Powerscreen of California, Nevada & Hawaii Hosts Open House...8

JCB Builds New $500M Factory in San Antonio...14

Volvo Masters Crowns Winners of Technicians Challenge...26

Powerscreen of California, Nevada & Hawaii Hosts Open House...8

JCB Builds New $500M Factory in San Antonio...14

Volvo Masters Crowns Winners of Technicians Challenge...26

is

By Irwin Rapoport CEG CORRESPONDENT

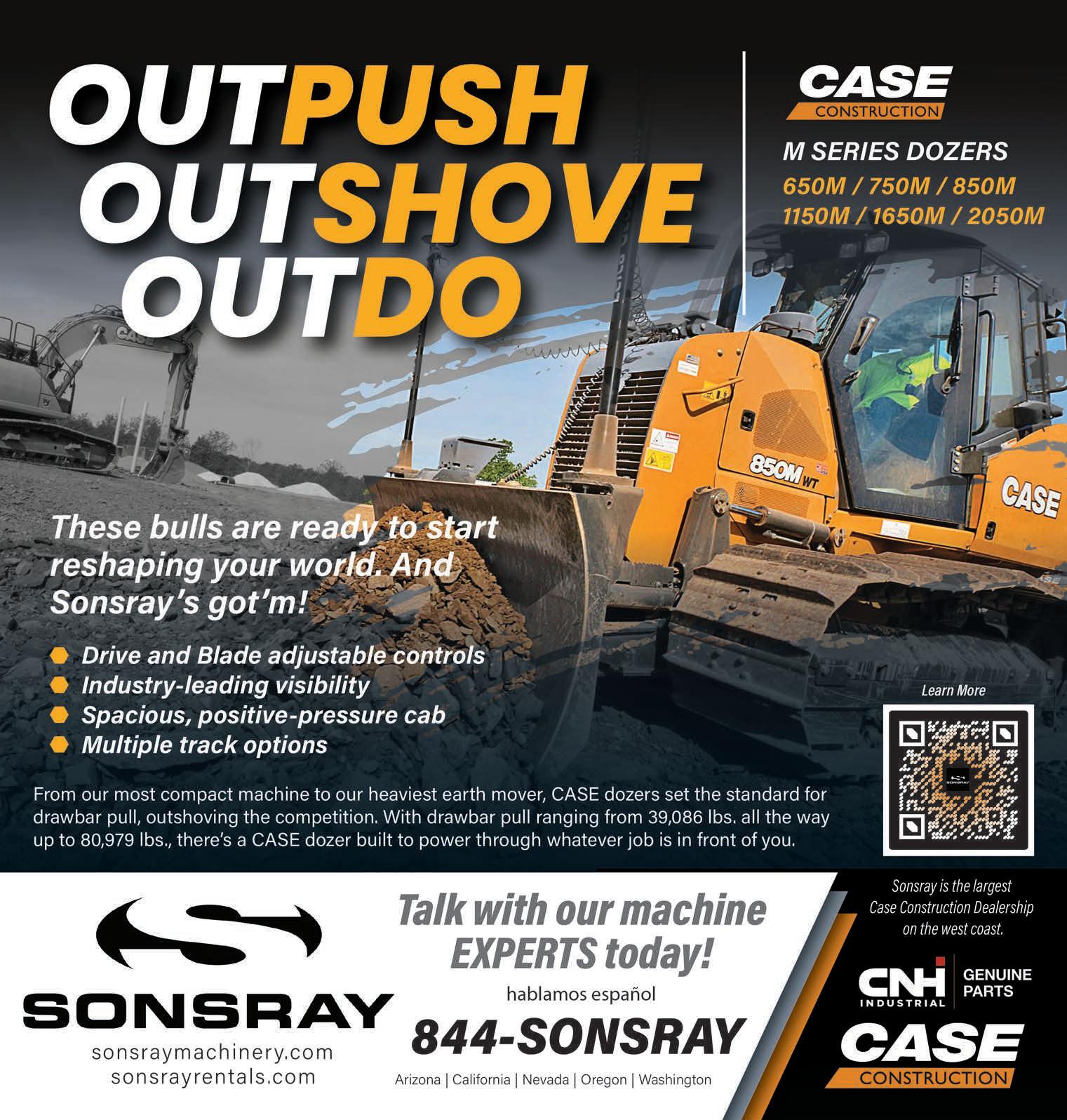

With Sundt Construction Company continuing work on the first portion of the Texas Department of Transportation’s (TxDOT) I-10 Widening West Project in El Paso County, the general contractor is

By Lucy Perry CEG CORRESPONDENT

The Biden administration’s clean hydrogen goals are in a state of hurry up and wait. The industry is champing to get started, but there may be too many challenges to advance the president’s dream of building out the U.S. clean hydrogen industry. The biggest issue may be the fact that with a possible change in administration next year, one that heavily favors fossil fuels, all progress may be reversed.

preparing to start operations on the second portion of the overall project valued at $120 million.

The initiative is widening I-10 from two concrete lanes in each direction to three. This project, located in the “Borderland” where New Mexico, Texas and Mexico all meet, is being constructed as two projects.

see TEXAS page 30

2014 Laymor SM400, Stk#: 12756, EROPS, A/C & Heat, 593 hrs., Water System, 8 ft. Broom, 225x75Rx15 Tires, 4 Cy. Kubota Eng $29,500

2018 John Deere 750K LGP, Stk#: 13236, EROPS, A/C & Heat, Radio, 6 Way Blade, 6,733 hrs., 33" Pads, 12 ft. Blade $129,500

The company invited customers to view its wide range of equipment from industry-leading brands such as Powerscreen, Bell Trucks, Kobelco and various Terex brands, as well as the announcement of its newest line — Hyundai.

Almost four dozen emerging leaders in transportation design and construction completed an introduction to federal legislative and regulatory issues during ARTBA Foundation’s Industry Leader Development Program.

An official groundbreaking ceremony at the site marked the beginning of construction, where The Hon. Alice Bamford, the daughter of company Chairman Anthony Bamford, turned the first shovelful of dirt on the property.

AED announced the addition of Jacob Asare to its government affairs team. This expansion reaffirms AED’s dedication to providing comprehensive support and advocacy for its members while enhancing its overall influence in the industry.

Trackhouse Racing and Kubota just launched a sweepstakes perfect for any NASCAR superfan where they can win an exclusive VIP experience at Miami-Homestead Speedway.

This position will oversee sustainability initiatives throughout Liebherr’s U.S. locations by educating stakeholders, implementing new processes and providing additional structure to current programs.

A global competition to find the very best of the best Volvo technicians has concluded after a 12-month endurance test of skills, knowledge, stamina and teamwork across all elements of aftersales operations.

Caterpillar released its latest reports highlighting the company’s environmental, social and governance (ESG) commitment, record financial accomplishments and contributions to helping customers build a better, more sustainable world.

The Top Gun award recognizes businesses who receive the PEG Award for Financial Excellence. The awards are given to the top 25 percent of rental operators based on financials verified by Peer Executive Groups.

34

After two days of hosting dealers and guests for its “Power Days Demo” event south of Atlanta, FAE USA territory managers and representatives from coast-to-coast gathered May 10, 2024, in Dawsonville, Ga.

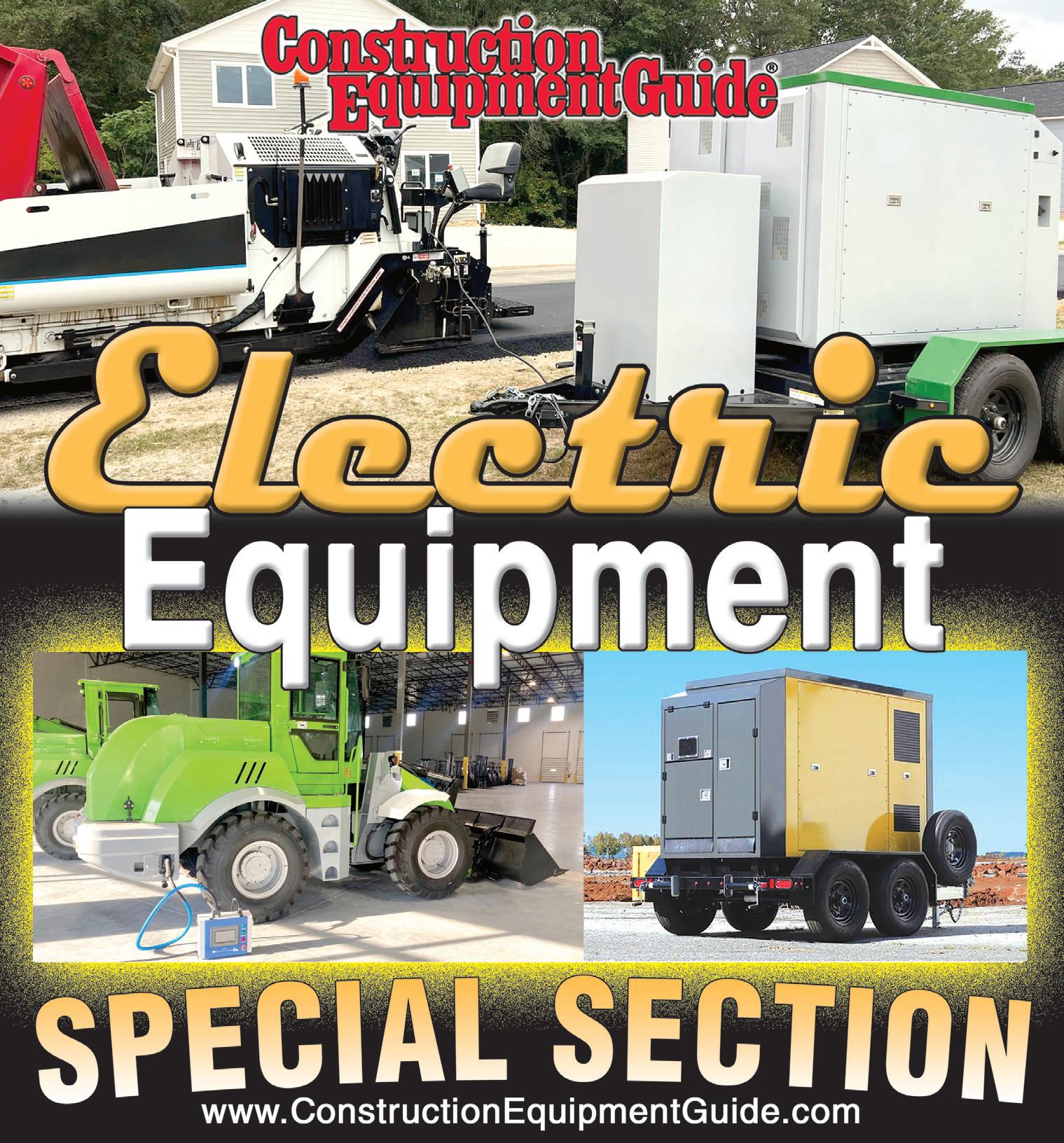

43 LEEBOY, PE COLLABORATE TO ADVANCE ELECTRIFICATION IN INDUSTRY

LeeBoy, a manufacturer commercial asphalt paving equipment, and Portable Electric, a manufacturer of portable and mobile e-Chargers and e-Generators, are working together to advance the electrification of the asphalt paving industry.

