By Irwin Rapoport CEG CORRESPONDENT

California's Mono County, in the central part of the state, adjacent to Nevada, has the smallest county population and being in a rural and isolated area, roadwork can be difficult for general contractors.

For one of those general contractors — Granite Construction — work resumed on a safety project along U.S. 395, where crews are widening the embankment and shoulders on the highway. The nature of this project along rugged terrain makes it a challenging one, particularly with its emphasis on earth work and utilization of heavy equipment such as excavators, dozers, skid-steers, loaders and graders.

And to make matters more challenging, the section of U.S. 395 — one lane in each direction

with shoulders on either side — makes it a tight work zone, but the experienced Granite Construction crews are up for the endeavor.

“The plan was to create a firm base at the bot-

By Lucy Perry CEG CORRESPONDENT

A safety project in central California resumed in June as construction crews from Granite are working to widening the embankment and shoulders on U.S. 395 in

tom of the slope with access points at the beginning and end for our heavy equipment to place and compact,” said Chris Killen, a Granite com-

The construction industry remains wide open and inviting for just about anyone seriously considering a rewarding career opportunity. The jobs are plentiful and employers are hot to hire committed workers. In fact, contractors are working hard to come up with new and inventive ways to attract and retain young skilled workers not only in the field but in the office. That’s encouraging news for those charting a career path. Competition for skilled trades workers is at an all-time high, said staffing firm Skinner Construction Services. see JOBS page 36

Electricians are in demand on practically every building construction project, but these trade workers are key to charging station and transmission line installs and maintenance. Adobe

EROPS, A/C & Heat, 593 hrs., Water System, 8 ft. Broom, 225x75Rx15 Tires, 4 Cy. Kubota Eng $29,500

2018 John Deere 750K LGP, Stk#: 13236, EROPS, A/C

John Shearer, CEO of 4Rivers Equipment and current AED chairman, took a less than traditional path to his leadership role in the equipment industry. After serving in the military as a technician, Shearer returned to a tough job market.

Kubota Tractor Corporation announced a partnership with downhill mountain bike legend Aaron Gwin, whose career highlights span five World Cup titles and eight U.S. National Championships.

Three outstanding service professionals — Larry Azdell, Roger Wilson and Stacy Blubaugh have been selected as winners of the Yanmar Service Awards. They were honored at a ceremony at the Osaka Institute of Technology, Japan.

16 VALUE IN REMANUFACTURING: REDUCE COST, DOWNTIME, CARBON FOOTPRINT

As the construction industry continues to make strides toward more sustainable and economical manufacturing practices, there are many considerations that come into play.

26 VOLVO CE BROADENS SERVICES COMMITMENT WITH VIZALOGIX

Volvo CE has taken a 22 percent ownership stake in VizaLogix, a U.S.-based software-as-a-service company specializing in digital, brand-neutral solutions for machine monitoring, servicing and tech support in multiple industries.

30 OSHKOSH CORPORATION ANNOUNCES PLANS TO ACQUIRE AUSA

Oshkosh Corporation announced it will acquire AUSACORP S.L., a privately held international company and manufacturer of equipment for the construction, material handling, agriculture, landscape and specialty equipment industries.

30 ROTOTILT INVESTS IN MAJOR FACTORY EXPANSION IN SWEDEN

Rototilt, which develops and manufactures tiltrotators for the global market, is investing heavily in the future by expanding its factory in Vindeln, Sweden. The investment includes the development of a modern robotic welding facility.

32

BTDT Inc. is celebrating its 15th year in business and will soon unveil a new, more dynamic website. In addition to a milestone year and website unveiling, the company also is bringing on a new marketing director, Dakota Collins.

40

To support its employees in their philanthropic pursuits, Bobcat matched employee donations dollar for dollar (up to $3,000 per person) to further amplify employees’ generosity.

40 EPIROC, MONTANA TECH PROFESSORS PARTNER TO DONATE EQUIPMENT

Montana Technological University’s Underground Mine Education Center (UMEC) has received a substantial donation in the form of an Epiroc Scooptram ST2D underground loader.

45

Since 1962, the James A. Rogers Excavating company near Little Rock, Ark., has been providing developers with site preparation, planning and earthmoving services. Success and growth have led to more job sites spread further apart.

46 BUYERS PRODUCTS ADDS TO ACCESSORY, EQUIPMENT LINEUP

Buyers Products announced an expansion to its line of equipment and accessories for service bodies. Newly released are a Kabgard Headache Rack System, an extended Ladder Rack and a universal Class 5 Hitch Receiver.

46 PREMIER WINS FOURTH PLACE IN NAFA TOP 100 COMMERCIAL FLEETS

Premier Truck Rental announced its recognition as the fourth-place winner in the NAFA Top 100 Commercial Fleets of America competition. NAFA commended PTR for its fleet management practices and contribution to the industry.

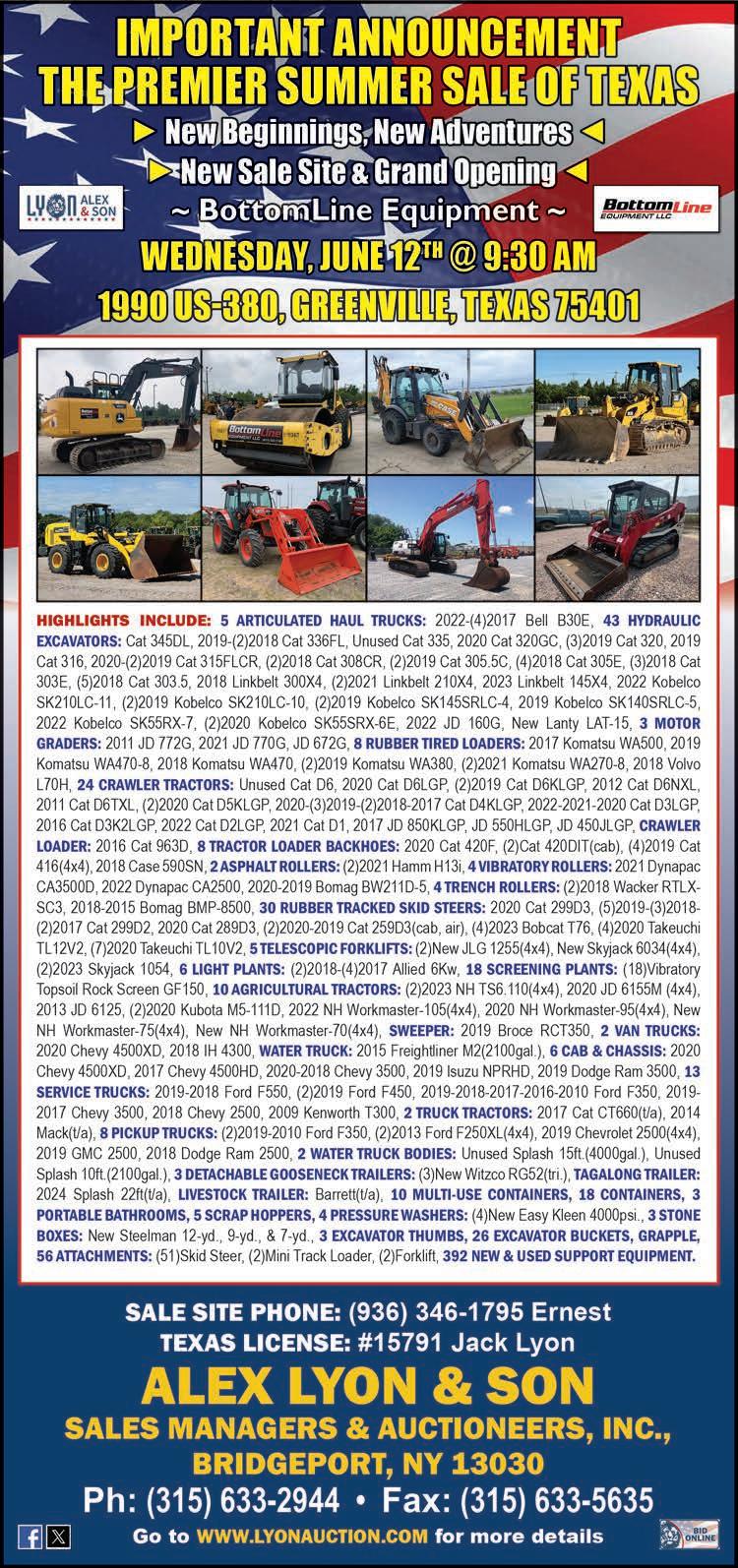

Alex Lyon & Son has announced a new sale site in Greenville, Texas, at the newest facility of Bottom Line Equipment. The grand opening will take

Palfinger showcased its diverse range of industry-leading solutions at the 2024 Waste Expo, which was held from May 6 to 9 at the Las Vegas Convention Center in Las Vegas.

