DAIRY ST R

Volume 24, No. 19

Volume 24, No. 19

CUBA CITY, Wis. –

Tim Vosberg was working a white-collar job in the Chicago suburbs when he was in his 20s. Employed by a dairy equipment manufacturer, he was sent around the country to troubleshoot issues on large dairy farms.

When his youngest brother died in 1997 and his dad needed help running the farm in Grant County, Vosberg traded his suit and tie for a life of dairy farming.

“When tragedy happens to your family, you really evaluate what’s important,” Vosberg said. “Climbing the corporate ladder didn’t seem

like it was all that important anymore.”

When Vosberg entered the world of dairy farming once more, he forged his path on a farm of his own while his brother, Mark, took over their father’s farm.

Today, Vosberg milks 120 cows on an organic farm with the help of his wife, Heidi, and their six children, Gwen, Wesley, Tabitha, Calista, Serena and Rachel.

Wesley’s girlfriend, Cailyn Lord, is also involved in the operation, and Vosberg’s nephew, Tyler, helps full time on the farm. The family farms 380 acres and has 70 acres in pasture.

Vosberg said he plans to transition the responsibilities of the farm to the next generation over the next 10 years and explore a different career path in his 60s.

“I want to transfer all

the responsibility to the next generation early,” Vosberg said. “I personally would

love to be one that transitions to something else and not be in charge until I’m 85

BRILLION, Wis. –

Three years ago, Brandon and Shianne Ferry and Brandon’s dad, Tim, decided to combine their milking herds. The arrangement gave way to needing less labor and providing the younger Ferry with a more consistent source of feed. Both generations were spread thin, and instead of continuing to farm separately, they pooled their resources and created a win-win situation for both father and son.

“My dad was looking for a way to cut down on labor, and I was looking for an easier way to nd feed,” Brandon said. “I had a hard time nding quality feed. But here, we have a consistent source, and that’s a big thing. Also, my wife and I

November 26, 2022

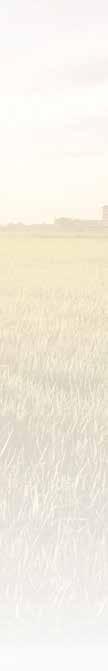

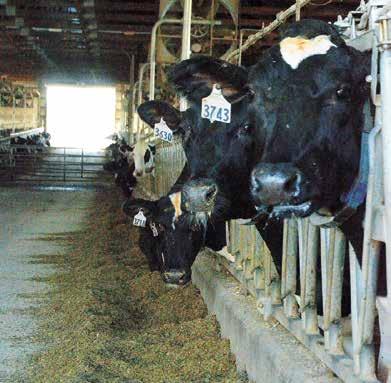

STACEY SMART/DAIRY STARThe Ferry family – Shianne (from le�), Brandon and Tim – milk 300 cows near Brillion, Wisconsin. The Ferrys combined herds at a rented facility in 2019 to help reduce labor and provide more consistent feed.

had two kids at the time and wanted to make it easier to farm while raising a family.”

Now, Brandon and his father share the work on the farm they rent near Brillion where they milk 300

cows. Their milking herds converged at a neutral location between their two farms when Brandon’s herd of 80 cows joined his dad’s herd of 220 in 2019. Tim has been milking at this location for 12 years

after moving his herd from Pickett, where Brandon grew up. Cows are milked twice a day in a double-8 herringbone parlor and housed in a 240-stall freestall barn. Tim and Brandon rent the buildings while another farmer rents the land.

“That farmer puts up the feed for us, and we purchase it from him,” Brandon said.

Brandon used to feed his cows corn silage, baled hay and top-dressed grain. Now, his cows receive a total mixed ration consisting of corn silage, haylage, and a corn and protein mix.

Brandon’s farm is about 5 miles away near Hilbert, and Tim’s farm is about 1 mile from the farm they rent. Youngstock remain at each of their respective farms. Tim also houses all of the dry cows and springing heifers, and all animals calve at his farm.

years old. I can still support

Dairy is in 96% of U.S. households using up 80% of what the United States produces. The rest is exported. That is where the United States Dairy Export Council comes in.

Krysta Harden is the U.S. Dairy Exports Council president and CEO.

“If you look at exports, there is no way that you can’t be excited about what’s coming,” Harden said. “Somebody is going to meet the demand. I think it should be the U.S.”

Consumers are becoming more aware of how dairy can be used, and marketing,

Ferrys combine herds for greater efciency

www.dairystar.com

ISSN Print: 2834-619X • Online: 2834-6203

522 Sinclair Lewis Ave. Sauk Centre, MN 56378

Phone: 320-352-6303 Fax: 320-352-5647

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com 320-352-6303 (ofce) 320-248-3196 (cell) 320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

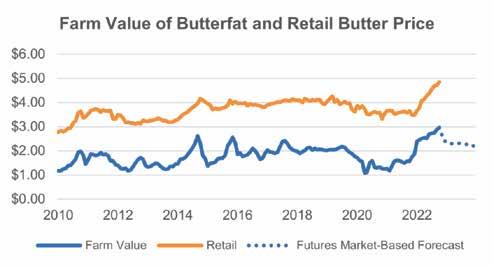

AgDairy marketing specialist Robin Schmahl expects Class III milk prices to remain steady with little change expected in milk production or consumer demand. “Higher demand probably isn’t going to happen because of the current economic situation, and it will take a while before milk production declines,” Schmahl said. “Dairy producers need to take a hard look at this market and when there are opportunities to protect prices, do some marketing or sign up for (Dairy Margin Coverage); they need to embrace those things.”

was extending the status quo timeline to match another union. If either of the two largest unions are still voting, the deadline could be extended again. The Class I railroads reportedly planned to start shutting down service in anticipation of a work stoppage. The unions claimed the railroads are trying to cause panic and manipulate Congress to intervene.

Karen Knoblach

• karen.k@star-pub.com Annika Gunderson • annika@star-pub.com

Tiffany Klaphake - Assistant Editor 320-352-6303

• tiffany.k@dairystar.com

Maria Bichler - Assistant Editor maria.b@dairystar.com • 320-352-6303

Danielle Nauman - Staff Writer 608-487-1101

• danielle.n@dairystar.com

Stacey Smart - Staff Writer 262-442-6666

• stacey.s@dairystar.com

Abby Wiedmeyer - Staff Writer 608-487-4812

• abby.w@dairystar.com

Grace Jeurissen - Staff Writer 320-352-6303

• grace.j@star-pub.com

Jan Lefebvre - Staff Writer 320-290-5980

• jan.l@star-pub.com

Taylor Jerde - Staff Writer 507-403-1680 • taylor.j@star-pub.com

Consultant

Jerry Jennissen 320-346-2292

Main Ofce: 320-352-6303 Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication Sales Manager - Joyce Frericks 320-352-6303 • joyce@dairystar.com

Mark Klaphake (Western MN) 320-352-6303 (ofce) 320-248-3196 (cell)

Laura Seljan (National Advertising, SE MN) 507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com

Jerry Nelson (SW MN, NW Iowa, South Dakota) 605-690-6260 • jerry.n@dairystar.com

Mike Schafer (Central, South Central MN) 320-894-7825 • mike.s@dairystar.com

Amanda Hoeer (Eastern Iowa, Southwest Wisconsin) 320-250-2884 • amanda.h@dairystar.com

Megan Stuessel (Western Wisconsin) 608-387-1202 • megan.s@dairystar.com

Kati Kindschuh (Northeast WI and Upper MI) 920-979-5284 • kati.k@dairystar.com

Julia Mullenbach (Southeast MN and Northeast IA) 507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell) bob.l@star-pub.com

The deadline for news and advertising in the Dairy Star is 5 p.m. Friday the week before publication.

One year subscription $40.00, outside the U.S. $200.00. Send check along with mailing address to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378.

Our ad takers have no authority to bind this newspaper and only publication of an advertisement shall constitute nal acceptance of the advertiser's order.

Letters

Letters and articles of opinion are welcomed. Letters must be signed and include address and phone number. We reserve the right to edit lengthy letters. The views and opinions expressed by Dairy Star columnists and writers are not necessarily those of the Dairy Star / Star Publications LLC.

The Dairy Star is published semi-monthly by Star Publications LLC, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378-1246. Periodicals Postage Paid at Sauk Centre, MN and additional mailing ofces.

POSTMASTER: Send address changes to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378-1246.

During a time of high commodity prices, rising land values and government payments, a percentage of farmers became complacent. Virginia Tech professor emeritus David Kohl made that point during the National Bankers Conference in Omaha, Nebraska. “You’re going to have a certain set of customers that are going to burn through working capital, liquidity and their equity, but you’re going to have another set of customers that will put prots on the table, build liquidity, build equity and they’re going to grow,” Kohl said. In this time of extreme volatility, Kohl said commodity prices could drop quickly. That makes it more important for farmers to know their breakeven costs and manage risk. The geopolitical environment can make changes in an instant. “Whether it’s China, the United States or the Federal Reserve, they’ll ip the switch and when change happens, it will happen very, very quickly,” he said.

