By Irwin Rapaport CEG CORRESPONDENT

On Oct. 14, 2024, Coffman Specialties Inc. started work on the California Department of Transportation’s (Caltrans) $27.5 million Interstate 215 pavement repairs project covering 6.2 mi. between the San Jacinto River Bridge and the Ramona Expressway in Perris.

That work continues and will be expanding.

The construction zone is both northbound and southbound of the bridge, with the major pavement rehabilitation expected to be completed by fall 2026. The project will refurbish the existing roads in Riverside County with new pavement, enhanced safety and improved accessibility.

“The pavement rehabilitation project will help improve safety, ride quality, reduce traffic disruption and extend pavement life. This is a meaningful investment to a growing region,” said Catalino Pining, Caltrans District 8 director. “This segment of Interstate 215 was identified through the Project Initiation Proposal Process to meet efficiency and roadway standards. The project see INTERSTATE page 38

By Lucy Perry CEG CORRESPONDENT

Unmanned aerial vehicles (UAVs), or drones, are more commonplace tools on the job site as they are growing more sophisticated in technology and application.

UAVs have proven to be a critical tool over the past couple of years in assessing site conditions before and during construction. After the project is completed, these devices are valued for monitoring pavement and structural conditions. Savings, safety, mobility and reliability are incentives for their growing use.

see DRONES page 16

2018 John Deere 310L, Stk#: HR-876, OROPS, 4WD, 780 hrs., 24" Bucket, Pilot, Controls, 12x16.5 Front Tires, 19.5Lx24 $56,500

2023 Dynapac CA30D, Stk#: HR-1489, 84" Smooth Drum, 450 hrs., 23.1x26 Tires ...... $109,500

2013 John Deere 750K LGP, Stk#: HR-13314, EROPS, A/C & Heat, Radio, 4,108 hrs., 6 Way Blade, 33" Pads, New Eng. Install at 3,800 hrs., New Rails & Sprockets, Winch, 12' 10" Wide $159,500

2019 John Deere 850K

2020 John Deere 650K LGP, Stk#: HR-1182, OROPS, 6 Way Blade, 2,385 hrs., 24" Pads, 100% U/C, 10' 4" Wide $79,500

2021 Linkbelt 145X LC, Stk#: HR-1275, EROPS, A/C & Heat, 3,582 hrs., Radio, 100% U/C, 38" Bucket, 24" Pads, Aux. Hyd. $89,500

2019 Kobelco SK210LC-10, Stk#: HR-13615, EROPS, A/C & Heat, Radio, 2,207 Hrs., 30" Bucket, 30" Tracks $109,500

2014 Cat RM300, Stk#: HR-13597, Road Claimer, OROPS, 8 ft. Mixer, 4,195 hrs., 28Lx26 Front Tires, 18.4x30 Rear Tires, Cat C11 Diesel Eng $199,500

For a company to successfully build construction and mining equipment to withstand the toughest environments on Earth, it needs veteran experts and skilled fabricators to satisfy the demands of its customers.

Contractors can purchase Trimble technology from Kirby-Smith, including the Trimble Works Subscription, which provides an entry-point, predictable monthly payment, upgrade flexibility, software and firmware maintenance and more.

Specializing in the restoration and certification of damaged cabs on heavy-duty machinery, Mano Engineering provides OSHA-compliant solutions that help businesses meet regulatory standards while maintaining operational safety.

The Yanmar attachments include a full range of buckets, augers, trenchers, stump grinders, soil conditioners, breakers, sweepers, pallet forks, brush mowers, grapple rakes, grapple buckets and snow and grading blades.

20 MONGO ATTACHMENTS EXPANDS CHOICES WITH NEW MULCHER LINE

Mongo Attachments, a leader in heavy equipment solutions, announced the launch of its new high-performance ProGrade forestry mulcher line, designed for excavators from 7,000-26,000 lbs.

24 LIEBHERR CONTRIBUTES TO SUCCESS IN ROUGH-TERRAIN SITUATIONS

With the help of two Liebherr HS 8100 HD crawler cranes, Densification Inc. completed an extensive dynamic compaction program to provide a solid foundation for a safer stretch of Utah highway along the U.S. Route 191 corridor.

30 MEYER MOVES PRODUCTION FROM CLEVELAND TO WISCONSIN FACILITY

Meyer Products has announced the relocation of its production from Cleveland, Ohio, to an Aebi Schmidt North America facility in Wisconsin. This move will better help Meyer's manufacturing efficiencies.

Hailing from County Tyrone, Northern Ireland’s “home of crushing and screening,” Omega Crushing and Screening has developed a range of plug-in, dual power, electric-drive jaw crushers.

34 HOW TO TURN RECYCLED CONCRETE INTO OPPORTUNITIES

Concrete isn’t just the backbone of modern construction — it’s also the key to its future. MB Crusher take a closer look at how to efficiently recycle concrete using its solutions.

36 METSO APPOINTS PASI KYCKLING ITS NEW CHIEF FINANCIAL OFFICER

Metso has appointed Pasi Kyckling as the company’s chief financial officer (CFO) and a member of the Metso leadership team. Kyckling will start in his role in July 2025 at the latest.

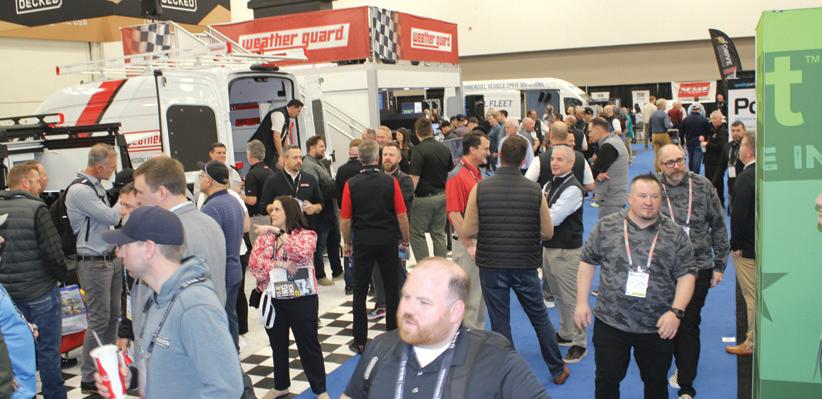

43 NTEA PRESENTS WORK TRUCK WEEK 2025 IN INDIANAPOLIS

Work Truck Week 2025 was the biggest reunion yet, bringing together a verified 16,413 industry professionals from 31 countries and all 50 U.S. states March 4-7, 2025, at the Indiana Convention Center in Indianapolis. 49 GRAHAM AUCTIONEERS HOSTS 25TH ANNUAL SALE IN ELK CITY

Graham Auctioneers held its 25th annual Oklahoma Statewide Surplus Equipment Auction March 7-8, 2025, at the Elk City Convention Center in Elk City, Okla. 52 DBIA’S STUDENT COMPETITION SHOWCASES AIRPORT EXPANSION

DBIA has officially opened registration for the 2025 National Design-Build Student Competition, offering students nationwide the opportunity to showcase their design-build expertise in a fast-paced, real-world challenge. 31 OMEGA’S ELECTRIC JAW CRUSHERS

HOW TO TURN RECYCLED CONCRETE INTO

APPOINTS

By Eric Olson CEG CONTRIBUTING EDITOR

For a company to successfully build construction and mining equipment to withstand the toughest environments on Earth, it needs veteran experts and skilled fabricators to satisfy the demands of its customers.

Hamilton Equipment Co. (HEC) is a prime example of an outfit that has used its many years of firsthand experience to create extremely durable water tanks and specialty trucks for use all over the world —from Africa to the Arctic Circle and Australia across North America to Europe.

HEC had been selling those products, along with lube trucks, fuel tankers and tank kits since the company was created in Knoxville, Tenn., in 1996 by Bill Hamilton (by then a veteran at selling these machines, along with new and used heavy equipment) and son, Ryan McGuire.

For almost three decades now, he and his son have seen their operations in eastern Tennessee grow to where they are today with two locations in Knoxville and nearby Lenoir City.

McGuire said that when they were looking to grow the business and have some stability, HEC began to concentrate heavily on manufacturing water tanks and specialty bodies with the help of other fabricators for a couple of years, an experience that he said, “turned into a nightmare.”

As a result, HEC bought another facility and started up its own fabrication shop.

“The lead times and the quality of work from other folks just could not meet our schedules, our criteria and our customer’s demands,” he said. “We got to the point where we said, ‘If we are going to be in this business, we need to have total control of it.’”

Hamilton added, though, that his company no longer produces as many lube trucks on a regular basis as it used to because of the difficulty in keeping up with demand. Instead, HEC primarily focuses its attention on water equipment.

The water tanks that HEC manufactures in 2025 generally range from 4,500-gal. units for on-road trucks, up to 18,000gal.-plus tanks for off-road vehicles with a rigid cargo body fixed on the axles, such as a mining truck.

“These tanks are not used in residential projects but in

large scale construction and mining at quarries or in the oil sands of Fort McMurray in Canada, for instance,” McGuire said.

HEC’s products are designed to fit onto the chassis of any make or model of truck, either new or used. In addition, most tanks are mated with late-model, low-hour truck chassis — like-new, but not brand-new, McGuire clarified. They also come with a three-year warranty, and the components themselves carry the manufacturer’s warranty.

“Our tanks are built to fit specific chassis, another of Hamilton Equipment’s advantages,” he added. “We don’t just fabricate a one-size-fits-all tank like other people in the business; rather, all of our tanks are custom-mated to the truck brand.”

Everything HEC does to build its equipment must achieve the company’s primary objective, according to Hamilton, which “is to make our products a lot better than everybody else. We are probably the best out there when it comes to parts and service, too. As far as the quality of the manufacturing process, we know we are the best because that’s what our customers tell us.”

