DAIRY ST R

Volume 24, No. 18

“All dairy, all the time”™

November 12, 2022

Volume 24, No. 18

November 12, 2022

ATHENS, Wis. –

Opportunities can arrive at unexpected moments, but for Ryan Talberg, a young farmer from Minnesota, the opportunity to grow his herd and acquire more land has come after a long search for the perfect place to call home.

Throughout the morning of Oct. 28, the entire Talberg family showed their emotions with the wiping of tears as they all kept busy nishing up the last chores before two cattle pots arrived to take their cattle to their new home in Athens.

After several trips back and forth leading up to the move, the day became surreal

By Tiffany Klaphake

By Tiffany Klaphake

NEW YORK MILLS, Minn. – More than 1,350 guests have visited Mursu Dairy during the last 10 years. A brown guest book lays open at the dairy, awaiting visitors who come for a tour. It is the second book of its kind, the rst had the names of more than 1,000 guests.

People from the neighborhood, county, state, country and around the world have made their way to Mursu Dairy to see the innovation of this small dairy farm near New York Mills. But now in addition to vast visitors, Mursu Dairy has been named the 2022 Minnesota Milk Producers of the Year.

for Talberg as he nished morning milking.

“This has been my home for almost my entire life; this has been my herd’s home for the last seven years,” Talberg said. “I wish I had an opportunity to stay, but with being landlocked, high land prices and neighbors with far deeper pocketbooks, this was my only option to grow and make my dream work. Out there I have room to grow not only my herd but maybe someday raise a family on the farm too.”

For the last seven years, Talberg has lived in Freeport, Minnesota, with his parents, Dan and Stephanie

Talberg, to pursue his dream of running a dairy farm. Talberg said they have been more than supportive since

the beginning, having dairy farmed themselves until 2001 when they dispersed the herd.

“I’ve been looking for a

Tammy serve on the Otter Tail County American Dairy Association. Jeremy serves on the West Central Holstein Club board.

The whole Mursu family is involved in planning and implementing an annual visit to the farm by the New York Mills kindergarten class. Each year, the students come to the farm to see and learn about where milk comes from. Princess Kay of the Milky Way usually pays a visit to the school that day as well. The event started in 2014 as an idea between Tammy and daughter Bridgett, who is a kindergarten teacher.

“We

little corner of the world,”

Tammy Mursu said.

The farm is run by Tom Mursu and his wife, Tammy, and their son, Jeremy Mursu, and his wife, Vanessa.

Tom said the award is an

honor.

“We were shocked,” he said.

Minnesota Milk selects a farm from those who have been nominated. Nominees are touted as being innovative and open to the public.

Tom said Mursu Dairy has seen an uptick in interest ever since they put two robotic milking systems on their farm.

“We’ve always had an open door,” Tom said.

Tom has served on cooperative boards, and Tom and

Mursu Dairy has come a long way in the past 70 years. Tom’s parents started to rent a dairy farm near New York Mills in the mid-1950s. After a couple of years of renting, they bought the farm.

Tom’s dad, Martin, would get up every morning and milk 12 cows by hand. Then, on his

GRACE JEURISSEN/DAIRY STARdo what we can in our

www.dairystar.com

Phone: 320-352-6303 Fax: 320-352-5647

Published by Star Publications LLC

Manager/Editor

320-352-6303 (ofce) 320-248-3196 (cell) 320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell

• nancy.p@dairystar.com

In its quarterly Agribusiness Review, Rabobank is forecasting Class III milk prices to trend lower through the rest of the year and into 2023. RaboResearch forecasts fourth quarter Class III prices to average $20.90 per hundredweight. U.S. milk production is expected to increase 1.4% year over year. Impressive dairy product exports are anticipated to prevent domestic supplies to become too burdensome.

Ag lender survey released

The U.S. supply of distillates, which includes diesel and heating oil, totaled 106.8 million barrels for the week ending Oct. 28. That’s nearly 20% below the ve-year average and the lowest on record for this time of the year.

Ag InsiderKaren Knoblach

• karen.k@star-pub.com Annika Gunderson • annika@star-pub.com

Editorial Staff

• tiffany.k@dairystar.com

Maria Bichler - Assistant Editor maria.b@dairystar.com • 320-352-6303

Danielle Nauman - Staff Writer 608-487-1101 • danielle.n@dairystar.com

Stacey Smart - Staff Writer 262-442-6666 • stacey.s@dairystar.com

Abby Wiedmeyer - Staff Writer 608-487-4812 • abby.w@dairystar.com

Grace Jeurissen - Staff Writer 320-352-6303 • grace.j@star-pub.com

Jan Lefebvre - Staff Writer 320-290-5980 • jan.l@star-pub.com

Taylor Jerde - Staff Writer 507-403-1680 • taylor.j@star-pub.com

Consultant

Jerry Jennissen 320-346-2292

Advertising Sales

Deadline is 5 p.m. of the Friday the week before publication Sales Manager - Joyce Frericks 320-352-6303 • joyce@dairystar.com

Mark Klaphake (Western MN)

320-352-6303 (ofce) 320-248-3196 (cell)

Laura Seljan (National Advertising, SE MN) 507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com

Jerry Nelson (SW MN, NW Iowa, South Dakota) 605-690-6260 • jerry.n@dairystar.com

Mike Schafer (Central, South Central MN) 320-894-7825 • mike.s@dairystar.com

Amanda Hoeer (Eastern Iowa, Southwest Wisconsin) 320-250-2884

• amanda.h@dairystar.com

Megan Stuessel (Western Wisconsin) 608-387-1202 • megan.s@dairystar.com

Kati Kindschuh (Northeast WI and Upper MI) 920-979-5284 • kati.k@dairystar.com

Julia Mullenbach (Southeast MN and Northeast IA) 507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell) bob.l@star-pub.com

Deadlines

Subscriptions

Advertising

Letters

Letters and articles of opinion are welcomed. Letters must be signed and include address and phone number. We reserve the right to edit lengthy letters. The views and opinions expressed by Dairy Star columnists and writers are not necessarily those of the Dairy Star / Star Publications LLC.

The Dairy Star is published semi-monthly by Star Publications LLC, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378-1246. Periodicals Postage Paid at Sauk Centre, MN and additional mailing ofces.

POSTMASTER: Send address changes to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378-1246.

Interest rate bumped another .75 basis points

“These really high summer prices limited the ability to accumulate inventories, and now we’re coming into the winter months hoping it’s not going to be a cold winter,” said Altin Kalo, chief economist, Steiner Consulting.

The National Milk Producers Federation leadership has unanimously endorsed a proposal to modernize Federal Milk Marketing Orders. NMPF has led more than 100 meetings over the past year to develop these recommendations.

The International Dairy Foods Association has submitted comments to the Federal Maritime Commission in response to the rulemaking process for the Ocean Shipping Reform Act. During the pandemic and supply chain disruptions, foreign-owned ocean carriers would often

Turn

leave U.S. ports empty and refused to negotiate shipping space to exporters. IDFA described this practice as “unacceptable” and asked for stronger rules.

More than 300 trade organizations signed off on a letter to President Joe Biden, asking the federal government to intervene in the dispute between railroads and its workers. The letter said the U.S. economy would see a major economic loss if a rail shutdown happens. The leadership of 12 rail unions approved a tentative agreement, but two of those unions refused to ratify the deal. Boozman seeks details on COVID relief

Congress allocated $11 billion in COVID-related support for agriculture in 2021. Senate Agriculture Committee Ranking Member John Boozman now wants to see how that money was spent. In a letter to Agriculture Secretary Tom Vilsack, Boozman said he is satised with the way the U.S. Department of Agriculture implemented most of the programs. However, Boozman believes USDA is using the remaining funds for projects unrelated to the pandemic.

Dairy Management Inc. CEO Barbara O’Brien outlined a new three-year strategy for the dairy checkoff program. This plan includes doing more with less, by making programs simpler and more focused. The emphasis will be on projects that can deliver the biggest impact for the dairy industry. The dairy checkoff plan also included a “doubling down” on research with a renewed investment in health and wellness.

The grocery store chain, Cub, awarded Midwest Dairy with its Vendor of the Year Award. Midwest Dairy was recognized for its June Dairy Month activities. In early June, Princess Kay of the Milky Way and Minnesota dairy ambassadors hosted an ice cream social at a recently rebuilt Cub in Minneapolis after it had been damaged due to civil unrest.

mate

For the rst time, the United Nations Climate Change Conference will consider food systems and the impact on the climate. The Humane Society of

the United States is hosting three events during the conference in Egypt, promoting a transition away from animal proteins. The animal rights activist group claims a shift to plant-based diets can reduce greenhouse gas emissions from the food system by nearly 50%.

