Kirby-Smith Machinery Announces Several Leadership Changes...6

Firms Merge to Create Second-Largest Civil Contractor in U.S. ...8

Komatsu Introduces Demolition Excavators to North America...28

Kirby-Smith Machinery Announces Several Leadership Changes...6

Firms Merge to Create Second-Largest Civil Contractor in U.S. ...8

Komatsu Introduces Demolition Excavators to North America...28

By Irwin Rappport CEG CORRESPONDENT

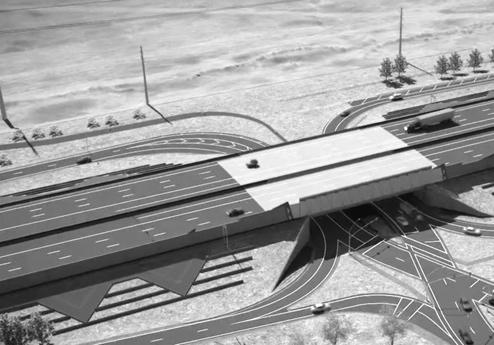

The Texas Department of Transportation’s (TxDOT) multi-billion, multi-year North Houston Highway Improvement Project (NHHIP) was given the green light on July 26, which will seriously transform a major freeway in downtown Houston, which happens to be the oldest in the state.

The initiative will improve traffic flow in Houston and reduce conges-

tion, as well as being a serious boon for general contractors and subcontractors, engineering firms, and producers of concrete, asphalt, and aggregates. Work on the project that is expected to be completed in 2042 is set to begin in October. The project had been discussed and studied for more than 20 years.

The NHHIP is a planned reconstruction of I-45N, between Houston’s

see HOUSTON page 50

By Lucy Perry CEG CORRESPONDENT

In July, the Biden administration announced it would fund $1.7 billion for electric vehicle component production at 11 manufacturing plants across the country. In doing so, the fed made progress toward both ending the nation’s dependence on China for batteries and meeting its 2030 goal of making 50 percent of all new U.S. vehicle sales electric or hybrid models. Eight plants currently shuttered or at-risk of closing are located in Georgia, Illinois, Indiana, Maryland,

Ohio, Pennsylvania and Virginia.

2013 Laymor 8HC, Stk#: 12935, OROPS, 1,007 hrs., 6' 3" Broom, 3,000 lbs $16,500

2014 Laymor SM400, Stk#: 12756, EROPS, A/C & Heat, 594 hrs., Water System, 8 ft. Broom, 225x75Rx15 Tires, 4 Cy. Kubota Eng $29,500

2016 Kobelco SK140SRLC-3, Stk#: 13546, EROPS, A/C, Heat, Radio, 4,463 hrs., 34" Bkt, 24" Pads, Aux Hyd, Back-Up Camera $52,500

Kelly Shuffield

cranes and lifting.

The Arizona Department of Transportation (ADOT) recently announced that construction on the $200 million Phoenix-area Loop 202 (Santan Freeway) Improvement Project has begun.

8 FIRMS MERGE TO CREATE SECONDLARGEST U.S. CIVIL CONTRACTOR

ACS Group and HOCHTIEF, the respective owners of Dragados and Flatiron, announced that they have agreed on key terms for the combination of the two companie.

12 LBX CO., EMPLOYEES CELEBRATE 150 YEARS OF LINK-BELT BRAND

The event featured various activities, including food, demonstrations, music and games. Employees reminisced about significant milestones in company history while looking toward future endeavors.

12 HD HYUNDAI, NED EXPAND, ADDING TEXAS ‘FLAGSHIP’ LOCATIONS

HD Hyundai Construction Equipment North America and National Equipment Dealers announced a five-year distribution agreement to accelerate Hyundai’s North American market coverage and growth initiatives.

14 KOMATSU INCREASING ITS SALES, SERVICE CAPACITY WITH NEW FACILITY

The expansion is centered on advancing sales and service capacity and will roughly triple the square footage dedicated to serving existing and new customers in the area.

16 TYLER RENTAL EXPANDS ITS TERRITORY IN WESTERN U.S.

Sandvik announced the expansion of Tyler Rental’s mobile crushers and screens distributor territory to include Washington, Oregon, Idaho and Montana.

20 LANDSCAPE CONTRACTORS TRY LATEST EQUIPMENT AT EQUIP EXPO

Equip Exposition, held Oct. 15-18 at the Kentucky Exposition Center, is where the newest outdoor power equipment and most innovative tools for landscape contractors can be explored and tested.

26 VERMEER ANNOUNCES IMPROVEMENTS TO RTX1250 TRACTOR

The RTX1250 is powered by a 127-hp (94.7-kW) Deutz TCD3.6L diesel engine and can be outfitted with a range of attachments for efficient installation of gas, fiber, water and electrical utilities.

28 KOMATSU INTRODUCES DEMOLITION EXCAVATORS TO NA MARKET

The PC490HRD-11, PC290LC-11, PC360LC-11 and PC490LC-11 have been successfully operating in the European market for more than 20 years and are now available to the North American demolition industry.

28 POLICY CHANGES MAY COMPLICATE PROGRESS, IIJA IMPLEMENTATION

In testimony before the U.S. House Highways & Transit Subcommittee, Tim Duit, president of Edmond, Okla., based Duit Construction, said regulatory proposals that are clear and well-defined can achieve their intended purpose.

42 DYNAPAC ADDS NEW DEALER TO NETWORK: CENTURY EQUIPMENT

Dynapac, a supplier of high-tech soil and asphalt rollers, compact equipment and pavers, announced the addition of Century Equipment to its growing network of authorized dealers.

46 CATERPILLAR UNVEILS FEATURES FOR VISIONLINK

Caterpillar’s online web platform, VisionLink Productivity, has been enhanced with the introduction of three new features — Cat Grade and Compact, Operator Coaching, and E-Ticketing.

The company has focused on technical excellence since its inception

Kirby-Smith Machinery Inc. (KSM) has announced several leadership changes related to its product support operations. Kelly Shuffield has been promoted to vice president of service; Wade Gaines to vice president of parts and product support sales; and Jeff Lechus to director of service of cranes and lifting.

As vice president of service, Kelly Shuffield now will be responsible for the strategic oversight of all service operations throughout KSM. With more than 30 years of equipment product support experience, Shuffield brings a deep understanding of building successful customer support operations to the role. Since joining KSM in 2005, Shuffield has held several key positions, including crane product service manager, general service manager and, most recently, vice president of product support of cranes and lifting.

Gaines' executive role has been expanded to include oversight of KSM's product support sales operations. Gaines, who has more than 33 years of experience in the heavy equipment industry, joined KSM in 2022 as vice president of parts. He has served in various parts sales management roles for Komatsu America Corporation.

With Shuffield's promotion, Lechus has also been promoted to director, service of cranes and lifting. Lechus has been with KSM for a combined total of 10 years and has more than 20 years of experience in heavy equipment service. Since starting at KSM in 2005, Lechus has held positions, including crane technician and product service manager, bringing a wealth of experience to his new role.

Weller, chief operating officer of KSM, believes these moves will further grow and strengthen KSM’s support

capabilities to its customer base.

“I am grateful for the leadership that Kelly, Wade and Jeff have continually provided for KSM,” said Weller. “I know that both our customers and employees will benefit from their increased responsibility.”

Kirby-Smith Machinery Inc. was established in 1983 and is recognized as one of the premier new and used heavy con-

struction equipment and crane dealers in the country. KirbySmith Machinery and its hundreds of dedicated professional employees are committed to providing reliable new and used equipment for sale and equipment rentals, as well as responsive service and equipment parts for multiple makes and models. Kirby-Smith Machinery has 12 branch locations in Oklahoma, Texas, Kansas and Missouri.

For more information about Kirby-Smith Machinery, call 888/861-0219 or visit kirby-smith.com.

The Arizona Department of Transportation (ADOT) recently announced that construction on the $200 million Phoenix-area Loop 202 (Santan Freeway) Improvement Project has begun.

The project, which the ADOT awarded to a joint venture between Sundt Construction Inc. and CS Construction Inc., will take approximately two-and-a-half years to complete.

Loop 202, the department said, is the primary freeway serving the area’s southeast valley and the widening project is necessary to ease traffic congestion in the growing area, particularly during morning and evening rush hours.

Maricopa County is one of the fastest growing regions in the United States — according to the ADOT — and the population is expected to increase by almost 30 percent between 2020 and 2040.

As part of the work, Sundt and CS will add new lanes and make interchange improvements along 8 mi. of Loop 202 between Loop 101 (Price Freeway) and Val Vista Drive in the cities of Chandler and Gilbert.

Specifically, the project includes:

• The addition of two general travel lanes in each direction from the Loop 202/Loop 101 interchange to Gilbert Road;

• The addition of one general travel lane in each direction from Gilbert Road to Val Vista Drive;

• Widening off-ramps and overpass bridges;

• Reconstruction of the eastbound Loop 202 on-ramp and bridge at Arizona Avenue;

• The installation of noise walls where necessary;

• Removal of existing asphalt pavement and diamond grinding of the existing concrete pavement to provide a

smooth roadway surface.

The county’s Proposition 400, a half-cent sales tax dedicated to transportation infrastructure spending, is funding the project.

Distribution of Prop 400 revenue is split — 56.2 percent to freeways and state highways; 33.3 percent to the public transportation fund; and 10.5percent to arterial street improvements.

