By Irwin Rapoport CEG CORRESPONDENT

Five general contractors — Teichert, Vanguard Construction, Dees Burke Engineering Constructors, Granite Construction and Q&D Construction — are engaged in emergency repairs on California’s Interstate 80 in Placer, Nevada and Sierra counties, an initiative that began approximately one year ago.

According to Caltrans, the agency performed an extensive field review of the I-80 corridor in 2023 and found an unprecedented amount of damage. Several areas exhibited moderate to high levels of rutting due to chain

Dees Burke Engineering Constructors, Granite Construction, Teichert, Vanguard Construction and Q&D Construction are engaged in emergency repairs on California’s Interstate 80 in Placer, Nevada and Sierra counties.

wear and required immediate repair. Five emergency contracts were executed in 2023 for the repairs, along with an additional four emergency contracts in 2024, totaling $107.4 million.

In addition to repairing ruts, crews from the general contractors are replacing concrete slabs.

“Where roadway structural section is structurally sound, but in need of wheel rut repair,” said Jason Fritz, granite’s area manager, of the scope of work needed. “A polyester concrete inlay is being placed to replace just the

see CALIFORNIA page 28

By Lucy Perry CEG CORRESPONDENT

The prefabrication concept is nothing new in the bridge sector. Temporary bridges have long provided a smart solution when routes are lost. But the prefab process is being incorporated into transportation construction in new areas. Water and rail are two infrastructure sectors being served successfully with prefab components. A growing number of contractors are looking to the prefab process to get jobs done more quickly and safely. see PREFAB page 48

construction industry considers prefabrication a good solution for the worker shortages on job sites across the country.

Laymor SM400, Stk#: 12756, EROPS, A/C & Heat, 593 hrs., Water System, 8 ft. Broom, 225x75Rx15 Tires, 4 Cy. Kubota Eng $29,500

2018 John Deere 750K LGP,

Technology

USDOT’s Federal Highway Administration announced the immediate availability of $6 million in “quick release” emergency relief funds for WYDOT to offset the costs of repairs in the Teton Range caused by a landslide in early June.

Two Powerscreen dealerships of the UK-based Molson Group announced the addition of Hyundai construction equipment to their growing portfolio of leading brands.

Gov. Gavin Newsom recently announced that the Wallis Annenberg Wildlife Crossing outside of Los Angeles is on track to open by early 2026.

During Mental Health Awareness Month, ConExpo-Con/AGG is demonstrating its commitment to construction professionals by donating $5,000 to the Construction Industry Alliance for Suicide Prevention (CIASP).

18 EPIROC USA LAUNCHES FIRST BOLTEC M10 BATTERY RIG IN U.S.

Epiroc, a global mining equipment leader, has successfully introduced the first Boltec M10 Battery rig in the United States at Nevada Gold Mines. This marks a significant step toward greener practices in the mining industry.

Founded in 1923, Nippon Pneumatic Manufacturing Co. Ltd. (NPK Japan) established itself as a manufacturer of air tools and expanded into chemical processing equipment production in 1945.

32 TRACTOR & EQUIPMENT COMPANY KEEPS ‘GOING THE EXTRA MILE’

‘Going the extra mile’ has been the company philosophy since Tractor & Equipment Company (TEC) first opened its doors back in 1943. Over the years, it has been paying dividends, and that continues today.

44 LIEBHERR USA APPOINTS GREER AS NEW DIVISIONAL

Greer brings 20 years of experience to lead the U.S. mining division. As divisional director, Greer will be responsible for managing the team of Liebherr sales, service and training staff for the mining equipment product range.

44 CAT GRADING BEAMS DELIVER HIGH PRODUCTIVITY MATERIAL GRADING

New Cat grading beams for Cat tiltrotators allow contractors to take on dynamic and efficient grading and compaction work using excavators.

49 REMEMBERING FELLING TRAILERS’ KEVIN ATHMANN

Kevin Athmann, beam welder operator, joined the Felling Trailers team in November of 1999, initially working with the Finishing team, and then transitioned to weld production.

50 THUNDER CREEK EXPANDS TRUCK UPFIT FUELING, SERVICE SOLUTIONS

Thunder

More than 600 items were up for sale, including late model Cat, John Deere, Komatsu and Link-Belt machines, along with utility equipment, aerial lifts, forklifts, trucks, trailers and attachments.

The U.S. Department of Transportation’s Federal Highway Administration (FHWA) recently announced the immediate availability of $6 million in “quick release” emergency relief funds for the Wyoming Department of Transportation to offset the costs of repairs in the Teton Range caused by a landslide in early June. The funds also will be used to build a safe, temporary detour near the Wyoming-Idaho border that restores critical access to popular tourist destinations such as Jackson Hole, Yellowstone National Park and Grand Teton National Park.

“The Teton Pass is a key route for workers

and visitors traveling between Idaho and Wyoming and the emergency funding we’re sending will help reopen and restore access to this important roadway as quickly as possible,” said U.S. Transportation Secretary Pete Buttigieg. “In discussing the situation with the Wyoming Department of Transportation, it has been clear how urgent the need is to support their efforts to reconnect one of the region’s heavily traveled mountain thoroughfares - and to make our infrastructure more resilient to future weather events.”

“The Federal Highway Administration is

working closely with the Wyoming Department of Transportation to repair the damage caused by the landslide at Teton Pass,” Federal Highway Administrator Shailen Bhatt said. “The Emergency Relief funding we are providing will help get repairs done as soon as possible and restore temporary access to the area during the busy summer tourist season.”

On June 8, Wyoming State Highway 22, also known as Teton Pass, experienced a catastrophic landslide causing a complete loss of the roadway at Mile Post 12.8. Another landslide occurred a day earlier at mile post 15, covering the highway in mud and debris. No vehicles were on the highway at the time of the collapse and there were no injuries reported.

Crews have been working continuously to clean up the water, mud and debris that’s been coming down the mountain at Mile Post 15. And at Mile Post 12.8, crews are working as quickly as possible to build the detour around the highway failure.

Wyoming Gov. Mark Gordon issued an executive order on June 8 declaring an emergency in response to both landslides. Wyoming DOT crews are evaluating the stability of the area and are assessing potential safety hazards. State geologists and engi-

neers are confident they can build a safe, temporary, two-lane detour around the slide area within a few weeks using local fill material with likely weight and width restrictions.

Drainage improvements, including a box culvert at the mudslide site at Mile Post 15, are also planned to be added while work on the temporary roadway is taking place. The goal is to restore essential traffic flow between Wyoming and Idaho for the residents, commuters and tourists who rely on this critical roadway to reach their destinations. Without a direct route, a normal 30min. commute can take an hour and a half.

On June 17, during his visit to Cheyenne, Buttigieg received operational updates on the emergency response to the landslide.

State officials and the US Forest Service are working to provide access to recreation areas and trails outside the slide area and to place signage on the roads to allow users to access campsites unaffected by the closure.

FHWA’s Emergency Relief program provides funding to states, territories, Tribes and Federal Land Management Agencies for highways and bridges damaged by natural disasters or catastrophic events.

(Photo courtesy of Wyoming Department of Transportation.)

By Luke Hill SPECIAL TO CEG

Technology is changing the way operators complete their work.

The latest equipment models can come equipped with polished yet practical features such as rear-view cameras, high-definition screens, sensors, telematics and autonomous control. These features not only improve accuracy and operator control but also reduce downtime — keeping your team productive and protecting your bottom line.

Depth check technology is no exception. Investing in this type of technology for your next compact excavator purchase can pay dividends in the long run. Its efficacy is proven throughout a variety of applications.

Bobcat digs deeper into why today’s groundbreakers are embracing grade indication technology for their compact excavators.

Grade indication technology like Bobcat’s Depth Check System eliminates the need for operators to exit the compact excavator cab to manually check the grade or depth.

Leveraging the capabilities of a Depth Check System improves the productivity of

your team by keeping them in the cab and focused on the task at hand. It also eliminates the need for another individual to be onsite.

The “grade stake” worker would now be available to operate a different machine on the same job site or tackling another task and driving revenue for the business.

