“All

Harvesting natural gas

Dairies pair with Novilla RNG to power city of Sioux Center

By Emily Breth emily.b@star-pub.com

MAURICE, Iowa — After two years of planning and construction, the West Branch project of Novilla RNG LLC has two renewable natural gas digesters in operation and is now injecting RNG into the city of Sioux Center’s lines.

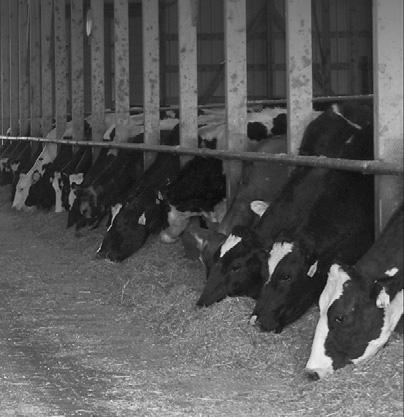

The digesters receive manure from four dairy farms. The rst is Maassen dairy, a 2,000-cow dairy operated by Aaron Maassen and partners, Adam, Stefan and Lee Maassen, near Maurice. The other three sites are operated by the Hoogland family. Two of the Hoogland dairies are located near Orange City and one is located near Maurice. There are a total of 4,500 cows milked at the Hoogland family’s three sites.

One digester is located on Maassen’s farm, which processes manure from his cows and one of the Hoogland farms. The other is located at one of the Hoogland dairies.

“I’m just happy that we’ve gotten to this point and it’s operating and producing gas,” Maassen said. “That’s exciting. I give Novilla RNG a lot of credit for following through with it and how they’ve gone through the construction phase.”

Digesters were originally used in water treatment plants. Dairies started utilizing digesters in the 1970s but became popular on dairies beginning in the 1990s. At rst the gas was used to run an engine to generate electricity. Now they have evolved into making puried renewable natural gas to power cities.

Transitioning from dad to daughters

Goedken prepares Lango Dairy for next generation

By Dan Wacker dan.w@dairystar.com

HOPKINTON, Iowa

Just off Quarter Road in Hopkinton sits Lango Dairy, a 170-cow dairy owned by Tim Goedken. The rst-generation farm was founded in 1992 as a 44-cow tiestall operation. Goedken has expanded the herd to its current size and now milks in a double-8 parabone swing parlor. He is passing the business to his daughters: twins, Sarah and Tara, and their younger sister, Courtney.

“They’ve always been involved and had their re-

Tim (from le ), Courtney, Tara and Sarah Goedken gather Dec. 18, 2024, on their farm near Hopkinton, Iowa. Goedken’s daughters have come back to the 170-cow dairy a er earning college degrees.

Mlodiks embrace dairying

By Danielle Nauman danielle.n@dairystar.com

WITTENBERG, Wis. — Andrew

Mlodik has been dairy farming his entire life, and as the fth generation on his family’s Marathon County dairy farm, he cannot imagine living his life or raising his family any other way.

Andrew milks 50 cows in a tiestall barn on the Wittenberg farm that has been in the family since 1913, shipping milk to Mullins Cheese. He farms together with his father, Arnold, who works full time off the farm with a contractor for the U.S. Postal Service. Andrew’s sister, Erin Mlodik, helps on the farm with milking.

“There is a lot of history here on the farm and in this area,” Arnold said. “We have been honored with the Century Farm Award at the state fair and by the Diocese of La Crosse and Marathon County.”

DAIRY ST R

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce) 320-248-3196 (cell) 320-352-0062 (home) Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com Editorial Staff

Stacey Smart - Assistant Editor 262-442-6666 • stacey.s@dairystar.com

Danielle Nauman - Staff Writer 608-487-1101 • danielle.n@dairystar.com

Dan Wacker - Staff Writer 608-487-3858 • dan.w@dairystar.com

Tiffany Klaphake - Staff Writer 320-352-6303 • tiffany.k@dairystar.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Emily Breth - Staff Writer emily.b@star-pub.com

Sarah Middendorf - Staff Writer sarah.m@star-pub.com

Advertising Sales Main Ofce: 320-352-6303 Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication Sales Manager - Joyce Frericks 320-352-6303 • joyce@saukherald.com

National Sales Manager - Laura Seljan (National Advertising, SE MN) 507-250-2217 • fax: 507-634-4413

laura.s@dairystar.com

Assistant Sales Manager - Kati Schafer (Northeast WI and Upper MI) 920-979-5284 • kati.s@dairystar.com

Adam McClary (SW MN, NW Iowa, SD, Nebraska) 605-951-5270 • adam.m@dairystar.com

Mike Schafer (Central, South Central MN) 320-894-7825 • mike.s@dairystar.com

Hannah Ullom (Western Wisconsin) 715-933-4045 • hannah.u@dairystar.com

Keya Sleister (Eastern IA, Southwest WI, IL) 563-608-5988 • keya.s@dairystar.com

Julia Merten (Southeast MN and Northeast IA) 507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell) bob.l@star-pub.com

Mark Klaphake (Western MN) 320-352-6303 (ofce) • 320-248-3196 (cell)

The land the farm is located on was deeded by the U.S. government to the Central Wisconsin Railroad Company in 1871. The land not needed for the railroad was sold to the Mohr-Burt Lumber Company in 1902.

In 1913 Arnold’s greatgrandparents, Mike and Mary Stroik, bought three 40s for $1,200. Everything had been logged off and the sawmill was shutting down. Mike had worked on the sawmill, sharpened blades and was the company barber.

In 1934, the second generation — Arnold’s grandparents, Henry and Laura Mlodik — purchased the farm from Laura’s parents. In 1957, the farm moved to the third generation, Arnold’s parents, Hubert and Veronica Mlodik.

“His parents never left the farm,” Andrew said. “They worked and farmed here their entire lives.”

Arnold had not planned to take over the family farm, but fate led him in that direction.

“I went to school at (University of Wisconsin)

in Stevens Point and graduated,” Arnold said. “My dad wasn’t feeling well and my mother asked for help, so I went home to help. Then my mother passed away in 1989 and I stayed to help Dad. I realized how much I actually enjoyed it.”

Throughout his farming career, Arnold has worked full time off the farm, serving 39 years in his postal contractor job.

When Hubert passed away in 2001, Arnold and his wife, Karen, decided to continue the family’s farming legacy, purchasing the farm from his siblings and raising their children on the farm.

“I have pretty much been in the barn since I was 2 months old,” Andrew said.

Arnold agreed.

“I had to go to work, Karen would milk with the kids in tow,” Arnold said.

For Andrew, continuing the family farm was never a question.

“I can’t imagine doing anything else,” Andrew said.

Erin (from le�), Karen and Arnold Mlodik stand in front of the milkhouse on their family’s dairy farm near Wi�enberg, Wisconsin. Erin helps on the farm with milking, a job Karen did for years, while Arnold worked full �me off the farm.

“This is what I have always wanted to do; I have never left and I don’t ever want to.”

Andrew and his wife, Cassie, are raising their children, Emmerson and Waylon, as the sixth generation of the family on the farm.

The Mlodiks are proud of the mark each generation of the family has left on the farm.

“All of these buildings, except one shed, were built by one generation or another of the family,” Andrew said. “(For) the machine shed, we hired a builder after our machine shed burned down. That was something we needed done quickly. Dad is the real builder; he’s built more than any other generation.”

The structures built on the farm have largely been made using lumber harvested from the farm, something

both men are proud of.

The Mlodiks farm 400 acres of owned and rented ground to grow corn, oats and hay to feed the herd, which is mostly Holsteins and a few Fleckviehs. Andrew has been building a small Angus cow-calf herd for diversication.

The Mlodiks make small squares of hay that are feed in the barn and grind feed from cob corn. The cows get grain, silage, haylage and mineral in the barn. The family green chops during the summer.

The Mlodiks do all their own eldwork, Andrew said, adding that he has several good friends who are available to help when extra hands are needed.

The cows spend as much time outside as weather permits, Andrew said, which he credits for the herd’s longevity.

“We’ve got a lot of cows that are 8

or 9 years old,” Andrew said. “Getting them outside and off concrete is important to me.”

The Mlodiks use bulls for breeding. The cows are with a Holstein bull four months of the year and an Angus bull the remainder of the year. The heifers are with a Holstein bull the entire year.

“With so many older cows, we don’t typically need a lot of heifers as replacements,” Andrew said.

The secret to being successful is keeping things simple, both Arnold and Andrew agreed.

