country musicians born there — is currently undergoing a $51 million construction project to widen the highway over a span of 5.34 mi. The widening project of SR 133 (Maynardville Highway) will run from the Knox County Line to just south of SR144 in Maynardville.

SR 33 serves as a critical connection route from Knoxville through Maynardville, according to the Tennessee Department of Transportation (TDOT).

“The purpose of widening SR 33 is to create a safer and more efficient route by improving traffic flow and increasing the roadway’s capacity. In its current configuration, SR 33 approaching Union County from Knoxville reduces from five lanes to two lanes until entering Maynardville. After this project is complete, the whole route from the Knox/Union County line to Maynardville will consist of four travel lanes with a center turn lane,” TDOT said.

Proposed improvements to SR 33 were first initiated nearly three decades ago.

The widening project of SR 133 (Maynardville Highway) will run from the Knox County Line to just south of SR144 in Maynardville.

The Biden administration’s clean hydrogen goals are in a state of hurry up and wait. The industry is champing to get started, but there may be too many challenges to advance the president’s dream of building out the U.S. clean hydrogen industry. The biggest issue may be the fact that with a possible change in administration next year, one that heavily favors fossil fuels, all progress may be reversed.

Officials in Chattanooga, Tenn., kicked off the city’s efforts to conduct the first major renovations of the 134-year-old Walnut Street Bridge in three decades by advertising the project for bids on May 26.

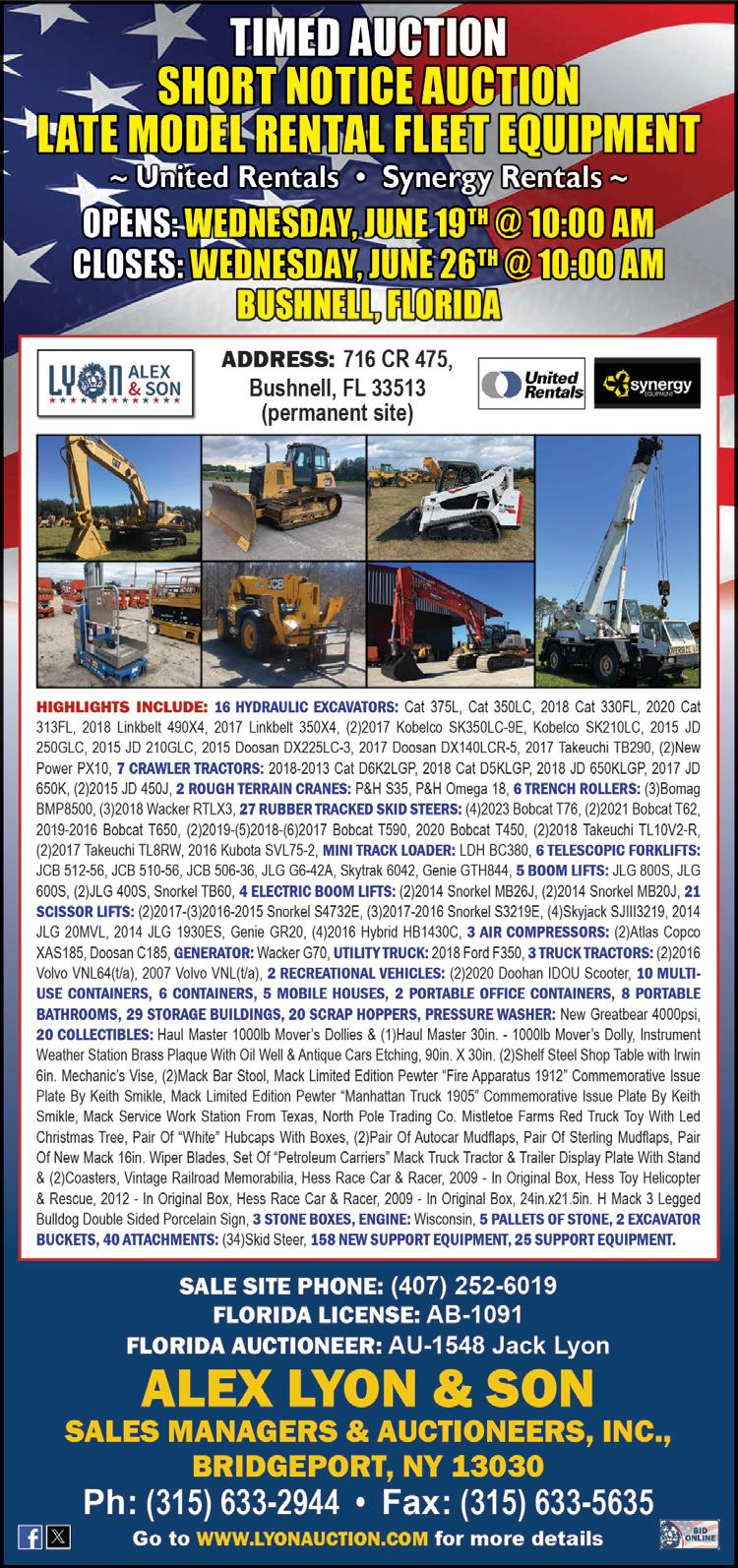

ASCENDUM Machinery held a customer open house in May at its Knoxville, Tenn., branch location to shine a spotlight on several new features within the facility.

16 THREE SERVICE PROS FROM YANMAR EARN NEW AWARD HONORS

Three outstanding service professionals — Larry Azdell, Roger Wilson and Stacy Blubaugh have been selected as winners of the Yanmar Service Awards. They were honored at a ceremony at the Osaka Institute of Technology, Japan.

22 LIEBHERR HIGHLIGHTS 75 YEARS AT FAMILY DAY IN NEWPORT NEWS, VA.

Liebherr USA Co. and Liebherr Mining Equipment Newport News Co. hosted Family Day at the Newport News, Va., campus. The celebration highlighted Liebherr’s 75th anniversary.

26 NINE CHILDREN OF FALLEN WORKERS TO RECEIVE ASSISTANCE

Nine children of highway workers who were killed or permanently disabled on the job will receive post-high school financial assistance for the 2024-25 school year due to the ARTBA Foundation.

After a highly successful demo event and used equipment sale at its Montgomery, Ala., location, Thompson Tractor followed up with another big show May 16, 2024, for its Florida Panhandle customers in DeFuniak Springs, Fla.

32 VERMEER SOUTHEAST SIGNS WITH CTE AERIAL LIFTS TO CARRY LINEUP

Vermeer Southeast, a provider of environmental and underground construction equipment, has signed with CTE North America to begin selling and servicing its line of Traccess aerial lifts.

After two days of hosting dealers and guests for its “Power Days Demo” event south of Atlanta, FAE USA territory managers and representatives from coast-to-coast gathered May 10, 2024, in Dawsonville, Ga.

Caterpillar released its latest reports highlighting the company’s environmental, social and governance (ESG) commitment, record financial accomplishments and contributions to helping customers build a better, more sustainable world.

The Top Gun award recognizes businesses who receive the PEG Award for Financial Excellence. The awards are given to the top 25 percent of rental operators based on financials verified by Peer Executive Groups.

50 MOUNTAIN BIKE LEGEND AARON GWIN, KUBOTA ANNOUNCE PARTNERSHIP

Kubota Tractor Corporation announced a partnership with downhill mountain bike legend Aaron Gwin, whose career highlights span five World Cup titles and eight U.S. National Championships.

Luby Equipment Services, a St. Louis-based Case Construction and Takeuchi dealer, announced June 3 an agreement to acquire Potter Equipment effective June 1, 2024.

At present, there is no

for Brightline’s planned train station in Cocoa, Fla., despite a similar construction project expected to begin in 2026 farther down the Atlantic Coast in the Martin County city of Stuart.

Officials in Chattanooga, Tenn., kicked off the city’s efforts to conduct the first major renovations of the 134-year-old Walnut Street Bridge in three decades by advertising the project for bids on May 26.

The legally required advertisement marks the official beginning of the project, according to the Chattanooga Times Free Press, and physical work is expected to begin around March of next year. Leaders expect construction will last 18 months, ending in the fall of 2026.

The Tennessee River bridge is safe to use, the city said, but it has developed wear and tear that workers cannot fix with occasional maintenance. Those issues could pose safety concerns in the near future if unaddressed. In addition, contractors will upgrade lighting and fix electrical issues on the span.

“The Walnut Street Bridge isn’t just a crucial gathering place and connection between downtown and the North Shore, it is a powerful symbol of Chattanooga and a source of civic pride,” Mayor Tim Kelly said in a news release. “Frankly, this work is overdue. For too long civic leaders have kicked the can down the road and let this shining jewel of our city fall into disrepair. It’s time to start the process of renovating the bridge so that it can enrich our city for the next 30 years the way that it has for the previous 30.”

Pedestrians will not be able to cross the river on the bridge during construction, but

parts of it will remain open. Chattanooga officials said they will plan to provide access to the structure for events like the city’s renowned Ironman triathlon and Seven Bridges marathon.

The tentative timeline for renovations to the Walnut Street Bridge includes:

• Bid opening, review and analysis in July.

• Bid selection and review by the Tennessee Department of Transportation (TDOT), and the contract award by the Chattanooga City Council in August.

• Execution of the contract in September.

• Public notice and pre-construction work in October.

• The start of construction and alternate pedestrian access to be opened in March 2025.

• Completion of the renovation project in the fall of 2026.

“There will be access to portions of the bridge during construction so folks can enjoy it as a public space,” Eric Holl, a city spokesperson, told the Times Free Press in a text. “You just won’t be able to use it to get all the way across the river.”

