DAIRY ST R

Volume 24, No. 22

Volume 24, No. 22

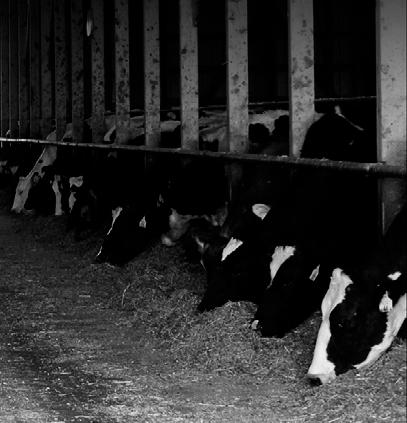

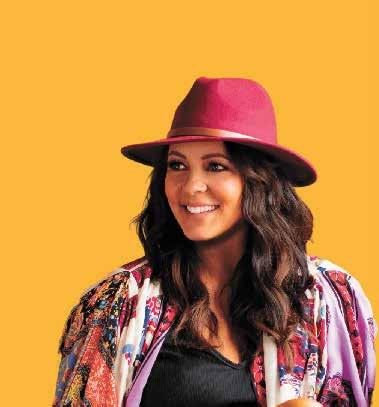

milking 160 cows and farming 300 acres near Oshkosh. Out of their ve children, Matt was the one who always wanted to be a farmer.

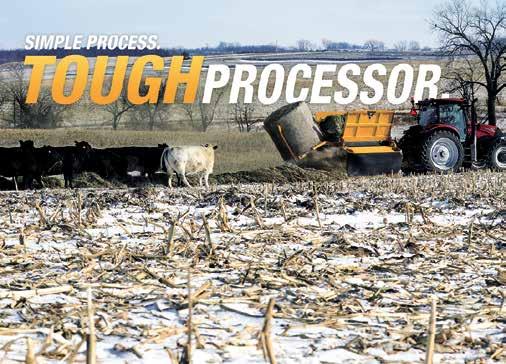

By Stacey Smart stacey.s@dairystar.comOSHKOSH, Wis. – From the rst barn re in 1980 to an expansion in 2013 that brought the third generation home full time, the skyline at Potratz farm is ever changing. Since Jim Potratz’s dad purchased the farm in 1947, the dairy has changed much in appearance and management style.

“There have been a lot of changes here over the years, and roads coming through changed the look of the place a lot too,” Jim said. “Highway 41 has taken away some of our land gradually. It went from two lanes to four, and then they added a frontage road as well.”

Jim and his wife, Paula, farm with their son, Matt,

“When I was a kid, I always said I wanted to take over the farm,” Matt said.

Matt and his wife, Megan, have four kids – Oliver, Addaline, Charlotte and Lincoln –who are the fourth generation on the farm. After holding jobs in a paint shop and the construction industry, Matt’s heart called him home. When working construction in between morning and night milkings, Matt’s thoughts often wandered to the farm as he found himself wondering if things were getting done during the day while he was gone.

“Once we put up the new barn, I had no time for construction anymore,” Matt said.

In 2013, the Potratz family built a freestall barn, milking parlor and liquid manure pit while nearly tripling the size of their herd.

barn, milking parlor and liquid manure pit.

Jim said it was a big step for the farm.

“We either had to get out

or get bigger to support two families, but Matt’s love of the farm pulled him back here,”

Jim said. “I was ready to step away and would have been happy to do something else, but then we took the plunge.”

They expanded from a 50-stall stanchion barn to a 4-row freestall barn. A swing-10 milking parlor was retrotted into the stanchion barn after gutting calf pens and cutting the hay mow oor out and raising it 4 feet to make room for the holding area. They also added a 2,000-gallon bulk tank as part of the expansion.

“It’s a lower cost parlor, but it’s worked well for our needs,” Jim said. “We utilized the area and saved a lot of cost.”

Cows went from lying on rubber mats in the stanchion barn to enjoying the luxury of waterbeds in the freestall barn. Stalls are bedded with a light covering of a mixture made from paper and lime.

Turn to POTRATZ

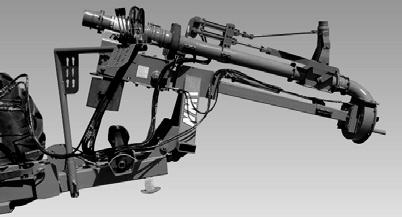

with their aerial apparatus.

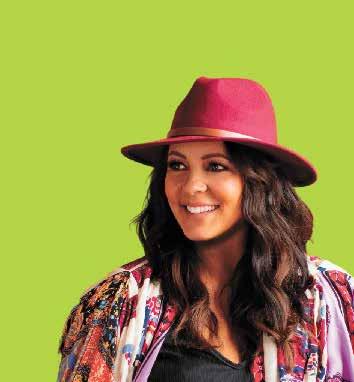

By Stacey Smart stacey.s@dairystar.comPORTAGE, Wis. – On the evening of Jan. 2, the Associated Milk Producers Inc. cheese packaging plant in Portage caught re. Thirty employees were in the plant at the time.

“Employees were immediately evacuated, and no one was injured,” said Sarah Schmidt, vice president of marketing at AMPI. “The re was contained to an area on the second oor and extinguished that night.”

Upon arrival at the scene, the Portage Fire Department reported heavy smoke and re coming from

Fire departments work to ex�nguish a re at the

The re started in a room where milk fat was being stored, and as it was heated, it began to ow throughout the structure. Fire crews attempted to gain access from each end of the structure to control the spread of the re, but they were halted due to the heavy smoke and runoff.

Crews were on the scene until 3 a.m. Jan. 3 as a total of 10 re departments worked to put out the re. The re was contained and extinguished before it could spread past the rewalls and throughout the building.

ing plant Jan. 2 in Portage, Wisconsin. Contained to an area on the

the

was ex�nguished that night, and nobody was injured.

AMPI is the largest cheese cooperative based in the U.S. Headquartered in New Ulm, Minnesota, AMPI is owned by dairy farm families from Wisconsin, Minnesota, Iowa,

Potratz family rolls with the punches while transforming their operationSTACEY SMART/DAIRY STAR The Potratz family – Addaline (front, from le�), Charlo�e and Oliver; (back, from le�) Jim, Paula, Ma� holding Lincoln, and Megan – milks 160 cows and farms 300 acres near Oshkosh, Wisconsin. During an expansion in 2013, the family nearly tripled the size of its herd and built a freestall PHOTO COURTESY OF PORTAGE FIRE DEPARTMENT Associated Milk Producers Inc. cheese packag- second oor, re

Flames consume area of second oor, no people injuredthe roof of the dairy plant. Fire crews stretched lines to the entrance door but were pushed back by the heat and smoke. Unable to access the structure, they used their monitor to ght the re until the Poynette and Kilbourne re departments arrived

www.dairystar.com

522 Sinclair Lewis Ave. Sauk Centre, MN 56378

Phone: 320-352-6303 Fax: 320-352-5647

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com 320-352-6303 (ofce) 320-248-3196 (cell) 320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach

• karen.k@star-pub.com Annika Gunderson • annika@star-pub.com

Editorial Staff

• tiffany.k@dairystar.com

Maria Bichler - Assistant Editor maria.b@dairystar.com • 320-352-6303

Danielle Nauman - Staff Writer 608-487-1101

• danielle.n@dairystar.com

Stacey Smart - Staff Writer 262-442-6666

• stacey.s@dairystar.com

Abby Wiedmeyer - Staff Writer 608-487-4812

• abby.w@dairystar.com

Grace Jeurissen - Staff Writer 320-352-6303

• grace.j@star-pub.com

Jan Lefebvre - Staff Writer 320-290-5980 • jan.l@star-pub.com

Consultant

Jerry Jennissen 320-346-2292

Advertising Sales

Deadline is 5 p.m. of the Friday the week before publication Sales Manager - Joyce Frericks 320-352-6303 • joyce@dairystar.com

Mark Klaphake (Western MN) 320-352-6303 (ofce) 320-248-3196 (cell)

Laura Seljan (National Advertising, SE MN) 507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com Jerry Nelson (SW MN, NW Iowa, South Dakota) 605-690-6260 • jerry.n@dairystar.com

Mike Schafer (Central, South Central MN) 320-894-7825 • mike.s@dairystar.com

Amanda Hoeer (Eastern Iowa, Southwest Wisconsin) 320-250-2884 • amanda.h@dairystar.com

Megan Stuessel (Western Wisconsin) 608-387-1202 • megan.s@dairystar.com

Kati Kindschuh (Northeast WI and Upper MI) 920-979-5284 • kati.k@dairystar.com

Julia Mullenbach (Southeast MN and Northeast IA) 507-438-7739

• julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell) bob.l@star-pub.com

Deadlines

Subscriptions

Advertising

Letters

The Dairy Star is published semi-monthly by Star Publications LLC, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378-1246. Periodicals Postage Paid at Sauk Centre, MN and additional mailing ofces.