“We’re kind of dinosaurs, the way we do things,” Arnold said. “But it works; we’re still here.”

Over the years the Mlodiks have watched the dairy industry dwindle in their corner of Marathon County.

“There used to be 30 or more farms in the township, but now there are just a couple,” Arnold said.

Keeping his family’s long-standing dairy farming tradition vibrant is important to Andrew, and he plans to continue by keeping things simple and paying attention to the details that matter.

“I don’t want to milk more than 50 cows,” Andrew said. “If I can’t make it on 50 cows by myself, I’m not going to make it on 200 cows.”

Con nued from MAASSEN | Page 1

Mark Hill, co-CEO of Novilla RNG, said the West Branch project has been operating smoothly since they started it last fall. Novilla RNG has been around for three years and is run by Hill and Jared Williams.

Novilla RNG is currently in the process of building ve more RNG sites. The rst step taken is going out to the farm to understand how the producer handles manure so they know what they will need to make it successful.

The company has four operating systems and partnerships with nine dairy farms. The latest partnership is the dairies of the West Branch project.

“In December 2024, 99% of the time we were injecting gas into the pipeline to Sioux Center,” Hill said. “It takes a couple of months to get the digester warmed up and get the bugs right in there that are eating the manure and releasing the biogas.”

The pipeline and gas are closely monitored by Novilla RNG and people in Sioux Center. Hill said they have fewer emissions with the methane gas collected from the digesters than normal geological gas.

As production goes into full swing, the digesters will be producing over 140,000 million British thermal units a year. The natural gas captured by these digesters is utilized to power the digesters themselves and the excess is brought to Sioux Center with the use of a six-inch natural gas pipeline. According to the U.S. Department of Energy, a household will average 77 million Btu a year, meaning the digesters could provide natural gas to around 2,000 homes.

“I think the biggest positive right now is the size and scope of the project between multi-sites and all the different things that had to come together to make it work,” Maassen said.

The day-to-day operations of the RNG digesters are fully operated by

employees of Novilla RNG who communicate with the dairies so they can make adjustments to ensure the proper functioning of the digesters.

“The (start-up has) been smooth,” Maassen said “There’s some adjustments about water that needs to be added to help the sand get cleaned (out of the manure). It’s just a day-today operation of maintaining the bacteria and digester.”

At the dairies, most of the water from the manure is drained out and gets cycled back to the dairy to be reused to remove sand from the manure. In Maassen’s case, this is used to charge his sand settling lane.

“We’ve always had a sand lane, so essentially, they just rerouted the ow from the end of the sand lane into their facility to dewater it and separate the solids out to go into the digester.”

Once the digested manure, called digestate, is returned to the farm, the farmers can utilize it in the manner they always have. There are several positives of using digestate.

“One of the big benets at the farms is we help reduce odors that would be coming out of the lagoon because … the manure goes to the lagoon and sits there and in the summer months it will get hot and release gas and some of those gasses can be smelly,” Hill said.

The digestate also offers more plant-available nutrients since it has already been digested once.

Hill said the project has come together due to the cooperation of everyone involved.

“It has been great working with the city of Sioux Center,” Hill said “It is neat when you have a local community looking at unconventional ways of getting gas through their lines. Our project would not have happened if we were not able to work cooperatively with Sioux Center.”

Con nued from GOEDKEN | Page 1 sponsibilities on the farm, so I hoped that one day maybe one of them would come back,” Tim said. “Even when they were at college, they kept showing interest in what I was doing. My rst thought when they wanted to come back (was that) I was relieved.”

Sarah graduated from Northeast Iowa Community College with a degree in dairy and animal science. Tara graduated from Kirkwood Community College with a degree in agriculture business. After college, Sarah dove in full time on the farm, and Tara split time at Lango Dairy and Vermazen Tax Service in Manchester. Courtney graduated from Kirkwood Community College in May with an agriculture business degree. She also returned to farm with her dad and sisters while working off the farm at Triangle Agri Services in Monticello.

Sarah has taken on the herdsman role. Tara works with calves, milks and uses her accounting background to keep farm records. Courtney works primarily with the calves and milks, while assisting Sarah where needed. Tim still handles the feeding and crops.

Sarah and her sisters realize the opportunity that is in front of them.

“It’s very benecial for us to have a place we can come back and start working at,” Sarah said. “It was nice to get away, learn and meet new people and now come back. It’s a little crazy that we’re doing this, and have this opportunity at 22 and 21 years old. It’s very humbling and we’re proud of where we come from. That’s why we want to come back and work here again.”

The sisters bring with them new ideas and practices they have picked up along the way. With new ideas comes new challenges and a growing level of trust between an experienced generation, and one eager to implement change.

“You don’t want to switch things up too fast,” Tim said. “Its tough to transition away from things that have worked, but maybe weren’t as efcient.”

One of the rst changes the sisters made was applying for a Choose Iowa Grant. Lango Dairy used that grant to purchase a Milk Taxi to complete the new calf barn addition that was started in 2023. They also used the grant to purchase Alta Cow Watch collars. Bringing in new technology to the farm was something the younger Goedkens

wanted to implement as soon as they could.

“Before the taxi and the collars, the idea of technology like that coming to the farm was a bit foreign,” Sarah said. “We would have tried to work towards it, but Tara put in the work to ll out the application and I can’t see us ever going without it again.”

Tim is gaining condence in the plans of his daughters.

“It’s tough to try and let go, but I trust them,” Tim said. “They are the future, so I’m a lot better at trusting them now than I used to be.”

Along with learning to trust have come opportunities to further educate and learn from decisions that were not as successful as projected.

“If we do something different than what we’ve done in the past and it fails, it becomes a teaching moment,” Sarah said. “We learn from it so we can be better. If we change something and it does well, good. But if it doesn’t do as well, we can learn from it and do better next time.”

That eagerness to learn from each other is an important aspect of the working relation-ship between the father and his daughters. It also has led to a better understanding of how to work with one another.

“Sometimes we can butt heads, but that’s when we realize how important communication is,” Tara said. “We’ve done things a certain way for a long time, and if you’re trying to change that, you need to communicate why you think your way is going to improve on what we’re doing.”

What brought the sisters back to the farm was the connection with each other and the farm. That especially rang true for the twins.

“When we rst went to school and split up, it wasn’t easy being away from the farm or each other,” Tara said. “You had to go out in your own world. It was hard to be away. We always enjoyed each other and being outside together, so I always hoped we could come back and work the farm together.”

For Tim, the girls came at just the right time.

“I got pretty burnt out there when the girls were all in college,” Tim said. “I was trying to do it all on my own with some help from some high school workers, and it became exhausting. To have them back here, I can’t explain what it means to me.”

24/7 ACCESS TO FRESH FEED

Don’t just push feed, remix it with DeLaval OptiDuo™. Instead of compressing feed, we remix it - making it much more appetizing for cows. Ideal for farms operating a onceper-day feeding frequency.

DAIRY ST R★

is published the second and fourth Saturdays of the

Advertising and news deadline is 5 p.m. the Friday before

From camping to crafting

Schlender, Peter of Never Rest Dairy reach out to community

By Stacey Smart stacey.s@dairystar.com

WATERTOWN, Wis. — Ashley Schlender and Olivia Peter are combining talents to educate and entertain members of their community. With a dose of creativity and a dash of imagination, the pair is zeroing in on camps and crafts, welcoming children through adults to Never Rest Dairy LLC.

“We’re in ag, we love ag, but sometimes ag can be hard,” Schlender said. “There’s a lot of volatility. This is something positive to focus on, and it’s neat to see the farm through other people’s eyes.”

Peter agreed.

“This helps us share the fun aspects of farming,” she said. “It reminds us of those aspects and allows us to share it with the community.”

Schlender and her husband, Troy, and their sons, Trent and Duke, milk between 230-240 cows with four DeLaval robots and farm 365 acres near Watertown while also operating a custom harvesting business. Peter is the herd

manager and has been part of the team for over ve years.

Looking for ways to diversify is a constant at Never Rest Dairy. After attending a University of Wisconsin-Extension women’s conference a year ago and listening to speakers talk about diversication, Schlender and Peter put their heads together and brainstormed possibilities.

“We came back with lots of ideas,” Schlender said.

It did not take long to put their ideas into action. Last summer, Never Rest Dairy offered its rst farm camps. The one-day camp held from 8 a.m. — 2 p.m. provided an opportunity to show kids where food comes from, learn the daily operations of a dairy, play games and make food, such as ice cream.

