By Sarah Middendorf sarah.m@star-pub.com

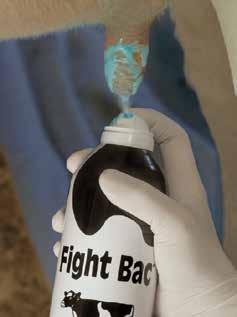

LENNOX, S.D. — Return better than it was given and leave it better than it was left is the motto by which ZahnTech operates. The company turns plastic waste into durable fence posts.

“(We are) making a difference, actually doing something

with the plastic,” said Dan Elliott, head of marketing and sales at ZahnTech.

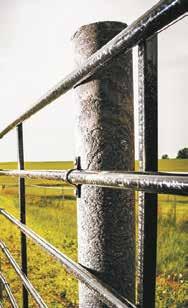

ZahnTech is currently on its fourth generation of fence posts. The second-generation fence post was strength tested and found to be around 10 times stronger than wood and lasts about 20 times longer, Elliott said.

“The great thing about it is it’s plastic, so you won’t need any extra insulation,” Elliott said. “If you are trying to wire it up you can screw right through it. You don’t need to have any more accessories or any more rigging for the electric.”

The company is planning on having a strength test done on their current model through South Dakota State University. Elliot said a common question farmers ask is whether their cows can push the posts over.

“We want to have hard data from a civil engineering department,” Elliott said. “We believe (it) is going to be even stronger.”

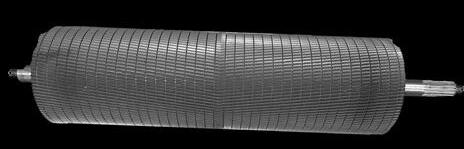

The journey from waste to a fence post begins by grinding down plastic, which then goes through different temperature processes to shape it into a post.

“It’s kind of like the secret

sauce,” Elliott said.

They offer fence posts in round and square options in various widths and lengths.

Elliott said they estimate there are 16,000 water bottles or 680 milk jugs in one 4-inch fence post.

“We are getting plastic right now from places all over the country,” Elliott said.

A lot of the landlls in their area are getting full and have expiration dates of when they

are going to be at full capacity.

“You go to a landll on a windy day and look in their fencing that’s all you’ll see is bags all over the trees and in

Fence post molds sit at ZahnTech’s plant near Sioux Falls, South Dakota. There are roughly 16,000 water bo les or 680 milk jugs in a single 4-inch fence post.

stuff we have bales and bales and bales that we use in our mix.”

The company pays nothing for the plastic they use. The company takes donations from landlls and individuals.

ZahnTech was founded by Avery Zahn who had a company that used plastic piping. When he sold that company, he had extra materials left over. The company got its initial start four years ago. One day Zahn’s horse had pushed over their railroad tie fencing. Zahn thought he should make a better fence and his dad suggested using the left-over piping materials to do so.

Zahn did research and development and was able to come up with a way to extrude different types of plastic for his fence post formula. This extrusion utilizes a large variety of plastics.

ZahnTech mostly does the processing of the materials, since they don’t have a eet of trucks for picking up the plastic.

Elliott said there is a new cattle yard that is using their fence post. The yard was struggling with wood posts, so they decided to switch to their fence posts.

“It’s exciting to see,” Elliott said. “Once people see it and see the durability and the strength of it there’s no going back.”

They plan to expand to different sizes of posts in the future. Elliott said they would like to go up to railroad tie size, which is eight-by-eight.

“Our end goal is to start putting up plants all over the country,” Elliott said. “We want to get into different construction-grade materials too.”

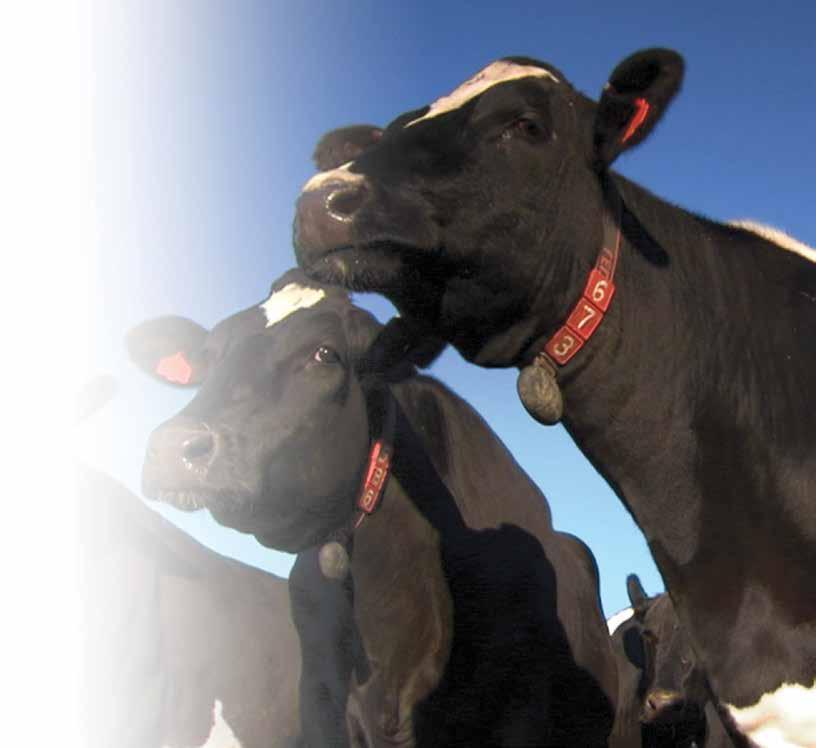

As reported last week, the U.S. Department of Agriculture has again lowered its 2024 and 2025 milk production forecasts in its World Agriculture Supply and Demand Estimates report, citing slightly less growth in milk per cow.

Class III and IV milk prices were also lowered, based on the latest dairy product price projections. The 2024 Class III price was projected to average $19.05 per hundredweight, down 40 cents from last month’s estimate, and compares to $17.02 in 2023 and $21.96 in 2022. The 2025 average was estimated at $18.95, down 65 cents.

The 2024 Class IV average was estimated at $20.80, down 20 cents from last month’s estimate, and compares to $19.12 in 2023 and $24.47 in 2022. The 2025 average was projected at $20.35, down 85 cents from a month ago.

The U.S. corn outlook’s projected beginning stocks were lowered 52 million bushels. Production was forecast at a near record 15.2 billion bushels, up 17 million from last month on a 0.2-bushel increase in yield to 183.8 bushels per acre, but down 1% from a year ago. The harvested area was unchanged at 82.7 million acres. Total use was raised to 15.0 billion bushels, reecting greater exports. Ending stocks were cut 58 million bushels to 2 billion. The season-average corn price was unchanged at $4.10 per bushel.

