Seven Ways Technology Will Turbocharge Warehouses, Factories..8

Blending ‘Men and Machines’ for Maximum Results...20

American Pavement Specialists ‘Paves the Way’ in Industry...26

Seven Ways Technology Will Turbocharge Warehouses, Factories..8

Blending ‘Men and Machines’ for Maximum Results...20

American Pavement Specialists ‘Paves the Way’ in Industry...26

By Irwin Rapoport CEG CORRESPONDENT

The Williams Brothers Construction Company (WB) is more than one year into the construction of the Texas Department of Transportation’s (TxDOT) $93.9 million SH 35 Griggs Road to I-45/Spur 5 project in the southeast Houston area to improve traffic flow, safety and meet the demands for increased population growth in the area.

The project is part of the Texas Clear Lanes program that is reducing congestion on some of the state’s busiest highways and is expected to be completed in fall 2026.

WB, which secured the contract in March 2023, is constructing a new eight-lane freeway, including 12-ft. wide mainlanes with ramps and four see HOUSTON page 46

Aside from building a wider freeway, crews are building four direct connectors; widening the existing bridge to increase capacity; reducing congestion; and improving overall traffic flow – particularly during hurricane evacuations.

By Lucy Perry CEG CORRESPONDENT

The transportation construction industry faces incredible challenges: As infrastructure ages, budgets tighten, the labor pool remains sluggish and projects increase in complexity, a true up-to-theminute picture of physical assets is critical. At the heart of it all, digital twin technology is transforming the way those who plan, build and maintain infrastructure do their jobs.

Digital technology in general is a powerful tool the industry can utilize to move light years ahead by simply accessing timely data on a project.

Laymor SM400, Stk#: 12756, EROPS, A/C & Heat, 593 hrs., Water System, 8 ft. Broom, 225x75Rx15 Tires, 4 Cy. Kubota Eng $29,500

2018 John Deere 750K LGP, Stk#: 13236, EROPS, A/C & Heat, Radio, 6 Way Blade, 6,733 hrs., 33" Pads, 12 ft. Blade $129,500

2020 Komatsu

EROPS, A/C, 3,625 hrs., 6 Way Blade,80% U/C, 34" Pads, 12' 7" Wide $149,500

Companies

This essential guide expands on DBIA’s Universal Best Practices, offering tailored support to professionals in the water and wastewater sector to enhance project efficiency and success.

The Snow and Ice Management Association (SIMA) held its 27th annual Snow and Ice Symposium June 25 to 28 at the David L Lawrence Convention Center in Pittsburgh, Pa.

18

The rigorous accreditation process required meeting a 40-plus point Accredited Training Provider Standard that included submitting hundreds of pages of documentation demonstrating that the standard was met.

18 TEREX SERVICE SCHOOL PROVIDES HANDS-ON INSTRUCTION FOR TECHS

In June, Terex Utilities held its 39th annual Service School at Lake Area Technical College for 56 participants from across the United States and Canada.

20

The right combination of skills, knowledge and equipment can transform the toughest job site into a success story. One of those stories is Anvil Builders and the company’s ability to help areas get life back to normal after wildfires.

24

Volvo CE, one of the world’s largest manufacturers of construction machinery, announced its partnership with the nonprofit Dream On 3 to become the national sponsor of the organization’s Collegiate Dream Team program.

24 LEEBOY CELEBRATES 60 YEARS OF INNOVATION, QUALITY, SUCCESS

Since 1964, the Lee family has been building and delivering products for the commercial asphalt industry. 2024 marks LeeBoy’s 60th year in business as it keeps its focus on maintaining close customer relationships.

26 AMERICAN PAVEMENT SPECIALISTS PAVES WAY IN INDUSTRY

Promoting American Pavement Specialists has always been a high priority for Bill Stanley, the company’s owner. The name came about partially because the “A” would put them at the top of the list of the Paving Category in the Yellow Pages.

32 DYNAPAC WRAPS PAVER TO SHINE LIGHT ON SUICIDE IN INDUSTRY

The construction industry, while often celebrated for its resilience and productivity, faces a silent crisis that demands urgent attention: suicide among its workforce.

36 BOMAG GROUP APPOINTS INGO ETTISCHER NEW PRESIDENT

On July 1, 2024, Ralf Junker will hand over his position as president of the BOMAG Group to Ingo Ettischer, who has been managing director chief operating officer at BOMAG since July 2023.

40 BOBCAT CO. REVEALS CONTEST WINNER’S BACKYARD MAKEOVER

Turlock, Calif., resident Julie Rummer now has her dream backyard due to the Bobcat backyard makeover contest. Last summer, Bobcat Company announced that Rummer had won the contest.

Case Construction Equipment is beefing up its offering for landscaping companies with new models and bigger features that boost productivity in the yard or on the job site.

Arizona Bejac Corporation www.bejac.com

GLENDALE 1 (800) 772-3522

California Bejac Corporation www.bejac.com

PLACENTIA

SACRAMENTO

1 (800) 772-3522

ANDERSON 1 (800) 772-3522

VISALIA

1 (800) 772-3522

Colorado Power Screening, LLC. www.powerscreening.com

Bane Machinery www.banemachinery.com

DALLAS (214) 352-2468

FORT WORTH (817) 847-5894

TYLER (903) 597-6641

LT T LAKE CITY 1 (800) 772-3522

Washington Orion Equipment www.orion-equip.com

SEATTLE (800) 280-8124

ANCOUVER (800)280-8124

HENDERSON V SAL Utah Bejac Corporation www.bejac.com

(303) 287-0100

Idaho Central Equipment Co. www.centralequipment.us

JEROME (208) 324-8515

POCATELLO (208) 233-2850

Nevada Bejac Corporation www.bejac.com

1 (800) 772-3522

New Mexico Power Screening, LLC. www.powerscreening.com

ALBUQUERQUE (505) 345-4467

Wyoming Power Equipment ofWyoming, Inc www.power-equip.com

CASPER (307) 577-9700

RENO (800) 2808124

Oklahoma Central Power Systems & Services www.cpower.com

OKLAHOMA CITY (405) 324-2330

TULSA (918) 984-6565

Texas Nueces Power Equipment www.nuecespower.com

CORPUS CHRISTI (361) 687-2284

VICTORIA (361) 433-0672

o. offers an extensive lin ing equipment and techn dlddf e distribution net e of earthmoving and ology in the USA. Main tdihb work (956) 267-1495

LAREDO (956)2671495

SAN BENITO (956) 361-0066

VINTON (915) 201-4115

CONVERSE (210) 807-8216

HUMBLE (713) 247-0066

Liebherr USA, C material handli t

components ar Liebherr or in c highest possib the entire drive variety of comp systems. Reach more informati e developed and manufactured in-house by lose collaboration with our partners to ensure the le quality standards.These components include and controltechnology, diesel engines, and a onents for hydraulics, gearboxes and electronic out to your local Liebherr distribution partnerfo on. e r

In the ever-evolving world of technology-driven innovation, the manufacturing industry stands at the forefront of digital transformation.

Companies are pushing toward smarter factories and more efficient warehousing by integrating a network of interconnected devices, machinery, and production systems. This big shift — driven by the need for seamless collaboration, improved data accessibility and enhanced operational efficiency — requires businesses to master the core principles and practical applications that can significantly elevate their operations.

The adoption of Artificial Intelligence (AI) in manufacturing is redefining quality assurance. Imagine a system where advanced algorithms and machine learning scrutinize extensive datasets to identify anomalies on the assembly line with pinpoint accuracy.

At Atlas Copco’s factory in Antwerp for example, AI-driven visual inspections guarantee that each product adheres to strict assembly standards. Early detection of errors reduces waste, curtails rework and maintains product integrity, thereby boosting overall quality and customer satisfaction.

In today’s manufacturing landscape, teams require a broader spectrum of knowledge to effectively assemble products. Unlike a decade ago, digital solutions now provide invaluable support with the bigger variation and complexity within products nowadays.

Atlas Copco embraces this evolution by equipping workers with digital resources tailored to each product. Through digital

instructions and immersive training via virtual reality (VR), workers are guided through assembly processes with improved precision.

This dynamic approach enhances efficiency and increases quality, while empowering workers with the skills needed to excel in the modern manufacturing environment.

Meet the cobots — collaborative robots primed to work alongside assembly teams. Armed with sensors and AI, cobots have quickly become dependable allies across the manufacturing sector, sharing the workload and boosting productivity. These clever machines shoulder repetitive or physically demanding tasks, while bringing an adaptability that ensures smooth transitions between operations. They represent a new paradigm in manufacturing, proving that automation can enhance human potential rather than replacing it; and driving efficiency and innovation to new heights through collaboration.

The Internet of Things (IoT) is the beating pulse of modern manufacturing, collecting troves of data ripe for AI analysis. These sensors can be embedded in everyday objects, machines, equipment and infrastructure to monitor and gather real-time information about their surroundings or operating conditions.

Atlas Copco taps into IoT insights to help fine-tune production processes and trim costs; using this highly advanced technology, can make data-driven decisions, optimizing operations and fuelling productivity.

