DAIRY ST R

Volume 24, No. 19

Volume 24, No. 19

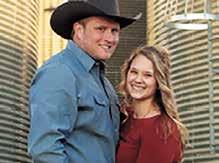

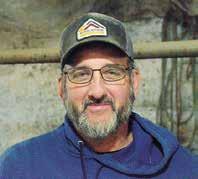

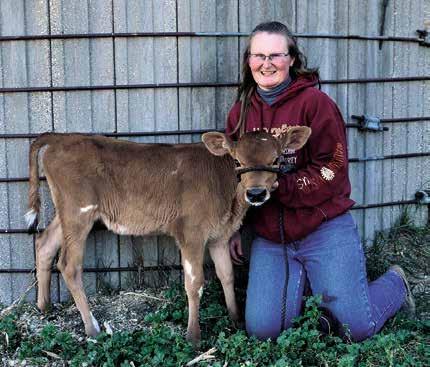

MANDAN, N.D. – Eighteen-year-old Dawson Holle may soon be swapping his chore boots for a suit and tie.

Holle will be sworn in Dec. 2 as a state representative for North Dakota’s District 31, making him the youngest representative in the state’s history. The teen grew up on a dairy farm and is a freshman at the University of Mary in Bismarck.

“I haven’t told too many people at college,” Holle said. “Those I have told don’t really believe me. They have to Google me.”

Holle’s family manages Northern Lights Dairy near Mandan. His grandparents,

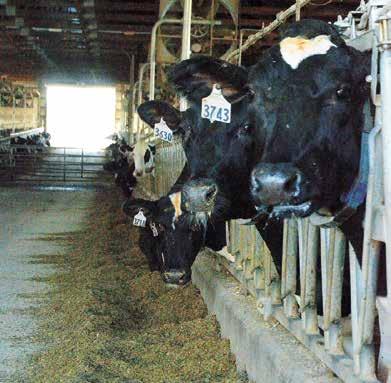

OSAKIS, Minn. – When Dale Niehaus is milking his herd of 100 Holsteins, his attention is split. His focus is on the task at hand but also on the pager on his hip.

Niehaus not only manages his herd in a tiestall barn near Osakis but has also been a volunteer reghter with the Osakis Fire Department for more than two decades.

Niehaus also farms 800 acres. Sometimes, his pager goes off in the middle of eldwork.

“I’ve had to shut off the tractor and go up to the re hall,” Niehaus said. “I have a truck or a four-wheeler nearby so that I can jump in it and get up there.”

Niehaus usually begins morning chores between 4:30 and 5. There are times he is on

Kenton and Bobby Jo, and his parents, Andrew and Jennifer, own the farm.

Holle and his three younger siblings are the fth generation on the farm.

The Holle family milks 800 Holsteins three times a day in a 36-stall rotary parlor. They also raise their calves on-site.

Earlier this year, after the then-senior’s hockey season, Holle decided to run for a seat on the Legislature.

“I didn’t want to do anything in politics growing up,” Holle said. “I wanted to go to college, get a degree, nd a job and maybe come back to the farm; I was undecided about life.”

However, Holle saw what was happening to dairy farms in the state.

“We lose on average one to two dairy farms in North Dakota per year,” Holle said. “I realized we need to change something or there won’t be dairy farms here for the generations to come. I want other families to experience the same things that I grew up with – North Dakota tradi-

tional farm values and knowing the importance of dairy and how dairy farmers contribute to the health of people in North Dakota with their milk and other dairy products.”

The idea of running for ofce began to form.

“There was a two-week period where I was bouncing back and forth with the idea of running,” Holle said. “I had a lot of supporters with my family and friends saying things like, ‘You should do it,’ or, ‘I could really see you making an impact.’”

Holle has always been active on the family farm by milking cows, feeding calves, and helping with eldwork and harvest. Holle balanced farm work while also being a three-sport athlete.

In addition, Holle began what he calls a hobby business in 2020. About once a month, he made and sold gelato made with milk from the dairy.

“I haven’t really done it

November 26, 2022

a re call all night then comes home and walks directly to the barn.

“When we have structure res, we leave at maybe 10:30 at night and don’t get done until

4 or 5 in the morning,” Niehaus said. “We get back to the station, and the guys say to me, ‘Well, I guess it’s time to milk cows.’”

However, Niehaus is quick to give credit to his fellow re-

ghters and said they have busy schedules too.

“There are guys who have other jobs that begin at 5 or 6,” he said. “They don’t get any sleep then either. You have to juggle your family, work and the calls. Your sleep has to come last to make it all work.”

A shortage of recruits 21 years ago led Niehaus to volunteer.

“The small towns were getting smaller, so they didn’t have as many business people right in town to be on the department,” he said.

Niehaus was farming with his dad, Joe, and stepmother, Beth. He has since taken over the farm. In the past, the farm had been considered too far from the station for Niehaus to be a candidate for the department.

The lack of recruits changed that.

“They expanded the response time (to get to the station) to six minutes,” Niehaus

Dairy is in 96% of U.S. households using up 80% of what the United States produces. The rest is exported.

That is where the United States Dairy Export Council comes in.

Krysta Harden is the U.S. Dairy Exports Council president and CEO.

“If you look at exports, there is no way that you can’t be excited about what’s coming,” Harden said. “Somebody is going to meet the demand. I think it should be the U.S.”

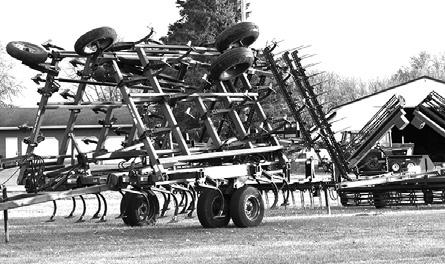

PHOTO SUBMITTED Dawson Holle will be sworn in Dec. 2 to the North Dakota Legislature for House District 31. The 18-year-old grew up on Northern Lights Dairy near Mandan, North Dakota. Turn to HOLLE | Page 7 MARK KLAPHAKE/DAIRY STARwww.dairystar.com

ISSN Print: 2834-619X • Online: 2834-6203

522 Sinclair Lewis Ave.

Sauk Centre, MN 56378

Phone: 320-352-6303

Fax: 320-352-5647

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com 320-352-6303 (ofce) 320-248-3196 (cell) 320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell

• nancy.p@dairystar.com

AgDairy marketing specialist Robin Schmahl expects Class III milk prices to remain steady with little change expected in milk production or consumer demand. “Higher demand probably isn’t going to happen because of the current economic situation, and it will take a while before milk production declines,” Schmahl said. “Dairy producers need to take a hard look at this market and when there are opportunities to protect prices, do some marketing or sign up for (Dairy Margin Coverage); they need to embrace those things.”’

Inc. Chair Marilyn Hershey participated in the United Nations Climate Change Conference in Egypt. “We are proud of U.S. dairy producers’ progress and leadership thus far,” Harden said. “But, we know we can do more.”

USDEC and DMI participated in forums on sustainable dairy production during the COP27 conference.

InsiderKaren Knoblach

• karen.k@star-pub.com Annika Gunderson • annika@star-pub.com

Editorial Staff

Tiffany Klaphake - Assistant Editor 320-352-6303

• tiffany.k@dairystar.com

Maria Bichler - Assistant Editor maria.b@dairystar.com • 320-352-6303

Danielle Nauman - Staff Writer 608-487-1101

• danielle.n@dairystar.com

Stacey Smart - Staff Writer 262-442-6666 • stacey.s@dairystar.com

Abby Wiedmeyer - Staff Writer 608-487-4812

• abby.w@dairystar.com

Grace Jeurissen - Staff Writer 320-352-6303 • grace.j@star-pub.com

Jan Lefebvre - Staff Writer 320-290-5980 • jan.l@star-pub.com

Taylor Jerde - Staff Writer 507-403-1680

• taylor.j@star-pub.com

Consultant

Jerry Jennissen 320-346-2292

Main Ofce: 320-352-6303 Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication Sales Manager - Joyce Frericks 320-352-6303 • joyce@dairystar.com

Mark Klaphake (Western MN) 320-352-6303 (ofce) 320-248-3196 (cell) Laura Seljan (National Advertising, SE MN) 507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com

Jerry Nelson (SW MN, NW Iowa, South Dakota) 605-690-6260 • jerry.n@dairystar.com Mike Schafer (Central, South Central MN) 320-894-7825 • mike.s@dairystar.com

Amanda Hoeer (Eastern Iowa, Southwest Wisconsin) 320-250-2884 • amanda.h@dairystar.com

Megan Stuessel (Western Wisconsin) 608-387-1202 • megan.s@dairystar.com

Kati Kindschuh (Northeast WI and Upper MI) 920-979-5284 • kati.k@dairystar.com Julia Mullenbach (Southeast MN and Northeast IA) 507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell) bob.l@star-pub.com

The deadline for news and advertising in the Dairy Star is 5 p.m. Friday the week before publication.