Soybean production was forecast at a record 4.6 billion bushels, down 4 million on lower yields but up 10% from 2023. Harvested area was unchanged at 86.3 million acres, up 5% from 2023. Soybean yield was projected at a record 53.1 bushels per acre, down 0.1 bushels from September’s forecast but up 2.5 bushels from a year ago. With lower production partly offset by slightly higher beginning stocks, supplies were lowered by 2 million bushels to 4.9 billion. Ending stocks were unchanged at 550 million. The season-average soybean price was unchanged at $10.80 per bushel, according to the USDA.

The U.S. corn harvest was at 47% as of the week ending Oct. 13, up from 30% the previous week, 5% ahead of a year ago, and 8% ahead of the veyear average. The latest crop progress report rated the corn 64% good to excellent, unchanged from the previous week. That compares to 53% a year ago.

Sixty-three percent of the soybeans were rated good to excellent, down 1% from the previous week, but compares to 51% a year ago. Sixty-seven percent had been harvested, up from 47% the previous week, 10% ahead of a year ago, and 16% ahead

of the average.

Dairy cow slaughter for the week ending Oct.5 totaled 51,400 head, down 700 from the previous week, and 5,700 or 10% below a year ago. Year to date, 2,100,500 dairy cows had been culled, down 334,700 head or 13.7% from 2023.

Dairy demand looked strong in August, based on the USDA’s latest supply and demand utilization data. Total cheese disappearance was up 1.2%, up 1.3% domestically while exports were up 14.8%. High Ground Dairy points out that CME (Chicago Mercantile Exchange) spot Cheddar prices continued to climb throughout August as months of limited production nally collided with rising domestic demand.

Butter was up 9.3%, most of it in domestic utilization, which totaled 196.4 million pounds, up 9.1%. Exports were up 17.3% but only amounted to 6.1 million pounds. HGD said, “For the second month in a row, stateside usage grew year-overyear, and exports logged their third month of an increase.”

Nonfat dry milk and skim milk powder utilization was still dragging, the seventh time in eight months, totaling just 176 million pounds, down 7.2% from a year ago. Domestic use was down 31.3% while exports were down 1.1%.

Dry whey usage was down 15.5%. Domestic disappearance was down 33.5% while exports were up 14.1%. HGD says USDA revised July’s total whey use down 15.1% year over year. Disappearance sank 15.5% and ended up being the lowest monthly volume since April 2023. High Ground says plant outages in August limited production, thus supporting CME prices near 60 cents per pound.

Fluid milk sales may have turned the corner after decades of decline. Sales have topped those of a year ago in six out of 2024’s rst eight months. The USDA’s latest data shows August packaged sales totaled 3.6 billion pounds, up 1.6% from August 2023. Conventional product sales totaled 3.4 billion pounds, up 1.3% from a year ago. Organic products, at 261 million pounds, were up 5.5%, and represented a typical 7.2% of total sales for the month.

Whole milk sales totaled 1.3 billion pounds, up 1.5% from a year ago, up 2.4% YTD, and represented 35.8% of total sales for the month. Skim milk sales, at 160 million, were down 5.1% from a year ago and down 11.5% YTD.

Packaged uid sales in the eight month period totaled 28.3 billion pounds, up 1.2% from 2023. Conventional product sales totaled 26.3 billion pounds, up 0.8% from a year ago. Organic products, at 2.0 billion pounds, were up 6.6%, and represent-

ed 7.1% of total milk sales in the eight months.

The Oct. 14 Daily Dairy Report said, “Fluid milk sales also climbed in 2020 when the government distributed food donation boxes that included milk. With that exception, this year marked the rst increase in milk demand since 2009. The dairy industry has worked hard to promote milk’s nutritional benets. At the same time, consumers have grown increasingly focused on health and wellness.”

More milk going into the jug means less milk going to vats, churns, and dryers, and puts more cash in farm milk checks. But the uncertainty of the U.S. milk supply is very real, as avian inuenza continues to take a toll on California herds. Ninteytwo cases have been detected in the past month, according to USDA’s Animal and Plant Health Inspection Service. High Ground Dairy says that brings the state’s total to 100, out of about 1,100 in the nation’s No. 1 milk producer.

The Los Angeles Times reports that some cows have died, but there have also been heat waves the past six weeks in the Central Valley and temperatures have exceeded 100 degrees, further compounding the impacts.

“Veterinarians familiar with the cases noted that HPAI is not the direct cause of death,” said HGD, “But pneumonia and bloat, occurring secondarily to the disease, are responsible.”

Speaking in the Oct. 21 Dairy Radio Now broadcast, StoneX broker Dave Kurzawski said they expect September milk, which will be announced Oct. 21, to be down 0.3%, largely driven by what is happening in California where about 20% of U.S. milk is produced. He expects an even bigger impact in October.

The rest of the U.S. is doing well, he said. Herd size is looking better and milk per cow is improving. However, when asked about rising milk components, Kurzawski said, “ they are up but, if you look at the past 5-7 years, they’ve been up about 2%. They’re now running about 1.5%. Genetics changes the last decade or two, feed changes, cow comfort, all the things that dairy producers do day in and day out to make high-quality milk, make a difference. Components are helping. (It is) doubtful it erases headline milk output, which is still negative.”

After four consecutive weeks of decline, CME block Cheddar closed mid-October at $1.9250 per pound, up 3.75 cents on the week and 13.75 cents above a year ago, as traders anticipated Monday’s September milk production report. The barrels n-

ished at $2.01, 12.25 cents higher, 30 cents above a year ago, and 8.50 cents above the blocks. Sixteen loads of block were traded and eight loads of barrel were traded.

Dairy Market News reports cheese demand remains about the same, according to Midwest cheesemakers. Some say orders are strong, particularly for retail. Others say demand is slow seasonally. Some plants were running busy schedules while others scheduled downtime this week. Spot milk prices were still all above Class III at mid-week. Some cheesemakers reported that Class I needs continue to keep overall milk availability somewhat snug.

Milk demand is stronger from Western cheese manufacturers, however, in parts of the West, weaker milk output is leaving less available. Cheese output is steady to stronger. Domestic demand is steady for most varieties. Cream cheese demand is moderate, and mozzarella demand has been and continues to be strong this year. Demand from international buyers is also stronger, according to DMN.

Lots of butter found its way to Chicago this week, setting a new record and saw its rst gain in six sessions Wednesday. It closed Friday at $2.66 per pound.

That is 3.50 cents higher on the week, ending ve weeks of losses but is 70 cents below a year ago. A record 161 loads traded hands on the week. The last three days of the previous week had double-digit sales and buyers stepped up the pace even more this week with 33 sales on Monday, 46 on Tuesday, 48 on Wednesday, 33 on Thursday and only one on Friday.

Butter production in the Central region remains busy but in line with cream availability, which was notable this week in the region. Processors say retail demand is busy, meeting seasonal expectations, while food service is not as bullish. Stocks are stable to long, according to DMN.

