By Eric Olson CEG CONTRIBUTING EDITOR

Southwestern University rests within a beautiful, leafy campus in Georgetown, Texas, approximately 30 mi. north of Austin.

The 183-year-old college, the oldest in the Lone Star State, is noted for its outstanding sciences, fine arts and music curricula, as well as its interdisciplinary and preprofessional programs. Its undergraduate enrollment is approximately 1,500 students.

To complement the natural beauty of the campus with the charm of its various buildings and facilities, Southwestern officials launched a $120 million campaign in 2022 to begin new construction and renovations at different points across its 700 acres.

The multi-year project got under way in September 2023 to build two new residence halls, a welcome center, a sports complex and a campus restaurant. Upgrades were also planned at a historic academic hall, the library and a learning commons hub.

A key goal of the building effort is to help Southwestern remain competitive with other colleges and universities in attracting students looking for modern facilities, according to Dinah Ritchie, the college’s vice president for integrated communications and chief marketing officer.

Each of the university’s construction and renovation see SOUTHWESTERN page 22

Kirby-Smith Machinery Inc. (KSM) has promoted Colin Brown to Oklahoma sales manager.

In his new role, Brown will lead the sales team in Oklahoma City, Tulsa and McAlester to drive revenue, grow market share and support customer relationships. Brown also was promoted to general manager of KSM’s Magni telehandler line and will continue to serve as Oklahoma City branch manager.

Gavin Cole, executive vice president of sales of KSM, spoke highly of the work Brown has done since rejoining KSM in 2022.

“Colin leads by example and has consistently stepped up to the plate to support the overall needs of Kirby-

Smith,” said Cole. “I know he will be incredibly successful in his new responsibilities.”

Focused on supporting KSM’s customers, Brown is ready for the challenges ahead.

“I cannot express how proud I am to be part of Kirby-Smith Machinery,” said Brown. “Kirby-Smith carries an incredible legacy of leadership that puts the needs of our customers first, earning the privilege of life-long relationships. It is an honor to be a part of that as we strive to provide our customers with the equipment, solutions and support they expect and deserve.”

2016 Kobelco SK140SRLC-3, Stk#: 13546, EROPS, A/C, Heat, Radio, 4,463 hrs., 34" Bkt, 24" Pads, Aux Hyd, Back-Up Camera $52,500

2018 John Deere 450K LGP, Stk#: 13610, OROPS, 2,399 hrs., 6 Way Blade, 24" Pads, 10' 4" Wide $59,500

2013

1,007

lbs

2014 Laymor SM400, Stk#: 12756, EROPS, A/C & Heat, 594 hrs., Water System, 8 ft. Broom, 225x75Rx15 Tires, 4 Cy. Kubota Eng .. $29,500

Tuttle,

operations.

With shovels in hand, Oklahoma Gov. Kevin Stitt and other state dignitaries recently helped celebrate the groundbreaking of a new 170,000 sq.-ft. paint facility at the Ditch Witch factory in Perry, Okla.

The hotel towers at the iconic Tropicana Las Vegas resort and casino are set to be imploded in early October to ready a portion of the site for the Oakland A’s baseball team’s planned ballpark construction next spring.

Many construction contractors are overlooking a partner in their quest for jobsite safety: their insurers. Taking advantage of safety analysis programs provided by insurance carriers can result in premium discounts for fleet liability plans.

TRNSACT announced a collaboration with Hyundai Construction Equipment Americas to launch a new Hyundai Dealer Finance Portal. This customized software is designed to transform and simplify the finance operations.

ABB and Komatsu have signed a Strategic Collaboration Agreement to collaborate on the development of integrated solutions that will help bring net zero emissions for heavy industrial machinery a step closer to reality.

For landscapers, dealers and contractors attending award-winning Equip Exposition for the very first time, show organizers are offering tips to help first-timers make the most of this blockbuster show.

BOMAG Americas, a Fayat Company, announced the promotion of Christoph Thiesbrummel to vice president of sales & marketing for North American operations effective July 22, 2024.

40

The newly founded National Equipment League has crowned Bryan Furnace as its first champion after four hotly contested events, hosted by HD Hyundai Construction Equipment North America.

42

JCB announced a special long-term partnership with multi-GRAMMY award winning musician and Rock and Roll Hall of Fame inductee Joe Walsh and his national non-profit veterans organization and annual benefit festival, VetsAid.

44 HOW TO CHOOSE THE RIGHT TOOLING

Tooling choice is a key decision when planning an upcoming auger boring crossing. With a plethora of varying ground conditions, and multiple different styles of cutting heads, how does one make the right choice?

48

Kubota Tractor Corporation announced 20 grant recipients in its fourth annual Kubota Hometown Proud grant program aimed at providing support across the country for local nonprofit organizations and their unique initiatives.

YODER & FREY HOSTS RETIREMENT SALES

Two sales in one week, each on opposite sides of the United States. Both were off-site dispersal sales, and that is where the similarities between the two auctions end.

dennishogeboom@cegltd.com

khogeboom@cegltd.com

CEG’s

On a job site near Yukon, Okla., an operator pushes material with a Komatsu D51EXi-24 IMC

When Kyle Kopp started his business six years ago, he wasn’t sure what to call it.

“My wife and I were trying to come up with a name, and we wanted something short and sweet,” Kopp said. “I love to fish, so my wife suggested Hook. It just stuck.” Tuttle, Okla.-based Hook Construction LLC has reeled in business by providing turnkey civil construction services throughout Oklahoma and northern Texas. Kopp is Hook Construction’s director of operations and his partner, Bill Estell, is the director of estimating. Together, they have decades of experience in the industry.

“Bill and I actually worked for the same company about five years ago, which is how we met,” Kopp said. “I headed up the concrete division, and he oversaw the earthwork side. When he joined Hook Construction a few years ago, we decided to put that expertise together and really focus on civil work.”

“I am mainly in the office crunching numbers for estimating and bidding, and Kyle does a lot of the field operations,” Estell said. “That’s worked really well for us. When it comes down to it, though, we both are willing to do whatever it takes to make the business successful.”

Kopp added, “That attitude has helped us grow to about 30 employees who are working on four to eight jobs at any one time.”

Most of Hook Construction’s projects involve complete site preparation, including clearing and stripping, mass earthwork, underground utility installation, fine grading, subbase placement and maintaining erosion control. The company also performs structural concrete work such as drainage flumes, meter boxes and retaining walls.

“About the only thing we don’t do at this time is large paving,” Kopp said. “We will take responsibility for it as part of a package, but we’ll subcontract that portion. We’re really geared toward getting the site ready to be built on and paved. It’s our preference to do comprehensive jobs that involve everything we offer, but we do break out our services and do just earthwork, utility, drainage and concrete.”

Recently, Hook Construction prepared a site for two new dorms on the University of Oklahoma’s main campus in Norman. After the existing seven-story building was demoed, Hook Construction filled in the old basement area with 15,000 yards of imported select fill. Once the new basement was done, the crew backfilled around it and completed the pads.

While that project was in the works, another Hook

Construction crew was doing drainage improvement work for the Oklahoma Military Department at an Oklahoma City-area location. The crew put in approximately 1,500 ft. of 18-in. to 54-in. concrete pipe, as well as associated structures.

see HOOK page 52

With shovels in hand, Oklahoma Gov. Kevin Stitt and other state dignitaries recently helped celebrate the groundbreaking of a new 170,000 sq.-ft. paint facility at the Ditch Witch factory in Perry, Okla. The event was a part of a stop from the Association of Equipment Manufacturers (AEM) Express Tour of manufacturing companies across the country.

The new paint line facility is expected to bring up to 100 new jobs to the area and will help drive greater operational efficiencies and capacity to better serve customers.

Celebrating 75 years in business, the expansion further reinforces the company’s long-standing commitment to Perry and the state of Oklahoma and positions the company to support future growth in the underground construction industry.

The groundbreaking event was kicked off by Kevin Smith, vice president of Ditch Witch, with welcoming remarks to the nearly 1,000 attendees. He shared the impact of each-andevery one of the employees for their commitment, hard work and dedication in helping power people’s lives.

“What we do matters. Within the first 30 minutes of your day, the work that we do makes a positive impact on people’s lives,” he said. “The first thing you do in the morning might be check your cell phone and look at the

Oklahoma Gov. Kevin Stitt joins AEM and Ditch Witch to break ground on the company’s new 170,000-sq.-ft. facility.

weather, or social media. We helped bring that into your hands. Then you flip on the light switch. We helped deliver that power to your house.

“This investment in the Perry facility will help expand our manufacturing capacity, reinforces our commitment to the many customers we serve around the world, and ultimately helps us continue to produce the world-class products Ditch Witch is known for well into the future.”

Ditch Witch traces its roots back to 1902 when Carl Malzhan opened a blacksmith shop with his sons in Perry. Its first production trencher came off the assembly line in 1949, and since that time, Ditch Witch has been the largest employer in Perry and has become a leading global provider of underground construction equipment. Today, the company employs more than 1,700 people in the community.

