By Irwin Rapoport CEG CORRESPONDENT

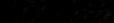

After years of planning, C.A. Rasmussen Inc. has made significant progress on the construction of the Wallis Annenberg Wildlife Crossing on U.S. Highway 101 in Los Angeles County.

It’s a $90 million project that the California Department of Transportation (Caltrans) is building, and various environmental organizations are financing.

Caltrans awarded a contract to C.A. Rasmussen with money provided by sources including the Annenberg Foundation ($25 million), the California Wildlife Conservation Board ($25 million), the state of California ($20 million) and other grants and private donations.

One of the main reasons for the initiative is to protect biodiversity, emphasizing the mountain lions/pumas that reside in the area. The life of a male mountain lion, P-22, who lived in the urban Santa Monica Mountains in Los Angeles, highlighted the need for the bridge to ensure that the local population would have access to the genetics of species on the opposite side of the highway. That population was essentially isolated by major highways.

“Caltrans is pleased with the progress of this project,” Caltrans Public Information Officer Michael Comeaux said in late October. “Construction is substantially complete for the reinforced concrete struc-

page 32

By Lucy Perry CEG CORRESPONDENT

In mid-January, FHWA published a final rule on the 1983 waiver of the regulation on the use of Americanmanufactured products on federal projects. The waiver limited application of the agency’s Buy America requirements to iron and steel. That allowed contractors on FHWA projects to seek other products from foreign sources. And that waiver flies in the face of former President Joe Biden’s goal to boost domestic manufacturing in transportation. see ROLLBACK page 38

2020 Komatsu D61PX-24, Stk#: 13536, EROPS, A/C, 4,268 hrs., 6 Way Blade, 80% U/C, 34" Pads, 12' 7" Wide $149,500

30

2016 Kobelco SK140SRLC-3, Stk#: 13546, EROPS, A/C, Heat, Radio, 4,751 hrs., 34" Bkt, 24" Pads, Aux Hyd, Back-Up Camera $48,500

2021 Komatsu D61PX-24, Stk#: 13393, EROPS, A/C & Heat, Radio, 5,220 hrs., 6 Way Blade, 34" Pads, 12' 7" Wide $149,500

2003 John Deere 550H LT, Stk#: HR-13608, OROPS, (Hour Meter Replaced Approx. 5,000 hrs) 650 hrs on New Meter, (10 hrs on New Eng) 6 Way Blade, 90% Plus U/C & 10 hrs on NEW Eng, Drawbar, 18" Pads, 8 Ft. Wide $36,500

2017 Atlas Copco 110CFM, Stk#: 13683, 2,102 hrs., 125 PSI, 2,700 100-128 PSI, 24hp., Weight 1,650 lbs. $8,500

2019 Kobelco SK210LC-10, Stk#: HR-13615, EROPS, A/C & Heat, Radio, 2,207 Hrs., 30" Bucket, 30" Tracks $109,500

2013 John Deere 750K LGP, Stk#: HR-13314, EROPS, A/C & Heat, Radio, 4,108 hrs., 6 Way Blade, 33" Pads, New Eng. Install at 3,800 hrs., New Rails & Sprockets, Winch, 12' 10" Wide $159,500

2019 John Deere 850K LT, Stk#: HR-1207, EROPS, A/C & Heat, Radio, 6 Way Blade, 6,728 hrs., 90% U/C, 24"

2014 Cat RM300, Stk#: HR-13597, Road Claimer, OROPS, 8 ft. Mixer, 4,131 hrs., 28Lx26 Front Tires, 18.4x30 Rear Tires, Cat C11 Diesel Eng $199,500

Stardust Power Inc., an American developer of battery-grade lithium products, broke ground on Jan. 22, 2025, on its lithium refinery at the Southside Industrial Park in Muskogee, Okla.

Tadano announced that it completed the acquisition of Manitex International on Jan. 2. Manitex is now a wholly owned subsidiary of Tadano Ltd., and, as a result, Manitex shares are no longer listed on Nasdaq.

World of Concrete (WOC), the largest and most expansive event dedicated to the growing concrete construction and masonry industries, hosted its 51st annual event from Jan. 19-22, 2025, in Las Vegas.

12 AED GATHERS IN ORLANDO, FLA., FOR ITS ANNUAL SUMMIT/CONDEX

The event was an opportunity for members to network, attend seminars, fundraise and see what’s new in the industry. CONDEX allowed equipment manufacturers the display the latest in equipment and technology and services.

14

Workforce challenges for the equipment industry — and potential solutions — are the subject of a report the National Immigration Forum and the Associated Equipment Distributors Foundation released during its 2025 Summit.

The AEDF announced the success of its 9th Annual Gala & Live Auction presented by AEDF & RB Global, held Jan. 15 during the AED 2025 Summit at the Hyatt Regency in Orlando, Fla.

14 EQUIP EXPOSITION ROLLS OUT NEW PLANS FOR OCTOBER ’25 SHOW

This October, Equip Exposition will unveil several new features for the award-winning trade show, including new equipment categories, top-notch entertainment and more.

Case Construction Equipment’s 580EV, the industry’s first electric backhoe loader in full production, has been awarded a prestigious Good Design Award in the Transportation category.

18

Volvo CE has maintained a healthy profitability on lower volumes for the fourth quarter, following 12 months of declining sales, impacted as it has been by an ongoing weaker market landscape across many regions in the world.

25 ARTBA CEO DAVE BAUER’S STATEMENT BACKS SEC. OF TRANSPORTATION

American Road & Transportation Builders Association (ARTBA) President and CEO Dave Bauer has issued a statement supporting Sean Duffy’s confirmation as Secretary of Transportation.

26 CATERPILLAR KICKS OFF ITS NEXT 100 YEARS OF INNOVATION

Caterpillar Inc. marked its 100th anniversary with celebrations throughout the United States that commemorate a monumental moment in the company’s history. The iconic manufacturing company officially turns 100 on April 15.

45 VOLVO TRUCKS

With

NEW 2024 CAT 725

5,000 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

NEW 2024 CAT 730

6,000 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

(2) New 2024 Hydrema 922G 4x4

4,250 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

Equipment for Builds/Order

Rigid Water Tanks up to 18,000+ Gallons 4,500-6,000 Gallon Water for Tandem/6x6 Chassis, Heavy Duty Off-Road Construction

Complete NEW CAT Articulated & Rigid Builds (any size) available with HEC tanks/bodies

New Articulated and Rigid Water Tanks for all Sizes and Brands installation at our place or yours Current stock for CAT 725, CAT 730, CAT 740, CAT 773/775, Bell B30, Bell B40

Fuel, Fuel/Lube Builds available. Articulated or Rigid. Open for warm weather or Up to Arctic Level enclosed for extreme cold operation

Stardust Power Inc., an American developer of batterygrade lithium products, broke ground on Jan. 22, 2025, on its lithium refinery at the Southside Industrial Park in Muskogee, Okla.

In December 2024, Stardust Power completed and announced the acquisition of its 66-acre site in Muskogee. Centrally located, the site benefits from proximity to the country’s largest inland waterway system, robust road and rail networks, and a skilled workforce rooted in the oil and gas sector. The site has excellent access to power and water with the project having received tremendous support from the community.

“Our lithium refinery will be crucial for addressing U.S. national security and supply chain risks,” Stardust Power founder and REO Rohsan Pujari said. “By onshoring critical mineral manufacturing, we are helping to sustain America’s energy leadership. With the land acquired and necessary construction permits secured in 2024, we are excited to break ground and begin construction.

“With continued support from the state of Oklahoma, especially Gov. Kevin Stitt, we are moving forward to becoming one of the country’s leading suppliers of batterygrade lithium. At a time when foreign entities of concern are attempting to consolidate critical minerals, Stardust Power is proud to play a key role in safeguarding American interests and supporting Oklahoma’s local economy.”

The project will be developed in two phases, with the first phase focused on constructing a production line capable of producing up to 25,000 metric tons per annum. The second phase will add a second production line, bringing the total capacity to 50,000 metric tons per annum. Sustainability is a core principle at Stardust Power, and this refinery reflects the commitment to responsible corporate practices, climate action and the energy transition.

Oklahoma’s leadership in sustainable energy aligns with Stardust Power’s commitment to help secure America’s energy future by onshoring critical mineral supply chains and supporting American jobs. The shovel-ready site near the Port of Muskogee offers key construction and operational advantages. After thorough due diligence, including environmental, technical, cultural and logistical reviews, the site was confirmed as ideal. It offers a location with an adjacent 40-acre parcel of land which the company has a right of first refusal for future expansion.

“Stardust Power’s decision to break ground on its lithium refinery in Muskogee is a significant step forward for Oklahoma’s role in reinforcing our critical mineral supply chains and bolstering national security,” Lt. Gov. Matt Pinnell said. “This project not only strengthens our state’s position as a leader in sustainable energy, but it also creates hundreds of good-paying jobs and drives economic growth for our communities. By attracting innovative companies like Stardust Power, Oklahoma is ensuring that we remain at the forefront of America’s energy future.”