Originally constructed in 1890, the Walnut Street Bridge is a 2,376-ft.-long structure connecting the city’s downtown with Chattanooga’s north shore of the river.

The bridge’s main spans are pin-connected Pennsylvania truss spans. It is regarded as being historically significant due to its length and structural design.

Opened with great fanfare in February 1891, the bridge was closed to automobile traffic in 1978 and once marked for demolition before repairs and structural modifications were made to convert it into a pedestrian walkway across the Tennessee River in 1993.

It is primarily constructed from steel, which can corrode when exposed to moisture and oxygen. Over time, this can weaken structural integrity. The bridge’s wooden deck also is vulnerable to warping, cracking and rot.

The Walnut Street Bridge is the middle of three river crossings in downtown Chattanooga — just upriver from the Market Street Bridge and downriver from the Veterans Memorial structure — each of which will see modifications.

City officials plan to add protected lanes to the Veterans Memorial and Market Street bridges during the Walnut Street Bridge construction to accommodate more pedestrians and bicyclists, the Times Free Press reported.

Because Market Street is a state road, the additional lanes on its river bridge must receive approval from the TDOT, which is pending. Adding lanes on the Veterans

Memorial Bridge will not require the transportation agency’s approval.

In speaking with the newspaper, Holl said current plans call for closing one lane on each bridge to cars and trucks.

On the Veterans Bridge, the third lane will be closed on the southbound side, which becomes an offramp as motorists approach downtown. Changes to Market Street still require review and approval from TDOT, but shutting down one of the lanes that runs along the sidewalk is likely, he explained.

“Obviously pedestrians and cyclists can already use the sidewalk on the Market Street Bridge, but we know it’s close quarters with traffic, which makes some folks uncomfortable,” Holl noted. “And we also know we’ll have increased demand with [the Walnut Street Bridge] no longer being an option to get across the river.”

Chattanooga will fund the renovations with a combination of federal dollars and hotel-motel taxes, which the city collects on hotel stays. According to Holl, the city has secured $18 million from the federal government and has already set aside $12 million in hotel-motel funds from previous years.

Additionally, Chattanooga will set aside another $6 million in hotel-motel tax money between now and the 2029 fiscal year. Officials are also reserving $500,000 in this year’s capital budget to add the alternate pedestrian routes.

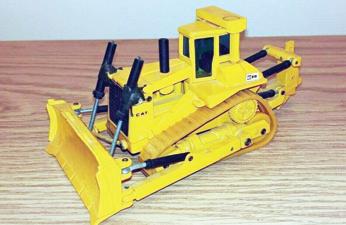

ASCENDUM Machinery held a customer open house in May at its Knoxville, Tenn., branch location to shine a spotlight on several new features within the facility.

The Knoxville location is one of two in Tennessee, along with ASCENDUM’s Chattanooga branch. The company maintains 10 additional Southeast dealerships across North Carolina, South Carolina and Georgia, in addition to a pair of North Dakota branches.

Carlo Gagliardo, ASCENDUM’s sales manager for Tennessee and North Carolina, said the open house’s goals included highlighting the Knoxville store’s revamped facilities, its service capabilities, its larger machine inventory and giving customers a chance to meet its personnel.

“We have a new management team that is covering the Knoxville and Chattanooga

territory, with three industry veterans that also have stakes in ASCENDUM’s North Carolina region: Kristin Parker, general manager of North Carolina and Tennessee; Cory Penland, product support manager of western North Carolina and Tennessee; and myself as sales manager for the two states,” Gagliardo said.

In addition, he noted that ASCENDUM used the forum to introduce its various programs and products to the east Tennessee event’s visitors.

“We want to increase our inventory on the yard, give customers a chance to come out and see the equipment, and put it to work in the Knoxville and Chattanooga area,” Gagliardo said. “ASCENDUM offers rentals, rental purchase options, leases and strong financial packages.”

Penland noted that ASCENDUM’s long-time and robust emphasis on cus-

(L-R): Joe and Brian Beretta, both of Newport Sand & Gravel in Newport, Tenn., talk with their ASCENDUM sales representative Tate O’Quinn about their equipment needs.

tomer support in its home state of North Carolina is being strengthened in its Tennessee market.

“Now that we are in Knoxville and Chattanooga, we are carrying that increase in product support over here through a lot of great programs, and we are going to roll out more that will involve machines, telematics, GPS tracking and managing technicians geographically and more efficiently across the region from North Carolina to Tennessee,” he said.

ASCENDUM said it is known for investing in its technicians to create a roster of highly-trained people working in-house at its dealerships. Each member of its service team is equipped with the most up-todate knowledge and technical tools to diagnose problems, make repairs and offer solutions, according to the company. see ASCENDUM page 74

(L-R): Michelle Williams, James Poling, Santa Morse, Toby and Tracy Claiborne, Preston Nelson and Jason Wiles, all of Claiborne Hauling in Knoxville, Tenn. The company also is engaged in hauling, grading, excavating and trucking and is a big user of Volvo wheel loaders.

ASCENDUM had its mobile simulator on hand for customers to try out. Complete with excavator controls, ADT and a wheel loader set up, the mobile training unit has been implemented to help its customers train operators and to introduce future operators at career fairs to just what these machines have to offer.

Cat 320 – 2021, MYK Series, 850 Hours, Auxiliary Hydraulics, Hydraulic Quick Coupler, 48” Bucket............................$214,500

Cat 12M3 AWD – 2019, N9B Series, 2,413 hours, Cab, Heat, A/C, Pushblock, Rear Ripper Scarifier, 17.5R25 Bridgestone Tires, 14’ Moldboard $299,500

Cat D2 – 2023, XKM Series, 170 hours, Cab, Heat, A/C, 6-Way Blade with Tilt and Shake, Sweeps, Rear Ripper $179,500

$164,500

Cat D1 LGP – 2021, XKL Series, 500 Hours, VPAT Blade, Rear Drawbar, Cab, A/C, Heat

Cat D6T XW – 2019, JNM Series, 1,150 Hours, VPAT Blade, Trimble Earthworks, Cab, A/C, Heat $CALL

Cat D6T XL – 2019, NDY Series, 4,550 Hours, 24” Shoes, Good undercarriage, S/U Blade with Tilt, Rear Ripper, Cab, A/C, Heat $CALL

Cat 12M3 AWD – 2019, N9B Series, 2,400 Hours, Accugrade Ready, Rear Ripper, 17.5R25 Tires, Cab, A/C, Heat ..............................

$299,500

Cat CP56B – 2019, P56 Series, 1,900 Hours, Cab, A/C, Heat, 84” Padfoot Drum, Good Tires

$155,000

Cat 330FL – 2018, MBX Series, 1,800 Hours, Auxiliary Hydraulics, Hydraulic Thumb, 54” Bucket

$CALL

Cat 336 – 2019, YBN Series, 3,200 Hours, Auxiliary Hydraulics, Quick Coupler, Rockwheel G40 Drum Cutter, A/C, Heat $289,500 Volvo EC350EL – 2022, 1,200 Hours, Auxiliary Hydraulics, FRD Fx770

Hydraulic Breaker $CALL

Cat 745 – 2018, 3T6 Series, 5,900 Hours, Cab, A/C, Heat, Good Tires ....

......................................................................................................$CALL

Dynapac CA30PD– 2022, 150 Hours, Cab, A/C, Heat, 84” Padfoot Drum $CALL

Dynapac CA30D – 2022, 30 Hours, Cab, A/C, Heat, 84” Smooth Drum

$164,500

Cat 313 GC – 2022, NFZ Series, 600 Hours, Bolt-On Rubber Track Pads, Auxiliary Hydraulics, FRD Fx175 Hydraulic Breaker

Cat 315 GC – 2021, FTY Series, 2,100 Hours, Auxiliary Hydraulics, Hydraulic Quick Coupler, Hydraulic Thumb, 42” Bucket

$126,500

Cat 323 – 2023, NDL Series, 500 Hours, Auxiliary Hydraulics, Hydraulic Quick Coupler, Progressive Link Hydraulic Thumb, 48” Bucket $249,500

$CALL

Freightliner M2 Water Truck – 2006, 53,000 Miles, Cat C7 Engine, 6 Speed Transmission, 2,000 Gallon Tank $39,500 McPherson M30G – Air curtain blower, 30’ Header, Deere Diesel Engine $CALL

Ring Power Utility, Tru and digger derricks to loaders, hydroexcava t

uck & Crane specializes in ever our vocational line of equipme ion trucks and contractor truc

rything from bucket trucks nt, including grapple ks.

RingPowerUtilityTruuck&Cranespecializesineverrythingfrombuckettrucks

We can handle all you truck mounted, rough

r lifting and rigging needs wit h terrain and industrial cranes.

lattice boom, crawler,

Three outstanding service professionals: Warranty Analyst Larry Azdell and Parts Sales Specialist Roger Wilson of Yanmar America, together with Service Technician Stacy Blubaugh from Yanmar America dealer Holmes Rental & Sales Inc., have been selected as winners of the Yanmar Service Awards.

They were honored at a ceremony at the Osaka Institute of Technology, Japan, on March 7 for their exceptional contributions to the company and its customers.

“Dedicated to excellence, Larry, Roger and Stacy exemplify the values Yanmar America stands for,” said Dustin Graham, manager of customer support, Yanmar America. “Their unwavering commitment to customer satisfaction is truly commendable, and we are delighted to celebrate their achievements.”