One year subscription $40.00, outside the U.S. $200.00. Send check along with mailing address to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378.

Our ad takers have no authority to bind this newspaper and only publication of an advertisement shall constitute nal acceptance of the advertiser's order.

Letters and articles of opinion are welcomed. Letters must be signed and include address and phone number. We reserve the right to edit lengthy letters. The views and opinions expressed by Dairy Star columnists and writers are not necessarily those of the Dairy Star / Star Publications LLC.

The Dairy Star is published semi-monthly by Star Publications LLC, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378-1246. Periodicals Postage Paid at Sauk Centre, MN and additional mailing ofces.

POSTMASTER: Send address changes to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378-1246.

During a time of high commodity prices, rising land values and government payments, a percentage of farmers became complacent. Virginia Tech professor emeritus David Kohl made that point during the National Bankers Conference in Omaha, Nebraska. “You’re going to have a certain set of customers that are going to burn through working capital, liquidity and their equity, but you’re going to have another set of customers that will put prots on the table, build liquidity, build equity and they’re going to grow,” Kohl said. In this time of extreme volatility, Kohl said commodity prices could drop quickly. That makes it more important for farmers to know their breakeven costs and manage risk. The geopolitical environment can make changes in an instant. “Whether it’s China, the United States or the Federal Reserve, they’ll ip the switch, and when change happens, it will happen very, very quickly,” he said.

A delegation led by U.S. Dairy Export Council President and CEO Krysta Harden and Dairy Management

For the past two years, President Biden has been in the Oval Ofce and the Democrats had the majority in the House and Senate. Republicans took control of the House in the election. Public policy consultant and lobbyist James Callan said this scenario will inuence the legislative agenda. “I think it will be difcult for the administration, if not impossible, to get anything major done.” If the Republicans win the majority in Congress, the chairmanship of the House Agriculture Committee would shift from current chairman David Scott of Georgia to G.T. Thompson of Pennsylvania. Callan believes Thompson would change the direction of the committee. “His priorities would be on dairy, forestry, nutrition from an oversight perspective and crop insurance,” Callan said. “Mr. Scott has

By Don Wick Columnist

focused on climate, racial equity and Southern commodities so I think there will be a signicant difference in their approach and priorities.” Thompson has already discussed an ambitious timeline for the farm bill, completing the legislation before its expiration at the end of September. Callan leads a public policy rm in Washington, D.C. and represents Midwestern farm groups.

It was a winning strategy for the incumbents across the three-state area. In Minnesota, House Agriculture Committee members Michelle Fischbach, Angie Craig and Brad Finstad were reelected.

Walz wins another term Minnesota Gov. Tim Walz has been reelected. The incumbent beat Republican challenger Scott Jensen with a margin of 52% to 44%. Jensen had the majority of the vote across most of outstate Minnesota, but it was not enough to overcome Walz’s lead in the Twin Cities and metro areas like Duluth, Rochester, Mankato and Moorhead.

A day after the election, Minnesota Gov. Tim Walz sat down with commissioners and state agency heads. Minnesota Agriculture Commissioner Thom Petersen said the administration is hitting the ground running and mapping out the next four years. “It’ll be a little different with a Democratic House and a Democratic Senate but with very close numbers,” Petersen said. “For agriculture, we’ve been able to pass bipartisan bills for the past four years I’ve been commissioner, and we hope to see meaningful investments in agriculture.” Walz was scheduled to be at the AgriGrowth annual meeting to deliver his State of the State of Agriculture address but shared video greetings instead.

There are 68 new legislators coming to St. Paul in January. “One-third

of the legislature is new, and when you add to that the people who won in 2020, which was about 20% new, you’re almost up to 50% that nobody’s actually lobbied, engaged with or met with in person,” said Blois Olson, political analyst. The House committee hearings were done remotely during the coronavirus pandemic. Speaking at the Minnesota Ag and Food Summit, Olson said the Republican brand was damaged in this election. “If you can’t win in the suburbs in Minnesota, you can’t be a statewide majority party,” Olson said.

The new DFL majority elected Kari Dziedzic of Minneapolis as the Senate majority leader. State Sen. Mark Johnson, of East Grand Forks, will serve as the minority leader in the upcoming session. In the House, Melissa Hortman, of Fridley, was reelected as the speaker. The new majority leader is Rep. Jamie Long, of Minneapolis. Rep. Lisa Demuth, of Cold Spring, is the minority leader.

Nikki Deyle has joined the Minnesota AgriGrowth staff as its director of strategic engagement. Nikki and Nathan Deyle own and operate Stone Hill Farms near Browerville, Minnesota. Deyle previously worked for AgriGrowth from 2005-08.

The youth wellness program created by the dairy checkoff and the National Football League is called Fuel Up to Play 60. That answers our last trivia question. For this week’s trivia, what country started the tradition of putting up a Christmas tree? We will have the answer in the next edition of Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network, based in Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two adult sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

Consumers are becoming more aware of how dairy can be used, and marketing, research and awareness of the benets of dairy in a diet is driving more interest in dairy around the world, according to Harden.

“We work on incorporating dairy into cultural favorites as well,” Harden said. “You shouldn’t have to eat American food or diets to enjoy American dairy.”

About 80% of U.S. exports are ingredients and include whey, whey protein concentrate and skim milk powder. These products are commonly used for smoothies, health bars and protein powders.

“Demand is great,” Harden said. “There’s a growing interest, growing awareness in U.S. products among other countries.”

Harden said the biggest challenge as of late is shipping.

During the coronavirus pandemic, many Americans turned to online shopping and therefore often buying foreign products. Harden said there was so much demand for goods coming into the U.S. that it was often cheaper for ships to unload their goods and turn around empty than to wait for U.S. goods to be loaded.

“The inbound, imports, were so great,” she said.

Moving products by rail and truck has also been a roadblock to exporting U.S. dairy products.

The Ocean Shipping Reform Act has eased some of the barriers.

“It is better,” Harden said. “It’s not xed, but it is better right now.”

Ination is also impacting the potential for countries to afford American goods.

“The pandemic really taught us all lessons that we are going to deal with these types of issues in different ways, and we don’t need to be dependent on just one country or one region,” Harden said.

The biggest competitors of the U.S. dairy industry are New Zealand and Europe, Harden said. But, New Zealand and countries in Europe are land locked, giving the U.S. the advantage because of its size and space.

“We know what we’re doing here, and we know how to do it very well,” Harden said.

Harden said the biggest importer of U.S. dairy is Mexico. Harden said the two countries have a good working relationship.

Other countries include China, Southeast Asia, Japan and Korea.

Harden said the U.S. is seeing consistent growth of imports to South America, the Middle East and northern Africa.

The USDEC opened an ofce in Singapore in 2020 and serves the 16 countries which make up Southeast Asia. The center includes a test kitchen to help nd new ways to use dairy products in the area’s cuisine.

China, because of its population, has been a key market for U.S. dairy.

Harden said the Chinese government has recommended consumers use more dairy in their diets. The USDEC has noticed an increase in products such as butter and whole milk powder.

“We work with local cultures to make sure it is incorporated into diets that just need fortifying,” Harden said.

South America, especially Chile, has been steadily increasing their imports of U.S. dairy.

“Our strategy has been to be as diversied as possible,” Harden said.

One product seeing an increase in demand is cheese. About 3,000 varieties of cheese are exported, and artisan cheeses are popular. Chile has the highest gross domestic product in South America; therefore, consumers have disposable income and appreciate U.S. cheese, Harden said.

“The Middle East is also very interested in our cheese,” Harden said. “That’s all they want to talk about.”

When the USDEC was created 27 years ago, the U.S. was exporting 2%-4% of what the country produced. Today, the U.S. exports 18% of its’ total production.

Looking ahead, USDEC expects the focus on health and wellness to continue. With dairy products being nutrient dense, the USDEC sees this as an opportunity to promote American dairy.

Harden said pizza is gaining in popularity across the globe bringing with it a demand for cheese. And, USDEC is working to nd ways to encourage other countries to incorporate dairy into their mainstay foods.

“Nobody works harder in the world than the dairy farmer,” Harden said. “The future is really bright for U.S. dairy. I would say to dairy farmers that the future is really for yours to drive. The world wants our products and needs our products. We can help nourish a very hungry, food insecure world.”

since I was running (for ofce), but it actually had gotten a lot of traction,” Holle said. “People are kind of mad at me because I haven’t made it for a while. Hopefully they will forgive me because of the campaign.”

After weighing whether or not to run for ofce, running won.

“I had the overwhelming feeling that if I didn’t run, I would regret it,” Holle said. “The worst thing that could happen is you lose, but you still get your name out there for future races, so I decided to give it a shot.”

However, Holle needed to get on the ballot rst, which required 200 signatures on a petition. It was already April, and the primary was set for June 14.

“It was actually not as hard as I thought,” Holle said. “People didn’t really know who their representatives were; we had redistricting at the time. People liked my agriculture background and the ideas I wanted to bring to the Legislature, and they said, ‘I’ll back you.’”

