By Irwin Rapoport CEG CORRESPONDENT

Construction of the Texas Department of Transportation’s (TxDOT) $39 million FM 110 North project will wrap up later this month with a ribbon cutting ceremony for the initiative that created a loop around the city of San Marcos, providing a much needed alternative to I-35. see LOOP page 26

By Lucy Perry CEG CORRESPONDENT

Though public spending on road construction is projected to increase by double digits again this year, contractors are cautious about this year’s business prospects. Given the continued challenges facing the construction industry in logistics logjams, labor shortages and rising interest rates, the overall mood is “decidedly mixed.”

ARTBA reported that the public highway, pavement and street construction sector is expected to see doubledigit growth for the second year in a row.

Th sid w Co f atorinterhisall-newoper es of the machine with t deg -popping 270- e ith ey ons and d ablebuttnfigur

Vi ASEMax he optional C reecameraviewstothe machine cessto eeper ac ntrol. y. ew displa rearand edata, his allnew oper e puts y

totalcon faceputsyouin

Ext-Hoe, Aux. Hyd. Thru ext-hoe, Pilot Control $69,500

2015 Cat CS44, Stk#: 12622, 66" Smooth Drum, 1,509 hrs., 14.9x24 Tires $69,500

2015 Bomag BW211D-50, Stk#: 12686, 84" Smooth Drum, 2,775 hrs., 23.1x26R3 Tires, 4 Cyl. Deutz Eng $66,500

The Associated Equipment Distributors (AED) convened for the group’s annual summit/CONDEX at the Mirage in Las Vegas Jan. 16 to 18, 2024.

Caterpillar announced the launch of a prototype demonstration project for a battery-powered field elevator with Flory Industries, a leader in nut-harvesting equipment.

Associated Builders and Contractors released a statement from Vice President of Regulatory, Labor and State Affairs Ben Brubeck opposing the U.S. Department of Labor’s independent contractor final rule under the Fair Labor Standards Act.

Irish phenom James Roe and Ring Power Corporation, the premier Cat dealer in north and central Florida, announced their continued partnership for the 2024 INDY NXT by Firestone season.

18 CONSTRUCTION ADDS NEARLY 12,000 JOBS IN DECEMBER 2023

The construction industry added 17,000 jobs on net in December, according to an Associated Builders and Contractors analysis of data.

18 LIUGONG NORTH AMERICA NAMES HAMRE EQUIPMENT AS DEALER

The Chico, Calif.-based company has expanded from material handling equipment (MHE) into construction equipment (CE) since being founded in the late 1980s and has established a foothold in the region.

PRINOTH

Coastline Equipment (Southern California and Nevanda), Western States CAT (Idaho, Montana, Wyoming, Oregon and Washington) and Papé Machinery (Northern California, Oregon, Washingon and Hawaii) became part of the Prinoth family.

22

The DX42-7 mini-excavator, DX225LC-7X crawler excavator and DX140W-7 wheel excavator were on on display at World of Concrete in Las Vegas, which was held Jan. 23 to 25, 2024.

24

The Slag Cement Association (SCA) announced Jan Prusinski (Skyway Cement Company) as its next president. Before becoming President, Prusinski served as SCA’s vice chair and was SCA’s first executive director when the association was established in 2001.

42 CASE INTRODUCES NEW WAYS TO WORK IN TIGHT JOB SITES

Case Construction Equipment is launching a sprawling lineup of new and enhanced machines that will help utility teams and other contractors work more productively.

46 DOOSAN BOBCAT SHOWCASES ITS VISION OF JOB SITE OF FUTURE

The company shared several examples of commercialized products, recent concept products and innovation advancements that demonstrate a significant shift in functionality and capabilities.

50 HD HYUNDAI WINS CES INNOVATION AWARD FOR SECOND STRAIGHT YEAR

HD Hyundai has once again won the CES 2024 Innovation Awards, following its wins in 2023. The consecutive wins underscore the company’s potential and competence in producing next-generation technologies to serve future humanity.

54 GM, KOMATSU COLLABORATE TO DEVELOP 930E ELECTRIC TRUCK

GM and Komatsu will co-develop a hydrogen fuel cell power module for Komatsu’s 930E electric drive mining truck.

58 THREE KEY ADVANCEMENTS CHANGING THE INDUSTRY

60 PERKINS JOINING OTHER FIRMS TO LEAD DEMONSTRATION OF HYDROGEN HYBRID POWER SOLUTIONS

62 CATERPILLAR VALIDATES RAJANT WIRELESS SOLUTION WITH CAT MINESTAR COMMAND FOR HAULING

62 LEICA GEOSYSTEMS BRINGS LEICA BLK2GO PULSE TO MARKET

64 TRIMBLE LAUNCHES NEW IONOGUARD TECHNOLOGY TO MITIGATE COSTLY GNSS INTERRUPTIONS

Arizona Bejac Corporation www.bejac.com

GLENDALE 1 (800) 772-3522

California Bejac Corporation www.bejac.com

PLACENTIA

SACRAMENTO

1 (800) 772-3522

ANDERSON 1 (800) 772-3522

VISALIA

1 (800) 772-3522

Colorado Power Screening, LLC. www.powerscreening.com

Bane Machinery www.banemachinery.com

DALLAS (214) 352-2468

FORT WORTH (817) 847-5894

TYLER (903) 597-6641

LT T LAKE CITY 1 (800) 772-3522

Washington Orion Equipment www.orion-equip.com

SEATTLE (800) 280-8124

ANCOUVER (800)280-8124

HENDERSON V SAL Utah Bejac Corporation www.bejac.com

(303) 287-0100

Idaho Central Equipment Co. www.centralequipment.us

JEROME (208) 324-8515

POCATELLO (208) 233-2850

Nevada Bejac Corporation www.bejac.com

1 (800) 772-3522

New Mexico Power Screening, LLC. www.powerscreening.com

ALBUQUERQUE (505) 345-4467

Wyoming Power Equipment ofWyoming, Inc www.power-equip.com

CASPER (307) 577-9700

RENO (800) 2808124

Oklahoma Central Power Systems & Services www.cpower.com

OKLAHOMA CITY (405) 324-2330

TULSA (918) 984-6565

Texas Nueces Power Equipment www.nuecespower.com

CORPUS CHRISTI (361) 687-2284

VICTORIA (361) 433-0672

o. offers an extensive lin ing equipment and techn dlddf e distribution net e of earthmoving and ology in the USA. Main tdihb work (956) 267-1495

LAREDO (956)2671495

SAN BENITO (956) 361-0066

VINTON (915) 201-4115

CONVERSE (210) 807-8216

HUMBLE (713) 247-0066

Liebherr USA, C material handli t

components ar Liebherr or in c highest possib the entire drive variety of comp systems. Reach more informati e developed and manufactured in-house by lose collaboration with our partners to ensure the le quality standards.These components include and controltechnology, diesel engines, and a onents for hydraulics, gearboxes and electronic out to your local Liebherr distribution partnerfo on. e r

Kirby-Smith Machinery’s Ed Kirby, chairman; John Arapidis, president; and JD Young, CFO, were in Las Vegas for the AED Summit.

The Associated Equipment Distributors (AED) convened for the group’s annual summit/CONDEX at the Mirage in Las Vegas Jan. 16 to 18, 2024.

In addition to networking, equipment dealers, manufacturers and service providers could attend seminars, fundraise and see what’s new in the industry. With seminar topics that included discussions on AI, data, hiring military vets, automation, taxes, and so much more, there was something for everyone.

To close out day one, there was a Women in Equipment Reception, which offered the perfect venue to network with peers and make connections. This event was followed by the AED Foundation’s Annual Fundraising Gala and Live Auction, presented by Ritchie Bros. Both live and silent auctions gave everyone a chance to win an item and raise money for the foundation.

On the final evening, a keynote dinner and conversation with General James Mattis was hosted by PEAC Solutions. Mattis served as the 26th Secretary of Defense of the United States and made history by securing special permission from Congress to lead the Pentagon, sooner than he was eligible.

For more information, visit aednet.org. CEG

(All photographs in this article are Copyright 2024 Construction Equipment Guide. All Rights Reserved.)

see AED page 70

buyers and sellers worldwide.

Okada Demolition Attachments’ Claudio Calzado (L), vice president of sales, and Mike McFarthing, regional manager, eastern Canada, were on hand to discuss the company’s offerings.

Caterpillar Inc. announced the launch of a prototype demonstration project for a battery-powered field elevator with Flory Industries, a global leader in the production of nut-harvesting equipment.