“I was super pleased with the rst camp we had,” Schlender said. “It was great.”

The community got behind their endeavor, and the farm received support in the form of sponsorships.

Ashley Schlender (le�) and Olivia Peter hold up a farm camp Tshirt Jan. 2 in the freestall barn at Never Rest Dairy near Watertown, Wisconsin. In addi�on to milking 240 cows and farming 365 acres, Schlender and her family and Peter began offering farm camps and cra� workshops last year.

to milk a cow, water a calf and cover a pretend bunker.

“Everyone loves the calves,” Peter said. “We try to let them feed a calf and see what we do on a daily basis. We harvest our own crops, so we also have equipment for the kids to climb on, and we let them honk the horn — they love that.”

Campers go home with a goody bag that includes recipes for making butter and ice cream and a trail mix labeled “TMR mix.” Part of the camp involves showing kids the different ingredients in a total mixed ration and explaining how feed is measured.

Schlender and Peter are looking to expand camp offerings next year. A family farm camp that allows parents to stay and learn with their children is an addition they would like to make.

“A lot of parents said they were interested in staying,” Peter said.

“We had signicant support from area businesses, including those we work with day in and day out,” Schlender said. “We need to educate youth. It’s so important. And hopefully, the kids go back and teach their parents too.”

The camp is targeted at children in third to fth grade and designed to accommodate 15 kids.

“This is a robotic dairy,

which is interesting for them to see,” Peter said. “I think robots are going to pull a slightly different crowd. It’s a little niche we have for our farm camp.”

One of the camp events is the Farmer for a Day Relay in which each camper pretends

Last summer, they hosted two camps in July and August with some of the same kids attending both camps. Schlender and Peter also worked in partnership with their local 4-H and did a bonus half-day Clo-

Turn

verbud camp for younger kids in kindergarten to second grade.

“We try to do different things at each camp so if someone wants to return, there will be new things to do,” Peter said.

Camp headquarters are located in a meeting and event space upstairs in the robot barn. Kids eat lunch there but spend most of their time doing activities around the farm.

“The kids like taking turns looking out the viewing window,” Peter said. “It’s very popular. It’s fun to see a bird’s-eye view of the cows.”

This year, all camps were held during the week, but next year, Schlender and Peter would like to host one camp on a weekend day as well. They are hoping to double the number of camps held in 2025 and offer a total of four or ve.

Schlender said they advertise on Facebook and have found social media and word of mouth to be the best promoters of their camps. Kids traveled from up to an hour away to attend camp, and there was also a child in attendance who was visiting from Florida.

In addition to farm camp, Schlender and Peter also started Cows and Crafts. These on-farm workshops are focused on craft projects, such as making greeting cards. Schlender

Ashley Schlender uses stamping products to make gree�ng card templates Jan. 2 at Never Rest Dairy near Watertown, Wisconsin. Schlender hosted her rst Cows and Cra�s workshop in the barn’s event space in November 2024 and has another cardmaking workshop scheduled for Jan. 25.

to

about di

erent types

held her rst card making workshop last November where attendees made truck-themed and coffee-themed cards using stamping products.

“I offer the class and a simple meal,” Schlender said. “I’ve done these classes for a while out of my house, but it’s hard because there’s

no separate space. This has been great having a setup in the barn.”

Schlender’s next workshop is scheduled for Jan. 25 where the focus will be on making greeting cards that feature cows. In the future, Schlender hopes to offer other workshops for hat burning and rustic sign making.

“Hat burning is super popular, and I’m working on leads for having guest people host workshops here,” she said.

Schlender would also like to rent the space for parties.

“We hosted a kid’s birthday party here,” she said. “I led a craft project, and they toured the farm. I also have a bachelorette party idea to do a craft, drink wine and see the cows.”

Schlender said the craft classes and camps are about exposure and getting people on a farm.

“It’s nice to know we’re having an impact in the community,” she said. “This is some-what nancially driven, but it will take time to build. Meanwhile, we’re creating steppingstones for protability in the future.”

Schlender’s husband has ideas too and would like to open an onfarm store this year to sell beef and pork. Furthermore, Schlender and Peter would like to host more on-farm events, such as “Cookies and Cows” at Christmastime. The ladies envision inviting families to decorate sugar cookies and take pictures with the cows.

“I want to host activities that engage the whole family,” Schlender said.

Farm and fun collide at Never Rest Dairy where the team continually looks to add value to their operation as they share it with others.

“We are proud of what we accomplished in one year,” Schlender said.

“We began looking at a bottle washer to keep bottles cleaner and eliminate an extra job. After seeing the option to purchase the bottle washer and pasteurizer combination, we started to look at its benefits. Once we calculated what we would save by not buying bags of milk replacers, it was an easy decision to add the pasteurizer. Since installing the new system of the bottle washer and pasteurizer combination the calves drink better and are healthier.”

H5N1 surveillance impacts all dairy farmers

The U.S. Department of Agriculture has established a goal of eradicating the H5N1 virus from the U.S. dairy herd. Lucas Sjostrom, a member of the government affairs team for Edge Cooperative, admits this is a new endeavor. “Dairy farmers (and) our poultry industry would all love this disease not to be affecting us, but what’s the best and most effective way to do that?” That’s where we’re trying to help our processors and our farmers gure out what is the most effective way to get to that goal.” Ultimately, Sjostrom said it is important to preserve the dairy industry’s export markets. “I hope dairy farmers realize whether you ship to the cheese plant down the road or one that’s shipping to Mexico every single day, this affects our milk price no matter who you are and where you are.”

Additional states added for milk testing

that we did, a consistency of commitment to very critically important respon-sibilities and missions of USDA.” Vilsack’s legacy has been the focus on small and medium-sized farms.

Wisconsin Farms Union awards presented

By Don Wick Columnist Ag Insider

USDA has announced the second round of states participating in its National Milk Testing Strategy. Seven states were added to the 13 original states being tested. The agriculture department requires raw unpasteurized milk samples to be tested for the H5N1 virus. At this point, Minnesota is not part of the surveillance effort.

High beef cattle prices inuencing dairy markets

The rebuilding of the U.S. beef herd remains nonexistent. USDA Chief Economist Seth Meyer says that is also being felt in the dairy market. “On the dairy side, protability has been good over the last year, but the ability to expand and respond to any protability has been hampered by that same contraction in the beef herd. It has made beef-dairy crosses for dairy heifers protable as well, so we may be a little short on the purebred dairy heifers needed to expand the herd.”

Farm bill future

The Wisconsin Farmers Union has presented its Friend of the Family Farmer Award to Randy Romanski and Zach Ducheneaux. Romanski is the secretary of the Wisconsin Department of Agriculture, Trade and Consumer Protection. Ducheneaux has been the administrator of USDA’s Farm Service Agency.

Olson retires

AgCountry Farm Credit Services Senior Vice President of Government and Public Affairs Howard Olson retired at the end of the year. Olson had been with AgCountry for 27 years.

Farm Credit Council selects Seyfert

The Farm Credit Council has named Christy Seyfert as its president and chief executive ofcer. Seyfert is now the executive director of government affairs for the American Soybean Association. She will begin her new role in mid-January.

Farm Credit Administration names Mosely for Ofce of Congressional and Public Affairs

Ben Mosely is the Farm Credit Administration’s Ofce of Congressional and Public Affairs director. Most recently, Mosely was a principal at a government affairs group known as the Majority Group. Previously, Mosely worked for the USA Rice Federation and on the Senate Agriculture Committee staff.

New leadership for Holstein USA

The new Congress is in place and a new farm bill will be on the radar. “We’ve been kicking the can down the road for quite some time,” said Sam Kieffer, vice president of public policy, American Farm Bureau. “The 2018 farm bill technically expired two years ago and here we are still operating under shortterm extensions.” Kieffer believes Minnesota Senator Amy Klobuchar and Minnesota Representative Angie Craig will help move a modernized farm bill forward. Klobuchar is the new ranking member of the Senate Agriculture Committee and Craig is the new ranking member on the House Ag Committee.

Lindsey Worden is the new CEO for Holstein Association USA. Worden has been with Holstein USA for 17 years, starting as a college intern. After college, Worden joined the organization as its public relations specialist. She later served as the communications manager, the executive director of the Holstein genetic services department and chief operating ofcer. Worden succeeds John Meyer, who was with Holstein USA for 23 years.

New Department of Natural Resources secretary appointed

• The highest air ow in a circulation fan - 33,900 CFM.