The new paint facility is scheduled to be completed in early 2027.

For more information, visit www.ditchwitch.com.

(Photos courtesy of Ditch Witch)

The hotel towers at the iconic Tropicana Las Vegas resort and casino are set to be imploded in early October to ready a portion of the site for the Oakland A’s baseball team’s planned ballpark construction next spring.

Bally’s Corp., the owner of the Tropicana, and the A’s will host a celebratory event on Oct. 8 that will include a drone and fireworks show just hours before the hotel’s implosion, tentatively scheduled to occur at 2:30 a.m. on Oct. 9.

The Tropicana closed permanently on April 2, almost exactly 67 years after it first opened. The hotel had long been in disrepair, though in its glory days, it was a big Rat Pack casino. When Sammy Davis Jr. bought a share of the Tropicana in 1972, it made him the first Black person to have an ownership stake in a Las Vegas Strip casino.

Clark County still needs to approve a permit application from Bally’s for the implosion, which will come after weeks of preliminary demolition carried out by GGG Demolition Inc. in Orange, Calif. Permit approval can occur up to one week before the planned destruction.

Imploding the resort will allow work

crews to clear the site before construction begins on the A’s stadium in April. The construction of the $1.5 billion ballpark is expected to take about three years and be ready for the team to begin play in Las Vegas for the 2028 Major League Baseball season.

Before that work can begin, though, the A’s must first finalize multiple agreements with the Las Vegas Stadium Authority and Clark County, the Review-Journal reported Aug. 26.

One of four agreements, the community benefits agreement, has already been approved, the news source noted. The development, lease and non-relocation deals have been introduced and are pending approval.

Steve Hill, chair of the stadium authority, has said on multiple occasions that he expects the three outstanding agreements to be negotiated over the next few months and be approved in early December.

The stadium authority board will next meet on Oct. 17 to present updated versions of the three documents. Hill said that one key

indicator that things are moving in the right direction was the fact that the board canceled planned meetings in September and November.

“Frankly, we’re having the meeting in October so we can get as close to a final document and allow the public and the board and everybody to review that and have any input that they would want to have,” Hill told the Review-Journal following the Aug. 15 meeting. “We’re rounding third and heading for home here. There are not many open issues left.”

The A’s could present the team’s detailed stadium financing plan at the October meeting, something that is required before up to $380 million in public funds would be made available to the team to help fund the ballpark construction.

The public funding, approved last year, includes $180 million in transferable tax credits from the state and around $120 million in bonds to be taken out by Clark County. Additionally, the county will provide the A’s with a $25 million credit to be used toward infrastructure work around the stadium site.

Sandy Dean, an executive with the A’s, previously detailed the team’s plan to use $350 million of the public funding, take on $300 million in debt financing and use $850 million in equity from team owner John Fisher’s family. The team’s management also is seeking potential local investors in the ballpark project that could reduce the equity contribution from the Fishers.

The baseball team has started the development agreement process with Clark County as well as the process to secure entitlements for the Tropicana site. An A’s lobbyist met on Aug. 5 with Clark County Commissioner Jim Gibson regarding those entitlements, the Las Vegas newspaper learned by accessing county records.

“[Clark County] has to go through a development agreement with the A’s, too. That has started,” Hill explained. “At some point, the A’s and the board have to ask Clark County to issue those bonds. But the timing of that hasn’t been determined. Because the A’s are going to be putting in a vast majority of the funding of the stadium, that bond funding doesn’t have to happen right at the beginning, but it could.”

By Lucy Perry CEG CORRESPONDENT

Many construction contractors are overlooking a partner in their quest for jobsite safety: their insurers. Taking advantage of safety analysis programs provided by insurance carriers can result in immediate premium discounts for fleet liability plans. However, insurers are not pushing their clients often enough to make simple changes to mitigate the safety risks on the job.

Contractors know company safety directly impacts insurance rates. Insurers assess the risk of covering contractors based on their safety practices.

“A strong safety record can lead to lower premiums,” said New York contractor GTL Construction.

A comprehensive employee safety training program should start with the proper use of equipment, hazard recognition and emergency procedures.

Regular safety audits and inspections can help identify hazards before they cause harm, said GTL.

“By addressing these issues proactively, firms can maintain a safer work environment and demonstrate their commitment to safety to insurers.”

So can ensuring that all workers use appropriate PPE such as helmets, gloves and safety glasses.

Not only do PPEs reduce the severity of injury, but they demonstrate a proactive approach to risk management, believes GTL.

The construction company advises contractors to promoting a culture of safety. The culture should make every employee understand their role in maintaining a safe work environment that can lead to fewer accidents and injuries.

“This culture should be supported by management and include regular safety meetings and open communication about safety concerns.”

The Experience Modification Rate (EMR) is a crucial metric used by insurance companies to determine workers’ compensation premiums.

GTL explained that the rate is a numerical representation of a company’s past injury claims compared to the injury average.

An EMR of 1.0 is considered average; below 1.0 indicates a better-than-average record. And an EMR above 1.0 means a worse-than-average safety record.

The EMR is calculated over a three-year period and considers the number of claims, their severity and the industry average, said GTL in a company blog.

“The EMR directly affects the cost of workers’ compensation insurance,” according to the blog. “A lower EMR results in lower premiums, as it indicates a lower risk

of future claims. Conversely, a higher EMR leads to higher premiums.”

Contractors can improve EMR by implementing robust safety programs, promptly addressing hazards and effectively managing claims.

“Reducing the frequency and severity of workplace injuries will lead to lower EMR over time,” said the construction company.

The topic of contractor-controlled insurance packages was discussed at a 2023 International Risk Management Institute

conference.

These packages can be structured to produce premium discounts when fewer claims are filed, according to risk management experts.

Writing for Insurance Journal, William Rabb said insurers are hands-off a lot of the time when it comes to advising their contractor clients.

“To a large degree, workers’ compensation and commercial liability insurers leave it mostly to contractors to vet their operations for safety,” wrote Rabb.

“It’s usually not until after the fact, after

something happens,” said TJ Lyons, a safety consultant who spoke at the construction risk conference

Contractors across the country are overlooking crucial changes in safety practices, said Lyons.

In fact, Rabb noted that unsafe practices in the United States contribute to approximately 2,000 construction worker fatalities each year.

Lyons believes the best way to foster safer job sites is to adopt best practices and insist on their consistent use. He thinks best practices and safer equipment should be part of any contracts between contractor and subcontractors.

Safety innovations should be built into a project at the design stage, said Lyons adding that safety folks are rarely involved at this point.

A strategic approach to improved safety and lower EMR needs management commitment, employee engagement and continuous improvement, believes GTL.

Start by developing a comprehensive safety program, suggests the company. “A well-structured program should include clear policies and procedures.”

A solid program also means regular training sessions and a system for reporting and addressing safety concerns.

“This program should be reviewed and updated regularly to incorporate new safety standards and best practices,” said GTL.

Involving employees can raise their commitment to a safe work environment, said GTL.

Safety committees, suggestion programs and recognition of safe behavior can engage employees.

Identify patterns and areas of needed improvement by tracking and analyzing detailed records of safety incidents. With this information, targeted interventions that reduce the risk of future incidents can be developed, said GTL.

Modern safety technology as well as effective injury management and return-towork programs can reduce the impact of incidents on EMR.

“Investing in safety and reducing the EMR can lead to significant financial benefits for construction firms,” said GTL, offering points to keep in mind:

A lower EMR results in lower workers’ comp premiums, leading to substantial cost savings over time. Companies with strong safety records and lower insurance costs can offer more competitive bids on projects, increasing their chances of winning contracts. A safe work environment leads to higher employee morale and retention, reducing turnover costs and increasing productivity. Fewer accidents and injuries

TRNSACT announced a collaboration with Hyundai Construction Equipment Americas to launch a new Hyundai Dealer Finance Portal.

This customized software, powered by TRNSACT, is designed to transform and simplify the finance operations for commercial Hyundai dealers, underscoring its dedication to delivering next-generation, user-centric solutions, according to TRNSACT.

• Instant Quoting Capabilities: Generate and present real-time finance quotes, ensuring customers receive the most accurate and current options available.

• Streamlined Application Management: Oversee and track credit applications with ease, all while maintaining clear and efficient communication in one integrated space.

• Apply online for

“We are excited to welcome Hyundai’s dealers and demonstrate how TRNSACT can enhance their finance processes with unparalleled speed and efficiency,” said Beckham Thomas, CEO of TRNSACT. “With our roots in the construction industry, this partnership is particularly significant as it aligns with our goal to modernize and streamline commercial finance.”

• Effortless Financing Integration: Dealers can now seamlessly connect to a range of financing programs through TRNSACT’s advanced platform.

• Enhanced Customer Satisfaction: Deliver fast and straightforward financing solutions, boosting customer satisfaction and purchasing power.

• Robust Data Security: Safeguard sensitive information with data protection protocols, ensuring compliance and security.

“We are confident that this partnership will bring forth a deeper dive into creating a more efficient process for all dealers, lenders and customers, said Deana Chung, Hyundai finance leader.