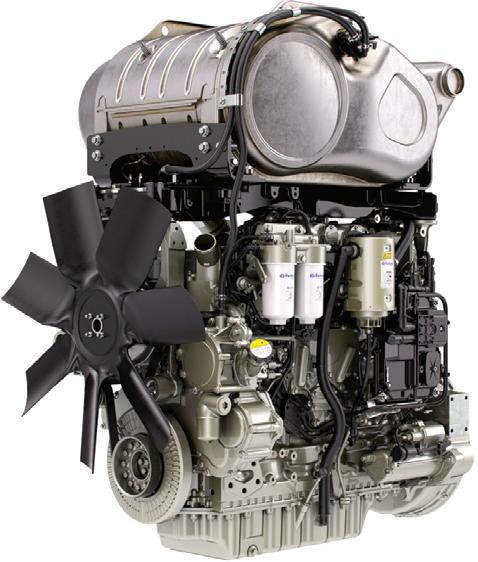

Supported by Holt of California, the local Cat dealer, the prototype will demonstrate how a 600-volt battery-powered powertrain can deliver the performance, reliability and durability currently provided in this application by a conventional 74-hp diesel engine while reducing maintenance and operating with zero tailpipe emissions.

The project is the first presentation of a prototype machine by a third-party original-equipment manufacturer (OEM) using Caterpillar’s battery-powered solution.

It also will leverage Caterpillar’s expertise in evaluating system requirements; optimizing system architectures; managing system controls development, calibration and verification; and performing final system validation.

Holt of California will apply its specific knowledge of Flory’s equipment architecture and duty cycles to provide day-to-day engineering, integration and testing support.

The electrified powertrain will feature Caterpillar’s new prototype battery, which uses lithium-ion technology and features a modular design to boost performance while minimizing packaging. Engineers will integrate the batteries with inverters, motors, electronic controls, digital services and other critical technologies in a power-dense solution that addresses common user concerns while demonstrating the numerous benefits.

Flory engineers will coordinate the demonstration project from the Flory Industries’ headquarters and development center in Salida,

Flory is scheduled for the second quarter of 2024, with pilot units available for customers in 2025 and full production expected in 2026.

Starting in 2002, Flory has specified Cat diesel engines for powered equipment in its fleet of agricultural equipment. The company currently uses U.S. EPA Tier IV Final Cat engines for self-propelled harvesters, shuttle trucks, elevators and brush shredders.

“Our customers have an intense, compressed timeline for harvesting, and they expect our machinery to work as hard as they do,” said Todd Wille, president and COO of Flory.

“We’ve relied on Holt of California and Cat engines to supply superior power performance for more than two decades, which is why we’ve decided to collaborate with them on a system that anticipates the increasing requirements for lower-carbon applications in agriculture without sacrificing productivity.”

David Leinfelder, industrial engine sales engineer at Holt of California, explained: “Flory is a recognized leader in nut harvesting equipment, with satisfied customers around the globe from California’s Central Valley to Chile, Spain and Australia. We share a common culture that prioritizes engineering excellence and customer service, which makes Flory ideal for demonstrating Caterpillar’s first battery application with a third-party OEM.”

“Like Caterpillar, Flory is a forward-thinking OEM leading its customers through the energy transition,” said Steve Ferguson, Caterpillar senior vice president of the Industrial Power Systems Division. “Their deep roots in heavy-duty agriculture machinery and commitment to superior performance make them ideal collaborators as our electrification capabilities gain further momentum across the industry.”

Associated Builders and Contractors released a statement from Vice President of Regulatory, Labor and State Affairs Ben Brubeck opposing the U.S. Department of Labor’s independent contractor final rule under the Fair Labor Standards Act.

“By undermining the flexible, independent work for millions of Americans, President Joe Biden’s DOL is choosing to move forward with a final rule that creates an ambiguous and difficult-to-interpret standard for determining independent contractor status,” said Brubeck. “Under the rule’s multifactor test, employers will now be forced to guess which factors should be given the greatest weight in making the determination. Instead of promoting much-needed economic growth and protecting legitimate independent contractors, the final rule will result in more confusion and expensive, time-consuming, unnecessary and often frivolous litigation, as both employers and workers will not understand who qualifies as an independent contractor.

“Legitimate independent contractors are a vital part of the construction industry...”

Ben

Brubeck

Labor and State Affairs

Caterpillar and Flory will showcase their capabilities in the South Exhibits at the 2024 World Ag Expo in Tulare,

Located in booth JK1, Caterpillar and its Customer Solutions Team will be on hand to speak with OEMs on the multiple pathways to manage the energy transition by offering options for continuing with diesel engines, repowering diesel-powered machinery already in the field with electrified powertrains, and ordering equipment with factoryinstalled electrified systems. Flory will present its lineup in booths N18-N22. For more information, visit caterpil-

“Regrettably, the confusion and uncertainty resulting from the final rule will cause workers who have long been properly classified as independent contractors in the construction industry to lose opportunities for work,” said Brubeck. “Legitimate independent contractors are a vital part of the construction industry, providing specialized skills, entrepreneurial opportunities and stability during fluctuations of work common to the industry. They play an important role for large and small contractors, delivering construction projects safely, on time and on budget for their government and private customers. This move will jeopardize the ability of construction firms to continue the industry’s longstanding practice of utilizing legitimate independent contractors.”

ABC strongly supported the 2021 final rule, which simplifies and clarifies the factors for determining when a worker is an independent contractor versus an employee under the FLSA. The Biden DOL froze and then rescinded the 2021 rule over the opposition of ABC and other industry associations.

In March 2021, ABC, its Southeast Texas chapter and the Coalition for Workforce Innovation filed suit against the DOL, which remains pending. In March 2022, the U.S. District Court for the Eastern District of Texas dealt a blow to the Biden administration’s efforts to delay and rescind the 2021 independent contractor final rule in that case. Under a decision applauded by ABC, the ABC-supported rule went into effect as scheduled on March 8, 2021. In October 2022, the DOL announced a new proposed rule to rescind and replace the 2021 final rule and ABC submitted comments in opposition on Dec. 13.

For more information, visit abc.org.

Buckle up, racing fans! Irish phenom James Roe and Ring Power Corporation, the premier Cat dealer in north and central Florida, announced their continued partnership for the 2024 INDY NXT by Firestone season.

This dynamic duo is back for another year of high-octane action, fueled by a shared passion for excellence and a relentless pursuit of victory.

“I’m incredibly grateful for Ring Power’s unwavering support,” said Roe. “Their dedication to pushing boundaries, both on and off the track, has been instrumental in my journey. This partnership isn’t just about sponsorships; it’s about a shared passion for exceeding expectations and achieving the impossible together.”

David Alban, president of Ring Power, echoed Roe’s sentiment.

“Continuing our partnership with James isn’t just about supporting a talented driver; it’s about aligning ourselves with the same values that drive Ring Power forward. His relentless pursuit of excellence, commitment, teamwork, integrity and unwavering focus on safety are the cornerstones of our company culture.

“We see James’s passion in every lap, and it mirrors our commitment to delivering

peak performance in everything we do.”

In 2023, Roe showcased his talent and dedication to his craft — with 10 top-ten finishes, including his first INDY NXT podium on the hallowed grounds of the

His success during the 2023 season demonstrated his ability to learn, adapt and conquer new challenges.

Building on this strong foundation, Roe is

poised for a break-out season in 2024 as he returns to pilot the No. 29 Topcon Dallara for the Andretti INDY NXT team.

The partnership between Ring Power and Roe extends far beyond the racetrack. Both parties share a deep-rooted passion for innovation and technology, constantly striving to push the boundaries of what’s possible. Ring Power leverages cutting-edge data analysis and advancements to optimize job site safety, equipment performance and productivity for its customers. This dedication to progress resonates with Roe’s relentless pursuit of excellence on the track, where every millisecond and strategic decision can make the difference between victory and defeat.

“At Ring Power, we believe in harnessing the power of technology to achieve optimal results,” said Alban. “It’s this shared commitment to pushing boundaries and embracing the latest advancements that truly cements the synergy between James Roe and Ring Power. We’re both constantly striving to be the best, and together, we’re unstoppable.”

The Ring Power logo will continue to be proudly displayed on the No. 29 livery, a symbol of unwavering support and a shared vision for success.

kirby-smith.com

OKLAHOMA

McAlester: 918-310-1550

Oklahoma City: 405-495-7820

Tulsa: 918-438-1700

TEXAS/NEW MEXICO

Abilene: 325-692-6334

Amarillo: 806-373-2826

Dallas: 214-371-7777

Ft. Worth: 817-378-0600

Hewitt: 254-261-1370

Lubbock: 806-745-2112

Odessa: 432-333-7000

smsequipment.com

Anchorage: 907-275-3300

The construction industry added 17,000 jobs on net in December, according to an Associated Builders and Contractors analysis of data released by the U.S. Bureau of Labor Statistics.

On a year-over-year basis, industry employment has grown by 197,000 jobs, an increase of 2.5 percent.

In December, nonresidential construction employment increased by 11,900 positions on net, with growth in 2 of the 3 subcategories. Nonresidential building added 8,100 positions, while nonresidential specialty trade added 4,300 jobs on net. Heavy and civil engineering lost 500 jobs.

The construction unemployment rate fell to 4.4 percent in December. Unemployment across all industries remained unchanged at 3.7 percent.