Those ideas are many, and Holle is straightforward when stating them. One focus he has is on protecting the dairy industry.

“I want to bring forth a bill that says that milk can only be called milk if it comes from (dairy animals),” he said. “Almond milk and other (non-dairy) milk needs to rebrand itself or have special labeling. A lot of people think they are drinking milk, but they are not getting the same nutritional values of milk.”

Another concern Holle has is for the people of the Standing Rock Sioux Reservation, which is located in District 31. Holle wants to make sure its citizens have equitable access to voting.

“We only have one voting site on that whole reservation, and the reservation spans upward of a hundred miles,” Holle said. “I want to put more voting sites there so that they are more accessible for people.”

Holle said he would also like to bring a bill forward to require students to recite

the Pledge of Allegiance while at school.

“There was a controversy in Fargo where the school board got rid of the Pledge of Allegiance,” Holle said. “We need to protect the pledge for veterans, so we remember who fought for us and our freedom that we have today.”

Protecting North Dakota’s export industries of coal and oil as well as supporting the Second Amendment and pro-life initiatives are also important to Holle.

His goals and ideas have resonated

with people in his area. Of the three Republicans running to become candidates for two House seats in District 31, Holle and incumbent Karen Rohr won.

“I honestly must say that I was shocked at the number of people who said they would support me, and they actually did,” Holle said.

Although it was a victory for Holle, it brought on a few concerns. His win ousted another incumbent Republican, Jim Schmidt, who was a colleague and friend

of Rohr. Also, Holle said people in the district thought Holle should wait until a retirement created an open seat.

Holle wondered what his overall reception might be.

The answer came when Rohr offered to join forces with Holle to defeat Democratic candidate Mike Faith.

“Karen and I worked together,” Holle said. “We decided we wanted to show a unied base, so we went door knocking together in every city in our district.”

Their teamwork paid off.

“People liked the approach we were showing, from someone young with an agriculture background and from a person who has experience in the Legislature and could guide the younger legislator.”

Friends and family held a watch party the night of the election at Seven Seas Bar and Grill in Mandan.

“It was probably about 11:30 at night when we realized we (he and Rohr) won,” Holle said.

Holle expected to feel exhilarated, but he felt something else.

“It was kind of an overwhelming feeling because you put in all that work for the past ve months,” Holle said. “It paid off, and you get to see that people want you in, but you realize that now the real work starts from here.”

He is not sure whether or not politics will be a mainstay in his future. Holle has chosen to minor in political science; his major is business management. Whatever his future, Holle said that growing up on a dairy farm helped prepare him for this position as a representative.

“A special quality that agriculture gives a person is grit,” Holle said. “Time is almost irrelevant on a farm because your work day is mostly when the sun comes up to when the sun goes down. I will put in the long hours and the grit to make sure that my bills get across the nish line or my voice or my constituents’ voices are heard because I have the determination to get things done.”

He

“What kid doesn’t want to be on the re department, right?” Niehaus said.

When Niehaus joined in June 2011, he was scheduled to begin his training that fall. Then on Sept. 11, the world changed. Within one morning at the World Trade Center, more than 300 reghters died in service along with other safety and rescue personnel. The images were everywhere in the media for months afterward.

“I thought, ‘What did I get myself into?’” Niehaus said. “It really made me think, do I really want to be here? But, I stuck with it, and it’s been great.”

Training changed in the wake of 9/11. For instance, a system for identifying reghters was put in place in case they were injured beyond recognition. Fireghters now have two metal tags with their identication number on them. If the re is big enough where more than one unit is called in, reghters pin one tag to their clothing and give one tag to the lead reghter before going into a burning building.

“That’s for accountability,” Niehaus said. “It all stems back to 9/11. The departments all had numbers but not the individual re ghters.”

Niehaus’ has No. 1139.

“The only other way (to identify a burned reghter) would be through DNA testing,” he said.

Niehaus went through 160 hours of medical and rst responder training along with two nights per week for four months of training in reghting and hazmat. Because Niehaus was the only one joining the Osakis department at the time, he drove to Parkers Prairie for training.

“I tried to get the chores done before I went,” he said.

Niehaus said he appreciates the support he has had all along to make his service possible.

“I’ve always had special people in place when I receive calls,” he said. “I’ve been blessed that way.”

In the beginning, his dad, sister and stepmother would help cover for him.

“When I was on the farm working with my dad, he understood,” Niehaus said. “He didn’t always like it when I left in the middle of chores or when in the eld, but he respected it. Other family and friends stepped in too.”

Today, he and his wife, Rachel, have six children. Niehaus also has an adult daughter who lives away from home. His oldest at home, Clayton and Garrett, are among those who step in for him now.

Like Niehaus did as a child, his children look up to reghters.

“It’s not just (toy) John Deere tractors at home,” Niehaus said. “It’s yellow retrucks. You’ve gotta have yellow. Sometimes we have to go online to nd them.”

The Osakis department has yellow trucks.

“They’re starting to change colors,” Niehaus said. “The red ones are used now for parade trucks. They’re nding out that yellow is a stimulant to the eye as a caution to slow down.”

Although Niehaus said he is glad he joined more than two decades ago, he and

his fellow reghters have to deal with the aftermath of difcult calls.

“That’s part of it when you live in a small town,” Niehaus said. “It can be people you know, so that can make things even tougher.”

As a farmer, barn res also feel especially personal.

“You go to a barn re and see a lot of dead cows,” Niehaus said. “It’s gut wrenching to see. The barn is engulfed in ames, and there is not much you can do. You feel the loss, but you have to do what you can do to put the re out.”

Niehaus said he became better equipped to leave calls at the department and focus on family and work again once he was home.

“You learn,” he said. “There are people who can help you if you can’t deal with it. For the most part, the guys on the department are the ones who help you get through it.”

Everyone on the team steps up to do whatever is needed and is trained in all the jobs of reghting.

“Generally, I’m one of the guys that goes into the re,” Niehaus said. “I’d rather do that than be a pump operator. It’s very stressful, but I’m more of an adrenaline junky, I guess.”

He has great respect for his fellow reghters.

“They really matter,” Niehaus said. “You all go in with the same mindset. Let’s get this re out or let’s get this accident taken care of, and we do what we have to do to get back (to the station) safely and back to our families.”

He also sees some similarities between dairy farming and reghting.

“It’s a lot of the same things,” Niehaus said. “If something goes wrong, you drop to a plan B or maybe even a plan C. Things go bad, things break, you have bad weather. You adjust to that and have a different plan in farming and in the re department.”

Josie Rozum was one of the rst students to complete Midwest Dairy’s Dairy Experience and Agricultural Leadership Program.

Rozum dairy farms with three of her siblings and her parents at Takes Family Farms near Ely, Iowa. They milk 120 Holsteins and also run Dan and Debbie’s Creamery in Ely.

“Because of our creamery, I probably deal with consumers more than the average dairy farmer,” Rozum said. “One thing I loved about the DEAL program is that it gave us a look into consumers in a different way and coached us in how to educate them about what we do. There’s a big gap between consumers and producers, and I loved getting the tools, resources and coaching that we need to do a good job of telling our story.”

Midwest Dairy launched DEAL in 2021 to help farmers, age 40 and younger, become effective spokespeople for the dairy industry. Rozum completed the program in the summer of 2021.

With Rozum’s class having completed the program, and the second group starting up, program facilitators and participants are seeing positive results.

Jenna Finch is the agricultural affairs manager for Midwest Dairy. She plans and oversees the DEAL program by arranging events and reaching out to the group with updates and learning opportunities.

“We were trying to ll a need for young, emerging dairy leaders who wanted to be engaged with Midwest Dairy and learn more about dairy checkoff and how we’re applying those resources to build trust in, and demand for, dairy,” Finch said. “They also wanted to grow their leadership and advocacy skills.”

The 18-month program helps participants forge relationships with their peers and others in the industry, learn how to successfully engage with consumers and the media and better understand the dairy checkoff.

“Participants love the networking that takes place within the program,” Finch said. “I consistently hear back from the group that it’s so nice to meet so many great people from different areas and learn from them too.”

For Rozum, the program has helped her navigate difcult questions from consumers.

“One of the toughest questions consumers ask is about separating the mom and baby,” Rozum said. “To others, that seems like an awful thing to do, but we have good reasons for doing that as a dairy farmer, so to be able to gracefully and tastefully answer those kinds of questions, and still be respectful to those who don’t understand the dairy industry, is really important.”

Midwest Dairy brings in speakers and groups from the industry and teaches social media and communication skills to build condence in representing and advocating for all things dairy. Although the core lessons remain the same, Finch and her team have been adding new opportunities and ne-tuning lessons based on feedback from DEAL students.

To select dairy farmers for the program, a committee looks through applications received from the 10-state region of Midwest Dairy and selects a class of 15. Midwest Dairy pays for the program and grants stipends to participants for stepping off the farm for the sessions. The students meet in person for three sessions over 18 months for a total of 11 days. Between sessions, participants do assignments aimed to build knowledge, condence and communication skills.

