DAIRY ST R

Volume 24, No. 23

Volume 24, No. 23

NEW ULM, Minn. –Associated Milk Producers Inc. was part of Donn DeVelder’s life even before he began his career there in 1984.

“I was raised on a dairy farm near Corsica, South Dakota,” DeVelder said. “My father was manager of the local creamery, which merged with the newly formed AMPI in the early 1970s.”

DeVelder retired this month from his position as co-president and CEO of AMPI. Sheryl Meshke, who has been co-president and CEO with DeVelder since 2015, was selected by the cooperative’s board of directors to continue as sole president and CEO.

“The dairy farmer-owners and employees of AMPI benetted from nearly four decades of Donn’s steady, consistent leadership,” Meshke said.

Steve Schlangen serves as chairman of the board for AMPI.

“Donn has been an absolute trouper his whole career, always willing to step up for any challenge and never forgetting where he came from,” Schlangen said. “I would take Donn on my team any day; he makes everyone around him better.”

Editor’s note: This is the rst story in a series highlighting families who are the last dairy farm to operate within their respective counties across our coverage area. Dairy Star hopes to shed light on the industry’s landscape surrounding these farms and how these isolated farms thrive.

MIZPAH, Minn. – Running the last dairy farm in Koochiching County requires dedication and independence.

“We’re very self-sufcient here,” Scott Albrecht said. “We keep a lot of extra parts on

LONG PRAIRIE, Minn. – Derek and Amanda Zigan both said they make a good team. Amanda said she is analytical and Derek is hands on. Together, they are the First District Association’s Young Cooperator of the Year.

“Winning the award and having our kids see us win this award shows that we are strong role models for our kids,” Amanda said. “I hope they are proud.”

Derek and Amanda and their children – Jax, Chloe, Jovi and Alec – milk 130 cows with two robotic milking sys-

hand, and we work on motors, transmissions and our own equipment.”

Scott and Darlys Albrecht and their youngest son, Dal-

las, farm near Mizpah, a small town in northern Minnesota located 70 miles south of the Canadian border. The area is

more known for logging than farming.

Turn to ALBRECHTS | Page 8

said. “We are always looking for ways to be efcient.”

First District Association names an individual or a couple once a year under the age of 45 who is active in the industry and in their community.

After receiving the award, Derek and Amanda will serve on the cooperative’s Young Cooperator board. Members of the board learn more about First District Association’s mission, how things are done and the governance. Anybody within the cooperative can nominate a farmer. The Zigans were nominated by Adam and Jenny Kalthoff, who won the same award in 2022.

tems near Long Prairie. They raise 400 acres of corn and alfalfa, and Derek does custom harvesting in the summer and

fall. The Zigans also have 23 beef cow-calf pairs.

“Every year, we try to improve something,” Amanda

Both Derek and Amanda have plenty of experience serving on committees as they are on the Todd County American Dairy Association board and Todd County Breakfast on the Farm committee. Amanda is on their church trust committee.

www.dairystar.com

ISSN Print: 2834-619X • Online: 2834-6203

522 Sinclair Lewis Ave. Sauk Centre, MN 56378

Phone: 320-352-6303 Fax: 320-352-5647

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce) 320-248-3196 (cell) 320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Minnesota Senate Agriculture, Broadband and Rural Development Committee Chairman Aric Putnam is in his second term in the Legislature and his rst term on the ag committee. During the rst hearing of the session, Putnam said he understood the committee is historically very bipartisan. “While I hold this gavel, that’s not good enough; we need to be better than bipartisan, we need to be non-partisan,” Putnam said. “I am disinclined to hear any bill from anyone that has ve signers of the same party. We need to work better and do better.”

Vang oversees rst ag committee hearing

Farm Bureau delegates complete policy book

American Farm Bureau Federation Vice President Scott VanderWal oversaw the resolution process at the group’s annual convention.

Karen Knoblach

• karen.k@star-pub.com Annika Gunderson • annika@star-pub.com

Editorial Staff

Tiffany Klaphake - Assistant Editor 320-352-6303

• tiffany.k@dairystar.com

Maria Bichler - Assistant Editor maria.b@dairystar.com • 320-352-6303

Danielle Nauman - Staff Writer 608-487-1101

• danielle.n@dairystar.com

Stacey Smart - Staff Writer 262-442-6666 • stacey.s@dairystar.com

Abby Wiedmeyer - Staff Writer 608-487-4812 • abby.w@dairystar.com

Grace Jeurissen - Staff Writer 320-352-6303 • grace.j@star-pub.com

Jan Lefebvre - Staff Writer 320-290-5980 • jan.l@star-pub.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Consultant

Jerry Jennissen 320-346-2292

Main Ofce: 320-352-6303 Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication Sales Manager - Joyce Frericks 320-352-6303 • joyce@dairystar.com

Mark Klaphake (Western MN)

320-352-6303 (ofce) 320-248-3196 (cell) Laura Seljan (National Advertising, SE MN) 507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com

Jerry Nelson (SW MN, NW Iowa, South Dakota) 605-690-6260 • jerry.n@dairystar.com

Mike Schafer (Central, South Central MN) 320-894-7825 • mike.s@dairystar.com

Amanda Hoeer (Eastern Iowa, Southwest Wisconsin) 320-250-2884 • amanda.h@dairystar.com

Megan Stuessel (Western Wisconsin) 608-387-1202 • megan.s@dairystar.com

Kati Kindschuh (Northeast WI and Upper MI) 920-979-5284 • kati.k@dairystar.com

Julia Mullenbach (Southeast MN and Northeast IA) 507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell) bob.l@star-pub.com

The deadline for news and advertising in the Dairy Star is 5 p.m. Friday the week before publication.

One year subscription $40.00, outside the U.S. $200.00. Send check along with mailing address to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378.

Our ad takers have no authority to bind this newspaper and only publication of an advertisement shall constitute nal acceptance of the advertiser's order.

Letters and articles of opinion are welcomed. Letters must be signed and include address and phone number. We reserve the right to edit lengthy letters. The views and opinions expressed by Dairy Star columnists and writers are not necessarily those of the Dairy Star / Star Publications LLC.

The Dairy Star is published semi-monthly by Star Publications LLC, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378-1246. Periodicals Postage Paid at Sauk Centre, MN and additional mailing ofces.

POSTMASTER: Send address changes to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378-1246.

In the rst hearing of the year, Minnesota House Agriculture Committee Chair Samantha Vang said she looks forward to this session. “Farmers represent less than 2% of the Minnesota population, yet 100% of us eat or have benetted from the work of our farmers,” Vang said. “Farmers are truly the backbone of Minnesota, and I am very excited about what this committee can do. I look forward to working with each and every one of you.” Agriculture Commissioner Thom Petersen was asked about last year’s drought relief package. Approximately 3,000 farmers applied for the assistance. “People got on the average 42% so I think $2,700 was the top payment that people got,” Petersen said. “Like I tried to say all along, it was going to help pay a bill or two, maybe help buy a load of hay or make a payment on something.”

In his inaugural address, Minnesota Gov. Tim Walz said gridlock is over and it is time to get things done. Walz said this includes serving the needs of farmers and rural communities. “We can make sure prosperity extends across the state,” Walz said. “Let’s make sure communities all across Minnesota have equal access to healthcare, childcare, high-speed internet and educational opportunities.”

Walz has signed the tax conformity bill. This bill updates several parts of the state’s tax code, putting it in compliance with the federal tax code.

“Our delegates voted to modernize the farm bill by expanding baseline funding and developing more exible disaster relief programs,” VanderWal said. “They also voted for more transparency for the federal milk marketing pricing system.” VanderWal, who also serves as the South Dakota Farm Bureau president, said labor shortages were addressed at the convention. “Right at the top of the list is labor issues and immigration, specically, xing our H2A system,” he said.

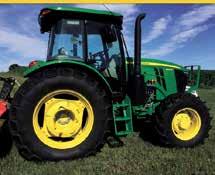

The American Farm Bureau Federation and John Deere have signed a memorandum of understanding, giving farmers the right to repair their own equipment. Farm Bureau President Zippy Duvall made the announcement at the organization’s convention in Puerto Rico. “This agreement will enable you and your independent mechanics to identify and x problems,” Duvall said. “You will have access to the diagnostic tools and information that you need, and you’ll get it all at a fair and reasonable price.” It took years of negotiations to secure this agreement. Discussions with other equipment manufacturers have already begun.

