covering East Anglia and the Midlands

Unrivalled spreading precision!

Spreading widths of 12 to 50 metres

Capacities from 1,000 to 4,200L

Very high flow rate of up to 500kg/min

‘EMC’ regulation to adjust the left and right application rates independently

Seed depth tail 40mm deep holding the seed at correct depth and placing seed on either side of

Twin hold roll pin blade removal system and backward leaning air borne upper blade for trash lift and ease of trash flow

Seed depth tail 40mm deep holding the seed at correct depth and placing seed on either side of

Triton launched its unique deep soil engagement direct drill in 2018 to give plough based yields from direct drilling. 6 years later we are consistently achieving higher yields from the Triton than from ploughed trials on our own land. The Triton is the only all weather seed drill on the market that gives the flexibility to grow maximum profit autumn sown crops whilst reducing blackgrass from late drilling... several manufacturers are now also claiming all weather capability... if these are false claims then the farmer’s new approach will be thwarted. Twin hold roll pin blade removal system and backward leaning air borne upper blade for trash lift and ease of trash flow

Buying a blade drill is now an open and shut case. Why? Because

Avirtual reality headset is helping to keep people safe in farming – by highlighting the dangers of working without eye protection.

The Farm Safety Foundation launched its virtual reality experience at last month’s LAMMA 2025 machinery event. Visitors flocked to the charity’s stand at the NEC, Birmingham, on 15-16 January.

Scenarios

Visitors had the chance to immerse themselves in three different scenarios to highlight the importance of wearing eye protection while carrying out regular working activities in the farm.

Farm Safety Foundation Manager Stephanie Berkeley said the idea was to open visitor’s eyes to the consequences of not wearing eye protection – and demonstrate how wearing PPE would prevent a serious injury.

Editor:

Johann Tasker | T: 07967 634971

E: johann@ruralcity.co.uk

Advertising sales: Danny Lewis | T: 01502 725862

E: danny.lewis@micropress.co.uk

Advertisement production: Jade Soanes | T: 01502 725840 E: jade.soanes@micropress.co.uk

Essential Farm Machinery

published monthly for farmers and growers in the eastern counties and the Midlands. It is mailed with Anglia Farmer Midland Farmer is also available at selected farm machinery and supplies outlets.

© Countrywide Publications 2025

Published by Countrywide Publications, Fountain Way, Reydon, Suffolk IP18 6DH T: 01502 725800

Printed by Micropress Ltd, Suffolk T: 01502 725800

tion – and what could happen based

Stephanie explained: “We know that young people learn in different ways and while watching someone’s

make them appreciate the importance of PPE and help them to work smarter and safer.”

The charity worked with Northern Ireland mobile app and software development agency Sugar Rush to create three scenarios. Each offers users a

gaging the next generation of farmers and equipping them for their chosen

“For a generation raised on interactive technologies, we really believe that using virtual reality in our sessions can help encourage active engagement and contribute to driving safer behaviours in the industry.”

The only completely natural product. Stand-alone. Truly sustainable. Excellent efficacy. Sequesters carbon during growth. Flexibility of timing.

Minimal weight loss in store. Curative and preventative. No MRL.

One day withholding period. No persistent residues on crops or in stores. Approved for use on organic crops. May be used in multi-use stores.

The

choice.

• Industry shrugs off difficult times

• Positive atmosphere at NEC event

• Strong footfall and good business

Over 40,000 attendees flocked last month’s LAMMA 2025 event – the highest attendance in the show’s 40-year history.

In the wake of a challenging period, the event served as a collaborative space for community engagement, welcoming people working across agriculture to come together and consider what the future holds.

NFU president Tom Bradshaw gave an opening address on day one of the show, held on 14-15 January at the NEC Birmingham. Mr Bradshaw discussed the NFU’s ‘Stop the Family Farm Tax’ campaign to halt changes to inheritance tax.”

“If farming sneezes, the whole industry will catch a cold,” said Mr Bradshaw, emphasising the ripple effect of recent budget constraints.

“Farming is a critical part of the rural economy, and we have to educate the government about this. They have underestimated the role that a thriving food and farming industry can have on our economy.”

Above: The twoday event was the most popular yet Below: Star attractions incuded Kaleb Cooper (far right) from Clarkson’s

Shadow Defra secretary Victoria Atkins also attended the show, meeting a focus group of farmers to hear their ideas and concerns about the direction of agricultural policy.

“Part of my job is drawing a line under what has happened last year,” she explained to the group. “It’s now time for us to start with a clean sheet and work out what we need to do better and what we did well.”

Visitor numbers and the positive atmosphere saw exhibitors praise the strong footfall and valuable opportu

en Selkin said: “LAMMA is the place to be seen in the industry, and the show has been very busy and productive for us. The atmosphere has been positive with a strong community spirit.”

Kuhn UK was back at LAMMA for the first time since 2020. Managing Director Siân Pritchard explained why they decided to return: “It’s given us the opportunity to see a lot of customers, field inquiries and meet up with our dealers.”