John Shearer, CEO of 4Rivers Equipment and current AED chairman, took a less than traditional path to his leadership role in the equipment industry.

After serving in the military as a technician in the late 1970s, Shearer returned from overseas to a tough job market.

“I was not able to find work as a tech, so I took a job trimming trees for a few years,” he said. “Finally, in 1984, I was able to get a position with the John Deere dealer in my hometown of Lebanon, Pa.

“I started at the bottom but took all the training I could possibly take and learned as much as I could,” he added. “Eventually, they put me out in the field in a service truck.”

Shearer worked his way up to service manager of Plasterer Equipment in Pennsylvania and then relocated to Virginia and accepted the same position with James River Equipment, where he would eventually be named vice president of product support. He served in that capacity for 13 years at which time he moved to 4Rivers Equipment in Colorado.

At 4Rivers, Shearer began as general manager of construction and forestry equipment. He was named COO in 2019 and then, CEO in 2021.

He was named AED board chairman at the beginning of 2024.

CEG recently spoke with Shearer about his 40-year career in the equipment industry and how the lessons learned along the way helped prepare him for the leadership positions he currently holds.

CEG: What did you like about being a tech at an equipment distributor?

Shearer: Plasterer was a very small dealer at the time with only two locations, and they operated a little differently than most dealerships. As a tech, we rotated to the parts department on Saturdays. We actually opened our own repair orders, and then pulled the parts from the parts department. Once I got into the field and had direct contact with customers, that really helped a lot. In the shop, there is no direct communication with the customer. Out in the field you do communicate directly and get to know their pain points and how important it is to get a machine back up and running. That’s when I started to understand what customers needed and what their concerns were. I really enjoyed that part of the job.

CEG: How did that help prepare you for your role as a CEO and ultimately, as chairman of AED.

Shearer: Eventually at Plasterer, the time came when we had to become computerized, and the service manager at the time threw up his hands and said, “I can’t do this, I’m not going to make the transition to a computer.” So, they asked me if I wanted to

be service manager. That’s really when things started to click. Deere would run these Mark of Excellence contests. You had to meet all kinds of criteria. At that time, service managers were just required to get things fixed, without much thought about making money. The sales department was where all the money was made. Our job was to keep the customer happy. The excellence program taught me about margins, about absorption rates, how to keep expenses in line, and how you could make money in service. I began to learn the economics of a dealership. That really started to prepare me for the role I ultimately ended up with.

CEG: Did you have your sights on running a dealership one day?

Shearer: Running a dealership wasn’t anywhere close to my mind. Plasterer’s owner would ask me what I wanted to do, and I always said I wanted to be a salesman. Once I became involved in the management of the service department and seeing how a dealership operated, it made me forget about being in sales.

CEG: What message would you send to

business.

Shearer: Well, certainly someone that is not afraid of hard work. Of course, we look for a person that scores well in aptitude tests. Back in the day, it was the guy that couldn’t do anything else, and that has certainly changed. I like to see curiosity, preparation and now we look for an outgoing personality, as well. They need to be able to ask questions, comprehend and follow a procedure to get to the finish line.

CEG: Aside from recruiting, what are the major issues facing equipment dealerships over the next five years.

Shearer: One would be the speed at which technology is coming at us. Is the dealership nimble enough to accept it, and then figure out how to use it to benefit the customer? It is amazing today, because of the shortage of operators, how much customers are demanding the machine do on its own. For instance, what safety devices are there to protect the machine against an operator that is not very good?

The other thing we need to be concerned with is the Right to Repair legislation.

That’s a big issue. If the government wanted to help with downtime and getting contractors and farmers up to speed quicker, they’d help us with the work force.

This all started at the state level here in Colorado and other places, where it did pass. Now, there has been a bill introduced on a federal level.

young people considering a career in the industry?

Shearer: If you look back, being a tech was not a glamorous job, or one where a person saw a lot of upward mobility, but that has changed with all the technology we have today, such as the automation being built into the machines and the fact that the dealers are branching out to more than just servicing a machine … now we are helping map out a job site and helping the customer make money. The idea of a tech being up to his elbow in grease and working with a sledgehammer is a thing of the past. In reality it is working with laptops.

But I definitely would tell them to learn how a dealership operates, how it stays profitable. If you learn those things, you have the opportunity to do anything you want to do in the industry. I think the door is now open for advancement on the support side of the business. The business is becoming “how are we taking care of the customer after the sale?”

CEG: What traits are dealers looking for in young people in the service end of the

While we don’t have any issues with customers fixing their own machines, we do have a problem with customers modifying their machines and disabling devices on the machine. There is probably an in-between, but typically the government is not very good at finding the in-between.

Officially, the position of AED is that we fully support customers being able to fix machines, we do not support customers being able to modify machines.

And then there is the uncertainty around taxes. First, we have 100 percent depreciation, then it goes away, then it comes back. It makes it tough to manage around day-to-day.

Today, dealerships work on thin margins; everyone has a lot of improving and consulting to do. So, we look for help from other places, such as AED (Associated Equipment Distributors). Financial planning and leadership training are two things that got me involved in AED.

The AED serves as a valuable resource for equipment dealers. They support the heavy equipment market by offering a variety of services and business development opportunities to their association members. Members can take advantage of tools such as webinars, seminars, certification tests to enhance your employee development.

Building on an extraordinary year of action sports partnerships on and off paved and dirt tracks, Kubota Tractor Corporation announced a partnership with downhill mountain bike legend Aaron Gwin, whose career highlights span five World Cup titles and eight U.S. National Championships, to support the newly-announced formation of Gwin Racing and his bike park, Windrock Bike Park, in Oliver Springs, Tenn.

A highlight of this collaboration is fully equipping Gwin’s tool shed at Windrock Bike Park with new Kubota equipment, including a KX080-5 power utility excavator, an R640 wheel loader, and an RTVX1130 and two Sidekick utility vehicles — all of which are already hard at work building new trails and tackling overall property maintenance.

The sponsorship, which also includes logo placement on Gwin Racing race jerseys, is part of the company’s commitment to supporting the action sports lifestyle and mountain bike enthusiasts, both important customer segments for Kubota.

“By partnering with Aaron and Gwin Racing, we are opening doors for the action sports community to showcase what’s possible for blazing new trails with durable and powerful Kubota equipment,” said Paul

Manger, executive director of product marketing, Kubota Tractor Corporation.

“Aaron’s work ethic on and off the trail aligns with our mission to empower our customers and partners with the right tools to help them succeed. We’re proud to be a part of Aaron’s future plans, to support his team, his fans, and to show the downhill mountain bike and action sports communities that the sky is the limit in #KubotaCountry.”

“I’ve been digging in the dirt and building trails since I was a little kid,” said Gwin. “It is the funest thing in the world for me, and I could spend all day, every day in the hills digging. For any trail build, the first thing you need is a good set of tools, and my Kubota excavator is definitely a multi-use tool, not only for trail building, but we’re also putting it to good use to build a new road and parking lot, and for maintaining the property overall. It’s amazing how much we can get done now.”

At Windrock Bike Park, Gwin and team are putting their hard-working Kubotaequipment to use in a wide range of applications. The KX080-5 and R640 are being used to build trails, clear land, build and maintain new roads and a parking lot, as well

as for landscaping and event service support.

The RTV-X1130 and Sidekick gas-powered utility vehicle are workhorses on the property tackling trail work, hauling tools and general maintenance across the 1,086acre bike park. The Sidekick also plays a vital role for Windrock’s EMT services, including rider extraction.

“Having the ability to quickly get up and down the hills in an emergency is a critical part of our jobs, and our Kubota utility vehicles are important team members for our work here.”

For more information on Kubota equipment, visit KubotaUSA.com. For more information on Aaron Gwin and Windrock Bike Park, visit WindrockBikePark.com.

(All photos courtesy of Kubota)

Realistic Scale Models of Construction Equipment, ideal gifts for the Holidays, Birthdays,

Chalmers HD-3 Dozer w/Backhoe, 1:16 scale - $200

Case 580SR Backhoe/Loader, 1:50 scale - $160

Three outstanding service professionals: Warranty Analyst Larry Azdell and Parts Sales Specialist Roger Wilson of Yanmar America, together with Service Technician Stacy Blubaugh from Yanmar America dealer Holmes Rental & Sales Inc., have been selected as winners of the Yanmar Service Awards.