POSTMASTER: Send address changes to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378-1246.

When the new Congress convenes next month, Pennsylvania Congressman Glenn “GT” Thompson will be at the helm of the House Agriculture Committee. Thompson said there are three options for the 2023 farm bill. No. 1, the bill could be allowed to expire at the end of September and revert to the language established during the Dust Bowl era of the 1930s. “No. 2, we could kick the can down the road and do an extension,” Thompson said. “But, that’s a failure to do our job because I think there’s improvements to be made.” Crop insurance and updated reference prices were cited as possible improvements for the next farm bill. The ag committee’s third option is to complete the farm bill before the current legislation expires. “Which really in my mind is the only option,” Thompson said.

Dairy industry praises Taylor conrmation

Year end with conrmation of ag trade ambassador

As the lame duck session approached the nish line, the Senate conrmed Doug McKalip as the chief agricultural negotiator for the Ofce of the U.S. Trade Representative. McKalip was nominated in July, but a hold was put on the conrmation. McKalip was the senior advisor for agriculture and rural affairs with the Biden administration’s Domestic Policy Council.

Canadian dairy farmers receive trade compensation payments

Ag Insider

Ag Insider

THE HAY AND FORAGE TOOL SPECIALISTS Mowers Mergers Rotary Rakes Wheel Rakes Tedders Harvesting high-quality hay and forage is the focus of KUHN's hay tool innovation. Our commitment is to help you gain a maximum return on investment by providing products known for performance, reliability, and longevity. THE MOST COMPLETE HAY LINE Cut • Dry • Harvest Save time, money and improve hay quality with KUHN. INVEST IN QUALITY ® www.kuhn.com Farmers’ Implement Allenton D & D Farm Supply Arcadia Cherokee Garage Colby Beaver Machine Coleman Kalscheur Implement Cross Plains Komro Sales & Service Durand Eron Equipment Junction City Luxemburg Motor Co. Luxemburg Riesterer & Schnell Marion Lulich Implement Mason Lindstrom Equipment Mondovi East Side Farm Equipment Monroe New Richmond Steinhart Farm Service Platteville Gruett’s Inc. Potter Gibbsville Implement Waldo Carl F. Statz & Sons Waunakee A.C. McCartney Durand, IL Peabudy's North Pecatonica, IL Visit your local Wisconsin KUHN Hay and Forage Dealer today!

Milk production in the 24 major dairy states totaled 17. 5 billion pounds in November. That’s up 1.4% from one year ago. Milk production increased 1.3% over the past year in Wisconsin and declined a fraction of 1% in California.

Milk prices are on pace to set an all-time record for the calendar year. The all-milk price is forecast to be at least $25.50 per hundredweight for 2022. That compares to the previous record of $24 per hundredweight that was set in 2014.

The International Dairy Foods Association has identied ve key objectives that will dene 2023 and beyond. Nutrition, health and wellness tops that list. Global competitiveness and the ability to capture more consumers worldwide is another priority. IDFA cites workforce challenges, sustainability and technology/innovation to round out the list.

Dairy Management Inc. has recapped the dairy checkoff highlights of the past year. Topping that list is a ve-year collaboration with the Mayo Clinic and research into dairy’s role in health and nutrition. Social media efforts with foodies and inuencers included the butter board craze that became a viral sensation. The checkoff also engaged in programs to help dairy farmers meet its 2050 Environmental Stewardship Goals.

Used equipment market not slowing down

Machinery Pete founder Greg Peterson has been tracking the used equipment market for 33 years. “I’ve never seen anything close to this; the market has just been on re since late 2020,” Peterson said. Used machinery values increased every month of 2022. “When the calendar ips, we might have a chance to catch our breath, but everything’s in place for used equipment values to remain strong,” Peterson said. The combination of tightness on late-model large equipment and scarcity of new equipment is driving demand.

Develder reects on career in the dairy business

Donn Develder started his career with Associated Milk Producers Inc. in 1985 as a eld representative in northern Minnesota. At the end of this week, he’ll retire as the co-op’s co-president and CEO. Thanks to the global demand for dairy products, Develder sees a bright future for the dairy industry. “If you consider the dairy products that are really in demand, which is cheese, butter and whey, the cheese basket of the U.S. is here in the Midwest,” Develder said. “The proximity to the East Coast, the better off you are. The infrastructure here in the Upper Midwest has always been strong, and it’s done nothing but get stronger.” Sheryl Meshke, who has been AMPI’s co-president and CEO since 2015, will continue to lead the company moving forward.

Wisconsin Gov. Tony Evers appointed Adam Payne as the head of the Wisconsin Department of Natural Resources. Payne succeeds Preston Cole, who retired. For the past 20plus years, Payne has been the county administrator for Sheboygan County.

The Wisconsin Farm Bureau has named Melissa (Doyle) Jacobson as its director of young leader programs. Jacobson has been the WFBF District 3 coordinator since 2015 and farms near Mineral Point, Wisconsin.

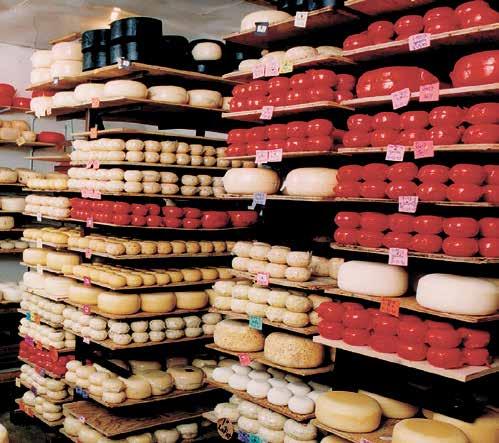

A turophile is the term for a connoisseur of cheese. That answers our last trivia question. For this week’s trivia, what business are you in if you are involved in caseiculture? We will have the answer in the next edition of Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network, based in Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two adult sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

Nebraska, South Dakota and North Dakota. Members annually market about 5 billion pounds of milk generating nearly $2 billion in sales.

The cooperative’s award-winning cheese, butter and powdered dairy products are produced at eight manufacturing locations in the Upper Midwest and marketed to foodservice, retail and food ingredient customers.

The Portage plant does not receive and process milk from member farms. Rather, this location produces and packages processed cheese in addition to packaging natural cheese for foodservice and ingredient customers. AMPI’s only butter plant is in New Ulm. No butter is produced at the Portage plant.

“While the term ‘butter’ has made headlines in connection to the re, the actual product impacted was milk fat,” Schmidt said. “Milk fat is used as an ingredient when making processed cheese.”

The original plant was established in 1951, and AMPI North Central Region acquired this plant in 1972. Various additions and improvements have been made to the plant since that time.

“AMPI thanks local re departments and rst responders involved

in controlling the re,” Schmidt said. “We appreciate their professionalism and hard work as well as that of our employees under difcult circumstances. Their collective response protected the local canal; responders blocked street drains and placed absorbent materials in the canal to minimize milk fats.”

Cleanup was overseen by spill response professionals from the Department of Natural Resources, and AMPI continues to work closely with state and local ofcials. DNR staff report that approximately 20 gallons of fat entered the adjacent canal via a storm sewer. Absorbent booms were deployed in the canal to contain the discharged material, and the fat has since been removed.

The storm sewers are currently clear due to the volume of re suppression water that ushed through them during the reghting efforts. The DNR reports that so far, environmental impacts are minimal.

As of Jan. 6, the cause of the re was under investigation, but foul play is not suspected, Schmidt said.

“We continue to assess damage at the plant and look forward to being back in production as soon as possible,” she said.

“We really like this bedding,” Jim said. “It’s helped with our somatic cell count and mastitis. Most big farms bed with sand, but it’s hard on equipment so we decided to try waterbeds instead and have had no issues with leaking or anything else.”

Cows are milked twice a day and went from averaging 65 pounds of milk per day in the stanchion barn to now averaging around 80 pounds.

“Financially, the new freestall barn is better than the stanchion barn,” Jim said. “The cows milk more and have greater comfort. The old stanchion barn was hard on cattle. They were restricted and had no freedom of movement and were prone to banging themselves up.”

Matt agreed.

“The cows were getting too big for our stanchion barn,” he said.

Several stanchions were retained in the barn for milking fresh cows and doing veterinary work. The remainder of the barn houses heifers. Matt and Jim are currently building a heifer barn that will be the future home of these animals. They then plan to gut that part of the stanchion barn and possibly put in maternity and hospital pens and pens for newborn calves.

The new 2-row freestall heifer barn to be completed this spring will measure 44 feet by 90 feet and contain about 50 stalls. The barn will house heifers 10 months old to breeding age and feature a drive-

thru feed alley and automatic waterers.

