By Emily Breth emily.b@star-pub.com

WRENSHALL, Minn. —

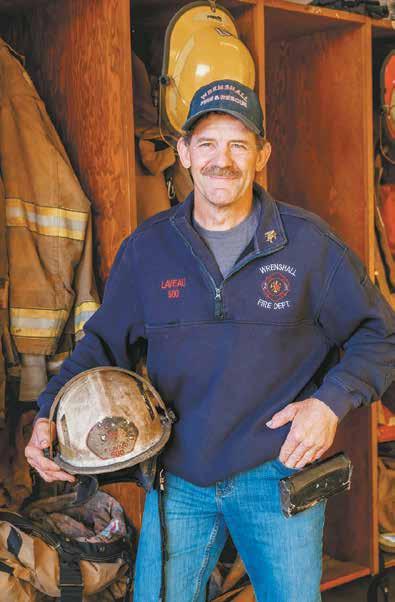

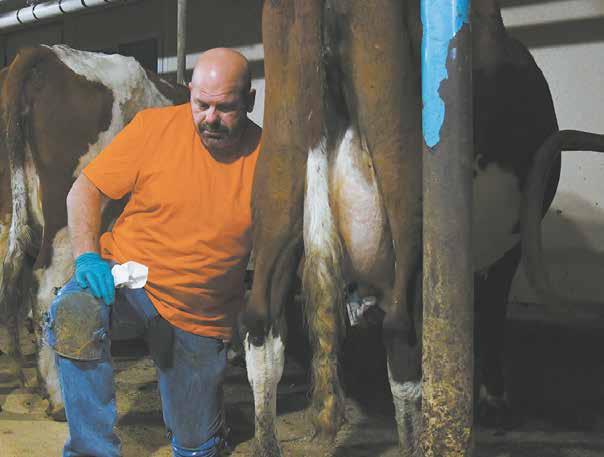

It is not uncommon to see farm equipment parked outside the Wrenshall re hall when re chief Peter Laveau gets a call while in the eld.

“I’ve made many trips to the re hall with the tractor,” Laveau said. “I give the guys grief because one time I was the rst person there and I was in a tractor.”

Laveau owns a dairy farm a little more than a mile from the re hall. He milks 100 cows in an L-shaped tiestall barn. Between rented and owned land, Laveau farms 650 acres. Some of the land is just a half mile from the hall. This explains why a plow, discbine and chopper have all been parked outside the re hall.

For 38 years, Laveau has had strong commitments to his farm and the re department where he has been chief for six

years. Through this, Laveau said having a support system is huge.

“You have to have a family that supports you,” Laveau said. “There was more than once when the (pager went) off in the middle of chores or milking and they know I’m going. They just have to step up and get it done.”

His wife, Kim, daughter, Samantha, a grandchild and a great-nephew have helped to operate the farm and get him to the hall when a call came in.

Whether he uses traditional transportation or farm equipment depends on his location in the eld.

“I keep my head on straight,” Laveau said. “I have my faith and I have good people around me. That is the main thing.”

Often, when a late-night call is made, Laveau nds himself working through the night nishing up details from a call at the station before heading home. This includes fueling trucks, washing hoses, replacing parts, cleaning all the equipment used, and ensuring everything is full and ready for the next call. As chief, he also les paperwork and debriefs his team.

“There have been lots of tough calls where I’m out all night and get home just in time to start milking,” Laveau said.

“And then some days I work all day. So, you have to be dedicated and have to like it.”

Just as his transportation varies, so do re calls. As chief, Laveau is in charge of many tasks, like gathering information, deciding on a plan, getting crews in place and assigning tasks to ofcers.

Before he became an ofcer, Laveau was one of the main reghters. He was among the rst to go into the building during an emergency. On occasion, he will still enter buildings. If they are out on a mutual aid call, he gears up to go inside every time, Laveau said.

After serving in the department for a couple of years Laveau was determined to become an ofcer after an experience in a mutual aid call. The re was not well assessed and the house was lost.

Following this experience Laveau spoke with his chief about becoming an ofcer and was made a lieutenant. Over the years he worked up the ranks from captain to second assistant and then to rst assistant, where he stayed for many years before being nominated for chief.

“I’ve heard lots of people say, ‘When Peter gets on scene things are going to get done,’”

Turn to LAVEAU | Page 4

Laveau said. “That’s just the way I’ve always been. I think it is part instinct, part guidance. The Lord helps me and I just know what to do.”

The idea of applying to be a reghter came to Laveau when he was dating his wife. Her father was in the department and Laveau always saw him driving past when there was a call. At the age of 18, he applied and was accepted.

For the rst six months, Laveau was on probation. He also had to complete two courses — reghter one and two — which added up to about 120 hours of training within his rst year on the department.

The Wrenshall re department has 20 members now. When Laveau rst started there

were 32 men and more who wanted to join but could not because there was no room. In hopes of expanding the team, the department will occasionally hold recruitment days. “A lot of these guys want to try and tell me they are too busy,” Laveau said. “There isn’t anyone busier than me and I nd time.”

pinecountrybank.com

By Danielle Nauman danielle.n@dairystar.com

DORCHESTER, Wis. — Two years ago, Leland Zimmerman began to think about creating a small-scale, specialty milk processing business. In April, those plans came to fruition as he launched Farmer Boy Creamery near Dorchester.

“I spent a while thinking about it, talking about it and looking at other small creameries,” Zimmerman said. “I wasn’t sure if I really wanted to do it. It was such a huge capital investment, but everything just kind of came together.”

Zimmerman developed a plan to purchase milk from a nearby dairy farmer by working through a milk broker, which allows him to purchase only the milk he needs. All the cows on the farm are certied A2A2, and Zimmerman is forgoing homogenization, bottling the milk as creamline.

Every Wednesday morning, Zimmerman picks up a small tank load of milk to meet his processing needs for the week.

Zimmerman converted an existing building that had previously been used as a wood shop to house his new creamery.

“We were able to renovate it to t our needs,” Zimmerman said. “The ofce was already here, but everything else, we built. It saved us a lot of time and money.”

It took a year from the time he decided to forge ahead with his idea until the rst milk was processed.

The biggest obstacle Zimmerman said he faced in creating the infrastructure for his new venture was ordering equipment. Zimmerman chose to work with an Israeli company that specializes in working with small processors.

“We were limited on space, and they would design the equipment to t the space we had,” Zimmerman said. “It’s custom-designed; it is fairly compact.”

Everything except for the bottler was ordered from Israel.

“We ordered the bottler from a

company in Pennsylvania,” Zimmerman said. “The Israeli company wanted to sell me two bottlers. I wanted one that could do four sizes, and the company in Pennsylvania provided that.”

When Zimmerman placed the initial equipment order in April 2023, he was told it would be ready for shipment in 3-4 months. Instead, it took nearly eight months for the equipment to be completed and shipped.

The original plan in place was for the 3-A Sanitary Standards Inc. inspection of the equipment to take place in Israel.

“About the time they were getting it done, the war broke out,” Zimmerman said.

The Hamas attack on Israel in early October 2023 made it unsafe for the inspector to travel to the region originally planned, delaying the immediate inspection and the shipment of the equipment.

“The equipment nally shipped in early November,” Zimmerman said. “It was two weeks on a cargo ship. It came into the port of New York and then took six weeks to get through customs.”

Zimmerman had purchased the container carrying his equipment, simplifying the trucking arrangements from New York to Wisconsin.

“They were able to just move the entire container rather than unpackaging the equipment to load onto the truck,” Zimmerman said. “It worked out well, as I am able to use the container for additional storage.”

The equipment arrived in central Wisconsin in January. An Israeli team followed to oversee the installation.

“The whole setup had been assembled in Israel,” Zimmerman said. “They knew all the pieces worked together. Everything was numbered for easy assembly. It took them about a day to set it up and then we just needed to get the boilers running and starting testing. The team from Israel was here about a week.”