A non-dairy version of the familiar Kraft cheese singles will be rolled out in 2023. Kraft NotCheese is made from coconut oil, modied starch, water and chickpea protein and is available in American, cheddar and provolone avors. Kraft ofcials claim the plantbased product tastes, smells and melts like real dairy cheese.

The Minnesota Milk Producers Association has contracted with Wisconsinbased Edge Dairy Farmer Cooperative for administrative and program services. Previously, Midwest Dairy handled the administrative duties for MMPA. Lucas Sjostrom will remain as the MMPA executive director as part of the Edge Dairy Farmer Cooperative staff.

Minnesota FFA ocks to national convention

Minnesota had a large delegation in Indianapolis for the FFA convention. “We have almost 16,000 students involved in FFA and over 1,000 of them are at convention,” said Minnesota FFA interim executive director Lavyne Rada. The convention is a life-long highlight for many FFA members. “It’s one of my favorite things to watch the student’s rst time in the arena when they see blue corduroy jackets just wall to wall,” Rada said.

October Co-op Month has been recognized nationally since 1964. That answers our last trivia question. For this week’s trivia, what is the name of the youth wellness program created by dairy checkoff and the National Football League? We will have the answer in the next edition of Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network, based in Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two adult sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

way to his job at Wadena Silo Company, he would drop the milk off at the creamery. As Tom got more involved in the farm, the cow numbers slowly increased.

By the mid-2000s, Tom was milking 50 cows in the 36-stall tiestall barn. In 2012, the Mursus talked about improvements.

“That got to be too labor intensive so something had to change,” Tom said.

Their solution was to build a new barn and purchase two Lely robotic milking units. Construction started for the project in fall 2012 and was completed in June 2013. Today, the Mursus milk around 145 cows.

“Those rst years, we had a lot of people come to visit,” Tom said. “It did not take long to ll the guest book Tammy had set out.”

The Mursus farm 500 acres of owned and rented land. They harvest dry corn, silage corn and high-moisture corn. They raise their replacements and forages.

“It was an excellent year for forage,” Tom said.

Jeremy farms full time with his dad and is in charge of robot maintenance, taking care of the cows, breeding and helping with eldwork. He has been farming full time since winter 2008.

When Jeremy graduated high school, he went to Minnesota State Community and Technical College in Fergus Falls. While there, he took a course in taxidermy and then did taxidermy work for the next two years. He then pursued a degree in elementary education.

While Jeremy was student teaching in fall 2008, he realized that was not the career for him. Since then, Jeremy has been farming with his dad. Vanessa cares for their two children and helps when she can, especially in preparation for the kindergarten visit.

Tammy helps on the farm by feeding the calves and does the bookwork. The calves are housed in the original barn that is more than 100 years old.

Tom and Tammy’s son, Trent, is a welder in Detroit Lakes. Both Bridgett

and Trent come to the farm to help at various times of the year.

Martin, 93, comes to the farm every week day.

Of Tom and Tammy’s 11 grandchildren, those who are old enough to join 4-H lease animals from Tom and Tammy and show at the county fair.

Tom and Jeremy are working with an estate planning attorney to transition the farm to Jeremy.

“I think exibility is the way to go,” Tom said.

The exibility is also why the Mursus decided to go with robotic milking in the rst place. Because they are a small farm, they do not have any employees and wanted to have the exibility to get other things done around the farm and off the farm. They never expected to have so much attention after putting in the robots. Almost immediately, the Mursus started to welcome visitors to see the robots.

“Robots are pretty common now, but when we rst got them, it was a new thing,” Tom said.

Word spread about the new technology and soon friends, friends of friends, neighbors, community members and church groups were coming to the dairy.

Tammy keeps the guest book in the ofce of the barn, and it contains names of people from around the world. One memorable guest was a woman from Malaysia, who was living in New York City to attend college and made her way to Mursu Dairy. She came to New York Mills with some friends who had family in the area.

“She didn’t know the difference between a hay eld and a corn eld,” Tom said. “We let her feed a calf; that was an experience for her.”

The Mursus said she learned a lot while visiting Minnesota and left an impact they will not soon forget. Tammy said they helped her see the good of the American farm.

“She came to realize that farmers do take good care of their animals, and in turn, the cows take care of us,” Tammy said.

at my parents’ place, and I don’t have enough acreage to accommodate my herd,” Talberg said.

Talberg began farming at the age of 17 and had a longing to raise his own registered Holsteins.

“I found a picture of my dad’s cows when I was in the fourth grade, and I knew immediately that I wanted to raise dairy cattle,” he said. “I keep that photo in the milkhouse as a reminder to myself of how far I’ve

come.”

That photo sparked a passion in Talberg that gave him the drive to pursue dairy in any way possible, from participating in dairy knowledge bowl, attending the National 4-H Dairy Conference and purchasing his own herd.

Talberg also made connections with industry professionals for guidance. He credits Jim Salfer from the University of Minnesota for keeping his hopes high in times of volatile milk prices and providing insight on grants and advice on nancing through the Minnesota Dairy Initiative.

In 2013, Talberg purchased his rst three cows from Art Stumpf of Pierz, Minnesota. Then in 2015, Talberg’s parents purchased 15 head from Mark and Natalie Schmitt of Rice, Minnesota. Talberg bought his parents out a few years later.

Talberg said the Schmitts have been close friends and mentors for him from the beginning, even arriving at the farm the evening of Oct. 26 to say goodbye and toast Talberg’s future in the dairy industry.

Once Talberg established his herd, the next step was to slowly grow. In Minnesota, he milked in a 35-stall tiestall barn on his parents’ farm and had 15 tillable acres to use toward feeding his herd.

As he looked for a possible farm to purchase, Talberg said he wanted a turnkey operation and something that was beautiful to look at. For him, the farm needed to have the ability to invite technology as he hopes to implement a robotic milking system.

On Sept. 16, Talberg visited the farm in Athens and felt a connection with the farm and the previous owners. Talberg’s offer was accepted, and by Oct. 13, he closed on the farm.

The site includes a calf barn, 67-stall tiestall barn, heifer barn, machine shed, enough storage for feed and double the tillable acreage he had in Minnesota.

“I have more acreage to feed my cows,” Talberg said. “With the additional acreage and current feed prices, I won’t have to purchase as much feed, which will help lower my costs now that I have a mortgage to pay for.”

Talberg said he will miss the companionship he has in Freeport. Having made friends with neighbors and area farm families, he is leaving most of his dairy connections in Minnesota.

“It’s scary to basically be starting new, but like I’ve been telling everyone, I’m only a phone call away,” he said.

Though Talberg smiled as he talked about the future of his herd,

he said he had few hours of sleep during the week leading up to the move because he had nerves that echoed fear of the unknown. Talberg said the change is scary, but he knows this was the right choice for his herd and himself. When he stepped foot on his new place in Athens, a sense of peace and home welcomed him into his next chapter. His milk will now be sent to Mullins Cheese in Mosinee.

“I’m slightly elevated on my new site,” Talberg said. “I wanted a site that, when you drive by, it’s picturesque. I drive down the road and think, ‘Wow, this is mine.’”

For Talberg, turning on the vacuum pump in the barn for the last time in Minnesota made him reect on the many memories and growing pains he has had on the farm. Remembering the rst time milking 10 Holsteins he purchased to start his herd, he laughed.

“The rst time I turned on the pump in the barn, the power went out,” Talberg said. “I’ve had my ups and downs, but I’ve always found a way to make it work.”

As the rst truck left with a portion of the herd, the family watched as the future approached. Talberg, though grateful for his dairy career in Minnesota, is ready to take the next step.

FARLEY, Iowa – Looking at photos of Doug Simon and Dan Hansen’s dairy farm, one may nd it hard to believe the farm is not real but instead a diorama display on a 1/64th scale.

In fact, the farm is so realistic that it won the national championship in its

class Nov. 5 at the 45th annual National Farm Toy Show hosted by the National Farm Toy Museum in Dyersville.

Although it was a thrill to be named champions, both Simon and Hansen said they had an excellent chance of winning that day.

“We were both condant that we were going to come home with a trophy,” Hansen said.

Simon agreed.

“It was the amount of time we put into it,” he said. “When we were putting the whole display together, both of us kept saying that it was going to be really hard for somebody to beat this because it was pretty amazing seeing it all come together. What we ended up with was pretty cool.”

Simon and Hansen used weekends and any spare time for about a year and a half to create their masterpiece. Hansen worked from his home in Beaver Dam, Wisconsin, and Simon from his home in Farley.

“I built the equipment for the display,” Hansen said. “Doug did all the scenery and weathering stuff – putting manure in places, dirt and dust on the equipment and grass and gravel on the display board. We used each other’s talents within the hobby to do our own parts. Then a few parts we collaborated on and did together.”