“The finance portal is a phenomenal way to keep everyone in the loop on current stages and updates for each applicant. This new process is forecasted to produce fast exponential results within a 90-day span.”

Niece Water Towers deliver reliability and durability when you need fast mobile water service. With a 12” discharge tube it fills your tanks at a rate of over 1,000 gallons per minute. Offers removable power pack for security, fifth wheel tow hitch, professionally engineered and constructed.

It features (8) legs for stability

5th wheel set up for quick “tow and go.”

ABB and Komatsu have signed a Strategic Collaboration Agreement to collaborate on the development of integrated solutions that will help bring net zero emissions for heavy industrial machinery a step closer to reality.

The collaboration brings two global leaders together to share industry expertise and products in a bid to create world-class solutions, ranging from renewable energy generation to fully electrified mining equipment.

Decarbonization of mobile mining equipment is needed to help mine operators achieve their greenhouse gas reduction targets. ABB and Komatsu’s collaboration is geared towards reducing diesel consumption and ultimately eliminating it through the electrification of mine operations. Innovation has been, and will continue to be, the primary catalyst for ABB, Komatsu and their mine customers to reach their carbon reduction goals.

“We’re pleased to embark on this collaboration with ABB and are excited to leverage one another’s industry leading products and technological expertise to help move mining operations toward net zero emissions,

ment to accelerate adoption into our customers’ operations.

“By working together, we will tackle electrification and make a revolutionary difference to the way mining companies operate their sites in the near future,” said Joachim Braun, division president, ABB Process Industries. “We recognize the strategic importance of this agreement and believe there will be mutual business benefits and potential technology solutions for the mining market. Collaboration across the industry has already been proven to enable real and faster progress and we look forward to driving what happens next.”

empowering a sustainable future where people, business and the planet thrive together,” said Dan Funcannon, senior vice president of surface haulage of Komatsu.

With the collaboration, ABB and Komatsu are deeply committed to providing customers with a portfolio of interoperable

solutions to meet their specific needs.

Recognizing the varying stages of electrification standards across the mining industry, ABB and Komatsu are focusing on haulage, loading and auxiliary equipment. This approach aims to build a comprehensive portfolio of production and support equip-

For a firsthand look at the collaboration, visit the Komatsu MINExpo 2024 booth from Sept. 24 to 26. The booth will be in Central Hall at the Las Vegas Convention Center and feature the ABB eMine Robot Automated Connection Device (ACD). The Robot ACD is planned to be a fully automated interoperable connection device part of the eMine FastCharge solution for future battery-electric trucks.

For more information, visit www.komatsu.com and www.abb.com.

For landscapers, dealers and contractors attending award-winning Equip

Exposition for the very first time, show organizers are offering tips to help firsttimers make the most of this blockbuster show, to be held Oct. 15 to 18 at the Kentucky Exposition Center (KEC).

“I’ve ‘only’ been to 18 of the 41 shows, but I have some advice. First, for the first-timer, it’s not really a one day show. For an immersive experience, you’ll want to be there all three days,” said Kris Kiser, president and CEO of the Outdoor Power Equipment Institute (OPEI), which owns and manages Equip Exposition, the international landscape, outdoor living and equipment exposition.

Last year, the show drew more than 27,000 people, and had more than one million square feet of exhibit space with a 30-acre Outdoor Demo Yard, which allows attendees to dig, drive, cut, mulch and other testing of new equipment they need for their businesses.

Equip Exposition photo

Last year, the show drew more than 27,000 people and had more than 1 million sq. ft. of exhibit space.

“Since OPEI has taken full ownership and management of the show, our goal has been to create a world class event for our attendees,” Kiser said. “This year, we’ve invested in more peer-to-peer social opportunities like renting Churchill Downs for our welcome reception, having Kevin O’Connor of This Old House as keynote speaker, a happy hour at Freedom Hall with the Crashers band and having Trace Atkins give an arena concert at the Yum! Center at no charge to attendees and more.”

But he noted planning is key to get the most out of Equip.

“Do some homework. Before you get here, download the app, go to the web site, look at the maps. Familiarize yourself with the logistics. It’s important to know how to get in and out of the KEC.

“It’s also the kind of event you want to share and bring your colleagues. It’s a teambuilding exercise where you can learn new things as well as from one another, have some fun and have a shared experience.”

A core mission of Equip is facilitating networking so attendees can meet people who are likely going through similar business challenges. It’s the industry’s family reunion.

“It’s crazy how willing people are to help other people [at Equip],” said Blake Albertson of B&B Lawn Care.

Identifying your business needs also is an important step when planning time at Equip.

“Last few times we’ve been here, we found new equipment to help us be more efficient in our business,” said Kendal Caldwell of Senske/Emerald Lawns.

Kiser offers these tips to help first-timers to Equip plan for the best experience possible:

• Register now. If you’re registered, you will receive Equip’s regular emails about everything going on at the show. Sign up at EquipExposition.com now. Don’t get stuck paying full price ($120) at the show.

• Add education, certification classes, and training to your registration before sessions sell out. Sessions are targeted to help you explore ways to grow their businesses, address common problems and develop employees. Other sessions will cover irrigation, pesticide management, tree and shrub pruning, pool and spa, outdoor lighting and more. Select classes, including the popular From Worker to Leader course, are available in Spanish.

• Book travel arrangements and hotel reservations. Louisville’s hotel rooms often sell out with thousands of Equip Expo attendees in town. You don’t want to stay miles away. Some hotels are along the trade show’s complimentary shuttle route.

• Invite others. Bring your teammates from your company (if you are a landscaper) or your contractor customers (if you are a dealer). Equip is a fantastic team building opportunity, through shared educational experiences and testing new equipment to having fun at concerts with one another. This makes acting on new knowledge and ideas when home easier.

• Download the Equip Expo app. The app is your event guide. It works with any Android or iPhone. On the app, find the Event Schedule with start times for all sessions and a tradeshow map for the entire facility. Every week leading up to the show it’s updated with even more information, like where the biggest Giveaways are and where you can find breakfast, lunch and coffee at the KEC. You can favorite any

event or location to build a custom schedule as well.

• Determine the top three business problems you are trying to solve. Look at the speakers, exhibits and education offerings and identify the ones that will help you the most with those problems.

• Familiarize yourself with the navigation tools. Many attendees drive in to the show so it’s important to map the route from your hotel to the KEC and other venues, and look at available shuttle or rideshare options.

• Learn the five main areas of the show. The North Wing has registration, exhibits, badge pickup and a coffee shop. The South Wing has exhibits and easy access to the Outdoor Demo Yard (which also has food trucks and tented areas to relax) and the UTV Driving Experience. The West Wing is loaded with exhibits, Mulligan’s Mutt Madness dog adoption event, the new Garden Center and food options (as well as the rideshare pickup/drop off zone). Freedom Hall will host the Happy Hour with the Crashers on Wednesday.

• Pack strategically. Check the weather and dress for both indoor and outdoor. Bring comfortable shoes, a printout of your registration confirmation (you can scan the QR code to print your badge), and dress in layers for any sudden weather changes.

The Outdoor Demo Yard is a real-world experience and can get cold so bring weather-appropriate clothes.

• Plan to meet others. Many events are planned to help facilitate networking so you can meet others to share relatable business challenges and solutions, learn what they know, and get real-world advice and ideas.

During

• Don’t get stuck in traffic. Remember parking is free. Hot tip: For ease of entry, don’t use the main gate at the show’s rush hour. If you are coming later than 10 a.m., use Crittenden Drive gate or the Preston Highway gate and park on the North side, which is the best way to enter the KEC. Leave via a similar route to avoid any bottlenecks at the main gate.

• Start your day in the West Wing. Ride shares and shuttles will drop off at the West Wing and there will be food options available.

• Avoid lines for badge pickup. Print your badge at the Welcome Reception at Churchill Down’s First Turn Club or in the North Wing at the Kentucky Exposition Center. More locations are scattered throughout Louisville Hotels, the Airport and the KEC.

• Don’t hesitate to talk with others. Equip is a city-wide event. That means people in your hotel elevator and restaurant are likely to be Equip attendees. Take time to meet people as you navigate the halls, stand in line or grab a bite to eat.

• Have fun at the pre-planned events. Go to the Welcome Reception at Churchill Downs sponsored by Cat, the Happy Hour on Wednesday with the Crashers in Freedom Hall, the Morning Show at Expo sponsored by Kohler on Thursday morning, Energize on Thursday afternoon, and the Trace Adkins concert sponsored by SENIX, Toro, Bobcat and Gravely. Join Equip attendees at the third-annual Mulligan’s 5K Fun Run and Walk, sponsored by Active Dynamics, on Wednesday morning at 7 a.m. where you’ll go across the Ohio River on Louisville’s Big Four Pedestrian Bridge.

• Follow up with the people you met at Equip. You can swap ideas, encourage each other in growing your respective businesses, or remind each other to do “that thing you said you would do” when you returned home.

