By Irwin Rapoport CEG CORRESPONDENT

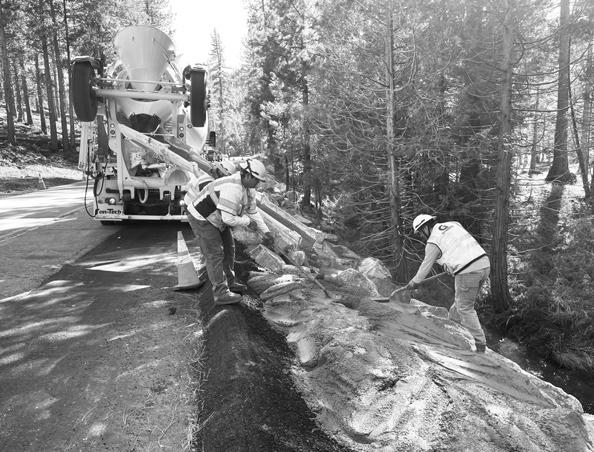

While Southern California contends with a historic atmospheric river, causing mudslides, crews from Granite Construction are engaged in road repairs and clearing operations caused by previous rock and mudslides in several areas to restore access through the Sequoia National Forest near Kings Canyon National Park (KCNP) in the southern Sierra Nevada mountain range.

The contract was awarded to Granite last August by the California Department of Transportation (Caltrans) and is expected to be completed in June.

“Granite has a long history of partnering with Caltrans District 6 to find innovative solutions to urgent and complex transportation system needs,” said Granite Vice President of Regional Operations Carter Rohrbough.

“There was a total of four major washouts along SR 180 that damaged the integrity of the roadway and blocked access, three of which impacted lanes for travel in both eastbound and westbound directions,” said Alex Aguilera, Caltrans public information officer, District 6.

To date, Granite has completed washout repairs, cleaned and repaired existing culverts, installed new culverts and

page 34

Granite Construction was tasked with making repairs at California’s Kings Canyon National Park in the southern Sierra Nevada after a total of four major washouts along SR 180 damaged the integrity of the roadway and blocked access to the Sequoia National Forest.

Construction contractors are between a rock and a hard place: What the Biden administration’s IIJA has gifted with a hike in construction work, Buy America policies have taken away by making the work much pricier to perform. Construction costs rose almost 3 percent during the first quarter of 2023, and contractors have seen a 50 percent increase over the past two years. That has the transportation industry nervous for the future.

Last year’s National Highway Construction Cost Index (NHCCI) shows it reached “a new all-time high” in the first quarter of 2023. The Bureau of Transportation Statistics (BTS) reported an increase of 2.7 percent from the last quarter of 2022. During the 2.5-year span, second quarter 2022 grew faster than see POLICY page 48

Aux. Hyd. Thru ext-hoe, Pilot Control $69,500

Cat CS44, Stk#: 12622, 66" Smooth Drum, 1,509 hrs., 14.9x24 Tires $69,500 2015 Bomag BW211D-50, Stk#: 12686, 84" Smooth Drum, 2,775 hrs.,

Company officials hosted a special media event on Jan. 17, 2023, in Las Vegas. It was during this event that DEVELON leaders unveiled the new brand for the first time, marking the beginning of a new era.

The not seasonally adjusted national construction unemployment rate was unchanged in December 2023 from the previous year, according to a state-by-state analysis of U.S. Bureau of Labor Statistics data released by ABC.

The American Road & Transportation Builders Association’s (ARTBA) Foundation is seeking eligible students for its 2024-25 “Lanford Family Transportation Construction Worker Memorial Scholarship Program.”

Jim Kempton, who has served the eight south-central Idaho counties as the District 4 representative on the Idaho Transportation Board since March 2012, announced his retirement at the end January.

The construction industry had 449,000 job openings on the last day of December, according to an ABC analysis of data from the U.S. Bureau of Labor Statistics’ Job Openings and Labor Turnover Survey.

World of Concrete recently concluded its 50th anniversary in Las Vegas. The 2024 edition, held Jan. 22-25, 2024, gathered nearly 60,000 registered professionals from various industry sectors, a 23 percent increase from 2023.

22

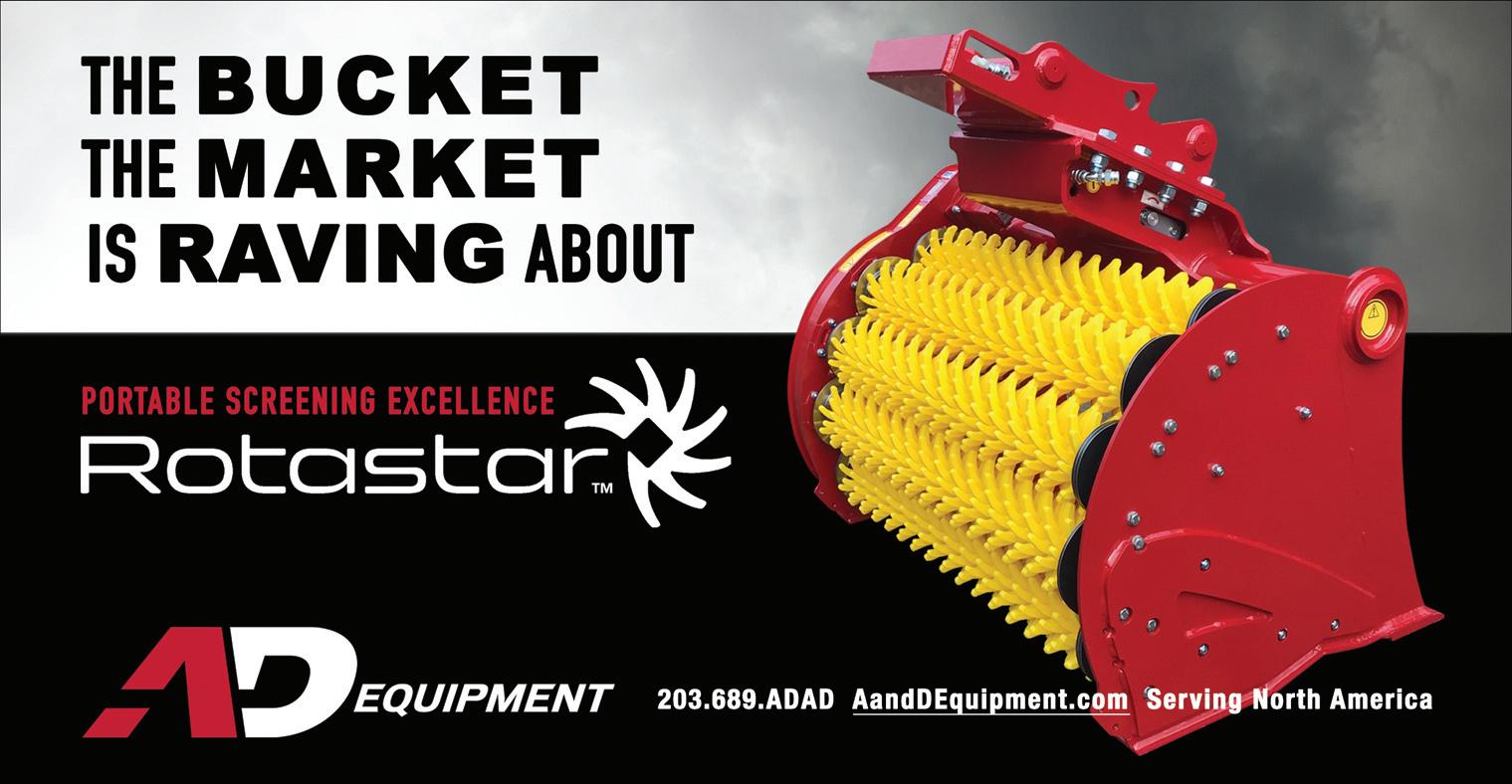

Mini-excavators, skid steers, compact track loaders — contractors hail these for their versatility and adaptability across various tasks. These machines can be equipped with various attachments, making them multi-functional powerhouses.

Doosan Robotics Inc., one of the world’s leading collaborative robot (cobot) manufacturers, is set to revolutionize the robotics industry at CES 2024 with its unveiling of cutting-edge cobots and AI technologies.

30

All Material Handling (AMH) believes that too many non-traditional lifts are still taking place using the wrong hoist rings and eyebolts, creating unnecessary safety risks.

42 THUNDER CREEK NAMES EQUIPMENTSHARE AS NEW DEALER IN MISSOURI, OKLAHOMA

Thunder Creek Equipment, a manufacturer of fueling solutions, has introduced EquipmentShare as its new dealer of its product sales and support lineup at locations in Columbia, Mo., and Oklahoma City, Okla.

42 TOPCON ANNOUNCES NEW GLOBAL SUSTAINABILITY INITIATIVES

The formation of a new global team dedicated to sustainability and corporate social responsibility (CSR) has been announced. It will be led by Michael Gomes as vice president of Global Sustainability and CSR.

44 TMAX 1-11 OFFERS INCREASED PAYLOAD, FUEL EFFICIENCY

The Stellar TMAX 1-11 aluminum mechanic truck combines extensive crane compatibility, customizable features and unparalleled quality. This vehicle has been engineered with precision to create a powerhouse. 45 VOLVO FH ELECTRIC WINS ‘TRUCK OF THE YEAR 2024’ AWARD

Volvo’s FH Electric, has been selected as International Truck of the Year 2024. In explaining its decision, the jury praised the electric truck’s performance, seamless acceleration, quietness and vibration-free behavior.

45 KENWORTH MAKES NEW ADAS FEATURES AVAILABLE FOR T680

Kenworth recently announced the latest iteration of its Advanced Driver Assistance System is now available for Kenworth T680s. The enhancements are part of the Bendix Fusion system.