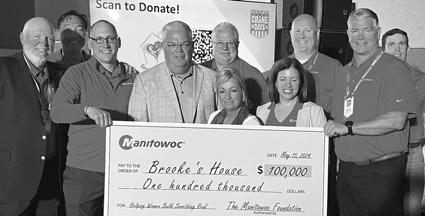

46 BROOKE’S HOUSE RECEIVES $150K DONATION FROM MANITOWOC

Brooke’s House, a rehabilitation center in Hagerstown, Md., dedicated to aiding women in recovery, has received $100,000 from Manitowoc and $50,000 from its dealers and customers.

ASSISTANCE

Nine children of highway workers who were killed or permanently disabled on the job will receive post-high school financial assistance for the 2024-25 school year due to the ARTBA Foundation.

48 WORLD OF ASPHALT SHOW HIGHLIGHTS ‘HEY NAPA’ AI

At the recent World of Asphalt Show in Nashville, thousands of attendees took advantage of the show’s education conference, aptly named the People, Plants and Paving Conference by the National Asphalt Pavement Association (NAPA).

Bobcat

Powerscreen of California, Nevada & Hawaii, a Molson Group Company, held an open house at its Dixon, Calif., facility on May 21 to 23, branded as XPO 24. The company invited its customers from across the country to view its wide range of equipment from industry-leading brands such as Powerscreen, Bell Trucks, Kobelco and various Terex brands, as well as the announcement of its newest line — Hyundai. Various lines and machines were on display and in action at the 5-acre facility.

The show opened with a rendition of the United States’ national anthem sung by Alexia Cunningham, below the impressive American flag that was hoisted above the grounds with a Fuchs MHL 360 material handler.

The total attendance for the three-day event exceeded 500. On the third day of the event, employees from all divisions were able to bring their children, who enjoyed being part of the celebration and were welcome to climb on the equipment.

There was a large variety of food truck options to satiate guests throughout their day, including morning coffee and breakfast burritos, numerous lunch options and a refreshing shaved ice to cool them off for dessert.

The demo area kept all guests entertained, where visitors could get their hands on the equipment. There were two timed challenges with a Kobelco excavator equipped with a breaker attachment for a balloon popping challenge and a Fuchs material handler with a Rotobec grapple attachment for a tire stacking challenge. It was a fun way to compete with their peers.

Inside, guests had opportunity to speak with their vendors and partners from Northland Capital, Rotobec Attachments, Zenrobotics, a Terex Brand, and a chance to create their own cowboy hat from Rancher Hat Bar. Proceeds from the hat bar were split between a number of local charities which were carefully selected by the company’s Community Champions of Change charity group, who lead their fundraising and community engagement. The charities the Community Champions chose to support at the event included: Thriving Pink, Helping Yolo County Breast Cancer Survivors Thrive, Friends of the Needy Food Bank, New Beginnings, Ending Domestic Violence by empowering survivors and community awareness, and lastly Dixon Family Services, striving to reduce and prevent child abuse and provide supportive services to children and families in Dixon. Guests could play a game of cornhole for an opportunity to voice how those funds would be dispersed.

Guests were also invited to a local restaurant for a hosted dinner with the Powerscreen of California team.

XPO 24 was filled with fun, games and hands-on experiences. Powerscreen of California and its sister companies, Powerscreen of Washington and Powerscreen Western, showed its combined strength in the market, as well as a strong commitment to customer service. Customers also experienced first-hand their knowledge in multiple industries, including aggregate processing, quarrying, mining, recycling, washing, construction and demolition, waste, landscaping, forestry, scrap, ports and other environmental sectors.

(All photographs in this article are Copyright 2024 Construction Equipment Guide, Except Where Noted. All Rights Reserved.) CEG

photo

Powerscreen of California, Nevada & Hawaii’s XPO logistics team provides guests with cold water, sunscreen and various branded merchandise, ensuring the best experience for their guests. (L-R): Amelia Hopley, Amy McNab, Steve Hughes, Annalea Ormiston, Suzanne Quinn, Jordan Fontaine, Richard Gilliver and James Dodkins.

photo

Representatives from Associated Equipment Distributors were impressed at the scale of XPO 24. (L-R): Jacob Asare, AED; James Dodkins, Molson Group; Andrew Gillen, Powerscreen of California, Nevada & Hawaii; Robert Henderson and Nichole Stoltz of AED; and Jordan Fontaine, Powerscreen of California, Nevada & Hawaii.

State-of-the-art engineering down to the smallest detail. The new gen 8 mid size wheel loaders feature a dynamic travel drive for increased productivity a d improved fuel consumption. www.liebherr.com

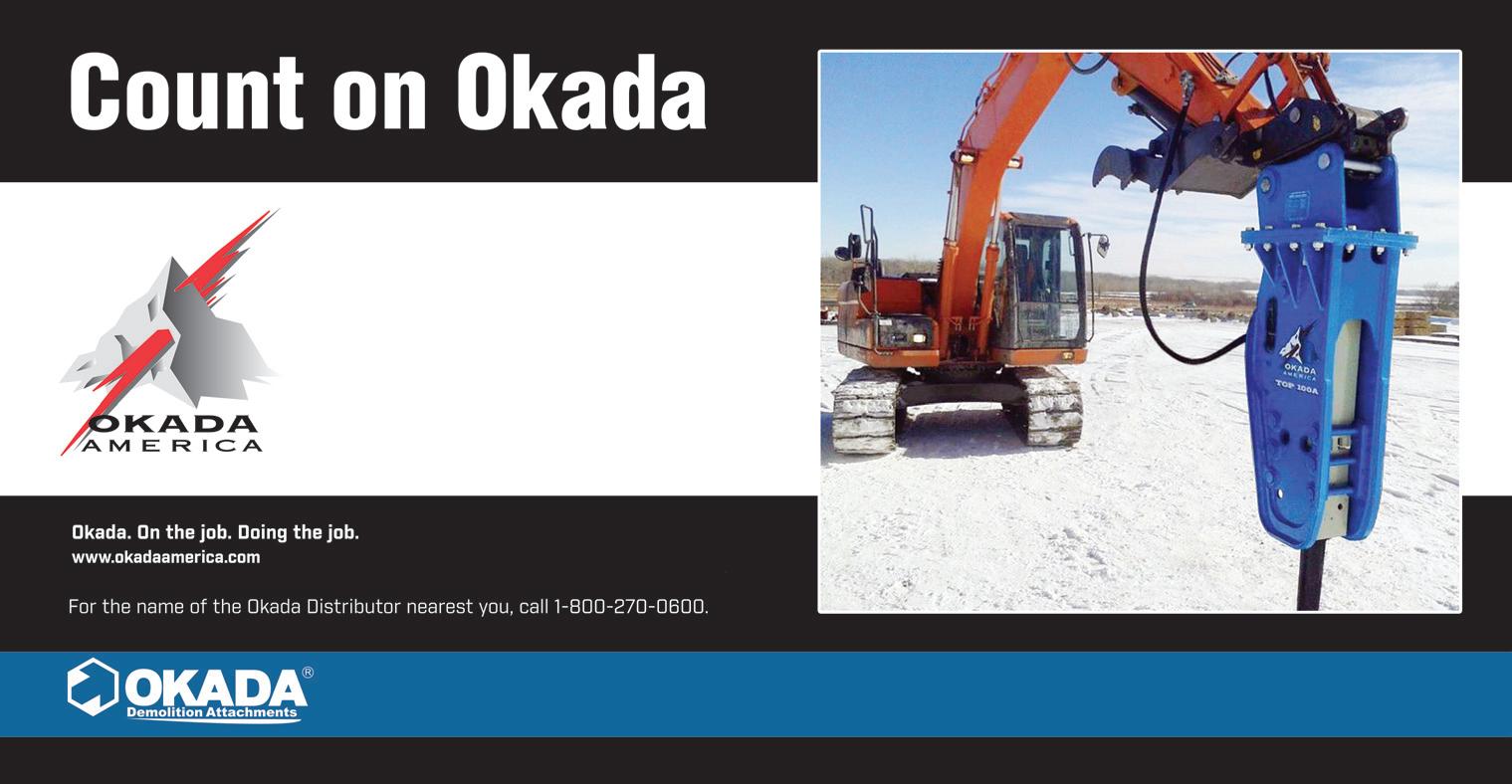

Effectively Handle Your Primary and Secondary Demolition Applications with NPK’s Newest Model V250R! (Suited for 24-35 metric ton carriers)

baconuniversal.com

HAWAII

Honolulu (Oahu): 808-839-7202

Wailuku (Maui): 808-244-9158

Hilo: 808-935-8595

Kailua-Kona: 808-326-1212

Lihue (Kauai): 808-245-8472

geehm.com

CALIFORNIA

Fresno: 559-834-3149

Redding: 530-229-3820

Santa Rosa: 707-544-4147

West Sacramento: 916-375-3540

kirby-smith.com

McAlester: 918-310-1550

Oklahoma City: 405-495-7820

Tulsa: 918-438-1700

Abilene: 325-692-6334

Amarillo: 806-373-2826

Dallas: 214-371-7777

Ft. Worth: 817-378-0600

Hewitt: 254-261-1370

Lubbock: 806-745-2112

Odessa: 432-333-7000

Anchorage: 907-275-3300

Fairbanks: 907-371-1501

tristatetruckandequip.com

MONTANA

Belgrade: 406-388-5815

Billings: 406-245-3188

Great Falls: 406-452-9551

WYOMING

Casper: 307-472-1818

Rock Springs: 307-362-4000

Almost four dozen emerging leaders in the transportation design and construction industry completed an intensive introduction to federal legislative and regulatory issues May 13-15 during the American Road & Transportation Builders Association (ARTBA) Foundation’s Industry Leader Development Program (ILDP).