Additionally, Depth Check technology improves machine productivity overall for your compact excavator. Tasks such as trenching for utility lines, digging basements or placing drainage ditches can be performed with improved ease, speed and effectiveness. This type of consistency reduces the time associated with backfilling, compacting fill material or manual labor to finalize a job site depth or grade.

alerts signal target depths or notify them that they’ve gone too far.

Bobcat’s E32-E88 compact excavator models can be equipped with the optional Bobcat Depth Check System technology — making the machines even more versatile, valuable and efficient than before.

Precision and accuracy are important on every job site, but this is especially true if a new operator on your team has had limited hours in the cab. There is undoubtedly a learning curve when it comes to managing and maneuvering construction equipment.

Advanced technology systems like Depth Check can prove beneficial for both new and seasoned operators to improve accuracy on the job and prevent rework from under- or over-digging.

ment requires accurate calculation and control.

Investing in Depth Check technology empowers operators to make more informed decisions during their dig, adjust or reposition as needed to avoid mistakes that lead to additional work and costs of correcting mistakes.

When used correctly, technology can be a major asset to your fleet of equipment — especially your compact excavators. At Bobcat, Depth Check technology is available for E32-E88 compact excavators — both short and long arm models — and can be installed on the machine through a dealership at any time.

Bobcat E48E88 compact excavator models come Depth Check ready where mounting provisions for the sensors are provided as standard equipment. This makes the installation quicker and more affordable for the end user, according to the manufacturer.

The intuitive technology of Depth Check system uses sensors that detect the position of the bucket’s teeth or cutting edge, allowing operators to set their desired dig depth and work against the benchmark. When an operator approaches grade point, audible

Operators may find themselves in work environments that are uniquely challenging and complex — from working around water lines and fiber optic cables to busy roadways and bridges where every machine move-

Digging, trenching and grading with accuracy is difficult work that requires an incredible amount of attention and care, and utilizing Depth Check technology is one way to make the job easier on your operator and more profitable for your business. (Luke Hill is a product specialist at Doosan Bobcat.)

Realistic Scale Models of

Two Powerscreen dealerships of the UKbased Molson Group announced the addition of Hyundai construction equipment to their growing portfolio of leading brands.

Through their locations in Dixon, Calif. (near Sacramento); Reno, Nev.; and Helena, Mont., the dealerships — Powerscreen of California, Nevada and Hawaii, and Powerscreen of Washington — will sell and service the full HD Hyundai Construction Equipment North America product line to customers in California, Nevada and Montana.

The addition of Hyundai mass excavators, wheel loaders, wheeled excavators and hydraulic breakers will provide a more comprehensive choice of equipment meeting the needs of a variety of applications for customers of both Powerscreen of California and Powerscreen of Washington.

Molson Group, the UK parent company of the two dealerships, has for the past two decades successfully supplied and serviced the Hyundai brand throughout the UK. This addition to their portfolio takes Powerscreen of California and Powerscreen of Washington another step forward in offering a full range of construction and recycling equipment for customers in the western United States.

The dealerships’ sales, parts and service teams are receiving training to support the full range of Hyundai crawler and/or wheeled 10-ton to full-sized 100-ton excavators.

One of the most important additions was the arrival of Hyundai wheel loaders, ranging from the 130 hp, 2.5 cu. yd. HL930A up to the 420 hp, 9.2 cu. yd. HL985A.

Powerscreen of California President Gary McConn, said, “The addition of Hyundai into our dealerships will allow us the opportunities we need to deliver an effective single-source supply option for our customers, whether that is for earthmoving, recycling or

quarrying applications. Our ability to support the Hyundai brand for our customers will be easier, thanks to our group’s experience with and knowledge of the product gained from more than 20 years of supplying and supporting the brand across the UK, even achieving the accolade of becoming the manufacturer’s biggest European dealer.”

Senior VP of HD Hyundai Construction Equipment North America Mike Ross added, “I am very excited to enter this new partnership with both dealerships. Their business intelligence, thanks to the digitization of their business, gives them extra insight and access to a granular level of

detail that will help us better serve their customers. This strong infrastructure and attention to detail, combined with a depth of knowledge from their UK operations, help ensure customers in the area will get the topcaliber service they expect for their Hyundai equipment.”

McConn noted that the Group’s unique familiarity with Hyundai products has allowed them to accurately stock up on consumables and spare parts, so that both new and existing customers will have immediate access to parts for their Hyundai equipment.

Powerscreen of California, Nevada and Hawaii and Powerscreen of Washington are dealerships serving customers across the western United States. Both dealerships are part of Molson Group, the UK’s largest independent new and used equipment dealer. Molson and its dealers serve customers across a wide range of applications, including general construction, earthmoving, quarry and mining, agriculture and recycling. For more information, visit www.powerscreenofcalifornia.com and www.powerscreen-wa.com.

The world’s largest wildlife crossing is getting closer to becoming a reality.

Gov. Gavin Newsom recently announced that the Wallis Annenberg Wildlife Crossing outside of Los Angeles is on track to open by early 2026.

Ahead of National Infrastructure Week, Newsom also announced that construction crews are now more than halfway through installing the beams that form the crossing. The work is part of Newsom’s infrastructure agenda to build more, faster.

In May, the first of 82 large concrete beams went up over U.S. Highway 101 at Liberty Canyon Road in Agoura Hills. The project has been made possible by a successful publicprivate partnership. Philanthropy has raised more than $34 million in funding, while California has provided $58.1 million in funding.

“Our work to build more, faster is already paying dividends across our state,” said Newsom. “This wildlife crossing is just one example of how California is building infrastructure that connects rather than divides. With projects like this, we’re reconnecting and restoring habitats so future generations can continue to enjoy California’s unmatched natural beauty.”

• U.S. Highway 101 is one of the biggest barriers to wildlife connectivity in Southern California. The Wallis Annenberg Wildlife Crossing will reconnect habitats and improve the health of the environment for many species in Southern California, including people;

• More than 30 years of conservation work has gone into strategic habitat linkages on both sides of U.S. Highway 101 so that this wildlife crossing will connect protected lands in the Santa Monica Mountains and the Sierra Madre Range;

• The overpass will reduce wildlife-vehicle collisions on one of the most congested highways in North America, decreasing the significant danger posed to people and vehicles by crossing animals;

• The crossing will provide a safe and sustainable passage for wildlife across U.S. Highway 101, creating increased access for animals to find food, shelter and mates, which is increasingly important in light of climate change and continued human development that is pressuring species survival;

• This project will help educate millions of Californians driving under the crossing and advance California’s 30×30 goal to conserve 30 percent of the state’s lands and coastal waters by 2030, ensuring that wildlife can move across conserved habitats that provide shelter, food and water.

lic-private partnership of monumental scope that has leveraged the expertise and leadership of dozens of organizations and institutions to protect and restore wildlife habitats in Southern California.

Wildlife crossings of all kinds are essential to building a network of interconnected conserved lands and waters that protect and restore biodiversity while also supporting transportation infrastructure.

(All photos courtesy of Caltrans.)

On Earth Day 2022, Newsom participated in the ground breaking for the Wallis Annenberg Wildlife Crossing, a pub-

Abilene Equipment Center abileneequipmentcenter.com

Abilene, TX 325-603-1328

ASAP Equip

*Compact Equipment Only asapequip.com

College Station, TX 979-690-1106

Bingham Equipment binghamequipment.com Tucson, AZ 520-889-6396

Cisco Equip cisco-equipment.com

Artesia, NM 575-748-1314

Lubbock, TX 806-745-9595

Odessa, TX 432-550-9181

San Angelo, TX 325-653-2121

G4 Const Equipment, LLC

g4hyundai.com

Commerce City, CO 888-987-3352

Jet City Equip jetcityequipment.com

Oak Harbor, WA 360-675-4441 Marysville, WA 360-651-9079 Wenatchee, WA 509-888-8181

Mecom Equipment mecomequipment.com

Stockton, CA 209-466-5135

National Equipment Dealers nedealers.com

Houston, TX 800-234-5007

Dallas TX 866-270-1700

Nueces Power Equip

nuecespower.com

Corpus Christi, TX 361-289-0066

Laredo, TX 956-725-0066

San Antonio, TX 210-310-0066

San Benito, TX 956-361-0066

Victoria, TX 361-576-0066

El Paso, TX 915-541-0066

Oklahoma Territory Const Equip callotce.com

Oklahoma City, OK 866-339-6827

Oregon Tractor oregontractor.com

Roseburg, OR 541-679-6211 Portland, OR 503-282-7211

Porter Rents porterrents.com

Corona, CA 951-674-9999 Lakeside, CA 619-390-1197

Pacoima, CA 818-834-0102 Wildomar, CA 951-678-9902

Powerscreen of Washington, Inc. powerscreen-wa.com Helena, MT 253-236-4153

Powerscreen of Northern California, Inc. powerscreenofcalifornia.com

Dayton, NV 888-797-7276

Dixon, CA 707-253-1874

R&S Industries Inc. rsindinc.com Amarillo, TX 888-871-8658

Clovis, NM 575-769-8659

Tri-State Equipment

*Compact Equipment Only tristateequipmentrentals.com Lake Havasu, AZ 928-680-6748 Fort Mohave, AZ 928-704-0101

Loved for the features. Trusted for the performance.