Retail and bulk butter production in the West is steady to strong. Some plants were running heavier due to upcoming equipment projects. Milk production is weaker in parts of the region, but cream is plentiful. Domestic butter demand is steady to lighter while international interest is stronger. Domestic prices have been more competitive than international prices thus far in October, said DMN.

Grade A nonfat dry milk closed Friday at $1.38 per pound, up 2.75 cents on the week and 14.75 cents above a year ago, on 24 sales for the week.

Dry whey saw its Friday closing at 60.25 cents per pound, up 0.75 cents on the week and 20.75 cents above a year ago, with 21 sales put on the CME board.

Dairy margins were mixed over the rst half of October, declining slightly in nearby periods while strengthening slightly further out on the curve, according to the latest Margin Watch from Chicagobased Commodity and Ingredient Hedging LLC. “CME milk futures slumped early in the month but then recovered with deferred Class III contracts moving to new contract highs as concerns mount that production will be restrained with a lack of dairy replacement heifers aging the milking herd while a recent slump in butter and cheese makes U.S. prices more competitively priced on the global market.”

After spending most of the summer above $3 per pound after breaching that level back in May, butter prices plunged nearly 60 cents to just over $2.60 as buyers backed away from the market after securing holiday needs early. August butter production was up 14.5% from last year and cumulative year-to-date production through the rst eight months of 2024 was up 4.8% from last year. Rising production caused inventories to eclipse prior-year levels for seven consecutive months, with August stocks of 323.3 million pounds up 10.8% from last year.

Cheese prices have also dropped sharply since mid-September, with Cheddar barrel plunging 78 cents from an all-time high of $2.6225 before recovering slightly to $2.00. While cheese production was also strong over the summer, a preference for Italian varieties left cumulative YTD Cheddar production through August down 6.6% from last year. Meanwhile, August cheese exports of 90.6 million pounds were up 14% from last year with strong sales to Mexico pacing the gains the MW said.

The Global Dairy Trade auction’s weighted average slipped 0.3% in the second event of October,

down from a 1.2% rise Oct. 1. Volume, which has topped 80 million pounds in the past three events, totaled 85.9 million, up slightly from 85.6 million Oct. 1. The average metric ton price, at $3,852 U.S., was up $1.00.

Lactose was down 5.8%, following a 6.7% gain Oct. 1. Skim milk powder was down 1.8%, after slipping 0.6%, and whole milk powder was unchanged, after rising 3.0%. Butter was off 0.3%, following a 1.4% drop, while anhydrous milkfat was up 0.3% following a 0.1% slip. Cheddar was up 4.2%, which follows a 3.8% rise Oct. 1, while GDT mozzarella was down 8.2% after dropping 7.7%.

StoneX says the GDT 80% butterfat butter price equates to $2.8741 per pound U.S., up 3.9 cents from Oct. 1, and compares to CME butter which closed Friday at $2.66. GDT Cheddar, at $2.1327, was up 4.3 cents, and compares to Friday’s CME block Cheddar at $1.9250. GDT skim milk powder averaged $1.2452 per pound, down from $1.2676, and whole milk powder averaged $1.6115, down from $1.6144. CME Grade A nonfat dry milk closed Friday at $1.38 per pound.

In politics, as part of National School Lunch Week, the International Dairy Foods Association reported that its Healthy School Milk Commitment is responsible for reducing added sugar levels by 10% in avored school milk between the 2023 and 2024 school years.

“The Commitment was launched in April 2023 by 37 school milk processors representing approximately 95% of the school milk volume in the United States,” said IDFA. “Since that time, added sugar in avored school milk, such as chocolate milk, has declined from 8.2 grams per serving to 7.4 grams. In the past year alone, school milk processors have removed 2.7 billion grams of added sugar, equal to 5.9 million pounds,” said IDFA.

The IDFA also said, “U.S. parents are calling for Congress to reinstate whole and reduced-fat (2%) milk in U.S. public schools. For 12 years, students in public schools have been unable to access these widely consumed milk options in school meals. A new Morning Consult poll, commissioned by IDFA, reveals that the vast majority of parents want these milk options to be available in school cafeterias, as they are at home.” Farmers and processors need to write to their elected representatives.

rst-ever

By Danielle Nauman danielle.n@dairystar.com

BATTICE, Belgium —

Six young dairy enthusiasts from the U.S. had the opportunity to travel to Belgium to take part in the Young Breeders School, Aug. 28-Sept. 1 in Battice. This is the rst time the U.S. has been represented in the 22-year-old European contest.

Dave Schmocker, a hoof trimmer based in Whitewater, Wisconsin, headed up the rst U.S. delegation to the event.

“It’s been something that has been in the works for ve or six years,” Dave said. “Erica (Rijneveld) has been after me for several years to bring kids over. She calls me every spring and I agree we need to get the ball rolling, but never seem to get it done. This year, she just booked it for us, so we needed to get it done.”

Rijneveld, a dairy cattle tter in the Netherlands, has been a long-time supporter of the school, teaching for at least 17 years, Dave said.

Since 1999, more than 2,000 young people represent-

ing 24 countries have traveled to Belgium to take part in YBS. The school is open to youth ages 13-25 and is taught in four languages. This year, 17 countries sent teams to compete.

Participants were tasked with preparing heifers for a show, plus each day included demonstrations and lectures on a variety of topics, including washing, creating a bedding pack, clipping, nutrition, judging and marketing. Each topic included a short exam, allowing the participants to collect points towards the nal standings.

Three Wisconsin youth from a nationwide pool of 23 applicants were chosen to attend by a selection committee: Alli Walker of Wisconsin Dells, Jacob Harbaugh of Marion and Stella Schmocker of Whitewater. Joining them on Team USA were Hayden Reichard of Chambersburg, Pennsylvania, Camryn Crothers of Pitcher, New York, and Lauren Silveira of Chowchilla, California.

Each year, the school is held in Battice in conjunction with a local agricultural exhibition.

“It would be like having it during a big county fair, here,” Dave said. “They usually have a cow show there, but this year it was canceled due to an outbreak of blue tongue. They only brought in the heifers used for the school.”

Local breeders supply heifers for YBS, and each par-

ticipant is randomly assigned a heifer, leaving much of the outcome to chance.

“There’s denitely an element of luck involved,” Dave Schmocker said. “I told the kids we weren’t going to win the conformation classes, and the heifers didn’t have great hair, so they weren’t going to win the tting contest. But we might as well make good use of our time and really focus on teaching and learning how to clip. They did a great job at that, working as a team. Our three younger girls probably learned more than anyone else there that week.”

Despite showing dairy cattle their entire lives, both Walker and Stella Schmocker agreed the clipping aspect was daunting.

“I knew the basics, but I really didn’t know how to carve out a topline or set it,” Stella Schmocker said. “That was something big I learned.”

Walker said despite being the oldest member of the team, the lack of experience in tting nearly kept her from applying for the opportunity.

“You certainly don’t need to be a tter to go,” Walker said. “I’m glad I didn’t let that fear hold me back.”