A 1/64th scale robo c barn was part of Dan Hansen and Doug Simon’s diorama display Nov. 5 at the Na onal Farm Toy Show compe on in Dyersville, Iowa. The replica barn is loosely based on the barn at Farnear Holsteins, owned by Simon’s two uncles.

Nothing on the display was simply purchased and placed. The farm equipment and some of the tractors were designed by Dan and then 3D printed by him. A few tractors began as Ertl, a replica toy line, tractors but were sandblasted and deconstructed down to the shell and then rebuilt and painted.

“Dairy cows in the barn are Ertl cows, but each one of them has been custom painted (by Simon) with differ-

Dan Hansen (le ) and Doug Simon receive the na onal championship trophy Nov. 5 at the Na onal Farm Toy Show in Dyersville, Iowa. Their 8-by-8 foot diorama display of an en re dairy farm won the 1/64th class at the contest.

ent markings because no two cows are alike,” Simon said. “Some of them are replicated off of show cows that my family shows competitively. The calves and the heifers, all the animals, were custom painted.”

For the contest, the display base had to be 8 feet by 8 feet, but materials used could be almost anything. Simon and Hansen were meticulous in their methods.

“Everything, even the littlest of

things and accessories, we either weathered or detailed or made it custom,” Simon said.

Some of the feed in the display was made from actual feed.

“I would occasionally take a bag of distillers or soybean meal or corn gluten pellets, and Doug and I used a small coffee grinder to make it even ner,” Hansen said. “It still had the color and smell

Turn to TOY FARM | Page 9

“For the feed in the mangers and the alleyways, there’s a blended turf that they use in railroad hobbies that looks like a ground cover,” Simon said. “It had the color variation of cattle feed. Within the hobby world, there’s a vast variety of products available to buy for making a display.”

Both Simon and Hansen have competed diorama display contests separately, but this was the rst Simon-Hansen collaboration. The partnership all began with a text.

“Doug sent me a text one day and asked if I had ever wanted to build a display for the national competition,” Hansen said. “I was hauling manure at the time, and I said yes. That was about a year and a half ago.”

Simon and Hansen grew up going to farm toy shows and became friends after meeting at one of them.

Simon now works for a trucking company, but he helps on a dairy farm, Farnear Holsteins, near Farley that is owned by his two uncles. The robotic dairy barn in the display is loosely based on their barn.

“My dad was a milk hauler for 35 years, so I grew up riding with him in the milk truck, going to all these different farms,” Simon said. “My mom worked for Ertl Toys nearby in Dyersville for a number of years. For birthdays or holidays, I would get toy tractors or farm and country playsets with every-

thing you need to create a farm scene. That would get my imagination going.”

Because Dyersville was only a few miles away, Simon also had easy access to the national toy shows.

“I saw all the display contests, and I got ideas,” he said.

Simon started creating scenes of his own. It seems his whole childhood was a rehearsal for building diorama displays.

Meanwhile, Hansen was growing up in Beaver Dam, Wisconsin, with his own interest in farm toys and replicas being honed.

“I grew up on the farm here at home, but the majority of my life I’ve worked at Brossard Dairy, a 450-cow dairy down

the road from me,” Hansen said. “This past year I started hauling cattle feed, mainly in the Midwest, so I’ve always had a connection to agriculture and farming since I was a little kid.”

Hansen’s dad owned a small equipment repair business and worked on tractors, various equipment and semis for farmers as well as hauled grain and hay .

“I’m more equipment focused from seeing tractors and equipment coming in and out of the yard,” Hansen said. “On top of that, I never had video games. It was always just toy tractors.”

His parents liked the farm toy shows and brought him every year to local ones as well as

the national show in Iowa.

“As I grew older, I got more into the hobby and wanted to change things,” Hansen said. “I’d take a tractor out of the package and, for example, if it didn’t have duals on it and I wanted more tires on it, I just glued more tires to it. From there, it progressed. If I wanted something that Ertl didn’t make, I would try to build it myself.”

As Simon and Hansen worked on their display, they received help from friends in the hobby world and beyond. Some helped build a few pieces, one friend loaned them shop space for putting the whole display together and another let them use his enclosed wagon to haul the main part of the display from the shop to the competition.

“We’ve had a few different people playing a hand in this,” Hansen said.

Family and friends came to the competition to cheer them on.

Simon and Hansen spent ve hours reassembling their display Nov. 4 for the judging that would take place by a panel later that day. They were competing against three other displays in their class. There were two other classes, a 1/16th class and a youth class.

The winners were not announced until Saturday, but the wait was worth it for Simon and Hansen as they heard themselves declared national champions.

“Doug and I looked at each other and gave each other a hug and a really hard high ve,” Hansen said.

Both felt a sense of accomplishment.

“We had been working on it for so long, basically calling each other about it or life in general every day,” Simon said. “It was pretty rewarding to see it come full circle.”

Hansen agreed.

“For two guys like us, who have gone to shows as long as we have and have seen so many winning displays, to actually leave with a win was awesome,” he said.

Simon and Hansen said they will now take a break from building displays, but neither is ready to say goodbye to the hobby.

“We’ve got some ideas in the works,” Simon said.

Editor’s note: This is part two of a two-part feature regarding farm transitions. In the previous issue of Dairy Star, we gave examples of challenges that occur during farm transitions. Here we present information for success.

Today’s farm families have more resources and places to turn for advice when planning a transition to the next generation. The help that is available, through extension services, colleges and universities, private rms and more, is often more personalized and leads families through the process.

Shawn Meyer is a farm business management instructor at Minnesota West Community and Technical College in Hutchinson, Minnesota. He has more than 17 years of experience in farm nance and working with farm families as they plan for transitions.

Meyer said walking families through the process, beginning to end, is better than tossing information at families and expecting them to apply it.

“Then the family leaves more confused than when they walked in because all we did was throw a bunch of options at them and didn’t help them through it,” he said.

Meyer said the process should include all family members and help the family establish clear goals.

“What should always drive the transition are your goals,” he said. “You also need to involve the off-farm siblings to the extent that they feel like they are included. It’s fair that they have part of that initial conversation. They might not get exactly what they want, but at least they had a chance to be part of the process.”

Meyer said farm transitions are more complex than most business transitions because they involve family members’ rooted emotions.

“We need to work through all the emotional and family dynamics before we ever worry about if it’s a (limited liability company),” Meyer said.

Helping farm families successfully transition is important to Jim Molenaar as well. For the past 41 years, Molenaar has worked as an instructor in farm business management, the past eight years at St. Cloud Technical and Community College. A specialist in farm succession planning, Molenaar also went through a farm transition himself and is a farm advocate for the Minnesota Department of Agriculture.

After looking for programs that could best help, Molenaar attended courses offered by Dave Goeller at the University of Nebraska-Lincoln, who had developed a successful program to guide farmers through transitions. With Goeller’s design in mind, Molenaar now partners with Megan Roberts from

the Southern Minnesota Center of Agriculture to offer free seminars.

“We team teach what I call a marriage encounter for farm families,” Molenaar said. “We’ve been doing this for farm succession for ve or six years.”

The seminars begin on a Friday night and then continue on Saturday.

“We try to get as many people of the farm family as we can into the room, and we go through a process that they can use to reach their own conclusions,” Molenaar said. “No two farms are the same. Each farm has its own unique challenges and ideas.”

The seminars are offered during the winter. During the sessions, Molenaar and Roberts ask questions that foster collaboration and goal setting. Legal and tax aspects of a transition are addressed as well.

“The very rst question we ask in our seminar is whether or not you want your farm to continue after your lifetime,” Molenaar said. “If the answer is no, then it’s pretty easy. All we need is a will, but if you do want it to continue, then the communication, expectations and what’s fair and what’s equal becomes more challenging.”

Molenaar said labor is the easiest portion of a transition. The most difcult is management. Families must discuss both, such as what would be fair compensation for the labor and when should the next generation become owners versus employees.

“The actual decision making of a farm is difcult to turn over,” Molenaar said. “Do I take off my manager hat and put on my mentor-teacher hat? If the older generation is able to let go of the reins and let the younger generation come in and implement things and get an operating interest, it’s huge.”

To bring the transitioning farm family to agreement, setting common goals is key.

“What does the family want their farm business to look like 30 years from now?” Molenaar said. “It’s a compromise like with anything else. It can work well if the older generation is willing to let go a little and there isn’t too much debt. Then, it’s really a matter of putting the puzzle together and deciding what the family wants to accomplish.”

Three of Molenaar and Robert’s seminars are already planned for winter 2023 in Minnesota: Feb. 4-5 in Mankato, March 10-11 in St. Cloud and March 31 through April 1 in Mahnomen.

