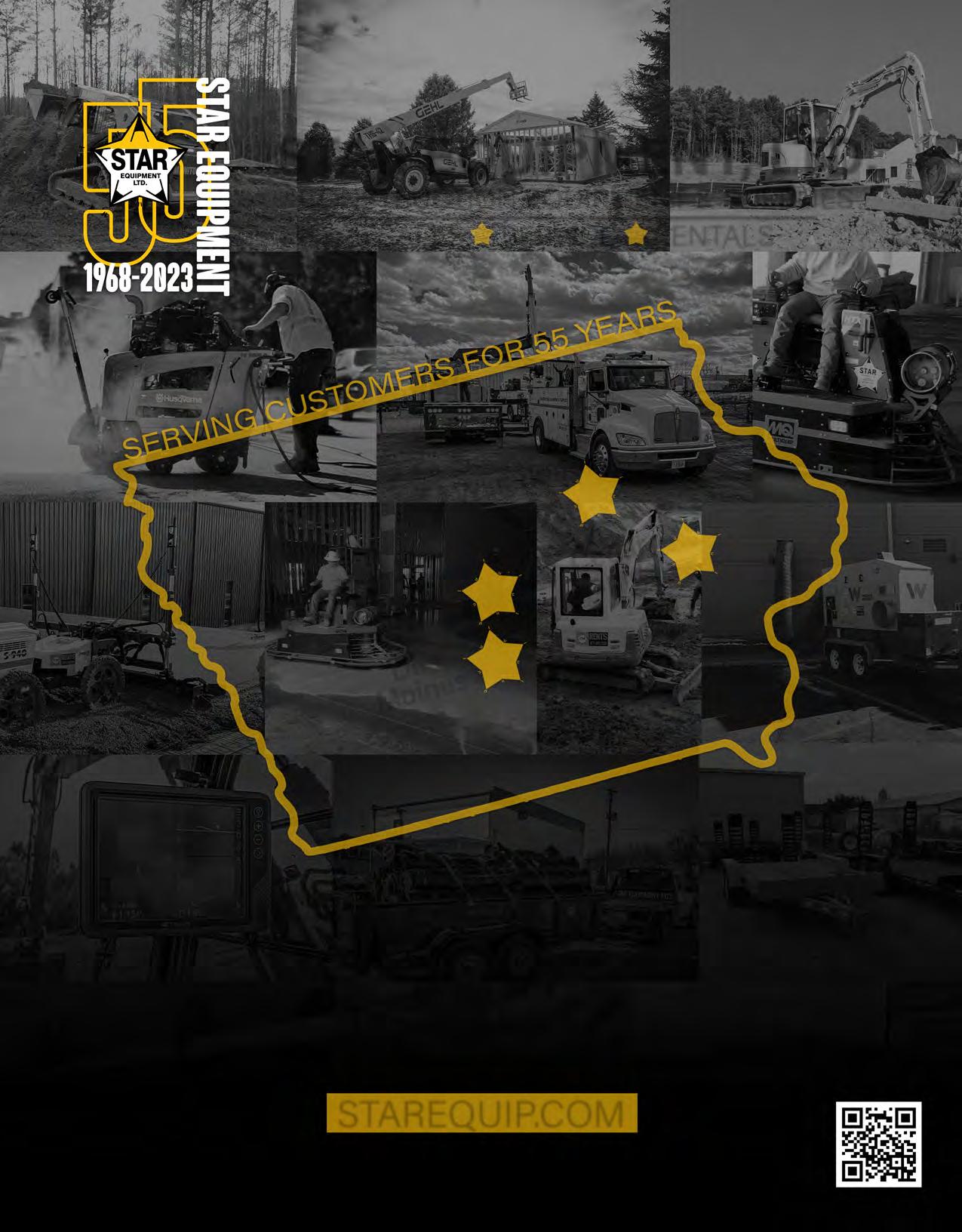

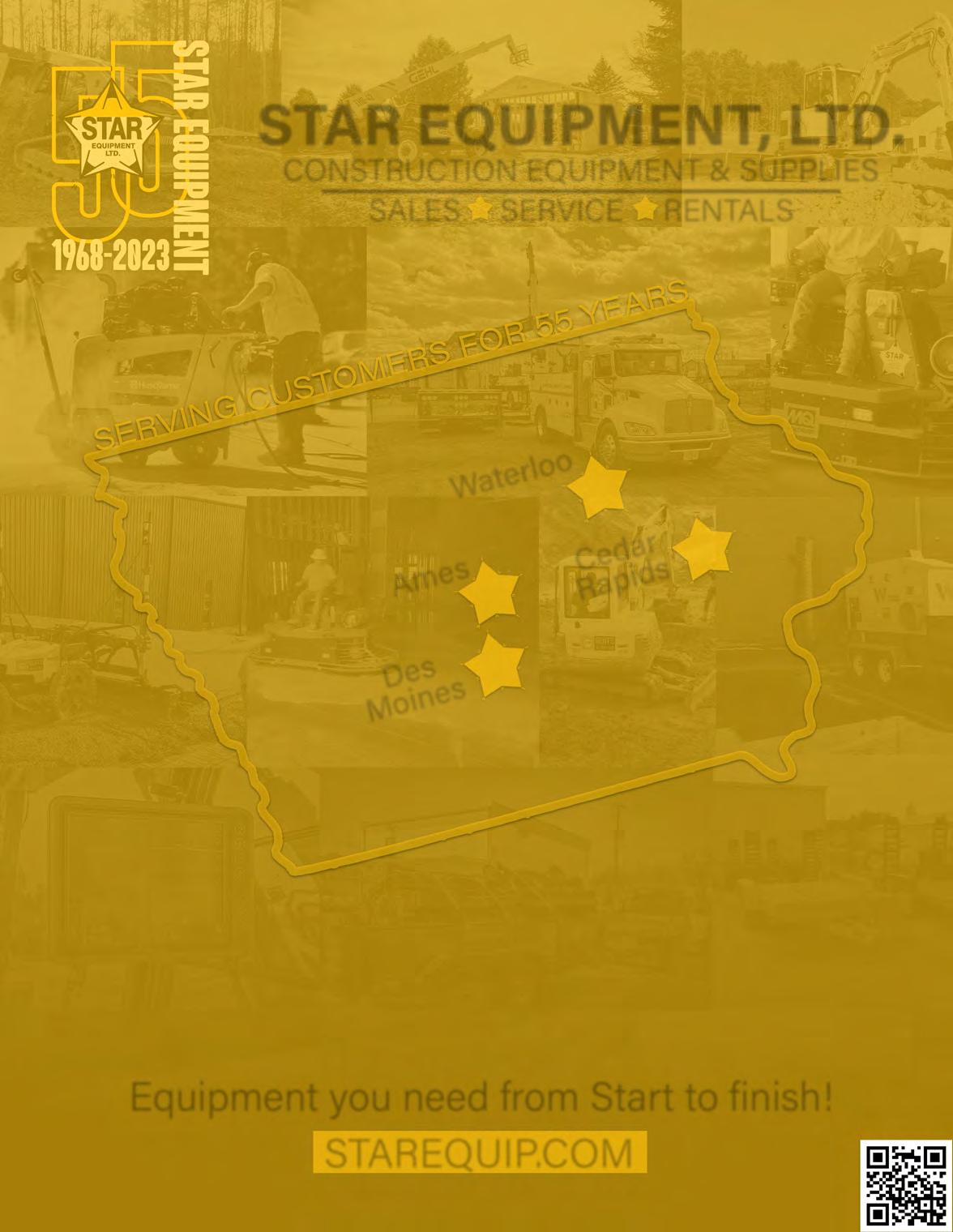

Since 1968, Star Equipment has been providing customers with high-performing compact construction machinery, light-to-general construction equipment and supplies. That’s 55 years staying on top of an industry that is in constant flux in its technology and subject to periodic economic dislocations.

“I think we have been through an awful lot of challenges,” said company President Bruce Bowman, looking back on Star’s five and a half decades of representing manufacturers. “We’re pretty resilient.” The record speaks for itself.

In the late 1970s — when the Des Moines, Iowa-based company was just 10 years old — the country was faced with soaring interest rates and fuel prices, neither of which was a boon to contractors or the dealers serving them. Star per-

severed. A decade later, the deep 2008 to 2009 recession saw a collapse in home construction and other building activity. Star survived. The recent pandemic harshly disrupted operations and supply lines but, once again, Star Equipment emerged fully intact.

“You think you have it all together,” said Bowman, “and then you get blindsided by a pandemic or something else. We’ve learned a lot of things in those times. In messes like that, you run off adrenalin and past experience and keep moving forward. If you don’t move forward, nothing good ever happens.”