“The death of a good business is growing too fast and not being able to deliver to your customers,” McGuire added. “We have had a steady, organic build, if you will, that has lasted close to 20 years. We just want [HEC] to be where we have everything in line and to our standards before we deliver our products to customers.”

NEW 2024 CAT 725

5,000 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

NEW 2024 CAT 730

6,000 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

(2) New 2024 Hydrema 922G 4x4

4,250 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

Equipment for Builds/Order

Rigid Water Tanks up to 18,000+ Gallons 4,500-6,000 Gallon Water for Tandem/6x6 Chassis, Heavy Duty Off-Road Construction

Complete NEW CAT Articulated & Rigid Builds (any size) available with HEC tanks/bodies

New Articulated and Rigid Water Tanks for all Sizes and Brands installation at our place or yours Current stock for CAT 725, CAT 730, CAT 740, CAT 773/775, Bell B30, Bell B40

Fuel, Fuel/Lube Builds available. Articulated or Rigid. Open for warm weather or Up to Arctic Level enclosed for extreme cold operation

Trimble announced Kirby-Smith Machinery Inc. as the first Trimble Technology Outlet based in the United States.

Kirby-Smith Machinery will now sell and support Trimble grade control technology directly to customers using Komatsu, Takeuchi and Hamm earthmoving equipment. Contractors can now purchase Trimble technology from Kirby-Smith, including the Trimble Works Subscription, which provides an easy entry-point, predictable monthly payment, upgrade flexibility, software and firmware maintenance and more.

Trimble Technology Outlets are a new part of Trimble’s evolved civil construction distribution strategy. By adding authorized resellers representing a wide variety of manufacturers to the Trimble distribution channel, it becomes easier for users of all machine types to purchase, install and use Trimble technology for improved jobsite productivity and profitability, according to Trimble.

“We are thrilled to announce Kirby-Smith Machinery as the first Trimble Technology Outlet in the United States,” said Ron Bisio, senior vice president, field systems of Trimble. “Across the United States and around the world, contractors who have better access to field-proven technology have a competitive advantage. Our goal is that anyone who wants to equip their machines with Trimble technology can do so easily, regardless of machine type. We look forward to working with Kirby-Smith to make this vision a reality for their customers.”

“Our customers have been requesting easier access to Trimble technology for years,” said Dennis Cox, director, smart construction of Kirby-Smith. “It’s exciting to share the news that they are now able to readily equip any of the machine types we sell with Trimble solutions. We anticipate that our customers will be as excited about the subscription purchase option as they will about the technology itself because it makes their technology investment so flexible, scalable and easy.”

Trimble’s grade control systems integrate sensors, software and automation features to help operators work more productively. From the precise positioning of buckets and other implements, to the optimization of equipment usage, Trimble technology helps improve accuracy and safety while reducing equipment

and fuel consumption, according to Trimble.

In industries where heavy equipment is essential, safety remains the top priority. Mano Engineering, in collaboration with Hurst and Henrichs MN Ltd. Structural Engineers, is at the forefront of ensuring the protection of machine operators through its Rollover Protective Structure (ROPS) and Falling Object Protective Structure (FOPS) re-certification services.

Specializing in the restoration and certification of damaged cabs on heavy-duty machinery, the company provides OSHAcompliant solutions that help businesses meet regulatory standards while maintaining operational safety.

Mano Engineering has successfully recertified equipment from leading manufacturers such as Caterpillar, Komatsu and John Deere. Its expertise and commitment to safety ensure that equipment operators remain protected from the risks associated with rollovers and falling objects, according to the company.

Replacing an entire cab can be an expensive and time-consuming process, often leading to significant equipment downtime. Re-certification is a much better way to restore structural integrity while keeping costs low and minimizing disruption to operations. Mano Engineering’s streamlined process ensures that businesses can maintain safety standards without the burden of full cab replacement.

Before and after pictures of a cab that was repaired and re-certified.

According to Mano Engineering, it follows a meticulous, fourstep process to ensure that each ROPS and FOPS system meets stringent safety regulations. These include:

• Pre-Check Evaluation — The process begins with a thorough initial assessment. Clients are required to submit images of the unit that needs re-certification. A highly experienced structural engineer carefully reviews the images to determine if re-certification is viable. If the unit is deemed repairable, the process moves to the next stage.

• Onsite Collaboration and Repairs — Once the unit is approved for re-certification, the Mano Engineering team schedules an onsite visit. Certified welding professionals conduct necessary repairs under close supervision, ensuring that all work adheres to OSHA and industry safety standards. Throughout this stage, the team provides real-time photo updates to the structural engineer for continuous monitoring.

• Engineer’s Approval and Final Inspection — Following the completion of repairs, the structural engineer rigorously evaluates the updated photos and repair work. If additional reinforcements are required, recommendations are provided to further enhance the structure’s integrity. Only after a comprehensive review does the engineer formally approve the repairs.

• Issuance of Certification and Compliance Placard — Upon final approval, the equipment receives an official metal compliance placard, signifying that it meets all required safety standards. In addition, a professional safety certificate is issued by a registered engineer, providing clients with documented proof of compliance for regulatory and operational purposes.

Understanding the urgency of equipment downtime, Mano Engineering offers express solutions, including next-day service options for clients who need rapid certification. Their mobile capabilities allow them to bring expert-level re-certification directly to job sites.

“Our process is designed to be as seamless and efficient as possible, ensuring that our clients receive safe, compliant and fully certified equipment in the shortest time frame possible,” said Dan Eldredge, sales manager of Mano Engineering. “We take pride in providing comprehensive safety solutions that allow businesses to maintain productivity without compromising on protection.”

According to the company, Mano Engineering’s reputation for delivering reliable, high-quality re-certifications has made it a trusted name in the industry. Its partnership with Hurst and Henrichs — a company with 25 years of experience — further reinforces its commitment to structural integrity and operator safety.

For companies in need of fast, onsite ROPS and FOPS re-certification, Mano Engineering offers a process backed by years of expertise and industry compliance.

For more information, contact Dan Eldredge: dan@manoengineering.com or 651/271-7747; Giridhar Addagudi, CEO: giridhar@manoengineering.com or 952/210-7209; and Prahasith (PK), engineer/inspector: pengineering@manoengineering.com or 682/386-1014.

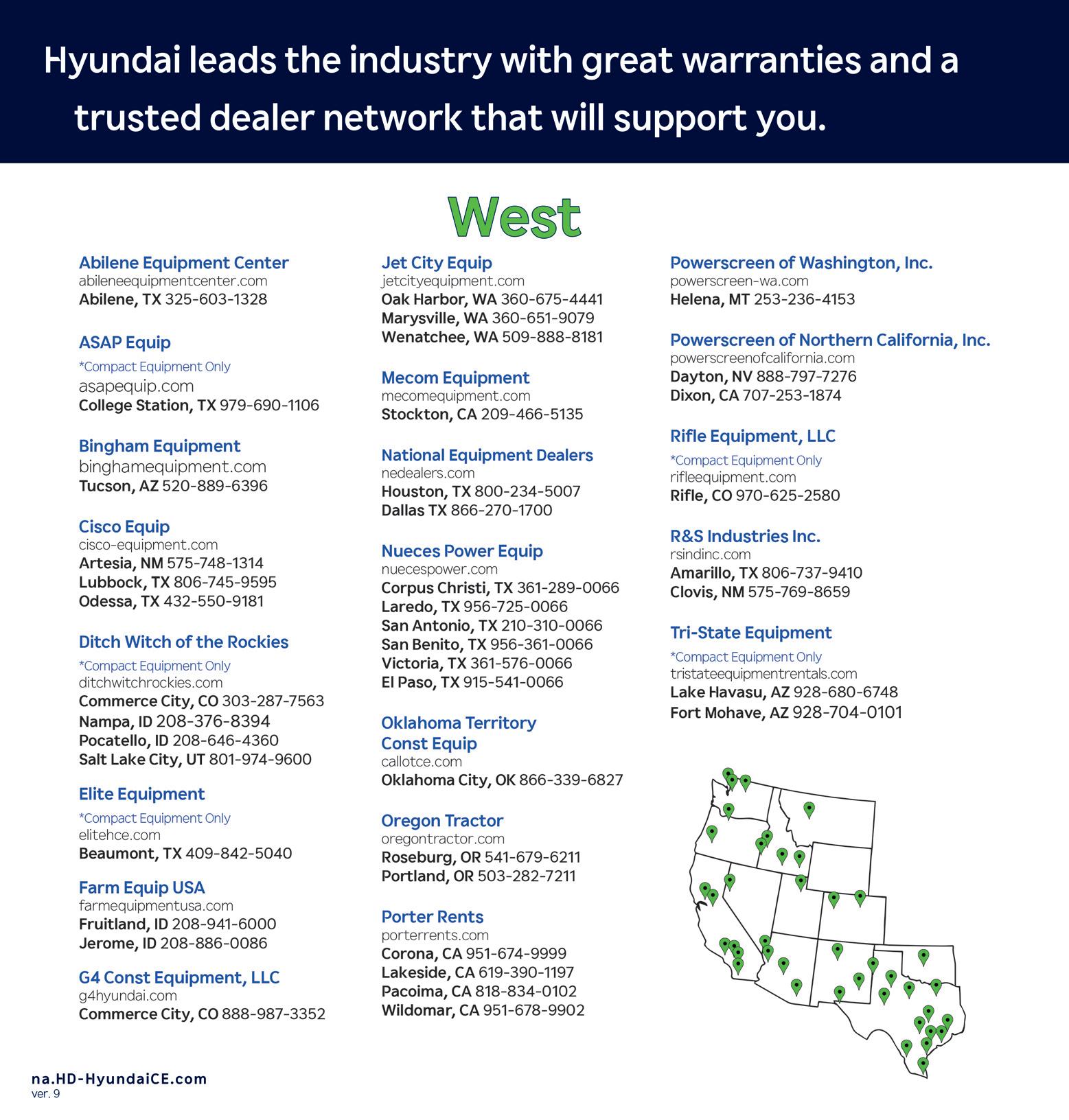

Loved for the features. Trusted for the performance.