Rabobank global strategist Stephen Nicholson said agriculture is suddenly getting much more complicated. “We’ve got complicated markets, but you have these macro-economic things

that are coming in,” Nicholson said. “I look at the money supply situation and realize it is no wonder ination is where it is with so much money in the system; you have the classic situation of more buyers than sellers.” Higher interest rates will likely be a reality for some time.

Environmental groups have asked the Federal Reserve to actively address climate change. Fed Chairman Jerome Powell responded in a panel discussion with other central bank ofcials, saying the Fed must avoid drifting into political issues that aren’t directly involved with its work on economic policy. Powell said the Fed is not, and will not be, a “climate policy maker.”

Minnesota Rep. Michelle Fischbach has been appointed to the powerful House Ways and Means Committee. This is the chief taxwriting committee in Congress. In a statement, Fischbach emphasized “the importance of a competitive tax code and robust market access” for agriculture. The lawmaker, who is in her second term, said the Ways and Means Committee provides the strongest platform to work on these important goals for agriculture.

No reelection bid for Stabenow

Senate Agriculture Committee Chair Debbie Stabenow does not plan to run for reelection in 2024. The Michigan lawmaker said she will help guide passage of the next farm bill. Stabenow chaired the ag committee from 2011 to 2015 and took over the job again in 2021.

MN native moves to Finstad staff

John Altendorf has joined the staff of Minnesota Rep. Brad Finstad as a legislative assistant with a focus on agriculture. Previously, Altendorf worked for North Dakota Sen. John Hoeven

Fuess named senior dairy analyst

Lucas Fuess has joined the RaboResearch Food and Agribusiness team as a dairy industry research analyst and economist. Previously, Fuess was the director of dairy market intelligence at HighGround Dairy.

During the American Farm Bureau Federation convention, Minnesota Farm Bureau President Dan Glessing was reelected to the board of directors.

The cleanup continues following a re at Associated Milk Producers Inc.’s cheese

packaging plant in Portage, Wisconsin, Jan. 2. Packaging in the natural cheese department is expected to resume in the coming weeks. The processed cheese operations will take longer to come back online. As a cheese packaging plant, milk is not received at the Portage plant.

Seeking a bigger piece of the budget pie

Vang is hopeful the state’s budget surplus will mean more money for the agriculture. “Usually, the agriculture committee has one of the smallest budgets compared to bigger committees, like education and public safety,” Vang said. “With the larger needs, I will advocate a higher budget for our committee to meet the needs of Minnesota’s ag industry.”

The Minnesota House Agriculture Finance and Policy Committee approved two identical bills that would appropriate $50 million from state bond proceeds for the Rural Finance Authority. HF103 is sponsored by Badger Republican John Burkel and HF463 is sponsored by Brooklyn Center DFL’er Vang. RFA funds can be used for beginning farmer loans, loan restructuring, ag improvement and livestock expansion loans. The House Capital Investment Committee is the next step for these bills.

IDFA names chief economist

Mike Brown is the new chief economist for the International Dairy Foods Association. Previously, Brown was the director of the dairy supply chain for the Kroger supermarket chain.

Peterson to consult for IDFA

The IDFA has added three dairy policy consultants. The trio includes former House Agriculture Committee Chairman Collin Peterson, who now leads The Peterson Group. In addition, Chip English of the Davis Wright Tremaine LLP law rm, and Steven Rosenbaum of the Covington law rm, have signed on with IDFA. Both have experience with Federal Milk Marketing Orders.

Caseiculture is the craft of making cheese. That answers our last trivia question. For this week’s trivia, what is the dish featuring fries, cheese and gravy? We will have the answer in the next edition of Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network, based in Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two adult sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

Field Silo & Equipment, Inc. 1310 Bus. Hwy. 18-151

Horeb, WI. 53572

Field Silo & Equipment, Inc. 1310 Springdale St. Mount Horeb, WI 53572 608-437-5561 gotofields.com

DeVelder’s entire career has been in dairy.

“After graduating from the University of Northern Iowa with a bachelor’s degree, I knew I wanted to be in the dairy business,” he said. “I began my career with AMPI as a eld representative near Alexandria.”

By the end of his career 38 years later, DeVelder was leading AMPI, which today annually markets about 5 billion pounds of milk and generates nearly $2 billion in sales.

AMPI is headquartered in New Ulm and owned by dairy farm families from Wisconsin, Minnesota, Iowa, Nebraska, South Dakota and North Dakota. It markets cheese, butter and powdered dairy products to food service, retail and food ingredient customers.

In his roles at AMPI, DeVelder had a front-row seat in the industry, seeing many changes take place over time.

“The biggest changes I have seen in the dairy industry through the years include the consolidation of farms and manufacturing plants and the increased value of whey,” DeVelder said. “When I began, whey was a byproduct of the cheesemaking process, and it was disposed of on land or fed to farm animals. Now, thanks to innovation and changes in manufacturing, it’s a principal contributor to dairy farmers’ milk checks.”

Throughout his experiences, DeVelder said his respect for dairy farmers has been a constant.

“What hasn’t changed is the ability of dairy farmers to adapt to changing times,” DeVelder said.

“They remain deeply committed to caring for their cows, the land and their families. They are truly experts at what they do.”

Through AMPI, DeVelder has formed relationships with many of those dairy farmers.

“I’ve enjoyed the opportunity to work with three generations of AMPI farm families,” DeVelder said. “I know grandpa and grandma, mom and dad, sons and daughters, and the spouses who joined the farm along the way. Seeing the transition from one generation to the next, and how they continue to improve and adapt, has been amazing and truly impressive.”

DeVelder said it is important that farmers realize their value and power.

“A continual challenge for the dairy industry and cooperatives is

access to capital,” DeVelder said. “It takes capital – on your farms and in your plants – to keep your infrastructure strong. Be proud of who you are and what you own. Ownership of manufacturing assets ensures better control of your dairy farming destiny. There is a reason about 80% of the milk in the U.S. ows through cooperatives.”

DeVelder has advice about how to maintain dairy infrastructure.

“Be at the table and involved in the decision-making process,” DeVelder said. … “This region has the resources and reputation for making fantastic cheese. Your goal should be to make perfect milk for cheesemaking.”

Cheese and butter are the money makers right now, DeVelder said.

“Demand for the products we make in the Midwest, particularly cheese and butter, continues to grow,” DeVelder said. “Per capita cheese consumption in the U.S. has increased by 13% in the past 10 years and butter 18% during that same time.”

He said he sees these products lling the gap from reduced sales in other areas.

“Sales of uid milk, however, have continued to decline,” DeVelder said. “The continued loss of these sales is a missing piece on farmer’s milk checks. We must continue to try and make up for that gap by realizing more value from other dairy products.”

Even though DeVelder has been an active advocate for the dairy industry, he said he is ready to enjoy retirement.

“My wife and I have been married for 42 years and have four grown children and ve grandsons,” DeVelder said. “Our retirement plans include spending lots of time at hockey rinks and soccer elds and volunteering and giving back to the community.”

As DeVelder steps more to the sidelines of the industry through his retirement, he said he sees a bright future for dairy in the Upper Midwest.

“If you consider the dairy products that are really in demand, which is cheese, butter and whey, the cheese basket of the U.S. is here in the Midwest,” DeVelder said. “The infrastructure here in the Upper Midwest has always been strong, and it’s done nothing but get stronger.”

“I chair the cookie fundraiser at our kids’ school, which is one of the biggest fundraisers for the school,” Amanda said.

The Zigans hosted the 2015 Todd County Breakfast on the Farm and recently hosted the cooperative’s summer picnic.

“I believe fellowship in a community is important,” Amanda said. “I love being involved with other people and hearing their stories.”

Their children are also active in 4-H, and Jax joined FFA as a seventh grader at Long Prairie-Grey Eagle High School.

The kids are involved on the farm and help with chores by feeding the calves, cleaning pens and sorting cattle. Derek’s dad helps full time on the farm as well. Their farm is entirely run by family as they have no employees.

“We are super lucky that both sides of our family are helpful whether it is

PHOTO SUBMITTED

The Zigan family – Chloe (from le ), Derek, Amanda, Jax, Jovi and Alec – received a canvas cow pain ng for being named First District Associaon’s Young Cooperator of the Year Jan. 7 in St. Cloud, Minnesota. The Zigans milk 130 cows near Long Prairie, Minnesota.

helping on the farm or helping with the kids,” Amanda said.