According to the 2023 Implementation Status of

Proposition 400 Annual Report prepared by the Maricopa Association of Governments, other projects that have benefited from the half-cent sales tax are:

• I-10 (Papago Freeway); SR 85 to Verrado Way (complete);

• SR 24 (Gateway Expressway) Interim Phase II (complete);

• I-10 (Maricopa Freeway): I-17 (Black Canyon Freeway) Split to SR 202L (Santan Freeway) (underway); and

• I-17 (Black Canyon Freeway): Peoria Avenue to Greenway Road. (All photos courtesy of ADOT.)

ACS Group and HOCHTIEF, the respective owners of Dragados and Flatiron, announced that they have agreed on key terms for the combination of the two companies, with ownership of the integrated company held 61.8 percent by ACS Group and 38.2 percent by HOCHTIEF. The company will be managed by Peter Davoren as chairman (in addition to his current role as chairman, CEO and president of Turner) and the current CEO of Flatiron, Javier Sevilla, as CEO. The trans-

action closing is expected during the second half of 2024.

The merger will create the second largest civil engineering and construction company in the United States.

“Bringing together Flatiron and Dragados creates a strong platform for organic growth in North America,” said Chief Executive Officer of HOCHTIEF, Juan Santamaría. “They have the expertise, the long-term clients and are geographically complementary, providing significant

synergies and economies of scale. We differentiate our commercial offering through our superior technical resources and skills.”

“Flatiron and Dragados North America employees have a long history of working together,” he added. “The new company will have the most respected and recognized value proposition in its sectors, having delivered renowned projects across the United States and Canada, and can look forward to an even stronger future.”

The transformation into a new and even stronger entity creates synergies and economies of scale. The simplified structure will ensure a consistent approach to operations, including tender processes, procurement strategies and risk management, and be value accretive for shareholders of ACS Group and HOCHTIEF. (All photos courtesy of TXDOT.)

The company, named Flatiron Dragados, will continue to serve clients across its existing diverse markets and support strong community and stakeholder relationships.

Realistic Scale Models of

LBX Company employees celebrated 150 years of the Link-Belt brand with a special event at the Customer Experience Center in Lexington, Ky.

The event featured various activities, including food, demonstrations, music and games. Employees reminisced about significant milestones in company history while looking toward future endeavors.

The Link-Belt brand was founded in 1874 by William Dana Ewart, who saw a need for reliable and durable innovations to help build emerging American infrastructure. Throughout the past 150 years, Link-Belt has grown from the invention of a “linked belt” chain drive to a leader in the industry.

The company has a long history of innovation, from introducing the first crawler-mounted crane shovels and wheelmounted excavators to many features that are now standard on excavators, including hydraulic controls.

Within the past 25 years, Link-Belt Excavator Company and its parent company, Sumitomo, have introduced a robust lineup of equipment encompassing six product series: Quantum, LX, X2, X3, X4, and the recently launched X4S. Further expanding its offerings, the 40 Series for forestry applications debuted in 2015, followed by the 2024 launch of the 40B Series.

LBX has established itself as a leader in excavators, material handling equipment and forestry products. Its commitment to excellence extends throughout North and Latin America, with LBX do Brasil as its subsidiary for distribution and support in Brazil and the broader Latin American market.

“We at LBX are proud of our Link-Belt heritage and are honored to be part of a legacy that spans 150 years,” said Eric Sauvage, president and CEO. “We shape our future together with our employees and our business partners, guided by our Long-Term Strategic Framework while leaning on our core purpose, living and breathing from our core values, and relying on our strategic anchors to be successful.” LBX Company has built its reputation on quality and customer service, demonstrating an unwavering commitment to providing its customers with the best possible products and services for many years.

For more information, visit lbxco.com.

LBX photo

LBX Company employees celebrated 150 years of the Link-Belt brand with a special event at the Customer Experience Center in Lexington, Ky.

HD Hyundai Construction Equipment North America and National Equipment Dealers (NED) announced a five-year distribution agreement to accelerate Hyundai’s North American market coverage and growth initiatives while expanding NED’s dealership territory coverage.

NED CEO Zack Kavanaugh and President and COO Jesse Beasley recently visited Hyundai’s top executive management in Seoul, Korea, to discuss the new agreement, which establishes multiple Hyundai “flagship stores” to expand NED’s dealer footprint.

The new NED branches will be Hyundai-branded stores. These strategic locations in high growth-potential markets include a recently-opened branch in Jacksonville, Fla., and future locations in Fort Myers, Fla.; and Austin and Dallas, Texas.

The new branches will stock Hyundai inventory ranging from compact excavators and skid steer loaders to larger crawler excavators, wheel loaders, and off-road haul trucks. They also will be well equipped with modern service facilities and tooling to provide firstclass service to Hyundai customers, according to the company.

“This strategic alignment with HD Hyundai along with our shared vision for growth and focus on new markets, will help us reach new Hyundai customers while providing exceptional product, sales, and service support to a broader customer base,” said Kavanaugh.

“HD Hyundai values our strategic relationship with NED,” said Stan Park, president, HD Hyundai Construction Equipment North America. “The new NED ‘flagship’ stores ensure high-profile presence for Hyundai in several fast-growing markets, with the further assurance of excellent customer support.”

For more information, visit na.hd-hyundaice.com.

The new facility, scheduled for completion in the spring of 2026, will be approximately 225,000 sq. ft., a significant increase from the current 75,000-sq.-ft. facility.

Stemming from its deep commitment to the area, Komatsu announced a significant greenfield expansion in Mesa, Ariz.

The expansion is centered on advancing sales and service capacity and will roughly triple the square footage dedicated to serving existing and new customers in the

area.

“We conducted an extensive search to best meet our growth needs and are proud that we will continue calling Mesa home,” said

Danny Murtagh, vice president of parts distribution at Komatsu.

“Between our highly skilled workforce, existing partnerships in the

area, and the projected economic outlook in the region, it is exciting to announce this expansion.”

The new facility, scheduled for completion in the spring of 2026, will be approximately 225,000 sq. ft., a significant increase from the current 75,000-sq.-ft. facility. The site of the new facility is conve-

niently located close to the airport in southeast Mesa.

The expansion will promote the creation of both short-term construction jobs and long-term jobs with Komatsu. In the first few years of operation, up to 100 additional jobs are estimated to be created as a result of the expansion.

The expanded sales and service facility represents a multi-million dollar strategic investment and underscores Komatsu’s commitment to the local economy and a positive outlook for economic growth in the region.

For more information, visit www.komatsu.com.

Sandvik announced the expansion of Tyler Rental’s mobile crushers and screens distributor territory to include Washington, Oregon, Idaho and Montana.

Tyler Rental will be responsible for selling Sandvik mobile crushers and screens in combination with full aftermarket support through the supply of spare and wear parts and local customer service.

said, “Tyler Rental is a well-established, leading equipment supplier in these states, and we are confident that with their customer knowledge and local market expertise, we will be able to develop the Mobiles’ business further together.”

For more than 30 years, Tyler Rental has been providing a wide range of rental equipment from leading brands to the construction and industrial sectors. It has an established sales and service network with six locations across the territories it covers. With a team of expertly trained staff combined with the best quality equipment in the industry and dependable service, it has become a leading supplier in these states.

Since 2017, Tyler Rental has successfully represented Sandvik in Alaska as a distributor of Sandvik underground mining, surface drills and mobile crushers. This expansion is a testament to the fruitful partnership and the company’s capability to cater to a broader market.

Tyler Rental will now offer Sandvik’s Q Range of tracked jaw, cone and impact crushers, screens and scalpers; as well as the heavy and wheeled U-Range products. This will perfectly complement its offering of shredders, trommels, conveyors and composting machinery, providing its customers with a one-stop shop for all their equipment needs.

Richard Furlong, dealer manager of Sandvik Mobile Crushing and Screening,

Tyler Rental will now offer Sandvik’s Q Range of tracked jaw, cone and impact crushers, screens and scalpers; as well as the heavy and wheeled U-Range products.

Randy Johnson, CEO and president of Tyler Rental, said, “We are proud to work with Sandvik and to have earned the opportunity to sell its high-quality brand of mobile crushers and screens. The partnership that we have built with Sandvik has enabled Tyler Rental to provide added value and a more comprehensive fleet offering for our customers.”

For more information, visit www.tylerrental.com.

Niece Water Towers deliver reliability and durability when you need fast mobile water service. With a 12” discharge tube it fills your tanks at a rate of over 1,000 gallons per minute. Offers removable power pack for security, fifth wheel tow hitch, professionally engineered and constructed.

It features (8) legs for stability

5th wheel set up for quick “tow and go.”

Technology is transforming how managed landscapes are cared for.

Equip Exposition, held Oct. 15-18 at the Kentucky Exposition Center, is where the newest outdoor power equipment and most innovative tools for landscape contractors can be explored and tested.

The award-winning and 5th largest trade show in the United States drew more than 27,000 contractors, dealers and manufacturers to the famed Derby City last year and has operated for 41 years.

“Robotic mowers, battery/electric outdoor power equipment, the latest utility type vehicles [UTVs], all terrain vehicles [ATVs], drones, and more will be available to take for a test drive to see if it works for you,” said Kris Kiser, president and CEO of the Outdoor Power Equipment Institute (OPEI), which owns the show.