Registration will soon be available at z.umn. edu/farmtransition. The website also offers tools and tips for planning a farm transition. Those with questions about the seminars can also email Molenaar at jmolenaar6@gmail.com.

“The seminars are really helpful if people take

the time to do it,” Molenaar said.

The University of WisconsinMadison also offers webinars and workbooks at farms.extension.wisc. edu.

Although each family has an individual situation and set of needs, when plans that were successful in the past are shared with families planning transitions today, the information can help those families create their own plans.

For example, one family of six children came up with their transition plan when the children were nearing adulthood. The farm was changed to a business corporation. Mom and Dad held almost all shares with each child receiving one share. Those who wanted to make the farm their profession received more and more shares from Mom and Dad’s shares through sweat equity and time. If the other children wanted to sell their shares back to the farm, they could, but the sale was nal. As time went on and the older generation neared retirement, the two children who farmed had worked their way up to being equal owners with their parents, thereby having an equal say in decisions.

Such a plan may not work for every family. But, knowing a variety of plans that have worked gives other families a place to start when brainstorming their own plans. Since specialists, such as Molenaar and Meyer, have discussed many farm-transition plans with families, getting advice from specialists means families have access to more ideas.

Attorney Shayna W. Borakove, of Borakove Osman LLC in Middleton, Wisconsin, has more than 14 years of experience as a farm continuation

practice leader at her rm.

She agreed getting advice is important.

“You don’t know what you don’t know,” Borakove said. “The outcome of planning one’s own farm transition without the advice and counsel of their attorney, certied public accountant, nancial advisor and/or other farm transition advisor would be about as predictable as a game of Plinko. With the advice and counsel of (a specialist), the client can understand the potential consequences of a plan and make better, more objective decisions.”

Borakove also helps families clarify their vision and set goals.

“To prepare, rst the family should ask themselves, if there were no rules, no taxes, no restrictions or judgment of any kind, what would we want to happen with the farm if we couldn’t make the decision?” she said. “Second, having a sense of the time horizon as to when a transition could or should happen, from the farm owner’s perspective as well as the farm successor’s perspective, would be helpful.”

Advisors agreed that planning, inclusion and communication are key.

“Farms that do the planning are much more likely to have a successful farm transition than those that do not plan,” Molenaar said. “It doesn’t guarantee success, but it improves the odds.”

I have used the ADGA ITP 02 APCS. I have also used the same test day samples to test for pregnancy in my does, to save a step during breeding season. Which is your favorite and why? I have only ever used the one test type, but have always been very satis ed with it.

How does testing with DHIA bene t your dairy operation? It is a wonderful aid in the monitoring of the health of our herd. The original purpose of the DHIR testing was to be able to test for and treat mastitis and tracking susceptible cows/ goats. It is also excellent for tracking who your most productive goats are. ADGA and DHIA work hand-in-hand to compile an annual list of top 10 goats for each bred, top 10 in total production, top 10 in protein production and top 10 in butterfat production. We have been fortunate to have two does that have made it on the preliminary list this year from last year’s production.

Tell us about your farm. We are a small hobby farm that strives to breed high quality Nigerian Dwarves that are productive and have excellent longevity. We also aim to produce goats that have a wonderful base temperament. We are an ADGA Plus herd, which means we participate in Linear Appraisal, DHIR and DNA testing.

Linear Appraisal is the evaluation of the goats conformation. We DNA type our goats so parentage can be proven but also we hope to test all of our goats to see which type of Alpha Casein gene they carry. We use all of these programs to try to breed the best goats we possibly can.

“It is a wonderful aid in the

By Abby Wiedmeyer abby.w@dairystar.com

By Abby Wiedmeyer abby.w@dairystar.com

LA CROSSE, Wis.

– Just like Wisconsin is famous for its cheese, LaCrosse is famous for the Pearl Ice Cream Parlor’s homemade ice cream.

“Our business is based in Wisconsin, which is America’s Dairyland for a reason,” Azia Thelemann said.

Thelemann manages the ice cream parlor with her sister, Dani Peterslie. The two have been operating the shop since 2016 when they took it over from their parents, TJ and Michelle Peterslie.

Thelemann said the ice cream parlor is successful because of the work of local farmers.

“Our business would not be here without the dairy industry,” Thelemann said. “Once one begins evaluating how many products we use that

contain dairy, it becomes evident what a signicant part of our business it is.”

Pearl Ice Cream Parlor uses Wisconsin dairy in its homemade ice cream. They also use butter in their homemade fudge,

and the connecting coffee shop has many drinks on the menu featuring milk. As supplies became scarce, and shopping became a challenge during the heart of the coronavirus pandemic, Thelemann said

she realized even more the importance of what they are offering.

“This is true now more than ever, as the last couple of years have shown the difculty with sourcing particular food items for

many businesses countrywide,” she said.

That was not always the case.

Pearl Ice Cream Parlor did not always make its own ice cream, but after being open a few years, TJ’s father, Oscar, decided they should.

Oscar, took an ice creammaking course from the University of WisconsinMadison and ew to Texas for training and to purchase the business’s rst batch freezer. Since then, Pearl Ice Cream Parlor has been making its own ice cream on-site, and the business has been growing year by year.

Pearl Ice Cream Parlor uses an ice cream mix with weekly deliveries ranging from 300-400 gallons in the summer. A vintage, commercial ice cream machine is used to create more than 20 avors of ice cream that is hand-scooped.

“By September, production really drops off,” Thelemann said. “But, we are making the sweet stuff all year long.”

The ice cream shop also uses butter in the homemade fudge that is sold in its adjacent confectionery. Each batch of fudge requires 2 pounds of butter. On a typical day of making fudge, the shop uses up to 16 pounds of butter.

Even with the adjoining coffee shop and confectionery, the bulk of the business is still making and selling ice cream to customers in the ice cream parlor. Ice cream is also sold by the pint and half-gallon for those who want to enjoy the treat from home. The mix is also frozen into hard ice cream without any avors or variegates that is later used to create hand-spun malts and shakes.

Pearl Ice Cream Parlor also bakes its wafe cones.

Thelemann said they are the topselling item.

“We roll cones daily,” Thelemann said. “They never stick around for very long.”

Thelemann said Pearl Ice Cream Parlor started as a way to attract families to Pearl Street. The parlor replaced a former bar and is located in one of the oldest historic commercial buildings in the city of La Crosse.

In keeping with the historic theme of the building, the interior emulates a 1930’s style ice cream parlor. They used items found from closed ice cream parlors across the Midwest and other antiques to create the ambiance in the space.

While the core avors are always on the menu, seasonal and never-before-seen avors do make an appearance.

“Any time we do a new avor drop, that sends folks in to try the latest usually in addition to their regular favorite that they always

have to get,” Thelemann said.

Except for 2020, the business has been growing each year and in turn increasing the amount of dairy products being used.

“Our current plans are to maximize the volume of ice cream that we can produce and sell from our location while still providing an old-fashioned ice cream parlor experience to each one of our customers,” Thelemann said.

Thelemann said there has not been a signicant change in customers’ purchasing trends since her ownership in 2016, although there is one popular dairy-free option on the menu.

“Customers are interested in new and interesting avors of ice cream, especially as the seasons change, but the classics are still in high demand as well,” she said. “From what we can tell, there will always be a spot in the freezer and room after dinner for an ice cream treat.”

Hunting whitetails is my favorite by far because there’s a challenge. I hunt with a bow and gun, and I get out for the muzzleloader season when I can.

What are some traditions you honor during hunting season? Growing up, we’d always get together for opening day and then have smoked venison bologna for Thanksgiving. Now, all of my kids enjoy hunting. For me, farming, nature and hunting brings you a lot closer to God and the circle of life. I don’t go there just to kill a deer. It’s good to go back and calm your mind and get closer to what we are.

How do you t hunting into your daily schedule on the farm? You go when you can. If you can’t go, you can’t go. I can always work later. It has to be a commitment and something you enjoy. We are lucky to have land right here, and my wife helps me milk so I can get out there.

How do you have your meat processed? What is your favorite wild game to eat and how do you prepare it? We love tenderloin. We process all of our own, and my wife does a lot of canning. It’s been a blessing that our second son, Christian, got right into skinning and cleaning the meat when he started hunting. He’s also a taxidermist. We do like to get hot dogs and bologna made. My wife also makes incredible turkey noodle soup. When it’s prepared right, I like any sort of wild game, but venison is my favorite.

Tell us about your most memorable hunt. One of the largest deer I ever shot was a few years back. It was around Thanksgiving, and I was frustrated because I didn't have a lot of time to hunt that year. I decided around 3 p.m. that day to go for a walk, and I ended up shooting my biggest buck I ever shot that night. We had been watching him on the trail cameras, and we had him named Crosby after the Packers football kicker. He was a big 10-pointer with about a 20-inch spread. I came up and told the kids to come help me get this doe out of the woods, and they went nuts when they saw I got Crosby.