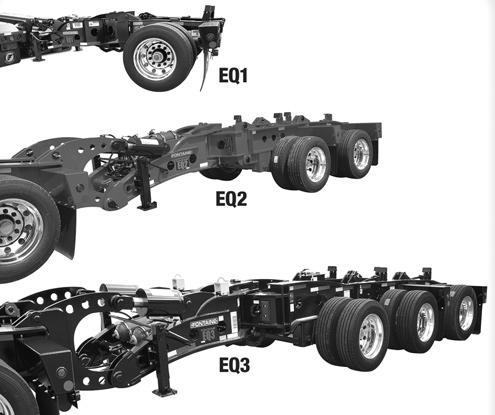

45 FONTAINE SPECIALIZED UNVEILS ENHANCEMENTS TO ITS LINEUP

Fontaine Specialized, a recognized technology leader and innovator in the lowbed trailer industry, has unveiled enhancements across its complete line of hydraulic equalizing spreaders for Magnitude Series lowbeds. 23 KLEEMANN MAKES PLANT COUPLING

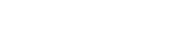

It’s been one year since the familiar brand of orange construction equipment, formerly known as Doosan construction equipment, was renamed DEVELON.

Company officials hosted a special media event on Jan. 17, 2023, in Las Vegas. It was during this event that DEVELON leaders unveiled the new brand for the first time, marking the beginning of a new era for the construction equipment manufacturer.

Under the new brand name, DEVELON is building on its success in North America over the past 30 years and throughout the world for 80 years. It has produced innovative products and solutions that have further solidified its status as a global leader in construction equipment and solutions in the construction industry.

“Early on, DEVELON took a strategic approach to launching the new brand,” said Todd Roecker, vice president of growth initiatives. “We leveraged ConExpo-Con/AGG 2023, helping customers recognize that we were the same company and product line, not a new entity to the North American market. We had a lot of interest and buy-in from dealers and customers. Since then, we’ve had tremendous achievements, including rebranding and expanding our product offerings, growing our dealer network and building on the success of the new brand.

“Another example of our early success was participating in the AEM Celebration of Construction on the National Mall in Washington, D.C. It was there that we joined other leading manufacturing companies to showcase the DEVELON brand and the latest safety features for the construction industry, including our exclusive Transparent Bucket feature.”

Since the transition, DEVELON has introduced innovative technologies to better shape the future of the construction industry and change how work is done. It demonstrated Concept-X2 autonomous construction equipment at ConExpo in March. The company showed safety innovations such as the optional around view monitor (AVM) camera system, object detection technologies and the industry first and only transparent bucket which is standard on all -7 Series 2023 and newer wheel loader models. Efforts also have been focused on advancing sustainable development through alternative energy sources of power for construction equipment like mini excavators.

The company also increased its product offering, adding a second dozer model: the DD130. It expanded its mini excavator lineup with the DX42-7, DX62R-7 and DX63-7. In 2024, DEVELON will launch its first compact track loader.

“By growing our construction equipment offering quickly and efficiently in North America, we can now be a full-line, single-source provider for our dealers and customers,” said Roecker. “Because of this expansion, we have established a stronger presence in the construction industry and look forward to continuing this momentum in the years to come.”

Due to the success at ConExpo, DEVELON is

Another result of DEVELON’s rebrand and growing industry presence is the expansion of its dealer network to more than 200 locations in the United States and Canada — a new pinnacle for DEVELON dealership locations.

“Early on, DEVELON took a strategic approach to launching the new brand,” said Todd Roecker, vice president of growth initiatives. “We leveraged ConExpo-Con/AGG 2023, helping customers recognize that we were the same company and product line, not a new entity to the North American market.”

increasing its participation in industry-wide trade shows as well as other local and regional shows this year. The company is exhibiting at World of Concrete and The American Rental Association (ARA) Show. DEVELON also will be making its debut at World of Asphalt in March and Equip Exposition in October.

DEVELON had a larger presence at the 2024 Consumer Electronics Show (CES) in Las Vegas, Jan. 9–12, showing full-size autonomous equipment prototypes for the first time in North America. The company also focused on promoting equipment that can create a safer job site and environment for customers.

“Trade shows are an important way to get our brand out there, where we can tell our own story the way we want it to be told,” said Roecker. “They open up opportunities to show off new products and innovations and reach new customers who are working in various applications that our company is interested in exploring.”

Another result of DEVELON’s rebrand and growing industry presence is the expansion of its dealer network to more than 200 locations in the United States and Canada — a new pinnacle for DEVELON dealership locations.

“Every dealer worked hard on converting their dealerships to the new brand when it was announced, from signage to new machine decals and uniforms,” said Roecker. “Due to their efforts promoting DEVELON in their markets, we’ve received more interest from new dealers and customers. We’ve also been able to hire better talent as a result. This transition of the company name would not have been successful without the support from our dealer network.”

A major launch in early 2024 is the 36-month, 5,000-hour full-coverage standard warranty on a purchase of a new DEVELON mini excavator, crawler excavator, wheel excavator, log loader, road builder, wheel loader or dozer.

“We’re pleased to offer one of the best construction equipment warranties in North America,” said Roecker. “We’re also very aggressive with our finance programs and rates as low as 0 percent for 60 months. We have some of the best finance rates in the industry and have an outstanding dealer network to support these programs. We are looking forward to expanding on and developing new programs for our customers.”

Since the name change, DEVELON has focused heavily on promoting the brand. However, as the company moves forward it will be putting a larger focus on connecting with customers, dealers and the industry.

“We will place an emphasis on telling the story of who we are so that we can create more meaningful interactions,” said Roecker. “In addition, we’ll add more products to our portfolio, like the compact track loader, and will be aggressive with our warranty programs. We’ll also focus on adding the right dealers and partners to make ourselves more competitive and to satisfy customers. We’ve got a lot in store and are excited for the future of DEVELON.”

(All photos courtesy of DEVELON)

Abilene Equipment Center

abileneequipmentcenter.com

Abilene, TX 325-603-1328

Alpine Equipment Repair

*Compact Equipment Only alpineequipmentrepair.com

American Fork, UT 801-874-6061

ASAP Equip

*Compact Equipment Only asapequip.com

College Station, TX 979-690-1106

Cisco Equip

cisco-equipment.com

Artesia, NM 575-748-1314

Lubbock, TX 806-745-9595

Odessa, TX 432-550-9181

Pflugerville, TX 512-535-3311

San Angelo, TX 325-653-2121

Earhart Tractor & Equip

earhartequipment.com

Tucson, AZ 520-889-6396

EquipmentShare equipmentshare.com

Billings, Montana 406-601-0333

Farm Equip USA farmequipmentusa.com

Caldwell, ID 208-941-6000

G4 Const Equipment, LLC

g4hyundai.com

Denver, CO 888-987-3352

Jet City Equip

jetcityequipment.com

Oak Harbor, WA 360-675-4441

Marysville, WA 360-651-9079

Wenatchee, WA 509-888-8181

Mecom Equipment mecomequipment.com

Stockton, CA 209-466-5135

National Equipment Dealers nedealers.com

Houston, TX 800-234-5007

Dallas TX 866-270-1700

Nueces Power Equip

nuecespower.com

Corpus Christi, TX 361-289-0066

Laredo, TX 956-725-0066

San Antonio, TX 210-310-0066

San Benito, TX 956-361-0066

Victoria, TX 361-576-0066

El Paso, TX 915-541-0066

Oklahoma Territory Const Equip callotce.com

Oklahoma City, OK 866-339-6827

Oregon Tractor oregontractor.com

Roseburg, OR 541-679-6211

Portland, OR 503-282-7211

Porter Group Usa portergroupusa.com

Corona, CA 951-674-9999

Lakeside, CA 619-390-1197

Pacoima, CA 818-834-0102

Newark, CA 510-713-7368

W Sacramento, CA 916-372-5925

Wildomar, CA 951-678-9902

R&S Industries Inc. rsindinc.com Clovis, NM 575-769-8659

Springdale Tractor springdaletractor.com

Springdale, AR 479-361-2513

Tulsa, OK 918-224-1565

Tri-State Equipment

*Compact Equipment Only tristateequipmentrentals.com

Lake Havasu, AZ 928-680-6748

Fort Mohave, AZ 928-704-0101

The not seasonally adjusted national construction unemployment rate at 4.4 percent was unchanged in December 2023 from the previous year, according to a state-by-state analysis of U.S. Bureau of Labor Statistics data released by Associated Builders and Contractors.

The analysis also found that 25 states had lower unemployment rates over the same period, four were unchanged and 21 states were higher.

National NSA payroll construction employment was 230,000 higher than in December 2022. Starting in February 2022 through December 2023, seasonally adjusted construction employment exceeded its prepandemic peak of 7.6 million.

In December 2023, 31 states had lower construction unemployment rates compared to December 2019, three states’ rates (Missouri, Oklahoma and Oregon) were unchanged and 16 states had higher rates.

“Continued high interest rates have been a drag on plans for new construction,” said Bernard Markstein, president and chief economist of Markstein Advisors, who conducted the analysis for ABC. “However, industry employment remains healthy, as builders work on their backlog of projects and employers fill some of their advertised posi-

tions. Nonresidential construction activity and employment is benefiting from federal funding and tax incentives for manufacturers, as well as funding for state and local infrastructure projects.”

National and state unemployment rates are best evaluated on a year-over-year basis because these industry-specific rates are not seasonally adjusted. However, due to the shifting effects on the economy from high interest rates, energy price fluctuations and other national and international developments, month-tomonth comparisons offer insight into the variable economic environment impact from these factors on construction employment.

NSA construction unemployment rates for December 2023 were:

• Maryland, 0.5 percent

• Georgia, 1.7 percent

• Utah, 1.9 percent

In December 2023, 32 states had lower estimated construction unemployment rates than in November, 17 states had higher rates and one (Maryland) had the same rate.

The five states with the lowest estimated

The American Road & Transportation Builders Association’s (ARTBA) Foundation is seeking eligible students for its 2024-25 “Lanford Family Transportation Construction Worker Memorial Scholarship Program.”

Applications are due April 19 and are available at www.artbafoundation.org.

