By Lori Tobias CEG CORRESPONDENT

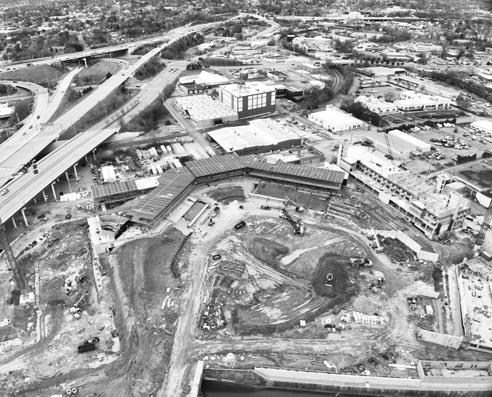

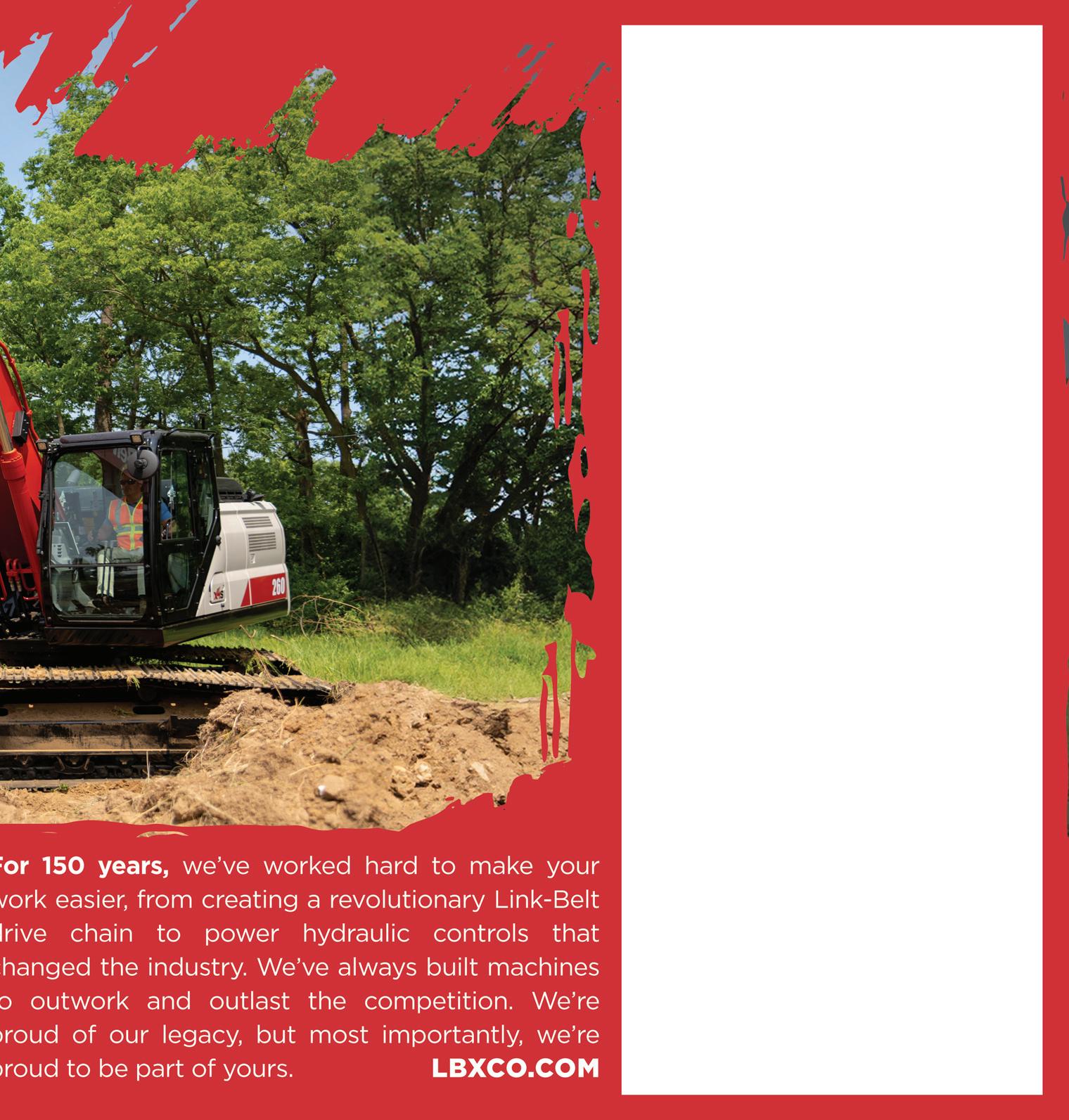

A $140 million project in urban Knoxville once known as “the bottoms” comes with a fair share of challenges, but when complete, the anticipated benefits will be nearly innumerable.

Work on the Knoxville multi-use stadium project began in 2021 with the demolition of a former slaughterhouse. Two years later, construction on the stadium, to be home stadium to the Chicago Cubs AA team Tennessee Smokies, was under way with about 60-percent of the job now complete. It is expected to be finished in 2025 and the first official pitch thrown at the April opening game of the AA league baseball season.

In addition to minor league baseball, the stadium will host concerts, soccer games and community events. It is one of the largest projects in the city’s history, according to Mohamed Abbas, senior project manager of contractor Denark Construction Inc.

The stadium is envisioned as a catalyst for redevelopment in East Knoxville, Tenn.,

ing it with the Old City and downtown.

By Lucy Perry CEG CORRESPONDENT

Rising highway construction costs are draining more dollars from BIL funds allocated for federal transportation projects across the country. The FHWA admits that what can be purchased today with BIL funds earmarked in 2021 is markedly less that what was pledged. Those construction costs rose an “unprecedented” 26 percent in 2022. The record annual increase was 20 percent in 2005, said the agency.

a badly needed bridge replacement project.

ACS Group and HOCHTIEF, the respective owners of Dragados and Flatiron, announced that they have agreed on key terms for the combination of the two companies.

The Lane Construction Corporation, the U.S. subsidiary of Webuild Group, has won a contract for taxiway pavement repairs at Naval Air Station (NAS) Oceana in Virginia Beach, Va.

12 COWIN EQUIPMENT OPENS REBUILD CENTER IN BIRMINGHAM

The new 14,000-sq.-ft. building is located on the property of the company’s headquarters facility on Pinson Valley Parkway, a campus that now encompasses more than 94,000-sq.-ft.

16 DYNAPAC CELEBRATES ANNIVERSARY BY SUPPORTING DREAM ON 3

On a recent summer day, Dynapac held a golf outing called Tee’ing Up Dreams to raise money for Dream On 3 at the Cramer Mountain Club in Cramerton, N.C.

18 PROJECT TO EXPAND ADVENTHEALTH DAYTONA BEACH HOSPITAL

Construction has officially begun at AdventHealth Daytona Beach in Florida on a multi-phased, $220 million project.

18 STEEL PEDESTRIAN BRIDGES TO BE INSTALLED ALONG ECUSTA TRAIL

The initial phase of construction on the Ecusta Trail in western North Carolina is moving forward with the installation of six new bridges along what was once an old railroad bed.

19 DOBBS EQUIPMENT, CEMEN TECH EXPAND PARTNERSHIP

This update expands the pair’s existing partnership in the central and south Florida markets.

20 NATIONAL EQUIPMENT LEAGUE LAUNCHES FIRST COMPETITION

The newly founded National Equipment League is broadcasting its first events starting online in partnership with HD Hyundai Construction Equipment North America.

20 MIAMI-DADE RECEIVES GRANT TO PRESERVE VENETIAN CAUSEWAY

The project, in collaboration with state and federal partners, aims to replace 11 of the 12 bridges that make up the causeway over Biscayne Bay connecting Miami with Miami Beach.

64 SOLAR PANELS OFFSET ENERGY COSTS AT TWO TAKEUCHI-US FACILITIES

The new solar panels will cover about 85 percent of the energy needs at those two facilities. The remaining 15 percent will be sourced as green energy from local electrical suppliers.

70 EQUIP EXPOSITION EXHIBIT SPACE SOLD OUT FOR OCTOBER

The grant will allow the four bridges, originally constructed in 1968, with narrow shoulders and roadway approaches, to be rebuilt into one bridge with two 12-ft. travel lanes in both the southbound and northbound direction.

Travelers driving across South Carolina’s largest lake may soon do so more safely after the state received federal funding for a badly needed bridge replacement project.

The South Carolina Department of Transportation (SCDOT) is set to embark on major work to replace four bridges carrying Interstate 95 traffic over Lake Marion in the central part of the state. The new project will undoubtedly affect travelers across the country as I-95 is a main artery that ties together most of the Eastern Seaboard from Maine to Florida.

In a July 17 news release, SCDOT revealed that it had received $175 million in federal funding to complete the project. That means the state now has the necessary $350 million to get the construction under way.

“Today’s announcement marks the beginning of a longawaited and nationally important project that will transform this region,” noted Justin Powell, the state’s secretary of transportation.

The health of the nation’s bridges took on new urgency after an out-of-control cargo ship crashed into a support column of the Francis Scott Key Bridge in Baltimore, Md., earlier this year, causing the bridge to collapse. The accident killed six road crew workers.

South Carolina’s roads and bridges are badly in need of repair, but work has been hampered by a lack of funding, according to previous Post and Courier reporting. Replacing the I-95 structures has been a years-long priority.