Hyundai wheel loaders have the power and performance, not to mention top-notch interiors, accurate onboard weighing system, industry proven drivetrain durability, clear sightlines, and handy tech that make life on the jobsite easier. So you can do more without feeling it. No wonder so many first-time Hyundai users become longtime fans.

See the Hyundai difference yourself at your local dealer or na.hd-hyundaice.com.

An analysis of available information was undertaken to identify drone applications, classify benefits, address challenges and suggest potential solutions.

The authors sought to understand the current body of knowledge covering the usage of drones for roadway condition monitoring (D-RCM).

Taraneh Askarzadeh, Raj Bridgelall and Denver D. Tolliver wanted to determine how that might help address ongoing issues.

According to an ASCE abstract, the trio explored the implications for new theories, management and impacts to society that arise from D-RCM.

Cost and time savings, safety enhancements, improved mobility and reliability are the primary drivers behind D-RCM adoption, said ASCE.

Applications categories included condition monitoring, situation assessment, network mapping, asset monitoring and construction inspection. Challenges, such as visual line-of-sight maintenance, limited flight time, payload capacity and engineering errors were found.

Emerging potential solutions included terrain-following features, optimizing battery capacityweight balance and employing trained personnel.

“Importantly, the study reveals considerable cost benefits and impressive return on investment of up to 980 percent,” said the abstract.

This revelation positions drones as “a promising, cost-effective tool for infrastructure management.”

The technology has “profound implications for theory, management and societal impacts of DRCM applications.”

Aerial photography company The Drone Life would agree about the profound implications.

“With live drone feeds, multiple team members can simultaneously review construction progress, ensuring quick, tactical decision-making,” said Allred. “A single drone flight can detect errors in fine grading or equipment placement, allowing crews to make corrections immediately.”

And for more in-depth analysis, drone data can be processed with advanced software within hours, offering teams precise insights for ongoing adjustments.

Drones also serve as a valuable legal safeguard. If a safety dispute arises timestamped drone footage can verify site conditions on any given day.

“This documentation not only protects contractors from liability but also reinforces a strong commitment to site safety,” said Allred. “Ultimately, drone data helps teams catch mistakes early, reduce costly rework and keep projects on track.”

The company sees major benefits to UAV technology for road and highway construction that can be applied just as well to tracking pavement conditions.

Christian Allred believes drones are revolutionizing highway construction by offering the industry the capability to make informed decisions on projects.

In a blog post for The Drone Life, Allred said crews are able to precisely conduct site surveys, monitor earthwork progress and oversee pavement placement.

“Real-time insights from UAVs not only enhance productivity but also improve safety and reduce project costs,” he said, offering a top five benefits list:

Drones are transforming how engineers assess terrain before road construction even begins, said Allred.

With advanced aerial surveying capabilities, UAVs can capture highly accurate, subcentimeter-level data.

The data offers crucial insights into soil conditions, elevation changes and potential obstacles to improve planning and reduce unexpected construction costs.

“Before asphalt paving begins, drones ensure the ground surface aligns with design specifications,” said Allred. “They even optimize haul route planning, reducing fuel

costs and project timelines.”

Leveraging physical markers placed across the site, drones achieve survey-grade accuracy once possible with costly traditional surveying methods, he said.

2.

Drones provide real-time aerial insights that significantly enhance on-the-ground decision-making.

By hovering above a construction site, UAVs can monitor supply levels, track equipment status and identify inefficiencies. The devices offer project managers the information to reallocate materials, report damages and adjust schedules before small issues escalate into costly delays.

3.

One of the main benefits of using drone technology in road construction in general is speed.

To send an engineer on foot to collect the same data with a handheld camera can be an incredibly slow process, Allred said.

“Drones can cover large stretches of road and they can capture far more data from various angles.”

Another reason drones can collect data faster is that they are not slowed down by on-the-ground hazards, he added.

“Site material, equipment and traffic can get in the way when you’re on foot,” said Allred. “But drones can map entire corridors, problem-free, from the air.”

“In the end, road construction surveys that used to take several weeks can now be done in a matter of days with drones,” he said. “And drones can give you more frequent reports while staying incredibly cost- and time-efficient.”

4. Visual Documentation

UAVs also provide better visual documentation of each layer of the road as it is laid.

Capturing aerial drone footage of each one before moving on to the next allows you to keep a detailed visual progress record as you go, said Allred.

5. Enhanced Worker and Site Safety

“Drones play a crucial role in improving worker safety and site security,” he said. By capturing aerial data, UAVs eliminate the need for personnel to inspect hazardous areas, reducing the chance of accidents.

“Their bird’s-eye view also helps crews identify and mitigate potential dangers before they escalate,” said Allred.

Caterpillar D3 Track-Type Tractor, 1:50 scale - $110

Lattice

Bobcat 743 Skid Steer Loader,1:25

Bucyrus Erie 22B Dragline,1:50 scale ....................................................

Bucyrus Erie 22B Cable Shovel,1:50 scale

Bucyrus Erie 22B Cable Backhoe,1:50 scale

Case 580D Backhoe/Loader, 1:35 scale ................................................

Case 580E Backhoe/Loader,1:35 scale

Case 580SR Backhoe/Loader,1:50 scale

Case 850B Angle/Tilt Dozer,1:35 scale ..................................................

Case 1845B Uni-Loader,1:35 scale

Case DH4B Trencher,1:35 scale

Case 9030B Excavator,1:50 scale ............................................................

Caterpillar D6H Track-Type Tractor,1:50 scale $90

Caterpillar 953 Traxcavator,1:50 scale

Caterpillar 955L Traxcavator,1:50 scale ..................................................$60

Caterpillar 988B Wheel Loader,1:50 scale $100

Caterpillar 988F Wheel Loader,1:50 scale $100

Caterpillar C-591 Pipelayer,1:70 scale ....................................................$70

Caterpillar D9N Track-Type Tractor w/black Tracks,1:50 scale $100

Caterpillar D9N Track-Type Tractor w/yellow Tracks,1:50 scale $100

Caterpillar D8L Track-Type Tractor,1:50 scale ......................................$100

Caterpillar D7C Track-Type Tractor,1:50 scale $110

Caterpillar D10 Track-Type Tractor w/ ripper,1:50 scale $100

Caterpillar D11R Track-Type Tractor,1:50 scale ......................................$75

Caterpillar D4E Track-Type Tractor, new color,1:50 scale $60

Caterpillar D4E Track-Type Tractor, old color,1:50 scale

936 Wheel Loader,1:50 scale

Caterpillar 920 Wheel Loader, 1:50 scale ..............................................

Caterpillar 438C Backhoe/Loader,1:50 scale ..........................................

Caterpillar 225 Crane w/clamshell bucket,1:50

Massey Ferguson 516 Skid Steer Loader,1:32 scale

Hamilton is proud to say that all the steel that goes into fabricating HEC’s equipment is “U.S. prime and comes from American mills. We get some foreign made stuff because we can’t get it anywhere in the states, like a spray head component or something like that. Most all of our plate and pipe suppliers are also U.S.-based.”

He also noted, “We process every bit of it ourselves, but we don’t burn it to process the patterns anymore. We have that done by others because the machines to do it became too expensive to operate —the burn tables and all that equipment. But the rolling and breaking and pipe welding are all still accomplished by us.”

HEC also is proud of the long lifespans of its tanks and equipment.

“The first water tank that we ever built ourselves in our shop was, I think, about 18 years ago, and just a couple months ago, we got a call from the customer asking for parts for that same machine,” McGuire said. “As far as I know, we have not had a tank fail or go out of service. The vessel and its structure are overbuilt, and our components are the best we can get, but at the same time it is the simplest system we can build.”

While some of HEC’s competitors put computer systems on their tanks, which he said end up needlessly overcomplicating the product, HEC aims for making its products simple and rock-solid, which his customers really appreciate.

“A water tank is not a production machine, but it is still a high-use product,” McGuire said. “We know the various environments that it is going into, how it is going to be used and when it needs to be fixed. The tank must be one where anyone at any time can repair it to make it operate properly, and we have been successful building them that way.”

Over the years, HEC also has worked diligently to make its tanks and truck bodies easy for transport.

“Our heights are down, and we emphasize a low center of gravity to make them safer on the job,” he said. “We still cut out the fenders, and our subframes are lower than most other manufacturers in the industry for safety reasons and for transport. The tanks are usually either right at the OEM’s cab or just below it, so we don’t have height issues.”

McGuire added that operators have no need to climb on top of HEC’s tanks as the access to them is through the bottom.

“That makes the safety man on the job really happy and fulfills our desire to make our products easy and safe to use,” he said.

For the past several years, HEC has limited its manufacture of fuel lube trucks to custom builds, but a lot of that equipment ends up serving mining customers working in the Arctic and at Fort McMurray, located in northeastern Alberta.

Although the Arctic is usually described as a frozen wasteland, below its land surfaces are large quantities of oil, natural gas and various minerals, including phosphate, bauxite, iron ore, copper and nickel.

“I have been up there to the northernmost open mine in the world putting on a fuel lube body when it was 50 degrees below zero and having to sleep in a tent,” McGuire said.

As a result of the region’s often harsh conditions, he said those work sites are regarded as outstanding proving grounds for testing the durability of HEC’s products.

“We built machines to work up there in

that environment and in various applications. We saw that they could stand up and operate as they should to pump out oil when it’s 70 to 80 degrees below zero due to their being insulated and kept warm with redundant heaters.”

In addition, he said that the work sites are often full of 4- to 5-ft.-deep ruts made by huge Cat 797 mining trucks with 8- to 10-ft.-high tires that articulated trucks must drive through, meaning any fabricated bodies in use there have to withstand often punishing terrain.