The program, which was expanded in 2023, provides post-high school financial assistance to the children of transportation construction workers killed or permanently disabled on the job. This includes industry professionals who were working on projects in these sectors: airports, bridges, marine, ports and waterways, public transit, roads, railroads, tunnels and utilities.

Established in fall 1999 as the “Highway Worker Memorial Scholarship” by Roanoke, Va., contractors and brothers Stan and Jack Lanford, the fund provided more than $800,000 in aid to 214 students in 38 states from 2000-2023.

Students must attend a post-secondary institution of learning that requires a high school diploma or its equivalent. This could include any public or private four-year accredited college or university; two-year

The fund provided more than $800,000 in aid to 214 students in 38 states from 2000 to 2023.

• Delaware and Tennessee (tie), 2.1 percent

accredited college; or vocational-technical college or training institution. Graduate students who meet the eligibility criteria are also able to apply. Scholarships have a value of up to $10,000 annually.

For more information, or if you have a lead on a student who might be eligible, contact ARTBA Manager of Safety and Foundation Programs Melanie Laird at mlaird@artba.org., or 202/683- 1029.

The five states with the highest December 2023 estimated NSA construction unemployment rates were:

• Vermont, 7.3 percent

• Illinois, 7.5 percent

• Alaska, 9.4 percent

• Connecticut, 10.5 percent

• Rhode Island, 11.3 percent

Alaska posted its lowest December NSA estimated construction unemployment rate on record and had the largest monthly decline in its rate (down 4.8 percent). Vermont had the third largest year-over-year drop in its unemployment rate, down 2.6 percent, behind South Dakota (down 3.4 percent) and Minnesota (down 2.8 percent).

Maryland and Georgia each posted their lowest December NSA estimated construction unemployment rate on record. Utah had its second lowest December rate, behind last year’s 1.8 percent. Delaware and Tennessee both came in with their lowest December rate on record for the second time (Delaware matching its December 2018 rate and Tennessee its 2022 rate). Note that Delaware’s unemployment rate is for construction, mining and logging.

For more information, visit abc.org.

Jim Kempton, who has served the eight south-central Idaho counties as the District 4 representative on the Idaho Transportation Board since March 2012, announced his retirement at the end January. At 11 years of service, Kempton is the longest-serving board member. He succeeded Gary Blick as the District 4 representative.

A native of Albion, Kempton is a graduate of the University of Idaho. Kempton was a decorated Air Force fighter pilot who served two tours of duty in Vietnam. Kempton served five terms in the Idaho House of Representatives, including as the chairman of the House Transportation and Defense Committee.

Kempton also represented Idaho for seven years on the Northwest Power and Conservation Council, was a former member of the Idaho Public Utilities Commission — including two years as its president — and served as assistant professor of physics at the Air Force Academy. He also was liaison between the Secretary of Commerce and the Secretary of Defense at the Pentagon.

He chaired the Forum on Transportation Investment during his time on the board and

Jim Kempton

was a key member of former Gov. Otter’s Task Force on Transportation Investment.

“Jim’s commitment to Idaho and its citizens is unrivaled,” said Idaho Transportation Board Chairman Bill Moad. “It’s evident his time in the Idaho Legislature and with the Public Utilities Commission has been invaluable as he helped guide us on critical issues addressing growth and investment in transportation.”

The construction industry had 449,000 job openings on the last day of December, according to an Associated Builders and Contractors analysis of data from the U.S. Bureau of Labor Statistics’ Job Openings and Labor Turnover Survey.

JOLTS defines a job opening as any unfilled position for which an employer is actively recruiting. Industry job openings decreased by 21,000 last month and are down by 39,000 from the same time last year.

“The construction industry averaged 445,000 job openings per month in the fourth quarter of 2023,” said ABC Chief Economist Anirban Basu. “That’s the highest quarterly level on record and a strong indication that the labor shortages that have long plagued the construction industry remain firmly in place. With more than half of contractors expecting to increase their staffing levels over the next six months, according to ABC’s Construction Confidence Index, the supply of workers is unlikely to meet demand for the first half of 2024.

“There is, however, some good news regarding worker availability,” said Basu. “While contractors are still laying off workers at a historically low rate, the rate at which construction workers are quitting has fallen below 2019 levels. This is likely a reflection of falling demand for labor in industries that compete with construction for talent, including trade, transportation and utilities, which has seen a 25 percent decline in job openings over the past year.”

For more information, visit www.abc.org.

ALASKA

NC MACHINERY

www.ncmachinery.com

800-478-7000

Anchorage, AK • 907-786-7500

Dutch Harbor, AK • 07-581-1367

Fairbanks, AK • 907-452-7251

Juneau, AK • 907-789-0181

Prudhoe Bay, AK • 907-659-6900

Wasilla, AK • 907-352-3400

ARIZONA

EMPIRE CAT

www.empire-cat.com

1725 S Country Club Mesa, AZ 85210

800-EMPIRE-1

CALIFORNIA

HOLT OF CALIFORNIA

www.holtca.com

Pleasant Grove • 916-921-8969

NEVADA

EMPIRE CAT

www.empire-cat.com

3300 St. Rose Parkway, Henderson, NV 89052

702-649-8777

Elko • 775-738-9871

Reno/Sparks • 775-358-5111

NORTH DAKOTA

TRACTOR AND EQUIPMENT

www.tractorandequipment.com

Williston • 701-572-8377

WYOMING

TRACTOR AND EQUIPMENT

www.tractorandequipment.com

Worland • 307-347-4747

MONTANA

TRACTOR AND EQUIPMENT

www.tractorandequipment.com

Billings, MT • 406-656-0202

Billings-Sgt. • 406-245-4426

Bozeman • 406-585-5800

Great Falls • 406-761-7900

Helena • 406-442-2990

WASHINGTON

NC MACHINERY

www.ncmachinery.com

800-562-4735

Seattle • 425-251-5800

Chehalis • 360-748-8845

Fife • 253-896-0878

Monroe • 360-805-6000

Mt. Vernon • 360-424-4292

Wenatchee • 509-886-5561

Yakima • 509-248-2371

Vermeer Corporation displayed a wide range of equipment at the show, from the ATX720 compact articulated loader to the VXT300 vacuum excavator (background). Seen here with the loader are Vermeer’s Jake Jeffords

and Zach Crabtree.

World of Concrete recently concluded its 50th anniversary in Las Vegas.

The 2024 edition, held Jan. 22-25, 2024, gathered nearly 60,000 registered professionals from various industry sectors for three days of exhibition and four days of education, a 23 percent increase from 2023. More than 1,400 companies and an all-time high 185 education sessions highlighted the event.

The second largest tradeshow in Vegas, covering more than 700,000 sq. ft. of indoor and outdoor space, convened large crowds in the exhibit halls, packed competitions and at-capacity training sessions. More than 450 international exhibitors from around the world, a milestone 325 first-time exhibitors, and well-known brand names comprised the tools, resources and tricks fueling the future of the trade. New audiences and the incoming next generation of concrete professionals continue to be a focus for increasing visibility in the sector.

“Every year, World of Concrete serves as the cornerstone where concrete and masonry professionals exchange knowledge and hone skills that propel businesses forward,” said Jackie James, vice president of World of Concrete.

“We are proud to host the global meeting point that serves the tradespeople who are building the future of America. We emphasize creating real-world scenarios, hands-on situations to try and test products and share expertise, which is what makes WOC so unique and our community so special. We look forward to continuing to share the latest and greatest in concrete and masonry for another 50 years to come.”

Events, in part, included the Concrete Industry Management (CIM) live and silent auctions, raising a collective $1.8 million for the Concrete Industry Management programs at five public universities, Chico State, Middle Tennessee, New Jersey’s Science & Technology, Texas State and South Dakota State, all of which offer four-year degrees in CIM. Auction items included a concrete mixer truck donated by Mack Trucks Inc. and Revolution Concrete Mixers; a Peterbilt and ConTech mixer truck; and a concrete pumper donated by Alliance Concrete Pumps and Pape Kenworth.

In honor of the 50th anniversary, World of Concrete donated 50 trees to the Las Vegas Tree Initiative. The ongoing program aims to lower the urban heat island effect that currently makes Las Vegas the fastest-warming city in the United States.

World of Concrete will return to the Las Vegas Convention Center Jan. 2123, 2025 (Education 20-23). CEG

(All

Liebherr’s 546 loader was prominently displayed at WOC. According to Liebherr, “The efficient hydrostatic travel drive and efficient components reduce operating costs in a sustainable way, putting more money in customers’ pockets.”

Representatives from GOMACO were at World of Concrete to discuss the industry’s first hybrid curb and gutter machine — the GT-3600. (L-R) are Kelly Steeves; Travis Brockman; Brad Zobel; Scott Pedersen; Kye Leners; Bryan Beck, district manager southwest; Randy Bean, Matt Morrison, manager JD Machine Controls; Logan Mohr, district manager western U.S., Kent Godbersen; and Rodney Harper.

Wacker Neuson was out in full force during World of Concrete 2024.

Fiori America continued the roll-out of its dumpers and concrete mixers to the American market at World of Concrete. (L-R) are Mauro Pelliciari, Fiori CEO; Neville Payner, executive vice president of Bell Trucks America; and Antonio Gallovich, Fiori export area manager. Bell Trucks America is Fiori’s master distributor for the United States.

At World of Concrete, Allen Engineering took the opportunity to continue the celebration of its 60th anniversary. Here, CEO Jay Allen is flanked by Joey Ward (L), vice president of sales and marketing, and Jeff Johnson, sales manager. The company offers a variety of equipment solutions for the concrete industry.

DEVELON’S 4-ton DX42-7 mini-excavator delivers excellent maneuverability and operator comfort according to Jacob Sherman, dealer and product marketing manager of DEVELON. The excavator drew a lot of attention from WOC attendees.

Doosan Robotics Inc., one of the world’s leading collaborative robot (cobot) manufacturers, is set to revolutionize the robotics industry at CES 2024 with its unveiling of cutting-edge cobots and AI technologies under the cohesive theme: Think. Sync. Link.