The ILDP, held in conjunction with the association’s Federal Issues Program and the Transportation Construction Coalition Fly-In, provided participants with a solid understanding of industry economics, how transportation work in the United States is funded and financed, how actions by the federal government impact the industry, and how they — and their company or agency — can become politically engaged.

ILDP attendees also met with their members of Congress to discuss ongoing implementation of the bipartisan infrastructure law.

The 2024 class included:

• Taylor Augustine, Michigan Paving and Materials, Canton, Mich.

• Troy Barnwell Brooks, North Carolina Department of Transportation, Raleigh, N.C.

• Kyle Chism, Parsons, Louisville, Ky.

• Richard Crochetiere, Reeves Construction, a Colas Company, Duncan, S.C.

• Neesha A. Desai, Gannett Fleming Inc., New York, N.Y.

• Chris Dillman, Ralph L. Wadsworth Construction, Draper, Utah

• Haley Duit, Duit Holdings Inc., Edmond, Okla.

• Nick Duncan, CRH/Callanan Industries, Albany, N.Y.

• Emily Gallo, HNTB Corp., New York, N.Y.

• Daniel Aaron Garcia, Texas Department of Transportation, Pharr, Texas

• Robby Graham, Cone & Graham Inc., Tampa, Fla.

• David Greenberg, CRH, Atlanta, Ga.

• Michael Izzo, TranSystems Corporation, Baltimore, Md.

• Mi Hyeon [Christy] Jeon, AtkinsRealis, Atlanta, Ga.

• Matthew D. Justice, Harrison Construction Company, APAC-Atlantic, Inc., Knoxville, Tenn.

• Jessica Kiesel, Ajax Paving Industries of Florida LLC, North Venice, Fla.

• Lane Kimble, Wisconsin Transportation Builders Association, Madison, Wis.

• Vance Koonce, The Lane Construction Corporation, Cheshire, Conn.

• Cathleen Kratz, Texas Department of Transportation, Austin, Texas

• Radha Krishna Swayampakala, RS&H, Charlotte, N.C.

• Patricia Lencki, CRH/PJ Keating, Lunenburg, Mass.

• Jeremiah Leyba, Michigan Infrastructure & Transportation Association, Okemos, Mich.

• William Linehan, CRH, New Britain, Conn.

• Ryan Matthew Macander, TranSystems Corporation, Lisle, Ill.

• Michelle Martin, WSP USA, Virginia Beach, Va.

• Brian McGarity, Superior Construction Company Southeast, LLC, Jacksonville, Fla.

• Matthew Miltner, The Lane Construction Corporation, Charlotte, N.C.

• Caleb Mulzer, JH Rudolph a CRH Company, Tell City, Ind.

• Junell O’Donnell, Parsons, Chicago, Ill.

• Andrew Parks, Branch Civil, Inc., Mooresville, N.C.

• Shannon Ramos, Texas Department of Transportation, Lufkin, Texas

• Lisa Rottmann, Stowers Machinery Corporation, Knoxville, Tenn.

• Paul Schmitz, Tensar, a division of CMC, Alpharetta, Ga.

• Chris Segur, Parsons, Sacramento, Calif.

• Andrew Shelton, Branch Civil, Inc., Chesapeake, Va.

• Meagan Smyth, Skanska USA Civil, East Elmhurst, N.Y.

• Jim Splendoria, Aldridge Electric Inc., Libertyville, Ill.

• Andrew J. Taylor, The Shelly Company, Thornville, Ohio

• Heath Thompson, Rogers Group, Cookeville, Tenn.

• Rachelle VanDeventer, Michigan Infrastructure & Transportation Association, Okemos, Mich.

• Connor VanSteenberg, AGC of Texas, Fort Worth, Texas

• Kush Vashee, RK&K, Fairfax, Va.

• Jaclyn Weaber, Pennsy Supply/CRH, Harrisburg, Pa.

• David Austin Williams, Terracon Consultants, Inc., Springfield, Mo.

More than 850 graduates from over 200 industry firms and public agencies have completed the ILDP since 1996. HNTB, one of the world’s leading infrastructure firms, is the program’s exclusive sponsor.

For more information, visit artba.org.

JCB began work on a new $500 million factory in San Antonio, Texas — the biggest investment in the company’s history.

An official groundbreaking ceremony at the site marked the beginning of construction, where The Hon. Alice Bamford, the daughter of company Chairman Anthony Bamford, turned the first shovelful of dirt on the property.

Work on the 720,000 sq. ft. factory is now under way on the 400-acre site. It will be the company’s second largest plant, rivalled only by JCB’s world headquarters in Rocester, Staffordshire, England, and create 1,500 new jobs over five years. The factory will make Loadall telescopic handlers and aerial access equipment, with production scheduled to start in 2026. The factory also will have the capacity to expand and build other products in the future.

Chairman Lord Bamford said, “Construction equipment manufacturers sell more than 300,000 machines every year in North America, making it the single largest market in the world. JCB has been growing its share of this important market steadily over the past few years and the time is now right to invest in our manufacturing capacity in North America, where we already have one factory.

“JCB really has come a considerable way since we sold our first machine here 60 years ago and it gives me immense pleasure to see how our business has grown in North America. Today really is a milestone day in the history of our family company,” Bamford said.

“Texas was this year named as The Best State for Business for a record-breaking 20th year, and I am proud to welcome JCB as the newest business to call our great state home,” said Gov. Greg Abbott. “Today’s groundbreaking marks a major milestone in JCB’s journey that will create 1,500 goodpaying jobs for hardworking Texans in Bexar County and bring hundreds of millions of new capital investment to San Antonio and beyond.

(L-R) are Adriana Rocha Garcia, city of San Antonio Councilwoman District 4; David Carver, operations director, JCB San Antonio; Rep. John Lujan, Texas House of Representatives District 118; Alice Bamford; Lord Bamford, chairman, JCB; Cecilia Abbott, First Lady of Texas; Mark Turner, chief operating officer, JCB; Rebeca Clay-Flores, Bexar county commissioner, Precinct 1; Richard Fox-Marrs, president and CEO, JCB North America; and Jenna Saucedo-Herrera, president and CEO, greater SATX. In addition to the traditional gold shovels, the groundbreaking ceremony for the new JCB San Antonio facility featured the iconic JCB backhoe loader, as well as the JCB 220X large excavator.

“‘Made in Texas’ is truly a powerful global brand, and I look forward to celebrating JCB’s continuing success as we work together to build a bigger, better Texas for decades to come.”

JCB CEO Graeme Macdonald said, “JCB’s business in North America has made tremendous progress in the past few years and the opportunity for growth here is vast. This record investment gives us a fantastic opportunity to build on our success and we look forward to the completion of this great new facility.”

Richard Fox-Marrs, president and CEO of JCB North America, said, “The Loadall telescopic handler is JCB’s biggest selling product in North America and it is also the single largest market for aerial access equipment worldwide, and therefore, it makes

great sense to build these two ranges here.

“Texas is an obvious choice for our new North American manufacturing facility, not least because the state is the largest consumer of construction equipment in the USA. San Antonio is also the logical choice as a location for our new factory because of its central location, proximity to the supply chain and great local labor force. We are really excited about JCB’s new San Antonio factory and for the future of our business in North America,” said Fox-Marrs.

JCB sold its first machine in North America in 1964 and opened its first U.S. manufacturing plant in 2001 in Savannah, Ga., which employs 1,000 people. The new facility will manufacture machines for customers specifically in North America.

JCB employs 19,000 people globally and

has 22 factories around the world, including 11 in the UK, seven in India, and others in Brazil and China. The company will mark its 80th anniversary in 2025.

For more information, visit www.jcb.com.

(All photos courtesy of JCB.)

Part of the extensive equipment lineup from Powerscreen of California, Nevada & Hawaii is the

line.

Powerscreen of California, Nevada & Hawaii is a fullservice location with a massive inventory of parts and equipment.

A BTA160 breaker was used in the balloon challenge. Guests were in the cab popping balloons for this fun challenge.

POWERSCREEN from page 8

James Dodkins (L) of Molson Group and Matt Gansser of HD Hyundai Construction Equipment North America. Hyundai is the newest addition to the Powerscreen equipment lineup.

Powerscreen photo

Powerscreen of California, Nevada & Hawaii team, along Molson Group, bring XPO 2024 to a close after days and weeks of hard work. (L-R): Eoin Fox, Jason Powles, Ollie Marshall, Ted Powell, Mick Crimmins, Jack Saward, Jordan Pendergrass, Tony Corr, Shaun Bates, Adam Waldron, Amy McNab, James Dodkins, Annalea Ormiston, Graham Henderson, Steve Hughes, Amelia Hopley, Ben Heywood, Luis Guzman, Jordan Fontaine and Darren Kane.

This Powerscreen is loaded and ready to transport to a customer.

Powerscreen of California, Nevada & Hawaii has a full fleet of service trucks ready to keep contractors on the job without delays.

Niece Water Towers deliver reliability and durability when you need fast mobile water service. With a 12” discharge tube it fills your tanks at a rate of over 1,000 gallons per minute. Offers removable power pack for security, fifth wheel tow hitch, professionally engineered and constructed.

It features (8) legs for stability

5th wheel set up for quick “tow and go.”

Associated Equipment Distributors (AED) announced the addition of Jacob Asare to its government affairs team. This expansion reaffirms AED’s dedication to providing comprehensive support and advocacy for its members while enhancing its overall influence in the industry.

Asare holds a B.A. in political science from California State UniversitySacramento and joins AED with more than 10 years of experience in government affairs, most recently serving as government affairs specialist for the California Association of Health Facilities (CAHF).

Asare’s role will enhance and extend AED’s reach within individual states.

Based in Sacramento, Calif., Asare will serve as AED’s state government affairs manager and will focus on the equipment industry’s policy priorities in California, Arizona, Colorado, Hawaii, Nevada, Utah and Wyoming.

“We are excited to further expand the reach of our government affairs program to ensure the equipment industry’s voice is heard in state capitals and enhance AED’s value proposition,” said Daniel B. Fisher, senior vice president of government and external affairs.

Asare’s appointment represents a strategic effort by AED to expand its influence and advocacy to the state level. While AED has successfully championed legislative priorities for equipment dealers nationwide,

“Arguably what happens at a state and local level is more impactful on day-to-day operations than the federal government, and the addition of Jacob will ensure that AED will have a seat at the table as state policy debates occur.”