The $175 million for the Lake Marion bridges is part of a $5 billion investment package announced recently by the Federal Highway Administration (FHWA). Officials in Washington provided the monies to replace or improve aging bridges in a total of 16 states, according to SCDOT.

The FHWA funding comes from a $1 trillion infrastructure package President Biden signed into law in 2021.

The rest of the money for the I-95 spans will come from $105 million in separate federal funds and $70 million in state funds, an SCDOT spokesperson told the Post and Courier Pee Dee in Florence, S.C.

In a recent press release, South Carolina Gov. McMaster credited the work of U.S. Sen. Lindsey Graham (R) and U.S. Rep. James Clyburn, D-6th District in securing the federal funding for the Palmetto State project. The interstate bridges are a critical link in the East Coast supply chain, he wrote in a November letter to federal Transportation Secretary Pete Buttigieg supporting the effort.

Replacing the Lake Marion bridges, first built in 1968, also will improve safety and reliability for travelers and support the economic development of the state and region, McMaster wrote.

Together, the four structures span a large swath of the lake, transporting people to and from Clarendon and Orangeburg counties.

While SCDOT reports indicate that portions of the bridges are still in fair condition, the agency predicts that the bridges will be in poor condition and may require load restrictions as soon as next year.

Their narrow shoulders also impede emergency responders during accidents, according to the state agency. That carries implications not just for daily traffic — which includes everything from families on road trips to truckers transporting essential goods — but also for vehicles evacuating the coast during tropical storms.

When construction is finished, the four bridges will be replaced by a single structure with two 12-ft. travel lanes in both the southbound and northbound directions. The work also would create a bicycle and pedestrian path separated from the roadway by a barrier. Additionally, plans call for the adjacent existing U.S. Highway 301 pedestrian bridge to be retained.

The new roadway bridge’s design will allow it to be expanded in future years to include an extra travel lane in each direction.

SCDOT said the existing bridges will remain in operation once construction begins on the new bridge, meaning there should not be any substantial road closures or detours during the work.

The transportation agency aims to have the project under contract sometime in 2025, the Post and Courier Pee Dee reported.

Lake Marion is South Carolina’s largest lake, encompassing 110,600 acres and 511 mi. of shoreline. The waterway touches Berkeley, Calhoun, Clarendon, Orangeburg and Sumter counties.

It also is one of two water bodies that comprise the Santee Cooper Reservoir, constructed to provide hydroelectric power to rural South Carolina.

ACS Group and HOCHTIEF, the respective owners of Dragados and Flatiron, announced that they have agreed on key terms for the combination of the two companies, with ownership of the integrated company held 61.8 percent by ACS Group and 38.2 percent by HOCHTIEF. The company will be managed by Peter Davoren as chairman (in addition to his current role as chairman, CEO and president of Turner) and the current CEO of Flatiron, Javier Sevilla, as CEO. The transaction closing is expected during the second half of 2024.

The merger will create the second largest civil engineering and construction company in the United States.

“Bringing together Flatiron and Dragados creates a strong platform for organic growth in North America,” said Chief Executive Officer of HOCHTIEF, Juan Santamaría. “They have the expertise, the long-term clients and are geographically complementary, providing significant synergies and economies of scale. We differentiate our commercial offering through our superior technical resources and skills.”

“Flatiron and Dragados North America employees have a long history of working together,” he added. “The new company will have the most respected and recognized value proposition in its sectors, having delivered renowned projects across the United States and Canada, and can look forward to an even stronger future.”

The company, named Flatiron Dragados, will continue to serve clients across its existing diverse markets and support strong community and stakeholder relationships.

The transformation into a new and even stronger entity creates synergies and economies of scale. The simplified structure will ensure a consistent approach to operations, including tender processes, procurement strategies and risk management, and be value accretive for shareholders of ACS Group and HOCHTIEF.

(Photo courtesy of TXDOT.)

Lane Construction photo

Work entails repairs to Phase I, Taxiway Alpha; and Phase II, Taxiway Alpha, Taxiway Bravo, Taxiway Papa and other related work at the naval air station.

The Lane Construction Corporation, the U.S. subsidiary of Webuild Group, has won a contract for taxiway pavement repairs at Naval Air Station (NAS) Oceana in Virginia Beach, Va.

The contract, valued at $207,849,000, is a testament to the company’s ongoing presence in the Mid-Atlantic region, a core market for Lane.

Awarded by the Naval Facilities Engineering Systems Command Mid-Atlantic (NAVFAC MIDLANT), work entails repairs to Phase I, Taxiway Alpha; and Phase II, Taxiway Alpha, Taxiway Bravo, Taxiway Papa and other related work at the naval air station. Work is expected to begin in the fall and be completed by early 2028.

This is the second contract in recent years that the company is completing at Oceana NAS. Lane previously repaired Runway 14L-32R and the associated electrical airfield lighting, as well as constructed new 4-ft.-wide taxiway shoulders in areas where the edge lighting systems were modified.

This latest win follows another recent $110 million contract in Virginia awarded to Lane earlier this year for the Newport News segment of the I-64 Hampton Roads Express Lanes (HREL). HREL is a multi-segment network of contracts for the Virginia Department of Transportation, that, once completed, will provide additional travel choices and help improve travel time reliability along one of the primary interstate roadways in Virginia.

Lane also is constructing the $441 million 495 Express Lanes Northern Extension (495 NEXT) in the state.

For more information, visit www.laneconstruct.com.

Cowin Equipment Company recently opened a Rebuild Center in Birmingham, Ala.

The new 14,000-sq.-ft. building is located on the property of the company’s headquarters facility on Pinson Valley Parkway, a campus that now encompasses more than 94,000-sq.-ft. The company already had a smaller parts and tool storage building adjacent to this newly built structure, which was used for large attachments and auxiliary parts. That building has been completely re-racked and restructured to serve the needs of the Rebuild Center. A concrete apron was poured between the parts building and the Rebuild Center to accommodate forklifts transporting parts between the structures.

The new Rebuild Center features an office area, breakroom/kitchen and locker room/shower to accommodate the staff. The 5-acre parcel of land, which is the footprint of the facility, had previously been a machine and attachment stocking area for Cowin’s headquarters. Machines were moved and dispersed to other locations to make room for this center. The construction of this building was started and completed within a 12-month period.

This portion of Cowin’s business is a separate department that serves all company branches for rebuilds of Volvo, Grove, Epiroc, ASTEC/Roadtec and other machines sold and serviced by Cowin. Members of the team in this center travel to the manufacturer for enhanced training on rebuilds at various levels.

Customers can get partial or complete rebuilds depending upon their needs. Rebuilds will be certified by the manufacturer and by Cowin.

Three of the six drive-through bays are designed for truck tractors and lowboys to pull directly into the bays and off load an inoperable machine through the heavyduty overhead crane system, which consists of two 30ton overhead cranes, two 15-ton overhead cranes and several additional structure-mounted swing out jib cranes. This machine handling system works efficiently in unison and eliminates the need to drop a machine on the yard and “drag it” into a bay to start the rebuild process.

The structural iron and concrete are rated for supporting any weight level of heavy machinery or cranes. The building is environmentally friendly and utilizes powerful exhaust fans to keep the shop area naturally cooled in the summer and utilizes a waste oil system to heat the entire shop throughout the cold months with the use of the EnergyLogic waste oil heaters.

New specialty equipment purchased for the center includes welding equipment, punch press, industrial band saws, miter saws, plasma cutters, 100-ton press, drill press, lathes, mills, line boring equipment and much more. A centralized lube and oil system also is incorporated.

For more information, visit www.cowin.com. CEG (All photographs in this article are Copyright 2024 Construction Equipment Guide. All Rights

To mark Dynapac North America’s 90th anniversary in 2024, the Fort Mill, S.C., maker of paving, compaction and light equipment for road construction recently hosted an event in support of Dream On 3, a local nonprofit that helps make sports dreams come true for children with life-altering physical, intellectual and developmental disabilities.

The Swedish/German manufacturer supports the U.S. market from its North American headquarters, located a few miles south of Charlotte, N.C.

Dream On 3 is dedicated to helping young people ages 521 realize their ultimate sports dreams. For more than a decade, the Charlotte-based organization has connected kids with sports-related trips and personalities through a core program known as Dream Experiences.

On a recent summer day, Dynapac held a golf outing called Tee’ing Up Dreams to raise money for Dream On 3 at the Cramer Mountain Club in Cramerton, N.C. In the end, the golf tournament raised $83,000 in sponsorships and donations for the nonprofit.

When asked why his company wanted to be a part of Dream On 3, Dynapac North America President Jamie Roush said, “The mission in general is sort of ingrained in our culture; the DNA of Dynapac is geared to support and grow such philanthropic efforts.”

He noted that one young boy named Brody saw his wish come true thanks to a participating company when he got to meet and pal around with several members of the NFL’s Carolina Panthers team.

“Now, Dynapac’s mission is to make another dreamer’s wish happen,” Roush said. “And Brody is our ambassador in this journey. We are learning as a company and all of the people here participating in this event are discovering Dream On 3 and how we can support it.”

Without the construction industry, including both contractors and equipment dealerships, Dream On 3’s expansion and services over the past 10-plus years would likely not have been possible. Generous funding and support from other metro-area businesses, via their sponsorships and Dream On 3’s annual Dream Gala in Charlotte, have allowed the nonprofit to grow and prosper.