“Despite strong construction industry employment growth, today’s jobs report was highly contradictory,” said ABC Chief Economist Anirban Basu. “On one hand, economywide payroll employment expanded faster than expected in December, and the unemployment rate remained unchanged at 3.7 percent, close to the lowest level in over a half a century. Construction employment increased for the ninth consecutive month, with the nonresidential segment adding jobs at a particularly rapid pace.

“On the other hand, the labor force shrank by 676,000 persons in December, the largest decline since early 2021,” said Basu. “Wage growth also accelerated, with average hourly earnings up 4.1 percent year over year across all industries. That’s faster than expected and a level not consistent with a return to 2 percent inflation. Construction industry earnings have increased at an even faster rate over the past year.

“This is only one month’s data and could contain significant statistical noise,” said Basu. “That said, the combination of faster wage growth and a smaller labor force suggests that interest rates could remain higher for longer.”

For more information, visit www.abc.org.

LiuGong North America welcomed Hamre Equipment to its dealer network.

The Chico, Calif.-based company has expanded from material handling equipment (MHE) into construction equipment (CE) since being founded in the late 1980s and has established a foothold in the region.

Hamre Equipment also has international roots, as company CEO Lee Hamre met AmeraMex International in Mexico when Hamre Equipment worked to expand into international markets. AmeraMex International has three business units: Hamre Equipment Inc., Hamre Heavy Haul and Hamre Parts & Service.

After starting as a dealer of forklifts and compact truck loaders, Hamre Equipment began adding construction equipment to its range of offerings. It serves the industrial construction, intermodal, sales, forestry and transportation industries.

Hamre Equipment President Brian Hamre noted the opportunity to join the LiuGong dealer network has come in two stages, starting in the material handling equipment space six months ago and adding construction equipment products two months ago. A cus-

tomer has already acquired a medium-size LiuGong wheel loader from Hamre.

“It’s pretty fresh, but we’re happy to add LiuGong products to our dealership,” Brian Hamre said. “We’re just getting our feet into it. We’ve had some good acceptance on the forklift side in the Northern California market. Now that we’ve added the construction equipment side, we’re just now ramping that up to get noticed.”

Andrew Ryan, president, LiuGong North America, hailed the Hamre group’s longtime standing within the region.

“We’ve added the Hamre group in Northern California, a longstanding equipment dealership network with a really strong forklift presence in that part of the world. We’re excited to have them as part of the LiuGong team,” Ryan said.

“The Hamre group has great history with material handling equipment,” added Jared Ward, vice president, Material Handling, LiuGong North America. “We look forward to growing with them as they join the LiuGong family.”

For more information, visit www.liugongna.com/.

Prinoth Crawler Carriers announced new dealer partnerships in the western part of the United States.

In early 2023, both Coastline Equipment (Southern California and Nevanda) and Western States CAT (Idaho, Montana, Wyoming, Oregon and Washington), became part of the Prinoth family.

In the fall of 2023, Papé Machinery (Northern California, Oregon, Washingon and Hawaii) also joined the Prinoth Crawler Carrier group.

Western States Equipment Company has a long legacy for providing quality equipment and excellent service to customers. Twenty-three years after its original inception in the early 1900’s, Western States applied for and was awarded the Caterpillar dealership service area for southern Idaho.

Western States Equipment has a proud history of acquisition and growth. What began as four service branches has grown into a much larger, award-winning organization with 17 general line and truck engine branches, and 15 Cat Rental Stores.

It will be responsible for Idaho, Montana, Wyoming, regions of Oregon and Washington.

Papé Machinery

Papé Machinery offers construction and forestry equipment for John Deere and currently operates just under 30 branches located in different western U.S. states. It provides equipment in many industries including general construction, power electric, oil and gas, firefighting and rescue and forestry.

“We are extremely excited to welcome these three industry stalwart to our dealer group. With their respective footprints and driven sales organizations, we feel confident that these new relationships will enhance our western foothold and brand presence tremendously. All threee of these companies are well-established distributors and have extensive knowledge of their dedicated markets. That should reflect in our crawler carriers sales and rental opportunities,” said Jody Beasley, VP of sales of Prinoth. For more information, visit www.prinoth.com.

Niece Water Towers deliver reliability and durability when you need fast mobile water service. With a 12” discharge tube it fills your tanks at a rate of over 1,000 gallons per minute. Offers removable power pack for security, fifth wheel tow hitch, professionally engineered and constructed.

It features (8) legs for stability

5th wheel set up for quick “tow and go.”

DEVELON showcased its three excavators at World of Concrete in Las Vegas, which was held Jan. 23 to 25, 2024.

The DX42-7 mini-excavator, DX225LC-7X crawler excavator and DX140W-7 wheel excavator were on on display. DEVELON staff were available to help visitors explore each machine’s features.

“DEVELON is excited to exhibit at World of Concrete, especially as the event celebrates 50 years in 2024,” said Jacob Sherman, product and dealer marketing manager DEVELON. “This trade show gives us a chance to promote our new brand and innovative products that help customers take on their biggest job site challenges.”

The conventional tail swing DEVELON DX42-7 miniexcavator is ideally suited for navigating tight, congested job sites and urban areas. Part of the next-generation -7 Series mini excavator lineup, the DX42-7 offers such impressive features as fast cycle times, efficient torquelimiting piston pumps that respond to load demands, and a larger counterweight for improved balance and durability. The machine comes equipped with a standard thumbready arm.

Two cabin options are available: open canopy and enclosed cab configuration. Enclosed cab models come with standard heating and air conditioning and hands-free

Bluetooth audio. Operators have an improved view of the job site due to a framed full-glass door, an optional rearview camera and high-illumination LED lamps to see the work group.

As with all -7 Series mini-excavators, a powerful telematics system is standard. DEVELON Fleet Management system monitors the machine’s location, health and productivity from a user-friendly website or mobile app.

The DX225LC-7X is the first electronically controlled crawler excavator from DEVELON. The system enables advanced machine guidance and machine control systems — including 2D grading for accurate earthmoving and grading work. The DX225LC-7X offers superior hydraulics and a strong workgroup to deliver ample power and durability to the arm and bucket, maximizing lifting capability.

improved heating and cooling with an optional heated/cooled seat, easy-to-use joystick controls, a rearview camera, Smart Touch screen and optional 360-degree around view monitor (AVM) camera system.

Designed for demanding tasks, the DX140W-7 wheel excavator delivers powerful digging and maneuverability when working on bridges and roadways or in urban areas. The machine has a balance of power and fuel efficiency, along with bestin-class comfort features, intelligent controls and smart machine functionality. It can be configured with a front dozer blade and independent rear outriggers or four independent outriggers.

An optional dozer blade and the standard counterweight design provide strength and stability. Operators also can activate the tiltrotator mode for enhanced precision when using a tiltrotator accessory. Added comfort features include

Comfort features include automotive-style heating and air conditioning, improved floorspace and excellent visibility from the spacious cab. A rearview camera is standard and an optional heated/cooled seat is available. The standard DEVELON Fleet Management system monitors the excavator’s health and maintenance schedule to help keep it running at peak performance.

(All photographs in this

The Slag Cement Association (SCA) announced Jan Prusinski (Skyway Cement Company) as its next president. Before becoming President, Prusinski served as SCA’s vice chair and was SCA’s first executive director when the association was established in 2001.

As an industry leader in cement, concrete, soil and byproduct stabilization, and pavements, Prusinski has led U.S. and state organizations in a wide range of programs to promote and advocate for the use of slag cement and other supplementary cementitious materials in concrete construction. In his current role, he works as the vice president of marketing at the Skyway Cement Company, a subsidiary of Eagle Materials.

“I am very excited to begin serving as SCA’s President,” said Prusinski. “The Slag Cement Association represents 95 percent of all slag cement producers and suppliers in the United States and performs an integral role as the leading advocate for the use of slag cement in improving the strength, durability and sustainability of concrete in the built environment.”

Lori Tiefenthaler (Heidelberg Materials) concluded her two-year term as SCA President at the end of December of last year. As President, Tiefenthaler hosted SCA’s inaugural and second annual Slag Cement Schools, oversaw the development of Slag Cement University, and awarded more than 30 concrete projects for their use of slag cement during the Slag Cement in Sustainable Concrete Awards.

“It has been an honor to serve as SCA’s President over these last two years,” said Tiefenthaler. “Slag is an exceptional product that the market continues to demand with volumes up over 5 percent in 2023. It has also been great to see our members expand production and announce new slag cement projects for 2024.” For more information, visit www.slagcement.org.

The newly constructed loop runs east of I-35 from south of Kyle to south of San Marcos.

“There were many who doubted this project would ever be built,” said Hays County Commissioner Debbie Ingalsbe. “The first discussions happened in the 1960s.”

Webber LLC, which began construction on March 1, 2022, built a 6.5 mi. road (one lane in each direction) that connects the middle and south sections, added 10-ft. shoulders from SH 80 to I-35 and a bridge over SH 21 and another over the railroad.