In the 30-acre Outdoor Demo Yard, attendees can “get their hands dirty” by mowing, mulching, cutting, chopping, digging, driving and more with the latest equipment. Attendees also can go the UTV test track to get behind the wheel and try out the latest four-wheel workhorses.

Inside, attendees also can meet and talk with equipment manufacturers designing and producing outdoor power equipment, drones, landscaping software and inter-connected technology products that improve how landscaping contracting businesses are run and sell services.

Attendees can meet and talk with equipment manufacturers designing and producing outdoor power equipment, drones, landscaping software and interconnected technology products that improve how landscaping contracting businesses are run and sell services.

Attendees can fly a drone in the Drone Zone in the West Wing and work toward drone pilot certification while at the show.

The session “Battery Transitions: Incentives, Regulations, and Innovations,” on Thursday, Oct. 17, will showcase perspectives from landscapers, manufacturers and regulators on the latest in technology developments and how they are adapting to advances in the field.

Historically, Equip Expo helps landscape contractors stay in the loop on technology and ahead of their competitors.

“Equip Expo helps us keep up with the latest trends in the industry as it’s changing so much with new technology,” said Antonio Zeppa, co-owner of Zeppa’s Lawn Service.

His company has registered 36 people to attend the trade show this year. Their staff loves attending the show, he said, because they can try new equipment in the Outdoor Demo Yard. They often find new ideas to improve their business.

“There’s tons of stuff we have adopted from the show,” said Zeppa, who added he has purchased new equipment to make working on job sites more efficient and cost-effective for his company’s crews after seeing it at the expo.

“It’s really interesting to be at the forefront of it and not be behind,” said Zeppa.

One of the biggest changes they are making now is adopting more battery/electric equipment. Zeppa said they learned about how to manage this significant transition by attending Equip Expo.

All registrants who book their hotel in advance through Equip’s housing provider are entered to possibly win a free three-night stay during Equip. Learn more and see the sweepstakes’ official rules on the website. Hotels can be booked through Equip’s official housing provider, Louisville Tourism, on the Equip website.

For more information, visit www.EquipExposition.com.

www.iron-hub.com

6515 I-30

Royse City, TX 75189

972-679-6971

www.ccrentalsparis.com

2720 North Main Street

Paris, TX 75460

903-784-8484

www.cpower.com

9200 Liberty Drive

Liberty, MO 64068

816-781-8070

Wichita, KS

316-943-1231

Great Bend, KS

620-792-1361

Liberal, KS

620-624-7274

Woodward, OK

580-256-6014

Salina, KS

785-825-8291

Colby, KS

785-462-8211

Springfield, MO

417-865-0505

Joplin, MO

417-726-5373

Riverside, MO

816-415-6787

Wichita, KS

316-789-7370

Yukon, OK

405-324-2330

Maryland Heights, MO

314-427-4911

Liberty, MO

806-415-6700

Tulsa, OK

918-984-6565

Engineered to boost the accuracy and productivity of your operation, the John Deere 333G SmartGrade™ Compact Track Loader (CTL) delivers precise grading performance while limiting technology includes the operator-friendly DozerMode Control system to enable intuitive crawler operation, with the Deere-designed and purpose-built six-way SG96 Dozer Blade powering the push. This skillful solution is designed to quickly and easily elevate your grades. It all adds up.

JohnDeere.com/SmartGradeCTL

HEAVY MACHINERY SERVICES www.doggettequipment.com 9111 North Freeway Houston, TX 77037 713-679-6700

Beaumont, TX 409-842-1754 Bryan, TX 979-823-1905

Corpus Christi, TX 361-289-0727

San Juan, TX 956-787-0001 Victoria, TX 361-570-6666

Alexandria, LA 318-442-0455

Baton Rouge, LA 225-291-3750

Broussard, LA 337-837-9481

Covington, LA 985-893-3005

Longview, TX 903-758-3326

Lufkin, TX 936-634-8801

Monroe, LA 318-343-8787

Shreveport, LA 318-631-3090

St. Rose, LA 504-466-5577

Tyler, TX 903-592-8900

The hard-hitting MAX-Series™ VT-100 gives you the tools to impr The vertical-lift machine excels in loading and grading applications

r ove productivity while working comfortably. in landscaping and construction.

CLM Equipment Co. Inc. www.clmequipment.com

3135 US Hwy 90 East Broussard, LA 70518 337-837-6693

4851 E Napoleon Road Sulphur, LA 70663 337-625-5942

2815 N Sam Houston Pkwy E Houston, TX 77032 281-598-2500

www.jetcityequipment.com 33345 SR20 Oak Harbor, WA 98277 360-675-4441 10219 State Avenue Marysville, WA 98271 360-651-9079 2713 Euclid Avenue Wenatchee, WA 98801 509-888-8181

Dallas (Carrollton), TX 214-819-4100 Austin, TX 512-388-2529

Corpus Christi, TX 361-881-4891

Ft. Worth, TX 817-626-2288

Longview, TX 903-758-5576 Mercedes, TX 956-565-0100

San Antonio, TX 210-648-4600

Stephenville, TX 817-626-2288

Equipment www.rgwequipment.com

700 W. Mossdale Road Lathrop, CA 95330 925-606-2477

550 Greenville Road Livermore, CA 94550 925-606-2403

6904 Banigan Road Anderson, CA 96007 925-606-2437

Amidst the hustle and bustle of the job site, where crew members are hard at work navigating narrow pathways and tight corners, a new contender emerges, poised to make a big impact despite its small stature. Introducing the latest addition to the DEVELON mini-excavator line: the DX17Z-7.

The DX17Z-7 weighs approximately 4,200 lbs and is the smallest member of the DEVELON mini excavator fleet.

Unlocking potential for landscaping, residential construction and utility work, the DX17Z-7 answers operators’ requests for a mini-excavator that can swiftly maneuver in tight work spaces.

The DX17Z-7 stands out in the DEVELON product line due to its compact size and specialized feature of a retractable undercarriage with a collapsible dozer blade. This enables the mini-excavator to squeeze into small spaces when needed and provides steady operation when working on slopes.

“Contractors can say goodbye to the days of difficult navigation and limited maneuverability with the addition of the DX17Z-7 to our mini excavator lineup,” said Andy Jeong, mini-excavator product manager, DEVELON. “This nimble piece of machinery helps jobs stay on track by tackling the toughest tasks in the tightest spaces. The DX17Z-7 features many of the same premium features as the rest of our mini-excavator line, with the added benefits of a compact footprint, retractable undercarriage and collapsible dozer blade.”

The 16-hp DX17Z-7 is designed with productivity and maneuverability in mind. Offering a 48-in. track width, the DX17Z-7 can travel between homes on tight lot lines or flush against existing structures in developed areas where larger equipment doesn’t fit. If the machine can access the work area, it has the potential to replace work that was previously done by manual labor with shovels and wheelbarrows. The machine’s zero tail swing design also makes navigating in urban areas and around confined work sites or obstacles easier than ever. Operators can maneuver with confidence next to structures without sacrificing turning, digging or lifting performance.

The new mini excavator features an open canopy cab for optimal operator

DEVELON photo

The DX17Z-7 weighs approximately 4,200 lbs. and is the smallest member of the DEVELON mini-excavator fleet.

visibility. A selectable control pattern switch gives operators the ability to change between ISO and “backhoe” patterns depending on their preference. The change valve is located beneath the floor cover and is easily accessible without the need for any tools. The machine comes standard with the new MY DEVELON telematics system that monitors the health, location and productivity of DEVELON equipment from a user-friendly mobile app and website.

Unique to the DX17Z-7, the retractable undercarriage and collapsible dozer blade offer versatility and efficiency when accessing and working in confined spaces. The retractable track is easily controlled via an electric switch on the control panel. The fully retracted undercarriage allows the excavator to enter narrow spaces. When fully expanded, the undercarriage provides optimum stability, especially when working over the side.

The collapsible dozer blade can be retracted or expanded to meet various job site needs. To make grading, leveling and backfilling as easy as possible, the blade float feature allows the blade to follow the contours of the ground without operator input.

Auxiliary hydraulics are configured with flush face couplers to make quick, easy hose connections when using augers, breakers and other hydraulic attachments. Like all DEVELON -7 Series mini excavators, the DX17Z-7 features a hydraulic quick-couplerready design with quick-coupler

hydraulic piping installed to the end of the arm. Additionally, the DX17Z-7 has a thumb-ready design to grab and lift objects.

The excavator’s undercarriage design helps protect against wear and tear of all retractable parts. The rubber track undercarriage provides superior flotation and traction on sensitive or soft surfaces and minimizes damage as it travels across them.

Standard cylinder guards protect the machine’s cylinders in the event of collisions with other objects. Onboard diagnostics enable proactive maintenance management to ensure the machine operates at its optimal performance.

New DEVELON machines include full coverage for 36 months or 5,000 hours, whichever comes first, with parts and service support from a local authorized DEVELON dealer. Local dealers provide responsive service, reliable parts and trusted advice, while experienced and highly trained professional technicians keep machines running at peak performance.

The new DX17Z-7 is ready to tackle the hard-to-reach places that other pieces of equipment can’t. Bringing precision and performance to the tightest corners of the job site, this compact but powerful machine is now available for order from your local dealer.

For more information, visit na.develon-ce.com/en.