At Doosan Robotics’ first-ever CES media day, the company signified a future where AI empowers cobots to be in perfect sync with humans, seamlessly integrating a cohesive, safe and innovative ecosystem. This convergence of AI, cobot and SW platform technologies is not just a technological advancement, but a journey into new horizons for all consumers.

Driving Doosan Robotics’ versatility within the robotics field is its introduction of Dart-Suite, a next generation robot ecosystem redefining the robot experience. The scalable platform enhances the capabilities of cobots by effortlessly incorporating AI, all while making the advanced technology accessible to the general public.

Dart-Suite offers an environment where each component works in harmony, enabling users to develop, sell, download and trigger actions through various interfaces, ultimately leading to robots’ transition from static tools to flexible partners.

Utilizing Integrated Development

Environment (IDE), Dart-Suite allows consumers to create modules tailored to their needs, much like mobile device apps. The robust software platform dramatically reduces the development time by up to 80 percent.

Working with Dart-Suite is comparable to the ease and usability of smartphones, shaping the user experience for a new era of robotics.

Underscoring Doosan Robotics’ vision to enhance daily life and transform work processes is their impressive line of AI cobots, set to revolutionize industries such as manufacturing, logistics, food & beverage, architecture, filmmaking, service sectors and medical environments. The best-in-class solutions break the limits of current robotics and navigate complex scenarios by injecting efficiency, safety, and creativity into every task.

The AI system continuously learns and updates its model by downloading modules automatically and easily as needed for seamless integration.

Doosan Robotics collaborated with leading global companies, each renowned for their expertise and market leadership, to develop and commercialize AI cobot solutions. These collaborations include Doosan Robotics’ AI-powered recycling cobot “Oscar the Sorter,” a 2024 CES Innovation Award Honoree which autonomously learns about

“Otto Matic” is a depalletizing and palletizing solution adept at handling unstructured and random-sized boxes.

products and sorts them even recognizing crushed items without human intervention.

TDK Qeexo, the first company to automate end-to-end machine learning for edge devices, applied its innovative machinelearning solutions to “Oscar the Sorter.”

Also unveiled was “Otto Matic,” a depalletizing and palletizing solution adept at han-

dling unstructured and random-sized boxes which was developed by AiV, one of the world’s best industrial deep learning computer vision technology providers, to bring transformative deep learning and computer vision technology to the cobot.

Lastly, CES guests were able to grab a drink from “Mixmaster Moodie,” a bartending cobot powered by Microsoft’s ChatGPT, coupled with “Tetote,” a Bridgestone’s soft robot hand powered by bendy rubber artificial muscle that employs a pioneering cocktail recommendation system to serve a cocktail based on visual and audio cues.

“As we unveil our groundbreaking DartSuite at CES, we recognize the strategic importance of this platform’s launch in providing direct access to consumers and a multitude of industries,” said William Ryu, CEO, Doosan Robotics.

“CES serves as the perfect stage for introducing innovations that transcend boundaries and resonate with the diverse needs of our target audience. The potential lies not only in showcasing the power of our cobot line but also in highlighting the customizable functionality and usage that sets our technology apart.”

For more information, visit www.doosanrobotics.com/en/.

By John Weber RDO EQUIPMENT CO.

Mini-excavators, skid steers, compact track loaders — contractors of all sizes hail these for their versatility and adaptability across various tasks. Whether digging, grading, lifting or hauling, these machines can be equipped with various attachments, making them multi-functional powerhouses. This adaptability saves time and space and minimizes the need for numerous specialized machines, effectively reducing costs and the environmental footprint.

Besides adaptability, contractors cite small construction equipment as their first steppingstone to grow their business. It’s cost-effective, has low-financing options and is easily found at local dealerships.

Compact equipment may be the key for those wanting to open the door to a new opportunity. Here are some challenges contractors said were solved by owning compact construction equipment.

With national average diesel fuel prices soaring at around $4 per gal., compact construction equipment (CCE) has become the preferred choice for contractors handling projects with tight budgets and schedules.

Their smaller size allows for efficient operation and maneuverability, optimizing site layouts and productivity.

According to its proprietary model, the Associated Builders and Contractors said the construction workforce shortage surpassed half a million in 2023, making it nearly impossible to find skilled operators. With user-friendly controls and intuitive interfaces, CCE empowers a broader range of operators to contribute effectively to construction projects, mitigating the impact of the labor shortage. Many contractors have

successfully onboarded team members who are entirely new to the industry, starting them as skid steer or compact wheel loader operators.

As urban areas expand, construction sites come in all shapes, sizes and schedules. Many contractors want machines that can work on several job sites with various attachments or technology upgrades. Contractors said they can evolve with their CCE through attachments like the 4-in-1 buckets, which are available to fit on skid steers, compact

track loaders and compact tractors.

Other contractors expand their consistent productivity through Topcon's GPS technology, including MC-Mobile, which combines machine control and survey technology to let compact equipment operators measure, design and build jobs with the same system.

When construction sites are tight, compact machines enhance job site safety by increasing visibility and control. Operators can maneuver these machines more precisely, minimizing the risk of accidents. Additionally, remote operation capabilities with Teleo’s Supervised Autonomy allow operators to control equipment from a safe distance, particularly in hazardous situations.

Once considered nice to have support equipment but secondary to heavy equipment counterparts, compact construction machines have earned their place in equipment fleets of all sizes. Not only have they become more sought after because of their proven capabilities, but their flexibility and lower cost of entry allow operators to take advantage of these machines’ proven efficiency. Contact a equipment expert if you’re ready to find the right machine — or multiple compact machines.

(This article was reprinted with permission of RDO Equipment Co.)

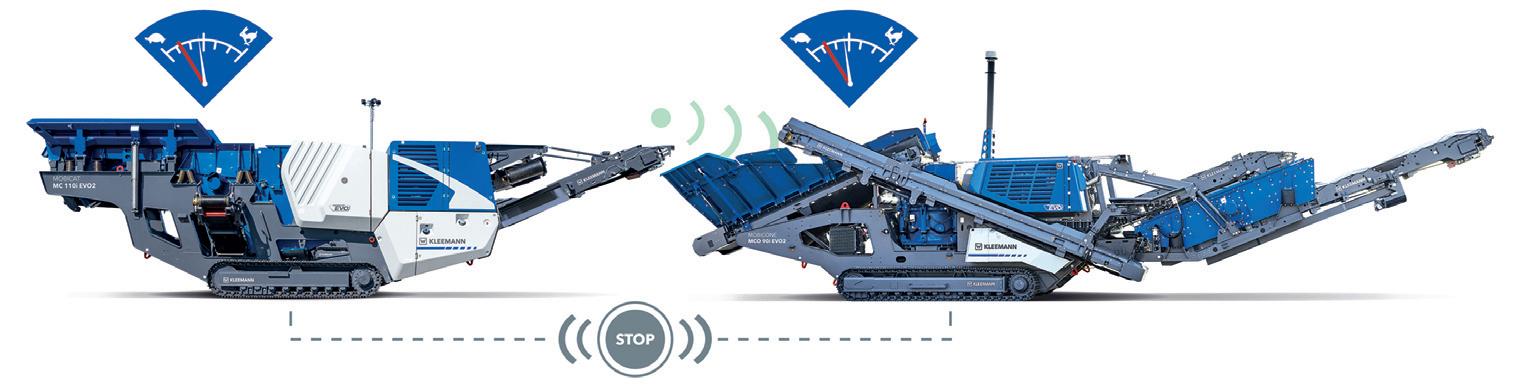

Clever line coupling allows Kleemann plants to be easily coupled with one another. The system has now been extended by a wireless version of the safety coupling.

The crushing process of the Kleemann crushing plants is optimized automatically by the innovative feed control CFS (Continuous Feed System) so that material is always conveyed with maximum efficiency through the machines. At the same time, the filling level of the plant’s crushing chamber is monitored. When the filling level reaches a height that can be defined in advance, the material feed of the machine is adjusted.

This system forms the perfect basis for the line coupling of an interlinked plant train. The optionally available probes at the crusher discharge conveyor and/or fine grain conveyor of the upstream machine monitor the filling level of the feeding unit of the respective upstream machine.

When the filling level also reaches a defined height here, the output of the upstream plant is temporarily reduced.

If an emergency stop button is pressed on the plant train, all machines are safely stopped. This is guaranteed by the safety coupling of the plants. For this purpose, apart from the cable connection new technology also is available: coupling via a radio system.

The “Wireless line coupling” is easier to handle and makes the typical workday of the

operator easier. Complex cable routing is no longer necessary and easy conversion of the plants is also possible. Due to the intelligent line coupling from Kleemann, overload situations and damage

are prevented. All of this combined results in a high availability and output with low wear.

The new technology “Wireless line coupling” is currently available as an option for the jaw crushers MOBICAT MC 110(i)

EVO2 and MC 120(i) PRO, cone crushers

MOBICONE MCO 90(i) EVO2 and MCO 110(i) PRO and the impact crushers

MOBIREX MR 110(i) EVO2, MR 130(i) EVO2 and MR 130(i) PRO.

Crushing plants can now also be safely connected per radio due to the Kleemann “wireless line coupling.”

Tech Specs

• 12’x 5’ Trommel Screen

• Stockpiles to 14ft

• Variable Speed Feeder

• Diesel/Hydraulic Drive System

Ship Anywhere in the USA Units in Stock Today

Best Bang for your Buck

Compact and Productive Tow with a Dump truck

High Production screener for Topsoil, Mulch, Compost, Recycling and more

Keep the screening revenue where it belongs…in your pocket

Fecon LLC, a global manufacturer of heavy-duty site preparation attachments and forestry accessories, has launched Fusion, a user-friendly telematics platform that uses modern features such as automatic machine calibration, location services and performance tracking to make industry-changing productivity gains in mulching operations.

