THORP, Wis. – Raising livestock inevitably comes with death loss, and in recent years, disposing of livestock has become a challenge for many dairy farmers.

Those challenges led Jeff Sauer, of Sauer Family Farms LLC, to think of a solution that would work for producers, be environmentally friendly and economically sustainable.

From many brainstorming sessions, the idea of Organic Waste Connections was born.

“I rst started playing around with the concept back in 2008,” Sauer said. “It was a bit controversial at the time.”

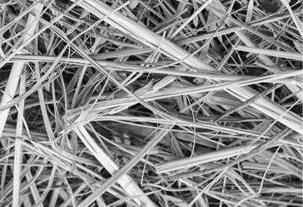

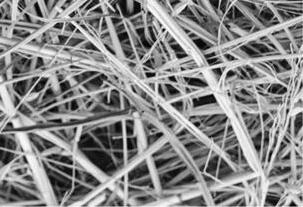

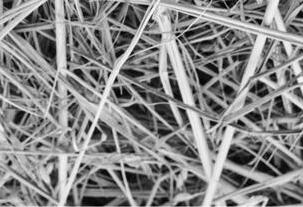

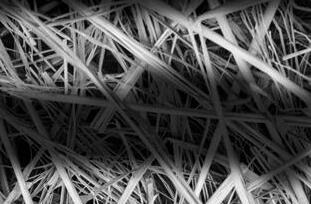

The concept was to compost carcasses to create a value-added, nutrient-dense, eco-friendly compost as the nal product.

Those earliest trials were burdened by public opinion and difculties guring out how the concept might t into the regulatory puzzle overseen by the state.

Thinking the idea was not going to work, Sauer walked away from the project for a time.

Then, in 2019, an area livestock processing facility faced the prospect of the rendering company they were working with going out of business. Sauer’s idea of commercially composting livestock carcasses bubbled back to the forefront.

“That plant was concerned there was nowhere left to dispose of the carcasses,” Sauer said. “I put a lot of thought into moving forward with the composting idea. I prayed a lot.”

One of the stumbling blocks Sauer had encountered was that the movement of dead livestock was regulated by the Wisconsin Department of Agriculture, Trade and Consumer Protection. No provision was made in the regulations for transporting carcasses for disposal methods outside of traditional rendering. After failing to nd an answer, Sauer went another route.

“In the waste management codes, anything that

is thrown away is considered a solid waste,” Sauer said. “We were able to reclassify the carcasses as solid waste and obtain the licensure we needed that way.”

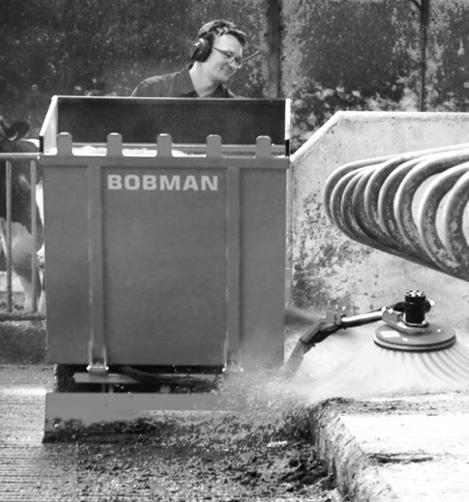

With the rst hurdle of regulatory obligations cleared, Organic Waste Connections began operating as a waste hauler in January 2020, removing carcasses from the processor to area landlls.

Sauer continued to work to obtain the permitting needed to begin the commercial composting of livestock, which began in June 2020.

“To my knowledge, we are the rst business in the U.S. to do what we are doing,” Sauer said.

Organic Waste Connections removes all species

of livestock carcasses and transports them to their composting site near Thorp.

“We service not only the dairy industry,” Sauer said. “We pick up exotics and equine; and we can take sheep and goats, which were never allowed in traditional rendering. We have been able to ll a real void to help people out with livestock mortalities. It has been very consistent. We are picking carcasses up every day.”

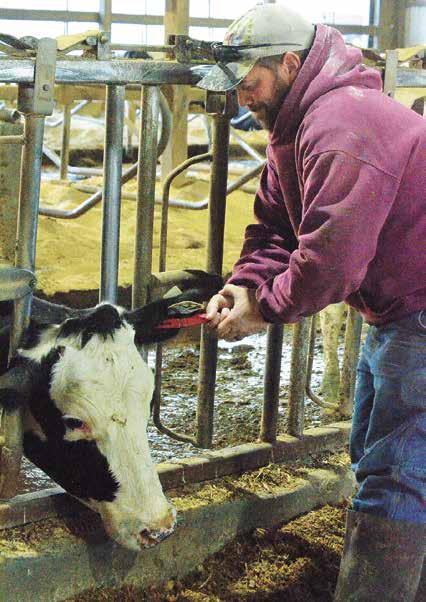

Sauer said he and his employees pride themselves on how the deceased livestock are handled.

“These animals mean something to the people who own them,” Sauer said. “We try to treat them as respectfully as we can. We also try and pick them up as quickly as we can.”

Drivers do not have to place hands on the carcasses. The trailers are equipped with a grapple, allowing the drivers to pick up and load the carcasses.

“It is much easier to hire people and keep good help,” Sauer said. “This is relatively clean work.”

Another contrast to traditional rendering, according to Sauer, is his ability to take carcasses of animals that have been euthanized with barbiturates.

“The University of Minnesota has done studies and found that absolutely no residue from the drug appears in the compost,” Sauer said.

imal is relatively fast, Sauer said.

“When composted at the proper temperature, a carcass can be completely gone in ve to seven days,” Sauer said.

DATCP guidelines require carcasses to be composted at a minimum of 130 degrees for 15 days to kill any pathogens, but Sauer said Organic Waste Connections exceeds those requirements.

“We hold heat on it for an average of six to 10 months,” Sauer said.

The second phase of the business

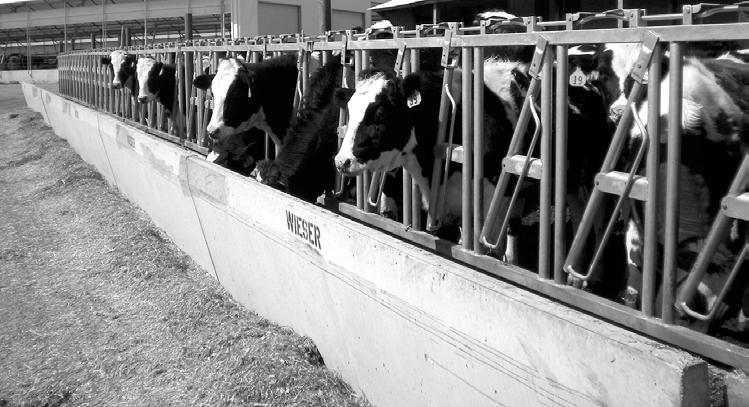

“I have purchased fences from TJ’s twice.

“I

using the 1-1/4” fiberglass rods for putting up electric fences. Using the swivel connectors for bracing corners is fast, super easy, economical, and doesn’t require expensive machinery to make it this easy! Makes for a nice looking and solid fence!”

Jordan Meyer, Caledonia, MN

Electric Fence Post

“I have had TJ’s Fencing’s fiberglass freestalls in my barn for 7 years. After seeing how much cows preferred them over steel stalls, it was an easy decision to install them in my new addition. They are also competitively priced and I like working with TJ’s.”

- Chad Nolting, Waukon, IA

My original fences were purchased 20 years ago and they have held up well. I enjoy not having to paint them. Recently, I purchased fences with rounded corners. These have been very sturdy and the ends cannot pop out of place. Both types of fences are very flexible and safe for my horses.”

-

-

John Bengfort, Bluff Country Equine Winona, MN

In order to compost the animals, Sauer works with area dairy farms that bring in refusal feed and discarded silage, which are used to help create the compost piles the carcasses are buried in.

The process of composting an an-

plan is the enriched compost that is created by the composting of the carcasses, which Sauer said they have been running trials on for the past two summers.

“We have been seeing some great results in crops raised using our compost compared to regular cow manure or even other composts. Based on the data we have collected, I really believe that our compost is second to none.”

JEFF SAUER, ORGANIC WASTE CONNECTIONS

“We have been seeing some great results in crops raised using our compost compared to regular cow manure or even other composts,” Sauer said. “Based on the data we have collected, I really believe that our compost is second to none.”

In side-by-side trials of no-till corn, Sauer said germination rates have been 80% to 82% using Organic Waste Connections compost, compared to 55% with no compost applied. Corn with compost applied was typically 6 to 8 inches taller than corn without.

A small potato trial showed the elimination of blight in a eld for the rst time in 25 years as well as an increase in potato production.

Organic Waste Connections has been approved as an organic fertilizer by the Midwest Organic Services Association, according to Sauer.

With the success of eld trials thus far, Sauer is looking forward to beginning to market the compost.

“This is such a unique concept and it checks so many boxes,” Sauer said. “It is both economically and environmentally sustainable, and it creates options for producers, both in terms of livestock mortalities and eld fertilizers.”

A

months

It matters to us because it fuels our farms and our families. It brings our dairy to tables around the world. Our mark stands for all the things that bring us together and make us stronger.Get to

know us at dfamilk .comCh l K K H l t i B ffl Mi

By Jan Lefebvre jan.l@star-pub.com

By Jan Lefebvre jan.l@star-pub.com

LITTLE FALLS, Minn. – When Missy Isder was a teenager in the late 1990s, she did not plan to be a dairy goat farmer. She started with a few goats for pets and 4-H projects, but soon, she needed to nd a market for all the milk.