“This barn will make caring for this age group a lot easier while providing better comfort and better ventilation,” Jim said. “We’ll be able to let them outside and give them access to a small pasture, too, which is something we can’t do now.”

When they expanded more than nine years ago, Matt applied for a rst-time farm loan. He owns 30% of the cattle under a separate limited liability company from his parents. He receives 30% of the profits from milk and cattle sales, and he and his parents each get their own milk check. The farm is an S corporation, and Paula and Jim own the land while the corporation rents the land from them.

“Paula and I are retirement age and wanting to slow down,

so Matt is kind of taking over,” Jim said. “He puts in long hours and long weeks because there is a lot of work to do.”

The Potratz family has learned to never back down even when hit head on with hardship. A three-time victim of re, the family has excelled in patience and persistence, rebuilding each time while looking at every setback as an opportunity to get better.

There were two res on the farm in Jim’s lifetime and one before he was born. The old farmhouse burned on Christmas Day in the 1950s. Then, in December 1980, the farm’s 30-stall stanchion barn and freestall barn burned to the ground. All of the family’s hogs perished in the re along with two calves.

“We got out of hogs after that,” Jim said.

In its place, the family built a 50-stall stanchion barn and freestall barn which are connected. Jim purchased the farm from his dad in 1984. In the summer of 1998, disaster struck once again on the Potratz farm when another re broke out, taking down the freestall barn and burning the top off of the stanchion barn.

“It was such a mess,” Jim said. “I’ll never forget the smell of a burnt-out barn and all the work that goes back into rebuilding it.”

The re in 1998 was caused by a torch cutter.

“It was a dry day, and the sparks caught and you can’t stop it,” Jim said. “It happened right in front of us. The kids were young, and it was traumatic for them.”

The Potratzes rebuilt the freestall barn a second time,

repaired the stanchion barn and moved cows home 10 days later. In the years that followed, they made additional updates to the freestall barn which houses breeding-age and springing heifers and dry cows. In 2016, they added 30 feet onto the building including another row of free stalls. Further renovations are planned for this barn in the near future.

Matt and his dad are constantly scoping out ways to enhance their operation. Three years after building their freestall facility, they added a covered walkway from the barn to the parlor, and the year prior, they added a lean-to onto the barn. Matt said both additions made a difference in keeping the barn warm. They also added rubber ooring in the walkway and feed alleys.

“The walkway made it much nicer for bringing up cows for milking, and the rubber ooring is nice for getting them off concrete,” Jim said. “The rubber is real durable, heavy-duty stuff.”

Out on the elds, this father and son team is making improvements as well.

“We’ve done a bunch of drain tiling here in the last ve years to improve the land,” Jim said.

As they continue to rene their operation, Matt has also given thought to adding a robotic milking system. To create the best version possible of the farm, the Potratzes always have a list of projects they are working on to update the dairy for the present and future.

Thursday, February 9

Pizza Ranch, Slayton, MN 10:30 AM – Leadership Meeting 11:30 AM – Lunch and Midwest Dairy Update

Thursday, February 16 Little Falls, MN 11:30 AM – Lunch and Midwest Dairy Update

Wednesday, February 22

Paynesville Legion, Paynesville, MN 11:30 AM – Lunch and Midwest Dairy Update

Thursday, February 23

Pizza Ranch, Wadena, MN 10:30 AM – Minnesota Milk 11:30 AM – Lunch and Midwest Dairy Update

Tuesday, March 14

Recreation Bar and Café, Lewiston, MN 12:00 PM – Lunch 12:30 PM – DHIA Annual Meeting 1:00 PM – Midwest Dairy Update 2:00 PM – DHIA Awards

CENTER CITY, Minn. –

Brenda Carlson does not have to search far to nd her needed recipe.

After all, Carlson is the third generation of Eichtens to make cheese using the same recipes her grandparents used.

Those avors are preserved at Eichten’s Cheese near Center City where cheese is crafted and sold on the family farm.

“We are the godfather of the farmstead cheese in the Midwest,” Carlson said. “We are the oldest company in Minnesota that makes farmstead cheeses.”

Milk for cheese production is purchased from neighboring farms and stored in a 5,000-pound tank. That volume can produce 500 pounds of cheese.

Eichten’s Cheese makes one to three batches of cheese a week, depending on the time of year.

“Christmas is crazy for us,” Carlson said. “We make cheese two to three times a week for the two to three months before

Christmas for the big Christmas sales.”

Eichten’s Cheese is known for its Gouda varieties, of which they have 17 avors.

“The big ones are the smoked Goudas,” Carlson said. “Our tomato basil Gouda started out as a holiday Gouda in the ‘80s, but it was so popu-

lar we had to keep making it.”

Eichten’s Cheese also has a line of hot Gouda cheeses such as a cran-chipotle and a jalapeno as well as the rst avored Gouda Carlson’s grandmother created, which is an herb Gouda. The newest avors being offered are a parmesan Gouda and an everything

bagel Gouda.

“Another well-known cheese that we make … is a Danish Tilsit,” Carlson said.

The company is known not only for its cheese but for giving back to the community as well as providing education.

“My grandparents trained a lot of people from Europe

and third-world countries on how to make cheese,” Carlson said.

One of the people they trained was a Turkish professor who came to the United States to learn how to make cheese from Carlson’s grandmother, Mary Eichten.

Because the Eichtens did not charge anyone to learn to make cheese, the professor asked if she could do anything for Mary.

Mary enquired about a recipe for Danish Tilsit. The professor sent Mary the recipe, but it was in Turkish and used metrics. With the help of the University of Minnesota, the recipe was translated and the family spent two years perfecting it.

“A Tilsit is a warm-room cheese,” Carlson said. “It goes in a room that is 65 degrees for two weeks.”

Carlson grew up working alongside her mom, Eileen, and her grandparents, Joe and Mary. All through high school, and on weekends when she was in college, Carlson helped make cheese. After moving away for 20 years, Carlson returned to the family business full time in 2010.

“I wanted to get back to my roots and be with family again,” Carlson said.

The idea of Eichten’s Cheese started in 1974 when milk prices were low and many farmers were dumping milk.

Joe and Mary participated in a University of Minnesota pilot program. The farmer had to fund a trip to Holland for six weeks, and the university sent a professor along who helped them learn to make cheese.

Upon their return to Minnesota, the professor helped the farmers establish on-farm cheese production as a valueadded entity. Six farmers participated in the program, but the Eichtens are the only family still making cheese today.

“Our rst wheel was produced in 1976 on our farm,” Carlson said.

Originally, the milk came from three herds owned by Joe and three of his sons. Eventually, milking cows and making cheese was too labor intensive. The family sold the cows in the 1980s.

Joe insisted on always using quality milk so the family could make quality cheese. They even purchase the cultures needed to craft cheese from Holland.

“My grandfather and grandmother were pretty innovative in thinking, so the rst thing they did was go to the grocery stores in the area and handed

out free samples,” Carlson said. “They also went to farmers markets and have been a member of the St. Paul Farmers Market since 1977.”

Today, the company also has a website and ships cheese all over the U.S.

“Our website is a big help in sales, and we belong to a couple of wholesale sites,” Carlson said. “So now any momand-pop shop out there can go in and buy our products for their store.”

Eichten’s Cheese is sold at the St. Paul, Richeld, Roseville and White Bear Lake farmers markets every week in the summer. Going to the markets is one of Carlson’s favorite parts of the job because she said she gets to meet fun and interesting people.

“I like to stay as local as I can,” Carlson said.

At the shop on the farm, they also offer a small selection of local artisan products.

No matter the avor of cheese Carlson creates, she takes pride in carrying on her grandparents’ legacy.

“My grandparents put their life savings into this, and I get to carry that on,” Carlson said. “It’s about being a good farmer and neighbor.”

Brandon and Kim Grewe of Cumberland, Wisconsin, traversed a number of highs and lows during 2021 with their homebred Guernsey cow taking top honors in the show circuit and their daughter, Brynn, coming down with a serious E. coli infection. The infection ultimately took both of Brynn’s feet and all of her ngers except her right thumb, causing the little girl to become an amputee before the age of 2.

Amidst the heartbreak of her illness, the Grewes continued to show Valley Gem Atlas Malt, who was named grand champion Guernsey at World Dairy Expo and supreme champion of the North American International Livestock Exposition – earning both titles for the second consecutive time.

When Becky Levzow received an invitation to visit Dubai in the United Arab Emirates to promote American dairy products, she did not hesitate to say yes. The ve-day mission was packed with opportunities to shed light on the quality, diversity and abundance of American-made dairy foods.

Levzow was joined by three other dairy farmers and staff from the U.S. Dairy Export Council. The trip’s goal was to increase dairy product exports into the Middle East by way of Dubai, a dynamic regional trade hub. The trip provided the Dubai market with direct dairy farmer contact and an opportunity to learn more about the people behind the products.