Azdell exhibits remarkable dedication to customer satisfaction within Yanmar America’s After-sales Support Division. Wilson consistently delivers top-notch customer service, actively listening to customer needs. Reaching outside Yanmar America for the first time, Blubaugh’s award recognizes his expertise in accurately diagnosing and swiftly repairing Yanmar equipment, coupled with meticulous attention to

to ensure all components function

For more information, visit yanmar.com/us.

Reconditioned 1674381 730 engine

State-of-the-art engineering down to the smallest detail. The new gen 8 mid size wheel loaders feature a dynamic travel drive for increased productivity a d improved fuel consumption. www.liebherr.com

Liebherr’s 75th anniversary was showcased throughout Family Day highlighting 75 years of moving forward.

Liebherr USA Co. and Liebherr Mining Equipment Newport News Co. hosted Family Day at the Newport News, Va., campus. The celebration highlighted Liebherr’s 75th anniversary and included carnival games, facility tours and showcased Liebherr machines from multiple product segments.

“Our employees are one of the successes behind Liebherr and it’s a great event to bring both facilities together,” said Vicki Wishon, director, Human Capital of Liebherr USA Co.

Liebherr’s 75th anniversary was showcased throughout Family Day, highlighting 75 years of moving forward. As a family-run company, Liebherr has developed into a successful global organization.

Liebherr’s pioneering spirit drives the company to explore innovative technologies and new markets. With extensive experience across various sectors, Liebherr excels in developing, manufacturing and servicing outstanding products. Offering customer-centric solutions, strong partnerships and reliability define Liebherr’s reputation, the company said.

Both facilities provided a variety of activities including carnival games, fair food and on-site machinery from multiple product segments. Guests also had the opportunity to tour the mining factory and learn about Liebherr’s vast product range.

Swicegood, senior human resources generalist. For more information, visit www.liebherr.com. (Photos courtesy of Liebherr)

Nine children of highway workers who were killed or permanently disabled on the job will receive post-high school financial assistance for the 2024-25 school year thanks to the American Road & Transportation Builders Association (ARTBA) Foundation’s “Lanford Family Transportation Construction Worker Memorial Scholarship.”

The program was established with a gift from two Roanoke, Va., highway contractors and their companies — Stan Lanford (1999 ARTBA chairman) of Lanford Brothers and Jack Lanford (1991 ARTBA chairman) of Adams Construction Company. Scholarships have a value of up to $10,000 annually.

The 2024 class includes:

• Amy McNeil, Lumberton, Texas — Amy’s father, Jeffrey McNeil, was killed in 2005 while working for the Texas Department of Transportation. Amy is a graduate student pursuing her master’s degree in nursing from the University of Texas, Arlington.

• Jenna Jares, West, Texas — Jenna’s father, Gregory Jares, was killed in 2001 while working for the Texas Department of Transportation special crews. Jenna is a graduate student studying occupational therapy at the University of Mary Hardin-Baylor in Belton.

• Breana Jones, Gaston, S.C. — Breana’s father, Standra “Stan” Jones Sr., died in 2007 after being struck by a vehicle while at work for the South Carolina Department of Transportation. Breana will be entering her junior year at Winthrop University studying graphic design.

• Katie & Christopher Hutt, Cleveland, Tenn. — Katie’s father, Chris, was struck and killed in 2006 while installing signage for United Rentals in a highway work zone. Katie will be a senior studying architecture at the University of Tennessee (UT), Knoxville. Chris’ son, Christopher, will be a freshman studying chemical engineering also at UT Knoxville.

• LaToya Hood, Houston, Texas — LaToya’s father, Paris Hood Jr., was killed on a roadway project while working for the Texas Department of Transportation in 1998. LaToya will be returning to Texas Southern University as a junior to complete her degree in healthcare administration.

• Zoe Watts, Marshall, Ark. — Zoe’s father, James “Kirk” Watts, was killed by overturned equipment while working for the Arkansas Department of Transportation in 2018. Zoe will be a freshman studying nursing at the University of Central Arkansas.

• Christopher “Tyler” Montgomery, Greenville, Miss. — Tyler’s father, Christopher Montgomery, also was killed by overturned equipment while working on a bridge project for Austin Bridge & Road in 2011. Tyler will be a freshman studying physical education at Arkansas State University.

• Bethany Rains, Memphis, Ark. — Bethany’s father, James “Bubba” Rains, died in 2013 while working for APAC in Tennessee. Bethany will be pursuing an undergraduate certificate in Nursing Assistance (CNA) at Arkansas State University, Mid-South.

Established in 1985, the ARTBA Foundation is a 501(c)3 tax-exempt entity designed to “promote research, education and public awareness” about the impacts of transportation investment.

For

visit

Effectively Handle Your Primary and Secondary Demolition Applications with NPK’s Newest Model V250R! (Suited for 24-35 metric ton carriers)

jamesriverequipment.com

Ahoskie: 252-332-5550

Asheville: 828-667-0176

Charlotte: 704-597-0211

beardequipment.com dobbsequipment.com

ALABAMA

Mobile: 800-848-8563

FLORIDA

Freeport: 850-835-3337

Jacksonville: 904-296-5000

Lake City: 386-752-9544

Ocala: 352-732-4646

Palatka: 386-325-6268

Panama City: 850-769-4844

Pensacola: 850-476-0277

Perry: 850-584-9200

Tallahassee: 850-575-5600

ALABAMA

Dothan: 334-794-8691 • Troy: 334-566-4181

FLORIDA

Daytona: 386-492-4480 • Fort Myers: 239-334-3627

Lutz (New Tampa): 813-995-0841 • Melbourne: 321-234-3344

Miami: 305-592-5740 • Orlando: 407-299-1212 West Palm Beach: 561-848-6618

PARTS ONLY: Pompano Beach: 954-977-9541 • Riverview: 813-621-4902

Sarasota: 941-960-2004

GEORGIA

Adairsville: 770-773-9857 • Albany: 229-888-1212 Atlanta: 404-691-9445 • Braselton: 770-965-1889

Brunswick: 912-264-6161 • Columbus: 706-687-3344

Grovetown: 706-855-5440 • Macon: 478-788-1586

Savannah: 912-964-7370 • Valdosta: 229-474-6680

SOUTH CAROLINA

Andrews: 843-983-7337 • Aynor: 843-358-5688

Ladson: 843-572-0400 • Simpsonville: 864-963-5835

Walterboro: 843-539-1420 • West Columbia: 803-794-9340

Elizabeth City: 252-679-7590

Fayetteville: 910-424-1200

Greensboro: 336-668-2762

Greenville: 252-758-4403

Monroe: 704-220-2575

Mt. Gilead: 910-439-5653

New Bern: 252-638-5838

Raleigh: 919-772-2121

Statesville: 704-872-6411

Wilkesboro: 336-973-8201

Wilmington: 910-675-9211

SOUTH CAROLINA

Rock Hill: 803-325-1555

striblingequipment.com

Arkadelphia: 870-246-8678 • Camden: 870-574-0290

Fort Smith: 479-646-8381 • Jonesboro: 870-268-9900

Little Rock: 501-455-2540 • Monticello: 870-367-3496

Springdale: 479-756-9779 • Texarkana: 870-772-9321

Biloxi: 228-396-2300 • Brookhaven: 601-835-4400

Columbus: 662-328-0820 • Hattiesburg: 601-544-3000

Jackson: 601-939-1000 • Meridian: 601-482-5575

Natchez: 601-442-3613 • Philadelphia: 601-656-1997

Tupelo: 662-844-3212 • Winona: 662-453-7556

Jackson: 731-422-2542 • Memphis: 901-345-5294

Chattanooga: 423-855-0633

Kingsport: 423-349-5001

Knoxville: 865-546-3207

Nashville: 615-501-8600 mccoycf.com

Graysville: 205-675-9045 • Madison: 256-233-1914

Monroeville: 251-575-7111 • Montgomery: 334-277-7260

Northport: 205-339-0300 • Oxford: 256-831-0921

Pelham: 205-988-4474

After a highly successful demo event and used equipment sale at its Montgomery, Ala., location, Thompson Tractor followed up with another big show May 16, 2024, for its Florida Panhandle customers in DeFuniak Springs, Fla.

The event drew another high turnout at the demo site just adjacent to Interstate 10, which, uncoincidentally, is the property that will eventually be the site of another Thompson Tractor branch facility in Florida.

As with the Montgomery show, the event introduced customers and prospects to the next generation Cat 255 and 265 compact track loaders. The demo was combined with a nice selection of red-tagged used equipment and included a technology expo with representatives from SITECH South and Trimble with their newest product offerings. Cat representatives and Thompson Tractor machine specialists also turned out in droves to showcase the new Cat machines, catch up with their customers on the latest Panhandle projects and to sit down to enjoy a catered lunch.

Other Cat compact track loader technology showcased and available for some demo time was the 289D3 with GB124 Smart Grader Blade attachment with a single GPS and sonic tracer. This setup allows a customer to work off a 3D design on the single GPS side and follow an existing grade on the sonic tracer side, which is optimal for operators needing to re-work roads and follow existing curb or gutter for holding a desired grade consistently.

Also available during the demo was a Cat 299D3 XE with a Cat BB124 box blade equipped with the Trimble Earthworks GO system, which is a basic 2D compact machine system that runs from a simple app from the app store. The system provides 2D grade capabilities through an iPhone, iPad, Android-based phone or tablet and allows for working in covered areas where clear line of site to the sky is not available.

