KUHN offers a wide range of equipment that improves land preparation according to farmers’ environmental conditions.

Anew trailer-mounted separator unit has been unveiled for contractors and multi-site farms looking to improve slurry quality before application.

Manufactured by Vogelsang, the XSplit unit enables contractors to offer separation as an additional service to customers. Alternatively, it can be used on farm to separate slurry or digestate.

“The new XSplit trailer is much lighter than previous versions and will come with the option of a remote control system that can be operated using a mobile phone,” says Vogelsang’s Andy Hayhurst.

Additions include 4G-enabled remote control technology that can be linked to a phone. This is part of a new control system available on the ‘expert’ model, bringing with it greater flexibility and reliability.

“The new remote system will enable one operator to use the trailer unit more safely. For greater safety it also features two boxes, one for high and another for low voltage.”

Editor:

Johann Tasker | T: 07967 634971

E: johann@ruralcity.co.uk

Advertising sales:

Danny Lewis | T: 01502 725862

E: danny.lewis@micropress.co.uk

Advertisement production: Jade Soanes | T: 01502 725840

E: jade.soanes@micropress.co.uk

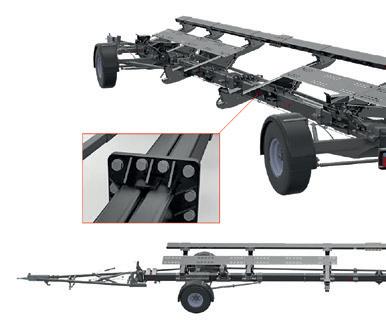

Mounted on the brand’s Pro Frame, the XSplit weighs 3.1 tonnes. It has been specially designed to sit low to the ground. This provides better stability and balance during transport as well as operation.

Essential Farm Machinery is published monthly for farmers and growers in the eastern counties and the Midlands. It is mailed with Anglia Farmer and Midland Farmer magazines and is also available at selected farm machinery and supplies outlets.

© Countrywide Publications 2024

Published by Countrywide Publications, Fountain Way, Reydon, Suffolk IP18 6DH T: 01502 725800

Printed by Micropress Ltd, Suffolk T: 01502 725800

The entire chamber is sealed with 15mm rubber discs so operators will not have to form a plug manually. Time is also saved by a quick and easy dry matter content adjustment system.

“These small but impor tant differences make the XSplit safer – especially for operators who may be unac customed to using separa tors,” says Mr Hayhurst. With the pressures farmers face, it will be a welcome so lution for farmers and contrac tors, he adds.

Andy Hayhurst: small but important differences

Via www.i-bidder.com and www.bidspotter.co.uk Opens 9am, Wednesday 9th October Closes from 9am, Wednesday 16th October VIEWING

Kuhn showcased its Multi-Leader XT plough range alongside the manufacturer’s cultivators and drills at last month’s Tillage Live event.

Organised by the Agricultural Engineers Association, Tillage-Live is the UK’s largest cultivations event focusing on crop establishment. This

year’s show took place on 18 September at Headley Hall, Tadcaster, North Yorkshire.

The Multi-Leader XT was recently updated to include Kuhn’s tilt correction system –aligning the working angle of the plough to maximise available tractor power, helping to reduce fuel use and implement wear.

The SH 600 seeding unit is a popular option for farmers requiring cost-effective cover crop establishment

A new Z-beam allows a streamlined design to accommodate a single 1,200mm x 500mm wheel, allowing operators to achieve the greatest efficiency from ploughing.

Kuhn arable product specialist Edd Fanshawe says: “The plough is still a vital tool for many farms and we are seeing some growers who previously turned away from ploughing now using one in a targeted way.”

Also working at the event was a Performer 4000, with optional SH 600 seeding unit, and a Prolander 6000 with a distribution head. These complete two jobs in one pass, helping to save time and money.

Mr Tanshaw says: “Optional seeding units have seen a lot of interest recently, with many growers entering Sustainable Farming Incentive agreements and requiring a cost-effective way to establish cover.”

The distribution head on the Prolander can be combined with a front tank, such as the TF 1512. With many growers trying to drill later, the machine offers a shallow stubble cultivator with the option to sow a crop at the same time.