The threat of a railroad strike is now off the table until Dec. 4 at the earliest. The previous strike deadline was Nov. 20. One of the major unions announced it

A delegation led by U.S. Dairy Export Council President and CEO Krysta Harden and Dairy Management Inc.

By Don Wick Columnist

By Don Wick Columnist

Chair Marilyn Hershey participated in the United Nations Climate Change Conference in Egypt. “We are proud of U.S. dairy producers’ progress and leadership thus far,” Harden said. “But, we know we can do more.” USDEC and DMI participated in forums on sustainable dairy production during the COP27 conference.

For the past two years, President Biden has been in the Oval Ofce and the Democrats had the majority in the House and Senate. Republicans took control of the House in the election. Public policy consultant and lob-

byist James Callan said this scenario will inuence the legislative agenda. “I think it will be difcult for the administration, if not impossible, to get anything major done.” If the Republicans win the majority in Congress, the chairmanship of the House Agriculture Committee would shift from current chairman David Scott of Georgia to G.T. Thompson of Pennsylvania. Callan believes Thompson would change the direction of the committee. “His priorities would be on dairy, forestry, nutrition from an oversight perspective and crop insurance,” Callan said. “Mr. Scott has focused on climate, racial equity and Southern commodities so I think there will be a signicant difference in their approach and priorities.” Thompson has already discussed an ambitious timeline for the farm bill, completing the legislation before its expiration at the end of September. Callan leads a public policy rm in Washington, D.C. and represents Midwestern farm groups.

Rep. Robin Vos, of Rochester, was reelected to serve as the speaker of the Wisconsin State Assembly for the 2023-24 legislative session. Vos is the longest serving speaker in state history. Rep. Kevin Petersen, of Waupaca, is speaker pro tempore and Rep. Tyler August, of Lake Geneva, is the majority leader.

Wisconsin will receive $7 million from U.S. Department of Agriculture’s Dairy Business Innovation Initiatives program. The funds will be used to increase milk processing capacity, making on-farm improvements and offering technical assistance. “As our dairy economy faces supply chain challenges, federal dollars will help Wisconsin dairy businesses to address those challenges,” Wisconsin Sen. Tammy Baldwin said.

Dairy farmers can enroll for 2023 Dairy Margin Coverage through Dec. 9. Last year, USDA took steps to improve coverage for small and mediumsized dairy farms. That includes the new Supplemental DMC program and an update to the feed cost formula.

UW-Oshkosh biogas project praised

In his report to the Board of Regents, University of Wisconsin System President Jay Rothman recognized University of Wisconsin-Oshkosh for its biogas program. UW-Oshkosh has partnered with Agra Energy, of Irvine, California, to break ground on Wisconsin’s rst commercial facility to turn dairy manure into renewable fuel. The $20 million facility will use new technology to produce 750,000 gallons of renewable diesel and jet fuel annually.

President Biden has signed a memorandum to strengthen the security of the U.S. food and agriculture system. This effort highlights the tools available to maintain food security, including the National Veterinary Stockpile, the Foot and Mouth Disease Vaccine Bank and the planned National Bio and Agro-Defense Facility.

For the nine months ending Sept. 30, St. Paul-based AgriBank had net income of $576.1 million. That’s up from $558.7 million during the same period one year ago. Net interest income topped $621 million, an increase of 8% from last year. Total loans in the portfolio were at $129.6 billion, up more than 6%. The increase in AgriBank’s wholesale portfolio was driven primarily by agribusiness and real estate mortgage volume, partially offset by declines in production and intermediate term volume.

The youth wellness program created by the dairy checkoff and the National Football League is called Fuel Up to Play 60. That answers our last trivia question. For this week’s trivia, what country started the tradition of putting up a Christmas tree? We will have the answer in the next edition of Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network, based in Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two adult sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

Consumers are becoming more aware of how dairy can be used, and marketing, research and awareness of the benets of dairy in a diet is driving more interest in dairy around the world, according to Harden.

“We work on incorporating dairy into cultural favorites as well,” Harden said. “You shouldn’t have to eat American food or diets to enjoy American dairy.”

About 80% of U.S. exports are ingredients and include whey, whey protein concentrate and skim milk powder. These products are commonly used for smoothies, health bars and protein powders.

“Demand is great,” Harden said. “There’s a growing interest, growing awareness in U.S. products among other countries.”

Harden said the biggest challenge as of late is shipping.

During the coronavirus pandemic, many Americans turned to online shopping and therefore often buying foreign products. Harden said there was so much demand for goods coming into the U.S. that it was often cheaper for ships to unload their goods and turn around empty than to wait for U.S. goods to be loaded.

“The inbound, imports, were so great,” she said.

Moving products by rail and truck has also been a roadblock to exporting U.S. dairy products.

The Ocean Shipping Reform Act has eased some of the barriers.

“It is better,” Harden said. “It’s not xed, but it is better right now.”

Ination is also impacting the potential for countries to afford American goods.

“The pandemic really taught us all lessons that we are going to deal with these types of issues in different ways, and we don’t need to be dependent on just one country or one region,” Harden said.

The biggest competitors of the U.S. dairy industry are New Zealand and Europe, Harden said. But, New Zealand and countries in Europe are land locked, giving the U.S. the advantage because of its size and space.

“We know what we’re doing here, and we know how to do it very well,” Harden said.

Harden said the biggest importer of U.S. dairy is Mexico. Harden said the two countries have a good working relationship.

Other countries include China, Southeast Asia, Japan and Korea.

Harden said the U.S. is seeing consistent growth of imports to South America, the Middle East and northern Africa.

The USDEC opened an ofce in Singapore in 2020 and serves the 16 countries which make up Southeast Asia. The center includes a test kitchen to help nd new ways to use dairy products in the area’s cuisine.

China, because of its population, has been a key market for U.S. dairy.

Harden said the Chinese government has recommended consumers use more dairy in their diets. The USDEC has noticed an increase in products such as butter and whole milk powder.

“We work with local cultures to make sure it is incorporated into diets that just need fortifying,” Harden said.

South America, especially Chile, has been steadily increasing their imports of U.S. dairy.

“Our strategy has been to be as diversied as possible,” Harden said.

One product seeing an increase in demand is cheese. About 3,000 varieties of cheese are exported, and artisan cheeses are popular. Chile has the highest gross domestic product in South America; therefore, consumers have disposable income and appreciate U.S. cheese, Harden said.

“The Middle East is also very interested in our cheese,” Harden said. “That’s all they want to talk about.”

When the USDEC was created 27 years ago, the U.S. was exporting 2%-4% of what the country produced. Today, the U.S. exports 18% of its’ total production.

Looking ahead, USDEC expects the focus on health and wellness to continue. With dairy products being nutrient dense, the USDEC sees this as an opportunity to promote American dairy.

Harden said pizza is gaining in popularity across the globe bringing with it a demand for cheese. And, USDEC is working to nd ways to encourage other countries to incorporate dairy into their mainstay foods.

“Nobody works harder in the world than the dairy farmer,” Harden said. “The future is really bright for U.S. dairy. I would say to dairy farmers that the future is really for yours to drive. The world wants our products and needs our products. We can help nourish a very hungry, food insecure world.”

consult but maybe have another career beyond this.”

The family has taken steps to make a transition possible by appealing for a larger quota from Organic Valley. The Vosbergs have until 2024 to raise milk production before setting a ceiling.

With their intentions focused on passing on the farm, the Vosbergs installed a used Germania double-12 herringbone parlor last year. The parlor was retrotted into the farm’s existing tiestall barn.

The cows were housed in a freestall barn prior to installing the parlor, so production did not vary. However, with the addition to the freestall barn that went in last year as well, there is more room for the springing heifers to join the herd, which Vosberg said will help them reach their goal of increasing milk production.

Vosberg said the older cows did not adapt well to the parlor.

“My nutritionist did say

that the old cows were going to nd their way out the door, and he was right,” Vosberg said. “They didn’t adapt. A few older cows are still here, but we’ve got a very young herd right now and a lot more coming in.”

The family also implemented an automatic feed pusher.

Since transitioning to organic farming in 2002, Vosberg saw a steady decline in crop yields every year. After talking with others, he heard about composting manure and rst tried the method in 2019.

To do this, manure is spread thin on a 30-foot evaporation lane. After 24 hours, the manure is dry. It is spread on the evaporation lane every day, and when it reaches approximately knee high, the lanes are pushed up and the pile is churned. In a matter of months, the pile looks like soil and can be spread onto elds.

The method requires a tractor with a hydrostatic

transmission that can go slow enough while still exerting the power needed to run the compost turner. Other equipment includes a compost turner and spreader.