Dairy farmers in the northwestern Wisconsin counties of Polk and Burnett are in a ght for their right to operate their family-owned farms, facing regulation from the town boards that govern their local municipalities. In the fall of 2021, six townships – ve in northern Polk County and one in southern Burnett County – began working in partnership to disapprove of the development of animal agriculture, particularly concentrated animal feeding operations.

Kristin Quist, who farms with her family on their 1,200-cow, fth-generation dairy farm in the township of Black Brook, is not taking the potential restrictions lying down as she works to increase public awareness about agriculture.

On the morning of Jan. 12, Eric Svenson carried a healthy newborn heifer calf out of the ashes of the previous night’s re that destroyed his family’s tiestall barn near Ringwood, Illinois. He named the calf Fire Truck in honor of the 20 re departments that helped quench the four-alarm re. Two springing heifers were also rescued from the wreckage unharmed. Finding survivors where none were expected was a blessing that Svenson and his family clung to during a dark time as they began raising money to rebuild their barn.

Born legally blind, Cory Brekken has lived a life seeing only shapes but no details at close range and seeing nearly nothing from far away. Suffering from Leber congenital amaurosis, Brekken is missing cells in both of his retinas. However, he can do many of the same things other dairy farmers do on his farm near McFarland, Wisconsin, such as milking, feeding, breeding cows, cutting hay and xing equipment. Milking 75 cows and farming 200 acres with help from his dad, Brekken relies heavily on his sense of touch to accomplish tasks.

Laura Herschleb fullled a lifetime goal when she stepped into the role of general manager at World Dairy Expo Feb. 28. Herschleb grew up on a dairy farm near Germantown, Wisconsin, and began her duties following the retirement of Scott Bentley. From a college student in the Badger Dairy Club, to ve years spent as the Dairy Cattle Show manager for World Dairy Expo in the late 2000s, to her return in 2018 as the marketing manager, Herschleb has spent many hours on the WDE grounds and looked forward to making the 2022 Expo an event to remember.

A tornado tore through the farm of James and Callie Amera March 5 near Stoughton, Wisconsin, leaving massive destruction in its wake. Despite its F-1 rating, the tornado was packed with fury and left nearly nothing untouched during the ve minutes it spent on the ground. A total of 18 structures were damaged – 11 of which were totaled. Their 60-cow herd was relocated to a neighboring dairy farm as the couple picked up the pieces of the rst tornado to hit Wisconsin last year.

Brekken does not let blindness slow him down

Ameras rebuild after being struck by March tornado

As parents of a 19-year-old son with disabilities who requires constant care, each day for Ron and Shirley Kohlbeck is lled with challenges above and beyond those typical of dairy farming. Mitchel, who is completely dependent on his parents, is suspected to suffer from mitochondrial disease, a rare disorder in which cells in the body do not receive proper oxygen. He has never walked and only once said the word da-da. The farm provides an outlet of stimulation and happiness for Mitchel, who enjoys being around the animals and going for tractor rides.

ies and spending time in three different hospitals. During this time, he also missed the birth of his third child. From profuse bleeding to extensive lung damage to being placed in an induced coma, Hedlund miraculously survived the unthinkable while his wife, Annie, continued to run their farm in Siren, Wisconsin. After 10 months of hospitalization, Hedlund continued to battle his way home.

When her husband was diagnosed with colon cancer in January 2021, Jacqui Davison’s mantra was, “It could be worse; it’s not one of the kids.” A year later, it got worse when Jacqui was diagnosed with breast cancer. She has the same type of estrogen receptive breast cancer her mother died of. After having surgery to remove a breast and multiple lymph nodes, Jacqui underwent chemotherapy treatments every other week all summer.

Jacqui continued working at the farm throughout her treatments, even while dealing with side effects. She farms with her family near Hillsboro, Wisconsin, where they milk 800 cows and farm around 1,200 acres. Her husband, Keith, works at a grain farm in the area. Despite the difculties of their illnesses, the Davisons have remained positive throughout their cancer treatments by focusing on what they are grateful for.

Adam Hedlund’s battle with the coronavirus, which began October 2021, was beyond anything his family could have imagined. His life was in jeopardy for months as he suffered with complications from COVID-19 induced pneumonia that resulted in him undergoing two lung transplant surgerSauk Centre, MN Buffalo, MN

the building, while Steve Stettler and his wife, George, own the business, equipment and marketing rights. With the expansion, volume could increase to 700,000 pounds of milk per day.

Sept. 11 was supposed to be the rst day away from the farm in a long time for the Plucinski family. But not much more than a half hour into their trip to Wisconsin Dells, Wisconsin, Meg and Derek received a call that their barn was on re. Fortunately, the cows were on pasture, but the tiestall barn was a complete loss, including the 6-stall walkthrough milking parlor they had put in nine months prior.

Tania Groen moved their farm and family halfway across the country to an area better suited for organic dairying. Landing in Amherst Junction, Wisconsin – 2,000 miles away from home – the Groens faced many challenges early on. But as the family closed the books on their rst year as Wisconsinites, they felt the positives of their relocation outweighed the negatives and had no doubt they would do it again.

An expansion is expected to be completed by Feb. 2 at Decatur Dairy in Brodhead, Wisconsin.

Decatur Dairy in Brodhead, Wisconsin, is undergoing a $6.2 million expansion that will add 24,000-squarefeet of space to the facility to be completed by February 2023. The addition will nearly double the cheese factory’s physical footprint. The expansion will include dry storage space, cold storage space, a new packaging room, curing room, new loading docks and a shipping ofce. As a result, the addition will open up space in the existing facility and also offer an area to add more processing capabilities.

The dairy takes in about 550,000 pounds of milk per day from 72 patrons which is made into cheese that is sold nationwide. As members of Decatur Swiss Cheese Co-op, the farmers own

These organic farmers spent the weeks that followed sifting through the rubble that once contained all their dreams on the farm they rent near Jefferson, Wisconsin. The future looked especially uncertain as they had been renting the farm for four years and were preparing to buy the place on a land contract. Holding fast to their faith, the Plucinskis’ goal was to bring their cows home as soon as possible.

in Hawaii in January, Tanner Schmaling suffered a swimming accident that left him 90% paralyzed. The young farmer broke his neck and was faced with spending the majority of his life in a wheelchair – a diagnosis he was not willing to live with. Two months later, Schmaling walked out of the hospital and returned to his farm determined to never use the wheelchair he was sent home with.

Schmaling and his wife, Maddie, own and operate Maple-Leigh Futures – a certied in vitro fertilization facility and boarding business for donors and show cattle near Delavan, Wisconsin. While undergoing outpatient physical therapy, Schmaling continued to progress in his physical abilities and did all the planting on the farm that spring.

In September, eight farmers received news Oberweis Dairy would no longer be buying milk direct from family farms. The news meant signicant price cuts for their long-time patrons. The remaining patrons included nine farms in southern Wisconsin owned by eight dairy producers who were informed of the decision via an online Zoom call Sept. 9. Oberweis Dairy, which is based in North Aurora, Illinois, is instead purchasing milk from the cooperative that took on its patrons. Oberweis’ claim that their milk still comes from small family farms is a claim that does not sit well with the farmers who previously supplied the dairy its milk.

Adam Hedlund, of Siren, Wisconsin, was hospitalized in October 2021 from complications of the coronavirus. Hedlund was transferred to multiple hospitals and received a double lung transplant over the course of 10 months. During his hospital stay, his wife Annie gave birth to their third child and kept their 100-cow dairy up and running with the help of friends and family.

of Auburndale, Wisconsin. Todd and Patti Bores milk 50 cows near Auburndale. Todd’s grandfather, Arnold, and father, Ralph, joined what was then the newly formed Auburndale Fire Department in 1965. Ralph retired after 55 years of service. Todd has been volunteering for 28 years. Todd and Patti’s sons, Riley and Collin, have 10 and eight years of service with the re department, respectively. Patti celebrated nine years with the EMS.

Six townships in Polk and Bennett counties in Wisconsin formed committees to craft ordinances related to animal agriculture. These rules would regulate animal numbers, hours of operation and permitting costs. Three of the townships adopted the ordinances.

April 11, 2022, was a comfortable 55 degrees in southwestern North Dakota, but April 12 brought a brutal blizzard to the northern Great Plains. Bob Hintz, who milks 250 cows near Flasher, North Dakota, estimated his farm received 2 feet of snow and wind gusts up to 74 mph over the course of three days. The Hintz family prepared for the storm by giving their cows extra feed and fueling up tractors and skid loaders ahead of time. Due to so many roads being closed, their milk hauler was not able to come for three days. Thankfully, the dairy did not have to dump milk.