• Cast aluminum blades have a lifetime warranty.

• Totally enclosed maintenance free, high ef ciency motors have a full two year warranty. Model VP CA:

Disaster relief payment rates updated

Ahead of the Christmas holiday, Congress passed a funding bill to avert a government shutdown, extended the farm bill for another year and provided farmers with economic assistance. Green Solutions Group farm management analyst Kent Thiesse said the 2025 economic outlook pushed Congress to action. “There was a survey about a month ago of ag lenders and 80% of them either said we were in a recession or headed toward a recession in 2025.” Disaster relief payment rates also received an update. “This will be based on actual planted acres in 2024 as reported to FSA ofces and for farmers that maybe have preventive planted acres, half of those acres would also count.”

USDA boosts support for organic dairy producers

USDA is allocating an extra $8.7 million to help organic dairy farmers offset rising costs and market instability. The money is part of the Organic Dairy Marketing Assistance program for 2024. This brings the total funding for the program to over $31 million. Payments will be based on 2023 or projected 2024 marketing costs.

The only three-term agriculture secretary Agriculture Secretary Tom Vilsack has served 12 years in that role, longer than any other person. Vilsack led USDA during the Obama and Biden administrations. “I’m just extraordinarily proud of the work

Effective Jan. 27, Dr. Karen Hyun will take over leadership of the Wisconsin Department of Natural Resources. Most recently, Hyun served as chief of staff for the National Oceanic and Atmospheric Administration. Governor Tony Evers announced the appointment.

Wisconsin dairy farm, Packers featured in new movie

A movie with a focus on the Green Bay Packers and a Wisconsin dairy farming family will be released at the end of the month. “Green and Gold” is set in the 1990s with a dairy farmer trying to save the family farm by betting on the Packers to win the Super Bowl. The movie was lmed in Wisconsin and made possible thanks to a partnership between the Packers and Culvers’ “Thank You Farmers Project.” The movie stars Craig T. Nelson, whose resume includes the “Coach” and the “Young Sheldon” television series.

Trivia challenge

The tradition of leaving milk and cookies for Santa Claus began during the Great Depression in the 1930s. That answers our last trivia question. For this week’s trivia, who served as Jimmy Carter’s agriculture secretary? We’ll have the answer in our next edition of the Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network of Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

Dairy Star’s digital review

Listed below are the most popular stories published on our website in 2024

1.

A shock to the system

Total views: 35,930

First-generation dairy farmers Dylan and Bryanna Handel had an unexpected halt in their dream. One evening they went to milk cows and their normally docile cows were acting strange. Low and behold there was stray voltage on the farm from a new substation nearby. This caused the cows to rise in somatic cell count, drop in milk production, abort calves and become unhealthy. After working with the electrical company, the voltage was reduced but the health problems were not. The couple is still trying to nd a solution to this problem.

2.

A cruel twist of fate

Total views: 22,612

Lexi Anderson, an avid Jersey showman from Cumberland, Wisconsin, was playing basketball one minute and the next she was unexpectedly diagnosed with a rare heart disease and added to the heart transplant list. Lexi was experiencing symptoms during a basketball game so her parents, Jamie and Tamala Anderson, made a doctor’s appointment. During that appointment, an electrocardiogram revealed that Lexi had restrictive cardiomyopathy. Even with the disease, Lexi was still able to show dairy and sheep at the Barron County Fair in Wisconsin. She hoped to be able to show at the Minnesota State Fair and World Dairy Expo as well.

5.

Deer, bear, elk wreak havoc

Total views: 4,505

Wildlife animals caused damage for many farmers in the north woods of Wisconsin. Mike Robers, a Sawyer County dairy farmer, and Dale and Connor Beissel, of Winter, experienced deer and bear damage rsthand. Farmers can enroll in a Wildlife Damage Abatement and Claims Program, but the program does not cover the full extent of damages. With the program, farmers must meet specic criteria. According to Robers and Dale, farmers are capped at $10,000 for crop damage reimbursement.

Starting from scratch

Total views: 3,442

Following their passion has allowed brothers Justin and Jared Roberts to expand their dairy and start selling milk near Cataract, Wisconsin. In 2017 their mom, Kelly Merow, decided to sell the herd. The brothers took that time to gain experience on a larger farm. Four years ago, their goal to dairy farm became a reality. They purchased ve heifers, milking them in an old pig barn with a show pump. Then, Justin purchased a site with a building they could renovate, and they are now milking their 17 cows in a 20-stall tiestall barn with four box stalls.

Koesters focus on genetics to achieve high production

Total views: 3,226

Dan and Amber Koester along with their children — Lance, Kyle, Brent and Bria — as well as Lance’s wife, Cynthia milk 400 cows near Dakota, Illinois. The cows are housed in a 6-row sand-bedded freestall barn and milked in a double-12 parlor. The farm currently milks three times a day and has a herd average of 35,493 pounds of milk. Their cows are dry for seven weeks and housed in the freestall barn. The herd’s somatic cell count averages between 100,000-150,000. The Koesters are currently using SenseHub activity monitors to provide health and reproduction alerts.

3. 4.

Growing from the ground up

Total views: 6,897

Growing up as a crop farmer but having a passion for dairy cows led Corey Metcalf to grow his dairy herd. Corey farms near Milton, Wisconsin, with his wife, Kristen, his parents, Terry and Jane, and help from his sister, Lauren. The family was able to double their herd within six years and now milks 750 cows. They built the barn with cow comfort in mind. Creating cows that are well-balanced and long-lasting is a goal for Corey.

42-year dairy career comes to a close

Total views: 4,694

After 42 years of milking cows, Richard and Sara Larson of Alma Center, Wisconsin, decided to sell their 26cow herd in April 2024. Richard’s dairy farming career began when he was 16 years old and decided to purchase the farm July 8, 1981. Richard and Sara were married in 1995 and a couple of years later the herd grew to 50 cows, which they were milking with Jon, Richards’s brother, at his farm. Through some unexpected health events with Jon, the Larsons ultimately renovated their barn and started milking their herd separately again.

6. 7.

Her favorite place to be

Total views: 4,437

As if one herd wasn’t enough, Madalyn Nielsen, of Lake Mills, Wisconsin, manages two herds — farm A and farm B. Nielsen has known she wanted to farm since she was 3 years old. Farm A has 65 cows housed in a tiestall barn and milked by six units. At Farm B, 80 cows are housed in sand-bedded free stalls and milked in a 52-stall stanchion barn. Nielsen strives to keep the cows clean to produce quality milk.

Eyes on the future

Total views: 3,764

Keeping the next generation in mind, Tom Kampsen and Becky Heinz of New London, Minnesota, renovated their tiestall barn into a parlor. The parlor is located where the rst 24 stalls used to be; while the holding area is where the other remaining stalls used to be. The couple now milks the herd in their new double-7 parlor. Throughout the renovation process they had family and friends who were willing to help with different tasks. The couple put in many late nights and early mornings to reach their goal.

Six generations keep farm in family

Total views: 3,499

Colette (Diers) Thorson and her husband, Andy, are fth-generation farmers at Diers Corporation near Waverly, Minnesota. The farm has seen many generations and is welcoming a sixth generation as well. The farm is still using buildings that were built in 1920. Collette wanted to take over the farm since she was in high school. Since meeting her husband, who also wanted to dairy farm, they have been able to accomplish that dream.

8. 9. 10.

“We

like the DHIA tags because we can get them customized to what we want.”

What do you like about the tags you order from DHIA?

We like the DHIA tags because we can get them custom to what we want on them: birthdate, sire, dam, etc. We also get the RFID and genomic tissue sampler with the tags.

Tell us about the convenience of going through DHIA for your ear tags. The process is very simple because our DHIA milk tester orders the tags every month. It is very easy to go in and add the tag series into the software.

Is a good tag product important for managing data within your farm? Yes, this keeps it easy. The tags are easy to read the entire life of the cows and the tags stay in well.

Why is testing with DHIA important to your dairy? for breeding decisions and deciding on cull cows using energy-corrected milk and cell count.

Tell us about your farm. Mulhern Dairy started in 1970 and is a fourth-generation family run dairy farm.

DHIA: Now MORE than ever

Sauk Centre, MN Buffalo, MN 763.682.1091 www.mndhia.org

February 24

and funeral, riding in on approximately 150 tractors.