The Demo Zone was back in action, giving visitors the chance to see machinery and equipment in action through walk arounds and demonstrations. A range of leading brands took part, including Quadfactors, Polaris,

Continued on p7

For the second year in a row, Knight Farm Machinery were awarded the 2025 Institution of Agricultural Engineers Ivel Award for Innovation of the Year for their chemical injection system Smart-Inject.

Award recipient Paul Harrison said: “We’re ecstatic, chuffed to bits. We won last year and to do it again is amazing. I’m proud of the team.”

The 2025 LAMMA Young Engineer Award was awarded to Somerset development engineer Alexander Sluijmers for Grain Sentry invention, an automated moisture control system for continuous flow grain dryers.

As part of the LAMMA Career Zone by Jobs In Agriculture, a panel hosted by Tess Howe of The Institute for Agriculture and Horticulture discussed why former armed services personnel could ease farming’s labour shortage.

People from the armed forces have a range of skills like communications, leadership and resilience. And businesses hiring military veterans don’t pay national insurance contributions in the first year of employment.

ing on a tractor.”

We’re ecstatic, chu ed to bits

In another session focussed on career opportunities in land-based sectors, Helen Martin of Bishop Burton College emphasised the importance of job seekers taking responsibility for their own development.

LAMMA will return to the NEC Birmingham on 14-15 January 2026. It will be co-located with CropTec for the first time to combine the strengths of both shows – and offer visitors a ‘one-stop shop’ for the UK arable sector.

Hugh Pearl Lane Drainage has over 60 years experience of contracting, and can supply all of your drainage and trenching requirements from design to construction.

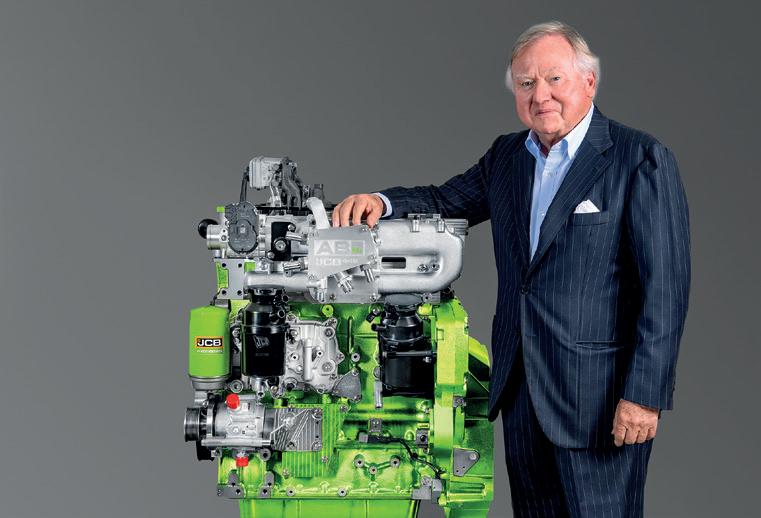

JCB says it has cleared another “significant hurdle” in the development of the company’s ground-breaking hydrogen combustion engine.

The engineering giant is the first of its kind to develop a fully working combustion engine fuelled by hydrogen. A team of 150 engineers has been working on the £100m project.

JCB confirmed that 11 licensing authorities across Europe have now given permission for JCB’s hydrogen engine to be sold across Europe – with authorities in other countries set to follow suit with certification in 2025.

It comes after JCB secured landmark rulings from the licensing authorities allowing the engine to be used commercially in a number of machines.

JCB chairman Anthony Bamford, who has led the company’s hydrogen engine project, said: JCB has proved in recent years that it is a proper zero emissions solution for construction and agricultural equipment.

“This is a very significant moment for JCB. To start the New Year with certification in place in so many European countries bodes very well for the future of hydrogen combustion technology.”

Formal approval paves the way for the sale and use of hydrogen engines right across the UK and Europe, says JCB.

Lord Bamford said: “I am delighted for our team of British engineers who have worked tirelessly to reach this stage.”

JCB has already produced more than 130 evaluation engines powering machines that include backhoe loaders, Loadall telescopic handlers and generator sets.

Weaving Machinery has introduced a redesigned tine combination drill, offering improved efficiency and adaptability for conventional farmers.

Available in 3, 4 and 6 metre working widths, the redesigned drill incorporates improvements aimed to increase productivity and ease of use.

Key features include hydraulic depth control, enabling precise adjustments directly from the cab. Coupled with an enlarged hopper capacity, operators can cover greater areas without needing frequent stops.

The drill’s electric driven metering unit and hydraulic fan ensure a consistent and accurate seed rate, while its robust design includes three rows of auto-reset tines and a double following harrow for effective seed placement and coverage.

Simon Weaving, Director of Weaving Machinery, explained: “Recent years of wet autumns have created significant challenges for farmers, increasing the demand for tine drills capable of handling challenging conditions.

