“All

Like father, like daughter Doug, Abby Fairbanks dairy side by side

Swept

Farmers reect on devastation in hurricane aftermath

By Meghan Kropp and Mark Klaphake

Writers

WAYNESVILLE, N.C.

When Hurricane Helene stormed its way through North Carolina and Tennessee, it caused casualties, extensive damage and washed away people’s livelihoods.

Brothers Dan and Steve Ross own and operate Triple R Dairy Inc. of Waynesville, roughly 30 miles west of Asheville. Dan’s children, John and Miranda, and Steve’s sons, Phillip and Mark, also work on the farm.

“There are cattle lost, lives lost, and homes lost,” Dan Ross said. “It’s just overwhelming.”

Across the area, rain gauges read between 14 and 30-plus inches of rain Steve said.

Dan said rain from a few days before the hurricane hit combined to create the devastating ooding.

“What hurt us so badly was the ground and creeks were so saturated because it rained ve or six inches before the hurricane came,” Dan said. “Most of the time, the ground doesn’t get wet until the hurricane comes.”

As the hurricane thundered down on the mountains, Dan, Steve and others worked to bring gasoline, feed, thousands of gallons of diesel fuel

By Amy Kyllo amy.k@star-pub.com

ANAMOSA, Iowa — Abby

Fairbanks has always known she wanted to dairy farm. Her dad, Doug, remembers her at 3 years old dashing barefoot down the driveway in pursuit as he drove to the dairy farm.

“I had no choice but to stop and pick her up,” Doug said. “She just always wanted to be on the farm with me. … She’d be out playing with the calves, or walking in her bare feet out in the cow pies and doing little farm girl things.”

The Fairbanks family milks 400 cows and farms 600 acres on their farm near Anamosa. Doug is assisted by Abby, his

wife, Jody, his nephew, Josh, and two full-time employees. Abby has been working full time on the farm for a year and a half since college.

“(When) you have a passion for something, it doesn’t need to be about the job or the lifestyle, it’s just everything in general,” Abby said. “I like working seven days a week. I love the cows. … I always wanted to do it.”

Doug said he encouraged Abby to look at other things before she made a decision to farm. “I don’t want them to come home unless they’re interested in coming home,” he said. “You can’t farm with part of a heart.”

DAIRY ST R

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce) 320-248-3196 (cell) 320-352-0062 (home) Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Cheyenne Middendorf • cheyenne@star-pub.com

Nadiia Griepentrog • nadiia@star-pub.com

Editorial Staff

Stacey Smart - Assistant Editor 262-442-6666 • stacey.s@dairystar.com

Danielle Nauman - Staff Writer 608-487-1101 • danielle.n@dairystar.com

Dan Wacker - Staff Writer 608-487-3858 • dan.w@dairystar.com

Tiffany Klaphake - Staff Writer 320-352-6303 • tiffany.k@dairystar.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Emily Breth - Staff Writer emily.b@star-pub.com

Consultant

Jerry Jennissen 320-346-2292

Advertising Sales

Main Ofce: 320-352-6303 Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication Sales Manager - Joyce Frericks 320-352-6303 • joyce@saukherald.com

National Sales Manager - Laura Seljan (National Advertising, SE MN) 507-250-2217 • fax: 507-634-4413

laura.s@dairystar.com

Assistant Sales Manager - Kati Schafer (Northeast WI and Upper MI) 920-979-5284 • kati.s@dairystar.com

Adam McClary (SW MN, NW Iowa, South Dakota) 605-951-5270 • adam.m@dairystar.com

Mike Schafer (Central, South Central MN) 320-894-7825 • mike.s@dairystar.com

Hannah Ullom (Western Wisconsin) 715-933-4045 • hannah.u@dairystar.com

Julia Merten (Southeast MN and Northeast IA) 507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell) bob.l@star-pub.com

Mark Klaphake (Western MN) 320-352-6303 (ofce) • 320-248-3196 (cell)

OF

Doug

runs out a total mixed ra on Sept. 14 at his farm near Anamosa, Iowa. Fairbanks started dairy farming in the early ‘90s on rented land and has since increased his farm to 600 acres.

Abby remained settled in her decision. She is the third generation of the Fairbanks family to farm the land.

“I’m proud of the farm as a whole,” she said. “It’s crazy to see how far it has progressed.”

Doug and Jody started dairy farming in the early ‘90s.

“Jody has been an awesome supporter of what I do,” Doug said. “I couldn’t have done it without her.”

The couple purchased cattle, equipment and feed from Doug’s parents, Charles and Carol. His parents had farmed the land as renters for 35 years. Challenges of the ‘80s farming crisis and more had prevented them from owning

the farm. Doug said he is grateful their legacy helped him dairy.

One of the things Doug credits for enabling the farm to grow from zero acres to 600 acres in 30 some years is having good loan ofcers that allowed him to have input.

In the ‘90s his loan ofcer wanted him to spend $80,000 to buy equipment to reduce custom work bills. Doug made him a counter offer. Instead, he used the $80,000 to build a step-up parlor to replace the 18-stall stanchion, doubled his herd to 120 cows and built a hoop barn for housing.

“I paid that loan really fast,” Doug said. “That gave me the cash ow to go

ahead and purchase the farm.”

In 1999, he bought his 180-acre home farm. Since then, he and Jody have made seven land purchases to increase the farmland to what it is today. All land is within manure hauling distance.

Doug’s philosophy on investment has remained constant over the decades: cows over equipment. He does not own a corn planter, combine or chopper. He said he does not want to invest money in something that predominantly sits and depreciates.

For additional stories from our other zone, log on to www.dairystar.com

Majestic View Dairy

“After installing our first SCR system 10 years ago we noticed better herd health, drop in death loss, and increased pregnancy rate. I like being able to virtually monitor cow health and activity without having to be physically on the farm. We most recently upgraded our SCR collars a few summers ago and love how advanced and precise the technology is.”

- Majestic View Dairy, Amanda Buschor

• Dual Germicide: Primary: Chlorine Dioxide promotes a quick kill. Secondary: LAS promotes a long-lasting kill.

• Effective against ALL Mastitis-Causing Organisms

• Contains Lactic Acid to promote Teat Exfoliation

• Teat skin conditioning – 12.4% skin conditioning package

• Green coloring for easy identification

“It takes labor to run them, which I don’t have, and it takes knowledge and cost to x them, which I don’t have,” Doug said. “I’m a dairyman. I love cows, and I want to spend every second I can with cattle.”

In 2014, Doug again made a facilities upgrade. Taking a eld across the road from his farm site, he built a 450-stall, sand bedded freestall barn and a manure pit. The building houses milking and dry cows, a double-12 rapid exit parlor and a holding pen.

“I felt like I had to do that to attract the next generation,” Doug said. “I wouldn’t want them to milk 180 cows three times a day in my step-up parlor.”

Doug and Abby combine to milk every cow at least one of the three milkings.

Abby Fairbanks gives grain to calves Sept. 14 on her family’s farm near Anamosa, Iowa. Fairbanks has been working full me on her family’s farm for a year and a half since college.

“I get up at 2:45 a.m. seven days a week,” Doug said. “I just feel like (milking) gives me an advantage, because I can keep such a handle on my herd.”

The herd has three strings of registered cattle: 240 Holsteins, 80 Brown Swiss and 80 Jerseys. Doug uses the colored breeds to augment components and protability without increasing herd size.

“I want to send a semi load of milk every other day,” Fairbanks said. “Once the tank gets full of milk, the next way to make it more protable is to make it heavier.”

He said shipping a semi load makes him competitive with any dairy.

“It can only leave (anywhere) one truck at a time,” Doug said.

The Fairbanks family beds with sand that is 90% recycled using their sand settling lanes. The lanes paid for themselves in 10 months. Josh is in charge of the lanes.

The Fairbanks family has diversied their income stream. They only raise the heifers they need and sell beef cross animals from the lower portion of the herd. They also sell about 120 herd bulls each year.

Doug and Abby each have their own roles on the dairy. The father-daughter

pair said they work well together, do not argue and keep things light-hearted.

“We have fun,” Doug said. “There just is no tension. … We think so much alike that it’s livestock rst. I think we both enjoy the farm so much. Our goals really align.”

Abby agreed.

“I can’t think of a time in my whole life where we didn’t really get along, especially with the farm,” she said. “We’ve just grown to appreciate each other and realize our own strengths and weaknesses, and made it work. We complement each other.”

Taking time off is one of Doug’s goals.

“I’ve been better at taking care of the cattle than I have taking care of myself,” he said. “I love what I do. … I just know that I can’t probably continue to work at this pace for a long time without some sacrices.”