Tell us about your farm. We own around 370 acres of which 270 is tillable with pasture. We raise almost all of our own crops of corn and hay and milk around 75 head. We raise close to 100 heifers. I farm with my wife, Amanda, and our kids, Sam, Christian, Olivia, Bo and Jack. Christian does a lot of food plots, and we also plan some of our crops around hunting. We make sure hay is cut in a timely manner so there's regrowth. Christian planted 1 acre of soybeans that’s saved for the deer and leaves some corn standing. He does all that work for all of us.

Richard Christensen Frazee, Minnesota Becker County 44 cows

Richard Christensen Frazee, Minnesota Becker County 44 cows

What hunting seasons do you participate in, and why do you enjoy these particular seasons? Rie and muzzleloading season for deer. I like being out in the woods, seeing things and hearing things. I really enjoy the peace and quiet and the anticipation of something big coming through.

What are some traditions you honor during hunting season? After we hunt, we cut up that night and talk about the hunt and how many mistakes were made. We cut up every day. I hunt with my family and most of us live in different houses on the same farm. I have one brother who comes down from Fargo, North Dakota, and a grandson who comes from Detroit Lakes, Minnesota, and a sister from Frazee who hunts with us. There are about nine of us on 320 acres.

How do you t hunting into your daily schedule on the farm? We milk earlier and do all the chores earlier in the morning. I usually quit around 4 in the afternoon and head home to start evening chores.

How do you have your meat processed? What is your favorite wild game to eat and how do you prepare it? We cut our deer into steaks or hamburger, and we mix pork with it. I really like venison and the sausage rings we make.

Tell us about your most memorable hunt. One year, we had 10 deer hanging in the garage. The biggest deer I ever shot was a 12-point buck with a 28-inch spread. I shot that one 15-20 years ago. I was up in my stand, and it was 75 yards away ghting with another buck, which was just about as big.

Tell us about your farm. I farm with my grandson, Blake, and we milk 44 cows. We both milk in the morning, and he milks at night. We both do chores together as well. We farm 120 acres of cropland, and we plant corn for silage and alfalfa for hay. We milk in a stanchion barn, and our milk goes to Bongards through the Perham Cooperative Creamery Association.

What hunting seasons do you participate in, and why do you enjoy these particular seasons? I bow and gun hunt deer mostly. I enjoy turkey hunting, too, but do not have as much time to get out for it. I enjoy it because it is peaceful out there, and you can do your own thinking. Now that the kids are getting into it, it adds to the fun.

What are some traditions you honor during hunting season? We get up early for chores on opening day so we can get out to the woods early. Family and friends who visit come out to get the barn smell on them before going out. We usually get together at someone’s shop to eat and talk about how it is going. I hunt with my kids until they get their rst deer just because I want to be there for that.

How do you t hunting into your daily schedule on the farm? When we get caught up with crops, we have a little more time to get out. Once the time change happens, we can usually sneak out in the evening before chores. Sometimes we bend the chore schedule a little bit to give us more time in the woods.

How do you have your meat processed? What is your favorite wild game to eat and how do you prepare it? I take the deer to the butcher. In the past, I would get together with a group of guys who all had processing equipment, and we would make everything from sausage to brats and burgers. My favorite wild game to eat is actually sh. Ice shing is my jam if I can get the time to go.

Tell us about your most memorable hunt. My daughter’s rst deer. She was 9 years old and with me for the youth hunt. We made a plan of how it would go if we saw a deer. When the time came, she followed that plan exactly how I told her to. She pulled up, took a deep breath and pulled the trigger. That deer just dropped.

Tell us about your farm. We raise dairy and beef. We fatten out all of our steers as well. Between my parents, Mark and Bridget, and my brothers, Eric and Charlie, we run about 500 acres and 500 head total. Eric has ve kids who are a great help along with my three kids as well.

What hunting seasons do you participate in, and why do you enjoy these particular seasons?

Park Rapids, Minnesota Hubbard County 50 cows

What hunting seasons do you participate in, and why do you enjoy these particular seasons? I hunt mostly deer, but we will hunt grouse once in a while when we have time. It’s something I have always done and have been doing it since I was around 10 years old. It’s a break from farming and an excuse to waste a good day. I enjoy getting together with the guys I hunt with. There is probably eight of us in the group. I’m the oldest hunter but not the oldest person. I like to walk in the woods on our land usually with my grandson when we grouse hunt. We hunt squirrels as well.

What are some traditions you honor during hunting season? We all get together during the day some time, and they usually stop over for coffee. They know what time breakfast is on and when there is coffee. My wife, Diane, usually feeds them pie, cookies and mufns. They usually stop over after the morning hunts. I hunt with two guys from Michigan. One has been hunting with me for 40 years. He worked with my cousin in the mines and started hunting then, and then, his brother started coming along as well.

How do you t hunting into your daily schedule on the farm? I usually don’t stand in the morning. This year I went out with my grand-

Jeremy Arceneau Elrosa, Minnesotadaughter at 7 a.m. She came up at 7:40 a.m., and I stayed out. Then, I saw a couple deer in the woods and shot one of them this year. At night, I might feed a little earlier and then go out and sit. I usually hunt during the days and late afternoons depending on what is going on at the farm.

How do you have your meat processed? What is your favorite wild game to eat and how do you prepare it? We cut the meat up ourselves and cut it up at my son’s shop. We will can all our trim meat. My son makes sausage, summer sausage, hot dogs and brats. I like antelope. My cousin shot several of them, and he brought some meat back. We fried some fresh steaks and chops; that was really good. It is kind of like eating lamb. It’s tender, juicy and has a ne texture.

Tell us about your most memorable hunt. One time, there was about nine of us that were going to make a drive. We were in the eld, and a doe and pair of fawns came out of the woods. We started shooting, and they ran in circles and then went back into the woods. There were 50-60 rounds shot, and nobody got anything. Another one was when we were going in on a drive and were walking through some balsam trees on a trail. There was a doe and a couple fawns, and it looked like a Christmas card. I shot the doe, and she fell. Then, we hollered to everybody else that we were full and done for the year.

Tell us about your farm. I farm here with my brother, Dean, and we milk 50 cows in a tiestall barn. We also farm 300 acres, and we plant corn, oat and alfalfa. I’ve been milking since I was around 12 years old and am 61 years old now. We ship our milk to Land O’Lakes, but it goes to Bongards in Perham, Minnesota.

Stearns

What hunting seasons do you participate in, and why do you enjoy these particular seasons? I just do the shotgun season for deer. I like the peace and quiet. Plus, you don’t have to worry about anything because the fall eldwork is done so, I am not as busy. I also do waterfowl for ducks and geese a couple times a year. I turkey hunt in the spring as well.

What are some traditions you honor during hunting season? I always go deer hunting with my brothers, Josh, Brent and Cole. We have a group text and gure out where we will all sit. If we get a deer, we cut it up ourselves and throw it in the freezer. We take it in later in the winter to a local meat shop. Our stands are usually a quarter to one-half mile apart. We usually work together to clean each deer. My cousin and brothers hunt geese with me as well. Usually, we do morning hunts for waterfowl, and after chores, we go turkey hunting. I enjoy turkey hunting in the spring. We usually breast them out and then smoke them.

How do you t hunting into your daily schedule on the farm? I usually milk early so I don’t have to adjust my schedule too much. I

am at the farm at 3:30 a.m. My dad, Fred, does the evening chores for me. When he goes mule deer hunting in Montana with my brothers, I stay back and do all the chores. I try to get out about four days during the shotgun season. I plan to go out the rst Saturday and Sunday, do my work during the week and get back out for the second Saturday and Sunday.

How do you have your meat processed? What is your favorite wild game to eat and how do you prepare it? We cut up our deer ourselves. Last year, we made hotdogs, pepper and honey barbecue sticks, and sausage out of the deer. My favorite to eat is the sticks. Each year, we mix pork in as well. My brothers made turkey burgers out of some of their turkeys, and those were really good.

Tell us about your most memorable hunt. When we were younger, we always drove or did pushes, and the adrenaline rush of what is going to come is really exciting. I have been 10 yards away when a deer ran by. One year, when we were doing a drive, I stepped on a big tom wild turkey. It was so close I had scratches on my cheek from the feathers when it ew away.

Tell us about your farm. I farm with my dad, Fred. We milk 44 cows in a tiestall barn. We farm 500 acres of land. We plant corn, soybean, oat and alfalfa. We ship our milk to Bongards.