The RTX1250 is powered by a 127-hp (94.7-kW) Deutz TCD3.6L diesel engine and can be outfitted with a range of attachments for efficient installation of gas, fiber, water and electrical utilities.

The Vermeer RTX1250 ride-on tractor has been updated with several improvements for increased efficiency and performance. These enhancements include updates to the tracks, axles, plow valve and retention pins, cab roof and headliner, as well as the auto stabilizer feature for the rockwheel attachment.

The RTX1250 is powered by a 127-hp (94.7-kW) Deutz TCD3.6L diesel engine and can be outfitted with a range of attachments for efficient installation of gas, fiber, water and electrical utilities.

Nick Olsen, Vermeer product manager, said that the manufacturer has implemented a series of updates to the RTX1250 based on insights and recommendations from its customers in the field.

The tractor is equipped with Vermeer onboard technology, including TrenchSense electronic control system and the EcoIdle engine control system. These systems actively monitor the engine’s operations to promote smooth trenching, prevent stalls and optimize fuel efficiency.

The Productivity Zone feature and Auto Plunge technology of the RTX1250 enhance its performance by determining the optimal operating range and ground speed for the attachments in use and by controlling the plunge rate for trencher or rockwheel attachments, respectively.

“These updates have been meticulously tested to deliver productivity in demanding environments.”

“These updates have been meticulously tested to deliver productivity in demanding environments. Vermeer is dedicated to consistently enhancing and refining their machinery to satisfy industry demands and customer needs. The latest version of the RTX1250 exemplifies this commitment.”

The RTX1250 is a versatile machine, able to operate as a trencher, rockwheel or vibratory plow with interchangeable attachments. These can be switched out in as little as an hour, offering options such as a backhoe, backfill blade or reel carrier attachment for the front of the machine and a vibratory plow, rockwheel, sliding offset rockwheel, sliding offset trencher or a trencher for the back end.

Nick Olsen Vermeer

The Vermeer RTX1250 prioritizes operator comfort and visibility. Its controls are located conveniently on the right-hand side, in line with the seat’s pivoting side.

The RTX1250 provides a quiet ride and features an isolated, cushioned operator’s platform. An optional climate-controlled cab is available for year-round operation. Depending on job requirements, the ride-on tractor can be outfitted with rubber tires or tracks.

The RTX1250 is Vermeer Fleet ready, which means owners can optimize productivity by staying in sync with their machine’s operations. Vermeer Telematics allows for monitoring engine operating hours, idle hours, fuel usage, fault codes and the machine’s location. It also incorporates geofencing capabilities.

For more information, visit w ww.vermeer.com.

Kent, WA 206-762-5933 Mount Vernon, WA 360-588-3083 Portland, OR 503-252-5933

Eugene, OR 541-343-6926

Spokane Valley, WA 509-534-5933 Pasco, WA 509-534-5933

www.ascoeq.com

806-435-7773 Clovis, NM 575-742-2726

Abilene, TX 325-698-2726 Amarillo, TX 806-372-8386 Lubbock, TX 806-745-2000 Perryton, TX

El Paso, TX 915-772-0613

Artesia, NM 575-746-6592

Austin Round Rock, TX

512-388-2529

877-851-1026

Buffalo Buffalo, TX 903-322-5602

Carmine Carmine, TX 979-278-3570

Corpus Christi Corpus Christi, TX 361-881-4891

Dallas Carrollton, TX 214-819-4100

800-227-6626

Ft. Worth Ft. Worth, TX 817-626-2288 866-966-4602 Houston Houston, TX 713-937-3005 800-865-6998

Longview Longview, TX 903-758-5576

Rio Grande Valley Mercedes, TX 956-565-0100

San Antonio San Antonio, TX 210-648-4600 800-966-4601

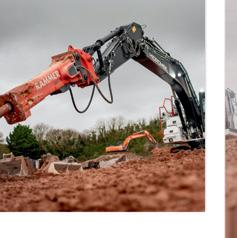

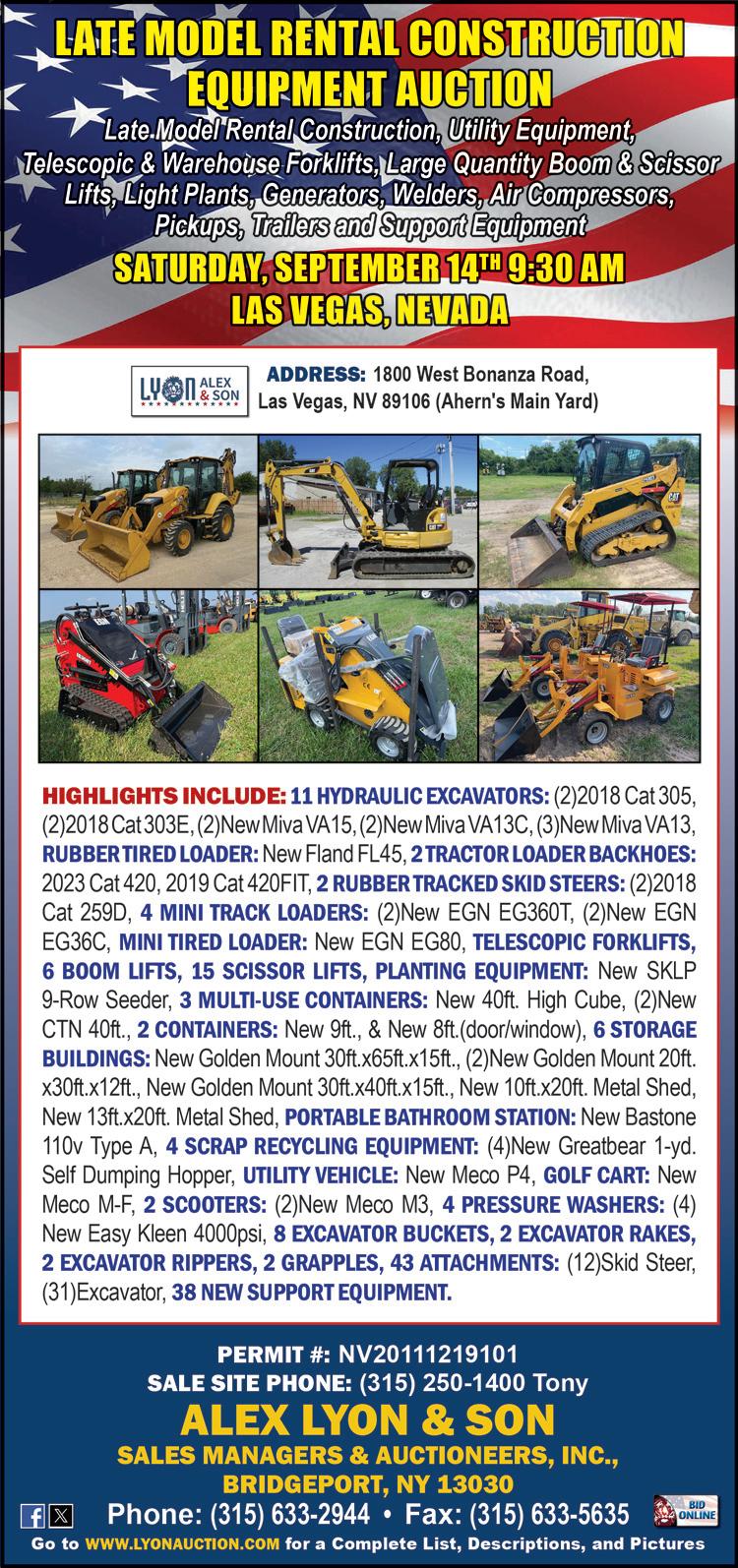

Komatsu has introduced a new machine portfolio of demolition excavators to the North American market.

The PC490HRD-11, PC290LC-11, PC360LC-11 and PC490LC-11 have been successfully operating in the European market for more than 20 years and are now available to the North American demolition industry, providing the opportunity for customers to increase job site efficiency.

The PC490HRD-11 demolition excavator features the K100 boom change system, enabling operators to begin working within minutes of arriving at a job site, and minimizing time for boom changes as the job progresses. The machine can reach up to 104 ft. and includes a full demolition guarding package, excellent visibility from a 45-degree tilting cab, and an informative human/machine interface panel.

The PC290LC-11, PC360LC-11 and PC490LC-11 straight boom excavators boost reach, providing 22 to 26 percent more reach than standard excavators, with easy customization that allows users to program up to 15 different tools. The machines are built to tackle tough demolition jobs with robust protection elements like heavy-duty revolving frame and under guards, bucket cylinder guard, boom light protection guards and reinforced attachment linkage.

Komatsu’s additional product line of Lehnhoff quick couplers and Montabert demolition attachments can be paired with these demolition excavators to further increase the ver-

Komatsu photo

The PC490HRD-11, PC290LC-11, PC360LC-11 and PC490LC-11 are now available to the North American demolition industry.

satility of these machines.

“Komatsu understands that the demolition industry is a fast growing and evolving segment that demands new product innovation,” said Bruce Boebel, director of products and services. “We are excited to be able to now provide this family of demolition excavator solutions in support of the industry, offering the ability to quickly customize for different working environments and provide versatility and efficiency at the job site.”

For more information, visit komatsu.com.

While more than 75,000 transportation improvement projects have been initiated, including one in nearly every congressional district, and 43,000 construction jobs have been created by 2021’s Infrastructure Investment and Jobs Act (IIJA), regulatory proposals threaten to hamper the law’s progress, American Road & Transportation Builders Association (ARTBA) Chair Tim Duit told a congressional panel July 24.