“Stardust Power’s investment places Muskogee at the forefront of the energy revolution,” Mayor Patrick Cale said. “Sustainable energy is key to the future, and this refinery strength-

Tadano announced that it completed the acquisition of Manitex International on Jan. 2. Manitex is now a wholly owned subsidiary of Tadano Ltd., and, as a result, Manitex shares are no longer listed on Nasdaq.

On Sept. 12, 2024, Tadano announced its plans to acquire all the remaining shares of Manitex that it did not previously own. Tadano first invested in Manitex in 2018 and held 14.5 percent of the outstanding common shares of Manitex at the time of the September announcement.

Tadano’s Mid-Term management plan outlines the company’s growth strategy and the objective to venture into new areas. The Manitex acquisition is a significant step in implementing this strategy to further diversify the Tadano product portfolio while remaining 100 percent committed to the lifting equipment industry.

ens America’s supply chain, creates hundreds of jobs and highlights our community’s dedication to innovation and progress.”

Stardust Power’s lithium refinery is expected to create hundreds of jobs across engineering, manufacturing and operations, and with the addition of construction and services roles, could potentially add hundreds more, which will significantly contribute to local economic growth.

In 2024, the city and county of Musgokee established a $27 million Tax Increment Financing district to support the project. The TIF is expected to fund key infrastructure improvements in the area, including upgrades to industrial roads, rail line rehabilitation and the replacement of a trestle bridge.

Also in 2024, Stardust Power received a General Permit for Stormwater Discharges from Construction Activities. (All photos courtesy of Stardust Power.)

In addition to other crane models, the strategic move adds mobile truck cranes and aerial work platforms to the Tadano portfolio to help expand the company’s global presence in these markets.

Commenting on the Manitex acquisition, Toshiaki Ujiie, president, CEO and representative director of Tadano, said: “We welcome Manitex as the newest members of the global Tadano team. Tadano enjoys a strong global market share in large cranes. In Japan, we are market leaders in truck loader cranes and aerial work platforms but have not yet been able to duplicate this success outside of the country.

“Combining the engineering, sales and service expertise of both companies allows us to rapidly expand Tadano’s global presence in these areas, so we can better support our customers’ lifting needs and further innovate. Together, we will work hard, grow strong, achieve great things and reach new heights.”

Hiroshi Nishizaki will assume the position of chairman of the board of Manitex International, bringing extensive experience in managing construction machinery businesses in the United States. Dean Barley, current president and CEO of Tadano America Corporation and Tadano Mantis Corporation, will take on the role of president and CEO of Manitex International in addition to his current responsibilities.

The former executives — Dave Langevin, chairman of the board; Michael Coffey, CEO; and Joseph Doolan, CFO — are stepping down but will remain with the organization for a transitional period as interim advisors to the new management and the Tadano team before their departure.

Serving the infrastructure, heavy industry and general construction markets, the acquired product line includes Manitex mobile truck cranes, PM knuckle boom cranes, Valla small electric cranes and Oil & Steel aerial work platforms. Tadano also gains five engineering and manufacturing locations throughout North America and Europe.

Additionally, this acquisition includes Rabern Rentals. For more information, visit www.tadano.com.

World of Concrete (WOC) kicked off 2025 with a gathering of 57,908 registered professionals from Jan. 1922 in Las Vegas.

Thousands of the latest tools, technologies and equipment were previewed throughout the expansive show floor inside and outside of the Las Vegas Convention Center. More than 1,500 exhibiting companies brought the world’s most sought-after heavy machinery, tools, products and services for material handling, concrete reinforcement, concrete masonry, cement production and decorative concrete for all types of building, repair, demolition and reconstruction.

see WOC page 44

Wacker Neuson brought excitement to the show floor with a dynamic range of equipment for the concrete and construction industries, featuring the DW30 concrete edition dumper and SM120 utility track loader. (L-R front row) are Mark Deitsch, Brian Cook, Randy Eubank, Maggie Janssen, Matthew Brooksher, Fred Paul, Luke Sevcik and Paul Rogers. (L-R back row) are Gage Rogers, Lee Lorentz and Brandon Roach.

At World of Concrete, Caterpillar’s Dustin Adams spoke with attendees about Cat’s special Centennial Edition machines like this 305 mini-excavator in the company’s throwback “commemorative gray.” Adams said the company is releasing a broad range of Centennial Edition models to celebrate Caterpillar’s 100 years.

Representatives of Liebherr engaged the construction media at World of Concrete. Liebherr’s U.S. headcount has increased threefold since 2019, representatives said while touting the company’s recent investments in facilities in Tupelo, Miss. The 38XXT concrete pump and 110-DK crawler pump were on display.

Bill Holton of Kubota introduces the company’s U17-5 next generation zero-tail swing compact excavator at World of Concrete on Jan. 21, 2025.

Andy Jeong of DEVELON demonstrates the accessibility of key components on the DX62R-7 compact excavator.

(L-R): Chris Holmberg, Mickey Wiese, Andrew Dillard and Kerri Green of the Purple Wave Auction team engage with World of Concrete attendees. The team is dedicated to connecting contractors and machine buyers.

MB Crusher makes an impression with its ongoing demonstrations, showcasing crusher buckets and accessories for excavators, skid loaders and backhoes for all sizes. (L-R front row) are Joshua Gibson, Paloma Baker and Regan Whitfield. (L-R back row) are Fausto Azzolin, William Yarborough, Cordell Hairston, Chris

and

The Associated Equipment Distributors (AED) gathered at the Hyatt Regency in Orlando, Fla., Jan. 15-17, 2025, for its annual Summit/CONDEX. The event was an opportunity for members to network, attend seminars, fundraise and see what’s new in the industry. CONDEX allowed equipment manufacturers the chance to show attendees the latest in equipment and technology and services.

Among the speakers at this year’s event was Florida Gov. Ron DeSantis. DeSantis spoke at the General Session. Other speakers included William P. Barr, former U.S. Attorney General; James Carville, political consultant; Sean Alexander, Microsoft; and Lauren Saidel-Baker, economist.

The theme for this year’s Gala and Live Auction was

see AED page 34

Christy

Workforce challenges for the equipment industry — and potential solutions — are the subject of a report the National Immigration Forum and the Associated Equipment Distributors Foundation (AEDF) released during its 2025 Summit held in Orlando, Fla.

Congressman Darren Soto (DFla.) joined AED to discuss important issues around comprehensive immigration reform. Among the findings: Because there aren’t enough qualified American technicians, the equipment industry can anticipate $2.2 billion in annual losses between 2023 and 2025. The industry increasingly will need foreign-born techs to augment its workforce.

The report also incorporates a survey of Associated Equipment Distributors (AED) members in which 71 percent say the shortage of technicians is causing delayed production or servicing of equipment. Researchers examine the challenges of current visa options for employers and offer policy solutions that have received bipartisan support in the past.

“The skilled worker shortage is one of the most pressing challenges facing the equipment industry today,” said Brian P. McGuire, president of the AEDF. “While we are committed to training and upskilling North American workers, the reality is that we also need to tap into the talent and expertise of foreignborn workers. Developing pathways for these individuals to contribute is critical to ensuring our industry can meet demand, drive innovation, and support economic growth.”

“We know the equipment industry wants to hire U.S. talent and is committed to apprenticeship programs, but that won’t be enough. It needs access to more foreign-born talent as well,” said Emily Foster, vice president and chief of Public Affairs at the National Immigration Forum. “We need new labor mobility pathways for the industry to thrive moving forward.”

The full report, “Utilizing Foreign Born Talent to Address the Workforce Shortage,” is available on the Forum and Foundation websites.

The Associated Equipment Distributors Foundation (AEDF) announced the success of its 9th Annual Gala & Live Auction presented by AEDF & RB Global, held Jan. 15 during the AED 2025 Summit taking place at the Hyatt Regency in Orlando, Fla.

This highly anticipated event brought together more than 700 industry leaders and supporters from across the industry to celebrate and raise more than $165,000 for critical initiatives that strengthen the equipment distribution sector.

The evening, themed “Havana Nights,” was filled with energy, camaraderie and generosity as attendees participated in the live auction hosted by RB Global, silent auction and networking opportunities. Due to the unwavering support of AED members and industry stakeholders, the gala achieved record-breaking proceeds that will directly impact the Foundation’s 3 pillars of accreditation and recognition, career promotion and industry research.

“We are deeply grateful for the incredible support shown tonight by our members and industry partners,” said Diane Benck, AED Foundation chairwoman and president of West Side Tractor Sales Co. “The success of this event is a testament to the commitment of our industry to invest in its future. These funds will enable us to drive meaningful progress in workforce development and career promotion, ensuring a robust and skilled workforce for years to come.”

