By Cindy Riley CEG CORRESPONDENT

The barrage of orange cones and heavy equipment is a familiar site for motorists who travel the Raleigh Beltline in Wake County, N.C. For almost half a decade, construction crews have been working on the $475 million effort known as the Blue Ridge I-440 Improvement project, taking place on the interstate between just south of Walnut Street in Cary and north of Wade Avenue.

“The I-440 Beltline is a critical link in the Triangle region roadway network,” said Cody Winkler, resident engineer of the North Carolina Department of Transportation (NCDOT). “Increasing capacity and making associated improvements at interchanges along this stretch will reduce congestion and resolve the bottleneck issue that exists on either end of the project, improving mobility and safety for drivers in the region.”

The redesigned Blue Ridge Road portion of the project will improve traffic flow at the busy junction Lane

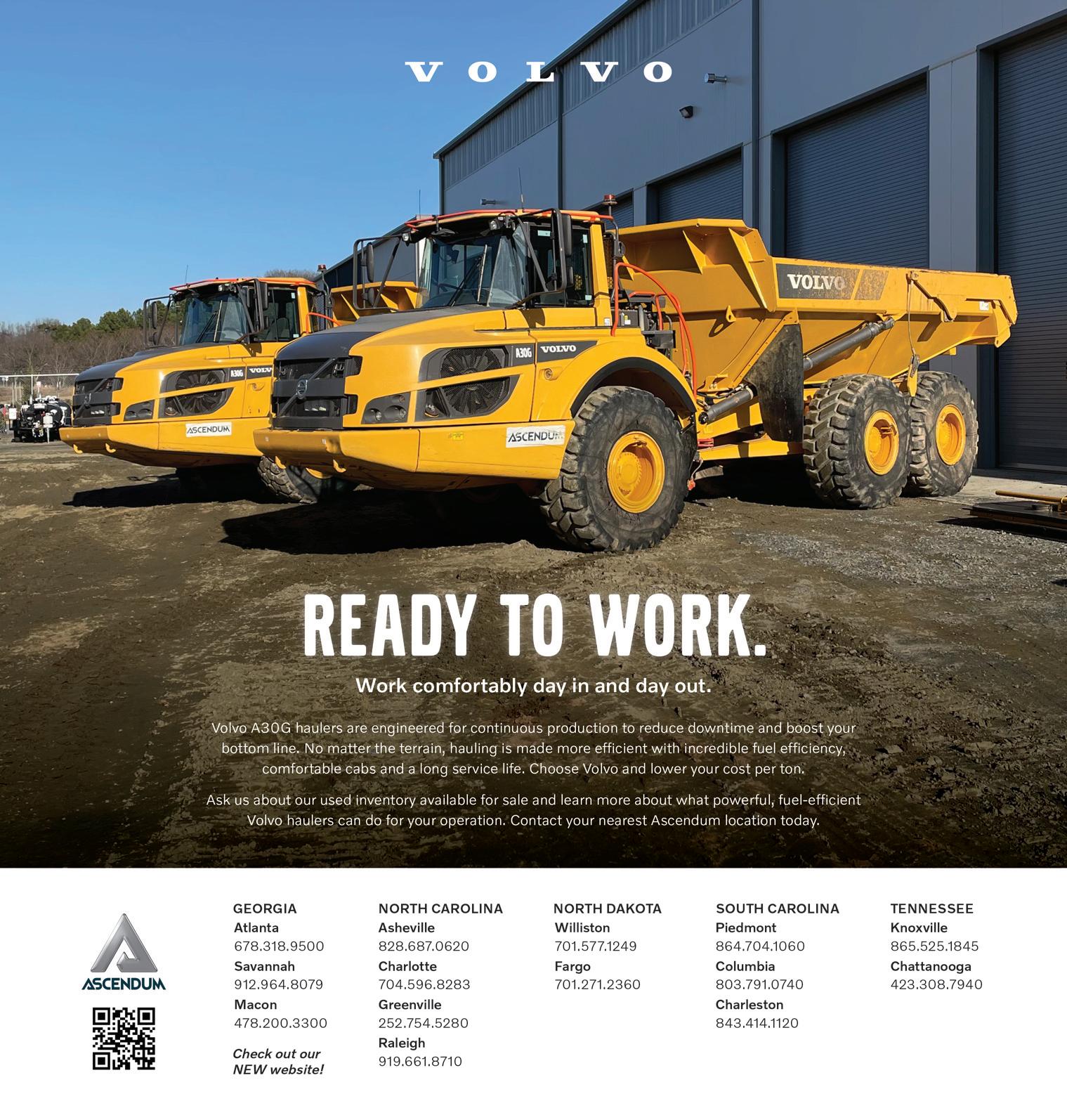

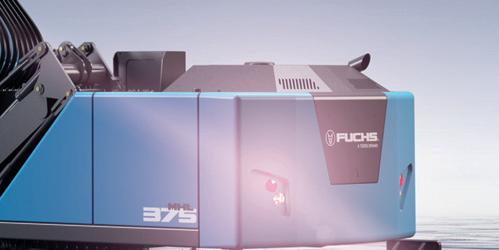

Heavy machinery being used includes excavators, bulldozers, hauling trucks, paving equipment, drill rigs, cranes, pump trucks and other construction equipment.

By Lucy Perry CEG CORRESPONDENT

The construction industry is no stranger to hard work. So, when it comes to workforce shortages, instead of throwing up their hands contractors are rolling up their sleeves. Companies have gotten clever in their strategies to overcome workforce issues. Not wasting time pointing fingers at the federal government’s preference for higher education over craft training, the industry instead is opting to develop a culture that invests in workers for the long haul.

In its annual workforce survey, the AGC finds its members are carving away at the “significant” impact of federal workforce policies.

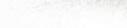

WE’RE IN THE BUSINESS OF KEEPING YOU IN BUSINESS.

DISCOVER THE ASV GENUINE PARTS & SERVICE ADVANTAGE.

ASV Genuine Parts are specifically engineered and guaranteed to maintain the integrity of your ASV machine. They’re designed, built, tested and re-tested to ensure equipment performance and reliability always stay at an all-time high – because less downtime for your machine means more uptime for you. Contact us now to learn more!

Construction

Louisiana’s most notorious

on Interstate 10 could

ultimately clearing a national chokepoint for improved cross-country commerce.

8

Nearly 221,800 U.S. bridges need major repair or replacement, an American Road & Transportation Builders Association (ARTBA) analysis of recently released federal government data shows.

10

In an emergency, officials in Melbourne, Fla., had to do things the hard way — and not exactly the most environmentally friendly way — to save a power pole and a stretch of Pineapple Avenue.

10 WORK NEARS COMPLETION ON CADDO LAKE HIGHWAY BRIDGE

More than a year of detours will soon be in the rearview mirror of motorists traveling over the Caddo Lake Bridge on Louisiana Highway 1 in the community of Mooringsport, northwest of Shreveport.

This past spring, officials with Vanderbilt University, located in Nashville, Tenn., proposed a $520 million graduate school campus for business and computing in West Palm Beach, Fla.

Calder Brothers Corp. in Greenville, S.C., makers of the Mauldin Paving Products line of machines, hosted a special event Aug. 27, 2024, to celebrate how much equipment manufacturing contributes to society in 2024.

16 AEM VISITS LEEBOY AS PAVER MAKER MARKS 60TH ANNIVERSARY

The Association of Equipment Manufacturers (AEM) stopped by the North Carolina production plant of LeeBoy Aug. 29, 2024, as part of the trade association’s Manufacturing Express bus tour.

20

The newly founded National Equipment League has crowned Bryan Furnace as its first champion after four hotly contested events, hosted by HD Hyundai Construction Equipment North America.

24

Takeuchi-US hosted the Association of Equipment Manufacturers (AEM) Manufacturing Express national tour at its compact track loader production facility in Moore, S.C., on Aug. 27, 2024.

For those attending award-winning Equip Exposition for the very first time, show organizers are offering tips to help first-timers make the most of this blockbuster show, to be held Oct. 15 to 18 at the Kentucky Exposition Center (KEC).

31

It was a great day for golf and networking at the second annual Werk-Brau Golf Classic to benefit Construction Angels held recently on the Scarlet Course at the Ohio State University Golf Club.

62 BOBCAT COMPANY CELEBRATES $3.26M RENOVATION AT BUFORD, GA., FACILITY

Bobcat Company recently completed a $3.26 million renovation at its Buford, Ga., location, which is home to Bobcat’s North American material handling sales, service, marketing, parts and logistics departments.

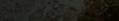

80 DEVELON WILL MAKE ITS EQUIP EXPOSITION DEBUT IN 2024

DEVELON will showcase three mini-excavators and the DTL35 compact track loader when it makes its first appearance at the Equip Exposition. The company will feature two mini-excavators and a DTL35 in its static display.