Ushering in the next generation in mulching, Fusion automatically calibrates the attachment to the carrier in real-time to optimize performance, minimize downtime and expand the machine’s lifespan. Fusion is initially available on high-flow Bull Hog and Blackhawk attachments.

Fecon brings intelligent control technology to a new level in the mulching industry, drastically improving mulching operations. The ingenuity of Fusion’s performance lies in its simplicity. From the get-go, Fusion automates mulcher set up to improve performance and productivity through its Plug n’ Play design that eliminates manual setup and tuning. With this feature, customers can attach their mulcher to any compatible carrier and run the machine with increased performance. The mulcher is optimized to the carrier and working conditions at all times with no extra work for the user.

Another attractive feature is how the technology continually collects and adapts to information based on dynamic conditions such as temperature, altitudes, carrier settings and carrier efficiency. At the start of the day Fusion will detect a cold carrier and automatically adjust and tailor machine settings to those that work best in colder temperatures. As the machine warms up throughout the day, Fusion will tune the settings for those higher temperatures. The machine starts learning as soon as it is attached to a carrier, but an operator can choose to initiate a learn sequence through the Fusion app. This learning system ensures a Fecon mulcher is always operating at peak performance.

“One of the biggest struggles both dealers and operators face is tuning the mulching head to the carrier,” said Ryan Bricker, Fecon senior product manager. “We’ve completely removed that hassle and any associated delay by offering this Plug n’ Play design. It ensures that no matter the carrier, its age and condition or the location and temperature, our customers will receive maximum performance out of the Fecon mulching head. And it makes it easy for them to swap carriers.”

Fusion’s benefits are not exclusive to its automatic calibration as its continuous collection of mulcher operational data enhances productivity in a variety of ways. Fleet managers, for example, can use the data to assess and improve machine performance, note a machine’s last location or identify problems in operations. Dealers can use the data to better service their customers by quickly identifying the source of a problem in machine function and make swift corrections.

With Fusion, users can see up to 50 percent faster rotor recovery times, 30 percent fewer stalls and 40 percent increase in jobsite efficiency, the manufacturer said.

Fusion works seamlessly with the Fecon mobile application, available in the Apple App Store, allowing users to easily incorporate the benefits of Fusion into their day-today operations. Users can use the Fecon Fusion app for several tasks, including changing the mulcher settings, initiating the learn function or simply viewing real-time information on how the mulcher is running. The real-time display offers operators convenient access to crucial information.

Fecon plans to continue to expand the benefits of the Fusion system by adding additional features to the software such as

performance modes that will allow users to automatically adjust machine settings to match the current job.

Similar to a four-wheel drive vehicle where a user has the option to select “snow” or “mud” based on current conditions, the upcoming performance modes will tailor the mulcher to the optimal settings for that particular application. These developments demonstrate Fecon’s commitment to continuing to evolve and revolutionize mulching applications through real-time data and automation.

While automated technology in equipment can sometimes seem intimidating, Jeff Stanley, Fecon’s senior vice president of product development, assures customers there is nothing intimidating about it.

“With Fusion, we’re adding so much value to the customer and simplifying the product. It has more technology, tools and expanded data capabilities, but it’s important that customers realize how easy it is to use.”

Through its comprehensive connectivity, Fusion is pioneering the future of outstanding mulching performance and empowering users to make real time data-driven decisions, optimize their operations and immediately achieve greater levels of productivity.

Bane Machinery 2449 Manana Drive Dallas, TX 75220 800-594-BANE (2263)

10505 North Freeway Fort Worth, TX 76177 800-601-BANE (2263)

3402 E. NE Loop 323 Tyler, TX 75708 800-594-2200

www.banemachinery.com

Cisco Equipment 1706 S. 1st Street Artesia, NM 88210 575-748-1314

2707 Slaton Hwy. Lubbock, TX 79404 806-745-9595

520 SE Loop 338 Odessa, TX 79762 432-550-9181

620 N. Bell Street San Angelo, TX 76903 325-653-2121

www.cisco-equipment.com

Oklahoma Territory Construction Equipment 3839 West Reno Ave. Oklahoma City, OK 73107 405-917-9191 866-339-6827

2520 E King Street Tulsa, OK 74110 918-835-7200 866-334-6827

www.oklahomaterritoryequipment.com

Nueces Power Equipment 7667 N Sam Houston Parkway Humble, TX 77396 713-247-0066 www.nuecespower.com

Triad Machinery 1601 E. Bay Street Tacoma, WA 98421 253-722-5600

910 N. Thierman Road Spokane Valley, WA 99202 509-534-1900

1210 Dale Lane Mt. Vernon, WA 98274 360-488-3948

4440 SW Airport Road Prineville, OR 97754 888-662-2940

91251 Coburg Industrial Way Coburg, OR 97408 541-342-7700

18200 NE Riverside Parkway Portland, OR 97230 800-221-8512

www.triadmachinery.com

1090 W 2181 N Salt Lake City, UT 84116 801-322-1300

atlasmachinery.us

6565 Smith Avenue Newark, CA 94560 510-400-5024

1535 SE 25th Street Oklahoma City, OK 73129

405-310-8700

2035 W Mountain View Road Phoenix, AZ 85021

480-463-4999

Equipmentshare.com

More work is needed to ensure that non-standard lifts are carried out safely, according to a leading expert.

All Material Handling (AMH) believes that too many non-traditional lifts are still taking place using the wrong hoist rings and eyebolts, creating unnecessary safety risks.

Peter Brettner, CEO of “below the hook” equipment supplier All Material Handling, said “Whether on a construction site, in a machine shop, or at a manufacturing facility, there are two primary goals: move the load without damaging it; and make it home safely at the end of your shift.

“We’re still seeing a lot of incorrect use of eye bolts in particular. Traditional eyebolts are best used for straight in-line lifts only, or they incur a significant reduction in the working load limit. The old school alternative was often to wrap a round sling around the load and see how it went, but frankly both can be an accident waiting to happen.”

While a sling and some hooks are usually suitable for a standard lift with easy connections such as a shackle and welded eye or plate, a non-traditional lift like a large motor or a flat gear can be much more challenging. In these cases, AMH recommends rotating

hoist rings, as they are specifically designed to lift from the focal point and keep the load centered — traditional eyebolts can tend to sideload.

AMH is adding the Cartec series of lifting points and rotating hoist rings to its product portfolio, ensuring that riggers have easy access to the right tools for the job when it’s a nonstandard load.

The Cartec 807 series of rotating eyebolts provide a 100 percent working load limit at any angle allowed by the corresponding user’s manual — and the load limit is clearly visible on the bolt itself, eliminating guesswork.

“Using the right swivel hoist ring and rotating eyebolt means there is no more second-guessing the reduced working load limit of a standard eyebolt because it is not an inline pull. The load limit is easily checked as it’s forged into the product and doesn’t change,” added Brettner.

“There is also no more shimming the shoulder to get a proper lift angle, which

can happen with traditional eyebolts — or worse, risk having lousy positioning and causing a failure. Contractors are increasingly focused on enhancing safety. While a swivel eyebolt has a slightly higher price than a standard eyebolt, this is nothing compared to the human and financial cost of an incident that causes injury or even death.”

AMH offers a full line of lifting points ranging from 6 mm all the way up to 100 mm, offering 0.3t to 40t WLL, available in both UNC and metric threads. Styles include rotating eyebolts, standard swivel hoist rings, off-set swivel hoist rings, ball bearing options for swiveling under load and even stainless-steel rotating eyebolts. For more information, contact AMH at 877/543-8264 or via email at sales@allmaterialhandling.com.

All Material Handling Inc. is dedicated to making lifting and handling safer and more efficient. The privately-owned company is a provider of material handling equipment and accessories to applications in construction, industrial supply, maintenance, marine, military, mining, petrochemical, railroad, rental, ship building and utilities.

Air Compressor Solutions, Inc. www.acsir.com

TEXAS

Odessa (432) 335-5900

Amarillo (806) 383-1213

Ditch Witch West www.ditchwitchwest.com

ARIZONA Phoenix (602) 437-0351

Tucson (520) 579-0261

Sierra Machinery, Inc. www.sierraelpaso.com

TEXAS El Paso (915) 772-0613

NEW MEXICO Artesia (575) 746-6592

Papé Material Handling Inc. www.papemh.com

OREGON

Portland (503) 639-8910

Portland (503) 286-6400

Eugene (541) 689-7407

Medford (541) 779-3444 NEVADA

Sparks (775) 356-9333

WASHINGTON Seattle (206) 722-5800

Arlington (360) 474-8461

Fife (253) 926-4386

Bellingham (360) 756-6572

Yakima (509) 248-5636

Pasco (509) 545-1959

Wenatchee (509) 884-2934

Spokane (509) 536-7300

from page 1

headwalls and finished slide cleanup. Over the next few months, efforts will focus on the installation of wood lagging and steel piles for a retaining wall, rebuilding a failed slope with wire mesh baskets, rock, soil and geo grid fabric. Roadway improvements — including concrete barrier, safety enhancements, paving repairs and placement of erosion control products — all are on tap.

The project has its fair share of challenges.

“We’re working in a remote location with little to no cell service,” said Jeff Grimm, Granite’s Fresno area manager. “The project team set up Starlink and a base camp for safety and communication. The project is 20 miles long and required our teams to work multiple headings simultaneously to adequately progress the work. This has created communication and logistic challenges that required extra planning to keep crews safe. The terrain is steep and rocky — just driving between work locations can be dangerous.

“Snow and ice are also issues,” he added. “The work is primarily at elevations between 3,000 to 4,000 feet, however, accessing the work requires traversing a pass at 6,800 feet. Usually this section of highway is closed from November to May each year, but due to damage from the hard winter of 2022-2023, this section of roadway has been impassable and remained closed to the public since November 2022. To keep the work moving, Granite is maintaining the roadway by plowing and sanding to remove snow and mitigate icy conditions, which allows the work to continue during the winter months.”

Safety is a constant concern and taken very seriously.