A standout moment of the evening was the recognition and celebration of the 2025 AEDF Knapheide Technicians of the Year. 2025 AEDF Knapheide Technicians of the Year

This October, Equip Exposition, the international landscape, outdoor living and equipment exposition, will unveil several new features for the award-winning trade show, including new equipment categories, top-notch entertainment and more.

From Oct. 21 to 24, 2025, thousands of landscapers, dealers, contractors, hardscape experts and outdoor power equipment manufacturers will gather at the Kentucky Exposition Center (KEC) in Louisville for the largest event of their industry.

“We are always aiming to improve what we can offer attendees, and the excitement around the 2025 show is already high. We’re well ahead in exhibitor space reservations this year over 2024,” said Kris Kiser, president and CEO of the Outdoor Power Equipment Institute (OPEI), an international trade association representing manufacturers and suppliers of power equipment, small engines, battery power systems, portable generators, utility and personal transport vehicles, and golf cars, which owns and manages the blockbuster show.

With more than 1.2 million sq. ft. of indoor and outdoor exhibit space, Equip Exposition is a “must see” for dozens of reasons, including the 30-acre Outdoor Demo Yard, unique peer-to-peer networking events, education and technical training offerings both in English and Spanish, highlevel speakers and world class entertainment.

But Kiser said landscapers, contractors, industry insiders and power equipment dealers should put Equip Exposition on their calendars early this year because several must-see events and offerings will be on hand, including:

• Dale Doll, Finning Canada

• Bert Jacobson, Coastline Equipment

• Brian Bruzewski, Parman Tractor & Equipment

• Adam Garcia, Closner Equipment Co. Inc.

• Anthony Burkholder, Stauffer Diesel Inc.

• Brian Drakeley, Burris Equipment Co. Inc.

• Jacob Steichen, RDO Equipment Co.

• Julien Loeven Seigle, Joe Johnson Equipment Inc.

The AEDF Knapheide Technicians of the Year Award, presented annually to outstanding technicians from various regions, honors the best of the best in the field.

“Recognizing outstanding technicians is vital in addressing the equipment industry’s technician shortage,” said AEDF President Brian P. McGuire.

“The AEDF Knapheide Technician of the Year Awards highlights the value of these technicians and inspires the next generation to pursue these rewarding careers, helping to secure the future of our industry.”

The proceeds from the gala will be used to expand training programs and certifications, foster partnerships with educational institutions, and accredit technical programs at colleges and high schools. By addressing the ongoing technician shortage and promoting rewarding careers in the field, AEDF ensures a steady pipeline of skilled professionals ready to support the industry’s future growth.

Additionally, the funding will enable critical industry research to generate actionable insights and innovative strategies for AED members and the industry overall.

For more information, visit www.aedfoundation.org.

• A special keynote speaker, Jesse Cole, founder of the wildly-popular baseball team, the Savannah Bananas, who will inspire attendees to grow their own businesses to new heights. As one of America’s most famous entrepreneurs, Cole will share what it takes to develop a great idea into a brand that people embrace and love, and how to keep creativity flowing for the long haul.

• Created just for Equip Exposition, an exclusive small batch Bourbon will be made by a Kentucky master distiller. For help in naming the bourbon, Equip welcomes input from attendees and exhibitors though a special naming contest.

• Boom trucks, lifts and other large vehicles will be available in an outdoor KEC parking lot as well as indoors on the KEC’s Freedom Hall floor.

• A newly-expanded and re-located UTV Test Track will move this year to a larger area. The relocation frees up additional space in the 30-acre Outdoor Demo Yard, where attendees will test equipment, drive, cut, chop, dig, trench and do more in the re-configured space.

• Top-notch entertainers Big & Rich and solo country artist Gretchen Wilson will perform an exclusive concert for show attendees at the Kentucky International Convention Center (KICC) in downtown Louisville on Thursday evening of the show. The concert, included with admission to Equip Exposition, is a great place to network and provides a load of fun.

Since assuming management of the business-to-business

see EQUIP page 30

Loved for the features. Trusted for the performance.

Hyundai articulated dump trucks have the power and performance — not to mention top-notch interiors, clear sight lines and handy tech — that make life on the jobsite easier. So you can do more without feeling like longtime fans.

See the Hyundai difference yourself at your local dealer or na.hd-hyundaice.com.

Case Construction Equipment’s 580EV, the industry’s first electric backhoe loader in full production, has been awarded a prestigious Good Design Award in the Transportation category.

The 580EV represents a big leap forward in electric construction machinery, combining the robust capabilities of its diesel counterpart with all the environmental and operational benefits of electric vehicle technology.

Zero emissions and minimal noise make the 580EV model an ideal solution for urban construction crews, utility teams, municipal crews and other contractors who want to work more productively while also minimizing carbon footprints, according to the manufacturer.

The Good Design awards, managed by the Chicago Athenaeum Museum of Architecture and Design and Metropolitan Arts Press Ltd, is one of the oldest and most respected awards programs for contemporary design. Each year the program celebrates the most innovative industrial, product and graphic designs produced around the world.

The Case 580EV, which was recognized for exceptional industrial design, seamlessly combines form and functionality to create an unmatched operator experience. Clean, flowing body lines accented with boldly colored “electric blue” decaling help call out the cutting-edge EV technology under the hood. Inside the cab, Case took an operator-first approach with an 8-in. color touch screen display, user-friendly controls and ergonomic membrane keypads protected against dust and other debris. Multicolored, four-corner strobe lights also let operators work safely and meet regulatory requirements, with adjustable colors, strobe patterns and an “always-on” feature for low-light conditions when strobes are not needed.

“We designed this workhorse machine from day one as a purpose-built, high-performing EV, but we also wanted it to have a look and feel that operators would love,” said Terry Dolan, vice president — North America, Case Construction Equipment.

“This recognition from Good Design underscores our continued leadership in design excellence and functional innovation as we work harder than anyone to give contractors more tools in the toolbox for them to succeed on the job site.”

For more information, visit www.CaseCE.com.

Volvo CE has maintained a healthy profitability on lower volumes for the fourth quarter, following 12 months of declining sales, impacted as it has been by an ongoing weaker market landscape across many regions in the world. But while net sales have dropped 16 percent in Q4, net order intake for the same quarter has risen 19 percent, driven by improvements in major markets across Europe, North America, Africa and Oceania.

And while South America has seen a growth in net sales of 19 percent and deliveries increased 29 percent for the last quarter,

overall global sales are down for the full year by the same Q4 drop of 16 percent. In Q4, net sales decreased by 16 percent to SEK 22,197 M (26,578), of which net sales of machines decreased by 19 percent and service sales decreased by 2 percent. Adjusted operating income amounted to SEK 2,609 M (3,320), corresponding to an adjusted operating income of 11.8 percent (12.5). For the full year 2024, net sales dropped by the same 16 percent, amounting to SEK 88,305 M (104,981). Adjusted operating income amounted to SEK 12,737 M (16,993).

Volvo CE is maintaining a more positive outlook coming into 2025, following a year of milestone investments and pioneering new product launches, continuing with its largest product portfolio overhaul in decades.

Melker Jernberg, president of Volvo CE, said, “Despite lower volumes, we have been able to maintain a healthy profitability, whilst at the same time introducing new products and services, including a new range of articulated haulers to our existing portfolio.

“As we navigate challenging market conditions, we stand firm in our commitments and continue to invest. This last quarter has seen us move forward with our biggest launch year ever, balancing tomorrow’s innovations with our customers’ needs for today. 2025 will see us continue with these exciting developments, strengthened by an incredible performance from all our employees around the world.”

New excavator models were rolled out, including the EC650 in China and the EC300 in South Korea, while in Europe, the latest generation of excavators was expand-

ed with the launch of three mid-size crawler excavators. In January, a comprehensive range of industry-leading articulated haulers was launched. The updated range consists of seven models from 25 to 60 tons including one completely new model, the A50, offering customers a new size class for unbeatable hauler performance, accessible to customers in global markets over the coming months.

Compared with the historically high levels in Europe and North America for the final quarter of 2023, the total machine market contracted in these regions, largely due to a saturated end customer demand in Europe, resulting in a 25 percent drop, and a normalization of replenished dealer and rental fleets in North America, prompting an 8 percent drop.

However, South America saw a 5 percent increase due mainly to improvements in Brazil, while government policies to stimulate the real estate market were the main driver for market growth in China (6 percent). Asia, excluding China, was flat with lower development in Southeast Asia, South Korea and Turkey, while markets in India and the Middle East grew.

Sandvik Mobile Crushers and Screens has introduced the UJ313, the latest addition to its line of heavy-duty wheeled crushers. This fully electric unit underscores the company’s commitment to eco-efficient rock processing.

Positioned as a versatile solution for both quarrying and recycling applications, the UJ313 is designed to meet the diverse needs of these sectors. Its innovative design not only enhances operational efficiency but also ensures adaptability to various working conditions.