JLG Industries Inc. announced that Oshkosh has completed the acquisition

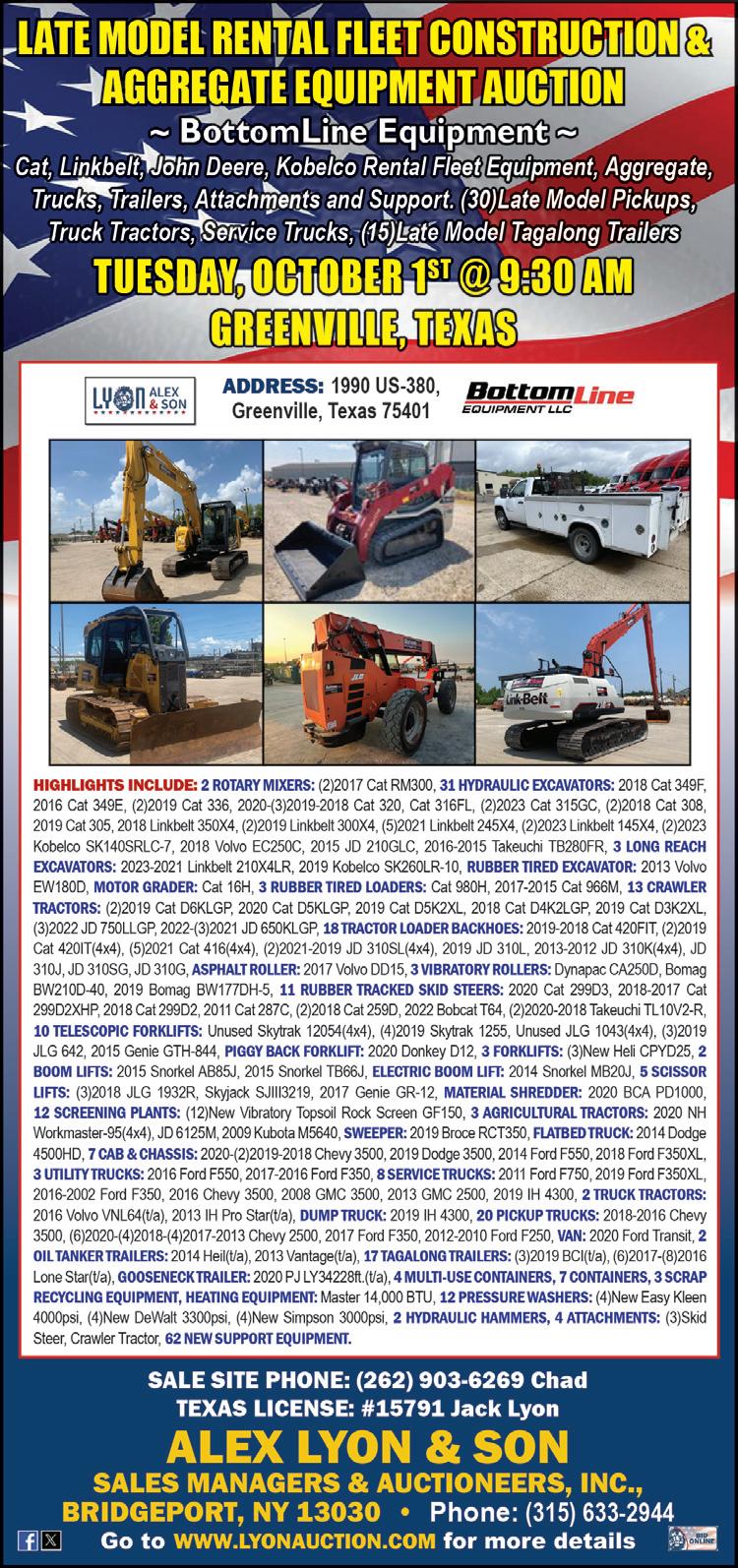

Construction to replace Louisiana’s most notorious bridge on Interstate 10 could finally begin this year, ultimately clearing a national chokepoint for improved cross-country commerce.

Republican Gov. Jeff Landry and Louisiana Department of Transportation & Development (DOTD) Secretary Joe Donahue announced a financial “notice to proceed” for the new $2.3 billion Calcasieu River Bridge in Lake Charles on Aug. 15.

“Since I took office in January, my administration has remained committed to getting this critical project off the ground,” Landry said in a statement. “Reaching the notice to proceed is proof of that dedication to the people of Louisiana, as well as our continued drive to improve and modernize Louisiana’s infrastructure.”

President Biden and former President Trump have both identified the existing 72-year-old Calcasieu River Bridge as a symbol of America’s aging infrastructure.

The span, which predates the country’s interstate highway system, is an iconic landmark with more than 5,000 decorative crossed flintlock derringer pistols on both side rails, but it often provides a white-knuckle ride for anyone driving vehicles across it. Unlike most modern bridges, the current Lake Charles span has steep approach grades and lacks shoulders and lighting.

Its notorious reputation is nationally known.

On a scale of 100, the structure is only rated 6.6 by the National Bridge Inventory, according to the Lafayette Daily Advertiser, and there were unconfirmed rumors that the U.S. Secret Service would not let President Biden cross it when he visited Lake Charles in 2021.

The old bridge was designed and built to have a 50-year capacity and carry about one-third of the 90,000-plus vehicles that cross it today.

“It impacts our supply chain for the entire country,” U.S. Transportation Secretary Pete Buttigieg told the USA Today Network in 2023 when he visited Lake Charles to announce

a $150 federal grant from the Bipartisan Infrastructure Act.

Now, DOTD has finally locked down about $1.2 billion federal and state money, with the balance to be raised in tolls after the new bridge is built. Additionally, the Louisiana State Bond Commission approved the sale of private activity bonds for the project at its July 24 meeting.

The new interstate bridge will not be as steep as its predecessor, and is designed to include additional lanes, full shoulders and roadway lighting.

“Tens of thousands of motorists cross the outdated existing bridge every day,” Donahue said in a news release. “A new bridge is long overdue, and clearing this hurdle puts our state closer than ever to seeing construction on this essential project.”

Louisiana signed the public-private partnership agreement with Calcasieu Bridge Partners (CBP) in January to build the new span and roadway, a project that will stretch 5.5 mi. from Lake Charles to Westlake. The corridor begins near Ryan Street in Lake Charles and runs west to the I-10/I-210 and I-10 interchange.

Its improvements include the new bridge and approaches, updated interstate roadways, ramps, I-10 service roads and interchanges at PPG Drive, Sampson Street and North Lakeshore/Ryan Street that connect the freeway to state roads and local streets. Sampson Street also will be elevated over railroad tracks to eliminate traffic blockages due to passing trains.

The Louisiana DOTD noted on its website that preliminary construction activities on the Calcasieu River Bridge project may begin as early as this year, with the entire effort anticipated to take approximately seven years to complete.

Once construction is finished, Calcasieu Bridge Partners will operate and maintain the new bridge for up to 50 years.

Tolls will not be charged until the new bridge is open to traffic, according to DOTD. The state will retain nearly 15 percent of toll revenues after construction, maintenance and debt service costs are paid.

The remaining fees collected from the bridge and roadway will be used to lower toll rates, shorten the toll’s halfcentury term, or fund future highway transportation infrastructure projects in Southwest Louisiana’s five-parish area.

“Secretary Donahue and I are focused on the positive economic impacts for our state and the region with the toll profit requirements that could result in lower rates or even more infrastructure improvements,” Landry added.

Nearly 221,800 U.S. bridges need major repair or replacement, an American Road & Transportation Builders Association (ARTBA) analysis of recently released federal government data shows.

Placed end-to-end, these structures span over 6,100 mi., or the equivalent of every mile of urban and rural interstate in California, Florida and Illinois.

Of the bridges needing repair, 42,067 are rated in poor condition and classified as “structurally deficient.” That is 324 fewer than in 2023.

States with the biggest decline in the number of bridges in poor condition: Pennsylvania (down 90), Louisiana (down 87), Florida (down 85), West Virginia (down 74) and California (down 64).

Bridges in poor condition represent 6.8 percent of the 2024 U.S. bridge inventory — compared to 7.3 percent in 2020.

“Over the last five years we have seen significant progress in states like Oklahoma, Pennsylvania, Mississippi,

Louisiana and West Virginia — reducing the number of bridges in poor condition,” said Alison Premo Black, ARTBA’s chief economist who conducted the analysis.

“While improvements can take time, every bridge repair increases the safety and efficiency of our network for the traveling public.”

States have received $15.9 billion in the first three years of the IIJA’s new $27.5 billion formula bridge program and, to date, have committed 46 percent ($7.3 billion) of these resources to over 4,170 bridge projects.

The remaining 54 percent ($8.5 billion) of already released bridge funds — plus the $10.6 billion that will be provided in the next two years — will support needed bridge improvements well into the future.

Twenty-three states have committed at least half of their available bridge formula funds, with the top 10 being: Georgia (100 percent), North Dakota (99 percent), Indiana (98 percent), Florida (96 percent),

Oklahoma (95 percent), Nebraska (91.5 percent), Idaho (91.5 percent), Arkansas (88 percent), West Virginia (85 percent) and Alabama (85 percent).

Bridges that have come off the “poor condition” list include:

• I-695 over U.S. 40, Maryland

• I-93 over Conley Street, Massachusetts

• I-680 over Capitol Avenue, California

• I-55 over Madison Street, Illinois

• I-95 over Route 608, Virginia Bridges newly rated in poor condition include:

• I-90 over Canal to Stewart Streets, Illinois

• Interstate 680 over Monument Boulevard, California

• I-93 over Mystic Valley Parkway, Massachusetts

• I-95 North and Southbound over Thurbers Avenue, Rhode Island

• IH-35 over Grand Avenue, Texas

Based on average cost data submitted by states to the U.S. Department of

Transportation, ARTBA estimates it would cost more than $400 billion to make all needed repairs to the 221,800 structures.

The data in the report is from the Federal Highway Administration’s National Bridge Inventory (NBI), downloaded on Aug. 20. Specific conditions on bridges may have changed because of recent work or updated inspections.

Bridges are classified in good, fair or poor condition based on their inspection ratings and definitions from U.S. DOT.

The definition of “poor” is when a key element of the bridge — the deck, superstructure, substructure or culverts, are rated in poor or worse condition. During inspection, the conditions of a variety of bridge elements are rated on a scale of 0 (failed condition) to 9 (excellent condition). A rating of 4 is considered “poor” condition. For more information, visit www.artbabridgereport.org.

More than a year of detours will soon be in the rearview mirror of motorists traveling over the Caddo Lake Bridge on Louisiana Highway 1 in the community of Mooringsport, northwest of Shreveport.

The Louisiana Department of Transportation and Development (DOTD) announced Aug. 30 that the bulk of the major construction of the modernized $17.3 million crossing project is finished. All that is left to do is install the bridge’s concrete barrier rail, signage and striping.

Approximately $18.2 million was initially allocated for the north Caddo Parish project, but DOTD Public Information Officer Erin Buchanan told the Advocate that the agency was able to save money when it realized the bridge needed to be demolished immediately rather than allowing one lane to remain open while the other was being worked on.

“We were able to expedite the project timeline [and save money] by doing that because the contractor did not have to manage any traffic control,” she said.

Construction on the new structure began in 2022 following necessary utility relocations.

Shortly after the beginning of 2024, all the concrete pile foundations were driven into place for the new La. 1/Caddo Lake Bridge project. Those types of piles act as posts or columns that are driven into the water to support the bridge.