In warehousing, AI-driven management systems play a pivotal role in optimizing inventory control and keeping operations nimble and responsive. These systems automate crucial processes such as tracking and handling of materials, significantly reducing the risks of overstocking or stockouts. Using its arsenal of sophisticated in-house systems

to ensure effective storage and movement of materials, Atlas Copco has detailed control over its inventory, supporting continuous production without surplus costs.

AI-powered maintenance, extends machinery lifespan and ensures that production processes run smoothly. Implementing a combination of AI data analysis and AI vision systems reduces operational disruptions and maintenance costs, contributing to more reliable production timelines.

Smart energy management systems are crucial for transformation. By harnessing real-time data, these systems unveil invaluable insights into energy consumption patterns, illuminating areas ripe for optimization. Case in point: by leveraging data analytics to identify and address inefficiencies, Atlas Copco’s Portable Air division made a bold transition to hydrotreated vegetable (HVO) oil in test cells and labs at its Antwerp facility; underscoring the transformative potential of data-driven initiatives.

As digital technologies evolve, their integration into manufacturing and warehousing is indispensable for companies aiming to remain competitive. By embracing a culture of innovation, businesses can reap the vast potential of digital transformation; while setting industry standards and shaping future industrial trends. This proactive approach not only meets current market demands but also anticipates future challenges, targeting long-term success when traversing the digital frontier.

For more information, visit www.atlascopco.com.

(All photos courtesy of Atlas Copco.)

The Design-Build Institute of America (DBIA) has released its updated Water and Wastewater Best Practices document.

This essential guide expands on DBIA’s Universal Best Practices, offering tailored support to professionals in the water and wastewater sector to enhance project efficiency and success. By addressing the unique challenges of this vital industry, these targeted Best Practices aim to ensure high-quality design-build projects that prioritize public health and safety.

A subgroup of DBIA’s Water/Wastewater Markets Committee, led by Chair David Hill, DBIA, and Co-Chair Drew Zirkle, DBIA, collaborated with a diverse team of experienced experts and partner organizations to update these best practices.

“The ever-increasing demands of water and wastewater as a musthave infrastructure require continuous improvement and innovation of not only what we build but how we deliver what we build,” said Hill. “The DBIA

Water/Wastewater Best Practices provide a continuous strong foundation to tackle these demands and deliver the highest certainty of outcome.”

The Water and Wastewater Best Practices Primer is essential for several reasons. It offers a structured approach to managing the unique challenges of water and wastewater projects, ensuring public health and safety are prioritized. The guidance on procurement and contracting helps streamline processes and mitigate risks, leading to more successful project outcomes.

By fostering collaboration among stakeholders and promoting ethical conduct and competence, the document supports the development of high-performing teams that can deliver exceptional results. DBIA is dedicated to continuous improvement and the dissemination of leading-edge information.

The Water and Wastewater Best Practices Primer aligns with DBIA’s Universal Best Practices, with an emphasis on the specific needs of the water and wastewater sector.

• Navigating Local Governance: The sector’s local implementation, often managed by cities, counties or quasi-governmental utilities, requires intricate procurement processes influenced by state statutes, local ordinances and utility board regulations. The Best Practices document provides guidance to navigate these challenges effectively.

• Addressing Technical and Logistical Challenges: These projects are inherently demanding due to their impact on public health and safety, the need for public stakeholder engagement and stringent regulatory approvals. The primer outlines strategies for addressing these demands, including integrating operations and maintenance

staff early to enhance collaboration and project success.

• Choosing the Right Delivery Models: The document emphasizes selecting the appropriate organizational structure and project delivery model, such as Progressive DesignBuild (PDB), Design-BuildOperate (DBO) and Design-BuildOperate-Maintain (DBOM). These models offer flexibility and expanded scope, including financing and maintenance services.

• Upholding Ethical and Professional Standards: The Best Practices are anchored by ethical conduct, demonstrated competence, sustainable professional development and support for diversity, equity and inclusion. These principles ensure projects are executed with integrity and excellence.

• Comprehensive SectorSpecific Guidance: Organized into three primary sections — Procuring Design-Build Services, Contracting for Design-Build Services and Executing DesignBuild Projects — the primer pro-

vides detailed best practices and implementation techniques tailored to the water/wastewater sector.

Backed by Industry Data, Trends

DBIA has released the updated Water and Wastewater Best Practices Primer at a time when design-build is increasingly recognized as the fastest-growing and most efficient project delivery method.

According to the 2023 FMI Mid-Cycle Update Report, designbuild construction spending is anticipated to reach over $405 billion by 2026, with a compound annual growth rate (CAGR) of 5.2 percent from 2022 to 2026. This growth is driven by the advantages of design-build, including faster project delivery, reduced costs and improved collaboration among project stakeholders.

Specifically, the water and wastewater segment is expected to see significant investment, accounting for 7 percent of the total design-build construction spending during this period.

The Snow and Ice Management Association (SIMA) held its 27th annual Snow and Ice Symposium June 25 to 28 at the David L Lawrence Convention Center in Pittsburgh, Pa. The national event brought together snow and ice management professionals, industry suppliers, and snow and ice product consumers.

The 2024 event featured keynote speakers, networking events, workshops, welcome reception and educational sessions centered on business, management and operations, process and leadership, all geared toward increasing efficiencies and generating sustained success and growth.

see SNOW page 40

equipment line and outstanding capabilities at the

ucts help remove snow and ice.

how their

Niece Water Towers deliver reliability and durability when you need fast mobile water service. With a 12” discharge tube it fills your tanks at a rate of over 1,000 gallons per minute. Offers removable power pack for security, fifth wheel tow hitch, professionally engineered and constructed.

It features (8) legs for stability

5th wheel set up for quick “tow and go.”

In June, Terex Utilities held its 39th annual Service School at Lake Area Technical College for 56 participants from across the United States and Canada.

The service school provides a hands-on experience that helps equipment technicians understand more on inspecting, maintaining, troubleshooting, servicing and operating equipment.

This year, the school consisted of nine stations, with Terex team member instructors from the Technical Support, Field Service, and the Regional Production Support Managers group. Stations included training on specific aerial devices and digger derricks and instruction on maintenance.

added a class on the new ANSI standard for 15-year structural testing which states that structural tests are required when a unit reaches the age of 15 years, then every 10 years. This station went over what this all entails and participants got to perform the test on an aerial unit.”

While the training is geared for technicians who work on the equipment, other individuals such as trainers, can benefit from this handson learning experience.

Roger Pothier is the owner and an instructor at Live Line Utility Training Inc. in Canada. With 20 years of experience as an automotive and heavy-duty mechanic, Pothier opened Live Line Utility Training in September 2023, which is an

“We are constantly looking for ways to improve the school by receiving feedback through surveys each year,” Will Biberdorf, product support tech said. “This year we

training supplier for the Canadian

For more information, visit www.terex.com/utilities.

Associated Training Services (ATS) has been qualified by CCO Education Services (CCO EDU) as an Accredited Training Provider (ATP).

John Klabacka, president of ATS, said, “We are proud and excited to be an Accredited Training Provider under the new CCO EDU accreditation standards. ATS understands the importance of training providers meeting higher level standards to give potential customers a measure of judging quality when it comes to training and preparation for CCO certification testing.”

dard was met. CCO EDU thoroughly audited ATS and conducted interviews to verify the information.

Organizations earning the prestigious ATP designation can be found at ccoedu.org/accreditedtraining-provider-listing/

The rigorous accreditation process required meeting a 40-plus point Accredited Training Provider Standard that included submitting hundreds of pages of documentation demonstrating that the stan-

CCO EDU launched the ATP program in 2024 to demonstrate evaluation and identification of high-quality training providers.

“The ATP designation identifies training organizations that have met the stringent standards put in place by CCO EDU,” said CEO Thom Sicklesteel. “We congratulate John Klabacka and ATS on meeting this standard and congratulate them on the well-deserved ATP recognition.”

]The right combination of skills, knowledge and equipment can transform the toughest job site into a success story. One of those stories is Anvil Builders and the company’s ability to help areas get life back to normal after the devastation from wildfires.

Cleanup after the Bay Branch wildfires south of San Francisco in 2020 presented a unique set of challenges: hazardous terrain, toxic substances from burned structures, and washed-out roads and mudslides in the middle of the rainy season. It was important to remove materials quickly and efficiently to prevent contamination of the environment and nearby communities.

Anvil Builders had a reputation and the qualifications to accomplish this project. Based on its experience handling similar scopes of work, its technical skills to perform the work and proven production capability, the company completed the project successfully, safely and on time.

“We’ve assembled a seasoned team of industry professionals with decades of experience,” said Richard Leider, founding partner and CAO. “We actively train and mentor at all levels to ensure we have the right people to drive our projects forward and continue to be best in class.”

The health and safety of those people is Anvil’s top priority, which goes hand in hand with identifying the best method to get jobs done safely and efficiently.