Once the equipment was installed, another 3-A SSI inspection was required.

“We had to run a batch of milk while the 3-A inspector was here, to make sure it wasn’t foaming too much,” Zimmerman said. “We did a batch of chocolate milk for that, it’s more likely

to be too foamy than white is.”

Zimmerman had already completed his two- day course at the University of Wisconsin-River Falls to become certied to commercially pasteurize milk in October in anticipation of the arrival of his equipment. He spent a day in Eau Claire becoming certied to test for antibiotics, as well as obtaining the necessary licensure for hauling milk and milk intake. Additional Grade A licensing from the Wisconsin Department of Agriculture, Trade and Consumer Protection ensued, following the installation of the equipment.

“It took ve or six different licenses to cover everything,” Zimmerman said. “There is so much regulation.”

With the licensure complete, Zimmerman was ready to launch.

“I take orders on Tuesday, process on Wednesday and deliver on Thursday,” Zimmerman said.

Zimmerman has a 300-gallon pasteurizer and can bottle 250 gallons of milk an hour.

“It takes about two hours (to) pasteurize a batch,” Zimmerman said. “It heats up to 145 degrees and holds it there for 30 minutes. Then the milk is transferred through a chiller and cooled down to 45 degrees before going into a holding vat to be bottled. I can bottle the rst batch while the second is being

pasteurized.”

Zimmerman is processing about 300 gallons of white milk and 135 gallons of chocolate milk each week. He bottles in gallon, half-gallon, pint and half-pint sizes.

“White milk is my biggest seller, by far,” Zimmerman said. “Everyone drinks white milk. Chocolate is more like a treat.”

Zimmerman started small, unsure of how his market would develop.

“It’s hard to plan for something like this,” Zimmerman said. “That’s why we’re starting out small. We don’t have much overhead. So far it is oating itself.”

Zimmerman sells most of his products within a 30-mile radius of his creamery, retailing in seven area grocery stores along with a few other smaller retailers. He is uncertain how fast or to what size his creamery will grow.

“We have quite a bit of room for growth, but we’ll wait and see how it goes for a year or two,” Zimmerman said. “It’s still too early to tell. Like any start-up, it’s going to take time to build a name. We started from scratch. Everything, from our name to our logo, started from the ground up.

The U.S. Department of Agriculture announced the nation’s September benchmark Class III milk price at $23.34 per hundredweight, up $2.68 from August, $4.95 above September 2023, and the highest Class III price since June 2022. That put the 2024 average at $18.37, up from $17.13 at this time a year ago and compares to $22.24 in 2022.

Late Friday morning Class III futures portended an October price at $22.63; November, $21.22; December, $20.72; and January 2025 at $20.21 per cwt.

The September Class IV price is $22.29, up 71 cents from September, $3.16 above a year ago, and the highest Class IV since November 2022. Its average stands at $20.69, up from $18.65 a year ago and compares to $24.81 in 2022.

Lots of eyes were on the International Longshoremen Association dockworkers strike at 36 United States Maritime Alliance terminals along the East and Gulf Coast this week. A new six-year labor contract was given a thumbs down.

The National Milk Producers Federation and the U.S. Dairy Export Council called on the Biden administration to immediately intervene, warning “This disruption could have a devastating impact on American dairy farmers and exporters who rely on the smooth functioning of these ports to get products to international markets.”

Dockworkers agreed to return to work Thursday after port operators enhanced their offer, extending the existing contract through Jan. 15, 2025. Other issues will have to be negotiated in the meantime, including automation in the ports.

Meanwhile, Chicago Mercantile Exchange cheese prices continued their descent ahead of Friday afternoon’s August dairy products report and in spite of news that bird u has spread in California, now conrmed in 53 dairies as of Oct. 2.

The Cheddar blocks closed Friday at $1.9475 per pound, down 16.25 cents on the week, lowest since Aug.8, down 26.75 cents from their Sept. 3 print, but still 24.50 cents above a year ago.

The barrels fell to $2.1450 per pound Tuesday, regained 0.75 cents Wednesday, but closed Friday at $1.9550, lowest CME price since Aug.7, down 34.25 cents on the week, down 30.50 cents on the month, but 37.75 cents above a year ago and 0.75 cents above the blocks.

Sales totaled 12 loads of block on the week and 34 for the month of September, down from 61 in August. There were four trades on barrel for the week and 21 for the month, down from 23 in August.

Dairy Market News reports that contacts say cheese demand has stalled somewhat. Others are

preparing for a busy holiday retail demand season, including work on gift baskets and other special orders. Barrel processors say they have had a slight growth in availability for spot market offers, but extra loads are moving briskly. Spot milk prices mid-week were above-Class levels, primarily due to some plants coming back online after recent downtime, says DMN.

Class III milk demand from cheese makers is steady in the West. Bottling demand continues to tug on milk supplies and some processors indicate that milk is tighter than a year ago, however, it can be obtained. Cheese output is steady along with contractual demand. Seasonally tighter milk volumes and a strong mozzarella market have contributed to tighter barrel stocks, according to DMN. Demand is steady from domestic and international buyers.

Butter started the week jumping 7.25 cents, with 16 loads traded, but it headed lower from there, closing Friday at $2.6875 per pound, down 4.50 cents on the week, 46.50 cents lower on the month, and 81.50 cents below a year ago. There were 59 sales on the week and 102 for the month, down from 223 in August.

Churning in the Central region is busy as current and mid-term cream availability is at unprecedented levels. Multiples below 1.20 were reported this week, and butter makers say they are getting offers from the West and, atypically, even East region sources. Hurricane Helene’s effects were backing up cream moving to normal destinations in the East. Butter demand is steady to quiet, said DMN.

Wester butter manufacturers note retail production is strong or steady and bulk production is strong to lighter. Stocks are being built to cover upcoming churn maintenance as well as anticipated fourth-quarter demand. Cream is widely available in most of the region but demand from butter makers is mixed. Domestic butter demand is steady to lighter, however, 2025 booking is picking up. Export demand is stronger as U.S. prices become more competitive, said DMN.

Grade A nonfat dry milk nished Friday at $1.3525 per pound, down a half-cent but 17.25 cents above a year ago. Sales totaled 18 for the week and 118 for the month, up from 113 in August.

Dry whey saw its Friday close at 60.50 cents per pound, 0.75 cents higher and 30.75 cents above a year ago. There were 12 sales on the week and 38 for the month, up from 26 in August.

The dairy industry has long used USDA’s monthly milk production data for tracking milk supplies and projecting dairy product output. Falling milk production typically signaled a decline in supplies of uid milk and components. But a report

this week from CoBank entitled “Why Milk Components Matter More Than Milk Production” challenges the norm.

The report said, “Decoupling uid milk production and milk component production represents an important paradigm shift for the industry given growing consumer demand for manufactured dairy products.”

Speaking in the Oct. 7 “Dairy Radio Now” broadcast, Corey Geiger, dairy economist for CoBank, said milk components have grown much. And, while milk output has been down for 14 consecutive months, components, such as butterfat and protein, have been up in 12 of those 14 months.

Geiger said 80% or more of U.S. milk goes into manufactured products like cheese and butter and 90% of dairy farmers are paid on multiple component pricing so, “It’s the components that matter, and components matter to processors, so this is a winwin situation.”

The report suggests the dairy industry would benet from a more comprehensive monthly report from USDA that includes milk, protein and butterfat production levels. Geiger said it will take some work to make this change happen but, “The industry needs to talk about how we get there.”

Falling corn, soybean, and hay prices and a rising milk price moved the August milk feed price ratio higher again, up for the sixth time in the past seven months. The latest ag prices report shows the August ratio at 2.79, up from 2.50 in July, and compares to 1.66 in August 2023.

The all-milk price averaged $23.60 per cwt., with a 4.09% butterfat test, up 80 cents from July, which had a 4.07 test, highest price since December 2022, and $4 above August 2023, which had a 4.00% test.