Preparing to exhibit dairy cattle they had never seen before and halfway around the world presented challenges for the group, Walker said.

Turn to YOUNG BREEDERS

SCHOOL | Page 9

Belgium.

“They gave us the basic supplies we needed, like a wheelbarrow, fork, shovel, rake and the sprays we would need,” Walker said. “All the heifers came with halters, but we did bring our own nylon ones. The display was challenging. I had made signs we could write on, but Dave had to go to a hardware store and buy things to make a display. Some of the European teams had really intricate, involved displays.”

Besides the obstacles the team faced in creating their display, the group had to invest in a complete set of tting supplies to share.

“Clippers over there run on 220,” Dave said. “Erica sold us clippers at her cost, but it was still $2,500 worth of stuff — clippers, blowers, Argos and brushes. Everything we bought or took over for the show this year, we were able to leave there for next year.”

Once they committed to the adventure, the group raised funds to help subsidize the trip. They raised enough money from cash donations, a donated embryo sale and an apparel sale to cover the expenses of all team members, as well as the needed purchases.

“Our industry is small enough, we need to make sure we are keeping the really good kids involved,” Dave said. “I think raising enough money that it’s a sponsored trip is important. It’s really not that much money for each kid — basically like $1,500 total. They stay with host families and all their food is covered. If our industry can’t raise $20,000 a year to invest in our youth, we are going to be in trouble.”

The learning experiences the group enjoyed were not limited directly to the competition at YBS.

“Meeting people, staying with a host family, seeing the countryside in Belgium and how they live — it was a great experience,” Harbaugh said. “You hear about how differently dairy farming has to occur in other areas of the world because of different laws and regulations, but it is really eye-opening to actually see it.”

Echoing her dad’s sentiments that the youngest participants learned the most, Stella said she has already noticed the impact of the communication skills she developed in that short week.

“My biggest takeaway was learning to open up and communicate,” Stella said. “Most of my life I’ve been kind of shy. At YBS I was forced to talk to more people, both my team and the other teachers and participants.”

Watching the development of the six youth he chaperoned and coached at YBS gave Dave Schmocker excitement for seeing the program continue.

“This is such a great program and offers so much more than just competing,” Dave said. “I hope to develop a committee to oversee it, to nd someone who can really give it the time and dedication to ensure it’s done right, to continue providing our youth with this experience.”

By Tiffany Klaphake tiffany.k@dairystar.com

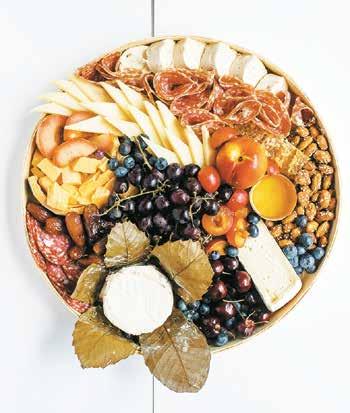

FARGO, N.D. — As a cheesemonger, Megan Lewis offers customers more than just cheese. She offers a cheese experience.

“We don’t run a traditional cheese counter,” Lewis said. “We started off doing catering with cheese platters and grazing tables and it just grew from there.”

Lewis owns Milk Made, a cheese charcuterie business based out of Fargo. In addition to its initial fare of charcuterie boards and grazing tables the company now offers cheese wheel cakes and charcuterie cones called “Oh Fer Cute-erie Cones.” Lewis and her staff operate a food truck that sells cheese at various events and also offer classes on cheese and cheese pairings.

“We open our customer’s mind to what cheese can be paired with,” Lewis said. “It’s not just wine, but coffee, tea and chocolate. We also do Hal-

loween candy pairings and Christmas cookies with cheese. It’s fun for people to see what cheese can be eaten with.”

Lewis has always had an artistic mindset, and several of her family members are artists. Lewis went to culinary school with plans on becoming a food stylist. She landed a job at a local artisan food shop for their cheese program.

“I fell in love with it pretty quick,” Lewis said. “Through that process, I started making platters and had that ‘ah-hah’ moment of food styling and cheese is my medium.”

After a few years, Lewis decided she wanted to stay home with her children, so she started Milk Made as a parttime business making charcuterie platters for additional income.

“It very quickly went from a part-time gig to a full-time gig,” Lewis said.

Now, Milk Made has been in operation for eight years. Lewis is the only full-time employee, but she has 10 parttime employees who assist with the food truck, prepping platters and teaching classes.

“Before we had our own storefront, the food truck was our way to connect and sell cheeses,” Lewis said.

The food truck, which the

Milk Made team affectionately calls Bessie, regularly attends the Fargo farmers market and local breweries and wineries. It also can be rented out for weddings, graduation parties, company parties and appreciation events around Fargo. The food truck has two windows that open. One reveals a 6-foot cheese case with 20-30 types of cheeses. At the other, customers purchase crackers, jams, mustards and other products to pair with their cheese.

“We really are a cheese shop on wheels, which is fun,” Lewis said. “We also sell miniplatters and cones in the food truck.”

Last year, Milk Made was able to purchase a storefront in Fargo, which allows for more kitchen space and a classroom for classes on cheese.

“We try to nd fun ways to teach people about cheese,” Lewis said. “We do classes and education on cheese and cheese pairings. Last year for Christmas we did charcuterie chalets instead of gingerbread houses.”

Milk Made offers public and private classes on cheese, hosting up to six classes a month.

Turn to MILK MADE

| Page 11

Bessie the food truck is lit up in 2020 at Milk Made’s loca�on in Fargo, North Dakota. The food truck frequents the Fargo farmers market in addi�on to local breweries and wineries, and can be rented out for private par�es.

“All cheese starts with four basic ingredients,” Lewis said.

These basics are milk, rennet, salt and cultures.

“People nd it fascinating that from four basic ingredients you can get such a wide variety of products,” Lewis said.

Most of the cheese Lewis sells is from the U.S. with the bulk of it coming from the Midwest. Lewis said the most popular cheeses are Cheddars, goudas and Havarti.

“I am a huge supporter of local cheeses,” Lewis said. “When people are buying their food, they want to know that story. We partner with a lot of local companies such as local breweries, wineries and other artisan food makers to help tell the story of our food.”

Lewis works with a distributor to bring in cheeses from around the world that are made differently or not found locally.

“We try to bring in new cheeses all the time and change out what produce we use with the seasons,” Lewis said. “We try to have a little bit of everything. That allows us to channel our creativity.”

Lewis is a certied cheese professional through the American Cheese Society. Lewis has served as a judge at the past American Cheese Society Judging & Competition.

“Through the ACS I get to meet the makers of a lot of cheeses and develop a relationship with the cheesemakers themselves, and I think that is so important,” Lewis said. “We, as cheese mongers, need to understand what the

PHOTO SUBMITTED

Charcuterie cones, called “Oh Fer Cute-erie Cones,” are showcased at Milk Made in Fargo, North Dakota. The cones are one of the offerings in Milk Made’s food truck.

cheesemaker wants the cheese to taste like so we are giving it to the customer in the best possible way. We need to have those relationships to tell the producer’s story.”