Trackhouse Racing and Kubota just launched a sweepstakes perfect for any NASCAR superfan where they can win an exclusive VIP experience at Miami-Homestead Speedway and the choice of a second trip for an exclusive tour of Trackhouse Racing’s headquarters in Concord, N.C, or $1,000.

Between now and Aug. 30, fans can enter for a chance to win a trip for two to Miami for a VIP experience at Homestead-Miami Speedway from Oct. 26 to 28, which includes roundtrip airfare for two, two nights’ hotel accommodations, two tickets to the race, pit road access for Saturday’s practice, a tour of the pits, garage and hauler, a meet-and-greet with Ross Chastain, and access to watch the race from pit road and a tour of the pit box.

The winner also receives their choice of a

second trip for an exclusive tour of Trackhouse Racing’s headquarters in Concord, N.C., (approximate value $2,650) or a check for $1,000. Approximate Retail Value (“ARV”) of the Grand Prize: $6,450 or $4,800, depending on choice of prize. No purchase necessary; a purchase will not increase your chances of winning. Open only to legal residents of the 50 U.S. states and Washington, D.C., 21 years of age and older. Void where prohibited by law. Sweepstakes end at 11:59 p.m. CT on 8/30/24. Subject to Official Rules, including how to enter, prize details, odds and restrictions, see info.kubotausa.com/vipraceday. Sponsor: Kubota Tractor Corporation, 1000 Kubota Drive, Grapevine, TX 76051. To enter and for more information, visit www.KubotaRaceVIP.com.

www.cpower.com

9200 Liberty Drive

Liberty, MO 64068

816-781-8070

Wichita, KS

316-943-1231

Great Bend, KS

620-792-1361

Liberal, KS

620-624-7274

Woodward, OK

580-256-6014

Salina, KS

785-825-8291

Colby, KS

785-462-8211

Springfield, MO

417-865-0505

Joplin, MO

417-726-5373

Riverside, MO

816-415-6787

Wichita, KS

316-789-7370

Yukon, OK

405-324-2330

Maryland Heights, MO

314-427-4911

Liberty, MO

806-415-6700

Tulsa, OK

918-984-6565

Engineered to boost the accuracy and productivity of your operation, the John Deere 333G SmartGrade™ Compact Track Loader (CTL) delivers precise grading performance while limiting technology includes the operator-friendly DozerMode Control system to enable intuitive crawler operation, with the Deere-designed and purpose-built six-way SG96 Dozer Blade powering the push. This skillful solution is designed to quickly and easily elevate your grades. It all adds up.

JohnDeere.com/SmartGradeCTL

HEAVY MACHINERY SERVICES www.doggettequipment.com 9111 North Freeway Houston, TX 77037 713-679-6700

Beaumont, TX 409-842-1754 Bryan, TX 979-823-1905

Corpus Christi, TX 361-289-0727

San Juan, TX 956-787-0001 Victoria, TX 361-570-6666

Alexandria, LA 318-442-0455

Baton Rouge, LA 225-291-3750

Broussard, LA 337-837-9481

Covington, LA 985-893-3005

Longview, TX 903-758-3326

Lufkin, TX 936-634-8801

Monroe, LA 318-343-8787

Shreveport, LA 318-631-3090

St. Rose, LA 504-466-5577

Tyler, TX 903-592-8900

The hard-hitting MAX-Series™ VT-100 gives you the tools to impr The vertical-lift machine excels in loading and grading applications

r ove productivity while working comfortably. in landscaping and construction.

CLM Equipment Co. Inc. www.clmequipment.com

3135 US Hwy 90 East

Broussard, LA 70518 337-837-6693

4851 E Napoleon Road Sulphur, LA 70663 337-625-5942

2815 N Sam Houston Pkwy E Houston, TX 77032 281-598-2500

City Equipment www.jetcityequipment.com 33345 SR20 Oak Harbor, WA 98277 360-675-4441 10219 State Avenue Marysville, WA 98271 360-651-9079 2713 Euclid Avenue Wenatchee, WA 98801 509-888-8181

www.romco.com

Dallas (Carrollton), TX 214-819-4100 Austin, TX 512-388-2529 Corpus Christi, TX 361-881-4891 Ft. Worth, TX 817-626-2288

Longview, TX 903-758-5576 Mercedes, TX 956-565-0100 San Antonio, TX 210-648-4600

Stephenville, TX 817-626-2288

Equipment www.rgwequipment.com

700 W. Mossdale Road Lathrop, CA 95330 925-606-2477

550 Greenville Road Livermore, CA 94550 925-606-2403

6904 Banigan Road Anderson, CA 96007 925-606-2437

Liebherr appointed Alexandra Hobgood as general manager of corporate responsibility and sustainability.

This position will oversee sustainability initiatives throughout Liebherr’s U.S. locations by educating stakeholders, implementing new processes and providing additional structure to current programs.

With a desire to positively affect her local community, Hobgood worked at the Hampton Roads Sanitation District where she completed lab work and water testing. She later transitioned to the Virginia Aquarium where Hobgood developed a taste for program management implementing safety and environmental programs for the aquarium.

As the new general manager, Hobgood is excited to continue building a strong program with potential initiatives including redirecting waste streams, diverting organics to composting, and completing energy studies.

“There are a lot of great processes

Liebherr photo Alexandra Hobgood

already being implemented at Liebherr, so the structure for building a strong program is already in motion,” said Hobgood. Hobgood plans to improve Liebherr’s current sustainability processes by not only implementing new programs but verifying they are

being utilized and maintained throughout Liebherr’s U.S. locations.

“I am excited to add in my own intent, heart and passion to help excel the program,” she said.

For more information, visit www.liebherr.com.

www.PacWestMachinery.com

8207 South 216th Street Kent, WA 98032

206-762-5933

Mount Vernon, WA 360-588-3083

Portland, OR 503-252-5933

Eugene, OR 541-343-6926

Spokane Valley, WA 509-534-5933

Pasco, WA 509-547-5933

www.rgwequipment.com

700 W. Mossdale Road Lathrop, CA 95330 925-606-2477

550 Greenville Road Livermore, CA 94550 925-606-2403

6904 Banigan Road Anderson, CA 96007 925-606-2437

1519 W Belt Line Road Carrollton, TX 75006 214-819-4100

Austin, TX 512-388-2529

Carmine, TX 979-278-3570

Ft. Worth, TX 817-626-2288

Houston, TX 713-937-3005

San Antonio, TX 210-648-4600

Buffalo, TX 903-322-5602

Corpus Christi, TX 361-881-4891

Mercedes, TX 956-565-0100

Stephenville, TX 254-266-2871

www.vcesvolvo.com

Bakersfield, CA 661-387-6090

Corona, CA 951-277-7620

Fresno, CA 559-834-4420

Sacramento, CA 916-504-2300

Lakeside, CA 619-441-3690

Redding, CA 279-201-4869

San Leandro, CA 510-357-9131

Turlock, CA 209-410-6710

A global competition to find the very best of the best Volvo technicians has concluded after a 12-month endurance test of skills, knowledge, stamina and teamwork across all elements of aftersales operations.

The team from Volvo dealer KSS Korea were named the well-earned winners of Volvo Masters 2024 — following an intense Grand Final at the Customer Center in Eskilstuna, Sweden, the headquarters of Volvo CE.

Some 2,235 participants from 634 teams took part in one of the largest collaborative learning experiences of its kind, from 134 Volvo dealers worldwide. Now in its 34th year, the epic contest is respected in the industry as an exciting way to showcase the talents of the many accomplished parts and service technicians working across Volvo CE’s dedicated dealer network.

Putting to the test their expertise in aftersales operations, the 14 teams who made it through to the Grand Final were tasked with six challenges on excavators, articulated haulers, wheel loaders, engines, electromobility and used equipment. Each challenge was based on the very latest solutions and technologies, with electromobility and digitalization playing a more prominent role than ever before.

Jan Fogelberg, Masters global lead at Volvo CE, said, “Volvo Masters is an exceptionally grueling experience and really tests the skills of our aftersales teams from around the world. Each time we put on this competition, we focus on coming up with more and more sophisticated and diverse challenges, and each time we are always overwhelmed at the expertise and passion on display.

“Huge congratulations, not only to the winners who really proved they had the spirit to get to the top, but to everyone whose engagement and dedication to take on any challenge, no matter how hard, is a testament to the high standards to which our customers hold Volvo CE and our incredible dealer network.”

New for 2024 was an arguably more high-pressured environment — with the grand final taking place in front of a live audience of guests at the customer center in Eskilstuna, creating a more sporting atmosphere. Just like the real thing, where customers expect optimum uptime to keep their busi-

ness operations running as smoothly as possible, the technicians were required to juggle the demands of the task with the need to complete it as quickly as possible.

The win by KSS Korea came after a nail-biting contest. Taking the silver medal was SMT Netherlands, while third and fourth place were won by Zhejiang Liyang from China and Ascendum Portugal respectively.

Two Volvo dealer teams each from Europe, Asia, China, North America, Latin America, India and Region International took part in the grand final on May 6-8. They qualified after six months of regional finals on home ground, which followed the first phase of the competition, involving three online rounds of questions and assessments.

The global competition brings different cultures and ways of working together. It is a great motivator for participants, as well as a boost to the reputation of hard-working technicians around the world.

(All photos courtesy of Volvo.)

Phoenix, AZ 480-545-2400

Phoenix, AZ 602-252-7121

Prescott, AZ 928-778-5621

Tucson, AZ 520-623-8681

Bakersfield, CA 661-695-4830 Mojave, CA 661-824-2319 Perris, CA 909-355-3600

*Formerly Road Machinery

www.wpi.com

12320 S. Main Street Houston, TX 77035 713-723-1050 Buffalo, TX 903-322-7150 Bryan, TX 979-314-1191

Corpus Christi, TX 361-884-8275 Edinburg, TX 956-386-0107

Kilgore, TX 903-984-2011

Lufkin TX 936-243-6056

Pflugerville, TX 512-251-0013 Port Arthur, TX 409-721-5305 San Antonio, TX 210-648-4444 Tomball, TX 281-351-9016

www.powermotivecorp.com Corporate Office 5000 Vasquez Blvd., Denver, CO 80216 303-355-5900 Colorado Springs, CO 719-576-5541 Grand Junction, CO 970-241-1550 Milliken, CO 970-587-1188 Cheyenne, WY 307-634-5149 Durango, CO 970-259-0455 Albuquerque, NM 505-345-8383 Bloomfield, NM 505-324-8601 Carlsbad, NM 505-485-1700 El Paso, TX 915-872-1001 Chandler, AZ 602-986-3003 Phoenix, AZ 602-463-3772 Tucson, AZ 520-649-2858

www.geehm.com

5461 S Nikita Avenue Fresno, CA 93725 559-834-3149

1164 Prestige Way Redding, CA 96003 530-229-3820

3650 Seaport Blvd. West Sacramento, CA 95691 916-375-3540

3350 Regional Parkway Santa Rosa, CA 95403 707-544-4147

TX 817-378-0600

CA 858-278-8338

Caterpillar Inc. released its latest reports highlighting the company’s environmental, social and governance (ESG) commitment, record financial accomplishments and contributions to helping customers build a better, more sustainable world.