California’s Office of Emergency Services (CalOES) awarded Anvil Builders the $244-million contract for fire debris and hazard tree removal from more than 1,000 damaged properties. Anvil’s team of 100 fire debris and 25 hazardous tree removal personnel began work in December 2020, building temporary replacements for burned-out bridges, improving roads to reach remote mountainous properties and felling trees that were a risk to critical infrastructure and people.

“It was spread out over five counties,” said Eric Damron, general superintendent of Anvil. This increased the need to coordinate efforts to be safe and efficient.

“There wasn’t much cell service, so you couldn’t talk throughout the day. It was in the mountains and road conditions were hazardous. People were living in isolation.”

Damron’s role was overseeing the day-today operations, from logistics to personnel. Preplanning had taken weeks and months to determine the best way to move equipment to far away locations, he said. Selecting the right equipment and individuals to execute the plan safely and efficiently was critical.

Anvil used a variety of machines made specifically for felling, handling, and pro-

cessing hazard trees, including SENNEBOGEN Tree Care handlers, Albach Diamant chippers, tracked chippers and chip vans.

Anvil Builders used SENNEBOGEN 718M E and 728M E machines for the Bay Branch project.

“Our SENNEBOGEN Tree Care handlers were able to minimize exposure to safety risks. We were able to reduce the crew size because they were multi-purpose,” said Damron. “The 50- to 70-foot reach for material meant we could dismantle a tree safely. It was huge. On a good day, we were able to remove 500 to 700 trees.”

Hayden Vreeburg, equipment manager, agreed.

“It has a lot of reach. You can take down a lot of trees in a day. It is high, high production. This helps with safety because we have less people on the ground.”

Several features of the machines enabled crews to work around existing trees, power lines, mountainous terrain, structures and devasted landscape. The reach, with the K13 boom and stick set-up, 6 ft. 9 in. telescoping arm, and elevating cab increased effectiveness and safety. Operators could work at a safe distance with clear visibility, said Damron.

“The most important feature was the reach, followed by the ability to elevate the cab so the operator can clearly see the work site.”

The speed of the machines and the responsiveness of the hydraulics allowed crews to cut down trees in a timely fashion.

The SENNEBOGEN urban Tree Care handler can grab, cut, move and stack tree sections more efficiently than conventional techniques. They are able to fully immobilize and cut trees up to 28 in. in diameter. With bullet-proof glass in front of them, operators have good sightlines from inside the cabs, improving productivity and safety.

Dan Hickman, fire debris project manager of Anvil, said having no one on the ground in the fall zone was another asset.

“The productivity of the SENNEBOGEN Tree Care handlers was very helpful.”

This applied to properties with both houses and trees or places where trees posed a hazard to the debris-removal team.

“It is dangerous work. Stuff breaks free. A burned house is not predictable. The SENNEBOGEN machines made the operations safer,” said Hickman.

“Being on rubber tires, as opposed to tracks, they sped up operations along roadways and without damaging any of the asphalt.”

Damron said the agility of the 718M E and 728M E machines allowed them to “run up and down roads.” This is handy when

SENNEBOGEN photo

Several features of the machines enabled crews to work around existing trees, power lines, mountainous terrain, structures and devasted landscape. The reach, with the K13 boom and stick setup, 6 ft. 9 in. telescoping arm, and elevating cab increased effectiveness and safety.

doing highway work, said Vreeburg.

“One of the advantages is being able to move around on a road. You can drive on the pavement. The transportability of the 718M E and 728M E is also huge. No special permits are required and with a lowboy, it is easy on and off.”

The machines also are low-weight and compact, making them easier to move into locations. The elevated cab on the 728M E provides a viewing height up to 20 ft. 5 in. and can be tilted up to 30 degrees, guaranteeing good sightlines. A roof and windshield guarding over the bullet-proof glass maximizes the protection.

Originally, the project was scheduled for completion in May 2021. However, CalOES issued Anvil Builders a $70-million change order to expand operations to include several state parks and regional summer camps, including Big Basin Redwoods State Park.

“One of the biggest challenges was that the project became five times what we were anticipating,” said Damron.

Hickman agreed: “The biggest challenge was coordinating so many different parcels rather than one contained site.”

Damron said the state parks were a challenge on their own, “a job within a job.”

They included lodges, maintenance buildings, homes and trees. Some buildings had historical significance.

“We had to be selective in what material we removed.”

Across five counties, hundreds of proper-

ties needed to be cleared. Each area presented unique conditions: different tree species, terrain and logistical challenges.

Working in remote areas also presented challenges in maintenance and safety.

“When you are a few hours away from a mechanic, all our operators are trained on how these machines work and how to work on them,” said Vreeburg.

SENNEBOGEN’s UPtime Kits provide parts and equipment for operators to repair on-site.

“They are very reliable, but sometimes you have damage from a limb falling. The SENNEBOGEN parts and service departments are really great,” said Vreeburg.

This was particularly true when specialty parts were required.

“Having SENNEBOGEN in the U.S. means if you need something, it’s only a day or two away. This is a big asset that helped to keep our projects on time.”

Over 10 months, crews from Anvil Builders safely took down more than 25,000 hazard trees, many of them 100 ft. redwoods and Douglas firs. Nearly 500,000 tons of fire debris was trucked to end-use facilities, often over narrow, winding backroads. More than 100,000 labor hours were logged with zero recordable injuries.

“SENNEBOGEN helped us meet the challenges,” said Hickman. “It streamlined how well the team performed.”

“The SENNEBOGEN machines are able to adapt to a lot of areas that other machines can’t,” said Damron. “I could send a SENNEBOGEN into any area, sight unseen, knowing it could take that tree down. The reach, mobility and the independent outriggers can level out any terrain. A ton of features make it easy to operate with minimal training. It is very operator-friendly.”

Having that confidence to meet any condition helps Damron do his job successfully. The results of a successful project are what motivates him.

“Helping people with all the cleaning up so they can have a fresh start” is his reward.

“When you see their faces and the reactions when they see what you’ve done, so they can start rebuilding.” That’s what matters. “At the end of a project, with nobody hurt and everything done, and you’ve met the timeframe from the state.” That’s job well done. “We can go after other tree projects because we are so efficient with the SENNEBOGENs. It’s changed the industry.”

Vreeburg said, “They were a gamechanger for us. They definitely cut a lot of wood. That’s the goal.”

For more information, visit www.sennebogen-na.com.