In the future, Doug wants to transition the farm.

“I don’t really see myself retiring,” Doug said. “I’m doing what I want to do. … At some point in time I want to not have all the management decisions.”

and equipment out of the areas they thought would ood. The animals also were fed at higher ground.

“I had the feed wagons on the other side of the eld,” Dan said. “I have pictures where the feed wagons were. The water was not very deep at all out there.”

Had the cows stayed near the feed wagons, they would have been ne, Dan said. But, as he watched, a group of roughly 70 heifers and steers instead ran toward lower ground.

“Something came down the creek and spooked them, then they ran back towards the highway where the water was deeper,” Dan said. “They got in deeper water, then they turned their heads the other way towards the creek. It kind of just lifted them off. It was just like a whirlpool and they were ghting for their lives.”

Within seconds, the cows were gone.

“That’s something you never want to see,” he said.

Neighbors and community members have been calling the Rosses and sending texts to let them know where some of the cows have turned up. After almost two weeks, Triple R Dairy is still missing 35 cows.

“They found a cow, found two

cows, found four cows,” Dan said. “You go here and you go there, and you’re so glad to see them. They are ne other than they’ve been in shock and scared. They are alright.”

Triple R Dairy cows have been found 2-5 miles away from home, Dan said.

“We’ve had a lot of neighbors call in saying they found our cows,” he said. “They will look after them until we can get there.”

Now, fencing needs to be put back into place to keep the cattle on the property.

“We’ve had to relocate and move a lot of cattle out, like the dry cows,” he said. “We had to relocate heifers and calves out of the barns. I was wading in water up to my knee, but I was able to save them. We’ve had to relocate all the smaller calves anywhere we could.”

Steve and Dan milk around 380 cows at Triple R Dairy and farm more than 300 acres of owned and leased ground. They grow silage corn, wheat, haylage and dry wheat.

“We had already cut some silage, around 130-140 acres,” Dan said. “There’s still a lot more. Some land we haven’t had a chance to see it to check on it. We’ve been busy.”

Along with crops that weren’t cut, Dan said haylage that had been wrapped up also received water damage, and topsoil has been washed away.

“This is not a 3- to 4-day problem,” he said. “This is an ongoing problem. It will take a year or two to get all the elds straightened out.”

Dan and Steve’s story is not the only one of its kind in the area.

“There’s been some mudslides,” Dan said. “I’ve got a good friend who had a mudslide come down by his house. It didn’t hit his house, but he heard it coming.”

While talking with community members and an older uncle, Dan said no one had witnessed anything like the ooding and devastation that followed.

“It’s overwhelming,” he said. “We’ll make it, but I feel for the families that lost lives. There is one family that lost all 11.”

Steve also spoke about the situation in the area.

“Cattle are up on rooftops,” Steve said. “There are caskets going down the river. We’ve seen them. It’s indescribable. The Commissioner of Agriculture of North Carolina (Steve Troxler) was here. He is absolutely overwhelmed.”

Steve said a family member’s dairy barn, commodity shed, calf hutches, new milk tank and more were washed away.

and employees of

The Ross family suffered damage to their dairy due to Hurricane Helene.

“Luckily, he got all the cows and calves out,” he said. “He got them up to high ground. He had to move them to one of his cousin’s barns. He has now sold all his cows because he can’t build back. There is nothing to build back, it’s all gone. He lost 1,000 tons of silage he’d already cut and piled up. It washed it away.”

Hank Ross of Ross Dairy Inc., a cousin to Dan and Steve, said his farm is sideby-side with Triple R Dairy. It was damaged in the hurricane too.

“Good Lord willing, we’ll be able to get those crop yields back, but it’s go-

ing to affect yields for years to come,” he said. “It’s very much an economic impact to the dairy industry, to the community, and to North Carolina.”

Multiple farms in the area are using their tankers to send water to the milk processing plant to keep the facility running, Hank said.

“We’re ne where we’re at,” he said. “There are people who have lost everything. Words can’t even describe what people are dealing with down here.”

Both Triple R Dairy and Ross Dairy receive their feed from Athens, Tennessee. With road closures and bridges out

due to ooding and mudslides, what would normally be a less than 3-hour trip is now taking approximately eight hours.

The dairies use grain from breweries to feed their cows. Due to the ooding and lack of clean water, the brewery was closed for a while.

“That has really affected our milk production,” Dan said. “The production is down and the change of rations has affected the cows on both dairies.”

Dan said putting the wreckage into words is hard.

“It’s just devastating,” he said. “But we will just keep working.”

Lauretta’s grand day

Salzls’ older cattle consistently shine at World Dairy Expo

By Sarah Middendorf sarah.m@star-pub.com

MADISON, Wis. — A goal for the Salzl family recently came to fruition on the colored shavings at World Dairy Expo.

Gin-Val Logic LaurettaEXP was named grand champion of the International Milking Shorthorn Show.

Lauretta is a 6-year-old daughter of GE Ginger-Effect Huck Laura sired by GMC Rebel Logic-ET. She is classied Excellent 93 and produced 34,037 pounds of milk during her last lactation.

“She has a big pedigree,” Kristen Salzl said.

Salzl and her husband, Cory, own Corstar Farm where they milk 25 cows and own 30 acres of land near Litcheld, Minnesota.

They purchased Lauretta in 2021 after she was tapped intermediate champion at Expo for a farm in New Hampshire. They brought her back to Expo in 2023, where she was named reserve grand champion of the International Milking Shorthorn Show.

The Salzls went to WDE

with the goal of Lauretta winning the title of International Milking Shorthorn Grand Champion. Little did they know their dream was going to become a reality.

“The aged cow class was probably more stressful because everybody all week said, ‘The aged cow class is going to be the hardest class of the day and whoever wins that is going to have a pretty good chance at grand,’” Salzl said.

During the aged cow class, Lauretta was not pulled in line rst. However, when the judge saw the cows side by side, he tapped her out for rst, Salzl said.

“You could hear the crowd cheering,” Salzl said. “That was one of the more awesome moments. There were some really big names in that class.”

Usually, the Salzls show at the Minnesota State Fair and WDE. This year they decided to not show at the Minnesota State Fair but made their way to WDE.

Lauretta’s journey does not end here.

“If she calves in next year and looks good, we will denitely keep showing her,” Salzl said

Ritchie Water is Smart Water

They also want to continue her bloodline.

“We need to make more babies and that’s the plan,” Salzl said.

The Salzls are hopeful that Lauretta is pregnant. They bred her and are waiting for a conrmed pregnancy.

“Either way we are going to (in vitro fertilize) her because her daughter, who we sold on the KCCK sale this spring and is now owned by Glamourview in Maryland was named reserve junior champion this year,” Salzl said.

The Salzls graze their

cows 12 hours a day and feed the cows baleage, dry hay and a pellet containing protein, vitamins and minerals in the barn. Allowing them to graze helps them get exercise to stay conditioned Salzl said.

Calf-Tel

“It works really well with the shorthorns,” Salzl said.

The Salzls have had reserve grand champion Milking Shorthorn at WDE the previous three years with three different cows.

This year they brought four cows to WDE. Three of those cows — a summer junior 2-year-old, a junior 2-yearold and an aged cow — placed rst in their classes. Their senior 2-year-old placed third in her class.

“Our junior two-year-old, owned

with Leah and Jason James, was named reserve intermediate champion, so during the champion drive, three out of six cows pulled out were bred or owned by Corstar,” Salzl said.

In their rst class of the day, the summer junior two-year-old was pulled into rst and awarded a trophy. They were overjoyed, but there was even more to come.

“It (was) a good day and it got even better,” Salzl said.

Seasonal strength in Class III milk

Switch to the Horning Shredder Mill for higher speed and profitability when processing high moisture shelled corn.

Despite a recent drop-off in cheese markets, the Class III milk market has been very resilient. At World Dairy Expo, Ever.Ag Principal Mike North credited seasonal tendencies. “We’ve got lower components as we’ve come through the summer. Production has been lower because the cows just aren’t there. We’ve been stressed with some of this bird u in key geographies around the United States and, by the way, now, we sent a bunch of kids back to school sucking milk back into the bottling realm, college kids back to their pizza diet and football launching at the same time.” North said that is why milk prices typically have these peaks in late September into early November. In the past, $20-plus milk prices would have a dramatic impact on production. Strong beef prices, an absence of heifers and an aging cow herd have changed that scenario during the current cycle.