With a host of new features, the UJ313 is poised to enhance productivity and reliability in the market, making it an indispensable asset for modern operations, the manufactur-

er said.

It is fully assembled on a single trailer frame, mounted on a triple axle bogie for easy transport and operational readiness. At its core is the Sandvik CJ211 jaw crusher, renowned for its exceptional reliability and high performance with minimal downtime.

Equipped with an advanced electric drive system, the UJ313 includes essential components such as all motors, starters, soft start for the crusher and frequency drive, all seamlessly controlled by a user-friendly UL/CE electrical control panel.

This innovative design allows for flexible running conditions, whether from an independent genset or the mains grid, optimizing running costs.

Ease of setup is a key feature of the UJ313, with a hydraulic self-locking feed hopper and onboard powerpack for quick, safe and easy machine setup.

The three-way diverter chute below the grizzly and a natural fines conveyor offers

onsite flexibility, maximizing capacities and the production of sellable products. Additionally, motorized pulleys on the conveyors reduce the need for oil changes, decreasing service and maintenance time and creating a safer work environment.

The large chamber opening of 43 by 27 in. allows for unrestricted material flow, enhancing the processing capabilities of the unit.

Safety remains a top priority. Hydraulic service platforms on both sides of the crusher allow for safe and stable access to the unit, reducing time spent on servicing and maintenance, and ensuring a safer working environment.

The UJ313 is designed with the future in mind, focusing on sustainability, productivity and reliability. Its electric power source and innovative features make it an ideal solution for the quarrying and recycling mar-

kets, offering significant benefits such as reduced operating costs, lower carbon emissions and enhanced safety.

Sandvik Mobiles distributor, Diesel Machinery Inc. (DMI), reported that its customer hasn’t looked back since introducing the UJ313 into its operations.

Working in a closed-circuit plant alongside a screen and then feeding a cone crusher, the UJ313 has “really performed well,” said Nick Wallin, Crushing and Screening Specialist at DMI with similar comments coming from the customer.

“The machine is well laid out and the operators have found nothing they dislike about the machine. It is quick and easy to adjust the CSS, and the big reduction capability is a huge benefit to them.”

The UJ313 is available to order now in North America, Canada and selected markets in Europe.

For more information, visit rockprocessing.sandvik.

mance

across the

Oklahoma City, OK 405-495-7820 Tulsa, OK 918-438-1700 McAlester, OK 918-310-1550

Odessa, TX 432-333-7000 www.kirby-smith.com Corpus Christi, TX 361-289-0066

www.nuecespower.com

Lubbock, TX 806-745-2112

Dallas, TX 214-371-7777

Ft. Worth, TX 817-378-0600

Hewitt, TX 254-261-1370

Abilene, TX 325-692-6334 Amarillo, TX 806-373-2826

Laredo, TX 956-725-0066 San Benito, TX 956-361-0066 Victoria, TX 361-576-0066

Vinton, TX 915-541-0066 Houston, TX 713-247-0066 San Antonio, TX 210-310-0066

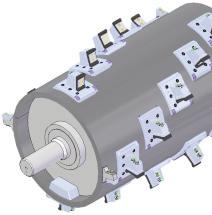

The Bandit team has brought the HM6420 hammermill grinder to market.

This highly productive 40 in. capacity grinder is designed and manufactured to be an alternative solution for those grinding applications that may contain contaminants. A Caterpillar C32, 1,200 hp engine provides ample torque and horsepower for optimal machine performance and productivity.

The heart of the HM6420 is a 50 in. diameter by. 66 in. wide hammermill. The heavy-duty mill features a 1.75 in. drum skin custom formed from rolled plate. The mill is supported by a 7 in. main shaft con structed of alloy steel that has been ultrason ic tested.

Each pocket within the mill is manufactured from high strength A-514 steel. These combinations create a structural sound mill for added durability and integrity. The mill is equipped with 20 carbide infused hammer inserts built to withstand the toughest material fed into the machine. Each holder is securely attached to the mill via a quick change pocket sys tem. Each holder recesses into the mill pocket, increasing durability.

dle allows for quick screen set-up changes. All work for screen changing is performed outside of the machine.

An impact detection system is standard and designed to limit damage if a contaminant is struck inside the grinding chamber. Once an impact event is detected, the grinder will idle down, open the

A top plate covers the pocket and holds in place by six hex bolts. The hammer insert is attached to each holder utilizing two bolts. With this set-up, the mill hardware is easier and quicker to replace.

A heavy-duty slat-style infeed conveyor is directly driven generating more than 18,000 lbs. of pulling power. The large diameter feed wheel is also directly driven and provides an additional 17,000 lbs. of pulling power and 8,650 to 17,300 lbs. of down force when hydraulic pressure is applied. These combinations allow the HM6420 to grind massive quantities of material efficiently and effectively at one time.

A proportional feed system is standard and regulates the feed system from 82 to 132 ft. per minute. The HM6420 has one of the fastest feed rates on the market allowing it to quickly process material. The proportional feed system allows operators to adjust the feed based on material being processed ensuring maximum output and grinder efficiency, all while achieving a higher quality end-product.

Three screens are located on the top side of the HM6420 mill. A variety of screen sizes are available up to 7 in. to produce various end-product sizes. The top feed wheel moves upward, and a removable screen cra-

gate, disengage the clutch, and reverse the feed.

A 56 in. dual discharge system with a stacking height of 16 ft. 8 in. is standard. The standard wireless remote controls all grinding and tracking functions and features an LCD screen that will display engine coolant temperature, engine oil pressure, engine load percentage, engine RPM, and battery voltage.

Bandit initially debuted the HM6420 at the 2023 ConExpo show. After the show, further evaluation and testing was conducted and the machine was then demonstrated to a variety of customers and dealers at Bandit’s 40th Anniversary event in September of 2023. Final testing of the HM6420 took place in the fourth quarter and the machine will begin production in the first quarter of 2024.

The addition of the HM6420 expands the already diverse line of Bandit horizontal grinders available.

For more information, visit banditchippers.com. in. diameter by 66-in. wide hammermill. The mill is equipped with 20 carbide infused hammer inserts built to withstand the toughest material fed into the machine.

806-364-5687

613 S. 4th Ave Mansfield, TX 76063 817-473-2110

3871 IH - 10 W. Freeway Exit 693 Columbus, TX 78934 979-732-6902

www.texasbearing.com

Dry stone walling is a traditional construction technique rooted in many cultures around the world, especially common in Europe.

These structures are crafted without any binding agents, relying on the precise interlocking of stones, where the weight and precise placement of each stone are used to create durable and resilient barriers. In addition to defining boundaries and shaping landscapes, they serve important ecological roles: they protect against desertification and soil erosion, help prevent landslides and provide shelter for a range of animal and plant species.

Despite the benefits of these structures, building and maintaining dry stone walls requires significant skill and meticulous attention to detail, making skilled laborers increasingly rare and valuable. The guardians of this tradition must carefully select and place each stone to ensure stability and longevity. However, due to technological advancements, even these traditional techniques can now be enhanced by equipment that simplifies construction, speeds up the process and delivers maximum precision with minimal effort — handled by a single operator seated in a machine.

MB Crusher’s MB-G selection grabs step in to lend a hand, enabling operators to grip, move and position stones of all shapes and sizes with accuracy, precision and safety.

The owner of Battaglia Costruzioni in Italy, said, “Purchasing the MB-G350 selection grab was a gamechanger for us — we can do whatever we want.”

Working in a hilly park, he is building a dry stone wall with the local stone — Euganean trachyte — a highly

durable stone also used to pave much of Venice’s walkways. In just four days, with the MB-G350 selection grab, Battaglia Costruzioni processed 55 cu. yd. of trachyte, creating a 170 ft.-long dry stone wall averaging 63 in. in height. Manually, this would have required at least five workers and 35–40 days of labor.

“Opening and closing the grab is incredibly simple. After only 10 minutes, the machine works as if it’s been in operation for months. You can even work with fine precision, slotting the stone exactly where you want it, turning it… you can do whatever you need to. It’s uniquely simple,” he said.

The MB Crusher grab also is ideal for constructing riprap embankments, commonly used along rivers in both mountainous and flat areas. These embankments vary by function but generally aim to protect banks from erosion and to control water levels. Here too, this isn’t a matter of merely piling stones but rather a painstaking process made easier, more precise, and safer with the MB Crusher selection grab.

Dry stone walls have been recognized as a UNESCO World Heritage asset, but they need to be “kept in practice” — enabled, passable, feasible and sustainable, not just preserved as museum pieces.

The combination of ancient techniques and modern equipment like MB Crusher’s MB-G grabs represents the future of dry stone walling and riprap embankments. With the support of MB Crusher’s equipment, we can sustain a centuries-old tradition while achieving high performance, safety and respect for the environment.