The COVID disruption altered the market somewhat, eliminating a couple of Star competitors, but strengthening some others.

“The market changed,” said the president. “We are seeing an onslaught of equipment brands out there that normally wouldn’t be active. Apparently, they were able to ship new equipment when our manufacturers couldn’t and gained some footing in the market.”

Jared Vaske, who manages the company’s store in Waterloo, Iowa, said the interruption of deliveries of machines and parts from the factory during the pandemic, had yin and yang consequences at his location.

“It impacted us in a good way, and in a bad way,” Vaske said. “It was harder to get machines, but buyers were a lot more ready to buy when we did have the machines.”

At Star Equipment’s Des Moines store, sales manager

Nate Sizemore said his sales staff methodically worked through the pandemic.

“The first two weeks of COVID, the shock of it slowed us down, but once we got over the shock, it became business as normal. Well, not normal, but it wasn’t the end of the world either. We had to work through not getting equipment, but we did. Now we have equipment sitting out front and it doesn’t look like we’re closed.”

“I liked construction equipment and what it could do, and I could see that it was going to change, and change pretty rapidly.”

Max BowmanBruce Bowman, president of Star Equipment Brett Bowman, vice president of Star Equipment Brad Bowman, vice president of Star Equipment

COVID threat.

“We learned that COVID was hard mentally and physically, so we adapted and tried to take care of our people. We found out some people worked right through it, some got COVID and went home, some didn’t really know if they had it or not.”

Brett Bowman, vice president and overseer of service at all four Star locations, monitored more than a dozen service techs who kept servicing equipment despite the

Brett Bowman, vice president and overseer of service at all four Star locations, monitored more than a dozen service techs who kept servicing equipment despite the

ILL WILL prec i s i on

THE YELLOW DR Airport 0 holes or 100,000 atched reliability,

runways or roadways. 10 holes. Our drills offer unm ontimeandonbudget

ILL.

a demo today and discover quality, performance and ease of use for yourself! Visit CIMLINE.COM or call 800-328-3874 to learn more!

800-899-3580

sales@berlon.com

331 Riverview Drive • Hustisford, WI 53034 18903 High Point Rd • Viola, WI 54664

Congratulations Star Equipment on your 55 year anniversary! We look forward to working with you for another 55.

LOWE® Trenchers

Berlon’s Skeleton Rock Grapple has dual independent claws for complete clamping down on awkward loads. This bucket is ideal for rock picking, clearing fence lines, construction, scrap metal and other clean-up applications. The LOWE® trenching attachments have proven to be one of the most useful tools in the attachment market. Primarily used on skid steer loaders, trenching attachments also excel on compact track loaders and a wide range of mini-loaders. With a large selection of boom lengths and digging chains available, the LOWE® trenching attachment can make your machinery investment more useful.

LOWE® Augers

The BP-Series planetary reduction auger drives bring elements of performance and dependability to the attachment marketplace. -Features include: increased gear strength, stronger shaft support and through hardened alloy drive shaft.

Berlon’s Heavy Duty Extended Lip bucket provides greater cutting edge visibility while standard heavy duty package makes it ideal for machines 75HP and greater. Features include: ¼” body, Reinforcement tube across back of bucket for added strength, Bucket bottom includes a heavy-duty dimple plate *A Berlon Exclusive* 3/4”x6” weld-on cutting edge w/holes.

Berlon’s Compact Articulating Loader bucket is ideal for loading feed mixers and other heavy duty material handling equipment. Features include: ¼” body, Reinforcement tube across back of bucket for added strength, Bucket bottom includes 5 wear bars for durability, 3/4”x6” weld-on cutting edge with holes.

Each branch kept functioning through the national dilemma, wiping down showrooms, spraying down service trucks, disinfecting machines that came in for servicing or were going out as rentals. The rentals side of the ledger actually was favorably impacted, at least in Cedar Rapids, according to sales manager Mitch McDonough.

“It didn’t hurt sales much, but the rental business increased. We couldn’t get parts or machines from manufacturers, so sales were hurt a little. Not because customers didn’t want the equipment, but because we couldn’t get it.”

So, people rented.

All in all, the pandemic was another learning experience for a company that seems open to learning and to adapting and to continuing to be there for its customers.