“We’re pleased to highlight the great strides the Caterpillar global team is making in executing our strategy and investing for long-term profitable growth. These reports tell the stories of our outstanding 2023 financial results, sustainability progress and active participation in the public policy process,” said Caterpillar Chairman and CEO Jim Umpleby.

“Our employees’ diverse backgrounds and experiences and strong focus on serving our customers contributed to delivering the best year in our nearly 100-year history in 2023.”

Highlights include:

• The Annual Report reviews how the global team delivered the best year in Caterpillar’s nearly 100-year history as the company continued executing its strategy for long-term profitable growth.

• The Sustainability Report provides an in-depth look at progress over the past year and how the company is helping its customers achieve their climate-related goals.

• The Task Force on Climate-related Financial Disclosures (TCFD) Report provides information about how the company governs climate-related opportunities and risks.

• The Diversity & Inclusion Report provides comprehensive information on Caterpillar’s progress to continue build-

These reports tell the stories of our outstanding 2023 financial results,sustainability progress and active participation in the public policy process.”

Jim Umpleby Caterpillar

www.garton.co

Turlock, CA • 209-632-3931

Fairfield, CA • 707-425-9545

Merced, CA • 209-726-4600

Modesto, CA • 209-538-0911

Newman, CA • 209-862-3760

Santa Rosa, CA • 707-586-1790

Stockton, CA • 209-948-5401

Tulare, CA • 559-686-0054

Ukiah, CA • 707-468-5880

Woodland, CA • 530-615-2828

Madera, CA • 559-674-2496 Fresno, CA • 559-485-9090

www.clmequipment.com

Lafayette, LA 337-837-6693 Lake Charles, LA 337-625-5942

ing an inclusive culture, representation advancements and key initiatives from the past year.

• The Lobbying Report, The Purpose of Engagement, outlines how we advocate for a policy and regulatory environment that supports our long-term success and provides value to shareholders.

For more information, visit caterpillar.com/reports.

Peer Executive Groups (PEG) has named the winners of its 2024 Top Gun Awards.

The Top Gun award recognizes businesses who receive the PEG Award for Financial Excellence. The awards are given to the top 25 percent of rental operators based on financials verified by Peer Executive Groups. This is the sixth year that PEG has named companies for this prestigious award.

“We apply owner compensation, expense, and rent tests to verify EBITDA and check financial reports and tax returns where appropriate. While our network shows EBITDA performance closer to 28 percent, our Top Gun members average north of 40 percent,” said President Dan Crowley.

The 2024 winners for Equipment Rental include:

• Austin Wilson, A to Z of NC

• Troy Roper, A-1 rentals Idaho

• Alexx Bacon, Aaberg’s Tool and Equipment Rental

• Tony Murray, American Rentals

• Beth Hoff Blackmer, Aspen RentAll

• Allan Haynsworth, Atlantic Lift Systems

• Garret Shurling, Badger Equipment Rental

• Meghan Boland, Boland Equipment Rental

• Steve Mau, Brainerd General Rental

• Tyler Doherty, Cal-West Rentals

• Kyle Keely, Chet’s Rent-All

• Matt Crawford, Far West Rentals

• David Betz, Goggin Rentals

• Tom Kirksey, Make Equipment

• Dillon Hughes, Only 1 Rentals

• Steve Berner, Rabern Rentals

• Kevin Reim, Redtail Rentals

• Isaac Black, Rent-All Equipment

• Eric Barron, Rent Ready Equipment

• Jaco du Plessis, Talisman Equip Rentals

• Haley Hennessey, Tates Rents

• Matt Musgrove, Tejas Equipment Rentals

• Chris Jarrett, Time Rentals

• Kurt Barney, Vandalia Equipment Rental

• Jeff Wiesman, Wood Street Rental Peer Executive Groups administers peer groups in variety of industries. Within the rental industry, more than 255 participants learn from each other in 25 peer groups.

www.banemachinery.com Dallas, TX 800-594-2263 Ft. Worth, TX 800-601-2263 Tyler, TX 800-594-2200

Columbiawesternmachinery.com 11125 SW Tonquin Road Sherwood, OR 97140 503-454-0902

The first portion, $174 million, began in June 2022 and has an anticipated completion date in fall 2025. In addition to widening, crews are reconfiguring ramps, reconstructing existing frontage roads, adding safety lighting and making operational improvements.

The second portion, also from the New Mexico State Line to SH 20 (North Mesa Street), is based on an accelerated Rack and Stack Program. The lane widening is 3.2 mi., going to six lanes and reconstructing the existing four lanes. The work also includes 11.2 mi. of aesthetic and landscape improvements, which Sundt will begin in late summer.

Each side of I-10 will have three 12-ft.-wide lanes and 10ft.-wide inner and outer shoulders. Furthermore, entrance/exit ramps are being reconfigured to X-pattern ramps throughout the limits of the project, auxiliary lanes will be implemented between ramps for additional safety and operational improvements, and the I-10 profile will be adjusted at existing overpass intersections in order to comply with TxDOT’s vertical criteria for Freight Corridors. The project will also upgrade the existing drainage systems in order to account for revisions to existing flow patterns as a result of the curb and gutter.

Sundt has met several benchmarks, with work continuing on roads, bridges, ramps and underground infrastructure.

Of the 36 bridges included in the first portion of work, 33 are being reconstructed and three are being refurbished.

The typical lengths are between 120 ft. and 300 ft. and have three lanes in each direction. Instead of demolishing whole bridges at one time, the plan has been to retain half of a bridge and rebuild the other half. Sundt has crews working on several bridges simultaneously.

“Cat 336 excavators with punches and pulverizers and press down upon the concrete,” said Vincente Garner, Sundt’s project superintendent. “As they move from bridge to bridge, the crews are honing their work.”

This project has 490,000 cu. yds. of dirt excavation and 455,000 cu. yds. of embankment.

The new bridges have one to two spans. Shafts are drilled between 6 ft. and 99 ft. deep.

“The average shaft is 36 inches wide and 30 feet deep,” said Jeff Danaher, Sundt’s project manager, who noted that cranes lift and place concrete beams to serve as a base for the deck.

The lengths of the beams range from 40 ft. to 108 ft. There are many different types of beams being used on this project, from 5XB20s up to TX54s.

This project has 490,000 cu. yds. of dirt excavation and 455,000 cu. yds. of embankment.

“The choice of beam depends upon the lengths and loads determined by the engineering design,” said Danaher.

There is nearly 89,000 ft. of new concrete barrier being installed on both the inside and outside shoulders of the highway and ramps. In some locations where concrete barrier is not required, there will be over 37,000 ft. of new metal beam guard fence placed.

There is a tremendous amount of roadwork.

The original asphalt lanes are being replaced with concrete lanes. The original lanes, the outer ones, are being rebuilt and the new lanes, two on each side, are placed in the median area.

For new and old lane construction, there are excavation, site prep and concrete pouring crews.

“It’s almost like a moving train,” said Danaher. “You have different disciplines going through.”

K-rail separates the crews building the new lanes from the constant traffic.

“We’ve already removed the asphalt from the existing lanes,” said Garner, who pointed out that the new lanes consist of a 6-in. subgrade, 12 in. of concrete and 4 in. of asphalt.

“The road work is going fairly well.”

The installation of the underground infrastructure, which is taking place at the same time as the construction of the new lanes, consists of storm drains, water lines and other elements.

Work on the frontage lanes and the rebuilding of ramps is also taking place simultaneously, using similar construction

techniques.

“We have a lot of lane reversals for the frontage roads,” said Danaher.

The Sundt management team includes project engineers and a team of experienced superintendents.

“We have an effective team dynamic,” said Danaher. “This is the first time Vinny and I are working together. We have a few people on the job that have worked together for quite a while.”

“The crews are working day and night, six days a week,” said Garner. “They are putting in long hours, working hard, and producing. They don’t hold back.”

Busy days have 200 Sundt and subcontractor personnel on-site. Sundt has hired Tri-State, Allied Paving Company, A Brothers Milling, Hernandez Concrete Pumping, Concrete Pumping Inc, Atwell, Apache Barricades, Hardy Hole Drilling, Pavement Markings LLC, CTC Innovations, Major Motion Logistics, Crane Services Incorporated, A-Core, Hawk Construction, National Wire, Scott Derr Painting and HDW Construction & Drilling Inc.

Efforts are ongoing to recycle as many materials as possible, with steel sent to recyclers.

“Where we can, we are using concrete rubble as fill,” said Danaher. “We’re milling the asphalt and stockpiling it at a TXDOT yard. They are using it for miscellaneous maintenance work and other purposes.”

With such a large amount of equipment on-site, maintenance is critical to meet benchmarks, be it daily repairs or routine maintenance.

“Wear and tear is mainly punctures of hoses, tires and hydraulic cylinders. Typical stuff,” said Garner. “We have on-site mechanics to do the repairs.”

Sundt crews are using a mixture of its own fleet and rented equipment. The company purchases and rents equipment from Sunstate Equipment, Wagner, Herc Rentals and United Rentals

The dealerships provide spare parts and repair models that they supply.

The construction is taking its toll on roads in the work zone.

“There is an overuse of frontage roads and alternate routes,” said Wright. “Pothole repairs can be done within a couple of days.”

Danaher noted that the roads and bridges his crews are replacing were well constructed.

“The portion of roadway we are working on is 30-plus years old and we had a bridge that was built in the 1970s,” he said. CEG

(All photos courtesy of Sundt Construction.)

The future highway-class BOMAG CR 1030 Series 10-ft. track paver, available for the 2025 paving season, features multiple design updates that improve operating efficiency and increase mat quality by reducing segregation occurrence. Additionally, the manufacturer is introducing the Versa 20 front mount screed, a new addition to the family of BOMAG screeds.

The Versa 20 Front Mount screed gives BOMAG’s customers more versatility for their paving needs, according to the manufacturer.