The loop is based on an asphalt road surface.

“These decisions are made during high-level preliminary engineering meetings when we evaluate the project’s needs, costs and lifecycle considerations,” said Willie Semora, TxDOT’s South Travis Area Engineer. “It’s not out of the ordinary for a roadway with FM 110’s character to be an asphalt surface. The construction materials and techniques designed into FM 110 are standard for the Central Texas region.There were very few traffic issues associated with the construction.”

“Given FM 110 was a green field [new ROW] project, there was very little need to manage traffic,” said Semora. “Traffic control plans were only used at SH 21 while building the bridge structure, SH 80 while making the final connection and Yarrington Road where we made the connection to the existing Yarrington Road. The traffic control plans worked well and achieved our goal to maintain safety within the work zone.”

The loop was opened to traffic in late December 2023. The remaining work consists of clean-up efforts.

“During construction, the team worked hard to manage utility impacts and site conditions,” said Semora. “Given this was a green field project, utilities were minimal. There were some impacts and TxDOT worked hard to coordinate and manage clearance. Also, with the severe drought conditions we experienced during the summer of 2023, soils in the

region challenged our teams to provide high quality projects. Lastly, managing the construction and interaction of the project at the SH 80, SH 21 and I-35 connections were a big challenge, as well as coordinating the SH 21 overpass construction with the airport.”

The construction of FM 110 was completed seven weeks ahead of schedule.

“As with most projects, there were some utility challenges,” said Semora, “but TxDOT and Webber met those head on and worked quickly to have them relocated and mitigate their impact. TxDOT has a great relationship with all our construction partners. Webber worked diligently with the TxDOT staff to address needs and solve challenges daily.”

The new section of the loop was mainly constructed from south to north to link the two existing sections.

“In general, TxDOT always prepares the right-of-way, makes the necessary cuts and fills, builds the drainage infrastructure, builds the road base and then places the final paving and safety features you see on the surface,” said Semora. “A good amount of the excess excavated material was used onsite as a recycled product for earth fill and select fill.”

Approximately 53,000 cu. yds. of material excavated by Weber crews.

“Existing vegetation and trees were cleared as needed within the new right-of-way for construction of the improvements,” said Semora, who noted that the new lanes are based on 2 ft. of embankment, 8-in. flexbase, 4-in. TY B HMA, 1.5in. TY D HMA and 1-in. TOM.

There are shoulders on either side of the loop. Drainage and underground infrastructure were installed ahead of the paving crews.

Equipment operators used many different pieces of iron, including cranes, dozers, loaders, rollers, motor graders, man lifts and many other vehicles typically found on a road project.

Two bridges were constructed — one 0.76 mi. long and the other .0.33 mi. long — along with two ramps. Prefabricated concrete and steel beams and other elements were used to build the bridges.

(All photos courtesy of TxDOT.) LOOP from page 1

“The bridges generally took the duration of the project from foundation all the way up to the final traffic rail to complete,” said Semora.

To build the bridges, crews used cranes, drill rigs, pump trucks, screeds, safety lines and other pieces of equipment.

Webber built 13.2 mi. of shoulders. The plan of attack was based on surveying, prepping the ROW, stake limits, the construction of roads and bridges and then surveying and marking out the location of striping, roadway and shoulders.

It took 440 days to install the shoulders, which were built using survey equipment, loaders, a road grader, skid steer and striping rig.

TxDOT’s team included Assistant Area Engineer Mark Baumann, Senior Project Manager Mike Harlin, Project Manager Todd McBride, Construction Engineer Camila Milon and RSH&H serving as the inspection team.

“As with all our projects the TxDOT team works cohesively to deliver projects in a safe and efficient manner,” said Semora. “Crews worked tirelessly through all types of weather and the heat to achieve the final product. We are pleased with the results and are grateful for their dedication and hours worked on this project to fruition.”

The amounts of new materials brought in have not been finalized.

Webber brought in subcontractors as needed.

Timely and efficient maintenance was essential to meeting construction benchmarks.

“Webber ensured that everyday wear and tear repairs were dealt with rapidly, and that routine maintenance was taken care of to ensure timely construction,” said Semora.

“Hays County remains one of the fastest growing areas in the country,” said Antonio Lujan, a TxDOT PIO of the Austin District. “The exponential growth has increased traffic in the San Marcos and Kyle communities. The FM 110 loop serves as an alternative to I-35, while providing access for new development and easing congestion in this fast-growing area. With an increased population, I-35 has seen a rise in traffic going south from Kyle to San Antonio, and FM 110 will offer an alternative to help alleviate the congestion on the interstate.”

Construction began in March 2022.

Hays County covered the cost of the project development and right-of-way purchases, while TxDOT financed the construction of the new road and infrastructure. The FM 110 North project was the last of three projects to complete the loop.

The North project was designed by LJA Engineering Inc.

“Hays County worked hard to balance the roadway’s new alignment with required right of way,” said Semora. “As with most projects, the engineers worked hard to ensure that the new alignment met our design and safety criteria while balancing the impacts to surrounding property. Management of new utilities and developments were also a challenge given the region’s fast-paced growth.”

Asked what the lifespan of the new road and bridge infrastructure, Semora replied: “TxDOT does not use a specific lifespan value. We design roadways to achieve a high level of mobility for the foreseeable future given the assumed growth rates. It’s important to note that FM 110 was built to only half of its ultimate forecast, including a plan to add future overpasses.” CEG

Equipped with an efficient John Deere engine and multiple features for the active protection of the environment, the Wirtgen W 220 XFi cold milling machine combines sustainability and productivity.

In all uses, from surface layer rehabilitation to complete asphalt removal, the carbon intensity is low and the milling performance as high as usual. Plus, in automatic mode, Mill Assist selects the operating strategy with the most favorable balance between milling performance and operating costs.

The Multiple Cutting System for milling widths between 7 ft. 3 in. to 12 ft. 6 in. makes it easy to quickly switch between milling drums and units. The machines are available around the world in countries that follow the EU Stage

5 / U.S. Tier IV Final emissions standards.

This large milling machine from the “Xtended F-Series” with a standard working width of 7 ft. 3 in. comes equipped with the latest and currently most environmentally friendly engine technology. The 18 L (1,100 cu in) John Deere JD18L engine provides up its maximum power of 840 hp even at only 1,500 rpm. It has been specially designed for cold milling, with high torque under all load conditions. Due to the dual shift transmission, the high torque can be used at low rpm for optimal milling performance.

Even at low engine speeds, high milling drum rotation speeds are possible.

The engine meets emissions standards without requiring DEF (diesel exhaust fluid / AdBlue).

The machine control system Mill Assist increases milling performance while simultaneously reducing diesel and water consumption and pick wear. The system controls engine speed automatically according to the needs of the operator. A wide range of uses are possible, due to the broad range of usable speeds in combination with the dual shift powershift transmission.

At lower speeds, fuel consumption, noise emission and pick wear

can be reduced significantly. The upper speed range makes optimum milling patterns possible at higher area performance rates.

The operator also can select one of three operating strategies: “ECO,” “performance-optimized,” or “milling pattern quality.” This makes it possible, for example, to pre-define the required milling pattern quality incrementally from coarse to very fine at the press of a button.

The machine control system Mill Assist and the Wirtgen Group Performance Tracker Milling (WPT Milling) assist operating personnel and increase milling efficiency. These systems have already delivered clear proof of

their potential in the other F-series cold milling machines.

With the W 220 XFi, these systems have been further developed to display CO₂ emissions. Both the current emissions and the carbon intensity can be easily viewed on the control screen in relation to milling mass. The automaticallygenerated WPT report also can include the CO₂ emissions of the entire project in addition to other construction-relevant data — an expansion of the data foundation used in jobsite analysis and documentation.

Different construction projects can now be compared in terms of carbon emissions, leading to new conclusions about how to optimize the next job.

For more information, visit www.wirtgen-group.com.

Efficiency and Productivity

Designed with safety and operator comfort in mind, the Shuttle Buggy® material transfer vehicle features adaptive cruise control, bright LED lighting, four-wheel steering for easy transport and ground-level maintenance access for added convenience. Operators can rely on clear sightlines and the ground operator is safely protected inside the structure of the machine. The Roadtec SB-3000 is the perfect blend of traditional craftsmanship and modern technology.

astecindustries.com

The American Concrete Pavement Association (ACPA) announced the 31 recipients of its 34th Annual “Excellence in Concrete Pavements” awards, which recognize quality concrete pavements constructed in the United States and Canada. The awards program encourages high-quality workmanship, quality and creativity in concrete pavement projects.

The award-winning projects were paved by 22 different contractors and are located in 12 states or regions represented by ACPA-affiliated chapters and state paving associations. Award winners were recognized during the annual Excellence in Concrete Pavements Awards Program held on Dec. 14, 2023, during ACPA’s 60th annual meeting in Marco Island, Fla. Thirty-five judges volunteered their time to select winners.