**

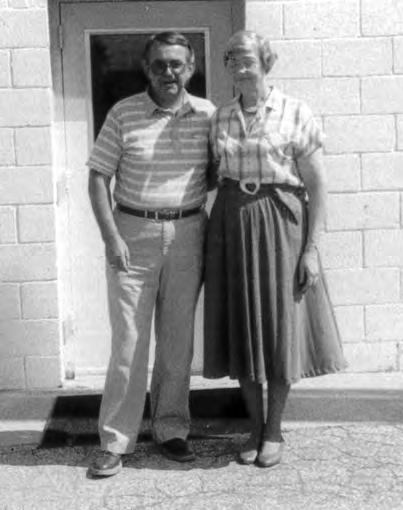

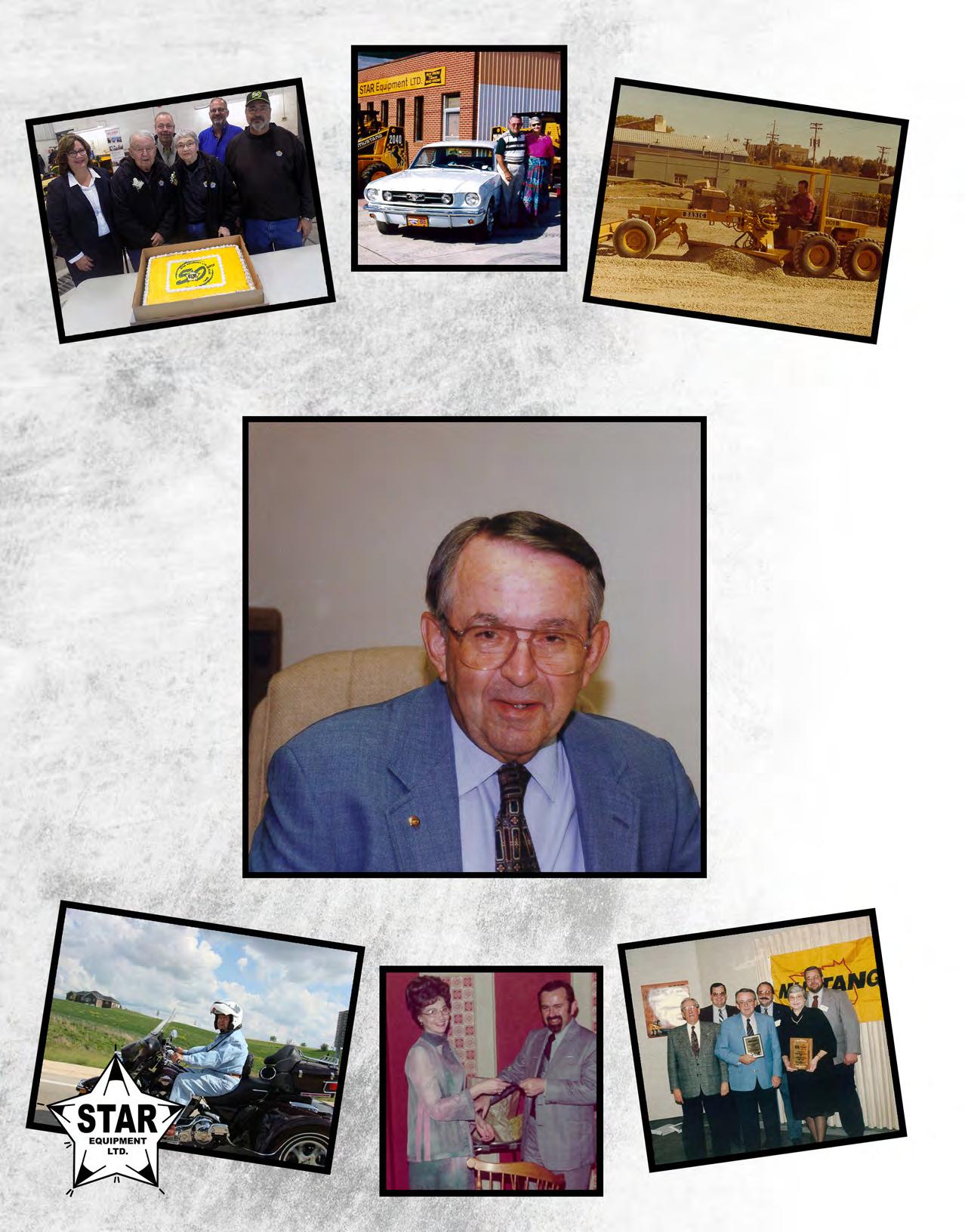

Company founders Max and Beverly Bowman were familiar with the industry before opening a dealership 55 years ago. Max Bowman had grown up around construction equipment and liked the work of digging in the earth and building things. And he saw changes coming.