PHOTO SUBMITTED

A charcuterie board is displayed at Milk Made in Fargo, North Dakota. Milk Made offers charcuterie boards, grazing tables, cheese wheel cakes, charcuterie cones and classes on cheese and cheese pairings.

ZIEGLER AG HAS INCREDIBLE DEALS ON THE HARVEST EQUIPMENT YOU

It’s harvest time, and you need some absolute beasts in your fields to hit the productivity and efficiency levels your bottom line demands. Take advantage of unbelievable 5.24% financing for up to 96 months* on Gleaner® S9 Series combines before they’re GONE FOR GOOD. AND enjoy LOW financing for up to 72 months* on the high-powered, versatile Massey Ferguson® S Series tractors, but only through October 31, 2024.

Stop in to your Ziegler Ag Equipment branch today to kick your harvest into high gear.

By Dan Wacker dan.w@dairystar.com

TOMAH, Wis. — Becoming a dairy farm milking over 1,000 cows is no accident, and the Chapmans of Tomah know exactly the kind of hard work and comradery it takes to hit that mark. Chapman Farms was established in 1882 and is now owned by brothers Duane and Gail Chapman, and their sons, David and John.

Working as a team was on display Oct. 16 as the four owners, with the help of Peter Chapman and Trevor Zellner, had a busy day. The squad had to work together to nish chopping corn silage, cover

their three bunkers and give a farm tour to local fourthgrade students along with everyday chores.

The Chapmans employ eight milkers, with teams of three working 12-hour shifts to accomplish the three milkings a day. Two get the day off. Milkers are on the cows at 4 every morning, with two workers milking in the double-15 parlor and one acting as the cattle pusher. The cattle pusher rotates through the barns housing the cows and then returns them to the correct area.

Gail starts his day using the skid loader to scrape the special needs barn and using sawdust to provide fresh bedding for those cows.

Each cow in the Chapman herd wears a leg band that registers with technology in the parlor. Their system

records daily milk weights along with components. It also tracks ovulation, notifying spikes in heat and shows the best time to breed.

David, who is Gail’s oldest son, is the herdsman in the morning. With the technology alerting the owners which cows are scheduled to be bred that day, David bred 11 cows during the morning milking. In turn, the Chapmans also had 11 cows calve during the day.

Duane gets to the ofce during the morning milking. He runs the latest reports on the current milking, checks test results and looks at the farm’s email. He also works on the nancial side and crop schedule and ensures they are working through their Department of Natural Resources permits when required. He is the farm’s administrator, and

pitches in to drive the tractor when needed.

Following morning milking, the Chapmans had to n-

ish chopping corn. At noon, their John Deere chopper started and made the

Turn to CHAPMAN | Page 14

behind the wheel. Peter and Zellner hauled wagons and took the freshly chopped silage up to the bunker. David went from herdsman to pack tractor driver, helping move and pack away the nal ve acres of the 750 the Chapmans chop for their herd.

While the chopper runs across the road, the yellow bus from the Tomah Area School District arrives with Ms. Gould’s fourth-grade class from Wyeville Elementary. Duane greets the bus at 12:30 p.m. and begins his mission of helping educate the youth on dairy farming. Duane takes the class through the parlor, letting the children test the cleaning unit while seeing the process of milking a cow. From there, Duane takes the class up to the second freestall barn, showing them the feed for the cows and where the cows relax during the day. Throughout this time, Duane elds questions from the 19 students and ve

chaperones.

“I like teaching the chaperones as much as the kids,” Duane said. “They always have very interesting questions. Some make you smile, and they make perfect sense if you don’t have the background knowledge.”

The tour wraps up at the front of the barn. Duane shows the class a few corn stalks, cut alfalfa and ground corn to help illustrate what the cows are eating and how it helps with milk production. At the conclusion of the tour, Duane brings out three calves that were born that morning, one just three hours before the class arrived. He hands out milk and string cheese and the class takes time with the calves and a snack before leaving Chapman Farms at 2 p.m.

“Wyeville is a school that has come to tour before and

Turn to CHAPMAN | Page 15

grain bank charges and excessive shrinks

Experience We’ve roasted millions of bushels

Convenience Fully equipped with fuel, electricity, boom auger discharge and operator. It only takes minutes to set up and then we roast 10 tons per hour.

we actually had a cow calve while they were here,” Duane said. “It happened three years in a row, and they started to think it was all part of the tour.”

With the tour gone and the corn chopped and packed into the bunkers, the time came to get the bunkers covered. The Chapmans originally planned to cover the bunkers the following day, but with a lack of labor and high wind in the forecast the team changed plans. Zellner and Peter car-

ried up the plastic cover, and with the help of four Amish workers, extended the plastic to cover the rst bunker. The crew did the same process to cover all three bunkers of its corn silage for the season.

With all the excitement going on, one thing remained consistent: John mixed feed. From the start of the day at 8 a.m. until it nished, John mixed 12 batches of feed for the herd, including six for the milking cows alone.

By Danielle Nauman danielle.n@dairystar.com

GREENWOOD, Wis. — Joseph and Emma Nolt began their dairy farming career in 2003, purchasing their current farm and a herd of Red & White Holsteins in 2007. Since then, they have focused their efforts on listening to their cows to determine how best to meet their needs.

“They might not be your typical grazing herd, but I have found that the Holsteins have been the ideal cow for me to graze with,” Nolt said.

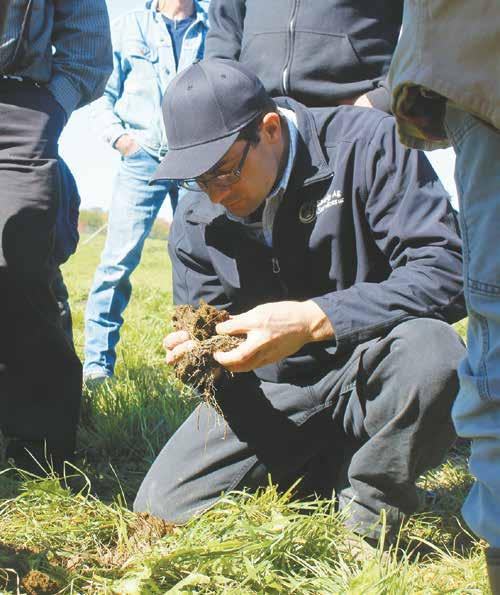

Nolt hosted a pasture walk and farm meeting on his farm Oct. 9. The event was put on by the Clark County ofce of the University of WisconsinMadison Extension.