“Once we saw that our products could survive those proving grounds, then we knew we had an excellent body,” McGuire said.

According to Hamilton, HEC’s parts and service business mimics what he learned many years ago working as a shop mechanic for Rozier Machinery, a Cat dealership in Tampa, Fla. While there, he took note of how hard one was expected to work to satisfy customer needs and has instilled that same ethic into his Tennessee business.

“I learned the old way that when a call came in, you took care of the customer,” he said. “At HEC, we’ve left out of here at 4 o’clock in the afternoon to fix somebody’s water truck that is three or four hours away so it could be ready for work the next morning. That’s the whole key to product support. We have young people here that know when to get in a service truck and quickly get out to where the repair is needed.”

His company does business with several Cat dealers and with James River Equipment, the latter of which recently sent some brand new 410-P 40-ton John Deere articulated dump trucks to Knoxville for HEC to fit new tanks onto for use at a massive phosphate mine located near the North Carolina coast.

“They need equipment that will run

seven days a week,” said Hamilton, “meaning we need to send a guy over there to put them in service. We have dealt with [the mine’s operators] a long time and they are a good customer.”

Training people to run its machines is another key function of HEC’s customer support.

“That is especially so with new customers,” according to McGuire. “Our people help familiarize them with the machine, demonstrate how everything works, explain how they can handle any potential issues that may come up and make ourselves available if they cannot.

“Everybody at Hamilton is accessible and that is one of our biggest strengths,” he added. “I have my phone on 24 hours a day and we have a technician that lives in Idaho, Zane Pilakowski, who does a lot of our field installs out west, and is usually accessible to customers, as is our parts and service manager, Brad Howard, located at the Lenoir City shop. If you call us, you will get hold of somebody.”

If there are issues with an HEC product in remote, far-flung locales like Australia or East Africa —places that the company’s people cannot easily reach, Hamilton said that his customers’ technicians have been fully trained by HEC’s service experts to handle any problems.

Because of its outstanding products and service over the past few decades, it is no surprise to learn that most of HEC’s success comes from repeat business, a testament to how well regarded it is among its customers.

“At the beginning of the year, we know that our order board is going to be 80 to 90 percent full of repeat business, and a lot of those customers have bought from us for 15 to 20 years,” McGuire said.

Hamilton has tremendous pride in the reputation his company has established within the construction and mining industries but gives the credit to his team of professionals, many of whom have been with him since they were young adults. Each one, he said, understands that they must adhere to HEC’s high standards in order to remain with the company.

“Some of the fabricators and welders come and go, but we pay our people well,” Hamilton said. “If they can’t do their best, they don’t stay here long — we’re not going to have it. The products that go out of here have to be the best this little family business and the people within it can make.”

For more information, visit www.hamiltonequip.com. CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

The new branded Yanmar compact track loader attachments include a full range of buckets, augers, trenchers, stump grinders, soil conditioners, breakers, sweepers, pallet forks, brush mowers, grapple rakes, grapple buckets and snow and grading blades.

Yanmar Compact Equipment has introduced a new line of branded attachments optimized for use with its compact track loaders.

The Yanmar attachments include a full range of buckets, augers, trenchers, stump grinders, soil conditioners, breakers, sweepers, pallet forks, brush mowers, grapple rakes, grapple buckets and snow and grading blades.

The introduction of the new attachments streamlines the purchasing process for fleet owners, contractors and rental centers by allowing Yanmar dealers to act as a one-stop shop for a comprehensive package of Yanmar equipment and attachments. Additionally, customers can be confident that their attachments are matched and tested to ensure maximum efficiency and performance when used with their Yanmar compact track loader.

“We’re excited to offer yet another reliable and versatile set of tools to help fleet customers and contractors be productive right out of the gate and conquer the evolving demands of any construction jobsite head-on,” said Frank Gangi, product manager — attachments, Yanmar Compact Equipment North America.

“Additionally, Yanmar customers can save time by buying their machine and attachments all from one place.”

The attachments, available through Yanmar’s dealer network, allow for seamless compatibility for use with all Yanmar-branded compact track loaders. This allows operators to simply attach the tool and get to work with the confidence to get the job done. Plus, owners have access to the same signature 24-month/2,000-hour warranty offered on Yanmar compact track loaders backed by the manufacturer’s unparalleled reliability and durability standards. This provides peace of mind with parts and support available directly from Yanmar.

In addition to offering the convenience of buying a compatible Yanmar attachment with a matching machine, the new attachment line is simple to finance. Eligible buyers can purchase a Yanmar machine through a Yanmar dealer and finance the attachment with the equipment as a bundle in one convenient package.

The new attachments will be available at Yanmar dealers alongside its full lineup of compact track loaders. Yanmar will continue to expand its attachment line to provide more versatility to its customers.

For more information, visit www.YanmarCE.com. (Photos courtesy of Yanmar Compact Equipment North America.)

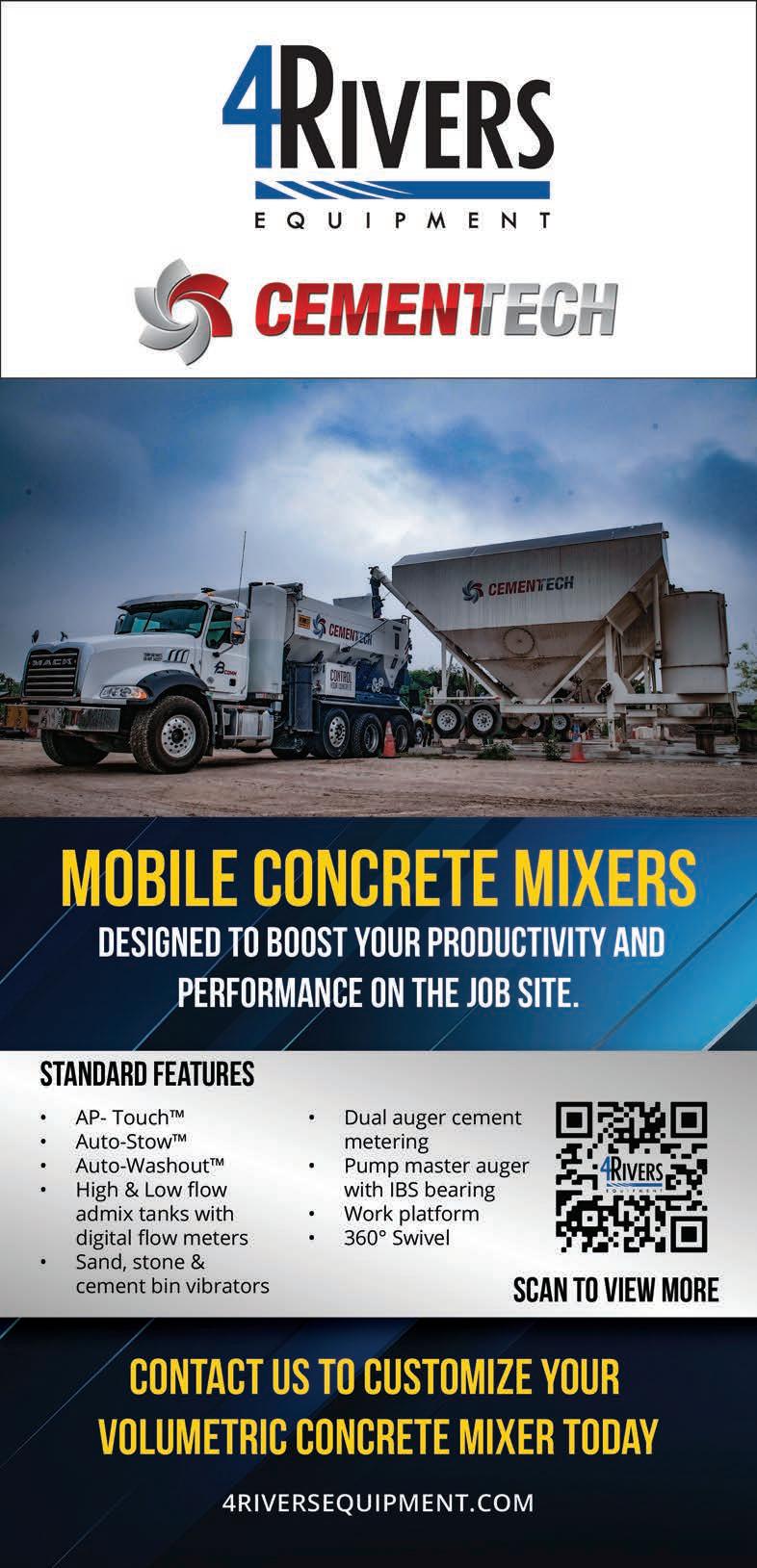

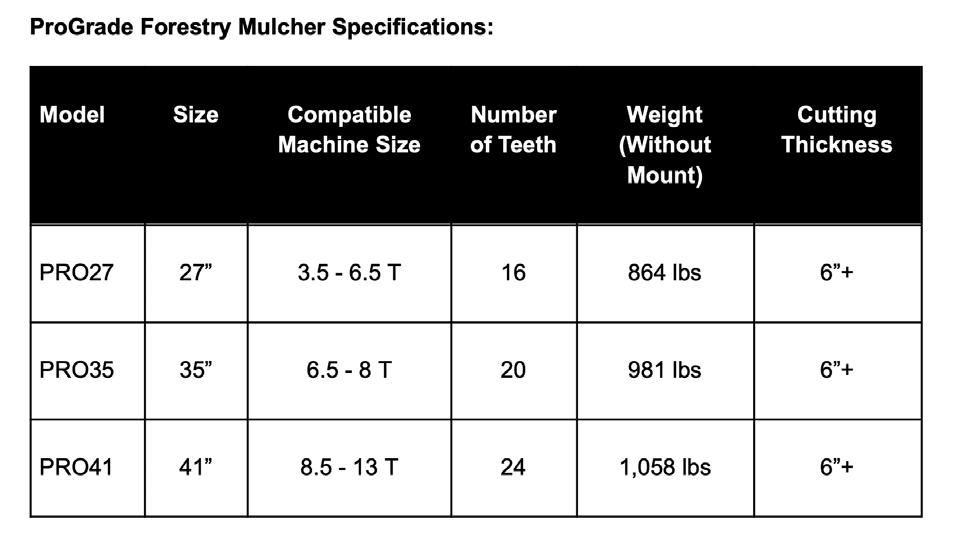

Mongo Attachments, a leader in heavy equipment solutions, announced the launch of its new high-performance ProGrade forestry mulcher line. Designed for excavators from 7,000-26,000 lbs., this line expands Mongo’s offerings and sets a new standard in land-clearing technology.