Do more without feeling like it in Hyundai’s easy to own, easy to operate, skid steer and compact track loader.

Standard features include:

• LED front and rear work lights

• Auto leveling bucket

• Ride control

• Review camera

• Two speed travel

• AM/FM bluetooth radio

• Free Hi MATE telematics access for 5 years

No wonder so many first-time Hyundai users become longtime fans. See the Hyundai difference yourself at your local dealer, or na.hd-hyundaice.com.

During Mental Health Awareness Month, ConExpo-Con/AGG is demonstrating its commitment to construction professionals by donating $5,000 to the Construction Industry Alliance for Suicide Prevention (CIASP), supporting their initiatives in mental health within the construction sector.

“CIASP estimates 10 to 12 construction workers die by suicide every day,” said Dana Wuesthoff, ConExpo-Con/AGG show director. “From the educational content at our events, to informative articles on our website, and now this contribution, ConExpo-Con/AGG is committed to tackling this statistic and supporting our industry.”

Founded by the Construction Financial Management Association (CFMA) in 2016, the CIASP’s mission is to dismantle the stigma attached to mental health within the industry. By 2018, it evolved into an independent 501(c)(3) entity, focusing on suicide prevention awareness, providing essential resources and fostering a commu-

nity committed to eliminating suicides in construction.

ConExpo-Con/AGG also created a comprehensive resource hub, where employers and employees can access valuable resources.

The ConExpo-Con/AGG 365 newsletter will feature content about mental health over the course of the next few months. While these topics can be challenging, we want to remind you about one underlying feature: hope.

The newsletter will tackle topics related to suicide, PTSD and other mental health conditions that are prevalent in the construction industry. There are resources to help — whether you need help yourself or want to help a friend. Where there is help, there is hope. One way to attack the mental health stigma is by telling your story.

If you are in a mental health crisis, call or text 988 to speak to a crisis counselor now. You can also text HOME to 741741 to reach the Crisis Text Line and speak to a live, trained crisis counselor.

M10

Epiroc, a global mining equipment leader, has successfully introduced the first Boltec M10 Battery rig in the United States at Nevada Gold Mines. This marks a significant step toward greener practices in the mining industry.

Russ Osborne, key account manager at Epiroc USA, said, “We’re thrilled to help our customers lead the charge in electrifying the U.S. mining sector with the Boltec M10 Battery.”

The Boltec M10 SG rock bolting rig for ground support brings multiple enhancements to underground operations, including an improved operator work environment, reduced noise and a smaller environmental footprint. The rig features an onboard charger for convenient battery charging during downtime, ensuring uninterrupted drilling operations.

Epiroc Competency Center for Underground Mining, headquartered in Elko, Nev., offers advanced technical support in the region, as well as specialized electrification, and battery-electric vehicle (BEV) expertise, including diesel-tobattery conversions. The center is equipped to service and support BEV transition.

“Nevada Gold Mines embraces shifting to a more decarbonized method of mining and is looking forward to the benefits of the BEV Boltec M10 and seeing its success. The Boltec M10 has proven to be a valuable asset in the industry, providing environmental benefits and optimizing operational efficiency,” said David Byrnes, mine manager, NGM Leeville Underground Complex.

This successful deployment of the first BEV Boltec in the United States underscores Epiroc’s dedication to advanced mining practices, aligning with the industry’s shift towards cleaner and more efficient technologies.

For more information, visit www.epiroc.us.

Founded in 1923, Nippon Pneumatic Manufacturing Co. Ltd. (NPK Japan) established itself as a manufacturer of air tools and expanded into chemical processing equipment production in 1945. In 1957, they established the construction equipment division, and it was then that NPK Japan pioneered the world’s first boom-mounted pneumatic hammer.

In 1985, the reputable designer and manufacturer of hydraulic hammers, crushers, shears and pile drivers joined with a group of partners in Cleveland, Ohio, to form NPK Construction Equipment Inc. This provided the means to build an extensive dealer network in the Americas, located in Walton Hills, Ohio. The foundation of this organization was to provide a durable, dependable product, supported by unmatched commitment to customer service provided by all departments of NPKCE, according to the company. NPKCE has proved this unwavering support over the last 35 years.

“Many others claim to have this same commitment, but we do it. It’s just part of our culture and company DNA,” stated Ken Skala, NPKCE district manager. “The sun never sets on an unanswered question.”

As demand increased, NPK Construction Equipment expanded by adding a fabrication facility in Wickliffe, Ohio, in 1989. Eventually outgrowing that facility, NPKCE purchased a new, larger facility adjacent to the main offices in Walton Hills, Ohio, in 2009. This expansion allowed for and led to future growth, including the addition of NPK Machining in 2013 and the new construction of a second manufacturing facility completed in 2023.

Favorably, this growth has melded all NPKCE divisions onto one campus; enabling a collaborative environment that is highly efficient and productive with streamlined processes and flow. The hydraulic attachment manufacturer’s 200,000sq.-ft. United States’ facility is situated on more than 16 acres in Walton Hills, Ohio, and equipped with state-of-the-art machining centers, robotic welders and welding bays that stay consistently busy.

As the company continues to grow both organically and with the acquisition of Genesis in 2019, NPK continues to fabricate its products in their manufacturing facilities based in Japan, the United States and Europe.

Many of the company’s 120 employees are long tenured. According to Chris Salerno, director of sales, “NPK employees are the most important company asset.”

Employee longevity certainly says a lot about a company. It is a key indicator of employee satisfaction combined with good work ethics and increased levels of knowledge and experience.

According to Tiffany Thomason, sales and marketing support of NPK Construction Equipment, NPKCE ranks high in this category with having almost 50 employees who reached a more than 20-year tenure, with 10 of them reaching 30 years or more. There also are many employees with five to nearing 20 years of service.

“As a 30-year employee, I can surely say NPK is a great company to work for,” said Thomason. “Regardless of

length of employment, every employee in every department plays a special role in the success of NPK…it is a team effort. We are dedicated, we care, and it clearly shows through our quality products, unmatched customer service, product support and highly satisfied customers. Now that is success.”

NPK offers full service and support to its dealers, including a full warranty in a protected territory to support end users. The company also trains all technicians around the country to provide all-inclusive dealer support. Yearly, more than 30 dealer technicians are trained in-house, while many more are trained at dealer locations.

“Something I often tell our dealers and customers is that NPK’s product support is not a department. It is an attitude,” said Mike Rzeszotarski, product support manager of NPK. “It’s not one single department within the company making NPK shine, rather it is an attitude that everyone has at NPK ensuring we provide the highest level of service, support and quality to our customers. We all work together as a team at NPK ensuring our highest and number one priority is taking care of our customers.”

The company has a 98 percent fill rate for parts and understands the importance of uptime.

“After-sales support is important. We pride ourselves on making sure our customers are taken care of and constantly review our inventory to ensure uptime,” said Salerno.

“The company is here for a common goal to support the customer and create a culture of customer-oriented mindset,” said Skala. “We help provide solutions to problems.”

NPK continues to innovate, as it introduces its V250R crusher pulverizer. This unit is ideal for primary and secondary demolition and is well-suited for high-reach applications. It has a recommended carrier weight of 53,000 to 77,000 lbs. The V250R is also equipped with full 360-degree rotation capabilities that allow for the best attack angles at all times, according to the company.