Dave and Hayden Kyle Kylecrest Holsteins and Jerseys Elkhorn, Wisconsin 150 cows total; 130 milking

Dave and Hayden Kyle Kylecrest Holsteins and Jerseys Elkhorn, Wisconsin 150 cows total; 130 milking

Describe your facilities and list your breeding management team. Cows are housed in a sand-bedded freestall barn. Half of it is sized for Holsteins, and the other half is sized for Jerseys. Dave is in charge of breeding decisions for the Holsteins while Hayden oversees breeding decisions for the Jerseys. Cows are milked twice a day in a double-6 parallel parlor. Dry cows are housed in two barns – one for faroff cows and one for close-up cows that includes a calving area. Both dry cow barns feature a row of free stalls, a bedding pack and access to pasture. Calves are housed in the old dairy barn in individual pens. They leave the farm at 3 months to be custom raised and return as springing heifers. We used to raise all of our heifers when we just had Holsteins, but we never had enough of our own feed. Our breeding management team includes the two of us and our veterinarian, Dr. Dave Chapman, from Stateline Veterinary Services. Dave is a really good t for us. We also consult with friends in the industry on their thoughts about certain bulls and what certain farms are using instead of just looking at sire proofs. I’ll also ask the appraiser or classier what bulls I should stay away from or what bulls he

likes the 2-year-olds from. But on the ipside, those cows might not milk. We have a big consulting team and get a lot of input. We do feel like every mating is pretty important. It’s an investment both in that offspring and how it will affect future matings.

What is your current pregnancy rate? It is 26%. It has been as high as 37% and as low as 19% in the last year for the whole herd. Jerseys on average run 4% higher than Holsteins. We house Holsteins for a few people – show cows – and these cows are not bred back as quickly. They are either kept open longer for showing purposes or have difculty in getting bred back. These cows can skew our numbers lower, and we struggled a lot with that this past summer.

What is your reproduction program? Do you use a synchronization program? How do you get animals pregnant? We do not use a synchronization program. We work with our vet and do a herd check every two weeks. We use Lutalyse on any cows over 65 days in milk who have not yet shown a heat. We’ll breed off the Lutalyse shot only if we see them in heat. We do most of the milking and know our cows well. If a cow comes in the parlor rst instead of last or looks at us funny, we know something’s up. Therefore, we might not breed off a standing visual heat and use other visual indicators instead.

In our last herd check, nine cows were checked, and seven were pregnant. That’s pretty standard. We have good luck getting cows pregnant and nd that the open ones are the kind that are always open. Our average days to rst service is 80 days, and average days to pregnancy is 122 days. Jerseys are so inquisitive and help with heat detection. They’re good at picking up cows in heat; whereas, we have Holsteins that never show heat.

Describe your breeding philosophy Dave: We try to breed for balanced cows, but our breeding philosophies are different. I want long-lasting, troublefree, healthy cows, but I never used to look at that until Hayden came back home. I always wanted super fancy show cows. I almost bred too much for extreme type, and in the long run, it probably hurt me some. You learn more from making mistakes. I had some great cows that didn’t live as long as they should. They were too big and did not breed back as easy. I wanted to get more milk too. It’s hard to nd a bull we like that’s polled. If we found one, we would use him a lot. But we’re not going to give up what we’re looking for in a bull in exchange for a polled animal.

Hayden: My breeding philosophy changed since rst getting into Jerseys. When I came home from college, I leaned more toward my dad’s philosophy of breeding for typier cows. I didn’t look at components or milk that much. I bred for very high udders and very good type as I gured you can feed for milk. Cows with a lot of type can also be longer lasting. Our Jerseys are larger than a lot of other Jerseys. Our breeding philosophy was always to breed for the bigger-framed cow. We bought our rst 20 to 50 Jerseys through the eyes of a Holstein breeder. We wanted them bigger and wider. Now, we’re going for a more average-sized cow. I was up to 50 Jerseys when I noticed my heifers weren’t getting pregnant. If an animal isn’t bred, we look at who the sire and dam are. We started paying attention

to daughter pregnancy rate, which was new at that time when we noticed heifers out of the same bull taking four or ve times to get pregnant. Now I look for bulls with a higher DPR. If an animal is hard to breed as a heifer, then she’s going to be like that as a cow. Cows that calve in more often and easier are the goal. I probably don’t put as much emphasis on type as my dad does. I try to use a handful of good bulls. We’ll go back and use a bull if we see success with him. We’ll use a bull a bunch and then stop and wait to see his daughters come up. If he produces a really good, consistent group of daughters, we’ll use him again.

What guidelines do you follow to reach the goals for your breeding program? Dave: We genomic test, which is probably as good of a report card as you can get. Of course environment and management inuence whether an animal is going to achieve her potential or not. Classifying is the other guideline I follow. It’s an opportunity to get an outside opinion on if we’re breeding the right kind. DHI testing is also a really good tool. You can nd reproduction numbers quick and know if you’re going in the right direction. When you have milking daughters out of certain bulls, you know if those sires are good or not. We also follow cow families.

Hayden: I was big into genomics in 2017 but have since backed off a little. I don’t care if it’s the best bull in the breed. If I can’t get cows pregnant, what good is that to me? I try to use all the tools on the table. I don’t lean just on proven bulls, production records or genomics. Instead, I take it all into consideration. Some cows are not the highest milkers, but they look so nice and are healthy and trouble-free. Health traits are so under appreciated. You might not get as much milk during the rst and second lactations, but I’d rather have a cow around three more lactations and get more daughters out of her. I try to

using anything but Udder Comfort. It works the best!”

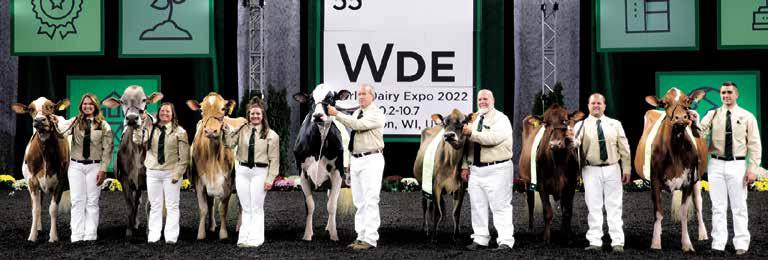

Tim ‘Cooner’ Coon, Copake, NY. He is the 2022 recipient of the prestigious AC ‘Whitie’ Thomson Memorial Award.

“We use it on fresh cows and show cows, any swelling. We wouldn’t use it if it didn’t work. Steve Vail, herdsman, EdgeView Elite Dairy II, Copake, NY, owned by Ken Main and Kenny Joe Manion. Steve and Cooner work with great cows like 2-time

“We use a lot of Udder Comfort. We lay it on the fresh cows after every milking for a week after calving.”

Brandon and Kim Grewe, Cumberland, WI. Their homebred Valley Gem Atlas Malt is now 3-time WDE Grand Champion Guernsey (2019, 2021, 2022).

OtherselectedcommentsatWorldDairyExpo: “You bet we use Udder Comfort!”

“Thank you for a product that works!”

“The better the swelling comes out, the better they look, and milk!”

use the highest genomic bulls out there, but I don’t want to give up what my dad and I have built just for a number.

What are the top traits you look for in breeding your dairy herd and how has this changed since you started farming? Hayden: I like cheese merit with an emphasis on type, components and health. Within those traits, I specically look at combined fat and protein, somatic cell count and udder. I place less emphasis on DPR now. I am 30% higher than the breed average for DPR at this point. Your breeding philosophy should change or adapt as your herd adapts. I can get away with not doing shots because I’m a big believer in good-settling bulls that match my cow. I don’t try to breed for super big cows. We are also big into udder composite.

Dave: I am focused on A2 genetics, and probably 85% of all our heifers (Holstein and Jersey) are A2. I don’t currently have a market for A2 milk, but I want to be in the position for it if the opportunity arises. You have to have your eyes down the road a bit. That’s why A2 is part of our breeding selection. I’m big into butterfat and concentrate on percentage fat, not pounds. I like cows with big butterfat records. I also look at health traits a lot now. My type traits are no longer too extreme. I want fancy, balanced cows, but I shoot for less extreme type. I had beautiful cows from the bull Atwood, but I couldn’t get his daughters pregnant because he had a negative 4 DPR. I’m a visual guy who likes to look at the linear on a bull. We treat our cows like individuals. I don’t want to make a problem worse.

What are certain traits you try to avoid? We avoid using bulls with a negative DPR and high somatic cell count. We also stay away from bulls

that are not positive for percentage fat and protein. We do not use bulls with negative components. We also will not use a bad-uddered bull, a low foot angle bull or a high-type bull with bad production numbers.