At the same time, Jensen Construction Co., an

Iowa contractor in charge of the project, poured concrete for the bridge deck, which makes up the driving surface. Nearby, work also progressed to complete the bent caps, which sit atop the piles and help distribute pressure as vehicles travel across the bridge. Once that task was done, crews moved on to the installation of the girders that serve to support the bridge deck.

In between recent rain showers this summer, the contractor worked on building the La. 1 roadway approaches that tie into the new bridge.

DOTD is anticipating that the Caddo Lake span will be fully open to traffic in early October, with its progress dependent on weather conditions and other factors that can impact construction timelines. If the job is completed by then, by Halloween those traversing the towns of Oil City, Mooringsport, and points north and south will have another way to do so.

The original Caddo Bridge, which was built in 1940, was removed in 2022 due to its deteriorating condition, and to help to expedite the new bridge project schedule. Prior to its demolition, about 4,800 vehicles crossed the structure daily.

It is adjacent to the 1914 Caddo Lake drawbridge designed by J.A.L. Waddell, the same engineer responsible for the A Truss Bridge over Cross Bayou in downtown Shreveport. That bridge has been listed on the National Register of Historic Places since 1996.

Some might say this project “rocks,” at least in how fast it got done.

But in an emergency, officials in Melbourne, Fla., had to do things the hard way — and not exactly the most environmentally friendly way — to save a power pole and a stretch of Pineapple Avenue.

Melbourne crews recently finished a $451,265 project to stabilize 137 yds. of the roadway’s embankment slope along the Indian River Lagoon, just north of Hiawatha Street. To get the work completed, the city covered 100 percent of the work’s cost.

Florida Today noted Aug. 18 that in a June 21 memorandum to City Manager Jenni Lamb, Melbourne public works and utilities officials wrote, “The embankment has washed out to the extent that a power transmission pole foundation is in jeopardy of being undermined.”

To secure shorelines, especially after hurricanes or when erosion leads to an emergency situation, cities and communities across many areas of Florida, including Melbourne in Brevard County, often opt for large rocks, concrete seawalls and

other “gray” structures, rather than mangroves, shellfish and other “green” methods.

But it is the “living shorelines” that combine manufactured wave breaks, mangroves and other native vegetation — options that offer much less expensive and better long-term protection, and are more lagoon-friendly, according to some experts.

In the case of Melbourne, located on Central Florida’s Space Coast, south of Cape Canaveral, municipal officials told Florida Today that they had no time to wait for mangroves and other plants to grow.

With an eye on the future, though, Melbourne officials said that they have approached the Brevard Zoo about the possibility of the nature sanctuary helping to plant mangroves in front of the rocks along Pineapple Avenue sometime in the future.

The emergency shoreline restoration project was completed two weeks ahead of schedule, reported Florida Today in Viera. The erosion was not tied to any specific storm, meaning the city could not pursue reimbursement from the Federal Emergency Management Agency (FEMA) for the project’s cost.

Shenandoah General Construction, a Melbourne contractor, used 1,335 tons of different-sized rocks to stabilize 410 ft. of the Indian River Lagoon shoreline. The work restabilized the road shoulder, protected the foundations of the Florida Power & Light (FPL) transmission pole at the site, and will prevent future erosion, city officials told the newspaper. FPL officials had expressed concerns to the city about the transmission pole.

No water or sewer pipes were at risk because they had already been relocated.

To complete the project, crews backfilled dirt and installed a geotextile fabric underlayment, as well as a 6-in.-thick layer of bedding stone, a 2-ft.-thick layer of riprap rock rubble, a turf reinforcement mat, pin-fastened sod and a contingency 52 tons of asphalt pavement replacement.

The stabilization effort required an administrative budget transfer of $230,000 from Melbourne’s general projects unappropriated budget savings.

In speaking with Florida Today, city leaders added that there is another nearby 350-ft. section of Pineapple Avenue to the north of the just-completed project that may soon need the same sort of rock armor; however, the portion of the street

with the FPL poles that feed downtown Eau Gallie needed attention first.

Rock and concrete seawalls blunt horseshoe crabs and other marine life and plants that can secure shorelines, such as mangroves, which like other trees are a significant countermeasure to climate change. In Brevard County, 80 percent of mangroves have vanished since the 1950s.

Mangrove leaves drop into the water and shed nutrients that sustain the tiny crabs and other marine life that fish eat.

Recently, the tide has been turning toward bringing estuaries like the lagoon back to their roots. Sunshine State cities are beginning to remove what is left of the “old guard” rock and concrete seawalls, as those fail in hurricanes, and now are trying to mimic with mangroves and other plants what nature did for millennia.

For example, earlier this summer, Brevard County launched a $4.2 million project to guard the A. Max Brewer Memorial Parkway in nearby Titusville with huge, pyramid-shaped concrete wave breaks, baby clams, seagrass plantings and sand.

This past spring, officials with Vanderbilt University, located in Nashville, Tenn., proposed a $520 million graduate school campus for business and computing in West Palm Beach, Fla.

That was followed in August by Florida officials giving a major boost to the effort by donating a 7-acre plot of land to the university.

After Vanderbilt Chancellor Daniel Diermeier and local South Florida developer Stephen Ross presented their plans for the campus, West Palm Beach city officials voted to donate 2 acres of land for the project on Aug. 20. The very next day, Palm Beach County contributed an adjacent 5-acre parcel, according to the Vanderbilt Hustler, the university’s official student newspaper, in a Sept. 3 report.

The entire 7 acres were initially intended for a University of Florida (UF) graduate campus. Fortune Magazine reported, however, that Vanderbilt alumni in the West Palm Beach area began trying to attract the university to the South Florida city in 2023 after the UF agreement fell through.

Before construction on the campus can begin, county and city officials must conduct a detailed review of the process and bring it up for a vote. Palm Beach County Mayor Maria Sachs believes that that process will take at least a month.

A university representative said Vanderbilt is working with local leaders in West Palm Beach to determine how it can best contribute to the community.

“We are assessing the potential for expanding our business education and computing programs to West Palm Beach — an area of tremendous growth and investment in private equity, venture capital, [financial technology, or fintech], and investment banking,” the representative said in a statement to the Vanderbilt Hustler. “We have begun meeting with West Palm Beach city and Palm Beach County officials about parcels of land we are exploring as the location for this project.”

If all goes well with the construction, West Palm Beach officials noted, the Vanderbilt graduate campus could open as early as Fall 2026.

Thomas Steenburgh, dean of the Owen School of Business at Vanderbilt, expressed his optimism about the university’s early plans for a South Florida campus. In speaking with the college’s student newspaper, he explained that the new campus would not only be a site for the business school but for a new Vanderbilt graduate school of “collective computing.”

“[At Vanderbilt,] we’re interested in being a business school of the future, a university of the future,” Steenburgh said in an interview. “The big picture is that branding-wise, we would be one of the only schools in the South where we have a presence in two [of the more] rapidly growing economic markets [in the region], and that would be terrific for us.”

He also emphasized the impact of the Vanderbilt graduate school campus on the local Florida economy and environment as far as job opportunities.

Calder Brothers Corp. in Greenville, S.C., makers of the Mauldin Paving Products line of machines, hosted a special event Aug. 27, 2024, to celebrate how much equipment manufacturing contributes to society in 2024.

Throughout July and August, the Association of Equipment Manufacturers (AEM) made an 11-state trip across the South to visit many of its member companies, including Calder Brothers Corp., manufacturers of Mauldin Paving Products, with the objective of touting the industry’s impact on this country and the economy as a whole.

AEM did so via its Manufacturing Express, an interactive mobile road tour that traveled thousands of miles and made dozens of stops this summer.

“The intention and mission of the AEM Manufacturing Express is to thank the men and women of the equipment manufacturing industry and highlight the importance of manufacturing in this country, in particular the production of construction and agricultural machines,” said Glen Calder, vice president of operations for Calder Brothers.

“One of the fascinating truths about the world is that everything we have, everything we see, and everything we touch is either grown or mined,” he added. “As an equipment maker, we are proud to be a part of AEM, an organization that is responsible for feeding, clothing, and powering the world.”

According to a recent AEM news release, the equipment industry has the numbers to support its significance to American citizens and their economic health.

“Eleven percent of manufacturing jobs are supported by equipment manufacturing, which represents 2.3 million men and women, and contributes $316 billion to the U.S. gross domestic product annually,” the group noted on its website. “From creating family-sustaining jobs and driving innovation, to supporting the movement of people and goods and helping to power vital public services and utilities, there is so much to celebrate, recognize, and admire about the industry.

AEM added that the goal of its largest-ever public engagement initiative was met “and will continue to remain the same: tell the story of the people, organizations, and programs driving equipment manufacturing forward.”

Due to Calder Brothers’s status as one of South Carolina top manufacturers, a number of prominent political leaders in the Palmetto State have visited the Greenville plant over the years and met with its officials and factory-floor employees as part of the AEM group, Calder said.

“We have had the privilege of hosting former South Carolina Gov. Nikki Haley, U.S. Sen. Lindsey Graham, former U.S. Congressman Trey Gowdy and current Lt. Gov. Pamela Evette, among others,” he said. “When Gov. Haley visited, that was part of our drive to get the federal infrastructure package passed, something of which we could all be proud and help give us the manufacturing edge that we currently lack.”

Now celebrating 30 years in business under Calder family leadership, Mauldin makes a range of asphalt pavers, road maintainers, asphalt rollers, motor graders, truck-mounted asphalt and water tanks and trailer-mounted liquid asphalt and emulsion tanks for contractors across the country through a vast network of dealerships. CEG (All photographs in this article are Copyright 2024 Construction Equipment Guide. All Rights Reserved.)

The Association of Equipment Manufacturers (AEM) stopped by the North Carolina production plant of LeeBoy Aug. 29, 2024, as part of the trade association’s Manufacturing Express bus tour.

Throughout the summer, the goal of the AEM Manufacturing Express initiative was to recognize and celebrate the industry by making 80 visits across 20 states. The tour also highlights the innovative technologies, processes, people, and products that are revolutionizing the U.S. manufacturing sector.