Dormie Roberts, Dynapac’s marketing and digital solutions manager, added that the manufacturer’s participation in the golf event and its association with Dream On 3 is all about its desire “to give back to the community we serve.”

“Supporting Dream On 3 isn’t only about giving; it’s about being part of a moment that changes lives,” Roberts said. “Every contribution helps enrich the lives of these kids, creating an experience of joy, hope and encouragement.”

At its annual gala event, Dream On 3 presents a Queen City Business of the Year award; earlier this year, LeeBoy, the Lincolnton, N.C.-based equipment maker, received the honor.

“We were a part of the gala last time when our friends at LeeBoy asked us to be a part of their fundraising event,” Roberts said. “They passed the torch on to us for this year,

and now we are in the running for the 2024 Queen City Business of the Year award.”

She said that Dynapac fully understands the need for giving kids the opportunity to meet and interact with their sports heroes as well as supporting effective mental health for people of all ages.

“At World of Asphalt this year in Nashville, we specially wrapped one of our pavers to bring awareness to the support systems for construction workers navigating mental health challenges,” Roberts added. “It is part of our culture and in our blood that we want to help people, including our customers and partners.” CEG

(All photographs in this article are Copyright 2024 Construction Equipment Guide. All Rights Reserved.)

see DYNAPAC page 68

Construction has officially begun at AdventHealth Daytona Beach in Florida on a multi-phased, $220 million project to add 104 inpatient beds, four new surgical suites and more than 240,000 sq. ft. to the facility.

The work includes vertical additions on two existing towers at the hospital: a four-story expansion on one building and a one-story expansion on a separate tower.

“This major expansion project will increase the community’s access to world-class, patient-centered, whole-person care and enable us to better meet the health care needs of our growing patient population well into the future,” explained David Weis, president and CEO of AdventHealth Daytona Beach and the East Volusia Market, in a July 22 news release.

He added that the construction “raises the bar on patient care excellence in the region and we could not be prouder to advance health care for the communities we are privileged to serve.”

Robins & Morton, an Alabama-based nationwide construction company — with Florida offices located in Orlando, Tampa and Miami-Fort Lauderdale — and HuntonBrady Architects in Orlando, recently joined with the hospital’s leadership to celebrate the project’s kickoff by planting a new Japanese Blueberry at the site. The tree signifies AdventHealth Daytona Beach’s deep roots and more than 40 years of service in the community.

Initially announced in April, cranes and other heavy

equipment were mobilized to the Daytona Beach hospital construction site, located at 301 Memorial Medical Parkway, in June.

Work is now in full swing as crews are actively building over AdventHealth Daytona Beach’s cafeteria to expand the one-story “low-rise” portion of the building which will house new space for the facility’s laboratory, surgical services, engineering and pharmacy.

In the upcoming weeks, construction will commence over the fourth floor of the second tower — the “high-rise” portion of the project — to add four more floors.

“This is something we’ve been planning for quite some time now and we are so thrilled construction has begun on this massive expansion project,” said Dave Tkachuck, COO of AdventHealth Daytona Beach. “In recent months, we’ve experienced a high volume of patients seeking our care, which reflects the deep trust our patients place in our clinicians. This is an honor and privilege we take seriously, and we are proud the skill and expertise of our teams has been recognized; just this week, we were named the No. 1 hospital in the area for the fourth consecutive year by U.S. News & World Report.”

Once completed, the healthcare facility will grow from 362 inpatient beds to 466 beds and total just under 1 million sq. ft. of space. Additionally, the number of surgical suites at AdventHealth Daytona Beach will expand from 18 to 22.

The project has been designed to add more intensive care and progressive care beds as well, including an expanded cardiovascular intensive care unit, or CV-ICU, and a dedicated neuro-ICU unit. Plans call for a growth in the hospital’s

The construction includes vertical expansions

existing towers at AdventHealth

four-story vertical expansion on one tower and a onestory vertical expansion on a separate tower.

support services, including an expanded sterile processing department, a new and enlarged pharmacy, a new lab department, and expanded imaging modalities, including an additional CT and MRI.

The expansion project at AdventHealth Daytona Beach is expected to be completed by fall of 2026, the hospital noted in its latest news release.

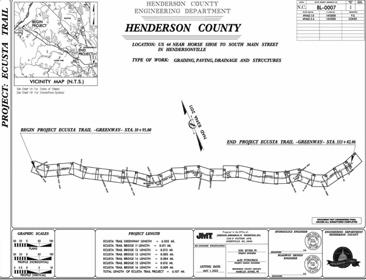

The initial phase of construction on the Ecusta Trail in western North Carolina is moving forward with the installation of six new bridges along what was once an old railroad bed.

The first phase is scheduled to open in December, Henderson County Engineer Marcus Jones told the Hendersonville Times-News. It will include 6 mi. of the trail’s 19.4 total miles and cost approximately $13 million.

When completed, the multi-use, paved Ecusta Trail will connect the mountain towns of Hendersonville and Brevard, south of Asheville.

The pathway is being created on what was the former Watco Rail line with the goal of providing pedestrians and cyclists the chance to explore a variety of scenic landscapes in the area, from the French Broad River to rolling hills and mountain peaks.

The trail site was once a Norfolk Southern rail line before being purchased by Watco; however, the line has not been in operation for nearly two decades.

In the first week of August, the half-dozen prefabricated steel bridges were brought to Henderson County from their manufacturing site in Alabama. Once at their designated locations, the bridges were set by Asheville-

based NHM Constructors LLC, the project’s contractor.

The Hendersonville Times-News reported Aug. 6 that the next step in the process is to level the bridges and fasten them to concrete bases on each end. Jones said this work should take anywhere from one to two weeks to accomplish.

He added that the new pedestrian bridges are replacing six railroad trusses that were previously on the land. Following their placement, no other new bridges will be required for Phase 1.

Early in the design, the Ecusta construction team evaluated the condition of each rail bridge as well as repair costs and whether they could be designed to carry an emergency or trail maintenance vehicle. Based on their findings, each existing bridge needed to be replaced with elevated prefabricated steel structures to avoid potential flood impacts.

Jones said each structure costs between $300,000 and $500,000, depending on its size. They vary in length, but their widths are either 12 ft. in more rural areas of the county or 14 ft. wide in the urban settings.

The six bridges due to be installed will be set along Fifth Avenue, U.S. Highway 64, Allen Street, Church and Main streets, Old Homestead Road, and at Turley Falls Road

and Brightwater Drive.

The Ecusta Trail’s first phase will stretch from South Main Street in downtown Hendersonville to the intersection of U.S. 64/Battle Creek Road in the small community of Horse Shoe. Although still in the design phase, the second portion of the proj-

ect will lead hikers and cyclists from there to Brevard’s Oskar Blues Brewing, noted the Ecusta Trail website.

The official Ecusta Trail groundbreaking was held last October at the site of the

Veterans Healing Farm in Hendersonville. Crews began work at the site in December with clearing and grubbing continuing into the spring, followed by grading.

Jones previously told the Times-News that the next portion of the trail is being designed and should be completed in about four years.

Other work being done on the Ecusta Trail includes the installation of draining system ditches and pipes, he added, noting that the subgrade for paving is nearly finished.

“The bridges were a pretty big milestone,” Jones explained. “But the paving’s going to be pretty significant, even just getting the first layer down.”

Tarheel Paving in Hendersonville is in charge of that work.

Jones said recent rainy weather sometimes prohibits work being done on the Ecusta Trail and slows down the process, but construction on the first phase is still on schedule to be wrapped by the December target date.

Jones previously told the Times-News that the next portion of the trail is currently being designed and should be completed in about four years.

For now, the Ecusta Trail will be closed while its first phase is being constructed.

Cemen Tech, a large volumetric concrete mixer manufacturer, announced a new agreement with Dobbs Equipment to be the exclusive dealer of the company’s full line of concrete production solutions in South Carolina.

This update expands the pair’s existing partnership in the central and south Florida markets.

“Having Cemen Tech in the Dobbs Equipment product lineup supports our commitment to best serve the needs of our customers with cutting-edge technology and top-quality equipment so they can build successful and profitable businesses,” said Matt Murphy, Dobbs Equipment president of South Carolina.

Streamlining the complexity of concrete projects in the construction industry, volumetric concrete mixers ensure precision in measuring, mixing and dispensing concrete from a single unit. Each ingredient – sand, stone, cement powder, water, additives — is

stored in separate compartments and mixed at the job site for fresh concrete every time.

The flexibility and efficiency of this technology not only reduce downtime and material waste, but empower business owners to build their bottom line by producing their own concrete.

“We understand that the availability and cost of concrete can be pain points for contractors, often hindering projects from staying on schedule and on budget. Volumetric technology mitigates these issues and allows contractors to broaden and diversify their business,” said Connor Deering, CEO and president of Cemen Tech.

“Like Cemen Tech, Dobbs Equipment stands behind its reputation for quality, service and support, making them a trusted and proven partner.”

For more information, visit CemenTech.com and DobbsEquipment.com.

The Miami-Dade County Department of Transportation and Public Works (DTPW) announced July 17 that it had received confirmation of a grant award of $100.5 million from the U.S. Department of Transportation Bridge Investment Program (BIP) for Miami’s Venetian Causeway Project.

The county office noted in a press release that the “vital funding will help support bridge replacement, resilience and preservation of the historic bridges along the Venetian Causeway.”