On Feb. 4, 2024, more than 350 people gathered at Farmers’ Implement LLC in Allenton, Wisconsin, to remember and honor Curtis Nehm. They came on tractors from ve counties to pay tribute to one of their own and support his family during a time of sorrow. Nehm died in a farm accident Jan. 27, 2024, at the age of 27. On the day of Nehm’s visitation and funeral, approximately 150 tractors, a combine, a chopper, a grain truck and several service trucks lined the road in front of the implement dealer where Nehm had worked since he was 15.

April 13

In March, cows on dairy farms in Texas and Kansas began exhibiting symptoms of an illness later identied as highly pathogenic avian inuenza. Wild migratory birds were believed to be the source of the infection in dairy cattle. As of April 9, 2024, the virus had been conrmed in 17 herds in six

states, including Texas, Kansas, New Mexico, Idaho, Michigan and Ohio. Milk from affected cows took on a colostrum-like consistency, and these cows also exhibited a decrease in feed intake, reduced rumen motility and fever. Cows suffering from symptoms were found to be second-lactation or older and at least 150 days in milk.

STACEY SMART/DAIRY STAR

Tracy (from le ), Kurt and Jacob Gagnow and UPS delivery driver Jon Strnad gather May 14, 2024, around Joni, the calf Strnad delivered on the Gagnows’ farm in between delivering packages April 15, 2024, near Seymour, Wisconsin. The Gagnows milk 50 cows and farm 350 acres.

May 11

For over 40 years, the Great Northern Land and Cattle Company played an integral role in marketing dairy cattle, not only in Wisconsin but throughout North America through a total of 961 sales. Business owners Rick and Paula Bovre closed out a 43-year career with the sale of the Great Northern facility in Fond du Lac, Wisconsin, after the nal cattle sale was held Jan. 30, 2024.

UPS driver assists laboring heifer on Gagnows’ farm

May 25

Jon Strnad went above and beyond his duties as a driver for UPS Inc. when he delivered a calf in between delivering packages April 15, 2024, at the Gagnow farm near Seymour, Wisconsin. When driving by in his UPS truck, Strnad noticed a heifer on pasture struggling to give birth on the farm where Tracy, Kurt and Jacob Gagnow milk

50 cows. Having grown up on a farm, Strnad knew what to do. He received a medal from the CEO of UPS for his heroic act, and the Gagnows named the calf Joni, after the man who saved her life.

Gajewski’s dairy farm destroyed in tornado

June 8

Jeff Gajewski spent his life building his dairy farm, but in a matter of seconds, it was destroyed when a tornado ripped through the Marathon County, Wisconsin, farm May 21, 2024. Prior to the storm, Gajewski milked 32 cows in the barn he rebuilt after purchasing the farm in the late 1970s. Gajewski’s barn and two silos took a direct hit from the tornado. Two cows were killed when the barn collapsed, and four additional cows were put down that night, due to the severity of their injuries. Gajewski evaded injury himself, having started chores early due to the fore-cast for severe weather.

Turn to YEAR IN REVIEW | Page 15

Crop season

August 10

Across central Wisconsin, many elds have been left unplanted and hay harvests have fallen behind schedule. According to the National Centers for Environmental Information, Marathon County received 16.89 inches of rain from April through June, making 2024 the third wettest April-June in the past 130 years. Neighboring Wood County received 18.58 inches during the same time, making it the wettest April-June period in the past 130 years for that county. Wausau saw 5.87 inches of rainfall in July, nearly 2 inches more than average. Area farmers were late in planting corn, with some of the corn crop never making it into the ground. Corn that did get planted grew with mixed results, ranging from good to bad. In addition, elds were damaged during harvest to the point that farmers worried about the impact on soil health.

USDA releases proposed changes to Federal Milk Marketing Orders

August 10

On July 1, 2024, the U.S. Department of Agriculture issued its recommended decision on the Federal Milk Marketing Orders hearing process. From August 2023 to January 2024, the USDA considered 22 proposals during 49 hearing days. The recommended decision included ve categories of amendments: milk composition factors, barrel cheese price, make allowances, base Class I skim milk price, and Class I and Class II differentials.

11-year-old Jersey breeder awaits heart transplant

August 24

PHOTO COURTESY OF DAIRY AGENDA TODAY

Lexi Anderson smiles while exhibi ng a Jersey heifer Nov. 5, 2023, at the All American Jersey Show in Louisville, Kentucky. Anderson enjoys exhibi ng her family’s dairy ca le at local, state and na onal shows.

Jamie and Tamala Anderson and their daughter, Lexi, are living a nightmare. Lexi was diagnosed with restrictive cardiomyopathy — a rare disease that does not respond to drugs or treatments. Restrictive cardiomyopathy causes the muscles in the heart to harden, and eventually, stop pumping. Only a heart transplant could save Lexi’s life. Tamala’s parents, Roger and Darice Riebe, operate Meadow-Ridge Jerseys near Cumberland, Wisconsin, where they milk 100 registered Jerseys with their sons, Mike and Mark. Lexi has grown up showing Jerseys alongside her sisters and cousins, and she continued showing both dairy and sheep while awaiting a new heart.

Haags host Wisconsin Badgers football team

September 14

On July 22, 2024, Virgil and Dawn Haag and their children, Karsen and Kody, welcomed 25 members of the University of Wisconsin-Madison football

PHOTO SUBMITTED

Drew Braam (le ) and Omillio Agard, members of the University of Wisconsin-Madison football team, interact with a cow July 22, 2024, at the Haag farm near Mount Horeb, Wisconsin. The Haags set up sta ons around the farm to give the athletes an overview of dairy farming.

team to their farm near Mount Horeb, Wisconsin, where they milk 260 cows. Most of the players had never stepped foot on a dairy farm and enthusiastically greeted the opportunity to learn about the dairy industry. The Haags partnered with Dairy Farmers of Wisconsin to host the event that was orchestrated by former NFL player, Travis Beckum. The Haags set up stations, and it was a lively day of learning as the athletes and farmers interacted.

chopper becoming

September 28

PHOTO SUBMITTED

The remains of a burned-out CLAAS chopper sit in the eld Sept. 20, 2024, at Lucky 7 Dairy near McBain, Michigan. There were roughly 180,000 wa s of electricity in the power line in which the chopper became entangled.

JP Koop of Lucky 7 Dairy recognizes he is a lucky man to be living past the rst day of corn silage harvest this year. The

day started normally, but when his chopper spout touched a low-hanging power line, the day went south as both he and the chopper became electried. Koop, his wife, Suzanne, and one of his seven children, Gavin, milk 1,800 cows and farm around 3,400 acres near McBain, Michigan. There were roughly 180,000 watts of electricity in the power line in which Koop’s chopper became entangled. Koop was able to jump off the chopper, incurring minimal injuries from what could have been a fatal event.

November 9

After 17 years of service in the U.S. Army, including four tours to Iraq and Afghanistan, Corey Trobaugh enjoys being with his cows. Trobaugh’s military career took him to the front lines of combat where he met the enemy face to face. The scars of war continued to haunt him long after returning home, but his cows have helped him through dark times. Trobaugh milks 55 cows and farms 200 acres near Milledgeville, Illinois.

December 21

In a continued effort to battle highly pathogenic avian inuenza H5N1 in U.S. dairy herds, the U.S. Department of Agriculture announced a new federal order Dec. 6, 2024, — the National Milk Testing Strategy — that will grow surveillance efforts to eradicate the virus. The test is extremely sensitive and can identify a single infected cow contributing milk to a silo that could contain milk from more than 70,000 cows. Processing facilities of any size that receive raw, Grade A cows’ milk intended for pasteurization will be the focus of sampling efforts. As of Dec. 18, 2024, a total of 865 dairies in 16 states had conrmed cases of the H5N1 B3.13 strain of HPAI.

from our side our side OF THE FENCE THE

What is a goal for your farm this year?

Andy Lejeune Viroqua, Wisconsin Vernon County 80 cows

How many years have you been dairy farming and what do you enjoy about dairy farming? I have been farming for 29 years. I enjoy seeing our young animals come into the herd and grow and produce. Seeing those animals you help bring into the world grow up and become contributors to the herd is great to see.

What accomplishments did you have on the farm in 2024? In 2024, we had about 60%-70% heifer calves. We are strictly a bull-bred herd, so to have that number of heifers was denitely an accomplishment and something that we really enjoyed.

What is a goal for the farm this year? For 2025, we hope to expand our herd a bit, hopefully add 10 or 20 more. We want to do that by providing great care to the cows and the herd we have. We might purchase a couple, depending on what the price is, but our goal is to add to our herd through the great care we can provide on our farm.