The Nolts milk 52 cows, which they calve year-round. In 2013 they transitioned their farm to organic production and began shipping their milk to Organic Valley. They average around 60 pounds of milk per cow per day on twice-a-day milking. The herd runs a 4.4%

Dry cows stand in front of a lane leading from the barn to the paddocks used for rota onal grazing Oct. 9 on Joseph and Emma Nolt’s organic dairy near Greenwood, Wisconsin. The dry cows are moved to new paddocks daily.

butterfat and 3.0% protein test.

The Nolts farm 200 acres. They grow 30-35 acres of corn each year for corn silage and commit everything else to pasture for hay or grazing. The Nolts recently purchased an additional 80 acres of land located across the road from their home farm and have begun the process of transitioning that property to organic production.

The majority of their cow’s diet comes from grazing and forages. While on pasture, the cows are supplemented with a total mixed ration mix consisting of snaplage, corn silage and baleage mixed with minerals. No additional protein supplementation is fed while the cows are pastured.

Nolt moves his milking herd to new paddocks twice daily during the grazing season. Those paddocks are equipped with water access, allowing the cows to eat rather

than travel for water.

“They spend most of their time grazing, day and night,” Nolt said. “I will bring them into the barn on very hot days. I know I’d rather be inside on a hot day. Maybe it’s just my cows, but they bunch up if it’s warm and humid and there are lots of ies. Those things affect their production.”

Dry cows are also grazed on new paddocks once daily.

The dry cows must return to the buildings to access water.

When the Nolts began their farming endeavor, they purchased a herd of Red & White Holsteins to launch their dairy. Over time, Nolt says those cows have continued to work well in his management system.

“There are now some Linebacks and some Jersey crosses in the herd, and we are breeding some to Angus,” Nolt said.

“But most of the herd remains

bred to Holstein bulls.”

Most of the herd is bred using A.I. Nolt does not used sexed semen. For nearly a dozen years, he has utilized the Animal Analysis Associates program to help determine the bulls to use within his herd to create the cows he considers optimal for grazing.

Developed by Bill Weeks in 1950, aAa serves as a guideline for producers, identifying traits that would improve the daughters of a cow using a series of three numbers that correspond to those traits. Bulls are also evaluated, with their three-digit aAa code identifying the traits they would bring to the mating.

During the summer, the Nolts raise the resulting calves with much the same philosophy they use to care for their

Turn to NOLT | Page 17

le.

dams. Calves are raised in pairs, in pens created of cattle panels, which are moved daily. Calves are fed a gallon of milk twice daily. They are weaned at 3 months of age. While they are on milk, they are fed no calf starter, only dry hay and the grass they graze.

Weaned calves and heifers are kept in two groups on Nolt’s farm. Both groups are rotationally grazed, moving pastures every 3-4 days a needed. During non-grazing months, the heifers are housed in a barn with outdoor access.

While on pasture, Nolt’s heifers must also return to the buildings to access water. There they are fed the manger cleanings as a supplement to the pasture they consume.

“I have had people ask me why I don’t put water out to the heifer paddocks,” Nolt said. “I like to see my heifers every day. If they don’t have to come up for water, I might not see them every day. They sometimes won’t even come back for water on cooler or wet-

ter days. You start to wonder if they are still there.”

The organic principle of requiring livestock to have free access to pasture throughout the grazing season suits Nolt’s farming philosophy well. Building organic matter within the soil and providing the soil with the nutritional supplementation it requires to produce the quality forages his herd requires is something he puts thought into.

Using visual cues and soil testing, Nolt said he lets his pastures and soils tell him what they need to be productive.

“Once or sometimes twice a year, I’ll supplement pastures with a little bit of sulfur and some boron,” Nolt said.

Nolt said he enjoys watching the pastures and elds on his farm thrive while building organic material in the soil. He experiments with different cover crops and grass mixtures, seeding in varieties he believes may be enjoyed by his herd.

we had rain. We have some barley and rye to plant, but we can’t because it won’t come up. The corn is done and we finished soybeans today (Oct. 23). Their average was 8-20 bushels an acre. They were waist high and set up to make 80 bushels, but they dried up. A lot of people are selling beef cows because it is so dry. We have no water, no pasture and we are still getting cold days.

About 80% of the corn in the area is done. I finished mine up Oct. 16 and we finished my dad’s Oct. 18. We picked most of our corn and averaged between 98-125 bushels per acre with 14% to 17% moisture. I was picking up corn stalk bales Oct. 22 and averaged 69 round bales off of 20 acres. All the soybeans are done in the area and some farmers started to plow those fields, but quit because of how dry it is. I normally plant rye, but with the dryness I decided to skip it this year.

We finished of our silage last week. We chopped over 300 acres for our farm. Most of the corn is out; I would say 90%. We have been hauling pit manure the last couple days. We haul it on top and chisel it into the ground. We should finish today (Oct. 23). We have 150 acres of corn to do yet. One half of that will be for high moisture corn. I am hoping to do 15,000 bushels of high moisture corn. We put that in a bunker. We also hope to do around 400 bales of corn stalks. Wayne,

Most of the soybeans in the area are finally out, I have not heard anything about how they were busheling though. My corn started getting combined Oct. 18 and will be finished up today (Oct. 22) or tomorrow. My irrigated land has been averaging 230 bushels an acre, while the dry land was averaging 200 bushels an acre. Most of it was coming out of the field at 14% to 15% moisture. They have hit some spots that were at 18% to 19% moisture. There have been some corn stocks being baled in the area. I also have about 125 acres of rye planted for the winter.

I am raking corn stalks today (Oct. 22) that we will bale this afternoon. There hasn’t been a lot of tillage done in the area. We are 5% to 10% done on our farm. The ground is so hard on top from being too wet to being too dry. I would say 15% to 20% of the corn is standing. We took some corn out and it was 15% to 18% moisture and ranged from 60-260 bushels within 100 feet. We did 8,000 bushels of high moisture corn. I would say 15% to 20% of the corn is standing. We baled third-cutting new seeding around Oct. 15. We are working on corn, tillage and corn stalks. We try to do 100 of both big squares and round bales.

I haven’t seen a bean field that wasn’t combined, but a few people are still working on getting their corn combined. A couple our neighbors have started to work on tillage, but it is pretty dry. We normally just strip till our corn, but we are going to hold out for a bit, hopefully to get some rain. On Oct. 12 we started planting our rye cover crop and finished it Oct. 17. We planted close to 250 acres on our own farm and custom planted 100 acres for a neighbor.

We finished our 50 acres of soybeans yesterday. They averaged around 75 bushels an acre. They combined nice and clean. We did high moisture corn and finished Oct. 17. That was about 30% moisture when we harvested. We have not combined any dry corn. We will either do that or make bedding next. We try to do 500 bales of corn stalks. The corn is probably 70% done in the area. We have to combine 85 acres. We have a dryer bin that we can dry 3,500 bushels at a time. It might take 7-10 days. It is really dry around here.

