By Irwin Rapoport

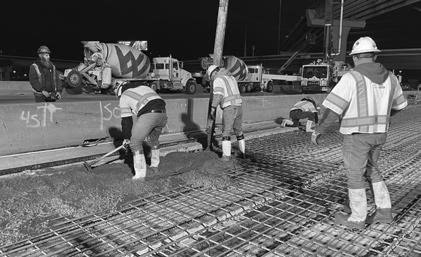

Over the last few months, Texas has experienced severe weather, heavy rain and flooding throughout many parts of the state that has general contractors out in full force helping conduct repairs, clear debris and restoring damaged infrastructure.

Statewide, between May 1 to May 21, there were 736 roads closed due to flooding and 135 locations had flood-related damages.

“The flooding washed out or collapsed complete sections of roadways in some areas,” said Adam Hammons, a TxDOT manager. “When that happens, crews quickly work with state partners to close the road and let everyone know as soon as possible. TxDOT then coordinates a detour and works on repairs.”

For example, one of the biggest incidents of road damage occurred in the Beaumont District at the FM 787 bridge at the Trinity River, where the western approach slab collapsed due to undermining. The damaged section was wide and deep, leading to an immediate road closure to allow for repairs. The Houston, Waco and Bryan districts also experienced damages that will require construction crews to make swift repairs.

“Our crews did an incredible job, working through multiple storms over the month of May and late April,” said TxDOT Emergency Management Coordinator Matthew Heinze. “We had multiple districts responding to storms with hundreds of personnel working on repairs, clearing debris and monitoring roads.”

In Houston, TxDOT and its crews were able to clear debris and help repair and restore power to parts of the state.

“Our crews are working diligently to restore our traffic signals and efforts to recover to normal operations across the Houston District, including Harris, Montgomery, Fort Bend and Waller counties,” said Eliza Paul, the TxDOT Houston District engineer said. “To expedite restoration TxDOT is leveraging our forces to get our system up and operating.”

While the Houston area has essentially recovered, other areas are in more dire situations as other parts of the state are still recovering from flooding. TxDOT crews remain out on the roads monitoring the situation, clearing debris, repairing damages and helping keep drivers safe.

Extensive flooding over the past few months has resulted in construction crews conducting repairs, restoring damaged infrastructure and clearing massive amounts of debris throughout many parts of the state.

“It’s been a long couple weeks for communities impacted by these storms,” said Heinze. “We are here to help in any way we can and our crews out there work hard to help ensure roads are clear and safe to drive.”

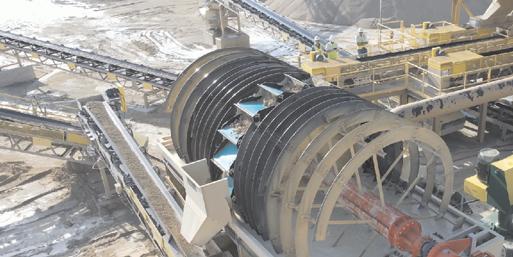

One of those crews is Knife River Corportation, who was brought in to make repairs in the Bryan District.

In Bryan, several sections of the FM 1374 in Walker County were affected with washed out roads, landslides adjacent to roads, flooded sections, damaged storm drains and the edges of lanes where the base was seriously damaged and nearly washed away. There also were sections of lane edges that just broke off. Immediate efforts to deal with the damage utilized small excavators and loaders to carry debris. Fortunately, no one was injured via the damage in Walker County.

Knife River Corporation has been making repairs at FM 1374 in Walker County, where the county has experienced washed out roads, landslides adjacent to roads, flooded sections, damaged storm drains and the edges of lanes where the base was seriously damaged and nearly washed away.

2015 JOHN DEERE 6215R......................$120,000

2020 JOHN DEERE 6130M....................$115,000

(5) 2018-2021 JOHN DEERE 6120M....From $67,500

2018 JOHN DEERE 5125R......................$98,500

2022 JOHN DEERE 5125M ....................$125,000 2023 JOHN DEERE 5115M......................$98,500 (3) 2021-2023 JOHN DEERE 5100M....From $81,000

Artic Trucks

(2) 2019 CATERPILLAR 745............From $289,500 (2) 2019 CATERPILLAR 740GC................$439,500 (2) 2022 CATERPILLAR 725............From $395,000 (5) 2023 ROKBAK RA30............................$CALL 2023 ROKBAK RA40................................$CALL

Attachments

(3) CATERPILLAR LIFTS......................$5,000 Ea.