“It was a little bit of an investment, but our yields are signicantly better,” Vosberg said. “Before, our hay would zzle out as the crops went. This year, we made ve crops of hay, and the fourth crop was just as good as the rst. The fth wasn’t bad either.”

Vosberg said the cost of the compost equipment has already paid for itself compared to what he used

to pay to empty the manure pit twice a year. He also said composting sequesters carbon, and the farm receives carbon credits for utilizing the method.

With ideas already in practice, Vosberg is open to even more ideas from the next generation.

“It’s a lot of pressure because now we have to gure out how to make the farm big enough to support all these people,” Vosberg said. “Tabitha has a lot of good ideas, and I told her to keep them coming.”

Vosberg said his previous career served him well, even though he does not

miss the work.

“I learned a lot and gained a lot of condence, but every time I would be on a dairy farm where a young couple was making it happen, I thought, ‘Oh man, I could do this,’” Vosberg said. “I wanted to get back to this area.”

Even though Vosberg knew he could carry out the demands of being a dairy farmer, he said switching from his career to the farm was an adjustment.

“It’s only by God’s grace that we were able to survive,” Vosberg said. “It’s been a wonderful place to raise a family.”

“It’s only by God’s grace that we were able to survive. It’s been a wonderful place to raise a family.”

TIM VOSBERG, DAIRY FARMER

Brandon’s wife, Shianne, takes care of the calves and heifers at their farm, which total 100 head. She also helps at the main farm if needed. The couple now has four children Bryleigh, Ryker, and twins Corbin and Ledger. For two years, Brandon and Shianne rented his parents’ farm in Pickett before purchasing their current farm in 2012. Brandon and Shianne milked 70 cows in a tiestall barn before joining Tim.

Tim was able to reduce labor by two employees, as Brandon lled their shoes when he took over day-today tasks on the farm. Three employees milk the cows while Tim and Brandon feed and handle breeding, treating sick animals, drying up cows and other daily chores. Tim used to hire out the breeding, but now Brandon does it all.

“My dad and I each have our areas we focus on,” Brandon said. “My dad does most of the feeding, and I do the majority of cow health. It works well.”

Brandon no longer milks since moving his cows in with his dad’s.

“I still spend time in the parlor assisting with the two high groups of cows, but it’s denitely a big change not milking every day,” Brandon

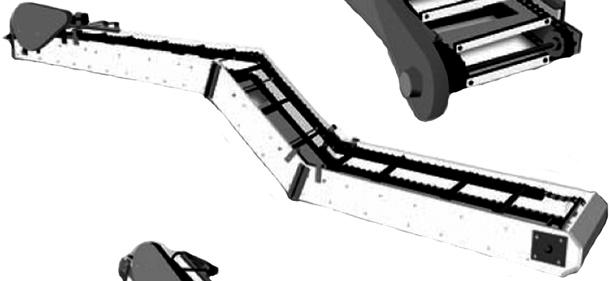

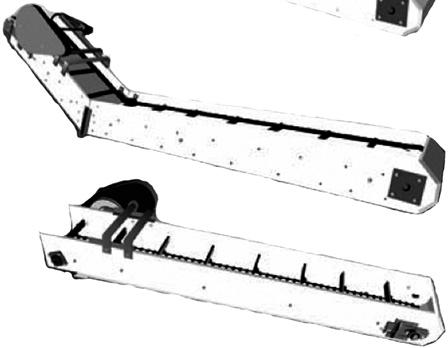

Cows are housed in this 240-stall freestall barn the Ferrys rent

Ferry has milked at this loca on for 12 years.

said. “I always enjoyed milking. It gives you time to think.”

The Ferry herds are Holstein with Jersey and Brown Swiss mixed in. Brandon also has Ayrshire and Milking Shorthorn heifers. Brandon’s cattle are registered under the prex Fer-Crest, while Tim’s cattle use the prex Fer-Li.

“The cattle are together, but we keep each herd under our own prexes allowing us to maintain our own genetics,” Brandon said. “Shi and I have

always focused on the genetic side. Since moving our herd, we still try to build off pedigrees and sire stacks and focus on genetics. Dad has a handful of registered cattle with good pedigrees also, but the majority of his herd is bred from a commercial standpoint for production and longevity.”

All expenses come out of the farm, and Brandon and Shianne receive payment for 40% of the milk their 80 cows produce, which equates to 7% of the gross milk check.

“Dad is covering all the

overhead, so it’s like we’re each getting a wage,” Brandon said.

Together, their rolling herd average is around 25,000 pounds of milk, and the Ferrys ship their milk to Baker Cheese. Brandon and Shianne emphasize type in their herd and have a BAA of 112.8, consistently putting them in the top 50 on the national list.

Previously housed on pasture mats bedded with wood shavings, Brandon said his cows are enjoying the comfort of sand-bedded stalls.

He makes an exception for his show cattle, housing select animals at his place.

“I keep the really good stuff at home and currently have four high-end cows at my farm,” he said. “I can keep a closer eye on them and feed them different during the show season.”

Brandon judges dairy cattle shows throughout the country and recently judged the junior Jersey show at the North American International Livestock Exposition in Louisville, Kentucky. Brandon also manages a tie-in string of 20 to 30 head at major shows.

“Between showing and judging, I can be on the road quite a bit,” he said. “The arrangement we have with my dad makes it easier for me to travel. Before, Shianne used to take care of everything, but the kids and farm became too much for one person to handle.”

By teaming up with his dad, Brandon laid the foundation for long-term success and took the burden off his young family.

“Initially, my dad and I didn’t farm together because we’re too similar,” Brandon said. “We have different ideas and viewpoints on farming, so it was good for me and Shianne to do it on our own as long as we did. But we hit a point where we needed him, and he needed us. We get along pretty good now.”

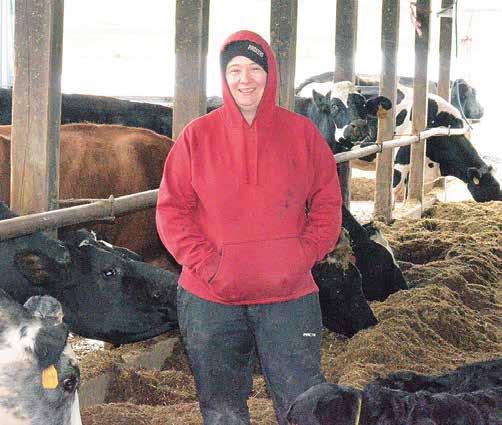

REEDSBURG, Wis. – Janice Hill is a rst-generation dairy farmer who has spent the last 14 years working her way through challenges as she pursued milking cows.

She has battled low milk prices by working off the farm and overcame stray voltage with the help of a nutritionist.

She does it all out of love for her animals.

“I enjoy the milking,” Hill said. “Just the cow contact and the connection to the calves.”

Hill milks 45 cows near Reedsburg. Cows are housed in a sand-bedded freestall barn and milked in a stanchion barn. She farms 100 acres to put up most of her own feed and has 30 acres of pasture for heifers in the summer.

Hill grew up dairying on her parents’ farm but decided to work for a year in 2007. She obtained her commercial driver’s license and hauled equipment for an asphalt and paving crew before the call to dairy brought her back to the Reedsburg area.

“I got a lot of experience out west, but I missed the cows and missed farm life,” Hill said.

Hill returned to Sauk County and bought her farm in 2008. Milk prices were $18 per hundredweight when she purchased her farm and dropped to $9 cwt the following year.

“I denitely drowned nancially for the rst eight years,” Hill said. “Thank God for good people taking payments and having faith, because if it wasn’t for them, there is no way I would’ve made it.”

Hill fell back on her experience driving truck and worked off the farm once milk prices dropped. She would milk at 3 a.m. in order to get in the truck by 7 a.m. and sometimes not return home until after 6 p.m.

When the schedule took a toll on the dairy, Hill decided to quit the day job and focus on her cows.

Meanwhile, the somatic cell count had been creeping higher and higher her rst few years on the farm. Hill discovered the vacuum pump was not putting out enough power to properly run her four milking machines. Upon further investigation, she discovered stray voltage issues from the bulk tank cooler and a couple silo unloader mo-

tors as well as the vacuum pump.

“The cell count just creeped and creeped, and then, it skyrocketed,” Hill said. “The cows started having health and reproductive problems. Finally, I found a guy that started nding all of it.”

The help came from John Sheer, a nutritionist who had a reputation for helping people with stray voltage. Hill said it took a long time for the herd to recover from all of the setbacks of stray voltage.

“John taught me that you can never cull your way out of a cell count problem because it’s normally your best cows that have the high cell count for whatever reason, and that was so true,” Hill said. “Some cows did go out the door, but if I would have culled like some people would, I would have lost all my best cows. You just have to work with them.”

Hill has continued to work with Sheer for nutrition and consulting work.