The ProGrade forestry mulchers feature an innovative bite-limiting design that maintains optimal rotor RPMs while requiring only 15-35 gpm hydraulic flow. That ensures superior performance across a range of challenging terrains and vegetation densities.

“Our new ProGrade line builds on the success of the Gen 2 forestry mulcher by addressing the evolving needs of operators tackling high-intensity projects,” said Adam Drummond, general manager of Mongo Attachments. “We’re not just expanding our product line: We’re redefining what’s possible in land clearing, while complementing our existing offers. This new addition ensures every customer has the right tool for the job, whether they need our trusted Gen 2 or the advanced capabilities of the ProGrade series.”

The ProGrade forestry mulcher delivers enhanced versatility and performance, according to the company. Its design features

non-proprietary teeth, a precision-balanced drum with access panels and an offset drum for efficient tree addressing. According to Mongo, this mulcher is built to excel in challenging environments. It features a reinforced shell for durability, a convenient kickstand, an adjustable back gate and an included mount and hose kit.

The introduction of this mulcher line reinforces Mongo’s dedication to providing comprehensive solutions for the industry. Customers can now select from a broader range of attachments, all backed by Mongo’s reputation for quality and service.

The ProGrade Mulching Head is available through authorized Mongo Attachments dealers.

For more information, email sales@mongoattachments.com or visit mongoattachments.com.

With the help of two Liebherr HS 8100 HD duty cycle crawler cranes, Densification Inc. completed an extensive dynamic compaction program to provide a solid foundation for a safer stretch of Utah highway along the U.S. Route 191 corridor.

Founded in 1994, Densification Inc. strives to provide property owners and developers with a cost-effective solution when encountering poor quality soil or fill during construction. Through the years they have become a premier dynamic compaction contractor, performing jobs across the United States and the Caribbean.

Dynamic compaction serves as an innovative and sustainable solution for soil densification and involves multi-ton weights being dropped repeatedly to create a shock wave that increases the density of the soil. Having completed more than 1,000 projects since its founding, Densification has the expertise and equipment to properly supply effective soil densification to sites across the nation due to its extensive crane fleet including multiple Liebherr HS 8100 HD duty cycle crawler cranes, according to Liebherr.

As one of the only companies in the United States using these machines for this application, Densification has seen the versatility of these machines first-hand and found a trusted partner in Liebherr.

Robert Shaffer, vice president of Densification Inc., said, “part of our decision to purchase and use Liebherr HS 8100s HDs was based on Liebherr’s reputation for durable, dependable cranes.”

Frequent drivers along U.S. Route 191 are familiar with the 2.6-mi. stretch of switchbacks located just north of Vernal, Utah. To improve this stretch of road and make it safer and more efficient for motorists and semi-trucks, the Utah Department of Transportation began the U.S.-191 Realignment Project to provide standard horizontal curves, optimize grades and eliminate switchbacks for the highway.

OEM authorized mining dealer www.coremachinery.com

Phoenix, AZ 480-545-2400

Phoenix, AZ 602-252-7121

Prescott, AZ 928-778-5621

Tucson, AZ 520-623-8681

Bakersfield, CA 661-695-4830

Mojave, CA 661-824-2319 Perris, CA 909-355-3600

*Formerly Road Machinery

www.wpi.com

The project began with the dynamic compaction of the uncontrolled embankment fill along the proposed realignment through an active sulfate mine through which the existing highway alignment traversed. Densification was brought in to perform dynamic compaction along the alignment, which was performed by two of its HS 8100 HD duty cycle crawler cranes working in tandem. The cranes used 18-ton weights dropped from a height of approximately 70 ft. for the high energy work and an 11-ton weight dropped from a 20-ft. height to complete the final ironing pass.

For dynamic compaction, HS 8100 HD key features include Liebherr’s advanced control system that lifts the drop weight to a pre-defined height and releases it in free-fall mode using both winches simultaneously. The winches brake automatically to prevent damage to the wire ropes. This process is repeated until a preset number of drops or the desired compaction depth is achieved. In addition, the operator’s cabin is equipped with armored glass to ensure the operator’s safety.

While this project was like the type of infrastructure projects Densification has been performing for decades, there was one variable that made this project different from all the others and that was the moderate slope of the site. From start to finish, there was a 500-ft. elevation change that Densification had to accommodate for to safely operate its machines.

Because of this, Liebherr created a custom load chart for the project’s unique specifications. The custom load chart provided the operators with the proper load capacities to complete the job safely and efficiently, according to Liebherr.

“We’re confident in our ability to stay on schedule and provide our clients with the best dynamic compaction solutions possible due to our HS 8100 HDs consistent performance and durability,” said Shaffer.

For more information, visit liebherr.com.

12320 S. Main Street Houston, TX 77035 713-723-1050 Buffalo, TX 903-322-7150 Bryan, TX 979-314-1191 Corpus Christi, TX 361-884-8275 Edinburg, TX 956-386-0107

Kilgore, TX 903-984-2011

Lufkin TX 936-243-6056 Pflugerville, TX 512-251-0013 Port Arthur, TX 409-721-5305 San Antonio, TX 210-648-4444 Tomball, TX 281-351-9016

Corporate Office 5000 Vasquez Blvd., Denver, CO 80216 303-355-5900 Colorado Springs, CO 719-576-5541 Grand Junction, CO 970-241-1550 Milliken, CO 970-587-1188

www.powermotivecorp.com

Cheyenne, WY 307-634-5149 Durango, CO 970-259-0455 Albuquerque, NM 505-345-8383 Bloomfield, NM 505-324-8601 Carlsbad, NM 505-485-1700

El Paso, TX 915-872-1001 Chandler, AZ 602-986-3003 Phoenix, AZ 602-463-3772 Tucson, AZ 520-649-2858

www.geehm.com

5461 S Nikita Avenue Fresno, CA 93725 559-834-3149

1164 Prestige Way Redding, CA 96003 530-229-3820

3650 Seaport Blvd. West Sacramento, CA 95691 916-375-3540

3350 Regional Parkway Santa Rosa, CA 95403 707-544-4147

45051 Industrial Drive Fremont, CA 94538 510-955-1170 NOW OPEN!!

ALASKA NC MACHINERY

www.ncmachinery.com

800-478-7000

Anchorage, AK • 907-786-7500

Dutch Harbor, AK • 07-581-1367

Fairbanks, AK • 907-452-7251

Juneau, AK • 907-789-0181

Prudhoe Bay, AK • 907-659-6900

Wasilla, AK • 907-352-3400

ARIZONA EMPIRE CAT

www.empire-cat.com 1725 S Country Club Mesa, AZ 85210 800-EMPIRE-1

CALIFORNIA HOLT OF CALIFORNIA

www.holtca.com Pleasant Grove • 916-921-8969

NEVADA EMPIRE CAT

www.empire-cat.com 3300 St. Rose Parkway, Henderson, NV 89052 702-649-8777

Elko • 775-738-9871 Reno/Sparks • 775-358-5111

NORTH DAKOTA

TRACTOR AND EQUIPMENT

www.tractorandequipment.com

Williston • 701-572-8377

WYOMING

TRACTOR AND EQUIPMENT

www.tractorandequipment.com Worland • 307-347-4747 MONTANA TRACTOR AND EQUIPMENT www.tractorandequipment.com

Billings, MT • 406-656-0202

Billings-Sgt. • 406-245-4426 Bozeman • 406-585-5800 Great Falls • 406-761-7900 Helena • 406-442-2990 TEXAS

CAT mustangcat.com Beaumont • 409-892-8412 Bryan • 979-775-0639 El Campo • 979-543-3389 Houston • 713-460-2000

• 936-639-5551

509-248-2371

1090 W 2181 N Salt Lake City, UT 84116 801-322-1300

atlasmachinery.us

6565 Smith Avenue Newark, CA 94560 510-400-5024

1535 SE 25th Street Oklahoma City, OK 73129 405-310-8700

2035 W Mountain View Road Phoenix, AZ 85021 480-463-4999

Equipmentshare.com

Meyer Products has announced the relocation of its production from Cleveland, Ohio, to an Aebi Schmidt North America facility in Wisconsin.

Meyer Products has announced the relocation of its production from Cleveland, Ohio, to an Aebi Schmidt North America facility in Wisconsin.

This move will better help Meyer's manufacturing efficiencies and support continued growth, according to Meyer.

“Beginning in April 2025, Meyer Products will operate out of the Aebi Schmidt facility in Wisconsin, which offers increased capacity and better accommodations for future growth, leading to improved product quality,” said

Meyer. “The sales and service teams will continue to operate in Cleveland, Ohio.”

“We believe this transition will enhance our manufacturing processes and better position Meyer to meet the growing demands of our customers,” said Nate Kallay, director of sales. “By consolidating production under one roof, Meyer will be able to streamline operations, improve efficiency and elevate product quality.”

For more information, visit meyerproducts.com/

Hailing from County Tyrone, Northern Ireland’s “home of crushing and screening,” Omega Crushing and Screening has developed a range of plug-in, dual power, electric-drive jaw crushers which deliver reliability, fuel savings and low/zero-emissions operation.