And during the event, guests could check out the newest 3D GPS technology options for Cat 330 excavators and the new Cat exclusive Steer Assist feature on the D4 dozer, which allows operators the ability to make perfect circular grades automatically without operator input. CEG

(All photographs in this article are Copyright 2024 Construction Equipment Guide. All Rights Reserved.)

see THOMPSON page 62

Vermeer Southeast, a provider of environmental and underground construction equipment, has signed with CTE North America to begin selling and servicing its line of Traccess aerial lifts.

The CTE Traccess 160/51, 230/75 and 270/88 will now be available for purchase at all Vermeer Southeast locations.

CTE North America is the exclusive distributor of Traccess lifts for CTE SpA, a leading European access platform manufacturer based in Veneto and Trentino, Italy, with more than 40 years of experience in the industry.

The North American branch opened in March 2022 and is headquartered in the Hartford, Conn., area. With models ranging from 51 – 88 ft., CTE compact crawler boom lifts provide aerial lift solutions to limited access jobs with compact configurations while still providing full horizontal outreach at maximum basket capacity.

“Work Becomes Easy” with CTE’s innovative product features, timely assistance, professional guidance and training. This commitment has been at the core of CTE’s operations since its inception, resulting in the distribution of more than 17,000 platforms worldwide.

Established in 1967, Vermeer Southeast serves Georgia, Florida and Alabama with equipment, parts, service and the right productivity solutions for tree care, landscape, wood waste, recycling, pipeline, underground construction, infrastructure, solar and vacuum excavation. With over 260 team members company-wide, its corporate office is located in Orlando, Fla., store locations include Boynton Beach, Clearwater, Ft. Myers, Jacksonville, Miami, Orlando and Pensacola. Georgia and Alabama locations include Buford, Marietta, Savannah, and Birmingham. As of 2018, Vermeer Southeast is a 100% employee-owned company. Because employees are responsible for the success of the company, customers receive outstanding service and individualized attention to their businesses.

Michael Gnazzo, CTE North America president, said, “It has been a very promising experience to develop our partnership with Vermeer Southeast. Their corporate values have been very aligned with ours at every step in the process. We look forward to a long and productive relationship serving our customers together.”

“We are excited to introduce the addition of CTE aerial lift equipment, which aligns with our commitment to providing our customers with the best tools to meet their operational needs,” said Scott Coley, CEO/president of Vermeer Southeast. “These new aerial lifts are engineered with the latest technology to ensure optimal performance and safety, allowing our customers to work more efficiently at elevated heights.”

Marco Govoni, CTE SpA COO, said, “The entire CTE family welcomes Vermeer Southeast with open arms and we look forward to a long successful relationship. We have worked in recent months collaborating with our new partner and look ahead to working together towards our common objectives.”

For more information, visit www.vermeersoutheast.com/cte-aerial-lifts and

The future highway-class BOMAG CR 1030 Series 10-ft. track paver, available for the 2025 paving season, features multiple design updates that improve operating efficiency and increase mat quality by reducing segregation occurrence. Additionally, the manufacturer is introducing the Versa 20 front mount screed, a new addition to the family of BOMAG screeds.

The Versa 20 Front Mount screed gives BOMAG’s customers more versatility for their paving needs, according to the manufacturer.

The new human-machine interface (HMI) features grouped functions on tractor console and a new screed control system with integrated MOBA automation features. For the console, similar functions such as the hopper, screed and feed controls are grouped together to allow the operator quicker identification and adjustment.

BOMAG photo

New for the CR 1030 T Series is the independent auger/conveyor system, with a proven outboard auger drive system. This new design allows the conveyors and auger to run independently of each other, with a 2 or 4 (optional) sensor control system.

The large, 7-in. multifunction color screen display at each console boasts a new experience for the operator with multiple configurable detailed screens. That’s a thoughtful design feature to accommodate various operator preferences and working conditions. By providing both a touchscreen display and a remote dial control option, operators can easily navigate and adjust settings even in situations where using a touchscreen may be impractical, such as when wearing gloves. This ensures that operators can maintain control and access critical functions and gauges without any hindrance, ultimately contributing to smoother operations and improved efficiency on the job.

The new Versa 20 frontmount electric screed on display with the CR 1030 T paver, which will be offered on the new series of pavers, offers infinitely variable paving widths ranging from 10 to 19 ft. at paving thicknesses reaching 12 in. Bolton screed left- and righthand extensions — available in 12-in., 18-in. and 24in. widths plus optional 12in., 18-in., or 24-in. berm screed plates — give contractors ultimate flexibility to vary paving widths up to a maximum, 23-ft.

Quick connections for these bolt-on extensions provide both heat and vibration for increased mat quality. The screed comes standard with a 10-ft. catwalk and foldable walkway extensions for the operator.

Overall, this feature demonstrates a proactive approach to maintenance and service, ultimately leading to improved reliability and customer satisfaction, the manufacturer said.

New for the CR 1030 T Series is the independent auger/conveyor system, with a proven outboard auger drive system. This new design allows the conveyors and auger to run independently of each other, with a 2 or 4 (optional) sensor control system. The raisable or fixed outboard driven auger system, which is a proven product from the CR Remix paver design, will vastly improve visibility into the conveyor discharge area, as

Incorporating fault code visibility on the touchscreen monitor is a smart feature for enhancing machine serviceability and troubleshooting efficiency. By alerting operators to paver issues directly on the monitor, they can promptly address any problems that arise during operation. This real-time feedback enables quick identification and resolution of machine issues right at the job site, minimizing downtime and maximizing productivity.

well as eliminate segregation in that area, resulting in better mat quality, according to the manufacturer.

The new BOMAG CR 1030 T rubber track paver on display at World of Asphalt, March 25-27, 2024, was powered by the 225 hp (167.7 kW) Cummins QSB 6.7 engine meeting the latest emission standards. Operator visibility into the 14-ton hopper is enhanced by the paver’s sloped hood design. It retains many of the legacy CR series features, including optional FRAME RAISE with fixed augers to improve mat quality and SMARTRAC system that automatically maintains proper track tension to significantly increase track life.

BOMAG’s exclusive SIDEVIEW innovation allows each seat and console to swivel outward at four different angles for unobstructed views to the paver sides and screed end gate.

The 11-in. deep hydraulic extensions, with manually adjustable angle of attack, allow for better density and mat quality than others in the front mount class. The hydraulically powered crown for the Versa 20 can be adjusted from 3-in. positive to 1-in. negative. The newly designed screed controls and remotes allow for better operator experience as well as accommodating special features like integrated MOBA automation.

Borrowing from the European BOMAG screed family design, robust telescopic tubes increase screed rigidity to minimize deflection at extended paving widths. Incorporating the proven tipping frame and match height features from the Stretch 20 Screed, the new Versa 20 is designed to better maintain setting adjustments between the main frame and extensions for a more consistent mat texture across the entire paving width, according to the manufacturer. For more information, visit www.bomag.com.

Bobcat Company, a global equipment, innovation and worksite solutions brand, has enhanced two of its North Dakota manufacturing facilities with the installation of 14 stationary, natural gaspowered fuel cells from HyAxiom Inc., a leading global fuel cell and hydrogen solutions provider.

Bobcat photo

fuel cells,” said Mike Ballweber, president, Doosan Bobcat North America.

These units will operate in parallel with the commercial power grid while carving a pathway to decarbonization by producing clean energy for the facilities’ operations.

The three fuel cells at the Bismarck facility and the 11 units at the Gwinner location are the first commercial installations of stationary fuel cells in the state. The recently commissioned fuel cells allow Bobcat to diversify its energy sources by supplying a majority of the annual power and heat needs of the Bismarck facility and about half the needs of the Gwinner facility.

“We are proud to be at the forefront of sustainable energy solutions with the installation of these new stationary

“This is just one example of our commitment to advancing our facilities today for a better tomorrow.”

“HyAxiom’s stationary fuel cell solutions provide efficient combined heat and power that will help Bobcat improve its operations and continue innovating for the smart job site of the future,” said David Alonso, chief commercial officer at HyAxiom.

Utilized in a wide range of applications, HyAxiom’s PureCell M400 is a proprietary phosphoric acid fuel cell (PAFC) that can use natural gas, hydrogen, LPG or a blend of fuels to produce rapidly deployable baseload electricity and heat that also are resilient, sustainable and affordable.

While this is the first installation of fuel cells in North Dakota, HyAxiom’s fuel cells are in operation nationwide and globally, providing power and heat for commercial and industrial uses. With load-following capabilities, they have fast become a resilient source of energy for micro grid applications, providing the ability to switch between grid connected and grid independent modes, facilitating the ease of accessibility to reliable and clean electricity.

In Bismarck, Bobcat is able to provide power back to the grid as a registered power producer. This reduces the demand on Bismarck energy providers and ensures there is enough power on the grid. Due to the useable heat produced by the fuel cells, Bobcat also has been able to reduce its overall energy use by eliminating two boilers previously required to produce heat on its paint line.

For more information, visit bobcat.com and hyaxiom.com.

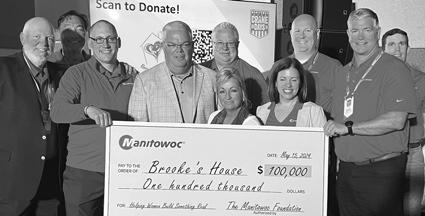

Brooke’s House, a rehabilitation center in Hagerstown, Md., dedicated to aiding women in recovery, has received $100,000 from Manitowoc and $50,000 from its dealers and customers.

The partnership has proven mutually beneficial, with Manitowoc employing nearly 20 Brooke’s House graduates who have gained valuable occupational skills and job training while recovering from substance abuse.