Together, the Zigans went from milking 80 cows in a 55-cow tiestall barn to milking 130 cows with two robotic milking systems in 2015.

“We strive for full potential on our farm,” Amanda said. “We want our calves to start strong and grow to be healthy cows.”

They are always thinking ahead and willing to try new things to improve their cows and their farm.

“I am the type of person who wants to learn it all,” Amanda said. “I want to learn to A.I. and someday drive semi.”

To continue to improve efciency, the Zigans are planning to build a calf barn and heifer shed.

“We want to do well,” Amanda said. “We want to be good stewards of the land. We want healthy cows, which is what all farmers strive for.”

Scott and Darlys have been milking together for 34 years. They do most of the dairy work themselves while Dallas mixes feed for all of the animals and is the go-to person for xing things. Dallas, along with his partner, Callie Murphy, and their children, Reed and Myles, live on the farm as well.

At 61 years old, Scott has lived on the farm his whole life as the second generation to milk cows, but the transition from father to son was not typical.

“My dad sold the dairy cows when I was around 7 years old,” Scott said. “My mother bought me a heifer calf when I turned 11, and I raised her. I’ve been milking cows ever since I was about 13 years old.”

Scott bought a few more heifers until he had enough to have milk picked up at the farm.

“By the time I was 16, I had 13 cows, and I nally had two buckets to milk with,” Scott said. “I milked in my

dad’s old barn, the old hip-roof barn. That’s when I started getting (the milk) picked up.”

The Albrechts now milk 90 cows in a double-10 parabone parlor. They bed with sawdust because it is readily available in their area.

The Albrechts’ milk was shipped to Thief River Falls until the plant there closed. Today, the family’s milk is hauled to Land O’Lakes in Perham. Milk is picked up every three days.

“When I rst got on the milk route, the truck picked up 46 of us in the area on the one route,” Scott said. “I’m the last one of them still milking cows.”

However, having milk picked up in Koochiching County is not a given.

“Land O’Lakes will keep coming to this farm as long as I am milking, but if I were to

move from this farm, or a new dairy moved in this area, they won’t haul their milk,” Scott said. “That’d be the end, and the sad thing is there would never be another milk truck coming to this county again.”

The conviction to retain the dairy industry in their county is one of the reasons the Albrechts persist in milking.

“I’ve been threatening to quit the last couple years, but I don’t know,” Scott said. “You just don’t give up.”

Although Darlys did not grow up on a dairy farm, Scott said she likes the cows even more than he does. When he has considered selling the milking herd, Darlys has held him back.

“When we think about selling the cows, I think, ‘What am I going to do to fulll that time?’” Darlys said. “I haven’t had to drive to work in 34 years.”

Darlys said she nds milking peaceful.

“You go out there, and it’s kind of my quiet time,” she said. “Nobody

bothers you when you’re out there because you’re busy.”

Darlys said there have been benets from marrying a dairy farmer and raising a family on the farm.

“When we started our own family, it was nice to work at home and be with our children,” Darlys said. “You turn around, and here they are raising families of their own, and you think, ‘Wow, where did the time go?’”

Now, the next generation is experiencing the farm and the lifestyle that parallels it.

“One of the special things is that the grandkids enjoy being here too,” Darlys said. “You get that connection being with your grandparents. Now, Dallas gets to see his kids during the day, and we get to see them too.”

Although farming can be tough in the area because of a shortened growing season and the lack of available resources, the Albrechts have found ways to persevere.

The Albrechts own spare equip-

stands in the saw mill Jan. 18 on his farm near Mizpah, Minnesota. In his spare me, Albrecht works in the mill and saws his own lumber.

ment in case of breakdowns.

“We’ve got three round balers and two big square balers, but we’ll only run one round baler and one square baler,” Scott said. “The others are always ready to go. If we need parts or equipment work done for the dairy, we’re just so far away from everybody.”

Tractors and other equipment are of the same make and model so they have interchangeable parts.

The nearest location for equipment service is more than 130 miles away, so the farm is stocked with an inventory to ensure needed parts and supplies are on the farm.

“We get a lot of people coming in and out of our yard because if they need something, they can always come here and get it – whether it’s a tool, a bale of hay, a piece of equipment or whatever,” Scott said.

Other decisions are made with distance factored in as well.

“If you have a cull cow to go to the sale barn, and it’s 130 miles to take her, you just don’t take one cow,” Scott said. “We generally go to (Winger Livestock Sales). The beef cattle go to (Bagley Livestock Exchange). That’s a little closer, only 100 miles.”

The Albrechts also purchase supplies in bulk.

When they need help during calving or with eldwork, their oldest son will step in or other family members. The Albrechts said there are not people nearby who they can hire for help.

Besides dairy farming, the Albrechts raise 250 beef cattle and farm about 1,200 acres of land across the area. They raise corn, soybean and hay. Through trial and error, they have worked to get the best yields possible.

“We use an 80-day variety (of corn),” Scott said. “As for the hay, if you take really good care of your al-

falfa, it does well. I’ve gotten four cuts, but you can generally always get three.”

The Albrecht farm began with one barn and has grown to include 15 buildings. The calving barn has a viewing room and is used for housing cattle during bad weather. The former milkhouse is now where laying hens are kept, and another building is used as a mill where Scott saws his own lumber to sell. Scott built the building himself, using lumber he produced.

“That’s my hobby,” he said.

The farm’s feedlot, with cement aprons on both sides, allows for driveby feeding. The Albrechts feed a total mixed ration to the milking herd.

Raising calves in Koochiching County can be complex.

“It’s a real challenge here to raise a calf because of the weather, so you try to make your cows last as long as you can,” Scott said. “If you pushed them hard, you’d burn them up that much quicker.”

Scott said he has respect for his cows.

“A cow gives so much,” he said. “A good cow is a good cow. We’ve never pushed our cows for a lot of milk, but we’ve always had good butterfat and protein.”

All hardships aside, Scott said he likes where the farm is located. He said there are good shing lakes in the area and plentiful wildlife, and he likes the scenery the farm offers.

“I own some ground that is 160 acres in one eld,” Scott said. “If I showed it to you, it’s the most unique ground up here. You step off the north edge of that eld, and it’s 70 miles to the Canadian border. It’s a beautiful eld.”

Mark Klaphake contributed to this article.

Scabbling makes a groove 2-1/2” wide and 3/16” deep which is wide enough for a cow to get her toe in. It is rough on the bottom and both sides, which gives your cow traction at ALL times!

COON VALLEY, Wis. – Big avor is coming from the small town of Coon Valley where Steve and Linda Schulte produce homemade fudge.

Their six-year-old business has fullled wholesale orders for every state in the country and recently sent a shipment to Liverpool, England.

Linda Schulte said it is all because of the butter.

“I truly believe that our fudge is the best because of the quality of the dairy products that are in it,” Schulte said. “We’ve always worked with Westby (Cooperative Creamery), and they’re just great.”

The shop goes through about 350 pounds of butter every week.

Schulte takes her car to the creamery’s distribution center and parks between the semi-trucks to retrieve butter every week. She and her husband are such good ambassadors for the butter they use that the cooperative made them honorary patrons. A sign hangs in the shop to commemorate the honor.

The many varieties of fudge are handmade in small batches under the name Valley Fudge and Candy. Schulte rst made fudge to sell in a craft show in 2016. Afterward, Schulte had requests from local shops who wanted to sell the fudge in their stores.

“I never intended to do anything like this,” Schulte said. “People just kept asking.”

Valley Fudge and Candy is part of the Sweet Valley Artisans store, which has products from 50 local vendors for sale.

The fudge business started in a small, rented kitchen and then moved into a space in downtown Coon Valley. The Schultes made their sweets in a 200-square-foot room. They had one fudge kettle and mostly did wholesale orders along with the fudge available at the store.

The demand for fudge started to grow, and soon Schulte was selling wholesale through an online system. They also took orders through their website.

In May 2020, the business saw its biggest growth yet. People started calling the store and complaining that the website was not working. They discovered it was due to the volume of people trying to place orders.

“Our IT person had to get us on a faster server,” Schulte said. “We couldn’t believe it.”