They were honored at a ceremony at the Osaka Institute of Technology, Japan, on March 7 for their exceptional contributions to the company and its customers.

“Dedicated to excellence, Larry, Roger and Stacy exemplify the values Yanmar America stands for,” said Dustin Graham, manager of customer support, Yanmar America. “Their unwavering commitment to customer satisfaction is truly commendable, and we are delighted to celebrate their achievements.”

Azdell exhibits remarkable dedication to customer satisfaction within Yanmar America’s After-sales Support Division. Wilson consistently delivers top-notch customer service, actively listening to customer needs. Reaching outside Yanmar America for the first time, Blubaugh’s award recognizes his expertise in accurately diagnosing and swiftly repairing Yanmar equipment, coupled with meticulous attention to detail to ensure all components function safely.

For more information, visit yanmar.com/us.

Loved for the features. Trusted for the performance.

Hyundai wheel loaders have the power and performance — not to mention top-notch interiors, accurate onboard weighing system, unique bucket design for better load retention, clear sight lines, and handy tech — that make life on the jobsite easier. So you can do more without feeling like

By Garrett Adamson SPECIAL TO CEG

As the construction industry continues to make strides toward more sustainable and economical manufacturing practices, there are many considerations that come into play.

Most OEMs have begun to prioritize the growth of hybrid and electric solutions, while others continue to evaluate their manufacturing practices in hopes of pioneering more sustainable and eco-friendly processes for the rest of the industry.

In recent years, there has been a major uptick in sustainability driven initiatives, however, there are some practices that have been instrumental for many years in making a similar impact. It’s important to consider the many different ways to maximize, or even repurpose, your equipment fleet where possible, and remanufacturing does exactly that.

Unlocking economic value across the lifecycle of a machine while also adopting more sustainable methods, the remanufacturing of construction equipment allows for more environmental outcomes in a customer’s business while maintaining product circularity. The process of remanufacturing transforms old components to like-new condition, saving customers time and money while boosting performance and sustainability.

Remanufacturing is an industrial process used by equipment manu facturers that utilizes previously sold, worn or no-longer functional machine components, and remanu factures them into like-new, or in some cases better than new, condi tion and comparable in quality and performance capabilities.

While remanufacturing may often be confused with the recycling or repairing of machine components, remanufacturing takes it a step fur ther. Required by design, to be con sidered a fully remanufactured machine, the product at the end of its life will be used for its raw materials and its core. The core will then be reprocessed as the main input for the remanufacturing process. In addi tion, by not having to make a new engine, axle, or cylinder head from scratch, the natural resources like iron ore are preserved, melting fur naces aren’t fired up, and carbon footprints are therefore smaller.

fee to the customer, which are then exchanged when a new or remanufactured component is purchased. Then, the core is utilized to fully remanufacture a like-new, functional machine, which will make its way back onto the job site.

At the end of a machine’s lifecycle, the cores are often lost when customers fail to return them to the manufacturer, leaving them without the capability to be reused in the remanufacturing process. In addition, high core yields are necessary for a sustainable business. Therefore, when the core of the machine goes unused following its full lifespan, there are less opportunities to remanufacture the machine or give it a second life.

When a machine breaks down, customers have a few options. They can fully remanufacture, recondition or rebuild their machines to get them back and running on the job site. When customers choose to rebuild or recondition the component, by fixing only what’s broken or replacing failed parts, there are some associated risks including dealing with the unknown costs and limited warranties.

Reconditioning is used when failed parts are replaced with new parts, inspected, and

may be tested prior to sending a machine back to the job. Rebuilding is used when failed parts are replaced with new or used parts, and therefore only what is broken is being fixed before going back into the field.

While often confused for reconditioned or rebuilt equipment, fully remanufactured equipment is held to a different standard. For a like-new performance at a fraction of the cost, and maximize your machine’s up time, remanufacturing is the way to go. In a remanufactured build, failed and other critical parts are replaced with OEM parts, inspected, and 100 percent dynamically tested to meet original performance criteria. These parts are often under warranty by the manufacturer.

Another differentiator in remanufacturing is that once a machine core is received, it is completely disassembled and cleaned. Then, each part is analyzed against current part specifications. Any part that does not meet the needed level of quality is either recycled of remanufactured using advanced reclaimed technique.

Finally, all components are inspected and tested to make they meet or exceed its original performance specifications. This makes remanufacturing an ideal solution for customers looking to retain the same performance they expect from a new machine, at a reduced cost.

Through the repurposing of salvageable machine cores and components, remanufacturing can support a circular economy while reducing the carbon footprint of many manufacturers. By being able to reduces energy consumption through the reuse, reclaiming and recycling of the core, remanufacturing is a more-sustainable way to bring life back into the components of a machine.

Reman operations are often focused on the remanufacturing of engines, electronics, drivetrain and hydraulic components of the machine. In 2022, nearly 27.6 million pounds of material were recycled through remanufacturing, according to the John Deere Sustainability Report.

In 2026, the anticipated material return is expected to exceed 49M pounds globally. Over time, this influx of salvaged materials helps reduce the amount of waste attributed to equipment manufacturing.

Additionally, according to a recent John Deere Life Cycle Assessment (LCA), there is a 54 percent reduction in CO2e when using a remanufactured axle. On average, there is a 2,647 kg CO2 reduction, which is equivalent to 6,652 driven miles in greenhouse gas emissions saved when utilizing a machine with a remanufactured axle. This helps reduce CO2 representing a carbon sequestration equal to 3.2 acres of U.S. forest.

During the remanufacturing process, the machine’s cores are derived from an up-front additional

Beyond its impact on sustainability, remanufacturing also can help customers save time and money, and supports a tiered portfolio. On average, the price of a remanufactured part versus the cost of a brand-new part is approximately 20-30 percent less. In addition, reman increases uptime by allowing a customer to drop a complete engine into the machine in approximately 8 hours as opposed to a complete rebuild of an engine which takes on average 40 hours to complete. This gets customers up and running on the job sooner, while saving additional costs in the process.

Looking at other key benefits, customers who remanufacture their equipment can reduce downtime due to faster repairs, save on costs associated with buying brand-new equipment or parts, and get back up and running on the job sooner.

To learn more about how to remanufacture your fleet, contact your local construction equipment dealer.

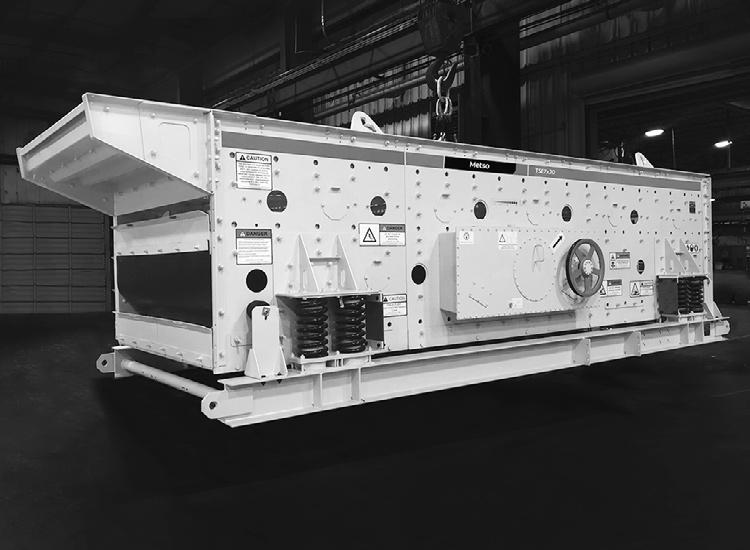

Metso is launching the XM Series, a highly advanced premium crushing solution that combines intelligence, durability and lifetime value with a new digital package, resilient engineering and unmatched warranties.

The groundbreaking Metso XM Series crushing solution designed for demanding mining applications is built to take crushing performance beyond the conventional, according to the manufacturer.

“What’s transformative in the XM Series package is that it combines and gives access to the latest in digital technologies, SmartCone, SmartStation and Mineral Crusher Pilot (MCP) automation,” said Vinicius Vilela, vice president, mining crushers at Metso.

“SmartCone, ideal for product size control, can increase production by up to 10 percent. MCP automation provides the easiest and fastest integration connectivity and allows for not just remote diagnostics, but remote actions, too. The three of these technologies combined give the edge needed to make smarter decisions about the crusher and prevent downtime.

“On top of this, as the first of its kind available in the min-

ing industry, the warranty covers up to 25 years of life for the crusher, conditional on following specific terms and conditions,” said Vilela.