Following are the categories and winners for each award:

Concrete Pavement Restoration for Highway, Airfields

• Silver Award — SP 4208-60th 59 CPR; Garvin, Minn. Contractor: Interstate Improvements

• Gold Award — Raleigh-Durham International Airport Runway 5L/23R and Taxiway B Preservation; Raleigh, N.C. Contractor: Zachry Construction Corp.

Concrete Pavement Restoration for Streets, Local Roads

• Silver Award — Concrete Pavement Rehabilitation, East 56th Street; Indianapolis, Ind. Contractor: Milestone Contractors LP

• Gold Award — 2022 Annual Landside Pavement Rehabilitation; Denver, Colo. Contractor: WW Clyde County Roads

• Silver Award — Meade County Road 2 Reconstruction; Meade County, Kan. Contractor: Koss Construction Company

• Gold Award — Bass Rd. Construction, Phases 2 and 3; Allen County, Ind. Contractor: Milestone Contractors LP

Roller Compacted Concrete — Industrial —Commercial

• Silver Award — Spokane International Airport Rail–Truck Transload Facility; Spokane, Wash. Contractor: Peltz Companies Inc.

• Gold Award — C&C Empty Container Yard at Bayport Terminal; Seabrook, Texas Contractor: A.G. Peltz Group LLC

Roller Compacted Concrete (Roadways, Airfields)

• Gold Award — RCC for Red Mountain Expressway; Birmingham, Ala. Contractor: A.G. Peltz Group LLC

Industrial Paving

• Gold Award — Old Dominion Freight Line; Bonner Springs, Kan. Contractor: Emery Sapp & Sons Inc.

Reliever, General Aviation Airports

• Silver Award — Ellsworth Municipal Airport Runway Reconstruction; Ellsworth, Kan. Contractor: Koss Construction Company

• Gold Award — ATW Runway & GA Taxiway Rehabilitation; Appleton International Airport, Wis. Contractor: Vinton Construction Company

Military Airports

• Gold Award — Cannon Air Force Base Reconstruct

Taxiway Mike and Taxiway Delta; Clovis, New Mexico. Contractor: Southwest Concrete Paving Company (SWCP)

Commercial Service Airports

• Silver Award — Rehabilitate Runway 1L-19R Phase 2; Kansas City, Mo. Contractor: Ideker Inc.

• Gold Award — Runway 13R-31L & Taxiway C Phase 1 Reconstruction; Dallas, Texas Contractor: Flatiron

Municipal Streets, Intersections (Less Than 30,000 sq. yds.)

• Silver Award — West 7th and 8th Avenue Concrete Reconstruction, West Homestead, Pa. Contractor: Golden Triangle Construction

• Gold Award — USH 63, Spooner — Hayward (Greenwood Ave. to Poplar St.); Washburn County, Wis. Contractor: Trierweiler Companies

Municipal Streets, Intersections (Greater Than 30,000 sq. yds.)

• Silver Award — Scott County MN CSAH 83; Scott, Minn. Contractor: Shafer Contracting Company Inc.

• Gold Award — Hennepin Ave Downtown Reconstruction; Minneapolis, Minn. Contractor: TiZack Concrete Inc.

Overlays (Streets, Roads)

• Silver Award — Intersection Improvements: Adams Ctr. And Tillman Rd.; Allen County, Ind. Contractor: Milestone Contractors LP

• Gold Award — Cannelburg Road Phases 4 & 5; Daviess County, Ind. Contractor: Milestone Contractors LP

Overlays (Highways)

• Silver Award — Iowa Hwy 3 Accelerated PCC Overlay SP#NHSN-003-1(106) 2R-75; Plymouth County, Iowa. Contractor: Croell Inc.

• Gold Award — Iowa 31 Washta; Cherokee County, Iowa. Contractor: Cedar Valley Corp.

State Roads

• Silver Award — US-287 Eads Passing Lanes; Kiowa County, Colo. Contractor: Castle Rock Construction Company

• Gold Award — US 169; Neosho/Allen Counties, Kan. Contractor: Emery Sapp & Sons Inc.

Urban Arterials & Collectors

• Silver Award — Castle Pines Parkway Reconstruction; Castle Pines, Colo. Contractor: Villalobos Concrete Company

• Gold Award — West Layton Avenue / CTH Y City of Greenfield; Milwaukee County, Wis. Contractor: Vinton Construction Company

Divided Highways (Urban)

• Silver Award — I-44 Pavement Replacement at 744/Mulroy Road; Springfield, Mo. Contractor: Emery Sapp & Sons Inc.

• Gold Award — Gilcrease Expressway; Tulsa, Okla. Contractor: Gilcrease Constructors — Duit Const. Co. Inc.

Divided Highways (Rural)

• Silver Award — I-80 East Bound, Rock Spring — Rawlins; Rock Springs, Wyo. Contractor: WW Clyde

www.arnoldmachinery.com

Las Vegas, NV 702-642-9000 Phoenix, AZ 602-414-1900 Tucson, AZ 520-294-7677

www.ascoeq.com

Beaumont, TX 409-212-8100 Brenham, TX 979-836-6641 (North) Houston, TX 281-987-1990 (South) Houston, TX 713-649-0940

www.beeequipmentsales.com

Lubbock TX 806-745-1511 • 866-796-3211

www.closner.com

Schertz, TX 210-732-2131 Rhome, TX 817-708-9108 Manor, TX 512-272-8200

Waller, TX 936-525-9949

• Gold Award — I-40 Vian; Sequoyah County, Okla. Contractor: Duit Construction Co. Inc. ARNOLD MACHINERY COMPANY

HD CompactLine compact rollers can be used virtually anywhere in the fields of asphalt construction, earthworks and landscaping. What many people don’t realize is that they are also necessary in railroad construction.

In Aarau in Switzerland, the Hamm HD 10C VV tandem roller was used in works to upgrade the switches. In these works, compacting the ballast is an integral part of the pre-compaction process. If a ballast bed is not cleanly compacted and homogenized, this can lead to costly processes further down the line.

Compact tandem rollers can achieve optimum compacting results on ballast layers, frost protection layers and base courses, as well as water-bound road surfaces and asphalt layers. The articulated compact rollers of the HD CompactLine are ideally suited to railroad construction — including the HD 10C VV tandem roller used for the project in Aarau.

The condition of the ballast bed upon which the rails are laid is one of the determining factors for the quality of the guideway. The ballast has a whole host of important jobs to fulfill, which require it to have very specific properties. The basic prerequisites: The ballast follows a clearly defined distribution of stone sizes and fulfills various geometric, physical and chemical requirements.

“The weight of a roller is a major consideration in railroad construction,” explained Jürgen Franzen, foreman of the Rhomberg Sersa Rail Group who are completing the construction works.

“Even from around three metric tons upward, you can see clear differences in the tracks the roller leaves behind. However, the actual problem is hard to see with the naked eye — namely, the graining. This means there are certain fracture points in the ballast. However, the ballast stones need to have certain properties to stick together as required. Too much weight would impair this characteristic. Plus, the compact proportions of the HD 10C VV also make it particularly easy to load onto transport vehicles, so it’s a great option for transporting around.”

The work to upgrade the switches generally take place during normal operation of trains on the adjacent track. In Aarau, the reconstruction work was carried out on a

three-shift rotation. Each work step intertwines with the next and they build on each other. This is important because the rail traffic generally resumes operations immediately after the switches are installed, since closures are kept to an absolute minimum.

The switches were upgraded once the W+ excavation system had excavated, cleaned and reapplied the ballast. While the W+ was doing its thing, the HD 10C VV was compacting the ballast.

The tandem roller with vibrating roller drums provides not only the initial compaction, but also a level surface on which to subsequently lay the sleepers flat. This initial compaction essentially gives a degree of compactness to the deposited material. The ballast here already has a certain sticking quality.

The HD 10C VV compensates for this with compression and vibration. This way, the material fuses together better. Then the mechanical surfacing stage of the switch construction began. After that, it was mechanically tamped to further homogenize the ballast.

“The HD 10C VV has everything I could possibly need to do my job properly. It’s intuitive to operate. It has really impressive visibility and excellent driving and handling characteristics,” said René Neujahr, operator of the Rhomberg Sersa Rail Group.

Jürgen Franzen, foreman of the company completing the construction works, added: “If there’s a raised section in the center beneath a sleeper, caused by an oversight in the compacting stage, that sleeper could crack. That is relatively easily remedied if it is a track sleeper. But the way the switch is here in Aarau means we can’t implicate any other switches. So everything would grind to a halt. You can tamp it, but you would still need to remove the sleeper afterwards and properly refurbish it. Our Hamm roller helps ensure this doesn’t happen.”

For more information, visit www.wirtgengroup.com.