Forage Harvester Spares (all makes)

Rake, Tedder & Mower Parts (all makes)

Maize Header Parts

Kemper, Claas RU/Orbis

Filter Kits for SPFH & Tractors (all makes)

Claas 492, JD7000 Series, Krone BigX 700, Plus NH FX60 feed roller assemblies & chopping units

autumn cultivations after a challenging season.

The load a tyre can carry is provided on the tolerances and gross weight provides most this relatively simple calculation can save efficiency while reducing soil compaction.

Reducing tyre pressure can reduce slip. reduces the impact of the tractor’s weight on the soil.

When pulling cultivation equipment, the weight of both implement and tractor should be calculated to establish the optimum pressure for the combined load. This will ensure both tractor and implement work to their full potential.

3. Save fuel

Red diesel prices are only going one way – and that is up. This means even small savings can become significant savings over the course of a year.

In a series of tests with Continental TractorMaster tyres, we ran a Fendt 724 Gen 6 with a Kuhn Optimer at 21 psi and 12 psi. The difference saw the slip drop from over 50% to below 10% when the pressure was lowered. This is represents a significant fuel saving across a wide area and well worth the short amount of time needed to adjust tyre pressures.

4. Ploughing

There is often a need to plough in some areas to either alleviate soil compaction or provide a suitable seedbed. Whether using an on-land or in-furrow plough, the same need for grip remains.

Self-cleaning tyre lugs will help tyres shed soil. However, more important is the choice of tyre. A narrow tyre will suit infurrow ploughing, whilst a wider tyre will be better for an on-land plough.

6. Road and field

Reducing operating pressure when transitioning from road to field will help all aspects of tractor operation, especially in soft, wet conditions.

Retrofitting a central tyre inflation system (CTIS), or making the most of an onboard OE factory-fitted air system, can provide significant improvements to grip and operating costs.

With grants available for up to 50% of the cost of a CTIS, the benefits far outweigh the investment cost.

Fendt’s Smart AG Engineering division has launched a raft of retrofit options for some of its most popular tractor models.

UK-listed options include additional hydraulic valves, retrofit side windscreen wipers, a cab-mounted MultifixBoard to attach control boxes, and a base plate to hold a trailer hitch, hand wash container or toolbox.

“Retrofit options help some of our older models remain versatile and comfortable for operators,” says Fendt retail market manager Ed Dennett. “There are some genuinely innovative options now available.”

The Fendt 200 and 300 Vario models have four hydraulic valves as standard. A front loader takes up two valves so the addition of two freely assignable hydraulic valves provides the option to use up to four valves to operate further implements.

“Both are installed in the rear yel-

low and blue valve spaces and the multi-coupler in the centre of the tractor occupies the yellow and blue valves as usual,” explains Mr Dennett.

The valves will be available towards the end of 2024 in the UK and the retrofit kit includes a cable set, piping, colour clips for the valve caps and in stallation instructions.

Additional storage to help 300 and 700 Vario customers has been de signed in the form of a base plate fit ted to the right side of the tractor. This enables a holder to be mount ed for the trailer hitch, or a hand wash container with integrated soap dispenser.

Operators can also opt to use the additional space to add a toolbox or a holder for brooms and shovels. The team has also designed a new retrofittable side windscreen wiper – helpful when using boom mowers and in poor weather conditions.

Clockwide from right: Cab-mounted Multifix Board, trailer hitch, side windscreen wipers and base plate

Pick up: Available from 3m 4m,5m 6m versions

4m to 16m available

Profits rose to £805.8 million last year at JCB, accord ing to the latest figures from the farm machinery and construction equipment manufacturer.

Global sales turnover grew to £6.5 billion – with the group maintaining a strong balance sheet with no net bor rowings throughout the year.

JCB chief executive Graeme Macdonald said: “Despite a global market for construction and agricultural machin ery which shrank by 4.3% in 2023, JCB’s sales increased by 14% to £6.5 billion.”

While UK sales remained largely flat in 2023, JCB in creased its share of the market. The full year market out look for 2024 is less positive, with challenging prospects in the UK for house-building.