Strong cheese demand

717.844.9069 | New Holland, PA

55” Panel Fans

OptiHarv launched at World Dairy Expo

During World Dairy Expo, Renovo Seed introduced a new forage mix called OptiHarv. The mix is a blend of millets, peas, beans, barley and brassicas and produces more tonnage for baleage, haylage or grazing. The Brookings-based Renovo Seed said OptiHarv is designed for cattle producers looking for a high-quality feed, such as dairy farmers.

By Don Wick Columnist Ag Insider

Honors for Commissioner Petersen

After tough times in the dairy sector, Associated Milk Producers Inc. Vice President of Marketing Sarah Schmidt said this year has been a good change. Demand is strong for all product segments. “This year it seems like cheese was put on promotion more at retail grocery stores. More consumers were grabbing that two-for-$5 deal and it’s really showing up in our milk price.” Schmidt also noted increased exports of U.S. dairy products because of a downturn in supply in other major dairy-producing countries.

The Voice of Milk

A new collaboration is in place for three Midwest dairy organizations. The Minnesota Milk Producers Association, Dairy Business Association and Edge Dairy Farmer Cooperative will work together on dairy policy issues. The collaboration is being branded as the “Voice of Milk.” The umbrella brand represents dairy farmers in nine states including Minnesota and South Dakota.

Election year impacts

Minnesota Agriculture Commissioner

Thom Petersen has received the University of Minnesota Distinguished Friend of Extension Award. Dean Bev Durgan made the presentation at the extension conference in Bloomington.

Place exits Farm Service Agency, joins University of Minnesota

Whitney Place made the move to the University of Minnesota Extension where she is the new director of government relations and agriculture outreach. Most recently, Place was the state Farm Service Agency director. Before that, Place was the Minnesota Department of Agriculture assistant commissioner.

Minnesota Farm Bureau Federation hires policy specialist

Hunter Pederson is the new public policy specialist for the Minnesota Farm Bureau Federation. Most recently, Pederson was the committee administrator for the Minnesota Senate Agriculture Committee.

Partners in Advocacy Leadership program goes to Washington D.C.

The lame-duck session after the election is bound to be busy, making it more difcult to pass a farm bill. Jim Callan, president, James Callan Associates, believes House and Senate Agriculture Committee leadership sincerely want a new farm bill. The election also has ramications. “Some folks think if Vice President (Kamala) Harris is elected, Democrats will want to wait until next year,” Callan said. “If President (Donald) Trump is elected again, Democrats may have a desire to pass the farm bill this year. Politics aside, folks want to get it done by the end of this year. Democrats and Republicans, that’s the desire.”

The American Farm Bureau selects 10 agriculture professionals to participate in its Partners in Advocacy Leadership program every two years. The two-year program provides participants with education and high-level skills to become better advocates in their communities, ag organizations and government. CoBank Relationship Manager Amanda Durow spent time in Washington D.C. as part of the PAL program. “We started in Gettysburg where we learned about leadership from a battleeld. Then we spent some time in D.C. talking with members of USDA about agriculture and policy.” Durow, who also farms at Hastings, said the skills learned will help her to support American farmers on a larger scale. “Working in farm credit, I want to leverage this opportunity to make a bigger impact on farmers.”

National Association of State Departments of Agriculture tribute honors Northey

• The highest air ow in a circulation fan - 33,900 CFM.

• Cast aluminum blades have a lifetime warranty.

• Totally enclosed maintenance free, high ef ciency motors have a full two year warranty.

Model VP CA: Belt Drive, 1 HP, 115/230 volt, 9.6/4.8 amps single phase one speed 587 rpm

Incentives proposed to move away from largescale animal agriculture

A group of East Coast Democratic lawmakers has introduced legislation that would pay large-scale livestock farms to transition into specialty crop production or pasture-based livestock operations. New Jersey Senator Cory Booker, North Carolina Representative Alma Adams and Massachusetts Representative Jim McGovern want to use existing funds from the Ination Reduction Act for this proposal. Climate-smart agriculture policies supported by the environment and animal welfare sectors are the foundation of this bill.

Relief for organic dairies

The U.S. Department of Agriculture is making $58 million available to organic dairy farmers to help offset market volatility, transportation costs and an unstable feed supply. Organic dairy farmers will be able to apply for this assistance through the Farm Service Agency.

Deere and DeLaval partner on dairy data platform

John Deere and DeLaval have launched a new digital platform called the Milk Sustainability Center. Dairy farmers will be able to track data from their crops and dairy herds in one system. In the future, this program will allow farmers to benchmark nutrient efciency and a reduction in carbon dioxide emissions. The Milk Sustainability Center is now available to a small group of dairy farmers in the U.S., Netherlands and Germany with plans to expand to other countries.

The National Association of State Departments of Agriculture honored former USDA Undersecretary Bill Northey with its Ambassador’s Circle Award. Northey also served as Iowa’s secretary of agriculture from 2007 to 2018. The award will now be known as the Bill Northey Legacy Award. Northey passed away this past February.

A winning tradition

The University of Minnesota has repeated as the top team in the National Intercollegiate Dairy Judging Contest at World Dairy Expo. Team members are Sarah Hagenow of Rio, Wisconsin; Megan Ratka of Cold Spring, Minnesota; and Megan Meyer of Rollingstone, Minnesota.

Trivia challenge

The colored shavings on the Coliseum oor of this year’s World Dairy Expo were pink. That answers our last trivia question. For this week’s trivia, what is the largest dairy cooperative in the United States? We’ll have the answer in our next edition of the Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network of Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

A family network of help

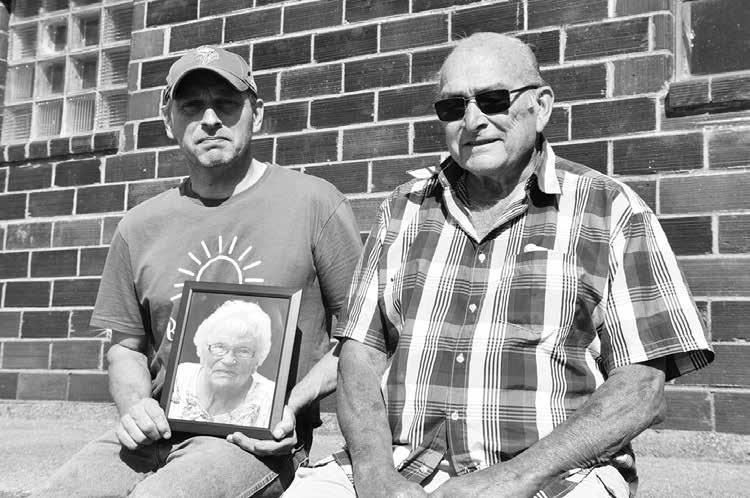

Jerry (le ) and Tom Jr. Gill sit beside their barn holding a picture of Jerry’s mother, the late Genevieve Gill, Oct. 1 at their farm near Albany, Minnesota. The Gill’s farm was recognized this year as a century farm.

Gill Dairy receives Century Farm recognition

By Ti

“Mom and Dad had 10 kids and all but two live close. I can call my siblings and nephews and they will be here in 10 minutes.”

any Klaphake ti

any.k@dairystar.com

ALBANY, Minn. — Gill Dairy knows what it means to be a family farm.

“The big theme here is that we are all about family,” Jerry Gill said.

This summer, Gill Dairy of Albany was recognized as a century farm by the Minnesota Farm Bureau Federation, the Minnesota State Fair and Stearns History Museum.

Turn to GILL | Page 12

“It gives me the information I need when I’m looking for it.”

How long have you been testing with DHIA? I have been testing with DHIA for 44 years.

What tests do you use and what do you like about those tests? We use the somatic cell count and pregnancy check test. I like the SCC test to gauge the cows history on SCC. We’ve been using the SCC test since the 1980’s. I like the pregnancy check test to get early results. It’s also less stress on the cows because you don’t have to catch and palpate the cows.

Which is your favorite and why? The SCC. We rank the cows according to SCC then we take care of the issues.

How does testing with DHIA bene t your dairy operation? It gives me the information I need when I’m looking for it.

Tell us about your farm. Our dairy cows are on a rented farm. We farm no land and purchase all of our feed. We are unconventional the way we feed our cows. We use balage, and beet pulp along with ground corn and a custom protein mix. We feed with a TMR in a free stall barn.

Jerry milks 58 cows in a tiestall barn, raises 80-90 head of youngstock and farms 150 acres at Gill Dairy.

“I am here every day but there is always someone else here,” Jerry said. “Some of my siblings or nephews are here too. There are four nephews in their 20s and 30s that help out consistently.”