Tanner Schmaling, of Delavan, Wisconsin, was on vacation with his family in Hawaii in early January 2022. While swimming in the ocean, he nearly drowned and sustained injuries that left him 90% paralyzed. Schmaling was told he would never walk again, but after physical therapy and determination, he was able to walk out of the hospital in March 2022 and return home to his 120cow dairy farm.

Janice Hill is a rst-generation dairy farmer from Reedsburg, Wisconsin. She milks 45 cows on her 100-acre farm. Hill grew up on a dairy farm, but she chose to work elsewhere for a number of years. In 2008, Hill purchased her own farm while continuing her day job. She has since quit that job to farm full time.

Jan. 4, 2022, was the worst day Glenn Heinen and his son, Aron, have faced. That morning, the family of St. Rosa, Minnesota, woke up to their barn engulfed in ames. They lost their barn, their 48 milking cows and 3,500 bales of hay. The family was able to save the farm’s calves and most of the heifers.

At just 9 months old, Abby Fick, of Lake City, Minnesota, was diagnosed with neurobromatosis type 1, which attacks nerves in the body and develops tumors. The disease stayed dormant until Fick was 14 at which time a cancerous tumor was discovered on her left shoulder. After trying chemotherapy with no success, the doctors determined they would need to remove her arm and shoulder. Fick now has a prosthetic shoulder and arm and is active in 4-H. Fick said she enjoys being with the animals on her family’s dairy farm where they milk 250 cows.

Nick Wienen knew he wanted to be a dairy farmer, but in 2020, his father, Tim, sold the family’s herd of cows after being diagnosed with cancer. Wienen had a job off the farm and continued to care for the remaining youngstock and farm the land with his dad. But, Wienen missed the dairy cows. So, Wienen and his wife, Tatum, purchased a group of cows to add to their freshening heifers to begin their own herd in September 2021. They milk 80 cows in a parallel parlor near Galena, Illinois.

Four generations of the Bores family have served on the re department or with the Emergency Medical Service in

At 9 p.m. Jan. 11, 2022, Eric Svenson received a call no dairy farmer ever wants to hear. The dairy farmer of Ringwood, Illinois, learned his family’s tiestall barn was on re. At the time of the re, there were four animals and a tractor inside the barn. Svenson and his wife, Mandy Parker, got the tractor and two cows out, but two springing heifers were housed in a different part of the barn that Parker and Svenson could not reach. The next morning, Svenson went to the damaged barn expecting to nd two deceased heifers. Instead, he found both alive and one had given birth to a healthy calf. The tiestall barn where the farm’s 160 cows were milked was a loss, but no animals were lost, and no other buildings were damaged. s in a parallel parlor near Galena, Illinois.

Cody and Arlisa Clements Coon Valley, Wisconsin Vernon County 80 cows

How many years have you been dairy farming? We have been farming for 5.5 years.

What were some of your accomplishments on the farm in 2022? After two years of grass-fed production, we were fortunate to secure a market with Organic Valley. We further completed expansion of all row crop land on our home farm to pasture, allowing 2 acres per cow.

What are you looking forward to most in 2023? The grazing season.

What is one goal you have set for the dairy this year and how do you plan to achieve it? Creating above ground water lines to the whole farm. At present, only 40 acres are equipped with lines, whereas the remaining 60 has to be brought in by trailer.

What do you think will be the greatest challenges for your dairy and the industry this year? Manure management remains the greatest challenge to our farm. With steep ridge slopes and heavy winter conditions, we still haul manure weekly when not grazing. We are investigating the feasibility of converting our facilities to a compost system for longer term storage. As to the industry as a whole, the inationary pressures are of no doubt great concern for all farmers. Beyond the high cost of production and feedstuffs, the ancillary costs attributed to small tasks, often overlooked, continue to drain most budgets.

Tell us about your farm. Highland Farm is a rst-generation, certied organic, certied grass-fed family farm, consisting of 100 acres of managed intensive paddocks with an additional 70 acres of summer pasture for dry cows and replacement stock.

How many years

dairy farming? We've been farming together for ve years. We both grew up on dairy farms. We met through my wife's parents when they sold their cows. I bought a Red and White Holstein heifer from my wife's parents, and then, the rest is history. We have four children.

What were some of your accomplishments on the farm in 2022? Some of our accomplishments in 2022 included an awesome crop year with everything above average. We also had a good year doing custom work.

What are you looking forward to most in 2023? We are looking forward to the new crop year and seeing how all the hard work turns out.

What is one goal you have set for the dairy this year and how do you plan to achieve it? One of my main goals is to reduce feed costs by putting up better forages and using less purchased protein.

What do you think will be the greatest challenges for your dairy and the industry this year? I see the biggest challenge to be inputs. Everything has skyrocketed in price and makes margins really tight.

Tell us about your farm. We farm alongside with Cody's dad, Alan. We milk 80 cows in a freestall and parlor setup with a swing-8 parabone. We raise our replacement heifers. We farm 550 acres of corn, hay and soybean. We also do custom farming services for area farmers. Those services include planting, big square baling, forage harvesting and combining. We hope that one day our children can have a future in this industry.

What were some of your accomplishments on the farm in 2022? My brother and I have shared equipment since we started farming, and this year, we were able to purchase our own corn planter. We also bought a cattle trailer. We have made purchases in the past but made more this year.

What are you looking forward to most in 2023? Building a new house. It will be the most momentous summer yet. Kurtis is a skilled carpenter and will build it with the help of his father.

What is one goal you have set for the dairy this year and how do you plan to achieve it? We do not have new goals for the dairy because we have spent the last year getting things in place so we have more time to build the house this summer. We hope to keep things running smoothly while we build.

What do you think will be the greatest challenges for your dairy and the industry this year? Keeping a good milk price. Hopefully the milk price does not crash before everything else like feed and fuel. Sometimes it does that, and the farmers have to make up the difference themselves.

Tell us about your farm. We milk 51 registered Holsteins in a tiestall barn. We farm just over 300 acres so that includes some cash crops. We have ve children. Both of our dads milked cows, and Valerie’s dad still does. All four of our grandfathers milked cows also.

Star Blends has been helping Midwest farm families by providing, high-quality feed, dairy nutrition, and commodity contracting for more than 20 years. Our state of the art mill can accuratelyblend anything from a custom pre-mix to complete feed, in balancing diets, or work with your private nutritionist or dairy consultant. Contact Star Blends at: 800-462-4125

have you beenCheyenne Christianson

Chetek, Wisconsin

Barron County

70 cows

How many years have you been dairy farming? I have been dairy farming for 30 years. I grew up on a small dairy. We started on our farm in 1993 when I was 21 and my wife, Katy, was 19.

What were some of your accomplishments on the farm in 2022? It was one of our driest years so it was a challenge to manage pastures and not overgraze or short the cows on quality forage. We supplemented with baleage and dry hay when needed to make sure cows and pasture were taken care of. Dry years show the benets of good pasture and soil management, and this past year really tested that. Increased organic matter soaks in the rain when we do get it and takes a lot longer to dry out than years back.

What are you looking forward to most in 2023? Rain. I am really hoping weather patterns change back to more normal rainfall as we have had three dry years in a row. I plan on seeding some elds with a good mix of alfalfa so we have more drought tolerance. We run long rotations, and alfalfa does well on our lighter soils. But, there isn't much left in many of our elds and pastures. Some alfalfa helps improve yields in the dry years.

What is one goal you have set for the dairy this year and how do you plan to achieve it? One goal is to cut back on cow numbers. Our herd has outgrown our acres and is creating more work than necessary, especially in dry years. We are thinking 50-60 cows total and less youngstock, but it may take a couple years to reach our nal goal.

What do you think will be the greatest challenges for your dairy and the industry this year? Continued weather extremes and the increased cost of everything are challenges we will face in 2023. Land prices are also too high for young folks to get into dairy.

Tell us about your farm. We are certied organic and 100% grass-fed. We have been shipping milk to Organic Valley since 1999 and have been on the grass milk route since 2014. We stopped feeding grain around 1998 and focused on forage-only milk production. Intensive grazing has been a key part of the success and protability of our farm.

Battist Farms Inc.

Jodie Bobolz (from left), Karen Battist, Jim Battist and Philip Battist Waterloo, Wisconsin Jefferson County

180 cows

How many years have you been dairy farming? Jim and Karen celebrated 80th birthdays in 2022 and have basically been farming their whole lives. Jodie started actively milking and feeding calves about age 8 but took off four years for college and taught grades K-3 for two years before returning to the family farm full time 31 years ago. Philip started actively milking and feeding calves at about age 8 but took off four years for college and was a nutritionist for a few years before returning to the family farm full time 25 years ago.