What are you looking forward to this year? We are looking forward to staying healthy and watching our kids grow. My wife and I have four kids, ranging in age from 14 to 1. The youngest just started walking and they always like to keep us on the move. We are also looking forward to another good growing season and seeing our new heifers enter the herd. It is rewarding to bring up those heifers and see how they can contribute to the herd when they get old enough. Each year is different and presents different challenges, so seeing how we handle those as a family and as a farm is something we look forward to.

What do you foresee being a challenge in 2025? Weather is always a challenge because it is so unpredictable. We have a general idea, but sometimes it does not always stick to the plan. With those changes in weather, the spikes in respiratory illnesses can be a challenge. Input costs are rising on machinery and labor and parts seem to be going up, so that will always challenge us a bit.

Tell us about your farm. My brother, Jeff, and my dad, Mike, and I work on our farm. We milk about 80 cows in a double-6 herringbone parlor. We sell to Westby Cooperative Creamery.

Gary Weiman Quincy, Illinois Adams County 15 cows

How many years have you been dairy farming and what do you enjoy about dairy farming? I started milking cows for my family when I was in grade school in 1969. My wife, Teresa, and I started our own herd here in 1981. I enjoy working with the cow families that we have developed and watching the kids and grandkids show them at our local shows.

What accomplishments did you have on the farm in 2024? At the end of 2023, our milk market changed, forcing us to nd a better way forward. We had been selling our dairy steers directly to consumers for seven years, so it seemed a logical next step to do the same with our milk. Today, all our milk goes off the farm in glass jars as farmfresh milk. This was a big step for us, not knowing if there was a local market for this.

What is a goal for the farm this year? Our goal for 2025 is to expand our retail sales of milk and meat. This means that we have to become even better at what we do. Taste has become more important in what we produce. Soil health is more important along with quality, sweet forage. This makes a better-tasting milk and meat.

What are you looking forward to this year? We are looking forward to moving into a new sales room that the grandkids and I have built onto the barn. We hope this will

John Bigham, Jr.

Abbotsford, Wisconsin Marathon County 34 cows

How many years have you been dairy farming and what do you enjoy about dairy farming? I got my rst cow when I was 13 years old, back in 2012. At the time, I lived on my parents’ farm in Ohio. I moved to Wisconsin in 2019 to take my dairy dream to the next level. I now milk 34 cows in a tiestall barn. I am a cow guy at heart; I love to be around the cows. I am especially passionate about grazing and mating cows. I spend most of my time in the barn working with the cows. I am passionate about my registered Jerseys, but I have room in my heart for all the breeds. Besides the Jerseys, I have Holsteins, crosses and a couple of Brown Swiss.

What accomplishments did you have on the farm in 2024? My biggest accomplishment this year was beating my record days on pasture by ve days. The cows were on pasture for 197 days this year, with 70%-80% dry matter intake from pasture. It was a rough start in the spring with all the rain we had, but it turned out to be a great grazing season with a nice long, dry fall.

What is a goal for the farm this year? I am focusing on getting more pounds of milk per cow. I am working on getting my rations more balanced and feeding more supplemental protein. I will be focusing on fresh cows and working up from there.

What are you looking forward to this year? I always look forward to the rst day on pasture. The highlight of my year is the grazing season. The cows are intensively grazed, so I move them twice a day at milking time.

What do you foresee being a challenge in 2025? The last couple of years the weather has been the biggest challenge. In 2023 it was too dry and then 2024 was too wet, so I am denitely anxious about what the weather in 2025 will bring. I am certied organic, so I think one of the biggest challenges for our industry is going to be getting enough milk supply to meet demand. That is one of the reasons I am focusing on production this year. There’s a lot of competition for milk out there and while I am very committed to my co-op, it is hard for some people to turn down super high prices some companies are offering. I will take co-op stability over temporary super-high prices any day.

Tell us about your farm. I rent my farm from Charles Wellner. I pretty much accomplish the daily farm tasks single-handedly. Charles helps with some eld work and various farm repairs. All the crop work is hired out to custom operators. This gives me the exibility to spend more time focusing on the cows. My milk is shipped to Organic Valley (CROPP Cooperative) and I serve on CROPP’s young leaders (Generation-Organic) committee, where we advise the board of directors on current and future issues relating to beginning farmers in our cooperative. I am passionate about CROPP — who we are and what we believe: providing a stable market for small organic farmers and protecting our natural resources through farming. I look forward to being involved for many years to come.

help us increase sales and give our customers a better experience when coming to the farm. Also, I hope this will create a future for our family to continue farming.

What do you foresee being a challenge in 2025? As we move into this year, our challenge is to right-size our farm for what we are doing today. Great-tasting milk and meat that is healthy for our local families is what drives us today. Building soil health and herd health creates healthy families.

Tell us about your farm. Our farm today consists of 15 cows and 25 fat steers with 200 acres of owned and rented land. We grow alfalfa, ryegrass, corn and beans as our crops. Our cows are milked in a 7-stall at parlor and housed in an open-front mono-sloped bedded-pack barn. Our cows are Ayrshire and Holstein. Our milk is sold directly to consumers at the farm. My wife, Teresa, and I are involved on the farm, and Teresa also works in a tax ofce. My son, Adam, and his wife, Kelly, are both schoolteachers and help on a daily basis. My daughter, Hannah, works on a research farm and has a young family but helps when needed. Several of our grandchildren help with farm chores.

How many times a day do you milk, and what is your current herd average, butterfat and protein? We milk two times a day. Our butterfat averages 4.6% and our protein averages 3.5%. Our rolling herd average is 27,500 pounds of milk.

Describe your housing and milking facility. Our cows are housed half of the time in a stanchion barn and the other half in a freestall barn. We milk in a 38-stall stanchion barn, then switch our cows, bringing the cows in from the freestall barn.

Who is part of your farm team and what are their roles? Rick is in charge of most things that take place on the farm. Rick and Ann do all the milking. Ann takes care of the calves, both morning and night. During the day, she works at Jordan Public Schools. Ann also does all the bookwork for the farm. Tony, Ann’s brother, helps with morning chores, including cleaning and bedding the barns, feeding youngstock and grinding feed for steers and calves. Our three sons, Kevin, Jason and Jeff, help out as needed, especially when we are doing eld work or taking some time off. They all are married and have off-the-farm jobs. Our daughter, Emily,

TOP PERFORMERS

lives out of state but helps with the milking and feeding whenever she is home. Our neighbor, Gene, lls in whenever he is needed for chores and eldwork.

What is your herd health program? We have a herd

exam every two weeks. We have been using the G6G breeding program for about 10 years and have had very good success with it. Twice a year, all the youngstock are vaccinated with a 9-way vaccine and a pour-on wormer. Newborn calves get two doses of

Nasalgen 3-PMH at 7 days old and again around 30-40 days old.

What does your dry cow transition program consist of? We dry our cows off 60 days before they are due. When drying them off, they

get milked once on the rst day, then skipped on the second day. On the third day, they are milked in the morning before receiving Quartermaster dry tubes and a sealant. They are vaccinated with Vira Shield and Endovac. We then put them with the bred heifers and other dry cows. Two weeks before freshening, they are brought into a close-up pen located in the corner of the barn. They are boosted again with Vira Shield and Endovac. We put them on a special dry cow feed consisting of dry hay, corn silage, ve pounds of ne ground corn and dry cow dietary cation-anion difference concentrate. After they freshen, they stay in the stanchion barn for two days before being switched in and out of the freestall barn with the rest of the herd.

What is the composition of your ration, and how has that changed in recent years? We feed a total mixed ration of corn silage, haylage, ne ground corn, a concentrate blend from Big Gain, cottonseed and EnerG-3. Over the years, we stopped feeding dry hay and coarse ground corn.

Turn

Bongards’ Creameries

Has been a quality market for MN dairy farmers for over 100 years. MN producers provide one of the country’s most distinctive brands of cheese that is still made using the same Old World craftsmanship and has been combined with cutting-edge technology to produce cheese that delivers unforgettable taste with unparalleled quality. MN Dairy farmers and Bongards, quality that stands the test of time. We offer a competitive base price, premiums, and the best eld representatives in the industry.