We had an unbelievable fall. We didn’t have any rain, so our total was 27.85 inches after how wet spring was. Our corn shake yielded at 29 ton per acre, that was fantastic. Soybeans were 64 bushels per acre since this was just my second year running beans on that ground. I heard beans were in the upper 40s and lower 50s for the corn and bean rotation farmers. Corn yields were around 120-220 bushels, depending on how bad the tar spot hit.

We finished high-moisture corn Oct. 10 and averaged 189 bushels per acre. Some of the lower ground didn’t yield so well, but over all I’m happy considering the year. We made 425 cornstalk bales Oct. 12-13 before hopping into dry corn Oct. 14. We had 140 acres left to do as of Oct. 22. Dry corn so far is averaging 207 bushels per acre., but the worst fields are yet to come. This spring, we had planted corn early and then got rained out for 10 days. It got cold and wet. What we have left to harvest is the rest of that colder planted corn.

We have not had rain in over four weeks. The ground is definitely getting hard with a lot of dust. We are topping off the silos as we finish corn silage. In the next several days we will be working on high moisture corn. We fill a 20 foot-by-70 foot silo and a 16 foot-by-50 foot silo. My dad has had a bad hip this fall limiting how he can help, so the rest of us are really swamped. We dug our potatoes in the last couple weeks and got around 1,000-1,200 pounds. We also are hauling our pit and continue to ship hay to Texas.

We’ve been pretty dry, just a few sprinkles here and there. We finished up our beans and averaged 58 bushels an acre, which is pretty good for around here. We should have been done with dry corn, but we ate a rock with the combine doing beans. We have been broken down since Monday afternoon. We had to go to South Dakota to get the part we needed. We should be up running later today (Oct. 23). We’ve emptied the pit once and the guys will start hauling again today, once we’re done with corn, we can get the solids out of the bottom.

We have had 0.4 inches, which as dry as we are hardly settled the dust. It’s been a good fall to get field work done, but we could use some moisture. We’ve been hauling manure, which we are pretty much done pumping lagoons and we’re finishing up tillage. Hopefully our new heifer barn will get finished up this next week so we can get moved in there.

Input

We started harvesting dry corn Oct. 13 and are running 197 bushels per acre. As of Oct. 22, I have 8 acres left to do. At 31% moisture, it’s going to sit for a while. Daryl has 30 acres to do and is going to wait a little bit for dry down as well, since his was at 21% moisture. I only had one bad field that didn’t yield very well. Everybody in the area is rushing around doing dry corn too. We’ve also been chopping stalks and starting a little fall tillage.

Paul Mueller Company’s HiPerChill™ 5 package chiller works in unison with a Mueller® Accu-Therm® plate cooler to instant cool your milk before it enters your milk cooler, ensuring the highest quality product from your robotic dairy.

With digital capacity control, the HiPerChill 5 lets your cows milk at their own pace while you benefit from greater energy savings.

Advanced Dairy Spring Valley, WI; Mondovi, WI; West Salem, WI; Mora, MN; Pierz, MN; Wadena, MN; St Charles, MN

Central Ag Supply Juneau, WI; Baraboo, WI

J. Gile Dairy Equipment, Inc. Cuba City, WI

Redeker Dairy Equipment Brandon, WI

Stanley Schmitz Inc. Chilton, WI

Tri-County Dairy Supply Janesville, WI

Fuller’s Milker Center

Lancaster, WI; Richland Center, WI

Eastern Iowa Dairy Systems Epworth, IA

Sioux Dairy Equipment Rock Valley, IA; Colton, SD

United Dairy Systems West Union, IA; Monticello, IA

Gorter’s Clay & Dairy Equipment

Pipestone, MN

Leedstone

Melrose, MN; Glencoe, MN; Plainview, MN; Menomonie, WI

Monroe Westfalia Surge Monroe, WI

Lely Center Monroe Monroe, WI

Total Dairy Service Kewaunee, WI

Midwest Livestock Systems

Zumbrota, MN; Renner, SD; Menomonie, WI; Kaukauna, WI; Weston, WI

Ederer Dairy Supply Plain, WI

Professional Dairy Services Arlington, WI

3 pounds hamburger, browned 1 tablespoon onions, minced 1 tablespoon Worcestershire sauce

2 cups barbeque sauce

8 ounces Dr. Pepper

Add minced opinions, Worcestershire sauce and barbeque sauce to browned hamburger in a skillet and mix well. Add roughly 8 ounces or more of Dr. Pepper depending on how “sloppy” you like your Joes. I like to make my recipe in a crock pot. It is good for lunch and supper.

4-6 boneless chicken breasts

1 pound bacon, cooked

Wednesday, October 30, 2024 at 11:00am HERD DISPERSAL

40 CERTIFIED ORGANIC Dairy Cows and Heifers, herd includes Holstein/Fleckvieh Cross and Short Horns. AI sired, bred Wagyu. Also selling 5 bred heifers, due March-April. low scc of 100. Coming from DeFere Family Farms REPUTATION CONSIGNMENTS

20 Fresh Holstein Dairy Cows, parlor/freestall. Current tank avg, 97# 4.3BF 3.4P 79scc. 30+ years AI breeding. Reputation consignor. Extensive vaccination program. This load includes fresh cows and a few bred back cows. Coming from an overstocked dairy! 100% guaranteed sound. Reputation consignor, out of one the top herds of MN! Coming from Shadycrest Holstein, Utica MN

8 Holstein Dairy Cows, 6 fresh cows and 2 springing dry cows, tie stall milked, this load averaging 90# AI sired, AI bred to Registered Holstein or Angus, vaccination program. Owner dispersing

2 cups shredded cheese

1/2 cup milk to start; add as needed Tater tots, frozen

In a crockpot, layer thawed, half of the diced chicken chunks. Add bacon, roughly one pound, again only half of what you have. Add shredded cheese. Add any seasonings you desire (I like garlic and herbstyle seasoning). Add enough tater tots (frozen yet). to cover the top layer Put a second layer of the above ingredients on top. Add some milk to help keep it all moist and cook on low for 6-8 hours. Mix intermittently, adding more cheese if desired and milk if needed.

2 heads cauliower

1 pound bacon

1/2 cup mayonnaise

1/2 cup sour cream 1/2 cup shredded cheese

31, 2024 at 10:00am Accepting Sheep & Goats Wednesday evening 5-8:30pm. Overnight sheep & goats selling rst. Have all

COMPLETE BOER GOAT DISPERSAL - 50 Boer Goats (20)bred boer does (20)doeling boer goats, 40-70# (10)boer billy goats, 40-70#

our website for all the details.

Chop cauliower and cook in a pot for only ve minutes once the water boils. Precook bacon. In a bowl mix mayonnaise and sour cream (I half and half this mixture, using roughly 12 ounces of each); add minimal shredded cheese of your choice, any type of seasoning (I am a garlic and herb gal, but powdered ranch is great also) and diced, cooked bacon (and mushrooms if you would like).