The project, in collaboration with state and federal partners, aims to replace 11 of the 12 bridges that make up the causeway over Biscayne Bay connecting Miami with Miami Beach. Ten of the causeway’s structures are fixed span bridges, while the other two are bascule leaf span bridges.

Constructed in the mid-1920s, with an initial design life of 50 years, the road structures are moderately to severely deteriorated and have been repaired numerous times, often as a result of the many hurricanes the causeway has weathered during its long history.

As such, Miami-Dade County, the Florida Department of Transportation (FDOT), and other agencies and stakeholders are working together to replace the causeway’s 11 bridges. Each of the structures due to be replaced have reached the end of their useful lives, according to officials, including the easternmost movable bridge.

“We are honored to receive this substantial investment,

and we are extremely grateful to the U.S. Department of Transportation, Secretary Pete Buttigieg, Congresswoman Frederica Wilson and our Congressional delegation for making it happen,” said Miami-Dade Mayor Daniella Levine Cava.

“This project is crucial to improve mobility to and from the beach on a vital roadway for residents who live and work there and for millions of tourists who visit our county as well as protect a key evacuation road during storms,” she continued. “This investment will help future-proof our infrastructure while generating jobs to support our local economy — a major step forward in our ongoing efforts to upgrade our infrastructure and build a resilient, futureready Miami-Dade.”

Miami-Dade officials believe that once completed, the replacement/improvement project will make the Venetian Causeway a safer and more efficient corridor for all users.

“The Venetian Causeway Project is such an important endeavor for resilience as well as public safety,” explained Jimmy Morales, Miami-Dade County’s COO. “We thank the county and DTPW teams that worked on the grant proposal and especially Mayor Cava for championing the proposal in Washington, D.C.”

The new bridges, designed to have a useful life of approximately 75 years, will honor the history and original

appearance of the Venetian Causeway while incorporating modern safety features.

They also will address environmental and mobility concerns by being 16 ft. wider, thus providing increased safety for vehicles, pedestrians and cyclists. Additional infrastructure improvements, such as Florida Power & Light feeder lines and water main replacement, will service the city of Miami Beach.

“The new bridges will address current safety concerns, including increased weight limits to improve the delivery of goods to area residents,” added Eulois Cleckley, the DTPW’s director and CEO. “We are excited to move this project forward and make the Venetian Causeway safer and better connected for all users.”

As part of the project’s timeline, DTPW hosted a public meeting to present plans and provide information about the Venetian Causeway’s design phase in April 2023. Since then, the project team has been working on finishing the 90 percent design milestone, scheduled for submittal at the end of this year.

Design and permitting are estimated to be completed by the end of 2025, followed by the construction’s advertisement for bids in early 2026. According to Miami-Dade officials in their recent press release, the DTPW will work closely with the county’s Regulatory and Economic Resources (RER) Department and other agencies during the permitting portion of the effort.

The newly founded National Equipment League is broadcasting its first events starting online in partnership with HD Hyundai Construction Equipment North America.

The National Equipment League — founded as a new entertainment platform to showcase the skills, character and passion of the construction industry through competition — will crown its first ever champion at the completion of four events broadcast over the course of the next month. The winner will be crowned the first ever National Equipment League Champion and take home the championship belt and additional prizes from Hyundai.

Competitors in the first competition include Mike Simon (AKA Dirt Perfect), Andrew Camarata, Bryan Furnace, Dave Buchakian and Geoff Dodge. Mr. Digg Ryan Williams also joined the fun as a member of the broadcast team.

All events were filmed at the HD Hyundai Customer Product Center in Carnesville, Ga., and will continue to be shared from Hyundai social platforms such as YouTube and Facebook.

“We had an incredible time putting this together with some of the biggest construction industry names in social media and YouTube,” said Susan Philpott, marketing

manager, HD Hyundai Construction Equipment. “The sense of competition and camaraderie is clear as each competitor gives it their all throughout the events — there’s lead changes, there’s competitive drama, and it all serves to highlight the passion and skills of the construction industry.”

“I see the National Equipment League existing somewhere at the crossroads of mixed martial arts and dirt track racing,” said Bill Elverman, commissioner of the National Equipment League. “It’s being built to give future generations an entertaining and dynamic view into an industry that

we’re all passionate about. We hope operators from all around North America will take note and want to test their skills in a competition that’s fun to watch but also serves as a showcase for our industry. And we hope it provides a platform for skilled trades men and women to serve as heroes to future generations.”

Future event dates are TBD, but the National Equipment League championship will be up for grabs throughout the year as both existing and new challengers

take on the eventual champion.

“This is definitely an ongoing, legacy championship,” said Elverman. “We want this to be like professional mixed martial arts where operators are calling each other out and continually going head-to-head with the best. If our first championship is any indication, there is excitement for that level of entertainment and competition.”

competition — will crown its first ever champion at the completion of four events broadcast over the course of the next month.

The first series of National Equipment League events will be broadcast from the Hyundai YouTube and Facebookchannels. Additional promotional considerations were made possible by Blue Diamond Attachments.

For more information on the National Equipment League, or to inquire about competing in and sponsoring/participating in future events, email Commish@EquipmentLeague.com, or fill out the form at EquipmentLeague.com.

The first episode can be watched at https://youtu.be/meyJ6b_E6F8?si=nn2jrlSE 8H2i5V-Y. (Photos courtesy of the National Equipment League.)

Electrification is a critical step toward reducing emissions from mining equipment and helping mining organizations meet their sustainability goals. Komatsu is excited to introduce the industry to its latest electrification solutions at MINExpo 2024 in Las Vegas, from Sept. 24 to 26.

Komatsu is committed to helping mining organizations reduce their environmental impacts by developing a range of products and solutions designed to meet their needs, wherever they are on the path to sustainability. The company’s electrification initiatives are built on its decades of experience electrifying equipment, both for the company’s electric drive trucks and loaders and for its fully electric underground soft rock mining machines.

Komatsu is now expanding on that knowledge to develop electrification solutions for all areas of mining.

Featured products will include:

• The WX04B, Komatsu’s first battery-electric powered LHD. Ideal for narrow vein mines, the WX04B, a 4-tonne capacity LHD, is designed with industry-leading battery technology to help customers achieve their goals for safety, durability and high performance. The WX04B will be shown alongside a new Komatsu-designed charging solution.

• The PC4000-11E electric drive hydraulic mining excavator. The PC4000-11E delivers the powerful digging force operators need and expect from high-performance diesel machines while enabling zero-emissions loading.

• The 930E PADT haul truck. Built on Komatsu’s modular power agnostic platform that will allow for transition from diesel to battery or even hydrogen fuel cell power sources, the 930E PADT also supports dynamic charging and trolley assist options to further reduce fuel consumption and emissions.

In addition to equipment, Komatsu will showcase its collaborations with other organizations working toward a more sustainable future, including GM and ABB.

At MINExpo 2024, Komatsu will demonstrate the company’s vision for sustainable mine optimization through solutions and technologies designed to prioritize safety, reliability, cost effectiveness and environmental impact.

Komatsu will be located at booth 7132 in Central Hall. Additional products and solutions will be highlighted at neighboring booths for Komatsu subsidiaries Hensley Industries (7114), Immersive Technologies (6823), Tramac (Montabert) (7314) and MST Global (7322). For more information, visit www.komatsu.com.

Realistic Scale Models of

“The site has not been short of challenges,” said Abbas. “The biggest thing has been all the different coordination aspects to the project. So, building the stadium, upgrading all the surrounding infrastructure. You’re also working adjacent to three brand new buildings. We’re also installing all the streetscapes and landscaping and plaza, so there's a lot of coordination with a lot of people, so that is a little challenging. The site also is a brownfield site. It has limitations on what you can do in soil testing. It also has archaeological significance because of ‘the bottoms.’ When we were doing excavation, we did all kinds of archaeological analysis and preservation. In addition to that, there’s a creek that runs through the site. So, another challenge is working around the creek and making sure that all the construction does not affect it whatsoever. All of the structure that surrounds the creek is self- supported off of rock and doesn’t actually touch it so that’s a little tricky.”

The stadium is envisioned as a catalyst for redevelopment

from page 1 see STADIUM page 60

in East Knoxville, connecting it with the Old City and downtown. Set on 12.1 acres, it will accommodate approximately 7,000 seats in traditional grandstand seating, as well as luxury boxes and more contemporary picnic pavilions, an outdoor restaurant and bar and Party Pavilions that will accommodate more than 10,000 people for concerts and special events. The stadium features a cross-laminated timber wood roof, batting cages on the upper floor with windows and a “huge” scoreboard in the shape of the state of Tennessee.

The seating bowl provides views of Knoxville’s skyline to the southwest. The exterior of the park is designed to be of stone, brick and steel to reflect its location in the heart of Knoxville’s historic warehouse district.

Funding for the project comes through a Sports Authority jointly formed by Knoxville and Knox County, with support from Knoxville, Knox County, the state of Tennessee and Randy Boyd, owner of the team, who also provided the land for the project.

A $140 million project in urban Knoxville once known as “the bottoms” comes with a fair share of challenges.

“When we were doing excavation, we did all kinds of archaeological analysis and preservation. In addition to that, there’s a creek that runs through the site,” said

Tracking numbers, the DOT Bureau of Transportation Statistics (BTS) found that from the first quarter of 2022 to 2023 costs rose 35 percent.