13200 Co. Rd. 51

Bongards, MN 55368 (952) 466-5521

Fax (952) 466-5556

110 3rd Ave. NE

Perham, MN 56573 (218) 346-4680

Fax (218) 346-4684

“It

“We have consistently been using Udder Comfort™ for over 15 years. It fits our focus on comfort and quality. Our goal is high component, low SCC milk, shipping at least 8 pounds of solids and 120 pounds of energycorrected milk per cow,” says Mitch Breunig, Mystic Valley Dairy, Sauk City, Wisconsin, home of Jenny-Lou Holsteins.

Of the 455-cow milking herd with records to 55,000M, 118 completed records over 150,000 lifetime milk in 2024. This 12-time Holstein USA PBR herd, based on production, homebred percentage (93.9%), and conformation, has earned 24 Progressive Breeder Awards and is in the top 25 Holstein herds for fat and protein in the U.S.

“Cows that start clean tend to stay clean throughout their lactation,” says Mitch.

“We spray every fresh udder with Udder Comfort 2x/day for 3 to 7 days and see SCCs come down much faster. It gets fresh cows off to a great start on a quality lactation,” he explains.

Udders Make Quality Milk

Tell us about the forages you plant and detail your harvest strategies. We plant all brown midrib corn for silage. The alfalfa is started in spring with a triticale and pea mixture. This is harvested for the heifers. We try to cut hay every 28-30 days. We like to cut it all at once. First and second cuttings are put in a silo and bag. Third and fourth cuttings are used to rell the silo. We big square the rest and use the bales to feed youngstock. The corn silage is stored in a pit silo, a stave silo and a bag. The bag is not opened until the next fall, in hopes we do not need to feed fresh silage until it has fermented for a few months.

What is your average SCC and how does it affect your production? Our somatic cell count averages about 120,000, although in the winter we can generally keep it under 100,000. In the summer it is a little tougher to keep it low. We use sand bedding in both the stanchion barn and the freestall barn. We think sand bedding and vaccinating with Endovac helps keep the SCC down.

What change has created the biggest improvement in your herd average? We work closely with our nutritionist, Frank, from Big Gain. We feed only high-quality feed, including ne ground corn and the BMR corn silage. Sand bedding, tunnel ventilation in the stanchion barn and more fans in the free stall barn have also

helped to increase the herd average. We also added a soaker line over the feed alley in the free stall barn to keep the cows cool in the summer.

What technology do you use to monitor your herd? We use the Dairy Herd Improvement Association report to monitor cows that have a high SCC and cows that are high in days in milk, but did not breed back. DHIA is also used to monitor low-producing cows. Using the two-week herd exam helps monitor open cows.

What is your breeding program and what role does genetics play in your production level? Everything is bred the rst time using the G6G program. We herd exam every two weeks. We use all high Net Merit bulls.

List three management strategies that have helped you attain your production and component level. Using BMR corn for silage, grinding the corn to 300 microns and feeding cottonseed have all played a role is helping us to reach our current levels of production and components.

Tell us about your farm and plans for the dairy in the next year. We live on a century farm where we plant 375 acres of corn, soybeans and alfalfa. We milk 85 cows and nish all of our steers. Our milk is shipped to Bongards. In the next year, we plan to continue striving for herd health and timely breeding to keep the farm protable.

TRACK TRACTORS

Contact one of the following dealers to learn more:

IOWA

Prairie Land Ag Supply Inc.

Rock Valley, IA 712-476-9290

United Dairy Systems, Inc. West Union, IA 563-422-5355

Monticello, IA 319-465-5931

WISCONSIN

Advanced Dairy Spring Valley, WI 715-772-3201

Bob’s Dairy Supply Dorchester, WI

715-654-5252

Ederer Dairy Supply Plain, WI

608-546-3713

DeLaval Dairy Service Kaukauna, WI 866-335-2825

Joe’s Refrigeration Inc. Withee, WI 715-229-2321

Mlsna Dairy Supply Inc. Cashton, WI 608-654-5106

Professional Dairy Services Arlington, WI 608-635-0268

Redeker Dairy Equipment Brandon, WI 920-346-5579

The Scharine Group Inc. Whitewater, WI 800 472-2880 Mt Horeb, WI 800-872-3470

MINNESOTA & SOUTH

DAKOTA Farm Systems

Melrose, MN

320-256-3276 Brookings, SD 800-636-5581

Advanced Dairy Mora, MN

320-679-1029 Pierz, MN

320-468-2494

St. Charles, MN 507-932-4288 Wadena, MN 218-632-5416

POLY-TANKS and TOTES

Wisconsin celebrates Holstein juniors

Hathaway, Noble claim association’s top awards

By Danielle Nauman danielle.n@dairystar.com

WISCONSIN DELLS,

Wis. — The Wisconsin Junior Holstein Association celebrated the achievements of its members at its annual convention Dec. 27-29, 2024, in Wisconsin Dells, where junior Holstein enthusiasts from across Wisconsin gathered to take part in activities and contests.

The top awards bestowed by the association, the Wisconsin Outstanding Holstein Boy and Girl, were presented to Evan Hathaway of Barneveld and Ainsley Noble of Lancaster.

Hathaway, a sophomore at the University of Minnesota Twin Cities, is pursuing a degree in animal science and agriculture communications marketing. He is the son of Alycia Hathaway and the late Josh Hathaway. Hathaway owns 15 registered Holsteins. Hathaway said he came

to embrace membership in WJHA through a non-traditional path.

“My family had a farm, but I didn’t grow up involved on the farm,” Hathaway said.

“I never thought it was something I was interested in. When I was in middle school, I ended up helping with calf chores one night, and realized maybe it was something

Air King industrial air cleaners are a valuable tool for capturing most airborne nuisance particulate. Our self-contained filtration units continuously pull contaminated air through multiple stages of highly efficient micro-glass filters. The filtered air is then recirculated back into the working environment without the need for duct work. This results in a cleaner, healthier atmosphere for employees, while saving you money by keeping heated or air-conditioned air inside your facility.

I could get into.”

Hathaway began exhibiting at the Iowa County Fair with his cousins and eventually followed them to junior Holstein activities.

“I saw things my cousin, Lily, participated in when she was younger and decided I wanted to do those things, too,” Hathaway said. “She took me to my rst dairy bowl practice.”

Hathaway found himself hooked by competing in dairy bowl. With Iowa County junior advisor Angela Brown, Hathaway attended one of the area event days held in place of a state convention in the aftermath of the coronavirus pandemic.

“After attending that, I became interested in being on the Junior Activities Committee and doing all the things,” Hathaway said. “I really caught the bug.”

Hathaway was elected to represent the southwest district on the JAC.

“That was an amazing experience, being able to step up to the plate and take on a large leadership role,” Hathaway said. “It gave me the opportunity to connect not only with many other juniors in the state but with adult members, too — people from the industry that I looked up to.”

Turn to WI JR. HOLSTEIN | Page 25

Shaping Tomorrow Together: FarmFirst Dairy Cooperative Annual Meeting in Onalaska, WI

Join us at the Stoney Creek Hotel and Event Center on February 7-8th, 2025, for an event filled with intrigue and excitement, where we come together to shape a brighter future.

Friday, February 7th At 1:30 PM, uncover the hidden truths of the FARM program at the Producer Discovery Workshop with Beverly Hampton Phifer (NMPF Senior Director of Animal Care) and FarmFirst’s certified animal evaluators.

As night falls, anticipation builds for the arrival of a mysterious guest. Who is this master conjurer? What tricks do we have up our sleeves? Only those present will discover the truth.

Following the banquet, our annual live auction begins. The stakes are high, the treasures invaluable, and our efforts will help support our scholarship program.

Saturday, February 8th Our business meeting will determine the future as we shape tomorrow together. Kevin Beauchamp from Galloway Company in Neenah, WI keynote address will inspire you as you learn the role of dairy farmers and processors in our future.

Embracing new experiences and the opportunities they created helped Hathaway lay a foundation for a future that was not on his radar a few years ago. He encourages other youth to do the same.

“Always say yes, always take chances and try something new,” Hathaway said. “By saying yes and taking a chance, it opened up doors that led me to where I am today.”

Noble, a junior at the University of Wisconsin-River Falls majoring in agricultural education, grew up on her family’s 430-cow dairy farm near Lancaster and has been involved in junior Holstein activities for most of her life. She is the daughter of Troy and Jaime Noble.

“Being a member of the (Wisconsin) Junior Holstein Association has taught me that you can dream big, but you have to work hard to make those dreams become a reality,” Noble said. “My parents have always been my biggest supporters. They pushed me to become involved and to work hard to reach my full potential.”