Hill said not having equipment loans has been benecial.

“I started off with a tractor, a (mixer) and a spreader,” Hill said. “Now, I have a decent skid steer and a decent tractor, but I don’t have a lot of equipment debt.”

In order to keep equipment costs down, Hill hires planting and chopping every year. She sometimes has to supplement feed with purchased hay or corn but usually gets pretty close with what she grows on her acreage.

The herd is fed a total mixed ration, and Hill raises most of her youngstock.

Hill manages the dairy with the help of one hired man who would like to start his own dairy in the next few years. After working a job in town, he milks for Hill at night and on his days off and is building equity in the meantime. So far, he owns eight cows which are housed on Hill’s farm.

“It’s more work that he has cattle here, but he’s here every night so I can’t ask for much more than that,” Hill said. “It’s the most reliable help I’ve ever had.”

Hill’s friends, Katie and Thom Statz, and their children, Raelynn, Olivia and Walter, help when Hill is in a pinch, and her parents, Brian and Peggy Hill, have offered support throughout her endeavor as well.

“My parents have been my biggest supporters and helped a lot,” Hill said. “Especially at the beginning.”

Hill said she enjoys different breeds of cattle and has started to incorporate beef breeds into the herd.

Hill’s herd includes Brown Swiss,

Lineback, Milking Shorthorn, Normande, Holstein, White Park and Dutch Belted.

Hill said she anticipates transitioning out of the dairy industry within the next ve years.

“It’ll be really hard to do nancially, and mentally, I’m really attached to the cows,” Hill said. “But, it’s hard to get away, and it’s hard to rely on anyone.”

Hill said her hired help will be on

his own by the time she transitions away from milking cows.

When she is not farming, Hill enjoys giving children who live in town the opportunity to show animals at the Sauk County Fair. She has one goat named Maddie that goes to the fair every year, and there are usually a string of calves that make the trip as well.

“It denitely can be draining, but I keep plugging along,” Hill said. “It’s where my heart is.”

“We began looking at a bottle washer to keep bottles cleaner and eliminate an extra job. After seeing the option to purchase the bottle washer and pasteurizer combination, we started to look at its benefits. Once we calculated what we would save by not buying bags of milk replacers, it was an easy decision to add the pasteurizer. Since installing the new system of the bottle washer and pasteurizer combination the calves drink better and are healthier.”Owen Murphy Murphy Dairy Farms Farley, IA ABBY WIEDMEYER/DAIRY STAR Janice Hill checks on her animals Nov. 14 at her farm near Reedsburg, Wisconsin. Hill milks 45 crossbred cows and farms 100 acres. ABBY WIEDMEYER/DAIRY STAR Youngstock rest Nov. 14 at Janice Hill’s farm near Reedsburg, Wisconsin. Beef breeds are incorporated into the dairy herd.

HARVARD, Ill. – The Davidson family has farmed in northern Illinois for more than 130 years. Starting out milking 13 cows, Richard Davidson’s great-grandparents immigrated from Ireland, and in 1889, they settled at a farm established during the Civil War. From generation to generation, the Davidsons worked together and grew their farming operations beyond that of the original farm.

“At one time, our family had four farms with cows on them,” Richard said.

Richard and Ella Davidson and their two sons, Gary and Andy, who are the fth generation, are the last of the Davidsons to milk cows. Operating two separate farms, Gary farms with his parents while Andy farms a mile down the road. However, a spirit of cooperation meshes the work into a seamless ow from farm to farm.

“Andy and I are not partners, but we work together,” Richard said. “We help each other out, and it benets both farms.”

Milking partially in a barn built during the Civil War, Richard and Gary milk 84 cows in an 84-stall stanchion barn. Andy milks 50 cows in a 56-stall tiestall barn.

“We usually sell eight to 10 cows in the fall to get down to a barn full,” Gary said. “Milking a second shift takes too long.”

The barn has been added onto over the years, but the original parts are still in use. A glass pipeline was installed in 1962 and is the same pipeline the Davidsons use today.

“It was the cutting edge of modern back then,” Richard said.

Richard and his father and two brothers farmed in partnership on the home farm; therefore, Andy stepped out on his own in 1996 after graduating from the University of Wisconsin-Platteville. The farm was owned by Richard and his brothers and parents. When his grandpa died, Andy bought out his grandma’s share in 2009 to become an owner.

Richard’s dad did not have a will, leaving his sons to gure out how to split up the farm when he passed. Richard’s brothers inherited separate farming operations, while Richard remained on the original Davidson farm.

“We were sort of in the process of separating operations anyway, but it made it more difcult without a will,” Richard said. “Things were entangled.

We bought land together in a combination of different owners. I took over the land with debt and paid it off, and nobody in this family has had any debt since. We’ve been staying away from debt. If we don’t have the money, we don’t buy it.”

Richard and his dad and brothers owned 1,000 acres of land in partnership. Today, Richard and his sons farm around 500 acres, which includes 200 acres of alfalfa, about 200 acres of corn, 50 acres of wheat and 50 acres of grass.

“It was a really good crop year this year,” Richard said.

The Davidsons hire out the planting, spraying and combining of corn as well as silage harvest.

“We do our own hay,” Richard said. “Andy has the big baler and the rake, and I have the Haybine. Sometimes we get too much cut, so we have to hire someone to help catch us up.”

Andy bought a new round baler last year and made more than 1,300 bales.

Cows go outside to eat during the day. At both farms, the Davidsons feed round bales of hay in feeders along with corn silage. No ration is fed. Small square bales provide overnight hay in the barn. The cows also eat pasture when in season.

Both herds are made up of registered Holsteins. Half of Richard’s herd and one-third of Andy’s herd are Red and Whites.

“We started with Reds in 1970 when I was a young man picking sires,” Richard said. “I knew we had cattle that carried the red gene. We used PineyHill Majority and got ve or six Red and Whites out of all black cows. Then Triple Threat came along, and we used him quite a bit and built up our Red and White herd over the years.”

A love for genetics and breeding quality cattle guided the Davidson farm mission for many years.

“There’s not as much demand for those kinds of animals anymore, and we sold our last show cow in 2011,” Gary said.

The Davidsons make the best of old facilities but have transitioned from upright silos to using a bunker to store silage.

“We don’t cover anything, and the cows eat it all,” Richard said.

Gary agreed.

“We’re all for simplicity and less work,” he said.

A heifer facility for pre-breeding animals is located across from Andy’s farm at Richard’s sister’s place. Heifers are housed there from mid-March to Nov. 1 and return to Richard’s farm during the winter. Breeding-age heifers from both farms are housed at Richard’s farm.

“We break the springers to milk, and then Andy comes and gets his and takes them back to his farm,” Richard said.

Each farm raises their own calves, except for those born of springing heifers – their calves stay at Richard’s.

“I have limited space at my farm, so this arrangement works out well,” Andy said.

The Davidsons know that backup is never far away and have come to rely on each other on a daily basis. And woven into their love for farming is their love for history. Richard adds his treasures to those store by family members who came before him.

“I’ve also become a collector,” Richard said.

His house, which is known as the Jacob A. Wood house, was built in 1876. The grand home was considered a mansion in its day and built to be used as multi-family living featuring separate entrances and common rooms. The dinner bell on top of the house still functions today.

“Generations before me moved in, lived here all their lives and then died,”

Richard said. “Then the next generation came in. That’s how we ended up with so much stuff. We still have the trunk that my great-grandmother used when moving here from Ireland.”

A museum of sorts can be found in one of the upstairs bedrooms containing priceless relics from the past. An antique rocking horse, sewing loom and other rare pieces ll the space. In 2015, Richard had his great-grandfather’s 1915 Model-T milk truck restored. Now, he uses the vehicle to take his grandchildren for rides.

The farm was originally owned by Wood. Rumor has it, when his sons wanted their money after coming home from the war, he pointed at the barn and said, “Here it is.” That same barn still stands as a piece of history. The Davidsons have not felt the need to modernize beyond what they need. They continue to live the Davidson family’s passion on a farm that has stayed true to its past.

WISCONSIN DELLS, Wis. – Nick and Jackie Morse love macaroni and cheese so much that when looking to open a new restaurant in downtown Wisconsin Dells, they chose to build their entire menu around this one dish. A far cry from macaroni and cheese in a box, these entrepreneurs took a family favorite and turned it into a gourmet meal.

“We focused on quality and ways to expand on a classic dish,” Nick said. “We wanted to elevate a food that people are familiar with and make at home. To create an identity, I knew we had to make our macaroni and cheese from scratch.”

The idea was bold yet brilliant. Featuring cheese as the star ingredient, the Morses invented a culinary delight worthy of sharing with the rest of Wisconsin. Made and served in a cast iron skillet, the concept was unlike any other the state had seen before.

The Morses decided to call their restaurant MACS Macaroni and Cheese Shop and designed a logo in which the letter

C in the word MACS resembles a macaroni noodle. In 2013, the Morses opened their agship store.