“It kind of grew,” Isder said. “You get attached to the goats and don’t sell them.”

Today, Isder has a herd of 150 registered Nubian goats on her farm, Sparkling-M’s Dairy Goats, near Little Falls. The 65-goat milking herd, which also includes crossbreds, is milked in a swing-6 parlor.

Isder is also the president and eld representative for Minnesota Goat Milk LLC, a cooperative of 33 farms, mostly all in the central part of the state.

“Our co-op is known for quality milk,” Isder said. “Companies have told us that.”

Isder herself received a Highest Quality Milk Award from Montchevre,

which used to buy all the co-op’s milk before Saputo purchased the company and now buys the milk instead.

Demand for goat milk has risen in recent years, Isder said.

“Things are a lot more stable now,” Isder said. “The market has grown. … It’s healthy, easier to digest. Anybody with allergies can generally drink goat milk. It even helps colicky babies.”

Isder said she has also heard that those who suffer from eczema are nding it helps to switch to goat milk.

“It’s naturally homogenized, so it separates very little,” Isder said. “In

Turn to ISDER | Page 7

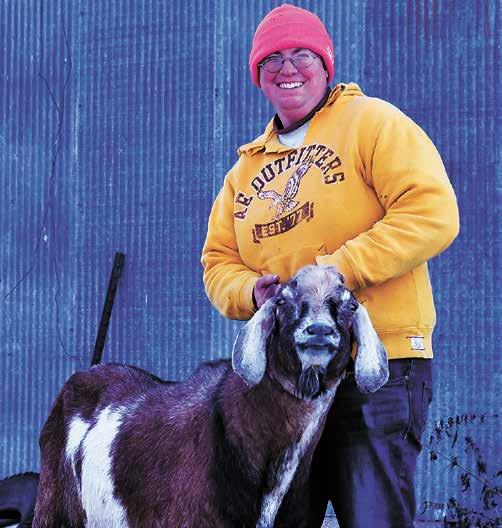

JAN LEFEBVRE/DAIRY STARMissy Isder shows one of her favorite bucks, Sparkling-M’s 52 Cards, Nov. 4 on her dairy goat farm near Li le Falls, Minnesota. Isder is part of a cooperave that sells its milk to Saputo, which uses it for cheese produc on.

order to make butter, you need a cream separator.”

Both goat cheese and goat butter are growing in popularity and becoming mainstream. Isder said that some of the cheese made from their co-op’s milk can be found in Coborn’s stores. Her favorites are the cranberry and blueberry cheeses that Saputo markets under the Montchevre label.

“It’s a soft cheese,” Isder said. “I like it plain, but it’s good with crackers.”

Although her dairy is doing well today, Isder said it was not always that way.

“There were a lot of bumps,” she said. “A lot of water went under the bridge when I rst started.”

By 2002, Isder’s hobby herd had grown bigger than it is today. She was selling milk to people with allergies or to farmers who wanted to feed the milk to calves.

She was also getting noticed. Schools, day cares and interested parties began to request tours and visited Isder’s dairy. By 2003, she was milking 170 goats and had a problem.

“I had to do something,” Isder said. “I had to either sell goats or ship milk. There was just too much milk.”

She found an answer with Stickney Dairy in Cold Spring. Isder said she was the rst Minnesota producer to ship goat milk there. Because there were no milk trucks for shipping goat milk, her mother’s cousin drove the milk in a pickup with a bulk tank in the bed.a

“I was the one who kind of started everything,” Isder said. “Then, some Amish farmers started (goat dairies) too. Many were just moving to the area then.”

Her milk volume problem was solved but only temporarily. Stickney Dairy began to drop some farms. Although Isder was not dropped, she moved with other farmers to Woolwich and signed a three-year contract. However, Woolwich then began dropping farmers.

That was 2010. Goat dairies in central Minnesota began drying off goats. Many closed that summer. Isder held on and hoped for an answer.

The answer came through Montchevre, which agreed to take the milk from Isder and area goat farmers but only if they became a cooperative.

That is how Minnesota Goat Milk LLC was formed. By early 2011, farmers in the co-op were able to get their does to milking again and were back in business.

Since then, other than a herd health issue Isder went through from which she is building back herd numbers, her business has been steady.

Isder said people today know more about goats. When she rst started raising them, good information was hard to nd.

“There wasn’t a lot of research out there,” Isder said. “You were on your own a lot.”

Isder said even veterinarians in the area then did not necessarily know a lot about goats or have much experience with them.

“There’s getting to be more information, especially nutritionwise, since there are more goats around, but when I rst started, nobody had a clue how to feed goats,” Isder said. “They were thinking they were like little cows, but they’re not.”

Isder also said there is lingering misinformation.

“People think that goats are stinky and eat tin cans,” Isder said. “Actually, they’re fussy eaters. The bucks really do stink this time of year, but only because they are in rut. Otherwise, they don’t stink either. They’re clean.”

Isder’s goats eat hay and grain. She crops both on her farm, and she mostly runs the dairy alone. Spreading the does’ kidding throughout the year allows Isder to manage the workload. Because goats usually birth two to three kids but can have four or more, kidding can get hectic.

“The most I’ve had from a doe was six,” Isder said. “I didn’t expect it, and it was Christmas Day.”

Isder’s parents, Arlene and Ken, live on the farm and help with feeding kids and other tasks as needed.

The ups and downs and all the work throughout the years has not deterred Isder. She plans to keep Sparkling-M’s Dairy Goats running for a long time. She also sells breeding bucks, markets meat and raises a few pigs, beef cattle, turkeys and other animals.

“It’s different, and it’s very challenging,” Isder said. “I’ll continue with

goats and other critters on the side.”

theSUBMITTED PHOTO Goats are milked in a swing-6 parlor at Sparkling-M’s Dairy Goats near Li le Falls, Minnesota. The dairy farm, owned by Missy Isder, has a herd of 150 head with 65 being milked twice each day.

“The market has grown. ... It’s healthy, easier to digest. Anybody with allergies can generally drink goat milk. It even helps colicky babies.”

MISSY ISDER, DAIRY GOAT FARMER

The October federal order Class III benchmark milk price was announced at $21.81 per hundredweight, up $1.99 from September, $3.98 above October 2021 and the highest October Class III since 2014. The 10-month average stands at $22.20, up from $16.86 a year ago, $17.89 in 2020 and $16.37 in 2019.

Late Friday morning’s Class III futures portended a November price at $20.69 and December at $20.19.

The October Class IV price is $24.96, up 33 cents from September, $7.92 above a year ago and the highest October Class IV ever. The 10-month average is at $24.82, up from $15.44 a year ago, $13.52 in 2020 and $16.23 in 2019.

Cash butter suffered a Halloween meltdown, plunging a ghostly 19.50 cents, rst time below $3 per pound since Aug. 19. It plunged a whopping 24.50 cents Tuesday, largest single-day fall since Dec. 10, 2015, when it lost 49 cents. Another 9 cents was whacked off Wednesday, with 15 loads being sold, and fell to $2.61 per pound, a low not seen since May 10.

Buyers grabbed the falling knife Thursday, and three sales took the price back up 5.75 cents. It added 10.50 cents Friday to close at $2.7725, down 36.75 cents on the week, lowest since May 17 but still 83.75 cents above a year ago as traders anticipated the afternoon’s September Dairy Products report. Sales totaled 27 for the week and 58 for the month of October, down from 87 in September.

Butter makers continue to report “normal conditions,” according to Dairy Market News. Cream is readily available. Churning has picked up in recent weeks and demand is steady to busy in the nal pushes of the holiday ordering season.

Cream volumes continue to increase in the West. Demand for cream is steady for both Class II and butter production, though some churning is limited by labor shortages. Food service butter demand is steady, but retail grocers have lled stocks in preparation for the holiday season and are reducing their butter orders.

Block cheddar, after falling almost a dime the previous week, closed the rst Friday of November at $2.01 per pound, up 5 cents on the week and 42.50

cents above a year ago. It closed October 4 cents lower than it began the month.

The barrels, after plunging 16.50 cents the previous week, nished Friday at $1.9750, also up 5 cents on the week, 47.25 cents above a year ago and 3.50 cents below the blocks. They closed October 26.75 cents weaker on the month.

Sales for Halloween week totaled three cars of block, with 18 for the month of October, down from 21 in September. Barrel sales totaled seven for the week and 43 for the month, up from 35 in September.

Dairy Market News said central cheese market tones were under some of the same bearish pressure that have impacted all dairy commodities in recent weeks. Contacts say there are two potential silver linings: lower prices prompting more sales and a closure of the block/barrel price spread. Most cheese processors have been reporting somewhat strong sales. Milk availability is slightly tighter, and offers were quiet this week. But, Class III producers are actively seeking milk. Cheese inventories are generally balanced.

Demand for cheese in the West is steady in food service markets, though retail demand is softening and below some previously forecasted levels. Export demand is strong as domestically produced loads are being sold at a discount to international suppliers. Cheese prices started heading south the week of Oct. 24 but saw some recovery Halloween week. Some attributed the lower prices to increased spot availability for both barrels and blocks in recent weeks. Milk is available for cheesemakers to run steady schedules, said DMN, though some continue to battle labor shortages and delayed deliveries of production supplies.