It reduces “the amount of highway infrastructure that can be bought today versus what could have been purchased prior to the price increases.”

The agency put it another way: “The same construction project today costs more than yesterday and significantly more than in 2021.”

The AGC noted that prices for construction inputs have risen faster than contractors’ bids every month so far in 2024.

“Persistently long lead times for electrical equipment are adding to the cost of building and infrastructure projects,” said Ken Simonson, chief economist. “Meanwhile, inflexible rules for sourcing materials could drive up prices for federally aided projects such as highways.”

The AGC partnered with ARTBA on a survey tracking the impacts on highway construction of proposed tighter Buy America requirements.

Some 69 percent of respondents said they’d “price” their bids to register uncertainty about costs of Buy America-compliant materials for particular projects.

“This reality usually results in higher project costs and diluted benefits from federal investment,” said Simonson. “In addition, if FHWA rolls back its waiver, respondents expect significant challenges in complying with Buy America requirements for many manufactured products.”

Less than 15 percent of respondents believe these products would be easy or possible to acquire in compliance with the Buy America policy.

Survey respondents listed numerous additional products that would be difficult or impossible to source without waivers.

“Federal officials are attempting to shut down a diversified global supply chain … before enough domestic supply exists,” said Jeffrey D. Shoaf, CEO of the AGC. “That’s a recipe for higher costs and delayed projects that will harm both the U.S. economy and highway safety.”

The BTS warned that if highway construction costs rise above their level at BIL signing, what can be bought with the funds in each fiscal year will decline.

The bureau looked at both High and Modest Inflation Scenarios in predicting what happens in the future. The High Inflation Scenario assumes construction costs continue to rise at their current rate using the average annual growth from 2021 and 2022.

“Under this scenario, only $224.2 billion can be bought with the $379.3 billion allotted for highways,” said BTS. “In other words, only 60 percent of what could have been bought … when BIL was signed can be bought over the five years from 2022 through 2026.”

The agency noted that situation represents a whopping 40 percent reduction.

The Modest Inflation Scenario assumes a more modest growth in construction costs equal to the average annual growth in 2019 and 2021.

“Under this more modest growth scenario, $260.5 billion can be bought with the $379.3 billion allocated … due to increased highway construction costs.”

This amount is 16 percent more than what could be bought if highway construction costs continue to rise at their current higher rate, said BTS.

But it’s still only 69 percent of what could have been bought when BIL was signed.

“In other words, a 31 percent reduction in what could have been constructed in 2021 when highway construction cost less.”

Materials prices are to blame for a lot of the headaches the construction industry faces with BIL projects. The bureau tracked increases in crude oil used to produce asphalt, which it said contributed to the situation. In fact, BTS reports U.S. crude oil increased 594 percent, from $16.55 per barrel in April 2020 to $114.84 per barrel in June 2022.

That’s the second highest price on record and makes asphalt a top contributor to increases in the National Highway Construction Cost Index (NHCCI). These numbers are from the last quarter of 2021 through the third quarter of 2022.

“Crude oil prices have fallen since the June 2022 high but have risen steadily since the beginning of 2024,” said BTS.

The bureau said that situation suggests construction costs may rise further in the future.

Supply-chain issues, which began in 2020 with COVID, are also contributing to the hike in the cost of highway construction.

The pandemic caused both temporary and permanent business closures. It also increased demand for durable goods.

“This, in turn, caused material prices to rise,” said the bureau. An increase in the producer price index (PPI) for all goods and services shows just how.

The PPI grew by 51 percent from April 2020, the lowest point since May 2016, to a new all-time high in June 2022, said BTS.

The NHCCI actually fell a half a percentage point from October to December of 2023, according to FHWA’s quarterly index.

Jeff Davis of thinktank Eno said that using the new NHCCI seasonal adjustment, the final quarter 2023 was still 4 percent above the previous period.

FHWA economists said, “there is a historically negative seasonal effect during Q4 and Q1 that may be contributing to the slight deflation.”

It’s visible on FHWA’s line chart of the NHCCI going back to its inception in 2003, said Eno.

The original index divots downwards in the fourth quarter of many years, as cold weather curbs construction activity and demand for materials.

“However, when you add it all together, year upon year, there is no real cumulative difference in the old rate vs the seasonally adjusted rate,” said Davis.

In both instances, the cumulative increase in highway construction costs since the October-December 2020 quarter is 68 percent.

“Converting this to actual dollars lost … the FHWA has signed $182.4 billion in contracts and other spending obligations since January 1, 2021,” added Davis.

Once the nominal dollars convert to “real” at the OctoberDecember 2020 quarterly NHCCI, that $182.4 billion drops down to $132.9 billion.

That means “that $49.4 billion has been lost to highway cost inflation since January 2021,” Davis said.

But, he added, even the nominal numbers reveal something interesting about FHWA and state DOTs.

The two signed a smaller dollar amount of contracts in the last two quarters of 2023 than in the last four quarters of 2022.

“This may be linked to the ongoing August Redistribution crisis,” said Davis.

He believes some states may be running out of ready-togo highway projects that can be put out to bid and started quickly.

Federal mandates pushing contractors to hire union labor is “the worst way to do infrastructure projects,” said Ben

Manitou has launched a new Woodcracker tree saw with grapple configuration for its rotating telehandler product line that will significantly improve performance and productivity in tree and limb removal operations — particularly in urban areas and roadside land management applications.

The Woodcracker tree saw with grapple is compatible with three Manitou rotating telehandlers — the MRT 2260, MRT 2660 and MRT 3060 Vision+. When matched with the MRT 3060 Vision+, operators can reach heights of more than 98 ft. and outreach to more than 84 ft. The maximum lifting capacity for the MRT with the tree saw attachment is 8,000 lbs.

Built from extremely highstrength steel and capable of cutting tree branches and trunks up to 29 in. in diameter, the new Manitou tree saw rotates into position to cut, hold and deliver each limb. It also can be matched with the Manitou rotating telehandler remote control to give the operator flexibility in how/where they perform the work.

“The off-road capabilities, 360degree rotation and the excellent reach of these rotating telehandlers makes this an extremely versatile solution for municipalities, public works departments and tree removal contractors regularly faced with challenging tree and limb removal jobs,” said Steve Kiskunas, telescopic handler product manager, Manitou.

“It delivers the ability to remove and place large and heavy tree limbs while maintaining excellent control of the load. This simplifies the work, helps keep the operator and other workers out of the fall zone, and gives the operator the ability to perform the work from the most advantageous vantage point when equipped with the remote control.”

Each Manitou MRT rotating telehandler equipped with the tree saw will include a

specialized forestry package with a windshield guard, boom covers and guards, hydraulic and electrical system covers and a second return-to-tank line. Manitou offers the attachment solution for new machine orders and for existing Manitou MRT Vision+ models: MRT 2260, MRT 2660 and MRT 3060.

While each Manitou rotating telehandler matched with the new tree saw with grapple is highly specialized, each machine retains compatibility with the full line of rotating telehandler attachments to deliver a highly versatile platform for businesses or public works departments.

“This new tree saw with grapple configuration delivers excellent heavy-duty performance for a specialized application while

still delivering a broad range of capabilities as a three-in-one machine — telescopic handler, jib and aerial work platform,” said Kiskunas. “This type of versatility can really be an asset in smart fleet building and management.”

The purposely matched solution of a rotating telehandler with a forestry package and a premium tree saw/grapple has an opportunity to evolve how tree removal, vegetation management, public works and other contractors approach safe limb and tree handling. It’s a solution that the Manitou dealer network has been hungry for, the manufacturer said.

“Our customers are impressed with Manitou’s MRT 3060 for its performance versatility, precision, and unparalleled com-

fort,” said Ben Siemen, vice president of sales for Shawmut Equipment. “This innovative piece of equipment is now designed to meet the demands of this harsh application — from the hydraulic hose and electrical component guarding at the boom tip, to the innovative remote control with designated controls for the grapple saw. The Manitou MRT line-up with the factory Installed Forestry Package offers our customers a complete package in one price, all backed by the service and support of the Manitou dealer network.”

The new Manitou tree saw for rotating telehandlers is available to order now in the North American market.

For more information, visit Manitou.com.

Werk-Brau introduced the FX26 forestry mulcher, a rugged, durable, well-balanced forestry mulcher for excavators from 8,000 to 16,000 lbs.

This stout mulcher has a direct coupled motor which provides more power with less maintenance than comparable models that use belts or pulleys. A heavy wall 14-in. rotor is fitted with 21 fixed knives to shred brush, limbs, and standing trees to 6-in. in diameter.

The bite-limiting tooth design maintains drum speed and prevents stalling and material is passed through two breaker bars to create fine mulch without sacrificing performance.

The FX26 weighs just 785 lbs. and requires just 15-35 gpm of hydraulic flow to power the gear motor but features a 26-in. working width for unmatched production. With just two grease points and no additional drive components, this simple design is easy to maintain, according to the manufacturer.

The lightweight yet durable construction, coupled with lower hydraulic flow requirements allow the FX26 to be paired with more excavator models down to 8,000 lbs. It is an ideal entry-level tool for contractors expanding into brush clearing, land management, defensible urban fire defense clearing, right of way clearing and more.

A universal bolt-on mount is included with each mulcher so installation is fast and simple (Tag or WainRoy mounts excluded but available at additional cost). Each FX26 includes 100 in. of hydraulic lines and ¾ in. flat faced couplers; case drain is not required.