CATERPILLAR D6 ANGLE BLADE................$7,500

CATERPILLAR D8T ANGLE BLADE..............$7,500

CATERPILLAR D10T SS RIPPER..................$CALL

CATERPILLAR ANGLE BLADE....................$7,500

CATERPILLAR WINCH..............................$CALL

Crawler Loaders

(4)

(2) 2019-2020 MOROOKA MST4000VD.................. ..............................................From $259,500

2018 MOROOKA MST3000VD......From $159,500 (3) 2018-2019 MOROOKA MST2200VD.................. ..............................................From $129,500

MOROOKA MST660VD....................$72,500

(2) 2007-2023 CATERPILLAR 815................$CALL 2017 CATERPILLAR CS66B....................$119,500

(7) 2016-2022 CATERPILLAR CP56B..From $119,500

(6) 2017-2022 CATERPILLAR CS56B..From $119,500 2013 HAMM H13I................................$79,500 2020 HAMM H12I..................................$CALL

Dozers - Crawler

2023 CATERPILLAR D10T2..................$1,950,000

2023 CATERPILLAR D9............................$CALL

(7) 2012-2022 CATERPILLAR D8T....From $279,500

(2) 2020 CATERPILLAR D6..............From $319,500

(13) 2019-2024 CATERPILLAR D6 LGP..From $239,500

(4) 2019-2020 CATERPILLAR D6XE LGP................ ..............................................From $229,500

2020 CATERPILLAR D6 XL....................$369,500

(3) 2018-2019 CATERPILLAR D6T XW..From $209,500

2018 CATERPILLAR D6N XL......................$CALL

2023 CATERPILLAR D5 LGP..................$415,000

2019 CATERPILLAR D5K2XL..................$169,500

2023 CATERPILLAR D4........................$275,000

(2) 2022-2023 CATERPILLAR D3......From $205,000

2022 CAT D2........................................$CALL

KOMATSU D61EXi-24....................$229,500

KOMATSU D71PX-24....................$269,500 (5) 2023 KOMATSU D71PXi-24........From $445,000

Dozers - Wheel

2015 CATERPILLAR 834K......................$285,000

2022 CATERPILLAR 395........................$965,000

2019 CATERPILLAR 390FL....................$925,000 (3) 2019-2021 CATERPILLAR 374FL..From $649,500 (2) 2021-2222 CATERPILLAR 352-07........$475,000

(2) 2017-2019 CATERPILLAR 349FL..From $229,500 (4) 2021-2022 CATERPILLAR 349....From $495,000

(3) 2019 CATERPILLAR 336............From $179,500

2018 CATERPILLAR 336FL....................$209,500

(2) 2023 CATERPILLAR 330-07................$339,500

2020 CATERPILLAR 326-07....................$289,500

2020 CATERPILLAR 320........................$189,500

2017 CATERPILLAR 316FL....................$149,500

(2) 2018 CATERPILLAR 304E2..................$52,500

2013 CATERPILLAR 6030....................$1,050,000

(2) 2022 CATERPILLAR 16..................$1,325,000

2024 CATERPILLAR 14........................$795,000

(3) 2020-2024 CATERPILLAR 150....From $359,500

2008 CAT 140M AWD..............................$CALL

2017 CATERPILLAR 140M3....................$269,500

(7) 2020-2021 JOHN DEERE 333G......From $59,500 (2) 2021-2024 CATERPILLAR 299D3 XEFrom $62,500 (2) 2020-2022 CATERPILLAR 299D3 XPS.............. ................................................From $67,500

2021 CATERPILLAR 299D3..............From $67,500

Water Equipment - Tower/Tanks (3) 2022-2024 KLEIN KPT-120

Water Equipment - Trucks

JCB began work on a new $500 million factory in San Antonio, Texas — the biggest investment in the company’s history.