“Equipment manufacturers are the backbone of America, representing $2.3 million employees,” Kip Eideberg, AEM’s senior vice president, said in a recent news release. “In North Carolina alone, our industry contributes 87,031 jobs and $11.3 billion to the state economy. The AEM Manufacturing Express is thrilled to be in North Carolina to celebrate the critical role of the state’s equipment manufacturers in building, powering, and feeding our nation.”

During its stop at LeeBoy’s Lincolnton factory, AEM also feted the company and its employees’ contributions at a time when the construction equipment maker is celebrating its 60th anniversary in business.

In addition, the AEM event, noted LeeBoy President Shannon Seymour, allows “us to let our associates get to know what AEM does for LeeBoy and showcase the company.”

Seymour added that AEM is made up of more than 1,000 member companies and approximately 2.3 million associates.

“It provides various resources for member companies such as data, market share analysis, and educational materials,” he said. “AEM is also very well tied into Washington and lobbies on our behalf to make sure that American manufacturing companies stay strong and remain a backbone of this country.”

For example, AEM often helps arrange for politicians to make stops on the factory floors of its member companies as a show of their encouragement and support.

In LeeBoy’s case, Seymour said that Mark Robinson, North Carolina’s current lieutenant governor and the Republican candidate for governor in November’s election, visited the Lincolnton plant in 2023. In addition, Pat Harrigan, a Republican running for the U.S. House to represent the state’s 10th congressional district, made a campaign stop at LeeBoy several months ago.

The manufacturing company has its origins in the Charlotte garage of LeeBoy’s late founder, B.R. Lee, who began making pavers there in 1964. Since then, the equipment maker has moved to a large, 33-acre production site in Lincolnton, northwest of Charlotte, where it produces a range of commercial paving equipment and machines, including pavers, motor graders, distributor trucks and brooms.

Over the past couple of years, Seymour said that LeeBoy also has introduced several new upgrades to its product lineup.

“The most notable improvements have been our electric products, which we brought out slightly more than a year ago,” he said. “Not only did we make the first commercial class electric asphalt paver, but we also introduced the first

electric broom. And LeeBoy is about to get back into distributing rollers. In fact, we have rollers available for order at the present time and will begin delivering them in January.”

Plans call for the equipment manufacturer to create a 1.25ton, 36-in.-wide roller, as well as a 3-ton model with a 48-in. width, and more models to come.

“LeeBoy will also begin selling and marketing soil rollers too, as well as rubber-tire machines,” he said. “This is a good opportunity for us because we believe LeeBoy is the only paver manufacturer that does not currently sell rollers. We did so up until a few years ago and are happy to re-start their distribution.”

The company has managed to remain among the market leaders in the commercial class paving equipment business, Seymour said, because LeeBoy has long realized “it is about connecting with and listening to our customers, understanding how they use the equipment, and constantly refining the equipment for more efficient usage.

“Quality and reliability are also an enormous factor – how we keep these pavers running for our customers,” he added. “Uptime is everything for them.”

Seymour noted that LeeBoy’s nationwide distributor network is seen as being “the front line” in terms of contact with the end customers.

“The dealerships that have great service departments and rapidly react to any potential repair issues that arise in the field are the ones that make a difference in the marketplace,” he said.

For its part, LeeBoy itself has proven to be outstanding at supplying parts to its dealers overnight or as needed, something that the equipment maker has prioritized to improve efficiency, according to LeeBoy.

With a warehouse built to be shared by both its production and parts departments, Seymour believes that LeeBoy has created an advantage for itself by having its entire operation under one roof.

“Let’s say we need a wiring harness for a 20-year-old machine. We just make it in this factory,” he said. “Or, if a weldment is required, we can run out to the weld cells and get that done quickly. That capability really helps us get service and parts needs turned around in a hurry.” CEG

(All photographs in this article are Copyright 2024 Construction Equipment Guide. All Rights Reserved.)

Loved for the features. Trusted for the performance.

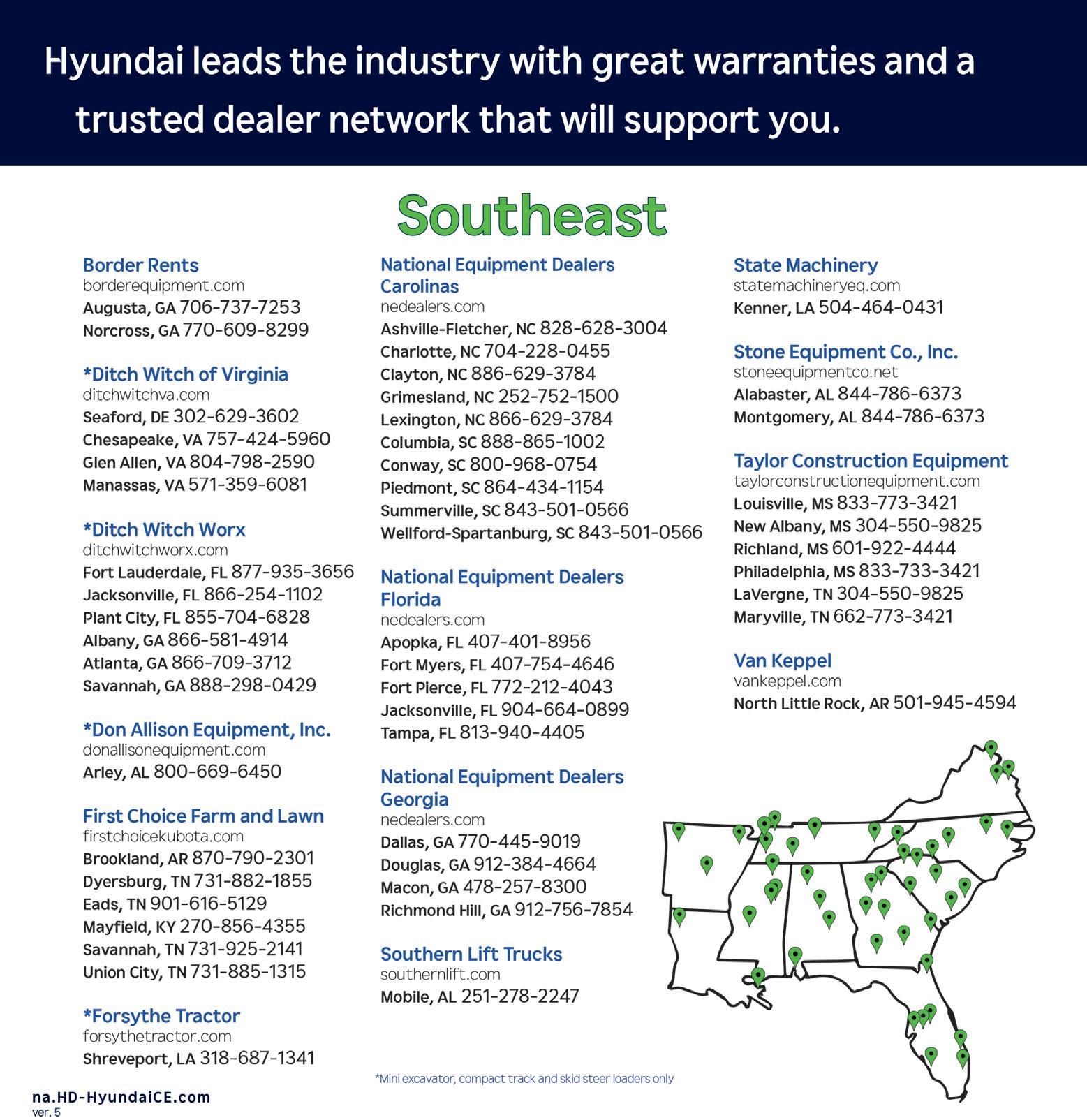

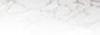

Hyundai wheel loaders have the power and performance, not to mention top-notch interiors, accurate onboard weighing system, industry proven drivetrain durability, clear sightlines, and handy tech that make life on the jobsite easier. So you can do more without feeling it. No wonder so many first-time Hyundai users become longtime fans.

See the Hyundai difference yourself at your local dealer or na.hd-hyundaice.com.

The National Equipment League is a new entertainment and competition platform that showcases the skills, character and passion of the construction industry through competition.

The newly founded National Equipment League has crowned Bryan Furnace as its first champion after four hotly contested events, hosted by HD Hyundai Construction Equipment North America.

The National Equipment League is a new entertainment and competition platform that showcases the skills, character and passion of the construction industry through competition.

Furnace, of Howell, Mich., is the owner/operator of his own earthmoving business who also hosts his own YouTube channel, Diesel & Iron. The competition has been documented over the course of four events, which can be viewed on HD Hyundai Construction Equipment North America’s YouTube page.

Additional competitors in the first events include Mike Simon (AKA Dirt Perfect), Andrew Camarata, Dave Buchakian and Geoff Dodge. Mr. Digg Ryan Williams served as a member of the broadcast team. All events were filmed at the HD Hyundai Customer Product Center in Carnesville, Ga., and broadcast via YouTube.

“The first events proved that skilled heavy equipment operation in head-to-head competition is entertaining, educational and highlights the talents of the workforce in the construction industry,” said Bill Elverman, commissioner, National Equipment League.

“As in any professional sporting event, we see that lead changes, scoreboard jockeying and often just a few seconds between competitors create compelling entertainment. Hyundai hosted a great competition and has shown its commitment to showcasing the talents and passion of the construction industry.”

The first series of National Equipment League events can be seen on the Hyundai Construction Equipment North America YouTube and Facebook channels.

Additional promotional considera-

tions were made possible by Blue Diamond Attachments. For more information on the National Equipment League, email Commish@EquipmentLeague.com or visit EquipmentLeague.com.

(All photos courtesy of the National Equipment League.)

SCHOOL from page 12

“It gives us access to great financial institutions — really important hedge funds, investment banks and venture capitalists,” Steenburgh explained. “They don’t have the talent to manage the businesses to the level that they’d like. [Building business programs] gives us a way to place our students very quickly in the areas of the economy that we’d like to have a presence in.”

Plus, he added that the South Florida campus will enhance the strength of Vanderbilt’s main campus in Nashville.

“We’re pretty good in fintech locally, but it’s stronger in South Florida, so it creates opportunity. Being closely aligned with more important industries is part of what we’re

“[At Vanderbilt,] we’re interested in being a business school of the future, a university of the future...”