Unit specs include:

• working weight — 6,065 lbs.

• max jaw opening — 35.4 in.

• cycle time — 1.8 close / 1 open (seconds)

• oil flow — 26 to 66 gpm

• operating pressure — 4,060 psi

• maximum crushing force at tip— 229,500 lbf

For more information, visit npkce.com. CEG

John and Heather Coulter have worked in the construction trades for more than a combined 40 years. Together, they made the observation that processing and disposing of demolition materials in the south Florida (Fort Lauderdale/ Miami) market was becoming increasingly challenging.

“There are a lot of factors that we had observed, and they added up to a significant problem, said John Coulter. “South Florida is growing at an unprecedented rate and the demand for demolition processing as new structures are being erected is growing at a tremendous rate.”

The method that had been used in south Florida to dispose

jaw crusher — to the construction site. The jaw crusher is used to create a reusable aggregate material, most commonly a ¾-inch minus. The contractor then reuses the material on the job site or, if he has no need for the material, it is sold to local contractors who have a need for the material on their own projects.

of demolition debris basically consisted of hauling all of the materials off site and finding someplace or someone who would accommodate the contractor in dumping the debris — typically, a swamp or some other geographic area that needed to be filled, or, if it is within a reasonable commute, taking it to a recycling facility.

The old way just really isn’t working any longer, John said.

“The cost of trucking has increased dramatically and increasingly there is a real issue with having a place to take the materials,” he said. “The swamps that were traditionally used have been filled, recycling facilities charge a tipping fee and with increased sensitivity to environmental issues in south Florida, finding anyplace that will receive is extremely challenging.”

John and Heather were familiar with a solution to this issue, one that has been used in other parts of the country for decades.

“My wife and I had done some research and it seemed to us that the market was right to start an onsite crushing service that would process primarily concrete,” he said. “A mobile crushing service is an ideal solution in a number of ways. The service provider brings a crusher — typically a mobile

“The whole process is a win-win for everyone,” he added. “The owner of the mobile crushing service is paid by the contractor and the contractor recoups his cost by using the material on site and not having to use an outside supplier. Or, if he has no need for the material, he generates revenue through the sale of the recycled material.

“The savings in trucking and labor cost are also significant. No more sending out expensive trucks with a driver to haul the material out, and in south Florida, you are always running the risk of the driver and the truck being held up for significant periods of time due to traffic.”

It was that thought process that led to the creation of AAA Crushing in Fort Lauderdale, Fla.

“My wife and I knew we had a couple of hurdles in front of us, the first of which was purchasing the right portable tracked crusher. Construction has been expanding at a very high rate in south Florida for decades and we are now experiencing the challenge of finding developable property for construction projects. Every inch of property on a site has to be strategically utilized and, in most cases, it involves taking down an existing structure to make room for the new one.

“The property is so valuable, using as much of the site as possible is critical. So, needless to say, many of the project sites that we would need to get into to process demolition have a very small footprint.”

John and Heather started their search for a portable tracked jaw crusher with three factors in mind: a small crusher that is extremely mobile is necessary because of the small footprint; a small crusher that is capable of strong production in spite of its size; and perhaps the most important factor is affordability. As a new business, that first purchase is critical; it can’t be a budget killer and the business need to find someone who will work with it to arrange the financing.

John started his search using a couple of different resources.

“I receive most of the industry trade publications and they were a great tool, but I needed some in-depth details about the machines before I contacted a manufacturer. I found that there was a tremendous amount of information available on the Web. Everything from testimonials to machine specs, pricing and YouTube gave us a tremendous to actually view the machines at work without traveling to a job site.”

After extensive research, the Coulters contacted Komplet America, which focuses on making small, portable concrete crushers, screeners, shredders and conveyors. Its product is manufactured in Italy and imported by Komplet America to its facility in Hillsborough Township in northwestern New Jersey.

The BL2/S/EX can mulch vegetation, shrubs and trees up to 6 in. in diameter. It is designed for forestry management; roadside and railway maintenance; maintaining the banks of canals; rivers and lakes; and managing and protecting wildlife areas.

FAE expanded its line of forestry mulchers with Bite Limiter technology with a model designed for mid-range excavators: the BL2/S/EX for 11–16 ton excavators.

The BL2/S/EX can mulch vegetation, shrubs and trees up to 6 in. cm in diameter. It is designed for forestry management, roadside and railway maintenance, maintaining the banks of canals, rivers and lakes, and managing and protecting wildlife areas.

The Bite Limiter technology on this head is ideal for high productivity vegetation management, with reliably efficient shredding. The rotor with Bite Limiter technology comes with special wear-resistant steel profiles that limit the reach (bite) of the teeth. This cuts down on power demand and promotes a consistent working speed, for excellent performance when mulching any kind of wood. Bite Limiter technology also minimizes rotor stalling and optimizes fuel consumption.

The sturdy steel frame is built to last, just like all FAE products. The toothed belt transmission provides optimal power transfer and long-term reliability. Interchangeable bolt-on Spike Pro counter blades and skids and a hydraulically adjustable hood also are major design features.

The BL2/S/EX also is available with FAE’s exclusive Sonic system, which keeps the operating carrier and the FAE mulcher completely aligned by automatically calibrating and constantly regulating the mulcher’s hydraulic parameters for a significant boost in productivity. The FAE app also is available for technical support and makes it possible to quickly and easily calibrate the Sonic system for fast and accurate connection to the operating carrier so you can get the highest level of productivity from your FAE mulcher.

The new BL2/S/EX can be equipped with BL blades or C/3 teeth and is available with a working width of 125.

Charlie Johnson (L) and Kristi Wendt, daughter of Barry Wendt, presented the award to Helm.

The 2024 Barry K. Wendt Memorial Commitment Award was presented to Mark Helm of Dolese Bros. Co. during the National Stone, Sand & Gravel Association (NSSGA) Annual Board and Membership Meeting.

“Mark is well-known for encouraging the long-term health of the aggregates industry through his commitment to the community,” said NSSGA President and CEO Michael Johnson. “His charitable work with rural communities and efforts to promote the next generation of aggregates professionals exemplifies why he is an outstanding choice for the Barry K. Wendt Memorial Commitment Award.”

Charlie Johnson, DSC Dredge LLC, presented the award to Helm in Johnson’s final duty as the 2023 Manufacturers & Services Division Chair. Barry Wendt’s daughter, Kristi Wendt, also was on hand to present the award.

The NSSGA’s Manufacturers & Services Division established the award in 1998 to annually recognize an individual in the industry who exhibits the dedication exemplified by Barry Wendt, both in commitment to the industry and the community in which they live. This award is the most distinguished individual award presented by the NSSGA.

“I am honored to accept this award as a reflection of Dolese Bros.’ strong commitment to our community,” said Mark Helm, president and CEO of Dolese Bros Co. “Thank you to NSSGA and Kristi Wendt, for carrying on Barry Wendt’s legacy and his tireless devotion to serving others and advancing the industry.”

Helm’s experience spans more than 40 years in construction and aggregates with both public and private organizations. He joined Dolese Bros. Co. in 2001. Helm also is a commissioner on the Oklahoma Mining Commission and serves on several boards, including the Oklahoma Aggregates Association, United Way of Oklahoma and the Oklahoma Nature Conservancy. He also is a Trustee on Foundations for Engineering at Oklahoma State University, the University of Oklahoma and Kansas State University.

For more information, visit www.nssga.org.

MDS, a manufacturer of specialist screening equipment, announced the launch of its new M518R compact recycling trommel. With a suite of new features and benefits designed to elevate performance and efficiency, the M518R excels in screening a variety of materials, including compost, green waste, biomass, municipal waste and more, according to the manufacturer.

The M518R is well-suited for small to medium-sized operations and contractors, particularly those with limited space and a need for easy transportation. Featuring a 180-degree radial fines conveyor, the machine offers efficient material handling, providing a radial stockpile capacity of up to 22,954 cu. ft.

Its compact dimensions and efficient folding mechanism of the radial conveyor ensure straightforward transportation, fitting neatly onto a standard 26-ft.-long trailer. Additionally, notable improvements in service access compared to the previous generation set a high standard for accessibility and maintenance ease. Overall, these features solidify the M518R as a highly efficient option within its class.