• Put new ideas you picked up at the show into action. Take that leap, do the “new thing,” roll out better pricing, marketing, services and more that you find applicable to your unique business.

• Register for next year’s show that is planned for Oct. 22 to 24, 2025.

“Though 40 years old, Equip Exposition remains the unique opportunity for the industry,” said Kiser. “It’s our industry’s largest event, and it continues to grow. We’re doing something right because every year we hear what an incredible return on investment it gives to the industry.”

For more information, visit https://help.equipexposition.com/knowledge.

SOUTHWESTERN from page 1

projects, she said, is designed to enrich the experience of all students, faculty and staff.

Ritchie described the various construction and renovation projects at Southwestern as part of a “strategic move” on the part of the college “to reinforce its commitment to delivering a premier liberal arts education in the 21st century.”

“The administration recognized the necessity of these efforts to stay competitive and continue attracting top-tier students, faculty and staff,” she added. “These investments are designed to enhance the campus environment, improve student outcomes and ensure the university remains a vibrant hub of learning and innovation for years to come.”

Another of the reasons that influenced university officials to build the new residence halls was to provide more housing for their first-, second, and third-year students — buttressed by the belief that on-campus housing not only helps students perform better in the classroom but saves them from paying expensive rents off campus.

The first onsite work at the school began in September 2023 at one of Southwestern’s most iconic buildings, the historic Mood-Bridwell Hall, an academic facility constructed in 1908 to serve as a men’s residence hall.

Crews from Linbeck Group, a Houston-based general contractor, are upgrading the three-story, 38,600-sq.-ft. structure to incorporate 21st-century technology with the building’s rich history, a legacy that placed it on the National Register of Historic Places in 1975.

Steven Kitchen, Southwestern’s interim associate vice president for facilities management, said the work at MoodBridwell includes a full renovation of the existing floorplan, which includes an annex, as well as new mechanical, electrical and plumbing (MEP) systems and finishes.

“In the year since the upgrades began at Mood-Bridwell, we have seen the demolition of its existing MEP systems and interior finishes, including windows, drywall, ceilings, flooring, fixtures, etc.,” he said.

“Once the demolition ended, framing work for the new

floorplan layout began,” Kitchen continued. “In addition, the MEP subcontractors have begun installing new systems throughout all levels of the building to include new electrical rooms and power distribution panels, mechanical systems and duct work, and plumbing for new restrooms on all levels.”

Before Mood-Bridwell Hall is finished next spring, work is needed to install a new skylight over the atrium’s multipurpose room, and the building’s second-level terrace, designed to be a new outdoor space for students, faculty and staff, will be built. Additional plans call for a new student collaboration space and coffee bar, along with other finishes, ceilings, fixtures, painting, flooring and windows.

Due to its being listed on the historic registry, Kitchen added, “special precautions are required to preserve all exterior architectural features of the existing stone façade.”

Construction started earlier this summer on building a new annex to Mood-Bridwell after heavy rain in May delayed the foundation work. By August, though, its structural steel was erected, and concrete pours were completed on the first and second levels of the addition.

“Originally, the existing annex was made up of a basement and first-floor level,” he said. “The new annex space will consist of an upgraded basement and first-floor level, plus a new second-floor level, which increases the original square footage by approximately 1,300 square foot.”

Among the key Texas subcontractors working for Linbeck Group at Mood-Bridwell Hall are:

• AAR Inc., a Houston environmental company.

• Curtis Hunt Restorations, based in Elmendorf, Texas.

• Berger Iron Works, a Houston steel fabricator.

• Fireproof Contractors, in Katy, Texas.

• Schulte Roofing, from Navasota.

• Five Star Drywall & Acoustical Systems, based in Kyle.

• Slater Controls, in Midland.

• FastTrack Construction, from Crockett.

• Graves Mechanical Inc., headquartered in Houston.

• Tumlinson Electric, from Round Rock.

Ritchie is excited about the benefits that students will receive from innovative classroom spaces in Mood-Bridwell Hall after it opens in 2025.

“The renovation of Mood-Bridwell will offer advanced facilities that not only support academic endeavors but also serve as hubs for community engagement and innovative teaching,” she said.

Most of the Southwestern University’s campus is located north of University Avenue/Texas Highway 29, but its eastern side has several undeveloped tracts of land. School officials chose that area to build a completely new Welcome Center and a residence hall specifically for first-year students.

Approximately a quarter mile west of those two projects, within the central part of campus, the university is shepherding the construction of a second-year student dormitory, immediately south of the Martin Ruter Residence Hall. In fact, the new, 36,380-sq.-ft. sophomore dorm was designed to take the place of Ruter Hall.

Site work at all three locales began in July.

“Our new welcome center will consist of a

theater, café, outdoor terrace, art gallery and bell tower,” Kitchen said. “And the first-year dorm, totaling 45,060 square feet, will include new indoor fitness and yoga studios.”

Southwestern’s office of admission and financial aid is due to move into the 19,646-sq.-ft. Welcome Center.

“For students, the new mixed-use residence halls will provide an integrated living and learning environment that nurtures both academic excellence and personal well-being,” Ritchie said. “These halls, equipped with classrooms, study areas, lounges and fitness facilities, are designed to foster a strong sense of community, which is vital for personal growth and academic success.”

A demolition crew, led by Sierra Demolition in nearby Round Rock, Texas, razed a pair of structures — known as the Kyle E. White and McCook-Crain buildings — that sat on the site of the planned first-year residence hall and the adjacent Welcome Center, according to Kitchen.

see SOUTHWESTERN page 50

Robust, powerful and reliable, the new generation BOMAG BMP 8500 multi-purpose compactor features an improved radio remote control design that allows the controller to be used on every BMP 8500 in the fleet.

The remote control’s unique “teach” function quickly and intuitively pairs the unit to the machine to save contractors time and money. Should the controller be misplaced, a new one can be paired to any machine in the fleet quickly and without special knowledge or tools.

With the BMP 8500, there is a secure, 100 percent connection between the remote-control unit and machine. Multiple trench rollers can be operated simultaneously at the job site without the need to coordinate or adjust individual radio frequencies, increasing operational flexibility, according to the manufacturer.

Now, two batteries are standard for the remote control, delivering a continuous combined worktime of up to 40 hours for more operating time. The twobattery solution allows one battery to charge while

the other powers the controller, so the BMP 8500 is always ready for work.

Battery charge status is displayed on the remotecontrol unit’s screen, alerting operators when the battery needs to be changed. Integrated into the trench roller’s storage compartment, an optional charger allows the second battery to be topped off during machine operation.

The lightweight remote controller features a new ergonomic design with paddle-style joysticks to simplify compactor travel and multiple indicator lights for intuitive control. BOMAG’s radio remote control offers reliable operation, even in direct sunlight.

Built for dependable operation in confined applications like trench and pipeline construction, the BMP 8500 also is ideal for landscaping, compacting backfill and foundation work.

For more information, visit www.bomag.com/usen.

FleetWatcher announced its participation in the Work Zone Data eXchange — a partnership with ICone that offers a breakthrough in work zone safety for the paving industry.

This nationwide initiative brings together technology partners, state, local and federal transportation agencies, and all consumer vehicle navigation systems (Waze, Google Maps, Apple Maps, Trimble and others) to raise awareness of work zones and the reduced speed limits through them. The program is designed to improve work zone safety and limit injuries and fatalities by alerting drivers to the presence of work zones so that they can slow down appropriately.

This is a free service to FleetWatcher users, they merely opt-in to enable the sharing of their data.

“Tragically, work zone deaths occur far too often, but this initiative can help save lives,” said FleetWatcher President Larry Baker. “Alerting drivers to the presence of work zones and the reduced speed limits within them will help to keep paving crews safe. We’re excited to be a part of this life saving program.”

photo FleetWatcher location data on pavers, shuttle buggies and mills is updated at frequent intervals on all major smartphone navigation apps and some in-car navigation systems.

FleetWatcher location data on pavers, shuttle buggies and mills is updated at frequent intervals on all major smartphone navigation apps and some incar navigation systems. The system sends lat/long location data and location accuracy information to these systems for pavers that are actively running. The navigation apps will use that information to identify work zones and display those zones with the adjusted construction zone speed limit.

This system will apply to all active roadway jobs including city, state, county and federal interstates. The Work Zone Data eXchange is expected to have an immediate impact by increasing safety within the work zones and saving lives.

Several state DOTs are mandating the technology, and some are helping to subsidize the cost of the technology that enables it.