An official groundbreaking ceremony at the site marked the beginning of construction, where The Hon. Alice Bamford, the daughter of company Chairman Anthony Bamford, turned the first shovelful of dirt on the property.

Work on the 720,000 sq. ft. factory is now under way on the 400-acre site. It will be the company’s second largest plant, rivalled only by JCB’s world headquarters in Rocester, Staffordshire, England, and create 1,500 new jobs over five years. The factory will make Loadall telescopic handlers and aerial access equipment, with production scheduled to start in 2026. The factory also will have the capacity to expand and build other products in the future.

Chairman Lord Bamford said, “Construction equipment manufacturers sell more than 300,000 machines every year in North America, making it the single largest market in the world. JCB has been growing its share of this important market steadily over the past few years and the time is now right to invest in our manufacturing capacity in North America, where we already have one factory.

“JCB really has come a considerable way since we sold our first machine here 60 years ago and it gives me immense pleasure to see how our business has grown in North America. Today really is a milestone day in the history of our family company,” Bamford said.

“Texas was this year named as The Best State for Business for a record-breaking 20th year, and I am proud to welcome JCB as the newest business to call our great state home,” said Gov. Greg Abbott. “Today’s groundbreaking marks a major milestone in JCB’s journey that will create 1,500 goodpaying jobs for hardworking Texans in Bexar County and bring hundreds of millions of new capital investment to San Antonio and beyond.

(L-R) are Adriana Rocha Garcia, city of San Antonio Councilwoman District 4; David Carver, operations director, JCB San Antonio; Rep. John Lujan, Texas House of Representatives District 118; Alice Bamford; Lord Bamford, chairman, JCB; Cecilia Abbott, First Lady of Texas; Mark Turner, chief operating officer, JCB; Rebeca Clay-Flores, Bexar county commissioner, Precinct 1; Richard Fox-Marrs, president and CEO, JCB North America; and Jenna Saucedo-Herrera, president and CEO, greater SATX. In addition to the traditional gold shovels, the groundbreaking ceremony for the new JCB San Antonio facility featured the iconic JCB backhoe loader, as well as the JCB 220X large excavator.

“‘Made in Texas’ is truly a powerful global brand, and I look forward to celebrating JCB’s continuing success as we work together to build a bigger, better Texas for decades to come.”

JCB CEO Graeme Macdonald said, “JCB’s business in North America has made tremendous progress in the past few years and the opportunity for growth here is vast. This record investment gives us a fantastic opportunity to build on our success and we look forward to the completion of this great new facility.”

Richard Fox-Marrs, president and CEO of JCB North America, said, “The Loadall telescopic handler is JCB’s biggest selling product in North America and it is also the single largest market for aerial access equipment worldwide, and therefore, it makes

great sense to build these two ranges here.

“Texas is an obvious choice for our new North American manufacturing facility, not least because the state is the largest consumer of construction equipment in the USA. San Antonio is also the logical choice as a location for our new factory because of its central location, proximity to the supply chain and great local labor force. We are really excited about JCB’s new San Antonio factory and for the future of our business in North America,” said Fox-Marrs.

JCB sold its first machine in North America in 1964 and opened its first U.S. manufacturing plant in 2001 in Savannah, Ga., which employs 1,000 people. The new facility will manufacture machines for customers specifically in North America.

JCB employs 19,000 people globally and

has 22 factories around the world, including 11 in the UK, seven in India, and others in Brazil and China. The company will mark its 80th anniversary in 2025.

For more information, visit www.jcb.com.

(All photos courtesy of JCB.)