The new M518R provides a versatile screening solution that can adapt to diverse operational requirements.

One of the many standout features of the M518R is its remote-controlled conveyor swivel, enabling operators to adjust positioning effortlessly during operation. This functionality minimizes downtime and

enhances productivity, reflecting a commitment to providing solutions that emphasize operational efficiency and user convenience.

“At MDS, we are continuously striving to innovate and produce machines that give our customers the edge they need to be successful in their own operations,” said

Steven Keenan, engineering manager at MDS. “Our new M518R machine is a good example of this and provides a versatile screening solution that can adapt to diverse operational requirements while bringing efficiency and value to recycling operations worldwide.”

For more information, visit terex.com.

Each product category is available in multiple machine sizes to cater to the needs of the typical small-medium size contractor. In the jaw crusher category, there are four different models to choose from:

• The K-JC 503 (the smallest model) comes equipped with a 25 hp engine, a 19 in. by 12 in. jaw, and a production capacity of up to 34 tons per hour (tph);

• The K-JC 604 comes equipped with a 55 hp engine, a 23 in. by 16 in. jaw, and a production capacity of up to 55 tph;

• The K-JC 704 comes equipped with a 74 hp engine, 27 in. by 16 in. jaw, and production capacity of up to 90 tph; and

• The K-JC 805 comes equipped with 130 hp engine, a 31 in. by 21 in. jaw, and a production capacity of up to 160 tph.

After considering all of the variables, John and Heather selected the K-JC 704 as being the right size and production capacity to meet their needs.

According to John, it wasn’t just size and capacity that determined the decision to go with Komplet.

“With a weight of only 26,455 pounds, the Komplet could easily be hauled with a trailer and any one of our trucks. The jaw can be adjusted hydraulically using a remote

control. We would be able to, if need be, run the crushing spread with one operator.

“From within the cab of whatever machine we choose to load the crusher, the Komplet remote control can sit on your lap and you can remotely operate every aspect of the crusher. There is a sensor above the jaw inlet that controls the feed of materials from the hopper to the crusher. It senses when there is too much material within the hopper and adjusts the crushing speeds accordingly.

“Another great feature is the jaw is reversible, which is ideal to clear blockages when they occur. The crusher also comes standard with a magnet that sorts out rebar that may have been missed when preparing debris for crushing.”

The next hurdle was financing.

“Even though the K-JC 704 was very reasonably priced, and in the world of construction equipment, not that big of an investment, we had concerns about financing. The finance department at Komplet America really went to work for us, convincing loan institutions that we had a smart business plan and working out interest rates and terms that we could handle. We could not have asked for any better service.”

704, the Coulters have continued to have a positive ownership experience.

“The staff and the overall support from Komplet have been excellent. They were very good at educating us exactly how to operate the machine, they gave us a great understanding of the many features and

“Needless to say, a jaw crusher is a high wear and abuse type of machine. Items are going to wear out. When you do run into an issue, the support team at Komplet America is excellent at helping us identify the source of the problem. Most important, when needed, parts accessibility has never been an issue. They always have in stock the items that we need and can talk us through addressing any issues.

“We now have a supporting dealer in Florida for parts and service, RPM Equipment Sales and Rentals in Lakeland, Florida.”

AAA Crushing has experienced tremendous growth since adding the Komplet to its equipment fleet.

Since the purchase of the Komplet K-JC

assisted us in becoming better operators. Once the machine was operating in the field, they sent a team to pay us a visit and they gave me some very good positive feedback and suggestions on how to improve the machine’s efficiency.

“Everything that we envisioned has happened. We were very confident that it would. The math just makes sense. When you can offer to turn a liability [demolition debris] into a profitable item [aggregate] the decision to use our services is easily made. South Florida contractors have embraced our services, and we are working six days a week to keep up with the demand. The Komplet crusher has been very reliable and has given us the production levels that we were expecting.” CEG

CALIFORNIA from page 1

rutted portion of the drive lane. The full lane replacement will start the lifespan of the roadway over, the polymer concrete that is being placed in the wheel ruts will act as a safety band aid for the traveling public.”

Emergency repairs started in the summer of 2023 after the extreme 2022/23 winter season.

“Several activities have a temperature and climate window for the repairs which resulted in activity being suspended during the 2023/24 winter season and resumed this spring once the snow melted and drier and warmer conditions were in the forecast,” said Jeremy Linder, a public relations officer of Caltrans District 3.

Work is currently taking place at five locations along westbound and eastbound sections of I-80 between Colfax and the Nevada state line:

• Location 1: between Colfax and Alta;

• Location 2: between Alta and Yuba Pass;

• Location 3: between Yuba Pass and Kingvale;

• Location 4: between Kingvale and Truckee; and

• Location 5: between Truckee and the Nevada state line.

The pavement for Location 1 is asphalt and the majority of the repairs were completed last year. The roads for Locations 2 to 5 are concrete.

The failing roadway sections are being removed by saw cutting existing concrete slab, then excavated out with two excavators.

“Crews are hammering the panels out with an excavator with hammer attachment followed by an excavator that is digging out the broken concrete,” said Fritz. “The broken concrete roadway chunks are being sent to Al Pombo Inc., a local commercial pit that recycles the concrete to be integrated into recycled aggregate base products. Work progress continues to improve each week. To date, crews have done a great job of working safely, maintaining environment best management practices and hitting Caltrans production milestones.”

Equipment operators are using a Cat 966 loader (concrete off haul), a John Deere 210 skip loader (miscellaneous work, cleaning up concrete floor), an Xtreme Forklift 1045 (site material management, concrete reinforcement), a Telehandler forklift, a Link-Belt hammer hoe 145X4 for concrete demolition and a Cat 315 loadout hoe.

Granite started the emergency work April 28 and plans to complete work in locations 4 and 5 in mid-October.

The majority of repairs are based on concrete slab/lane replacement and polymer paving rut repair.

“Construction operations are taking place during the summer months in an effort to avoid inclement weather conditions,” said Fritz. “Construction operations follow Caltrans traffic charts and allow work with lane restrictions from Sunday night to Friday at 12:00 noon. Granite is working to fix encompasses of varying conditions and ages of existing roadway. Some roadway appears to be at the end of its lifecycle and needs full reconstruction. Other areas, the overall structural integrity of the roadway, seems to be effective but the chain wear has damaged the surface causing ruts.”

Granite has successfully removed approximately 12,000 lineal ft. of damaged roadway section and replaced 3,500 cu. yds. of Portland Cement Concrete Paving as of June 12.

“Currently we have approximately 11,000 cubic yards of remaining concrete roadway to remove and replace,” said Fritz.

Granite in conjunction with subcontractors — ACME Concrete Paving, Meyers and Sons and ABSL — has completed roughly 7 mi. of rut repair. Currently, the project has another 7 mi. to 10 mi. of remaining rut repair to complete.

The majority of repairs are based on concrete slab/lane replacement and polymer paving rut repair.

“The work consists of completing safety repairs to remove and replace old concrete pavement where the roadway is failing and repairing areas where there is severe rutting from snow chain damage with a polyester concrete inlay,” said Fritz. “Caltrans and Granite are completing the work with utmost attention to safety, production and traffic restrictions.”

Concrete roadway removal operations are being completed during night shifts when traffic volumes are less and all roadway sections are placed back the following mornings. Rut repair is completed with roadway rut removal and grinding during night shift with polyester concrete being placed the following morning.

“All roadway improvements controlled by Granite and team have been completed on time allowing for no traffic restrictions throughout the weekend,” said Fritz.

The slab replacement is being replaced with concrete sourced in Truckee, Calif., from Truckee North Tahoe Materials. Concrete reinforcement materials are being supplied from K&K Construction Supply (DBE), which sources its materials from American Highway Products. The rut repair is being replaced by a subcontractor that sources polyester concrete materials from Kwik bond from Benicia.

Granite’s project team consists of Project Manager Ryan Murray, Project Engineer Baylee Bishop, Peter Rondeau and

Amanda Knowles and interns Megan Madole and Livea Muqatash.

There are four Granite construction crews totaling more than 40 on-site employees between night and day shift. Working in a remote area places a greater stress on maintenance.