For more information, visit www.fleetwatcher.com/work-zone-safety.

closner.com

6532 East Highway 114 Rhome, TX 76078 817-708-9108

21910 FM 2252 Schertz, TX 78154 210-732-2131

13800 FM 973 N Manor, TX 78653 512-272-8200

18851 GH Circle Waller Industrial Park Waller, TX 936-525-9949 ascoeq.com

5980 S M L King Jr Pkwy Beaumont, TX 77705 409-746-5102

202 I-35 Frontage Road Belton, TX 76513 254-613-1500

2800 Hwy 290 E Brenham, TX 77833 979-836-6641

1875 N Earl Rudder Fwy Bryan, TX 77803 979-779-8942

1512 Neptune Dr. #9706 Clinton, OK 580-323-3422

2019 Airport Fwy Euless, TX 76040 817-283-2844

980 N Sam Houston Pkwy E Houston, TX 77032 281-987-1990

6203 Long Drive Houston, TX 77087 713-649-0940

27500 E University Drive Aubrey, TX 76227 972-441-2726

12805 US-290 E Manor, TX 78653 512-272-8922

7100 SW 3rd Street Oklahoma City, OK 73128 405-789-6812

902 SE 9th Avenue Perryton, TX 79070 806-435-7773

1920 S East Loop 410 San Antonio, TX 78220 210-333-8000

3600 US-82 Sherman, TX 75090 903-893-7586

401 FM 148 Terrell, TX 75160 972-563-2171

12210 E 1st Street Tulsa, OK 74128 918-437-5085

2602 E Front Street Tyler, TX 75702 903-593-0201

2900 Henry S Grace Fwy Wichita Falls, TX 76302 940-687-2726

beeequipmentsales.com

2506 East Slaton Highway Lubbock, TX 79404 806-745-1511 855-813-3775

nixonegli.com

2044 S. Vineyard Avenue Ontario, CA 91761 909-930-1822

800 E. Grant Line Road Tracy, CA 95304 209-830-8600

2750 Marion Drive Las Vegas, NV 89115 702-342-8100

The CP100II sets the standard for versatility, component lifecycle and mat quality. With a powerful 100 horsepower engine, an array of configurations and the class-leading Carlson EZCSS single slide screed, it’s easy to see why the CP100II is the ideal choice for heavy-duty commercial paving.

The Carlson CP100 II sets the standard for versatility, component lifecycle and mat quality. With a powerful 100hp engine, an array of configurations and the class-leading EZCSS single slide screed, it’s time to see why the CP100 II has fast become the contractor’s choice for heavy-duty commercial paver platforms.

FAYAT has acquired a controlling interest in Asphalt Drum Mixers LLC (ADM), based in Huntertown, Ind., which manufactures asphalt plants and components for contractors and asphalt producers worldwide.

Through the acquisition of ADM, FAYAT further strengthens its strategic position in the road construction and maintenance equipment segment.

ADM is joining the FAYAT Mixing Plants business unit, which includes the brands ERMONT, a worldwide leader in continuous mixing plants, and MARINI a worldwide leader in batch mixing plants. The acquisition of ADM allows FAYAT to expand its strategic position in North America, by leveraging synergies with the following brands already present in the asphalt business: BOMAG, DYNAPAC and SECMAIR.

Being a family-owned business with decades of experience in the road construction and maintenance equipment business, the FAYAT Group will provide ADM with the backing to be a growing and long-term dependable partner for its customers, the company said.

Moreover, to ensure continuity and an effective transition, the Boyd-Devine family will remain as a minority owner and Mike Devine remains as president of ADM, a position he has served since 2004.

Under the FAYAT umbrella of companies, ADM will operate as an autonomous manufacturer continuing to

market its products under the brand ADM. ADM also will continue to provide its customers with long-lasting solutions to meet the custom requirements of every job, from planning to production to service after the sale.

In the development of future technologies, ADM will collaborate with other companies within the FAYAT Group to offer customers the best solutions for tomorrow’s challenges.

“This acquisition is a great opportunity for the FAYAT Group and its customers, as ADM is a key player in the road construction equipment market in North America, with a highly recognized brand,” said Jean-Claude Fayat, president of the FAYAT Group.

“ADM has an excellent strategic place in our group, and we plan to grow and expand its presence and product offering. We will leverage its expertise and technologies together with our existing portfolio to continuously develop equipment that closely addresses our customers’ needs.”

“We are very happy to join the FAYAT family and have already seen many opportunities to grow ADM and to offer more and better solutions to our customers,” said Mike Devine, president of ADM. “We look forward to a long-lasting partnership with the FAYAT Group.”

For more information, visit https://fayat.com/en and www.admasphaltplants.com.

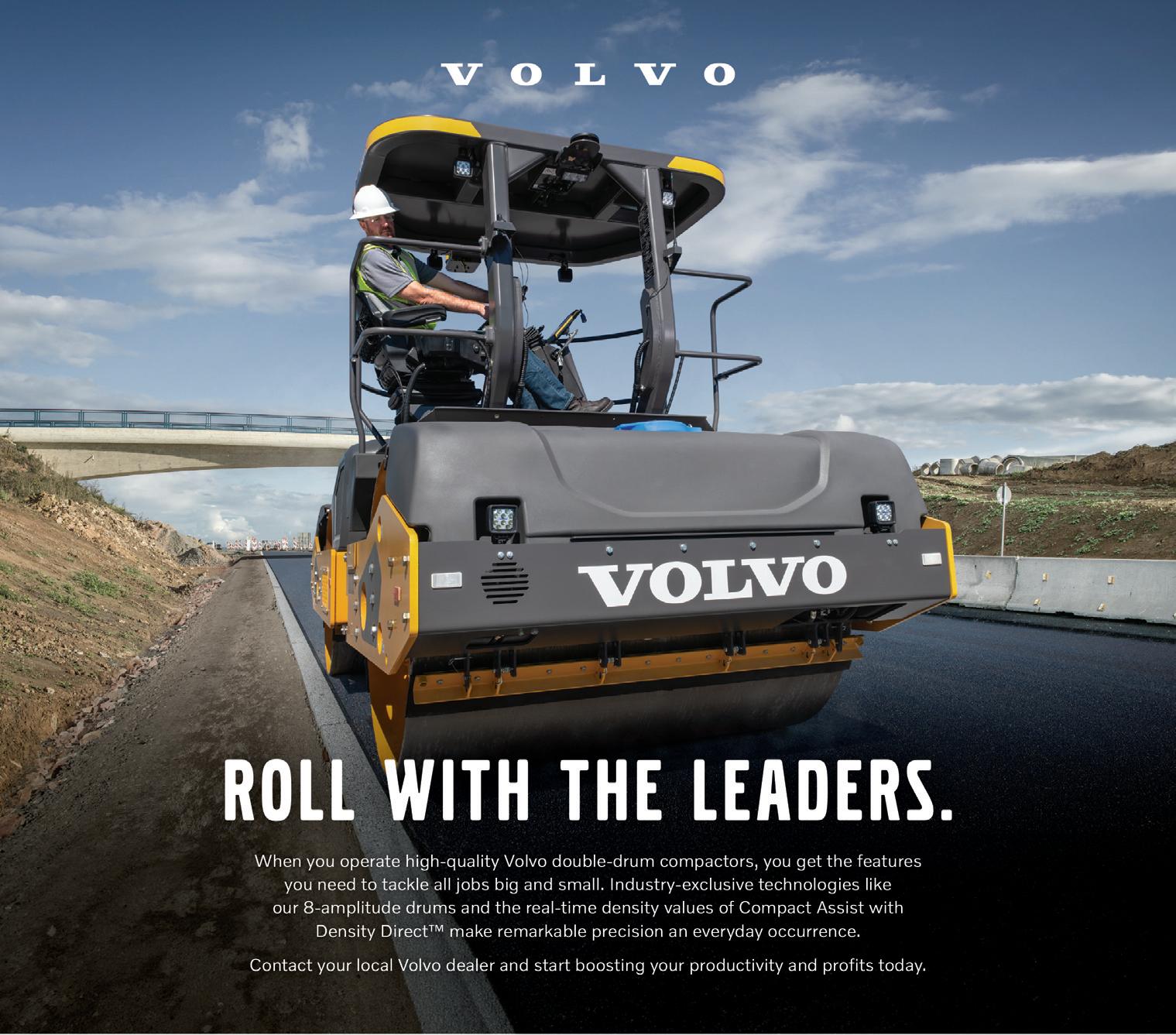

At World of Asphalt, Dynapac introduced its Seismic technology for asphalt compaction.

The intelligent Seismic Asphalt system improves compaction performance significantly compared to conventional compaction carried out at a fixed frequency, according to the manufacturer.

Seismic Asphalt automatically detects the optimum compaction frequency and continuously adjusts it accordingly. Due to the Seismic Asphalt system, Dynapac can offer an increase in efficiency and lower cost of ownership from fuel savings and less wear-and-tear on the roller.

Traditional double drum vibratory rollers deliver a rapid succession of impacts to the surface at a frequency that is either pre-set at a high or low amplitude or at a frequency that is adjusted manually. Seismic Asphalt from Dynapac does it differently. Since the drums and the material act

as one dynamic system, several benefits can be found from the system’s natural resonance frequency. By compacting at the natural frequency of the asphalt mat, Seismic Asphalt avoids double-jumping of the drum and losing any compaction effort.