The Omega project was conceived when the team became aware of an interest in the market for a more simply-designed machine which contained fewer complex electronic and hydraulic components, and which would be straightforward to both operate and maintain.

While the Omega machines themselves are powered by either the mains electrical supply or an on-board generator, all of their main components also are electrically driven, such as the head and tail drums of the conveyors and the motors that run the feeders.

“Many quarry machines today have become very high-tech, whereas the user often wants a simple, user-friendly machine,” said Anthony Carlin, technical support director. “The control panel is very straightforward — there are no parameters or PLCs that you need to look at. It also uses a three-phase electrical system which is quite easy for electricians to work on.

“We have also done away with the complicated hydraulic toggle tensioning system on the crusher and gone back to the single drawback rod tensioning system. This, combined with hydraulic wedge adjustment makes it simple and reliable,” he said.

With other manufacturers now offering dieselelectric hybrid machines, Omega Crushing and Screening has chosen to take the next step in this direction and make its offering fully electric. The crushers can be plugged into the power grid and run without any diesel power input.

Alternatively, when an external power source is not available, the wheeled and tracked models share a dual-power option. This means the machines can run off an onboard 220 kVa powerpack with a Stage V/Tier 5 Deutz engine.

Among the benefits of electric power is the ability of the machine to run without producing exhaust gases.

Sales Director Colin Daly described how the clean-running crushers have found a niche with some customers in urban applications.

“As all three models in our range can run on mains elec-

tricity, all three are being used in metropolitan areas where emissions are an issue. For example, we recently sold a machine in Bulgaria. The company that bought it was going to work on a government project where particular emissions targets had to be hit. Our machine was a perfect fit as it could work on mains power and produce zero emissions,” he said.

Another strength of the Omega machines is the dramatically lower fuel consumption they offer in comparison to conventional hydraulic machines. When running on mains

electricity, fuel burn is reduced to zero. Even when using the onboard diesel generator, the J1065 range consumes fuel as low as 10 liters per hour, a saving of approximately 10-12 liters versus a similar hydraulic-drive machine.

Lastly, the electric drive is capable of operating efficiently in the world’s most extreme climates. Omega has recently completed a sale of a machine to the United Arab Emirates, where daytime temperatures can exceed 40 C and hydraulic machines can only run at night. In contrast, another Omega customer is operating a crusher in northern Norway, where lows of -20 C are experienced.

Omegas range consists of tracked, wheeled and static jaw crushers. Launching later this year, the range will now expand to include cone crushers and screens.

Omega has a strong presence worldwide and some of the major markets it currently has presence includes UK, Europe, USA and South America. Omega’s emphasis on quality and service has secured it strong relationships globally with its partners.

Omega recently won the Best in Quarry Equipment Manufacturing at the Machinery Movers Industry Awards 2024.

of

astecindustries.com

613 S. 4th Ave Mansfield, TX 76063 817-473-2110

3871 IH - 10 W. Freeway Exit 693 Columbus, TX 78934 979-732-6902

www.texasbearing.com

Portland, OR 503-252-5933 Pasco, WA 509-547-5933 Eugene, OR 541-343-6926 Albuquerque, NM 505-345-8411 Aurora, CO 303-739-3000 Bloomfield, NM 505-634-4500

Concrete isn’t just the backbone of modern construction — it’s also the key to its future.

MB Crusher take a closer look at how to efficiently recycle concrete using its solutions.

Recycling concrete isn’t just an option anymore — it’s a necessity. In many parts of the world, landfills are reaching capacity and environmental concerns are growing. In others, transportation challenges and rising costs make logistics more difficult. As the industry moves toward sustainability, the focus is shifting to smarter ways of managing concrete waste.

The solution is simple: Don’t just demolish — recycle, reuse, reinvent.

Instead of seeing used concrete as waste, look at it from a different perspective — right from the excavator cab — as MB Crusher’s attachments transform it into valuable materials for new projects.

Construction and demolition companies face increasing environmental regulations. But those who choose MB Crusher attachments have discovered a way to transform waste into a valuable resource — right on site, according to the company. Here’s how it works

• Attach an MB Crusher bucket — Compatible with any brand of excavator, MB Crusher buckets turn demolition sites into on-thespot recycling centers.

• Crush concrete — The powerful jaws break down reinforced concrete with ease, even separating iron rebars.

• Reuse material immediately — Once processed, the crushed material is ready for backfilling, road foundations or new construction projects, cutting down the need for fresh aggregates.

In short, by equipping heavy machinery with an MB Crusher attachment, operators create a closed-loop system that converts rubble into high-quality recycled aggregates, according to the company.

MB Crusher attachments are designed to work with any brand of excavator, according to the company. Plus, MB Crusher offers a wide range of units that fit carrier machines as small as 6.5 tons — turning them from simple diggers into powerful mobile crushers. Whether you’re using loaders, skid steers, mini-, midi- or large excavators, there’s an MB Crusher unit ready to get the job done.

From Demolition to Railway Infrastructure With a Large Excavator

A Liebherr 954 excavator equipped with an MB Crusher BF135.8 turned a massive pile of concrete rubble into high-quality roadbed material for a new railway project — eliminating waste and cutting costs.

Simplifying Tight-Space Logistics

A Caterpillar machine fitted with an MB BF70.2 crusher bucket effortlessly transformed concrete waste into reusable material, reducing transportation and disposal expenses.

Backhoe Loader Becomes Mobile Jaw Crusher

A JCB 3CX 8-ton backhoe loader, equipped with an MB-L160 crusher bucket, reclaimed debris from a house renovation and repurposed it into a durable driveway surface — turning waste into a functional, eco-friendly upgrade.

For more information, visit www.mbcrusher.com.

Thanks to its robust

systemcontrolthatreducestheriskofoperatinge variety of applications. The coarse screening plant locations and new operating conditions - making i range of screen linings, the MSS 802 EVO can eas

safetyTheMOBISCREE functions can be operat safety The MOBISCREE system control that redu

uces the risk of operating e

error. And all relevant

ed from a safe distance for

802 EVO - the heav

error.Andallrelevant features an intuitive t ideal for a wide ily adapt to changing design and extensive solution in natural stone

and recycling.

With the largest selection of adjustable bar grizzlys available anywhere YOU DON’T HAVE TO COMPROMISE Produce Many Products With A Single Grizzly Set the deck bar opening you need and produce the exact material required You don’t have to settle for reducer grates that only allow two sizes, usually too large or too small

• Deck Bar Adjustments In 1” Increments • New Deck Bar Attachment System • Safe / Self Cleaning ROCK RELEASE • Easy Deck Bar Replacement

Metso has appointed Pasi Kyckling as the company’s chief financial officer (CFO) and a member of the Metso leadership team. Kyckling will start in his role in July 2025 at the latest.

Kyckling holds a master’s degree in economics, and he serves as the acting CFO and group transformation officer at Stora Enso. Previously, he has held several finance, strategy and IT related leadership roles in the Biomaterials division, Group Treasury and Group Controlling at Stora Enso.

“We warmly welcome Pasi to Metso and I am convinced that his diverse experience and expertise will play a significant role in Metso’s development, growth, and value creation,” said Metso’s President and CEO Sami Takaluoma.

“I am excited about this opportunity to join Metso, which is known as a leading company in its field and has interesting opportunities ahead. I look forward to working with my new colleagues to develop not only all areas of Metso’s financial management but also the company’s strategy and future direction towards even greater suc-

cess,” said Kyckling.

As previously announced, Metso’s current CFO Eeva Sipilä will leave Metso to join another employer by April 2025 at the latest. For more information, visit www.metso.com. Metso photo Pasi Kyckling

INTERSTATE from page 1

was created to address minor distress and generalized poor ride quality of the existing roadway. ADA improvements are included to meet current standards. Worker safety elements were included to meet deficiencies.”

Roadway safety improvements include the existing mainline and ramps paving; pedestrian curb ramp upgrades; guardrail replacement with the Midwest Guardrail System; vegetation control and construction maintenance vehicle pullouts; slope stabilization and erosion control measures; and the placement of rumble strips along the inside and inside shoulders and in missing locations.

Caltrans is rehabilitating other sections of I-215, too.

“We have a $27 million pavement rehabilitation near Murrieta from just north of Clinton Keith Road to north of Newport Road,” Pining said. “This work has started, with paving expected this spring. Another $24 million pavement rehabilitation project is soon to begin [likely spring 2025] in the city of Riverside from just south of Martin Luther King Boulevard to north of Chicago Avenue. Finally, a $55 million pavement rehabilitation project in the city of Riverside from north of Ramona Expressway to Martin Luther King Jr. Boulevard is expected to begin summer 2026.”

The San Jacinto River Bridge to the Ramona Expressway project is funded through Senate Bill (SB) 1, the Road Repair and Accountability Act of 2017. SB 1 provides $5 billion in transportation funding annually split between the state and local agencies.

The project was designed by Caltrans.

“We had a design change for the material used for paving the freeway,” said Mohamad AlSheikh, resident engineer of Caltrans District 8. “We had to add areas that needed a thicker section of removing and replacing the asphalt due to bad road conditions and add extra temporary barriers for safety reasons to some locations. The lifespan of an asphalt freeway typically ranges 25 years, depending on various factors such as traffic volume, weather conditions and maintenance practices.

“Highways experience heavy loads and constant traffic, which can lead to wear and deterioration over time. Proper installation, including a well-compacted base and quality asphalt mix, is essential for longevity. Regular maintenance, such as crack sealing, resurfacing and timely repairs, can

extend the freeway’s lifespan, ensuring a smooth and safe driving experience for motorists.”

The hot-mix asphalt (HMA) is a combination of asphalt binder and aggregates heated and mixed at high temperatures, typically between 275-325 degrees F.