“I liked construction equipment and what it could do, and I could see that it was going to change, and change pretty rapidly,” he said in an interview 10 years ago.

Bowman passed away in 2020 at age 85. Part of his legacy is his enduring reputation as a far-seeing businessman, a company owner capable of sensing looming changes in the industry and positioning his company to accommodate the shift.

“I miss him every day. He taught me a lot and I thank him every day for that. He taught us boys how to be hard workers and tried to teach us that right is right and wrong is wrong. He tried to train all the employees the right way to do things.”

Brett BowmanThese Manitou track loaders are lined up outside Star’s Des Moines store.

“Visionary” is the word Brad Bowman, vice president and manager of the Cedar Rapids store and overseer of the Waterloo location, uses to describe his father. The example he gives is compact loaders — that is, skid steers and track loaders.

“Many years ago, he saw the future in skid steers and loaders, back when people thought if you didn’t have a two-yard or three-yard wheel loader you weren’t serious about your work, or they thought skid steers would just be used to clean out a wheel loader bucket.”

Among the first manufacturers taken on by Star was the Uniloader skid steer, followed by the Mustang skid steer, which still is in Star showrooms. They were precursors of the skid steer and track loaders operated today by nearly every contractor.

“He could see what was coming down the pike,” Brad Bowman said.

Beverly Bowman kept the books for the young company.

“She was a calming influence at times,” Bruce Bowman said of his mother. “She was someone you turned to when you needed reassurance. She made sure vendors got paid, called customers who hadn’t paid us, paid the taxes, and so on.”

The co-founder will turn 90 in August. Star had 25-30 employees when Beverly Bowman decided to retire. It has 92 employees today and operates in four locations in Iowa — Des Moines, Cedar Rapids, Ames and Waterloo.

Brad Bowman sums his mother’s work this way: “She made sure we didn’t spend too much money.”

Brother Brett Bowman elaborates a little.

“She was a steady right-hand person. She did it all from running equipment around the lot to paying bills to cleaning the bathrooms. And then if you were doing something a little wrong, you got some motherly advice — whether you were a Bowman or an employee.”

Bruce Bowman said his father, when working, “could be a little intense. When he was relaxing, he would kid and joke around. But ultimately, what he was respected for was his decision-making. I was eight when he started the company, and he did what it took to make the company successful.”

The founder’s influence lingers. The president tells how Max Bowman catered to cus-

tomers in subtle ways.

“As I was growing up, he insisted that employees — and sons — answer the phone in three rings or less and, if a call was transferred, make sure the customer didn’t have to repeat himself to the next person. He preached that from Star’s inception in 1968. I remember watching a training video in 2010 and you would have thought he wrote it, as it paralleled what he taught us. He had a particular way he wanted business conducted and we have tried to continue that.”

Said Brett Bowman: “I miss him every day. He taught me a lot and I thank him every day for that. He taught us boys how to be hard workers and tried to teach us that right is right and wrong is wrong. He tried to train all the employees the right way to do things.” **