Realistic Scale Models of

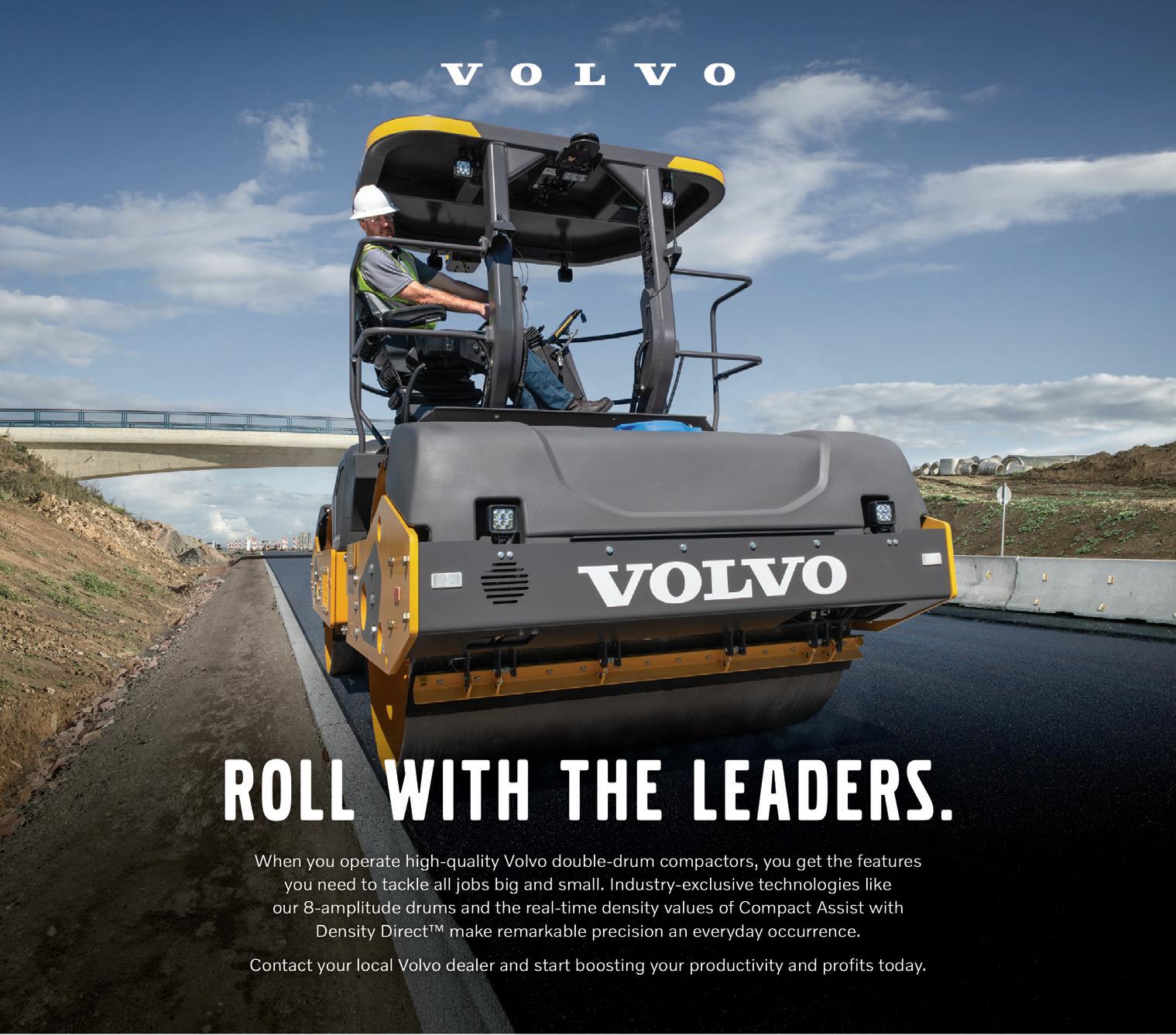

Volvo Construction Equipment, one of the world’s largest manufacturers of construction machinery, announced its partnership with the nonprofit Dream On 3 to become the national sponsor of the organization’s Collegiate Dream Team program.

The two organizations have teamed up to bring the fastestgrowing Dream On 3 (DO3) program to communities across the United States and Canada. For more than 10 years, DO3 has granted sports-tied wishes for individuals with life-altering conditions, including mental health challenges and intellectual disabilities.

The Collegiate Dream Team program, established in 2020, allows student leaders to rally behind an individual within their community who is living with a life-altering medical condition by making their sports dream a reality, within the framework of their school’s athletic culture. DO3’s exclusive curriculum-based program is designed to help students grow personally and professionally while giving them the opportunity to make a meaningful impact in their community.

Volvo CE is investing in the program as an expansion of its Building Tomorrow Project, a global initiative to spread social good through meaningful activities at the local level. In addition to the corporate sponsorship, Volvo CE dealers across North America are hosting Collegiate Dream Teams within their regions. To date, commitments have been signed with Ascendum, ROMCO Equipment Co., Alta Equipment Company and Cowin Equipment Company, with several more expected to be announced soon.

“Dream On 3 allows Volvo and our dealer network to step outside of our day-to-day work and rally behind a larger

cause that empowers both the individual and the student leader teams,” said Scott Young, head of sales Region North America of Volvo CE. “Through these events, we not only raise awareness of the challenges people with special needs face, but we also raise spirits and a sense of belonging within the wider sports community.”

Dream Team activations span all genres of athletics, including football, basketball, weightlifting and soccer. Students create the experience for their school’s Dream Team recipient, and Dream Team sponsors provide ongoing mentorship and event-day support. College Dream Teams are active at 18 universities nationwide. With the Volvo CE sponsorship, that number is expected to grow.

“By working together, we are confident we can help break down barriers that often prevent people with disabilities from realizing full equity, inclusion and access to community,” said

In September 2023, Texas dealer ROMCO Equipment helped a Dream Team wish recipient fulfill his goal of meeting the Southern Methodist University football team at their home game against the University of Nebraska.

Brandon Lindsey, co-founder of DO3, “It’s one thing to simply offer this kind of programming; we believe that engaging student leaders in the process is the critical action needed to make a lasting difference.”

In September 2023, Texas dealer ROMCO Equipment helped a Dream Team wish recipient fulfill his goal of meeting the Southern Methodist University football team at their home game against the University of Nebraska. The staff also hosted a full-on tailgate in his honor and presented him with a pair of custom cowboy boots.

Upcoming activities with Volvo dealers Alta Equipment Group and Ascendum Machinery are planned at the University of Miami and North Carolina State, respectively, in early February.

For more information, visit dreamon3.org.

(Photos courtesy of Volvo.)

Since 1964, the Lee family has been building and delivering products for the commercial asphalt industry. 2024 marks LeeBoy’s 60th year in business as it keeps its focus on maintaining close customer relationships while delivering what its customers want and need, to better their paving operations.

BR Lee developed the first self-propelled commercial paver in 1970. That Model 500 featured three patents — for its tilt hopper, its hydraulic extensions and its under-auger cutoff gates — and can be said to have opened the door to profitable commercial paving for thousands of paving contractors.

BR’s son, Mike Lee, is still involved in the business today. He has seen the company grow and change in many ways over the years, but listening to their customers on how they can help them improve their business performance has always been a priority at LeeBoy.

“I’ve seen a lot of hard work over the years to get LeeBoy to where it is today,” Lee said. “We are continuously making our products better, faster and more reliable for our customers and dealers. We value feedback from our customers to build and deliver the best products.”

From humble beginnings in BR’s garage

where he built one drag box, the company has invested heavily in its own operations over the years to develop the equipment and innovations the industry needs to thrive.

“LeeBoy’s mission is to improve our customers’ lives and livelihood,” Shannon Seymour, president and CEO at LeeBoy said. “We aim to produce the most productive, reliable and easy-to-use equipment in the industry. We listen to the voice of the customer through our dealers, through sales and service associates, and directly at our factory proving grounds.”

LeeBoy also has been an innovator in its equipment development, improving models

with customer requests and as the needs of the industry have changed. To do this, LeeBoy has vastly improved its internal processes to be able to achieve the needs of its customers.

“LeeBoy has invested heavily in manufacturing operations,” Seymour added. “We have grown from a lean and scrappy, yet effective business into a more structured organization with documented processes and procedures. We also view service parts fulfillment as a key element in keeping our customers up and running, which keeps them buying LeeBoy equipment.”

Over the years, the company has evolved by hiring and developing teams to ensure the LeeBoy name continues to be known as a valued partner in the industry.

“In 2001, LeeBoy hired the first group of engineers to assist in creating drawings to develop higher quality parts to make our machines function at peak performance,” Mark Bolick, general manager of product support at LeeBoy said. “Over the last 15 years, our engineering team has vastly improved documentation for equipment and parts manuals to ensure that our products continue to be the leaders of the commercial asphalt paving industry.”

LeeBoy has advanced in service process-

es and operations to avoid machine down time for customers.

“Five years ago, the field service representatives were relocated into the manufacturing facility, forming the Rapid Response team as we know today. This team is dedicated to providing service support for our dealers,” Bolick added. “LeeBoy Rapid Response along with our certified service schools, help our dealer technicians know more about our products which allows them to make faster repairs for the end users.”

While much has changed over the years at LeeBoy, the feeling of family is something that has remained the same and those relationships will continue to drive success for the business and their customers.

“The close-knit feeling that emerged from the Lee family business years ago still exists today with our customers and dealers,” Bolick said. “We continue to introduce our valued business partners to the latest trends and technology to outpace the competition. Our customers are the backbone to our success and we will always continue to build our equipment with the paving professional in mind.” For more information, visit www.leeboy.com.

An online web platform, VisionLink Productivity for cold planers delivers near real-time machine and jobsite data designed to improve the contractor’s productivity.

Available for Cat PM620, PM622, PM820, PM822 and PM825 cold planers, VisionLink Productivity gathers, analyzes and summarizes detailed data such as time spent waiting for trucks, cutting and travel at the jobsite as well as distance cut, fuel burn, location and cycle mapping.

This gives contractors insights into jobsite productivity and equipment utilization.

VisionLink Productivity segments data into easy-to-navigate dashboards, providing multiple ways to view more detailed data and key product indicators (KPIs). Contractors can quickly track the hours and distance milled each day and visualize excess travel, slow milling speeds and stoppage.

Eliminating manual data gathering, detailed reports are available in PDF, Excel and CVS formats and can be scheduled for email inbox delivery.

This powerful reporting technology enables contractors to measure performance of cycle segments; track and eliminate unnecessary fuel consumption; and compare operations between shifts, machines and projects. Allowing for the identification and reduction of unnecessary waiting, companies can achieve longer, more productive milling cycles, improve

mating for future projects, and

optimize profitability by increasing efficiency and reducing costs, according to the manufacturer.

A cloud-based platform, VisionLink Productivity gathers and summarizes machine telematics and jobsite data from all equipment at the job site, regardless of the brand, and can be accessed anywhere via a mobile, tablet or desktop device. Fleets with mixed OEM equipment brands can all be incorporated into VisionLink Productivity.

For more information, visit www.cat.com.

Promoting the brand American Pavement Specialists has always been a high priority for Bill Stanley, the company’s owner. Thirty years ago, when he started the company, the name American Pavement Specialists came about partially as a result of the fact that the “A” in the American Pavement Specialists name would put them at the top of the list of the Paving Category in the Yellow Pages.

But that was 30 years ago, and the Yellow Pages have all but disappeared. In the early 2000s, Stanley saw that the trends had shifted, and it was time to put more emphasis on Web-based marketing.