Seismic Asphalt automatically determines the optimal drum vibration frequency for the compacted material, constantly monitors the variations of the asphalt layer, and automatically adjusts to changing temperature conditions. The operator no longer has to manually set the frequency or guess what asphalt material type or frequency should be used at any given time. By using the pre-set on the speed limiter, a constant speed and optimal compaction is ensured, thus allowing the operator to focus on meeting the compaction requirements.

Dynapac’s well-renowned tools such as Dynapac Compaction Meter and Dyn@lyzer ensure that these requirements are met. It will be a standard feature for the CC2200VI-CC6200VI and the CO2200VI-CO6200VI roller ranges. For more information, visit https://dynapac.com/us-en/.

Closner Equipment

www.closner.com

Rhome, TX 817-708-9108

Schertz, TX 210-732-2131

Manor, TX 512-272-8200

www.pacwestmachinery.com

Seattle, WA 206-762-5933

Spokane, WA 509-534-5933

Pasco, WA 509-547-5933

Mt Vernon, WA 360-588-3083

Waller, TX 936-525-9949 PacWest Machinery

Portland, OR 503-252-5933

www.power-equip.com

Farmington, NM 505-326-1413

Durango, CO 970-247-8830

Denver, CO 303-288-6801

Eugene, OR – Branch 541-302-3762 Power Equipment Company

Colorado Springs, CO 719-392-1155

Grand Junction, CO 970-243-0722

Greeley, CO 970-353-1224

Albuquerque, NM 505-345-7811

Tri-State Truck and Equipment

www.tristatetruckandequip.com

Belgrade, MT 406-388-5818

Billings, MT 406-245-3188

Casper, WY 307-472-1818

Great Falls, MT 406-452-9551

Rock Springs, WY 307-362-4000

wwwshaferequipmentco.com

Sparks, NV 208-801-7772

www.boxcerequipment.com

Tulsa, OK 918-272-7237

BOMAG Americas, a Fayat Company, announced the promotion of Christoph Thiesbrummel to vice president of sales & marketing for North American operations effective July 22, 2024.

In his new position, Thiesbrummel will lead BOMAG Americas’ dealer channel sales, rental channel sales, sales administration, product management and marketing activities.

“Our entire team is committed to a customer-first approach and will continue to find innovative solutions for our customers’ individual needs.”

Thiesbrummel brings more than 10 years of industry experience to his new position, all within the BOMAG organization. After receiving his doctorate in marketing and business management, he began his career with BOMAG at the Boppard, Germany, headquarters as pricing and business analytics manager. He then moved to BOMAG Americas to assume the position of sales administration manager, where he oversaw the inside sales team. He also worked with the field sales team, managing market and new dealer development for BOMAG Americas.

For the last two years, Thiesbrummel served as BOMAG Americas’ director of sales, dealer channel for the eastern United States.

“Christoph is incredibly talented, has deep knowledge of the BOMAG organization and equipment, and has delivered successful results at every level within the organization he has worked,” said Brian Bieller, president

of BOMAG Americas.

“He recently completed Fayat’s one-year advanced program for high-potential personnel, the Global Fayat Road Academy management training program. His knowledge, dedication and in-depth experience with BOMAG make him the right fit for the position.”

“I am excited for this new opportunity to grow the BOMAG brand in North America, working together with our strong network of partners across all sales channels and the BOMAG team in the U.S. and Canada,” said Thiesbrummel. “Our entire team is committed to a customer-first approach and will continue to find innovative solutions for our customers’ individual needs. Let’s grow together!”

For more information, visit www.bomag.com/us-en.

Efficiency and Productivity

Designed with safety and operator comfort in mind, the Shuttle Buggy® material transfer vehicle features adaptive cruise control, bright LED lighting, four-wheel steering for easy transport and ground-level maintenance access for added convenience. Operators can rely on clear sightlines and the ground operator is safely protected inside the structure of the machine. The Roadtec SB-3000 is the perfect blend of traditional craftsmanship and modern technology.

astecindustries.com

BANE MACHINERY, INC.

MACHINERRY

www.banemachinery.com

2449 Manana R (214) 352-2468 (817) 847-5894 (903) 597-6641

2449 Manana Dr. Dallas, TX 75220 (214) 352-2468

Ft. Worth, TX (817) 847-5894

Tyler, TX (903) 597-6641

CLAIREMONT EQUIPMENT

7651 Ronson Roa San Diego, CA 92 (858) 278-8351 1330 W Mission Ro Escondido, CA 92 (760) 739-9100

www.clairemontequipment.com

(318) 442-0455

7651 Ronson Road

Baton Rouge, LA (225) 291-3750

San Diego, CA 92111 (858) 278-8351

West Aten Ro

1330 W Mission Road

Broussard, LA (337) 837-9481

Escondido, CA 92029 (760) 739-9100

Covington, LA (985) 893-3005

440 West Aten Road

(337) 430-3045

Imperial, CA 92251 (760) 355-7700

Monroe, LA (318) 343-8787

4726 Convoy Street

Shreveport, LA (318) 631-3090

BEE EQUIPMENT SALES LTD.

www.beeequipmentsales.com

2506 Slaton Highway Lubbock, TX 79404 (806) 745-1511

West Reno A (800) OKC-BOYD • (405 Ardmore, OK (866) 720-2693 • (580) Lawton, OK (800) 633-2693 • (580) /

K 224-2693 /355-6667

C. L. BOYD CO., INC. www.clboyd.com

COOPER EQUIPMENT CO.

www.cooperequip.com

(409) 842-1754 Boise, Idaho (208) 336-8670 Jerome, Idaho (208) 324-4522 (800) 829-4450

5210 N Loop 1604 E San Antonio, TX 78247 (210) 657-5151

201 Commerce Blvd. Georgetown, TX 78626 (512) 930-5151

6532 East Highway Rhome, TX 7607 (817) 708-9108

21910 FM 2252

Schertz, TX 7815 (210) 732-2131

4220 West Reno Ave. Oklahoma City, OK 73107 (800) OKC-BOYD • (405) 942-8000

Ardmore, OK (866) 720-2693 • (580) 224-2693

Lawton, OK (800) 633-2693 • (580) 355-6667

13800 FM 973 N Manor, TX 78653 (512) 272-8200

San Diego, CA 92111 (858) 278-8338

St. Rose, LA (504) 466-5577

Beaumont, TX (409) 842-1754

Bryan, TX (979) 8231905

Corpus Christi, TX (361) 289-0727

Houston, TX (713) 679-6700

Longview, TX (903) 758-3326

EQUIPMENT www.closner.com

6532 East Highway 114 Rhome, TX 76078 (817) 708-9108

21910 FM 2252

Lufkin, TX (936) 634-8801 San Juan, TX (956) 787-0001

Schertz, TX 78154 (210) 732-2131

MODERN MACHINERY

www.modernmachinery.com

Corporate Office

Missoula, Montana (409) 842-1754

Boise, Idaho (208) 336-8670

Jerome, Idaho (208) 324-4522

Pocatello, Idaho (800) 829-4450

ROAD MACHINERRY Y www.roadmachinery.co 902 S. 7th Street X g (800) 304-4421

Billings, Montana (800) 735-2589

Spokane, Washington (800) 541-0754 om n COOPER EQUIPMEN www.cooperequip.

13800 FM 973 N Manor, TX 78653 (512) 272-8200

5210 N Loop 1604 San Antonio, TX 78 (210) 657-5151 201 Commerce Blv Georgetown, TX 78 NT CO. .com

18851 GH Circle

E 8247 vd. 8626 (903) 592-8900 Victoria, TX (361) 570-6666

Waller Industrial Park Waller, TX (936) 525-9949

Columbia Falls, Montana (800) 434-4190

Eugene, Oregon (800) 826-9811

Portland, Oregon (800) 950-7779

Kent, Washington (800) 669-2425

Phoenix, AZ 85034 (480) 545-2400 Prescott, AZ (928) 778-5621 Tuscon, AZ (520) 623-8681 (661) 695-4830 Perris, CA (909) 355-3600

Rochester, Washington (800) 304-4421

Spokane, Washington (800) 541-0754

www.iron-hub.com

6515 I-30

Royse City, TX 75189

972-679-6971

www.ccrentalsparis.com

2720 North Main Street

Paris, TX 75460

903-784-8484

www.cpower.com

9200 Liberty Drive

Liberty, MO 64068

816-781-8070

Wichita, KS

316-943-1231

Great Bend, KS

620-792-1361

Liberal, KS

620-624-7274

Woodward, OK

580-256-6014

Salina, KS

785-825-8291

Colby, KS

785-462-8211

Springfield, MO

417-865-0505

Joplin, MO

417-726-5373

Riverside, MO

816-415-6787

Wichita, KS

316-789-7370

Yukon, OK

405-324-2330

Maryland Heights, MO

314-427-4911

Liberty, MO

806-415-6700

Tulsa, OK

918-984-6565

Your work involves more than moving material. You need to stay on top of jobsite productivity. Our new 450 P-Tier, 550 P-Tier, and 650 P-Tier Dozers can put you in charge of the challenges. Precise hydraulics, nimble machine stability, a comfortable cab with advanced displays and expansive jobsite visibility, simplified service, and flexible grade-control solutions including fully integrated SmartGrade™ help you keep things running smoothly and on schedule.