The XM series solution uses the robust and safe Nordberg MP Series cone crushers and Superior MKIII primary gyratory crushers. The Xtreme forged head of the Nordberg MP Series crushers are three times more robust than industry standards and are the most durable head designed for the most demanding crushing applications. Other notable upgrades for the MP XM series include top-mount clamping cylinders, hydraulic socket, accumulator monitoring system and tramp release half nut.

The lifetime of the cavity liner also can be increased up to 50 percent and the protective parts’ lifetime four times. The lifetime of the Superior primary gyratory’s mantle shell is up to 50 percent longer and offers double the concave and protective parts lifetime. The option of Rotable top shell solution decreases downtime, improves safety and has sustainability advantages.

For more information, visit metso.com.

(All photos courtesy of Metso)

Thanks to its robust IMPRE SS IVE FR O M A T O Z .

systemcontrolthatreducestheriskofoperatinge variety of applications. The coarse screening plant locations and new operating conditions - making i range of screen linings, the MSS 802 EVO can eas

uces the risk of

error.Andallrelevant features an intuitive t ideal for a wide ily adapt to changing design and extensive solution in natural stone safetyTheMOBISCREE functions can be operat safety The MOBISCREE system control that redu

Metso expands its standard product offering of screens for the North America, Mexico and Central America markets with TSE Series triple shaft screen.

design with less natural frequencies and a much larger operating window.

ed from a safe distance for EN MSS 802 EVO - the heav

and recycling.

The new TSE series screen is a high-performance horizontal screen used in a wide range of wet or dry applications in coarse or fine screening. The TSE series screens are designed for superior accuracy and efficiency in a very compact installation, the manufacturer said.

“At Metso we have extensive experience in designing and supplying vibrating equipment, and we have selected the best features and attributes to offer a wide range of vibrating screens and feeders. We are proud to introduce the TSE Series screen which is tailored especially for the North and Central Americas’ market needs. We expect the new screens to have a large customer interest that can already be foreseen from the bookings and sold screens already before the launch,” said Eduardo Freire, vice president of the screening business line at Metso.

The TSE Series offers a robust design to support the stresses generated by the highperformance mechanism that produces the high G elliptical motion. The rigidity in the design is provided by frames made from standard sections with K-bracing and with side plates that are huck bolted without any welding. The result is a reliable screen

The high-performance mechanism offers the flexibility to operate the screen in a large range of applications due to the ease of gear and counterweight adjustments. The TSE Series screen’s elliptical motion is combined with high acceleration, thereby bringing more performance in terms of throughput and screening efficiency.

The TSE Series screen is suitable for replacement of most standard triple shaft machines on the market in which minimal changes are required.

Metso TSE Series offers several benefits including:

• Robust, compact design: Portable design due to low height. Heavy duty construction.

• High efficiency screen: High performance elliptical motion up to 6.5G’s bringing efficiency at the separation of near-sized material.

• Wide range of applications: Wet or dry screening applications, including coarse and fine screening and hard-to-separate sticky material.

• Flexible production: Easy adjusting mechanism enabling the changing of the elliptical stroke and stroke angle for better production based on material type.

For more information, visit www.metso.com.

The Screencore range of Orbiter trommels is available in a variety of sizes, encompassing features making them ideal for landscaping and organic material handling applications.

In addition to the trommels, Screencore has developed a range of stackers equipped with a purpose designed mulch hopper and high-speed auger. These features make them both ideal for composting applications and processing organic materials for reuse in a variety of applications, according to the manufacturer.

Screencore has since its inception used its extensive expertise to develop and introduce a range of modern, mobile crushing, screening, stockpiling and pugmill solutions. The range has in a relatively short period found that its modern productivity and environmentally friendly attributes are highly suited to aggregate production on a truly global scale.

In addition to the processing of virgin rock and the recycling of construction materials, the Screencore Orbiter trommel range and purpose developed stackers, also have proved to be ideal for processing organic materials.

“Screencore continuously engages with our dealers and end-users to innovate and

refine our products,” said director Ciarán Ryan. “As a result, we have developed a range of Orbiter trommel screens and stockpilers that are specifically designed for the efficient handling and processing of organic materials. Like all our products, these new additions prioritize ease of transport and user-friendliness, ensuring that they meet the practical needs of our customers while setting new standards in the industry.”

The Screencore trommel and stacker ranges have rapidly gained recognition in both Europe and the United States. In France, an Orbiter 237 trommel, distributed by Screencore’s partner Starloc Auvergne, has been instrumental in processing various organic materials at a specialized site. This model is particularly suited to large-scale operations with its 23 ft. drum length and radial fines stacker. Additionally, the Orbiter 237 features a 18 cu. yd. dump-hopper and is tailored for the largest operators in the industry.

“The [48 in.] wide feed belt connects to a load-sensing drum, ensuring that the machine maximizes productivity

The Orbiter 125 is designed for work sites where space is at a premium and ideal for a contractor who needs to relocate quickly and often.

autonomously,” said Ryan. “Each element of the Orbiter 237 is specifically designed to ensure continuous operation without the need for constant operator input.”

The Screencore range of Orbiter trommels consists of three base machines ranging from the powerful yet compact 125, to the 237, which is aimed at the larger producers. The Orbiter 125 is designed for work sites where space is at a premium and ideal for a contractor who needs to relocate quickly and

often. The Orbiter 175 delivers high productivity from a compact chassis and features hydraulic folding conveyors and drum angle adjustment with a large infeed hopper and a Cat 130hp engine.

Designed to work on their own, but also designed to work alongside the Orbiter trommels, Screencore stackers have proved ideal for dealing with organic material due to their unique features. Specifically, the option of a high-speed auger in the hopper. For more information, visit www.screencore.ie/.

from page 1

munications and marketing manager. “We also needed the area to be accessible for the trucks to be able to dump material without the worry of getting stuck.

“Shoulders were widened 10 feet on average with a 2:1 fill slope down to the catch point,” added Killen, who pointed out that safety was a priority when working along steep slopes. “Creating a shoulder widened area is very technical with lots of safety implemented. Our operators are skilled and undergo training along with daily safety meetings to ensure that they place the machines where it is safe and stable to do so.”

Granite secured the contract in January 2023, which gave it five months to plan the schedule, secure materials for the work season, send equipment to the site and secure billeting for the crews.

To date, Granite has completed the following:

• Roadside clearing along with clearing and grubbing the slopes to be widened;

• 11 drainage systems, which included the diversion of Wilson Creek and a refurbishment of the existing system;

• A total of 41,950 tons of import borrow to widen the shoulders and wood mulch with hydroseed to protect the slope as permanent erosion control.

The remaining work will focus on the final drainage system work, the shoulder roadway structural section excavation, along with laying the hot mix asphalt, a roadway grinding and HMA overlay near Conway Ranch Road, a restripe of the entire project utilizing Methyl Methacrylate paint, establishing the electrical for roadside solar lights and the final touches of the plant establishment and erosion control.

Granite crews are experiencing many challenges, but their experience ensures these hurdles can be overcome.

“Drainage systems is one of them, [such as] the detailed processes of the diversion system at Wilson Creek,” said Killen. “The plans offered little detail on how the diversion should function and be workable around to perform the necessary repairs/rehabilitation of the original drainage system. Granite was able to have an engineer design a drawing that suspended the outlet of the diversion safely to allow workers underneath the flowing diversion pipe. The initial plans for the planned alignment had an incorrect alignment with the existing roadway. This required a substantial modification to the shoulder widening quantity along with a few sections that had a high water table. This posed a challenge to the operators along with the design team to find a suitable solution for a structurally sound subgrade.

“In order to complete the work for this project, there have been many days of flagging traffic control,” he added. “This creates an issue among travelers along U.S. 395 with not ideal traffic queues. Maintaining the flow of traffic is a large part of Granite’s day-to-day operation that keeps the public safe from potential exposures when reworking the drainage systems, large drop-offs for the shoulder work, and miscellaneous operations where equipment is traveling the site. This also protects the workers from the high-speed traffic along the 65 mph highway and allows for faster project completion time."

Killen noted that the progression of the project has been satisfactory.

“Granite is on target to finish on schedule in August this

Shoulders were widened 10 ft. on average with a 2:1 fill slope down to the catch point.

year,” he said.

Water is also an issue.

“The groundwater is significantly higher than expected,” said Killen. “This caused issues when building the shoulders out with heavy equipment. We also experienced the groundwater while excavating the drainage headwalls. Many pumps had to be placed in well points to run continuously to collect/distribute while performing the work.”

Space in the construction zone is limited, but efforts helped minimize this issue.