Cole Hoyer is a member of the current class, which has completed two of the three sessions. He and his wife, Katie, along with her parents, milk 120 cows on their dairy near Estelline, South Dakota.

Hoyer applied for DEAL when a local dairy farmer suggested doing so. Hoyer said he is looking forward to the next DEAL assignment.

“It is to get involved with some type of promotion, whether that’s hosting people on your farm to educate them about dairy, going to someone else’s farm, working at some event Midwest Dairy is involved in – something to help promote dairy,” he said.

“There’s a lot of options.”

Hoyer said he appreciates what he is gaining through DEAL. His last session focused on how to create a social media presence for a farm and present on social media in a positive way.

“I learned that I have a lot to learn, especially on the social media side of things,” Hoyer said. “I enjoy interacting with consumers, but it’s also intimidating in some ways, especially nowadays with the internet the way it is. You can say something, and seconds later people can have it up on their phones.”

DEAL sessions also connect farmers to people they might not be aware of in the industry.

A recent presenter was from GoodSport, which makes a sports drink from ultraltered milk.

“I had never heard of that company or the drink,” Hoyer said. “I wish

the general farming population could know how much Midwest Dairy is doing to get milk consumed and used so that we can keep having a market and keep being able to do what we love.”

Lindsey Borst is also a member of the current DEAL class. A veterinarian and a calf and heifer nutritionist by trade, Borst helps at Borst Family Dairy near Rochester, Minnesota, which milks 230 cows. The farm is owned by Borst’s husband, Kevin, and his brother, father and uncle. Borst said she appreciates opportunities that have come her way through DEAL. Recently, Finch asked her to be on a discussion panel that Midwest Dairy is sponsoring at the Dairy Girl Network

national conference.

“I absolutely would not (have said yes), so DEAL has opened up doors for me to doing new things and given me condence to do so and to continue with social media,” Borst said. “It’s also given me more motivation.”

Midwest Dairy plans to open up applications for the third DEAL class in fall 2023.

Finch said she is excited to see the program continue.

“I feel so lucky that I get to be part of this program and work with these energetic, fun emerging leaders,” Finch said. “I’m in awe of how strong this industry is and how bright the future is.

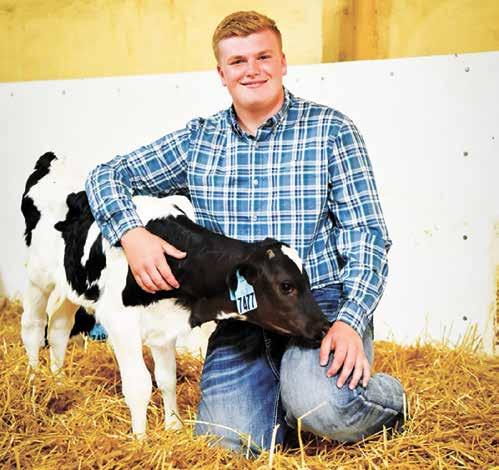

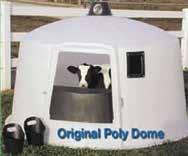

“We began looking at a bottle washer to keep bottles cleaner and eliminate an extra job. After seeing the option to purchase the bottle washer and pasteurizer combination, we started to look at its benefits. Once we calculated what we would save by not buying bags of milk replacers, it was an easy decision to add the pasteurizer. Since installing the new system of the bottle washer and pasteurizer combination the calves drink better and are healthier.”Owen Murphy Murphy Dairy Farms Farley, IA

DEAL helps young farmers become advocates for industryPHOTO SUBMITTED Current students of Midwest Dairy’s Dairy Experience and Agricultural Leadership Program – Jessi Sayers (front, from le ), Stacy Rethman, Nicole Engelken, James Goldsmith and Ray Hildebrandt; (back, from le ) Cole Hoyer, Elle Tibor, Lindsey Borst, Kevin Borst, Dan Venteicher, Natalie Barka, Paige Roberts and Courtney Lintker – gather Feb. 24 at their rst session in Denver, Colorado. This is the second group of dairy farmers to go through the DEAL program, which helps young farmers become advocates for the industry. Jenna Finch Midwest Dairy

EDEN VALLEY, Minn. – What started as a goal for the eldest of six Gathje children also became the goal for the rest.

Over the span of a decade, Scott and Denise Gathje’s half-dozen children – Joe, Anne, James, Katherine, Greg and Jonathon – have achieved the American FFA Degree, the highest degree possible for the organization’s members.

The American FFA degree is achieved by less than 1% of FFA members.

Tracy Huhn began teaching agricultural education at Eden Valley-Watkins High School in 2008 and was the FFA advisor for all of the Gathje children.

The FFA chapter has grown to include three advisors, Huhn, Tyler Warren and Kayla Gratz.

“It made me proud to see all of them go all the way to get their American Degree,” Huhn said.

All of the Gathjes held the ofce of president or vice president with their chapter but each chose their own path in FFA. They competed in a variety of career development events and took classes of interest. Some went on to be regional ofcers; others attended the Washington Leadership Conference in Washington, D.C.

“It was pretty cool to see all of them go as far as they did,” Scott said.

Scott was in FFA but said it never crossed his mind to get his American Degree.

Denise said she enjoyed seeing her children grow and develop leadership skills. She said FFA allowed her children to practice skills of interviewing, writing, lling out applications and making connections that encouraged them to pursue other opportunities.

“They all enjoyed it,” Denise said.

The Gathjes milk 65 Holstein, Brown Swiss and Jersey cows. They farm 200 acres of alfalfa and corn and raise their youngstock. In addition to the cows, they also have a horse, ducks, sheep and chickens. Each of the Gathje children showed the various animals in 4-H.

For the kids, the relationship with FFA started in 2008 when Joe joined FFA as a freshman. Huhn encouraged Joe to begin a supervised agricultural experience and obtain the State FFA Degree.

Joe said he enjoyed his time in FFA and was involved in dairy evaluation, dairy foods, helping with the chapter corn drive, helping with the chapter corn test plot and becoming a chapter ofcer.

“FFA was what I looked forward to,” Joe said. “It really helped carry me through school.”

After achieving the State FFA Degree, Huhn encouraged Joe to try for his American Degree. Joe agreed to apply.

In 2012, at the 85th National FFA Convention and Expo in Indianapolis, Indiana, Joe walked across the stage to receive his American FFA Degree.

Joe went to college at South Dakota State University for agricultural science and now works at a cooperative, helps his parents on the farm and runs a manure pumping business on the side.

When Anne started high school, she too joined FFA, but she chose to be on the meat judging, dairy handling and prepared public speaking teams. Anne said she enjoyed her time in FFA so much that she chose to pursue an agricultural education degree at South Dakota State University. While in college, she decided to take what she learned in her business and accounting classes to form a career.

“I am currently working in accounting for Novita Nutrition, an animal nutrition company located in Aurora, South Dakota,” Anne said. “With the background and connections I have made in the agricultural industry, it has been fun to be growing my accounting career within the agricultural industry.”

After seeing his two older siblings meet the requirements and get their American Degree, James also set his sights on the degree. He had already met many of the requirements with his dairy production SAE, volunteering with his 4-H club and working on his parents’ dairy farm. James was involved on the dairy judging team, was a chapter and region ofcer, and attended the WLC

“I loved that I got to travel all over the Midwest and to WLC,” James said. “I was very grateful for that.”

James said because he had a positive experience while in Washington, D.C., he went to school at St. John’s University for political science and economics. While in college, James returned to Washington, D.C. for an internship.

“FFA has impacted me in so many ways,” James said. “The skills are very transferable to real life.”

James credits FFA for helping establish his skills in writing, job interviewing, leadership development and teamwork.

Katherine became the fourth of the Gathjes to get her American Degree and credits her active chapter and her advisors with spurring her on.

“The leadership experiences I gained in FFA gave me the foundation for my career,” Katherine said. “It gave me the good leadership and good communication skills I needed to succeed.”

Katherine now oversees the leadership development program for young professionals at the Kanas City Chamber of Commerce.

Unlike the rest of his siblings, when Greg joined FFA, he was in poultry judging and took classes in sh and wildlife. Greg said he never con-

sidered getting his American Degree until he walked across the stage at the Minnesota State Convention and received the State FFA Degree. Then, the American Degree became a possibility.

Greg said he enjoyed being in FFA with his friends and getting to know kids from other schools.

“FFA helped expose me to the career path I am on,” Greg said.

Greg is attending Bemidji State University and majoring in biology.

Jonathon also joined the poultry judging team. Additionally, he joined the parliamentary procedure team and helped on committees. For Jonathon’s

SAE project, he chose sheep entrepreneurship. He purchased two bottle lambs and raised them. Jonathon now has six ewes and one ram. Jonathon wanted to get his American Degree not only because the rest of his siblings did but because he felt it was easy to do once he got his State FFA Degree.