The national corn price averaged $3.84 per bushel, down 39 cents from July and $1.89 below a year ago. Soybeans averaged $10.30 per bushel, down $1.00 from July and $3.80 per bushel below a year ago. Alfalfa hay averaged $175 per ton, down $8 from July, and $55 per ton below a year ago.

Looking at the cow side of the ledger, the August average cull price for beef and dairy combined was unchanged at $142 per cwt., $27 above August 2023, and $70.40 above the 2011 base average.

Quarterly milk cow replacements averaged $2,360 per head in July, up $240 from April, and $600 above July 2023. Cows averaged $2,100 per head in California, up $200 from April, and $435 above a year ago. Wisconsin’s average, at $2,650 per head, was up $270 from April, and $740 per head above July 2023.

Milk production margins moved to the highest level since October 2014, at $15.14 per cwt., and were $1.45 per cwt. above July, according to dairy economist Bill Brooks of Stoneheart Consulting in Dearborn, Missouri.

“Income over feed costs in August were above the $8 per cwt. level needed for steady to higher milk production for the 10th month in a row,” Brooks said. “Input prices were lower in August with all three input commodities remaining in the top 11 for August all-time. Feed costs were the ninth highest ever for the month of August and the lowest since the $8.43 recorded in December 2020.”

“Dairy producer protability for 2023 in the form of milk income over feed costs, was $8.00 per cwt.,” Brooks said. “Protability was $3.91 below 2022 and $1.72 lower than the 2018-22 average. In 2023, the decrease in milk income over feed costs was a result of the milk price decreasing more than feed prices dropped. Income over feed in 2023 was around the level needed to maintain or grow milk production.”

“Milk income over feed costs for 2024 (using Sept. 27 CME settling futures prices for Class III milk, corn, and soybeans plus the Stoneheart forecast for alfalfa hay) are expected to be $13.94 per cwt., a loss of 14 cents per cwt. versus last month’s estimate. Income over feed in 2024 would be above the level needed to maintain or grow milk production, and up $5.94 per cwt. from 2023,” Brooks said.

“Milk income over feed costs for 2025 is expected to be $14.27 per cwt., a gain of 33 cents per cwt. versus 2024. Income over feed in 2025 would be above the level needed to maintain or grow milk production, and down 16 cents from last month’s estimate,” Brooks said.

Meanwhile, dairy margins were steady over the second half of September with rising milk prices and increasing feed costs roughly offsetting one another, according to the latest Margin Watch from Chicagobased Commodity and Ingredient Hedging LLC.

“USDA’s monthly milk production report continued to highlight declining year-over-year output, with 18.8 billion pounds produced in August down 0.1% from last year and the f14th consecutive month of lower year-ago comparisons,” MW said. “The milking cow inventory held steady from July to August at 9.325 million head, down 40,000 from August 2023. While the average national milk yield bested last year’s low bar, productivity has slowed as the milking herd ages with heifer replacements increasingly expensive and harder to come by.”

“USDA’s Cold Storage report showed total cheese stocks at the end of August were 1.4 billion pounds, down 0.2% from July and 6.4% lower than last year. Cheese stocks have contracted for six consecutive months even as cheese production during that period has expanded which is a testament to strong exports and domestic demand,” according to the MW.

“Cheddar block and barrel prices collapsed in the second half of the month following barrel prices soaring to new all-time highs above $2.60 per pound.”

“A preference to produce Italian-variety cheeses at the expense of American helped support the Cheddar market at the CME all summer,” the MW concluded.

The U.S. corn harvest was at 21%, as of the week ending Sept. 29, even with a year ago but 3% ahead of the ve-year average. The week’s crop progress report also showed 75% was rated mature, up from 61% the previous week, 4% behind a year ago, but 5% ahead of the ve-year average. Sixty-four percent was rated good to excellent, down 1% from the previous week, but compares to 53% a year ago.

Checking the beans, 81% were dropping leaves, 1% behind a year ago, but 8% ahead of the veyear average. Sixty-four percent were rated good to excellent, unchanged from the previous week, but compares to 52% a year ago. Twenty-six percent have been harvested, 6% ahead of a year ago, and 8% ahead of the average.

Dairy cow slaughter for the week ending Sept. 21 totaled 51,600 head, up 300 from the previous week, but 7,200 or 12.2% below a year ago. Year to date, 1,997,000 dairy cows had been culled, down 324,500 head or 14.0% from 2023.

Tuesday’s Global Dairy Trade weighted average was up 1.2%, following a 0.8% advance on Sept. 17. Volume, at 85.6 million pounds, mirrored that on Sept. 17, and the average metric ton price slipped to $3,851 U.S., down from $3,883.

The gains were led by lactose, up 6.7%, which followed a 3.5% rise on Sept. 17. Buttermilk powder was up 5.0% and whole milk powder was up 3.0%, after a 1.5% gain. Skim milk powder was off 0.6%, following a 2.2% rise. Cheddar was up 3.8%, after a 2.9% gain, but Mozzarella was down 7.7%, after jumping 4.5%.

GDT butter was down 1.4%, following a 1.7% drop, and anhydrous milkfat was off 0.1%, after slipping 1.2% Sept. 17.

StoneX says the GDT 80% butterfat butter price equates to $2.8353 per pound U.S., down 6.2 cents from Sept. 17, and compares to CME butter which closed Friday at a bargain $2.6875. GDT Cheddar, at $2.0895, was up 7.5 cents, and compares to Friday’s CME block Cheddar at $1.9475. GDT skim milk powder averaged $1.2676 per pound, down from $1.2740 and whole milk powder averaged $1.6144 per pound, up from $1.5640. CME Grade A nonfat dry milk closed Friday at $1.3525 per pound.

‘21 Bobcat S76, SJC, 1,500 hrs. ‘20 Bobcat S76,ONLY 233 HRS. ‘22 Bobcat S64, 4,100 hrs. ‘21 Bobcat T76, SJC, 600 hrs.

‘21 Bobcat T76, SJC, 689 hrs.

‘21 Bobcat S76, CAH, SJC, 1,800 hrs. Bobcat T76, 882 hrs.

‘22 Bobcat T666, 30 hrs.! ‘21 Bobcat T64, 577 hrs.

‘22 Bobcat S64, SJC, 4,100 hrs.

‘21 Bobcat S64, foot, 2,900 hrs.

‘21 Bobcat T870, highflow, 1,300 hrs.

‘15 Bobcat T870, SJC, highflow, 1,700 hrs.

642, 4,300 hrs. ‘02 Bobcat S300, 4,200 hrs. ‘04 Bobcat T300, CAH, 4,300 hrs.

‘07 Bobcat T250, CH, 4,100 hrs. ‘15 Gehl R190, 1,900 hrs. ‘13 Mustang RT2100 track ldr., 3,000 hrs

Deere 324E, CAH, 5,200 hrs.

2,700 hrs.

The U.S. Department of Agriculture announced $58 million available for marketing assistance to eligible organic dairy producers through the Organic Dairy Marketing Assistance Program 2024 to help expand the market for organic dairy and increase the consumption of organic dairy.

ODMAP 2024 helps mitigate market volatility, higher input and transportation costs, and unstable feed supply and prices that have created unique hardships in the organic dairy industry. Specically, through ODMAP 2024, Farm Service Agency is assisting organic dairy operations with projected marketing costs in 2024 calculated using their marketing costs in 2023. FSA began accepting ODMAP 2024 applications on Sept. 30. Eligible producers include certied organic dairy operations that produce milk from cows, goats and sheep.

Dairy producers who participate in ODMAP 2024 will benet from improvements to provisions outlined in the program. Specically, ODMAP 2024 provides for an increase in the payment rate to $1.68 per hundredweight compared to the previous $1.10 per cwt. Additionally, the production level eligible for marketing cost-share assistance has increased to 9 million pounds compared to the previous 5 million pounds.