“Caltrans has been proactive in solving issues as they arise,” said Killen. “There have been many minor changes that needed to be resolved in the field in order to progress the project.”

The remote status of the project posed a major issue when coordinating with subcontractors and Granite employees to build the work.

“The majority of the crew would lodge in Mammoth, along with some renting an Airbnb in June Lake to host the weekly crew,” said Killen.

Granite has a local material yard in Lee Vining and in Bishop.

“However,” said Killen, “heavy equipment is generally shared throughout each project in the Bakersfield area. The process of requesting and mobilizing equipment up to the project site was very tedious and schedule intensive. For this project, the material is generated from our Lee Vining plant. Unless there are specific materials or requirements beyond the Caltrans standard provisions, our plant extracts, processes and provides all of the roadway material. Granite did uti-

The groundwater is significantly higher than expected, which posed an unexpected challenge for the contractor. Many pumps had to be placed in well points to run continuously to collect/distribute while performing the work.

lize Mammoth Ready Mix and 711 Materials for the slurry backfill and structural concrete for the drainage systems. The roadway materials from our Lee Vining plant are roughly 20 minutes each direction and the drive time for ready mix can range from 40 minutes up to 1 hour and 45 minutes each direction.”

Granite has utilized wide areas on the project to store equipment, materials and its temporary job-site office trailer for the upcoming work being performed.

“We allowed all subcontractors to also use our Lee Vining plant in the cases where large breaks in the schedule had occurred such as the winterization of the project,” Killen explained.

Serious planning has ensured that each aspect of the work proceeds smoothly.

The work to create the half-mile extension of the northbound chain-up area will take place in July and August.

“The plan of attack is to excavate the trenches for the new electrical lighting along with pouring the foundations for the poles and cabinets,” said Killen. “The challenges with electrical items are the lead times and approval processes associated with the material. We will be excavating the trenches after the shoulders are paved, which allows for a safer work environment and better progression of the schedule. The foundations will be poured for the poles and cabinets and final wiring will be pulled for connection. The last piece is having the controller turn on the power to complete the circuit.”

The culvert work is ongoing.

The lighting will be the final piece of the project and is currently scheduled for mid- to late August..

The Granite management team includes Foreman Clyde Burget, Project Engineer Kyle Jameson and Project Manager Jeff Cox.

“The team dynamic is very driven, from planning/scheduling to execution,” said Killen. “Granite includes everyone that is involved to have a say, with their experience, which allows for a better overall performance. The efforts of each crew is shown on the project. They are very productive and communicate very well with everyone about daily tasks, safety hazards and production.”

On busy days there are close to 15 Granite and subcontractor personnel on-site, with the major subcontractors being Synergy Traffic Control; J&M Land Restoration for temporary and permanent erosion control; Specialized Pavement Markings; Premier Valley Transport and Conspec for the hauling of materials; Camblin Steel for the rebar in the headwalls; DMC Sweeping for project maintenance; ABSL for pavement grinding; and A.C Dike for paving/dike.

New materials include approximately 600 cu. yds. of concrete/slurry, 4,350 tons of asphalt and 16,400 lbs. of steel.

Granite has crews working on many projects in California, so ensuring that equipment is always ready is critical to meet deadlines.

“Granite utilizes an on-site mechanic for most repairs,” said Killen, “but for those that are more severe, once the piece is mobilized back to Bakersfield, it will spend its time in the shop to be promptly repaired. Due to the nature of the remote location, preparation for the week is crucial ensuring that material needed for potential repairs are in hand or can be brought up at a moment’s notice. Granite crews perform daily equipment inspections on all operated equipment. We have on-site mechanics available during higher risk operations [HMA for this project].” CEG

(All photos courtesy of Granite Construction.)

1090 W 2181 N Salt Lake City, UT 84116 801-322-1300

atlasmachinery.us

6565 Smith Avenue Newark, CA 94560 510-400-5024

1535 SE 25th Street Oklahoma City, OK 73129 405-310-8700

2035 W Mountain View Road Phoenix, AZ 85021

480-463-4999

Equipmentshare.com

Volvo CE has taken a 22 percent ownership stake in VizaLogix, a U.S.-based software-as-a-service (SaaS) company specializing in digital, brandneutral solutions for machine monitoring, servicing and tech support in multiple industries.

The deal supports the Volvo CE strategy to grow services that customers are looking for as digitization and data take on increasing importance among construction and mining fleets and equipment dealers.

“This partnership is a great fit because VizaLogix and Volvo CE have a common goal to improve customer experience through increased efficiency, uptime and productivity,” said Scott Young, head of region North America, Volvo CE. “VizaLogix provides brand-neutral SaaS solutions that are easy to integrate and use, helping fleets, dealers and OEMs make smarter decisions.”

VizaLogix, based in Connecticut, will continue to operate independently and support multiple brands with its products to provide best-in-class support for mixed fleets operations.

“As we embark on this exciting new chapter with Volvo, we are thrilled to welcome them as a strategic minority investor in VizaLogix. This partnership marks a significant milestone for us, reaffirming our commitment to pioneering innovative solutions in the construction equipment industry and we are confident that together, we will drive even greater value for our customers and stakeholders,” said Shawn Bonnington, CEO, VizaLogix.

VizaLogix offers products that are differ-

ent from and, in some cases, complementary to Volvo services. Supporting mixed fleets and mixed data connections uniquely defines the VizaLogix product approach and market differentiation. These include:

• TethrITNow — equipment and technician support that includes real-time collaboration over multiple channels, including video calls that allow for augmented reality overlays that let users visually point, highlight and mark exact areas of focus.

• TechnicianNow — streamlined technician deployment that lets customers request service via mobile application, eliminating

wait times and providing them with real-time availability of parts and services.

• 3602 — 24/7 machine health monitoring that integrates multibrand fleet data into one platform.

• Vantage Point — stores quarry site productivity and utilization data in one data-agnostic platform, allowing for easy access to real-time and historical data.

For years, Volvo CE has been developing innovative services that improve customer uptime, productivity and safety. These include ActiveCare Direct advanced telematics, Assist machine control systems and productivity services like Connected Map, Task Manager and Connected Load Out.

“Volvo CE recognizes that services are growing to be just as important to fleets as their machines, and our investment in VizaLogix extends our commitment,” Young said. “It’s by combining the right machine with the right services that users get the best solution for their unique needs.”

For more information on VizaLogix software solutions, visit www.vizalogix.com.

2449 Manana Drive Dallas, TX 75220 800-594-BANE (2263) 10505 North Freeway Fort Worth, TX 76177 800-601-BANE (2263)

3402 E. NE Loop 323 Tyler, TX 75708 800-594-2200

Rototilt, which develops and manufactures tiltrotators for the global market, is investing heavily in the future by expanding its factory in Vindeln, Sweden. The extensive investment includes the development of a modern robotic welding facility at a cost of approximately SEK 35 million.

“Even though the economic situation is challenging right now, we believe in continued growth and require greater flexibility and capacity in order to meet our customers’ high demands. This investment is a step to improve our position, enabling us to deliver with speed and precision, which is crucial in our market segment,” said Anders Jonsson, CEO

A new robotic welding system is currently being introduced, linking up handling robots and welding robots. The investment is generating customer value by providing opportunities for improved delivery times and quality. The construction project, which was launched in October 2023, includes an expansion of the factory totalling 11,625 sq. ft., spread over two floors.

The new welding section will be ready for final inspection in May 2024.

“The global situation is placing new demands on us, and we are dealing with this at the same time as attempting to develop our business. We are now creating the conditions to improve our delivery precision, which is something we are constantly focusing on, since we know how important it is for our customers,” said Jonsson.

Rototilt’s production facility is powered by fossil-free energy, and the extended factory is being built with an advanced energy recovery system. The heat from the welding process is recovered via the ventilation system, thereby reducing both energy consumption and the climate footprint.

The factory’s primary heating source is district heating, which is produced from local biofuel.

“The new welding facility will contribute to a lower proportion of goods transport. All

the elements that are contributing are important, and we are constantly thinking about how we can reduce our climate footprint,” said Ida Skaring, sustainability strategist at Rototilt.

During the autumn 2023, Rototilt also invested in one of Sweden’s largest private charging parks, with 178 vehicle spaces outside the factory in Vindeln. All the parking spaces are equipped with sockets for engine heaters as well as electric car charging.

“We are proud to be creating a greener workplace and to be supporting the ongoing transition to sustainable travel. Half of our employees commute from other municipalities, and this development is making it easier for anyone who drives an electric car to get to the workplace. It will hopefully also encourage more people to switch to an electric car. Our aim is not only to offer innovative products, but also a pro-

Rototilt’s production facility is powered by fos sil-free energy, and the extended factory is being built with an advanced energy recovery system. The heat from the welding process is recovered via the ventila tion system, thereby reducing both energy consumption and the climate footprint.