“My vision was a website that would help customers understand what we offer and what various aspects of their project would look like,” he said. “I envisioned a website that would have a ‘Paving’ tab and give a video of what paving looks like. The same idea with ‘Milling,’ ‘Striping,’ and any of the services that we offer.

“Unfortunately, Web development at that time was very expensive and it was difficult to accomplish exactly what I was looking for,” he added. “It didn’t really have a name at the time, but we were one of the first companies to use social media to promote ourselves. There was no Instagram, Tik Tok or YouTube, but what was out there was a site called Facebook that was wildly popular with young people, and that’s where our social media presence started.

“We made up our own Facebook business page account and we started by taking pictures of trucks, primarily because my kids were at an age when they thought trucks were really cool and would get a lot of attention. We then started to put pictures of projects that were completed or in the process of being worked on. In no amount of time at all our Facebook became wildly popular. The best part was it was free.

“Over time we loaded Facebook with pictures and videos of everything we do. If we were quoting a milling job and the customer asked about the milling process or what equipment we use, we could send them straight to Facebook. When Instagram came along, we immediately got involved with project pictures and in no time at all we had 10,000 followers. Instagram, with its heavy emphasis on photographs, turned into an overnight sensation for us. We currently have 143,000 followers on Instagram.

“YouTube has been another big success for us. We just keep feeding it videos of our projects. The YouTube channel has been a big hit within the industry. I am constantly amazed by how many of our fellow contractors and people involved in paving equipment manufacturing are tracking our posts on YouTube.”

Stanley’s sons have been involved in the business since a very young age, and they take a lot of pride and an active role in the company’s Web marketing — they developed the idea of becoming social media influencers within the paving industry. They also developed the phrase “Raised on Blacktop.”

The idea was to create a forum that promotes the asphalt and paving industries as well as giving information on how paving contractors can improve their businesses. Once again, it became nearly an overnight sensation, Stanley said.

Today “Raised On Blacktop” has 75,000 Instagram followers as well as several thousand followers on Facebook. In fact, the “Raised on Blacktop” concept has become so popular it now has its own apparel line. There is a daily stream of orders for branded hats, t-shirts and hoodies. In 2023, they had hundreds of thousands in just t-shirt sales. Orders come from across the world, including Paraguay, Australia and

Saudi Arabia.

The company is even currently working on a deal to create “Raised on Blacktop” work shoes.

According to Stanley, the Raised on Blacktop theme has become so popular that companies like LeeBoy, Mauldin, John Deere, Bagela, Wirtgen, Trout River Trailers, XBroom Sweepers and Shoulder Master sweepers have released special “Raised on Blacktop” editions of their equipment.

“They pay us to operate their equipment and then promote it on our social media platforms,” Stanley said. “As an example, Mauldin released a Raised on Blacktop motor grader that includes the Raised on Blacktop logo prominently displayed on the machine and a number of upgrades to the machine that we worked with Mauldin to develop, including a special lighting package, a more comfortable seat and a special paint job.

can maintain work at healthier pricing levels because they’re not competing with competitors that do inferior work.

“Trout River Trailers worked closely with us to develop an auger truck for an asphalt transfer trailer. It features an 8foot auger for unloading in specific spots, particularly in hard-to-reach areas, and the auger is completely operated by a remote control to give very precise delivery and allowing your worker to see exactly what is going on. The end result is something that looks a little bit like a hybrid of an asphalt trailer and stone slinger. “Trout River was amazing to work with. We had a concept of what we wanted but did not have the capacity to create it and their engineers worked very closely with us to create a new product to help us specifically meet some of our needs.”

XBroom, a sweeper company, also has gotten onboard with a Raised on Blacktop special edition. Like the others, it features the Raised on Blacktop logo and then some added features that aren’t included in its standard lineup.

“The LeeBoy special edition model is a LeeBoy 8520 paver, again with the Raised on Blacktop logo and some extra features that we worked with LeeBoy on. For instance, we made a tool carrying kit that holds shovels, rakes, etc. It has a special color scheme, additional LED lighting and strobe lights for visibility. More than 250 machines have been sold thus far.

“This machine is so popular that LeeBoy has them on backorder. LeeBoy was the first company to work with us on special edition machines. We have a great history with LeeBoy; we’ve done business with them since we opened our doors and I’ve probably bought 20 LeeBoy machines in the past 25 years. We’ve stayed very loyal to the LeeBoy brand. They demonstrate a huge commitment to the paving industry, and they are leaders in innovation. Just about every year there are improvements to the machines that were close to perfect to begin with.

“Raised on Blacktop is designed to accomplish that, but also to help encourage a new generation of people coming into this industry and make sure that they are well suited to do excellent work.

“We consider ourselves a premium contractor. We do extremely good work and as a result we get paid a premium price. We are showing other contractors how to achieve getting themselves into this premium contractor position. It is to our advantage at American Pavement Specialists to have as many paving contractors as possible doing premium work. The reason, if everyone is doing premium work, the industry

“I have been in this business for 45 years, where I started with a pick and a shovel. We have a lot of experiences to share. We are always looking for ways to do a better job and when we find them, we use Raised on Blacktop and its social media presence to share that information.

“We try to instill in all of our followers the importance of giving your employees as good a working environment as you can possibly have, considering the extreme conditions we work in. For instance, we have started ordering our asphalt rollers with a heated and air-conditioned cab. It’s critical these days to keep your employees as happy as possible. We don’t find ourselves in the polarizing position of not being able to find help.

“Through things like putting cabs on rollers, we make our employees’ working environment as pleasant as possible. The machines in our fleet are new or like-new, which is a pleasure for an employee to operate. After every job, we clean and service every piece that’s been used so that our employees have good and reliable equipment to go out and work with. American Pavement Specialists has built a brand that people want to work for.”

The service and maintenance of the equipment fleet does a lot more than just keep employees happy. The equipment in the fleet is typically worth hundreds of thousands of dollars. Keeping machines in peak working order is a part of the company’s philosophy that pays off with significantly longer life of the machines, which in turn pays big dividends.

Stanley’s heavy emphasis on marketing his company, producing excellent quality work and taking good care of his equipment has all paid off. In Connecticut, Stanley said, he is known as the guy you want doing your job. It’s not unusual for potential customers to immediately say, “yes, I’ve heard about you guys, you do really good work.”

American Pavement Specialists is a marketing-driven company, and it does far more than market its website and its social media platforms. For example, at one time it sponsored a car in the NASCAR truck series that was driven by Spencer Boyd. Another aspect of its marketing vision is having every machine in the fleet carefully detailed with the company’s logo, and then making sure that every machine looks as shiny and clean as the day it was purchased when it is delivered at the job site, further enhancing American Pavement Specialists’ image.

For more information, visit www.americanpavement.com. CEG

(Photo copyright 2024 Construction Equipment Guide. All Rights Reserved.)

Efficiency and Productivity

with

and operator comfort in

adaptive

and

astecindustries.com

Closner Equipment

www.closner.com

Rhome, TX 817-708-9108

Schertz, TX 210-732-2131

Manor, TX 512-272-8200

Waller, TX 936-525-9949

www.pacwestmachinery.com

Seattle, WA 206-762-5933

Spokane, WA 509-534-5933

Pasco, WA 509-547-5933

Mt Vernon, WA 360-588-3083

Portland, OR 503-252-5933

www.power-equip.com

Farmington, NM 505-326-1413

Durango, CO 970-247-8830

Denver, CO 303-288-6801

Eugene, OR – Branch 541-302-3762 Power Equipment Company

Colorado Springs, CO 719-392-1155

Grand Junction, CO 970-243-0722

Greeley, CO 970-353-1224

www.tristatetruckandequip.com

Belgrade, MT 406-388-5818

Billings, MT 406-245-3188

Casper, WY 307-472-1818

Great Falls, MT 406-452-9551

Albuquerque, NM 505-345-7811 Tri-State Truck and Equipment

Rock Springs, WY 307-362-4000

wwwshaferequipmentco.com

Sparks, NV 208-801-7772

www.boxcerequipment.com

Tulsa, OK 918-272-7237

The construction industry, while often celebrated for its resilience and productivity, faces a silent crisis that demands urgent attention: suicide among its workforce. It’s crucial to shine a light on this pressing issue and mobilize efforts to support those in need within the construction sector.

“Supporting suicide prevention efforts in the construction industry isn’t just about saving lives; it’s about recognizing the inherent dignity and value of every individual within our workforce,” said Jamie Roush, president and general man-

At World of Asphalt, Dynapac addressed the silent crisis and shined a light on suicide in the construction industry with a D30W highway paver, bringing awareness to the support systems for construction workers navigating mental health challenges.

ager of Dynapac.

“By fostering a customer of empathy, support, and understanding, we not only protect the mental health and wellbeing of our workers but also strengthen the foundation upon which our industry thrives.”

Dynapac has a longstanding relationship with Dr. Vince Hafeli, signing the Suicide in Construction Awareness Proclamation at the Florida Transportation Builders’ Association on Feb. 7, 2023. Since then, Hafeli has spoken at Dynapac company events, and when presented with the idea of a special wrapped machine, both parties were all in.