Bobcat of Abilene

325-673-7361

Bobcat of Amarillo

806-622-9593

Bobcat of Austin 512-251-3415

Bobcat of Buda 512-884-5533

Bobcat of Corpus Christi 361-884-3959

Bobcat of Lubbock 806-745-1322

Bobcat of Marble Falls 830-220-6070

Bobcat of Marion 830-420-9020

Bobcat of Midland–Odessa 432-685-9298

Bobcat of Pleasanton 830-580-4020

Bobcat of the Rio Grande Valley 956-425-4300

Bobcat of San Antonio 210-337-6136

Bobcat of Temple 254-523-4900

Bobcat of Victoria 361-579-0922

Bobcat of Waco 254-488-7004

Bobcat of Wichita Falls 940-285-7777

Ranchers ATV and Tractor Kerrville 830-315-2330

e r • T ailer W

• Overall W

• Deck Length: 21’ Flat (model shown)

• 6’ Beaver

• Deck Height: 34" tail

• Brakes: Air (Full ABS System) ires: Eight 215/75R17.5 (H) i

• Ramps: 72" Long x 22”

• T R72"L22”

Wid

Durable Composite Decking is

Outboardbrakedrumsforeasier HUBPILOTEDWHEELS

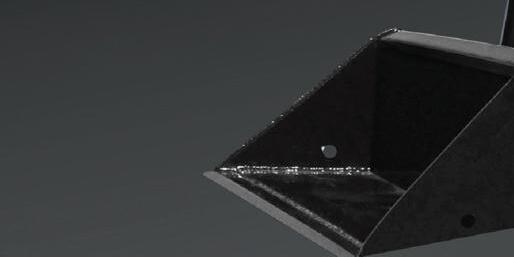

Niece Water Towers deliver reliability and durability when you need fast mobile water service. With a 12” discharge tube it fills your tanks at a rate of over 1,000 gallons per minute. Offers removable power pack for security, fifth wheel tow hitch, professionally engineered and constructed.

It features (8) legs for stability

5th wheel set up for quick “tow and go.”

With hydraulic hammers — including an NPK GH-23 mounted on a Cat 349 — the contractor was able to break through the limestone.

As one of the larger civil construction firms in the Lone Star State, DNT Construction LLC is used to dealing with a range of challenges on its projects. As a result, the company has an equally full range of solutions ready to meet those challenges. Often, however, the impediment to production can be something as simple as a vein of hard rock, interrupting the normally smooth site prep effort.

Such was the case at a massive residential development in San Marcos, where a shelf of limestone running through the site added a step to the mass excavation/grading process.

Armed with hydraulic hammers — including an NPK GH-23 mounted on a Cat 349 — they showed the limestone to be little more than a temporary inconvenience. And all the rock being dealt with is effectively downsized and re-used on site. Big reductions, big efficiencies and big productivity. It’s the Texas way.

Now entering its 15th year in business, DNT Construction serves south central Texas customers in an area generally bordered by San Antonio, Austin and Houston. With 750 employees, the company handles residential, commercial and municipal projects from excavation to utilities, and more. According to Hunter Drummond, a DNT vice president and equipment manager, that broad-scope capability has allowed them to grow into the company they are today.

“We consider ourselves a turnkey civil construction company,” he said. “In addition to excavation, we do wet and dry utilities, retaining walls and, because this area is just exploding with growth, we have a large focus on residential subdi-

visions. The San Marcos area, in which one of our major, ongoing projects is located, is almost halfway between San Antonio and Austin, so the development around here is just through the roof.”

The project to which Drummond refers, Kissing Tree, is a 1,300-acre, 55-year-old and up community which offers all of the amenities common to similar developments like The Villages, any Del Webb community, etc. DNT has been the site contractor on it for more than eight years and estimates that they are currently about halfway through the duration of the project. When complete, developers envision the gated community housing some 3,000 residences.

True to form, DNT’s scope of work at Kissing Tree is extensive, tackling everything from site excavation to utility work to creation of retaining walls. The excavation/grading facet of the job includes pads for houses and community areas, as well as all new roads and sidewalks. Drummond said that their portion of the road work includes the subbase and base layer work — essentially everything up to asphalt.

“The utility work is quite extensive as well,” he added. “We are doing all water, sewer, storm, fiber optics, gas, etc. It is in many of these areas that we encounter rock and need to turn to the hydraulic hammers. Our work over this last decade and a half has resulted in us putting together a pretty extensive fleet of 39 NPK hammers in addition to eight plate compactors — all of which we get from and have serviced by Waukesha Pearce, Inc.’s Pflugerville [Texas] branch.”