Grade A nonfat dry milk fell to $1.37 per pound Wednesday, lowest since Sept. 28, 2021, but rallied to a Friday close at $1.40, down 3 cents on the week, 17 cents below a year ago and down 11.75 cents on the month. There were eight cars sold on the week and 29 in October, down from 78 in September.

Dry whey nished Friday at 46.75 cents per pound, up 3.75 cents on the week but 19.25 cents below a year ago, and unchanged from Oct. 3. Sales totaled three for the week and six for the month of October, down from 18 in September.

Dairy farm protability crept out of the red a

little in September. The month’s milk feed price ratio inched higher, ending seven consecutive months of decline. The U.S. Department of Agriculture’s latest ag prices report shows the September ratio at 1.74, up from 1.70 in August, and compares to 1.66 in September 2021.

The index is based on the current milk price in relationship to feed prices for a ration consisting of 51% corn, 8% soybeans and 41% alfalfa hay. In other words, 1 pound of milk would purchase 1.74 pounds of dairy feed of that blend.

The all milk price average crept up to $24.40, up a dime from August after dropping $1.40 the previous month and is $6.10 above September 2021.

California’s all milk price fell to $25.10, down a dime from August but $7.10 above a year ago. Wisconsin’s, at $22.10, was unchanged from August but $3.70 above a year ago.

The September national average corn price was $7.09 per bushel, down 15 cents from August but is $1.62 per bushel above September 2021.

Soybeans fell to $14.10 per bushel, down $1.20 from August, after falling 20 cents last month but are still $1.90 per bushel above September 2021.

Alfalfa hay gained $2, averaging $277 per ton, a record high, and $63 per ton above a year ago.

The cull price for beef and dairy combined averaged $91.20 per cwt, up $1.10 from August, $18.30 above September 2021 and $19.60 above the 2011 base.

The recovery will be short-lived, however, as butter and cheese prices have fallen. October will be decent, said dairy economist Bill Brooks, of Stoneheart Consulting in Dearborn, Missouri. Speaking in the Nov. 7 Dairy Radio Now broadcast, Brooks warned that things will head south from there.

September’s gain in the income over feed calculation broke a three-month run of declines, said Brooks. Income over feed costs were above the $8 per cwt level needed for steady to increasing milk production for the 12th month running.

Feed costs were the highest ever for the month of September and the third highest all time. The all milk

price stayed just outside of the top 10 at the 13th highest recorded, according to Brooks.

Brooks said dairy producer protability for 2022 milk income over feed costs using Oct. 31 CME settling futures prices for milk, corn and soybeans plus the Stoneheart forecast for alfalfa hay – are expected to be $11.77 per cwt, a loss of 11 cents per cwt versus the previous month’s estimate. 2022 income over feed would be above the level needed to maintain or grow milk production and $3.98 per cwt above the 2021 level, Brooks said.

Looking at 2023, milk income over feed costs –using Oct. 31 CME settling futures prices for milk, corn and soybeans plus the Stoneheart forecast for alfalfa hay – are expected to be $8.41 per cwt, a loss of 69 cents per cwt versus last month’s estimate. 2023 income over feed would be above the level needed to maintain or grow milk production but down $3.36 per cwt from 2022’s estimate.

He urges producers to look at all of their risk management opportunities, get signed up for the Dairy Margin Coverage program and look for opportunities on the feed side to get those costs locked in if you can.

Meanwhile, the latest Margin Watch from Chicago-based Commodity and Ingredient Hedging LLC says dairy margins deteriorated further over the second half of October on a continued decline in milk prices while feed input costs held steady.

The MW warned both corn and soybean meal prices held steady over the past two weeks but are showing renewed strength on news that Russia will be pulling out of the Black Sea grain deal.

Speaking of feed, the U.S. corn harvest was 76% completed, according to USDA’s latest Crop Progress report, as of the week ending Oct. 30. That’s up from 61% the previous week, 3% ahead of a year ago and 12% ahead of the ve-year average. The soybean harvest was at 88%, up from 80% the previous week, 10% ahead of a year ago and 10% ahead of the veyear average.

International dairy markets remain weak. The Nov. 1 Global Dairy Trade weighted average dropped 3.9%, following the 4.6% decline Oct. 18, and 3.5% Oct. 4. Traders brought 63.6 million pounds of product to market, down from 64.8 million Oct. 18. The average metric ton price fell to $3,537, down from $3,723 last time and the lowest average since Jan. 5, 2021.

Powders led the declines, starting with buttermilk powder down 11.4%. Skim milk powder was down 8.5%, after leading the Oct. 18 declines with a 6.9% drop. Whole milk powder was down 3.4%, following a 4.4% drop. Lactose was off 1%. Anhydrous milkfat was down 1.7%, after dropping 2.7%, but butter inched up 0.2%, following a 2.6% decline last time. GDT cheddar inched 0.9% higher after dropping 3.9% Oct. 18.

StoneX Dairy Group says the GDT 80% butterfat butter price equates to $2.1468 per pound, down 5.8 cents after dropping 16.50 cents in the last event and compares to CME butter which closed Friday at $2.7725. GDT cheddar, at $2.1632, was down 9 cents after losing 8.2 cents and compares to Friday’s CME block cheddar at $2.01. GDT skim milk powder averaged $1.4744 per pound, down from $1.5864 (11 cents), and whole milk powder averaged $1.5519, down from $1.6208 (7 cents). CME Grade A nonfat dry milk closed Friday at $1.40.

The Dairy and Food Market Analyst reports European dairy prices remain under pressure. European 82% fat butter sold for around $2.62 per pound the last week of October, down 28 cents, and cheddar cheese changed hands for between $2.33 and $2.40, down 7 cents. Dry whey traded around 41 cents the previous week, down 2 cents, and skim milk powder around $1.35 per pound, down 13 cents.

The Analyst said milk production in Europe is showing sustained growth. Output is above prior-year levels in each of the big-three milk producing regions of Germany, France and the United Kingdom, up 1.1%, according to latest weekly data. Looking down under, New Zealand September output was down 3.8%, which followed a 4.9% decrease in August, according to the Analyst.

The export market remained a huge factor of support, according to September data. Dry whey exports totaled 49.7 million pounds, up 22.4% from September 2021. Growth into China was the largest for whey product and lactose, according to HighGround Dairy, with dry whey exports the strongest since March 2021.

Nonfat dry milk/skim milk powder totaled 142.8 million pounds, down 7.1%, but dairy exports to Mexico reached a 15-month high driven by skim milk

powder.

Butter totaled 10.7 million pounds, up 49.2%, with growth to Canada third largest.

Exports of cheese were up for the 15th consecutive month, hitting 78.8 million pounds, up 5.1%. Cheddar made up 13.8 million of that total, up 51.9%. Exports were strong to Mexico, South Korea and Japan, and grew to United Arab Emirates and Saudi Arabia, according to HGD. Year-to-date cheese exports are up 12.5%, with cheddar exports up 68.8%.

The Nov. 3 Daily Dairy Report stated compared to the already strong trade reported a year ago, aggregate U.S. dairy exports were up 20.3% in value and 7.7% in volume. The report suggested that foreign buyers likely booked most of the September business earlier this year when the dollar was weaker and U.S. cheese and butter prices were lower than they are today. The DDR warned that recovery in European milk output and waning global demand could stiffen competition for market share in 2023.

Down on the farm, culling in the week ending Oct. 22 totaled 60,900 dairy cows, up 1,500 from the previous week and 100 head, or 0.2%, above a year ago.

Slaughter of dairy cows staying strong continues to limit the ability of growth in the dairy herd, says StoneX, which will impact how fast milk volume in the U.S. will be able to expand from current levels.

In politics, Green Bay-based Edge Dairy Farmer Cooperative reported on a mid-October industry-wide effort to build consensus on milk pricing reforms.

The American Farm Bureau Federation hosted farmers and industry groups in Kansas City, Missouri, to discuss meaningful changes to the U.S. dairy pricing system, according to an Edge press release.

Tim Trotter, Edge CEO, said, “Edge is grateful for the opportunity to join other dairy groups in this collaborative forum to share ideas on the future of our milk pricing system. Discussion highlighted an interest in collaboration and laid a strong foundation for the dairy community to move toward the expectation

of consensus laid forth by Agriculture Secretary Tom Vilsack.

“Edge is committed to building a more transparent pricing system that allows dairy farmers and their processor-partners to thrive. It is with meaningful and comprehensive reform that we can accomplish these goals and forge stronger farmer-processor relationships built upon a foundation of trust and transparency.”

EXPECTING OUR USUAL RUN OF 250-300 HEAD.

JWO NOTES & MARKET REPORT: Big enough to make a difference, small enough to care! How can so many hunters be able to count the points on a trophy buck, get a pretty exact estimation on the spread and actual live weight, but never get a shot at the deer?! Because... He was too far away. He was too close. The wind was in the wrong direction. There was a twig. The phase of the moon. Etc, etc. Not only that, they’ll spend nine and a half minutes describing a 27 second event and if you at all act interested, another 11 minutes filling in the parts they missed the first time!

Continued beautiful harvest weather and a smallish buyer crowd.

Top cows $2,000, $1,950, $1,900 Willard Brubacker, Edgar. $2,000, $2,000, $1,900 Jonathan Horst, Loyal. Many good cows $1,400-1,900. Older and blemished cows $1,000-down.

Good springing Holstein heifers $1,500-1,700. Plain springers $950-1,200. Opens 85-1.05. Single birth Holstein heifer calves $15-60. Few $95-110.