In testimony before the U.S. House Highways & Transit Subcommittee, Duit, president of Edmond, Okla., based Duit Construction, said regulatory proposals that are clear and well-defined can achieve their intended purpose. He cited a recent Federal Highway Administration (FHWA) proposal that placed greater emphasis on positive separation between roadway workers on construction sites and motorists. He said such a measure would improve safety for everyone.

“In other instances, however, while the road to regulation is paved with good intentions, the outcomes can cause uncertainty and a lack of clarity for the companies working on transportation projects,” Duit said, referring to a variety of proposals being implemented by federal agencies.

He outlined several major policies making it harder to initiate transportation system improvements:

• The Environmental Protection Agency (EPA)’s noncompliance with the U.S. Supreme Court’s 2023 decision on EPA’s “Waters of the United States” rule, which treats roadside ditches as protected waterways. Despite the Court’s definitive clarification, federal agencies have not fully compiled, resulting in continued confusion.

“Historic levels of infrastructure investment ... can result in timely completion of transportation projects that move people and products safely and efficiently.”

Tim Duit

American Road & Transportation Builders Association

• Inconsistent implementation of the IIJA’s “Buy America” provisions, especially FHWA’s proposed rollback of its waiver for manufactured products.

• FHWA’s attempt to impose greenhouse gas performance measures on state transportation departments — a provision that members of Congress debated in a bipartisan manner and deliberately left out of the IIJA.

• A Fish and Wildlife Service proposal against accidental harming of migratory birds, which could cause work stoppages on transportation construction sites.

Duit closed by saying, “Historic levels of infrastructure investment, when accompanied by the harmonious regulatory environment intended by Congress, can result in timely completion of transportation projects that move people and products safely and efficiently.”

For more information, visit www.artba.org.

www.equipmentshare.com

295 S Redwood Rd North Salt Lake, UT 84054 385-308-5516

2590 Main Street Chula Vista, CA 91911 619-510-6825

412 E Gowan Road North Las Vegas, NV 89032 725-221-0051

Corporate Office

5000 Vasquez Blvd., Denver, CO 80216 303-355-5900

Colorado Springs, CO 719-576-5541

Grand Junction, CO 970-241-1550 Milliken, CO 970-587-1188 Cheyenne, WY 307-634-5149 Durango, CO 970-259-0455 El Paso, TX 915-872-1001

www.kirby-smith.com

6715 W. Reno Ave Oklahoma City, OK 73127 800-375-3339

4617 Powell St. McAlester, OK 74501 918-310-1550

12321 E. Pine St. Tulsa, OK 74116 800-375-3733

12035 Interstate 20 W Abilene, TX 79601 877-577-5729

3922 I-40 E Amarillo, TX 79103 800-283-1247

3419 E Slaton Rd. Lubbock, TX 79404 866-289-6087

7301 E Interstate 20 E Odessa, TX 79765 877-794-1800

415 Enterprise Blvd. Waco (Hewitt), TX 76643 254-261-1370

Pkwy Humble, TX 77396 713-247-0066

Caterpillar Inc. announced updates to the mid-sized asphalt compactor line. The Cat CB7, CB8, and CB10 asphalt compactors continue to build upon the proven performance of their predecessors with edge-management options, optional cab, optional split drums, and a new mapping display.

Asphalt compaction can make or break a project and meeting the required density and smoothness specifications can be essential to maximizing profitability. In doing so, having operators that can stay alert for longer periods of time to perform effective rolling patterns that cover the entire surface can be a key to success.

Features like AM/FM Bluetooth Radio and the heated seat combine with spacious seating and legroom, unobstructed sight lines and climate control functions that can help operators perform at their best.

Proper management of unconfined edges can help optimize density and lead to better road quality. The vertical edge created by the cut-off wheel helps provide a stable vertical face for joint matching on the next paving pass. The bevel edge options provide sloped profiles for smoother transitions on and off the paved surface.

Three versions are available to help contractors meet job site requirements.

The new mapping display provides an enhanced on-screen visual for easier recognition and touchscreen capability for simplified setup. Cat Compact helps operators visualize the coverage area while recording pass-count and temperature data.

The system utilizes infrared temperature sensors and GPS mapping to keep the operator informed of current mat temperatures, machine position, pass-count and pass cov-

erage. This intuitive system enhances nighttime performance, while also capturing data for future process analysis and quality control documentation.

Asphalt compaction can make or break a project and meeting the required density and smoothness specifications can be essential to maximizing profitability. In doing so, having operators that can stay alert for longer periods of time to perform effective rolling patterns that cover the entire surface can be a key to success.

When combined with drum edge and drum surface lighting, Cat Compact helps extend the workday and increase daily production.

Making tight turns on hot asphalt can result in mat tearing that can lead to quality issues. The dual split-drum option on the front drum can help eliminate tears when maneuvering around obstacles or when compacting tight turns by reducing the speed of the inner drum half. The split drum option can be a great solution for parking lots, driveway approaches and other applications that

require frequent turning.

VisionLink is a cloud-based software application that provides data to your desktop or mobile device, taking the guesswork out of fleet management with key insights to maximize performance — regardless of fleet size or equipment manufacturer. The system provides maintenance needs, machine hours, location, fuel usage, idle time, diagnostic codes and other machine data to your mobile device, desktop or through an API to other software applications.

For more information, visit cat.com. (Photos courtesy of Caterpillar.)

Built in 1927 as Stadio dei Cipressi (Cypress Stadium), the Stadio Olimpico has hosted a wide variety of major events, from the Summer Olympic Games and concerts to the 2020 European Cup.

The stadium in the center of Rome has now been the scene of extensive renovation work. Wirtgen supplied a W 200 Fi for the project, and the cost-efficient, resource-friendly cold milling machine impressed with outstanding flexibility, speed and outstanding performance.

The renovation was commissioned to prepare the sporting facilities in time for the 26th European Athletics Championships in 2024. The resurfacing of the athletics track followed on from the modernization of the stadium for Euro 2020 (the 2020 UEFA European Football Championship).

The first step involved the removal of the synthetic track surface — also known as “tartan track”. The upper asphalt layer below this was then milled off with a Wirtgen W 200 Fi cold milling machine and given the appropriate cross-slope for the new surface layer.

The so-called cross-slope, barely perceptible to the human eye, is essential for optimal water drainage from the track surface and is extremely important for runners. The resurfacing process followed in reverse order.

A new layer of asphalt was placed on top of the remaining base layer. This was followed by an elastic layer, and then the later visible wear layer, consisting of EPDM (ethylene propylene diene monomer rubber) and PUR (polyurethane). Here, high quality paving of the asphalt sub-base is essential for ensuring the evenness and surface quality of the tartan track.

Since the whole project was on a very tight schedule, the asphalt removal needed to be completed within the space of two days, during which uncompromising quality of the milled surface had to be guaranteed. In view of this, the lead contractor chose to use a high-performance W 200 Fi large milling machine fitted with Mill Assist as a standard feature.

“The machine brings us the high speed and reliability we need. The automatic programs make our colleagues’ work easier,

improve efficiency, and therefore also helps to reduce environmental impact. It’s exactly what we need for our projects,” said lead contractor Schiavi S.r.l’s project manager.

The milling team on the athletics track milled off the surface strip-by-strip. The big challenge here was getting a sufficient number of trucks onto the site to remove the enormous quantities of milled material this produced. With ideal logistics, a 2-meter class cold milling machine can mill off and transfer more than 9,568 sq. yd. of surface layer material to trucks for removal from the site in a single day.

On this project, the logistical situation was extremely challenging, as the limited space inside the stadium made it difficult to drive the trucks in and get them into position. However, the “compact” model among the large milling machines not only delivers powerful performance, but also is extremely agile, which meant that maneuverability was no problem at all.

This made it possible to complete the milling work within only one working day, including the removal of the milled material from the project site.

The surface area of the athletics track to be milled amounted to a total of around 4,784 sq. yd., 2,990 sq. yd. of which were running track and 1,794 sq. yd. infield areas. The W 200 Fi cold milling machine milled off the surface layer to a depth of .4 to .8 in.

(All photos courtesy of Wirtgen.)

Efficiency and Productivity

Designed with safety and operator comfort in mind, the Shuttle Buggy® material transfer vehicle features adaptive cruise control, bright LED lighting, four-wheel steering for easy transport and ground-level maintenance access for added convenience. Operators can rely on clear sightlines and the ground operator is safely protected inside the structure of the machine. The Roadtec SB-3000 is the perfect blend of traditional craftsmanship and modern technology.

astecindustries.com

BANE MACHINERY, INC.