HAMMERS page 16

HOUSTON (AP) A bridge near Galveston, Texas, that was damaged recently when a barge carrying fuel broke free from a tugboat has reopened to vehicle and pedestrian traffic after safety inspections deemed it safe, officials said.

The barge crashed into a pillar supporting the Pelican Island Causeway span on May 15. The impact caused the bridge to partially collapse and cut off the only road connecting Galveston to Pelican Island.

After a review of the bridge by the Galveston County Navigation District No. 1 and underwater inspectors with the Texas Department of Transportation, the structure was reopened. Officials have set weight limits for vehicles using the bridge.

Early estimates had indicated that up to 2,000 gal. of oil spilled into surrounding waters following the collision.

On Sunday, the U.S. Coast Guard updated that figure, saying approximately 20,000 gallons (75,708 liters) of oil were spilled.

After the oil spill, authorities deployed a boom, or barrier, to contain the spill, forcing the temporary closure of about 6.5 miles (10.5 kilometers) of the waterway.

Clean up efforts have ended around Pelican Island. But crews were still removing oil and washing shoreside rocks along

Swan Lake, a coastal recess located several miles west of Pelican Island along the Texas Coast.

During the clean-up efforts, crews recovered three dead, oiled birds from around Swan Lake: two brown pelicans and a laughing gull.

Nine other birds that were alive but covered in oil were spotted around Swan Lake, but officials said they were not able to recover them.

“To further protect wildlife, acoustic can-

nons were placed to provide an audible distraction to shore birds,” the Coast Guard said.

After the barge collision, Texas A&M University at Galveston, which has a campus on Pelican Island, had closed its facility. Fewer than 200 people related to the school were on the island at the time.

The university said the campus resumed normal operations on Monday.

The Coast Guard said the tugboat had lost control of the 321-foot barge “due to a break

in the coupling” that had connected the two vessels.

The affected area is miles from the Gulf Intracoastal Waterway, which sees frequent barge traffic, and the Houston Ship Channel, a large shipping channel for ocean-going vessels.

The accident came weeks after a cargo ship crashed into a support column of the Francis Key Bridge in Baltimore on March 26, killing six construction workers.

(All photos courtesy of TxDOT.)

DISASTER from page 1

“Knife River helped us get our roads back together,” said Bob Colwell, a Bryan District public information officer. “We had flooding in six of the 10 counties in the district. Walker County was hit the hardest with over 40 inches of rain in a three week timeframe.”

“TxDOT works extensively with its general contractor partners and has a close partnership with them to be prepared for severe weather,” said Heinze.

“Crews have spent the last few days clearing debris from roadways and working to restore operations in the Houston area,” it stated. “TxDOT’s current priority is restoring and repairing signal operations impacted by the storm. Of the 1,100 signals throughout the Houston District, roughly 125 are in need of repair.”

To ensure a swift recovery, TxDOT mobilized crews from across the state to assist with Houston’s emergency operations and recovery efforts. The Houston District also geared up to augment signal restoration efforts in support of the local municipalities.

TxDOT works closely with its state partners in response to storms, including the Texas Department of Emergency Management.

In addition to repairing roads, crews from TxDOT throughout the state cleared debris in drains before the storm,

which helped to provide relief during heavy rain events; monitored road conditions, looking out for flooding and damages; removed debris over the road; inspected road damages and worked on current and long-term repairs. In some areas, crews have repaired all flood-related road damages; and restored power to and repaired damaged traffic signals.

Hammons stressed that TxDOT prepares year-round for

events such as the spring storms and that crews are ready to respond rapidly.

“When water rose and began to flood roadways, TxDOT was ready with traffic control measures and kept the public informed about closures and alternate routes,” he said.

(All photos courtesy of TxDOT.)

The hammers in DNT’s inventory vary in size from smaller PH-3’s, used on mini-excavators to the GH-23 for 400 class excavators. As is common in the industry, the choice of hammer is dependent on a number of factors including volume and hardness of the material being encountered and a need to maintain a desired production rate.