Choice Holstein steers $129-137. Top $141.50. Beef cross up to $143. Holstein feeder steers $105-140. Beef cross up to $155. Holstein bull calves $35-120, few to $135. Beef cross bull and heifer calves $135-300.

Sows $61-71. Butchers $70-90. Boars $26-44.

20% of Market cows sold $74-83. Several High dressing Holstein freestall cows weighing over a ton $85-88.

3x3x8 Alfalfa $85-115. 3x4x8 Alfalfa $135-150. Grass rounds $35-65. Rounds corn stalks $25-32.50. Small squares grass $4.00. Thank you for your business!!

Sanborn, MN

Meadowlands

Farmers Co-op 6.5514.41

Almena, WI

Synergy Cooperative 5.9713.71

St. Cloud, MN

ADM 6.3014.30

Westby, WI

Premier Co-op 6.3013.10

Cadott, WI

Cadott Grain Service 6.0313.76

Pipestone, MN

Cargill 6.7514.50

Muscoda, WI Riverdale Ag Service 6.2413.72 Wheat 7.57

Gar eld

Pro-Ag Farmer’s Co-op 6.3414.37 Wheat 9.18

Monona, IA

Innovative Ag 6.2613.77

Watertown, SD

Watertown Co-op Elevator 6.8414.44 4.07 S. Wheat 8.93 W. Wheat 8.81

Whitewater, WI

Landmark Services Co-op 6.3013.67 Wheat 6.94

Dennison, MN

Central Farm Service 6.2414.22

Belleville, WI

Countryside Co-op 6.2813.67 Wheat 6.94

Glenwood, MN

CHS Prairie Lakes 6.3914.42 S. Wheat 8.73

My hope this week is that I can provide the reader with a good market overview without leaving them feeling like the world is coming to an end. I heard a motivational speaker once say that the best way to stay positive is to turn off the news. All they report on is bad stuff

In our business we try to help our clients make well informed un-emotionally biased market decisions. Although we have to look at the good and the bad, at the end of the day we need to use this information to help them position their business to protect positive outcomes as it relates to market movements. That means everything has to be looked at from the positive influence standpoint to make a decision. My advice for the reader this week is don’t worry, be happy, think, plan, and expect the best!

On a positive note, milk markets have improved over the past week. CME Group spot block and barrel cheese trading is pushing back over $2.00 per pound. As of this writing, Class III futures are projected to settle near $20.60 based on the cash market.

Since March of this year whey prices have dropped over 30 cents per pound. This represents $1.75/cwt of lost Class III value. The reality is that 80 cent whey was devastating on demand. The flip side of this is mid 40 cent

whey prices should keep whey demand functioning well. Whey prices appear to be supported for the moment, but stocks of high protein whey are growing as production has shifted to those whey product categories.

Class IV prices have been helping milk checks in FMMO regions with higher Class 1, 2, and IV utilizations. This is being reflected in strong PPD’s through most of 2022. Internationally, butter and powder prices have been coming under pressure. This has U.S. nonfat dry milk trading 12-15 cents premium to EU and NZ at $1.47/ lb. and butter 20-55 cents at $2.77/lb. Volatility is and will continue to increase in this product class as U.S. prices react to changes in export demand.

On a positive note, U.S. dairy exports remain robust and are setting records for certain product categories. Data is delayed, so keep in mind that this reflects prior market situations that are changing daily. It has been a good run for Midwest dairy producers, as profitability has been very good for over a year now. Thank you God for this blessing!

Fort Atkinson Hay

Ft. Atkinson, Iowa • 563-534-7513 Nov. 2, 42

1st

1st

Rock Valley Hay Auction Co. Rock Valley, Iowa • 712-476-5541

Nov. 3, 85 loads

Large Squares

1st crop

$255-285/ton

2nd crop $275/ton 3rd crop $257.50-265/ton Grass $175-255/ton Straw $160.00-167.50/ton

Large Rounds

1st crop $227.50-260/ton 2nd crop $245-267.50/ton 3rd crop $262.50-272.50/ton Grass $160-240/ton Mixed $210-235/ton Straw $165/ton Corn stalks $72.50-77.50/ton

Information at your ngertips- Easy, clean, fast. When you are looking for resources you’ll nd them on our site. Our clean, easyto-navigate site makes it simple to locate the information you’re searching for.

RIPON, Wis. – The Pollack family is devoted to conservation practices like no-till farming, cover crops and planting green. Each year, they increase the number of acres utilizing these practices. In 2022, their mission was to expand their use of cover crops and plant options suitable for grazing.

“We’ve been doing some no till for about 10 years, but in the last three to four years, we’ve really pushed toward

getting as many acres as we can into no till and cover crops,” Chris Pollack said. “This year, we were really aggressive. Any ground we can get cover on, we’re trying to get something out there and are also working on harvestable buffers.”

Pollack-Vu Dairy and Steer Farm held a eld day Oct. 12, inviting others to see the progress of their cover crops designed for grazing. Challenged with an inadequate amount of pasture for their expanding beef herd, the Pollacks planted a multi-species cover crop mix after canning peas and interseeded cover crops into corn with plans to use both elds for grazing cattle.

“This is the rst year our cattle are going to get out on cover crops,” Pollack said. “By doing this, we can give

our pasture a little break in the fall and again in the spring.”

Pollack farms with his parents, Larry and Deb, and his wife, Kelly, and their four children. The Pollacks milk 150 cows and farm 850 acres near Ripon growing corn, soybeans, wheat, alfalfa, peas and lima beans. This year, they also grew rye for cover crop seed.

Three-fourths of the farm’s corn and over half of their soybeans were no till this year. Wheat was all no till, and new seeding alfalfa was also no till.

“Canning crops make it a challenge because they want stuff worked, so we try to put those on less erodible

ground,” Pollack said.

The Pollacks also raise 60 beef steers, cows and calves. The family sells steers directly to the consumer in quarter and half carcasses.

“It’s fun to be on the retail side whereas milk is the wholesale side,” Pollack said. “But it also brings new opportunities and challenges with the surrounding land. This is why we’re trying to grow cover crops to put our beef cattle on. We’re looking to feed livestock without a lot of effort for as much of the year as we can.”

Rain fell persistently throughout the eld day event hosted by the Upper Fox-Wolf Demonstration Farm Network, preventing those in attendance from getting into the elds.

As a result, Derrick Raspor, a resource conservationist at the Natural Resources Conservation Service, brought the eld inside. He highlighted samples of each plant within the ninespecies, warm-season cover crop mix which contains sorghum, two different millets, cow peas, sunower, sun hemp, oats, collards and rapeseed.

“Overall, this is a really good grazing mix,” Raspor said. “We’re looking for plants that do different things, and this mix has that diversity component. The sunower’s massive taproot breaks up the soil to prevent compaction, whereas millets and sudan grass have a lot of ne roots. Sun hemp doesn’t have much of a root system, but it’s in the legume family so it should offer some nitrogen xation.”

The Pollacks planted peas in late May, which pushed cover crop planting back to early August.

“We planted peas later than we wanted to,” Pollack said. “I wish we could’ve planted the cover crop in the middle of July, then we probably would have had cattle on it for a month already.”

The multi-species cover crop mix was planted at a rate of 24 pounds per acre at a depth of one-half inch to threequarter inch.

“It’s interesting to see what pushed through early on,” Pollack said. “For example, sunowers and collards popped up real quick. There’s a lot of growth out there, including pockets that are waist high.”

Raspor said the Pollacks’ cover crop mix costs about $30 per acre.

“Feed is the biggest cost on a dairy, but you can try to reduce that by feeding cover crops,” he said.

The hope is to come back with cereal rye, which Raspor said is a good scavenger crop that captures excess nutrients.

The rye cover crop would allow for a spring grazing prior to planting the next annual crop.

The Pollacks have received 2 inches of rain since planting the mix.

To get more mass next year, Raspor said they might try to mix some rye in for quick growth along with other fast-growing crops like buckwheat,

turnip, radish and clover.

A little more than 40 acres of cover crop was planted into the pea ground, and 30 acres of cover crops were also interseeded into corn in the eld north of the peas. The interseeded sections will be used for grazing cattle as well once the corn is harvested. The farm planted four mixes into the corn. One was a mix of crimson clover, radish, rapeseed, ax, medium red clover, oat, rye grass and buckwheat. A second mix contained all of the aforementioned plus vetch, Japanese millet, cow peas and sunower.

“Both mixes did well throughout the season, and there’s still a fair amount of green out there from the cover crop,” Pollack said. “Our interseeding was done earlier this year than in the past.”

The Pollacks fenced off a little over 80 acres, placing perimeter fencing on three sides and a temporary fence on the fourth side. The plan is to permanently fence in all four sides with steel post and high tensile wire. The Pollacks will divide the eld into smaller paddocks to manage the cover crop more precisely and allow animals to rotationally graze.

“This ensures better utilization of cover crops and better manure distribution throughout the eld,” Raspor said.

The pea eld will be corn in its next rotation and interseeded with cover crops to graze after harvest, and the eld to the north of it will be lima beans followed by another cover crop mix for grazing.

Raspor said it is a good practice to rest perennial pasture at this time of year to allow for a longer break in the fall.

“Recovery for grass takes longer,” he said. “The plant is putting a lot of energy into the root so it’s ready to go by spring. If we graze that plant too short, it has to use that stored energy for regrowth, and we will reduce pasture productivity. The cover crop mix Chris planted is made up of annuals, most of which will not overwinter. Annuals focus their energy on seed development, leaving less of a concern about over-

grazing them.”