The new human-machine interface (HMI) features grouped functions on tractor console and a new screed control system with integrated MOBA automation features. For the console, similar functions such as the hopper, screed and feed controls are grouped together to allow the operator quicker identification and adjustment.

BOMAG photo

New for the CR 1030 T Series is the independent auger/conveyor system, with a proven outboard auger drive system. This new design allows the conveyors and auger to run independently of each other, with a 2 or 4 (optional) sensor control system.

The large, 7-in. multifunction color screen display at each console boasts a new experience for the operator with multiple configurable detailed screens. That’s a thoughtful design feature to accommodate various operator preferences and working conditions. By providing both a touchscreen display and a remote dial control option, operators can easily navigate and adjust settings even in situations where using a touchscreen may be impractical, such as when wearing gloves. This ensures that operators can maintain control and access critical functions and gauges without any hindrance, ultimately contributing to smoother operations and improved efficiency on the job.

The new Versa 20 frontmount electric screed on display with the CR 1030 T paver, which will be offered on the new series of pavers, offers infinitely variable paving widths ranging from 10 to 19 ft. at paving thicknesses reaching 12 in. Bolton screed left- and righthand extensions — available in 12-in., 18-in. and 24in. widths plus optional 12in., 18-in., or 24-in. berm screed plates — give contractors ultimate flexibility to vary paving widths up to a maximum, 23-ft.

Quick connections for these bolt-on extensions provide both heat and vibration for increased mat quality. The screed comes standard with a 10-ft. catwalk and foldable walkway extensions for the operator.

Overall, this feature demonstrates a proactive approach to maintenance and service, ultimately leading to improved reliability and customer satisfaction, the manufacturer said.

New for the CR 1030 T Series is the independent auger/conveyor system, with a proven outboard auger drive system. This new design allows the conveyors and auger to run independently of each other, with a 2 or 4 (optional) sensor control system. The raisable or fixed outboard driven auger system, which is a proven product from the CR Remix paver design, will vastly improve visibility into the conveyor discharge area, as

Incorporating fault code visibility on the touchscreen monitor is a smart feature for enhancing machine serviceability and troubleshooting efficiency. By alerting operators to paver issues directly on the monitor, they can promptly address any problems that arise during operation. This real-time feedback enables quick identification and resolution of machine issues right at the job site, minimizing downtime and maximizing productivity.

well as eliminate segregation in that area, resulting in better mat quality, according to the manufacturer.

The new BOMAG CR 1030 T rubber track paver on display at World of Asphalt, March 25-27, 2024, was powered by the 225 hp (167.7 kW) Cummins QSB 6.7 engine meeting the latest emission standards. Operator visibility into the 14-ton hopper is enhanced by the paver’s sloped hood design. It retains many of the legacy CR series features, including optional FRAME RAISE with fixed augers to improve mat quality and SMARTRAC system that automatically maintains proper track tension to significantly increase track life.

BOMAG’s exclusive SIDEVIEW innovation allows each seat and console to swivel outward at four different angles for unobstructed views to the paver sides and screed end gate.

The 11-in. deep hydraulic extensions, with manually adjustable angle of attack, allow for better density and mat quality than others in the front mount class. The hydraulically powered crown for the Versa 20 can be adjusted from 3-in. positive to 1-in. negative. The newly designed screed controls and remotes allow for better operator experience as well as accommodating special features like integrated MOBA automation.

Borrowing from the European BOMAG screed family design, robust telescopic tubes increase screed rigidity to minimize deflection at extended paving widths. Incorporating the proven tipping frame and match height features from the Stretch 20 Screed, the new Versa 20 is designed to better maintain setting adjustments between the main frame and extensions for a more consistent mat texture across the entire paving width, according to the manufacturer. For more information, visit www.bomag.com.

BANE MACHINERY, INC.

MACHINERRY

www.banemachinery.com

2449 Manana R (214) 352-2468 (817) 847-5894 (903) 597-6641

2449 Manana Dr. Dallas, TX 75220 (214) 352-2468

Ft. Worth, TX (817) 847-5894

Tyler, TX (903) 597-6641

CLAIREMONT EQUIPMENT

7651 Ronson Roa San Diego, CA 92 (858) 278-8351 1330 W Mission Ro Escondido, CA 92 (760) 739-9100

www.clairemontequipment.com

(318) 442-0455

7651 Ronson Road

Baton Rouge, LA (225) 291-3750

San Diego, CA 92111 (858) 278-8351

1330 W Mission Road

Broussard, LA (337) 837-9481

Escondido, CA 92029 (760) 739-9100

Covington, LA (985) 893-3005

440 West Aten Road

(337) 430-3045

Imperial, CA 92251 (760) 355-7700

Monroe, LA (318) 343-8787

4726 Convoy Street

Shreveport, LA (318) 631-3090

BEE EQUIPMENT SALES LTD.

www.beeequipmentsales.com

2506 Slaton Highway Lubbock, TX 79404 (806) 745-1511

West Reno A (800) OKC-BOYD • (405 Ardmore, OK (866) 720-2693 • (580) Lawton, OK (800) 633-2693 • (580) /

K 224-2693 /355-6667

C. L. BOYD CO., INC. www.clboyd.com

COOPER EQUIPMENT CO.

www.cooperequip.com

(409) 842-1754 Boise, Idaho (208) 336-8670 Jerome, Idaho (208) 324-4522 (800) 829-4450

5210 N Loop 1604 E San Antonio, TX 78247 (210) 657-5151

201 Commerce Blvd. Georgetown, TX 78626 (512) 930-5151

6532 East Highway Rhome, TX 7607 (817) 708-9108

21910 FM 2252

Schertz, TX 7815 (210) 732-2131

4220 West Reno Ave. Oklahoma City, OK 73107 (800) OKC-BOYD • (405) 942-8000

Ardmore, OK (866) 720-2693 • (580) 224-2693

Lawton, OK (800) 633-2693 • (580) 355-6667

13800 FM 973 N Manor, TX 78653 (512) 272-8200

San Diego, CA 92111 (858) 278-8338

St. Rose, LA (504) 466-5577

Beaumont, TX (409) 842-1754

Bryan, TX (979) 8231905

Corpus Christi, TX (361) 289-0727

Houston, TX (713) 679-6700

Longview, TX (903) 758-3326

EQUIPMENT www.closner.com

6532 East Highway 114 Rhome, TX 76078 (817) 708-9108

21910 FM 2252

Lufkin, TX (936) 634-8801 San Juan, TX (956) 787-0001

Schertz, TX 78154 (210) 732-2131

MODERN MACHINERY

www.modernmachinery.com

Corporate Office

Missoula, Montana (409) 842-1754

Boise, Idaho (208) 336-8670

Jerome, Idaho (208) 324-4522

Pocatello, Idaho (800) 829-4450

ROAD MACHINERRY Y www.roadmachinery.co 902 S. 7th Street X g (800) 304-4421

Billings, Montana (800) 735-2589

Spokane, Washington (800) 541-0754 om n COOPER EQUIPMEN www.cooperequip.

13800 FM 973 N Manor, TX 78653 (512) 272-8200

5210 N Loop 1604 San Antonio, TX 78 (210) 657-5151 201 Commerce Blv Georgetown, TX 78 NT CO. .com

18851 GH Circle

E 8247 vd. 8626 (903) 592-8900 Victoria, TX (361) 570-6666

Waller Industrial Park Waller, TX (936) 525-9949

Columbia Falls, Montana (800) 434-4190

Eugene, Oregon (800) 826-9811

Portland, Oregon (800) 950-7779

Kent, Washington (800) 669-2425

Phoenix, AZ 85034 (480) 545-2400 Prescott, AZ (928) 778-5621 Tuscon, AZ (520) 623-8681 (661) 695-4830 Perris, CA (909) 355-3600

Rochester, Washington (800) 304-4421

Spokane, Washington (800) 541-0754

After two days of hosting dealers and guests for its “Power Days Demo” event south of Atlanta, FAE USA territory managers and representatives from coast-to-coast gathered May 10, 2024, at a site in the picturesque city of Dawsonville, in north Georgia.

The event provided an in-depth training session of the company’s paving products. At the heart of the demo was the new series of skid steer- and compact track loader-mounted RPL/SSL series of road planers, which were just introduced in 2023 at ConExpo and come in three working widths (18 to 30-in., widths). FAE touts these compact road planer attachments as a “must” for small scale and fine milling in conjunction with all larger milling jobs.

FAE also demonstrated the FAE MTL 175, which has been on the market for quite some time. This PTO-driven product line has evolved in design and focus over the years and re-engineered to fall into FAE’s “multitask” line, which allows the maximized usage of the attachment as a stabilizer, stone crusher or asphalt shredder/miller.

And an FAE RCU-75 remote-controlled forestry mulcher provided support during the event. This compact tracked mulcher assisted in removal of vegetation overgrowth at the demo site. In addition to practicing their paving product skills, FAE managers mastered their abilities on operation of these remote-controlled mulching units while at the training session.

CEG

(All photographs in this article are Copyright 2024 Construction Equipment Guide. All Rights Reserved.)

Machine/attachment details and tips from the experts for the products about to be showcased required a bit of classroom time beforehand.

Adrian

and

discuss optimal operation of the remote-control unit for the RCU-75 before putting the machine to work.

Closner Equipment

www.closner.com

Rhome, TX 817-708-9108

Schertz, TX 210-732-2131

Manor, TX 512-272-8200

www.pacwestmachinery.com

Seattle, WA 206-762-5933

Spokane, WA 509-534-5933

Pasco, WA 509-547-5933

Mt Vernon, WA 360-588-3083

Waller, TX 936-525-9949 PacWest Machinery

Portland, OR 503-252-5933

www.power-equip.com

Farmington, NM 505-326-1413

Durango, CO 970-247-8830

Denver, CO 303-288-6801

Eugene, OR – Branch 541-302-3762 Power Equipment Company

Colorado Springs, CO 719-392-1155

Grand Junction, CO 970-243-0722

Greeley, CO 970-353-1224

Albuquerque, NM 505-345-7811

Tri-State Truck and Equipment

www.tristatetruckandequip.com

Belgrade, MT 406-388-5818

Billings, MT 406-245-3188

Casper, WY 307-472-1818

Great Falls, MT 406-452-9551

wwwshaferequipmentco.com

Sparks, NV 208-801-7772

Rock Springs, WY 307-362-4000 Shafer Equipment

www.boxcerequipment.com

Tulsa, OK 918-272-7237

Efficiency and Productivity

Designed with safety and operator comfort in mind, the Shuttle Buggy® material transfer vehicle features adaptive cruise control, bright LED lighting, four-wheel steering for easy transport and ground-level maintenance access for added convenience. Operators can rely

and

astecindustries.com

Engineered with a blend of durability, reliability and operator simplicity, the STPH is poised to revolutionize road maintenance across the globe, according to the manufacturer.