At this World of Asphalt, Dynapac addressed the silent crisis and shined a light on suicide in the construction industry with a D30W highway paver, bringing awareness to the support systems for construction workers navigating mental health challenges. Dynapac also raised funds for the cause with an interactive experience that will allow attendees to take the #NotToday pledge by having their photo taken by the display.

“As we unite in solidarity, let us reaffirm our commitment to prioritizing mental health, breaking down barriers to care, and ensuring that no construction worker suffers in silence. Together, we can build a brighter and healthier future for all those who contribute to the fabric of our communities,” the company said.

If you or someone you know is struggling or in a crisis, help is available. Call or text 988 or chat 988lifeline.org.

Kasi Infrared, a pioneer in innovative asphalt restoration solutions, presented the Patriot Infrared System at World of Asphalt 2024.

This truck-mounted, self-contained infrared restoration system is poised to transform the way asphalt repairs are performed, offering unmatched efficiency, convenience and sustainability, the manufacturer said.

The Kasi Patriot integrates multiple functions onto a single chassis, streamlining the asphalt restoration process. Featuring a 48 sq. ft. infrared pavement heater, a 3 or 5-ton capacity asphalt reclaimer, ample tool storage, compactor compartment and a dumping waste bin, the Patriot provides a comprehensive solution for asphalt restoration needs.

Hydraulic controls ensure ease of operation, empowering a two-person crew to execute top-quality asphalt restorations with precision and efficiency.

“At Kasi Infrared, we are committed to pushing the boundaries of asphalt

www.arnoldmachinery.com

Las Vegas, NV 702-642-9000 Phoenix, AZ 602-414-1900 Tucson, AZ 520-294-7677 Albuquerque, NM 505-895-1565

Beaumont, TX 409-212-8100 Brenham, TX 979-836-6641 (North) Houston, TX 281-987-1990 (South) Houston, TX 713-649-0940

restoration technology,” said Daniel Martin, marketing manager at Kasi Infrared. “The Patriot Infrared System represents the culmination of our dedication to innovation, design excellence and superior workmanship. By integrating advanced features and functionality, the Patriot delivers unparalleled performance, durability, and ease of use.”

The Infrared Process employed by

the Patriot System offers numerous advantages over conventional repair methods. With repair times as short as 25 minutes, minimal disruption to traffic is ensured, enhancing safety and efficiency on roadways. Additionally, the Patriot’s all-in-one design reduces the need for multiple pieces of equipment, streamlining operations and saving valuable resources. Its ability to prevent cold joints ensures long-lasting repairs that resist future deterioration, while its environmentally friendly approach recycles existing asphalt and minimizes waste, contributing to sustainability efforts, according to the manufacturer.

“By choosing the Kasi Patriot, road maintenance professionals can enjoy faster repair times, reduced equipment requirements, lower material consumption, decreased manpower needs and a more environmentally friendly approach to asphalt restoration,” added Martin.

For more information, visit www.kasiinfrared.com.

www.closner.com

Schertz, TX 210-732-2131 Rhome, TX 817-708-9108 Manor, TX 512-272-8200 Waller, TX 936-525-9949

closner.com

6532 East Highway 114 Rhome, TX 76078 817-708-9108

21910 FM 2252 Schertz, TX 78154 210-732-2131

13800 FM 973 N Manor, TX 78653 512-272-8200

18851 GH Circle Waller Industrial Park Waller, TX 936-525-9949 ascoeq.com

5980 S M L King Jr Pkwy Beaumont, TX 77705 409-746-5102

202 I-35 Frontage Road Belton, TX 76513 254-613-1500

2800 Hwy 290 E Brenham, TX 77833 979-836-6641

1875 N Earl Rudder Fwy Bryan, TX 77803 979-779-8942

1512 Neptune Dr. #9706 Clinton, OK 580-323-3422

2019 Airport Fwy Euless, TX 76040 817-283-2844

980 N Sam Houston Pkwy E Houston, TX 77032 281-987-1990

6203 Long Drive Houston, TX 77087 713-649-0940

27500 E University Drive Aubrey, TX 76227 972-441-2726

12805 US-290 E Manor, TX 78653 512-272-8922

7100 SW 3rd Street Oklahoma City, OK 73128 405-789-6812

902 SE 9th Avenue Perryton, TX 79070 806-435-7773

1920 S East Loop 410 San Antonio, TX 78220 210-333-8000

3600 US-82 Sherman, TX 75090 903-893-7586

401 FM 148 Terrell, TX 75160 972-563-2171

12210 E 1st Street Tulsa, OK 74128 918-437-5085

2602 E Front Street Tyler, TX 75702 903-593-0201

2900 Henry S Grace Fwy Wichita Falls, TX 76302 940-687-2726

beeequipmentsales.com

2506 East Slaton Highway Lubbock, TX 79404 806-745-1511 855-813-3775

nixonegli.com

2044 S. Vineyard Avenue Ontario, CA 91761 909-930-1822

800 E. Grant Line Road Tracy, CA 95304 209-830-8600

2750 Marion Drive Las Vegas, NV 89115 702-342-8100

On July 1, 2024, Ralf Junker will hand over his position as president of the BOMAG Group to Ingo Ettischer, who has been managing director chief operating officer at BOMAG since July 2023.

With the handover to Ettischer, an experienced top manager will take over the leadership of the construction machinery manufacturer.

Ettischer looks back on many years of global experience from leading positions in operations management. Before joining BOMAG in 2023, he spent 21 years in management at Mercedes-Benz AG in the truck, van and car divisions in various global executive and production roles. Prior to that, he successfully led several strategy and operational excellence projects in different industries at a top management consultancy for a number of years.

“BOMAG is set to continue to grow internationally in size and portfolio. We are confident that Dr. Ingo Ettischer, with his experience, knowledge and energy, will boost the company’s growth and lead BOMAG successfully into the future,” said Jean-Claude Fayat, owner and president of the FAYAT Group.

“I am very excited to step into Ralf Junker’s shoes and lead the BOMAG Group going forward,” said Ettischer on his new role. “Together with a strong management team and a highly skilled workforce, we will steer BOMAG into a successful future.

"The close relationship with our cus-

tomers, our innovative strength based on knowledge and commitment, and our enthusiasm for our machines and technologies will be decisive in this respect. By clearly focussing on our customers, innovative products and an internationally oriented production network, we will position ourselves competitively as a technology leader and thus continue to grow in the future.”

The outgoing president, Ralf Junker, looks back on a long and successful career at BOMAG.

Since 1988, he has held various positions in production at the Boppard site before taking over responsibility for production at BOMAG’s worldwide production sites. In 2001, he became a member of the BOMAG executive board and was appointed managing director in 2009. He has been president of BOMAG since 2017. From 2017 to 2020, he also was responsible for global sales.

After 36 years at BOMAG, Junker will retire but continue to advise the FAYAT Group.

“Ralf Junker has significantly shaped the company over the years. Particularly noteworthy is his central role in the reorganization of BOMAG, especially during the integration process into the FAYAT Group. His leadership, commitment and extensive expertise have always contributed to putting BOMAG on a strong growth trajectory, with sales now exceeding one billion euros,” said Jörg Unger, president of the FAYAT Road Equipment Division.

The CP100II sets the standard for versatility, component lifecycle and mat quality. With a powerful 100 horsepower engine, an array of configurations and the class-leading Carlson EZCSS single slide screed, it’s easy to see why the CP100II is the ideal choice for heavy-duty commercial paving.

The Carlson CP100 II sets the standard for versatility, component lifecycle and mat quality. With a powerful 100hp engine, an array of configurations and the class-leading EZCSS single slide screed, it’s time to see why the CP100 II has fast become the contractor’s choice for heavy-duty commercial paver platforms.