“The food here is not premade,” Nick said. “Every dish is built to order. Customers can also customize their creations.”

The dishes are called MACS. Crispy on the top and creamy on the inside, at the base of each is the cheesiest macaroni and cheese around. From there, every creation contains

the freshest ingredients, including chicken, pork, beef, onion, mushroom, broccoli or spinach, to name a few. The menu is lled with recipes for all kinds of palettes and avorful options to satisfy everyone’s inner child.

Serving fast, fresh, comfort food is what the Morses do best. Energized by tourism, these Wisconsin Dells natives seized an opportunity when they saw a prime location on the main strip become available. Jackie was

doing interior design work, and Nick was teaching at the time.

“We were looking to do something on our own, so we started brainstorming ideas,” Nick said. “We didn’t want a standard restaurant; we wanted something unique. We decided to stay focused on a single item and make it the cornerstone of our business.”

Food was a perfect t for Nick and Jackie, both of whom grew up in the restaurant indus-

try.

“We were making a lot of mac and cheese for our 1-yearold at the time,” Nick said. “We like it and know that lots of other people like macaroni and cheese too. It’s a food that transcends different age groups. Being in the heart of Wisconsin, we’re also in a good spot for mac and cheese. Doing something with dairy just made sense.”

Nick and Jackie experimented with ideas at home, making all kinds of macaroni and cheese recipes. It was a process of trial and error as they gured out which toppings made the best concoctions. Starting with 12 entrees, the Morses focused on quality ingredients and processes when building their menu.

Jackie designed their restaurant and gave it a rustic feel. A brick wall serves as an accent wall – a design element found in all MACS stores. Creating a place where people want to linger was the goal.

“A warm, inviting atmosphere is what we’re going for,” Jackie said.

MACS acquired an intense following, and the Morses opened their second restaurant almost a year to the day on the other side of town. From that point forward, a new MACS opened every year through 2019. In July, they opened their eighth location.

There are two locations in the Milwaukee area in Brookeld and Oak Creek, two in the Madison area, two in Wisconsin Dells, one in Green Bay and one in Appleton. All stores are owned by Nick and Jackie and are open every day from 10:30 a.m. to 9 p.m.

“We get lots of requests for different markets, but it has to be the right location at the right time,” Nick said. “We have a lot of out-of-state interest, but we’re not looking to franchise. Operationally, we want to keep it tight and grow closer to home without stretching ourselves too thin or hurting our product and brand.”

The family ties in downtown Wisconsin Dells are strong; the building once belonged to Jackie’s grandparents who owned The Patio restaurant.

“We get customers from all over, and this is a nice showroom,” Nick said.

The Morses staff and monitor every location and have 120 to 170 employees across all shops. The number of employees varies by season.

“We travel a lot from store to store and are fortunate to have a close-knit management group,” Nick said.

Now, MACS offers 18 macaroni and cheese dishes along with two monthly specials. The most popular creation on the menu is the chicken bacon ranch MAC featuring cheddar, mozzarella, chicken, bacon and ranch dressing. The loaded baked potato MAC is a close second containing cheddar, mozzarella, baked potato, bacon, sour cream and chives. The original MAC smothered in cheddar and mozzarella is also a crowd pleaser.

The Morses marry popular food entrees into their mac and cheese like tacos in their taco MAC featuring pepper jack, mozzarella, pico de gallo, seasoned ground beef, cheddar, sour cream, guacamole and tortilla strips. Their cheeseburger MAC with its cheddar, mozzarella, ground beef, pickles and dressing toppings satises a craving. In addition, six melts or specialty grilled cheese sandwiches can be found on the menu.

“We offer salads, too, to balance out our offering,” Nick said. “There’s something for everyone at MACS.”

Cheese, milk and butter are the soul of MACS, which takes a hands-on approach to food preparation. Chicken is shredded on-site, and the Morses’ cheese sauce is made from scratch with over 25,000 gallons made year to date. The sauce starts with their homemade roux, which is a mix of butter and our. They then add milk, proprietary seasonings and a combination of shredded cheeses as it thickens.

“The cheese sauce is Jackie’s dad’s recipe, and it’s a big point of pride in what we do,” Nick said. “Very few of our

ingredients come out of a box. We pride ourselves in doing a lot of baking and cooking. Our staff works hard to execute this, and we appreciate what they bring to MACS. Service is important to us, and we keep kitchen and order taking duties separate.”

So far this year, MACS stores have used 33,000 pounds of butter and more than 150,000 pounds of cheese.

“The dairy industry means everything to our business,” Nick said. “We started with a simple concept to hang our hat on and make our identity. But it’s not just about me and Jackie. MACS is part of Wisconsin, which is where we want to grow. The mural in every shop tells our story.”

Featuring a cow, a barn, the shape of the state of Wisconsin and other agricultural symbols, the mural depicts the essence of MACS’ foundation.

“We felt more condent in being able to specialize with Wisconsin’s history in the dairy industry anchoring us,” Nick said. “I knew we needed quality behind our dishes.”

This past summer, the Morses opened Huckleberry’s Ice Cream and Bakery next door to the downtown MACS location. The elegantly decorated dessert venue is connected to MACS, making it easy for customers to grab both salty and sweet food in one visit.

“It’s the best of both worlds – lunch and dessert,” Nick said. “Jackie designed Huckleberry’s, and it has great curb appeal. MACS has gained customers who originally came for the ice cream.”

Purchased from different providers, Jackie is hoping she and Nick can make their own ice cream one day. The couple now has three children – Julian, Olivia and Max – and raising a family while running the MACS restaurants keeps Jackie busy to the point that she no longer does interior design for other clients.

Filled with personal touches, the Morses go out of their way to make dining at MACS a memorable experience. From food presentation to the food itself, the Morses spare no detail. For example, MACS uses real butter on its toasties –the little pieces of toasted bread served with each mac and cheese dish.

“It’s painstaking, but it makes a difference in the quality we provide,” Jackie said.

MACS is a cozy place to get away from it all while escaping into a skillet of mac and cheese bliss. People walk away content after eating cuisine that warms the heart. As they continue to specialize in the one dish their customers keep coming back for, Nick and Jackie keep their eye on the right opportunity for the next location.

PULSNEXUS G2 Monitoring System

Keeping full-time watch on hose detachment, damage, & blockage; & the proper

PULSNEXUS offers:

•Adaptation to any system

•Pulsator control & performance

SCANNEXUX G2

Stand-Alone Milk Meter

this solution is not a milk yield indicator— there’s no need to lift or restrict milk to be accurate. The Stand-Alone Milk Meter offers:

•Adaptation to any system

•Pulsator control & performance

Annie and Adam Hedlund Siren, Wisconsin Polk County 100 cows

Annie and Adam Hedlund Siren, Wisconsin Polk County 100 cows

What are you thankful for this year? I am thankful for family and friends and good co-workers. I have an appreciation of those things. I talk to a lot of people. I often ask others, “Do you have help or not?” It’s getting to be less and less people who do. But, we’re still fortunate to have good help.

Describe a moment this year that made you grateful. World Dairy Expo. We are only a part of the animals we breed or sell, and we wouldn’t be able to do what we do without the people we partner with. They are a big part of our success. Eight of the top-six nishes at Expo were animals we bred or cobred in every breed except Milking Shorthorn. We didn’t exhibit any of these cattle and wouldn’t be able to have them recognized if it wasn’t for other people. There are others continuing our hard work on that side of things and having success, and I’m grateful for them. Just being able to attend World Dairy Expo is something I’m also grateful for.

Who is someone in your life you are thankful for?

I am thankful for my kids. I have two daughters who are 6 years old and 2. They provide me with a very different mindset and different approach to life.

How do you show appreciation for the people you work with every day? The simplest answer is saying hello every single morning to everybody. Starting with positive communication is a great way to start the day. Saying thank you is also important.

How do you celebrate Thanksgiving? We get work done in the morning and go eat for as many hours as we can while visiting with both sides of the family.

Tell us about your farm. At Red Carpet Holsteins, we do extensive in vitro fertilization work almost exclusively with show cattle. We also farm about 3,500 acres, the majority of which is organic. We do some boarding and have partnerships with other breeders. We’re always looking for people who share our same interests and have good cattle they want to develop. In addition, we manufacture a nitrogen drop called EZ-DROPS. I farm in partnership with my dad, Steve, and my two brothers, Jeffrey and Gilman.

What are you thankful for this year? I am thankful for a healthy herd of cows. Cows are the top priority; they are what make us money. I’m thankful for the family that has surrounded us this past year. My fatherin-law stepped up in place of my husband, and my brother-in-law fed the cows this past year. My mom and mother-in-law have taken care of the kids while I milk.

Describe a moment this year that made you grateful. The moment I am extremely grateful for this year was April 5, when my husband received a second chance at life by receiving a pair of new lungs and the chance to see his kids grow up.