“This material is widely used in road construction, highways and airport runways due to its durability, flexibility and smooth riding surface,” AlSheikh said. “The key components of HMA include the asphalt binder, a petroleum-based substance that binds the aggregate together and provides water resistance. The aggregates, consisting of crushed stone, sand and gravel, give the mixture its strength and stability. Additionally, modifiers and additives, such as polymers, fibers and rejuvenators, can be included to enhance performance, increase flexibility and extend the pavement's longevity.

Flexibility is important in keeping the work moving.

“We can relocate equipment within one hour,” said Mary De La Rosa, a Coffman Specialties project manager.

For this and other work, operators are using a shuttle buggy, a Cat AP-1055D paver, a Cat 160 motor grader, BOMAG 120MG rollers, a Cat CS-563E vibratory smooth drum roller, a water truck and a skiploader.

Pedestrian curb ramp upgrades are being conducted at night. At several locations, the hot mix is laid around poles. Work has started on slope stabilization and erosion control measures.

“HMA is valued for its ability to withstand heavy traffic loads, resist water damage and provide a long-lasting pavement solution,” he said. “With proper design and maintenance, it ensures smooth and durable roadways that support transportation infrastructure efficiently.”

Coffman Specialties crews are ramping up to improve pedestrian curb ramps.

“Traffic safety is being resolved with use of K-rail barriers and lane and ramp closures in work areas,” said Carolina Rojas, Caltrans District 8 spokesperson.

I-215 has three lanes in each direction, with shoulders on the outer sides.

Pavement repairs require lane closures. An Oct. 24, 2025, night operation on the I-215 southbound ramp blocked off a section as K-rail was placed to provide crews with a safe place to work. The K-rail was shipped to the site on flatbeds and lifted to form a line.

Starting on April 1, crews will conduct asphalt paving on I-215 for 70 days over a three- to four-month period.

“The whole section is being rehabilitated through milling and the overlay of existing mainline and ramps and shoulders,” Rojas said.

“Temporary binder has been placed at the slopes,” De La Rosa said. “Once the irrigation is complete, we will do a final hydroseed. [At Ramona, Nuevo and Redlands] New plants will be installed and new irrigation lines to be installed with concrete curbs separating mulch and gravel.”

De La Rosa is assisted by Project Engineer Shane Morales and Project Superintendent Robert Nicholas.

As for subcontractors, Composite Technology International is performing the milling operations; Essential Building Services is handling the stamped concrete and the replacement of the pedestrian curb ramps; and Chrisp Co. is doing the striping.

In addition, Maneri is performing traffic control, CPE is overseeing ramp metering, Sequoia Consultants is handling quality control, DC Hubbs Construction is working on the guardrails and the Griffith Co. is performing landscaping.

Crews anticipate removing 90,000 tons of asphalt and concrete. New materials are expected to include 90,000 tons of asphalt and 300 cu. yds. of concrete.

Long hours can take a toll on equipment, and Coffman Specialties and the subcontractors said that wear and tear repairs and routine maintenance are dealt with promptly. The firms buy and rent equipment from local and regional dealerships. CEG

3100 N 1st Street Bloomfield, NM 87413 505-324-8601

4304 Monica Lane Carlsbad, NM 88220 505-485-1700

1181 Burgundy Drive El Paso, TX 79907 915-872-1001

25015 S McQueen Road Chandler, AZ 85249 602-463-3772

3300 E. Michigan Street Tucson, AZ 85714 520-649-2858

from page 16

This mitigation can result in fewer injuries, lower liability and reduced insurance costs for the contractor or the site owner.

Chris Grazioso of Dart Drones said when they first landed in construction, UAVs were used by private entities for photography, videography and mapping.

As technology grew more sophisticated, drones became the go-to tools for public entities such as state DOTs.

These agencies are “now using them more than any other public entity in the country,” said Grazioso, an instructor of the UAV training company.

State DOTs are using drones for an array of applications including bridge inspections, accident assessments, roadway surveying and risk identification.

“DOTs have many jobs, and each year they and their contractors are figuring out how to utilize drones in their projects,” Grazioso said. “Today, DOTs are paving the way for drones to be used more effectively while keeping them under safe regulations.”

North Carolina’s DOT received the firstever waiver from the FAA in 2022 to fly beyond visual line-of-site for bridge inspec-

To

ASSOCIATED GENERAL CONTRACTORS (AGC)

AGC Events Calendar:

All AGC Web-Eds are scheduled in Eastern Standard Time (EST). Conferences are scheduled using the local time zone where the event takes place.

• AGC Mental Health & Suicide Prevention Forum

Date: Wednesday, April 16, 2025 (2:00 PM) –Wednesday, April 16, 2025 (3:00 PM) Online, Virtual Safety and Health

• Focused Topics in Construction (FTC)

Dates: Monday, April 21 – Thursday, April 24, 2025 Arlington, Virginia Safety and Health

• AGC EDGE Construction Supervision Fundamentals in Spanish

Dates: Tuesday, April 22 – Thursday, May 1, 2025 Online, Virtual Training/Professional Development

• AGC of America HR Master Class Powered by Segal

A 6-Part Online Training Program

Date: Thursday, April 24, 2025 (7 AM – 5 PM) Virtual Labor and HR

• AGC Diversity & Inclusion Roundtable

Date: Tuesday, April 29, 2025 (9 AM – 5 PM) Arlington, Virginia

Other

• AGC EDGE Lean Construction Education Program, 2nd Edition (https://edge.agc.org/course/vlea250501/)

Dates: Monday, May 5, 2025 (11:00 AM) – Wednesday, May 21, 2025 (3:00 PM) Online, Virtual

tions. This expanded not only the applications but also how the drone executes these applications, including pavement condition monitoring.

Grazioso’s laundry list of UAV possible uses by state departments of transportation is extensive itself. The devices can track construction projects, traffic patterns, accident clearing, road congestion, surface deformation, flooding, landslides and rockslides.

They can be used in inspections of routine maintenance, bridge supports and decks, confined spaces, light poles, road damage and equipment condition.

For data gathering, UAVs can be used in land surveying, asset inventory and management, operational and scientific research and emergency response plans.

Grazioso pointed out that many operations conducted by DOT employees and contractors are inherently dangerous.

“The implementation of drones can reduce the risk involved in these types of operations,” he said. “The less time that employees spend in hazardous work areas, the lower the degree of risk.”

Plus, drones can reduce the risk to the public by allowing jobs to be completed faster than with traditional methods.

Training/Professional Development

• AGC of America HR Master Class Powered by Segal

A 6-Part Online Training Program

(https://www.agc.org/industry-priorities/labor-hr/hr-masterclass)

Dates: Thursday, May 15, 2025 (7:00 AM) – Thursday, May 15, 2025 (5:00 PM) Virtual. Labor and HR

Association of Women Contractors (AWC)

Our Mission

The Association of Women Contractors provides advocacy, collaboration and industry leadership to support and enrich women-owned companies in the construction industry.

AWC MEMBER MINGLE

April Member Mingle – Hosted by (The Builders Group) TBG

Date: Wednesday, April 9, 2025

Time: 3:00 PM – 5:00 PM (CST)

Venue: THE BUILDERS GROUP (TBG) 2919 EAGANDALE BLVD SUITE 100 EAGAN, MN 55121

Members can join us on Wednesday, April 9 from 3 PM to 5 PM for our April Member Mingle hosted by Associate Member (and 30th Anniversary Sponsor!) TBG (The Builders Group) at their Eagan offices.

Registration will start on Thursday, March 12 at 7:00 AM.

Registration is closed on Monday April 7 at 5:00 PM. If registration has closed and you still wish to attend, please email admin@awcmn.org.

Member Mingles are our monthly networking events. They are hosted by our members, for AWC members only.

On the second Wednesday of each month, we visit a different member’s office for two (2) hours of open-house style networking with your fellow industry professionals. For more information:

Association of Women Contractors (AWC) 1337 Saint Clair Avenue, Ste. 4 Saint Paul, MN 55105

Phone: 651/489-2221

Association of Women Contractors (AWC)

Our Mission

The Association of Women Contractors provides advocacy, collaboration and industry leadership to support and enrich

“This reduces the time a work zone is open, which in turn minimizes the number of public individuals entering,” said Grazioso.

The Minnesota Department of Transportation uses drones to inspect structures previously not inspected.

That was due to the hazards imposed by traditional methods, said Grazioso. “Drones have improved their safety margins considerably.”

These UAVs can be launched on short notice, improving both project flexibility and turnaround times.

“Minnesota DOT’s typical small unmanned aircraft system [sUAS] workflow has a turnaround time of 48 hours start to finish,” said Grazioso.

That turnaround time includes defining a flight plan, flying and post processing the data.

A standard bridge inspection uses costly inspection vehicles, ranging from $250,000 to $500,000 and requires a multi-day effort.

Minnesota DOT has calculated a 40 percent cost savings using drones, said Grazioso.

“The average cost to inspect a bridge using traditional methods was $40,800. A comparable sUAS assisted inspection costs a mere $19,900.”

women-owned companies in the construction industry. AWC MEMBER MINGLE

MAY MEMBER MINGLE – Hosted by Rock Leaf Water

Environmental

Date: Wednesday, MAY 14, 2025

Time: 3:00 PM - 5:00 PM (CST)

Venue: Rock Leaf Water Environmental 1461 94th Ln NE Blaine, MN 55449

Registration will start on Thursday, April 10 at 7:00 AM.

Registration is closed on Monday, May 12 at 5:00 PM.

If registration has closed and you still wish to attend, please email admin@awcmn.org.

Member Mingles are our monthly networking events. They are hosted by our members, for AWC members only.