As the business grew, Schulte’s landlord continued to renovate the space to accommodate the growing demand. The business now operates with ve fudge kettles and 14 employees.

The process of making fudge revolves around the steam kettle. It begins with a powdered milk formula that is custom made for Valley Fudge and Candy. Then, water, butter, milk solids and vanilla are added and mixed for about half an hour. Inclusions like candy and nuts are mixed in at the end.

The fudge is then poured into pans and left to set. During busy seasons, the fudge is made and shipped on the same day. During the warm summer months, fudge is packaged with ice and stored in a large freezer for 24 hours before being shipped.

“It makes a lot more expense and work, but nobody wants melted fudge,” Schulte said. “We work with FedEx and UPS on how to get it from point A to point B as fast as we can because fast is the trick.”

“It’s expensive, but we always believe that if you don’t put highquality ingredients in, it’s not going to taste as good.”

LINDA SCHULTE, VALLEY FUDGE AND CANDY

said one of their favor-

ite events to attend and sell fudge at is World Dairy Expo in Madison.

“We love being there as part of the dairy industry,” Schulte said. “Anytime there’s anything dairy going on we try to support it.”

They recently gave their booth location at a local craft fair to a youth dairy club and sold them fudge at wholesale prices so the club could use it as a fundraiser. They also support the club at the county fair.

While the Schultes both have experience as former dairy farmers, they are happy to continue to support the industry through the use of butter. When butter prices rose last year, they took it in stride.

“It’s expensive, but we always believe that if you don’t put high-quality ingredients in, it’s not going to taste as good,” Schulte said. “And, if I had to give extra money to anybody, I’m glad it went to the dairy farmers.”

Becky Bitzan 5-1/2 yrs. with DHIA

What counties or area do you cover? I mostly test in Otter Tail and Douglas counties. I occasionally venture into Todd County.

What do you enjoy about the farmers you work with? I love talking with the farmers about how their farms, families, and cows are doing. I have learned a lot from them and have implemented a few things on our dairy at home.

What do you like about your work for DHIA? No two days are the same and no two farms are the same. The farmers are what make the job worthwhile. It’s also fun to work with DHIA coworkers at large dairies.

What do you do in your free time? In my free time, I enjoy milking cows, gardening, and watching a good TV show.

Sauk Centre, MN Buffalo, MN 763.682.1091 www.mndhia.org

By Jerry Nelson jerry.n@dairystar.com

By Jerry Nelson jerry.n@dairystar.com

CHANDLER, Minn. –Bill and Merri Post faced a life-changing dilemma.

In 2011, they found themselves at a crossroads on their farm, Middleroad Acres Land & Cattle.

“We were milking 120 head in our stanchion barn,” Bill said. “The barn was at its limit. We were told that the only way we could increase milk production was to add a third milking.”

But, there was a problem with that idea.

“Bill’s body was wearing out from all those years of milking,” Merri said. “His knees were shot, and his shoulder was giving him problems.”

Middleroad Acres Land & Cattle, near Chandler, has been in the Post family since 1931. The Posts’ herd, which has a long history of Red and White Holstein genetics, has been closed since the early 1970s.

“I told Bill that if we were going to quit milking he should imagine the day that the cows leave,” Merri said. “He said that he couldn’t do it. That’s when we decided to take the next step.”

The next step for the Post family was building a new dairy facility that included a pair of robotic milking systems.

“We visited several different robotic operations before we settled on the design of our new barn,” Merri said. “We eventually landed on a design that didn’t involve a lot of extra bells and whistles.”

The Posts’ new facility included tunnel ventilation, sand-bedded free stalls and translucent panels on the sidewalls. They milked their rst cows in the new barn Dec. 11, 2012.

Bill and Merri’s children, Sarah and Jake, were teenagers at the time.

“We made an alley of farm machinery and walked the cows from the old barn to the new one,” Sarah said. “Jake and I had show cows that we led with halters.

That helped keep the other cows calm.”

Many things have changed over the decade.

Sarah is now married to Jacob Bierstedt and has two children, Aiden and Coby. Jake married Megan Popkes in 2019. The couple has two children, Addie and Willa.

The Posts live in three separate houses located on their farmstead.

“Everyone helps out on

taughtPHOTO SUBMITTED The Post family includes Jake (from le ) holding Addie, Megan holding Willa, Bill, Merri, Sarah Bierstedt holding Coby, and her husband, Jacob Bierstedt, holding Aiden. The Posts built a new robo c milking facility for their herd of 120 Holstein cows 10 years ago. JERRY NELSON/DAIRY STAR

the farm whenever they can, including Jacob and Megan,” Bill said. “We’ve also gotten a tremendous amount of help for many years from our herdsman, Daryl Rylaarsdam.”

Merri said the transition to the new facility was a good one.

“We had a steep learning curve during the rst few weeks in the new barn,” Merri said. “But after a few months, we and the cows were much more comfortable with the situation.”

Sarah said the family has only had to sell one cow because she failed to adapt to the robots. And Jake said they have learned to bed the free stalls every seven to 10 days.

“We struggled with our (somatic cell count) for the rst ve years,” Merri said. “We tried different liners and experimented with our takeoff settings. One change we made was to gradually lower our box time limit to 11 minutes.”

These efforts have paid off. The Posts’ herd has a SCC that hovers between 110,000 and 180,000. Their herd is averaging 94 pounds of milk per cow per day with 4.1% butterfat.

The barn has an insulated ceiling which also aids in production.

“We chose that to keep the barn cooler in the summer,” Bill said. “But it’s also warmer in the wintertime. This keeps the cows comfortable, which makes them more inclined to visit the robots.”

The Posts have gone through numerous iterations of the pelleted feed that the cows consume when they visit the robots.

Sarah said they have learned that healthy cows will go through the robots, and those who are not as healthy and do not have udder pressure will not go through as often. They encourage the cows as best they can.

“We did a lot of tweaking to our pellets,” Sarah said. “We tried adding liquids and tried multiple avors.”

Jake said the Posts switched from storing their silage in bags to making a silage pile.

“The feed quality from the pile is much more consistent,” Jake said. “Cows thrive on consistency. Our milk production lows aren’t as low as they used to be.”

Bill said they began using genomic testing a year ago.

“We genomic test all of our heifers,” Bill said. “This enables to breed the bottom third of our herd to beef bulls. We have so many replacements on hand that we can cull cows that are too good to go to slaughter, so we sell them to other dairy farmers.”

Sarah said they breed for type, good feet and feed for production. The breeding program has also focused on increasing protein and fat production.

Merri said they have helped other dairy farmers during the startup of their robotic milking facilities.

“We could see the terror on their faces during the rst few hours,” Merri said. “But it was comforting for them to see us.”

Bill has endured more than his share of health issues over the past decade. He has had both of his knees replaced and has undergone surgery on a shoulder and a foot. But that paled in comparison to the news he received in 2017.

“Bill seemed tired all the time, so I made him go to the doctor for a checkup,” Merri said. “That’s how we learned that he has chronic leukemia. It’s a very manageable, very livable form of the disease. It only means taking one pill a day. If we didn’t have the robotic milking facility, we would have had no choice but to sell the cows.”

After 10 years in their new barn, there are very few things the Posts would change. They encourage others to build a robot barn for cow comfort not human comfort. Bill said while robots are a great addition, the technology goes not allow farmers to walk away from the operation.

“I spend as much time with the cows as I did before,” he said. “It’s just that now I get to choose when I spend that time.”

How do you prepare your animals and farm for blasts of cold weather? We give them plenty of bedding and plenty of feed. We try to have a foot of wheat straw in the calf hutches and for the monoslope heifer barn.

What challenges have you had on the farm during cold weather and how did you overcome them?

A challenge we had was driving the football eld-long hill down by the hay shed with the mixer, and we overcame that by putting sand down so we have traction. We have a sand pit off to the side of the driveway, and we take the loader tractor and sprinkle it on. We have to do that every time we get a snowfall.

What do you do to maintain equipment in cold weather? We run No. 1 fuel and keep our everyday equipment inside. We try not to use the silo unloaders in the winter. We feed out of the bags in the winter. We haven’t had much trouble with the heated waterers this winter.

What apparel would you not leave the house without during cold snaps? A heavy Carhartt jacket, bibs and Thinsulate hat, and I wear mittens.