Jerry’s 85-year-old father, Tom Jr., plays an active role on the farm by taking care of the bookwork. They both live in the house that was built in the 1800s.

The farm was originally purchased by Ben and John Woebkenberg in 1911. They farmed 150 acres until their nephew, Tom Gill Sr., married Gertrude Gill and purchased the farm in 1933. In 1973, Tom Gill Sr. passed the farm onto his son, Tom Gill Jr., and his wife, Genevieve Gill. In 2000, Tom Jr. and Genevieve passed

the farm to their son, Jerry Gill.

During that time, modications were made to the farm including building a new brick barn in 1950 after the origina was destroyed in a re that claimed the lives of all the cattle inside.

“They built the new barn to milk 20 cows at rst and everyone thought Grandpa (Tom Sr.) was nuts for taking on 20 cows,” Jerry said. “That barn was one of the rst barns that Worms Lumber in New Munich built. They still have a picture of it in their business.”

“Mom and Dad had 10 kids and all but two live close. I can call my siblings and nephews and they will be here in 10 minutes.”

remodeled from 20 stalls to 36 stalls and a pipeline was installed. In 2008, an additional 22 stalls were added to the barn and a manure pit was added. A new heifer facility was constructed in 2011 that holds up to 68 head.

JERRY GILL

Through the modications and additions, the Gill family helped each other out, whether there was corn or alfalfa needing to be harvested or cleaning up the farm to host a nephew’s wedding reception.

In the 1980s, the brick barn was

LIGHT WEIGHT, FAST AND BUILT TO LAST

“Sometimes we get a dozen (people) to come out like when a load of straw comes,” Jerry said. “Everybody helps out.”

This continues to ring true for the rest of the month of October, while Jerry recovers from having his second hip replacement. Jerry’s brother, Joe Gill, will do morning chores and Jerry’s nephews, Cole, Luke, Zach and Isaac Zink, will take care of evening chores for ve weeks.

Jerry had his rst hip replaced last year, and at the time, had help from three local youth – Kyle Boeckermann, Trevin Wohletz and Ethan Gerads. Ethan started working on the farm when he was 13 years old. At 16, he led the other boys and started to do milkings on his own before tragically passing away three days after Jerry returned to farming full-time.

Turn to GILL | Page 13

You’ll

for

AirFLEX SDX is the clear-cut choice for soybean growers. It offers streamlined flex cutting for your soybeans, providing optimal ciency with fewer components, making it simpler to maintain. The harvest window is short for soybeans. You want to get them off the ground fast and into your bins where they’ll be warm, dry and safe.

soy e efficie mak s sooybea t gr where

and the extra money it will generate.

“Overall, I’m going to say that the header is above anything that I have run personally. It’s simple yet it does exactly what you want it to do. It’s not a complicated head; it’s not complicated electronically or mechanically. They’ve done a good job of keeping it simple so its maintenance over time is going to be easy. I don’t think that’s going to be an expensive header to keep operating.” - Bruce Baldwin, Kalvesta, Kansas

“He really loved (farming),” Jerry said. “He didn’t grow up on a farm but his mom reached out because he had such a strong interest in farming. He was talking about going to Ridgewater College for an ag degree.”

Today, many of the Gill children hold careers in the agriculture industry due to their interest from growing up on the farm.

“Some of the other kids liked farming too, but the farm wasn’t big enough to support more than one family,” Tom Jr. said. “By the time I was ready to be done, the other boys all

had good jobs in town.”

Jerry said that while his siblings hold full-time jobs off the farm, they are glad they grew up on the farm and are always willing to help.

“It was nice to raise the family (on the farm),” Tom Jr. said. “I’d do it again.”

Jerry agreed.

“Working with family, there are days where things aren’t perfect,” Jerry said. “But as a family, we hug it out and keep going. This place means so much to all of us because we all grew up here.”

E-EDITION

from our side our side OF THE

What are the advantages and disadvantages of dairy farming in your area?

Joe Rocha

Tillamook, Oregon

1,400 cows

Tell us about this year’s growing season. We had favorable spring conditions, but it was a very cool growing season on the coast. Grass crops did extremely well. We plant 71-day corn in a typical year, but this year we had very few warm days, so it struggled to mature. We farm about 1,200 acres, split between grazing, grass crops and corn. We typically only plant around 300 acres of shortday corn due to our cool summer season.

What management practices keep your farm sustainable? We are members of the Tillamook County Creamery Association and get high premiums for quality. We keep our somatic cell count under 100 and our bacteria counts low to get into the top tier premiums. We sell some replacements every year and some genetics (semen and embryos). We also tend to sell some higher-end heifers in a few sales every year.

What are the advantages and disadvantages of dairy farming in your area? Tillamook County Creamery Association is a growing brand of dairy products that is entirely owned by the 54 memberowners in Tillamook County. It allows the dairy industry to survive in an area that has many cost disadvantages. We also have integrated hauling of our own feed and do all the crops ourselves.

What is a growing industry trend in your area? Tillamook has a natural resource economy. It is mostly dairy, forest and sawmills. There is a little tourism on the beach, so without dairy, our county would be much worse off.

Why is dairy farming the career for you? I couldn’t imagine another career. I love working with cows and the land every day. It’s an incredible way to raise a family.

Tell us about your farm. Our farm has been in Tillamook for 32 years. The farm is family-owned and operated. There are three generations involved on the farm in some way. Our cows and heifers are all housed in freestall barns. The cows are milked in a double-24 parlor. We try to continue to invest in cow comfort projects regularly. We also do some seasonal grazing.

Lisa Leach Linwood, Kansas 35 cows

Tell us about this year’s growing season. We have about 200 acres. We planted about 85 acres of soybeans and about 85 acres of corn. It was a little wet when it was time to plant, but we have had a drought for several years, so we were thankful for the moisture.

What management practices keep your farm sustainable? We sell a lot of seed stock and sell some of our lower-end cows to homesteaders.

What are the advantages and disadvantages of dairy farming in your area? The biggest disadvantage is there are no other dairy farms in the area. We are not able to go to town and get farm necessities. Most of our supplies need to be ordered. Vets are getting few and far be-tween. Our vet is roughly 40 miles away and nearing retirement, so we are doing a lot of stuff ourselves. Our milk goes south to Tulsa right now to Blue Belle Creameries for ice cream.

What is a growing industry trend in your area? There really are not any.

Why is dairy farming the career for you? Mainly because we have always enjoyed genetics and show cows. Raising and breeding some really good cows is something we enjoy.

Tell us about your farm. Our dairy is called Lincrest Farm. My husband, Rob, and I are involved daily. My three daughters — Taylor Hildebrandt, Erin Leach and Sophie Leach — maintain an interest in the farm. My husband’s mother also helps, and my sister helps in the evenings. Our parlor is a retrotted semi-trailer that is a single-7 herringbone parlor. This is the fourth year that we have been milking in this setup. We sell our milk to Dairy Farmers of America.

Hank Van Exel Lodi, California

2,200 cows

Tell us about this year’s growing season. We planted 2,100 acres of corn and 500 acres of alfalfa. We also have a winter forage crop. We irrigate all of our land for moisture. We had extreme hot conditions. We have never been this warm this long.

What management practices keep your farm sustainable? We sell a lot of cattle. We are kind of known for our herd so we sell a lot of heifers and some fresh cows. We also sold some feed this year and put in solar panels. We also farm about 170 acres of grapes.

What are the advantages and disadvantages of dairy farming? We have a wonderful climate for dairy farming. We have a nice Delta Breeze and nice fertile ground which gives us good crops. There are a lot of people that are moving into the area and they are more inclined to have grapes or almond trees. We have a lot of constraints on our water.

What is a growing industry trend in your area? There isn’t any. Agriculture is as bad as it has been.

Why is dairy farming the career for you? My mom and dad started in it and our area is one of the best for dairy farming. I love cattle and I got involved with the genetics of it.

Tell us about your farm. We sell our milk to Hilmar Cheese Company Inc. We have two different facilities; one milks the Jerseys and elite genetics while the other milks the rest of the cattle. All of our cattle are housed in a freestall barn. The farm consists of myself, my wife and my son and daughter-in-law.

Austin Schwartzbeck

Peace and Plenty Farm LLC

Union Bridge, Maryland

250 milking cows

Tell us about this year’s growing season. It was a good start to the year planting-wise. We were able to get everything in the ground without too much turmoil. It was not a very wet spring. We were able to make triticale on time, which is around the second week of May. Following the triticale, we plant about half (200 acres) of our corn. Summer started with some nice rains. Once we hit late June to early July it started drying up. We had around 20 days of no rain, which hurt the yields. There was a lot of 4- to 5-foot corn, which is way less than average. There was a hurricane that came through the middle of August, which gave us about eight inches of rain in three days. The ground soaked all of it up and in about 2-3 days after that, we were able to haul manure and do regular things in the eld. That rain did help with the hay and pushed our corn yield from about 50-60 bushels to about 100-110 bushels.