DOGGETT HEAVY

SERVICES www.doggettequipment.com 9111 North Freeway Houston, TX 77037 713-679-6700

Beaumont, TX 409-842-1754

Bryan, TX 979-823-1905

Corpus Christi, TX 361-289-0727

San Juan, TX 956-787-0001

Victoria, TX 361-570-6666

Alexandria, LA 318-442-0455

Baton Rouge, LA 225-291-3750

Broussard, LA 337-837-9481

Covington, LA 985-893-3005

Longview, TX 903-758-3326

Lufkin, TX 936-634-8801

Monroe, LA 318-343-8787

Shreveport, LA 318-631-3090

St. Rose, LA 504-466-5577

Tyler, TX 903-592-8900

The National Equipment League is a new entertainment and competition platform that showcases the skills, character and passion of the construction industry through competition.

The newly founded National Equipment League has crowned Bryan Furnace as its first champion after four hotly contested events, hosted by HD Hyundai Construction Equipment North America.

The National Equipment League is a new entertainment and competition platform that showcases the skills, character and passion of the construction industry through competition.

Furnace, of Howell, Mich., is the owner/operator of his own earthmoving business who also hosts his own YouTube channel, Diesel & Iron. The competition has been documented over the course of four events, which can be viewed on HD Hyundai Construction Equipment North America’s YouTube page.

Additional competitors in the first events include Mike Simon (AKA Dirt Perfect), Andrew Camarata, Dave Buchakian and Geoff Dodge. Mr. Digg Ryan Williams served as a member of the broadcast team. All events were filmed at the HD Hyundai Customer Product Center in Carnesville, Ga., and broadcast via YouTube.

“The first events proved that skilled heavy equipment operation in head-to-head competition is entertaining, educational and highlights the talents of the workforce in the construction industry,” said Bill Elverman, commissioner, National Equipment League.

“As in any professional sporting event, we see that lead changes, scoreboard jockeying and often just a few seconds between competitors create compelling entertainment. Hyundai hosted a great competition and has shown its commitment to showcasing the talents and passion of the construction industry.”

The first series of National Equipment League events can be seen on the Hyundai Construction Equipment North America YouTube and Facebook channels.

Additional promotional considera-

tions were made possible by Blue Diamond Attachments. For more information on the National Equipment League, email Commish@EquipmentLeague.com or visit EquipmentLeague.com. (All photos courtesy of the National Equipment League.)

MAKE YOUR MOVE

Push

... more material with the new Hyundai HD100 crawler dozer's best-inclass power-to-weight ratio.

See

...more than ever with the unobstructed view to the blade.

Engage

...more accurately and more productively with standard 2D or optional 3D machine guidance.

Doze

...with confidence, knowing your new 115 hp Hyundai crawler dozer delivers the quality and value you expect from Hyundai, with the peace of mind that comes with our industry-leading warranty.

No wonder so many first-time Hyundai users become longtime fans. See the Hyundai difference yourself at your local dealer, na.hd-hyundaice.com.

JCB announced a special long-term partnership with multi-GRAMMY award winning musician and Rock and Roll Hall of Fame inductee Joe Walsh and his national 501(c)3 non-profit veterans organization and annual benefit festival, VetsAid. The partnership will raise awareness and funds for U.S. veterans through the power of rock and the transformative process of rebuilding.

JCB, one of the world’s largest privately-owned manufacturers of construction and agricultural equipment, often deploys its machines in war-torn regions, playing a crucial role in the rebuilding process after conflicts. Recognizing their shared values and goals, Alice Bamford and Ann Eysenring of the JCB family company, reached out to their friends Joe and Marjorie Walsh and devised a partnership to generate additional valuable funds for American veterans who have served their country with dignity, compassion and honor.

The creative partnership kicked off with the official premiere of “Dig It” — an original song by Joe Walsh, debuting in London on July 13th during Monster Jam. This powerful anthem, also featuring Walsh’s brother-in-law Ringo Starr on drums, will be the soundtrack for JCB’s DIGatron and serve as an uplifting call-to-action to support the vital mission of VetsAid.

Inspired by Bamford and Eysenring’s eight-year-old son Otis, a monster truck enthusiast himself, Walsh sought to capture the excitement of a child and the raw energy of monster truck action in his composition.

Additionally, JCB has pledged $250,000 to VetsAid to kick-off the partnership. Next up, supporters also can look out for limited-edition merchandise, a special JCB DIGatron toy and even a limited edition JCB machine, with a percentage of sales benefiting the non-profit organization.

“It is absolutely amazing to be working with Joe Walsh to raise further awareness for U.S. veterans,” said Bamford. “This is a legacy project between two families which will help give veterans and their families in the U.S. a better future, and offer them the care and support they deserve, which is something very close to all our hearts.”

Veterans and their families have always been important to Walsh, a Gold Star son himself who lost his father, Robert Newton Fidler, a U.S. Army Air Corps flight instructor for the first American operational jet-powered aircraft, while he was on active duty over Okinawa when Walsh was only 20 months old.

“VetsAid isn’t just about raising money and awareness for America’s veterans and their families,” Walsh said. “It’s also about finding common ground amongst music-lovers of all backgrounds and coming together to build and rebuild communities around a shared love of country. It’s a privilege for us at VetsAid to expand upon this vision with Alice and Ann, and our friends at JCB, and to keep the party going with this kick-ass new song and exciting partnership.”

For more information, visit www.jcb.com and www.vetsaid.org.

Werk-Brau’s FHX66 Defender forestry mulcher is a robust mulcher for standard flow skid steers and track loaders.

Engineered to perform, this rugged mulcher eradicates materials to 10-in. in diameter with just 17 gpm of hydraulic flow, and 3,350 psi. A 12 ¾ in. diameter cutting drum is ¾-in. thick and fitted with 36 Quadco Quad Tooth cutter knives. Constructed of alloy steel, these 1-piece, easy to change 2-in. knives are rotatable with four positions (cutting edges).

Werk-Brau photo

The FHX66 mulcher eradicates material up to 10-in. in diameter and requires just 17 gpm of hydraulic flow, so it pairs well with standard flow skid steers and track loaders.

An abrasion resistant liner ensures wear resistance and strength. High strength, cogged carbon chain timing belt increases efficiency, power and torque. An electronically balanced cutter drum with serviceable hubs ensures straight shafts that run smooth for years of reliable, vibration-free operation.

The FHX series maximizes production with each pass. The stout FHX66 features a 54-in. working with, making it ideal for property maintenance, right-of-way clearing, cre-

OEM authorized mining dealer www.coremachinery.com

Phoenix, AZ 480-545-2400 Phoenix, AZ 602-252-7121 Prescott, AZ 928-778-5621 Tucson, AZ 520-623-8681

Bakersfield, CA 661-695-4830 Mojave, CA 661-824-2319 Perris, CA 909-355-3600

*Formerly Road Machinery

www.wpi.com

12320 S. Main Street Houston, TX 77035 713-723-1050 Buffalo, TX 903-322-7150 Bryan, TX 979-314-1191 Corpus Christi, TX 361-884-8275 Edinburg, TX 956-386-0107

Kilgore, TX 903-984-2011

Lufkin TX 936-243-6056 Pflugerville, TX 512-251-0013 Port Arthur, TX 409-721-5305 San Antonio, TX 210-648-4444 Tomball, TX 281-351-9016

ating and maintaining defensible spaces in wildfire zones, and more, according to the manufacturer.

An adjustable brush/tree bumper pushes debris into cutting path. With efficient cutter design, the FHX66 can shred material to 10-in. in diameter intermittently, and 6-in. in diameter continuously.

Power unit must be equipped with ½-in. Lexan glass (or equal) and falling object protection.

Werk-Brau recently partnered with Valley Tool Manufacturing to provide Werk-Brau branded BrushHound mulchers, brush shredders and flail mowers, and RockHound landscape rakes through Werk-Brau’s nationwide dealer network. For larger projects, the FHX86 is available, with a cut width of 78-in. Each FHX series mulcher is manufactured by Valley Tool but serviced through the Werk-Brau network, providing single-source convenience for customers. For more information, visit www.Werk-Brau.com and ValleyToolMfg.com.

www.powermotivecorp.com

Corporate Office 5000 Vasquez Blvd., Denver, CO 80216 303-355-5900 Colorado Springs, CO 719-576-5541 Grand Junction, CO 970-241-1550 Milliken, CO 970-587-1188 Cheyenne, WY 307-634-5149 Durango, CO 970-259-0455 Albuquerque, NM 505-345-8383 Bloomfield, NM 505-324-8601 Carlsbad, NM 505-485-1700

El Paso, TX 915-872-1001 Chandler, AZ

602-986-3003 Phoenix, AZ

602-463-3772 Tucson, AZ 520-649-2858

www.geehm.com

5461 S Nikita Avenue Fresno, CA 93725 559-834-3149

1164 Prestige Way Redding, CA 96003 530-229-3820

3650 Seaport Blvd. West Sacramento, CA 95691 916-375-3540

Rosa,

Tooling choice is a key decision when planning an upcoming auger boring crossing. With a plethora of varying ground conditions, and multiple different styles of cutting heads, how does one make the right choice? Barbco breaks it down.