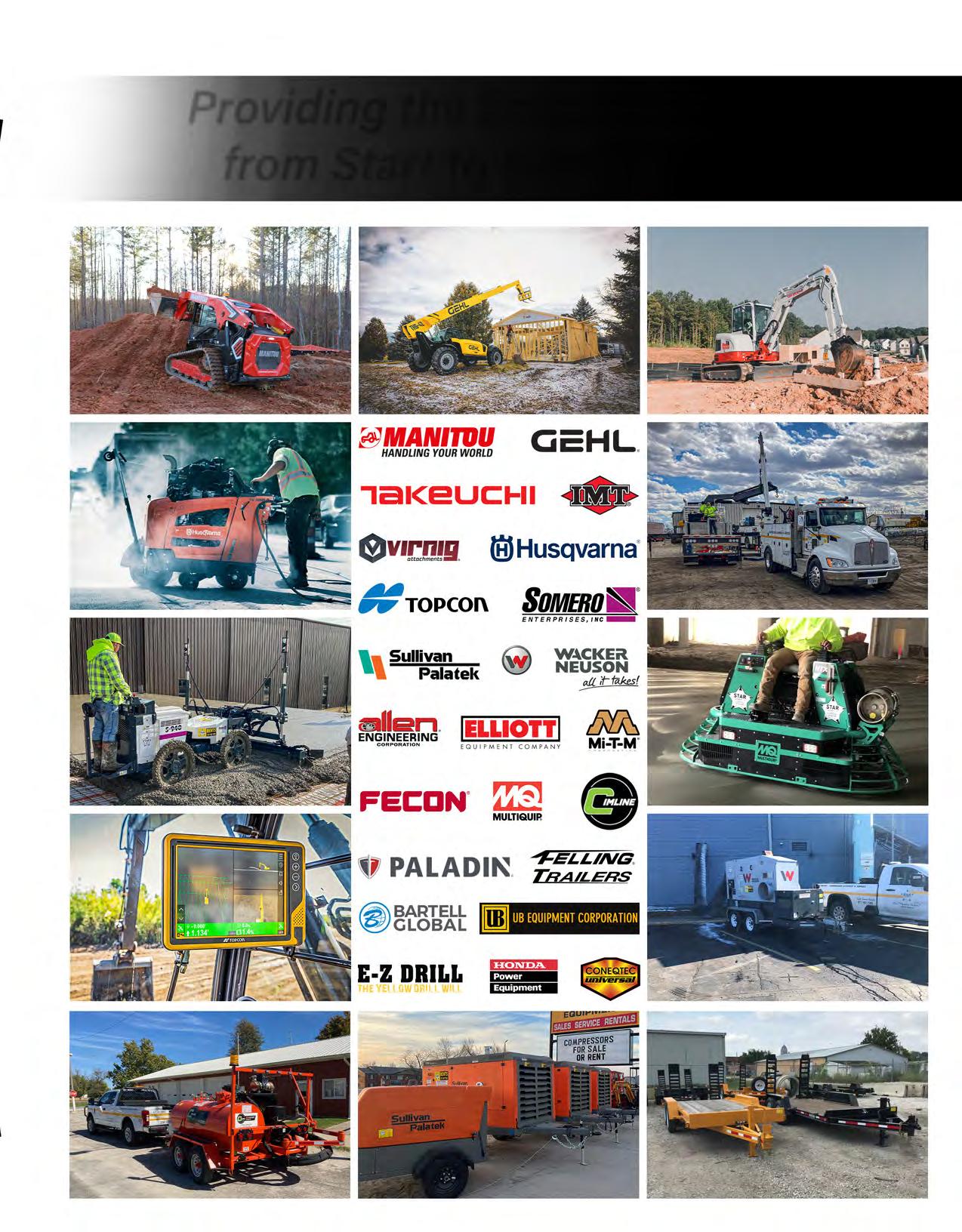

Some dealerships are diverse. Star Equipment goes way beyond diversity and offers an abundance of product lines. Scroll down the showroom section of the company website and what will you find? Fully 90 brands of machines, tools and systems — from curbing to flooring to trailers, from GPS units to truck bodies to concretehandling machinery.

“It is an advantage to be diverse in your offerings,” said Sizemore.

Conceded Bruce Bowman: “It definitely would be easier to offer fewer lines of equipment and, honestly, we have consolidated in a couple of areas.”

One of the consequences of selling so many manufactured products is the necessity of stocking parts for all of them. The president said Star Equipment typically has more than 16,000 different parts in stock.

“Some days it is kind of overwhelming,” he said. “The

pandemic didn’t just hit the manufacturers of equipment, after all. It affected our ability to get repair parts.”

The company responded by increasing its already large parts inventory.

“We brought on a significant amount more parts, increasing our inventory by as much as 35 percent, so we could better take care of our customers. That was a singular investment. Now on any given day, we probably have more than three million dollars in parts on our shelves.”

Flagship brands at Star include Manitou, Gehl, Takeuchi, Husqvarna power tools, Allen Engineering, Multiquip, Wacker Neuson, Sullivan Palatek, IMT service and lube trucks, Topcon GPS machine controls, BOMAG asphalt rollers, Felling trailers, Genie and Skyjack lifts, Virnig and Paladin attachments and Honda power units. There also are niche products like Green Climber robotic mulchers, Somero concrete laser screeds and Cratos Sherpa electric mini-skid steers.

Top sellers across the company include Takeuchi track loaders and mini-excavators and Gehl telehandlers. In Des Moines, Sizemore said the SharpGrade laser-controlled box blade for skid steers is finding new rental fans among contractors wanting precision leveling.