Stepp Manufacturing, a leading innovator in asphalt maintenance equipment, unveiled its latest breakthrough in road repair technology at World of Asphalt 2024: the STPH asphalt pothole patch truck.

Engineered with a blend of durability, reliability and operator simplicity, the STPH is poised to revolutionize road maintenance across the globe, according to the manufacturer.

Designed to tackle the most demanding road maintenance needs, the STPH offers a comprehensive suite of features that empower operators to achieve unparalleled efficiency and precision. From the optional on-board tack tank system to the compactor plate carrier, spoils bin, hydraulic jackhammer, and air blowout options, the STPH is the ultimate patching body for any road maintenance task.

At the heart of the STPH lies its oil-jacketed diesel heating system, setting a new standard for heating efficiency and material quality. With automatic temperature controls and a stainless-steel burner liner, the system ensures consistent and even heating of patch materials, minimizing waste and maximizing performance. Additionally, the 6 in. by 3/8 in. AR 400 hardened auger and auger trough, coupled with the hydraulic direct drive, guarantee smooth and reliable material delivery.

to tackle even the toughest repair challenges with confidence and ease.”

Key features of the STPH include:

• Oil Jacketed for the smoothest heating system on the market.

• 6 in. by 3/8 in. AR 400 hardened auger and auger trough, and hydraulic direct drive.

• Automatic temperature controls with diesel burner.

“With its advanced features and user-friendly design, the STPH empowers road maintenance professionals to tackle even the toughest repair challenges with confidence and ease.”

Stepp Stepp Manufacturing

• Internal oil jacketed baffle to provide heat to the middle of the hopper where it’s needed the most.

• 270-degree full opening hydraulic top doors.

“The STPH represents a significant leap forward in pothole patching technology,” said Jason Stepp, VP/ national sales manager of Stepp Manufacturing. “With its advanced features and user-friendly design, the STPH empowers road maintenance professionals

• Folding shovel pan that allows you to dispense material directly on the road for large patches.

• Stainless steel burner liner.

• Electric over hydraulic system. For more information, visit www.steppmfg.com.

The CP100II sets the standard for versatility, component lifecycle and mat quality. With a powerful 100 horsepower engine, an array of configurations and the class-leading Carlson EZCSS single slide screed, it’s easy to see why the CP100II is the ideal choice for heavy-duty commercial paving.

The Carlson CP100 II sets the standard for versatility, component lifecycle and mat quality. With a powerful 100hp engine, an array of configurations and the class-leading EZCSS single slide screed, it’s time to see why the CP100 II has fast become the contractor’s choice for heavy-duty commercial paver platforms.

LeeBoy, an industry leader in commercial asphalt paving equipment, and Portable Electric (PE), a leading manufacturer of portable and mobile e-Chargers and eGenerators, are working together to advance the electrification of the asphalt paving industry.

Introduced at ConExpo, LeeBoy’s 8520C E-Paver is a commercial-class electric asphalt paver that utilizes various electric vehicle components and propulsion technologies supplied by General Motors, engineering assistance from Engine Power Source and Powertrain Control Solutions. This prototype serves as a demonstration of the electrification potential within the commercial asphalt paving sector.

During a recent demonstration, the Voltstack 30k, an all-in-one mobile site power and equipment charger, played a key role in successfully charging the 8520C E-Paver, ensuring maximum uptime performance. LeeBoy is utilizing the Voltstack 30k unit as both companies collaborate to explore future solutions for paving electrification.

Voltstack mobile electric equipment chargers are designed to promote electric machinery adoption and provide a versatile on-site power solution at construction job sites. The Voltstack 30k e-Charger offers a range of charging solutions while serving as a silent, emission-free on-site power source. Its innovative “Smart Hybrid” feature seamlessly integrates with traditional gas or diesel generators, optimizing efficiency and reduc-

ing carbon emissions.

“We are excited to collaborate with LeeBoy in electrifying the paving industry,” said Keith Marett, CEO of Portable Electric. “This collaboration marks the beginning of an exciting journey to redefine how paving is done, focusing on efficiency, innovation and the ability to meet future demands of the industry.”

“Working with Portable Electric is a significant step forward. The Voltstack ecosystem will play a crucial role in ensuring the success of our electric equipment and maximizing uptime on our construction projects,” said Chris Broome, senior product manager at LeeBoy.

“Today, with the Voltstack Level 2 e-Charger, we have the ability to recharge the paver for 15 minutes at Level 2 and get an extra 19 tonnes of asphalt. In terms of future solutions, Level 3 is critical to our success. With Level 3 charging, the same 15minute charging window will lead to an additional 57 tonnes of asphalt. That extra production will be game-changing.”

For more information, visit LeeBoy.com and portable-electric.com.

closner.com

6532 East Highway 114 Rhome, TX 76078 817-708-9108

21910 FM 2252 Schertz, TX 78154 210-732-2131

13800 FM 973 N Manor, TX 78653 512-272-8200

18851 GH Circle Waller Industrial Park Waller, TX 936-525-9949

5980 S M L King Jr Pkwy Beaumont, TX 77705 409-746-5102

202 I-35 Frontage Road Belton, TX 76513 254-613-1500

2800 Hwy 290 E Brenham, TX 77833 979-836-6641

1875 N Earl Rudder Fwy Bryan, TX 77803 979-779-8942

1512 Neptune Dr. #9706 Clinton, OK 580-323-3422

ascoeq.com

2019 Airport Fwy Euless, TX 76040 817-283-2844

980 N Sam Houston Pkwy E Houston, TX 77032 281-987-1990

6203 Long Drive Houston, TX 77087 713-649-0940

27500 E University Drive Aubrey, TX 76227 972-441-2726

12805 US-290 E Manor, TX 78653 512-272-8922

7100 SW 3rd Street Oklahoma City, OK 73128 405-789-6812

902 SE 9th Avenue Perryton, TX 79070 806-435-7773

1920 S East Loop 410 San Antonio, TX 78220 210-333-8000

3600 US-82 Sherman, TX 75090 903-893-7586

401 FM 148 Terrell, TX 75160 972-563-2171

12210 E 1st Street Tulsa, OK 74128 918-437-5085

2602 E Front Street Tyler, TX 75702 903-593-0201

2900 Henry S Grace Fwy Wichita Falls, TX 76302 940-687-2726

beeequipmentsales.com

2506 East Slaton Highway Lubbock, TX 79404 806-745-1511 855-813-3775

nixonegli.com

2044 S. Vineyard Avenue Ontario, CA 91761 909-930-1822

800 E. Grant Line Road Tracy, CA 95304 209-830-8600

2750 Marion Drive Las Vegas, NV 89115 702-342-8100

Nine children of highway workers who were killed or permanently disabled on the job will receive post-high school financial assistance for the 2024-25 school year thanks to the American Road & Transportation Builders Association (ARTBA) Foundation’s “Lanford Family Transportation Construction Worker Memorial Scholarship.”

The program was established with a gift from two Roanoke, Va., highway contractors and their companies — Stan Lanford (1999 ARTBA chairman) of Lanford Brothers and Jack Lanford (1991 ARTBA chairman) of Adams Construction Company. Scholarships have a value of up to $10,000 annually.

The 2024 class includes:

• Amy McNeil, Lumberton, Texas — Amy’s father, Jeffrey McNeil, was killed in 2005 while working for the Texas Department of Transportation. Amy is a graduate student pursuing her master’s degree in nursing from the University of Texas, Arlington.

• Jenna Jares, West, Texas — Jenna’s father, Gregory Jares, was killed in 2001 while working for the Texas Department of Transportation special crews. Jenna is a graduate student studying occupational therapy at the University of Mary Hardin-Baylor in Belton.

• Breana Jones, Gaston, S.C. — Breana’s father, Standra “Stan” Jones Sr., died in 2007 after being struck by a vehicle while at work for the South Carolina Department of Transportation. Breana will be entering her junior year at

Winthrop University studying graphic design.

• Katie & Christopher Hutt, Cleveland, Tenn. — Katie’s father, Chris, was struck and killed in 2006 while installing signage for United Rentals in a highway work zone. Katie will be a senior studying architecture at the University of Tennessee (UT), Knoxville. Chris’ son, Christopher, will be a freshman studying chemical engineering also at UT Knoxville.

• LaToya Hood, Houston, Texas — LaToya’s father, Paris Hood Jr., was killed on a roadway project while working for the Texas Department of Transportation in 1998. LaToya will be returning to Texas Southern University as a junior to complete her degree in healthcare administration.

• Zoe Watts, Marshall, Ark. — Zoe’s father, James “Kirk” Watts, was killed by overturned equipment while working for the Arkansas Department of Transportation in 2018. Zoe will be a freshman studying nursing at the Univ. of Central Arkansas.

• Christopher “Tyler” Montgomery, Greenville, Miss. — Tyler’s father, Christopher Montgomery, also was killed by overturned equipment while working on a bridge project for Austin Bridge & Road in 2011. Tyler will be a freshman studying physical education at Arkansas State University.

• Bethany Rains, Memphis, Ark. — Bethany’s father, James “Bubba” Rains, died in 2013 while working for APAC in Tennessee. Bethany will be pursuing an undergraduate certificate in Nursing Assistance (CNA) at Arkansas State University, Mid-South. For more information, visit artbafoundation.org.

Brooke’s House, a rehabilitation center in Hagerstown, Md., dedicated to aiding women in recovery, has received $100,000 from Manitowoc and $50,000 from its dealers and customers.

The partnership has proven mutually beneficial, with Manitowoc employing nearly 20 Brooke’s House graduates who have gained valuable occupational skills and job training while recovering from substance abuse.

Manitowoc

(L-R) are David Hull, Ion Warner and Aaron Ravenscroft, all of Manitowoc; Kevin and Dana Simmers, Brooke’s House; and Les Middleton, Jennifer Peterson, James Cook, Brian Regan and Chase Seely, all of Manitowoc.

Dave Hull, Manitowoc’s general manager of mobile cranes, North America, shared the story behind the partnership during a customer event at the company. He praised the efforts of Kevin and Dana Simmers, founders of Brooke’s House, and expressed his admiration for the initiative, the commitment of Manitowoc’s executive team to support the cause, and funding from the Manitowoc Foundation.