Oshkosh Corporation, a leading innovator of purpose-built vehicles and equipment, announced it has entered into a definitive agreement to acquire AUSACORP S.L. (AUSA), a privately held international company and manufacturer of wheeled dumpers, rough-terrain forklifts and telehandlers for the construction, material handling, agriculture, landscape and specialty equipment industries.

Upon closing, AUSA will become part of the Oshkosh Access segment.

“AUSA’s history of producing highquality, purpose-built equipment aligns with our Innovate. Serve. Advance. strategy, allowing us to broaden our product offerings in both current and adjacent markets,” said John Pfeifer, Oshkosh Corporation’s president and chief executive officer. “We look forward to welcoming the AUSA team into the Oshkosh family.”

AUSA products will enhance the JLG line of telehandlers, as well as Hinowa tracked dumpers and forklifts to strengthen the Access segment’s portfolio of equipment. The companies began working together through a partner agreement in 2020, with AUSA manufacturing the JLG-branded SkyTrak 3013 compact tele-

handler.

“We are excited to join forces with a proven partner like AUSA,” said Mahesh Narang, executive vice president, Oshkosh Corporation, and president, Access. “Combining our advanced technology capabilities and robust training, support and service infrastructures will allow us to better serve customers and enable targeted growth.”

“We constantly pursue excellence in our products, services and business,” said Ramon Carbonell, AUSA’s chief executive officer. “A deeper relationship with Oshkosh will expand the reach of our products, which is an objective our companies share.”

AUSA, which was founded in 1956 in Barcelona, Spain, reported sales of approximately $132 million euros in 2023. The company’s near 350 team members and 600 dealers bring with them a long history of innovation, quality and customer service.

The AUSA acquisition supports the Oshkosh accelerated growth strategy. The transaction, which is subject to customary closing conditions, is expected to close within 90 days.

For more information, visit JLG.com.

Oshkosh Corporation announced that it is acquiring AUSA, a manufacturer of wheeled dumpers, rough-terrain forklifts and telehandlers for the construction, material handling, agriculture, landscape and specialty equipment industries. Upon closing, AUSA will become part of the Oshkosh Access segment, which includes the JLG, Jerr-Dan and Hinowa brands.

Manitou has launched a new Woodcracker tree saw with grapple configuration for its rotating telehandler product line that will significantly improve performance and productivity in tree and limb removal operations — particularly in urban areas and roadside land management applications.

The Woodcracker tree saw with grapple is compatible with three Manitou rotating telehandlers — the MRT 2260, MRT 2660 and MRT 3060 Vision+. When matched with the MRT 3060 Vision+, operators can reach heights of more than 98 ft. and outreach to more than 84 ft. The maximum lifting capacity for the MRT with the tree saw attachment is 8,000 lbs.

Built from extremely highstrength steel and capable of cutting tree branches and trunks up to 29 in. in diameter, the new Manitou tree saw rotates into position to cut, hold and deliver each limb. It also can be matched with the Manitou rotating telehandler remote control to give the operator flexibility in how/where they perform the work.

“The off-road capabilities, 360degree rotation and the excellent reach of these rotating telehandlers makes this an extremely versatile solution for municipalities, public works departments and tree removal contractors regularly faced with challenging tree and limb removal jobs,” said Steve Kiskunas, telescopic handler product manager, Manitou.

“It delivers the ability to remove and place large and heavy tree limbs while maintaining excellent control of the load. This simplifies the work, helps keep the operator and other workers out of the fall zone, and gives the operator the ability to perform the work from the most advantageous vantage point when equipped with the remote control.”

Each Manitou MRT rotating telehandler equipped with the tree saw will include a

specialized forestry package with a windshield guard, boom covers and guards, hydraulic and electrical system covers and a second return-to-tank line. Manitou offers the attachment solution for new machine orders and for existing Manitou MRT Vision+ models: MRT 2260, MRT 2660 and MRT 3060.

While each Manitou rotating telehandler matched with the new tree saw with grapple is highly specialized, each machine retains compatibility with the full line of rotating telehandler attachments to deliver a highly versatile platform for businesses or public works departments.

“This new tree saw with grapple configuration delivers excellent heavy-duty performance for a specialized application while

still delivering a broad range of capabilities as a three-in-one machine — telescopic handler, jib and aerial work platform,” said Kiskunas. “This type of versatility can really be an asset in smart fleet building and management.”

The purposely matched solution of a rotating telehandler with a forestry package and a premium tree saw/grapple has an opportunity to evolve how tree removal, vegetation management, public works and other contractors approach safe limb and tree handling. It’s a solution that the Manitou dealer network has been hungry for, the manufacturer said.

“Our customers are impressed with Manitou’s MRT 3060 for its performance versatility, precision, and unparalleled com-

fort,” said Ben Siemen, vice president of sales for Shawmut Equipment. “This innovative piece of equipment is now designed to meet the demands of this harsh application — from the hydraulic hose and electrical component guarding at the boom tip, to the innovative remote control with designated controls for the grapple saw. The Manitou MRT line-up with the factory Installed Forestry Package offers our customers a complete package in one price, all backed by the service and support of the Manitou dealer network.”

The new Manitou tree saw for rotating telehandlers is available to order now in the North American market.

For more information, visit Manitou.com.

BTDT Inc. is celebrating its 15th year in business and will soon unveil a new, more dynamic website. In addition to a milestone year and website unveiling, the company also is bringing on a new marketing director, Dakota Collins.

Collins, who has more than a decade of experience at his family’s trucking firm, Collins Trucking, based in Jackson, Ga., is a Georgia Southern University graduate with a degree in logistics and marketing. This lends a new approach to the overall scope of BTDT’s marketing endeavor, according to the company.

SNS products, a manufacturer of specialty products for the construction equipment industry, supplying a wide range of excavator and wheel loader attachments.

BTDT was founded by U.S. Marine Corp veteran Tim O’Malley following a career in the construction equipment industry. He started his career with Caterpillar and Komatsu before moving on to Daewoo/Doosan.

BTDT is an exclusive U.S. distributor of

photo

SNS utilizes a comprehensive Structural Test System to pursue Zero Defect design and manufacturing of all products. The staff and engineers for R&D provide BTDT with high-quality products and work hand-inhand for first rate post-sale service, the company said.

SNS produces a broad array of booms, arms and attachment configurations, and BTDT specializes primarily in the product applications for excavator conversion products such high-reach, long-reach and material handler booms with a wide array of attachments.

For more information, call at 770/3354360; email tim@btdtinc.com or dakota@btdtinc.com. CEG

ABILENE, TX • 877-577-5729

AMARILLO, TX • 800-283-1247

DALLAS, TX • 800-753-1247

FT. WORTH, TX • 877-851-9977

HEWITT (WACO), TX • 254-261-1370

LUBBOCK, TX • 866-289-6087 MCALESTER, OK • 918-310-1550 ODESSA, TX • 877-794-1800 OKLAHOMA CITY, OK • 800-375-3339 TULSA, OK • 800-375-3733

MISSOULA, MT • 800-332-1617

BILLINGS, MT • 800-735-2589

BOISE, ID • 800-221-5211

COLUMBIA FALLS, MT • 800-434-4190

EUGENE, OR • 800-826-9811

JEROME, ID • 800-221-5211 KENT, WA • 800-869-2425

POCATELLO, ID • 800-829-4450

PORTLAND, OR • 800-950-7779

ROCHESTER, WA • 800-304-4421

SPOKANE, WA • 800-541-0754

Contractors are devoting a lot of time to exploring new ways to hire. Some are boosting compensation, others investing in professional development.

“Construction workers in this landscape are empowered to select employers who support their career growth and align with their values,” blogged Skinner.

What’s considered the hottest construction job titles these days depends on who produces the list.

What’s consistent is the fact that the highest paying in-demand jobs don’t require a college degree. For young job seekers, that opens more doors to strong career choices and is why the job security that skilled labor currently offers is so attractive.

Continuing labor shortages worsened by disruptions from the COVID pandemic, have created more competition for talent, said McKinsey & Co.

Add to that the fact that more construction workers are retiring each year and the industry is constantly working to attract young people to fill their places. As a result, wages for skilled trade jobs have risen by more than 20 percent since the first quarter of 2020, noted the global management consultant.

“Demand for skilled tradespeople is expected to increase over the next decade and remain high in the U.S.,” said McKinsey.