Describe the toughest winter you remember. In 1998, an ice storm caused us to be out of electricity for three days. We had to run the tractor and generator for all three days.

If you could get away during the winter and go anywhere, where would you go? Anywhere warm to get away, enjoy the warm weather and not have to worry about everything. Tammy would like to go to Hawaii. Landon would go to the NCAA wrestling tournament wherever that was being held.

Tell us about your farm. We milk our cows in a double-8 herringbone parlor. Our freestall barn holds about 140 cows. We farm 500 acres of hay and corn. We ship our milk to the Nelson Creamery Association, which is part of First District Association. We also have 50 Red Angus and Angus cow-calf pairs. Landon will be getting married this August.

Herman Massmann Melrose, Minnesota Stearns County 67 cows

Herman Massmann Melrose, Minnesota Stearns County 67 cows

How do you prepare your animals and farm for blasts of cold weather? We make sure to give plenty of straw to our heifers and steers that are in group housing. All the animals are kept inside a shed in the winter. Our youngest calves are kept in group housing attached to the barn and get wheat straw. Older heifers and steers get corn straw.

What challenges have you had on the farm during cold weather and how did you overcome them? We’ve had frozen heated waterers that needed repair or replacement. All of our youngstock and steers are in group housing in sheds and each has a heated waterer. We’ve had at least four out of the six waterers that we have freeze up over the years. We’ve also had silo unloaders break down and need repairs. I’ve also had to chip away at frozen feed inside silos.

What do you do to maintain equipment in cold weather? We keep our skid loaders, tractors and manure spreader in a heated shop.

What apparel would you not leave the house without during cold snaps? I wear a ski mask, insulated pants, heavy jacket and layered socks with boots when it gets really cold out.

Describe the toughest winter you remember. During the winter of 2013-14, it stayed cold for the longest period. We had lots of ice chipping and went through a lot of bedding that winter.

If you could get away during the winter and go anywhere, where would you go? I like being home, so in the house. I don’t have a desire to travel anywhere else because I have everything I want or need here.

Tell us about your farm. I milk my cows in a tiestall barn and raise my youngstock including nishing out about 50 steers. I farm 260 acres of corn, alfalfa and oats. I have three kids and four stepkids. Some of the older kids help when they are home on break from college. My mom and wife also help when I need an extra hand. I am a thirdgeneration dairy farm, and I ship my milk to Land O’Lakes.

How do you prepare your animals and farm for blasts of cold weather? All the animals that are outside have a shelter, and I make sure that everyone’s bedding is clean and dry. I give them all extra feed for extra energy during cold snaps.

What challenges have you had on the farm during cold weather and how did you overcome them? I haven’t had any major setbacks or challenges with cold snaps because I do a lot of preventative maintenance to my animals and equipment.

What do you do to maintain equipment in cold weather? The only piece of equipment I need every day is a skid loader, which I keep in a heated shed. I make sure my skid loader has regular oil changes and is greased. I have a stationary mixer so I don’t need to start a tractor every day. But, I do keep a tractor and generator in the heated shed just in case of a power outage.

What apparel would you not leave the house without during cold snaps? My insulated bids when it’s really cold out.

Describe the toughest winter you remember. In the 1990s, there were a lot of cold winters. Before we had the manure pit, it was always tough hauling manure every day in the winter. You had to make sure the apron was loose and had to make sure all the manure got off the spreader, that you didn’t get stuck and that your tractor didn’t gel up. Years ago, the winters were much tougher than they are now.

If you could get away during the winter and go anywhere, where would you go? I have not done much traveling in the past, but I would denitely go somewhere warm. I would go to Mexico or Hawaii or Arizona to get a break from the cold.

Tell us about your farm. I operate 215 acres of corn and alfalfa, and milk 50 cows in a tiestall barn. I ship my milk to First District Association. My son has a crop farm and helps me with eldwork in the summer. I have been dairy farming my whole life.

Marvin and Tammy Byer (pictured) and their son, Landon Byer Dairy Frazee, Minnesota Becker County 130 cows

Deb Dolence Grey Eagle, Minnesota Todd County 50 cows

Marvin and Tammy Byer (pictured) and their son, Landon Byer Dairy Frazee, Minnesota Becker County 130 cows

Deb Dolence Grey Eagle, Minnesota Todd County 50 cows

We have a naturally ventilated freestall barn, so we try to keep the doors closed and the sidewalls covered to help keep the temperature up. We try to keep the youngstock bedded and comfortable. Waterers can always be a challenge so just making sure that the heating elements are working is critical.

What challenges have you had on the farm during cold weather and how did you overcome them? One challenge we can struggle with is frostbite on springers’ teats. Getting them trained to use the free stalls and making sure that they stay clean and dry is important. We post-dip springers with a different dip that has more conditioners to keep skin soft and smooth. It’s also important to get good milk ow from them. If they don’t let their milk down, we will use oxytocin on them. We’ll run them with the hospital cows on a bedding pack during severely cold weather.

What do you do to maintain equipment in cold weather? Keeping equipment indoors is helpful. We have a nice-sized heated shop, which is very helpful. Our feeding equipment stays in the freestall barn with the loaders, which is usually warm. We try to schedule certain things and rotate equipment in and out of the shop. We also use treated diesel fuel and cold weather additives.

What apparel would you not leave the house without during cold snaps? Insulated coat and gloves.

Describe the toughest winter you remember. Honestly, it’s probably this one so far. I graduated from high school in 2015, and this is the most snow I remember during these seven years. The cold snap we had in December was pretty brutal. I can’t say that I can remember windchills that low since I’ve been working.

If you could get away during the winter and go anywhere, where would you go? I’d say anywhere warm. Wherever my wife and kids would choose to relax and spend time together.

Tell us about your farm. I farm with my dad, Rodney, and two of my brothers. We also have three milkers who help us. We milk in a double-8 herringbone parlor, and our herd of Jersey cows are housed in a freestall barn. We farm 520 acres and grow a ro-tation of corn and soybeans along with 35 acres of alfalfa. Our milk is shipped to Land O’Lakes.

By Jan Lefebvre jan.l@star-pub.comWORTHINGTON, Minn. – Many people, when needing medical attention, have experienced being driven to a hospital, but not many can claim to have been driven there by tractor.

That is what Joe Vander Kooi did for two stranded motorists Dec. 23, 2022, when they were caught in a blizzard near his farm and needed help.

“They might have been just ne, but it might have been a bad deal,” Vander Kooi said. “Things can go south (in a blizzard) pretty fast.”

When Vander Kooi set out in his tractor that afternoon, it was to clear the road so his employees could safely come in for the third milking shift. He and his wife, Rita, are in partnership with his father, Dave Vander Kooi, at Ocheda Dairy where they milk a couple thousand cows south of Worthington.

The temperature was about 15 degrees below zero that day with 30-40 mph winds.

“It was a 50-below windchill,” Vander Kooi said. “It was wicked – a white out.”

Vander Kooi’s tractor had a front wheel assist with a silage blade, so he could plow snow as he went. The tractor’s height helped, Vander Kooi said, but visibility was only about the distance between the electric poles.

Vander Kooi has lived near Worthington his whole life and is used to Minnesota blizzards, but he said the night before he already realized this one was extreme.

“I have an open cattle lot with bales protecting the cattle from the wind,” Vander Kooi said. “It was probably the rst time I thought that there was a chance I could have dead animals in the morning.”

Vander Kooi’s plans to clear the road that afternoon changed when he came across a car in the middle of the road, blocking his way. He jumped out of the tractor to talk to the two young people inside.

“They were looking for their friends who were stuck and thought they were right over the hill,” Vander Kooi said. “I didn’t make too much of it. I told them to be careful and kept going. When I came back 20 minutes later, they were still there, in my way, but in a different spot.”

Vander Kooi checked in with them again.

“They had their phone out,” Vander Kooi said. “Their friends were on speaker phone saying, ‘We’re so cold. We don’t know how far we can walk.’”

It was then Vander Kooi realized they needed help.

The group said they were using an app to pinpoint where each pair was, using it to try to walk toward each other.

“I told (the stranded pair) to get back to their car if they could, and I would pick them up, guring their car was on the road,” Vander Kooi said. “Then I looked at their (app) and realized they weren’t over the hill; they were 2.5 miles away down a not-so-good road.”