MACHINERRY

www.banemachinery.com

2449 Manana R (214) 352-2468 (817) 847-5894 (903) 597-6641

2449 Manana Dr. Dallas, TX 75220 (214) 352-2468

Ft. Worth, TX (817) 847-5894

Tyler, TX (903) 597-6641

CLAIREMONT EQUIPMENT

7651 Ronson Roa San Diego, CA 92 (858) 278-8351 1330 W Mission Ro Escondido, CA 92 (760) 739-9100

www.clairemontequipment.com

(318) 442-0455

7651 Ronson Road

Baton Rouge, LA (225) 291-3750

San Diego, CA 92111 (858) 278-8351

1330 W Mission Road

Broussard, LA (337) 837-9481

Escondido, CA 92029 (760) 739-9100

Covington, LA (985) 893-3005

440 West Aten Road

(337) 430-3045

Imperial, CA 92251 (760) 355-7700

Monroe, LA (318) 343-8787

4726 Convoy Street

Shreveport, LA (318) 631-3090

BEE EQUIPMENT SALES LTD.

www.beeequipmentsales.com

2506 Slaton Highway Lubbock, TX 79404 (806) 745-1511

West Reno A (800) OKC-BOYD • (405 Ardmore, OK (866) 720-2693 • (580) Lawton, OK (800) 633-2693 • (580) /

K 224-2693 /355-6667

C. L. BOYD CO., INC. www.clboyd.com

COOPER EQUIPMENT CO.

www.cooperequip.com

(409) 842-1754 Boise, Idaho (208) 336-8670 Jerome, Idaho (208) 324-4522 (800) 829-4450

5210 N Loop 1604 E San Antonio, TX 78247 (210) 657-5151

201 Commerce Blvd. Georgetown, TX 78626 (512) 930-5151

6532 East Highway Rhome, TX 7607 (817) 708-9108

21910 FM 2252

Schertz, TX 7815 (210) 732-2131

4220 West Reno Ave. Oklahoma City, OK 73107 (800) OKC-BOYD • (405) 942-8000

Ardmore, OK (866) 720-2693 • (580) 224-2693

Lawton, OK (800) 633-2693 • (580) 355-6667

13800 FM 973 N Manor, TX 78653 (512) 272-8200

San Diego, CA 92111 (858) 278-8338

St. Rose, LA (504) 466-5577

Beaumont, TX (409) 842-1754

Bryan, TX (979) 8231905

Corpus Christi, TX (361) 289-0727

Houston, TX (713) 679-6700

Longview, TX (903) 758-3326

EQUIPMENT www.closner.com

6532 East Highway 114 Rhome, TX 76078 (817) 708-9108

21910 FM 2252

Lufkin, TX (936) 634-8801 San Juan, TX (956) 787-0001

Schertz, TX 78154 (210) 732-2131

MODERN MACHINERY

www.modernmachinery.com

Corporate Office

Missoula, Montana (409) 842-1754

Boise, Idaho (208) 336-8670

Jerome, Idaho (208) 324-4522

Pocatello, Idaho (800) 829-4450

ROAD MACHINERRY Y www.roadmachinery.co 902 S. 7th Street X g (800) 304-4421

Billings, Montana (800) 735-2589

Spokane, Washington (800) 541-0754 om n COOPER EQUIPMEN www.cooperequip.

13800 FM 973 N Manor, TX 78653 (512) 272-8200

5210 N Loop 1604 San Antonio, TX 78 (210) 657-5151 201 Commerce Blv Georgetown, TX 78 NT CO. .com

18851 GH Circle

E 8247 vd. 8626 (903) 592-8900 Victoria, TX (361) 570-6666

Waller Industrial Park Waller, TX (936) 525-9949

Columbia Falls, Montana (800) 434-4190

Eugene, Oregon (800) 826-9811

Portland, Oregon (800) 950-7779

Kent, Washington (800) 669-2425

Phoenix, AZ 85034 (480) 545-2400 Prescott, AZ (928) 778-5621 Tuscon, AZ (520) 623-8681 (661) 695-4830 Perris, CA (909) 355-3600

Rochester, Washington (800) 304-4421

Spokane, Washington (800) 541-0754

Robust, powerful and reliable, the new generation BOMAG BMP 8500 multi-purpose compactor features an improved radio remote control design that allows the controller to be used on every BMP 8500 in the fleet.

The remote control’s unique “teach” function quickly and intuitively pairs the unit to the machine to save contractors time and money. Should the controller be misplaced, a new one can be paired to any machine in the fleet quickly and without special knowledge or tools.

With the BMP 8500, there is a secure, 100 percent connection between the remote-control unit and machine. Multiple trench rollers can be operated simultaneously at the job site without the need to coordinate or adjust individual radio frequencies, increasing operational flexibility, according to the manufacturer.

Now, two batteries are standard for the remote control, delivering a continuous combined worktime of up to 40 hours for more operating time. The two-battery solution allows one battery to charge while the other powers the controller, so the BMP 8500 is always ready for work.

Battery charge status is displayed on the remote-control unit’s screen, alerting operators when the battery needs to be changed. Integrated into the trench roller’s storage compartment, an optional charger allows the second battery to be topped off during machine operation.

The lightweight remote controller features a new

ergonomic design with paddle-style joysticks to simplify compactor travel and multiple indicator lights for intuitive control. BOMAG’s radio remote control offers reliable operation, even in direct sunlight.

Built for dependable operation in confined applications like trench and pipeline construction, the BMP 8500 also is ideal for landscaping, compacting backfill and foundation work.

For more information, visit www.bomag.com/us-en.

Women of Asphalt (WofA) announced the launch of a scholarship program in partnership with Caterpillar Inc., aimed at empowering women in the asphalt industry.

This initiative aligns with WofA’s mission to increase awareness of career opportunities, elevate knowledge through education and research, and provide a supportive community for women in the asphalt industry.

The Women of Asphalt Scholarship Program offers recipients the unique opportunity to attend the Caterpillar Paving Operations Training, scheduled for the week of Nov. 18, 2024. This comprehensive training program is designed to enhance participants’ skills and knowledge in paving operations, providing them with valuable insights and hands-on experience.

The scholarship covers the full cost of the weeklong course and includes travel expenses up to $2,000, with the total value of the scholarship exceeding $6,000. This is an excellent opportunity for women who are currently employed in the asphalt industry, seeking employment, or actively engaged in furthering their skills and

knowledge in this field.

To be eligible for the scholarship, applicants must meet one of the following criteria:

• Currently employed in the asphalt industry

• Seeking employment in the asphalt industry

• Actively engaged in furthering their skills and knowledge in the asphalt industry

The application process requires detailed information about the applicant’s background, including employment history, education status and participation in relevant clubs or organizations. Applicants also must submit an essay explaining why they are a good candidate for the award, highlighting their career aspirations and any relevant experiences.

All applications must be submitted by Aug. 1, 2024. The Women of Asphalt Awareness Committee will review all applications and announce the award winners via e-mail.

(Logo courtesy of Women of Asphalt.)

www.closner.com

Rhome, TX 817-708-9108

Schertz, TX 210-732-2131

Manor, TX 512-272-8200

Waller, TX 936-525-9949

www.pacwestmachinery.com

Seattle, WA 206-762-5933

Spokane, WA 509-534-5933

Pasco, WA 509-547-5933

Mt Vernon, WA 360-588-3083

Portland, OR 503-252-5933

Eugene, OR – Branch 541-302-3762 Power

www.power-equip.com

Farmington, NM 505-326-1413

Durango, CO 970-247-8830

Denver, CO 303-288-6801

Colorado Springs, CO 719-392-1155

Grand Junction, CO 970-243-0722

Greeley, CO 970-353-1224

wwwshaferequipmentco.com

www.tristatetruckandequip.com

Belgrade, MT 406-388-5818

Billings, MT 406-245-3188

Casper, WY 307-472-1818

Great Falls, MT 406-452-9551

Albuquerque, NM 505-345-7811 Tri-State Truck and Equipment

Rock Springs, WY 307-362-4000

Sparks, NV 208-801-7772

www.boxcerequipment.com

Tulsa, OK 918-272-7237

Dynapac, a supplier of high-tech soil and asphalt rollers, compact equipment and pavers, announced the addition of Century Equipment to its growing network of authorized dealers.

This strategic partnership aims to enhance the availability of Dynapac’s innovative construction solutions across Utah, New Mexico and Wyoming.

Century Equipment, renowned for its extensive experience and commitment to customer service in the heavy equipment industry, will now offer the full range of Dynapac products. This includes the latest models of soil compactors, asphalt rollers and pavers designed to meet the evolving needs of the job sites.

“We are excited to welcome Century Equipment as a partner in the West region,” said Jim Bansen, senior director of sales and channel development. “Their reputation for excellence and deep industry knowledge makes them an ideal partner to help us expand our reach and better serve our customers. This collaboration underscores our commitment to providing top-tier equipment and support to the industry.”

Century Equipment’s dedication to customer satisfaction and its robust service capabilities will be instrumental in ensuring that Dynapac’s clients receive unparalleled support and maintenance services, the company said.

“Partnering with Dynapac allows us to offer our customers some of the best road construction equipment available in the market today,” said Tyler Hill, vice president at Century Equipment. “We are thrilled to add Dynapac’s high-quality products to our inventory and are confident that this will benefit our customers by providing them with reliable, efficient, and innovative solutions for their construction projects.”

This new partnership will enable both companies to leverage their strengths and continue to drive innovation and excellence in the construction industry. Customers can expect enhanced access to Dynapac’s products and services, ensuring that they have the tools they need to complete their projects successfully and efficiently, the company said. For

The CP100II sets the standard for versatility, component lifecycle and mat quality. With a powerful 100 horsepower engine, an array of configurations and the class-leading Carlson EZCSS single slide screed, it’s easy to see why the CP100II is the ideal choice for heavy-duty commercial paving.