“Due to the steep terrain and tightly radiused corners with rock outcroppings, most deliveries of equipment and materials happen miles above the actual work locations in a large turnout called the Helipad — named for the fact it is an actual dirt Helipad for emergency fire and evacuation equipment during the summer months — at the top of the mountain,” Grimm explained.

This requires double handling of most deliveries and tracking equipment long distances, so logistics are not easy.

To assess the work early in construction, a small side-byside ATV was used to gain access to portions of the job

where regular-sized vehicles were not an option. Many work locations required 4-wheel drive trucks to transport crews and navigate the poor road conditions, especially during inclement weather.

“The storm damage eroded many sections of the roadway where an entire lane or more has been washed away leaving barely a single lane of travel and in some instances on blind curves.” said Grimm. “We’ve used two-way radios for communication around blind curves.”

On the positive side, there are no utility issues.

Granite has provided crew accommodations to support the teams working on the project.

“We have employees staying on-site in RV trailers at our base camp where internet service is provided,” said Grimm. “Employees have the option to stay on-site or drive home.”

The plan for the clearing and removal of the debris is based on reuse and minimizing the transportation of materials off-site. The debris consisted of rock, dirt and vegetation.

“Granite’s plan is to use the material from the mud/rockslides to construct embankments at the washouts around the project,” Grimm explained. “Most of the material has been removed from the roadway at this stage of the work. Rock from the rockslides was salvaged and sized when needed by blasting, screening or with the use of hydraulic hammers and reused on-site as rip-rap and common fill. Some rocks that fell onto the roadway were nearly the size of a school bus. The use of existing on-site material eliminated costly export and import of replacement materials, helping reduce the overall cost of the repairs significantly. Vegetation debris was hauled offsite to dump.”

Most of the material was separated on-site when doable.

“This reduced the material that needed to be exported from the site and maximized the amount of material that could be incorporated into the reconstruction process,” continued Grimm. “There are soil grading requirements for the embankment construction, so Granite ran the material through a grizzly screen to make a 3-inch minus material.”

Approximately 60,000 cu. yds. of soil and rock have been moved throughout the site using Super 10-wheeler trucks and a Cat 740B haul truck.

Given the extreme nature of the project site, the right equipment was crucial for the success of these operations. Crews also used: Cat excavators: two 352s (one with a breaker excavator), 320, 330, 335 and a 308 (mini); loaders: a Cat 966, Cat 963 track loader and several John Deere models — a 744 and 210 skip loader; a John Deere 710 backhoe; Cat D6 and D4 dozers; and a Cat 140 motor grader.

The construction of the retaining walls required a change in plans.

“Originally it was anticipated that several walls and even a viaduct would need to be constructed to safely restore and reopen the roadway,” said Grimm. “However, Caltrans and Granite collaborated on design solutions for each repair area and only one soldier pile wall and one stabilized soil wall are being constructed. Other locations were repaired using conventional earthen fills and many of the slopes were stabilized with rip-rap from on-site rock slides or mined from on-site locations.”

The plan of attack has crews drill for piles and then install lagging, ground anchors, piping and slab and barrier wall. Materials include steel

To date, Granite has completed washout repairs, cleaned and repaired existing culverts, installed new culverts and headwalls and finished slide cleanup.

piles, timber lagging and concrete slab and barrier.

The retaining walls are up to 10 ft. below the existing roadway on the down slope side.

“Working next to a steep slope posed a safety challenge,” said Grimm.

This work has operators using a Komatsu PC490 LC-10 excavator, a TR150-60 auger, John Deere excavators and a reach lift.

For drainage systems, crews are installing corrugated metal pipe and other elements.

“Some of the drainage systems require the installation of cast-in-place concrete headwalls,” said Grimm. “One system required the installation of pipe, a drain inlet and a grated line drain. Determining the size and quantity of each system, dig/set pipe and backfill was a factor in the work. The challenges were digging and setting in steep terrain. We utilized a track loader for this. All the systems were in the roadway and access was cut off to the job site during installation.”

Drain inlet and a grated line drain are among the construction materials used.

The reconstruction of sections of SR 180 is addressing various types of damage to the asphalt surface including divots from falling rock, potholes from failed culverts, failures from mud and rockslides on top of the roadway and areas where the entire roadway was destroyed from fill slope failures and erosion.

“We will fine grade and place asphalt during spring when temperatures are favorable,” said Grimm. “Currently, aggregate base is placed to allow the highway to be passible and we are reestablishing failed shoulders and guardrail only.”

Granite’s management team includes Construction Manager Kevin Paul, Project Manager Chris Fiester and Project Superintendent Eric Rawls.

“The team is collaborative, innovative and adaptive to changing conditions,” said Grimm. “The crews are hardworking and putting in long hours.” CEG

(All photos courtesy of Granite Construction.)

35-41

Bobcat Company continued to expand its attachment offerings in 2023, empowering customers to accomplish more in landscaping, construction, forestry, agriculture and other industry applications. Bobcat offers hundreds of highquality attachments and implements, providing customers with leading jobsite versatility.

“Compact loaders, excavators and other carriers are only as productive as the attachments and implements they power,” said Lee Smith, general manager of Bobcat attachments. “Bobcat is continually developing attachments that help our customers expand their jobsite capabilities and accomplish more.”

Bobcat has expanded its lineup of hydraulic-powered augers with four new models, the 12PH, 14PH, 20PH and 25PH, which offer a variety of torque and speed options to match a wide range of soil conditions and applications.

In 2023, Bobcat continued to expand its diverse lines of attachments and implements to include the following new products:

• Super-Flow Planers: Bobcat super-flow planers are high-powered attachments capable of milling concrete and asphalt up to 7 in. thick. These versatile attachments take advantage of the extra hydraulic power available in the Bobcat T86 compact track loader and S86 skid-steer loader — the only compact loaders to offer three hydraulic flow options in one machine, with super flow generating up to 42 gpm and 4,061 psi. The super-flow planers are available in 24-in. and 48-in. cutting widths. Bobcat also offers a 40-in. planer compatible with both super-flow and high-flow hydraulics.

• Disc Mulchers: Bobcat introduced its disc mulcher attachment to help operators power through tough landclearing applications. Compatible with a host of Bobcat skid-steer and compact track loaders, the disc mulcher features a high-velocity disc fitted with four-point, hardenedsteel teeth that make fast work of trees and thick brush. The disc mulcher cuts down trees up to 14 in. thick and can turn heavy brush and trees up to 6 inches thick into a bed of mulch,. The disc mulcher is available in 48-in. and 60-in. cutting widths.

• Drum Mulchers: Bobcat has introduced a drum mulcher attachment for select excavators. Previously offered for select compact track loaders and skid-steer loaders, drum mulchers make fast work of heavy brush and trees up to five inches thick. This attachment allows excavator operators to clear trees and stubborn overgrowth along steep roadsides, riverbanks and other hard-to-reach areas. Bobcat offers three models, the 28DMX, 36DMX and 50DMX, with cutting widths of 28, 36 and 50 in., respectively.

Available in two sizes, the 48in. grapple is compatible with Bobcat 1000-platform sub-compact tractors while the 60-in. grapple fits all 2000-platform compact tractor models.

Bobcat photo

Maintain large lawns with PTO-driven finish mowers that are compatible with select Bobcat compact tractors, sub-compact tractors and the UW53 Toolcat utility work machine.

With the Bobcat family of utility vehicle plows, operators can push back winter to get more use from their machine.

Bobcat photo

The brush cutter’s high-efficiency, direct-drive AP4 motor maximizes hydraulic horsepower for optimal cutting of tall, thick vegetation, including trees up to 10 in. in diameter.

• Augers: Dig holes with speed and plumb-line accuracy with a Bobcat auger attachment. Bobcat has expanded its lineup of hydraulic-powered augers with four new models, the 12PH, 14PH, 20PH and 25PH, which offer a variety of torque and speed options to match a wide range of soil conditions and applications. Durable Bobcat augers are compatible with compact loaders, excavators, compact wheel loaders, telehandlers, small articulated loaders, Toolcat utility work machines and mini track loaders.

• Heavy-Duty Brush Cutters: The Bobcat heavy-duty brush cutter makes fast work of clearing heavy brush and small trees. The brush cutter’s high-efficiency, direct-drive AP4 motor maximizes hydraulic horsepower for optimal cutting of tall, thick vegetation, including trees up to 10 in. in diameter. The high cutting speeds, combined with the heavyduty blades and stump jumper, maximize inertia to cut through dense vegetation in one pass. Compatible with a variety of compact track loaders and skid-steer loaders, the heavy-duty brush cutter is available in 62-in., 74-in. and 86in. cutting widths.

• Grapples: Bobcat has expanded its diverse lineup of grapples to include an 80-in. and 86-in. root grapple, industrial bucket grapple and industrial fork grapple. There are 16

are high-powered attachments capable of milling concrete and asphalt up to 7-in. thick.

Bobcat photo

Bobcat offers three models of drum mulchers, the 28DMX, 36DMX and 50DMX, with cutting widths of 28, 36 and 50 in., respectively.

total models to tackle a variety of jobsite needs.

• Brush Grapples: Bobcat brush grapples for compact tractors are the ideal property management attachment for gathering and stacking brush, tree limbs and other loose materials. Available in two sizes, the 48-in. grapple is compatible with Bobcat 1000-platform sub-compact tractors while the 60-in. grapple fits all 2000-platform compact tractor models.

• Snow Blades for UTVs: With the Bobcat family of utility vehicle plows, operators can push back winter to get more use from their machine. Plow through deep drifts and quickly clear snow from wide sidewalks, walkways and driveways with the heavy-duty V blade, heavy-duty straight blade or the medium-duty, straight-blade attachment.

• Finish Mowers: Maintain large lawns with PTO-driven finish mowers that are compatible with select Bobcat compact tractors, sub-compact tractors and the UW53 Toolcat utility work machine. These implements feature high blade speeds, convenient access to maintenance points and a rear discharge that allows operators to mow close to buildings and other structures. Bobcat finish mowers are available in widths of 60 and 72 in. For more information, visit Bobcat.com.