Thomas

Steenburgh Vanderbilt University

looking to get out of this,” Steenburgh said from his Nashville office. “Anything we do down there is not taking away from what we do up here. This gives us access to new forms of capital, and people that we don’t know now, so it’s really extending the importance of what we’re doing.”

On Aug. 16, Dennis Grady, interim CEO of the Chamber of Commerce of the Palm Beaches, announced on LinkedIn that the local economic impact of the graduate school campus project will be $500 million and require $100 million of annual spending from the university.

Steenburgh told the Vanderbilt student newspaper that the faculty is still in its early phases of thinking about the West Palm Beach campus, while adding that the project’s future is dependent on the university’s ability to raise funding for it. The next step will be getting a group of faculty together to discuss the specific programs that the graduate school could offer, he noted.

“Everything is going to be governed out of [Nashville], so we’re going to have academic control over what happens.”

Steenburgh sees Vanderbilt’s embrace of “radical collaboration” as being a large part of what makes it special as a university.

“That’s the genesis of things — people with new points of view finding a new way of doing things,” he said. “Making sure that that remains strong here [in Nashville] is really important, so we’ll continue to build that too.”

At Blue Diamond Attachments, all we do is manufacture attachments that make you better at all you do. From excavators, skid and track loaders to tractors and more, our commitment to quality shines through in every weld and every design. Crafted with precision and innovation, our complete attachment solutions redefine durability and performance.

So, whether you’re breaking ground or finishing a project, trust the experts who focus on one thing, and when it comes to your equipment, demand the attachments that excel. Choose Blue Diamond

where all we do is elevate everything you do.

Scan the QR code or go to www.AllWeDoBDA.com to find your nearest dealer. It’s time to take your projects to a whole new level.

Takeuchi-US hosted the Association of Equipment Manufacturers (AEM) Manufacturing Express national tour at its compact track loader production facility in Moore, S.C., on Aug. 27, 2024.

AEM recognized Takeuchi-US and its employees as industry leaders for their contributions to the local community and manufacturing industry. At the event, Takeuchi-US also celebrated the production of its 10,000th compact track loader, a TL12 model, at the Moore facility, which opened in September 2022.

Takeuchi’s employees signed the interior of the TL12’s rear cover, and soon, this unique, one-of-a-kind 10,000th machine will be delivered to a Takeuchi customer.

Congressman William Timmons, 4th District, South Carolina spoke at the event, noting the importance of manufacturing in Spartanburg County and thanking Takeuchi-US for putting its faith in the Moore community by locating its compact track loader production facility there two years ago.

Several other dignitaries also were on hand for the festivities, including:

• David Britt, Spartanburg (SC) County council vicechairman

• Allen Smith, president and CEO, OneSpartanburg Inc.

• Kyle Sox, VP of Industrial Development, OneSpartanburg Inc.

• Katherine O’Neill, chief economic development officer, OneSpartanburg Inc.

• Dwayne Hatchett, director of existing industries, OneSpartanburg Inc.

• Cole Alverson, administrator, Spartanburg County

• Carter Smith, advisor, OneSpartanburg Inc.

“As proud AEM members, we believe in the importance of American manufacturing, and we were pleased to host the AEM Manufacturing Express tour,” said Jeff Stewart, president of Takeuchi-US. “We enjoyed celebrating our employees and the Moore community while highlighting our contributions to the local, regional and national economies.

“We’ve only been open for business in Moore for two years, but we’ve already manufactured 10,000 machines and now employ more than 150 people here. We thank our local policymakers for joining us at this celebration and learning more about how we’re helping drive innovation and eco-

nomic growth in this region.”

Takeuchi-US was the 43rd stop on the AEM Manufacturing Express tour, which will visit 80 manufacturers across 20 states. The tour showcases the cutting-edge technology and innovations that power modern equipment, as well as the innovative technologies, processes, people and products revolutionizing this industry across America.

“We were thrilled to join so many community leaders and supporters of Takeuchi-US at this amazing opportunity to highlight the importance of American off-highway equipment manufacturing in Moore, South Carolina,” said AEM President Megan Tanel.

“The AEM Manufacturing Express is more than just a bus tour; it is an opportunity to tell the stories of the men and women of our industry in the Greenville area and highlight how their grit, determination and can-do spirit has contributed to the American way of life.”

For more information, visit www.takeuchi-us.com and www.manufacturingexpress.org.

(All photos courtesy of Takeuchi.)

For landscapers, dealers and contractors attending award-winning Equip

Exposition for the very first time, show organizers are offering tips to help firsttimers make the most of this blockbuster show, to be held Oct. 15 to 18 at the Kentucky Exposition Center (KEC).

“I’ve ‘only’ been to 18 of the 41 shows, but I have some advice. First, for the first-timer, it’s not really a one day show. For an immersive experience, you’ll want to be there all three days,” said Kris Kiser, president and CEO of the Outdoor Power Equipment Institute (OPEI), which owns and manages Equip Exposition, the international landscape, outdoor living and equipment exposition.

Last year, the show drew more than 27,000 people, and had more than one million square feet of exhibit space with a 30-acre Outdoor Demo Yard, which allows attendees to dig, drive, cut, mulch and other testing of new equipment they need for their businesses.

Equip Exposition photo

Last year, the show drew more than 27,000 people and had more than 1 million sq. ft. of exhibit space.

“Since OPEI has taken full ownership and management of the show, our goal has been to create a world class event for our attendees,” Kiser said. “This year, we’ve invested in more peer-to-peer social opportunities like renting Churchill Downs for our welcome reception, having Kevin O’Connor of This Old House as keynote speaker, a happy hour at Freedom Hall with the Crashers band and having Trace Atkins give an arena concert at the Yum! Center at no charge to attendees and more.”

But he noted planning is key to get the most out of Equip.

“Do some homework. Before you get here, download the app, go to the web site, look at the maps. Familiarize yourself with the logistics. It’s important to know how to get in and out of the KEC.

“It’s also the kind of event you want to share and bring your colleagues. It’s a teambuilding exercise where you can learn new things as well as from one another, have some fun and have a shared experience.”

A core mission of Equip is facilitating networking so attendees can meet people who are likely going through similar business challenges. It’s the industry’s family reunion.

“It’s crazy how willing people are to help other people [at Equip],” said Blake Albertson of B&B Lawn Care.

Identifying your business needs also is an important step when planning time at Equip.

“Last few times we’ve been here, we found new equipment to help us be more efficient in our business,” said Kendal Caldwell of Senske/Emerald Lawns.

Kiser offers these tips to help first-timers to Equip plan for the best experience possible:

• Register now. If you’re registered, you will receive Equip’s regular emails about everything going on at the show. Sign up at EquipExposition.com now. Don’t get stuck paying full price ($120) at the show.

• Add education, certification classes, and training to your registration before sessions sell out. Sessions are targeted to help you explore ways to grow their businesses, address common problems and develop employees. Other sessions will cover irrigation, pesticide management, tree and shrub pruning, pool and spa, outdoor lighting and more. Select classes, including the popular From Worker to Leader course, are available in Spanish.

• Book travel arrangements and hotel reservations. Louisville’s hotel rooms often sell out with thousands of Equip Expo attendees in town. You don’t want to stay miles away. Some hotels are along the trade show’s complimentary shuttle route.

• Invite others. Bring your teammates from your company (if you are a landscaper) or your contractor customers (if you are a dealer). Equip is a fantastic team building opportunity, through shared educational experiences and testing new equipment to having fun at concerts with one another. This makes acting on new knowledge and ideas when home easier.

• Download the Equip Expo app. The app is your event guide. It works with any Android or iPhone. On the app, find the Event Schedule with start times for all sessions and a tradeshow map for the entire facility. Every week leading up to the show it’s updated with even more information, like where the biggest Giveaways are and where you can find breakfast, lunch and coffee at the KEC. You can favorite any

event or location to build a custom schedule as well.

• Determine the top three business problems you are trying to solve. Look at the speakers, exhibits and education offerings and identify the ones that will help you the most with those problems.

• Familiarize yourself with the navigation tools. Many attendees drive in to the show so it’s important to map the route from your hotel to the KEC and other venues, and look at available shuttle or rideshare options.

• Learn the five main areas of the show. The North Wing has registration, exhibits, badge pickup and a coffee shop. The South Wing has exhibits and easy access to the Outdoor Demo Yard (which also has food trucks and tented areas to relax) and the UTV Driving Experience. The West Wing is loaded with exhibits, Mulligan’s Mutt Madness dog adoption event, the new Garden Center and food options (as well as the rideshare pickup/drop off zone). Freedom Hall will host the Happy Hour with the Crashers on Wednesday.

• Pack strategically. Check the weather and dress for both indoor and outdoor. Bring comfortable shoes, a printout of your registration confirmation (you can scan the QR code to print your badge), and dress in layers for any sudden weather changes.

The Outdoor Demo Yard is a real-world experience and can get cold so bring weather-appropriate clothes.

• Plan to meet others. Many events are planned to help facilitate networking so you can meet others to share relatable business challenges and solutions, learn what they know, and get real-world advice and ideas.

During

• Don’t get stuck in traffic. Remember parking is free. Hot tip: For ease of entry, don’t use the main gate at the show’s rush hour. If you are coming later than 10 a.m., use Crittenden Drive gate or the Preston Highway gate and park on the North side, which is the best way to enter the KEC. Leave via a similar route to avoid any bottlenecks at the main gate.

• Start your day in the West Wing. Ride shares and shuttles will drop off at the West Wing and there will be food options available.

• Avoid lines for badge pickup. Print your badge at the Welcome Reception at Churchill Down’s First Turn Club or in the North Wing at the Kentucky Exposition Center. More locations are scattered throughout Louisville Hotels, the Airport and the KEC.

• Don’t hesitate to talk with others. Equip is a city-wide event. That means people in your hotel elevator and restaurant are likely to be Equip attendees. Take time to meet people as you navigate the halls, stand in line or grab a bite to eat.