That last point — maintaining a specific production rate — came into play at Kissing Tree when a particularly hard seam of rock was encountered. According to Brad Dillon, one of DNT’s excavation superintendents, it was challenging, even by Texas standards.

“The material we’re encountering in one area, while still limestone, is much harder than we were anticipating,” he said. “To give you an idea of how dense it is: if you pick up a pretty good-sized piece of it and drop it, it sounds like a China plate breaking — it’s just nasty. I had two Cat 336s with GH-18 hammers working in that area and we were maxing out at 400 yards of material a day between two machines — well below what we were hoping to get. We knew we needed to take things up a notch.”

Dillon and his managers called for a larger hammer, an NPK GH-23 mounted on a 105,000 lb. Cat 349 machine and, after arrival, saw immediate results.

“The single, bigger machine/hammer combo was bettering the production rate of the two smaller machines,” he said. “Going with that larger hammer and machine not only got us better in line with our goals, it also freed up that pair of 336s to do other work on site. We are fortunate to have that kind of flexibility and make it work for us.”

If Drummond seems like he knows his way around a hydraulic hammer, it’s because he does. Prior to coming to the contractor side, he was a service supervisor for a company that, at the time, was an authorized NPK dealer. That afforded him a much deeper knowledge of the hammers than most and allowed him to make an “apples-to-apples” comparison.

“While at that dealership, I had the opportunity to see and work on other brand hammers as well,” he said. “Even back then it was obvious that the NPK hammers, particularly those in high production usage, were lasting probably twice as long as others between rebuilds. In addition, they're much more mechanic-friendly when it’s time for that rebuild — there’s no need for special stands or specialized tooling to get the work done. And their longevity speaks for itself; we've got quite a few in the 15-plus year-old range that we're still regularly using. In fact, we just recently finished rebuilding one that is 20 years old. While they're not the cheapest hammer to purchase, when you look at how long they will be in service, and the outstanding support they provide, they’re really the logical choice.”

The thousands of yards of rock DNT is hammering out at Kissing Tree will be used as fill in areas outside of the house pads — those in which material density isn’t a factor. In addition, it can find use throughout the development as retaining wall material and could be crushed for use at a later date.

“Because this site is so massive, the earthmoving and grading effort is balanced, so there’s no need to take material off site or — with the exception of specialized product — bring any on,” said Dillon. “Being able to use the hammered rock plays into that scenario nicely.”

Drummond added that an obvious partiality for one brand of hammer over any others is not unique to DNT, citing the fact that the two other largest contractors in that region also share their preference.

“Construction is a game of productivity, and you have to go with the tools that are going to serve you best, providing you with solid production and minimal downtime. We, along as the other big players in this market, have learned that NPK fits that bill. That’s why, several years back, when our existing dealership took on another line of hammers and dropped NPK, we didn’t change hammers, we changed dealers — the next day. We believed in it that strongly, and it’s proven to have been the right choice every day since.”

(All photos courtesy of DNT.)

DNT’s work over this past decade and a half has resulted in it putting together an extensive fleet of 39 NPK hammers in addition to eight plate compactors — all of which it gets from and is serviced by Waukesha Pearce Inc.’s Pflugerville (Texas) branch.

Premier Truck Rental (PTR), a leader in the work truck and trailer rental industry, announced its 10th anniversary.

Since its inception in 2014, the company has continuously pushed the boundaries of innovation, achieved significant milestones and set new standards in the equipment rental space.

Started by a father-daughter pair, PTR quickly grew in reputation and impact, growing rapidly in fleet numbers and personnel. This growth is a testament to the company’s commitment to quality, customer satisfaction and relentless pursuit of excellence.

Over the past decade, Premier Truck Rental has transformed from a visionary startup into a robust market leader. Key achievements include:

• Innovative Solutions: Pioneering groundbreaking products and services, like a custom-built 2-ton framer for power projects.

• Customer Trust: Building a loyal customer base across the United States.

• Awards and Recognitions: Garnering numerous industry awards, like being named the National Fleet Management Association (NAFA) Top 100 Commercial Fleets two years in a row.