ODMAP 2024 provides a one-time cost-share payment based on marketing costs on pounds of organic milk marketed in the 2023 calendar year or estimated 2024 marketing costs for organic dairy operations that have increased milk production or entered the organic dairy market. The assistance provided by ODMAP 2024

and the original ODMAP 2023 is provided through previously unused Commodity Credit Corporation funds remaining from earlier pandemic assistance programs.

ODMAP 2024 provides nancial assistance that immediately supports certied organic dairy marketing during 2024 keeping the organic dairy market sustainable until markets return to more normal conditions.

FSA will be accepting applications until Nov. 29. To apply, producers should contact FSA at their local USDA Service Center. To complete the ODMAP 2024 application, producers must certify to pounds of 2023 milk production, show documentation of their organic certication, and submit a completed application form.

Organic dairy operations are required to provide their USDA certication of organic status conrming operation as an organic dairy in 2024 and 2023 along with the certication of 2023 milk production or estimated 2024 milk production in hundredweight.

ODMAP 2024 complements other assistance available to dairy producers, including Dairy Margin Coverage, with more than $36 million in benets paid for the 2024 program year to date. Learn more on the FSA Dairy Programs webpage.

To learn more about FSA programs, producers can contact their local USDA Service Center. Producers can also prepare maps for acreage reporting as well as manage farm loans and view other farm records data and customer information by logging into their farmers.gov account. If you don’t have an account, sign up today.

By Sherry Newell Contributing writer

MADISON, Wis. — Calling themselves the “Power Puff Girls,” three students from the University of Minnesota claimed the top title Sept. 29 at the National Intercollegiate Dairy Cattle Judging Contest at World Dairy Expo. It was the Gophers’ second straight victory at the contest, achieved by a margin of 22 points over the University of Wisconsin-Madison.

The team of Sarah Hagenow of Poynette, Megan Meyer of Rollingstone, Minnesota, and Megan Ratka of Cold Spring, Minnesota, bested 16 other teams in the reasons category, defeating the Madison team by 10 points.

with her husband, Eric, and Isaac Hagen, was optimistic.

“Everyone else seemed to be worried about that, but we weren’t,” Houdek said. Minnesota’s victory came on the strength of its fourth, fth and sixth-place individual placings of Meyer, Hagenow and Ratka, respectively. In reasons, Meyer was third, Hagenow fourth and Ratka fth.

Kylie Konyn from UW-Madison captured the high individual award when her top reasons score was used to break a tie with Naomi Scott of Iowa State University. Both women amassed 861 points, but Konyn’s 283-point day in reasons bested Scott’s by ve.

The U of M also won the contest in 2023. This year, the win was more impressive to some, because the team of three was unusual. Most teams have a fourth score, allowing for the lowest individual point total to be dropped.

“It was the rst time I’ve had a threeperson team in any contest, ever,” Dr. Les Hanson, the team’s longtime coach, said. Hanson’s teams have won four titles in the contest in the past decade and are the only team to have more than a single win during that time.

“That’s not easy to do,” Hanson said. “There’s talent, there’s coaching, and then there is a lot of luck.”

Even with only three competitors, Gabriella Houdek, who also coached the team

Konyn, who comes from the last dairy in San Diego County, California, said her goal was to win reasons and she was happy to accomplish that. As her team listened for results, they knew how things would shake out for the team.

Individually, Konyn also won Brown Swiss and Guernseys.

“The cuts were in my favor,” she said. “I loved the classes.”

It was not the rst time Konyn’s individual score was tied for the win. In a previous contest she lost in a tie with her teammate, Natalie Roe of Monticello. Chloe LaCrosse of Forestville and Emma Dorshorst of Marsheld completed the UW-Madison team.

The U of M judges said they had high hopes for the national contest after competing in Harrisburg, Pennsylvania, earlier this fall. At the contest held with the All-American Dairy Show, Ratka was sixth individual while Hagenow was 10th. The team was fth overall but took home the reasons title.

“That was a tune-up,” Meyer said. “We knew we were capable. We get our strength from each other.”

As placings in various breeds began

University of Minnesota

off their awards earned as high overall team and high

for reasons Sept. 29 in Madison, Wisconsin. The team won the Na�onal

collegiate Dairy Ca�le Judging Contest at World Dairy Expo.

during the judging awards banquet, the team wondered whether they could come out on top.

“Our mentions were very spread out,” Hagenow said. “We kind of came from behind.”

The team scored wins in Guernseys and Milking Shorthorns, and Ratka was high individual in Milking Shorthorns. She also was one of only two contestants to score a perfect reasons score of 50.

“This is everything I could dream of,” Ratka said. “You start judging when you’re little and think one day you can win at Expo, but then it happens … I’m not sure I’m awake.”

Iowa State University placed third in

the team competition, followed by Purdue University. The UW-River Falls was fth.

In the concurrent National 4-H Dairy Cattle Judging Contest, Wisconsin’s team from St. Croix County placed third overall and second in reasons, Milking Shorthorns and Red & Whites.

Wisconsin 4-H member Lilly Peterson was third in reasons and in the Ayrshire, Milking Shorthorn and Red & White breeds, while her teammate, Stella Kamm, placed third in Holsteins.

Sophia Kamm and Makayla Weyer completed the Wisconsin 4-H team.

Minnesota 4-H team member Klaudia Biel was sixth high individual.

Wisconsin. The team placed third out of 17 teams.

By Sherry Newell Contributing writer

MADISON, Wis. — Through the course of 12 placing classes and six sets of reasons in a college-level judging contest, it might seem unlikely for any top score to end up in a tie.

But for Naomi Scott of Westgate, Iowa, it happened not once, but twice this fall. She tied for high individual at the National Intercollegiate Dairy Cattle Judging Contest Sept. 29 at World Dairy Expo in Madison.

She also tied for the winning spot at the contest held with the All-American Dairy Show in Harrisburg, Pennsylvania, earlier this fall.

Both times, the Iowa State University senior ended up second based on the tiebreaker — the reasons score.

This has not dampened Scott’s enthusiasm for dairy judging, in which she’s been competing for at least 10 years.

“I love judging,” she said. “I think it’s so much fun to evaluate cows and see good dairy cattle. At the end of the day, I’m still very happy.”

Scott’s Iowa State University team placed third out of 17 teams in the Expo contest, behind the University of Minnesota and the University of Wisconsin-Madison, respectively. Her teammates, Louis Hamlett of Aurora, Iowa, Raegan Kime of Waukon, Iowa, and Irene Nielsen of Potterville, Michigan, were rst in Red & White judging and second in Ayrshires.

Scott had the best placing score of 64 individuals by ve points. But, her reasons score fell ve points behind Kylie Konyn of the UW-Madison team, which made for the tie. Konyn’s reasons score broke the tie.

In Harrisburg, Scott tied with a Pennsylvania State University student. The ISU team was third at that contest as well.

“I know it’s something I’ve never been quite as good at as everyone else,” Scott said. “But I denitely think I have improved. I’m just not quite there yet.”

Scott had a streak of six perfect scores in the placings category, earning the maximum 50 points possible in a judging class. She had two 48s, two 47s and a 45 in reasons.

“My goal was to never get below a 45, and I gave a 43 (on Milking Shorthorns),” she said. “When you’re doing six sets, it’s tough.”

Scott said she previously dreaded reasons, but with coaching at her former college, Kaskaskia College, and at Iowa State, things have changed.

“I’ve gotten over that,” Scott said. “I love sorting through classes. I’m seeing cows well and it feels really good.”

Scott has had experience to help hone her skills. Through her 4-H and junior college judging, then Iowa State University, she has participated in contests in Fort Worth, Texas, Harrisburg, Pennsylvania, and Louisville, Kentucky. This was her third time judging at Expo, once each for 4-H, junior college and now ISU.