The consulting firm attributes this to infrastructure needs, a surge in real estate redevelopment and investments in renewable energy.

Construction is among the three most indemand job fields that companies are hiring for this year. In the mix are manufacturing and plumbing.

Specific titles Payscale and ZipRecruiter shared with CNBC include construction superintendent, production manager and journeyman plumber.

ZipRecruiter tracked a 16-percent increase in all of these jobs between October 2023 and March 2024.

Construction superintendents have seen the largest uptick in demand, with openings surging more than 128 percent, according to the CNBC report.

The survey found other high-paying trade jobs that have seen slightly less demand, “but are still hiring at a good clip, include fleet managers.”

Construction careers, prioritizing skills over degrees, offer some the best chances to earn six figures without a college degree, said Payscale’s Ruth Thomas.

Though more companies are dropping degree requirements, skills-based hiring has still not become common practice across all

industries, she added.

Jonathan Jones of Construction Coverage said despite inflation, high interest rates and recession fears, the outlook for construction is bright.

The construction software developer noted a recent AIA report that a 4-percent growth in non-residential construction is expected this year.

That follows an already impressive 22percent hike in 2023. Job growth in construction will be steady into the future, said Jones.

“High demand for construction across the board has helped boost the industry over the past three years,” he said.

That demand could help construction companies weather a potential recession, Jones said, noting the fed has invested heavily in infrastructure.

The series of COVID relief packages in 2020 and 2021 sent billions of dollars flowing to the industry, as well.

But the fed investment centerpiece is the IIJA, funding major new transportation construction projects and driving labor demands, noted Jones.

Plus, the construction industry bypassed the pandemic layoff hits that many other industries saw. So, it recovered jobs more quickly, said Jones.

“Construction employment had a strong bounce-back after lockdowns and other restrictions began to ease in the late spring of 2020,” he said.

And the market has only continued to grow since. In fact, construction hiring passed pre-COVID levels three months before the economy as a whole.

Jones predicts industry technological changes will streamline many processes, in turn changing the composition of jobs in the industry.

“As the industry modernizes, many professions set for the greatest rate of growth are in fact jobs not commonly associated with construction,” he blogged.

Demand for construction market research analysts, software developers, logisticians and financial managers is projected to be robust in the coming years.

“But construction industry jobs with the greatest projected growth rates are related to renewable energy, including wind and solar,” added Jones

Skilled trade workers “are striking gold in the job market” said job placement firm Skinner in a spring report. The company attributes the strong job market to singlefamily housing and industrial construction which are currently in high demand.

“Trillion-dollar public infrastructure projects are taking shape,” said Skinner, also

crediting an expected “historic” boom in the remodeling market.

“These days, it seems like every industry needs tradespeople — and as the skills gap grows, pay may rise as fast as competition.”

The company believes trade workers are experiencing some of the fastest growing wages in the country. As a result, contractors are strategizing to recruit high-demand workers, said Skinner, “especially if a tightening budget is a concern.”

Skilled trade workers can take this time to shift into much-needed roles, the company advised. This are the firm’s top in-demand construction jobs:

• Electricians

“Electricians are needed for practically every building construction project — but that’s far from where the demand ends,” said the company.

As the United States goes green, trade workers will be key hires for charging station and transmission line installs.

Maintenance brings demand as well.

“We’re also seeing ongoing demand for low-voltage technicians, driven by new fiber optic networks, alarm systems, rewiring projects and other work.”

Skinner believes that’s why the BLS expects the electrician job outlook to grow much faster than average through 2032.

• Pipefitters

Industrial development is driving demand for pipefitters, said Skinner, as semiconductor businesses and automakers build facilities.

Predicted resurgences of oil and gas production could boost demand even further, believes Skinner.

“We’re already seeing pipefitter salaries exceed what electricians make, and turnover and retirements will increase job openings and pay in the U.S.”

• Ironworkers

Where there’s new infrastructure, there will be ironworkers. These professionals “are expected to thrive in the coming years,” said Skinner.

Federal funding is driving the growth of transportation, bridge and highway projects, further ramping up ironworker hiring, the firm noted.

• Masonry Workers

“You may have heard masonry is a dying trade, but demand for this traditional skill isn’t going away,” said Skinner.

Bricklayers, stonemasons and other mason workers — crucial for building fences, walls, walkways and more — are still in short supply.

Simply put, schools and companies still struggle to build interest in masonry among the next generation of workers, said the firm.

“The aging workforce, as well as the growing number of masons switching

careers, will keep the number of these skilled trade positions high.”

Citing the AGC, Skinner noted that bricklayers and cement masons are the most difficult tradespeople to recruit regionally. Recognizing this, organizations are hosting workshops in hopes of closing the widening skills gap.

“Workers with the skills needed to fill mason positions now can find plenty of lucrative opportunities.”

Construction Coverage used BLS data to form its list of the fastest-growing jobs in the construction industry, across 190-plus occupations.

The list includes:

• Market research analysts and marketing specialists

“Software companies have transformed the construction industry in recent years by automating processes that used to require hours of manual work.”

The developer said the most noteworthy new products include takeoff, estimating, construction accounting and field service management software.

This job category is expected to see 8 percent growth over the next 10 years, adding 1,300 new workers.

• Electricians

The 10-year projected employment growth for electricians is more than 8.5 percent, resulting in a projected employment growth of 46,400 over that period.

• Telecommunications line installers and repairers

An employment increase of 9.3 percent over 10 years is expected for line installers and repairers. This will add 2,900 workers to the job field.

• Occupational health and safety specialists

The 10-year employment growth forecast is 11.9 percent for health and safety specialists. The job field will grow by 1,900 workers.

• Logisticians

Logisticians will see a 10-year projected employment growth of +12.1 percent. The job field will draw 200 workers over that time span.

• Radio, cell and tower installers and repairers

Over a 10-year period this job category is projected to grow by 13.6 percent. It will bring 300 workers into the construction market.

• Solar photovoltaic installers

The 10-year projected employment growth for solar installers is 29.0 percent, seeing 4,800 more workers take this job title.

• Wind turbine service technicians

In the meantime, said the placement firm, workers can leverage the current market to elevate their careers. CEG

ALASKA NC MACHINERY

www.ncmachinery.com

800-478-7000

Anchorage, AK • 907-786-7500

Dutch Harbor, AK • 07-581-1367

Fairbanks, AK • 907-452-7251

Juneau, AK • 907-789-0181

Prudhoe Bay, AK • 907-659-6900

Wasilla, AK • 907-352-3400

ARIZONA

EMPIRE CAT

www.empire-cat.com

1725 S Country Club Mesa, AZ 85210

800-EMPIRE-1

CALIFORNIA

HOLT OF CALIFORNIA

www.holtca.com

Pleasant Grove • 916-921-8969

NEVADA

EMPIRE CAT

www.empire-cat.com

3300 St. Rose Parkway, Henderson, NV 89052

702-649-8777

Elko • 775-738-9871

Reno/Sparks • 775-358-5111

NORTH DAKOTA

TRACTOR AND EQUIPMENT

www.tractorandequipment.com

Williston • 701-572-8377

WYOMING

TRACTOR AND EQUIPMENT

www.tractorandequipment.com

Worland • 307-347-4747

MONTANA

TRACTOR AND EQUIPMENT

www.tractorandequipment.com

Billings, MT • 406-656-0202

Billings-Sgt. • 406-245-4426

Bozeman • 406-585-5800

Great Falls • 406-761-7900

Helena • 406-442-2990

TEXAS

MUSTANG CAT

mustangcat.com

Beaumont • 409-892-8412

Bryan • 979-775-0639

El Campo • 979-543-3389

Houston • 713-460-2000 Lufkin • 936-639-5551

WASHINGTON

NC MACHINERY

www.ncmachinery.com

800-562-4735

Seattle • 425-251-5800

Chehalis • 360-748-8845

Fife • 253-896-0878

Monroe • 360-805-6000

Mt. Vernon • 360-424-4292

Wenatchee • 509-886-5561

Yakima • 509-248-2371

Montana Technological University’s Underground Mine Education Center (UMEC) has received a substantial donation in the form of an Epiroc Scooptram ST2D underground loader. This collaboration between Epiroc and dedicated educators marks a significant milestone in bolstering the educational resources available to students at the UMEC.

The Scooptram ST2D, tailored for narrow-vein operations, with a capacity of 3.6 metric tons, represents a cuttingedge addition to the UMEC’s training equipment. This loader, designed for navigating mining tunnels and efficiently removing material, promises to elevate students’ hands-on learning experiences in underground mining, providing them with practical skills on industry-standard equipment essential for successful careers in mining engineering.