For more information, visit mbcrusher.com.

American Road & Transportation Builders Association (ARTBA) President and CEO Dave Bauer has issued the following statement:

“Sean Duffy’s decisive confirmation as secretary is a testament that bipartisanship remains key to advancing meaningful transportation policy.

“We are eager to partner with him and the U.S. Department of Transportation team to highlight the vital economic and safety benefits of robust federal investment in highways, bridges, public transit, and airports, and to reduce the regulatory burdens that increase project costs and delays.

“We are also committed to helping Secretary Duffy bring President Trump’s vision for America’s future infrastructure to life as we prepare for the next long-term federal surface transportation authorization, due in fall 2026.”

For more information, visit www.artba.org.

Caterpillar’s unwavering commitment to customer success has been a driving force for a century. As the celebrates its 100th anniversary, it continues to innovate, adapt and evolve, always looking forward to the next challenge, the manufacturer said.

Cat Trial 14: After Hours brings Cat equipment from past and present to life in a nighttime spectacle. This visual display demonstrates how the company has stood side by side with its customers for 100 years, and how it is digging in for the decades to come.

The roots of Caterpillar’s innovative spirit can be traced back to before the 1920s, with the groundbreaking work of Holt Manufacturing Company and C. L. Best Gas Traction Company.

Following World War I, these two companies found themselves at a crossroads. The market was flooded with surplus machines, depressing demand for new tractors. Best brought to the table a strong domestic market presence, an advanced dealer network, and a diverse product line. Holt contributed its worldwide reputation, the iconic “Caterpillar” name, and state-of-the-art manufacturing facilities.

Their merger in 1925 laid the foundation for what Caterpillar is today.

Throughout the past century, Caterpillar expanded globally and worked inventively to benefit worldwide customers. For example, the company introduced game-changing products such as the D10 track-type tractor with an elevated sprocket design and the 797 mining truck. Plus, it embraced technological advancements in multiple ways, such as introducing an autonomous mining truck in 1996 to help customers increase job-site safety.

And now, as the company celebrates its centennial in 2025, it introduces a line of Limited Edition Centennial Grey paint machines, represented by the Cat Centennial D3 Dozer in Cat Trial 14: After Hours, as a testament to its enduring legacy.

The Cat Trial 14 video also features other noteworthy machines, including the versatile Cat TH1255 Telehandler and a one-of-a-kind, real-life Power Loader, built by Hacksmith Entertainment, based on the iconic, futuristic machine from a popular movie franchise.

Cat Trial 14: After Hours showcases a power display that features industrial, marine products and electric power that meet worldwide power needs in an impactful way.

“If we were to aggregate all of Caterpillar’s current genset power, it would be enough to power the entire country of Brazil — the world’s seventh-largest consumer of power, with a population of 214 million,” the company said.

“All of these power offerings are part of our broader strategy to support customers where, when and how they need power to get the job done.”

Caterpillar’s worldwide presence has been a cornerstone of its success since the early days, when its heavy-equipment models began making their mark around the world.

In 1908, the first Holt Manufacturing Company gasoline-powered “Caterpillar” tracktype tractor was sold, quickly finding its way across the globe. By 1914, Caterpillar machines were introduced in Asia, with the first units sold in Indonesia for plowing sugarcane fields. Soon after, customers in India and Japan were experiencing the benefits of the products.

Today, the Cat dealer network covers more than 190 countries with nearly 170,000 Cat dealer employees worldwide. Many of these dealerships are independent, family owned businesses, and some even predate Caterpillar’s 1925 founding.

The average Cat dealership worldwide boasts over 50 years of experience.

“As we celebrate the past, we also look toward the future — and we will continue to help our valued customers do the work in which they excel. Our commitment to them is unwavering, as evidenced by our substantial investment in research and development,” the company said.

“In the 2023 financial year alone, Caterpillar allocated $2.1 billion to R&D to ensure that our engineers are constantly innovating and anticipating future trends. This proactive approach ensures that when our customers need new solutions, we’re not just ready — we’re ahead of the curve. That’s what they count on.

“With Cat Trial 14: After Hours, we celebrate our customer’s success by spotlighting the rich history of cutting-edge solutions. In full support of them, we will continue to shape the future of the industries we serve for the next hundred years and beyond.

For more information, visit https://www.cat.com/trial14.

(All photos courtesy of Caterpillar.)

a one-of-a-kind,

Salt Lake City, UT 84116 801-322-1300

atlasmachinery.us

Equipmentshare.com

trade show in 2022, OPEI has worked to energize Equip Exposition’s offerings. The show broke attendance records in 2022 with 25,000 attendees, in 2023 with 27,000, and again in 2024 with 28,500.

Registration is only $25 through May 31, 2025. The blockbuster trade show brings more than $25 million annually to Louisville.

For more information visit www.EquipExposition.com.

CROSSING from page 1

ture including the bridge deck which spans this very busy freeway. This will reconnect wildlife habitat on both sides of the roadway and restore an essential natural corridor for wildlife to survive and thrive.”

The current structure is Stage 1 of the project (the crossing over the freeway, U.S. Highway 101 or the Ventura Freeway).

“In Stage 1, we have placed more than 13,447 tons of structural concrete — that’s more than 26.9 million pounds,” Comeaux said. “The concrete is reinforced with more than 1,082 tons of rebar, equal to more than 2.1 million lbs. In Stage 2, we anticipate using larger quantities of both concrete and bar reinforcement than are used in Stage 1. Stage 2 will involve utility relocation, construction of the crossing over Agoura Road — a city street parallel to the freeway — and significant earthwork. Stage 2 is expected to go out to bid in the near future.”

In the first stage, a waterproofing layer is being installed on the bridge deck. Next, a drainage system and an aggregate base layer will be placed on the bridge deck.

“At this time, soil is being prepared — one might say the soil is being curated or cultivated — and will be placed on top of the bridge deck starting late this year, approximately,” Comeaux said. “Vegetation that will be planted in the soil has been grown in a nursery near the project site. The plants grew from seeds that were collected within a 5-mi. radius of the project site. As a result of this process, the vegetation on the crossing will be ideally suited to the location. The goal is to create a vegetated bridge deck that is a living part of the natural wildlife habitat on both sides of the freeway.”

The construction phase of the bridge project began in spring 2022. Completion of both stages is expected in 2026.

A Caltrans construction advisory in September illustrated the progress.

“Crews are constructing sound walls and concrete barriers on the wildlife crossing above traffic lanes,” it stated. “Crews are removing temporary supports [steel beams, timber posts and diagonal bracing] next to traffic lanes under the wildlife crossing.”

Comeaux is pleased that wildlife is already aware of the project, explaining how an owl was among the first customers.

“This part of U.S. Highway 101, also called the Ventura Freeway at this location, is one of the busiest freeways in Los Angeles County,” he said. “It is used by about 300,000 vehicles a day, on average. Scientists and researchers report that

traffic noise and bright illumination from vehicle headlights at night are deterrents to the movement of wildlife. In 2024, while girders were being placed above the traffic lanes — which created a large, darkened area over the freeway — an owl was seen flying over the wildlife crossing, which is believed to be the first known instance of wildlife crossing over the still-unfinished Wallis Annenberg Wildlife Crossing.

“The project employs methods, such as sound walls, to dampen traffic noise to create a quiet crossing over the freeway,” he added. “Also, the project design includes methods to reduce the impact of artificial lighting on wildlife. For example, the roadway lighting provided for motorists will have a lower color temperature than is normally used at a highway bridge. Also, the pigment in the concrete used for this crossing gives the concrete a darker shade to reflect less light which will help darken the area of the crossing at night, further reducing the impact on wildlife.”

Fencing 12 ft. high will be installed along both sides of the freeway to guide wildlife to the crossing. The fencing is an essential element of the project. A convenient observation

point will be constructed nearby to enable in-person viewing by visitors who wish to see the crossing in use.

“Caltrans and the state of California place high importance on reducing impacts on wildlife from the state transportation system,” Comeaux said. “Caltrans has taken meaningful steps to enhance wildlife corridors in California and plans to continue doing so.”

The bridge was designed by a variety of state agencies, including Caltrans.

“The weight of the completed crossing will include a layer of gravel, topped by a layer of soil — roughly three feet of soil on average, though the soil depth will vary between approximately one foot and four feet deep at various locations on the bridge,” Comeaux said. “The bridge is 174 ft. wide, and it is 210 ft. long. It crosses eight traffic lanes, plus entrance/exit lanes which run between successive interchanges. Therefore, the bridge crosses 10 lanes of pavement. The bridge is wide enough that if it had been designed for vehicles, it could accommodate five or six lanes in each direction, depending on their configuration.”