915-872-1001 Farmington, NM 505-324-8601

Closner Equipment

www.closner.com

Rhome, TX 817-708-9108

Schertz, TX 210-732-2131

Manor, TX 512-272-8200

Waller, TX 936-525-9949

PacWest Machinery

www.pacwestmachinery.com

Seattle, WA 206-762-5933

Spokane, WA 509-534-5933

Pasco, WA 509-547-5933

Mt Vernon, WA 360-588-3083

Portland, OR 503-252-5933

Eugene, OR – Branch 541-302-3762

Power Equipment Company

www.power-equip.com

Farmington, NM 505-326-1413

Durango, CO 970-247-8830

Denver, CO 303-288-6801

Colorado Springs, CO 719-392-1155

Grand Junction, CO 970-243-0722

Greeley, CO 970-353-1224

Albuquerque, NM 505-345-7811

Tri-State Truck and Equipment

www.tristatetruckandequip.com

Belgrade, MT 406-388-5818

Billings, MT 406-245-3188

Casper, WY 307-472-1818

Great Falls, MT 406-452-9551

Rock Springs, WY 307-362-4000

Shafer Equipment

wwwshaferequipmentco.com

Sparks, NV 208-801-7772

Boxcer Equipment

www.boxcerequipment.com

Tulsa, OK 918-272-7237

Volvo Construction Equipment (Volvo CE) and the Ammann Group have reached an agreement whereby Ammann will acquire Volvo CE’s global ABG paver business.

As a result of the planned transaction, the Volvo Group’s operating income will be negatively impacted by approximately SEK 650 M in the fourth quarter of 2023.

The divestment includes the ABG paver production and technology center in Hameln, Germany, and will ensure the availability of the range and full support through the Ammann Group distribution channels and selected Volvo CE dealers.

Volvo CE and the Ammann Group see this as the best way to maintain and develop the long established ABG heritage in the paver business for relevant customers, dealers, suppliers and employees. As a consequence of the divestment, production of Volvo CE compaction equipment in Hameln will be phased out.

In 2022, ABG paver business had revenues amounting to SEK 1,100 M. As part of the divestment process, about 400 people will move from Volvo CE to join the Ammann Group.

The negative earnings effect will be reported in the segment Construction Equipment and be excluded from adjusted operating income. The transaction is subject to regulatory approvals. Closing is anticipated in the first half of 2024. As a consequence of the divestment, production of Volvo CE compaction equipment in Hameln will be phased out.

The CP100II sets the standard for versatility, component lifecycle and mat quality. With a powerful 100 horsepower engine, an array of configurations and the class-leading Carlson EZCSS single slide screed, it’s easy to see why the CP100II is the ideal choice for heavy-duty commercial paving.

The Carlson CP100 II sets the standard for versatility, component lifecycle and mat quality. With a powerful 100hp engine, an array of configurations and the class-leading EZCSS single slide screed, it’s time to see why the CP100 II has fast become the contractor’s choice for heavy-duty commercial paver platforms.

BANE MACHINERY, INC.

www.banemachinery.com

2449 Manana Dr. Dallas, TX 75220 (214) 352-2468

(214) 352-2468 (817) 847-5894 (903) 597-6641

Ft. Worth, TX (817) 847-5894

CLAIREMONT EQUIPMENT

7651 Ronson Roa San Diego, CA 92 (858) 278-8351 1330 W Mission Ro Escondido, CA 92 (760) 739-9100

Tyler, TX (903) 597-6641 BEE EQUIPMENT SALES LTD.

www.beeequipmentsales.com

2506 Slaton Highway Lubbock, TX 79404 (806) 745-1511

C. L. BOYD CO.,

4220 West Reno A (800) OKC-BOYD • (405 Ardmore, OK (866) 720-2693 • (580) Lawton, OK (800) 633-2693 • (580) / INC. K 224-2693 /355-6667

www.clairemontequipment.com

(318) 442-0455

7651 Ronson Road

Baton Rouge, LA (225) 291-3750

San Diego, CA 92111 (858) 278-8351

1330 W Mission Road

Broussard, LA (337) 837-9481

Escondido, CA 92029 (760) 739-9100

Covington, LA (985) 893-3005

440 West Aten Road

eet 111 (337) 430-3045

(858) 278-8338

Imperial, CA 92251 (760) 355-7700

Monroe, LA (318) 343-8787

Shreveport, LA (318) 631-3090

COOPER EQUIPMENT CO.

www.cooperequip.com

(409) 842-1754 Boise, Idaho (208) 336-8670 Jerome, Idaho (208) 324-4522 (800) 829-4450

5210 N Loop 1604 E San Antonio, TX 78247 (210) 657-5151

201 Commerce Blvd. Georgetown, TX 78626 (512) 930-5151

C. L. BOYD CO., INC. www.clboyd.com

4726 Convoy Street San Diego, CA 92111 (858) 278-8338

6532 East Highway Rhome, TX 7607 (817) 708-9108

21910 FM 2252 Schertz, TX 7815 (210) 732-2131

4220 West Reno Ave. Oklahoma City, OK 73107 (800) OKC-BOYD • (405) 942-8000

Ardmore, OK (866) 720-2693 • (580) 224-2693

Lawton, OK (800) 633-2693 • (580) 355-6667

13800 FM 973 N Manor, TX 78653 (512) 272-8200

St. Rose, LA (504) 466-5577

Beaumont, TX (409) 842-1754

Bryan, TX (979) 8231905

Corpus Christi, TX (361) 289-0727

Houston, TX (713) 679-6700

Longview, TX (903) 758-3326

Lufkin, TX (936) 634-8801 San Juan, TX (956) 787-0001

6532 East Highway 114 Rhome, TX 76078 (817) 708-9108

21910 FM 2252

Schertz, TX 78154 (210) 732-2131

CO. .com

13800 FM 973 N Manor, TX 78653 (512) 272-8200

18851 GH Circle

MODERN MACHINERY

www.modernmachinery.com

Corporate Office

Missoula, Montana (409) 842-1754

Boise, Idaho (208) 336-8670

Jerome, Idaho (208) 324-4522

Victoria, TX (361) 570-6666

Washington

Pocatello, Idaho (800) 829-4450

ROAD MACHINERRY Y www.roadmachinery.co 902 S. 7th Street X g (800) 304-4421

Billings, Montana (800) 735-2589

Phoenix, AZ 85034 (480) 545-2400

Spokane, Washington (800) 541-0754 om n COOPER EQUIPMEN www.cooperequip. 5210 N Loop 1604 San Antonio, TX 78 (210) 657-5151 201 Commerce Blv Georgetown, TX 78

(512) 930-5151

E 8247 vd. 8626 (903) 592-8900

Waller Industrial Park Waller, TX (936) 525-9949

Columbia Falls, Montana (800) 434-4190

Prescott, AZ (928) 778-5621

Eugene, Oregon (800) 826-9811

Tuscon, AZ (520) 623-8681

Portland, Oregon (800) 950-7779

(661) 695-4830

Perris, CA (909) 355-3600

Kent, Washington (800) 669-2425

Rochester, Washington (800) 304-4421

Spokane, Washington (800) 541-0754

www.cpower.com

9200 Liberty Drive

Liberty, MO 64068

816-781-8070

Wichita, KS

316-943-1231

Great Bend, KS

620-792-1361

Liberal, KS

620-624-7274

Woodward, OK

580-256-6014

Salina, KS

785-825-8291

Colby, KS

785-462-8211

Springfield, MO 417-865-0505

Joplin, MO 417-726-5373

Riverside, MO 816-415-6787

Wichita, KS 316-789-7370

Yukon, OK 405-324-2330

Maryland Heights, MO 314-427-4911

Liberty, MO 806-415-6700

Tulsa, OK 918-984-6565

Glenn B. Dorning

www.gbdorning.com

1744 E. Holt Blvd. Ontario, CA 91761 909-983-2089

Case Construction Equipment is launching a sprawling lineup of new and enhanced machines that will help utility teams and other contractors work more productively and profitably in the face of ever-evolving jobsite challenges.

This next generation of Case machines was on full display at The Utility Expo in Louisville, Ky., Sept. 26 to 28, 2023.

Highlighting the booth was Case’s re-entry of the wheeled excavator market in North America, its new Construction King backhoe models (center pivot and side shift), enhanced dozers with electrohydraulic (EH) blade control, and a sneak peek of one of its newest electric vehicles (EV), a 2.5 metric ton mini excavator.

“The construction industry faces a unique inflection point with historic levels of government investment, yet a resourceconstrained labor market. That’s why we’re launching the next generation of our swift, smooth, smart machines this year to help contractors get more work done smarter, faster and easier than ever,” said Terry Dolan, vice president, North America, Case Construction Equipment.

To share the benefits of these latest models, Case experts hosted special launch presentations throughout the show.

This fall, Case re-enters the wheeled excavator market to help crews who need more maneuverable machines for today’s constricted urban job sites.

them the visibility they need to work safely and efficiently — a critical improvement when digging around active gas lines or an electrical box.

The expanded Case backhoe offering also is compatible with numerous attachments, giving crews a big toolkit for improving productivity, speed and accuracy on highly varied jobs.