Earlier this summer, the company marked the 20th birthday of its JCB Power Systems plant in Foston, Derbyshire. The facility has gone from producing three engines a day to making almost 300.

The company says the factory has become a world leader in the design, development and manufacture of diesel engines and is now leading the way with the pioneering development of hydrogen engines.

The business initially employed 20 people but has expanded its workforce to more than 400. To mark the anniversary,10 employees with a combined 200 years’ service, planted an oak tree in the grounds at Foston.

A team of more than 150 engineers at Foston are engaged in developing hi-tech hydrogen combustion engines for use in JCB machines. More than 120 engines have come off the production line so far – with more machines undergoing evaluation.

Hugh Pearl Lane Drainage has over 60 years experience of contracting, and can supply all of your drainage and trenching requirements from design to construction.

• Vintage tractor and heritage show

• Two-cylinder John Deere engines

• ‘’Exceptional’ power and economy

tage Tractor & Heritage Show.

The modern 8RX 410 may look a far cry from its 1949 ancestor, but John Deere says it is the natural successor to the Model R. A shining example of the classic machine will be at the Newark Showground on 9-10 November.

A special exhibitor class for original two-cylinder John Deere diesels has been created and will be judged at this year’s show. This will include 70, 720, 730, 80, 820 and 830 models.

Introduced in 1949, the Model R marked John Deere’s entry into the production of diesel-powered farm equipment. It continues to be a leading manufacturer of efficient diesel engines.

Between 1949 and 1954, more than 21,000 Model R tractors were produced at John Deere’s factory in Waterloo, Iowa. The rugged and dependable 6.8 litre, two-cylinder, 47 hp diesel engine was the forerunner of a range of twocylinder models famous for exceptional power delivery and economy.

tractor set the fuel efficiency record of 17.97 horsepower hours per gallon at 100% maximum load, a record not broken until 1983..

Record-breaker

From 1960 onwards, John Deere tractors were powered by three, four, six or eight-cylinder engines and still offer industry-leading efficiency.

In a recent test by Profi magazine, the 8R 410 eAutoPowr recorded the highest average in-field total fluid efficiency when compared to competitors in the 400hp-class.

While John Deere offers a range of machines powered by alternative fuels and renewable energy, diesel continues to be the most convenient, efficient, and environmentally acceptable solution for large agricultural and industrial engines.

The Newark Vintage Tractor & Heritage Show.has been running for more than 20 years and attracts 10,000 visitors to see more than 1,000 exhibits. For full details, visit www. newarkvintagetractorshow.com.

Preparations are in full swing for next year’s Tractor World Show, due to take place at the Three Counties Showground in Worcestershire on 22-23 February 2025.

The show will showcase veteran, vintage, classic and brand new trac tors – as well as Land Rovers, clas sic lorries and trucks, horticultural and gardening equipment, including classic and modern ride-on mowers.

The 2025 event has been enlarged and expanded to include all four show ground halls at the Malvern show ground. It will also feature a new vin tage autojumble, increased exhibits and other visitor attractions.

Advance online day ticket prices are £15 (adult). Under 15s free with accompanying adult. Weekend tickets are £20 (adult), £75 (three nights weekend camping for two adults). Dogs on leads are welcome, say organisers. For full details, visit www. tractorworldshow.co.uk.

Maximise nitrogen e ciency with STABUR

Stabur is a premium protected urea that meets the new rules governing the use of urea-based fertilisers. Stabur’s unique, patented coating cuts ammonia losses by up to 98% - the highest reduction available on the UK market. This means more nitrogen availability from urea for crops, optimising both yield and quality.

IS AVAILABLE EXCLUSIVELY THROUGH GLASSON

Richard Hellyer

Farm

Manager

on a 700ha heavy clay farm at Hatley St George, Bedfordshire

We purchased the Triton 6m drill in 2021 to replace heavy cultivations and reduce labour and fuel costs. The Triton has allowed us to maximise our winter wheat acreage and drop spring drilled crops from the rotation. The Triton drill has exceeded our expectations with a dramatic reduction in costs and with wheats averaging 11tha which is higher than we were getting from our previous heavy cultivation and plough system. It is true to say that the Triton will drill clay effectively in virtually any conditions and gives the confidence to drill wheat later to reduce black grass.

labour and fuel costs. The Triton has allowed us to drop spring drilled crops from the rotation. The Triton drill has exceeded our expectations with a dramatic reduction in costs and with wheats averaging 11tha which is higher than we were getting from our previous heavy cultivation and plough system. It is true to say that the Triton will drill clay effectively in virtually any conditions and gives the confidence to drill wheat later to reduce black grass.