Manitowoc photo

(L-R) are David Hull, Ion Warner and Aaron Ravenscroft, all of Manitowoc; Kevin and Dana Simmers, Brooke’s House; and Les Middleton, Jennifer Peterson, James Cook, Brian Regan and Chase Seely, all of Manitowoc.

Dave Hull, Manitowoc’s general manager of mobile cranes, North America, shared the story behind the partnership during a customer event at the company. He praised the efforts of Kevin and Dana Simmers, founders of Brooke’s House, and expressed his admiration for the initiative, the commitment of Manitowoc’s executive team to support the cause, and funding from the Manitowoc Foundation.

“I’ve known Kevin for 35 years and

Reynolds-Warren Equipment Company www.reynoldswarren.com

1945 Forest Parkway Lake City, GA 30260 800/875-5659 404/361-1593

180 Thunderbird Drive Richmond Hill, GA 31324 800-875-5659 912-445-2880

RJV Equipment www.rjvequipment.com

Knoxville, TN 865/970-2840

I understand the journey that he and Dana have been on. I’m incredibly proud of my company for supporting Brooke’s House. Every person on the stage here has visited Brooke’s House, met the women, and witnessed the real impact of our support. This is not just a partnership, it’s a commitment to building something real and meaningful in our community,” Hull said.

Kevin Simmers also spoke at the

event, discussing Brooke’s House’s origin and future goals, including expanding mental health services by building a $1.5 million equine therapy facility. He emphasized the importance of community and industry support in making a difference.

“We’re extremely grateful. Manitowoc gives Brooke’s House graduates the chance to join its workforce and build a new life. The support we’ve received from Manitowoc and its community truly exemplifies what makes this country great. Thank you all very much,” Simmers said.

The partnership between Manitowoc and Brooke’s House dates back to 2020. In 2023, a small ceremony marked the designation of a restored bungalow in Hagerstown, where some of Brooke’s House graduates live, as “The Manitowoc House.”

For more information, visit www.manitowoc.com.

www.stoneequipmentco.com Montgomery, AL 844/786-6373

taylorconstructionequipment.com Philadelphia, MS 601-650-9600

Richland, MS 601-922-4444

GSE - Great Southern Equipment Company www.gsequipment.net

Tampa, FL

866/586-8956

Pompano Beach, FL 954/327-8808

Ft. Myers, FL 239/334-6063

Tallahassee, FL 850/574-0892 Orlando, FL 407/859-9160 Jacksonville, FL 904/268-4400

Mills River (Asheville) NC 828/820-5265

Leland (Wilmington) NC 910/800-2070

658-0200

843/225-9377

Greenville SC

864/546-5208 Savannah, GA

866/830-7577

Miami, FL

(305) 477-2442

Miami, FL (305) 477-2442

Davie, FL (954) 581-4744

Davie, FL (954) 581-4744 Alta Equipment Company www.construction.altg.com

T Fort Myers, FL (239) 481-8554

Fort Myers, FL (239) 481-8554

Tampa, FL (813) 630-0077

Taampa, FL (813) 630-0077

Orlando, FL (407) 850-9614

Orlando, FL (407) 850-9614

Lake City, FL (386) 758-7444

Lake City, FL (386) 758-7444

Jacksonville, FL (904) 737-6000

Jacksonville, FL (904) 737-6000

Midway, FL (850) 583-2700

Birmingham, AL 205) 323-6108

Gray, TN 423) 2825462

Memphis, TN (901) 260-2310

Murfreesboro, TN (629) 3353077

After two days of hosting dealers and guests for its “Power Days Demo” event south of Atlanta, FAE USA territory managers and representatives from coast-to-coast gathered May 10, 2024, at a site in the picturesque city of Dawsonville, in north Georgia.

The event provided an in-depth training session of the company’s paving products. At the heart of the demo was the new series of skid steer- and compact track loader-mounted RPL/SSL series of road planers, which were just introduced in 2023 at ConExpo and come in three working widths (18 to 30-in., widths). FAE touts these compact road planer attachments as a “must” for small scale and fine milling in conjunction with all larger milling jobs.

FAE also demonstrated the FAE MTL 175, which has been on the market for quite some time. This PTO-driven product line has evolved in design and focus over the years and re-engineered to fall into FAE’s “multitask” line, which allows the maximized usage of the attachment as a stabilizer, stone crusher or asphalt shredder/miller.

And an FAE RCU-75 remote-controlled forestry mulcher provided support during the event. This compact tracked mulcher assisted in removal of vegetation overgrowth at the demo site. In addition to practicing their paving product skills, FAE managers mastered their abilities on operation of these remote-controlled mulching units while at the training session. CEG

(All photographs in this article are Copyright 2024 Construction Equipment Guide. All Rights Reserved.)

discusses the inner workings of the attachment.

As the paving demo gets in full swing, an FAE territory manager operates the powerful 74 hp RCU-75 tracked mulcher for clearing overgrowth next to the parking lot demo site. FAE representatives from coast-to-coast

Early morning on May 10, FAE product specialists roll in to a north Georgia site to “dial in” the compact track loader/road planer combination for a demo with its U.S. territory managers.

they are about to demo.

Dynapac has introduced the new 8-ton tandem asphalt roller CC2200 VI.

The CC2200 VI belongs to a series of new rollers from 8 to 10 ton with drum width 59 to 66 in. It comes with numerous new features that ensure optimal paving results, operational efficiency and operator comfort, the manufacturer said.

The new range includes three articulated models (CC2200VI, CC3200VI, CO2200VI) and an additional two fixed frame pivot steer split drum models (CX8 and CX9) from 59 to 66 in. drum widths. Combination versions also will be available in select models of this range.

The New VI Generation mid-range roller uses several technologies from its larger counterpart CC4200VI-6200VI, like 180-degree seat rotation, an efficient eccentric system combined with active ECO mode to reduce fuel consumption and carbon footprint, and full backup water sprinkler systems. A newly upgraded simplified operator control panel for this series with a full-color seven-inch touchscreen display provides more machine controls for the operator.

The Dynapac CC2200 VI has been designed for maximum operator comfort and safety. Its ergonomically designed interior comes with a new operator interface, including a full-color seven-inch touch display and easy access to all controls. The optional 360-degree pedestrian detection camera provides opera tors with a continuous “bird’s eye” view while working, offering more comfort and safety on the job site.

The corrosion-free water tank is mounted low in the front frame, which contributes to the 1x1 m view and full visibility of the drum surface and drum spray nozzles. The seat and steering module welcome drivers with 180degree rotation and full sliding function.

The CC2200 VI also can be equipped with various extra features designed to best fit local conditions includ ing an operator’s platform with CAB, Automatic Climate Control, Full 255degree seat rotation and more.

The Dynapac CC2200 VI comes with SEISMIC asphalt technology that offers benefits for both optimal compaction and operator comfort. SEISMIC asphalt automatically determines the optimal frequency for any compacted material, constantly monitoring the variations of the asphalt layer, and automatically adjusts to temperature conditions. The SEISMIC asphalt system is active on both

drums to help reduce the required vibration power and energy consumption during compaction. The resulting lower noise levels and vibrations within the cabin provides the operator with greater comfort while delivering optimal compaction on the job site, according to the manufacturer.

The Dynapac CC2200 VI can be equipped with the optional unique Dyn@Lyzer system. As a state-of-the-art compaction control and documentation system, Dyn@Lyzer records and maps the stiffness and compaction progress of the compacted asphalt layer in real-time, as well as measures the asphalt temperature and number of completed passes. It additionally functions as a quality control and assurance device, as well as a productivity tool to optimize the compaction effort.

Seamless communication is key during any compaction job, which is why operators can also look forward to an open interface for 3rd party compaction control systems.

As with all Dynapac products, the CC2200 VI meets the strictest environmental regulations including automatic idling to reduce fuel consumption and lower noise emissions. Additionally, the unique active ECO mode can save up to 20 percent more fuel and comes standard for the Tier IV final and Stage V engines. Biodegradable hydraulic fluid is an optional alternative. SEISMIC asphalt system will improve upon these to further increase fuel savings even

For more information,

beardequipment.com

6870 Philips Highway Jacksonville, FL 32216 (904) 296-5000

2578 SE Baya Drive Lake City, FL 32025 (386) 752-9544

4539 NW 44th Avenue Ocala, FL 34482 (352) 732-4646

356 N. Hwy 17 Palatka, FL 32177 (386) 326-6268

3033 US Hwy 27 E. Perry, FL 32348 (850) 584-9200

7566 W. Tennessee St. Tallahassee, FL 32304 (850) 575-5600

www.reynoldswarren.com

1945 Forest Parkway Lake City, GA 30260 (800) 875-5659 (404) 361-1593

180 Thunderbird Drive Richmond Hill, GA 31324 (912) 445-2880

www.richmondmachinery.com

2350 Greystone Ct. Rockville, VA 23146 (804) 359-4048

150 Piper Lane Alabaster, AL 35007 (205) 621-2489

5336 Messer-Airport Hwy Birmingham, AL 35212 (205) 591-2131

800 Church St. N.E. Decatur, AL 35601 (256) 355-0305

4307 Reeves Street Highway 431 North Dothan, AL 36303 (334) 678-1832

www.tec1943.com (844) 4 MY

243 South Jackson St. Grove Hill, AL 36451 (251) 275-4158

108 Skylab Drive NW Huntsville, AL 35806 (256) 851-2222

2100 East I-65 Service Rd. North Mobile, AL 36617 (251) 457-8991

3285 Selma Highway Montgomery, AL 36108 (334) 288-6580

309 Hamric Drive West Oxford, AL 36203 (256) 831-2440

3820 Greensboro Ave. Tuscaloosa, AL 35405 (205) 752-0621

3305 Highway 77 Panama City, FL 32405 (850) 763-4654

9036 Pine Forest Rd. Pensacola, FL 32534 (850) 505-0550

www.dobbsequipment.com

2730 Falkenburg Road HQ Riverview, FL 33578 (813) 620-1000

4343 Northwest 77th Ave Miami, FL 33166 (305) 592-5740

3933 Martin Luther King, Jr. Blvd West Palm Beach, FL 33404 (561) 848-6618

4333 North John Young Pkwy Orlando, FL 32804 (407) 299-1212

3005 Hanson Street Fort Myers, FL 33916 (239) 334-3627

4618 Scarborough Drive Lutz, FL 33559 (813) 995-0841

1730 N. Nova Road Holly Hill, FL 32117 (407) 299-1212 1705 Columbia Lane Melbourne, FL 32904 (321) 234-3344

2710 Falkenburg Road Riverview, FL 33578 (813) 621-4902 - Parts 1751 Copans Road, Unit 8 Pompano Beach, FL 33064 (954) 977-9541 - Parts