What management practices keep your farm sustainable? In Maryland, we are unique with our access to the Atlantic Ocean. We are very close to the Chesapeake Bay, so the state of Maryland offers a lot of grant money to help with manure management. They provide an opportunity to haul manure and will give us an incentive to inject it into the soil. We pretty much strictly no-till our crops. We also compost on our farm. We use a squeezer so we can use that for bedding and will bring the rest out to the farmland and will inject it there.

Delbert and Heather Yoder

West Salem, Ohio

40 cows and 50 youngstock

Tell us about this year’s growing season. While we don’t grow crops, we do buy all our feed from neighboring farms. This growing season has been challenging and very dry. We have only had around four inches of rain total during this year’s season.

What management practices keep your farm sustainable? We only milk a small group of cows because we are more focused on showing and genetics, so we rely on off-farm income to stay sustainable. Delbert is a full-time hoof trimmer. I work for Golden Link Microbial Supplements, sell Blondin sires and Kilgus sires, and travel to work a few shows and sales throughout the year. We also house around 10 donor cows and raise in vitro fertilization calves to help market for ourselves as well as others.

What are the advantages and disadvantages of dairy farming in your area? We are located in one of the largest dairy areas in our state, so we are fortunate that we can still market our milk. Many smaller family farms are not

The compost barns are also assisted by the state of Maryland. In Maryland, we are not able to haul manure from December until March due to runoff into the waterways.

What are the advantages and disadvantages of dairy farming in your area? We have decent weather, and the winters aren’t too harsh. We can get into the ground at a decent time and aren’t in a locked-down window to plant. We usually don’t get a killing frost until December. The state of Maryland really helps dairy farmers. They want to keep dairy in Maryland and keep us sustainable and environmentally friendly. We are about an hour from Baltimore, a little over an hour from Washington D.C. and a little under an hour from Philadelphia, so really the people base of where we are at is good. We have a lot of people in our area to feed. We are also really close to the port of Baltimore for shipping products.

What is a growing industry trend in your area? One of the growing trends is injecting manure and the benets it offers. There is also a lot of niche marketing in the area, such as producers making their own cheese or ice cream.

Why is dairy farming the career for you? It’s something new every day. I like working with cattle, doing eldwork and just about every part of this business. It gives you a drive every day to do better with your cattle and your crops and try to be as protable as you can.

Tell us about your farm. Everybody — my grandparents, my uncle, my parents, my sister, my brother, my wife, and I — is very involved with different aspects of the farm. We all have diverse roles and it is pretty much all family. We have a couple of hired hands who are basically family for milking and help with feeding. We ship our milk to Maryland & Virginia Milk Producers Cooperative Association.

as fortunate and have lost their milk market or hauling. One of the challenges in our area is the cost of land. It makes it hard for any farms to expand. It is upwards of $15,000 per acre. Also, the cost of construction and materials have more than doubled in the last 10 years.

What is a growing industry trend in your area? A growing trend in our area is farmers marketing their own product. They are selling raw milk, cheese, ice cream and meat products.

Why is dairy farming the career for you? We both have a love for animals. Delbert‘s family grew up dairy farming. I started working on a dairy farm my sophomore year of high school. Both of us have shown cows in 4-H and FFA where we grew a passion for developing and showing cows with great genetics. Delbert was a tter of show cattle for over 25 years and after meeting me, we both travelled to shows and sales together. This only ignited our passion for the industry more.

Tell us about your farm. Our farm was ofcially established in 1998 with the start of the prex Brook Hollow farm. The rst cow we bought together was a Guernsey named Jastes Ben Joy. She was intermediate champion and reserve grand champion at World Dairy Expo in 1995. We were mainly Holstein breeders. In 2004 we bought our rst and only Brown Swiss cow named Top Acres Pre Para. She has produced over 110 offspring with the Brook Hollow prex. Our milk is shipped to Borden Dairy in Oberlin, Ohio.

How many times a day do you milk and what is your rolling herd average? We milk twice a day and our rolling herd average is 27,448 pounds of milk, 1,275 pounds of butterfat and 885 pounds of protein.

Describe your housing and milking facility: Our cows are housed in a three-row freestall barn. The stalls have waterbeds and are bedded with sawdust daily. We milk our cows in a double-6 stepup parlor.

Who is part of your farm team and what are their roles? Rich does most of the feeding, manure scraping and crop management. Michael is employed full time on the farm and does the milking, all the calf care and handles all the breeding. Makayla helps with eldwork, milking and calf chores. Tyler does milking shifts, eldwork and much of the maintenance on the farm. Both Makayla and Tyler have full-time jobs off the farm.

What is your herd health program? We do herd health every Monday morning. The

TOP PERFORMERS

vet comes and we do pregnancy checks and general herd health. We vaccinate every spring with J-5 for mastitis. At dry off, cows receive a booster of Ultrabac 7 and Scour Bos and are dry treat-

ed with Quartermaster and a teat sealer. After they freshen, they get Bova-Shield Gold HB booster and another Bova-Shield Gold HB booster after they are conrmed pregnant.

What does your dry cow and transition program consist of? Dry cows are in a dry cow lot with free stalls in a lean-to on the old tie-stall barn. The ration consists of straw, corn silage, dry cow

concentrate and haylage.

What is the composition of your ration, and how has that changed in recent years? Our rations consist of corn silage, haylage, high moisture corn and custom supplements. We have continued to supply more nutrients (lysine, methionine and a proper balance of trans fatty acids) as the herd has progressed.

Tell us about the forages you plant and detail your harvest strategies. We grow HarvXtra alfalfa, which allows us to cut every 30-35 days without losing forage quality. We cut four crops with the last cutting shortly after Labor Day. Our corn silage is regular eld corn. Our feed is stored in upright stave and Harvestore silos. Any excess feed is stored in bags.

What is your average somatic cell count and how does that affect your production? Our SCC average runs between 80,000150,000.

• Zero Maintenance, zero electricity, no chemicals

• Observations have shown greater resistance and reduced losses due to salmonella and avian influenza.

• Reduction and in many cases elimination of bacteria load in water.

• Improves medication performance in water, when used.

• Helping to improve profitability in these narrow margins

“Our waterers are cleaner than they have ever been with the peroxide system saving labor in daily cleaning, keeping excess water out of the lagoon which saves in manure hauling expense.”

“Water tank was clean in just a week, didn’t lose any measurable milk in last year’s heat.” David Wohlt Dairy, 220 cows, Northeast, WI

Norswiss Dairy, 4000 cows, Northeast WI

Bongards’ Creameries

Has been a quality market for MN dairy farmers for over 100 years. MN producers provide one of the country’s most distinctive brands of cheese that is still made using the same Old World craftsmanship and has been combined with cutting-edge technology to produce cheese that delivers unforgettable taste with unparalleled quality. MN Dairy farmers and Bongards, quality that stands the test of time. We offer a competitive base price, premiums, and the best eld representatives in the industry.

13200 Co. Rd. 51

Bongards, MN 55368 (952) 466-5521

Fax (952) 466-5556

110 3rd Ave. NE

Perham, MN 56573 (218) 346-4680

Fax (218) 346-4684

SCHOENE KUH DAIRY, Millville, Minnesota

Staci Sexton, owner, AFBF 2023 MN Young Farmer

Multi-year MN Holstein Progressive Breeder 60 reg. Holsteins and Jerseys earn

“We’ve used Udder Comfort™ over 10 years: Blue spray on fresh animals and lotion with massage for any flareups. We tried others but always came back to this product because it works,” says Staci Sexton. In 2013, she started Schoene Kuh Dairy, today milking 60 registered Holsteins and Jerseys with a genetic focus on production, health traits, and components. Along with the Irish Ridge herd of her parents and brother, where she helps with herd work, 125 cows are milked at the Millville, Minnesota dairy farm that has been in the family over 160 years.

Schoene Kuh is German for ‘beautiful cow.’ Staci loves working with cows and genetics, earning progressive breeder and milk quality awards. Her 9th AI bull in 10 years is a homozygous polled, high cheese merit bull named King Kong.

“It’s exciting to breed, flush, and wait nine months hoping to get something great,” she says, and when it comes to first calvers “we use Udder Comfort to reduce swelling. Fresh heifers are comfortable with better, faster milkout. It’s easy to use and helps keep our SCC low.”