“Reaching this ten-year milestone is a moment of pride for everyone at Premier Truck Rental,” said PTR President Adriene Horn. “We’re grateful to our dedicated team, loyal customers, and supportive partners who have been instrumental in our success.”

As Premier Truck Rental embarks on the next chapter, the focus remains on driving innovation, enhancing customer experience, and expanding its national footprint.

Kirby-Smith Machinery Inc. (KSM) announced the promotion of JP Cotton to the role of assistant sales and operations manager for the Dallas branch.

Cotton will be responsible for supporting Sales and Operations Manager Chad Cox with the day-to-day operational needs of the Dallas branch and provide increased focus on growing additional sales opportunities.

This new position for Cotton will help Kirby-Smith expand capabilities in the DFW market and also will serve as a developmental role, reflecting the commitment to raising the next generation of leaders at KSM.

Cotton started his career at KSM in 2017 as a territory manager and has served the past several years on the KirbySmith Finance Team, with a focus on West Texas and industrial equipment. With 16 years of experience in the heavy equipment industry, spanning both the manufacturer and distributor sides, Cotton brings a wealth of knowledge and expertise to his new role.

“I don’t have the words for what this opportunity means to me, except there’s nothing like KSM anywhere else out there, and I’m excited to work with Chad and do my part to help lead the charge in Dallas,” said Cotton. “One of our core foundations is family first and I’m grateful for the opportunity to now be a lot closer to my own family in DFW. But more than anything, I want to say thank you to my KirbySmith family.”

Gavin Cole, executive vice president of sales, said, “This new position of assistant sales and operations manager will allow [Cotton] to further hone and develop his skills as a manager and I look forward to seeing what he does with this new opportunity.”

For more information, visit kirby-smith.com.

The first construction phase includes building a naphtha hydrotreater and reformer, which is expected to be operational by 2027.

A Houston company will construct the largest new refinery in the last 50 years in Brownsville, Texas.

Element Fuel Holdings LLC is spending between $3 and $4 billion on the project, which will produce more than 160,000 barrels per day of gasoline, diesel and jet fuel from shale oil production, according to a report by the Houston Business Journal.

“Since no one’s built a refinery in 50 years, there’s probably a better way to do it,”

Element Fuels Founder and co-CEO John Calce told the business outlet. “Let’s optimize it.”

The refinery will be located in the Port of Brownsville and constructed in three phases.

The first construction phase includes building a naphtha hydrotreater and reformer, which is expected to be operational by 2027.

Element also will build a power plant that uses hydrogen and natural gas to produce energy and include carbon capture and storage to reduce the facility's carbon footprint.

Element Fuels told the Houston Business Journal that it intends to produce enough hydrogen to supply all the refinery’s power needs, significantly reducing the refinery’s emissions compared to older refineries that

run on diesel.

The Houston-based firm said that in its second phase it will also add a crude distillation unit and diesel hydrotreater. In its third phase, the refinery will investigate using excess hydrogen and carbon dioxide to make biofuels.

According to a report by the U.S. Energy Information Administration, refinery utilization rates are forecasted to average 90.3 percent in 2024, a significant increase from the 2020 pandemic low of 78.8 percent, offering a hopeful outlook for the industry’s growth and the prices upstream of gasoline.

Refinery activity reached 95.4 percent capacity in June, processing 17.584 million barrels per day of crude oil and other feedstocks, according to the EIA. This surge in activity has led to gasoline and other feedstock inventories growing well above figures from the same period in 2023 and 2022.

Element plans to process U.S. shale oil, which is a type of light crude that older refineries in the country are not optimized to handle. The company expects to provide 1,000 new jobs in Brownsville and grow its Houston headcount by about 80 employees.

A congested triangle of highway interchanges is becoming a distant memory after a massive overhaul of the corridors wraps up in Irving.

The Irving Interchange surrounds the old Texas Stadium site in the Dallas District and is where SH 183, SH 114, Loop 12 and Spur 482 intersect. Outdated cloverleaf designs, narrow highways and growing traffic demands caused significant delays for commuters and travelers and landed this location a spot on the Texas Clear Lanes Congestion Relief planning list.