Each year, Iowa 4-H sends the team placing rst at the state contest to the Expo contest, and Scott was on that team in 2021.

This year, Iowa was represented by Winneshiek County, with team members Anders and Mara Lovstuen, Kelsey Timp and Hanna Vagts. They were coached by Blake Courtney. The team won the Jersey breed and was sixth of 20 teams overall.

4-H member Anders Lovstuen placed 12th overall and was third in Jersey judging, while Kelsey Timp won the Ayrshire breed.

Scott has one judging contest left before she earns her degree in dairy science with a minor in agriculture entrepreneurship. The Iowa State University team will compete at the North American International Livestock Exposition in Louisville in November.

Scott said she has high hopes for a successful nish. With any luck, it will not end in a tie.

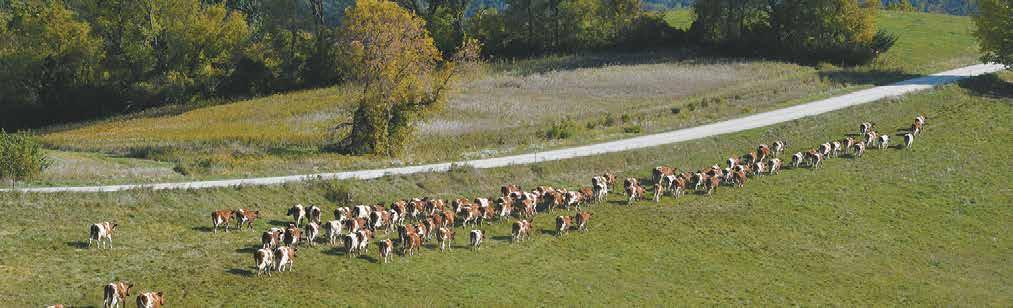

Cows walk home for evening milking Oct. 3 at Enchanted Meadows Farm near La Crescent, Minnesota. The herd is trained so that once started in the right

on they will take themselves home.

By Amy Kyllo amy.k@star-pub.com

LA CRESCENT, Minn.

On Oct. 3, the barn door at Enchanted Meadows Farm framed the dawn as it transitioned from darkness to purple and pink, and then to morning sunshine that revealed the

farm’s pastured terrain. Inside the 56-stall tiestall barn, Chad and Melissa Crowley milked the herd of 97 organic Ayrshire cows.

Morning began at 5 a.m. with the Crowleys sending the cows from the pasture to the barn.

Milkers were going on at 5:30 a.m. Assisting the Crow-

leys for the rst hour was Art Thicke. The Crowleys are part owners and the next, non-family generation on Art and Jean Thicke’s farm. The Crowleys, while being the next managers, are partners with Art on day-today work and decisions. That morning Art had to leave early for a golf outing.

“We like to see Art be able to farm as long as he can,” Melissa said. “He still enjoys coming out.”

During milkings Chad and Melissa visit about their family, farm, to-dos and goals. Melissa said milking allows her to “talk his ear off.”

Chad appreciates that they milk together. For a lot of farm couples, Chad said unfortunately one of the two must get an off-farm job.

“We don’t have to do that,” Chad said. “We get to share in the enjoyments of farming together and the trials and tribulations and everything else that goes with it, and because of that, we can understand each other.”

Around 6:20 a.m. the Crowleys brought the second half of the cows into the tie stalls for milking.

to CROWLEYS | Page 14

Con

| Page 13

The Crowley’s herd is fed eight pounds of grain each day along with unlimited rst-cutting hay when they are in the yard. Through the day, they are pastured.

One-hundred twenty acres of pasture are divided into 48 paddocks for the cows that produce about 1 million pounds of milk, Chad said.

“No matter if we have 110 cows, or if we have 85, that’s what the farm puts out,” he said.

Melissa said they are not production minded.

“We’re sustainable minded and longevity (minded), taking care of the land and taking care of the animals,” Melissa said.

The Crowleys have had a cow last 16 lactations. Chad said the average age of cows in their herd is 5-8 lactations.

“If a cow only makes three lactations in our system, that is not what we’re looking for,” Chad said. “We’re looking for cows that’ll make 10 years. That’s where we prot.”

Around 7:15 a.m. the last milkers were coming off. Me-

lissa started getting the milkers washed and feeding the last two calves of the season while Chad nished milking and sent the cows out.

Calves are fed unpasteurized whole milk mixed with warm water in small groups of up to six on barrel feeders.

The Crowleys have a closed, line-bred herd. They calve seasonally, with 70% of calvings occurring during March-April. The other calving season is from mid-August through September.

They use an outside beef bull for clean-up for the spring calving season and all fall calves. Beef calves are sold. They calve in 24-26 dairy heifers a year.

After Chad scraped the barn and fed grain to this spring’s crop of future herd bulls, he was ready before 8 a.m. to give the cows fresh pasture.

The cows had walked out and were waiting. They receive fresh pasture twice daily.

Turn to CROWLEYS | Page 15

of

of

Crowley divided a new section using poly-wire. The Crowley’s pastures are on bluff land with views of miles of nearly untouched terrain.

“We enjoy calling this home,” Chad said.

The Crowleys use wait times of 50-70 days between grazing. Last year, they grazed until December.

“Even in drought years, we’ve never run out of grass,” Chad said. “We’re able to maximize the entire farm and stay protable.”

The Crowleys manage their pastures by clipping. They also hand dig thistles out of fence lines.

By 8:30 a.m. all chores were done except Melissa’s graining of the spring calves and letting them out to pasture.

After chores, Chad and Melissa

took a break to eat breakfast, relax, work on inside tasks and get ready for their afternoon project.

Around noon, the Crowleys started preparing a pasture lane for winter. They cleaned out trees, brush and an old barbed wire fence. Once cleared, they plan to bring in loads of lime to keep the lane from becoming muddy.

Chad operated a chainsaw. Melissa dissembled the barbed wire and they both hauled the brush.

“We joke, ‘Why do the trees always fall into the pasture? Why can’t they fall into the woods?’” Melissa said. “We are always maintaining different fence line areas.”

At 2:45 p.m. Melissa brought in the spring calves, gave them grain and locked them in for the evening. The Crowleys balance the calves’ ration by controlling the amount of grass, hay and grain they receive. The calves are also still in the process of being trained on pasture.

Then, Melissa took a water truck to the heifers to ll their stock tanks.

Around 3:30 p.m. Chad started the cows walking back to the barn and went to prepare their evening pasture.

The Crowleys have trained their cows to follow them and come at their call. Once started in the right direction, the cows will take themselves home.

In the late afternoon, a calf buyer came for two beef calves.

At the barn, milkers were on at 4:30 p.m. At 7 p.m. the Crowleys were wrapping up milking and doing cleanup. They nished their day with relaxation and bowls of chili with cornbread.

Drain Tile Design/ Installation • Ditch Cleaning & Grading • Fenceline Clearing Changing weather and higher inputs got you down? Using Drain Tile to manage excess moisture in the soil pro le is the foundation for increasing pro tability per acre. - Less compaction - Better soil Structure - Allows more days per year for eld operations - More Yields with same or less inputs

By Emily Breth emily.b@star-pub.com

Goats are sometimes pictured as animals that can live off anything. However, they need a hardy diet just like other ruminants.

Fred Hall, a dairy specialist with Iowa State University Extension and Outreach, delivered a webinar about managing and making decisions about forages fed to dairy goats.

“Goats are very active foragers,” Hall said. “They have a small mouth, a narrow muzzle and split upper lips, which enable them to pick off small leaves, owers, fruits and the plant parts that they deem as the tastiest. Fortunately, that often is also the most nutritious.”

There were three types of forages Hall focused on — pasture, hay and silage. Hall said a benet of pastureland is goats can decide what forages they want to eat, and, being natural browsers, they tend to nd feed with good nutritional value.