3100 N 1st Street Bloomfield, NM 87413 505-324-8601

4304 Monica Lane Carlsbad, NM 88220 505-485-1700

1181 Burgundy Drive El Paso, TX 79907 915-872-1001

25015 S McQueen Road Chandler, AZ 85249 602-463-3772

3300 E. Michigan Street Tucson, AZ 85714 520-649-2858

Steve Paone (L) and Darrell Banks, both of Midland Machinery, attended the Summit.

(L-R) are Sam Terrell, regional service manager; Ignasi Moner, director of national and strategic accounts, both of HiPower Systems of Olathe, Kan., a division of Himoinsa Power Systems Inc.; and Rafael Acosta, president of Himoinsa Power Systems Inc.

FAE of Flowery Branch, Ga., had the whole team on hand. (L-R) are Joe Duszynski, territory manager; Fabrizio Bastone, general manager; Chris McNany, territory manager; Giorgio Carera, CEO; Tom Durant, territory manager; and Bradley Wiseman, marketing director.

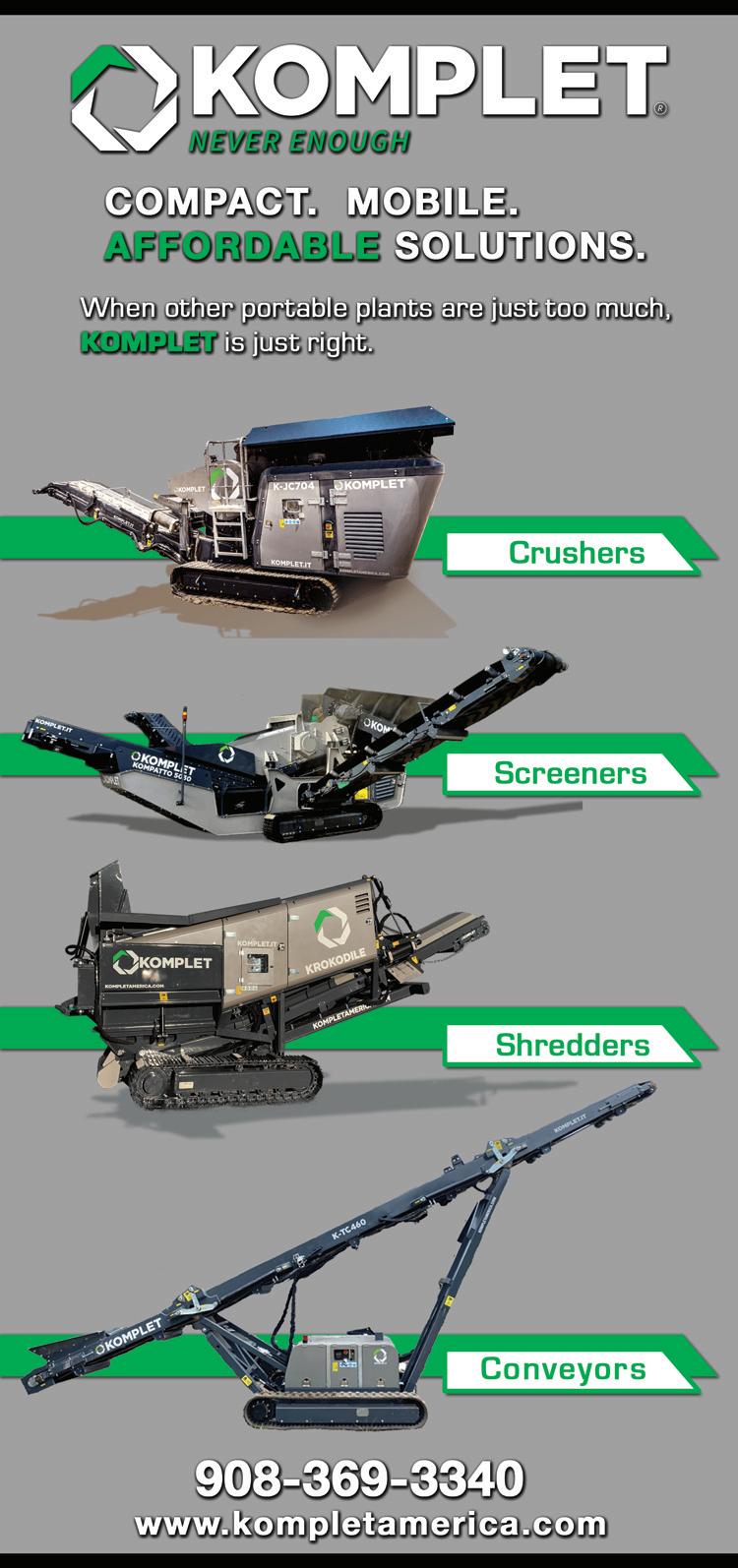

Cody Price, operations manager of Komplet, Hillsborough, N.J., was at CONDEX to share what Komplet’s crushing and screening products had to offer.

AED from page 12

“Havana Nights.” This event helped raise more than $165 million to support The AED Foundation as it offers long-term career pathways and continuing education for employees.

AED was founded in 1919 by Morton R. Hunter and serves the construction, mining, forestry power generation, agricultural and rental industries.

For more information, visit aednet.org. CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

Blue Diamond Attachments announced its full line of brush cutter attachments.

Blue Diamond skid steer, compact track loader, mini skid steer, excavator and mini excavator brush cutters have been widely accepted by contractors in North America for their ability to handle site prep and clearing. Because of that success, the company has grown its offering — now providing heavy, extreme and severe duty models — designed to handle any job, large or small.

Blue Diamond provides 13 different models of brush cutters for use with mini skid, skid and track loaders:

• 36 in., 42 in. and 50 in. mini skid steer closed front

• 36 in., 42 in. and 50 in. mini skid steer open front

• 60 in. and 72 in. heavy duty models

• 60 in. and 72 in. extreme duty models

• 72 in. severe duty model

• 44 in. swing arm cutter

• 84 in. dual motor brush cutter

The company also offers seven mini excavator and excavator brush cutter models:

• 60 in. extreme duty for excavators

• 60 in. severe duty for excavators

• 36 in., 42 in. and 50 in. heavy duty for mini excavators

• 42 in. severe duty for mini excavator

Blue Diamond Attachments offers a few

key differentiators that add performance and value to its brush cutters, versus an add-on from the manufacturer.

• All Blue Diamond brush cutters are engineered for specific applications to fit different classes of machines with different power levels as well.

• Blue Diamond has parts in stock and live support to back its products.

• Blue Diamond attachments are designed to work with all equipment brands.

• Blue Diamond ships each brush cutter ready to use, versus other options on the market where additional hoses or oils are required.

“Our full line of brush cutters offer landscapers, contractors, farmers, municipalities and more the breadth and depth of attachment they need to get any job site cleared,” said Drew Truan, chief operating officer at Blue Diamond Attachments. “Our full line of cutters are compatible with most OEM machines and are supported by Blue Diamond and our extensive dealer network.”

The brush cutter attachments come with the Blue Diamond Satisfaction Guarantee, and all are backed by a 1-year warranty. For more information, visit www.bluediamondattachments.com.

(All photos courtesy of Blue Diamond Attachments.)

TRAMAC, a wholly owned subsidiary of Montabert, designs and builds stationary boom systems that pair perfectly with Montabert variable-speed breakers to productively break oversize rocks prior to primary crushing.

TRAMAC offers nine models of stationary boom assemblies for rock breakers that — depending on the model — provide horizontal reach from 14 to 65 ft., 170 to 360degrees of swing arc, and 1,500 to 13,000 ft. lb. of hammer impact. Boom weights range from 5,850 to 55,000 lb. and accommodate hammer weights from 1,098 to 9,920 lb.

Standard across its entire boom line, TRAMAC builds rugged cylinders of highstrength steel and welded construction from chrome-plated, high-tensile steel rods. Heavy-duty, oversize pins are fitted with replaceable aluminum bronze bushings.

Self-aligning spherical bushings on the cylinder rod and barrel end ensure long equipment life. An extremely strong, lowprofile base of shaped plate steel attaches easily to any platform foundation, according to the manufacturer.

Montabert photo

TRAMAC offers nine models of stationary boom assemblies for rock breakers that — depending on the model — provide horizontal reach from 14 to 65 ft., 170 to 360-degrees of swing arc, and 1,500 to 13,000 ft. lb. of hammer impact.

TRAMAC also offers a number of boom, HPU, hammer and control options, as well as custom design services. For more information, visit tramac.com and montabert.com.

The Biden administration sought to discontinue the Reagan-era waiver by directing agencies to review and reconsider waivers of general applicability.

In 1983, FHWA determined it would be in the public interest to waive Buy America requirements for manufactured products. Under the Manufactured Products General Waiver manufactured products incorporated into federal-aid projects did not need to be produced domestically.

That stood apart from predominantly iron or steel components of manufactured products.

During the Biden administration, FHWA determined the thought behind the waiver was no longer applicable. As a result, the agency proposed revising regulations to “harmonize” the Buy America program with its Build America Buy America (BABA) requirements.