• Have fun at the pre-planned events. Go to the Welcome Reception at Churchill Downs sponsored by Cat, the Happy Hour on Wednesday with the Crashers in Freedom Hall, the Morning Show at Expo sponsored by Kohler on Thursday morning, Energize on Thursday afternoon, and the Trace Adkins concert sponsored by SENIX, Toro, Bobcat and Gravely. Join Equip attendees at the third-annual Mulligan’s 5K Fun Run and Walk, sponsored by Active Dynamics, on Wednesday morning at 7 a.m. where you’ll go across the Ohio River on Louisville’s Big Four Pedestrian Bridge.

• Follow up with the people you met at Equip. You can swap ideas, encourage each other in growing your respective businesses, or remind each other to do “that thing you said you would do” when you returned home.

• Put new ideas you picked up at the show into action. Take that leap, do the “new thing,” roll out better pricing, marketing, services and more that you find applicable to your unique business.

• Register for next year’s show that is planned for Oct. 22 to 24, 2025.

“Though 40 years old, Equip Exposition remains the unique opportunity for the industry,” said Kiser. “It’s our industry’s largest event, and it continues to grow. We’re doing something right because every year we hear what an incredible return on investment it gives to the industry.”

For more information, visit https://help.equipexposition.com/knowledge.

www.equipmentshare.com

10179 US-78 Ladson, SC 29456 843-709-2458

145 Thunderbird Dr. Richmond Hill, GA 31324 912-400-0752

2919 E. Napolean St. Sulphur, LA 70663 337-284-9804 HEAVY MACHINES, INC. www.heavymachinesinc.com

120 Mann Drive Piperton, TN 38017 (Memphis) 800-238-5591

2115 N. Thompson Lane Murfreesboro, TN 37129 877-200-5654

5200 Hollywood Ave. Shreveport, LA 71109 800-548-3458

364 Bob Jobe Rd. Gray, TN 37615 855-201-7453

10110 Roberts Way Covington, GA 30014 770-788-0888

7651 Theodore Dawes Rd. Theodore, AL 36582 251-653-5955

825 31st Street North Birmingham, AL 35203 205-323-6108

LINK-BELT MID ATLANTIC www.link-beltmidatlantic.com Ashland, VA 866-955-6071 Chesapeake, VA 800-342-3248 Frederick, MD 833-546-5235

www.parmantractor.com

3570 Dickerson Pike Nashville, TN 37207 615-865-7800

1485 Bear Creek Pike Columbia, TN 38401 615-865-7800

MID SOUTH MACHINERY, INC. www.gomidsouth.com

3233 Highway 80 West Jackson, MS 39204 601-948-6740

3145 Cliff Gookin Blvd. Tupelo, MS 38801 662-690-6553

7422 Hwy 49 N Hattiesburg, MS 39402 601-268-2222

In addition to the low score medalist honors, the day’s festivities included a “closest to the pin” contest, as well as a unique putting contest — using a compact excavator fitted with a Werk-Brau tiltrotator and a one-of-a-kind Werk-Brau putter head attachment.

It was a great day for golf and networking at the second annual Werk-Brau Golf Classic to benefit Construction Angels held recently on the Scarlet Course at the Ohio State University Golf Club.

The event raised more than $100,000 to aid families of fallen construction workers in Ohio. The sold-out field of 36 foursomes included contractors across the state — from small operations to nationally known companies like Kokosing, Miller Brothers, George J. Igel and Shelly Company as well as construction suppliers and those allied to the industry.

In addition to the low score medalist honors, the day’s festivities included a “closest to the pin” contest, as well as a unique putting contest — using a compact excavator fitted with a Werk-Brau Tiltrotator and a one-of-a-kind Werk-Brau putter head attachment.

“The construction industry in Ohio showed up big time,” said Werk-Brau regional manager and golf outing chairman Neil Recker. “Thanks to the golfers, sponsors, customers, partners and volunteers who made the day a resounding success. Many Ohio families of fallen construction workers will be helped because of your tireless efforts. Thanks to everyone who made it a great day.”

The team from Shelly Company took home medalist honors with a 56 in the closely contested scramble format, followed by Stoepfel Drilling in second and Rudd Equipment in third, which were determined by a score card playoff tied at 57.

Leeco Steel and FST America Machinery Division were raffle prize sponsors, while Progressive Mechanical Inc. donated prized prizes. Raffle prizes included many summer essentials including grills, coolers, unique dining experiences and more.

and more.

Werk-Brau was the presenting sponsor, with Murphy Tractor and Alta Equipment stepping up as platinum angel sponsors. Oho Cat was the gold angel sponsor, and Kalida Truck Equipment, Kokosing Inc, Miller Bros. Construction, Rudd Equipment and Quanta Infrastructure Solutions Group – QISG were silver angel sponsors. Though there were some close shots, no one carded an ace on the $10,000 Hole-in-One Challenge, which was featured on every par three.

Southeastern Equipment, Associated Equipment Distributors, Valley Tool and Manufacturing, and Worldwide Logistics started off the day as the breakfast sponsors.

Columbus Equipment, Exact Crane & Equipment Corp and NPK Construction Equipment sponsored the essential beverage cart, while lunch was sponsored by Marmon and The Shelley Company. Black Cat Wear Parts, Chicago Tube & Iron, Tenna and Weir Group sponsored beverage stations — including a Bloody Mary bar and Margarita station.

The scorecards were sponsored by Jarrett Logistics, while Trinity Products and Black Cat Wear Parts were cigar sponsors.

PSS Industrial Group, BOMAG Fayat Group, Lindner and American Traffic Safety Services Foundation.

Construction Angels is a non-profit organization that provides immediate financial support and grief counseling to the children and spouse when a construction worker suffers a fatality on the job site. They are financially supported by many companies, organizations, unions and construction associations within the industry.

IC-Fluid Power Inc, Ohio 811, Air GET, Valley Tool & Manufacturing, Chicago Tube & Iron were pin flag sponsors for the event. Hole sponsors included Chicago Tube & Iron, Clouse Construction, M-B Companies, Olympic Steel, Stoepfel Drilling, Unified Technologies, Ideal Steel, Wahl Marketing Communications, Sure Grip Controls, Velosio, Lehman Daman Construction, Valley Tool & Manufacturing and National Tube Supply.

National sponsors of Fallen Angels include Advanced Drainage Systems, J. Alexander Law, John Deere, Dobbs Equipment, United Rentals, Friedman Legal, SimForMotion, Core & Main, Total Teks Group, Flagger Force, Wirtgen Group, GRH, U.S. Pipe, Heritage Construction & Materials, Werk-Brau, Case Construction,

The Bureau of Labor Statistics estimated there are 7.2 million people working in the construction industry with projected steady growth over the next 10 years. OSHA reports there are well over 5,000 work site deaths each year in the USA, over 20 percent are in the construction industry. This is approximately 4.5 construction workers killed per working day in the United States.

“Huge thank you to the entire Werk-Brau team for another awesome event! Your hard work and dedication mean so much to the Ohio families that we serve,” said Kristi Gibbs, Construction Angels CEO and founder/national executive director.

“Events like this take a lot of time and effort, and Neil and the crew at Werk-Brau always go above and beyond. We are so grateful for your support and look forward to the years to come.”

station.

“This event has quickly become a “can’t miss” event of the summer for the Ohio construction industry, and we’re so thankful for that. Our goal is to provide an elevated experience compared to any other outing. We have several machines brought in for display, and make sure the prizes and raffles are top notch so people leave with a positive impression and lasting memory,” said Recker. “We’re already making notes and starting to plan to make next year’s outing even better.”

For more information, visit Werk-Brau.com and constructionangels.us/.

(All photos courtesy of Werk-Brau.)

Blue Diamond Attachments photo

Compatible with compact, mid-sized and full-sized excavators ranging from 4 to 20 metric tons, Blue Diamond excavator drum mulchers are built with high-quality components and steel to stand up to the harshest land clearing and mulching conditions.

The new lineup of excavator drum mulchers from Blue Diamond Attachments includes three models (heavy duty, extreme Duty and severe duty) with cutting widths ranging from 30 to 50 in.

Compatible with compact, mid-sized and full-sized excavators ranging from 4 to 20 metric tons, Blue Diamond excavator drum mulchers are built with high-quality components and steel to stand up to the harshest land clearing and mulching conditions.

Many components, including the frame, are made with high-strength structural steel, and the frame of each model has been reinforced for added rigidity and strength. Parts exposed to wear, like the skids and counterblades, are built from wear-resistant steel.

Counterblades on the heavy and extreme duty models are heat treated and reversible to double their life span. The severe duty model features rigid counterblades more suited for aggressive working conditions, according to the manufacturer.

Cutting capacities range from 4 to 7 in., and models are available to work with excavator auxiliary hydraulic flows from 9 to 45 gpm.

Blue Diamond Attachments has designed these mulchers with an adjustable input counterblade that can be brought closer or moved away from the rotor depending on the finish you want. The distance between the hammer and the counterblades also has been optimized to produce the best finish while ensuring optimal machine efficiency.

A manual gate/door is available on the heavy duty model, while the extreme duty and severe duty models feature a hydraulic gate/door.

For more information, visit BlueDiamondAttachments.com.