“[The main wear is on] parts such as hammer hoe shafts, cutting edges, and grinding teeth due to excavating and grinding concrete,” said Fritz. “Repairs to excavators and skip loaders are primarily done on-site by Granite employed mechanics. Each grinding subcontractor has in-house mechanics that swap out their respective grinding heads, drums, and teeth.”

Granite, Meyers and Sons Construction, Acme Concrete Paving and ABSL Construction all have in-house mechanics that complete repairs on-site as necessary.

Granite purchases and rents equipment from Cashman Equipment and H&E Equipment Services in Reno, Nev.

“Equipment dealerships help with providing equipment as needed for specialized operations and if Granite does not have a piece of equipment available,” said Fritz.

Although this section of I-80 is in a remote part of the state, it is a major roadway.

“I-80 is a vital part of California’s economy, offering a direct corridor connecting the east coast and west coast for commercial goods and services,” said Linder. “The highway is also used by motorists living in communities within the Sierra Nevada mountains along with seasonal recreational travel connecting the San Francisco Bay area, Sacramento and Reno. In 2022 Caltrans estimated the annual average daily traffic volume across Donner Summit at 32,000 vehicles.

“The solution is to remove and replace the damaged concrete, grinding and installing a polyester inlay where required. This provides a wearing surface and helps to prevent intrusion of salts and other chemicals into the concrete. Rut repair is a strategy that can repair a significant amount of damage in a short amount of time and is Caltrans current chosen method for this kind of maintenance. Wheel rut repair is also a more economic choice when the concrete pavement is structurally in good condition. For the areas with more extensive damage crews are performing full concrete slab replacements.

“Crews are focused on getting as much work done as possible with the funding that was approved for the contracts,” said Linder. CEG

(All photos courtesy of Caltrans.)

2449 Manana Drive Dallas, TX 75220 800-594-BANE (2263) 10505 North Freeway Fort Worth, TX 76177 800-601-BANE (2263)

3402 E. NE Loop 323 Tyler, TX 75708 800-594-2200

1090 W 2181 N Salt Lake City, UT 84116

801-322-1300

atlasmachinery.us

6565 Smith Avenue Newark, CA 94560

510-400-5024

1535 SE 25th Street Oklahoma City, OK 73129 405-310-8700

2035 W Mountain View Road Phoenix, AZ 85021

480-463-4999

Equipmentshare.com

‘Going the extra mile’ has been the company philosophy since Tractor & Equipment Company (TEC) first opened its doors back in 1943. Over the years, it has been paying dividends, and that continues today.

At a recent trade show in Las Vegas, Chad Stracener and his team received the award for being the Top SENNEBOGEN Tree Care Dealer for 2023.

“Part of our ongoing success is the fact that SENNEBOGEN Tree Care machines can make a positive and ongoing contribution to our customers’ lives and operations. These machines can be a real gamechanger,” said Stracener.

Not unlike any other significant investment, whether it is a residential/commercial arborist or one that works “Right of Way” corridors, they all want to see “how it works”. That’s

why, he said, that they have a very active demo program.

“Nothing works better than actually seeing up close, how it really is going to change the way you do business.” He also indicated that they can call upon SENNEBOGEN to assist them with the demo.

“Their assistance is invaluable. Whether it is one of their Tree Care specialists or someone from their User Experience [UX] Team, they all help with our customers who really enjoy interacting with the factory.”

“We were thrilled to be recognized amongst all their World Class Dealers,” said Stracener. “SENNEBOGEN is a great product, and we have placed a big focus on it. We continue to invest in the free factory training that SENNEBOGEN provides for their dealers and end users. We are also fortunate to get ongoing factory support. All of this makes it possible for us to succeed.”

According to Stracener, the SENNEBOGEN team is invaluable, and Greg Roberts, the tree care manager, has a vast knowledge and understanding of the industry and the marketplace. His background and familiarity with the machines and the various market segments make him a valuable addition to our team when called upon.

“Greg’s knowledge and passion for the product instill so much confidence in our sales group and customer base,” said Stracener

Stracener also felt that the team at SENNEBOGEN, led by Constantino Lannes, president, is a contributing factor to both their successes.

“We share many of the same ideals including being ‘customer centric.’ This means that we are all onboard with the concept of parts and product support so our customers trust that we can keep their equipment running smoothly.”

According to Stracener, a good salesperson with a good piece of equipment can sell the first piece. However, it is the parts and service support that keeps the customer coming back.

“We are very proud to have Tractor & Equipment Company on our side,” said Lannes. “They continue to do a great job for us, not only on the tree care line but with the material handling machines as well.”

“Of course,” said Stracener, “we couldn’t do it without the trust of our customers. We continue to build on that trust every day. We have increased our investment in parts inventory, technician training, and the number of service trucks serving our region. We have also embraced the latest innovations from SENNEBOGEN, their Uptime Kits and their Preventive Maintenance Kits. We know from our conversations with our customers that this attention to detail gives them the confidence that we will have their machines up and running with as little downtime as possible.”

To build on and support this trust-building, TEC has developed NODS (Network Overnight Delivery System), a delivery system that starts with three distribution warehouses and interconnects its 20 branch locations. This, according to Lannes, is just another example of Tractor & Equipment Company “Going the Extra Mile”.

Ignite Attachments, a manufacturer of compact equipment attachments, adds to its growing lineup of direct-toyou products with three new mini grapple offerings.

The new mini bucket, mini rock and mini rake grapples are available in 36- and 44-in. working widths. An innovative dual interface ensures easy, hassle-free paring with any brand of mini track loader making this an ideal solution for rental centers and mixed-fleet landscape operations.

The new attachments continue Ignite’s tradition of durable, costeffective grapple solutions, providing high-quality workmanship, smart engineering and ideal performance, according to the manufacturer.

“When it comes to working in the tightest spots, more and more people are turning to mini track loaders or skid steers,” said Trisha Pearson, business director of Ignite Attachments.

“Ignite Attachments works to meet owners/operators where they are, not the pigeonhole our stagnant industry tries to put them in. We recognize the need for cost-effective mini solutions that are dependable, versatile and easy to use.”

Like the company’s line of full-size grapples, the mini bucket grapple, and others in the new offering, feature a laser-cut Grade 50 steel design. This results in a tighter fitting attachment with a long service life. The mini bucket grapple strikes a balance between weight and strength, allowing operators to lift more and do more.

With a grapple opening of 26.6 in. and a minimum height of 22.1 in., the Ignite mini bucket grapple easily maneuvers in tight spaces. An innovative design puts the single 2.25-in. bore by 1-in. rod cylinder behind the

bucket, rather than on top, for complete protection even in the most demanding applications.

Combined with standard Faster flat-faced couplers and full-length nylon hose sleeves, this unique design feature minimizes unnecessary downtime and ensures a long service life, according to the manufacturer.

The mini rock grapple features many of the same base benefits. This includes Ignite’s exclusive dual interface. These brand-agnostic attachments easily pair with both mini Bob-Tach and CII machines due to a unique faceplate design,

allowing for seamless integration with mixed fleets or new carrier investments.

The grapple opening on this offering is 25.9 in. with a tine spacing of 3 in. for effective rock and debris removal.

The mini rake grapple features slightly wider tine spacing, 6.75 in. on the 36-in. model, which allows operators to remove debris with less soil disturbance. It offers a 36-in. grapple opening.

Greaseable pins and heavy-duty cylinder protection minimize downtime and offer increased service life in a wide range of applications.

“Compact equipment owners and operators are constantly looking for easier, more cost-effective ways to get the job done,” Pearson said. “Our lineup of mini grapples are reliable, cost-smart and productive no matter your carrier brand. They’re designed to stand up to the toughest challenges and, when they outlast your existing machine, they’ll easily transfer to your new model.”

Ignite Attachments offers qualitydesigned and -manufactured tools that are easy to purchase, attach and use. In today’s fast-paced, connected economy, Ignite offers a reliable, cost-effective solution for compact equipment operators of any brand. Online ordering and direct shipping allow customers to shop confidently and on their schedule. Ignite backs every attachment with a comprehensive warranty and excellent customer support, ensuring customers can rely on their tools for years to come, the manufacturer said. For more information, visit www.igniteattachments.com. (All photos courtesy of Ignite Attachments.)