In the Reagan years, FHWA concluded that manufactured products were used in insufficient quantity on highway construction projects. It was felt that the practice failed to incentivize domestic manufacturing, resulting in little benefit to applying the protections afforded under Buy America.

With BABA provisions a part of the bipartisan IIJA infrastructure law, FHWA sought to align the highway program with government-wide standards. The agency said by placing greater value on domestic manufacturing for highway construction, the new rule will encourage investment in this sector. It also will protect and expand domestic manufacturing and increase reliance on U.S.made products. Finally, it will ensure federal highway projects benefit from the broader domestic manufacturing base created by BABA for all fed programs.

“As we rebuild America’s infrastructure, we want federal highway projects to use domestically manufactured products,” said Pete Buttigieg, Biden transportation secretary.

The agency wants to see products “that create good-paying jobs and promote private sector investment and small business opportunity,” he said.

“The final rule we’re announcing today is right in line with the work … done over the past four years to boost domestic manufacturing and support livelihoods.”

This reverses decades-old policy that allowed taxpayer dollars to purchase foreign products for domestic purposes, said Gloria Shepherd, FHWA acting deputy administrator.

“American businesses now have a unique opportunity to take advantage of the broader federal government market,” she said.

But the law also added certain categories of construction materials to Buy America coverage.

The bipartisan IIJA requires federal agencies to periodically review these types of waivers. That combined with Biden’s broad tightening of domestic preference mandates moved FHWA to reconsider the waiver over two years ago.

ARTBA argued that rescinding the waiver would risk increased project costs and delays.

“Ultimately, the administration chose to prioritize its manufacturing agenda,” ARTBA said.

FHWA estimates that compliance with the new policy will cost up to $8.5 billion over the next 10 years.

From there rules for manufactured products will match those prescribed by BABA with one important exception, said law firm Crowell & Moring.

Concrete products and cabinets or other enclosures of transportation systems that incorporate steel or iron will still be separately subjected to Buy America requirements for iron and steel.

That means all manufacturing processes for the iron and steel occur in the United States.

However, iron and steel components of other manufactured products are not subject to this requirement.

Bottom line, the new rule does not change the Buy America requirements that currently apply to iron or steel products. It differentiates between products that must comply with Buy America for iron and steel and those that must comply with rules for manufactured products.

Lamenting the rising cost of construction materials since the coronavirus pandemic, last year the AGC noted that prices rose faster than contractors’ bids.

“Inflexible rules” for sourcing materials could drive up prices for federally aided projects such as highways, Ken Simonson, AGC chief economist, warned.

ARTBA and the AGC tracked the impacts of the rollback through an industry survey last year.

Some 69 percent of respondents said their bids would reflect the cost uncertainties of Buy America-compliant materials.

“This reality usually results in higher project costs and diluted benefits from federal investment,” Simonson said at the time.

“In addition, if FHWA rolls back its waiver, respondents expect significant challenges in complying with Buy America requirements,” he added.

Less than 15 percent of those surveyed thought these products would easy or possible to acquire. They listed numerous additional products that would be difficult or impossible to source without waivers.

The new rule aims to maximize use of domestically produced manufactured products permanently incorporated in federal-aid highway and bridge projects.”

The rule will be rolled out in two project obligation phases:

• For projects obligated on or after Oct. 1, 2025, final assembly of all manufactured projects must occur in the United States.

• For projects obligated on or after Oct. 1, 2026, in addition to the final assembly requirement, the cost of components of products that are mined, produced or manufactured in the United States must be greater than 55 percent of the total cost of all components of the manufactured product.

Updating its members on the final rule, ARTBA said FHWA will begin applying Buy America requirements later this year.

“Since 1983, the agency has used its waiver authority to exempt this wide array of items used on federal-aid highway projects,” said the association.

That item list includes electronics, ITS hardware, electrical equipment, signal boxes, pumps and many more.

“This action represents … likely one of the final initiatives of the outgoing Biden administration to strengthen domestic manufacturing capabilities,” said ARTBA.

As the association noted, IIJA maintained domestic requirements for iron and steel incorporated into federal-aid highway and bridge products.

“Federal officials are attempting to shut down a diversified global supply chain … before enough domestic supply exists,” said Jeffrey D. Shoaf, CEO of the AGC. “That’s a recipe for higher costs and delayed projects that will harm both the U.S. economy and highway safety.”

Under the 2025 revised rule, manufactured products will need to be assembled in the United States. And, more than 55 percent of components of those products must be made in the United States.

In analyzing the effects of the waiver rollback, Wiley Law said the extent of the impact is unclear.

FHWA recognizes if not implemented carefully, the new rule may mean “cost increases, project delays and product unavailability.”

from page 32

Forty-one girders span the southbound lanes of the freeway, stretching from the southern abutment to the median; another 41 girders span the northbound lanes. After those girders were placed, concrete was placed on top of them to construct the bridge deck.

Dave Dubois, C.A. Rasmussen’s project manager and an experienced bridge builder, is elated to be constructing a bridge for wildlife.

“Temporary support during construction of the bridge was a challenge,” he said. “One hundred board ft. of lumber was placed along with over 11,000 ¾-inch bolts to temporarily support the structure during construction.”

Dubois said the construction process is rigorous and methodical.

“We started the project by installing shoring for the abut-

ments,” he said. “Once the abutments were complete, we built the center bent consisting of 10 concrete columns varying in height from 20-25 feet. We placed 82 precast concrete girders on the abutments, with the center bent weighing 60 tons each and over 100 ft. in length. We used a 500-ton crane to set each individual girder. The concrete deck was poured with concrete pumps and a Bidwell bridge paver.”

Dubois’ management team consists of Project Engineer II Daniel Gonzales and Project Engineer I Alex Carillo.

“Self-performing much of the work has allowed us to control the schedule and impacts on the public,” Dubois said. “Since we started, there has been over 50,000 field manhours on the project. This project has utilized all trades carpenters, operators, cement masons and laborers. Some of our key subcontractors are Malcolm Drilling, Integrity Rebar, Coreslab, Comet Electric.”

Busy days have 40 C.A. Rasmussen and subcontractor employees on-site.

The amounts of excavated materials and new materials have not been finalized.

C.A. Rasmussen has a large fleet and having equipment in tip-top shape is essential for steady progress on its projects.

“C.A. Rasmussen owns and operates a large equipment fleet of over 300 pieces of iron,” Dubois said. “The majority of the earthwork fleet is made up of John Deere and Caterpillar machines, with the asphalt paving equipment being Roadtec. The project will utilize excavators, loaders, dozers and the asphalt paving spread to complete the [work].”

C.A. Rasmussen is supported by Coastline Equipment for John Deere, Quinn for Caterpillar and Hermann Equipment for Roadtec.

“Our equipment division, led by Chris Quillen, is in close contact with all our dealers to ensure we minimize downtime,” Dubois said. CEG

OEM authorized mining dealer www.coremachinery.com

Phoenix, AZ 480-545-2400 Phoenix, AZ 602-252-7121 Prescott, AZ 928-778-5621 Tucson, AZ 520-623-8681

Bakersfield, CA 661-695-4830 Mojave, CA 661-824-2319 Perris, CA 909-355-3600

*Formerly Road Machinery

www.wpi.com

12320 S. Main Street Houston, TX 77035 713-723-1050 Buffalo, TX 903-322-7150 Bryan, TX 979-314-1191 Corpus Christi, TX 361-884-8275 Edinburg, TX 956-386-0107 Kilgore, TX 903-984-2011

Lufkin TX 936-243-6056 Pflugerville, TX 512-251-0013 Port Arthur, TX 409-721-5305 San Antonio, TX 210-648-4444 Tomball, TX 281-351-9016

www.powermotivecorp.com

Corporate Office 5000 Vasquez Blvd., Denver, CO 80216 303-355-5900 Colorado Springs, CO 719-576-5541 Grand Junction, CO 970-241-1550 Milliken, CO 970-587-1188 Cheyenne, WY 307-634-5149 Durango, CO 970-259-0455 Albuquerque, NM 505-345-8383 Bloomfield, NM 505-324-8601 Carlsbad, NM 505-485-1700 El Paso, TX 915-872-1001 Chandler, AZ 602-986-3003 Phoenix, AZ 602-463-3772 Tucson, AZ 520-649-2858

www.geehm.com

5461

Oklahoma City, OK 405-495-7820 McAlester, OK 918-310-1550 Tulsa, OK 918-438-1700

Abilene, TX 325-692-6334 Amarillo, TX 806-373-2826 Dallas, TX 214-371-7777 Ft. Worth, TX 817-378-0600

Hewitt, TX 254-261-1370 Lubbock, TX 806-745-2112

TX 432-333-7000

858-278-8338

www.ncmachinery.com

800-478-7000

Anchorage, AK • 907-786-7500

Dutch Harbor, AK • 07-581-1367

Fairbanks, AK • 907-452-7251

Juneau, AK • 907-789-0181

Prudhoe Bay, AK • 907-659-6900

Wasilla, AK • 907-352-3400

85210

Elko • 775-738-9871 Reno/Sparks • 775-358-5111 NORTH

TRACTOR AND EQUIPMENT www.tractorandequipment.com

Billings, MT • 406-656-0202

Billings-Sgt. • 406-245-4426 Bozeman • 406-585-5800 Great Falls • 406-761-7900 Helena • 406-442-2990 TEXAS

409-892-8412

Bryan • 979-775-0639 El Campo • 979-543-3389 Houston • 713-460-2000

Lufkin • 936-639-5551

Kato Equipment showcases its compact loaders, excavators and crawler carriers.