Raspor also ran a rainfall simulator during the event to demonstrate how rain affects four management types. The side-by-side comparison of similar silt loam soils included conventional tillage, unmanaged perennial cool season grass, no-till soybeans after harvest and Pollacks’ living cover crop mix.

After running about an inch of water that mimicked a steady rain, it was clear which management type suffered the most runoff as sediment collected in the jars beneath each sample tray. Conventional tillage had the highest amount of runoff, followed by the soybeans. Third was Pollacks’ cover crop while the perennial grass experienced zero runoff; its jar was empty. The simulator proved to be an eye-opening experiment illustrating the effectiveness of a cover crop in preventing runoff.

“A perennial soil holds its structure well,” Raspor said. “It has a lot of root mass and no runoff. This is what we’re trying to achieve. This type of system

keeps our water bodies clean. It can be hard to build a system similar to perennials since we’re working with annuals. By using a combination of conservation practices, you can build a whole management system that focuses on soil principles that simulate a perennial system.”

In contrast, the bulk of nutrient and soil loss comes from tillage, and the rst 80% of loss is a result of the rst rain after tillage, according to Raspor. The conventional tillage in the simulator inltrated no rainfall because it all ran off due to lack of soil structure and surface cover.

“Following soybeans with a cover crop throws resiliency into the system,” Raspor said. “Otherwise, you’re going to eventually end up with a bare eld.”

Raspor said in spring, things start moving, and they take the soil with it.

“We’re trying to build a resilient system that can take a little punishment and bounce back,” Raspor said. “Through Chris’ cover crops, no till and grazing practices, he is working toward that type of system.”

The RECAL line of probio cs is NOT just another probio c on the market. RECAL is a probio c heavily weighted towards be er diges on and u liza on, primarily FIBER DIGESTION. There are a lot of nutrients in your forages that can be u lized by improving diges on.

RECAL is also a probio c that produces more B-vitamins in the rumen of that cow, mainly vitamin B12. B-vitamins are well known to aide in s mula ng appe te, stress, immune system, reproduc on and also very important in rumen diges on. Not all probio cs are the same. There are hundreds of various strains and combina ons.

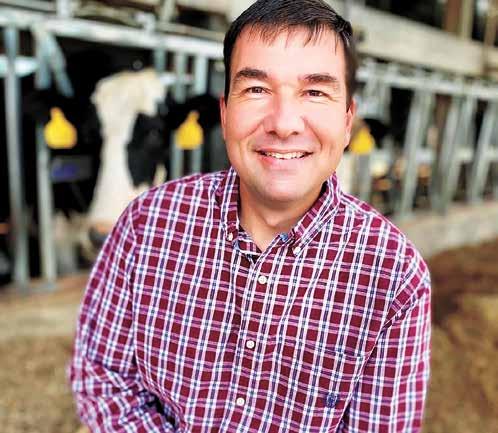

In March of 2021 a friend of mine told me that he was using and really liked the RECAL probio c and that I should check into it. I wasn’t having any issues but I was seeing a fair amount of corn passing through the cows. I asked my nutri onist about it and he said that products like that don’t do any good and that it would be a waste of money. I decided to go ahead and call Jamie Troxel about the RECAL anyhow as I had been seeing his adver sements. We talked on the phone and Jamie said he was going to be in my area that next week, so I told him to stop in.

Jamie came to my farm and looked at my diet, saying that he doesn’t want to change anything, he just wants to see what type of diet I was feeding. He looked at the feed, the cows, and the manure, and asked some ques ons about the herd and where produc on was at. He then talked about the RECAL Probio c and the three di erent products that he has to o er to feed on a daily basis. He then o ered me a free 30-day trial and explained how that worked. I thought what the heck, I don’t have anything to lose so I took him up on the o er.

Jamie will tell you it is not all about milk produc on. It is the li le things!!! If you don’t get the li le things right you aren’t going to get higher produc on and be more pro table. He will also tell you that the RECAL isn’t for just herds with issues, it can improve all herds but not all herds see the same results, every farm is di erent. Since I was seeing a fair amount of corn passing through the cows, he recommended I start with RECAL Plus SS. He showed me how to feed it and told me what to watch for. The cows don’t lie but you need to know what to be looking for. When I started the RECAL Plus SS the manure was consistent but s and had a fair amount of corn and ber showing. Milk produc on was hanging right about 81#, 4.00% BF, 3.10% Pro, 12 MUN, 100,000 SCC. Within three days I could see a di erence in the manure. It was ge ng creamier and a few days a er that I could see that there was less corn and ber in the manure. I did gain about three pounds of milk about a week a er star ng the RECAL. I was seeing stronger heats too and I was extremely happy with what I was seeing in the cows. Since then, I have switched to feeding just the RECAL Plus.

I milk about 80 cows near Quarryville, PA and I highly recommend every dairyman call Jamie and try the RECAL Probio cs even if your nutrionist tells you otherwise. With the 30-day trial he o ers, what do you have to lose????

By Abby Wiedmeyer abby.w@dairystar.com

By Abby Wiedmeyer abby.w@dairystar.com

NORWALK, Wis. –

When the sun rises over St. Mary’s Ridge near Norwalk, it shines on the freestall barn at Brueggen Dairy Farm. Lights are on by 4 a.m. when the rst

shift of milking begins.

“I’m starting to appreciate the view more in the last couple years,” Randy Brueggen said. “Every day that sun is right there.”

Randy begins his day around 3:30 a.m. when he arrives to push up feed and check in with the employees

Tim

p.m. Nov. 1

who start milking.

cows.

Brueggen Dairy Farm is owned by Randy and his mother, Betty Brueggen. Betty handles the bookwork while Randy operates the farm with his brother, Tim Brueggen, their nephew Chad Herricks and their employees.

On Nov. 1, Tim began mixing feed by 4:45 a.m. There are nine batches of feed to mix every day. Tim also serves as the main maintenance person for the farm and will breed cows when Herricks has a day off.

“Ever since I was little, I knew I wanted to milk cows with my big brother. He’s always looked out for me.”

Herricks serves as herdsman for the farm. He grew up in southeastern Wisconsin

“My favorite part is working with family,” Tim said. Turn

and spent every summer working at Brueggen Dairy Farm. After graduating from the University of Wisconsin-Madison Farm and Industry Short Course in 2006, Herricks returned to the farm full time.

“I spent as much time here as I could,” Herricks said. “Every summer, and then when I got my license, there were a lot of weekends I’d drive up. It’s all I’ve ever wanted to do.”

Herricks’ day began around 7 a.m. when he arrived to check for fresh cows and communicate with the milkers. All the cows wear an activity collar, so after checking the calving pen, Herricks consults the computer for reports on cows in heat.

On the morning of Nov. 1, there was one cow starting to calve when Herricks arrived. After moving her into the calving pen, he began his regular herdsman duties. First, Herricks gave a couple fresh cows a calcium bolus. Next, he replaced a missing ear tag on a cow and also tagged a fresh heifer with a RFID tag. Randy had already brought a load of fresh cows up to the parlor to be milked, so they were ready in the post-fresh pen for Herricks to check on.

replacements. Randy said there is a constant ow of calves.

“Some days there’s none, but some days there’s 10,” Randy said. “You just never know.”

to cow moved had calf. Older cows are e plenty of heifer

The footbath needed to be refreshed so while Herricks worked on that, Randy came in and alerted Herricks to the fact that the cow he had moved into the calving pen had delivered a beef-crossed bull calf. Older cows are crossbred to Angus because the farm has

After the two cows that were in heat, Herricks and went to take care of the fresh cow in the pen from the night before, which Herricks vactheir calves are raised to around 10 months of age.

After breeding the two cows that were in heat, Herricks and Randy went to take care of the fresh cow and new calf. There were two Holstein heifer calves cinated and delivered to the neighboring farm, where Randy fed 4 quarts of colostrum to the new bull calf,

and Herricks put the calf in the calf barn that sits near the calving pen.

Randy and Herricks reconvened in the herdsman ofce around 9 a.m. to make a plan for the rest of the day. With about a day and a half of combining left to do, the family needed to make room for corn storage. This year, most of their shell corn is being stored off-site. Herricks took the last load of corn to the offsite storage facility while Randy rounded up some help. He removed tires from a bunker

silo to make room for the rest of the shell corn to be ground and stored at the farm.

After lunch, Randy went to combine. A family friend, David Brueggen, came to drive the tractor and grain cart while Tim hauled loads from the eld with the grain truck. Back at the farm, Herricks operated the hammermill and packed the bunker silo. The nutritionist stopped by for a moisture sample around 1:45 p.m.

The guys combined and ground corn until 9 p.m. when they nally called it a day.

They hoped to be nished with combining by the following night. Once that is done, they will leave the corn stalks in the eld. For fall tillage, they do not go deep enough to break the ground; rather, they aim to cut the stalks so they are easier to get through with the no-till planters in the spring. They have practiced no-till farming for the last 25 years.

Tim said the trio works well together.

“We’re all here for the same reason,” Tim said. “It’s not for a job; it’s for a dream.”

PRIOR LAKE, Minn. – Maternity and neonatal calf management are critical aspects of any dairy farm. While the work is time intensive, it can also make a difference in the trajectory of an animal’s health.

“You have to nd what works for you,” said Ann Hoskins, a calf and heifer specialist from Vita Plus. “Take the time to learn how your own maternity area works.”

Hoskins, along with Jennifer Birchen of Birchen Farms, presented on maternity cow and neonatal calf management Nov. 1-3 at the Dairy Girl Network national conference in Prior Lake.