The Carlson CP100 II sets the standard for versatility, component lifecycle and mat quality. With a powerful 100hp engine, an array of configurations and the class-leading EZCSS single slide screed, it’s time to see why the CP100 II has fast become the contractor’s choice for heavy-duty commercial paver platforms.

closner.com

6532 East Highway 114 Rhome, TX 76078 817-708-9108

21910 FM 2252 Schertz, TX 78154 210-732-2131

13800 FM 973 N Manor, TX 78653 512-272-8200

18851 GH Circle Waller Industrial Park Waller, TX 936-525-9949 ascoeq.com

5980 S M L King Jr Pkwy Beaumont, TX 77705 409-746-5102

202 I-35 Frontage Road Belton, TX 76513 254-613-1500

2800 Hwy 290 E Brenham, TX 77833 979-836-6641

1875 N Earl Rudder Fwy Bryan, TX 77803 979-779-8942

1512 Neptune Dr. #9706 Clinton, OK 580-323-3422

2019 Airport Fwy Euless, TX 76040 817-283-2844

980 N Sam Houston Pkwy E Houston, TX 77032 281-987-1990

6203 Long Drive Houston, TX 77087 713-649-0940

27500 E University Drive Aubrey, TX 76227 972-441-2726

12805 US-290 E Manor, TX 78653 512-272-8922

7100 SW 3rd Street Oklahoma City, OK 73128 405-789-6812

902 SE 9th Avenue Perryton, TX 79070 806-435-7773

1920 S East Loop 410 San Antonio, TX 78220 210-333-8000

3600 US-82 Sherman, TX 75090 903-893-7586

401 FM 148 Terrell, TX 75160 972-563-2171

12210 E 1st Street Tulsa, OK 74128 918-437-5085

2602 E Front Street Tyler, TX 75702 903-593-0201

2900 Henry S Grace Fwy Wichita Falls, TX 76302 940-687-2726

beeequipmentsales.com

2506 East Slaton Highway Lubbock, TX 79404 806-745-1511 855-813-3775

nixonegli.com

2044 S. Vineyard Avenue Ontario, CA 91761 909-930-1822

800 E. Grant Line Road Tracy, CA 95304 209-830-8600

2750 Marion Drive Las Vegas, NV 89115 702-342-8100

Caterpillar’s online web platform, VisionLink Productivity, has been enhanced with the introduction of three new features — Cat Grade and Compact, Operator Coaching, and ETicketing.

This unified platform is designed to give managers insights into jobsite productivity and equipment utilization. The scalable cloud-based application collects and summarizes data from any subscribed machine equipped with a Cat Product Link device, ensuring that fleets with mixed OEM equipment can be seamlessly incorporated into one unified platform.

VisionLink Productivity simplifies data management with its user-friend-

Cat Compact summary dashboards show the amount of work completed for each day and calculate the fill volume. Using the Cat Compaction Algorithm (CCA) or Landfill Compaction Algorithm (LCA), it also will show the percent of covered area at target compaction. Landfill material compaction density can be viewed when operators enter weights per day.

The scalable cloud-based application collects and summarizes data from any subscribed machine equipped with a Cat Product Link device, ensuring that fleets with mixed OEM equipment can be seamlessly incorporated into one unified platform.

ly dashboards. These include a comprehensive jobsite summary and detailed insights with key performance indicators (KPIs). The platform analyzes standard telematics data, such as machine location, fuel burn and idle time, providing a clear overview of machine performance.

For more in-depth analysis, advanced data from machines equipped with Cat Payload, Grade, and Compact systems provides more job-specific details.

VisionLink Productivity now incorporates Cat Grade 3D and Cat Compact data into its robust reporting platform. Leveraging Cat Grade Connectivity, the platform enables 3D design files and updates to be seamlessly distributed to all machines at the job site, eliminating the need for USB uploads.

VisionLink Productivity further improves accuracy through GNSS corrections for position validation rather than installing a base station with high set-up costs for short projects. Grade Connectivity also minimizes machine downtime by reducing the need to send a technician onsite to diagnose Grade related issues, improving overall jobsite productivity.

Operator Coaching is a powerful tool that empowers operators of all experience levels to enhance their skills, efficiency and productivity. Two categories of operator coaching tips — Operating Efficiency and Machine Health — are tracked. During machine operation, the operator receives an onboard notification when an action with a corresponding tip is detected, putting them in the driver’s seat of their improvement journey. This helps to improve operational efficiency and increase machine longevity. When paired with the offboard VisionLink Productivity, managers can remotely view what coaching tips their operators have activated. This enables site managers to track improvements over time and focus training on areas specific to the operator’s needs and overall operations. Dashboards, lists and maps allow quick views of each coaching tip’s count, time and location.

The new E-Ticketing feature brings convenience, eliminating the need for manual or printed tickets generated by onboard Cat Payload systems. Key personnel can now receive an electronic copy of the tickets via email, including detailed information on individual buckets, total payload, truck and material type. Tickets can be quickly recalled using ID or number or filtering based on material type or truck name. Key performance indicators tracked by E-Ticketing include ticket count, average truck rate, pass count per ticket and total ticket payload.

For more information, visit www.cat.com.

(All photos courtesy of Caterpillar.)

Turlock, CA • 209-632-3931 Fairfield, CA • 707-425-9545

Merced, CA • 209-726-4600 Modesto, CA • 209-538-0911 Newman, CA • 209-862-3760

Santa Rosa, CA • 707-586-1790

Stockton, CA • 209-948-5401

Tulare, CA • 559-686-0054

Ukiah, CA • 707-468-5880

Woodland, CA • 530-615-2828

Madera, CA • 559-674-2496 Fresno, CA • 559-485-9090

www.clmequipment.com Lafayette, LA 337-837-6693 Lake Charles, LA 337-625-5942

TX 800-594-2263 Ft. Worth, TX 800-601-2263 Tyler, TX 800-594-2200

11125 SW Tonquin Road Sherwood, OR 97140 503-454-0902

www.PacWestMachinery.com

8207 South 216th Street Kent, WA 98032

206-762-5933

Mount Vernon, WA 360-588-3083

Portland, OR 503-252-5933

Eugene, OR 541-343-6926

Spokane Valley, WA 509-534-5933

Pasco, WA 509-547-5933

www.rgwequipment.com

700 W. Mossdale Road Lathrop, CA 95330 925-606-2477 550 Greenville Road Livermore, CA 94550 925-606-2403

6904 Banigan Road Anderson, CA 96007 925-606-2437

www.romco.com

1519 W Belt Line Road Carrollton, TX 75006 214-819-4100

Austin, TX 512-388-2529

Carmine, TX 979-278-3570

Ft. Worth, TX 817-626-2288

Houston, TX 713-937-3005

San Antonio, TX 210-648-4600 Buffalo, TX 903-322-5602

Corpus Christi, TX 361-881-4891

Mercedes, TX 956-565-0100

Stephenville, TX 254-266-2871

www.vcesvolvo.com

Bakersfield, CA 661-387-6090 Corona, CA 951-277-7620

Fresno, CA 559-834-4420

Sacramento, CA 916-504-2300

Lakeside, CA 619-441-3690

Redding, CA 279-201-4869

San Leandro, CA 510-357-9131

Turlock, CA 209-410-6710

www.wpi.com

12320 S. Main Street Houston, TX 77035 713- 723-1050

1720 Hicks Street Tomball, TX 77375 281- 351-9016

2077 N. Craig Drive Buffalo, TX 75831 903-322-7150

8903 Memorial Blvd Port Arthur, TX 77640 409-721-5305

www.construction-edge.com

5732 S MacArthur Drive Alexandria, LA 71302 318-408-3099

7502 Pecue Lane Baton Rouge, LA 70809 225-800-3711

125 E Airline Hwy Kenner, LA 70062 504-467-5906

4031-B Paramount Parkway Temple, TX 76502 254-727-2488

6514 N Interstate 35 Frontage Road Waco, TX 76706 254-855-6242

ss or implied, or any liability from the use of this pu

otice.There may be differences n only and is not intended as an ormation that is published in the ublication.

downtown and the North Sam Houston Tollway, also known as Beltway 8, that includes segments of connecting freeways. This project will improve I-45 from Beltway 8 to I-10 and reroute I-45 through the downtown Houston area along I-10 and U.S. 59/I-69. Portions of I-10 and U.S. 59/I-69 will be improved as well.

The I-45 was constructed in the 1940s and opened in the early 1950s.

The freeway is linked to nine of the 20 most congested roadways in the state.

“This is going to be a major transformation for the city,” said TxDOT spokesperson Danny Perez. “It’s going to improve mobility and enhance safety.”

The project is divided into three segments: Segment 1 is Beltway 8 North to I-610; Segment 2 is I-610 to I-10; and Segment 3 is the Downtown Loop System: I-45, I-10 and U.S. 59/I-69.

The first contract, 3B-1, was let in June of 2024 and was awarded to Harper Brothers Construction LLC.

The overall NHHIP project starts with Segment 3, which is divided into four separate projects lasting until 2037.

Segment 3 will reconstruct all existing interchanges in the downtown Houston loop system and reroute I-45 to be parallel to I-10 on the north side of downtown and parallel to U.S. 59/I-69 on the east side of downtown.

According to TxDOT, Segment 3 project will ultimately reconstruct portions of I-10, I-45, I-69 and SH 288 around downtown Houston.