“It is a nice nal touch to my FFA career,” Jonathon said.

Jonathon attends Alexandria Technical and Community College for diesel mechanics and has a job lined up after his graduation this spring to work with Arnold’s Equipment in St. Martin.

WISCONSIN DELLS, Wis. – Nick and Jackie Morse love macaroni and cheese so much that when looking to open a new restaurant in downtown Wisconsin Dells, they chose to build their entire menu around this one dish. A far cry from macaroni and cheese in a box, these entrepreneurs took a family favorite and turned it into a gourmet meal.

“We focused on quality and ways to expand on a classic dish,” Nick said. “We wanted to elevate a food that people are familiar with and make at home. To create an identity, I knew we had to make our macaroni and cheese from scratch.”

The idea was bold yet brilliant. Featuring cheese as the star ingredient, the Morses invented a culinary delight worthy of sharing with the rest of Wisconsin. Made and served in a cast iron skillet, the concept was unlike any other the state had seen before.

The Morses decided to call their restaurant MACS Macaroni and Cheese Shop and designed a logo in which the letter

C in the word MACS resembles a macaroni noodle. In 2013, the Morses opened their agship store.

“The food here is not premade,” Nick said. “Every dish is built to order. Customers can also customize their creations.”

The dishes are called MACS. Crispy on the top and creamy on the inside, at the base of each is the cheesiest macaroni and cheese around. From there, every creation contains

the freshest ingredients, including chicken, pork, beef, onion, mushroom, broccoli or spinach, to name a few. The menu is lled with recipes for all kinds of palettes and avorful options to satisfy everyone’s inner child.

Serving fast, fresh, comfort food is what the Morses do best. Energized by tourism, these Wisconsin Dells natives seized an opportunity when they saw a prime location on the main strip become available. Jackie was

doing interior design work, and Nick was teaching at the time.

“We were looking to do something on our own, so we started brainstorming ideas,” Nick said. “We didn’t want a standard restaurant; we wanted something unique. We decided to stay focused on a single item and make it the cornerstone of our business.”

Food was a perfect t for Nick and Jackie, both of whom grew up in the restaurant indus-

try.

“We were making a lot of mac and cheese for our 1-yearold at the time,” Nick said. “We like it and know that lots of other people like macaroni and cheese too. It’s a food that transcends different age groups. Being in the heart of Wisconsin, we’re also in a good spot for mac and cheese. Doing something with dairy just made sense.”

Nick and Jackie experimented with ideas at home, making all kinds of macaroni and cheese recipes. It was a process of trial and error as they gured out which toppings made the best concoctions. Starting with 12 entrees, the Morses focused on quality ingredients and processes when building their menu.

Jackie designed their restaurant and gave it a rustic feel. A brick wall serves as an accent wall – a design element found in all MACS stores. Creating a place where people want to linger was the goal.

“A warm, inviting atmosphere is what we’re going for,” Jackie said.

MACS acquired an intense following, and the Morses opened their second restaurant almost a year to the day on the other side of town. From that point forward, a new MACS opened every year through 2019. In July, they opened their eighth location.

There are two locations in the Milwaukee area in Brookeld and Oak Creek, two in the Madison area, two in Wisconsin Dells, one in Green Bay and one in Appleton. All stores are owned by Nick and Jackie and are open every day from 10:30 a.m. to 9 p.m.

“We get lots of requests for different markets, but it has to be the right location at the right time,” Nick said. “We have a lot of out-of-state interest, but we’re not looking to franchise. Operationally, we want to keep it tight and grow closer to home without stretching ourselves too thin or hurting our product and brand.”

The family ties in downtown Wisconsin Dells are strong; the building once belonged to Jackie’s grandparents who owned The Patio restaurant.

“We get customers from all over, and this is a nice showroom,” Nick said.

The Morses staff and monitor every location and have 120 to 170 employees across all shops. The number of employees varies by season.

“We travel a lot from store to store and are fortunate to have a close-knit management group,” Nick said.

Now, MACS offers 18 macaroni and cheese dishes along with two monthly specials. The most popular creation on the menu is the chicken bacon ranch MAC featuring cheddar, mozzarella, chicken, bacon and ranch dressing. The loaded baked potato MAC is a close second containing cheddar, mozzarella, baked potato, bacon, sour cream and chives. The original MAC smothered in cheddar and mozzarella is also a crowd pleaser.

The Morses marry popular food entrees into their mac and cheese like tacos in their taco MAC featuring pepper jack, mozzarella, pico de gallo, seasoned ground beef, cheddar, sour cream, guacamole and tortilla strips. Their cheeseburger MAC with its cheddar, mozzarella, ground beef, pickles and dressing toppings satises a craving. In addition, six melts or specialty grilled cheese sandwiches can be found on the menu.

“We offer salads, too, to balance out our offering,” Nick said. “There’s something for everyone at MACS.”

Cheese, milk and butter are the soul of MACS, which takes a hands-on approach to food preparation. Chicken is shredded on-site, and the Morses’ cheese sauce is made from scratch with over 25,000 gallons made year to date. The sauce starts with their homemade roux, which is a mix of butter and our. They then add milk, proprietary seasonings and a combination of shredded cheeses as it thickens.

“The cheese sauce is Jackie’s dad’s recipe, and it’s a big point of pride in what we do,” Nick said. “Very few of our

ingredients come out of a box. We pride ourselves in doing a lot of baking and cooking. Our staff works hard to execute this, and we appreciate what they bring to MACS. Service is important to us, and we keep kitchen and order taking duties separate.”

So far this year, MACS stores have used 33,000 pounds of butter and more than 150,000 pounds of cheese.

“The dairy industry means everything to our business,” Nick said. “We started with a simple concept to hang our hat on and make our identity. But it’s not just about me and Jackie. MACS is part of Wisconsin, which is where we want to grow. The mural in every shop tells our story.”

Featuring a cow, a barn, the shape of the state of Wisconsin and other agricultural symbols, the mural depicts the essence of MACS’ foundation.

“We felt more condent in being able to specialize with Wisconsin’s history in the dairy industry anchoring us,” Nick said. “I knew we needed quality behind our dishes.”

This past summer, the Morses opened Huckleberry’s Ice Cream and Bakery next door to the downtown MACS location. The elegantly decorated dessert venue is connected to MACS, making it easy for customers to grab both salty and sweet food in one visit.

“It’s the best of both worlds – lunch and dessert,” Nick said. “Jackie designed Huckleberry’s, and it has great curb appeal. MACS has gained customers who originally came for the ice cream.”

Purchased from different providers, Jackie is hoping she and Nick can make their own ice cream one day. The couple now has three children – Julian, Olivia and Max – and raising a family while running the MACS restaurants keeps Jackie busy to the point that she no longer does interior design for other clients.

Filled with personal touches, the Morses go out of their way to make dining at MACS a memorable experience. From food presentation to the food itself, the Morses spare no detail. For example, MACS uses real butter on its toasties –the little pieces of toasted bread served with each mac and cheese dish.

“It’s painstaking, but it makes a difference in the quality we provide,” Jackie said.

MACS is a cozy place to get away from it all while escaping into a skillet of mac and cheese bliss. People walk away content after eating cuisine that warms the heart. As they continue to specialize in the one dish their customers keep coming back for, Nick and Jackie keep their eye on the right opportunity for the next location.

PULSNEXUS G2 Monitoring System

Keeping full-time watch on hose detachment, damage, & blockage; & the proper

PULSNEXUS offers:

•Adaptation to any system

•Pulsator control & performance

SCANNEXUX G2

Stand-Alone Milk Meter

this solution is not a milk yield indicator— there’s no need to lift or restrict milk to be accurate. The Stand-Alone Milk Meter offers:

•Adaptation to any system

•Pulsator control & performance

Brent Havlik Norwalk, Wisconsin Monroe County 54 cows

What are you thankful for this year? We are glad to live in a time when a family can farm together and still make a living. We are thankful to God for health, a family who loves and lives for the Lord and a growing family. We are expecting our rst grandchild in a couple weeks.

Describe a moment this year that made you grateful. It is difcult to come up with just one. Our creamery has been supportive, and our feed company works hard to meet the dairy goat nutritional needs. All around, it has been a good year.

Who is someone in your life you are thankful for? Our parents. They have raised us to be strong and grateful and to never take our faith or blessings for granted. They also taught us to work hard and to creatively problem solve.

How do you show appreciation for the people you work with every day? With words of sincere gratitude. Also, by getting our hands dirty together and working alongside them. We are all in this together.

How do you celebrate Thanksgiving? By cooking a homegrown meal with a mixture of American and heritage foods. Then, sharing in a prayer of gratitude for God’s provisions and taking the time to count our many blessings.

Tell us about your farm. We are glad to be stewards of 120 acres of which 90 are tillable. They are planted into hay which supplies our goats’ hay needs and a little more to sell, which helps offset our feed costs. We sell young bucklings and some doelings each year. We raise our replacement dairy does. We ship our milk to Stickney Hill Dairy Inc. out of Cold Spring, Minnesota.