Vander Kooi told the friends to drive to town instead of trying to follow him on the dangerous roads and he would keep them updated. Then, he set out in his tractor

to locate the stranded car.

“It’s a road I take to work every day; it’s a beautiful drive on a bluff overlooking a lake and a winding road,” Vander Kooi said. “But, in a blizzard, I don’t take that road because right now the cut on either side of it is taller than your vehicle, and in a wind storm, it’s bad. I ended up going through another section to get to where (the stranded motorists) were.”

When Vander Kooi found them, they were in their car.

“(One of the pair) told me he couldn’t feel his feet and his leg had turned purple,” Vander Kooi said. “But, they got in my tractor on their own power. They didn’t look terrible; they didn’t look awesome, but I told them that it was nothing to mess around with.”

Vander Kooi drove his passengers into Worthington by tractor and dropped them off in front of the emergency entrance at the hospital. It was 6:30 p.m. – about 3.5 hours after rst coming across the motorists looking for their friends.

Vander Kooi said his passengers were humble and thankful for the help.

“They were saying, ‘God bless you,’ the whole time,” he said.

Since that day, Vander Kooi has not spoken with them, but the mother of one contacted Rita on Facebook to thank him and let him know both were ne.

Vander Kooi said he is uncomfortable talking about the incident because he does not want attention for what he sees as a normal act on his part. He was in the right place at the right time and knows, amid a Minnesota blizzard, it is better to be safe than sorry.

“It might have been ne, but in those conditions, it might have had a different ending,” Vander Kooi said. “How do you ever know?”

This year, GEA ProManure welcomed a NEW addition to the 10-inch lagoon pump family, the Lagoon Agi-Pompe.

The 10-inch Lagoon Agi-Pompe features a field-proven heavy-duty propeller capable of displacing tens of thousands of gallons of manure every minute. No matter the quantity or consistency of manure you have to deal with, GEA ProManure has a five-star pump made for you!

Your Local GEA Manure Equipment Dealers:

Field’s Mt Horeb, WI • 608-437-5561

Brynsaas Sales & Services Decorah, IA • 563-382-4484

Courtland Waste Handling Courtland, MN • 507-359-4230

Gorters Clay & Dairy Equipment Pipestone, MN • 507-825-3271

Hartung Sales & Service, Inc. Freeport MN • 320-836-2697

We have a new family member!

How do you prepare your animals and farm for blasts of cold weather?PHOTO SUBMITTED Joe Vander Kooi snapped a photo from the cab of his tractor of two young people he had driven to the hospital Dec. 23, 2022, a er they were stranded near his farm in blizzard condi ons near Worthington, Minnesota. Both passengers were reported to be in good health a er their ordeal.

Levi Ulrich Crowncrest Jerseys Ogema, Wisconsin Pierce County 24 cows

Levi Ulrich Crowncrest Jerseys Ogema, Wisconsin Pierce County 24 cows

Describe your facilities and list your breeding management team. I have a tiestall facility. Cows are housed in stalls, and heifers are in packs and pens. I handle all of the management of my breeding program myself but work closely with my vet and my nutritionist to make sure the cows have everything they need to be reproductively sound and efcient.

What is your reproduction program? I typically try to breed everything off natural heats. It seems I get the best results that way. If I have a certain animal I am having trouble getting bred, and she is getting a bit far out, I will use a fertility program. I will also try to synchronize if I am aiming for certain dates for potential show calves. Everything is bred using A.I.

Describe your breeding philosophy. I try to make mating decisions with corrective mating in mind. I breed cows to bulls that I believe will improve on their faults. My main emphasis is on sound, functional type.

What guidelines do you follow to reach the goals for your breeding program? I don’t really follow set guidelines. I spend time looking through other herds, seeing what other breeders are doing and how certain bulls are crossing on different cows. I use that information to help determine how those bulls might complement my own cows. Going to shows and seeing daughters of many different bulls helps make those decisions too. I also belong to social media groups where breeding dairy cattle, particularly Jerseys, is the topic.

What are the top traits you look for in breeding your dairy herd and how has this changed since you

started farming? I have always placed an emphasis on hard tops, wide chests, correct feet and legs, spring of rib, good rumps and especially high, tight udders.

If anything has changed, I breed for a higher-type cow than I used to, working to meet the changing goals I have set for myself.

What are certain traits you try to avoid? I avoid the opposites of the traits that are in my goal set: weak loins, narrow chests, sickled legs, shallow and tight rib, extremely high or low pins, and poor udder traits.

Describe the ideal cow for your herd. My ideal cow is one that will be around for a long time, 10 years or more. She has to be bred correctly to last that long, meaning she is not falling apart and that her top remains strong. She must have great width to withstand years of production and consume the forage she needs. Her udder must remain above her hocks as she ages. Her feet and legs are correct and allow for trouble-free mobility.

What role does genetics have in reaching the goals of your farm? Genetics play a huge role in the goals I have set for my herd. With-

“What I like best about Udder Comfort™ is really two things that are related: The removal of swelling and how it helps with cell counts. We started using it more routinely with our fresh cows 5 years ago. The Udder Comfort Sprayer makes it easy, fast and uses 30 to 50% less spray per application. With more routine use of Udder Comfort, we get better results, seeing consistently lower SCCs, now averaging below 100,000, and the savings from better udder health,” says Matt Nealy.

Matt is the ‘cow guy.’ He and his father Steve, cousin Tommy and uncle Tom operate the third generation Nealand Farms, milking 400 cows near Newville, Pennsylvania, MDVA co-op’s 2020 Producer of the Year, recognized for outstanding milk quality, animal care, farm and environmental practices.

“Udder Comfort is something we don’t cut. It gets swelling out faster for better milkouts and higher quality milk. We do every fresh cow for a week after calving. We mark high-count cows on DHIA and do them too. We tried knock-offs. They don’t work. Udder Comfort works!”

out working to improve each generation, you are sitting idle with nothing changing positively. To me, that is never a good thing.

What percentage of your herd is bred to sexed, conventional and beef semen?

On average, I use about 50% conventional and 50% sexed semen. Maybe 30% of the herd gets bred to beef. I am hoping to begin doing some embryo transfer and in vitro fertilization work on some of my top cows in the near future.

What is your conception rate? How does this differ with different types of semen? My conception rate is about 90%-95% on everything. Working with my nutritionist to make sure the vitamins and minerals in my ration are up to par; having the vet check cows right away when I am suspecting an issue; and breeding mostly off of natural heats are what make that possible for me.

What is the greatest lesson you have learned through your breeding program? The key to developing the best genetics for your herd

are working with really good cow families. That is so important in my opinion.

What is the age of your heifers at rst service? I

evaluate my heifers individually to determine when to breed. I’ve bred heifers as young as 12 months and as old as 18 months. I’ll typically try to grow them to

start breeding at 14 months.

How does your heifer inventory affect your breeding program? I try not to have a huge inventory of

heifers. Everyone knows that they are not cheap to raise. That is why I started breeding some of my lowend cows to beef and will probably up that percentage. The heifers I do have and keep are of a higher quality, and I want and need them to add value to my breeding program.

Tell us about your farm. I own Crowncrest Jerseys, which is a small herd of registered Jerseys with a showtype focus. My barn holds 24 cows, but I currently have 18. I have two cows scored EX-94, one EX-93, one EX-92, one EX-91, three EX-90, two VG-88, four VG-87, two VG-85 and two unscored 2-year-olds. I buy all my feed and graze when I can. I’m not located in the greatest area to farm. It is not convenient here, especially business-wise. My goal right now is to nd a larger facility to double my herd size in the MedfordDorchester-Curtis area to get into a larger farming community that would allow me more options, opportunities and conveniences close by.