What change has created the biggest improvement in your herd average? The implementation of G6G and CowManager have given us a higher pregnancy rate and fewer average days in milk. In turn, we are getting more milk out of the cows.

What technology do you use to monitor your herd? We have used CowManager for a year and that has helped Michael nd cows in heat along with nding sick cows sooner. This in turn, has brought the pregnancy rate up 6% in the past year and allowed us to treat cows earlier for illness.

What is your breeding program and what role do genetics play in your production level? We enroll all rst service cows in G6G at 45 days and rebreeds get put on ovsync along with heifers if they didn’t get picked up by the CowManager system. We believe that getting our average days in milk to 150-165 keeps the averages up. Additionally, Michael has taken over all breeding and works closely with Select Sires to try and keep a competitive edge on generations to come. That has shown on our rst lactation heifers.

List three management strategies that have helped you attain your production and component level. Selective breeding. Working closely with our nutritionist to keep a balanced ration with on- and off-farm feed stuffs. Milking and feeding times stay consistent.

Tell us about your farm and your plans for the dairy in the next year. We are a multi-generation farm. Rich is fth generation and our

children are the sixth generation. We are very family oriented, and we wish to pass the farm down to the next generations. We have looked into other ways to expand and become more efcient due to our very fast-growing family. It’s not easy in today’s times, but we are trying to make it work because it is not very often nowadays that you get the opportunity to pass on the family farm to the next generation.

EMILY BRETH/DAIRY STAR

A cow with a CowManager tag eats total mixed ra on Oct. 8 at Richview Dairy near Belle Plaine, Minnesota. The rolling herd average is 27,448 pounds of milk, 1,275 pounds of bu erfat and 885 pounds of protein.

Rich Lambrecht holds a handful of feed Oct. 8 at Richview Dairy near Belle Plaine, Minnesota. The cows’ ra on consists of corn silage, haylage, high moisture corn and a custom supplement.

Contact one of the following dealers to learn more:

IOWA

Prairie Land Ag Supply Inc. Rock Valley, IA 712-476-9290

United Dairy Systems, Inc. West Union, IA 563-422-5355

Monticello, IA 319-465-5931

WISCONSIN

Advanced Dairy Spring Valley, WI

715-772-3201

Bob’s Dairy Supply Dorchester, WI

715-654-5252

Ederer Dairy Supply Plain, WI

608-546-3713

DeLaval Dairy Service Kaukauna, WI 866-335-2825

Joe’s Refrigeration Inc. Withee, WI 715-229-2321

Mlsna Dairy Supply Inc. Cashton, WI 608-654-5106

Professional Dairy Services Arlington, WI 608-635-0268

Redeker Dairy Equipment Brandon, WI 920-346-5579

The Scharine Group Inc. Whitewater, WI 800 472-2880 Mt Horeb, WI

800-872-3470

MINNESOTA & SOUTH

DAKOTA Farm Systems

Melrose, MN

320-256-3276 Brookings, SD 800-636-5581

Advanced Dairy Mora, MN

320-679-1029 Pierz, MN

320-468-2494

St. Charles, MN 507-932-4288 Wadena, MN 218-632-5416

A successful succession plan

Jungemann family introduces another generation to the farm

By Emily Breth emily.b@star-pub.com

WOLSEY, S.D. — Keeping the farm rolling through the generations has been a priority for the Jungemann family, leading to the creation of Lazy J Dairy LLC.

Russell and Janet Jungemann and their son, Lucas, and his wife, Kari, can be found operating their 900-cow dairy near Wolsey that has been slowly growing over the years.

Lazy J Dairy is a product of a successful succession plan that has been in place for around 15 years.

“When (Lucas) came back from college, he initially had cattle and rented land,” Russell said. “Around 2007 we built a freestall barn and I told him if he wanted to milk cows, we would add space and he would pay (us for the space).”

Lucas bought his own feeders and used that income to nish paying off college debt and save up to invest in the farm. By the time of the expansion in 2007, he was able to buy his own 100 cows to add to the herd.

“I paid my dad for feed and I got my portion of the milk check,” Lucas said. “Then I

started renting a few acres here and there to add feed to the pile for my cows.”

The Jungemanns currently milk their herd in a double-16 parallel parlor. They also manage 1,800 acres of corn, alfalfa and soybeans, and occasionally raise specialty forages and grains.

“Janet and I started farming in 1980 and we casually grew from ve cows to 900,” Russell said. “(Around) 2012, Lucas joined the farm (as a partner) and we created Lazy J Dairy LLC.”

To get the succession plan started, the family worked with Thompson Law PLLC in Sioux Falls. The family was then able to develop the limited liability company and form a trust.

“We couldn’t have done it without them,” Janet said. “We wouldn’t have even known where to start.”

As the years went on, the family had the plan redone a couple times and switched rms when their lawyer passed away.

“Things in life change and it needs to be updated,” Janet said. “I think that is important along with explaining to all of your family what’s happening. Communication is key.”

Lucas started his owner-

ship in the farm with 11%, which included some cattle and machinery. The family then created a contract for deed for an additional 14%. After that was paid off, another contract of deed was made for a purchase of 25% of the farm. Currently, Lazy J Dairy LLC is 50-50 ownership between both couples, with no plans of changing.

“Years ago, Russell

thought Lucas should buy more and own 70%,” Janet said. “I think we all agreed and settled that 50% is ne.”

The rst experience Lucas had farming on his own, was managing a eld when he left for college. This began his appreciation for farming.

“When I was going to college, I wanted to be in agriculture but didn’t want to farm,” Lucas said. “I wanted to do

something different. But I had to pay for college and the deal my parents made with me was they’d rent me 80 acres to manage.” Lucas oversaw all the decisions with guidance from his parents, from planting and harvesting to hiring and paying custom crews.

Russell and Janet’s other son, Adam, and their daughters, Libby Flemming and Emily Stahl, received this same opportunity.

“While I was in college, I gured out farming is a good lifestyle,” Lucas said. “By the end of college, I came home and started working as a hired hand.”

The family has a good work relationship they said. Decisions are made together based on everyone’s input.

Everybody on the farm has their respective roles, however, everyone will chip in wherever needed. Janet mainly handles individual cow health and records. Kari is primarily in charge of the bookwork for the farm.

“(Dad) is the big picture guy,” Lucas said. “He is always looking at the daily production of the cows and prices. I am the x-it guy in the shop getting

equipment and the parlor going.”

When it comes to the eldwork, the whole family works together to get it done. This includes other family members coming home to help at times.

“There is still that feeling of family camaraderie when it is silage time and they all come back to help,” Janet said. “That all feels close-knit and that brings (Russell and me) a lot of joy.”

Having the next generation step up to take over the farm makes the couple happy they said, knowing their hard work over the years was worth it. The return of Lucas and Kari has also changed the character of the farm.

“If we didn’t have them coming back, we wouldn’t keep increasing,” Janet said. “We might have asked ourselves why we want to if no one is going to take over. I think that would have not been nearly as fullling for both Rus-

sell and me to say we did this and now we’re done.”

The family feels comfortable with their plan, Janet said, even though Russell had concerns about bringing a family member into the farm. However, since the kids were young, having family involved on the farm was of value to them, a value they passed on to their children.

PHOTO SUBMITTED (Le ) Cows stand at the top of the barn July 10, 2018, at Lazy J Dairy LLC near Wolsey, South Dakota. Janet and Russell Jungemann started farming in 1980 and slowly grew their milking herd from ve cows to 900.

PHOTO COURTESY OF AJ PRODUCTION CO (Below) Janet (le ) and Kari Jungemann collect milk samples Jan. 30, 2019, at Lazy J Dairy LLC near Wolsey, South Dakota. The Jungemanns milk in a double-16 parallel parlor and manage 1,800 acres of corn, alfalfa, soybeans and specialty forages and grains on occasion.

“Raising a family is where I really enjoy it,” Lucas said. “Kari and I have

three kids (Vonn, Walker and Ava). Seeing them on the farm and watching Grandpa and Dad doing stuff is really about the best part of it.”

Fresh, unlimited dairy

Immanuel Lutheran School-Silo installs bulk milk machine

By Amy Kyllo amy.k@star-pub.com

LEWISTON, Minn. — North from Lewiston among the rolling corn elds stands Immanuel Lutheran SchoolSilo. There, 100 elementary and middle school students are now enjoying fresh, cold, unlimited milk from a bulk milk dispenser thanks to an Undeniably Dairy Grant.