Who is someone in your life you are thankful for? Someone in my life that I am thankful for is my husband. This past year, since he has been hospitalized, it has taught me never to take anything for granted. He is my best friend, and we did everything together. To have that ripped from me is something I cannot even explain.

How do you show appreciation for the people you work with every day? We have one employee, and especially this year, she has stepped up to help our farm. To show appreciation, I like to slip treats in the milking bucket for her. I write notes on the white board for her. And if possible, I just do things that will make her chores a little easier.

How do you celebrate Thanksgiving? We go to Adam’s aunt’s house, have dinner and hang out with family. Every year gets a little more interesting because every year there are more kids added. We usually eat so much that we complain during chores about how much we ate.

Tell us about your farm. We milk around 100 cows in a double-5 parlor. The herd is mostly Holstein, but there are more Jerseys added all the time and one Brown Swiss. My husband and I own the farm, and Adam’s dad helps at the age of 72. We have one employee and a part-time milker when her or I can’t milk. We grow hay, corn and soybean to feed the cows but some is cash cropped. Adam and I have three young children. They help feed calves with me almost every night.

Brent Havlik Norwalk, Wisconsin Monroe County 54 cows

What are you thankful for this year? I’m thankful I’m still in business. With the price of inputs so high, it seems like there's no room for error, and things better go good. I’m also thankful for a good crop year that provided plenty of hay. I’ve got a family that supports me and helps me when I need it. We have a 2-year-old grandson who comes to the farm so that is encouraging.

Describe a moment this year that made you grateful. I enjoy spending time with family, and everyone is healthy and happy. We had no major weather disasters this year, no ooding and had timely rains we needed.

Who is someone in your life you are thankful for? My wife, Sarah, because she has always been there to support me. She’s got a job too, which helps because there are times we wouldn’t survive with just the farm income. I am also blessed with good neighbors: the Lelands, Randy next door, and Dawn and Chad Powell. They are kind of like extended family. It’s so good to have good neighbors who are willing to help.

How do you show appreciation for the people you work with every day? Thanking them for their help. Everybody is busy and has plenty to do on their own.

How do you celebrate Thanksgiving? We get together as a family at our house. We get up and do chores early to get home for dinner. We play games after the meal. Our grown kids return home to celebrate with us.

Tell us about your farm. We are an organic dairy with about 60 head. I started farming later in life, so I rent the farm. We cover 250 acres and ship our milk to Westby Cooperative Creamery.

Johnathan Heinsohn (Pictured with his wife, Joanna, and daughters, Finley (left) and Navy.) Kirkland, Illinois DeKalb County 250 cows

Johnathan Heinsohn (Pictured with his wife, Joanna, and daughters, Finley (left) and Navy.) Kirkland, Illinois DeKalb County 250 cows

What are you thankful for this year? I am thankful for the late summer rain that broke the long dry spell we had through most of the summer. I am thankful for everyone being healthy this last year. I am thankful for neighbor farmers who we are able to depend on to help when needed, and we can in turn help them. None of us can do this alone.

Describe a moment this year that made you grateful. I was able to help my son move into his dorm at the University of Wisconsin-Platteville for his rst year studying mechanical engineering. I was grateful he was comfortable and condent enough to move more than three hours away from both myself and his father to pursue his dreams.

Who is someone in your life you are thankful for? I am thankful for my partner, Tom, who has welcomed me into his farm business over the last 3.5 years. He is consistently positive and looking for ways we can improve

Nichole Lurvey Wonewoc, Wisconsin Juneau County 200 cowsWhat are you thankful for this year? I'd like to think we always live a life of gratitude, but this year has been especially signicant in giving thanks because we've been able to make big changes in our dairy operation that have made for an incredible life change for us as a family. We were able to sell our second farm which was 50 minutes away and install robots to milk all our cows here at home. I'm thankful for time spent making memories with my husband and our three boys at home instead of being on the road. We're also giving thanks for the upcoming arrival of our fourth child.

Describe a moment this year that made you grateful. We've been blessed with so many amazing people in our life. The most overwhelming and memorable moments were when our loved ones – neighbors, friends and family – came together to help bring me home for Christmas. I was basically living at our other farm, milking cows three times a day, with great friends helping me, until the new barn was done. My husband was staying up night and day to nish the barn, and at the end, he had the most wonderful people working right beside him. We were thankful for my mother's help with the boys through those months as well.

the farm together. Our teamwork has made it possible for us both to farm full time, and I will always be thankful for that.

How do you show appreciation for the people you work with every day? Since we are such a small farm, we only work with family on a daily basis. I try to make sure Tom knows I appreciate all the extra work he puts in as well as to help him as much as I can to make his day go smoother. We do our best to make the time to do fun things with the kids throughout the year, whether it is a day at the lake or picking up ice cream from the creamery to enjoy together.

How do you celebrate Thanksgiving? This year, we will spend the afternoon of Thanksgiving with Tom’s extended family having a big meal in the church basement and playing card and dice games together. Saturday, my two kids will join us along with my mom and aunt for another small meal. The rest of the weekend will be spent relaxing and visiting.

Tell us about your farm. Tom and I milk 40 cows once a day and ship our milk to Organic Valley on the grass-only route. Our animals are rotationally grazed throughout the summer and are fed hay and baleage all winter. We raise our calves being fed once a day with nurse cows and raise our replacements as well as a few steers for us and family each year. Tom has been milking on this farm for over 20 years, and I joined the farm in 2019.

Who is someone in your life you are thankful for? I could not do life without my husband. He is the strongest and most hard-working man. His constant love and dedication to our family and the life we're making together is second to none, making every day we share here on the farm enjoyable. I'll be thankful for him every day of my life because he's given me the life of my dreams.

How do you show appreciation for the people you work with every day? We don't have any employees, but we have lots of companies we've worked with for years. We're always sure to let them know just how crucial their involvement is to our farm. I love to bake. Whenever I have anything extra, that all the boys in our house don't nibble up right away, I'm always eager to share.

How do you celebrate Thanksgiving? We love spending time with our family and friends in between chores on Thanksgiving. Oftentimes, holidays are spent gathering in our home because our family likes to make it easier for us to attend. It is pretty easy when the party comes to you.

Tell us about your farm. Twelve years ago, my husband and I were fortunate enough to nd a lender that believed in us, and we bought our farm. We milk about 200 cows in a robotic facility, raise our heifers and harvest our crops. It's a lot of work for two people with three young sons, but we love it. We're thankful every day for the opportunity to start our own farm and for the wonderful people in this small community who have been so supportive.

Deb

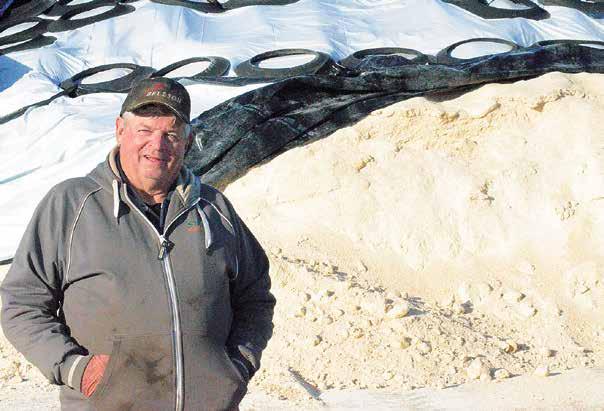

Describe your farm and facilities. The cows are housed in two freestall barns. They are both 4-row barns with deep-bedded sand stalls.

What forages do you harvest? HarvXtra alfalfa, corn and brown midrib corn for silage.

How many acres of crops do you raise? We farm 1,200 acres.

Describe the rations for your livestock. We feed the milk cows roughly 55% forage – 60% corn silage and 40% haylage – whey, corn and protein mix. Dry cows get haylage, corn silage, mineral and straw. Heifers get haylage, corn silage, hay, mineral and soybean meal.

What quality and quantity do you harvest of each crop? We harvest 10,000 tons of corn silage at 65%67% neutral detergent ber digestibility and 30%-35% starch. We harvest 5,000 tons of haylage at 150 relative feed value. And, we harvest 60,000 bushels of high-moisture corn ground to 600 microns.

Describe your harvesting techniques for alfalfa and corn silage. Sullivan Custom Farming and Co-

rey Sullivan take care of our cutting, merging and hauling needs. We chop ourselves with a John Deere chop-

per. We chop our own corn silage as Turn to FORAGE

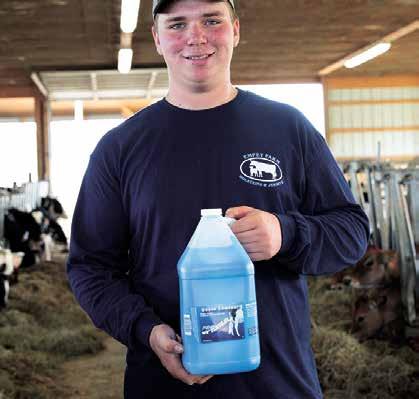

“Starting every fresh cow and heifer with Udder Comfort™ is an important step for quality and that next pound of milk. Udder Comfort is the best product available, and it’s part of what we do for milk production and quality,” says Rick Empet, Empet Farm, Kingsley, Pa., explaining that they spray fresh udders after each milking for 5 days after calving to soften udders.