“Dirt” can be broken down into many different things. As true as it is, we generally describe dirt as “ground most commonly dug with a backhoe tooth bucket”.

When encountering dirt, you must make one of two distinctions — is the ground stable or unstable? Stable dirt, like “dense clay,”is generally dealt with by using a backhoe style tooth, cutting head. This style head will cut, and pull the “cuttings” back into the auger the fastest. This slight pull effect significantly helps reduce head bawling, in which the ground material is sticky enough to retain itself onto the face of the cutting head. Head bawling increases down hole torque, and can significantly reduce overall production.

Unstable dirt can mean that there is high sand content present in the ground formation, which resists the ground from being fully bonded. When encountering unstable formations, it is important to evaluate the ground water content in the bore path. If there is no ground water, a good choice of head is a 3 or 4-bank dirt head. With the standard head having two banks, an additional bank or two, creates extra surface area on the cutting face of the head, and decreases the size of the entry points for the cuttings.

If low groundwater or controlled groundwater (dewatering in place) is encountered while in unstable ground, a sand head is the most limiting cutting head for auger boring. A sand head has the smallest entry point to cutting surface area ratio, of all cutting heads available.

Glacial till can be a very challenging ground condition to encounter. Glacial till is generally described as dirt, sand, cobble and boulder, combined in varying amounts. The vast possibilities and inconsistencies of this ground condition is what makes glacial till such a challenge.

Considering all the different mixtures of this ground, using a versatile cutting head is the answer.

An appropriate choice of cutting head in this ground condition is a 3-bank DT87, or as Barbco calls them, Sharkteeth, style cutting head. The reason this style of head is a good choice is due to its adaptability. A shark-tooth head can handle consistent dirt, sand or other displaceable ground just fine, all while being able to cut rock. Additionally the sharktooth head provides a stronger “tooth support”, which allows these heads to handle sudden impact, like intermittent cobbles, better than any of its standard counterparts.

Although these heads are very versatile, this comfortability should never supersede the decision to stop, pull augers and address an ever evolving down hole environment, when casing size and permits allow. This decision can be the difference between a successful or unsuccessful trenchless crossing.

Rock

Rock is a ground condition that strikes many people as being difficult or something to shy away from. Fortunately,

by asking ourselves some simple questions, we can deal with rock easier than you think.

Some main rock attributes to asses are density (psi) and RQD (Rock Quality Designation).

The best way to analyze rock is to collect a sample and send it to a geological bioengineer. But if time is pressing, the big question is, can you dig it? If a backhoe bucket can scratch, fracture and dig the formation, then most standard rock heads will perform sufficiently in this type of softer formation.

If the rock formation can not be scratched or fractured by a bucket, can a hammer attachment handle the formation or is blasting required? In the case of a hammer attachment being able to fracture the rock formation sufficiently, and the rock is solid and consistent throughout the bore path, there are two options in the more serious class of rock: retractable roller-cone heads and disc-cutter heads.

Disc-cutter heads have been a staple in the industry when it comes to some of the hardest rock bores accomplished over time. While roller-cone heads have not been known to handle the hardest of rock as effectively as a disc-cutters, the roller-cone head is able to be retracted out of the casing, unlike a disc-cutter head which is welded to the front or lead casing. This major design difference plays a big role in the decision making process, especially in an industry where resourcefulness is key.

Non-consistent rock can be encountered due to depth of bore, where the bore path is not fully engaged into the solid rock formation. Barbco calls this type of rock formation a “split-face,”or mixed ground condition.

Another non-consistent rock formation is created by weathering. “Weathered rock” is generally softer than its original state, and can be dealt with by utilizing a variety of standard rock heads. However, generally a roller-cone head will be most productive in this ground condition.

If the split-face ground condition is encountered, it’s typically the most challenging of all ground conditions. When the cutting face is split with rock and dirt, the chances of torque up’s from sudden head impact is heightened. In this type of ground condition, an ample choice of cutting head is the roller-cone head.

Being the most versatile head, the roller-cones can handle rock, cobble, boulder and dirt split-faces. Additionally, the roller-cone heads are based on bearing supported cones. The bearings allow this head to roll through the sudden impacts that a standard head could hang up on.

Most important to note, the ability to stop, pull augers and address the down hole conditions, are not forfeited with a retractable roller-cone head, Barbco said.

Trenchless crossings are an ever evolving environment where sometimes there is no perfect tool for the job. Ground formations can vary so aggressively that it is impossible to have one specific cutting head for any ground condition. Due to this reality, the best way to approach these choices is to narrow down which cutting head provides you with the most versatility in your specific ground condition, and always be prepared to pull auger, before you put yourself and your equipment into an unexpected situation.

For more information, visit barbco.com.

ASCO EQUIPMENT www.ascoeq.com Contact your local dealer:

PACWEST MACHINERY www.PacWestMachinery.com

Kent, WA 206-762-5933

Mount Vernon, WA 360-588-3083

Portland, OR 503-252-5933

Eugene, OR 541-343-6926

Spokane Valley, WA 509-534-5933

Pasco, WA 509-534-5933

Abilene, TX 325-698-2726

Amarillo, TX 806-372-8386

Lubbock, TX 806-745-2000

Perryton, TX

806-435-7773

Clovis, NM 575-742-2726

SIERRA MACHINERY, INC. www.sierraelpaso.com

El Paso, TX 915-772-0613

Artesia, NM 575-746-6592

Rock, TX

512-388-2529

877-851-1026 Buffalo Buffalo, TX 903-322-5602 Carmine Carmine, TX 979-278-3570

Corpus Christi Corpus Christi, TX 361-881-4891

Dallas Carrollton, TX 214-819-4100

800-227-6626 Ft. Worth Ft. Worth, TX 817-626-2288 866-966-4602 Houston Houston, TX 713-937-3005 800-865-6998

Longview Longview, TX 903-758-5576

Rio Grande Valley Mercedes, TX 956-565-0100 San Antonio San Antonio, TX 210-648-4600 800-966-4601

3135 US Hwy 90 East

Broussard, LA 70518

337-837-6693

4851 E Napoleon Road Sulphur, LA 70663

337-625-5942

2815 N Sam Houston Pkwy E Houston, TX 77032

281-598-2500

33345 SR20 Oak Harbor, WA 98277 360-675-4441 10219 State Avenue Marysville, WA 98271 360-651-9079 2713 Euclid Avenue Wenatchee, WA 98801 509-888-8181

Dallas (Carrollton), TX 214-819-4100 Austin, TX 512-388-2529 Corpus Christi, TX 361-881-4891

Ft. Worth, TX 817-626-2288

Longview, TX 903-758-5576 Mercedes, TX 956-565-0100 San Antonio, TX 210-648-4600

Stephenville, TX 817-626-2288

700 W. Mossdale Road Lathrop, CA 95330 925-606-2477 550 Greenville Road Livermore, CA 94550 925-606-2403

6904 Banigan Road Anderson, CA 96007 925-606-2437

As part of its continued commitment to dealers, customers, and local communities, Kubota Tractor Corporation announced 20 grant recipients in its fourth annual Kubota Hometown Proud grant program aimed at providing support across the country for local nonprofit organizations and their unique initiatives.

Each of the 20 hometown projects now goes to a public vote, and the project with the most votes in each of Kubota’s 10 operating districts will turn its $10,000 grant into a $50,000 grant.

“The Kubota Hometown Proud grant program was created four years ago as a way for Kubota to give back to our dealers’ hometowns in a meaningful way,” said Todd Stucke, president of Kubota Tractor Corporation and senior vice president of Kubota North America.

“Today we are announcing more grants than ever before — for 20 nonprofits from various hometowns across the country — to help with community projects that will make a positive impact in these communities for years to come. We hope the next phase in our program generates even more hometown pride by rallying around each organization and helping to shine a light on the important work they all do.”

The community projects with the most votes will be announced in September.

The 2024 Kubota Hometown Proud grant program recipients and their projects that are now up for vote include:

• Ag Alley at Shanél Valley Academy (Hopland, Calif.)

• Agricultural Education Space for Black Youth and Adult Land Stewards by Black Oregon Land Trust (Corbett, Ore.)

• Barns Repair and Restore at AACORN Farm (Kalamazoo, Mich.)

• Bristow Town Square Renovation by Bristow Historical Society (Bristow, Okla.)

• Bryant City Park Improvement Project by Bryant Up & Coming (Bryant City Park, S.D.)

Farm, Inc. (Tully, N.Y.)

• New Heart: Feeding Those in Need by Fed By Faith (Joelton, Tenn.)

• Pony Van for Stable Moments by Justin’s Place (Wilmore, Ky.)

• Refugee Children Farm Educational Shelter by Transplanting Traditions Community Farm (Chapel Hill, N.C.)