Associate Professor Scott Rosenthal and Adjunct Professor Sonya Rosenthal spearheaded the initiative to procure the Scooptram ST2D for the UMEC. Their commitment to mining education and the future of aspiring professionals in the field led to the realization of this donation, facilitated by Epiroc’s exceptional concessionary pricing arrangement.

Assistant Professor Chris Roos, instrumental in identifying this opportunity, recognized the transformative potential of integrating the Scooptram ST2D into the UMEC’s curriculum during his attendance at Yellowstone Dig It Days.

Scott Rosenthal, inaugurating the Scooptram ST2D, highlighted the donation’s significance for the UMEC, stating,

OEM authorized mining dealer www.coremachinery.com

Phoenix, AZ 480-545-2400

Phoenix, AZ 602-252-7121 Prescott, AZ 928-778-5621 Tucson, AZ 520-623-8681

Bakersfield, CA 661-695-4830 Mojave, CA 661-824-2319

Perris, CA 909-355-3600

*Formerly Road Machinery

www.wpi.com

“We saw the opportunity to provide a tangible benefit to the students. The introduction of the Scooptram ST2D allows students to gain practical skills on industry-standard equipment, preparing them for successful careers in mining engineering, and we have received great response and profound gratitude from our mining engineering students.”

For more information, visit www.epiroc.us.

Bobcat Company and its employees held their annual fall giving campaign, garnering more than $175,000 in donations to nonprofit organizations in 17 states.

To support its employees in their philanthropic pursuits, Bobcat matched employee donations dollar for dollar (up to $3,000 per person) to further amplify employees’ generosity. Employees were eligible to select any organization with a 501(c)(3) status to donate to.

“We are thrilled we could further our employees’ donations and help them give back in a way that was personally meaningful to them through our fall giving campaign,” said Tina Amerman, Bobcat Director People Programs.

“We continue to see strong participation in this annual event and have donated hundreds of thousands of dollars over the years to positively impact a wide variety of local organizations.”

Bobcat continues to partner with United Way — a relationship that has spanned more than 20 years — to support its mission of inspiring and activating communities to improve lives.

United Way remained a featured charity for this year’s campaign, receiving strong employee and organizational support in addition to more than 100 other nonprofit recipients selected by employees.

The fall giving campaign wrapped up a season of volunteering and community efforts on behalf of the company. For example, in September, Bobcat announced that more than 1,000 employees dedicated their time and talents to participate in more than 100 volunteer projects globally. The companywide volunteer projects aimed to give back to the communities where Bobcat employees live and work. This volunteerism is on top of the generosity Bobcat employees exhibited financially.

Additionally in 2023, Bobcat donated $5 million to support a new engineering facility at North Dakota State University and partnered with the National Recreation and Park Association with $250,000 in grants to help create sustainable community park and recreation areas throughout the United States.

In addition, Bobcat supports educational STEM programs through its annual grant program and serves as the lead sponsor for the Bobcat North Dakota Open, donating more than $1.2 million since 1984, in support of The Village Family Service Center’s community outreach services.

Bobcat is committed to investing time and resources in its communities. The organization has a long history of volunteer efforts, including providing time, resources and charitable contributions to help create a stronger tomorrow.

For more information, visit bobcat.com.

12320 S. Main Street Houston, TX 77035 713-723-1050 Buffalo, TX 903-322-7150 Bryan, TX 979-314-1191

Corpus Christi, TX 361-884-8275 Edinburg, TX 956-386-0107

Kilgore, TX 903-984-2011

Lufkin TX 936-243-6056 Pflugerville, TX 512-251-0013 Port Arthur, TX 409-721-5305 San Antonio, TX 210-648-4444 Tomball, TX 281-351-9016

www.powermotivecorp.com

Corporate Office 5000 Vasquez Blvd., Denver, CO 80216 303-355-5900

Colorado Springs, CO 719-576-5541 Grand Junction, CO 970-241-1550 Milliken, CO 970-587-1188 Cheyenne, WY 307-634-5149 Durango, CO 970-259-0455

5461

Albuquerque, NM 505-345-8383 Bloomfield, NM 505-324-8601 Carlsbad, NM 505-485-1700

El Paso, TX 915-872-1001 Chandler, AZ 602-986-3003 Phoenix, AZ 602-463-3772 Tucson, AZ 520-649-2858

www.geehm.com

OK 918-438-1700

Abilene, TX 325-692-6334 Amarillo, TX 806-373-2826 Dallas, TX 214-371-7777

Ft. Worth, TX 817-378-0600

Lubbock, TX 806-745-2112

Odessa, TX 432-333-7000

Waco, TX 254-261-1370

c ) ol (IMC r achine Cont anced autom tes with adv yg . ned plans ou an help y ation

efully design w and car e

face to design sur uickly

www.clairemontequipment.com San Diego, CA 858-278-8351

Indio, CA 760-863-5558 San Diego, CA 858-278-8338

Escondido, CA 760-739-9100 Fontana, CA 909-429-9100 Imperial, CA 760-355-7700

By Cole Walker SPECIAL TO CEG

Since 1962, the James A. Rogers Excavating company near Little Rock, Ark., has been providing developers with site preparation, planning and earthmoving services.

The continued success and growth of the company has led to more job sites spread further apart — which creates all new challenges for two of the most important tasks that face heavy equipment fleet managers: greasing and fueling.

“We do small dirt work and multi-million-dollar jobs,” said David Miller, preventative maintenance lead and self-described grease monkey, James A Rogers Excavating.

“This market’s booming. We have been awarded more jobs in recent years and even hired about 30 new employees last year. Right now, we’re hitting our goals, and we’re expecting to perform well beyond our goals.

“Obviously, with more jobs you need a bigger fleet of equipment and that means a lot more fuel. We have eight service trucks at any one time with either 100-gallon fuel carrying tanks or 62-gallon tanks, and they were really struggling to keep up.”

With the cost and limitations of adding more service trucks to the company’s existing lineup, it began exploring other options. It decided to purchase a Thunder Creek 920gallon multi-tank trailer (MTT920).

“The Thunder Creek trailer arrived about the same day I did,” Miller said. “On my first day on the job, I did a quick tutorial and I hit the road. We really didn’t have a choice. We had a lot of machines working and we couldn’t keep up with fueling.”

Thunder Creek multi-tank trailers allow business owners and fleet managers to haul bulk diesel to their job sites without requiring a CDL or HAZMAT endorsement from the driver (Miller has neither). This is made possible by isolating diesel in eight separate 115gal., DOT-compliant non-bulk

tanks. Tanks are joined by a manifold to a common pump, creating complete isolation during transport and controlled dispensing of fuel at the job site.

Each trailer is built to maintain a low profile and is configured to provide optimal balance and a smooth ride at highway speeds, as well as in the most rugged, off-highway conditions.

Each trailer can be outfitted with an optional utility box that houses additional tools such as air compressors, greasing systems and more — and the front compartment is designed to handle Thunder Creek’s exclusive 2-in-1 diesel exhaust fluid (DEF) storage and dispensing system.

“I currently don’t have a CDL,” said Miller, who also does not carry a HAZMAT endorsement. “That was my first concern when I interviewed. But, with the Thunder Creek MTT 920, we’re at 115 gallons of fuel

per tank, which is under the 119-gallon threshold. Just to make sure, we filled the trailer up completely and put it on a scale. It’s under the [CDL] weight limit, which is great for someone like me with just a regular driver’s license. I can get the job done without having to worry about any extra qualifications. It’s also great for a lot of business owners, because the demand for workers is extremely high right now.”

Miller put more than 12,000 miles on his truck and trailer in the first four months the company owned it — and it has been front and center in keeping the company’s equipment fueled and greased.

“On some of our bigger jobs, things can get busy,” said Miller. “At one job I’m thinking of, we started with a D-11, 330, 336 and a 380 all moving on the same site. I was dumping 600 gallons of fuel every day and filling a 1,000-gallon tank that was there. I would make a run once a day — no matter what — and sometimes twice a day. To keep machines moving at full potential, I had to be on my toes.”

The focus also is not just on the big equipment — each site includes countless pieces of compact equipment that are critical to uptime, even if they take lower quantities of fuel.

“There are also lots of job sites where we have small equipment running and there aren’t enough service trucks to fuel them,” said

Miller. “Every one or two days, I swing by those jobs and fill up the smaller equipment.”

The rear utility box with air compressor and 35-lb. greasing kit also has been critical for the company’s fleet management activities. While built primarily for fuel, the Thunder Creek trailer helps considerably in daily tasks critical to keeping equipment up and running — especially in hot and dusty Arkansas summers.