6265 E Sawgrass Road Sarasota, FL 34240 (941) 960-2004 - Parts

TDOT from page 1

That proposal came in 1998 in response to concerns raised about transportation needs by the Knoxville Metropolitan Planning Organization. TDOT’s suggested improvements were intended to address congestion; correct operational and geometric deficiencies; and support future economic development activities in and around the study area. The proposed improvements along SR 33 included the reconstruction and widening of approximately 16 mi. of a primarily two-lane roadway in Knox and Union counties from north of SR 71 in Knox County to SR 61 in Maynardville. The overall improvements were broken up into three projects. The SR 33 project is the third of the three projects.

As designed, the 5.34-mi.-long project will include 5.08 mi. of widening from the Knox County line tying into the existing pavement south of SR 144. The alignment will feature four 12-ft. travel lanes, two in each direction, with a 12-ft. center turn lane

see TDOT page 48

The Carlson CP100 II sets the standard for versatility, component lifecycle and mat quality. With a powerful 100hp engine, an array of configurations and the class-leading EZCSS single slide screed, it’s time to see why the CP100 II has fast become the contractor’s choice for heavy-duty commercial paver platforms.

Caterpillar Inc. released its latest reports highlighting the company’s environmental, social and governance (ESG) commitment, record financial accomplishments and contributions to helping customers build a better, more sustainable world.

“We’re pleased to highlight the great strides the Caterpillar global team is making in executing our strategy and investing for long-term profitable growth. These reports tell the stories of our outstanding 2023 financial results, sustainability progress and active participation in the public policy process,” said Caterpillar Chairman and CEO Jim Umpleby.

“Our employees’ diverse backgrounds and experiences and strong focus on serving our customers contributed to delivering the best year in our nearly 100-year history in 2023.”

Highlights include:

• The Annual Report reviews how the global team delivered the best year in Caterpillar’s nearly 100-year history as the company continued executing its strategy for long-term profitable growth.

• The Sustainability Report provides an in-depth look at progress over the past year and how the company is helping its customers achieve their climate-related goals.

• The Task Force on Climate-related Financial Disclosures (TCFD) Report provides information about how the company governs climate-related opportunities and risks.

• The Diversity & Inclusion Report provides comprehensive information on Caterpillar’s progress to continue build-

These reports tell the stories of our outstanding 2023 financial results,sustainability progress and active participation in the public policy process.”

Jim Umpleby Caterpillar

(844) 4 MY DOBBS www.dobbsequipment.com

2730 Falkenburg Road HQ Riverview, FL 33578 (813) 620-1000

4343 Northwest 77th Ave Miami, FL 33166 (305) 592-5740

3933 Martin Luther King, Jr. Blvd West Palm Beach, FL 33404 (561) 848-6618

4333 North John Young Pkwy Orlando, FL 32804 (407) 299-1212

3005 Hanson Street Fort Myers, FL 33916 (239) 334-3627

4618 Scarborough Drive Lutz, FL 33559 (813) 995-0841 1730 N. Nova Road Holly Hill, FL 32117 (407) 299-1212 1705 Columbia Lane Melbourne, FL 32904 (321) 234-3344

2710 Falkenburg Road Riverview, FL 33578 (813) 621-4902 - Parts

ing an inclusive culture, representation advancements and key initiatives from the past year.

• The Lobbying Report, The Purpose of Engagement, outlines how we advocate for a policy and regulatory environment that supports our long-term success and provides value to shareholders.

For more information, visit caterpillar.com/reports.

Peer Executive Groups (PEG) has named the winners of its 2024 Top Gun Awards.

The Top Gun award recognizes businesses who receive the PEG Award for Financial Excellence. The awards are given to the top 25 percent of rental operators based on financials verified by Peer Executive Groups. This is the sixth year that PEG has named companies for this prestigious award.

“We apply owner compensation, expense, and rent tests to verify EBITDA and check financial reports and tax returns where appropriate. While our network shows EBITDA performance closer to 28 percent, our Top Gun members average north of 40 percent,” said President Dan Crowley.

The 2024 winners for Equipment Rental include:

• Austin Wilson, A to Z of NC

• Troy Roper, A-1 rentals Idaho

• Alexx Bacon, Aaberg’s Tool and Equipment Rental

• Tony Murray, American Rentals

• Beth Hoff Blackmer, Aspen RentAll

• Allan Haynsworth, Atlantic Lift Systems

• Garret Shurling, Badger Equipment Rental

• Meghan Boland, Boland Equipment Rental

• Steve Mau, Brainerd General Rental

• Tyler Doherty, Cal-West Rentals

• Kyle Keely, Chet’s Rent-All

• Matt Crawford, Far West Rentals

• David Betz, Goggin Rentals

• Tom Kirksey, Make Equipment

• Dillon Hughes, Only 1 Rentals

• Steve Berner, Rabern Rentals

• Kevin Reim, Redtail Rentals

• Isaac Black, Rent-All Equipment

• Eric Barron, Rent Ready Equipment

• Jaco du Plessis, Talisman Equip Rentals

• Haley Hennessey, Tates Rents

• Matt Musgrove, Tejas Equipment Rentals

• Chris Jarrett, Time Rentals

• Kurt Barney, Vandalia Equipment Rental

• Jeff Wiesman, Wood Street Rental Peer Executive Groups administers peer groups in variety of industries. Within the rental industry, more than 255 participants learn from each other in 25 peer groups.

1751 Copans Road, Unit 8 Pompano Beach, FL 33064 (954) 977-9541 - Parts

6265 E Sawgrass Road Sarasota, FL 34240 (941) 960-2004 - Parts

www.reynoldswarren.com

1945 Forest Parkway Lake City, GA 30260 (800) 875-5659 (404) 361-1593

180 Thunderbird Drive Richmond Hill, GA 31324 (912) 445-2880

www.richmondmachinery.com

2350 Greystone Ct. Rockville, VA 23146 (804) 359-4048

www.tec1943.com

150 Piper Lane Alabaster, AL 35007 (205) 621-2489

5336 Messer-Airport Hwy Birmingham, AL 35212 (205) 591-2131

800 Church St. N.E. Decatur, AL 35601 (256) 355-0305

4307 Reeves Street Highway 431 North Dothan, AL 36303 (334) 678-1832

243 South Jackson St. Grove Hill, AL 36451 (251) 275-4158

108 Skylab Drive NW Huntsville, AL 35806 (256) 851-2222

2100 East I-65 Service Rd. North Mobile, AL 36617 (251) 457-8991

3285 Selma Highway Montgomery, AL 36108 (334) 288-6580

309 Hamric Drive West Oxford, AL 36203 (256) 831-2440

3820 Greensboro Ave. Tuscaloosa, AL 35405 (205) 752-0621

3305 Highway 77 Panama City, FL 32405 (850) 763-4654

9036 Pine Forest Rd. Pensacola, FL 32534 (850) 505-0550

www.powerequipco.com 3300 Dozer Lane Knoxville, TN 37920 (HQ) (865) 577-5563

2578 SE Baya Drive Lake City, FL 32025 (386) 752-9544

4539 NW 44th Avenue Ocala, FL 34482 (352) 732-4646

356 N. Hwy 17 Palatka, FL 32177 (386) 326-6268

3033 US Hwy 27 E. Perry, FL 32348 (850) 584-9200 7566 W. Tennessee St. Tallahassee, FL 32304 (850) 575-5600

4295 Bonny Oaks Drive Chattanooga, TN 37406 (423) 894-1870 1487 Rock Springs Road Kingsport, TN 37664 (423) 349-6111 320 Waldron Rd. LaVergne, TN 37086 (615) 213-0900 3050 Ferrell Park Cove Memphis, TN 38116-3502 (901) 346-9800 1545 Highway 45 Saltillo, MS 38866 (662) 869-0283 beardequipment.com 6870 Philips Highway Jacksonville, FL 32216 (904) 296-5000

and 10-ft. shoulders, which will extend across the length of the project. The proposed project includes the construction of one 200-ft. I-beam bridge over Bull Run Creek, as well as the construction of a box bridge and the installation of multiple roadway signs and pavement markings, according to TDOT.

Charles Blalock and Sons Inc., headquartered in Sevierville, Tenn., was awarded the bid for $50,280,578.07 in February 2022. Work began in early April 2022 and is scheduled for completion by Oct. 31, 2026.