News and Dairy Views from across the region

Minnesota Jersey Cattle Association is searching for queen candidates

Young women must: Be at least 16 years of age, and not older than 22, on Jan. 1 of the contest year; indicate involvement in the Jersey breed by personal activities and involvement in state and national organizations (i.e. Minnesota Jersey Cattle Association, 4-H, FFA, etc.); demonstrate an active knowledge of the Jersey breed and the dairy industry; be in attendance and represent the Minnesota Jersey Cattle Association at several functions; and clearly show that the

Contact one of the following dealers to learn more:

IOWA

Kramer Bros. Monticello, IA 319-465-5931

Prairie Land Ag Supply Inc. Rock Valley, IA 712-476-9290

United Dairy Systems, Inc. West Union, IA 563-422-5355

WISCONSIN

Advanced Dairy Spring Valley, WI 715-772-3201

Ederer Dairy Supply Plain, WI 608-546-3713

DeLaval Dairy Service Kaukauna, WI 866-335-2825

Joe’s Refrigeration Inc. Withee, WI 715-229-2321

Mlsna Dairy Supply Inc. Cashton, WI 608-654-5106

Professional Dairy Services Arlington, WI 608-635-0267

Redeker Dairy Equipment Brandon, WI 920-346-5579

The Scharine Group Inc. Whitewater, WI 800 472-2880 Mt Horeb, WI 800-872-3470

MINNESOTA & SOUTH

DAKOTA

Farm Systems Melrose, MN 320-256-3276 Brookings, SD 800-636-5581

Advanced Dairy Mora, MN 320-679-1029 Pierz, MN 320-468-2494 St. Charles, MN 507-932-4288 Wadena, MN 218-632-5416

Jersey breed is their top breed to represent.

This year’s contest will be held during the Minnesota All Breeds convention March 4. Contact Kristin Reiman Duden for an application and for more information at reim0060@ umn.edu or 763-260-3796. Application deadline is Feb. 28.

Applications are being accepted for a new grant program to support Minnesotans purchasing their rst farm. The Down Payment Assistance Grant Program is managed by the Minnesota Department of Agriculture and offers dollar-for-dollar matching up to $15,000 for qualied small farmers to purchase farmland.

The MDA’s Rural Finance Authority is awarding this funding using a rst-come, rst-served application process. The Minnesota Legislature appropriated $500,000 in scal

year 2023 for these grants. The RFA expects to award between 30 and 40 grants in this cycle, depending on the size of requests. A second cycle of $750,000 in funding has been secured and will be made available on July 1.

Farmers must be Minnesota residents who will earn less than $250,000 annually in gross agricultural sales and plan on providing the majority of the day-to-day physical labor on the farm for at least ve years. Applicants must not have previous direct or indirect farmland ownership.

Applications will continue to be accepted until a waitlist of 100 applicants forms, or May 15, whichever comes rst. Approved applications will remain valid for purchases closing within 90 days of approval or until May 15, whichever comes rst.

The application and more information on the Down Payment Assistance Grant can be found at https://www. mda.state.mn.us/down-payment-assistance-grant-program

UPSALA, Minn. – At snack time, students of Upsala Area Schools race to get in line. They are headed not for the snack line but rather the milk line.

The school district in Upsala, which has all grades in one building, made the switch to a bulk milk dispenser Oct. 1, 2022.

Alice Westrich and her team of lunch staff – Lisa Yurczyk, Jackie Wolbeck and Sandy Boeckermann – led the effort toward the transition.

“The kids were very excited,” Westrich said. “Our administration has been super supportive.”

The students, faculty and staff said they immediately noticed the difference in the taste of the milk.

“They let us know right away they like it better,” Westrich said. “The kids like that the milk is at the right temperature. It’s really good and cold.”

Yurczyk agreed.

“Even the teachers commented on how they like it better,” she said.

Yurczyk is in charge of dishwashing and was concerned about how much more work it would be to wash all the cups instead of discarding cartons.

“I haven’t even noticed a difference,” Yurczyk said.

The kids take a cup when going through the line at lunch or at snack time and ll it up themselves. Once they are done, they put their cup in a tray, which lunch staff then picks up and brings to the dishwasher.

“The kids love that they can push the lever and ll their own cup,” Westrich said.

The process of getting the bulk milk dispenser to the school began last spring. The lunch staff said they noticed milk consumption decreasing during the previous school year and were concerned about the health impact on students.

“Our current cooler for the milk was keeping the milk too cold, and it would freeze,” Westrich said. “We tried adjusting the temperature, but it didn’t make a difference. So, we would need to replace

our cooler or do something different.”

At the time, students were opting for water over milk. A co-worker of Westrich’s mentioned she heard of another school that had switched to bulk milk dispensers.

“I did some research and found a grant from Midwest Dairy,” Westrich said.

Westrich was awarded a grant so Upsala Area Schools could add a bulk milk dispenser.

“We are very grateful to Midwest Dairy for that grant,” Westrich said.

The move has also signicantly decreased the amount of garbage at lunch and snack time.

“It was denitely a huge cost savings and time savings,” Westrich said.

With the bulk milk, lunch staff no longer have to check dates on milk cartons and have saved 100 gallons per day of trash. Milk consumption has increased by 2 gallons per day, and the

school is saving an average of 15% on cost due to the fact they are buying their milk in bulk.

Upsala Area School gets its milk from Kemps and serves skim chocolate and 1% milk with the school breakfast, lunch and snack time. The milk comes in 5-gallon bags, which the lunch staff change out as needed.

“There really isn’t a lot of waste,” Westrich said.

Lunch staff said they were impressed by how well the kids took to the change. They also said there are hardly any spills and very little milk dumped. The staff keeps a pail in the cafeteria for kids to pour out any milk they did not drink. Westrich and her team said they have been surprised by the lack of waste.

“I think we were all afraid about how it would go, but it’s only been good,” Westrich said. “It’s well worth it.”

MELROSE, Minn. –

Twenty-four years ago, when Neal and Karen Klaphake decided to transition their dairy farm to organic, Karen had one request for her husband.

“I told him, ‘Just don’t tell my family. They’re going to really think we’re weird,’” Karen said.

Today, the Klaphakes have traversed varying opinions of organic production and now milk 80 Holsteins in a double-8 parabone parlor on their 260-acre farm south of Melrose.

When the Klaphakes began converting their crop ground, the initial results looked unpromising.

“We had our doubts,” Neal said. “The rst couple years, our elds looked tough.”

Karen agreed.

“We had some pretty ugly corn,” she said. “We didn’t know much about organic back then. There was very little of it.”

One day during a dry year in the middle of the Klaphakes’ transition, an agrono-

mist was checking one of their corn elds, and Neal asked him how he thought the eld would do for yields.

“The guy said, ‘About 26 bushels an acre,’ and I thought, ‘Holy cow,’ Neal said. “I asked how his corn was doing, and I think he said it was about 110. I wasn’t very proud.”

A denite learning curve was present.

“We didn’t have anything gured out yet,” Karen said. “There weren’t a lot of people then who could guide you. We were organic when organic wasn’t cool.”

The next generation of the family is following suit.

Neal and Karen’s son and daughter-in-law, Nick and Hope Klaphake, milk 80 Holsteins on their organic farm down the road, and their daughter and son-in-law, Carlee and Jacob Gaebel, have an organic dairy farm northwest of Melrose. Three daughters –Samantha, Apryl and Crystal – live off-farm, but they and their families come by to help or visit. Their youngest son, Josh, who graduated from high school last year, wants to take over the home farm.

It is safe to say the Klaphake family has embraced the organic movement.

“It’s been very rewarding,” Neal said. “Sometimes the family gets together, and

afterward Karen will say to me, ‘You can’t just talk about farming.’”

However, Karen said going organic was the right choice for their family.

“(Neal and I) have often said that, even if organic fell apart, we would still farm the same,” Karen said. “Once we

Greg Malone was hooked on a Pro-Tec building the moment he stepped foot in one. “The light is No. 1,” Malone said. “I looked at one at my nephew’s and one at Mid-Central; just walking through and I was sold on it.”

Malone, who dairy farmed up to 2013, now raises beef cattle and sheep with his daughter, Nicole, and wife, Mary. They also farm 1,000 acres of land.

Currently, their 36- by 100-foot barn serves double duty; there is a calving area on one end and sheep are housed on the other.

“It’s so easy to keep an eye on the animals because of the light coming in,” Malone said. “The barn is easy to clean.”

Malone’s vision for the barn included 7-foot sidewalls and white steel on the front, and those plans came to fruition with the help of Mid-Central Equipment.

“Nathan has been awesome to work with,” Malone said. “He’s been really accommodating.”

The barn was finished in the fall of 2021 and continues to impress Malone.

“To be able to find it for what we did has been nice; for the space, it was a good investment,” Malone said.

MN (218) 583-2931

realized that (organic farming) works, it’s become a way of life for us.”