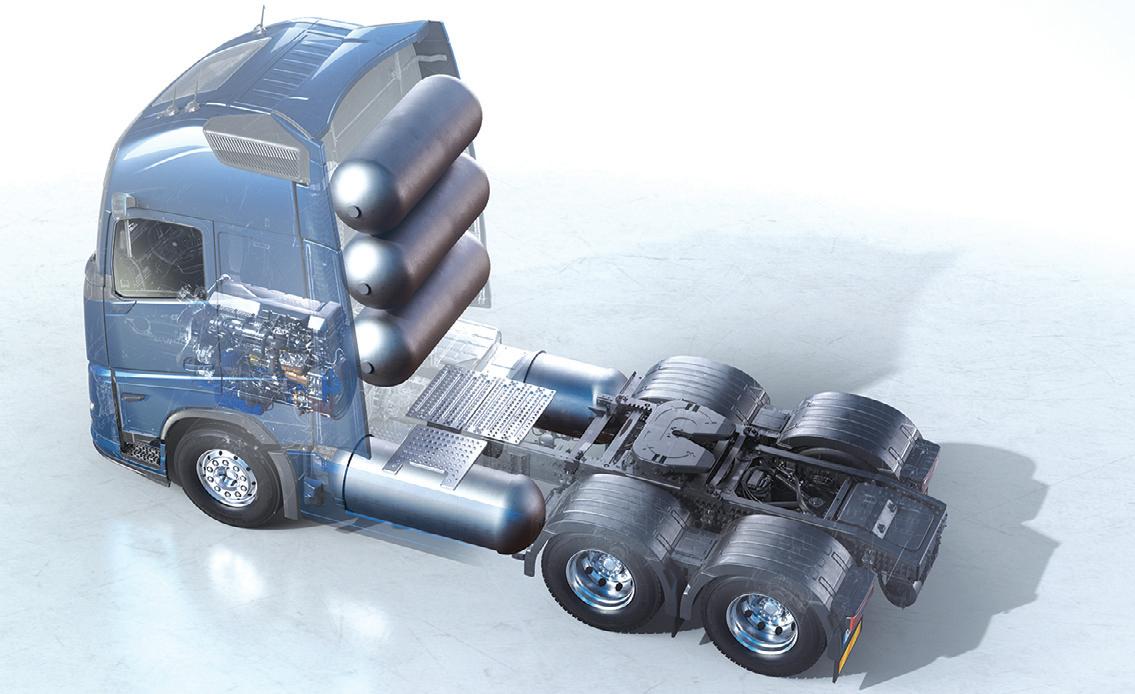

Trucks that run on green hydrogen instead of fossil fuels provide one way to decarbonize transport. Hydrogen trucks will be especially suitable over longer distances and in regions where there is limited charging infrastructure, or time for, recharging of batteries.

Volvo will begin customer tests with trucks using hydrogen in combustion engines in 2026, and the trucks will be commercially available towards the end of this decade.

Already, testing in labs and in vehicles is ongoing. The hydrogen-powered combustion engine trucks will complement Volvo’s offering of other alternatives, such as battery electric trucks, fuel cell electric trucks and trucks that run on renewable fuels, like biogas and HVO (Hydrotreated Vegetable Oil).

“Trucks where the traditional internal combustion engine remains but runs on hydrogen will have the same performance and reliability as our diesel trucks, but with the added benefit of potentially net zero CO2 emissions well-to-wheel. They will be a valuable complement to our battery electric trucks, which have been on the market for several years,” said Jan Hjelmgren, head of product management and quality, Volvo Trucks.

Volvo trucks with combustion engines powered by green hydrogen have the potential to deliver net zero CO2 well-to-wheel when using renewable HVO as ignition fuel and are categorized as “Zero Emission Vehicles” (ZEV) under the agreed new EU CO2 emission standards.

“It’s clear that several kinds of technology are needed to decarbonize heavy transport. As a global truck manufacturer, we need to support our customers by offering a variety

of decarbonization solutions, and customers can choose their alternative based on transport assignment, available infrastructure and green energy prices,” said Hjelmgren.

Volvo trucks with hydrogen-powered combustion engines will feature High Pressure Direct Injection (HPDI), a technology where a small amount of ignition fuel is injected with high pressure to enable compression ignition before hydrogen is added. The advantages of this technology include higher energy efficiency with lower fuel

Volvo will launch trucks with combustion engines that can run on green hydrogen. These trucks provide a significant step to decarbonize heavy transport.

consumption, and increased engine power.

Volvo Group has signed an agreement with Westport Fuel Systems to establish a joint venture utilizing HPDI technology.

• Hydrogen-powered Volvo trucks will have an operational range comparable to many diesel trucks, depending on the type of transport.

• Due to the low CO2 emissions from hydrogen combustion, these trucks are cate-

gorized as “Zero Emission Vehicles” under the agreed new EU CO2 emission standards.

• Hydrogen combustion engines will also emit very small amounts of nitrogen oxides and particles.

• Hydrogen also can be used to power fuel cell electric trucks, where electricity is produced on board the truck. Fuel cell electric trucks do not emit any tailpipe emissions, only water vapor.

For more information, visit www.volvotrucks.com.

www.companywrench.com

11301 Reames Road Charlotte, NC 28269 980-859-4680

125 Wilsons Mills Rd. Extension Smithfield (Raleigh), NC 27577 919-938-8145

141 Brickyard Rd. Lexington (Columbia), SC 29072 803-520-0032

6325 Central Avenue Pike Knoxville, TN 37912 865-766-2571

www.ringpower.com

Isuzu Commercial Truck of America Inc. has been awarded zero-emission certifications by the California Air Resources Board (CARB) and the Environmental Protection Agency (EPA) for the Isuzu NRR-EV.

CARB and the EPA have been accelerating the adoption of zero-emission vehicles across the United States to combat climate change, reduce air pollution and promote sustainable transportation solutions nationwide. Their requirements mandate ambitious targets for companies to transition to cleaner, zero-emission technologies.

The new Isuzu NRR-EV is now approved for sale in all 50 states. The NRR-EV will be assembled in Charlotte, Mich., starting in August 2024.

The zero-emission certifications validate Isuzu’s adherence to stringent emissions standards and regulatory requirements, demonstrating compliance with federal and state environmental regulations. The new Isuzu NRR-EV is positioned as a viable medium duty truck option for fleets seeking to both reduce their carbon footprint and comply with increasingly strict emissions regulations.

“For us at Isuzu, this truck showcases our commitment to innovation in delivering sustainable transportation solutions for the future. The certifications for our NRR-EV are a major step in providing customers with a medium-duty vehicle that lessens their carbon footprint and meets new fleet regulations,” said Shaun Skinner, president of Isuzu Commercial Truck of America.

For more information, call 866/441-9638 or visit www.isuzucv.com.

Kenworth recently announced the latest iteration of its Advanced Driver Assistance System (ADAS) is now available for Kenworth T680s.

The enhancements are part of the Bendix Fusion system and feature Adaptive Cruise Control (ACC) Stop and Auto Go. When a commercial truck follows a lead vehicle in cruise control, this enhancement enables the system to apply braking to maintain a safe following distance and will bring the truck to a complete stop, if necessary, and will hold the truck in place. When the truck can move forward, it will automatically accelerate to the vehicle set speed without driver intervention and maintain a safe following distance.

In the event a truck departs the roadway, the new Highway Departure Braking to Zero feature will provide an audible chime and apply braking to reduce vehicle speed if the vehicle begins departing the roadway. In some circumstances, the system may reduce the vehicle speed to a full stop until the driver re-engages.

ing behavior and provide drivers more convenience operating in cruise control.”

In addition to these new features, Kenworth is building upon its previous driver assistance system offerings with improved Adaptive Cruise Control, Autonomous Emergency Braking (AEB), and more. Kenworth’s ADAS driver technology suite includes Collision Mitigation, designed to alert the driver to nearby vehicles and objects so pre-emptive braking action can be taken; Lane Departure Warning, providing continual monitoring of the truck’s location to prevent lane drift, and Side Object Detection, alerting the driver with audible and visual notifications to help with safe navigation and lane changes.

“Driver assistance systems play a key role in making com-

mercial trucks easier and less fatiguing to operate,” said Jim Walenczak, Kenworth assistant general manager of sales and marketing. “These new features will complement safe driv-

Advanced driver assistance technologies complement safe driving practices. No commercial vehicle safety technology replaces a skilled, alert driver exercising safe driving techniques and proactive, comprehensive driving training. Responsibility for the safe operation of the vehicle remains with the driver at all times. For more information, visit www.kenworth.com.

In addition to sponsoring the race and Chastain’s No. 1 Chevrolet and Rhodes’ No. 99 Ford F-150 at Kansas Speedway, Kubota also will be active in the Fan Zone with an equipment display and will have company representatives on-hand to discuss job openings at its Kansas facilities.

Kubota is partnering with Kansas Speedway for one of the most important races of the 2024 NASCAR CRAFTSMAN Truck Series season.

Kansas Speedway announced that its NASCAR CRAFTSMAN Truck Series race on Sept. 27, will be named the Kubota Tractor 200. It will serve as the final race in the NASCAR CRAFTSMAN Truck Series Playoffs’ Round of 10, with two drivers eliminated from championship contention by the end of the night.

“We’re thrilled to have Kubota playing such an important role in one of the most pivotal races of the season,” said Kansas Speedway President Pat Warren.

“Their commitment to Kansas City, the state of Kansas and to NASCAR racing overall is incredible, and we’re excited to partner with them to make this an event to remember.”

Kubota Tractor Corporation is based in Grapevine, Texas, and has a significant Kansas presence with its Midwest Division office and North American Distribution Center in Edgerton, manufacturing and assembly facilities in Salina and Abilene, and 17 dealerships across the state. Nationwide, there are more than 1,000 authorized Kubota dealerships and additional manufacturing, administrative and distribution facilities, with more than 7,000 employees who fabricate, weld and assemble compact equipment with domestic and globally sourced parts.

Since 2022, Kubota has been embedded within the NASCAR community and currently serves as the Official Tractor Company and a primary sponsor of Trackhouse Racing and NASCAR Cup Series driver Ross Chastain’s No. 1 Chevrolet, and ThorSport Racing and defending NASCAR CRAFTSMAN Truck Series champion Ben Rhodes’ No. 99 Ford F-150.

In addition to sponsoring the race and Chastain’s No. 1 Chevrolet and Rhodes’ No. 99 Ford F-150 at Kansas Speedway next month, Kubota also will be active in the Fan Zone with an equipment display and will have company representatives onhand to discuss job openings at its Kansas facilities.

“Kansas is an important market for Kubota and we’re proud to partner with NASCAR and Kansas Speedway on this race in a region where so many of our employees, dealers, and customers call home,” said Todd Stucke, president, Kubota Tractor Corporation.

“We’re proud to continue investing in America, and particularly in Kansas, to respond to increased demand for our products — and to do that, we’re looking to fill more than 300 positions across our company to strengthen our operations nationwide.”

Kansas Speedway was the site of the closest NASCAR Cup Series finish in history in May when Kyle Larson edged Chris Buescher for the win in a photo finish for the ages. That sets the stage for the Hollywood Casino 400 presented by ESPN BET on Sept. 29, the opening race of the NASCAR Cup Series Playoffs’ Round of 12.