ABILENE, TX • 877-577-5729

AMARILLO, TX • 800-283-1247

DALLAS, TX • 800-753-1247

FT. WORTH, TX • 877-851-9977

HEWITT (WACO), TX • 254-261-1370

LUBBOCK, TX • 866-289-6087 MCALESTER, OK • 918-310-1550 ODESSA, TX • 877-794-1800 OKLAHOMA CITY, OK • 800-375-3339 TULSA, OK • 800-375-3733

MISSOULA, MT • 800-332-1617

BILLINGS, MT • 800-735-2589

BOISE, ID • 800-221-5211

COLUMBIA FALLS, MT • 800-434-4190

EUGENE, OR • 800-826-9811

JEROME, ID • 800-221-5211 KENT, WA • 800-869-2425

POCATELLO, ID • 800-829-4450

PORTLAND, OR • 800-950-7779

ROCHESTER, WA • 800-304-4421

SPOKANE, WA • 800-541-0754

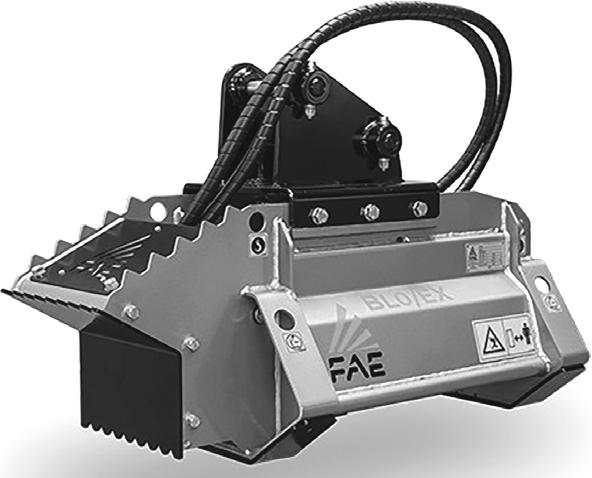

FAE introduced the new BL0/EX forestry mulcher for 2 to 4 ton excavators, bringing Bite Limiter technology to even the smallest excavators.

The BL0/EX is one of the smallest fixed-tooth mulchers on the market, capable of shredding light vegetation, shrubs and trees up to 3.2 in. in diameter. It can be used for vegetation maintenance along roadsides, railroad tracks, canals, rivers and lakes, for managing and protecting wildlife habitats, and for maintaining commercial green areas and sporting grounds.

The head is designed for high-productivity, durability and easy maintenance.

Bite Limiter technology is ideal for high-productivity vegetation management, designed with reliable and efficient shredding in mind. The rotor with Bite Limiter technology comes with special wear-resistant steel profiles that limit the reach (bite) of the teeth. This reduces power demand and promotes a consistent working speed, ensuring excellent performance when mulching any type of wood. Bite Limiter technology also minimizes rotor stalling and optimizes fuel consumption, according to the manufacturer.

The BL0/EX’s Direct Drive motor minimizes maintenance and enables a more compact body size for better maneuverability. The head’s clean profile and compact design are also made possible by the hydraulic block with a flow regulator valve built into the motor, along with the thumb bracket in the frame.

The new BL0/EX can be equipped with BL/MINI blades or C/3/MINI teeth and is available in two working widths: 22 and 31.5 in.

For more information, visit www.faegroup.com.

The BL0/EX is one of the smallest fixed-tooth mulchers on the market, capable of shredding light vegetation, shrubs and trees up to 3.2 in. in diameter.

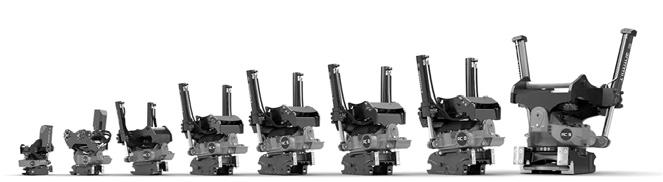

It has been a year since Rototilt launched its new Rototilt Control product line, which has been positively received by the market. Today, Rototilt can announce that the product line is now complete, as the two smallest tiltrotators receive their successors in the RC series.

“This is what we’ve been working towards all along,” said Sven-Roger Ekström, product manager at Rototilt.

The company has now launched sales of all the tiltrotators in the RC Tiltrotators product line. The last to be released are the RC1 and RC2 compact tiltrotators. This means that excavators from weighing from 1.6 to 47.4 tons can now use the products that make up the Rototilt Control product line.

According to Rototilt, compact tiltrotators have increased in popularity in recent years and have become bestsellers in a small format.

“We are seeing more and more people discovering the benefits of tiltrotators for small excavators,” said Ekström. “They work well in confined spaces and the extra flexibility that a tiltrotator provides can make a big dif-

ference. We are happy to also be able to offer our latest product line to users who work in this type of environment.”

In contrast to the previous R series, the SecureLock safety lock and the ILS central lubrication system are included as standard with RC1 and RC2. Another piece of good news is that these models also come with all the benefits of the RC System control system. This means that users can use RC Connect for remote support as well as Rototilt’s own new RC Joysticks.

“Users who want to take their tiltrotator system to the next level will be pleased to learn that RC Joysticks and RC Connect will also be available for the very smallest excavators,” said Ekström. “Both this and the previous options that are now included as standard give the system that little bit extra. The whole system has been given a boost, both in terms of servicing and safety.”

The fact that all tiltrotators in the RC series have the SecureLock safety lock as standard means that the entire chain now satisfies the new requirements according to the EN474 standard. According to Rototilt’s lead engineer, Niklas Bjuhr, this is something that has been a priority throughout the project.

“We view it as only natural that our products must live up to the market’s demands and current regulations, so there was never any question about this when we developed RC Tiltrotators,” said Bjuhr.

“SecureLock is an innovative solution for locking your work tool securely and easily. It provides reassurance for our users.”

For more information, visit www.rototilt.com.

Ignite Attachments, a manufacturer of compact equipment attachments, added to its growing lineup of direct-to-you products with a new mini excavator (MEX) auger.

The launch expands Ignite’s lineup of augers for compact equipment. Like other models in the lineup, the MEX auger offers self-aligning vertical accuracy for precise, accurate vertical holes in any situation and planetary drive system for ample torque for even the toughest drilling conditions.

Compatible with Kubota KX057-5 models, the new auger features a high-quality hydraulic motor and 2-inch HEX shaft for powerful drilling capabilities in landscaping, construction, road, municipality or agricultural applications.

“Agility is one of the primary drivers for Ignite Attachments,” said Matthew Foley, lead engineer. “Whether that’s direct-to-you shipping, transparent pricing or expanding our product line to fill a gap in the market. Our design team brought the award-winning features of our auger lineup to mini excavator oper-

Compatible with Kubota KX057-5 models, the new auger features a high-quality hydraulic motor and 2-in. HEX shaft for powerful drilling capabilities in landscaping, construction, road, municipality or agricultural applications.

ators looking to maximize their fleet versatility.”

The new auger has a drilling depth of 50 in. with a standard bit, or up to 86 in. with optional extension.

Like other auger offerings, the MEX auger attachment features a unique joint between the mounting frame and drive unit to ensure straight, vertical holes, even while working on contoured, sloped or uneven ground.

“We’ve taken the guesswork out of drilling,” Foley said. “With our self-balanced alignment feature, customers get perfectly straight holes without spending time worrying about the carrier’s stance.”

Ignite Attachments offers quality-designed and -manufactured tools that are easy to purchase, attach and use. In today’s fast-paced, connected economy, Ignite offers a reliable, cost-effective solution for compact equipment operators of any brand. Online ordering and direct shipping allow customers to shop confidently and on their own schedule. Ignite backs every attachment with a comprehensive warranty and excellent customer support, ensuring customers can rely on their tools for years to come, the manufacturer said.

For more information, visit www.igniteattachments.com.

Thunder Creek Equipment, a manufacturer of innovative and premium fueling and preventive maintenance solutions, has introduced EquipmentShare as its new dealer of its product sales and support lineup at locations in Columbia, Mo., and Oklahoma City, Okla.

Thunder Creek Equipment designs and manufactures products that are used in a variety of industries including construction, roadbuilding, oil and gas, and utility construction. This includes the original, industry-leading, No-HAZMAT Fuel & Service Trailer (MTT), the Multi-Tank Oil Trailer (MTO), and the Service and Lube Trailer (SLT).

“EquipmentShare has a mission that combines technology, equipment and support to ensure uptime, productivity and efficiency,” said Larry Lea, vice president of sales, Thunder Creek Equipment.

“Thunder Creek will support that mission by providing contractors in the region with innovative new ways to manage fueling, preventive maintenance and mobile fleet man-

agement.”

Established in 2015, EquipmentShare provides multiple lines of equipment manufacturers for a wide variety of customers, from large commercial construction to local contractors.

“Ensuring uptime through the smart use of technology is what has made EquipmentShare one of the fastest-growing integrated equipment rental and equipment asset management companies in the United States,” said Thomas Pedrick, retail sales manager, EquipmentShare.

“Thunder Creek’s product offering delivers a complete rethinking of how businesses take control of their fleet fueling and preventive maintenance activities in a way that saves time, money and labor. Their solutions support the value we provide to our customers and we look forward to offering these products at two of our locations.”

For more information, visit EquipmentShare.com and ThunderCreek.com.

Topcon Positioning Systems announced a series of new developments and initiatives as part of its ongoing sustainability efforts.

First, the formation of a new global team dedicated to sustainability and corporate social responsibility (CSR) has been announced. It will be led by Michael Gomes as vice president of Global Sustainability and CSR. Much of his career with Topcon has been dedicated to the advancement of more sustainable agricultural practices. He will now lead a global team dedicated to sustainability for all markets and product lines, which will connect into Topcon’s parent organization, Topcon Corporation, in Japan to effectively support the corporation’s multiple divisions.