Early on, though, both had to take a leap of faith when their future in organic farming was just a seed of an idea, and that idea came through an indirect route. The Klaphakes were having issues with mastitis in their herd. Neal began attending classes on the subject where he heard that a low-line parlor could make a difference. The Klaphakes built such a parlor in 1999.

However, Neal was absorbing other information at the meetings as well.

“I remember going to a meeting and hearing that you

could actually treat cows and not have to throw the milk away,” Neal said. “That was interesting, because every time a cow had mastitis, you’d give it a shot of penicillin and have to dump the milk.”

In the late 1990s, there were other reasons to consider organic production.

“There was more money in organic,” Neal said. “The price was higher.”

When their son, Nick, began farming near them in 2005, he began transitioning to organic as well.

Soon after, Neal went to one of Nick’s elds and started cultivating it. Neal realized the eld was already a disaster.

“I told Nick, ‘We’re starting over; go get the digger out,’” Neal said. “It was the beginning of June.”

Nick was horried, Neal said, but they worked the eld, making sure every weed was dead. Then they planted corn – again.

“That fall, when we chopped the eld, it was beau-

tiful corn,” Neal said. “It was tall and nice.”

Over time, the Klaphakes’ elds improved through a series of trial and error.

“As we’ve been doing this longer and longer, we’ve learned with weed control what to do and what not to do,” Neal said. “Rotation was huge, and liming was huge.

We worked with an agronomist who helped us with balancing soils. That helped a lot.”

After three years, on Oct. 15, 2002, Neal and Karen had their rst organic corn in the harvester. Their milk became certied organic Jan. 15, 2003.

SOUTH DAKOTA

Pfeifer

Midwest Machinery Co. (Full Line) Osceola, WI

Tractor Central Arcadia, WI Cameron, WI

Chippewa Falls, WI Durand, WI Granton, WI

Then, they received what they said was a fortunate break. Organic Valley of Wisconsin came calling in December 2002.

“We were transitioning to organic but didn’t know if we would have a place for our milk,” Karen said. “We just had hope and faith that we would. Then, Organic Valley came to us.”

There was no longer a need to nd a market, and the family could focus all efforts on farming.

The Klaphakes are with the company today. They are also seasoned organic farmers who share what they have learned with other organic farmers who come to them for advice.

Neal said one of the main principles of organic farming is keeping his soil balanced and in harmony with his crops.

“When we had elds that we needed (to turn organic), we rst planted it into hay,” Neal said. “We’d take the hay off and plow it under and then grow corn there. It’s easy to grow corn after hay. The soil is looser. Weeds prefer tight soils.”

Neal adds bacteria to the farm’s manure and makes a compost he stores in a compost barn.

“Once you get the manure and lime right and the soil balanced, the soil turns so soft, almost like potting soil,” Neal said. “It’s like you’ve got more life in the soil.”

The Klaphakes also learned it is better to grow corn one to two years at most before rotating it out. Neal likes to plant barley next, interseeded with hay.

Neal waits until the ground is warmer to plant corn, and once it is about 10 inches tall, cultivates it to bury the weeds. Sometimes, depending on weather, he only has to cultivate it once.

“It’s crucial to plant when it’s not wet and cold,” Neal said.

That requires not paying attention to what other farmers are doing.

“Sometimes that is hard,” Karen said. “Everyone else’s corn is coming up, and we’re just starting to plant.”

Another technique the Klaphakes use is roasting their grain.

“It kills all the weed seeds that are in the grain,” Neal said. “Also, by roasting it, the starch changes to dextrose in the grain itself, so the cows can digest it better. You don’t need to feed as much.”

After he harvests grain, he runs it through the roaster and then puts it in the bin. He has found it works best with a bit of moisture in the grain because it will expand and split open. He even roasts all of his dry corn.

As far as treating illnesses in calves and cows, the Klaphakes have found organic remedies for pneumonia and other illnesses. They use garlic, aloe and an herbal tea. They also use a whey injection under calves’ skin that has colostrum from cows more immune to mastitis. These treatments have worked well for them, Neal said.

“Twenty years ago, the treatments weren’t as accessible, but now there are a lot of companies that make stuff like that,” Karen said. “The vet outlet has a whole area where you can get (such products).”

Neal said he believes in building the immune systems in his animals.

“If you can get the cow to help its own immune system, to x its own problem, then it’s xed instead of just putting a Band-Aid on the problem,” Neal said. “Otherwise, the temperature drops and (the cow) is sick again. We have a lot less repeat (illnesses).”

The Klaphakes rotationally graze their milking herd across four paddocks.

“When the cows are grazing, I can get a lot of feed out of a pasture with the blend, almost more than I can out of a hay eld,” Neal said. “That changed a lot since I started (organic farming). It’s close to 15 different varieties of species that I plant in there.”

When the grazing season is done, Klaphakes feed a ration of 1 pound dry corn, 3 pounds roasted barley, 15 pounds snaplage, 25-30 pounds corn silage and haylage for the rest.

Looking back at 20 years of organic farming, the Klaphakes agreed their enjoyment of learning new things has kept them positive and focused, getting them to where they are today, which both Neal and Karen said is a good life, one that allows their small farm to be self-sufcient.

“With organic, you can make a nice living without farming a lot of land; you don’t need 1,000 acres,” Neal said. “I don’t buy any protein. I had to buy some hay this year, but it was very minimal. I hadn’t bought feed in many years. I can grow enough feed on my own. When the prices of things go up, it doesn’t affect me very much because I don’t sell it and I don’t buy it.”

Karen said organic has afforded them the size and style of farming they want.

“Back when we were going organic, it seemed that a lot of farms were quitting or else were going big,” Karen said. “We were able to keep our family farm this size and operate it ourselves.”

Kristen Metcalf

Milton, Wisconsin

Rock County 350 cows

Family: I farm with my husband, Corey, and his parents, Terry and Jane. My sister-in-law, Lauren, also helps on the farm part time. Additionally, I own a small herd of registered Holsteins with my mom, Phyllis Broege, and my sisters, Jenna and Nicole Broege. We enjoy showing them at local, state and national shows.

Tell us about your farm. Our farm, Glacier Edge Dairy, was established in 2017. We milk 350 Jersey cows and grow 1,200 acres of crops. The milking herd also includes about 15 registered Holsteins and Red and White Holsteins – my pride and joy. Our operation is fairly unique in that our dairy was built from the ground up without any pre-existing buildings or cows. Since building our freestall barn, milking parlor, machine shed and manure storage in 2017, we have added a hay storage shed and youngstock barn, where we raise our calves and heifers. We also raise our beef to nishing age, at which point we sell them to market or privately to consumers. Outside of our family, we have three full-time and two parttime dedicated employees. At Glacier Edge Dairy, we are proud of our highperforming cows and our exceptional team.

What is a typical day like for you on the dairy? My husband and I start our chores in the morning, feeding between 80 to 100 calves on milk, feeding grain

to youngstock, taking care of newborn calves and any other immediate tasks. By 8 a.m., I start my full-time job as the events manager for Genex Cooperative. I’m fortunate to be able to work from my home or the desk I have at our farm. Around 5 p.m., we start chores again –watering all the youngstock and feeding calves. Outside of my full-time job and on the weekends, I assist with herd health, moving cattle, eldwork and employee management.

What decision have you made in the last year that has beneted your farm? Most recently, we have converted to feeding our calves 3 quarts of milk twice a day. This is an increase from 2 quarts twice a day. We are seeing a signicant increase in rate of gain through colder temperatures. In addition, we harvested high-moisture corn instead of snaplage for the rst time and added it to the ration. We’ve seen an increase in starch digestibility.

Tell us about your most memorable experience working on the farm. It’s hard to narrow down one single experience. Growing up on my family’s dairy farm, I have special memories of riding in the tractor with my dad and learning the ropes of feeding calves at an early age. Currently, it’s the moments leading up to developing a great cow or bull – a true sense of pride in what we do is shown through those animals. This past summer when we hosted the dairy breakfast, seeing people amazed by our robotic feed pusher and herd monitoring collars will always be fond memories.

What have you enjoyed most about dairy farming or your tie to the dairy industry? The people – hands down. From the other passionate people at dairy cattle shows, to the advisors we work with at our farm, to my co-workers, to the youth I teach, I could go on and on. I can easily say that my great friends, family and network of professional connections pretty much all stem from the dairy industry.