They discussed the importance of designing the maternity area, the time of calving, navel dipping, moving the calf, warming the calf and colostrum.

The presentation contained information that dove deeper into how to effectively manage maternity pens and newborn calf facilities that can be often overlooked as a driver of future performance.

“It’s a high-impact area that really affects the cow and her future lactation,” Hoskins said. “It drives the fu-

ture success of that calf.”

And while Hoskins stressed that farms should be putting the time and effort into maternity areas, she said it can be labor intensive.

Hoskins said success begins with how the calving area is designed. Hoskins said farmers should ensure there is enough space. Animal ow and sanitation also need to be considered as does the ease of cleaning the maternity area.

There are different types of calving systems, and pen design can be driven by which system a farmer prefers.

At the time of calving, procedures may be disregarded because it can be hectic, Hoskins said, but corners cannot all be cut as it is a critical time for the calf.

Hoskins recommends dipping the navel in 7% iodine and saturating it for 10 seconds all the way to the belly wall right after birth. This step is crucial in preventing umbilical infections, Hoskins said, which can increase the risk for respiratory disease, cause decreased growth rate and increase the mortality rate. Hoskins also recommends using disposable cups to keep the equipment sanitary.

Hoskins said thermoregulation of the calf is also essential to the calf’s well-being. It is important to get the calf dry as quickly as possible so the calf does not lose extra energy on simply staying warm. The goal is to get the calf dry within 24 hours. Hoskins

said there are many ways to ensure this happens, such as a heater, heat lamps, covering the calf in clean and fresh bedding, or drying the calf with a towel. Some farms have even adapted and dry the calf with a large blow dryer.

While Hoskins said farmers may recognize the importance of keeping maternity pens and calf pens clean, it is just as important to clean anything used during the transfer method including tools, boots, bibs and gloves.

Hoskins said colostrum is key, and farmers have about 24 hours to set the stage for a newborn calf and give it what it needs to survive. Colostrum has the largest inuence on calf health and survival preweaning, Hoskins said. It also is important in the prevention of diarrhea and pneumonia. It is estimated that approximately 34% of calves experience some sort of health disorder preweaning, Hoskins said. Quality colostrum measuring 22-24 on a Brix test should be fed to the calf as soon as possible to help minimize the potential for future health issues.

Hoskins recommends once the colostrum is collected, it should be cooled immediately. If colostrum is left out, it can enhance bacteria growth. If a farmer chooses to heat treat their colostrum, it should be done at 140 degrees for 60 minutes.

Hoskins also discussed the importance of cleaning and sanitation.

It is recommended all supplies and utensils are rinsed rst, washed

with hot soapy water, post-rinsed with acid, air dried and nally sanitized.

Sanitation is important in all aspects of dairy but is critical in maternity and neonatal calf management, Hoskins said. She recommends having sanitation protocols in place on farms to ensure the future health of the herd.

Birchen said she practices just-intime calving and has someone walk the pre-fresh pen every 20 minutes. She also stressed the importance of having all protocols printed out for the employees to reference.

The protocols and procedures discussed during the presentation add up to real dollars and consequences on the farm.

Hoskins said 10 years ago, 12% of all U.S. calves died pre-weaning. That number has signicantly dropped to 5%, and farmers can decrease that number farther, the presenters said, by having set protocols in maternity and calf areas.

If farmers continue to decrease the calf mortality rate, then they decide which calves to keep and which to cull.

“We no longer leave it up to the calves,” Hoskins said. “It’s important for farmers to have the ability to decide who to cull out of our herd and who to keep because we spend a lot of money on genetics. We spend a lot of money to get that calf on the ground. So, let’s make sure we have the ability to keep the calves we want.”

PRIOR LAKE, Minn. – Cows in the transition period are undergoing many changes and can be at high risks for health complications. Effectively monitoring these cows is crucial to ensuring future lactation success.

Dr. Barry Bradford, a professor at Michigan State University, discussed factors that inuence inammation in transition cows and some possible ways to overcome them. He discussed these details at the Dairy Girl Network national conference Nov. 1-3 in Prior Lake.

Cows that are in the transition period can experience problems such as mastitis, ketosis, metritis, displaced abomasum, hypocalcemia or retained placenta.

Farmers can overlook the transition period prior to calving, and animals can respond to potential health challenges with either tolerance or resistance. The goal is trying to keep the perfect balance between the two, Bradford said.

Bradford also discussed potential causes of postpartum inammation in dairy cows. Some plausible causes are: social stress, oxidative stress, leaky gut, mastitis, heat stress and uterine involution metritis. Minimizing the potential of these issues can reduce inammation, Bradford said.

Often times, he said, the top condition many farms face with transition cows are mastitis and ketosis. Those conditions can lead to a decrease of 1,000 pounds during the related lactation compared with herd mates – costing farmers time and money when it comes to care.

To prevent or reduce the risk of

postpartum challenges, Bradford said some farmers give anti-inammatory drugs pre-calving. However, he said, that method can block inammation on the day of calving which can interfere with the inammatory signals needed to expel the placenta. Giving such drugs prior to calving can also increase the risk of stillbirth, he said.

“Inammatory signals are critical to parturition,” Bradford said.

Cows need inammation to have an immune response and calve, but Bradford said the goal is to rapidly reduce the inammation, ideally within ve days.

Bradford said increased inammation over time can decrease milk production, promote joint problems and lameness, and can lead to early pregnancy loss.

Bradford said he recommends reducing inammation by completing herd-level assessments with the lab every four to six months to check for haptoglobin, which may signal an internal issue. Another way to bring inammation under control is to institute an anti-inammatory feeding strategy. Omega-3 fatty acids can be

expensive but may also reduce the risk of pregnancy loss, Bradford said.

Bradford said a review paper that came out last year showed giving an NSAID at the time of embryo transfer showed an average increase of 15% in pregnancies per embryo transfer, but giving an NSAID at the time of A.I. showed mixed results.

Bradford also said studies have shown giving an NSAID treatment post-calving followed by the trim and treat protocol can reduce the risk of lameness in dairy cattle.

Inammation in dairy cows is needed but should be reduced as rapidly as possible. Doing so can allow farmers to keep cows in their herd for more lactations.

“Inammatory signals are critical to parturition.”

DR. BARRY BRADFORD, MICHIGAN STATE UNIVERSITY

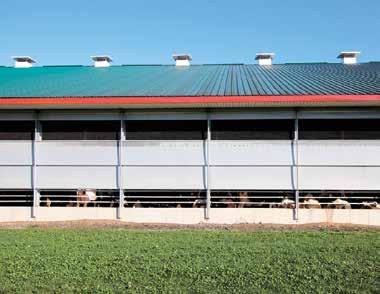

THORP, Wis. – Ventilation is just one of many important pieces to consider when it comes to creating the best possible environment for young calves.

That was a topic of discussion at the Professional Dairy Producers Calf Care Connection workshop Oct. 25 at Dutch Dairy in Thorp.

The Dairyland Initiative outreach specialist Courtney Halbach was on hand to discuss all things ventilation. Halbach works with the University of Wisconsin’s School of Veterinary Medicine to help provide resources and support to dairy farmers throughout the state.

“Ventilation means that fresh air is being provided into a building space,” Halbach said.

Rather than simply moving air, the air from inside a building is actually exchanged with fresh air coming from outside. That fresh air displaces heat, moisture, noxious gases and airborne pathogens.

During cold weather, air should be exchanged a minimum of four times each hour,” Halbach said. “As the temperatures go up, the ventilation rate needs to go up as well.”

Halbach said often times ventila-

tion gets blamed for causing problems that have grown from other sources.

“I get a lot of questions about issues with respiratory disease in calf barns, and people say they think ventilation is to blame,” she said. “Yes, ventilation can sometimes be to blame, but there are a lot of different aspects to look at in calf management.”

Halbach referenced a troubleshooting list created by her colleague Dr. Teri Ollivett which, in order of priority, looks at the stocking density or space per calf; failure of passive transfer; hygiene and bedding management; feeding rates and consistency; accurate and early disease detection; ventilation and nally vaccination.

“I argue that stocking density has a huge effect on air quality and how well the ventilation system is working,” Halbach said. “Before I even start to assess a ventilation system, I am looking at how many calves are in the barn.”

Halbach said the outer limits of stocking density are often pushed too far.

“I know it is so easy when you see an open space to put a calf in the barn,” Halbach said. “But when you add that calf to the facility, you are contaminating the air more; there is increased bacteria and moisture in the air. You also are affecting hygiene. As you put more calves in, the space starts to get dirtier.”

Stocking density can be measured from several points of view. Halbach said stocking density can mean the total barn volume but can also refer to the amount of space each calf has to lie down in. Halbach said a good rule to follow is to allow at least 35 square feet of bedded pack space or resting area per calf until the weaning period.

“The more room, the better,” she said. “If you were to double the stocking density of a barn, you would have to increase the ventilation 10-fold in order to keep an equivalent air quality as a properly stocked barn. When it is zero degrees out, do you want to be ventilating a barn at four air exchanges per hour or 40?”

The challenges of ventilating a calf barn begin when the barn is enclosed to help provide a comfortable environment for the caregiver.

“I wouldn’t be afraid of the cold,” Halbach said. “I wouldn’t try to make a calf barn warm. We don’t want to add heat to the building; all that does is create a nice environment for the bad bacteria to grow. I am OK with cold barns.”