What were some of your accomplishments on the farm in 2022? I hate to admit it, but everything on the farm is getting older – people, buildings and equipment. Every time we can x or modify something on the farm to save money, or make our jobs easier, we consider that a major accomplishment. In 2022, we constructed our rst commodity shed to replace our elderly feed bins. This made feeding chores much easier and more time efcient.

What are you looking forward to most in 2023? In 2023, we are looking forward to seeing all the new blessings the Lord has in store for us – whether it be the beautiful sunrises and sunsets, or the almost daily

miracle of new life as calves are born, or the sprouting of seeds and harvesting of crops, or simply working together as a family pursuing our passion of dairy farming.

What is one goal you have set for the dairy this year and how do you plan to achieve it? My goal remains the same every year. I actively search sire summaries and ask many questions to try to nd the best sires for our herd. I wish to maintain size, strength and, above all, production so I can continue to have trouble-free cows that stay with us for a long time. I have several 10-year-olds and a 12-year-old. I also want to use a variety of bloodlines to keep our bull customers happy when they come to choose their next bull.

What do you think will be the greatest challenges for your dairy and the industry this year? The greatest challenge for our farm and the dairy industry, in general, is how to give our youth and next generation the passion to stay on the family farm or in the dairy industry. Without young blood and new ideas, the family farms will slowly fade away. We cannot let that happen.

Tell us about your farm. We farm roughly 1,000 acres around the farmstead that Grandpa bought about 80 years ago. My parents developed a well-known registered Holstein herd and started selling registered Holstein breeding bulls to customers more than 55 years ago. Twenty-two years ago, we built a double-10 herringbone parlor and freestall setup and increased the herd size to around 180 registered Holsteins with a few Red and White Holsteins which are my passion. Our milk is shipped with Family Dairies. We raise our heifers and all of our bulls, which are available for sale. My brother and I feel blessed to be following our passion of dairy farming alongside our parents who are an active part of the farm at age 80.

740 cows

740 cows

Describe your facilities and list your breeding management team. Cows are housed in a freestall barn and bedded with manure solids. They are milked in a double-12 parabone parlor. The treated cows are milked in a single-6 parlor separate from the other cows. I am the farm’s herdsman, and Matt Grams is a full-time employee of Engelmann Farms. Together, we do the breeding on the farm. We do genomic testing, and Select Sires Inc. chooses matings.

What is your reproduction program? Do you use a synchronization program? How do you get animals pregnant? After 30 days in milk, cows are given prostaglandin. Two weeks after that, they are given a second shot of prostaglandin. A week later, a GnRH shot is given. The following week, they are given Lutalyse, and a heat patch is applied. If cows do not show heat, they get a CIDR 10 days later.

Describe your breeding philosophy. We use genomics to keep the herd improving. It helps make breeding decisions easier. We work closely with representatives from Select Sires who choose which cows are bred with sexed semen and which are bred with beef.

What guidelines do you follow to reach the goals for your breeding program? We try to keep the cow in the herd, so if she doesn’t stick after the sixth service, we don’t breed her again. We walk through pens three times a day to catch cows in heat.

What are the top traits you look for in breeding your dairy herd and how has this changed since you started farming? In the beginning of the farm, Roger Engelmann was picking for type traits and production due to their kids showing cattle. As the farm grew and time went on, we adjusted the breeding program to t a commercial dairy herd. Now, we don’t look at bulls that are tall and show high dairy type. We breed for moderate frames, good daughter pregnancy rate, high fat and protein, and exceptional feet and legs. We

use all genomic bulls through Select Sires, who do a majority of the bull selection.

What are certain traits you try to avoid? Tall cows, high somatic cell counts and low components.

Describe the ideal cow for your herd. Our cows need to have livability and perform in the freestall barn and parlor. They need to have good feet and legs, a moderate stature and high production without sacricing components.

What role does genetics have in reaching the goals of your farm? We use genomics, which helps boost the rate at which our herd is improved.

What percentage of your herd is bred to sexed, conventional and beef semen? We use 60% beef semen and 40% sexed semen, which helps control heifer inventory.

What is your conception rate? Our conception rate is 48%.

What is the greatest lesson you have learned through your breeding program? I like working on the farm, as I do something different every day. I’ve been working here for 12 years, and what I’ve learned is that we have to be simple with the breeding program. We walk the pens three times a day to watch for heats. It helps to keep a watch over these things because we end up saving on days in milk, and cows are lasting longer in the herd.

What is the age of your heifers at rst service? The heifers are around 407 days old.

How does your heifer inventory affect your breeding program? We use sexed semen to manage heifer inventory.

Tell us about your farm. We milk 740 cows and farm 2,500 acres. Our milk is shipped to Bongards. We raise the heifers from birth to production. The heifer farm in Mayer, Minnesota, holds heifers from 3 months to around breeding age when they are brought back to Plato, Minnesota. The beefon-dairy calves are raised until about 500 pounds and then are sold.

“What I like best about Udder Comfort™ is really two things that are related: The removal of swelling and how it helps with cell counts. We started using it more routinely with our fresh cows 5 years ago. The Udder Comfort Sprayer makes it easy, fast and uses 30 to 50% less spray per application. With more routine use of Udder Comfort, we get better results, seeing consistently lower SCCs, now averaging below 100,000, and the savings from better udder health,” says Matt Nealy.

Matt is the ‘cow guy.’ He and his father Steve, cousin Tommy and uncle Tom operate the third generation Nealand Farms, milking 400 cows near Newville, Pennsylvania, MDVA co-op’s 2020 Producer of the Year, recognized for outstanding milk quality, animal care, farm and environmental practices.

“Udder Comfort is something we don’t cut. It gets swelling out faster for better milkouts and higher quality milk. We do every fresh cow for a week after calving. We mark high-count cows on DHIA and do them too. We tried knock-offs. They don’t work. Udder Comfort works!”

JUNEAU, Wis. – Dr. Gavin Staley has been studying the long-term impacts of calving in heifers at a younger age. While he agreed there are economic reasons to bring heifers into the milking string earlier, he has studied the impacts of these heifers not being mature at calving.

Milk production ultimately suffers, and it goes deeper than the rst lactation alone. Staley has studied production data from 500,000 cows and has discovered a formula that proves the importance of mature heifers.

“I call it the Peter Pan problem, alluding of course to the children’s comic character,” Staley said. “The individual that never grows up.”

Staley is a technical services specialist with Diamond V and a veterinarian who spoke in a Profes-

sional Dairy Producers podcast Dec. 28, 2022.

Heifer maturity means the phenotypic characteristics – frame and body weight – that allow full expression of genetic potential over the animal’s lifetime. For a long time, the standard has suggested heifers need to be 85% of the mature body weight post-calving, and close-up heifers should be about 95% of mature body weight.

If an animal does not reach the required level of maturity before calving, she will reach it during lactation at the expense of production, Staley said. She will inevitably reach the benchmark on the lactating ration, ultimately increasing the growing cost.

“It nets out to an 8:1 ratio,” Staley said. “For every 1 pound that she has to mature after calving, it will cost 8 pounds of milk.”

Staley said it also takes longer because the daily growth rate drops signicantly after calving. Sometimes it can take up to 500 days, which could be a lactation. Some heifers simply never catch up.

Staley has determined that week 10 of the rst lactation approximates the herd annual average milk.

“If you want a 100-pound herd, you’ve got to have a 10-week lactation one that is 100 pounds,” Staley said. “Ninety-two percent of the average annual herd milk variation can be explained in lactation one.”

This predicts the average annual milk for the entire herd from a single value. It also works in reverse,

with the rst lactation setting the ceiling for the whole herd.

“The herd cannot outperform the production level set by lactation one,” Staley said. “You can’t cull your way there, you can’t repro your way there, and you can’t feed your way there. It’s basically the ace card.”

Staley and colleagues have determined that the age at freshening impacts the second and third lactations also.

“This is unfortunately the gift that keeps on giving,” Staley said. “It leaves an awfully long shadow.”

In order to evaluate a herd and be able to shift the focus to mature heifers, Staley said the third- and fourth-lactation groups of cows need to be weighed in order to determine the herd’s mature body weight. Then, springing heifers and fresh cows need to be weighed. After that, the weight difference between desired and actual weights can be calculated. This way, it is clear what the system is delivering, Staley said. From there, the average daily gain can be calculated to see what the heifer raising system is achieving.

The average daily gain or the age at freshening are the two variables to consider when deciding what to change, Staley said. And, if the average gain cannot be increased, breeding must be delayed until the animal reaches that mature point.

Staley said dairy farmers should set health and growth goals for all key stages of growth from birth to calving. The goal can be to calve heifers as early as possible, but they must be mature at calving.

Staley said there has been a trend over the past 20 years encouraging producers to calve their heifers in at a younger age. The thought was the animal would begin milk production earlier, reduce heifer inventory and lower heifer feed costs. The message that got missed, however, is to manage the heifers to be mature at a younger age.