The new combidrill was launched at last month’s LAMMA event

“With this redesigned combi drill, we’ve not only improved performance but also introduced a multi-fit system – his feature allows the headstock to accommodate a range of power harrows, providing greater flexibility for operators.”

The machine was showcased at last month’s LAMMA event. The two-day show saw Weaving Machinery receive the prestigious Gold Award in the British and Irish Manufacturer of

the Year category during the event’s 2025 Innovation Awards.

Simon Weaving said: “We are always looking for ways to improve the results our customers can achieve using our machinery.

“We are pleased to also announce that later this spring, a disc version of our combi drill will also be available for purchase featuring a double disc opener on a parallel linkage with a rubber closing press wheel.”

Direct drilling experts Claydon launched an addition to its range of Opti-Till crop establishment machinery at LAMMA 2025.

Two versions of the Claydon NutriSeeder are on offer for Claydon’s 7.5m straw harrow, a single 200-litre hopper with a single metering mechanism, or twin-hopper design with dual metering systems.

The latter, which allows two types of seed to be applied at the same time and mixed in the distribution head, provides higher seed capacity, more accurate metering and avoids seed separation in the hopper.

“The NutriSeeder has been designed to allow farmers to establish cover crops quickly, accurately, reliably and economically,” says sales manager David Furber.

“It has been proven on the Claydon fam-

ily’s own arable farm and will be a popular addition to our range given the increasing take up of Sustainable Farming Incentive (SFI) schemes and cover crops.”

Both NutriSeeder models incorporate a hydraulic fan and electronic control with forward speed rate mechanism.

On headlands, the NutriSeeder is started and stopped by the operator via a hydraulic cylinder, as best practice is to leave the Straw Harrow down so as not to release weed

seeds or drop clumps of straw.

Fitting different metering wheels/sections enables seed rates to be adjusted up to 30kg/ha for wheat, 15kg/ha for grass seed and 25kg/ha for cover crop mixes, at a forward speed of 15kph.

Eight spreader plates at the front of the Straw Harrow distribute seed evenly in front of the implement’s standard 14mm or optional 16mm-diameter tines which create a shallow tilth up to 30mm deep.

Four in ten farmers now use variable-rate technology for fertiliser applications and seed drilling, suggests a survey.

Carried out by agronomy company Hutchinsons, the study found that 76% of respondents are using autosteer with a smaller proportion, 21%, using variable-rate applications for spraying.

Almost half of respondents said digital technology would help them meet the growing challenges of compliance and environmental production. More than one third of re-

vestment were clear issues, pointing out for the larger farms, integration between different software was also a notable barrier to usage.

“Across the whole survey, more than one quarter cited solution integration as being important in the future,” said Mr Rainsley. “In fact, it was the number one requirement.”

In an encouraging sign, some 77% of respondents rated themselves as five or above out of 10 when it came to their confidence in using digital tech. “For

Hutchinsons believes the findings back up its strategy to support farmers with increasingly smart digital technology.

“Our decision to invest in Omnia is backed up by the survey and indeed take-up of the solution,” said Hutchinsons chairman Andrew McShane.

“We have placed significant emphasis on making the tool as easy to use as possible, ensuring farmers can have as much of their data in one place as possible through thirdparty integrations.”

Hutchinsons has also invested heavily in ensuring

Crop nutrition experts from Yara are working with potato supplier Branston to reduce the carbon footprint of the UK crop.

The partnership will see Yara provide Branston with lower carbon fertilisers as well as crop nutrition support to reduce carbon footprint and improve yield. The initiative is being trialled in Lincolnshire.

Already a buyer of Yara’s liquid and solid fertiliser products, Branston’s commitment to achieving longterm sustainability led to discussions around how the company could help them lower their carbon footprint by using lower carbon fertilisers.

Yara products YaraMila, YaraBela and YaraLiva have been lower carbon since 2006 when the fertiliser giant introduced state-of-the-art abatement technology to reduce nitrous oxide emissions.

But this is only part of the picture. Alongside supplying fertiliser products, Yara will provide Branston with comprehensive potato crop nutrition support focusing on whole plant health to improve yield.

This will involve carrying out soil and leaf testing at its Lancrop Laboratories to assess NUE and identify nutrient deficiencies and providing micronutrient products from the YaraVita range to ensure crops have everything they need.

The initiative amounts to a proofof-concept project for Yara, aimed at gathering data to demonstrate to Branston and Tesco just how much of a carbon reduction is possible with its lower carbon fertilisers.

“Introducing this holistic crop nutrition program approach will positively impact the potato crop at Branston’s by lowering carbon foot-

The goal is more sustainable potato production

prints whilst maintaining or increasing yields,” says Yara key account manager Gareth Flockhart.

“Our hope is that through this initiative, we can demonstrate that by making the switch to lower carbon fertilisers is the way to a more sustainable food system for the future.”

Branston agronomy director Mark Willcox said: “We hope innovative products like as these will be incorporated into our recipe for low carbon, or even Net Zero, potato production.”