BANE MACHINERY, INC.

www.banemachinery.com

2449 Manana Dr. Dallas, TX 75220 (214) 352-2468

(214) 352-2468 (817) 847-5894 (903) 597-6641

Ft. Worth, TX (817) 847-5894

CLAIREMONT EQUIPMENT

7651 Ronson Roa San Diego, CA 92 (858) 278-8351 1330 W Mission Ro Escondido, CA 92 (760) 739-9100

Tyler, TX (903) 597-6641 BEE EQUIPMENT SALES LTD.

www.beeequipmentsales.com

2506 Slaton Highway Lubbock, TX 79404 (806) 745-1511

C. L. BOYD CO.,

4220 West Reno A (800) OKC-BOYD • (405 Ardmore, OK (866) 720-2693 • (580) Lawton, OK (800) 633-2693 • (580) / INC. K 224-2693 /355-6667

www.clairemontequipment.com

(318) 442-0455

7651 Ronson Road

Baton Rouge, LA (225) 291-3750

San Diego, CA 92111 (858) 278-8351

1330 W Mission Road

Broussard, LA (337) 837-9481

Escondido, CA 92029 (760) 739-9100

Covington, LA (985) 893-3005

440 West Aten Road

eet 111 (337) 430-3045

(858) 278-8338

Imperial, CA 92251 (760) 355-7700

Monroe, LA (318) 343-8787

Shreveport, LA (318) 631-3090

COOPER EQUIPMENT CO.

www.cooperequip.com

(409) 842-1754 Boise, Idaho (208) 336-8670 Jerome, Idaho (208) 324-4522 (800) 829-4450

5210 N Loop 1604 E San Antonio, TX 78247 (210) 657-5151

201 Commerce Blvd. Georgetown, TX 78626 (512) 930-5151

C. L. BOYD CO., INC. www.clboyd.com

4726 Convoy Street San Diego, CA 92111 (858) 278-8338

6532 East Highway Rhome, TX 7607 (817) 708-9108

21910 FM 2252 Schertz, TX 7815 (210) 732-2131

4220 West Reno Ave. Oklahoma City, OK 73107 (800) OKC-BOYD • (405) 942-8000

Ardmore, OK (866) 720-2693 • (580) 224-2693

Lawton, OK (800) 633-2693 • (580) 355-6667

13800 FM 973 N Manor, TX 78653 (512) 272-8200

St. Rose, LA (504) 466-5577

Beaumont, TX (409) 842-1754

Bryan, TX (979) 8231905

Corpus Christi, TX (361) 289-0727

Houston, TX (713) 679-6700

Longview, TX (903) 758-3326

Lufkin, TX (936) 634-8801 San Juan, TX (956) 787-0001

6532 East Highway 114 Rhome, TX 76078 (817) 708-9108

21910 FM 2252

Schertz, TX 78154 (210) 732-2131

CO. .com

13800 FM 973 N Manor, TX 78653 (512) 272-8200

18851 GH Circle

MODERN MACHINERY

www.modernmachinery.com

Corporate Office

Missoula, Montana (409) 842-1754

Boise, Idaho (208) 336-8670

Jerome, Idaho (208) 324-4522

Victoria, TX (361) 570-6666

Washington

Pocatello, Idaho (800) 829-4450

ROAD MACHINERRY Y www.roadmachinery.co 902 S. 7th Street X g (800) 304-4421

Billings, Montana (800) 735-2589

Phoenix, AZ 85034 (480) 545-2400

Spokane, Washington (800) 541-0754 om n COOPER EQUIPMEN www.cooperequip. 5210 N Loop 1604 San Antonio, TX 78 (210) 657-5151 201 Commerce Blv Georgetown, TX 78

(512) 930-5151

E 8247 vd. 8626 (903) 592-8900

Waller Industrial Park Waller, TX (936) 525-9949

Columbia Falls, Montana (800) 434-4190

Prescott, AZ (928) 778-5621

Eugene, Oregon (800) 826-9811

Tuscon, AZ (520) 623-8681

Portland, Oregon (800) 950-7779

(661) 695-4830

Perris, CA (909) 355-3600

Kent, Washington (800) 669-2425

Rochester, Washington (800) 304-4421

Spokane, Washington (800) 541-0754

Turlock, Calif., resident Julie Rummer now has her dream backyard due to the Bobcat backyard makeover contest. Last summer, Bobcat Company — a global equipment, innovation and worksite solutions brand — announced that Rummer had won the contest, which awarded her a $25,000 backyard makeover using Bobcat equipment.

Rummer survived a car crash in 1995 that left her paralyzed as a quadriplegic and dependent on a power wheelchair. An avid gardener, Rummer loved to spend time in her backyard, but navigating loose, dusty soil and thorny vegetation in her backyard became a challenge. She described the yard as an “eyesore, a big disaster” and an “embarrassment.”

Winning the contest has completely transformed her backyard into a wheelchairaccessible “paradise,” according to Rummer’s husband Rich. With the help of Bobcat and the use of equipment from local dealer Bobcat Central Inc., as well as the work of area contractors and friends and family, Julie’s dreams became a reality.

“I just feel happy; it’s a happy place to be,” she said about her new backyard. “I can’t even shut the curtains at night, the backyard is so beautiful. Having complete

access to nature and my garden is freedom.”

The backyard makeover demonstrated the power of Bobcat equipment to get the job done, transforming the overgrown and compact backyard into an accessible and aesthetic space for the Rummer family.

“The team at Bobcat is thrilled that we could help Julie achieve her dream of a wheelchair-accessible backyard with room to garden, entertain and get away,” said Laura Ness Owens, Doosan Bobcat vice

president of brand and marketing. “Bobcat exists to empower people to accomplish more, and this is a perfect example of doing just that. We hope others are inspired by this transformation and recognize the potential in their own outdoor spaces.”

Rummer’s project was kicked off by using a Bobcat skid-steer loader to prepare the area, as well as the demolition and removal of an existing patio, which made room for a new ramp that the Rummers

needed for their back door. Tree removal, relocation and planting was done by HIS Tree Service and concrete work preparations by Ultimate Concrete. Then came Bobcat Central with a Bobcat MT100 mini-track loader to complete work in the fenced-in area. Crews installed concrete paths, which was preferred for accessibility rather than stone pathways or a patio.

The finished landscaping includes a water and irrigation system, new drought-tolerant plants, compost and fertilizer. New cedar mulch was placed to prevent weeds and hold moisture during the summer. After additional lighting, a fire pit, sound system and other items were installed, the job was done.

When Rummer submitted her contest application, she did not have her hopes up. However, when her story was chosen as a finalist entry, her community rallied to show support and help Rummer win the grand prize.

“I appreciate everyone’s vote and everybody who picked up a shovel or lent a hand clearing, shredding, spreading,” Rummer said. “Every day can be a challenge for me, but the kindness, love and support from everyone during this process just fills my heart. So, thank you, Bobcat, for empowering me and making my backyard dream come true.”

(L-R): Case Construction Equipment’s Ed Flynn, Ryan Mitvalsky and Michael Montose were ready to provide information to attendees about Case equipment applications for snow and ice maintenance.

SNOW from page 14

The event combined educational sessions with an industry trade show where more than 150 exhibitors showcased the latest in products, equipment and services including snowplows and spreaders, deicing materials, software systems, trucks, as well as compact and large equipment. CEG

(All photographs in this article are Copyright 2024 Construction Equipment Guide. All Rights Reserved.)

Fisher Engineering’s Norm Klimko (L) caught up with Western Snowplow’s Jeff Kopp at the Snow and Ice Show in Pittsburgh, Pa.

www.iron-hub.com

6515 I-30

Royse City, TX 75189

972-679-6971

www.cpower.com

9200 Liberty Drive

Liberty, MO 64068

816-781-8070

Wichita, KS

316-943-1231

Great Bend, KS

620-792-1361

Liberal, KS

620-624-7274

Woodward, OK

580-256-6014

Salina, KS

785-825-8291

Colby, KS

785-462-8211

Springfield, MO

417-865-0505

Joplin, MO

417-726-5373

Riverside, MO

816-415-6787

Wichita, KS

316-789-7370

Yukon, OK

405-324-2330

Maryland Heights, MO

314-427-4911

Liberty, MO

806-415-6700

Tulsa, OK

918-984-6565

The hard-hitting MAX-Series™ VT-100 gives you the tools to impr The vertical-lift machine excels in loading and grading applications

r ove productivity while working comfortably. in landscaping and construction.

CLM Equipment Co. Inc. www.clmequipment.com

3135 US Hwy 90 East Broussard, LA 70518 337-837-6693

4851 E Napoleon Road Sulphur, LA 70663 337-625-5942

2815 N Sam Houston Pkwy E Houston, TX 77032 281-598-2500

www.jetcityequipment.com 33345 SR20 Oak Harbor, WA 98277 360-675-4441 10219 State Avenue Marysville, WA 98271 360-651-9079 2713 Euclid Avenue Wenatchee, WA 98801 509-888-8181

Dallas (Carrollton), TX 214-819-4100 Austin, TX 512-388-2529

Corpus Christi, TX 361-881-4891

Ft. Worth, TX 817-626-2288

Longview, TX 903-758-5576 Mercedes, TX 956-565-0100

San Antonio, TX 210-648-4600

Stephenville, TX 817-626-2288

Equipment www.rgwequipment.com

700 W. Mossdale Road Lathrop, CA 95330 925-606-2477

550 Greenville Road Livermore, CA 94550 925-606-2403

6904 Banigan Road Anderson, CA 96007 925-606-2437

www.PacWestMachinery.com

8207 South 216th Street Kent, WA 98032

206-762-5933

Mount Vernon, WA 360-588-3083

Portland, OR 503-252-5933

Eugene, OR 541-343-6926

Spokane Valley, WA 509-534-5933

Pasco, WA 509-547-5933

www.rgwequipment.com

700 W. Mossdale Road Lathrop, CA 95330 925-606-2477

550 Greenville Road Livermore, CA 94550 925-606-2403

6904 Banigan Road Anderson, CA 96007 925-606-2437

1519 W Belt Line Road Carrollton, TX 75006 214-819-4100

Austin, TX 512-388-2529

Carmine, TX 979-278-3570

Ft. Worth, TX 817-626-2288

Houston, TX 713-937-3005

San Antonio, TX 210-648-4600

Buffalo, TX 903-322-5602

Corpus Christi, TX 361-881-4891

Mercedes, TX 956-565-0100

Stephenville, TX 254-266-2871

www.vcesvolvo.com

Bakersfield, CA 661-387-6090

Corona, CA 951-277-7620

Fresno, CA 559-834-4420

Sacramento, CA 916-504-2300

Lakeside, CA 619-441-3690

Redding, CA 279-201-4869

San Leandro, CA 510-357-9131

Turlock, CA 209-410-6710

OEM authorized mining dealer www.coremachinery.com

Phoenix, AZ

480-545-2400

Phoenix, AZ 602-252-7121

Prescott, AZ 928-778-5621

Tucson, AZ 520-623-8681

Bakersfield, CA 661-695-4830

Mojave, CA 661-824-2319

Perris, CA 909-355-3600

*Formerly Road Machinery

www.wpi.com

The Case CX50D mini- excavator offers more lifting capacity and better digging performance with a deeper reach, making it an ideal solution for bigger projects like pools or ponds.