Werk-Brau recently partnered with Valley Tool Manufacturing to provide Werk-Brau branded BrushHound mulchers, brush shredders and flail mowers, and RockHound landscape rakes through Werk-Brau’s nationwide dealer network. Each FX26 mulcher is manufactured by Valley Tool but serviced through the Werk-Brau network, providing single-source convenience for customers.

For more information, visit www.Werk-Brau.com and www.ValleyToolMfg.com. (Photo courtesy of Werk-Brau.)

AI - 196 Magnesium steel, outlast competitive blades 4 to 1.

Shown with guide rail.

Blue Diamond Attachments has announced the launch of a new line of standard- and medium-duty 3-point rotary cutters.

The new tractor attachment offering extends the company’s full-line of cutters and allows for the effortless cutting of overgrown grass, stalks and light brush up to 1in. thick.

Key features of the new line of Blue Diamond Attachments cutters include:

• 12-gauge steel for the 4-6-ft. standardduty models and 10-gauge steel deck construction on the 7-ft. medium-duty model; the new rotary cutters also have heavy-duty steel bracing for extra strength.

• A balanced stump-jumper blade pan that protects cutter blades from rocks, stumps and roots.

• The heavy duty heat-treated free-swinging blades with suction lift are ½ in. thick by 3-in. wide on the standard-duty and ½ in. thick by 4-in. wide on the medium-duty.

• A tapered round back design allows tighter turns for maneuvering around trees, or in tight spaces.

• On the 4-6-ft. standard-duty models, a

The new tractor attachment offering extends the company’s full-line of cutters and allows for the effortless cutting of overgrown grass, stalks and light brush up to 1-in. thick.

shear bolt through the input shaft protects the gearbox and driveline from damage.

• Rear wheel adjustment to set the height of the cutter, from 1.5 to 11 in.

• 15-in. laminated wheel design for all types of tough terrain.

• A 3-point quick hitch-compatible hitch for attaching the rear-mounted rotary cutter to a compact tractor.

For more information, visit www.bluediamondattachments.com.

More than 200 of Felling’s team members gathered to enjoy an afternoon filled with games, food and prizes, along with the opportunity to visit with fellow team members, policymakers and AEM team members.

Felling Trailers took the opportunity to celebrate its 50th anniversary and team member appreciation with the AEM Manufacturing Express, gathering employees to celebrate the company’s history and continued development.

“2024 is a milestone year for Felling Trailers. Fifty years ago, on November 1st, 1974, my parents, Merle and Kathy Felling, purchased a small welding shop on Pine St. in downtown Sauk Centre, Sauk Centre Welding. Fast forward a few years, and Merle’s trailer designs and quality craftsmanship quickly got noticed. Trailer orders increased, and risk and growth took place. In the mid-late 1980s, the business moved to its current location and became doing business as Felling Trailers Inc.,” said Brenda Jennissen, president/CEO and co-owner of Felling Trailers Inc.

“The

“When we purchased the company from Merle and Kathy nearly a dozen years ago, we knew we had an enormous responsibility to follow in their footsteps, continuing to be good community stewards to our team members, customers, and the communities we call home. This tour serves as a uniquely valuable opportunity to reflect on the people who have made that happen and where we want to take things over the next half-century,” said Jennissen.

More than 200 of Felling’s team members gathered together by the company’s new powder coat facility to enjoy an afternoon filled with games, food and prizes, along with the opportunity to visit with fellow team members, policymakers and AEM team members. The games provided by AEM are part of their Manufacturing

‘Manufacturing Express’ celebrates our team members and community while highlighting our contribution to American manufacturing and the U.S. economy,” said Patrick Jennissen, vice president of sales and marketing. see AEM page 38

11301 Reames Road Charlotte, NC 28269

980-859-4680

125 Wilsons Mills Rd. Extension Smithfield (Raleigh), NC 27577 919-938-8145

141 Brickyard Rd. Lexington (Columbia), SC 29072 803-520-0032

6325 Central Avenue Pike Knoxville, TN 37912 865-766-2571

Ford Motor Company announced plans to assemble F- Series Super Duty pickups at its Oakville Assembly Complex in Ontario, Canada, starting in 2026, boosting production of one of the company’s most popular and profitable vehicles.

The move to add production of up to 100,000 units of its best-selling Super Duty to Oakville expands Super Duty production across three plants in North America, including Kentucky Truck Plant and Ohio Assembly Plant, which are operating at full capacity. It also paves the way to bring multi-energy technology to the next generation of Super Duty trucks, giving customers more freedom of choice and supporting Ford’s electrification plans.

“Super Duty is a vital tool for businesses and people around the world and, even with our Kentucky Truck Plant and Ohio Assembly Plant running flat out, we can’t meet the demand. This move benefits our customers and supercharges our Ford Pro commercial business,” said Jim Farley, Ford president and CEO.

“At the same time, we look forward to introducing three-row electric utility vehicles, leveraging our experience in three-row utility vehicles and our learnings as America’s No. 2 electric vehicle brand to

deliver fantastic, profitable vehicles.”

In total, Ford plans to invest approximately $3 billion to expand Super Duty production, including $2.3 billion to install assembly and integrated stamping operations at Oakville Assembly Complex. When complete, Oakville Assembly Complex will be a fully flexible plant.

Boosting Super Duty assembly will initially secure approximately 1,800 Canadian jobs at Oakville Assembly Complex, 400 more than would initially have been needed to produce the three-row electric vehicle. Unifor-represented employees at Oakville Assembly Complex will return to work in 2026, a full year earlier than previously planned. The increased production also adds approximately 150 jobs at Windsor Engine Complex, which will manufacture more V8 engines for Super Duty.

print, and our investments will have a fast payback.”

Ford plans to hire new employees and add overtime at U.S. component plants that support Super Duty production.

• Sharonville Transmission Plant in Ohio

— $24 million investment and additional overtime

approximately 20,000 American workers.

Ford is a leader in producing and selling trucks in America, with two F-150 plants in Michigan and Missouri, two Super Duty plants in Kentucky and Ohio, and a Ranger plant in Michigan. Ford truck production directly and indirectly supports more than 500,000 jobs in America.

In the first half of 2024, Kentucky Truck Plant and Ohio Assembly Plant produced more than 200,000 Super Duty trucks. Order banks remain healthy since the launch of the new 2024 model year Super Duty, and demand from Ford Pro customers is higher than what Ford can produce now.

“This investment will benefit Ford, our employees in Canada and the U.S., and especially our customers who want and need Super Duty for their lives and livelihoods,” said Kumar Galhotra, Ford’s chief operating officer. “It is fully consistent with our Ford+ plan for profitable growth, as we take steps to maximize our global manufacturing foot-

• Rawsonville Components Plant in Michigan — $1 million investment and roughly 20 new jobs

• Sterling Axle Plant in Michigan — approximately 50 new jobs

Across powertrain, transmission, stamping and final assembly operations, 10 U.S. plants in five states support Super Duty production. Those plants directly employ

“There is durable demand for Super Duty from Ford Pro customers as spending on infrastructure and related construction activity remains high,” said Ford Pro CEO Ted Cannis.

“Many retail customers have not been able to get their trucks fast enough because of our production constraints. Unlocking Super Duty volume will also support businesses and tradespeople who rely on these trucks and first responders who serve their communities.”

Challenge; the online video games invite participants to tackle industry-themed questions for a chance to win prizes. Team members lined up to participate in the various games and show their support for the I Make America campaign.

“The ‘Manufacturing Express’ celebrates our team members and community while highlighting our contribution to American manufacturing and the U.S. economy,” said Patrick Jennissen, vice president of sales and marketing.

The “AEM Manufacturing Express” made its 10th stop on its national tour at Felling Trailers Inc. The tour covers more than 20 states with 80 stops at equipment manufacturers to showcase the cutting-edge technology and innovations that power modern equipment and the innovative technologies, processes, people and products revolutionizing this industry across America.

“The Manufacturing Express is more than a bus tour. This event allows us to tell your story and celebrate the amazing products you make right here in Sauk Centre, Minn. Behind every piece of equipment, there is a story, and we are excited to tell those stories of the 2.3 million women and men in our industry,” said Kelly Lang, senior director of sales and engagement with AEM.

For more information, visit www.felling.com and manufacturingexpress.org.