Instead of warming the barn, Halbach looks at means, such as nutrition and bedding, to keep calves thriving.

Halbach said the thermoneutral zone of a newborn calf is in the range of 50 to 78 degrees. As calves grow, they become more tolerant of cold and their thermoneutral zone drops to the range of 32 to 73 degrees.

“In their thermoneutral zone, calves do not have to expend extra energy warming or cooling themselves,” Halbach said. “One way we can help keep them comfortable is to give them a nice, deep place to rest.”

Halbach said a system of nesting scores are used to evaluate the bedding pack available to calves. A nesting score of one means that when a calf is laying down, the legs are entirely visible with no bedding covering them up. Use of sawdust and corn stalks typically result is a nesting score of one. A nesting score of two means that the legs are partially visible while the calf is laying down; meanwhile, a score of three means the legs are generally not visible.

When it comes to creating a deep nest for calves, Halbach said long straw is the gold standard over a gravel oor or concrete sloped to a drain. Allowing urine to leave the building is important to keep the bed from becoming wet and lled with ammonia gas.

Using wood shavings as a bed keeps the urine from running out of concrete-based pens, but they create a wet base and a build-up of ammonia. Pens bedded with a shaving base need to be cleaned frequently.

The design of individual pens can also play a factor in air quality.

“Individual pens are a microenvironment,” Halbach said. “We have to gure out how to ventilate them without creating a draft on the calf.”

Creating that balancing act can be a challenge, Halbach said. While solid partitions between calves limit calf-tocalf contact, they also limit airow; the opposite is true of wire panel dividers. Halbach said the happy medium is to have solid panels between calves and use open wire panels to create the front and rear boundaries of the pen.

“There are many things that play into creating the best environment to raise calves,” Halbach said. “But stocking density, ventilation and sanitation all play key roles.”

40 cows, 340 acres

We finished chisel plowing last night. We finished doing corn stalks for a guy last night as well. We finished our corn stalks about a week ago. We did 630 bales for our farm. Most farmers are done with harvest, but I have a couple of neighbors that have corn to do. We finished with four cuttings of hay and our corn averaged 150 bushels an acre. It was a fairly dry year on our sand and overall, was a mediocre year.

300 cows, 430 acres

We got done with liquid manure a week ago and solid manure a couple days after that. We finished our 100 acres of corn stalks. The rye we planted is coming slow. It might have been short of rain. I was talking to farmer near us and he said he had corn fields that averaged 200 bushels an acre. We got 3 cuttings of hay on all fields except one which we got 4 cuttings. Our corn was excellent. I think we had a really good year. The crops were good, we had good rain and the prices are good.

250 cows, 320 acres

We’ve been hauling manure. We finished the lagoon yesterday (Nov. 7) and we incorporated it in the fields. We also finished hauling dry lots. It was an above average year crop wise.

We did four cuttings of alfalfa and there was not a lot of difference in the crops. The corn we had finished around 190 bushels an acre. We thought we were dry but the corn found moisture. The soybeans ran 42-45. We didn’t get the rains at the right times.

300 cows, 650 acres

We finished up with all tillage on Nov. 5, just working on hauling out manure now. Corn stalk bales actually yielded quite well, but the dry corn yields were down. Everything was below average because of the lack of rain. Alfalfa was down as well, but we did get four cuttings. We thankfully did produce enough to feed all of our animals for the next year. We didn’t even plant any cover crops this year because we knew they would not germinate. We struggled to get everything planted this spring because it was so dry, but then it just stopped raining altogether and we were in a drought for the rest of the year.

100 cows, 540 acres

Overall, things were good. Average to above average for moisture. Summer never got too extremely hot, thankfully. We were some of the lucky ones and got rain when we needed it. We got four cuttings of hay, which yielded right around average. Finished corn two weeks ago, again was average at 180 bushels per acre. We had a really hard rain this spring right after we planted and that caused a lot of washouts, so we are pleased with our yields. We finished tillage Nov. 8.

41 cows, 205 acres

Finished field work Nov. 8. Corn averaged 197 bushels per acre, and beans were a little below average. Hay was average to above average, we got 3 nice cutting of hay this year. Planted cover crops are very happy how those add to the ration. Finished corn early to mid- October. We are doing some tiling so we finished a little earlier than normal. Given the late spring we had we are very pleased with the yields we ended up with. This fall we need to haul some manure yet and we are finally getting the roofs fixed from the storm that went through this spring.

Independence, IA (Buchanan County)

RICK MILLER

130 cows, 269 acres

Our son-in-law is finishing corn tonight (Nov. 8). I will finish my last 30 acres of corn tomorrow. We have to so some tillage and I plan to make a couple hundred more corn stalk bales. I talked to a farmer and he said his 400 acres west of here averaged 287 bushels an acre. My son-in-law got four cuttings of alfalfa and his corn averaged 266 bushels an acre. We had a very good year. I was well satisfied.

220 cows, 520 acres

It’s still wet out there and we can’t get out there but we got all of our cover crops in. All the fodder bales are made and moved. Overall, we were a little drier but we had timely moisture when the rains came to help us out. All things considered I think we had a pretty good year.

With planting cover crops I think our soil has been healthier and when we do get rain the soil can soak in. One thing I’ve noticed in the last year is I’ve paid attention to sunrises and the sunsets and how beautiful the sky is. It’s a good time to appreciate everything you have.

140 cows, 160 acres

Corn yields were average. The biggest thing this year was variability, corn on corn ground did not do well. Corn on rotation was much better. Bean yields were pretty good, those August rains were very helpful and saved the farmers of our area. It was too late for anyone who put cover crops in as most farmers around here said they did not germinate. We finished corn stalks yesterday (Nov.7), and finished corn Oct. 29. We are all done with everything, since we don’t do any fall tillage. We had some decent rains this spring, but then things got dry. This is the second year in a row of noticeably dryer than average weather.

240 Cows, 750 acres

We had about 1.8 inches of rain in the last two weeks, we had quite a wind storm last week.

We still have 220 acres of corn we are waiting on. First it wasn’t dry enough and then we had trouble getting the bagger, hammermill and combine all lined up. We are scheduled now for this week, and we are going to go no matter what. We are almost out of high moisture corn and I am not buying any. Overall, I have been pretty satisfied with the year. We are maybe a little short on yields because it has been so dry. We have enough to feed the cows for the year, just no extra to sell. What we have has been testing out to be really good feed, too. It is good to know we won’t have to buy a lot of soybean meal to add.

530 cows, 1,700 acres

cows, 330 acres

We got all of our crops in; except we still need to combine sunflowers. We combined our corn Oct. 28-29 and then made some corn stalk bedding. We plant an 84day variety of corn and we were right about 175 bushels an acre, which is average for us. The soybeans yielded pretty well. It got a little dry in June and early July but later we were able to get timely rain to help fill the corn and beans out. Our hay crops were decent, except second was pretty light because we were so dry and had a lot of bug pressure. The third crop was pretty average, but first and fourth were good. We feel very fortunate, we have friends 20 miles from here that everything almost burnt up, they were so dry.

400 cows, 1,675 acres

We finished high moisture corn Oct. 29 and have 200 acres of dry corn left that should be done by Thanksgiving. We put another 100 acres of a rye cover crop in. All corn acres are going to beans next year, so we’ll put a cover crop on another 100 acres as well. We had an excellent year – God really blessed us. We had timely rains and good quality and quantity on all crops. We had 4 crops of hay that resulted in the largest quantity of high-quality forage we’ve ever had. We got 28 tons/acre of corn silage and 215-220 bushels/acre for corn. We got around 80 bushels of wheat per acre and 6070 bushels/acre of soybeans.

This year was average at best. It was decent but it was so dry that it really hindered the hay and even the corn some. Overall, it wasn’t terrible but it could’ve been better with a couple more inches of rain in July. We are still waiting to get a combine for beans. We got all the rye in and that is looking nice. We hope to finish up manure hauling this week. Then we will put things away for the year. It will be good to get done before the cold that is supposed to set in next week.

1,600 cows, 2,500 acres

We finished chopping corn silage Oct. 29 and went right into high moisture corn. We combined about 100 acres and covered that Nov. 1. All cover crops are in. We’ll take 5th crop hay on everything except our new seeding. It’s been a great harvest year. I couldn’t ask for better weather than what we had. We harvested 12,000 tons of haylage with 4 cuttings across an average of 1,055 acres. That’s a dry hay equivalent of 5.44 ton/acre. Corn silage varied from 13 ton/acre to over 26 ton/ acre. Our highest yielding corn silage was on ground that has been in no-till for over 10 years planted May 12. We planted corn as late as June 20 and still had a yield of 18 ton/acre. We averaged 71 bushels of wheat across 164 acres.