Describe the ideal cow for your herd. Our ideal cow is the invisible cow – one that is problem-free and low maintenance. She is a cow we can be proud of and enjoy seeing in the barn. You don’t have to think about her all the time because she does her job, comes into natural heat and breeds right back. You have to breed for type too. We want cows that are scored Very Good or Excellent. We have a whole herd of cows that we’re proud of, and people respect the job we do. We have consistency, and it’s hard to nd a bad cow in our herd. In breeding the ideal Jersey, we shoot for 90 to 100 pounds combined fat and protein. We want high components. It’s better to

Enogen ® corn for feed can help deliver improved feed efficiency to help lower feed costs.

according to recent feeding trials at leading universities

ship less water. We also feel that higher component cows are healthier than big milk cows.

What role does genetics have in reaching the goals of your farm? Genetics are pretty important to us. We use genomics, real production and conrmation in helping reach our goals. If we see a nice-looking heifer, we’ll place bets on who the sire is. We’re able to enjoy genetics and have fun with it. It’s almost like a contest. If you shoot for numbers, it’s not as much fun. The milking part is secondary. We both enjoy the genetics of the dairy farm more than anything. Figuring out how we can both breed the best cow that we both will like is a fun challenge.

What percentage of your herd is bred to sexed, conventional and beef semen? Sexed is 30%, conventional 10%, beef 50% and embryos 10%. Our top cows get sexed semen, and the bottom 50% are bred to beef. A select few problem breeders get conventional semen. Hayden: I don’t want Jersey bull calves. I also don’t want a daughter out of a hard breeder. Even my best cows are only bred twice to sexed semen, and after that, I’m switching over to beef semen.

What is your conception rate? How does this differ with different types of semen? We don’t have conception numbers for the individual types of semen. Overall, our Holsteins average 2.1 services per conception, and our Jerseys average 1.8 services per conception. We try to use high-conception bulls while also thinking about calf livability.

What is the greatest lesson you have learned through your breeding program? Dave: I am a big believer in learning from mistakes and admitting if I am wrong. Perhaps we didn’t do enough research on a bull. You always have to evolve and change, be willing to admit you made a mistake and be willing to change. I like to go to shows and see the daughters of different bulls. That’s a good learning opportunity.

Hayden: It’s always a gamble with genetics, but I haven’t gone back on anything. You can’t focus on one thing too much when breeding cows. Even if you think it’s going to be a perfect cross, there’s always that chance it won’t. That’s how genetics are. I don’t get as anxious about bull selection as I used to. You have to look at the big picture and enjoy the victories. Don’t get too

tied up on specic numbers and benchmarks. Stick with your gut. Nothing’s guaranteed.

What is the age of your heifers at rst service? Our heifers are tail chalked every day. They are put in the breeding program at 12 months of age, and we hope to have them bred by 14 months. However, our custom raiser bases it more off size than actual age.

How does your heifer inventory affect your breeding program? You can’t keep all your heifers, so if we’re going to raise a heifer, she has to be a good one. If we’re low on replacements, we can easily go buy a cow. We need about 25 heifers a year of each breed and are raising about 35 of each breed for a total of 70 heifers. Our cull rate in the herd is 20%, so we do have a cushion with the number of replacements we are raising. We try not to calve our heifers from Christmas to the end of February because it is harder on the calves and the udders. We breed 100% of our heifers to conventional semen. For the Jerseys, we might switch to top genomics getting sexed semen and the rest getting beef. We’re going to breed fewer cows to sexed semen in the future and breed more heifers to sexed instead.

Tell us about your farm. We have shifted from Holsteins to Jerseys in recent years, and our herd is now about 75% Jersey and 25% Holstein. Hayden went to the University of WisconsinMadison Farm and Industry Short Course with plans of returning to the farm and milking Holsteins like his dad. A friend of Hayden’s milked Jerseys, and as Hayden learned they require less manure storage, have higher feed efciency, higher components and higher pregnancy rates, he decided to go with Jerseys instead. We started with two and bought adjustable free stalls from a farm that was selling out and continued to expand the portion of the Jersey herd from there. We also own a coffee shop and may consider going down the route of ag tourism in the future. Our coffee shop customers love when they hear we have a farm. We have hosted our county’s dairy breakfast three times and are involved in the community. We also do a lot of tours. We don’t want to grow bigger but instead get better and keep the labor inhouse. We don’t want to have a lot of employees. It’s not just about numbers to us, and the cows are not just cows to us. The cows are part of our family. It’s fun seeing them grow up.

JD S680 2012, 2WD, Duals, 2624 hrs., 1790 Sep. hrs., #548165 ......... $147,500

JD S670 2013, PRWD, Duals, 2700 hrs., 1700 Sep. hrs., #550092....... $152,000

JD S660 2014, 2WD, Duals, 1976 hrs., 1408 Sep. hrs., #547013 ......... $175,000

JD S660 2012, 2WD, Duals, 1878 hrs., 900 Sep. hrs., #539380 ........... $185,000

JD S660 2014, PRWD, Duals, 1555 hrs., 1181 Sep. hrs., #532082....... $189,500

JD S680 2015, PRWD, Singles, 2441 hrs., 1762 Sep. hrs., #190078 .... $191,000

JD S680 2014, PRWD, Duals, 2248 hrs., 1668 Sep. hrs., #531966....... $195,000

Case IH 8240 2017, 2WD, Duals, 1733 hrs., 1318 Sep. hrs., #191428 $212,000

JD S680 2017, PRWD, Duals, 1507 hrs., 1053 Sep. hrs., #273646....... $249,900

JD S670 2015, PRWD, Duals, 1712 hrs., 905 Sep. hrs., #550309......... $259,000

JD S770 2018, PRWD, Duals, 1999 hrs., 1458 Sep. hrs., #549678....... $259,900

JD S780 2018, PRWD, Singles, 2489 hrs., 1686 Sep. hrs., #549036 .... $274,900

JD S690 2017, PRWD, Duals, 1429 hrs., 1187 Sep. hrs., #549457....... $294,000

JD S780 2018, 2WD, Duals, 1123 hrs., 700 Sep. hrs., #531873 ........... $319,900

JD S780 2018, PRWD, Duals, 1618 hrs., 1131 Sep. hrs., #276170....... $329,900

JD S790 2018, 2WD, Duals, 1264 hrs., 915 Sep. hrs., #273973 ........... $334,900

JD S790 2018, PRWD, Duals, 1564 hrs., 1177 Sep. hrs., #549847....... $339,900

JD S780 2019, PRWD, Duals, 1559 hrs., 1131 Sep. hrs., #549680....... $339,900

JD S790 2018, PRWD, Duals, 1488 hrs., 1092 Sep. hrs., #549845....... $349,900

JD S790 2018, PRWD, Duals, 1695 hrs., 1214 Sep. hrs., #543163....... $352,900

JD S790 2019, PRWD, Duals, 1390 hrs., 1110 Sep. hrs., #532032....... $359,000

JD S790 2018, PRWD, Singles, 1314 hrs., 949 Sep. hrs., #549846 ...... $359,900

JD S780 2019, PRWD, Duals, 1178 hrs., 920 Sep. hrs., #548046......... $360,000

JD S780 2019, PRWD, Floaters, 1278 hrs., 889 Sep. hrs., #275242 ..... $369,900

JD S780 2018, PRWD, Duals, 1060 hrs., 773 Sep. hrs., #523885......... $379,000

JD S780 2019, PRWD, Floaters, 1559 hrs., 1058 Sep. hrs., #549682 ... $379,900

JD S780 2019, PRWD, Floaters, 1161 hrs., 830 Sep. hrs., #549684 ..... $384,900

JD S780 2020, PRWD, Duals, 1267 hrs., #531610 .............................. $385,000

JD S780 2019, PRWD, Duals, 876 hrs., 725 Sep. hrs., #542133........... $389,900

JD S780 2020, PRWD, Duals, 1123 hrs., 800 Sep. hrs., #191082......... $390,000

JD S790 2019, PRWD, Duals, 1280 hrs., 709 Sep. hrs., #550196......... $396,500

JD S780 2020, PRWD, Duals, 1440 hrs., 990 Sep. hrs., #550187......... $407,500

JD S790 2020, PRWD, Duals, 1151 hrs., 865 Sep. hrs., #275917......... $429,900

JD S780 2020, PRWD, Singles, 833 hrs., 640 Sep. hrs., #532517 ........ $439,000

JD S780 2020, PRWD, Duals, 880 hrs., 634 Sep. hrs., #531647 .......... $439,900 JD S790 2020, PRWD, Duals, 1100 hrs., 685 Sep. hrs., #274274......... $449,900 JD S780 2020, PRWD, Duals, 1021 hrs., 596 Sep. hrs., #188309......... $454,900

S780 2020, PRWD, Duals, 951 hrs., 539 Sep. hrs., #188459........... $454,900

S780 2020, PRWD, Duals, 1031 hrs., 626 Sep. hrs., #188458......... $454,900

IH 8250 2021, 2WD, Tracks, 400 hrs., 400 Sep. hrs., #550253

2021, PRWD, Singles, 682 hrs., 345 Sep. hrs., #190866

IOWA

Prairie Land Ag Supply Inc. Rock Valley, IA 712-476-9290

United Dairy Systems, Inc. West Union, IA 563-422-5355

WISCONSIN

Advanced Dairy Spring Valley, WI 715-772-3201

Ederer Dairy Supply Plain, WI 608-546-3713

DeLaval Dairy Service Kaukauna, WI 866-335-2825

By Tiffany Klaphake tiffany.k@dairystar.com

By Tiffany Klaphake tiffany.k@dairystar.com

ATWATER, Minn. – For many years now, sisters Kim and Katie Olson have been leasing their animals to 4-H’ers of Meeker, Kandiyohi, Stearns and Chippewa counties. The sisters take pride, as 4-H alums, in helping youth gain experience in showing and learning more about the dairy industry.