(All photos courtesy of Felling Trailers.)

www.equipmentshare.com

10179 US-78 Ladson, SC 29456 843-709-2458

145 Thunderbird Dr. Richmond Hill, GA 31324 912-400-0752

2919 E. Napolean St. Sulphur, LA 70663 337-284-9804

120 Mann Drive Piperton, TN 38017 (Memphis) 800-238-5591

2115 N. Thompson Lane Murfreesboro, TN 37129 877-200-5654

5200 Hollywood Ave. Shreveport, LA 71109 800-548-3458

364 Bob Jobe Rd. Gray, TN 37615 855-201-7453

10110 Roberts Way Covington, GA 30014 770-788-0888

7651 Theodore Dawes Rd. Theodore, AL 36582 251-653-5955

825 31st Street North Birmingham, AL 35203 205-323-6108

Ashland, VA 866-955-6071 Chesapeake, VA 800-342-3248 Frederick, MD 833-546-5235 PARMAN TRACTOR &

3570 Dickerson Pike Nashville, TN 37207 615-865-7800

1485 Bear Creek Pike Columbia, TN 38401 615-865-7800

MID SOUTH MACHINERY, INC. www.gomidsouth.com

3233 Highway 80 West Jackson, MS 39204 601-948-6740

3145 Cliff Gookin Blvd. Tupelo, MS 38801 662-690-6553

7422 Hwy 49 N Hattiesburg, MS 39402 601-268-2222

www.gsequipment.net

Tampa, FL 866-586-8956 Pompano Beach, FL 954-327-8808 Ft. Myers, FL 239-334-6063 Tallahassee, FL 850-574-0892 Orlando, FL 407-859-9160 Jacksonville, FL 904-268-4400

By Eric Olson CEG CONTRIBUTING EDITOR

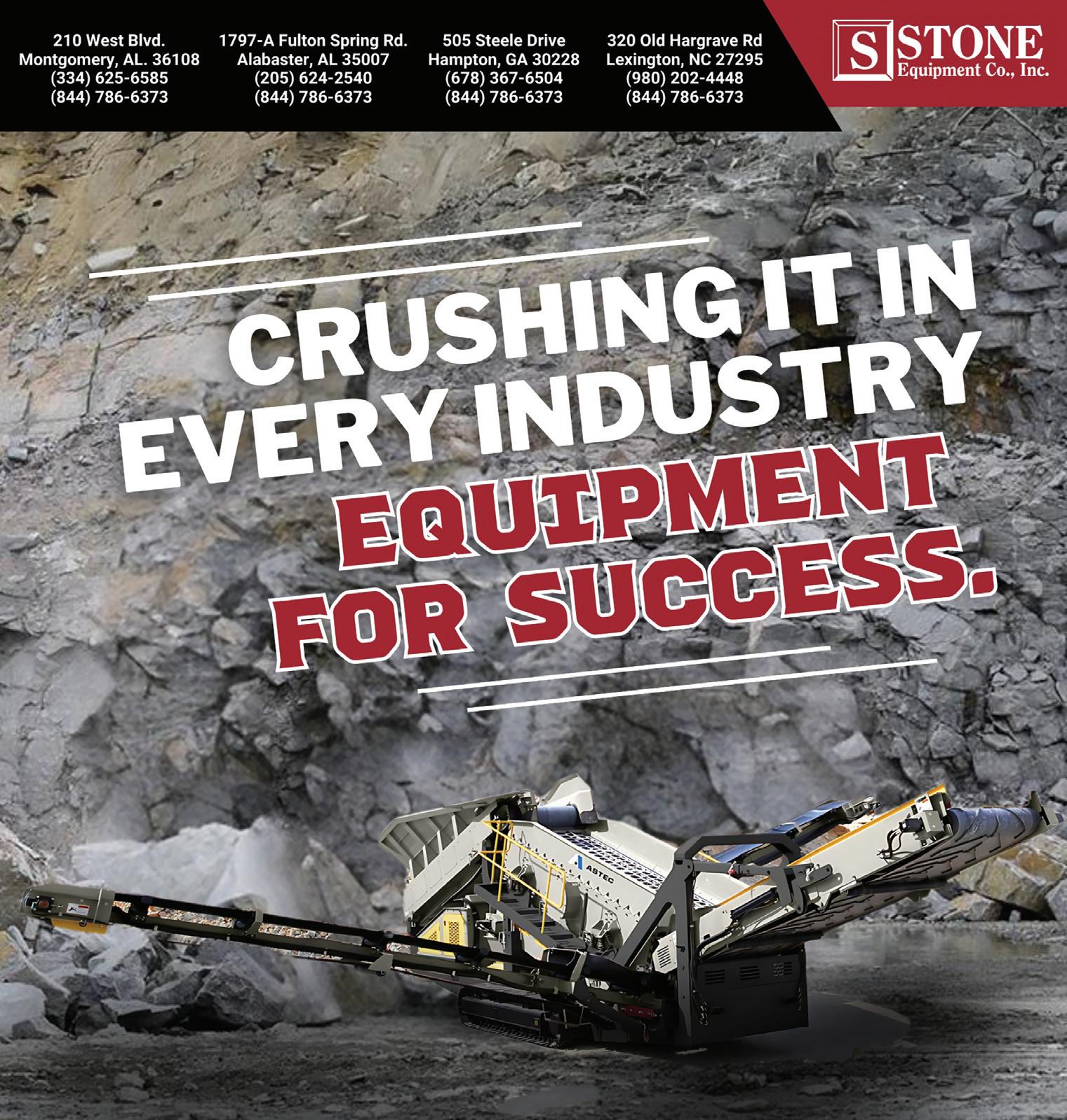

Sand Science Inc., a Beaufort, S.C., supplier of screening, conveying, crushing and recycling equipment, is currently undergoing a major effort to expand the availability of the Roto-Screen portable trommel screening plant in the United States through the formation of Roto-Screen USA and the development of a full-service dealer network.

As a long-time distributor of the product line, Sand Science has become the primary dealership of Roto-Screens in this country.

Located just off the busy Interstate 95 corridor in South Carolina’s Low Country, approximately 30 mi. north of Savannah, Ga., Sand Science has significantly grown from a local and regional distributor of material handling equipment when it was first established in 1985 to a nationwide one.

That fact alone made Sand Science an obvious choice for Roto-Screen Canada in selecting the South Carolina distributor to represent its products in the United States. Another point in Sand Science’s favor is that for three decades it has been an outstanding partner to Roto-Screen in the sales, rental and service of its trommel screens.

Now, Sand Science is the largest Roto-Screen dealer in America, said Eoin Kenny, vice president of marketing and sales for the distributor.

He, along with his brother, Adam, Sand Science’s vice president of operations, work alongside their father, Gerry, the company’s owner and founder.

Roto-Screen Canada began to express more of an interest in expanding its nationwide product availability following the end of the pandemic, according to Eoin Kenny.

“We were asked by the factory in Canada to take over its American distribution,” he said. “So, over the past eight months, we

have begun the process of building a master distributorship with dealers across the U.S. to fully focus on rentals and sales of the Roto-Screen in different regions of the country.”

As a result, Roto-Screen USA was formed and has helped to bring on three new distributors for the Roto-Screen 454 trommel screener in that time, Kenny said.

“We have JGB Recycled Aggregate Materials, in Marshfield, Mass., which will

Roto-Screen USA recently delivered a R-545 trommel to JGB Aggregates in Marshfield, Mass. (L-R) are Adam Kenny and Eoin Kenny, both of Roto-Screen USA; and Andrew Backman and Mike Gallant, both of JGB Aggregates.

be focusing on the Northeast for us. It already serves Massachusetts and Rhode Island, but now includes Maine and New Hampshire, as well,” he said, “and MHK Equipment Services, based in Michigan, will be concentrating on the Midwest. Additionally, we just signed up another distributor, RTL Equipment Inc., that will cover Minnesota, Iowa and North and South Dakota. And more dealership opportunities are available.”

Sand Science will serve as the dealer for the Southeastern states, Kenny said, and Roto-Screen USA will continue to expand and serve all remaining territories directly. The agreements represent the first steps in a controlled, long-term plan to create a nationwide dealer network for the RotoScreen product.

In the months and years ahead, Roto-

Screen USA also wants to see its products offered through more dealerships in the Deep South, Texas, the Rockies and the Northwest states.

“If we are going to do that, we must also see to it that each dealership can offer the parts and service capabilities to support the Roto-Screen,” Kenny said. “We want our customers to get the best, most timely help possible, no matter where they are.”

Earlier this year, Roto-Screen USA delivered two machines to the JGB facility, south of Boston, where the aggregate recycling outfit intends to rent and aggressively expand its business, he said.

“JGB Aggregates had an open house day there in April where their customers came in and looked over the machines. We were able to explain everything about the RotoScreens and do some training. JGB was really excited to get the machines out there, and

By Eric Olson CEG CONTRIBUTING EDITOR

A line of small- to mid-size mobile crushers, screening plants and shredders distributed by N.J.-based Komplet America has recently been added to the inventory of R.R. Equipment Co. LLC, a South Carolina manufacturer and dealer of machines for the aggregates and processing industries.

Robert Rossi Jr., managing member of R.R. Equipment, located south of Charlotte, N.C., in Lancaster, S.C., said that bringing on the Komplet products in June was done to better serve the company’s clients and offer a full lineup of crushers, screening plants, and shredders — from the very smallest units to mid-size machines — that would allow them to process all types of material.

Rossi’s idea for having Komplet products in his dealership also included being able to give its customers an introductory-level crushing machine to help them eventually grow to where they could acquire larger processing equipment, such as his own company’s Rebel Crusher, a mid-size rock recycling, crushing and screening system that he considers to be the “Swiss Army knife” of the industry.

“We want to make sure that clients have enough material to match their machine investment,” he said. “So, if they don’t have enough material to justify our Rebel Crusher, let’s say, because it is a mid-size unit, we can offer them smaller options for crushing and recycling and help them stay profitable.

“They may then keep that crusher for two, three or four years and eventually upgrade. If they do not, at least they are still experiencing recycling and crushing with an affordable, well-made piece of equipment.”

Rossi added that his dealership’s smallest

machine before taking on the Komplet line was the mid-size Rebel Crusher. Komplet’s four smaller crusher models, therefore, fill a niche for R.R. Equipment and give its customers more variety and choice.