Each day, the school uses about 10 gallons of chocolate and white milk for its staff and student body.

Kevin Meyer is the principal.

“The milk tastes so much better for the kids,” he said. “I’ve always drunk carton milk as well, but I always took a sniff test before that rst swallow. … It’s just so much more enjoyable (now) to drink.”

Dairy farm community members Emily Tweten and Kristi Tveten are both connected to the school and collaborated to help get the grant. Tweten’s children attend the school as does one of Tveten’s grandchildren.

The Twetens milk 800

cows near Lewiston.

Tveten is the preschool aide at the school. The Tvetens retired from dairy farming after 47 years in August.

Before switching to the bulk milk dispensers, the school used cartons.

“We discovered that most kids didn’t like the taste of milk out of cartons,” Tveten said. “I’m of the belief that if you don’t teach a child to drink milk when they’re young, they tend to not carry the habit on. So, we wanted to bring in good, fresh milk, and have all they could possibly drink available.”

After research, the pair found out that as dairy farmers they could apply for a grant through Midwest Dairy. Tweten said a challenge they faced was the small size of the school, since these grants are meant to impact as many as possible. To expand their impact, they have plans beyond the daily meal program to use the dispenser at sports tournaments and larger events to push more milk into the community.

In preparation for the project, Tveten, Tweten and the head of the school lunch program, Teresa Fortsch, vis-

ited Goodhue Public Schools which had installed bulk milk dispensers.

“(We) wanted to really study and understand the challenges of a new bulk milk machine in a school,” Tweten said. “(They) let us know all of the ins and outs and what to do and what not to do.”

The group had begun discussing getting a bulk milk dispenser several years ago. However, concerns over labor changes, keeping the machine clean and more, slowed the

process by one year for the school to get a machine.

The school began using their bulk milk dispenser early in the 2023 school year. The grant covered the majority of the project expenses, with the school covering the rest.

Fortsch said it took time to get used to the new set up.

“It was a little rough at the rst couple weeks, but once I got into a routine and gured out the best way to ll it, it’s pretty smooth,” Fortsch said.

The school allows students

to come back for rells.

“First and foremost, it’s way better than anything else they’re probably going to drink,” Meyer said. “It really isn’t costing us that much more to allow them to be able to drink (what they want).”

The milk costs the same amount for 80 servings now as it did for 50 servings before.

“Being in a farming community, we have a lot of kids who drink milk and would like to drink more,” Meyer said.

The dispenser has cut down on waste. The school throws away about half the amount of milk as before.

“We had a fair amount of waste milk that was always getting dumped out of cartons at the end of the lunches,” Meyer said. “Everybody was required to take a milk, but again, because it didn’t taste the best, they didn’t drink it. … Through this we have virtually very little waste milk, and they’re taking how much they want, and … a lot of them are going back for seconds.”

The school is not Tweten and Tveten’s only project to get milk into the hands of consumers. The two dairy farmers started a nonprot called One Gallon at a Time. Through their nonprot they give dairy products to those in need.

Their nonprot grew out of them donating 55 gallons of milk and 15 half gallons of milk to Food for Families once a month. During the COVID pandemic, the need for their milk dropped off because the organization was getting extra funds.

Today, their nonprot focuses on providing Kwik Trip dairy gift cards to food shelves to distribute.

Another bulk milk dispenser project the pair completed was getting a bulk milk machine into The Crossings Center in Lewiston. The space has regular events for youth and families, which Tweten said are well attended.

“(The dispenser) really gets used a lot,” she said.

Back at the school, One Gallon at a Time is also helping the students give. Last year, at a food drive, they promised the kids their non-prot would match the food donations the children collected with dairy donations for double the impact.

Whether donating to the community for Tweten and Tveten or bringing fresh dairy into his school for Meyer, milk’s nutrition is important to the group.

“Milk has everything every kid needs,” Tveten said. “The nutrient value in milk is huge, and we know for sure they get it twice a day (through the school’s meal program).”

Meyer agreed.

“In today’s world we see a lot of different substitutes for milk, but most of those substitutes are adding a lot of things milk already has,” he said. “It provides the kids with what they need, the nutrients they need, the vitamins, minerals that they need.”

Cletus Fischer unloads silage into a bagger Oct. 1 near Lastrup, Minnesota. Fischer planned to ll two 9x200 bags and was hoping to nish Oct. 2. He and his wife, Sheila, milk 40 cows.

The University of Minnesota Department of Animal Science hosted the Minnesota Nutrition Conference Sept. 18-19 at the Mayo Clinic Health System Event Center in Mankato, Minnesota. The dairy program covered a wide range of applied nutrition topics, from calf nutrition to transition cow health.

I kicked off the dairy session by presenting updates on my team’s research, which focuses on the relationship between circadian rhythms and feed efciency of dairy cows. I shared recent ndings from our lab on the impacts of automated mixing and feeding robots on feed bunk nutrient variability and bulk tank milk fatty acid proles. We observed that herds using automated feeding robots showed lower variation in dry matter and ber concentrations at the feed bunk, as well as higher bulk tank de novo fatty acid concentrations, which suggests more stable rumen fermentation.

moderate ber in calf starters or offering limited amounts of alfalfa hay can enhance rumen development, starter intake and overall calf performance at weaning. He also discussed the benets of gradually reducing milk replacer starting at around 4-5 weeks of age to ease the transition from milk to solid feed and reduce weaningrelated health and performance issues.

By Isaac Salfer University of Minnesota

Dr. Jim Drackley from the University of Illinois was our second speaker. He presented research focused on pre-weaning nutrition in dairy calves, emphasizing strategies to promote high starter intake before weaning to minimize post-weaning declines in performance and efciency. The key, he stressed, is ensuring sufcient starter intake to support proper rumen development. He suggested that feeding

Dr. Kirby Krogstad, a newly hired professor at Ohio State University, summarized research on the impacts of feeding Enogen corn silage, conducted by his group and others. Enogen is a genetically engineered corn hybrid that produces higher levels of a-amylase, leading to greater starch breakdown during ensiling. His research showed modest increases in neutral detergent ber and starch digestibility when feeding Enogen corn silage but found no signicant effects on dry matter intake, milk production or feed efciency. However, they did observe reduced milk urea nitrogen, indicating improved nitrogen use efciency due to enhanced starch digestibility. In contrast, research from Pennsylvania State University showed increased milk protein and improved feed efciency with Enogen corn silage, though both studies reported no signicant impacts on energy-corrected milk yield.

Our fourth presenter was Dr. Isaac

TRUST THE EXPERTS

Haagen from UMN. He reviewed the genetic factors associated with feed efciency in dairy cows and calves, specically discussing the implementation of the “feed saved” trait in dairy genetic evaluations and its potential to improve herd protability. He shared recent estimates from the Council on Dairy Cattle Breeding, which show that the heritability of the “feed saved” trait is approximately 0.19 — higher than several health traits. He also presented his team’s research showing that the heritability of gross feed efciency (gain per unit of feed) in heifers is approximately 0.25 and suggested that crossbred calves have better feed conversion ratios than purebreds. Overall, he highlighted the signicant potential for improving feed efciency through genetic selection.

Dr. MaryGrace Erickson, a recent University of Wisconsin graduate and current postdoctoral researcher in the UMN biosystems and bioproducts engineering department, presented her work on feeding low-protein diets and oscillating protein strategies. She discussed how environmental pressures to reduce nitrogen emissions, particularly ammonia and nitrous oxide, have led to a push for lower dietary crude protein levels in dairy cow diets to improve nitrogen use efciency. However, their research showed that dietary CP levels below 14.5%, even in late-lactation cows, can severely impair ber digestion,

Dana Adams adam1744@umn.edu 320-204-2968

Joe Armstrong armst225@umn.edu 612.624.3610

Luciano Caixeta lcaixeta@umn.edu 612-625-3130

Gerard Cramer gcramer@umn.edu 612-625-8184

Marcia Endres miendres@umn.edu 612-624-5391

Les Hansen hanse009@umn.edu

612-624-2277

Brad Heins hein0106@umn.edu 320-589-1711

Nathan Hulinsky huli0013@umn.edu 320-203-6104

Karen Johnson ande9495@umn.edu 320-484-4334

Emily Krekelberg krek0033@umn.edu 507-280-2863

cow performance and body weight without signicantly improving nitrogen use efciency. She also presented ndings from a study using an oscillating protein feeding strategy, where cows alternated between diets with 15.5% and 13.8% CP every 48 hours. This approach resulted in reduced nitrogen outputs (urine, manure, and milk urea nitrogen) without major impacts on milk production, indicating cows’ resilience to alternating between proteinadequate and protein-decient diets.