Pictured here in front of the CL-35 track loader (L-R) are Ryan Donahue, Jenny Price, Bart Dehaven, Charles Baldwin and Austin Howell.

Bobcat began shipping its new B760 backhoe at the end of 2024, and it received a lot of interest at World of Concrete. Product specialist Jamison Wood was on hand to field questions about the machine.

GOMACO occupied its traditional spot in Central Hall. Among those on hand to greet customers and answer questions (L-R) are Kelly Steeves, Kyle Leners, Parker Rasmussen, Jason Wulf, Ross Biely and Michael Munoz.

WOC from page 10

More than 180 educational sessions supplied contractors, builders and companies with the skills to bring operations to the next level through business strategy and project management. Concrete fundamentals courses support those entering the workforce, while leadership courses enable participants to succeed in professional development. Experts shared insights into current industry topics such as changes in regulations, geological conditions, work force trends and growth opportunities throughout the sector. CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

Volvo Trucks North America has unveiled significant enhancements to its Blue Service Contract, a dealer-managed preventive maintenance solution designed to maximize fleet uptime and efficiency.

Powered by proprietary artificial intelligence (AI) models, the adaptive maintenance system adjusts service intervals dynamically based on factors such as fuel consumption, idle time and oil samples. This data-driven approach replaces traditional static intervals with customized and optimized schedules, ensuring the right maintenance at the right time. By consolidating services into fewer planned stops, the system maximizes uptime for customers and keeps trucks on the road longer.

The announcement was made at the American Trucking Associations’ (ATA) 2024 Management Conference & Exhibition in Nashville, Tenn.

With the highly adaptive Blue Service Contract, customers benefit with service schedule optimization, bundling services into one stop, leading to reduced operating costs. Conversely, if a truck has seen unusually demanding conditions for a prolonged period of time, the adaptive maintenance AI model will recommend service sooner, reducing the likelihood of unplanned downtime.

In both scenarios, uptime is improved, resulting in better economic outcomes for customers. Dealers proactively schedule service visits using connectivity within the Blue Service Contract, allowing customers to focus on business growth while knowing maintenance is being managed efficiently to keep trucks in peak operating condition.

These new features are enabled by Volvo Trucks’ integrated connectivity solutions, which monitor the entire truck that is connected to the 24/7 Volvo Trucks Uptime Center. This allows fleet managers and their dealers to monitor and manage trucks in near real-time. The Blue Service Contract leverages this connectivity and ensures that the service bay, technician, and all necessary Volvo genuine parts are on-hand when the truck arrives at the dealership, expediting service and returning the truck to the road quickly.

Powered by proprietary artificial intelligence (AI) models, the adaptive maintenance system adjusts service intervals dynamically based on factors such as fuel consumption, idle time and oil samples.

“There have been substantial improvements in service intervals in our products over the years. We find that many fleets are over-maintaining their trucks, which can be costly. Applying AI to optimize maintenance intervals based on truck specs, operating conditions and actual use ensures our customers can maximize the uptime of their Volvo trucks,” said Magnus Gustafson, vice president connected services, Volvo Trucks North America.

“The Blue Service Contract leverages the integrated connectivity of our trucks and incorporates our uptime services to provide customers with a simplified and more effective maintenance solution. This connectivity is a defining feature of Volvo trucks, including on the all-new VNL, the most connected truck ever built.”

This service is available throughout Volvo Trucks’ expansive dealer network, regardless of where the truck was purchased.

In addition to adaptive maintenance, the Blue Service Contract now offers increased flexibility, allowing customers to choose specific services covered under their contract. New contract service options include fuel filters, valve adjustments, pickup and delivery, truck washes, DOT inspections, additional chassis lubes, and other add-on services, providing a white glove experience for drivers and fleets. These services can be customized for individual trucks, enabling operators to create a tailored fleet management strategy that makes their job simpler and hassle-free.

The Blue Service Contract can be paid via ACH, FleetPreferred or as part of truck financing through Volvo Financial Services in fixed monthly payments with no interest expense. The Blue Service Contract is available on all Volvo trucks that are 2023 model year and newer. During launch activities for the all-new Volvo VNL, customers reported a day of downtime represented a revenue loss of between $800 and $5,000 underscoring the importance of optimized maintenance. Volvo Trucks continues to onboard dealer locations with training and sales support, to ensure they can offer the Blue Service Contract and bring all these benefits to customers. Dealer management groups such as Bruckner’s Truck & Equipment (13 locations), Vanguard Truck Centers (10 locations), Nextran Truck Centers (8 locations), Bergey’s Truck Center (6 locations), Nacarato Truck Centers (6 locations), McMahon Truck Centers (3 locations), TriState Truck Center (3 locations), Northwest Equipment Sales and others, are among the growing list of certified Blue Service Contract dealers. For more information, visit volvotrucks.us.

Volvo photo

South Texas Truck Centers accepts the Volvo Trucks North America 2024 U.S. Dealer Group of the Year award from Peter Voorhoeve, president of Volvo Trucks North America. (L-R) are Peter Voorhoeve, James Mims (South Texas Truck Centers, vice president, sales), Mike Stricker (South Texas Truck Centers, dealer principal), Edward Hernandez (South Texas Truck Centers, vice president, operations), David Bradley (South Texas Truck Centers, partner) and Scott Parten (regional vice president, Southwest Region, Volvo Trucks North America).

Volvo Trucks North America recognized the outstanding achievements of South Texas Truck Centers as the recipient of the prestigious 2024 U.S. Dealer Group of the Year award. This recognition underscores their exceptional contributions in critical areas, including sales volume, market share, investments and commitment to exemplary customer service.

The 2024 U.S. Dealer Group of the Year title was awarded to South Texas Truck Centers, a growing dealer from the southwest region. Led by dealer principal, Mike Stricker, South Texas Truck Centers’ remarkable performance includes a market share of 22 percent within its area of responsibility, nearly 104 percent parts objective achievement and significant investment in its Volvo franchise.

Its utilization of Volvo’s captive finance company, Volvo Financial Services, is evidenced by a lease line and floorplan services and more than 76 percent of its Volvo business financed through Volvo Financial Services. As a result of this strong performance and commitment to the Volvo brand, South Texas Truck Centers achieved two additional accolades: the Volvo Financial Services Dealer Group of the Year and Southwest Region Dealer Group of the Year.

“The trucking industry is demanding and the need to deliver uptime and exceptional service to our customers is the top priority for every employee at South Texas Truck Centers,” said Stricker. “We’re proud of our partnership with Volvo Trucks North America, Volvo Financial Services and the best-in-class products and services that we can bring to our customers through that partnership. But we couldn’t have won this prestigious award without all of the hardworking men and women at our South Texas Truck Centers locations who choose to deliver

excellence every day.”

When presenting the awards, Peter Voorhoeve, president, Volvo Trucks North America noted, “South Texas Truck Centers has been instrumental in enhancing Volvo Trucks’ market presence and customer satisfaction, demonstrating unwavering commitment to delivering top-notch sales and service. Given their remarkable performance in all criteria, we are thrilled to recognize South Texas Truck Centers as the 2024 U.S. Volvo Dealer Group of the Year.”

South Texas Truck Centers began Volvo operations six years ago as a single line dealer in Corpus Christi, Texas, adding locations in Pharr and Laredo shortly after. They are strong supporters of the Laredo Motor Carrier Association and Texas Trucking Association.

The winners of the U.S. Dealer Group of the Year Award were unveiled at Volvo Trucks’ recent annual awards dinner in New Orleans. The ceremony also included the recognition of regional winners, highlighting outstanding performances across the United States:

• Central Region: Kriete Truck Centers

• Northeast Region: Stykemain Trucks

• Southeast Region: General Truck Sales & Service

• Southwest Region: South Texas Truck Centers

Volvo Trucks North America will recognize its Canadian Dealer Group of the Year at an awards ceremony in Mississauga this February. This event will highlight the exceptional performance of Canadian dealers who have demonstrated excellence in sales, service, and customer satisfaction, further strengthening Volvo Trucks’ commitment to providing top-tier transport solutions across North America.