Hall discusses the differences in hay types. Alfalfa hay normally has a higher protein level at 15%-21% while grass hay averages 10%-12% depending on when it is cut and how it grew previously.

“Alfalfa hay is the most popular for feeding goats and it has more protein, vitamins and minerals than grass hay,” Hall said. “This is especially important for early pregnancy does.”

The nal category of feed Hall mentioned was silage — both corn silage and haylage.

“Silage, especially high moisture corn silage, can be used in substitution of dry ground corn,” Hall said. “It can be used in the formulation of diets because it improves dry matter digestibility.”

Hall also said having fresh, clean water is an important part of a goat’s diet. The more water a goat drinks, the higher its feed intake and feed efciency.

Stage of lactation should also be considered feed-wise, starting with the far-off dry does, Hall said.

“The requirement for feeding at this point is sufcient nutrition to improve body condition if needed and providing adequate nutrients for the fetus and to prepare the digestive tract for changes after kidding,” Hall said.

The goal to aim for is 11.5% crude

discharge, chain and slat conveyor table that continuously rotates the bale while the heavy-duty rotor and hammers process the material. The 2665 Shortcut Balebuster also comes with more hammers, more stripper kits, and more slug bars giving you additional cutting and ultimately a shorter product.

protein with 0.5-1 pound of concentrate mixed in the feed. Hall said this is not the time to aim for the most change in the body condition score.

The next stage is the close-up dry period. This is when the doe should be worked slowly up to 2-2.5 pounds of concentrate a day.

“The close-up dry period is one of those that has some really interesting aspects to it,” Hall said. “The risk of metabolic and infectious diseases are particularly high during this transition period.”

Three weeks before and after parturition is when does require the most energy and the highest quality forages for support Hall said. Energy is essential to make it through pregnancy and lactation.

“This is the time that we can start bringing in some of these fermented feeds so that by the time they are peaking they’ve got the (ability to) digest that,” Hall said.

Next, Hall discussed the early and mid-lactation diet. Early lactation does should be expected to lose 1-2 pounds a week initially.

“It’s not uncommon to see a body condition score at 2.0,” Hall said. “We really don’t ever want to see it get less than that, but we know these hardworking does are going to see that happen.”

Hall said producers should provide a minimum of 2.5% of the doe’s body weight in forages and no more than 55% of the diet from concentrates. The required amount of concentrate will depend on forage quality.

“Slugging can become a problem if more than 2 pounds of concentrate is fed at a time,” Hall said.

Finally with late lactation does, total daily nutrition received from concentrate should be decreased. Their dietary energy should also be reduced 2-3 weeks before dry-off so they can have a smooth transition period.

Throughout all stages, high and quick gains in BCS should be avoided. It is best if increases are slow.

One of the nal topics Hall discussed was feed quality. A way to guarantee the goats are receiving enough nutrition is by testing the forages. Including corn silage into a total mixed ration for the goats is a good way to ensure they are getting good quality feed with every bite they take.

“Quality corn silage is kind of a natural t because it is still a forage because you’ve got a lot of the leaves, cobs and stocks but it (also) has a lot of grain in it,” Hall said. “We certainly want to have every mouthful be the most dense nutrient package that we can.”

around us. They look great and the farmers are happy with the crop. We are going to do 300-400 acres of fifth-crop alfalfa as an insurance policy. We plan to haul manure soon. We surface apply half and inject the other half. The lagoon is three-fourths full. There is a lot of down trees that need to be cut. We had a lot of wind this summer and there are branches overhanging on the fields.

I got my small squares baled Sept. 25-26 and I was happy with the yields. On one field, about 17 acres, I got close to 370 bales. The 25 acres of silage corn I planted late was taken out Sept. 28 and 30. It yielded slightly better than the rest. I’d say it was right around 14 ton and acre. For soybeans, the neighbors kept saying they were too wet and then all of the sudden they were at 7%-10% moisture. I know they did not yield as good as some neighbors were thinking, but it was still an okay crop. As for combining corn, I took off some end rows and they were sitting at 17% moisture.

We started chopping at the neighbors two weeks ago. We did one bunker here last week and will do the other one next week. Some of it was pretty nice. It was a lot better than I thought it would be. Some of it is 25 ton an acre and some is 15 ton an acre because it couldn’t take the water. We chopped 130 acres. The soybeans are done around here. I heard some was 65-70 bushels an acre. I would say some of the corn is down to 19%. Once we finish chopping, we plan to haul our manure pit. It’s getting pretty full. It hasn’t rained around here for a month and a half.

I got my fifth-cutting hay put up in good shape around Sept. 25. It really dried in a hurry and I got around a ton an acre. Some of the neighbors started taking out their soybeans and then switched to corn because of how tough the stems were. The beans are plenty dry already so they figured they might as well let the stems dry more. We did have one fire in the area, but luckily it did not get out of hand. I hand shelled some corn and a lot of it is 11%-18%, so I am hoping to start soon.

Harvest is going along good. We finished our soybeans on Sunday (Oct. 6). They were below average. If we would have had rain at the end of the summer, they would have been a lot better. Most of the soybeans in the area are harvested. We were getting to high moisture corn, but it might be too dry. I would say 10% of the corn is taken out. The moisture is 16%-17%. There are a lot of sugar beets going out now. The harvest is not as good as they had hoped. We are cutting some third-crop new seeding hay now.

Our fourth-cutting alfalfa was baled Sept. 26 with a bit of a lower yield than we would like. We were happy since it was the first time all year we had a perfect stretch to make hay. The soybeans in the area have not been yielding what we thought they would. There are quite a few green ones in the field, but the rest are sitting at 8%-9% moisture. We started combining corn Oct. 7 and our 101-day corn it at 13% moisture while the 105day corn was at 19% moisture.

We are going to start on high moisture corn today (Oct. 8). I have corn that has milk in the kernels and some at 18%. Farmers around here are not hitting it hard. They are waiting and watching the points come down. The only corn out is high moisture corn. I would say 75% of the soybeans are done. It has been a good crop. We have had a couple combine fires in the area because it is so dry. We finished chopping corn Sept. 28. We knocked down 45 acres of fifth cutting and 30 acres of second-crop new seeding. I have never seen hay dry that fast in October. We cut it Sept. 30 and baled it dry Oct. 2-3. The hay was knee high.

We haven’t gotten any rain up here lately, but that’s made corn silage go quick. Its smoking right along with this kind of weather, snaplage too. I’m hearing that some of it is getting too dry. Soybeans are coming off like crazy with yields all over the boards. I’ve heard upper 20s to low 60s, same with corn. Yields as low as 120, some better corn doing 160. I’ve talked to some people that said corn is more sensitive than we realize. The days start getting shorter and it starts getting ripe. With the summer winding down, the corn is acting the same way. As I look across the field to my neighbor’s tree line, I’m starting to see the leaves change color.

We finished harvesting soybeans Oct. 3. We had good but not great yields. Some soybeans were so short we couldn’t even harvest them because the beans were too low to the ground. It was not a bumper crop, but it was still a good crop. We made bales from soybean stalks for heifer bedding because everything is so dry. We started high-moisture corn Oct. 7. It was 20%-21% moisture. Last year, our whole pile averaged 30% because it was so wet. This year, we’ve had beautiful days stacked upon beautiful days. We have to get 35,000 bushels done. We’re going to make some cornstalk bales next because the forecast is dry, and then we’ll hop right into dry corn.

We are working on corn silage. The yield check is in the upper 200s which is the highest we have ever had. We put up 125 acres or more to corn silage. Out of that we have 40-50 acres complete. We use a pull type chopper so it is not as fast as the self-propelled choppers. Moisture is right around 65%-67%. We are making piles right now, so the moisture is right for that. Once we are done with piles, it should be dry enough to put in the silos. We are also hauling manure because the pit is full due to the rain. We usually do not have to start that this early. We are also shipping hay to Texas.