“We’ve had the attachment for years, but now it’s Bluetooth — no wires — battery-powered, and very user-friendly.”

The core of Star Equipment is the service that it provides to its customers, general and flat work contractors, rentals, GPS machine control and service trucks. Field service technicians and other mobile applications have kept the service truck division busy. Bruce Bowman was asked if he foresees sales of the truck units continuing to be steady, or if the company runs the chance of running out of customers.

“That will never be a finite market,” the president said and has numbers to support that view.

According to Bowman, the average lifespan of a service truck body is seven to 10 years with some fleets having upwards of 300 trucks.

“It remains one of the leading products of Star Equipment, along with the core business of construction equipment and GPS controls.”

All four Star locations offer the truck bodies, with sales of the units handled statewide by one person operating from Des Moines. A growing incentive for truck fleet owners is the shortage of qualified help coming into the service and maintenance industry.

“What is helping drive it is that there are fewer people out there ready to do the work,” Bowman said. “The trucks have more tools and equipment now — they have laptops on them — and can stay out in the field longer. That’s where we see the service truck going, doing more with fewer people.”

Some trending machines in the Star Equipment lineup

include electric-powered compact machines.

“We saw that coming,” said Brad Bowman. “We added electric stand-on skid steers, power buggies, mini-excavators, concrete buggies, some of the machines small enough to ride on an elevator. It’s worked out pretty well for us.”

Emission concerns will continue to feed popularity of the equipment, even though the practicality of the electric equipment is limited at the moment by battery life and recharging times. Yet Manitou offers an electricpowered telehandler and company executives are thinking about adding a battery-powered full-sized skid steer.

“In clinics and hospitals and around the food industry, we are going to see growing use of electric-powered equipment,” said Bowman. “Over time, it will become a bigger part of our business.”

A key ingredient in the company’s success is concrete. As the manager of the Ames location, Scott Thompson said, “We try to be the expert on the concrete side.”

That is, equipment that helps contractors transport, shape and otherwise work with the concrete is what Star Equipment offers.

“Basically, if we see something that can save our customers labor, that’s what we try to provide them, because labor is a hard thing to get these days.” **

Star Equipment has quality employees. That’s the good news. On the other hand, like every other company in the construction and heavy equipment industry, it is having trouble adding to its ranks of employees.

“The aging workforce in our industry worries me,” said the company president. “An awful lot of people out there have been discouraged by parents or high school counselors from working with their hands. Getting good people who want to work and stay with us is very, very hard. Too many of them want instant gratification, as far as work-life balance. We need to redirect our society to the notion that working with our hands is not a bad thing. That is one thing that keeps me awake at night.”

A practical consequence for any company of not being able to hire a desired number of people is that performance can suffer. “We make mistakes we don’t normally make, or we can’t get around to customers as quickly as we would like, things like that,” said Bowman, who adds that he would like to bring on another half-dozen or so people.

To mitigate the problem, the company at its various locations is working with local community colleges and high schools to acquaint young people with modern generations of equipment and the rewards of working in the trades. It offers internships as well.

“There is a good market out there for the talents of ambitious young people,” said Bowman. “The con-

struction industry is larger than the auto industry. Autos probably wouldn’t even exist if we didn’t have contractors building roads. We need to bring that perspective back into our schools.”

Adds Brett Bowman: “Not long ago there was a twoyear waiting line to get into our tech college. Now you can get in right away. They’re having trouble getting young people to enroll. That makes me a little nervous.”

The labor situation at Star Equipment is not critical by any stretch of the imagination, due to the longevity of its employees. Numerous members of the team have worked at Star for 15 to 20 years or more.

Mitch McDonough is one of them. The sales manager at Cedar Rapids came aboard almost 19 years ago after seeing an ad in a newspaper about Star Equipment wanting a truck driver. He applied. He was hired. Today, he’s not driving trucks anymore.

From working behind a wheel, McDonough moved to working behind a counter in the parts department, and from there to sales in and around Cedar Rapids before doing specialty equipment sales statewide. He now manages sales for the entire eastern half of the state.

“Basically, if we see something that can save our customers labor, that’s what we try to provide them, because labor is a hard thing to get these days.”

Scott Thompson

Proud supplier to Star Equipment IA of Grader Blades

Box Blades

QuadGrade Machine Control

McDonough said the stability of Star’s employee ranks is a plus for the company.