In a 9-by-13 pan, pour the strained cauliower from the pot and add the bacon mixture. Bake in a 375-degree oven for roughly 30 minutes. As long as the sides are bubbling, it is done. At this point, I like to add some shredded cheese on top and place it back into the oven just to melt the cheese on top.

Gehl R165, T-Bar Ctrls, 70HP Dsl,

‘22 Gehl R220, T-Bar H-Ctrls, Dsl, 2500 Lift Cap, C&H, 2 Spd 4,012 hrs ............$28,000

‘15 Gehl R220, JS Ctrls, Dsl, 2500 Lift Cap, C/H/ A, 2 Spd, Hydra Glide, 3,125 hrs .........................................$28,500

‘18 Gehl R220, JS Ctrls, Dsl, 2200 Lift Cap, SS, 4,854 hrs...................................$17,500

‘17 Gehl R220, H-Ctrl, Dsl, 2500 Lift Cap, C&H, 2 Spd, 4635 hrs .....................$28,500

‘20 Gehl RT165, Pilot Ctrls, Dsl, 1650 Lift Cap, C/H/A, 2 Spd, Hydra Glide, 876 hrs ...........................................$43,000

Gehl V400, T-Bar Ctrls, Dsl, 4000 Lift Cap, C/H/A, 2 Spd, 2,570 hrs ..................$37,750

‘21 Gehl V330, JS Ctrls, Dsl, 3300 Lift Cap, C/H/A, 2 Spd, Hydra Glide, 1224 hrs$53,900

‘19 Gehl V270, JS Ctrls, 73HP Dsl, 2700 Lift Cap, C&H, 2 Spd, 250 hrs...............$57,500

‘17 Gehl V270, ISO Ctrls, Dsl, 2700 Lift Cap, C&H, 2 Spd, 3,950 hrs ....................$26,500

‘17 Gehl RT250, ISO/Dual H-Ctrls, Dsl, Camso Tracks HXD 450x86x58, Both Standard And Hi-Flow Hyd, 2 Spd, Hydra Glide, 295 hrs, Warranty Till 6-30-26 or 1000 Hrs ...$48,500

‘20 Gehl RT165, T-Bar H-Ctrls, 70HP Dsl, 15.5” All Season Tracks, 2100 Lift Cap, C/H/A, 1,875 hrs .............................$36,800

‘19 Gehl RT165, ISO/JS Ctrls, Dsl, 15 1/2 All Season Tracks, Lift Cap 1800 @ 35% And 2400 @ 50%, C/H/A, 2 Spd, 1,758 hrs. .......................................$39,500

Gehl RT135, ISO Ctrls, 46HP Dsl, 1350 Lift Cap, C/H/A, SS, 107 hrs. ................$46,500

Gehl R190, Dual-H Ctrls, Dsl, 2150 Lift Cap, C&H, 2 Spd, 6,130 hrs ....................$22,500 GEHL 4835, T-Bar Ctrls, Deutz, C & H, SS, 4,600 hrs ........................................ $15,500

‘22 Manitou 1650RT, H/Ft Ctrls, Dsl, 12” Tracks, 1650 Lift Cap, C/H/A, 2 Spd, 169 hrs $56,500

‘20 Mustang 3300V NXT2, ISO/JS ctrls, dsl, 3300 lift cap, C/H/A, 2 spd, Hydra Glide, 5,090 hrs .........................................$26,500

‘19 Mustang 2700V, ISO Ctrls, 72HP Dsl, 2700 Lift Cap, C/H/A, 2 Spd, Hydra Glide, 14 Pin, Back Up Camera, 261hrs. ............................................$58,900

‘20 Mustang 2150RT, JS Ctrls, 72HP Dsl, 18” All Season Tracks, 2300 At 35% - 3000 At 50%, C/H/A, 2 Spd, 2,265 hrs. ........................................$39,750

‘13 Mustang 2056 II, Case Ctrls, 68HP Dsl, 2150 Lift Cap, C & H, 2 Spd, 2,530 hrs ........................................ $19,500

‘18 Mustang 1650RT, H/F Ctrls, Dsl, 2350 Lift Cap, C/H/A, 2 Spd, 975 hrs ............$50,900 ‘21 Mustang 1650R, H/F Ctrls, Dsl, C/H/A, SS, 3,640 hrs .........................................$32,900 Mustang 345, T-Bar/H/Ft Ctrls, 35HP Dsl, 1000 Lift Cap, 2,540 hrs............................ $6,800

‘20 Deere 332G, ISO/Dual H-Ctrls, Dsl, 3600 Lift Cap, C/H/A, 2 Spd, 1021 hrs ..........................................$47,000

‘06 Bobcat MT52 standon ldr., 20HP dsl, tipping load 1600 lbs, standard auxiliary hyd, 411 hrs ............................................$13,900

‘17 Case SV280, Switchable ISO/Dual H-Ctrls, Dsl, 2800 Lift Cap, Hi-Flow, C/H/A, 2 Spd, 360 hrs. ...........................................$55,500

‘23 NH L320, ISO/Dual H-Ctrls, Dsl, 2000 Lift Cap, C/H/A, 2 Spd, 270 hrs ........... $49,000

Of New, 2

VB750, 600 Bu,

Struck, Sequence Valve Flow Ctrl, Wood Rails, Stone Guard, Endgate .................................$39,500

Hagedorn Hydra-Spread Extravert 5440, 684 Cu Ft Heaped, 440 Cu Ft Struck, Sequence Valve Flow Ctrl, Wood Rails, Stone Guard, Endgate

,

3/8

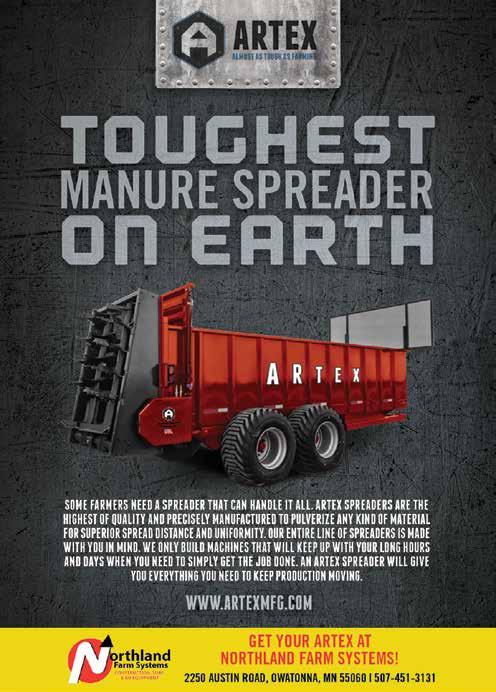

PTO,

........................................$47,500 ‘20 Artex SBX800, 800 Cu Ft, Guillotine Endgate, 88C Apron Chain, Hyd Apron Pressure Relief Kit, Heavy Duty Vert Beaters, Teeth & Rippers Updated .................$57,500