Komplet’s K-JC 503 mobile jaw crusher, the maker’s smallest unit, is a machine that features a magnet and a 19-in.-wide feed opening, he said.

“It typically takes 10- to 12-inch chunks of material,” according to Rossi. “I can make base out of it and remove the wire in the rebar at the same time. The 503’s capacity is also rated up to 30 tons per hour. It is fully adjustable to cut material down to as small as ½-inch minus with the optional special jawdie combination. Otherwise, 1.5-inch minus is easily achievable.”

Furthermore, the K-JC 503, he said, “is made for the average contractor to get started, and then that client can grow with us as his business grows.”

see KOMPLET page 50

IMPRESSIVE FROM A TO Z. Thanks to its robust design and extensive range of screen linings, the MSS 802 EVO can easily adapt to changing locations and new operating conditions – making it ideal for a wide variety of applications. The coarse screening plant features an intuitive system control that reduces the risk of operating error. And all relevant functions can be operated from a safe distance for increased work safety. The MOBISCREEN MSS 802 EVO –the heavy-duty, versatile solution in natural stone and recycling. www.wirtgen-group.com/kleemann

dobbsequipment.com

Riverview, FL

813-620-1000 – Main office 813-621-4902 - Parts Miami, FL 305-592-5740

West Palm Beach, FL 561-848-6618 Orlando, FL 407-299-1212

Fort Myers, FL 239-334-3627

Lutz, FL 813-995-0841

Daytona, FL 407-299-1212

Pompano Beach, FL 954-977-9541 (Parts) Sarasota, FL 941-960-2004 (Parts) Melbourne, FL 321-234-3344

Andrews, SC 843-983-7337

Aynor, SC 843-358-5688

Ladson, SC 843-572-0400

Simpsonville, SC 864-963-5835 Walterboro, SC 843-539-1420 West Columbia, SC 803-794-9340 www.tec1943.com Birmingham, AL 205-591-2131 Alabaster, AL 205-621-2489 Anniston, AL 256-831-2440 Decatur, AL 256-355-0305

Tuscaloosa, AL 205-752-0621

Panama City, FL 850-763-4654

Dothan, AL 334-678-1832 Huntsville, AL 256-851-2222 Mobile, AL 251-457-8991 Montgomery, AL 334-288-6580

Pensacola, FL 850-505-0550 Atlanta,

Other Komplet small mid-size crushers now available at R.R. Equipment are the model K-JC 604, 704 and 805 mobile units as well as the KIC 70 impact crusher.

In addition to those products, Komplet also provides wood processing equipment, Rossi said.

“We have a shredder and screening plants as well,” he said on July 18. “It has only been about 30 days since we signed the agreement with Komplet, and now we have eight pieces on the ground. Everything is diesel, track-mounted and radio remote-controlled.

“We are also able to supply this equipment to people who are not just handling hard material, like concrete and asphalt, but also demolition debris like sheetrock and two-by-fours. The Komplet Krokodile shredder, for instance, will process old tires and grind up tree stumps — things that are soft and that we typically would not throw into a rock crusher. The screening plants we have on hand also screen topsoil, wood and mulch.”

Invented and patented by R.R. Equipment, Rebel Crusher has long been the company’s bestknown product. It features a 3-ft.-wide opening that is designed to take 2- to 3-ft. chunks of concrete with rebar, asphalt and a variety of other hard materials.

“It also has a pre-screening system for remov-

ing dirt or any natural fines as well as a self-cleaning magnet and a two-deck screening system to screen the crushed products into two or three different sizes, from which you can make whatever number of other sizes you would like,” he added.

Eventually, Rossi hopes that today’s Komplet product users will become tomorrow’s Rebel Crusher owners, or any of R.R. Equipment’s other crushing and screening machines, including its CrushKing and ScreenKing plants and the Crush-All, the industry’s first impact and jaw bucket crusher attachment.

“We would hope that a client could grow into an American-made Rebel Crusher. In the interim, though, we are just keeping them all in the family by having these other machines available,” he said.

Rossi feels that R.R. Equipment has an edge in the marketplace in that it not only engineers and makes many of its own products, but also stocks and distributes them — including the new Komplet line — and services every machine in its yard.

“Another advantage is our centralized location,” he said, where the dealership maintains its headquarters and primary production facility. “By operating in the greater Charlotte area, we are smack down in the middle of the two Carolinas.”

Kuhn Equipment &

MPP Aftermarket announced the appointment of Matt Sloniker as MPP Aftermarket sales director. In his role Sloniker will work closely with the MPP Aftermarket business unit team to grow the spares and wear business, particularly within the North American dealer network.

Sloniker joins MPP Aftermarket, a business unit of MPP Global, with more than 20-years experience in customer service and parts in the materials processing industry. Most recently, Sloniker was the director of Classic Crusher Spares SVS for Metso. Through this role, he has developed a wealth of product support and customer service knowledge.

“On behalf of the entire sales and marketing team at MPP, we are delighted to extend our warm welcome to Matt,” said Anthony Bouvie, VP Sales & Marketing — MPP Global. “Matt is bringing an extensive experience in leadership within the Crushing and Screening Aftermarket solution with a very strong knowledge and expertise that will enrich our team dynamics and by improving together with our partners, our end-customer product experience and success.”

In his role, Sloniker is responsible for the aftermarket spare and wear parts sales program for all MPP Global business units, including McCloskey International, Lippmann, Tesab, McCloskey Environmental and MWS Equipment.

“I’m excited to see where I can make a difference within MPP and help our dealer network grow,” said Sloniker. “I hope that my experience in this industry can make a positive impact in supporting our great dealer network.”

Sloniker will be based out of Brookfield, Wis., and can be reach at 414/412-0794 or msloniker@mpp-global.com.

330 Lee Industrial Blvd Austell GA 30168 678-718-6500

1604 South Slappey Blvd Albany, GA 229-435-6262

4165 Mike Padgett Hwy Augusta, GA 706-790-1300

370 Perry Lane Rd Brunswick, GA 912-265-5010

130 Robinson Rd NW Calhoun, GA (706) 629-0776

2946 Smith Rd Columbus, GA 706-653-0043

335-A Hurricane Trail Dacula, GA 770-963-6868

2697 McCollum Pkwy NW Kennesaw, GA 678-915-1177 5905 Hubbard Town Rd. Cumming, GA 30028 470-560-6750 1025 Frank Amerson Pkwy Macon, GA 478-788-1773

187 Interstate South Dr McDonough, GA 770-288-4000 1465 US 80 East Pooler, GA 912-964-7150

8555 Hwy 301 Statesboro, GA 912-871-6506

2966 US 84 Valdosta, GA 229-242-8610

228 Andrew Dr Washington, GA 706-678-3211

1899 Knight Ave Waycross, GA 912-283-9321

8255 NW 58th St Miami, FL 305-592-5360

801 E Sugarland Hwy Clewiston, FL 863-983-8177

2801 Reese Rd Davie, FL 954-581-8181

9651 Kelly Tractor Dr Ft. Myers, FL 239-693-9233

5460 Okeechobee Blvd West Palm Beach, FL 561-683-1231

6301 Old Rutledge Pike Knoxville, TN 37924 865-546-1414

10644 Lexington Dr Knoxville, TN 37932 865-218-8800

1825 Veterans Blvd Sevierville, TN 37862 865-595-3750

9960 Airport Pkwy Kingsport, TN 37663 423-323-0400

4066 South Access Rd Chattanooga, TN 37406 423-698-6943

215 Interchange Dr Crossville, TN 38571 931-456-6543

1245 Bridgestone Blvd. LaVergne, TN 37086 615-256-2424 3565 New Tullahoma Hwy. Manchester, TN 37355 931-461-5000

Corporate Ave. Memphis, TN 38132 901-332-3051 3199 S Frontage Rd. Columbus, MS 39701 901-401-7011

MDS, a manufacturer of specialist screening equipment, announced the launch of its new M518R compact recycling trommel.

With a suite of new features and benefits designed to elevate performance and efficiency, the M518R excels in screening a variety of materials, including compost, green waste, biomass, municipal waste and more, according to the manufacturer.

The M518R is well-suited for small to medium-sized operations and contractors, particularly those with limited space and a need for easy transportation. Featuring a 180-degree radial fines conveyor, the machine offers efficient material handling, providing a radial stockpile capacity of up to 22,954 cu. ft.

Its compact dimensions and efficient folding mechanism of the radial conveyor ensure straightforward transportation, fitting neatly onto a standard 26-ft.-long trailer. Additionally, notable improvements in service access compared to the previous generation set a high standard for accessibility and maintenance ease. Overall, these features solidify the M518R as a highly efficient option within its class.

The new M518R provides a versatile screening solution that can adapt to diverse operational requirements.

One of the many standout features of the M518R is its remote-controlled conveyor swivel, enabling operators to adjust positioning effortlessly during operation. This functionality minimizes downtime and

enhances productivity, reflecting a commitment to providing solutions that emphasize operational efficiency and user convenience.

“At MDS, we are continuously striving to innovate and produce machines that give our customers the edge they need to be successful in their own operations,” said

Steven Keenan, engineering manager at MDS. “Our new M518R machine is a good example of this and provides a versatile screening solution that can adapt to diverse operational requirements while bringing efficiency and value to recycling operations worldwide.”

For more information, visit terex.com.

the interest in the product is very strong in that area.”