“I’ve known Kevin for 35 years and

MECOM EQUIPMENT www.mecomequipment.com 4546 N Wilson Way, Stockton, CA 95205 209-466-5135

JET CITY EQUIPMENT www.jetcityequipment.com

33345 SR 20, Oak Harbor, WA • 360-675-4441 Marysville, WA • 360-651-9079 Wenatchee, WA • 509-888-8181

R & S INDUSTRIES, INC. www.rsindinc.com 951 CR G, Clovis, NM 88101 575-769-8659

I understand the journey that he and Dana have been on. I’m incredibly proud of my company for supporting Brooke’s House. Every person on the stage here has visited Brooke’s House, met the women, and witnessed the real impact of our support. This is not just a partnership, it’s a commitment to building something real and meaningful in our community,” Hull said.

Kevin Simmers also spoke at the

event, discussing Brooke’s House’s origin and future goals, including expanding mental health services by building a $1.5 million equine therapy facility. He emphasized the importance of community and industry support in making a difference.

“We’re extremely grateful. Manitowoc gives Brooke’s House graduates the chance to join its workforce and build a new life. The support we’ve received from Manitowoc and its community truly exemplifies what makes this country great. Thank you all very much,” Simmers said.

The partnership between Manitowoc and Brooke’s House dates back to 2020. In 2023, a small ceremony marked the designation of a restored bungalow in Hagerstown, where some of Brooke’s House graduates live, as “The Manitowoc House.”

For more information, visit www.manitowoc.com.

MAKE YOUR MOVE

Push

... more material with the new Hyundai HD100 crawler dozer's best-inclass power-to-weight ratio.

See

...more than ever with the unobstructed view to the blade.

Engage

...more accurately and more productively with standard 2D or optional 3D machine guidance.

Doze

...with confidence, knowing your new 115 hp Hyundai crawler dozer delivers the quality and value you expect from Hyundai, with the peace of mind that comes with our industry-leading warranty.

No wonder so many first-time Hyundai users become longtime fans. See the Hyundai difference yourself at your local dealer, na.hd-hyundaice.com.

At the recent World of Asphalt Show & Conference in Nashville, thousands of attendees took advantage of the show’s education conference, aptly named the People, Plants and Paving Conference by the National Asphalt Pavement Association (NAPA).

In the People track, AI: The Road to Efficiency, Insight and Innovation in Asphalt, was led by XBE CEO and Founder Sean Devine.

XBE, an operations management software company for the horizontal construction industry, developed “Hey NAPA”, an artificial intelligence search engine. The platform has been trained on hundreds of NAPA publications and can provide answers and resources to a variety of asphalt pavement questions.

“It’s good at technical things, business related things, and at giving management advice,” said Devine during his presentation. “It’s good at a lot of things and it’s totally free.”

Devine walked attendees through examples of how to engage with “Hey NAPA” to solve issues rising up on the job including:

• Creating a public information plan to soothe residents upset about the cost and disruption caused by a project.

• Explain to an asphalt foreman the impact to cost and quality of mixing asphalt at too hot a temperature.

Devine also encouraged attendees to consider implementing AI platforms outside of “Hey NAPA” into their companies. He explained these tools can help managers and staff on a variety of topics, including:

• safety plans

• advertising

• and even streamlining payroll systems.

Devine shared AI platforms are constantly evolving and improving.

“I anticipate by summer of 2024, we’ll see an entirely new generation of [AI] models released, enabling even more amazing things,” said Devine.

Devine also urged company owners and leaders to consider developing AI policies and strategies to set clear expectations with employees.

“When running an organization, model behavior from the top,” said Devine. “People are looking to you for permission and encouragement. If you show you’re not afraid, they won’t be afraid.”

Education at World of Asphalt’s People, Plants & Paving Conference and the AGG1 Academy totaled more than 120 sessions. Some of the most popular sessions included Best Practices for Milling & Profiling, Best Practices for Residential & Commercial Paving, and Relational Leadership.

Held every year except during ConExpo-Con/AGG years, World of Asphalt is the leading trade show and conference focused on the asphalt and paving industries. The show features the best education, and latest equipment, products, services and technologies for the asphalt and paving industries.

The next World of Asphalt, co-located with the AGG1 Academy & Expo, will be held March 25-27, 2025, in St. Louis, Mo. World of Asphalt is majority owned by NAPA and partially owned by AEM, who produces the show.

For more information on World of Asphalt, visit www.WorldOfAsphalt.com.

Bobcat Company, a global equipment, innovation and worksite solutions brand, has expanded its product portfolio with the introduction of forklifts; industrial air compressors; turf renovation equipment; and portable power products including air compressors, generators and light towers.

“Through our unwavering commitment to innovation and excellence, we have significantly broadened our product portfolio to not only meet the needs of our loyal customers but also to inspire and empower new customers to conquer their toughest job site challenges,” said Scott Park, CEO and vice chairman of Doosan Bobcat Inc.

“With an expanded range of solutions, we’re empowering even more customers to accomplish more.”

These products are now available at select Bobcat dealerships throughout North America. Last year, Bobcat announced Doosan Industrial Vehicle, Doosan Portable Power, Doosan Industrial Air and RYAN turf renovation products would change to the

6715 W. Reno Ave Oklahoma City, OK 73127 800-375-3339

4617 Powell St. McAlester, OK 74501 918-310-1550

12321 E. Pine St. Tulsa, OK 74116 800-375-3733

12035 Interstate 20 W Abilene, TX 79601 877-577-5729

3922 I-40 E Amarillo, TX 79103 800-283-1247

3419 E Slaton Rd. Lubbock, TX 79404 866-289-6087

7301 E Interstate 20 E Odessa, TX 79765 877-794-1800

415 Enterprise Blvd. Waco (Hewitt), TX 76643 254-261-1370

Bobcat brand as part of the organization’s global brand strategy. All product lines have officially rebranded under Bobcat in North America with transitions on these product lines also happening globally in applicable markets.

Customers can now purchase these Bobcat branded products, which

includes:

• Forklifts: Internal combustion cushion and pneumatic tire forklifts, electric counterbalance forklifts, narrow aisle forklifts, pallet trucks/stacker forklifts and warehouse vehicles.

• Industrial air: Industrial air compressors ranging from 30- to 200-hp, with both fixed and variable speed offerings.

• Turf renovation equipment: Aerators, sod cutters, dethatchers, overseeders and other specialty products that serve landscaping and grounds care professionals across a variety of industries including golf, sports turf, landscaping and rental.

• Portable power: Air compressors ranging from 185 to 1600 CFM, mobile generators ranging from 25 to 570 kVA and light towers with runtime up to 105 hours.

Customers can search bobcat.com/dealer to find their local dealer offering these newly rebranded Bobcat products.

(Photo courtesy of Bobcat.)

www.witchequipment.net 7717 Highway 69

Realistic Scale Models of Construction Equipment, ideal gifts for the Holidays, Birthdays,

Chalmers HD-3 Dozer w/Backhoe, 1:16 scale - $200

Case 580SR Backhoe/Loader, 1:50 scale - $160

By Lucy Perry CEG CORRESPONDENT

Electric-powered equipment is nothing new to job sites. Manufacturers have been developing battery-powered machines for years before the fed adopted its goal of zero emissions by 2050. But now mobile crane manufacturers are setting their own zero-emission goals and rolling out new models that use no diesel fuel. Though many are taking a wait-and-see attitude, the road is wide open for a sustainable crane market.

The crane industry “must be open-minded and bold to break new ground,” said Gerhard Frainer, managing director, sales of Liebherr-Werk Nenzing.

“If you go out about three years, there will be approximately 700 different types of electric vehicles roadside,” said David Knight, CEO of Terbine.

The company provides technology for the exchange of IoT data between the mobility and energy sectors. He spoke at ConExpo in March.

Knight urged the construction industry to prepare for the widespread adoption of electric vehicles in the not-too-distant future. He noted five main reasons equipment end users in the construction industry in general are investing in electric machinery.

Lower operating costs, lower maintenance costs, federal and state tax credits, carbon credits and offsets and environmental, social and corporate governance (ESG) goals all play a part.

First, the savings on diesel costs, alone, are significant, he said. Most OEMs cite four to eight hours of runtime for average use on electric compact equipment, with an eighthour overnight charge.

There’s no idle on an electric machine. An operator can get a day or more of productive work in because they’re not running a machine for eight hours a day.

Knight pointed out that reciprocating engines possess many friction-generating parts, which fail. The friction and heat generated with a running engine are really what contributes to parts replacement and maintenance.

Incentives can offer savings in the tens of thousands, or even hundreds of thousands of dollars, across a single fleet.

As Knight explained it, carbon credits, also known as carbon allowances, “work like permission slips” for emissions. When a company buys a carbon credit, usually from the government, they gain permission to generate one ton of CO2 emissions. When one company removes a unit of carbon from the atmosphere as part of their normal business activity, they can generate a carbon offset. Other companies can then purchase that carbon offset to reduce their own carbon footprint.

ESG goals are trending and expected to become more common with time, said Knight. Without goals and corresponding policies, organizations risk loss of investors, a damaged reputation and fines for regulatory noncompliance.

There is every reason to believe the electric vehicles and electric equipment will continue to develop and improve over time, said Knight.

This evolution, in turn, will make a greater level of adoption even more likely in the very near future.

The architectures of electric vehicles are going to even higher voltages, he said. The higher the voltage, the less current needed. That also means less heat. And, while voltages are very good now, they are expected to improve signifi-

cantly in the coming years, he said.

“They’re going to be really good in three to five years, and that’s going to allow for even faster and more efficient charging than ever before.”

At ConExpo this year, more than one construction crane manufacturer unveiled new electric-powered models. Here are two stand-out introductions.

To show it means business, Tadano adopted a new motto to mark the occasion: “Our True Mission: Zero Emissions.”

“This shows that we’re on the right path with Our True Mission: Zero Emissions and our Tadano Green Solutions,” said Toshiaki Ujiie, CEO. “We’ll be able to achieve our sustainability goals in our role as a highly innovative company that is aware of its responsibility towards our world.”

He said, too, the company will “take on a trailblazer role in our industry with our technologically leading solutions.”

Tadano is committed to reducing CO2 emissions from its business activities by 25 percent and from the use of its products by 35 percent by 2030.

The Houston, Texas, crane manufacturer’s ultimate goal is to be completely climate neutral by 2050. Corporate has grouped its sustainability solutions under Tadano Green Solutions (TGS), and includes fully electric rough-terrain cranes.