April 1

727 Large Rounds 10 8.43 81.89

693 Large Rounds 11.32 16.06 116.48

21.17 $75.00

24.23 $145.00

692 Large Rounds 12.92 11.98 89.24 1 8.12 $125.00

675 Large Rounds 14.66 9.35 88.98 1 27.87 $95.00

728 Large Rounds 11.06 14.03 103.08 2 9.41 $155.00

720 Large Rounds 11.73 19.02 138.37 2 20.02 $165.00

689 Large Rounds 11.9 7.1 79.3 2 27.24 $100.00

734 Large Rounds 11.98 18.59 118.9 2 24.61 $160.00

673 Large Rounds 12.27 18.07 122.18 2 19.93 $130.00

688 Large Rounds 12.27 18.07 122.18 2 19 $145.00

714 Large Rounds 12.27 18.07 122.18 2 19.92 $155.00

750 Large Rounds 12.5 15.63 101.75 2 14 $45.00

719 Large Rounds 12.65 18.48 139.98 2 20.71 $145.00

700 Large Rounds 12.67 22.25 139.8 2 25.07 $160.00

749 Large Rounds 12.98 23.82 143.73 2 19.23 $185.00

674 Large Rounds 13.07 18.93 140.34 2 20.22 $140.00

687 Large Rounds 13.07 18.93 140.34 2 19.32 $160.00

715 Large Rounds 13.07 18.93 140.34 2 20.01 $155.00

725 Large Rounds 13.07 18.93 140.34 2 19.68 $155.00

711 Large Rounds 13.97 15.32 99.55 2 19.04 $115.00

730 Large Rounds 14.18 16.5 119.18 2 20.98 $155.00

671 Large Rounds 14.24 21.19 144.03 2 20.46 $170.00

713 Large Rounds 14.24 21.19 144.03 2 19.23 $165.00

724 Large Rounds 14.24 21.19 144.03 2 20.01 $155.00

717 Large Rounds 14.32 19.59 139.82 2 21.23 $165.00

703 Large Rounds 14.66 9.35 88.98 2 25.12 $85.00

682 Large Rounds 14.87 18.43 106.61 2 19.17 $145.00

705 Large Rounds 14.91 21.7 120.37 2 17.64 $155.00

716 Large Rounds 15.32 15.32 99.55 2 21.03 $115.00

718 Large Rounds 13.15 17.95 130.79 3 22.2 $165.00

712 Large Rounds 12.46 9.81 71.94 22.96 $90.00

710 Large Rounds 14.69 8.98 69.33 15.61 $95.00

731 Large Squares 10.06 19.22 124.22 1 22.93 $160.00

732 Large Squares 10.76 6.9 80.31 1 21.43 $130.00

733 Large Squares 13.88 10.28 91.52 1 27.99 $130.00

738 Large Squares 10.46 16.37 105.12 2 23.47 $170.00

737 Large Squares 10.59 18.35 119.32 2 23.61 $165.00

660 Large Squares 10.88 22.23 153.14 2 26.73 $155.00

669 Large Squares 12.88 18.08 123.36 2 23.28 $150.00

704 Large Squares 13.28 21.08 133.09 2 24.39 $170.00

676 Large Squares 13.3 19.22 122.45 2 24.06 $155.00

667 Large Squares 13.74 20.22 113.35 2 25.15 $145.00

665 Large Squares 14.47 20.64 115.85 2 24.64 $145.00

698 Large Squares 14.64 20.48 122.1 2 23.12 $170.00

672 Large Squares 14.67 22.63 113.97 2 21.46 $150.00

679 Large Squares 14.82 20.43 119.14 2 22.34 $155.00

678 Large Squares 15.75 20.09 115.89 2 22.15 $155.00

702 Large Squares 15.75 20.09 115.89 2 14.87 $155.00

694 Large Squares 16.75 12.09 133.39 2 25.54 $150.00

743 Large Squares 12.12 21.47 151.85 3 26.93 $185.00

748 Large Squares 12.35 20.31 163.17 3 24.18 $185.00

742 Large Squares 21.82 21.82 177.66 3 26.77 $195.00

754 Large Squares 11.21 24.6 183.76 4 25.08 $225.00

680 Large Squares 10.81 16.58 108.62 22.27 $155.00

681 Large Squares 15.94 16.39 73.55 25.05 $100.00

690

741

739

745

740

661

663

744

684

736

685

662

Large Squares 15.94 16.39 73.55 26.25 $100.00

Medium Squares 11.55 19.04 133.11 1 27.04 $170.00

Medium Squares 14.21 20.97 163.37 1 27.78 $230.00

Medium Squares 10.65 16.32 89.38 2 25.24 $160.00

Medium Squares 12.07 18.5 100.58 2 23.96 $160.00

Medium Squares 14.03 21.18 129.43 2 26.81 $140.00

Medium Squares 14.34 20.67 127.17 2 26.75 $170.00

Medium Squares 12.18 22.07 205.77 3 27.48 $200.00

Medium Squares 14.14 23.07 144.6 3 20.29 $165.00

Medium Squares 14.65 24.61 185.07 3 25.78 $180.00

Medium Squares 15.56 23.96 154.26 3 25.94 $175.00

Medium Squares 16.15 23.06 150.09 3 26.35 $170.00

747 Medium Squares 14.78 26.18 196.92 4 23.32 $185.00 670 Medium Squares 17.62 25.73 216.4 4 25.29 $235.00 735 Medium Squares 14.12 19.88 154.14 3&4 25.72 $225.00 707 Small Rounds 12.95 9.6 94.82 1 34 $30.00 721 Small Rounds 13.71 9.73 83.55 1 19.08 $95.00 708 Small Rounds 12.64 16.05 125.28 2 7.68 $150.00 677 Large Rounds STRAW 34 $40.00 691 Large Rounds STRAW 34 $42.50 706 Large Rounds STRAW 34 $31.00 722 Large Rounds STRAW 34 $32.50 723 Large Rounds STRAW 26 $50.00 726 Large Rounds STRAW 34 $30.00 729 Large Rounds STRAW 20 $30.00 746 Large Rounds STRAW 38 $25.00 752 Large Rounds STRAW 34 $30.00 666 Large Squares STRAW 23.27 $120.00 668 Large Squares STRAW 23.12 $120.00 683 Large Squares STRAW 18.8 $100.00 686 Large Squares STRAW 24.9 $115.00 701 Large Squares STRAW 24.86 $110.00 709 Large Squares STRAW 21.79 $117.50 664 Medium Squares STRAW 72 $40.00 699 Medium Squares STRAW 78 $47.00 751 Medium Squares STRAW 72 $35.00 695 Large Rounds CORN STALKS 16 $25.00 696 Large Rounds CORN STALKS 30 $25.00 697 Large Rounds CORN STALKS 30 $25.00 753 Large Rounds CORN STALKS 26 $20.00 755 Medium Squares CORN STALKS 72 $15.00

It sounds like everyone will be making their way home for Thanksgiving this year. I’m so excited to have a house full of hungry people and a table full of favorite dishes. I am especially thankful that many hands will be preparing the meal we share. I have to shake my head trying to comprehend when our children grew up. It feels like a few years ago when they were jockeying for a position in the kitchen next to me to help make their favorite dish. Now, they will be carrying in the pies and salads they made to share with the family around our table. I truly feel blessed to see our children carrying on a long line of family traditions shared around the table.

If I have any turkey leftovers, they will be used in these two favorite postThanksgiving dinner dishes.

If you’re not ready to give up treats around the campre, try these s’more bars. This is a great way to use up the remaining marshmallows and graham crackers from the fall treats because we all know the chocolate bars are the rst thing to disappear.

Creamy turkey tetrazzini

1 package linguine, cooked

2 cups cubed cooked turkey

1 cup shredded cheddar cheese

1 can cream of mushroom soup

1 medium onion, chopped

2 cans sliced mushrooms, drained

1/2 cup milk

1/4 cup chopped green peppers

1 jar chopped pimentos, drained

1/4 teaspoon salt

Dash pepper

Parsley

Cook linguine according to package directions. Rinse cooked noodles and mix together with remaining ingredients. Pour into greased casserole dish. Bake at 375 degrees for 40-45 minutes. Top with extra cheese just before done if you like.

Wild rice soup (My neighbor’s, Joyce’s, recipe)

2 cups cooked wild rice

1/4 cup our

1/4 cup butter

2 large carrots (1 cup raw) chopped

1 large onion, chopped

1 1/2 stalk celery, chopped

2 large mushrooms, sliced (optional)

2 cups cooked chicken or turkey, chopped 8 cups chicken broth, plus two bouillon cubes

To cook wild rice: Wash rice in hot water. In saucepan, add rice and three times amount of water. Bring to a boil, cover and reduce heat to low. Simmer 30-45 minutes until rice is tender and most of the water is absorbed. Sauté all vegetables in butter; add our to vegetables. Slowly add broth, then rice and chicken. Add salt and pepper to taste. Stir occasionally until heated through.

S’more bars

8 cups Golden Grahams cereal

1/4 cup lite corn syrup

5 cups mini marshmallows

5 tablespoons butter

1 1/2 cups milk chocolate chips

1 teaspoon vanilla

1 cup mini marshmallows

Butter a 9-by-13 pan. Microwave 2-3 minutes: 5 cups marshmallows,

chips, syrup and butter stirring every minute until smooth. Add vanilla. Pour over cereal in large bowl. Toss until evenly coated. Stir in 1 cup marshmallows. Press mixture into pan. Let cool before cutting.

S’more Texas brownies

1 cup water

1 cup butter (two sticks) 4 tablespoons cocoa

2 cups our 2 cups sugar

1 teaspoon cinnamon

1/2 cup sour milk

1 teaspoon soda

1 teaspoon vanilla

2 eggs

Boil water, butter and cocoa together. Cool slightly. Mix our, sugar and cinnamon together in mixing bowl. Pour cocoa mixture over dry ingredients. Stir together. Mix milk, soda, vanilla and eggs together. Pour over chocolate mixture. Stir together until smooth. Pour into greased jelly roll pan. Bake at 350 degrees for 20 minutes.

Frosting: 1/2 cup butter

4 tablespoons cocoa

6 tablespoons milk

1 box powdered sugar

1 teaspoon vanilla