The nal presenter of the day was Dr. Luciano Caixeta from the UMN College of Veterinary Medicine. Dr. Caixeta discussed their research on hyperketonemia in postpartum cows, exploring why some cows with this condition maintain milk production while others do not. Their research showed that cows diagnosed with hyperketonemia in the rst week postpartum were far more likely to experience low milk production, poor reproductive performance and early culling compared to those diagnosed in the second week. He also presented ndings suggesting that cows with high rumination times and hyperketonemia produced more milk than non-hyperketonemic cows.

Overall, the 2024 Minnesota Nutrition Conference featured an excellent lineup of speakers and topics. We hope you can join us for the 2025 conference next September.

Claire LaCanne lacanne@umn.edu 507-332-6109

Brenda Miller nels4220@umn.edu 320-732-4435

Isaac Salfer ijsalfer@umn.edu 320-296-1357

Jim Salfer salfe001@umn.edu 320-203-6093

Mike Schutz mschutz@umn.edu 612-624-1205

Melissa Wilson mlw@umn.edu 612-625-4276

Isaac Haagen hagge041@umn.edu 612-624-7455

Michael Boland boland@umn.edu 612-625-3013

Sabrina Florentino slpore@umn.edu 507-441-1765

Thousands of manure samples tell us we need to continue to test

By Erin Cortus, Nancy Bohl Bormann, Melissa Wilson

ManureDB is a new web-based portal that aggregates and summarizes manure composition data for over half a million samples from 1998 to the present. Having current values of U.S. manure nutrients gives an improved baseline of values for farmers, consultants, regulators and researchers when accounting for manure nutrients. ManureDB can be found at http://manuredb.umn.edu/, where options to view summary statistics and download data are available to the public.

While annual manure sample analysis remains a best management practice for livestock farms for nutrient management planning, there are instances where we rely on approximations. For example, manure nutrient value estimations are needed to determine the land base for manure spreading before new livestock farms are permitted. Most published manure nutrient concentration approximations — book values — used today were pulled from narrow U.S. regions with limited samples decades ago. A common reference is the American Society of Agricultural and Biological Engineering D384 Standard on Manure Production and Characteristics. This reference prescribes a typical fertilizer content, expressed as nitrogen – phosphate – potassium oxide, of 6-311 pounds per 1,000 gallons for dairy lagoon efuent and 25-25-40 pounds per 1,000 gallons for dairy slurry and approximately 13-9-13 pounds per ton for solid manure scraped from lots.

What can over 70,000 dairy manure samples tell us about dairy manure in the last decade? The graphs display dairy manure fertilizer nutrient values for solid and liquid samples in ManureDB. Solid manure includes samples with more than 10% solids and liquid represents samples with solids content less than 10%. The graphs represent data from 2012 to 2022, for regions of the U.S. with more than 500 manure samples in the database for the time range and region. The Midwest region includes Michigan, Ohio, Wisconsin, Minnesota, Iowa, Missouri, Indiana and Illinois. The Northeast combines data for Maine, Vermont, New Hampshire, Connecticut, Massachusetts, New York, Pennsylvania, Rhode Island, Delaware, Maryland, New Jersey and West Virginia. The Southeast region covers Virginia, Kentucky, Tennessee, Arkansas, Louisiana, Mississippi, Alabama, Georgia, Florida, South Carolina, North Carolina, the District of Columbia and Puerto Rico. The graphs demonstrate the medians and the 25th to 75th quartiles. This means that for all the concentration data in the database, 50% of samples have a concentration within the bars in the graphs. This also means that 50% of samples fall outside these bars.

For solid manure, the Southeast region had greater total nitrogen, phosphate (P2O5), and potassium oxide (K2O) compared to the Midwest or Northeast regions. However, the ammonium nitrogen (NH4-N) was lower in the Southeast. Unfortunately, the database cannot tell us all the particulars behind every sample that inuences manure composition, like bedding and storage types. However, we can suppose that warmer conditions in the Southeast promote ammonia loss from stored manure. For all regions, the median fertilizer nutrient content was less than the D384 Standard.

Median manure concentra ons for solid manure samples. The ver cal bars represent the 25th and 75th quar les, meaning 50% of the sample data falls within the range of the bars. [Total N = total nitrogen; NH4-N = ammonium nitrogen; P2O5 = phosphate; K2O = potassium oxide].

For liquid manure, there were small differences in the medians for the Midwest and Northeast samples, likely because of similar storage and climates across the two regions. The median fertilizer nutrient content is less than the book value from the D384 Standard for slurry, especially for phosphate and potassium oxide. The concentrations in liquid samples were considerably lower in the Southeast and are not very different from the D384 Standard. In warmer climates, lagoons with larger volumes and more dilution are more prevalent, in addition to warmer weather promoting ammonia emissions.

Median manure concentra ons for liquid manure samples. The ver cal bars represent the 25th and 75th quar les, meaning 50% of the sample data falls within the range of the bars. [Total N = total nitrogen; NH4-N = ammonium nitrogen; P2O5 = phosphate; K2O = potassium oxide].

Variation between regions is understandable. It is also important to recognize the variability for any of the manure analytes within a region. For example, while the median total nitrogen concentration for Midwest manure samples is 18 pounds per 1,000 gallons, 50% of samples fall within the range of 13-22 pounds per 1,000 gallons. Minnesota’s Manure Application Rate Guide for sweep injection of liquid dairy manure and 195 pounds per acre of plant available nitrogen for corn recommends application rates of 15,000-28,000 gallons per acre for that 50% sample range. The risk of underapplying nutrients could shortchange the crop and overapplication could lose nutrients to the environment. These graphs are a snapshot. With annual additions to the database of more samples, ManureDB can track changes over time as well. These numbers tell a history and express the variability in manure within and between regions. Ultimately, these data are a reminder that we need to regularly sample and analyze manure nutrients to make safe and efcient use of them.

Stewardship at Trailside Holsteins

Johnson family named 2024 Fillmore County Farm Family of the Year

By Ben Sonnek Staff Writer

FOUNTAIN, Minn. — It has been nearly 50 years since Trailside Holsteins started with a family and a half dozen cows. This year, the multigeneration farm was presented with the 2024 Fillmore County Farm Family of the Year award from the University of Minnesota, recognizing their commitment to the environment and community contributions.

“It’s quite an honor to be recognized as Farm Family for Fillmore County,” Margaret Johnson said. “We try to stay active within the community, and so people can recognize dairy farmers as active people. … It is important to be good stewards of the land, which is something dairy farmers have been doing for generations.”

Trailside Holsteins started in 1977 when Jon Johnson bought the family’s home farm and started with six cows. His son, Michael Johnson, joined the farm in 2009 after graduating from college. Today, the Johnson family consists of Jon and his wife, Sharon, as well as Michael and his wife, Margaret, and their ve children: Sawyer, Levi, Claira, Jacob and Royal.

The farm itself has grown to 1,400 animals. The Johnsons and their staff

at the Fillmore County Fair in Preston, Minnesota. The Johnson family milks 650 cows.

milk 650 cows three times a day in a double-8 parallel parlor. All of their replacement animals are raised on the farm, and the feed they eat is grown on the farm. Trailside Holsteins maintains 1,200 acres of alfalfa, corn and rye.

Cows are housed in sand-bedded freestall barns — the rst of which was built on the farm in 1996.

“Sand bedding is really a great way to house animals, dairy cows in particular,” Margaret said. “It’s very clean, it’s very comfortable for the

cows, kind of like being on a beach. The sand molds to their body, and it’s the cleanest, most comfortable option for cows. Also, in southeast Minnesota, it’s a resource we have available to us. We have all these little sand bluffs around southeast Minnesota, and we have our own sandhill we can take sand out of for our cows.”

Sustainability is a major focus of Trailside Holsteins, preserving the land and managing it for the community and the next generation. They use multiple sustainable farming practices such as crop rotations, contour strips, cover and perennial crops and manure fertilizer. They use LED lighting and other technological utilities to minimize their electricity and water usage.

“Jon has always been very cautious with tillage practices and soil conservation,” Margaret said. “We’ve always been very conscious of taking care of the cows. Jon always says, ‘Take care of the cows, and they’ll take care of you.’ (We’re) working hard to conserve all the resources we have available to us, and it works into our end goal of being able to maintain not only a business but a lifestyle we all enjoy.”

The Johnson family’s impact is felt beyond Trailside Holsteins as they involve themselves in their community. They are members of the Minnesota Farm Bureau Federation, the Fillmore County American Dairy