What are you thankful for this year? I’m thankful I’m still in business. With the price of inputs so high, it seems like there's no room for error, and things better go good. I’m also thankful for a good crop year that provided plenty of hay. I’ve got a family that supports me and helps me when I need it. We have a 2-year-old grandson who comes to the farm so that is encouraging.

Describe a moment this year that made you grateful. I enjoy spending time with family, and everyone is healthy and happy. We had no major weather disasters this year, no ooding and had timely rains we needed.

Who is someone in your life you are thankful for? My wife, Sarah, because she has always been there to support me. She’s got a job too, which helps because there are times we wouldn’t survive with just the farm income. I am also blessed with good neighbors: the Lelands, Randy next door, and Dawn and Chad Powell. They are kind of like extended family. It’s so good to have good neighbors who are willing to help.

How do you show appreciation for the people you work with every day? Thanking them for their help. Everybody is busy and has plenty to do on their own.

How do you celebrate Thanksgiving? We get together as a family at our house. We get up and do chores early to get home for dinner. We play games after the meal. Our grown kids return home to celebrate with us.

Tell us about your farm. We are an organic dairy with about 60 head. I started farming later in life, so I rent the farm. We cover 250 acres and ship our milk to Westby Cooperative Creamery.

Norm and Camille Zacharias Hinckley, Minnesota Pine County 70 cows

What are you thankful for this year? For our wonderful family of ve children, who have grown to be humble, young adults. A beautiful, peaceful place to live and plenty to eat. A bountiful corn silage harvest in spite of the drought.

Describe a moment this year that made you grateful. My husband and I had a minor accident with the all-terrain vehicle while working cattle this summer. We are grateful no one was seriously injured.

Who is someone in your life you are thankful for? Good neighbors who always have our back and help one another out. They are always willing to help us with an extra set of hands or with machinery maintenance. They have our back, and we have theirs.

How do you show appreciation for the people you work with every day? By working together and helping one another. When we all work together, we get done sooner and more efciently.

How do you celebrate Thanksgiving? Our family gets together with turkey and dressing and all the trimmings. All ve of our children come home to our house, even our two boys who live in South Dakota.

Tell us about your farm. Norm started dairying in 1988 on his parents’ farm, which we eventually purchased. We built a milking parlor in 2006. We raise our heifers, hay and corn silage. Our ve children grew up working on the farm and all have an excellent work ethic. One son lives at home and works on the farm. One daughter lives at home and has a job in town. She helps on the farm. We ship our milk to Burnett Dairy Cooperative.

Star Blends has been helping Midwest farm families by providing, high-quality feed, dairy nutrition, and commodity contracting for more than 20 years. Our state of the art mill can accuratelyblend anything from a custom pre-mix to complete feed, in balancing diets, or work with your private nutritionist or dairy consultant.

Rod and Barbara Lindell Browerville, Minnesota Todd County 150 goats

Rod and Barbara Lindell Browerville, Minnesota Todd County 150 goats

What are you thankful for this year? I am thankful for the improvements we've made to feeding the cows and the heifers. We made a double-sided feeding lane for the cows and poured cement and installed headlocks for the heifers; it has made feeding easier for everyone. I am thankful that my family is happy and healthy. I am also thankful to always have family around on the farm whether it is my sisters visiting or the cousins spending time with my boys.

Describe a moment this year that made you grateful. My most grateful moment this year was moving back home to the farm. I have been driving back and forth for years and can nally walk right out to the barn again. It has been so wonderful.

Who is someone in your life you are thankful for? I am thankful for my dad who has taught me everything I know about farming. He's al-

Annie and Adam Hedlund Siren, Wisconsin Polk County 100 cowsWhat are you thankful for this year?

I am thankful for a healthy herd of cows. Cows are the top priority; they are what make us money. I’m thankful for the family that has surrounded us this past year. My father-in-law stepped up in place of my husband, and my brother-in-law fed the cows this past year. My mom and mother-in-law have taken care of the kids while I milk.

Describe a moment this year that made you grateful. The moment I am extremely grateful for this year was April 5, when my husband received a second chance at life by receiving a pair of new lungs and the chance to see his kids grow up.

Who is someone in your life you are thankful for? Someone in my life that I am thankful for is my husband. This past year, since he has

ways been there when I need him and has been a great mentor. He has done an amazing job raising us six girls after the loss of our mom 16 years ago.

How do you show appreciation for the people you work with every day? I show appreciation to the people I work with by being kind and being there if they need someone to listen. I also like to bake and make homemade jam so they get treats and jam quite often.

How do you celebrate Thanksgiving? We always celebrate Thanksgiving at home here on the farm. Most of the time, all my sisters and their families come home. We have a house full of laughter and kids running around.

Tell us about your farm. I farm with my dad, Tom, and two boys, Cody and Chase. My husband, Jason, works off the farm. My uncle and a cousin also help. We milk 70 cows, mostly Holstein with a few Jerseys and a couple Brown Swiss crossbred cows. We raise corn for silage and some alfalfa. We pasture our cows in the summer and started feeding a total mixed ration this year on our new feeding lane. I also have a small ock of sheep. We ship our milk to the Nelson Creamery in Nelson, Minnesota.

been hospitalized, it has taught me never to take anything for granted. He is my best friend, and we did everything together. To have that ripped from me is something I cannot even explain.

How do you show appreciation for the people you work with every day? We have one employee, and especially this year, she has stepped up to help our farm. To show appreciation, I like to slip treats in the milking bucket for her. I write notes on the white board for her. And if possible, I just do things that will make her chores a little easier.

How do you celebrate Thanksgiving? We go to Adam’s aunt’s house, have dinner and hang out with family. Every year gets a little more interesting because every year there are more kids added. We usually eat so much that we complain during chores about how much we ate.

Tell us about your farm. We milk around 100 cows in a double-5 parlor. The herd is mostly Holstein, but there are more Jerseys added all the time and one Brown Swiss. My husband and I own the farm, and Adam’s dad helps at the age of 72. We have one employee and a parttime milker when her or I can’t milk. We grow hay, corn and soybean to feed the cows but some is cash cropped. Adam and I have three young children. They help feed calves with me almost every night.

Describe your farm and facilities. The cows are housed in two freestall barns. They are both 4-row barns with deep-bedded sand stalls.

What forages do you harvest? HarvXtra alfalfa, corn and brown midrib corn for silage.

How many acres of crops do you raise? We farm 1,200 acres.

Describe the rations for your livestock. We feed the milk cows roughly 55% forage – 60% corn silage and 40% haylage – whey, corn and protein mix. Dry cows get haylage, corn silage, mineral and straw. Heifers get haylage, corn silage, hay, mineral and soybean meal.

What quality and quantity do you harvest of each crop? We harvest 10,000 tons of corn silage at 65%67% neutral detergent ber digestibility and 30%-35% starch. We harvest 5,000 tons of haylage at 150 relative feed value. And, we harvest 60,000 bushels of high-moisture corn ground to 600 microns.

Describe your harvesting techniques for alfalfa and corn silage. Sullivan Custom Farming and Co-

rey Sullivan take care of our cutting, merging and hauling needs. We chop ourselves with a John Deere chop-

per. We chop our own corn silage as Turn to FORAGE

“Starting every fresh cow and heifer with Udder Comfort™ is an important step for quality and that next pound of milk. Udder Comfort is the best product available, and it’s part of what we do for milk production and quality,” says Rick Empet, Empet Farm, Kingsley, Pa., explaining that they spray fresh udders after each milking for 5 days after calving to soften udders.

“We love Udder Comfort,” son Alex adds. Alex was excited to learn he won a free Udder Comfort gallon in the August Comfort Matters Enews drawing after signing up at Empire Farm Days. We caught up with Rick, Dana and Alex busy working on their 6th generation dairy farm. Along with son Aiden and daughter Chelsea, the family is engaged as agvocates with Chelsea serving as a dairy ambassador.

well. We cut alfalfa at a 35to 37-day interval and aim for 60%-63% moisture. For corn silage harvest, we aim for 68% moisture.

What techniques do you use to store, manage and feed your forages? All feed is stored in bunkers; we strive for a high packing den-

sity to ensure proper fermentation. Bunkers are covered immediately after lling with a vapor barrier and two layers of plastic held down by tire sidewalls. Bunkers are defaced nightly for the next morning’s feeding. We keep the face even and smooth throughout.

Lacta ng cows

the cows’ ra on comes from forages.

Describe a challenge you overcame in reaching your forage quality goals. Several years ago, we invested in a self-propelled chopper; it allows us to be efcient in putting up high quality feed in a timely manner.

How do quality forages play a part in the production goals for your herd? High quality forages allow for the

cows to be productive, reproductively efcient and improve overall cow health.