“We’ve done a lot of leasing to 4-H kids over the years,” Kim said.

Kim and Katie, of Oat Hill Dairy near Atwater, are providing a Jersey calf named Oat Hill Voucher Opal for Dairy Star’s Great Christmas Giveaway for youth in the 17 and under category.

Oat Hill Voucher Opal comes from a long line of show cattle.

“We chose this calf because we have a lot of 4-H kids lease from this cow family,” Kim said.

Today, the farm is owned by Kim Olson and Gordon Larson. The farm has one full-time employee and four part-time employees. Kim and her husband, Ken Housman, live on the dairy. Katie lives a few miles away.

Katie is in charge of the cows 60 days prior to calving and the calves until they are 6 months. Once the calves are 6 months, they are moved to the heifer shed and are then under Kim’s care. Kim breeds all the animals. Once the heifers are conrmed pregnant, they are moved to Larson’s farm site until 60 days before they calve, which is when they return to being cared for by Katie.

Joe’s Refrigeration Inc. Withee, WI 715-229-2321

Mlsna Dairy Supply Inc. Cashton, WI 608-654-5106

Professional Dairy Services Arlington, WI 608-635-0267

Redeker Dairy Equipment Brandon, WI 920-346-5579

The Scharine Group Inc. Whitewater, WI 800 472-2880 Mt Horeb, WI 800-872-3470

MINNESOTA & SOUTH

DAKOTA

Farm Systems Melrose, MN 320-256-3276 Brookings, SD 800-636-5581

Advanced Dairy Mora, MN 320-679-1029 Pierz, MN 320-468-2494 St. Charles, MN 507-932-4288 Wadena, MN 218-632-5416

The 120-cow herd is milked with an AMS Galaxy robotic milking system, which was installed in March.

“We are still working on getting everything trained, including us,” Kim said.

Oat Hill Dairy uses activity monitors for heat detection. They also have cameras in all the calving and heifer barns that are connected to an app, which they each have installed on their phones.

SD

“Kim

All the animals at Oat Hill Dairy are registered. When making mating decisions, Kim focuses on type, fat and protein.

Oat Hill Dairy is home to Jerseys, Guernseys, Red and White Holsteins and Holsteins as well as Milking Shorthorns.

Together, they show Jerseys, Guernseys and some Red and White Holsteins. Kim owns all the Guernseys at Oat Hill Dairy, and together, Kim and Katie own the Jerseys.

Kim said she is partial to the Guernsey breed because that is what she grew up showing in 4-H. Their parents had switched to Holsteins eight years later by the time Katie was active in 4-H.

“I purchased a Guernsey at World Dairy Expo in 2004, and now, almost all of our Guernseys all trace back to that one,” Kim said.

The sisters have exhibited at World Dairy Expo. In 2015, they sold a Jersey spring yearling that won junior champion at World Dairy Expo and then was later named supreme junior champion at The Royal Agriculture Winter Fair in

Canada that same year.

In addition to the farm, Kim is a full-time veterinarian, and Katie is full-time orist.

The farm site is where Kim and Katie grew up milking and showing cows. Their father sold the cows in 1986.

After the town’s veterinarian passed away, Kim decided she should study to become a veterinarian.

“Must have been a good choice because I am still here,” Kim said.

Katie started working at the oral shop in town while

in high school. “I got into the oral industry because of FFA,” Katie said.

Katie said she enjoyed her time in the oral shop so much she purchased the business after earning her degree in horticulture.

In the fall of 1997, the sisters started construction of an ofce building in Atwater, they moved in spring of 1998; half the building is for Katie’s oral business, and the other half is for Kim’s practice.

Then, in 2001, as a partnership between Kim, Mark Adams, and Russ and Heather Thyen, Oat Hill Dairy was founded.

“The whole partnership started because we like cows and wanted to show,” Kim said. “And, we hoped to sell good cows.”

On Oct. 13, 2001, for the rst time since their youth, cows were milked once again at the sisters’ home farm. The original barn is now the calving barn, and the freestall barn is now the dry cow barn. They built a double-4 herringbone parlor and freestall barn for the milk cows. In 2006, a new addition was added to house more cows.

The Olson sisters said they enjoyed showing and seeing young people get into showing by leasing out their animals. Katie said those feelings inspired them to donate to this year’s giveaway.

“We thought it would be a great idea to give a young person the opportunity to show or have a Jersey calf,” Katie said.

ALLAMAKEE COUNTY

• K & R Feed and Grain

Dorchester

• 563-568-4513

BREMER COUNTY

• Via eld

Sumner • 563-578-3214

DELAWARE COUNTY

• Del-Clay Farm Equipment

Edgewood • 563-928-6445

• Edgewood Feed Mill Edgewood • 563-928-6405

DUBUQUE COUNTY

• Brunkan Equipment

Worthington • 563-855-2434

• CJ Beeps Equipment Farley • 563-744-5010

• Eastern Iowa Dairy Epworth • 563-876-3087

• Helle Farm Equipment Dyersville • 563-875-7154

• New Vienna Ag Automation New Vienna • 563-921-2896

• Roeder Implement

Dubuque • 563-557-1184

• Scherrmann’s Implement Dyersville • 563-875-2426

• Skip Breitbach Feeds Balltown • 563-552-2393

• Ungs Shopping Center (IAS) Luxemburg • 563-853-2455

FAYETTE COUNTY

• Via eld

Elgin • 563-426-5566 Maynard • 563-637-2285

FLOYD COUNTY

• Livestock Systems

Charles City • 641-220-5257

HOWARD COUNTY

• Farmers Win Co-op Cresco West • 563-547-3660

SIOUX COUNTY

• Sioux Dairy Equipment, Inc. Rock Valley • 712-476-5608

WINNESHIEK COUNTY

• Brynsaas Sales & Service Decorah • 563-382-4484

• Franzen Sales & Service Fort Atkinson • 563-534-2724

• Lang’s Dairy Service Decorah • 563-382-8722

BECKER COUNTY

• Adkins Equipment Inc. Detroit Lakes • 218-847-3131

BENTON COUNTY

• Farm-Rite Equipment St. Cloud • 844-262-2281

• First National Bank of MilacaGilman Of ce • 320-387-2233

• Gilman Co-op Creamery Gilman • 320-387-2770

• Midwest Machinery Sauk Rapids • 320-259-6222

BROWN COUNTY

• New Ulm Regional Vet Clinic New Ulm • 507-233-2500

CARVER COUNTY

• Bongards’ Cologne • 952-466-5521

• Lano Equipment of Norwood Norwood/Young America 952-467-2181

• Storms Welding Cologne • 952-466-3343

DAKOTA COUNTY

• Midwest Machinery North eld • 507-645-4886

• Werner Implement Vermillion • 651-437-4435

DOUGLAS COUNTY

• Midwest Machinery Alexandria • 320-763-4220

• Nelson Creamery Nelson • 320-762-0115

• Osakis Creamery Assn. 320-859-2146

• Pro Ag Farmers Co-op Gar eld • 320-834-2271

• Farmers Win Co-op

Rushford • 507-864-2161

• First Southeast Bank Harmony • 507-886-6922

• Hammell Equipment Harmony • 507-886-2255 Rushford • 507-864-2845

• Midwest Machinery Grand Meadow • 507-754-1100

GOODHUE COUNTY

• Ag Partners Farm Store

Goodhue • 651-923-4496

• Midwest Livestock Systems, LLC Zumbrota • 507-732-4673

• Midwest Machinery Cannon Falls • 507-263-4238 Wanamingo • 507-824-2256

• Midwest Machinery Elbow Lake • 218-685-4438

• Caledonia Haulers

Caledonia • 507-725-9000

• ESB Bank