On the second Wednesday of each month, we visit a different member’s office for two (2) hours of open-house style networking with your fellow industry professionals. For more information:

Association of Women Contractors (AWC) 1337 Saint Clair Avenue, Ste. 4

Saint Paul, MN 55105

Phone: 651/489-2221

Restoration Industry Association (RIA) International

Restoration Convention & Industry EXPO

Convention Dates: Monday, April 28, 2025, to Wednesday, April 30, 2025

Convention Location & Housing: The Hilton West Palm Beach 600 Okeechobee Boulevard West Palm Beach, FL 33401 USA

The Hilton West Palm Beach is directly connected to the Palm Beach County Convention Center, where the Convention & Expo will take place, via a covered walkway.

Travel

Attendees should closely monitor all travel alerts issued by the U.S. Department of Homeland Security.

Top Reasons to Attend

The Premier Event for Restoration & Reconstruction Professionals!

Join us at the International Restoration Convention & Industry Expo, the must-attend event for industry professionals looking to connect, learn and grow!

Unlock Valuable Opportunities to:

State DOTs are leveraging the use of drones because they lower risk, manpower, equipment and time in the field while raising quality of deliverables.

Drones provide access to high-resolution data “like never before,” said Grazioso.

“So, in using them, DOTs get the best of both worlds for savings and improved work.” The proof is in the data,” he said.

DOT reports show that drones save an average of between 60 percent and 70 percent on labor and hardware expenses alone.

“Time-wise, drones can do day-long jobs in an hour, bringing in even more savings,” he said, adding bridge inspections are a common example, where the savings are among the largest of any other use-case.

Once a lengthy and dangerous process, bridge inspections are done in one-eighth the amount of time with drones compared with humans or bucket trucks.

“In addition to the time savings, the use of drones does not require bridge or road closures, turning the economic impact to the lowest states have seen,” he said.

“For many DOTs, this means that the drone — as well as drone program, or the drone contractor they work with — pays for itself in savings,” added Grazioso. CEG

Network with like-minded professionals, exchanging ideas, challenges, and innovative solutions.Get informed about RIA’s latest advocacy efforts supporting the restoration industry. Explore the Expo Hall – Connect with top service partners and discover cutting-edge products to streamline operations, enhance efficiency, and drive business growth! Gain Expert Insights from industry thought leaders through impactful educational sessions.

Earn Credits from RIA & IICRC to advance your career. Don’t miss this opportunity to expand your knowledge, grow your network, and stay ahead in the restoration industry! Advocacy

Joining the Advocacy and Government Affairs movement, this effort is providing a voice for restorers.

Unity

Network with the best and brightest restorers in the industry.

Progress

Take your professional development to the next level by taking the pre-convention prerequisite training courses, designed to help you prepare for RIA’s advanced designations.

West Palm Beach, Florida

Experience the perfect blend of business and pleasure and make plans to join us in West Palm Beach in April, with endless possibilities for advancing your network and growing your business.

Situated along Florida’s sun-kissed Atlantic Coast, April offers attendees warm temperatures and refreshing ocean breezes. Creating an inviting backdrop for business and leisure activities.

Exhibitors & Sponsors

Become a sponsor and exhibitor at the only convention dedicated to the Restoration Industry that offers unparalleled opportunities to showcase your brand to a targeted audience. Badges: You must always wear your badge.

CE Credit: Earn 13 CEC by participating in the full convention. Attire: Business Casual Attire is suggested for all RIA Events. Contact us: We are happy to assist you with any questions you may have!

RIA Office Hours are Monday through Friday from 9 AM to 5 PM EST.

Feel free to Email: meetings@restorationindustry.org Call: 856/439-9222

Joel Stutheit (L), senior manager, and Tucker Perkins, president and CEO, both of Autogas Development, at the 2025 Work Truck Show. The Propane Education and Research Council (PERC) promoted the benefits of propane as a fuel source for commercial vehicles, highlighting its potential for cleaner emissions.

Chris Shallenberg of PALFINGER helped introduce the enhanced PALPRO 43 mechanics truck with new features like 52-in. compartments and a load moment indicator system.

Gilbert (L) of VMAC and Christina Arrington of Stealth Power unveil the VMAC E30 battery electricpowered rotary screw air compressor featuring 92 percent more run-time per charge.

Work Truck Week is more than a trade show — in fact, many regular attendees describe it as the commercial vehicle industry’s annual reunion. Work Truck Week 2025 was the biggest reunion yet, bringing together a verified 16,413 industry professionals from 31 countries and all 50 U.S. states March 4-7, 2025, at the Indiana Convention Center in Indianapolis.

Work Truck Show exhibit space was sold out, with 549 companies filling the exhibit hall and new Exhibitor Pavilion with the latest vehicles, equipment and technology.

Produced annually by NTEA — The Work Truck Association, Work Truck Week encompasses The Work Truck Show, Green Truck Summit, NTEA Annual Meeting, Ride & Drive, educational programs and more. It’s designed to provide industry professionals with opportunities to explore the

primarily for residential use

low profile heated lights, built and sourced in the United States.

latest trucks, trends and technology; discover new ideas; and connect with the people and companies they need to thrive. This is the third year in a row North America’s largest work truck event has set a new attendance record.

“The commercial vehicle industry certainly showed up in Indianapolis this year,” said Steve Carey, NTEA president and CEO. “With new products on every aisle, impressive engagement in educational sessions and lively networking events, we couldn’t have asked for a better week. People were excited to be there and are already actively looking forward to next year. Even before we closed the doors on Work Truck Week 2025, many company representatives were sharing their plans for product introductions and suggestions for new educational sessions at Work Truck Week 2026.”

see NTEA page 44

NTEA from page 43

Work Truck Week 2025 kicked off March 4 with Green Truck Summit, a full-day immersion into advanced commercial vehicle technology. As the industry grapples with an uncertain regulatory environment, Jennifer Brace, chief futurist of Ford Motor Company, delivered a keynote address designed to help attendees develop a framework to better prepare their operations for the future. A verified 715 participants attended Green Truck Summit sessions throughout the day.

A major draw of Work Truck Week is the ability to check out what’s new in the industry. Dozens of companies launched products, announced business relationships, celebrated milestones and showcased technology developments at this year’s event.

Attendees who wanted time behind the wheel of commercial vehicles with the latest advanced fuels and technology needed to look no further than Ride

& Drive. This unique event March 5-6 let hundreds of attendees drive or ride in 20 vehicles spanning Classes 2-8, including all-electric vans, trucks and chassis, as well as internal combustion vehicles featuring advancements to improve fuel utilization and reduce greenhouse gases or particulate matter.

Making its debut on March 6, Commercial Vehicle Data Exchange and Reception attracted professionals interested in uncovering and expanding the commercial vehicle industry’s data ecosystem. It was part of the extensive educational program focused on providing insights and strategies for enhancing operational growth. Other sessions covered industry trends, vehicle engineering and compliance, government regulations, exclusive updates from 15 chassis OEMs, workforce development, fleet management, vehicle propulsion and sustainability solutions, and more.

Attendees who purchased a Green

Truck Summit or Work Truck Week Conference Package can access ondemand educational content through April 14 by logging in to their WTW25 Planner at wtw25.mapyourshow.com/8_0/login/login.cfm and selecting on-demand.

Industry professionals caught up with colleagues and made new connections at the Opening Reception, the Generation Next Leadership Workshop and Networking Reception, the Commercial Vehicle Data Exchange and Reception and the NTEA Annual Meeting with Keynote Speaker Mike “Coach K” Krzyzewski, head men’s basketball coach of Duke University (1980-2022). Work Truck Week returns to Indiana Convention Center March 10-13, 2026. CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide, except where noted. All Rights Reserved.)

Tucson, AZ

520-579-0261 Phoenix, AZ

602-437-0351 Spokane, WA

509-536-7300

El Cajon, CA

619-448-0770

Corona, CA

800-491-9004

Ditchwitchwest.com

Lewiston, ID 208-743-0866

Snohomish, WA 360-863-2552

Richland, WA 509-578-5900

Petersandkeatts.net

nixonegli.com

WANTED (WORLDWIDE): CATERPILLAR 140K MOTOR GRADER.

EMAIL: MBUSIINGE@YAHOO.COM; PHONE: 077-791-2153

WANTED (OH): CASE 580SM2 BACKHOE LOADERS.

EMAIL:JERRY@VIOXEXCAVATING.COM; PHONE: 513-460-3315

WANTED (WORLDWIDE): VERMEER

RTX 750 / RTX8550 EQUIPPED WITH A LARGE CUTTING WHEEL.

EMAIL: RENATO.NASCIMENTO@ELEBBRE.COM

PHONE: +55 11 994602266

WANTED (KS): VERMEER TRACK TRENCHER.

EMAIL: STATELINEDIG@DIODECOM.NET

PHONE: 402-806-0073

WANTED (US): KOMATSU 270-8 WHEEL LOADERS - LOOKING FOR KOMATSU WA270 OR WA200 WHEEL LOADERS WITH THE FOLLOWING CRITERIA: HOURS: UNDER 5,000 (PREFERRED), BUT HIGHER HOURS ARE ACCEPTABLE AT A LOWER PRICE. YEAR: BETWEEN 2014 AND 2018. BUDGET: AROUND $75,000, DEPENDING ON CONDITION AND HOURS.

EMAIL: AMERICAUSEDEQUIPMENT@ GMAIL.COM

WANTED (US): LIEBHERR LTM 1220 ALL TERRAIN CRANES.

EMAIL: ILYAS.MTCPK@GMAIL.COM; PHONE: 346-484-0369

WANTED (AZ): MECALAC 10 MCR EXCAVATORS.

EMAIL FAWCETT.HOTSHOT@ GMAIL.COM; PHONE: 870-321-9572

WANTED (US): JOHN DEERE 850K LGP CRAWLER DOZER 2017-2021 ENC SIX WAY FROM USER NO HACKER MUST WITH WINCH, SMART GRADE, UNDER 1200 HOURS, MUST BE CLEAR ENC

CAB NO JUNK UNDER $75000,00CDN.

EMAIL: JEANMAURICEBOUTIN@ VIDEOTRON.CA; PHONE: 1-450-346- 8975