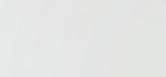

Waratah Forestry Equipment has unveiled the H216 — a new two-roller head added to its 200 Series lineup.

Built for hardwood, the H216 is strong enough to handle the toughest tree forms with accuracy and efficiency. Its simple design with excellent feed power, delimbing and large cut capacity provide productive tree harvesting.

“The H216 is specially designed for hardwood,” said Brent Fisher, product marketing manager of Waratah. “This head not only provides our customers reliable performance in hardwood but is equally capable of handling softwood, debarking and everything in between.”

Weighing in at 3296 lb., this 200 Series head features a two-roller design ideal for hardwood harvesting, late or final thinnings. Floating roller arms allow for superior and easy tree horizontal movement and easy log transport through the head. High performance single or multi-speed options keep timber moving quickly.

The H216 features the efficient SuperCut 100S saw unit with improved auto tensioning and easier servicing. With large sawing capac-

ity, this head can cut logs up to 29.5 in. in diameter, while an optional top saw tackles heavy branching. The delimb arms provide excellent delimbing power across all diameter ranges, while drive wheel options offer maximum traction for crooked wood.

The H216 harvester head utilizes the TimberRite H-16 control system for optimum head performance, productivity and measuring accuracy.

The H216 is built to tackle the toughest, crooked timber to the straightest postwood and everything in between. While also naturally capable in softwood, debarking or multitree handling, this head is designed for efficiency and agility in thinning and harvesting applications with quick cycle times.

A heavy-duty main chassis saw box, as well as tilt frame and guarding, provide added protection and reliability. Maintenance is simplified through one position daily servicing and easy open/close hinges on the valve cover.

The Waratah H216 is available to customers in the United States, Canada, Europe, Australia, New Zealand, Asia Pacific, Brazil and Latin America.

For more information, visit Waratah.com.

Superior Broom announced the offering of its new optional heavy-duty SM74 front mount broom. The broom is available on all front mount SM74 Superior Brooms. This heavy-duty option includes a reinforced brush core support frame, split hydraulic hose connections to brush and heavy-duty steel hose covers that protect hydraulic hoses from the core motor. The broom features a massive heavy-duty back bumper highlighting 1 in. by 12 in. steel along with the front and rear fenders with 3/16 in. steel.

For more information, visit www.superiorbroom.com.

Can you improve your energy efficiency when working with your excavator? The answer is yes, in Rototilt’s opinion — by using a tiltrotator. Both because of the way it changes how you perform your tasks, and according to early tests that indicate significant energy savings when using their latest tiltrotator series.

“The results are impressive, to say the least,” said Sven-Roger Ekström, product manager at Rototilt.

According to Sven-Roger Ekström, product manager of Rototilt, the tiltrotators in the company’s new RC Tiltrotators series can further increase the positive impact due to their improved energy efficiency, as a result of Rototilt’s pressure-compensated hydraulics.

“A tiltrotator makes it easier for you to work with an excavator, thanks to the increased flexibility of the work tool’s movements. It enables you to adjust the angle and rotation of the work tool, which in turn makes it easier to carry out tasks with fewer machine movements. This saves fuel, but it has even more advantages in the long run,” said Ekström.

“We call this the tiltrotator effect,” Ekström said. “We have always known that there is a big difference between working with and without a tiltrotator. Not only do you need to use fewer machines, but you can also carry out the task at hand with fewer

movements and changes of position. This saves both fuel and time, as well as reducing the impact on the ground where you are working. It therefore has a number of positive environmental effects.”

Tiltrotators provide multiple benefits when it comes to productivity and the envi-

ronment, however — what is it that makes Rototilt’s tiltrotators unique? According to Ekström, the tiltrotators in the company’s new RC Tiltrotators series can further increase the positive impact due to their improved energy efficiency, as a result of Rototilt’s pressure-compensated hydraulics.

“We have taken measurements comparing our previous series with the new, pressure-compensated hydraulics in the RC4-RC9,” said Ekström. “The results are impressive, to say the least. We have managed to improve the efficiency of our product, enabling it to perform the same task with reduced energy consumption.”

The time saved simply by using a tiltrotator, coupled with the energy improvements in RC Tiltrotators, can consequently make a major difference to a project’s efficiency and energy consumption. But what level of fuel saving are we actually talking about?

“Our lab tests indicate a reduction in fuel consumption of between 1-2 litres per hour for a 20-tonne machine, compared to our previous tiltrotator series,” said Ekström.

“Out in the field, the savings are affected by a number of factors, such as the type of machine and the job in question. In terms of diesel per year, this could mean savings amounting to thousands of euros.”

For more information, visit www.rototilt.com.

ABILENE, TX • 877-577-5729

AMARILLO, TX • 800-283-1247

DALLAS, TX • 800-753-1247

FT. WORTH, TX • 877-851-9977

HEWITT (WACO), TX • 254-261-1370

LUBBOCK, TX • 866-289-6087

OK • 918-310-1550 ODESSA, TX • 877-794-1800 OKLAHOMA CITY, OK • 800-375-3339 TULSA, OK • 800-375-3733

MISSOULA, MT • 800-332-1617

BILLINGS, MT • 800-735-2589

BOISE, ID • 800-221-5211

COLUMBIA FALLS, MT • 800-434-4190

EUGENE, OR • 800-826-9811

JEROME, ID • 800-221-5211 KENT, WA • 800-869-2425

POCATELLO, ID • 800-829-4450

PORTLAND, OR • 800-950-7779

ROCHESTER, WA • 800-304-4421

SPOKANE, WA • 800-541-0754

ALASKA NC MACHINERY

www.ncmachinery.com

800-478-7000

Anchorage, AK • 907-786-7500

Dutch Harbor, AK • 07-581-1367

Fairbanks, AK • 907-452-7251

Juneau, AK • 907-789-0181

Prudhoe Bay, AK • 907-659-6900

Wasilla, AK • 907-352-3400

ARIZONA

EMPIRE CAT

www.empire-cat.com

1725 S Country Club Mesa, AZ 85210

800-EMPIRE-1

CALIFORNIA

HOLT OF CALIFORNIA

www.holtca.com

Pleasant Grove • 916-921-8969

NEVADA

EMPIRE CAT

www.empire-cat.com

3300 St. Rose Parkway, Henderson, NV 89052

702-649-8777

Elko • 775-738-9871

Reno/Sparks • 775-358-5111

NORTH DAKOTA

TRACTOR AND EQUIPMENT

www.tractorandequipment.com

Williston • 701-572-8377

WYOMING

TRACTOR AND EQUIPMENT

www.tractorandequipment.com

Worland • 307-347-4747

MONTANA

TRACTOR AND EQUIPMENT

www.tractorandequipment.com

Billings, MT • 406-656-0202

Billings-Sgt. • 406-245-4426

Bozeman • 406-585-5800

Great Falls • 406-761-7900

Helena • 406-442-2990

TEXAS

MUSTANG CAT

mustangcat.com

Beaumont • 409-892-8412

Bryan • 979-775-0639

El Campo • 979-543-3389

Houston • 713-460-2000 Lufkin • 936-639-5551

WASHINGTON

NC MACHINERY

www.ncmachinery.com

800-562-4735

Seattle • 425-251-5800

Chehalis • 360-748-8845

Fife • 253-896-0878

Monroe • 360-805-6000

Mt. Vernon • 360-424-4292

Wenatchee • 509-886-5561

Yakima • 509-248-2371

Liebherr USA Co. appointed Johnny Greer as divisional director of mining, effective May 6, 2024. Greer brings 20 years of experience to lead the U.S. mining division.

As divisional director, Greer will be responsible for managing the team of Liebherr sales, service and training staff for the mining equipment product range. He will spearhead efforts to continue building a strong market presence across the United States.

“We are thrilled to have Johnny Greer join Liebherr USA Co. as the new divisional director of mining. He brings a wealth of operational and industry knowledge, providing the quality, reliability and efficiency needed to successfully to promote Liebherr’s range of outstanding mining solutions,” said Kai Friedrich, managing director of Liebherr USA Co.

“Greer has a vast amount of experience across a full range of applications in North, South and Central America. His professionalism and experience will help us grow our brand further and expand our mining footprint in the USA.”