“We have a lot of folks who have been in the industry and in the company for a long time. Customers appreciate that. Customers don’t like to have to learn new people in the industry. They want their person who they can call or come see and get what they need. People with longevity in the company and good product knowledge is what keeps a lot of folks coming back.”

So, why do Star employees tend to hang around? McDonough said it is the feel of working at a family-owned company.

“People with longevity in the company and good product knowledge is what keeps a lot of folks coming back.”

Mitch McDonough

Ames Branch (L-R) are Brandon Tankersley, Terry Coleman, Tote Randall, Derek Huffman, Tyler Sage, Dan Coats, Matt Whitaker and Scott Thompson.

Kevin Arens, marketing

Accounting department (L-R) are Matt Wubben, Sherri Caldwell, Ann Prymek, Carissa Ullrick, Brenda Hall and Ben Littler.

Ames Branch (L-R) are Brandon Tankersley, Terry Coleman, Tote Randall, Derek Huffman, Tyler Sage, Dan Coats, Matt Whitaker and Scott Thompson.

Kevin Arens, marketing

Accounting department (L-R) are Matt Wubben, Sherri Caldwell, Ann Prymek, Carissa Ullrick, Brenda Hall and Ben Littler.

“We hear a lot back from customers about that, about the way Star takes care of its equipment. Reliability is never an issue.”

Jared Vaske

“They treat employees like part of their family. That’s important to me. I’ve never even looked to go anywhere else. Max Bowman was very much involved on the front lines and the boys are very much the same. Your people work for you easier when you are there working with them.” **

Fifty-five years, not that anyone at Star Equipment is counting. It’s pretty much business as usual. Year after year, quality products are offered to customers — a lot of the same brands, too.

“We still have something in the neighborhood of 40 percent of our original lines of equipment. We have some lineage and that makes a difference,” said Brad Bowman, who’s been working with those lines since 1975.

While three-quarters of the business volume is sales of

equipment, rentals will remain a big component of the company’s success as it moves forward. One reason for that, according to Jared Vaske, the Waterloo manager, is that the rental fleet is well-maintained.

“We hear a lot back from customers about that, about the way Star takes care of its equipment. Reliability is never an issue.”

Such dependable maintenance of equipment goes along with the company’s service department reputation.

“We have a lot of customers come to Star just because of the service department,” said Sizemore, the Des Moines sales manager. “We stand behind what we say and what we sell.”

A chunk of that service is provided in the field, with several mobile service units racing to job sites around Iowa. About 40 percent of those calls are for routine maintenance — oil changes and the like — and the rest are emergencies, such things as broken hoses and electronic red flags. Because of Star’s voluminous parts inventory, manufacturer’s still-disrupted supply lines are a minimal complication.

Bruce Bowman believes the combination of knowledgeable people, quality products and responsive customer service will carry the company forward for decades to come. What’s more, a third generation of the family, stepson Remington Lawyer, “has shown an interest in going forward with the company,” he said.

Founder Max Bowman coined the phrase “The Problem Solvers” to describe his company. His prescription for the company’s success, according to Brad Bowman, was “quality products and service at fair prices.”

It’s worked for 55 years and seems likely to continue. CEG

“We still have something in the neighborhood of 40 percent of our original lines of equipment. We have some lineage and that makes a difference.”

Brad Bowman

• 3,700 FT. LBS OF DESTRUCTIVE ENERGY

• LOW MOUNTING PROFILE PROVIDES FOR EASY ENTRY AND EXIT WITH ENCLOSED CABS

• EASY OPERATION REDUCES OPERATOR ERROR & FATIGUE

• SHOCK FREE SKID SYSTEM KEEPS THE HURRICANE GROUNDED & DISSIPATES THE SHOCK AS IT PULVERIZES THE CONCRETE

• DESIGNED, TESTED AND MANUFACTURED BY THE ORIGINAL DROP HAMMER DEVELOPERS

• LOW MAINTENANCE & MINIMAL WEAR ITEMS REDUCES DOWNTIME

• HIGH PRODUCTION IS MAINTAINED DUE TO THE BROAD FACE OF THE STRIKING SURFACE WHICH ALLOWS FOR EXCELLENT AREA COVERAGE & PRODUCTION

CALL 800-525-6828 OR VISIT WWW.UITHURRICANE.COM

TO WATCH THE HURRICANE IN ACTION E-MAIL US AT SALES@UITHURRICANE.COM

UNIVERSAL SALES PARTS FOR ALL OTHER BRAND DROP HAMMERS INCLUDING CYCLONES