For the past decade, TxDOT has steadily made improvements in the corridors leading up to this $301 million project. To make the junctions function, this phase included the construction of 10 new direct connectors, 22 new overpasses and nearly five miles of widened highway lanes and new pavement. Work started in 2020 and

183, SH 114, Loop 12 and Spur 482 intersect.

all new bridges and lanes opened to traffic in spring 2024.

To celebrate the transformation, local and state leaders joined TxDOT in May to cut a ceremonial ribbon and view the changes. As traffic flowed in the surrounding corridors, Texas Transportation Commissioner Robert C. Vaughn commented on the impact the Texas Clear Lanes program is making.

“Reducing congestion in our metro areas through “Texas Clear Lanes” is an ambitious task, but we’re committed to following Governor Abbott’s direction and working with state and local leaders to make a difference for drivers,” Vaughn said. “Since 2015, this new congestion relief program now has $75 billion of non-tolled projects that are completed, under construction, or planned.”

As final items are wrapped up on the Irving project, drivers are reminded to use caution in work zones. To view current highway projects in Texas visit DriveTexas.org.

(All photos courtesy of TxDOT.)

To encourage road safety while also encouraging travelers to keep roads clean, a TxDOT team recently devised a plan to reach the masses through art at the Houston Art Car Parade.

Traffic Engineer James Keener had a vision more than 10 years ago to enter a TxDOT vehicle in the Houston Art Car Parade. The parade attracts many participants and thousands of spectators each year. Entries include anything on wheels from bicycles and unicycles to lawnmowers, cars and go-carts.

Last year, the Houston team was able to enter a vehicle called the Traffic Safety Cone Monster, which received first-place honors while helping to highlight work zone awareness and other traffic safety messaging.

In 2019, Keener began coordinating with a friend who works with the Houston Independent School District’s Secondary Visual Arts Implementation program. He wanted to enlist the help of high school students to decorate the vehicle. Then, the Covid-19 pandemic began and the idea had to be scrapped.

Keener resurrected the art car idea in 2023.

“This competition rekindled the fire of perhaps seeing an art car created,” Keener said.

Keener assembled his team of volunteer TxDOT employees and they decided to enter two vehicles for the 2024 parade. Over a few weeks, the art car team gathered supplies and secured two TxDOT vehicles, which were temporarily loaned for the effort.

Working a few hours at a time, TxDOT Houston District staff teamed up to build the two vehicles to promote work zone safety

and the Don’t Mess with Texas campaign.

“The team made two cars this year, Game of Cones-Construction is Coming and Found on Road-Don’t mess with Texas,” Keener said. “The Game of Cones was decorated with barrels, cones, safety vests, signs, barricades, signals, reflective sheeting and other materials.”

The goal of the Game of Cones vehicle was to bring attention to the importance of work zone safety and how important it is to slow down, stay off the phone and use caution while traveling through work zones.

The Don’t mess with Texas vehicle was adorned with anti-litter messaging but also featured various pieces of debris found on state roadways including a car bumper and furniture pieces. The vehicle helped to encourage the public to not litter on state roadways while also highlighting the kinds of debris that wind up on state roads.

The parade of vehicles made its way through downtown on a Saturday in April.

“Many folks from around the country came out and got up close to the creations — including our vehicles,” Keener said.

An estimated 350,000 people attended the parade and associated festivities. The TxDOT art car team also spent time working several booths set up along the parade route and in Sam Houston Park HEB Kids Zone.

“Our team at the booth passed on our messages of safety and keeping roads clean to many thousands of individuals while both vehicles rolled through the parade route to many cheers,” Keener said. “At the end of the day the team was tired, hot, but so happy that the day was such a success.”

(Photo courtesy of TxDOT.)

Bane Machinery is a family owned and operated business that offers heavy machinery sales, rentals, parts, and service. We are proud to offer Liebherr equipment with full service including preventative maintenance and warranty up to OEM standards.

Liebherr machines are custom-engineered to perform efficiently. From material handling to waste management, these machines showcase a range of what’s possible.

Contact us today to find the right solution for your project application.