We haven’t had any rain in the last two weeks — it’s been sunny, windy and warm. We have had frost the last three mornings (Oct. 7-Oct. 9). We cut and merged our sorghum yesterday (Oct. 8) and will chop it today. We have our high-moisture corn done, although some was not very high in moisture. It went as low as 19% and averaged 25%-26% moisture with about 178 bushels per acre. We’ll switch to combining beans here in the next few days, then all that is left is hauling manure solids and doing dry corn. Other than making hay, it’s been a good year crop-wise.

We haven’t had any rain in the last two weeks. We have had a killing frost. I don’t think it quite killed the hay, but any corn that was still standing is dead now. We have everything harvested. All of our corn was chopped, we don’t do any dry or high-moisture. We are just hauling manure and getting some fall tillage done where we can. Most of the beans in our area are being harvested and there are guys around us doing highmoisture corn.

120

We finished harvesting soybeans Oct. 1. My fields ran 43 bushels/acre, while Daryl’s and Lee’s fields ran 45 bushels/acre on the low, flat ground and 60 bushels/acre on the high ground. The same day we finished beans, we jumped in the combine and started shelling corn. We finished high-moisture shell corn in our 25-by-45 Harvestore Oct. 3. It was running about 21% moisture at 175 bushels/acre. We have close to 400 acres of dry corn to shell next, but we’re waiting for it to dry down. We’re still green feeding, but it takes a lot of acres now as we get to the end of the season. I usually do it until it snows or gets too cold.

By Dan Wacker dan.w@dairystar.com

Fifty years ago, a group of breeders brought a new breed of cattle to the North American dairy industry. On Sept. 21, the North American Normande Association celebrated those pioneers at its annual meeting and dinner in Mineral Point.

Co-chairs Brenda Conley and Sarah Vosberg planned the celebration recognizing the importation of Normande cattle and semen from France in 1974.

Normande cattle are a dual-purpose breed from France. Their milk averages 4.2% butterfat and 3.5% protein. After the milking life of the animal concludes, they put on weight.

“The rst life is a milk cow, but it’s also a heavier muscled animal,” Vosberg said. “After the milk life, they have a second life as a meat animal with high marbling.”

Conley shared about how the breed is viewed internationally.

“Here, we think of Angus as the top beef breed,” Conley said. “But in France, they have that same thought process towards the Normande breed.”

Conley said the breed blends well within any herd because of its multi-purpose nature.

“Our farm is focused more on dairy, but the great thing about Normandes is that when their milk career is over, they start naturally putting on weight as a beef animal,” Conley said. “They dress out just like a beef animal and have a lot better carcass quality than a traditional Holstein.”

There is no change in diet or ration needed as the animal progresses to the beef portion of its life.

“They do it naturally,” Conley said. “When they stop producing as much milk, their body regulates it to the fat on their back and they gain weight that way.”

The afnity for an animal that serves two purposes is national. At this year’s annual meeting, nine states were represented: Illinois, Iowa, Kansas, Michigan, Minnesota, Missouri, Virginia, West Virginia and Wisconsin.

To kick off the ‘Cheers to 50 Years’ celebration, Conley and Vosberg asked NANA members to introduce themselves and give a brief description of how they got started

Petersen (from le

at the North American Normande Associa

in Mineral Point, Wisconsin. The award is the rst of its kind from NANA, recognizing members who played a vital role in bringing Normandes to the U.S. in the 1970s.

working with Normandes.

“It was really cool to hear the stories of some of those pioneer breeders,” Vosberg said. “(For) one gentleman, the Normandes have taken him to South America, Costa Rica and Mexico just to see Normandes (and) to try to get those genetics into the U.S.”

Getting to know breeders of impact was a highlight of the celebration for Conley.

“It was great to get to meet and talk with all these breed-

ers who we’ve read so much about,” she said. “It was really good to talk with the other breeders and see how others are growing their herds.”

Conley, Vosberg and Vosberg’s father, Mike Mueller, took on the challenge of setting up the celebration. Conley, owns High-Gem Holsteins & Normandes with her husband, Chris. They milk 52 cows in a tiestall barn. About half the herd is Normande. Vosberg and her husband Derek, milk

190 cows. Twelve are Jerseys. The rest are crossbreds with at least 50% Normande genes; 145 are 75% Normande.

“We thought it was important to make this year special,” Vosberg said. “Some of our pioneer breeders are getting a little older, so we wanted to make sure we could celebrate with them.” Turn to NANA | Page 21

Bonnie (from le ) and Carl Werner are presented with the Dis nguished Breeders Award by Chris Conley, the president of the North American Normande Associa on, for their contribu ons to the dairy industry at the NANA Na onal Normande Show Sept. 21 in Mineral Point, Wisconsin. The Werners helped bring Normande gene cs to the North American dairy industry.

At the Friday night event, NANA recognized four Legacy Award winners, including Merle Petersen of Junction, Iowa; Bruce Bolen of Greentop, Missouri; and David Bolen of Tama, Iowa, and Ben Bolen of Tama, Iowa. The Legacy Award was presented to members who played a vital role in bringing Normandes into the U.S. in the 1970s and helped promote the breed in the early years.

Also on Friday night, NANA introduced a new award, the Distinguished Breeders Award. Recipients were nominated by NANA members for their role in breeding and expanding the Normande herd and inuencing other breeders. This year’s recipients for dairy were Carl and Bonnie Werner of Beaver Dam. The beef recipient was Brian Toivola of Grove Village, Illinois.

Conley chalks up her appreciation of Normandes directly to the Werners.

“If it wasn’t for Carl and Bonnie, Chris and I wouldn’t be Normande breeders,” Conley said. “We walked into their barn as Holstein breeders not knowing what the breed was. Then we

talked to Carl and we left that night saying we needed to get one of those in our herd and that’s how we started.”

Vosberg is another breeder who was inuenced by the Werners. Vosberg Valley View Farm bought one of the Werner’s animals at their dispersal sale and continue to put those genetics into their own herd.

Jeff Bock earned the second annual Distinguished Service Award, which is presented to a Normande breeder for their assistance in promoting the Normande breed and their service to the organization.

The event was a chance for Normande breeders from across the country to meet, network and discuss their appreciation of the breed with one another, and it closed with the NANA National Normande Show. This year, 15 exhibitors showed 53 head.

“We may be a very small organization and a bit of an unknown breed, but we’re like a family,” Conley said. “We love the breed. We love to promote it and educate others about it.”

Even though I am a beef girl through and through, I still enjoy a meal with the “other white meat.” I found the recipe for Maple-Glazed Ribs years ago in Taste of Home. It is a family favorite. Served with roasted potatoes and sweet potatoes as well as fresh applesauce makes a restaurantworthy meal. Of course, do not forget the soup, salad and dessert for the complete experience. Enjoy.

Maple-Glazed Ribs

Taste of Home

3 pounds pork spareribs, cut into serving size pieces

1 cup maple syrup

3 tablespoons orange juice concentrate

3 tablespoons ketchup

2 tablespoons soy sauce

1 tablespoon Dijon mustard

1 tablespoon Worcestershire sauce

1 teaspoon curry powder

1 garlic clove, minced

2 green onions, minced

1 tablespoon sesame seeds, toasted Pre-heat oven to 350 degrees. Place ribs, meaty side up, on a rack in a tinfoil lined 9-by-13 baking pan. Cover pan tightly with foil. Bake 1 1/4 hours. Meanwhile, combine next nine ingredients in a saucepan. Bring to a boil over medium heat. Reduce heat; simmer 15 minutes, stirring occasionally. Drain ribs; remove rack and return ribs to tinfoil lined pan. Cover with sauce. Bake, uncovered 30 minutes or until meat is tender, basting occasionally. Sprinkle with sesame seeds just before serving. Tinfoil helps with an easier clean up.