Staley said calving immature heifers has not been successful because the growth management was not changed.

“I’m not saying you should not breed heifers earlier, but you should get them to maturity earlier,” Staley said. “You can have your cake and eat it too.”

IOWA

Prairie Land Ag Supply Inc. Rock Valley, IA 712-476-9290

United Dairy Systems, Inc. West Union, IA 563-422-5355

WISCONSIN

Advanced Dairy Spring Valley, WI 715-772-3201

Ederer Dairy Supply Plain, WI 608-546-3713

DeLaval Dairy Service Kaukauna, WI 866-335-2825

Joe’s Refrigeration Inc. Withee, WI 715-229-2321

Mlsna Dairy Supply Inc. Cashton, WI 608-654-5106

Professional Dairy Services Arlington, WI 608-635-0267

Redeker Dairy Equipment Brandon, WI 920-346-5579

The Scharine Group Inc. Whitewater, WI 800 472-2880 Mt Horeb, WI 800-872-3470

MINNESOTA & SOUTH

DAKOTA

Farm Systems Melrose, MN 320-256-3276 Brookings, SD 800-636-5581

Advanced Dairy Mora, MN 320-679-1029 Pierz, MN 320-468-2494 St. Charles, MN 507-932-4288 Wadena, MN 218-632-5416

Winter is the only season to mark the close of a year and the beginning of another.

While winter happens to, more often than not, show the worst weather and the best views, it is the time of year for reection.

One of my favorite scenes are freshly-covered evergreen trees. There are three in my backyard, and during a frosty sunrise, I can usually crack my frozen face to make a smile.

The end of the year gives many families time to gather and celebrate life. With the holiday gatherings, and more time spent indoors, it can also make a person appreciate their alone time. Who would have thought hauling manure could be therapeutic.

By Grace Jeurissen Staff Writer

For me, 2022 has marked large milestones in my life and self-discovery.

In January 2022, I was helping on the farm. Then in February, I started my work with Dairy Star. Coming out of college with zero writing experience, colleagues took me under their wing and showed me the importance of print. I visited a few expos and realized how much people appreciate our content.

It is always nice to receive recognition for the work you are doing. That goes for all career elds.

This brings me to the reason behind Dairy Star. We are so fortunate to have rich dairy owing in the Midwest and so many passionate people to share stories of. Farmers deserve to receive recognition for their challenges and career achievements.

My visits with farmers always make me feel at home. But once I nish their story, the feeling of fulllment oats away because my mind is no longer living their story.

I ran into a young farmer who started farming when he was about my age. When I asked about why he chose dairy farming, he told me this.

“I feel at home here. I knew if I didn’t have a farm of my own, I wanted to be a herdsman for someone else, or I’d be trying to nd every way to make this dream work.”

This made me think on my drive to my parents’ farm that day. Against all odds, that young farmer is pushing through some of the most trying times in the dairy industry.

The passion in each farmer’s voice when we talk about cows together always excites me; I’m interested in their experiences and wisdom. Maybe the reason I feel connected to the stories until they are nished being written is because deep down I wish I was living their life, waking up early, seeing cows greet me at the gate, feeding a new born calf and cutting hay.

I thought the time wasn’t right for me to pursue my next goal, but when God presented me with the opportunity to farm, despite it having underlying concerns, I had to go for it.

I love it.

Every day, I set up the barn and get the barn moving. Then, I start my computer to plug away at work for Dairy Star and Country Acres. After, I have the freedom to take a break from my desk and help on the farm.

I’m truly getting the best of both worlds, and I couldn’t be happier. Like winter, I started my year how I ended it, in the barn.

What stands out to me the most over the last year is that nearly every farmer I have had the privilege of talking to has hope. They show resilience in everything they do, and despite the odds of volatile markets and high inputs, they try new things to make their operation work.

From the family that manages 20 employees to the young guy who milks 50 cows on his own, one thing stands true: No matter what the world around us does, farming is not only a job, but rather a way of life.

By Stacey Smart stacey.s@dairystar.com

By Stacey Smart stacey.s@dairystar.com

MADISON, Wis. – Dairy farmers may question the value of the dairy checkoff program. They wonder, “How are my checkoff dollars being spent? Do checkoff dollars equate to more money on my milk check? Am I getting a decent return?”

Through the use of checkoff dollars, Dairy Farmers of Wisconsin promotes dairy products across the U.S. in a variety of ways – from instore campaigns and media interviews to classroom education and online advertising, reaching millions of consumers along with retail and foodservice buyers.

“I could speak for days about programs and promotions DFW has created and implemented to drive demand for Wisconsin dairy products and to build trust in dairy,” said Chad Vincent, CEO of DFW. “We work extensively with all the major grocery

chains across the country to the point where Wisconsin cheese can now be found in 99% of grocery stores nationwide and in 140 countries.”

Since 1983, total dairy consumption has increased nearly every year and is standing at record levels. Consumer consumption of cheese has doubled, and U.S. per capita cheese consumption is up over 70%. Butter consumption is currently the highest it has been in 50 years.

Yogurt consumption has increased more than 300%, which Vincent attributes to new product development.

“The Dairy Farmers of Wisconsin checkoff has supported the Center for Dairy Research since the early 1990s, giving Wisconsin processors the rst opportunity at the innovation, skills, and technologies available through this world-class facility,” Vincent said. “Research conducted here has jumpstarted the development of new products using dairy –

from sports drinks to entirely new varieties of cheese.”

The dairy checkoff program began in 1983 when dairy farmers voted in favor of the milk marketing order and created the Wisconsin Milk Marketing Board (DFW) to build awareness and demand for Wisconsin dairy farmers’ milk.

Fifteen cents for every 100 pounds of milk is deducted for the checkoff, and this deduction has remained the same since 1983. Therefore, when milk is at $16 per hundredweight, promotion deductions are less than 1%. Five of the 15 cents go to the national checkoff organization – Dairy Management Inc. – while the remaining 10 cents stay instate with DFW.

Total milk usage over the last 35 years has increased by 79%, and since 2013, annual cheese sales have risen by 45 million pounds. Furthermore, about 16% of dairy is exported outside the country.

“Dairy economists estimate this export impact returns nearly $4 to the milk price,” Vincent said. “By law, checkoff cannot get involved with any lobbying efforts nor

impact milk pricing or supply. Obviously, farmers know there are still a lot of factors that inuence their milk price; however, growing exports will continue to benet them.”

Partnering with retailers via in-store demonstrations, print ads, point-of-sale materials, and digital and social marketing helps drive sales of Wisconsin cheese which results in a home for farmers’ milk, Vincent said.

DFW built the Wisconsin Cheese brand, and now Proudly Wisconsin Cheese and Proudly Wisconsin Dairy badges can be found on more than 4,650 Wisconsin dairy products. Vincent said consumers look for this identication and see it as a sign of quality.

“The badges, driven by Wisconsin dairy farmer checkoff dollars, make it easy for consumers to recognize and trust our outstanding cheeses when making purchase decisions,” Vincent said. “Cheeses identied as Wisconsin Cheese sell four times faster than non-Wisconsin identied cheeses.”

DFW regularly has promotions running in 5,000 grocery stores at one time. The More the Merrier holiday sales promotion is one of Vincent’s favorite promotions to date. Its purpose was to promote and sell Wisconsin Cheese in 2021 and 2022 during the November and December holiday shopping period – traditionally a peak time for specialty cheese. Retailers partaking in the promotion leverage recipes and how-to videos to educate shoppers on building beautiful cheeseboards.

“Because we know shoppers are looking for specialty cheese at that time of year, we want to make sure they see and choose Wisconsin specialty cheese over anything else in the case,” Vincent said.

The More the Merrier campaign highlights the Proudly Wisconsin Cheese badge through retailer print and digital ads, online events, sampling and point-of-sale materials. Beyond in-store promotion, sales and merchandising, Vincent said the campaign created excellent brand awareness using a store’s social media and digital marketing to reach millions of people.

“The More the Merrier program is one of our most successful campaigns because of the awareness it drives for Wisconsin Cheese along with the lift in sales we help generate,” Vincent said. “It

takes roughly 10 pounds of milk to make 1 pound of cheese, so promoting Wisconsin Cheese during the highest purchase period moves a lot of Wisconsin milk.”

The Cheese is Our Love Language campaign, held from Jan. 20 – National Cheese Lover’s Day – through Valentine’s Day, has helped replace traditional gifts of chocolates and owers, thereby promoting Wisconsin cheese and cheese boards as the gift many want to receive.

According to Vincent, May is not typically a month for high cheese sales at retail, but since DFW’s Wonders of Wisconsin campaign – a monthlong celebration in May – launched in 2021, participating retailers have seen an average increase in sales of more than 35%.