“We love Udder Comfort,” son Alex adds. Alex was excited to learn he won a free Udder Comfort gallon in the August Comfort Matters Enews drawing after signing up at Empire Farm Days. We caught up with Rick, Dana and Alex busy working on their 6th generation dairy farm. Along with son Aiden and daughter Chelsea, the family is engaged as agvocates with Chelsea serving as a dairy ambassador.

well. We cut alfalfa at a 35to 37-day interval and aim for 60%-63% moisture. For corn silage harvest, we aim for 68% moisture.

What techniques do you use to store, manage and feed your forages? All feed is stored in bunkers; we strive for a high packing den-

sity to ensure proper fermentation. Bunkers are covered immediately after lling with a vapor barrier and two layers of plastic held down by tire sidewalls. Bunkers are defaced nightly for the next morning’s feeding. We keep the face even and smooth throughout.

Lacta ng cows

the cows’ ra on comes from forages.

Describe a challenge you overcame in reaching your forage quality goals. Several years ago, we invested in a self-propelled chopper; it allows us to be efcient in putting up high quality feed in a timely manner.

How do quality forages play a part in the production goals for your herd? High quality forages allow for the

cows to be productive, reproductively efcient and improve overall cow health.

What are management or harvesting techniques you have changed that have made a notable difference in forage quality? A few years ago, we experimented with HarvXtra alfalfa. It allows for exibility in our cutting

interval, offers high digestibility and increased tonnage. We also transitioned from four cuttings to three cuttings per season. The same goes for BMR corn silage as it has increased ber digestibility. Increasing the digestibility of our own forages has allowed us to decrease the amount of purchased feedstuffs and increases overall production.

JD S680 2013, PRWD, Duals, 2485 hrs., 1604 Sep. hrs., #551147....... $165,000 JD S780 2018, PRWD, Singles, 2489 hrs., 1686 Sep. hrs., #549036 .... $274,900 JD S680 2012, 2WD, Duals, 2631 hrs., 1790 Sep. hrs., #548165 .......$147,500 JD S680 2013, PRWD, Singles , 2635 hrs., 1854 Sep. hrs., #551017 ... $173,900 JD 9760 STS 2004, PRWD, Duals, 3500 hrs., 2251 Sep. hrs., #549273 . $68,000

JD 9500 1995, PRWD, Singles, 3543 hrs., 2208 Sep. hrs., #551180 ...... $27,500

Case IH 2388 1998, 2WD, Singles, 3876 hrs., 2943 Sep. hrs., #549406 $34,900

JD 9660 STS 2006, PRWD, Duals, 3925 hrs., 2453 Sep. hrs., #545355 . $72,000

JD 9500 1995, PRWD,

9750 STS 2000, 2WD, Duals, 5299

IOWA

Prairie Land Ag Supply Inc. Rock Valley, IA 712-476-9290

United Dairy Systems, Inc. West Union, IA 563-422-5355

WISCONSIN

Advanced Dairy Spring Valley, WI 715-772-3201

Ederer Dairy Supply Plain, WI 608-546-3713

DeLaval Dairy Service Kaukauna, WI 866-335-2825

Joe’s Refrigeration Inc. Withee, WI 715-229-2321

Mlsna Dairy Supply Inc. Cashton, WI 608-654-5106

Professional Dairy Services Arlington, WI 608-635-0267

Redeker Dairy Equipment Brandon, WI 920-346-5579

The Scharine Group Inc. Whitewater, WI 800 472-2880 Mt Horeb, WI 800-872-3470

MINNESOTA & SOUTH

DAKOTA

Farm Systems Melrose, MN 320-256-3276 Brookings, SD 800-636-5581

Advanced Dairy Mora, MN 320-679-1029 Pierz, MN 320-468-2494 St. Charles, MN 507-932-4288 Wadena, MN 218-632-5416

The smell of coffee, Shania Twain on the radio and the milk pump going are the three most prominent things I keep close to my heart from growing up on a dairy farm.

Being involved in the dairy industry has always been a passion. I knew from a young age I wanted to milk cows like my grandparents and parents. Today, I can proudly say I have my own small herd of registered Holsteins.

Growing up, I enjoyed being in the show ring with my dairy heifers. My parents put me on a halter the day I could walk. From there, it grew into more than just a passion but a lifestyle. I enjoyed showing in 4-H, FFA and the Minnesota Junior Holstein Association.

By Taylor Jerde Staff WriterI come from my family’s fth-generation farm. The farm has had beef cattle, pigs, sheep, horses and of course dairy cattle. I learned what hard work was at a young age from my initial chore of feeding calves.

Even though I had my chores on the farm, I was fortunate to be able to participate in sports and other extracurricular activities. I was in volleyball, dance line, track, National Honor Society and was a senior leader. Some of my proudest accomplishments were breaking a school record in track and advancing from sections to compete at the state dance tournament for multiple years.

I recently graduated from South Dakota State University with a degree in dairy production. Throughout college, I was heavily involved in organizations and clubs. I enjoyed being active in Dairy Club, Block and Bridle, Little International, intramural sports and a small group Bible study.

Being an active person has helped me stay true to myself and be thankful for the rural upbringing I had. Like many, I value my family and enjoy spending time with them when I can. Whether it’s going to a Wild game, traveling to a cattle show, going to a dance competition or going on vacation, I always seem to follow my roots back home. I have always liked living in the country and being around animals.

My family often refers to me as the cow whisperer. I, like many farmers, have had my fair share of favorite cows. Early on, I had a calf named Carli who sparked my passion for showing. Elberta was my next favorite; she was a large Holstein who I referred to as a gentle giant. She knew exactly who I was and only ever listened to me. Stella and Time are my current favorites, as both are previous show heifers who became a little too tame to be normal barn animals.

Perhaps these animals are the reason I love being a part of the dairy industry and telling farmers’ stories. In 2020, I was a Princess Kay of the Milky Way nalist, so I am no stranger to sharing the stories of farmers. I enjoy learning about different farms and the family members who came before them.

Dairy Star is a great way for me to be able to fulll that passion. I am excited to learn about farmers, tell their stories and share the good they are doing. I look forward to continuing to share my passion.

MELROSE, Minn. – For 23 years, Joel Middendorf and his family milked in a 62-stall tiestall barn. And for the last several years, they have been switching the tiestall barn at least once to milk the farm’s 113 cows.

Now, in addition to farming 700 acres, Middendorf and his family – dad Eugene, wife Julie and their children – milk a portion of their herd using a DeLaval robotic milking system on their farm near Melrose.

“I look back on how much simpler things have been since April, and I genuinely don’t know how we ever made it to the boy’s football games and track meets,” Middendorf said. “The way we are doing things now has made me wonder why we didn’t put it in seven years ago when we rst thought about it.”

On April 14, the Middendorfs walked the better producing 60% of their herd into a new freestall barn equipped with a robot, exible stall system and rubber mats. For two weeks, the family eased the herd into its new lifestyle.

“It’s a night and day differ-

ence,” Middendorf said. “We were bedding the bed pack three times a week, and the cows just weren’t performing like they should; they were uncomfortable and that reected in our production.”

Since the transition, milk production went up nearly 20 pounds of milk per cow per day within the rst month of using the robot. Milk quality has improved, too, with a somatic cell count below 200,000.

In addition to improvements the Middendorfs have seen in their herd, the family now has more time to focus on other aspects of the farm. Middendorf said milking in the tiestall barn was taking nine hours a day.

“I think our forages this year have been way better,” Middendorf said. “I can check the barn whenever it ts my schedule. I don’t have to stop making hay to go milk, and Connie, our hired hand, takes care of milking the tiestall cows.”

The Middendorfs built the freestall barn with the next generation in mind. The Middendorfs’ sons – Gentry, Jesse and Jordy – are instrumental to the dairy and help on the farm when

they are able.

“We set it up for the future,” Middendorf said. “We have the ability to add east and then an addition west to have four total robots. We have what will suit us now, but if the kids decide to come back, in say ve years, the option to go all robotic milking

is there for them.”

The Middendorfs also implemented an activity monitoring system. The collars help record which cows are having problems during milking, who is in heat and how often the cows are getting up to eat.

All of the information is ac-

cessible through an app. They receive notications as to who has not been milked in a while, and with that information, they fetch cows and coax them to the robot for milking.