Noble spent her youth attending Cow Camp and junior conventions, showing her registered Holsteins, and competing in dairy bowl and jeopardy. She was selected as a national Young Distinguished Junior Member in 2019 and a national Distinguished Junior Member in 2023. Striving to grow as a leader, Noble also served on the JAC representing the southwest district.

Noble said building and creating her own story has been the foundation of her junior Holstein career.

“Growing alongside other members, seeing how our stories have

transpired, and watching others succeed is so gratifying,” Noble said. “Now watching this huge group of younger members just starting their own stories — it’s so cool to see that and think back, remembering when I was in their shoes, just starting to create my story and all those small milestones that have added up to the big ones.”

Recalling her time at the 2023 National Holstein Convention competing for a spot as a national DJM, Noble recalls the connections she created with the other 11 semi-nalists.

“(I enjoyed) seeing their stories, where they came from — how different, yet how similar we all were,” Noble said. “We came from different things, had different goals in life, but the commitment to our stories remained the same.”

Noble urges youth to think about the story they want to create, and how they can be impactful to others.

“Dream big, work hard and stay humble — those are words I try to live by,” Noble said. “It’s your story; never be afraid to share that. Not every kid comes from a farm or an ag background, but in this organization, you can become as inuential or impactful as you want to be, regardless of that background. Just remember why you began, who pushed you and keep pursuing that.”

In addition to Hathaway and Noble, Wisconsin Distinguished Junior Member awards were presented to Emma Bangart, Stratford; Lauren Breunig, Sauk City; Sara Dorshorst, Marsheld; Catherine Gunst and Christopher Gunst, Pine River; Elizabeth Gunst, Hartford; Jacob

Harbaugh, Marion; Madeline Hensel, Pittsville; Brianna Meyer, Chilton; Tristen Ostrom, DePere; Ella Raatz, Colby; and Garrett Ulness, Valders.

Breunig, Hathaway, Meyer and Ulness were selected to represent Wisconsin in the national DJM competition.

Young Distinguished Junior Member awards were presented to Justin Brandel, Lake Mills; Kayla Buttles, Lancaster; Gavin Carncross, Lodi; Alison Gartman, Sheboygan; Madison Harbaugh, Marion; Vivian Lichty, Beaver Dam; Leah Mess, Rosendale; Abby Meyer, Chilton; Brooke Mueller, Brodhead; Laney Neuser, Cato; Mallory Nifong, Orfordville; Payton Sarbacker, Verona; Abigail Schultz, Valders; and Alivia Wiese, Wrightstown.

Brandel, Carncross, Mess and Meyer were selected to apply for national recognition.

The 12 & Under Member Recognition award was presented to Carter

Coffeen, DePere; Elise Gilbertson and Naydeen Gilbertson, Hollandale; Callie Krohlow and Conway Krohlow, Poynette; George Linscheid, Cobb; Adella Loehr, Eden; Siera McCullough, Juda; Reagan Sarbacker, Verona; and Mylie Wendorf of Ixonia.

Jazmyn Heeg of Colby was named the 2025 Wisconsin Holstein Princess, and Tianda Hildebrandt of Hustisford was named the Wisconsin Holstein Princess Attendant.

The juniors elected four new representatives to the JAC. McKenna Niemeier of Dodgeville was elected to join Kelsey Hardy, also of Dodgeville, representing the southwest district. Sara Dorshorst of Marsheld will serve with Aspen Hagen of Loyal representing the northwest district. In the southeast district, Mallory Nifong of Orfordville will join Tessa Schmocker of Whitewater. Madison Wiese of Wrightstown will join Garrett Ulness of Valders in representing the northeast district.

NEED A MACHINE?

Conservationist promotes cover crops

Guilette presents at Wisconsin Water and Soil Health Conference

By Dan Wacker dan.w@dairystar.com

WISCONSIN DELLS, Wis. — Agronomist Nick Guilette is an advocate for cover crops. A certied crop advisor since 2004, Guilette sees the value in using cover crops to mitigate a variety of challenges — from erosion to compaction.

Discussing how cover crops can help producers manage soil and water quality was the focus of Guilette’s presentation at the Wisconsin Water and Soil Health Conference last month in Wisconsin Dells.

Guilette, who was the winner of the 2019 Certied Crop Advisor Conservationist of the Year Award, works for Ebert Enterprises LLC, a sixth-generation dairy near Algoma, where he leads innovation and conservation practices. Guilette works specically to improve efciency and produce cow rations.

Cover crops can be a dual-purpose plant, Guilette

said. They cover the soil, reduce erosion, suppress weeds and promote biodiversity.

“If a eld drains poorly, one strategy to improve that would be to plant a cover crop with a living root,” Guilette said. “That living plant helps to utilize that excess water.”

Through these practices, the ability of soil to absorb water is improved, thus limiting runoff and keeping the soil and nutrients where they belong.

“We’re in the animal business, and all of us know animals produce manure,” Guilette said. “It’s our responsibility to use manure as a positive and keep the environment clean. Cover crops help with that aspect of agriculture.”

Guile e, of Ebert Enterprises LLC near Algoma,

a dual purpose for cover crops, no ng they can help to prevent soil erosion, suppress weeds, add biodiversity and improve feed quality for dairy ca le.

Cover crops provide plant diversity in the crop rotation and, if using a legume species, can produce nitrogen. They can also be used to produce a forage for harvest. Planting something that can be harvested can help improve the soil, while also improving feed quality for dairy cattle.

One of the crops that Guilette has implemented at Ebert Enterprises is winter rye.

“Winter rye is its own animal,” Guilette said. “It’s a resilient plant that can germinate near freezing. In 2023, we planted rye in midNovember and by the end of March, we had 1- to 2-inch plants out of the ground. The important thing was getting seeds planted. Even though it

was late in the fall, they could still achieve more soil health benets in the spring.”

Having rye in the ground during the winter gives the plant a chance to continue to improve the soil, which benets the corn the following spring.

“The rye contributes to soil health,” Guilette said. “Earthworms can feed on it all season long. It scavenges nutrients from all around it, relaying those nutrients to the next spring for the corn crop.”

Soil compaction is another challenge that is presented to farmers. Guilette provided some practices to overcome those challenges.

“Occasional tillage helps alleviate compaction,” Guilette said. “But another could be a living cover crop. A living cover crop fractures the soil to keep it open. …. The important thing is to really know your elds. Each one could use a different practice for optimization.”

Another practice that Guilette discussed was planting green. This practice involves planting a corn crop into a cover crop that is still living.

Shortly after planting the corn, the cover crop is terminated. When the cover crop dies, it forms a compost that later can feed the corn until harvest. By using this practice, in addition to years of not tilling the same eld, there will be a change in the water inltration rate. When rain falls on the eld, more water will make it into the soil.

This practice helps reduce runoff. The elds begin to drain differently, allowing the soil to better absorb nutrients.

Guilette did warn however that the living cover crop could attract army worm moths, something that can be addressed by additional scouting and integrated pest management practices.

Use dictates which cover crop should be planted with corn. Farmers could plant a lower quality feed for higher tonnages for heifers, or a higher quality feed for the milking herd.

“You need to be as realistic as possible for what the use of your cover crops will be,” Guilette said. “That needs to be communicated with everyone involved; the nutritionist, the crop consultant, everyone. There are some people who are reluctant to use cover crops in the ration for dairy cattle, so being on the same page from the beginning is vital.”

• Multi Species Consulting

• Custom Rations and Feed Testing

• Commodity Contracting

• House and Name Brand Feeds

• Calf Feeds, Milk Replacers, and Housing

• Show Feeds and Supplies

• Covers, Wrap, Bags, Inoculant, and Twine

Guilette also provided advice for those farmers who might be new to the cover crop business.

“Use a certied crop advisor and make sure they stay involved,” Guilette said. “Really hold their feet to the re if you need to. You also really need to be on top of your game and (be) ready to go. When rye is growing, it can get away from you quickly.”

Continuing to learn and grow through the process is an important element of these practices.

“Never forget your successes when working on cover crops,” Guilette said. “Learning from your mistakes and attempting to limit your variables as much as possible will help you to learn and improve what you’ve done.”

Guilette said those who have experience working with different cover crops should help those with less experience.

Guilette also shared how to get started without completely revamping a crop strategy for those apprehensive about cover cropping.

“It can be the very back 10 acres of your farm, but starting somewhere is what’s important,” Guilette said. “You’ll see the results in the smaller elds and see how you can adapt and adjust to elds all over the farm.”

Your Chilling, Cooling, Storing, and Monitoring Partner!