Twin hold roll pin blade removal system and backward leaning air borne upper blade for trash lift and ease of trash flow

Twin hold roll pin blade removal system and backward leaning air borne upper blade for trash lift and ease of trash flow

Twin hold roll pin blade removal system and backward leaning air borne upper blade for trash lift and ease of trash flow

Seed depth tail 40mm deep holding the seed at correct depth and placing seed on either side of seed terrace

Seed depth tail 40mm deep holding the seed at correct depth and placing seed on either side of seed terrace

Triton launched its unique deep soil engagement direct drill in 2018 to give plough based yields from direct drilling. Six years later we are consistently achieving higher yields from the

whilst reducing blackgrass from late drilling. A number of other manufacturers are now claiming all weather capabilities – don't

Triton launched its unique deep soil engagement direct drill in 2018 to give plough based yields from direct drilling. Six years later we are consistently achieving higher yields from the Triton than from ploughed trials on our own land. The Triton is the only all weather seed drill on the market that gives the flexibility to grow maximum profit autumn sown crops whilst reducing blackgrass from late drilling. A number of other manufacturers are now claiming all weather capabilities – don't be caught out, get a demo against a Triton.

Triton launched its unique deep soil engagement direct drill in 2018 to give plough based yields from direct drilling. Six years later we are consistently achieving higher yields from the Triton than from ploughed trials on our own land. The Triton is the only all weather seed drill on the market that gives the flexibility to grow maximum profit autumn sown crops whilst reducing blackgrass from late drilling. A number of other manufacturers are now claiming all weather capabilities – don't be caught out, get a demo against a Triton.

Downward facing upper blade does not hook grass weed seed up from below stale seed bed and field surface

Downward facing upper blade does not hook grass weed seed up from below stale seed bed and field surface

Triangular tungsten tiles for reduced draught and soil disturbance

Triangular tungsten tiles for reduced draught and soil disturbance

SOIL SURFACE

SOIL SURFACE

labour and fuel costs. The Triton has allowed us to drop spring from Triton drill has exceeded our a dramatic reduction averaging which is higher than we were previous heavy cultivation plough system. is say that Triton will drill clay effectively in virtually conditions and gives the to wheat later to reduce black Abington Farm Park, Great Abington, Cambridgeshire CB21 6AX

Drilling at 40mm depth

Drilling at 40mm depth

Drilling at 40mm depth

Downward facing upper blade holds field surface

Downward facing upper blade holds field surface in place minimising soil eruption in the stale seed bed

Downward facing upper blade holds field surface in place minimising soil eruption in the stale seed bed

14cm deep lower blade takes blade deep below ground for air drainage and rooting

14cm deep lower blade takes blade deep below ground for air drainage and rooting

14cm deep lower blade takes blade deep below ground for air drainage and rooting

Triton UK: 01223 891888 (East Anglia & Midlands)

Triton UK: 01223 891888 (East Anglia & Midlands)

Triton North & Scotland: 07712 831718 (Steve) (S.T. Gowan Agri) Southern agent: 07970 549012 (Richard Peck)

Triton North & Scotland: 07712 831718 (Steve) (S.T. Gowan Agri)

Triton UK: 01223 891888 (East Anglia & Midlands) Triton North & Scotland: 07712 831718 (Steve) (S.T. Gowan Agri)

Abington Farm Park, Great Abington, Cambridgeshire CB21 6AX

Abington Farm Park, Great Abington, Cambridgeshire CB21 6AX

www.tritonseeddrills.com

(90%)

Mounted, Totally Independent Hydraulics, V4 Revolution EDS Controls, Variable Forward Reach

£29,250 +VAT