“The goal of each campaign is to create demand and sales for Wisconsin Cheese and drive awareness and visibility of the Proudly Wisconsin Cheese Badge,” Vincent said. “We often have retailers reporting a double-digit sales increase of Wisconsin Cheese resulting from these promotions.”

Through educational initiatives like the Adopt a Cow program, DFW interacts with schools in Wisconsin, teaching students and educators about the importance of dairy and agriculture. The program has reached 60,000 students in 71 of Wisconsin’s 72 counties within 2,100 classrooms as they follow the life of a real dairy calf.

DFW also funds Alice in Dairyland and helps tell dairy farmer stories and get consumers to visit farms through June National Dairy Month activities. In 2021, DFW had more than 45 farm families on local news stations telling their stories, reaching more than 3 million people in the state and beyond.

DFW engages with inuential dairy organizations and local grass roots dairy promotion groups to promote and activate nearly 70 breakfast on the farm events and elevate in-state pride to tell positive stories about dairy farmers and their commitment to the health of Wisconsin’s communities and land.

DFW has also invested in strategic partnerships with digital media outlets that reach core consumers. Most recently, they invested in a partnership with Food52 that reaches consumers nationwide who believe food is central to their world. This partnership

brought to life the Wisconsin Cheese story through video storytelling that was promoted on the Food52 website and social channels. The promotion also included a custom Wisconsin Cheese brand- focused landing page as well as traditional digital ads running throughout the website and on relevant content.

“These types of partnerships allow us to share our story in a way that is interesting and engaging to our audience,” Vincent said.

DFW also invested for the rst time in advertising through podcasts. Saveur, a popular site for foodies, entered the podcast world with Wisconsin Cheese as its main partner. Through this, DFW was able to insert its messages into all episodes and share the Wisconsin story through a feature on a Wisconsin cheesemaker.

DFW also continuously works to combat the alternative milk category by increasing positive perceptions of dairy.

“Over 96% of U.S. households contain dairy,” Vincent said. “Real dairy milk contains 13 essential nutrients that are unmatched by alternatives, and we are excited to see real dairy towering over plantbased beverages in size and absolute growth. Plantbased beverages are seeing signicantly less growth over the past year.”

The Brighteld Group’s consumer insights team found that purchases of plant-based creamers fell 25% in the second quarter of 2022, dairy-free yogurt sales were down 9%, dairy-free cheese fell 8%, and dairy-free ice cream realized a 3% loss.

“Price is one factor affecting declines, but the category’s health and environmental halos also lose their luster as more consumers look for clean labels including familiar ingredients,” Vincent said.

DFW proactively reaches out to media with positive stories, building trust in dairy products and dairy farming to grow demand for real Wisconsin dairy products.

“DFW is a tireless advocate for our dedicated dairy farmers,” Vincent said. “I encourage farmers who want a deeper understanding of how their checkoff dollars are being used to call us, call their elected board representative, and visit the Dairy Farmers of Wisconsin website.”

ARCADIA, WI

D&D Farm Sup. 608-323-7001

FREEPORT, MN Arnzen Construction 320-836-2284

FREEPORT, MN Hartung Sales & Serv. 320-836-2697

JANESVILLE, WI Tri-County Dairy Sup. 608-757-2697

LANCASTER, WI

Fuller’s Milker Center 800-887-4634

MARSHFIELD, WI

Podevels Farm Serv. 715-384-6193 800-742-5748

MELROSE, MN

Farm Systems 320-256-3276

MENAHAGA, MN Dairyland Equip. 218-564-4958

PENNOCK, MN D&D Ag Supply & Construction 320-599-4466

RICHLAND CENTER, WI

Fuller’s Milker Center 608-647-4488

ROCK VALLEY, IA Prairie Land Ag Sup. 712-476-9290

SAUK CENTRE, MN Dairyland Supply 320-352-3987 800-338-6455

SPARTA, WI Preston Dairy Equip. 608-269-3830

ST. CHARLES, MN Advanced Dairy 507-932-4288

WEST UNION, IA

United Dairy Systems 563-422-5355

WHITEWATER, WI

The Scharine Group 608-883-2880

WITHEE, WI Hoover Silo Repair 715-229-2527

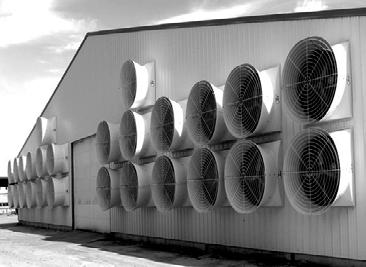

OSSEO, Wis. – The Osseo-Fairchild High School is $20,000 richer after being awarded a grant from the CHS Foundation.

In celebration of its 75th year, the cooperative awarded $75,000 to agriculture instructors across the country. The top prize went to Osseo-Fairchild High School of Osseo after their new ag teacher, Amelia Hayden, applied.

“As a rst-year teacher, I have a lot of dreams for where I want the Osseo-Fairchild ag department to go and things I want to teach the students,” Hayden said. “I knew that $20,000 would help me a lot to give them those experiences so I gured I would apply.”

Hayden plans to use the funds to grow the ag program at the school. The rst item on the agenda includes xing the school’s greenhouse. The broken ventilation system prevents students from using the greenhouse in spring or summer months because it gets too hot.

Once that is xed, Hayden plans to fund the new biotechnology class

she introduced to the program this year. The class covers subjects like animal genetics and genetically modied crops.

“There’s a lot of really cool ties to the science of agriculture with that class that we’re going to buy supplies to support,” Hayden said. “We’ll be able to give students hands-on experiences.”

One of Hayden’s seventh grade students acquired two calves to raise for the fair, and Hayden is hoping to make a school project out of it by housing the animals in the school shop. The shop has a ventilation system, and Hayden secured grant funding to purchase gates to construct a livestock pen. Hayden said it is everything a person needs to raise a calf indoors, and the shop is vacant due to no mechanics classes being held this semester.

“I’m game for any new adventure that will give students experiences,” Hayden said. “Some people have classroom rabbits and guinea pigs, and we’re going to have classroom calves.”

The dairy science class is learning how to articially inseminate cows this semester as well. Hayden is partnering with CentralStar Cooperative and going to a farm to practice A.I. on cull cows.

“I’m super excited about it,” Hayden said. “I’m still working on building those connections with local agriculture as I get to know more people.”

Hayden is from Walworth County and moved to the area after accepting the teaching position in 2022. She grew up involved in FFA and 4-H, and served as a state FFA ofcer for two years. She was also a 2022 top candidate for Alice in Dairyland.

The application process for the CHS grant involved answering essay questions and submitting a video. Hayden learned in October 2022 that she was one of the top three nalists

in the nation.

“As one of the top three, you’re guaranteed at least $10,000,” Hayden said. “So, I was already excited for the school to have funding.”

To narrow down the winners, the nalists attended the CHS annual meeting in December 2022. While there, they gave speeches and showed videos to the farmers in attendance. Those farmers voted live for the top prize winner.

“That’s the even cooler part,” Hayden said. “Not only did I get the grant for my ag education program, but the fact that it was farmers who selected me makes it all the more rewarding.”

As part of the effort to involve the community, Hayden and the students have put on various events and projects. Last fall, the FFA students hosted an event with pumpkin painting, bouncy houses and a cornhole tournament. They also hosted a supper to celebrate the opening of hunting season. In December 2022, they held a wreath making event as well.

“I talk (to the students) about wanting to get more involvement in

the local community and really give back to the people that raised them,” Hayden said. “It also gives the community an opportunity to learn more about FFA and all the ways that we’re working with youth in agriculture.”

Hayden said it is important to impart to students the importance of how much the agriculture community cares about and supports each other.

“I want students not only to leave my classes knowing the concrete skills that they need to pursue those careers but also to have that mentality of helping your neighbor and being involved in the community and giving back,” she said.

Hayden believes the grant will help to make her teaching dreams a reality by offering opportunities to her students to gain practical knowledge.

“We’re doing more than just talking about agriculture and what it means to be involved in the industry,” Hayden said. “But really giving the students the experience and career skills that they need to be successful.”

“As one of the top three, you’re guaranteed at least $10,000. So, I was already excited for the school to have funding.”

AMELIA HAYDEN, OSSEO FAIRCHILD HIGH SCHOOL AG INSTRUCTOR

Norwalk, Wisconsin Monroe County

Family: I farm with my two brothers, Walker and Tanner, and my grandparents, Bob and Connie, and my mom and her husband, Andi and Lawrence.

Tell us about your farm. We milk in a double-12 parallel parlor that we built in 2016. We direct ship to Grassland. All of our replacements are raised, and the bull calves go to my mom’s where they are raised as steers. We milk our treated and fresh cows in our original parlor and that milk is pasteurized and fed to the calves.