Case Construction Equipment is beefing up its offering for landscaping companies with new models and bigger features that boost productivity in the yard or on the job site.

As the landscaping industry steadily grows year over year, Case geared its latest round of innovations toward helping landscaping crews take advantage of bigger opportunities to grow their business.

“Many landscaping companies today are experiencing significant growth, but they also have a lot of challenges to navigate, like labor shortages, highly varied job sites and a very competitive market,” said Terry Dolan, vice president — North America, Case Construction Equipment.

“Our newest launches aim to support landscapers in navigating these demands more effectively than ever with swift, smooth, smart machines right-sized for the scale of opportunity.”

The enhanced lineup of Case machines adds to the company’s substantial product launches last year of small articulated loaders and a mini track loader. This year’s launch includes a new upsized 5.5 ton mini excavator and a new, full-sized wheel loader that’s an easy-to-use versatile machine for bolstering productivity. The company also is launching innovative upgrades for its compact wheel loaders and rough-terrain forklifts.

For landscaping crews who need to handle tough jobs faster, the all-new Case CX50D mini excavator offers more lifting capacity and better digging performance with a deeper reach, making it an ideal solution for bigger projects like pools or ponds. The 5.5 ton class machine packs a lot of power into a compact design, so operators can work up close to buildings or other structures in tight job sites.

Landscapers will be able to find a big range of use cases for this larger mini excavator, due to an impressive array of compatible attachments and options. With standard multifunctional hydraulics and a second auxiliary circuit, as well as an optional third auxiliary circuit, this machine can power a wide assortment of attachments, from tilt rotators to grapples, according to the manufacturer.

In addition, the Case CX50D offers an optional dedicated auxiliary hydraulic circuit to run advanced attachments such as a mulching head, making it a useful tool for clearing brush or wooded sites. Landscaping crews also can opt for a six-way blade to boost capabilities for backfilling or light grading.

“Landscapers are increasingly turning to mini excavators as a labor-saving solution because of their power and versatility,” said Diego Butzke, product manager — excavators. “With our latest machine, they’ll be able to scale up productivity even more to take on bigger jobs more efficiently.”

The new CX50D helps fill out the D Series lineup in the 4.4 to 5.5 ton class, carrying over many of the operator-friendly features and options customers expect from Case, including an automotive-style cab with auto climate control, a customizable LCD screen and an optional object handling kit with check valves on the boom and arm for material handling applications.

The all-new, easy-to-operate Case 651G full-size wheel loader can be a game changer for landscapers who need an allaround workhorse for tough jobs like moving boulders, removing snow or loading trucks with mulch or bulk materials in the yard.

With a breakout force of nearly 24,000 lbs., a lifting capacity of over 16,100 lbs. and a higher hinge pin height for more bucket clearance during dumping, this machine adds more productivity for material handling.

Operation is made easier with a touchscreen display and adjustable, intuitive electrohydraulic controls that allow the operator to independently set boom and bucket responsiveness to smooth, moderate or aggressive. A roomy cab with all the comforts, like AC and heat, heated seats, Bluetooth radio and phone connectivity, lets operators work comfortably while the rear sloping hood and optional backup camera improve visibility.

The new full-sized wheel loader offers three optional loader configurations and is compatible with a variety of tools like brooms and forks, making it a versatile solution for landscapers who deal with a broad range of jobs.

For more information, visit CaseCE.com. Case photo

12320 S. Main Street Houston, TX 77035 713-723-1050

Buffalo, TX 903-322-7150 Bryan, TX 979-314-1191

Corpus Christi, TX 361-884-8275

Edinburg, TX 956-386-0107

Kilgore, TX 903-984-2011

Lufkin TX 936-243-6056 Pflugerville, TX 512-251-0013

Port Arthur, TX 409-721-5305 San Antonio, TX 210-648-4444 Tomball, TX 281-351-9016

www.powermotivecorp.com

Corporate Office 5000 Vasquez Blvd., Denver, CO 80216 303-355-5900

Colorado Springs, CO 719-576-5541

Grand Junction, CO 970-241-1550 Milliken, CO 970-587-1188

Cheyenne, WY 307-634-5149

Durango, CO 970-259-0455

Albuquerque, NM 505-345-8383 Bloomfield, NM 505-324-8601 Carlsbad, NM 505-485-1700 El Paso, TX 915-872-1001 Chandler, AZ 602-986-3003 Phoenix, AZ 602-463-3772 Tucson, AZ 520-649-2858

www.geehm.com

5461 S Nikita Avenue Fresno, CA 93725 559-834-3149

1164 Prestige Way Redding, CA 96003 530-229-3820

3650 Seaport Blvd. West Sacramento, CA 95691 916-375-3540

3350 Regional Parkway Santa Rosa, CA 95403 707-544-4147

www.kirby-smith.com Oklahoma City, OK 405-495-7820 McAlester, OK 918-310-1550 Tulsa, OK 918-438-1700

Abilene, TX 325-692-6334 Amarillo, TX 806-373-2826 Dallas, TX 214-371-7777

inate potential damage peed qu , cr erators up to s our machines y omfr s Intelligent M Komastu’ our job si y on y oductivit

Ft. Worth, TX 817-378-0600

Lubbock, TX 806-745-2112

Odessa, TX 432-333-7000 Waco, TX 254-261-1370

c ) ol (IMC r achine Cont anced autom tes with adv yg . ned plans ou an help y ation

efully design w and car e

face to design sur uickly

WA 800-304-4421 Spokane, WA 800-541-0754

www.clairemontequipment.com San Diego, CA 858-278-8351

Indio, CA 760-863-5558 San Diego, CA 858-278-8338

Escondido, CA 760-739-9100 Fontana, CA 909-429-9100 Imperial, CA 760-355-7700

from page 1

direct connectors; widening the existing bridge to increase capacity; reducing congestion; and improving overall traffic flow, particularly during hurricane evacuations.

To this point, the contractor has completed the following elements:

• New pavement at the intersection of Wheeler Avenue and Spur-5/SH-35, including the segment of northbound frontage road leading up to University Drive;

• All water and sanitary sewer line installations;

• Approximately 70 percent of storm drain installations; and

• Approximately 30 percent of the substructures (e.g. drilled shaft, columns, abutments and bent caps) for the bridge that will span over Brays Bayou, Wheeler Avenue and University Drive.

Over the next few months, efforts will concentrate on construction of bridge substructures, roadway reconstruction and continued storm drain installations.

Challenges are being overcome through solid planning and collaboration.

“Relocation of existing utilities in conflict with the proposed work [is an issue],” said TxDOT Houston District Public Information Officer Kristina Hadley. “These challenges have been mitigated by maintaining regular coordination meetings with the utility providers and stakeholders since the beginning of the project. We are pleased at the progress of work.”

Crews are benefitting from an open work space.

“This is primarily a daytime project, but some operations do require nightly work,” said Hadley. “TxDOT and the contractor maintain a collaborative partnering approach towards the successful completion of this project. One operation for this construction project will require running a new CTMS conduit across the existing IH-45 northbound mainlanes, over UPRR tracks. However, this work will not affect railroad operations/traffic. When work of this nature takes place, TxDOT and the railroad company coordinate extensively. A railroad flagger is present during operations, to ensure the safety of all involved staff.”

The construction of the new freeway lanes, ramps and direct connectors are proceeding as planned, with a new freeway section being constructed from end to the other.

“The current construction project will construct the SH-35 mainlanes from IH-45 up to Kuhlman Gully, with entrance/exit ramps to Griggs Road at the southmost limit,” said Hadley. “Future segments of SH-35 currently in design will continue the mainlane construction, to eventually connect with IH-610.”

Utility relocation is a challenge, but constant communication and coordination for timeliness of relocations is minimizing the hurdles.

“To continue with the project moving forward, on-time and on-budget, TxDOT, the contractor and pertinent stakeholders will tackle each obstacle as they arise,” said Hadley.