The town of Maynardville, population just shy of 2,300 and the county seat of Union County, may be familiar to country music fans as the birthplace of Carl Smith and Roy Acuff. Chet Akins, Lois Johnson and Kenny Chesney were born in Union County. Maynardville also is mentioned in the theme song from the movie Thunder Road.

Civic pride was evident at the start of the SR 33 project when local and state officials turned out to “turn some dirt,” calling it a

“landmark day” in Union County.

Steve Borden, Region 1 director, and representing Tennessee Commissioner of Transportation Joe Galbato III, noted the widened corridor will help traffic flow and will boost economic development.

Union County Mayor Jason Bailey said the project is not just the widening of the road but “also the widening of opportunity. The road will be a safer and smoother ride to jobs for commuters in Union County and Claiborne County. The road will be an opportunity for economic development. People will want to follow SR 33 to Union County for low taxes, for access to broadband, for recreation and for affordable housing.”

To date, Blalock & Sons have completed the left side of the box culvert at Raccoon Valley and the pavement at bridge ends for Phase 1. Currently, Comcast is working on sections 3 and 2 of the project, and 18-in. storm pipe and a catch basin are being installed near Raceway Drive. Sewer and water facilities continued to be installed.

Carolina Cat carolinacat.com

9000 Statesville Rd Charlotte, NC 704-596-6700

40 Interstate Blvd Asheville, NC 828-251-2500

8522 NW 58th Street Miami, FL 305-592-5360 2801 Reese Road Davie, FL 954-581-8181

500 World Commerce Pkwy St. Augustine, FL 904-737-7730

14300 Ponce De Leon Blvd Brooksville, FL 352-796-4978

401 N Tomoka Farms Rd Daytona Beach, FL 386-947-3363

4900 N Main St Gainesville, FL 352-371-9983

2070 Corporate Woods Dr Alabaster, AL 205-664-4833

121 Gilbert Ferry Rd SE Attalla, AL 256-570-1100

2401 Pinson Valley Pkwy Tarrant, AL 205-841-8601

5749 John Givens Rd Crestview, FL 850-682-6510 6969 US-31 Tanner, AL 256-353-7721 118 Vulcan Way Dothan, AL 334-671-1040

6215 Swiggett Rd Greensboro, NC 336-294-5240

1201 US-70 Hickory, NC 828-464-7045

Kelly Tractor kellytractor.com

5460 Okeechobee Blvd. West Palm Beach, FL 561-683-1231

801 E Sugarland Hwy Clewiston, FL 863-983-8177

330 Pecan Park Road Jacksonville, FL 904-714-2600

390 SW Ring Ct Lake City, FL 386-755-3997

3425 Reynolds Rd Lakeland, FL 863-606-0512

6200 North US 301/441 Ocala, FL 352-732-2800

9901 Ringhaver Dr, Orlando, FL 407-855-6195

Thompson Tractor Company www.TMCat.com

6307 Co Rd 490 Hanceville, AL 205-283-0128

3600 Governors Dr SW Huntsville, AL 256-532-1776

30950 AL-181 Spanish Fort, AL 251-626-5100 10120 US-80 Montgomery, AL 334-215-5000

508 Columbus Pkwy Opelika, AL 334-749-3359

2300 AL-21 Oxford, AL 256-831-4104

2211 Morgan Mill Rd Monroe, NC

704-292-1555

7394 Old US 421 S Boone, NC 828-268-9992

9651 Kelly Tractor Dr. Ft. Myers, FL 239-693-9233

415 Community College Pkwy SE Palm Bay, FL 321-952-3001

7500 26th Ct E Sarasota, FL 941-359-6000

32000 Blue Star Hwy Tallahassee, FL 850-562-2121

10421 Fern Hill Dr Tampa, FL 813-671-3700

4109 Cato Rd Panama City, FL 850-785-4007

2670 W 9 Mile Rd Pensacola, FL 850-471-6700

2501 Joe Davis Industrial Blvd Thomasville, AL 334-636-0420

3550 Joe Mallisham Pkwy Tuscaloosa, AL 205-247-2800

1030 State Hwy 20, Tuscumbia, AL 256-381-2771

Building on an extraordinary year of action sports partnerships on and off paved and dirt tracks, Kubota Tractor Corporation announced a partnership with downhill mountain bike legend Aaron Gwin, whose career highlights span five World Cup titles and eight U.S. National Championships, to support the newly-announced formation of Gwin Racing and his bike park, Windrock Bike Park, in Oliver Springs, Tenn.

A highlight of this collaboration is fully equipping Gwin’s tool shed at Windrock Bike Park with new Kubota equipment, including a KX080-5 power utility excavator, an R640 wheel loader, and an RTV-X1130 and two Sidekick utility vehicles — all of which are already hard at work building new trails and tackling overall property maintenance.

The sponsorship, which also includes logo placement on Gwin Racing race jerseys, is part of the company’s commitment to supporting the action sports lifestyle and mountain bike enthusiasts, both important customer segments for Kubota.

“By partnering with Aaron and Gwin Racing, we are opening doors for the action sports community to showcase what’s possible for blazing new trails with durable and powerful Kubota equipment,” said Paul Manger, executive director of product marketing, Kubota Tractor Corporation.

“Aaron’s work ethic on and off the trail aligns with our mission to empower our customers and partners with the right tools to help them succeed. We’re proud to be a part of Aaron’s future plans, to support his team, his fans, and to show the downhill mountain bike and action sports communities that the sky is the limit in #KubotaCountry.”

“I’ve been digging in the dirt and building trails since I was a little kid,” said Gwin. “It is the funest thing in the world for me, and I could spend all day, every day in the hills digging. For any trail build, the first thing you need is a good set of tools, and my Kubota excavator is definitely a multi-use tool, not only for trail building, but we’re also putting it to good use to build a new road and parking lot, and for maintaining the property overall. It’s amazing how much we can get done now.”

At Windrock Bike Park, Gwin and team are putting their hard-working Kubota-equipment to use in a wide range of applications. The KX080-5 and R640 are being used to build trails, clear land, build and maintain new roads and a parking lot, as well as for landscaping and event service support.

The RTV-X1130 and Sidekick gas-powered utility vehicle are workhorses on the property tackling trail work, hauling tools and general maintenance across the 1,086acre bike park. The Sidekick also plays a vital role for Windrock’s EMT services, including rider extraction.

“Having the ability to quickly get up and down the hills in an emergency is a critical part of our jobs, and our Kubota utility vehicles are important team members for our work here.”

For more information on Kubota equipment, visit KubotaUSA.com. For more information on Aaron Gwin and Windrock Bike Park, visit WindrockBikePark.com. (All photos courtesy of Kubota)

Gwin is regarded as one of the world’s best downhill mountain bikers and the best American downhill mountain biker of all time.

BLANCHARD MACHINERY www.blanchardmachinery.com/paving Columbia, SC 803-791-7100

Florence, SC 843.678.8520

Rock Hill, SC 803.324.9600

Simpsonville, SC 864.963.3645

Myrtle Beach, SC 843-399-2074

Summerville, SC 843.871.2001

Hilton Head, SC 843-784-6766

Asheville, NC 828-251-2500

Greensboro, NC 336-294-5240

Hickory, NC 828-464-7045

Monroe, NC 704-292-1555

Boone, NC 828-268-9992

Chattanooga, TN 423-698-6943

Crossville, TN 931-484-4040

Knoxville, TN (East) 865-546-1414

Knoxville, TN (West) 865-218-8800

Sevierville, TN 865-595-3750

Tri-Cities, TN 423-323-0400

A global competition to find the very best of the best Volvo technicians has concluded after a 12-month endurance test of skills, knowledge, stamina and teamwork across all elements of aftersales operations.

The team from Volvo dealer KSS Korea were named the well-earned winners of Volvo Masters 2024 — following an intense Grand Final at the Customer Center in Eskilstuna, Sweden, the headquarters of Volvo CE.

Some 2,235 participants from 634 teams took part in one of the largest collaborative learning experiences of its kind, from 134 Volvo dealers worldwide. Now in its 34th year, the epic contest is respected in the industry as an exciting way to showcase the talents of the many accomplished parts and service technicians working across Volvo CE’s dedicated dealer network.

Putting to the test their expertise in aftersales operations, the 14 teams who made it through to the Grand Final were tasked with six challenges on excavators, articulated haulers, wheel loaders, engines, electromobility and used equipment. Each challenge was based on the very latest solutions and technologies, with electromobility and digitalization playing a more prominent role than ever before.

Jan Fogelberg, Masters global lead at Volvo CE, said, “Volvo Masters is an exceptionally grueling experience and really tests the skills of our aftersales teams from around the world. Each time we put on this competition, we focus on coming up with more and more sophisticated and diverse challenges, and each time we are always overwhelmed at the expertise and passion on display.

“Huge congratulations, not only to the winners who really proved they had the spirit to get to the top, but to everyone whose engagement and dedication to take on any challenge, no matter how hard, is a testament to the high standards to which our customers hold Volvo CE and our incredible dealer network.”

New for 2024 was an arguably more highpressured environment — with the grand final taking place in front of a live audience of guests at the customer center in Eskilstuna, creating a more sporting atmosphere. Just like the real thing, where customers expect optimum uptime to keep their business operations running as smoothly as possible, the technicians were required to juggle the demands of the task with the need to complete it as quickly as possible.

The win by KSS Korea came after a nailbiting contest. Taking the silver medal was SMT Netherlands, while third and fourth

place were won by Zhejiang Liyang from China and Ascendum Portugal respectively.