“The next contract is 3B-2, scheduled to let in September 2024,” said Perez, who noted that TxDOT will let more in the next few years as the work expands. The segments are subdivided into various projects, which vary in size from $150 million to $850 million for traditional design-bid-build delivery, except for two projects in Segment 3 [3C-2 and 3D] which are planned Design-Build projects greater than $1.3 billion.”

The work includes the addition of four non-tolled managed lanes, two lanes in each direction, 24/7 operations for carpool and transit on I-45 from Beltway 8 North to downtown Houston with improvements continuing south along U.S. 59/I-69 to Spur 527; the reconstruction of mainlanes and frontage roads; the rerouting of I-45 in the downtown area to be parallel with I-10 on the north side of downtown and parallel with U.S. 59/I-69 on the east side of downtown; providing access to the west side of downtown via downtown connectors which would provide access to and from various downtown streets; and realign both I-10 and U.S. 59/I-69 within the proposed project area to eliminate the current roadway curvature.

Furthermore, it will add four I-10 express lanes between I45 and U.S. 59/I-69; reconstruct the interchange at I-45 and I-610N to improve sight distances on direct connectors and replace outdated left lane exits where drivers expect right lane exits; the connection of I-45 and I-610 frontage roads with new intersections in Segment 2 and add one frontage road lane in each direction in Segment 1; and the addition of shoulders that are full width; bike/pedestrian features along frontage roads and affected cross streets, and trails parallel to bayous within the right of way.

Segment 1 is broken down into three ports: 1A, $296,800,000 (2034-2038); 1B, $386,400,000 (2033-2037);

and 1C, $224 million (2032-2035).

“The project brings significant economic impacts to the Houston area as well as much needed safety improvements to one of the state’s most congested highways,” states the web page. “Some 92,000 direct jobs are being created with an additional 89,000 indirect jobs generated from this project. The overall statewide economic impact of NHHIP is estimated at $19.2 billion.The future of transportation is changing and the infrastructure in the nation’s fourth largest city needs to change with it. Parts of the I-45 corridor have not changed since being constructed over 50 years ago.

“The I-45 improvement project not only brings these highways up to current standards, but also prepares for the future by improving resiliency to weather events and providing safer, more efficient travel that could accommodate the transition to electric and self-driving vehicles,” it added. “And, importantly, it will increase the opportunity for transit and high-occupancy vehicles as a mode choice for those traveling along the I-45 North Houston corridor. Additionally, the neighborhoods in the project area will see many specific benefits beyond the economic and safety improvements.”

This segment will improve the I-45 between I-610 and Beltway 8 by widening the roadway to accommodate four lanes known as MaX lanes. The roadway would have: four general purpose lanes in each direction with auxiliary lanes; two MaX (Managed Express) lanes in each direction operating 24/7 carrying HOV (high-occupancy vehicle) and METRO bus traffic; the addition of full-width shoulders and bicycle/pedestrian features frontage roads, as well as enhanced bicycle/pedestrian features on streets crossing I-45. Drainage in this segment would be improved for residents and businesses along I-45 with the addition of 11 new detention ponds including a joint regional detention pond facility with Harris County Flood Control District (HCFCD) on Halls Bayou just east of I-45 and with the use of increased storm sewer pipe sizes to provide in-line detention.

Segment 2 is based on 2A, $604,800,000 with $100 million in current funding (2028-2032) and 2B, $1,015,400,000 (2032-2037). This segment will improve the I-45 mainlanes and frontage roads from I-10 north to I-610 and rebuild the I45/I-610 interchange.

The work is widening I-45 in this area to accommodate four MaX lanes. The proposed roadway would include 10 general purpose lanes (five in each direction), four MaX lanes (two in each direction), and two to three frontage road lanes in each direction. The MaX lanes would increase the HOV space in the middle of the I-45 mainlanes from one lane to four. Only buses and vehicles with two or more people in them would be able to travel in the MaX lanes

“Segment 3, excluding 3A, was originally planned to be Design-Build,” states the web page. “Now, Segment 3B, 3A, and various other portions of Segment 3 will be constructed as traditional Design-Bid-Build projects, in which design plans are developed prior to construction contractors providing bids. TxDOT studied elevated lanes, depressed lanes, underground tunnels, and combinations of all three. The only alternative that had a significant and positive impact was to depress U.S. 59/ I-69 between Commerce Street and Spur 527, and shift I-45 from the current alignment along Pierce Elevated and make it parallel with I-10 on the north side of Downtown and U.S. 59/I-69 on the west side of Downtown.”

OEM authorized mining dealer www.coremachinery.com

Phoenix, AZ 480-545-2400

Phoenix, AZ 602-252-7121 Prescott, AZ 928-778-5621 Tucson, AZ 520-623-8681

Bakersfield, CA 661-695-4830 Mojave, CA 661-824-2319 Perris, CA 909-355-3600

*Formerly Road Machinery

www.wpi.com

12320 S. Main Street Houston, TX 77035 713-723-1050 Buffalo, TX 903-322-7150 Bryan, TX 979-314-1191 Corpus Christi, TX 361-884-8275 Edinburg, TX 956-386-0107

Kilgore, TX 903-984-2011

Lufkin TX 936-243-6056 Pflugerville, TX 512-251-0013 Port Arthur, TX 409-721-5305 San Antonio, TX 210-648-4444 Tomball, TX 281-351-9016

www.powermotivecorp.com

Corporate Office 5000 Vasquez Blvd., Denver, CO 80216 303-355-5900 Colorado Springs, CO 719-576-5541 Grand Junction, CO 970-241-1550 Milliken, CO 970-587-1188 Cheyenne, WY 307-634-5149 Durango, CO 970-259-0455 Albuquerque, NM 505-345-8383 Bloomfield, NM 505-324-8601 Carlsbad, NM 505-485-1700

El Paso, TX 915-872-1001 Chandler, AZ

602-986-3003 Phoenix, AZ

602-463-3772 Tucson, AZ

520-649-2858

www.geehm.com

5461 S Nikita Avenue Fresno, CA 93725 559-834-3149

1164 Prestige Way Redding, CA 96003 530-229-3820

3650 Seaport Blvd. West Sacramento, CA 95691 916-375-3540

3350 Regional Parkway Santa Rosa, CA 95403 707-544-4147

45051 Industrial Drive Fremont, CA 94538 Coming Soon

858-278-8338

Bobcat Company has launched a nationwide Bobcat Park and Rec Makeover Contest to give one community a $100,000 park makeover.

To kick off the contest, Bobcat teamed up with its brand ambassador and renovation expert Chip Gaines for a baseball field makeover to inspire communities to see the potential in their local park and recreation spaces.

Bobcat brought its iconic white and orange equipment and a fleet of volunteers to Gaines’ hometown of Waco, Texas, to make over a local ballfield.

Gaines, host of the hit show “Fixer Upper” and Magnolia co-founder, is an advocate for youth sports, having played baseball growing up and during college.

“I grew up playing ball at local parks, and now, my boys have too. Spending time outside and being involved in community sports is such a big part of our family’s life, which makes me thrilled to partner with Bobcat here in Waco to renovate a local ballpark as they launch their national contest,” said Gaines.

“It’s projects like this that really bring a community together, today but also decades down the road.”

The Bobcat Park and Rec Makeover Contest is open to communities in the United States with a shovel-ready park and recreation project. Funds can be used to renovate or create a park and recreation space or facility based on the winning community’s needs.

“Bobcat is so much more than machines; we’re a team and a brand committed to community and we’re demonstrating that commitment by investing our time and resources to help build a stronger, better tomorrow,” said Laura Ness Owens, Bobcat vice president of global brand and marketing.

Bobcat has long supported communities where its customers, dealers and employees

Bobcat brought its iconic white and orange equipment and a fleet of volunteers to Gaines’ hometown of Waco, Texas, to make over a local ballfield.

Bobcat Company has launched a nationwide Bobcat Park and Rec Makeover Contest to give one community a $100,000 park makeover.

Bobcat teamed up with its brand ambassador and renovation expert Chip Gaines for a baseball field makeover to inspire communities to see the potential in their local park and recreation spaces.

live and work. In 2023, Bobcat partnered with the National Recreation and Park Association (NRPA) to offer grants to create sustainable community park and recreation areas. Bobcat continues to work with NRPA as its partner for its Park and Rec Makeover Contest, as well as through its sponsorship of Park and Recreation Month.

“At Bobcat, we’re all about building the kind of world we want to live in, and this contest is just one of the ways we’re giving back to help communities thrive,” Ness Owens explained.

“Teaming up with Chip to fix up a ballpark in the Waco area is our way of encouraging people to take action in their own towns. It could be by nominating their community for a similar makeover or simply volunteering and getting involved. We want this partnership with Chip and our shared dedication to community to light a spark in others to give back and strengthen communities everywhere.”

For full contest details, rules and regulations, and to enter for a chance to win, visit bobcat.com before Aug. 16, 2024.

(All photos courtesy of Jenn Ackerman.)

Tsurumi Pump, a pioneering pump manufacturer founded in Osaka, Japan, in 1924, is celebrating its 100th anniversary this year.

The company has focused on technical excellence since its inception as an equipment manufacturer, gaining recognition across Asia and expanding to the United States and Europe.

In 1979, Tsurumi America Inc. was established, creating a strong network of dealers, distributors and partners. The company’s resolute commitment to quality has driven its success in various markets, including construction, mining, flood remediation, food processing, wastewater treatment and water features.