Case also showcased its latest round of dozer enhancement to the Case M Series, bringing contractors more precision, reliability and control than ever before, according to the manufacturer.

New electro-hydraulic controls allow the operator — of any skill level — to set steering and shuttle settings to smooth, moderate or aggressive to better dial that machine to their preference, which simultaneously reduce operator fatigue and increase productivity.

With the ability to travel up to 25 mph, the new E Series wheeled excavators give contractors the ability to self-deploy from job site to job site, while minimizing the time and expense involved with transporting by trailer.

Offering the same powerful hydraulic performance and massive attachment flexibility as their steel-track counterparts, these fully featured rubber-tired excavators also offer significantly lower total cost of ownership than machines with a steel track and undercarriage, allowing utilities contractors to improve their bottom line.

“The new Case wheeled excavators bring a whole new dimension to our E Series excavator lineup, offering invaluable benefits in terms of flexibility, performance, efficiency and serviceability,” said Diego Butzke, product manager, North America, Case Construction Equipment. “These five new wheeled models give utility teams the versatility, agility and power they need to take on the toughest jobsite challenges.”

Another booth highlight for Utility Expo attendees was the new Case Construction King backhoe models — the original two-in-one tool-carrying machines.

Particularly useful for utility crews is the side-shift backhoe, which lets operators shift the boom left or right to give

www.garton.co

Turlock, CA • 209-632-3931

Fairfield, CA • 707-425-9545

Merced, CA • 209-726-4600

Modesto, CA • 209-538-0911

Newman, CA • 209-862-3760

Santa Rosa, CA • 707-586-1790

Stockton, CA • 209-948-5401

Tulare, CA • 559-686-0054

Ukiah, CA • 707-468-5880

Woodland, CA • 530-615-2828

Madera, CA • 559-674-2496 Fresno, CA • 559-485-9090

CO.

www.clmequipment.com Lafayette, LA 337-837-6693 Lake Charles, LA 337-625-5942

Case Universal Machine Control also is available with these machines, which allows them to be outfitted with machine control solutions from any of the three major suppliers of precision construction technology. Each dozer also is available with factory-fit solutions from Leica Geosystems that simplify the ordering and setup process.

“When we set out to make our strong dozer offering even stronger, we did so with an operator-first mindset,” said Jeremy Dulak, product manager, North America, Case Construction Equipment.

“With these latest enhancements, Case M Series dozers are more comfortable, more precise and more intuitive to operate than ever, making it easier for operators to dominate the job site all day long.”

Because government and municipalities are early adopters of electrification, Case also offered a sneak peek of one of its latest electric models — the CX25EV all-electric mini excavator launching in 2024.

With the same power and performance as diesel-powered machines, new Case EV equipment is easy to charge, transport and service, while providing the additional value of zero on-site emissions, minimal noise and reduced maintenance costs.

“Like all our machines, we designed these new and enhanced models with practical innovation based on contractors’ needs today and where we see the industry evolving,” Dolan said. “We’ve done this so utility teams and construction contractors are best prepared to tackle their toughest jobsite challenges and improve their business with the right machines, with the right attachments, at the right time.”

For more information, visit CaseCE.com.

www.banemachinery.com Dallas, TX 800-594-2263 Ft. Worth, TX 800-601-2263 Tyler, TX 800-594-2200

11125 SW Tonquin Road Sherwood, OR 97140 503-454-0902

The 316GR and 318G Skid Steers and 317G Compact Track Loader are impressively tough because real-world customers like you helped design them.With your input, we pushed the limits of durability, engine power, and fuel capacity in some pretty big ways. And with fewer grease zerks and extended oil-change intervals compared to earlier models, servicing is even simpler. Including the radial-lift 316GR, these G-Series small frames can take down the biggest jobs — and your operating costs — all at the same time. To learn more, call or visit us today.

DOGGETT HEAVY MACHINERY SERVICES www.doggettequipment.com 9111 North Freeway Houston, TX 77037 713-679-6700

Beaumont, TX 409-842-1754

Bryan, TX 979-823-1905

Corpus Christi, TX 361-289-0727

San Juan, TX 956-787-0001

Victoria, TX 361-570-6666

Alexandria, LA 318-442-0455

Baton Rouge, LA 225-291-3750

Broussard, LA 337-837-9481

Covington, LA 985-893-3005

Longview, TX 903-758-3326

Lufkin, TX 936-634-8801

Monroe, LA 318-343-8787

Shreveport, LA 318-631-3090

St. Rose, LA 504-466-5577

Tyler, TX 903-592-8900

During CES’ Media Days event, Doosan Bobcat Inc., a company within Doosan Group, showcased how the company is driving equipment advancements by leveraging emerging technologies.

“We ignited an entire industry 65 years ago with the creation of the compact loader, and today, we are leading the equipment industry into a bold new future,” said Scott Park, Doosan Bobcat CEO and vice chairman.

“Founded on iron, we are reimagining the future of our equipment to give customers more power, performance and control with a focus on connectivity, alternative power sources, autonomous capabilities and more.”

The company shared several examples of commercialized products, recent concept products and innovation advancements that demonstrate a significant shift in functionality and capabilities. Among its latest concept updates and introductions, it unveiled the industry’s first autonomous and electric articulating tractor — the Bobcat AT450X enabled by Agtonomy.

Bobcat established a partnership with Agtonomy, a Silicon Valley-based, ag tech software company, to develop autonomous equipment innovations that increase ag productivity and performance.

“Our mission at Bobcat is to empower people to accomplish more. Through strategic partnerships with companies like Agtonomy, we are committed to advancing our worksite solutions to help solve our customers’ toughest challenges,” Park said. “By combining our proven equipment with the latest technologies, we are reinventing how work gets done.”

ed number of connected machines simultaneously which can yield a positive ROI for owners.

• The machine leverages AI to constantly “learn” and dynamically react to its environment. Through vision-based systems, it can detect known and unknown objects to autostop operation if needed.

• Capable of 24/7 operation, the AT450X can swap batteries when it needs to replenish its energy source. It does this by returning to its home base when its battery is low, switching to a fully charged battery and placing its drained battery back to its charging station.

• Commercialization details will be announced at a later date.

“With our company’s beginnings in agriculture, we have a strong connection to the land and an appreciation for the farmers who work long hours in a wide variety of conditions to feed the world,” said Joel Honeyman, Doosan Bobcat vice president of global innovation.

“As we innovate for the work sites of tomorrow, solutions like the AT450X will help make farming more productive, efficient and sustainable through digital advancements.”

Designed with wheels instead of tracks to optimize battery run time, the RogueX2 also features axial flux motors that give the machine incredible pushing power.

The battery-powered AT450X combines Bobcat’s tough and versatile articulating tractor with Agtonomy’s software and embedded-computing technology to support emissionsfree and autonomous operation, thus allowing farmers to automate labor- and time-intensive tasks.

The AT450X is designed to autonomously or remotely carry out critical farm tasks in compact applications, such as vineyards and orchards. Farmers can remotely direct the tractor to execute a wide range of tasks, including mowing, spraying, precision weeding, product and material transport and other labor-intensive activities.

“By digitally transforming the equipment farmers know and trust, we can help them combat the daily challenges they face, such as labor constraints and the ever-increasing demand for sustainable farming practices in specialty crops,” said Tim Bucher, CEO and co-founder of Agtonomy.

“The Bobcat AT450X with Agtonomy’s TeleFarmer technology makes the perfect end-to-end solution for agriculture and other industries allowing both companies to make a positive impact and that is what it is all about.”

• To operate, users plot the machine’s mission path via Agtonomy’s mobile application. This allows the end user to easily plan, execute and monitor jobs running on an unlimit-

At CES 2024, Bobcat also is showcasing the next evolution of its RogueX concept loader with the all-electric and autonomous RogueX2. Designed with wheels instead of tracks to optimize battery run time, the RogueX2 also features axial flux motors that give the machine incredible pushing power.

Together, the RogueX and RogueX2 concept loaders have garnered many new patents pending.

“These patents represent more than new features on a machine — they signify how we are breaking rules to define something new,” Honeyman said.

“To build a smarter, more sustainable and connected future, we must ask the questions no one else has thought to ask before and invent new solutions.”

During Media Days, the company also shared updates on its autonomous mower designed to operate with Greenzie software and the all-electric Bobcat S7X skid-steer loader, which was recognized as a CES Innovation Award honoree in two categories.

Among its new concept introductions, Bobcat has commercialized several innovations in the areas of connectivity, electrification and autonomous operation, including its battery-electric excavators, the all-electric Bobcat T7X compact track loader, Bobcat MaxControl remote operation, Bobcat Machine IQ, Features on Demand, among others.

“Invention is not new for our company; it’s how we started and how we continue to evolve,” Park said. “And just as our equipment design has evolved over the past six-plus decades, we are continuing to advance it with new technologies to be smarter, faster, more powerful and more sustainable. We are re-envisioning our solutions through the lens of tomorrow’s jobsite and our customers’ needs.”