Two Volvo dealer teams each from Europe, Asia, China, North America, Latin America, India and Region International took part in the grand final on May 6-8. They qualified after six months of regional finals on home ground, which followed the first phase of the competition, involving three online rounds of questions and assessments.

The global competition brings different cultures and ways of working together. It is a great motivator for participants, as well as a boost to the reputation of hard-working technicians around the world.

(All photos courtesy of Volvo)

Electrification of construction machinery is hardly a new concept. For years, electric equipment has been commonly seen in a variety of applications, from demolition and mining to aerial lift and industrial work.

Now, however, electric equipment is becoming increasingly prevalent on and around job sites. Its potential is evident. Its benefits are clear. Its long-term place in the industry is no longer up for debate. And, as electric vehicles continue to be more widely adopted by consumers, all that’s left to do is examine — and try to accurately determine —how the construction industry should prepare for the technology to become fully mainstream in the not-too-distant future.

“If you go out about three years, there will be approximately 700 electric vehicles roadside, and that’s not even getting into construction and agriculture,” said David Knight, CEO of Terbine, a provider of technology for the seamless exchanging of IoT data between the mobility and energy sectors, who spoke on how the construction industry should prepare for the widespread adoption of electric vehicles in the not-toodistant future at ConExpo-Con/AGG 2023.

According to Knight, there are five main reasons why equipment end users in the construction industry are strongly considering

investing (or already have invested) in electric machinery. They are:

1. Lower operating costs — The savings on diesel costs, alone, are significant. Most OEMs cite a range of four to eight hours of runtime for “average” use on electric compact equipment, with an eight-hour overnight charge. And while it’s quick and easy to compare run times on a fully charged electric machine with a full tank on diesel units, there’s no idle on an electric machine. Therefore, an operator can get a day or more of productive work out of it because they’re typically not running a machine for eight continuous hours a day.

2. Lower maintenance costs —

both regionally and nationally.

4. Carbon credits and offsets — Carbon credits, also known as carbon allowances,

“They’re going to be really good in three to five years, and that’s going to allow for even faster and more efficient charging than ever before.”

5. ESG goals — Many organizations are setting and working toward Environmental, Social and Corporate Governance (ESG) goals, and it’s a trend that’s only expected to become more common with time. Without goals and corresponding policies, organizations face ESG risk, which includes loss of investors, a damaged reputation and fines for regulatory noncompliance.

David Knight Terbine

Reciprocating engines possess many friction-generating parts, which fail. The friction, and the frictional components and amount of heat generated with an engine running, is really what contributes to parts being replaced and maintained.

3. Federal and state tax credits —

Incentives can offer savings in the tens of thousands, or even hundreds of thousands, across a single fleet. Because they change all the time, it’s important for organizations to stay up to date regarding what’s available,

work like permission slips for emissions. When a company buys a carbon credit, usually from the government, they gain permission to generate one ton of CO2 emissions. When one company removes a unit of carbon from the atmosphere as part of their normal business activity, they can generate a carbon offset. Other companies can then purchase that carbon offset to reduce their own carbon footprint.

There is every reason to believe the electric vehicles and electric equipment will continue to develop and improve over time, said Knight, thus making a greater level of adoption even more likely in the very near future. According to the Terbine CEO, the architectures of electric vehicles are going to even higher voltages. The higher the voltage, he explained, the less current is needed for a given amount of wattage. That also means less heat. And, while voltages are very good now, they are expected to improve significantly in the coming years.

“They’re going to be really good in three to five years, and that’s going to allow for even faster and more efficient charging than ever before,” he added.

LeeBoy, an industry leader in commercial asphalt paving equipment, and Portable Electric (PE), a leading manufacturer of portable and mobile e-Chargers and eGenerators, are working together to advance the electrification of the asphalt paving industry.

Introduced at ConExpo, LeeBoy’s 8520C E-Paver is a commercial-class electric asphalt paver that utilizes various electric vehicle components and propulsion technologies supplied by General Motors, engineering assistance from Engine Power Source and Powertrain Control Solutions. This prototype serves as a demonstration of the electrification potential within the commercial asphalt paving sector.

During a recent demonstration, the Voltstack 30k, an all-in-one mobile site power and equipment charger, played a key role in successfully charging the 8520C E-Paver, ensuring maximum uptime performance. LeeBoy is utilizing the Voltstack 30k unit as both companies collaborate to explore future solutions for paving electrification.

role in successfully charging the 8520C E-Paver, ensuring maximum uptime performance.

Voltstack mobile electric equipment chargers are designed to promote electric machinery adoption and provide a versatile on-site power solution at construction job sites. The Voltstack 30k e-Charger offers a

range of charging solutions while serving as a silent, emission-free on-site power source. Its innovative “Smart Hybrid” feature seamlessly integrates with traditional gas or diesel generators, optimizing efficiency and reduc-

ing carbon emissions.

“We are excited to collaborate with LeeBoy in electrifying the paving industry,” said Keith Marett, CEO of Portable Electric. “This collaboration marks the beginning of an exciting journey to redefine how paving is done, focusing on efficiency, innovation and the ability to meet future demands of the industry.”

“Working with Portable Electric is a significant step forward. The Voltstack ecosystem will play a crucial role in ensuring the success of our electric equipment and maximizing uptime on our construction projects,” said Chris Broome, senior product manager at LeeBoy.

“Today, with the Voltstack Level 2 e-Charger, we have the ability to recharge the paver for 15 minutes at Level 2 and get an extra 19 tonnes of asphalt. In terms of future solutions, Level 3 is critical to our success. With Level 3 charging, the same 15minute charging window will lead to an additional 57 tonnes of asphalt. That extra production will be game-changing.” For more information, visit LeeBoy.com and portable-electric.com.

With John Deere Connected Support™, your machines are constantly under the watchful eye of both John Deere and your local dealership. Together we can reduce, or even prevent, costly downtime. All of which keeps you up and running, so you can stay connected to your operation and the work you need to do.

Beard Equipment Company www.beardequipment.com

Mobile, AL

251/456-1993

Freeport, FL 850/835-3337 Jacksonville, FL 904/296-5000

Lake City, FL 386/752-9544

Ocala, FL 352/732-4646

Palatka, FL 386/325-6268

Panama City, FL 850/769-4844

Pensacola, FL 850/476-0277

Perry, FL

850/584-9200

Tallahassee, FL 850/575-5600

Dothan, AL 334/794-8691 Troy, AL 334/566-4181

Riverview, FL (HQ) 813/620-1000 Miami, FL 305/592-5740

West Palm Beach, FL 561/848-6618 Orlando, FL 407/299-1212

Fort Myers, FL 239/334-3627

Lutz, FL 813/995-0841

Daytona, FL 407/299-1212

Riverview, FL 813/621-4902

Pompano Beach, FL 954/977-9541

Sarasota, FL 941/960-2004 Melbourne, FL 321-234-3344

Adairsville, GA 770/773-9857 Albany, GA 229/888-1212

Atlanta, GA 404/691-9445

Braselton, GA 770/965-1889

Brunswick, GA 912/264-6161

Columbus, GA 706/687-3344

Grovetown, GA 706/855-5440

Macon, GA 478/788-1586

Savannah, GA 912/964-7370

Valdosta, GA 229/474-6680

Andrews, SC 843/983-7337

Aynor, SC 843/358-5688

Ladson, SC 843/572-0400

Simpsonville, SC 864/963-5835

Walterboro, SC 843/539-1420

West Columbia, SC 803/794-9340

JohnDeere.com/Connected

McCoy Construction & Forestry

mccoycf.com

Chattanooga, TN

423/855-0633

Nashville, TN

615/501-8600

Kingsport, TN 423/349-5001

Knoxville, TN 865/546-3207

Electric-powered equipment is nothing new to job sites. Manufacturers have been developing battery-powered machines for years before the fed adopted its goal of zero emissions by 2050. But now mobile crane manufacturers are setting their own zero-emission goals and rolling out new models that use no diesel fuel. Though many are taking a wait-and-see attitude, the road is wide open for a sustainable crane market.

The crane industry “must be open-minded and bold to break new ground,” said Gerhard Frainer, managing director, sales of Liebherr-Werk Nenzing.

“If you go out about three years, there will be approximately 700 different types of electric vehicles roadside,” said David Knight, CEO of Terbine.

The company provides technology for the exchange of IoT data between the mobility and energy sectors. He spoke at ConExpo in March.

Knight urged the construction industry to prepare for the widespread adoption of electric vehicles in the not-too-distant future. He noted five main reasons equipment end users in the construction industry in general are investing in electric machinery.

Lower operating costs, lower maintenance costs, federal and state tax credits, carbon credits and offsets and environmental, social and corporate governance (ESG) goals all play a part.

First, the savings on diesel costs, alone, are significant, he said. Most OEMs cite four to eight hours of runtime for average use on electric compact equipment, with an eight-hour overnight charge.

There’s no idle on an electric machine. An operator can get a day or more of productive work in because they’re not running a machine for eight hours a day.

Knight pointed out that reciprocating engines possess many friction-generating parts, which fail. The friction and heat generated with a running engine are really what contributes to parts replacement and maintenance.

Incentives can offer savings in the tens of thousands, or even hundreds of thousands of dollars, across a single fleet.

As Knight explained it, carbon credits, also known as carbon allowances, “work like permission slips” for emissions. When a company buys a carbon credit, usually from the government, they gain permission to generate one ton of CO2 emissions. When one company removes a unit of carbon from the atmosphere as part of their normal business activity, they can generate a carbon offset. Other companies can then purchase that carbon offset to reduce their own carbon footprint.