Orange Pecan Salad

2 oranges, peeled and sectioned OR

1 can (11 ounces) mandarin oranges, drained

1 bag romaine lettuce, torn

1/2 cup chopped pecans

1/2 cup peach yogurt

3 tablespoons Miracle Whip

Toss oranges, lettuce and pecans in large salad bowl; set aside. Combine yogurt and Miracle Whip; pour over salad just before serving.

Hearty Three Bean Veggie Stew

Undo It! by Dean and Annie Ornish

2 cups coarsely chopped onion

2 cups coarsely chopped red bell pepper

2 cups coarsely chopped zucchini

1 tablespoon nely minced garlic

1 tablespoon chopped thyme or 1 1/2 teaspoons dried

2 teaspoons fresh chopped marjoram or oregano or 1 teaspoon dried

1/2 teaspoon salt

1/4 teaspoon pepper

3 1/2 cups low sodium vegetable juice

1 can (15 ounces) cannelloni, rinsed and drained (1 1/2 cups)

1 can (15 ounces) black beans, rinsed and drained (1 1/2 cups)

1 can (15 ounces) red kidney beans, rinsed and drained (1 1/2 cups)

2 teaspoons lemon zest

2 tablespoons lemon juice

1 tablespoon maple syrup

1/4 teaspoon crushed red pepper akes

3 cups chopped destemmed kale or chopped cabbage

In a large heavy bottomed pot, over medium heat, sauté onions, red pepper, zucchini, 1/4 cup water, garlic, thyme, marjoram or oregano, salt and pepper. Stir frequently and cook until onions are translucent, and vegetables have softened, about 10 minutes. Add vegetable juice, beans, lemon zest and juice, maple syrup and red pepper akes. Bring to a simmer and let cook, stirring frequently for 15 minutes. Fold in kale and cook another 3-4 minutes. If you want a soupier consistency, add a little more vegetable juice.

Double Chocolate Cake Family Circle November 2009

Cake:

2 cups our

1/2 cup unsweetened cocoa powder

1 box chocolate cook and serve pudding

1 tablespoon baking powder

1/2 teaspoon salt

3/4 cup butter, softened

1 ½ cups sugar

3 eggs

1 cup milk

2 teaspoons vanilla

Chocolate Glaze:

6 tablespoons heavy cream

6 ounces semisweet chocolate chips

Drizzle:

3 squares (1 ounce each) white baking chocolate, broken apart 1 teaspoon vegetable oil

Cake:

Heat oven to 350 degrees. Coat 12-cup Bundt pan with nonstick cooking spray. Combine our, cocoa, pudding mix, baking powder and salt in bowl. Beat butter and sugar until light, about two minutes. Beat in eggs, one at a time, beating well after each. Alternately beat in our mixture and the milk, beginning and ending with our mixture. Stir in vanilla and pour into prepared pan. Bake at 350 degrees for 45-50 minutes or until cake springs back when pressed. Cool cake in pan 15 minutes. Remove cake from pan to rack; let cool completely.

Chocolate Glaze:

Place cream in small saucepan. Bring just to a boil over medium heat, about three minutes. Add chocolate; stir until melted and smooth. Return to low heat, if needed. Spoon over cake; let stand.

Drizzle:

Combine white chocolate and oil in small microwave safe bowl. Microwave about one minute, stirring halfway through, until melted. Stir until smooth. Let cool slightly, 5-10 minutes. Drizzle over chocolate glaze; let set.

As their four children pursue dairy careers off the family farm, Natalie and Mark Schmitt started an adventure of milking registered Holsteins just because they like good cows on their farm north of Rice, Minnesota.

6 cups peeled, diced russet potatoes

1 1/2 cups chopped yellow onions

1 1/4 cups peeled, diced carrots

1 cup diced celery

2 14.5-ounce cans low-sodium chicken broth

Salt and pepper to taste

1/3 cup butter

1/3 cup all-purpose our

2 1/2 cups milk

1/2 cup sour cream

Optional toppings: chopped bacon or ham, shredded cheddar cheese, chopped green onions or chives

Combine diced potatoes, carrots, celery and onions with chicken broth in a large pot and season to taste with salt and pepper. Cover pot and bring to a boil over medium-high heat. Once it reaches a boil, reduce heat to medium and continue to cook 15-20 minutes longer, until pota-toes are very soft when pierced with a fork. In a medium sauce pan, melt butter over medium heat, add our and cook for one minute while whisking constantly. While whisking, slowly add milk and cook. Add thickened milk mixture to potato soup mixture and stir. Add sour cream and mix well. Top each serving with desired toppings.

From the Kitchen of Julie Middendorf

1 1/2 pounds ground beef

3 slices bread, torn into small pieces

1 egg

1 cup milk

1 small onion, chopped

1 tablespoon Worcestershire sauce

1 teaspoon salt

1/2 teaspoon dry mustard

1/4 teaspoon pepper

1/4 teaspoon rubbed sage

1/8 teaspoon garlic powder

1/2 cup ketchup, chili sauce or barbecue sauce

Mix all ingredients except ketchup. Spread mixture in ungreased loaf pan, either 8 1/2- by 4 1/2- by 2 1/2-inch pan , or 9- by 5- by 3-inch pan. Spoon ketchup over top. Bake uncovered in 350-degree oven, one hour to an hour and 25 minutes. Remove from pan.

1 box French vanilla cake mix

1/2 cup butter, melted

3 large eggs

1 8-ounce package cream cheese

2 1/2 cups plus 2 tablespoons confectionersʼ sugar

1 21-ounce can cherry pie lling

Preheat oven to 325 degrees. Grease 9- by 13-inch baking pan. Combine cake mix, butter and one egg in a large bowl until well blended. Reserve 1/3 cup of mixture for topping. Press re-maining mixture into the bottom of prepared pan. Beat cream cheese with electric mixer in large bowl. Beat in remaining eggs and 2 1/2 cups confectioner ʼs sugar. Pour over cake mixture in pan. Spread cherry pie lling on top and sprinkle with reserved cake mixture. Bake one hour or until golden brown. Refrigerate until chilled. Cut into bars and sprinkle with remaining confectioner ʼ s sugar.

Wednesday, October 16, 2024 at 11:00am

REPUTATION CONSIGNMENTS

20 Fresh Holstein Dairy Cows, 2 & 3 year olds, parlor/freestall, from an excellent herd with RHA of

CALL WITH YOUR CONSIGNMENTS

Always a great selection of dairy cattle at Premier Livestock and Auctions! DRIVE-INS ARE ALWAYS WELCOME! PLEASE HAVE IN BY 9:30 AM TO BE INCLUDED IN THE DAIRY CATALOG

AND OVER 1200 CALVES! Weekly Highlights at Premier Another busy week at Premier Livestock and Auctions, selling over 3,000 head. Tuesday special feeder cattle auction 575 head of feeder cattle sold on a strong market. Predominantly new crop calves offered most from $250-375 per#. Holstein steers lightly tested mostly from $160-275#. Wednesday Dairy Cattle auction we had 135 dairy cattle. Top fresh Holstein fresh cows bringing $2,800-3,700, with many top loads averaging $2,800-3,200. Top Holstein springing heifers $2,500-3,300. One load of springing heifers. Lesser quality and blemished cows and springing heifers $2,000 and down. Private treaty sales available. We sold seven dairy herd dispersals the the last three weeks private farm to farm!! See our website for all the details. Thanks for all your business!!

“The Hanson Silo Bunker empowers us to control shrink loss. With our piles, we used to see lots of spoilage. But now we see very little, if any at all.”

Sako Vandermeer - White, South Dakota

• Engineered for strength and long-term durability

• DRY CAST formulation creates low porosity and slump

• Computerized batching for uniformity

• Robotic mold system provides consistency

• Quality nished for smooth edges and sure footing

• Manufactured in a controlled environment (Steam Beds) for faster curing

• Delivered, professionally leveled and installed

• Strength Compression Tests to exceed quality standards

• Modular design for easy installation