For more information, visit bobcat.com.

(All photos courtesy of Bobcat)

www.mecomequipment.com 4546 N Wilson Way, Stockton, CA 95205 209-466-5135

33345 SR 20, Oak Harbor, WA • 360-675-4441 Marysville, WA • 360-651-9079 Wenatchee, WA • 509-888-8181

www.rsindinc.com 951 CR G, Clovis, NM 88101 575-769-8659

www.oklahomaterritoryequipment.com Oklahoma City, OK 405-917-9191

www.cisco-equipment.com 1706 South 1st Street, Artesia, NM 88210 575-748-1314 Odessa, TX • 432-550-9181 Lubbock, TX • 806-745-9595 San Angelo, TX • 325-653-2121

- TEXAS (Formerly Four Seasons Equipment) www.NEDealers.com Houston, TX • 800-234-5007 Dallas TX • 866-270-1700

www.nuecespower.com 7510 IH-37 Access Rd., Corpus Christi, TX 78409 361-289-0066 Laredo, TX • 956-725-0066 San Antonio, TX • 210-310-0066 San Benito, TX • 956-361-0066 Victoria, TX • 361-576-0066 El Paso, TX • 915-541-0066

Loved for the features. Trusted for the performance.

Hyundai wheel loaders have the power and performance — not to mention top-notch interiors, accurate onboard weighing system, unique bucket design for better load retention, clear sight lines, and handy tech — that make life on the jobsite easier. So you can do more without feeling like

www.clmequipment.com

3135 US Hwy 90 East Broussard, LA 70518 337-837-6693

4851 E Napoleon Road Sulphur, LA 70663 337-625-5942

2815 N Sam Houston Pkwy E Houston, TX 77032 281-598-2500

www.jetcityequipment.com 33345 SR20 Oak Harbor, WA 98277 360-675-4441 10219 State Avenue Marysville, WA 98271 360-651-9079

2713 Euclid Avenue Wenatchee, WA 98801 509-888-8181

Dallas (Carrollton), TX 214-819-4100 Austin, TX 512-388-2529

Corpus Christi, TX 361-881-4891

Ft. Worth, TX 817-626-2288

Longview, TX 903-758-5576 Mercedes, TX 956-565-0100

San Antonio, TX 210-648-4600

Stephenville, TX 817-626-2288

www.rgwequipment.com

700 W. Mossdale Road Lathrop, CA 95330 925-606-2477

550 Greenville Road Livermore, CA 94550 925-606-2403

6904 Banigan Road Anderson, CA 96007 925-606-2437

www.PacWestMachinery.com

8207 South 216th Street

Kent, WA 98032

206-762-5933

Mount Vernon, WA 360-588-3083

Portland, OR 503-252-5933

Eugene, OR 541-302-3762

Spokane Valley, WA 509-534-5933

Pasco, WA 509-547-5933

www.rgwequipment.com

700 W. Mossdale Road Lathrop, CA 95330 925-606-2477

550 Greenville Road Livermore, CA 94550 925-606-2403

6904 Banigan Road Anderson, CA 96007 925-606-2437

www.romco.com

1519 W Belt Line Road Carrollton, TX 75006 214-819-4100

Austin, TX 512-388-2529

Carmine, TX 979-278-3570

Ft. Worth, TX 817-626-2288

San Antonio, TX 210-648-4600

Buffalo, TX 903-322-5602

Corpus Christi, TX 361-881-4891

Mercedes, TX 956-565-0100

Stephenville, TX 254-266-2871

www.vcesvolvo.com

Bakersfield, CA 661-387-6090

Corona, CA 951-277-7620

Fresno, CA 559-834-4420

Sacramento, CA 916-504-2300

Lakeside, CA 619-441-3690

Redding, CA 279-201-4869

San Leandro, CA 510-357-9131

Turlock, CA 209-410-6710

HD Hyundai has once again won the CES 2024 Innovation Awards, following its wins in 2023. The consecutive wins underscore the company’s potential and competence in producing next-generation technologies to serve future humanity.

HD Hyundai’s three award-winning products and solutions for the CES 2024 Innovation Awards are:

• HD Hyundai XiteSolution: Smart Collision Mitigation with Sensor Fusion, X-Agent (AI-based machine assistance for construction equipment)

• Avikus: NeuBoat Navi (autonomous navigation solution for recreational boats)

The CES Innovation Awards is an annual competition held by the Consumer Technology Association (CTA), which honors products with outstanding technologies and innovation. The awards are announced each year ahead of CES, the world’s largest IT and consumer electronics trade show held in Las Vegas.

In its first year being entered in the CES Innovation awards, HD Hyundai XiteSolution won in two categories — Vehicle Tech & Advanced Mobility and Mobile Devices, Accessories & Apps.

HD Hyundai XiteSolution features Smart Collision Mitigation with Sensor Fusion, which is a system that prevents the risk of job site accidents by automatically stopping the machine when detecting people or objects within a certain range of the excavator.

HD Hyundai XiteSolution is the first construction equipment manufacturer in the world to use fusion technology to supplement a machine’s cameras and radars. Adding fusion technology greatly elevates accuracy in detecting obstacles and distance from equipment compared to machines with a single sensor.

HD Hyundai XiteSolution also features X-Agent, which is an AI-based machine-assistance solution for excavators, wheel loaders, articulated dump trucks and other construction equipment. X-Agent helps advance machine operation and productivity and is created with HD Hyundai’s unmanned automation technology.

This technology self-recognizes and judges equipment information, site environment, and work plan using AI and provides optimized machine operation guidance to the operator. Remote control also is an option with X-Agent for tasks at job sites that are restricted for limited time and space constraints.

Avikus, an HD Hyundai company that specializes in autonomous ship navigation, won the Innovation Award in 2023 for its NeuBoat product. NeuBoat is an autonomous navigation solution for recreational boats. This year, Avikus won a second consecutive Innovation Award for an updated version of the product known as “NeuBoat Navi,” which includes enhanced AI cognition and control features as well as

Smart Collision Mitigation with Sensor Fusion is a system that prevents the risk of job site accidents by automatically stopping the machine when detecting people or objects within a certain range of the excavator.

a more user-friendly display.

According to HD Hyundai, “It is an honor to be recognized in the CES Innovation Awards with other world-class technology companies as we work to prove our commitment to developing future solutions for land and sea. We will continue to do our best to develop unrivaled technologies that secure our position as a changemaker in the industry.”

HD Hyundai is exhibiting at CES 2024, Jan. 9-12, in booth number 4517 in the Las Vegas Convention Center West Hall. HD Hyundai Vice Chairman and CEO Kisun Chung is a keynote speaker on Jan. 10. Chung will showcase how comprehensive innovation in building smart infrastructure will shape a more sustainable future. The keynote will be given at the Venetian hotel in the Palazzo Ballroom on Level 5.

HD Hyundai XiteSolution markets construction equipment in North America under the DEVELON and Hyundai Construction Equipment brands. These brands sell heavy and compact construction equipment in the United States and Canada through independent dealer networks. The construction equipment includes crawler, wheel, and mini excavators; wheel loaders; articulated dump trucks; dozers; material handlers; and log loaders.

Better? It’s something we all strive for. But to be better you must be efficient. Be productive. Be versatile. Be dependable. And you need equipment that supports you every step of the way, no matter how big or small the task. Because good enough is never good enough.

Check out our full line of JCB products at your local dealer or visit JCB.com today.

520 SE Loop 338 Odessa, TX 79762 432-550-9181

www.cisco-equipment.com 2935 Lincoln Road Las Vegas, NV 89115 702-432-2200

461 Pioneer Place Las Cruces, NM 88005 575-524-1671

2240 W. Buckeye Road Phoenix, AZ 85009 602-454-9808

www.swjcb.com

General Motors and Komatsu will co-develop a hydrogen fuel cell power module for Komatsu’s 930E electric drive mining truck, the world’s best-selling ultra-class haul truck.

GM, a leader in hydrogen fuel cell technology, and Komatsu, a global manufacturer of mining and construction equipment, will jointly design and validate the technology.

Lightweight and quick to refuel, hydrogen fuel cells are ideal for electrifying applications traditionally powered by diesel engines. Hydrogen provides an effective method to package large quantities of energy onboard the vehicle, without compromising payload carrying capacity.

Additionally, fuel cells provide an excellent zero tailpipe emissions solution for vehicles with extreme hauling requirements, like the Komatsu 930E mining truck, with its nominal payload of 320 tons. These vehicles typically operate at a single mine throughout their life, which simplifies the challenges of sizing and deploying an effective hydrogen refueling infrastructure to service the vehicle fleet.

“At GM, we believe fuel cells can play an integral role in a zero-emissions future, helping to electrify heavier-duty applications, beyond passenger vehicles,” said Charlie Freese, executive director of GM’s Global HYDROTEC business.