“Sustainability has long been a part of the fabric of Topcon and is something we take very seriously as we take actions to support our global initiatives,” said Gomes. “As we look ahead, we’ll endeavor to support, at every level, the advancement of the industries and communities we serve.

OEM authorized mining dealer www.coremachinery.com

Phoenix, AZ 480-545-2400 Phoenix, AZ 602-252-7121 Prescott, AZ 928-778-5621 Tucson, AZ 520-623-8681

Bakersfield, CA

661-695-4830 Mojave, CA 661-824-2319 Perris, CA 909-355-3600

*Formerly Road Machinery

The work we do is modeled on the sustainable development goals adopted at the United Nations Summit in 2015 and has been part of Topcon’s vision statement since 2016.”

Topcon’s dedication to sustainability is further demonstrated by the inauguration of a new 60-acre Research & Validation Center at its global headquarters in Livermore, Calif. Its team has worked closely with Alameda County in the approval and development of this expansive, ecologically diverse location that will support the increasing needs for research and validation of new technologies, the company said.

The site was strategically planned in collaboration with students and faculty from the BioResource and Agricultural Engineering Department at Cal Poly San Luis Obispo. The team employed a multi-disciplinary approach, providing a site analysis with soil evaluations and recommend-

ed crops, maps for planting and additional site development recommendations.

This new facility joins global validation centers in Concordia, Italy, and Adelaide, Australia, all working on research and validation of innovative precision technologies.

“Through these three centers, there is research and testing under way at Topcon, somewhere in the world, any time of day,” Gomes said.

TPS Global Headquarters Moves to Solar Power

Another recent initiative is the conversion to solar power for the Livermore campus. Initial planning began in October 2022, and the project is under way. Once the project is completed, the campus, including multiple buildings, manufacturing facilities and electric car charging stations, will be powered by solar energy.

“This is a great opportunity for us to reduce our Scope 2 emissions and energy costs,” Gomes said.

For more information, visit topconpositioning.com/sustainability.

www.wpi.com

12320 S. Main Street Houston, TX 77035 713-723-1050 Buffalo, TX 903-322-7150 Bryan, TX 979-314-1191 Corpus Christi, TX 361-884-8275

Edinburg, TX 956-386-0107

Kilgore, TX 903-984-2011

Lufkin TX 936-243-6056

Pflugerville, TX 512-251-0013 Port Arthur, TX 409-721-5305 San Antonio, TX 210-648-4444 Tomball, TX 281-351-9016

www.powermotivecorp.com

Corporate Office

5000 Vasquez Blvd., Denver, CO 80216 303-355-5900

Colorado Springs, CO 719-576-5541 Grand Junction, CO 970-241-1550 Milliken, CO 970-587-1188

Cheyenne, WY 307-634-5149

Durango, CO 970-259-0455

Albuquerque, NM 505-345-8383 Bloomfield, NM 505-324-8601 Carlsbad, NM 505-485-1700

El Paso, TX 915-872-1001 Chandler, AZ 602-986-3003 Phoenix, AZ 602-463-3772 Tucson, AZ 520-649-2858

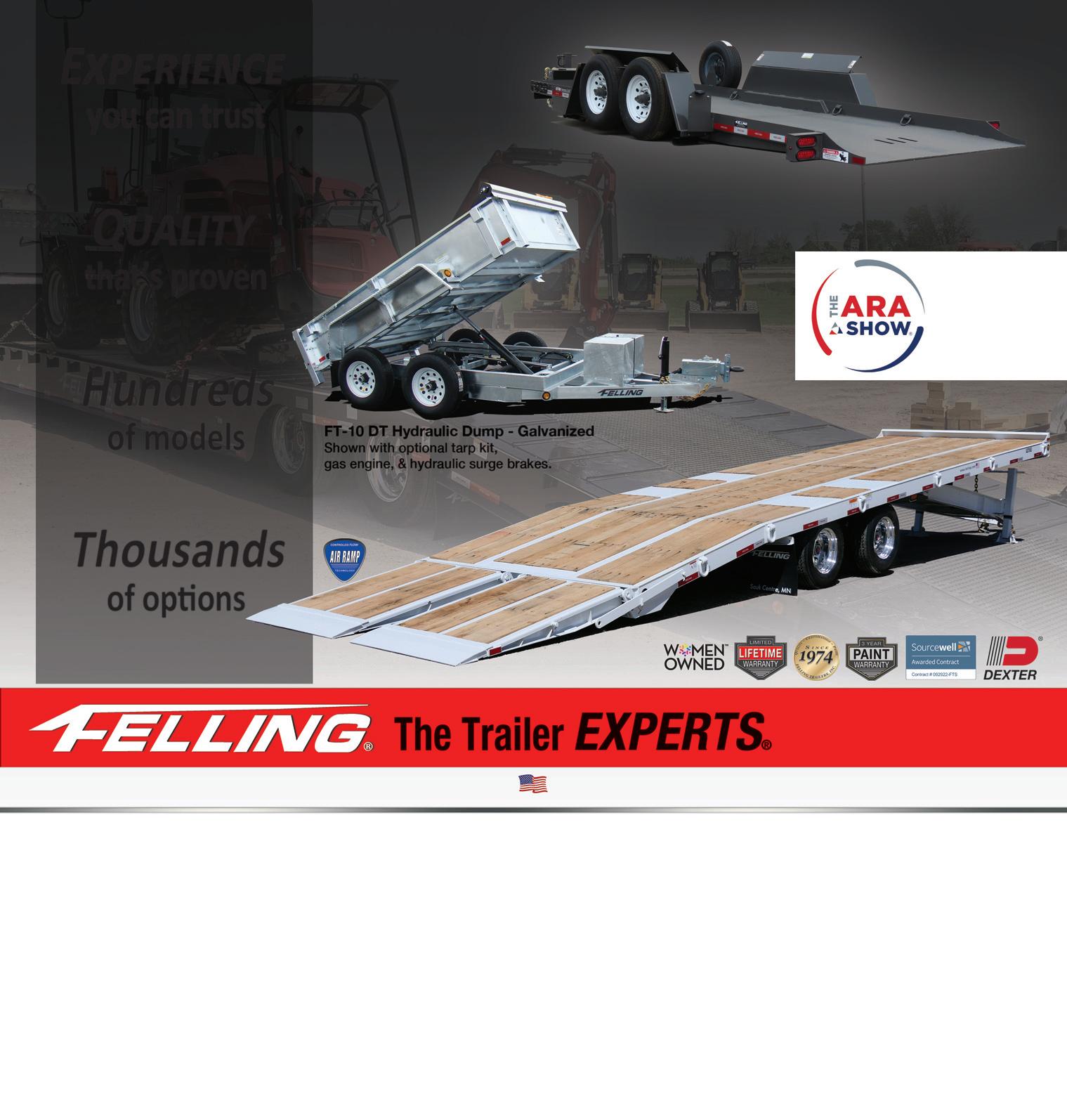

Weighing an average of over 800 lbs. lighter than comparable steel-bodied trucks, the TMAX 1-11 offers increased payload capacity and enhanced fuel efficiency. Its aluminum construction not only reduces weight but also combats corrosion, ensuring a longer operational lifespan.

The Stellar TMAX 1-11 aluminum mechanic truck combines extensive crane compatibility, customizable features and unparalleled quality.

This vehicle has been engineered with precision, utilizing cutting-edge materials to create a powerhouse that outperforms its counterparts. With its unmatched design and incredible capabilities, the TMAX 1-11 sets new standards in the world of mechanic service trucks, the manufacturer said.

Weighing an average of over 800 lbs. lighter than comparable steel-bodied trucks, the TMAX 1-11 offers increased payload capacity and enhanced fuel efficiency. Its aluminum construction not only reduces weight but also combats corrosion, ensuring a longer operational lifespan.

Stellar’s torq-isolator crane support design isolates the crane compartment from the rest of the side pack. This allows the lifting stresses to be channeled through stabilizers and a robust box-type subframe, safeguarding compartment doors and enhancing overall structural integrity, the manufacturer said.

Adaptability is key, and the TMAX 1-11 delivers with an aluminum extruded top boasting drill-free mounting rails. This feature makes adding a diverse range of mechanic service truck accessories effortless, giving users the flexibility to tailor the truck to their specific needs and enhance its capabilities as their requirements change.

The TMAX 1-11’s double-panel 1/8 in. aluminum tailgate, complete with hinged arm brackets, presents a robust working surface for enhanced productivity.

Compartment options include 250-lb.capacity, adjustable divider shelves constructed from spangled galvanized steel and drawer sets, both offering practical storage solutions for various tools and equipment.

A durable undercoating, featuring a petroleum base material, shields the TMAX 1-11 from corrosion and road debris, ensuring its longevity and reliability in diverse environments.

Additional features:

• 21 in. steel workbench bumper with

integrated full-width long bar storage compartment and vise mounts ensures a versatile workspace.

• Stainless-steel billet-style hinges with hidden fasteners and a robust 5/16 in. stainless-steel rod guarantee years of heavy-duty use.

• Rotating master-lock system provides top-notch security, safeguarding valuable tools and equipment.

• Exterior mounted light box simplifies accessory installation while minimizing potential entry points.

• 3-point compression latches maintain tight weatherstripping, ensuring weather resistance while allowing easy access.

In addition, the TMAX 1-11 mechanic truck is expertly configured to seamlessly accommodate Stellar Hydraulic Service Cranes, including the Stellar 8630 Hydraulic Service Crane. The 8630 crane boasts 8,600lb. capacity and a 30 ft. of reach.

The crane’s distinctive boom design strikes the perfect balance between weight reduction and unwavering strength, while

the compact boom tip effortlessly extends into tight spaces, the manufacturer said. What’s more, users can elevate their control with the CDTpro Control System with Range Finder technology.

Users also can add a Stellar lube skid to their TMAX 1-11. A lube skid reduces downtime and saves money by letting users perform lube services in the field as an affordable alternative to a dedicated lube truck. Mobile and permanent lube skid options are available, along with a range of new and waste oil tank capacities.