Greer previously held various roles for Austin Engineering from 2005 to 2024, including Supply Chain, Materials and Production Control Manager North America, Supply Chain Manager Americas, General Manager South America, and General Manager North America. Greer also was an active member of multiple accredited mining organizations including the Society for Mining, Metallurgy, and Exploration, the National Mining Association, the Nevada Mining Association, the Mining Association of Wyoming,

and the Wyoming Mining Association.

“Liebherr is an innovative company with excellent core values that align with my personal values. I am very excited to join the Liebherr team and have the opportunity to provide the U.S. mining industry with high-quality equipment and solutions,” said Greer.

New Cat grading beams for Cat tiltrotators allow contractors to take on dynamic and efficient grading and compaction work using excavators.

Pairing with Cat tiltrotators enables 360-degree bidirectional and 40-degree left-and-right rotation of the grading beam to increase attachment versatility. The grading beams’ mechanically adjustable roller — 0.40 in. below frame to 0.79 in. above — flexibly tailors the desired level of compaction based on material type. Preventing material from sticking to the roller, the adjustable roller scraper allows the attachment to be used with clay, silt and other sticky materials.

Available in five widths from 49 to 118 in., Cat grading beams quickly tackle a range of applications from grading sidewalks to larger site prep applications. The design’s large top opening with solid extended sides and side plates allow the beam to spread, compact, and grade materials quickly and effectively.

Phoenix, AZ

480-545-2400

Phoenix, AZ 602-252-7121

Prescott, AZ 928-778-5621

Tucson, AZ 520-623-8681

Bakersfield, CA 661-695-4830 Mojave, CA 661-824-2319 Perris, CA 909-355-3600

www.wpi.com

12320 S. Main Street Houston, TX 77035 713-723-1050 Buffalo, TX 903-322-7150 Bryan, TX 979-314-1191 Corpus Christi, TX 361-884-8275

Edinburg, TX 956-386-0107

Kilgore, TX 903-984-2011

Lufkin TX 936-243-6056 Pflugerville, TX 512-251-0013 Port Arthur, TX 409-721-5305 San Antonio, TX 210-648-4444 Tomball, TX 281-351-9016

Highly abrasion resistant, Hardox 500 wear protection at the bottom of the beam protects the frame for long-life

Grading beams are constructed with support plates and abrasionresistant material to support

operation. The beam’s welded frame increases structural rigidity, while additional support plates on the heavy-duty frame extend beam strength and overall service life.

Compatible with Cat Grade technology via the Cat tiltrotator attachment, contractors can grade to plan using Cat grading beams, improving accuracy and saving time. Available tool recognition automatically confirms the identity of the attachment to ensure all settings — pressure, flow and dimensions — are correct, allowing operators to quickly get to work.

Standard Cat PL161 attachment technology provides simple attachment tracking across all work sites, reducing the chance of a lost grading beam and assisting with maintenance and replacement. The PL161 integrates into VisionLink for fleet management from a single mobile device.

For more information, visit www.cat.com. (Photo courtesy of Caterpillar.)

www.powermotivecorp.com Corporate Office

5000 Vasquez Blvd., Denver, CO 80216 303-355-5900

Colorado Springs, CO 719-576-5541

Grand Junction, CO 970-241-1550 Milliken, CO 970-587-1188

Cheyenne, WY 307-634-5149 Durango, CO 970-259-0455

Albuquerque, NM 505-345-8383 Bloomfield, NM 505-324-8601 Carlsbad, NM 505-485-1700 El Paso, TX 915-872-1001 Chandler, AZ 602-986-3003 Phoenix, AZ 602-463-3772 Tucson, AZ 520-649-2858

www.geehm.com

5461 S Nikita Avenue Fresno, CA 93725 559-834-3149

1164 Prestige Way Redding, CA 96003 530-229-3820

OK 918-438-1700

Lubbock, TX 806-745-2112

Odessa, TX 432-333-7000

Abilene, TX 325-692-6334 Amarillo, TX 806-373-2826 Dallas, TX 214-371-7777 Ft. Worth, TX 817-378-0600

Waco, TX 254-261-1370 www.clairemontequipment.com San

858-278-8338

In fact, contractors are devoting larger chunks of the budget to prefab operations.

FMI found that contractors on average are spending 18 percent of their time in craft labor hours on prefab for construction projects.

The engineering consulting firm surveyed 250 contractors as an update to its 2023 Labor Productivity Study of just how prefab ties to labor numbers.

Contractors said they anticipate craft hours dedicated to prefab would double to approximately 34 percent over the next five years.

FMI’s 2024 update supports the idea that the industry looks to prefab as a possible solution for the ongoing labor shortages across all construction sectors.

They’re familiar with the technology, too. Some 86 percent of respondents already have single-trade prefab services in place. And three quarters of responding concrete contractors said they are prefabricating on the job site, as are 57 percent of self-performing GCs.

But in the FMI survey, respondents said the biggest perceived benefit to prefab is improved quality.

One contractor believed prefab reduces the risk and variability, noted bdcnetwork.com in an article on prefab construction trends.

Reduced construction schedules and improved worker safety were cited by respondents, most of whom were MEP contractors. Others, in framing and drywall.

The prefab concept is growing in popularity for projects that wouldn’t ordinarily fit the typical construction application.

An argument is being made for the benefits of prefab in high-speed rail (HSR). A hub for construction of HSR infrastructure is emerging in California.

A joint venture pre-cast facility, the hub serves as a manufacturing facility producing wide-flange girders, deck panels, tub deck panels and piles.

The Hanford Sentinel reports more than 100 craft workers, including operators, masons, carpenters and ironworkers, are employed there.

The prefab components made there include welded wire mesh, bent and straight rebar, concrete and pre-stressed strands.

Craig Watts, pre-cast manager, said the facility produces structural components for a regional rail guideway.

Among equipment on the site, 110-ton mobile gantry cranes are used to lift and load girders onto trailers.

“We use it to go in and out of the rows,” Watts said. “They’ll go over the top of a row of girders and pick it up, pull it out and load it onto a trailer.”

When the pre-cast facility shuts down operations, the site will convert to the Kings/Tulare High-Speed Rail station.

HRS officials anticipate the first rail section to operate between 2030 and 2033. Trainset testing is estimated to start as early as 2028.

Could incorporating prefab and modularization into the build strategy of water projects help mitigate risks in construction sequencing?

The technology has the potential to benefit the water infrastructure industry in a big way, said one piping system consultant.

Ernie Maschner, vice president of global water of Vitaulic piping systems, believes prefab can mitigate civil-structural-mechanical sequencing.

In a Water Collaborative Delivery Association blog, he highlighted potential efficiencies in construction and scheduling and reduced dependence on labor.

“Prefabrication is not widely used on municipal water and wastewater treatment projects compared to private sector projects,” said Maschner. “But its benefits are well suited and complementary to collaborative delivery projects.”

Maschner believes collaborative delivery methods are optimal for prefab when the construction team and supply chain are involved early on.

“These benefits aren’t available under design-bid-build delivery because construction begins immediately after bid,” he said.

That rapid jump to construction “doesn’t allow time for the proper planning associated with prefabrication,” according to Maschner.

He believes prefab can reduce construction time by standardizing components and processes. He said modular components manufactured off site in control environments allow for mechanical systems construction that parallel site construction activities.

“This approach reduces onsite labor requirements and the potential for delays due to adverse weather conditions, resulting in faster project delivery.”

It also helps when full modularization is already utilized and accepted in engineered equipment and treatment systems.

Completed modules are then released for fabrication early in the design process and delivered on site.

“Expanding the practice to pumping systems, for example, reaps the same benefit of saving time during the build,” said Maschner.

Prefab also facilitates construction and storage of piping systems while site construction is under way.

This, in turn, allows for faster install once work areas are released to piping installers.

Maschner believes modularity and prefab offer “substantial” cost savings in collaborative delivery projects.

He maintains that offsite prefab allows for bulk material purchasing, reduces waste generation and improves quality control for big cost reductions.

“Furthermore, prefabrication minimizes onsite labor requirements, reducing the need for specialized and skilled workers,” said Maschner.

Utilizing a centralized prefabrication facility allows for multiple projects to be constructed at once.

The result is leveraged productivity of the facility without dependence on weather or other site disruptions.