What are management or harvesting techniques you have changed that have made a notable difference in forage quality? A few years ago, we experimented with HarvXtra alfalfa. It allows for exibility in our cutting

interval, offers high digestibility and increased tonnage. We also transitioned from four cuttings to three cuttings per season. The same goes for BMR corn silage as it has increased ber digestibility. Increasing the digestibility of our own forages has allowed us to decrease the amount of purchased feedstuffs and increases overall production.

JD S680 2013, PRWD, Duals, 2485 hrs., 1604 Sep. hrs., #551147....... $165,000 JD S780 2018, PRWD, Singles, 2489 hrs., 1686 Sep. hrs., #549036 .... $274,900 JD S680 2012, 2WD, Duals, 2631 hrs., 1790 Sep. hrs., #548165 .......$147,500 JD S680 2013, PRWD, Singles , 2635 hrs., 1854 Sep. hrs., #551017 ... $173,900 JD 9760 STS 2004, PRWD, Duals, 3500 hrs., 2251 Sep. hrs., #549273 . $68,000

JD 9500 1995, PRWD, Singles, 3543 hrs., 2208 Sep. hrs., #551180 ...... $27,500

Case IH 2388 1998, 2WD, Singles, 3876 hrs., 2943 Sep. hrs., #549406 $34,900

JD 9660 STS 2006, PRWD, Duals, 3925 hrs., 2453 Sep. hrs., #545355 . $72,000

JD 9500 1995, PRWD,

9750 STS 2000, 2WD, Duals, 5299

IOWA

Prairie Land Ag Supply Inc. Rock Valley, IA 712-476-9290

United Dairy Systems, Inc. West Union, IA 563-422-5355

WISCONSIN

Advanced Dairy Spring Valley, WI 715-772-3201

Ederer Dairy Supply Plain, WI 608-546-3713

DeLaval Dairy Service Kaukauna, WI 866-335-2825

Joe’s Refrigeration Inc. Withee, WI 715-229-2321

Mlsna Dairy Supply Inc. Cashton, WI 608-654-5106

Professional Dairy Services Arlington, WI 608-635-0267

Redeker Dairy Equipment Brandon, WI 920-346-5579

The Scharine Group Inc. Whitewater, WI 800 472-2880 Mt Horeb, WI 800-872-3470

MINNESOTA & SOUTH

DAKOTA

Farm Systems Melrose, MN 320-256-3276 Brookings, SD 800-636-5581

Advanced Dairy Mora, MN 320-679-1029 Pierz, MN 320-468-2494 St. Charles, MN 507-932-4288 Wadena, MN 218-632-5416

The smell of coffee, Shania Twain on the radio and the milk pump going are the three most prominent things I keep close to my heart from growing up on a dairy farm.

Being involved in the dairy industry has always been a passion. I knew from a young age I wanted to milk cows like my grandparents and parents. Today, I can proudly say I have my own small herd of registered Holsteins.

Growing up, I enjoyed being in the show ring with my dairy heifers. My parents put me on a halter the day I could walk. From there, it grew into more than just a passion but a lifestyle. I enjoyed showing in 4-H, FFA and the Minnesota Junior Holstein Association.

By Taylor Jerde Staff WriterI come from my family’s fth-generation farm. The farm has had beef cattle, pigs, sheep, horses and of course dairy cattle. I learned what hard work was at a young age from my initial chore of feeding calves.

Even though I had my chores on the farm, I was fortunate to be able to participate in sports and other extracurricular activities. I was in volleyball, dance line, track, National Honor Society and was a senior leader. Some of my proudest accomplishments were breaking a school record in track and advancing from sections to compete at the state dance tournament for multiple years.

I recently graduated from South Dakota State University with a degree in dairy production. Throughout college, I was heavily involved in organizations and clubs. I enjoyed being active in Dairy Club, Block and Bridle, Little International, intramural sports and a small group Bible study.

Being an active person has helped me stay true to myself and be thankful for the rural upbringing I had. Like many, I value my family and enjoy spending time with them when I can. Whether it’s going to a Wild game, traveling to a cattle show, going to a dance competition or going on vacation, I always seem to follow my roots back home. I have always liked living in the country and being around animals.

My family often refers to me as the cow whisperer. I, like many farmers, have had my fair share of favorite cows. Early on, I had a calf named Carli who sparked my passion for showing. Elberta was my next favorite; she was a large Holstein who I referred to as a gentle giant. She knew exactly who I was and only ever listened to me. Stella and Time are my current favorites, as both are previous show heifers who became a little too tame to be normal barn animals.

Perhaps these animals are the reason I love being a part of the dairy industry and telling farmers’ stories. In 2020, I was a Princess Kay of the Milky Way nalist, so I am no stranger to sharing the stories of farmers. I enjoy learning about different farms and the family members who came before them.

Dairy Star is a great way for me to be able to fulll that passion. I am excited to learn about farmers, tell their stories and share the good they are doing. I look forward to continuing to share my passion.

ST. PAUL, Minn. – The University of Minnesota dairy judging team was named victorious at the North American International Livestock Exposition dairy cattle judging contest Nov. 5 in Louisville, Kentucky.

This is the seventh consecutive year that Minnesota has taken rst place at the NAILE contest. The team has taken home the rst-place prize 10 of the past 12 years.

This year’s team includes Ben Styer, of Menomonie, Wisconsin; Kendra Waldenberger, of Spring Grove; Isaac Rott, of Elgin; and Matthew Gunst, of Hartford, Wisconsin.

All four of the team members placed in the top 10 individually.

“I was stoked,” Styer said. “We were hopeful but not expecting it.”

Minnesota received rst overall with a 64-point margin, rst team oral reasons, rst team Ayrshire, second team Guernsey, second team Jersey, third team Brown Swiss and third team Holstein.

The team was coached by Dr. Les Hansen and alumni Eric and Gabriella Houdek.

Styer, who was rst overall and

fth in reasons, majors in animal science. He started showing cattle when he was 5 and has been judging since he was 8.

“Dairy has been a big part of my life from a young age,” Styer said.

After graduation, Styer wants to

get a job in the dairy industry for a few years and then plans to return home to work on his parents’ dairy farm.

Waldenberger, who placed third overall, is a senior studying animal science and agricultural communications and marketing.

“I really enjoy going to all the different farms in Minnesota, Wisconsin and Iowa,” Waldenberger said.