That race will cap an incredible weekend of racing at Kansas Speedway, featuring four races over three days. It begins Friday, Sept. 27, with a doubleheader featuring the Kubota Tractor 200 and the ARCA Menards Series’ Reese’s 150, and continues Saturday, Sept. 28, with the NASCAR Xfinity Series’ Kansas Lottery 300. And then on Sunday, Sept. 29, the NASCAR Cup Series returns to the site of the closest finish in series history with the Hollywood Casino 400 presented by ESPN BET.

Tickets for all seats are on sale and can be purchased at www.kansasspeedway.com.

Nashville 140 Charter Place LaVergne, TN 37086 615-793-7576

Knoxville 3356 Rudy Street Knoxville, TN 37921 865-970-2840

www.lindertt.com

4737 McConnell Center Drive Greensboro, NC 27405 336-792-3412

1530 Middle River Loop ayetteville, NC 28312 910-483-3892

1501 N. Memorial Drive Greenville, NC 27834 252-695-6200

5504 15th Street E Bradenton, FL 34203 941-755-5722

505 US Highway 82 West Leesburg, GA 31763 229-435-2212

1205 Veterans Parkway North Moultrie, GA 31788 229-985-3882

2902 US Highway 84 West Valdosta, GA 31601 229-588-8100

www.masontractor.com

1050 Appalachian Hwy Blue Ridge, GA 30513 706-632-3777

2510 Dahlonega Hwy Cumming, GA 30040 770-887-6119

395 Industrial Blvd. McDonough, GA 30253 770-957-3370

5038 Buford Hwy. Norcross, GA 30071 770-582-0377

1275 Carrollton Villa Rica Hwy. Villa Rica, GA 30180 678-952-2037

912 Jernigan Street Perry, GA 31069 478-987-1173

BROOKS SALES, INC. www.brookssales.com

3144 Hwy 74 East Monroe, NC 28112 704-233-4242

CREEL TRACTOR CO.

www.creeltractor.com

3771 Palm Beach Blvd. Fort Myers, FL 33916 239-694-2185

www.coastalmachinery.com

6701 Mobile Highway Pensacola, FL 32526 850-944-2002

1147 S. Ferdon Blvd Crestview, FL 32536 850-682-3366

Discover how MB Crusher is transforming excess concrete washout with innovative attachments for the construction industry. Turn hardened concrete into recycled aggregates for your next project.

MB Crusher jaw crushers provide contractors and readymix plants with the capability to turn leftover concrete into another revenue source.

Ready-mix concrete is a pre-mixed concrete that is manufactured in a batching plant or factory and delivered to the construction site in a ready-to-use form.

Excess concrete can come from concrete waste from equipment, tools and machinery used in the construction process. As a result, piles of leftover concrete continue to mount onsite.

Companies must provide a safe and proper way to clean and dispose of excess concrete known as washout. Washout ensures the excess concrete is removed and disposed of properly to prevent environmental factors such as runoff to storm drain systems. However, companies are left with limited options to deal with concrete stockpiles onsite.

Without an efficient concrete washout recycling system, companies are wasting money and decreasing productivity.

MB Crusher helps contractors and ready-mix plants solve the problem of excess concrete by crushing and recycling hardened concrete onsite. Therefore, companies can use the recycled aggregate as backfill, materials for new construc-

Excess concrete can come from concrete waste from equipment, tools and machinery used in the construction process. As a result, piles of leftover concrete continue to mount onsite.

tion projects or create an additional revenue source by selling the aggregate.

One customer received the equivalent of two years of leftover concrete washout returned to his plant. Instead of continuing to spend lots of money on transportation and crushing services, the company purchased an MB Crusher BF 80.3 crusher bucket. The company used the BF 80.3 crusher bucket to transform their excavator into a mobile recycling center on site by crushing the leftover stockpile of concrete as recycled aggregate.

MB Crusher attachments are easy to mobi-

lize and fast setup on site. In fact, all MB Crusher attachments can be operated by a single person on any brand of heavy equipment, according to the company.

The MB-L160 crusher bucket can be utilized in multiple locations allowing companies to move the attachment from plant-to-plant.

Now, contractors and ready-mix plants can quickly and frequently crush concrete washout, as well as avoiding expensive transportation and service fees, and increasing profit margins from recycled aggregate sales.

For more information, visit mbcrusher.com/us/us/. (Photos courtesy of MB Crusher.)

As the SENNEBOGEN Dealer of the Year for two years running, Vinicius Casselli, director of Envimat, the SENNEBOGEN dealer in Brazil, said his plan was to make Envimat the top dealer. And Plan B was to make Plan A work. Well, it is working as well as he expected. But as he said recently, “Although SEN-

NEBOGEN material handlers are relatively easy to sell because of their engineering and overall product quality, their customers expect their machines to be able to operate 24 hours a day.”

To make that happen, he has an army of mobile factory trained mechanics to do just that.

At a recent ISRI Show, today known as the ReMA Show (Recycled Materials Association), Constantino Lannes, president of SENNEBOGEN America, Envimat was once again named Top Dealer in the SENNEBOGEN America family.

“We are very proud of the accomplish-

ments of all our dealers. We have the best dealers in the industry,” said Lannes. Brooke Tyler IV of Tyler Equipment Company with company offices in Massachusetts and Connecticut, this year’s first runner-up (and the 2022 Tree Care Dealer of the Year) said that since

see AWARDS page 54

GA 770-887-6119

Hiawassee, GA 706-970-3077

McDonough, GA 770-957-3370

Villa Rica, GA 678-952-2037 Perry, GA 478-987-1173

6301 Old Rutledge Pike Knoxville, TN 37924 865-546-1414 10644 Lexington Drive Knoxville, TN 37932 865-218-8800 1825 Veterans Boulevard Sevierville, TN 37862 865-595-3750

9960 Airport Parkway Kingsport, TN 37663 423-323-0400

4066 South Access Road Chattanooga, TN 37406 423-698-6943 215 Interchange Drive Crossville, TN 38571 931-456-6543

www.gatewaydealer.com

Bobcat of Charleston North Charleston, SC 843-725-6330

Bobcat of Columbia Columbia, SC 803-933-9996

Bobcat of Greenville Piedmont, SC 864-269-3600

Bobcat of Spartanburg Spartanburg 864-342-9003

Bobcat of Savannah Bloomingdale, GA 912-236-5588

Bobcat of Seneca Seneca, SC 864-873-8908

Bobcat of Clarksville Clarksville, TN 931-436-9555

Bobcat of Nashville La Vergne, TN 615-941-4000

Bobcat of McMinnville McMinnville, TN 931-488-4767

Bobcat of Maury County Columbia, TN 931-981-9909

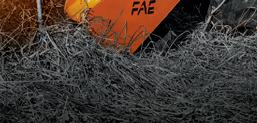

FAE has completely updated its top tracked carrier, introducing the PT550 to replace the PT475.

The PT550 is the FAE tracked carrier for big challenges, ideal for major jobs in large, wooded areas and along oil and gas pipelines.

Capable of working on large areas of soft, uneven or swampy ground, this vehicle can handle longitudinal slopes up to 45 degrees and transverse slopes up to 32 degrees. All this due to a low ground pressure of 13 psi.

This new vehicle has many updated features, from design changes to technological upgrades, starting with the completely redesigned cab for added operator comfort and safety. The PT550’s Cat. 2 ROPS/FOPS/OPS approved cab has a new configuration and an integrated cabin pressurization system, an industry benchmark.

Other improvements for added operator comfort and productivity include large Lexan glass windows, ergonomic joysticks, a pneumatic seat, a large 10 in. touch screen display to control all operating functions, a 360-degree camera system and display, and a heated and refrigerated compartment with cup holder.

The Caterpillar C13B six-cylinder engine in the FAE PT550 guarantees strength, reli-

ability and global support. Equipped with a turbocharger with after cooler, the Tier IV Final/Stage V engine delivers 536 hp. The combined diesel particulate filter (DPF), selective catalytic reduction (SCR) and diesel oxidation catalyst (DOC) guarantee compliance with Tier IV Final/Stage V.

The PT550 also is available with a Tier III/Stage III A engine for emission-free markets, rated at 475 hp. The large 12.5-L displacement and the electronically controlled proportional and reversible fan cooling system, designed specifically for the FAE PT550, guarantee superior performance for heavy jobs and in tropical climates, according to the manufacturer.

The FAE PT550’s heavy-duty undercarriage is designed to provide enhanced performance and reliability, even in the most demanding conditions.

the PT550 offers enhanced grip and comfort.

The FAE PT550’s heavy-duty undercarriage is designed to provide enhanced performance and reliability, even in the most demanding conditions. The lubricated track chains last longer than conventional chains and provide a smoother ride. When combined with the reliable dozer-type rollers and oscillating undercarriage technology,

There are two roller guard options to adapt perfectly to different environments. The conventional geometry means a low center of gravity and optimal contact between the chain and the drive wheel, two fundamental elements that provide the best performance, even on slopes, according to the manufacturer.

The FAE PT550 wheelbase also extends the load distribution area, which means lower specific pressure against the ground. The undercarriage frames are designed to withstand major stresses and make maintenance easier.

The PT550 can be equipped with a forestry mulcher or a multitask head to crush stone and till soil. Each machine benefits from Active Power Management technology, which combines the Floating System function with the Load Control function, ensuring that the head always precisely follows along the ground and that power is managed effectively during operation.

Combined with the 300/U/SONIC and 500/U/SONIC forestry mulchers, FAE’s exclusive Sonic technology enables the head to work at maximum capacity at all times. Sonic technology adjusts the torque in real time according to the force required, for up to 30 percent higher productivity.

For more information, visit www.fae-group.com.

AWARDS from page 48

SENNEBOGEN machines are purpose-built, he has technicians and service vehicles that have also been “purpose-built” with factory training and stocked with UPtime Kits and all the special tools they might need to service a SENNEBOGEN material handler.

Chad Stracener, from Tractor & Equipment Company of Alabama, the second runner-up (and the 2023 Tree Care Dealer of the Year) also talked about their service trucks, and factory-trained technicians that are out there every day meeting the needs of their customers while continuing to build customer trust and confidence. As well, he recounted that TEC continues to invest in inventory and an inventory delivery system that ensures continuous uptime and machine availability.