She said in preparation for the

ALLAMAKEE COUNTY

• K & R Feed and Grain

Dorchester

• 563-568-4513

BREMER COUNTY

• Via eld

Sumner • 563-578-3214

DELAWARE COUNTY

• Del-Clay Farm Equipment

Edgewood • 563-928-6445

• Edgewood Feed Mill Edgewood • 563-928-6405

DUBUQUE COUNTY

• Brunkan Equipment

Worthington • 563-855-2434

• CJ Beeps Equipment Farley • 563-744-5010

• Eastern Iowa Dairy Epworth • 563-876-3087

• Helle Farm Equipment Dyersville • 563-875-7154

• New Vienna Ag Automation New Vienna • 563-921-2896

• Roeder Implement

Dubuque • 563-557-1184

• Scherrmann’s Implement Dyersville • 563-875-2426

• Skip Breitbach Feeds Balltown • 563-552-2393

• Ungs Shopping Center (IAS) Luxemburg • 563-853-2455

FAYETTE COUNTY

• Via eld

Elgin • 563-426-5566 Maynard • 563-637-2285

FLOYD COUNTY

• Livestock Systems

Charles City • 641-220-5257

HOWARD COUNTY

• Farmers Win Co-op Cresco West • 563-547-3660

SIOUX COUNTY

• Sioux Dairy Equipment, Inc. Rock Valley • 712-476-5608

WINNESHIEK COUNTY

• Brynsaas Sales & Service Decorah • 563-382-4484

• Franzen Sales & Service Fort Atkinson • 563-534-2724

• Lang’s Dairy Service Decorah • 563-382-8722

BECKER COUNTY

• Adkins Equipment Inc. Detroit Lakes • 218-847-3131

BENTON COUNTY

• Farm-Rite Equipment St. Cloud • 844-262-2281

• First National Bank of MilacaGilman Of ce • 320-387-2233

• Gilman Co-op Creamery Gilman • 320-387-2770

• Midwest Machinery Sauk Rapids • 320-259-6222

BROWN COUNTY

• New Ulm Regional Vet Clinic New Ulm • 507-233-2500

CARVER COUNTY

• Bongards’ Cologne • 952-466-5521

• Lano Equipment of Norwood Norwood/Young America 952-467-2181

• Storms Welding Cologne • 952-466-3343

DAKOTA COUNTY

• Midwest Machinery North eld • 507-645-4886

• Werner Implement Vermillion • 651-437-4435

DOUGLAS COUNTY

• Midwest Machinery Alexandria • 320-763-4220

• Nelson Creamery Nelson • 320-762-0115

• Osakis Creamery Assn. 320-859-2146

• Pro Ag Farmers Co-op Gar eld • 320-834-2271

• Farmers Win Co-op

Rushford • 507-864-2161

• First Southeast Bank Harmony • 507-886-6922

• Hammell Equipment Harmony • 507-886-2255 Rushford • 507-864-2845

• Midwest Machinery Grand Meadow • 507-754-1100

GOODHUE COUNTY

• Ag Partners Farm Store

Goodhue • 651-923-4496

• Midwest Livestock Systems, LLC Zumbrota • 507-732-4673

• Midwest Machinery Cannon Falls • 507-263-4238 Wanamingo • 507-824-2256

• Midwest Machinery Elbow Lake • 218-685-4438

• Caledonia Haulers

Caledonia • 507-725-9000

• ESB Bank

Caledonia • 507-725-3329 Eitzen • 507-495-3321

La Crescent • 507-895-2227

• Farmers Win Co-op Caledonia • 507-725-3306 Houston • 507-896-3147

• Hammell Equipment Eitzen • 507-495-3326

• Midwest Machinery Caledonia • 507-725-7000

• Midwest Machinery Princeton • 763-263-6000

KANDIYOHI COUNTY

• D&D Ag Supply & Construction Pennock • 320-599-4466

• Farm-Rite Equipment Willmar • 877-484-3211

• Midwest Machinery Stewart • 320-562-2630

MCLEOD COUNTY

• Leedstone Glencoe • 877-864-5575

• Midwest Machinery Glencoe • 320-864-5571

• Mueller Sales & Service Dairy Equipment Glencoe • 888-205-0974

• Farm-Rite Equipment

Dassel • 888-679-4857

• Schlauderaff Implement Co. Litch eld • 320-693-7277

MILLE LACS COUNTY

• First National Bank of Milaca

Milaca • 320-983-3101

• Foreston Farmer’s Co-op Creamery Foreston • 320-294-5711

MORRISON COUNTY

• Central MN Credit Union Little Falls • 888-330-8482

• Lash’s Auto Pierz • 320-232-0537

• Litke’s Veterinary Service Pierz • 320-468-6666

• Midwest Machinery Little Falls • 320-632-5469

• Modern Farm Equipment Pierz • 320-468-2161

• Pierz Co-op Pierz • 320-468-6655

• Sunrise Ag Cooperative Buckman • 320-468-6433 Lastrup • 320-468-2543 Little Rock • 320-584-5147

OLMSTED COUNTY

• Ag Partners Stewartville • 507-533-4222 Lewiston • 507-523-2188

• Hammell Equipment Chat eld • 507-867-4910

OTTER TAIL COUNTY

• Bongards’ Perham • 218-346-4680

• Farmers Elevator of Fergus Falls & Henning 218-736-3301

• PCCA-Country Store Perham • 218-346-7075

• Perham Stockyards Perham • 218-346-3415

• Pro Ag Farmers Co-op in Henning 218-583-2947

• Pro Ag Farmers Co-op in Urbank 218-267-2401

PIPESTONE COUNTY

• Gorter’s Clay & Dairy Equipment Pipestone • 507-825-3271

POPE COUNTY

• Midwest Machinery Glenwood • 320-634-5151

RICE COUNTY

• Ag Partners - Agronomy Le Center • 507-357-6868

STEARNS COUNTY

• A&C Farm Service

Paynesville • 320-243-3736

• Albany Chrysler Dodge Jeep Ram Albany • 320-845-2801

• Arnold’s of Kimball Kimball • 320-398-3800

• Arnold’s of St. Martin St. Martin • 320-548-3285

• Arnzen Construction/St. Rosa Lumber Freeport, In St. Rosa 320-836-2284 or 1-888-276-1751

• Magni Financial Albany • 888-330-8482 Avon • 888-330-8482 Belgrade • 888-330-8482 Cold Spring • 888-330-8482 Freeport • 888-330-8482 Melrose • 888-330-8482 Paynesville • 888-330-8482 Sauk Centre • 888-330-8482

• Centre Dairy Equipment & Supply Inc. Sauk Centre • 320-352-5762 or 1-800-342-2697

• Dairyland Supply Sauk Centre 320-352-3987 or 1-800-338-6455

• Ecker Feed Service, LLC New Munich • 320-837-5800

• Elrosa Grain & Feed Elrosa • 320-697-5515

• Elrosa Lumber Elrosa • 320-697-5591

• Farm Systems Melrose 1-800-636-5581 • 1-800-247-0012

• Feed Co.

Paynesville • 320-243-3938

• Freeport State Bank Freeport • 1-800-252-9856 320-836-2126

Greenwald • 320-987-2265 New Munich • 320-837-5297 Melrose • 320-256-7208

• Hartung Sales & Service, Inc. Freeport • 320-836-2697

• Lake Henry Implement Lake Henry • 320-243-7411

• Leedstone Melrose • 800-996-3303

• Melrose Implement Inc. Melrose • 320-256-4253

• Midwest Machinery Paynesville • 320-243-7474 Sauk Centre • 320-352-6511

• Modern Farm Equipment Sauk Centre • 320-352-6543

• Nutrien Ag Solutions 320-352-6564

• Northland Farm Systems Owatonna • 507-451-3131

SWIFT

• Midwest Machinery Benson • 320-843-2610 Madison • 320-598-7575 Morris • 320-589-2011

TODD

• Magni Financial Grey Eagle • 888-330-8482 Long Prairie • 888-330-8482

• Farm-Rite Long Prairie • 866-514-0982

• Olson’s Custom Farm Service Staples • 218-894-2474

• Pro-Ag Farmers Co-op in Browerville Browerville • 320-594-2711

• Pro-Ag Farmers Co-op in Clarissa Clarissa • 218-756-2112

• Pro-Ag Farmers Co-op in Eagle Bend Eagle Bend • 218-738-2552

WABASHA

• Ag Partners Farm Store Plainview • 507-534-2531

• Beck Implement Elgin • 507-876-2122

• Leedstone Plainview • 800-548-2540

• Midwest Machinery Plainview • 507-534-3116

• Wingert Sales & Service Plainview • 507-534-2285

WADENA COUNTY

• Dairyland Equipment of Menahga Menahga • 218-564-4958

• Midwest Machinery Wadena • 218-631-2311

• Olson’s Custom Farm Service Verndale • 218-445-5500 Sebeka • 218-837-5749

WINONA COUNTY

• Elba Co-op Creamery Elba • 507-796-6571

• Lang’s Dairy Equipment Lewiston • 507-452-5532

• Lewiston Rentals and Repairs Lewiston • 507-523-3564

• Midwest Machinery St. Charles • 507-932-4030

WRIGHT COUNTY

• Hobert Sales Inc. Cokato • 320-286-6284, 1-800-820-6455

• Midwest Machinery Howard Lake • 320-543-2170

BROOKINGS COUNTY

• W.W. Tire Brookings • 605-696-7400

CODINGTON COUNTY

• Glacial Lakes Livestock Watertown • 605-886-5052

MINNEHAHA COUNTY

• Central Valley Dairy Supply Garretson • 605-467-0812

• Midwest Livestock Systems Renner • 605-274-3656

ROBERTS COUNTY

• Valley Dairy Supply Corona • 605-432-5224

berger said.

Waldenberger did not grow up on a dairy farm but instead got involved in showing cows with a dairy farm through the 4-H leasing program. When she became employed at the

neighboring dairy, she found her passion. After graduation, Waldenberger intends to work with dairy cattle genetics.

Rott, who was eighth overall, is also an animal science major.

“My favorite part of being on the judging team is hanging out with all my teammates on judging trips,” Rott said. “While we are stressed out, we still have fun.”

The rest of the team agreed.

Rott grew up on a dairy farm. His family has since sold the cows and now raises heifers for another dairy farm. After graduation, Rott hopes to get a job in the dairy industry for a few years then return to the farm.

Gunst, who placed ninth overall, is a senior majoring in animal science and agricultural communications and marketing.

“To say I am sincerely blessed to have been a member of the teams representing the University of Minnesota would be an understatement, and I can wholeheartedly say I have developed both personally and professionally from these experiences,” Gunst said.

For Gunst, the NAILE contest was bittersweet; this was his last judging contest as a senior member of the dairy judging team.

“I wanted to go out with a bang and take the win for the U of M,” Gunst said. “Our team had practiced countless hours, and we were all lled with anticipation for the results.”

Gunst grew up as the sixth generation on his family farm. His family sold the cows in 2011, and now, Gunst and his sister run a custom boarding business. After graduation,

Gunst plans to work in marketing for an agricultural company and continue to breed and show top quality dairy cattle.

Hansen has been leading the dairy judging team at the school since 1981. Growing up on a Minnesota dairy farm himself, Hansen has been fascinated by the genetics in dairy cattle. Hansen said he appreciates how hard the team has been working.

“Success requires commitment; one feeds the other,” he said.

Hansen said this year’s team has been thrilled to get back to in-person activities. Hansen teaches his students that the goal is not to win trophies but rather to learn, bond with teammates and develop decision-making.

“It feels fantastic,” Hansen said. “I have a tremendous pride in each and every one of them.”