CALUMET COUNTY

• D&D Equipment

Chilton • 920-849-9304

• Stanley Schmitz Inc Appliance & Dairy Center Chilton • 920-849-4209

CHIPPEWA COUNTY

• Chippewa Farm Service, LLC Chippewa Falls • 715-382-5400

• Chippewa Valley Dairy Supply Stanley • 715-644-2350

CLARK COUNTY

• Cloverdale Equipment Curtiss • 715-223-3361

• Premier Livestock Withee • 715-229-2500

• Silver Star Metals Withee • 715-229-4879

COLUMBIA COUNTY

• Central Ag Supply Baraboo • 608-356-8384

DANE COUNTY

• Argall Dairy Systems Belleville • 608-424-6110

DODGE COUNTY

• Central Ag Supply Juneau • 920-386-2611

• Knowles Produce & Trading Co. Knowles • 920-583-3747

DUNN COUNTY

• Leedstone Menomonie • 866-467-4717

• Midwest Livestock Systems Menomonie • 715-235-5144

FOND DU LAC COUNTY

• Redeker Dairy Equipment Inc. Brandon • 920-346-5576

• Argall Dairy Systems, West Platteville • 608-348-3385

• Dickeyville Feed Dickeyville • 608-568-7982

• Fuller’s Milker Center, LLC Lancaster • 608-723-4634

• J. Gile Dairy Equipment Inc. Cuba City • 608-744-2661

• Premier Co-op Lancaster • 608-723-7023

• Scott Implement Platteville • 608-348-6565

GREEN COUNTY

• Monroe WestfaliaSurge/Koehn, Inc. Monroe • 608-325-2772

• Top Notch Feed & Supply New Glarus • 608-527-3333

IOWA COUNTY

• Farmer’s Implement Store

Mineral Point • 608-987-3331

• Premier Co-op Mineral Point • 608-987-3100

JACKSON COUNTY

• W.H. Lien, Inc. Hixton • 715-963-4211

KEWAUNEE COUNTY

• Luxemburg Motor Company Luxemburg • 920-845-2011

• Spartan Construction Luxemburg • 920-845-9892

LAFAYETTE COUNTY

• Center Hill Veterinary Clinic Darlington • 608-776-4083

MANITOWOC COUNTY

• EIS Implement

Two Rivers • 920-684-0301

MARATHON COUNTY

• Brubacker Ag Equipment, LLC Edgar • 715-613-7308

MONROE COUNTY

• Preston Dairy Equipment Sparta • 608-269-3830

PEPIN COUNTY

• Anibas Silo & Repair Arkansaw • 715-285-5317

POLK COUNTY

• Midwest Machinery Osceola • 715-220-4256

RICHLAND COUNTY

• Fuller’s Milker Center, LLC Richland Center • 608-647-4488

• Premier Co-op Richland Center • 608-647-6171

ROCK COUNTY

• Tri-County Dairy Supply Janesville • 608-757-2697

SAUK COUNTY

• Central Ag Supply Baraboo • 608-356-8384

SHEBOYGAN COUNTY

• Perfect Circle Tire Co. Waldo • 920-528-7277

VERNON COUNTY

• Koon Kreek Feeds Coon Valley • 608-452-3838

• Premier Co-op Westby • 608-634-3184

ALLAMAKEE COUNTY

• K & R Feed and Grain Dorchester • 563-568-4513

DUBUQUE COUNTY

• Brunkan Equipment Worthington • 563-855-2434

• CJ Beeps Equipment Farley • 563-744-5010

• Eastern Iowa Dairy Epworth • 563-876-3087

• Helle Farm Equipment Dyersville • 563-875-7154

• New Vienna Ag Automation New Vienna • 563-921-2896

• Roeder Implement Dubuque • 563-557-1184

• Scherrmann’s Implement Dyersville • 563-875-2426

• Skip Breitbach Feeds Balltown • 563-552-2393

• Ungs Shopping Center (IAS) Luxemburg • 563-853-2455

HOWARD COUNTY

• Farmers Win Co-op Cresco West • 563-547-3660

WINNESHIEK COUNTY

• Brynsaas Sales & Service Decorah • 563-382-4484

• Franzen Sales & Service Fort Atkinson • 563-534-2724

• Lang’s Dairy Service Decorah • 563-382-8722

• Midwest Machinery North eld • 507-645-4886

• Werner Implement Vermillion • 651-437-4435

• Caledonia Haulers Caledonia • 507-725-9000

• ESB Bank Caledonia • 507-725-3329 Eitzen • 507-495-3321 La Crescent • 507-895-2227

• Farmers Win Co-op Caledonia • 507-725-3306 Houston • 507-896-3147

• Hammell Equipment Eitzen • 507-495-3326

• Midwest Machinery Caledonia • 507-725-7000

• Ag Partners Farm Store Goodhue • 651-923-4496

• Midwest Livestock Systems, LLC Zumbrota • 507-732-4673

• Midwest Machinery Cannon Falls • 507-263-4238 Wanamingo • 507-824-2256

WABASHA

• Ag Partners Farm Store Plainview • 507-534-2531

• Beck Implement Elgin • 507-876-2122

• Leedstone Plainview • 800-548-2540

• Midwest Machinery Plainview • 507-534-3116

• Wingert Sales & Service Plainview • 507-534-2285

WINONA

• Elba Co-op Creamery Elba • 507-796-6571

• Lang’s Dairy Equipment Lewiston • 507-452-5532

• Lewiston Rentals and Repairs Lewiston • 507-523-3564

• Midwest Machinery St. Charles • 507-932-4030

*Enter as often as you like. One entry per store visit, please. Winners must be 18 years or older and a Grade A or B dairy farmer for adult prize, or 17 years or younger and a son or daughter of a Grade A or B dairy farmer for heifer calf. Winners must also live in the Dairy Star circulation area to be eligible and are responsible for transport of animal.

Middendorf said in the next few months, he would like to increase the number of times the cows visit the robot from around 2.6 to closer to three

“There are already several cows that go to the robot three times a day, but I want that number to be higher,” Middendorf said. “I haven’t had to treat anyone in the barn yet for mastitis, which means they are going to the robot often enough, and their quarters

aren’t being over milked.”

Middendorf said he appreciates that the robot pulls the milking unit off each individual teat, which prevents over milking. He said when milking in the tiestall barn, the units are watched closely, but because no quarter is the same as the next, some cows are over milked.

Middendorf said the 43 cows being milked in the tiestall barn have seen production improvements too. Without

having to share space with the rest of the herd, those cows are more comfortable and easier to manage.

“Connie wanted to keep milking for another ve years in the tiestall barn,” Middendorf said. “I’m ne with that, because we are still making use of the barn, and we milk the fresh cows there once before rotating them into the freestall barn.”

With their herd on an upward trend,

the Middendorfs are looking forward to the continued use of robots for both themselves and the next generation should they decide to take over the family farm.

“There is so much to be learn about these robots,” Middendorf said. “But I already know that I like it, and I want to learn more about it to help my herd improve.”

LA CROSSE, Wis. – Many farmers are hesitant to begin transition planning because they think they need to have all the answers before speaking with a professional.

Kelly Wilfert, an agricultural attorney from Green Bay, said all a farmer needs to know is their ideal situation for their farm. The rest of the details can be gured out together with a professional.

“If we’re doing transactional work like succession planning, your imagination can sometimes be the bounds,” Wilfert said. “There are some rules that we have to keep in mind, but if you come up with a goal of what you want the farm to look like, we have a lot of options as far as how to do that.”

on the funding they will need for regular maintenance or expansion of the farm, and the overall viability of the farm.

“It’s not only balancing what the folks who are passing the farm on want but also what does the farm itself need in order to keep running,” Wilfert said.

Besides the primary owners, Wilfert said it is important to include third parties who may not be driving the conversation but need to know what is going on. This can include siblings, spouses, advisors, creditors, investors and business partners.

With so many people involved in the planning process, Wilfert stressed the importance of exibility in a succession plan.

When putting together succession planning documents, Wilfert said plan for change, such as losing or gaining a person.

Kelly Wilfert agricultural attorney

Kelly Wilfert agricultural attorney

Wilfert spoke Nov. 4 about the transition process as part of a succession planning workshop hosted by the University of Wisconsin-Extension.

Because farm succession involves the future of the farm by transitioning the farm from one owner to another, Wilfert said the rst place to start is by identifying who is on the team. This includes the primary owners and the primary successors. Oftentimes, these are parents and children but not always.

Wilfert said as an attorney, she can only represent one party, the primary or succeeding party. According to Supreme Court rules, attorneys must avoid conict of interest for their client.

“In succession planning context, we have the farm entity, current owners and future owners,” Wilfert said. “What’s best for one might not be the best for the other. Technically, their interests are averse to each other, and sometimes those parties could and should get their own representation.”

Once the primary parties are established and represented, consideration needs to be given to each member’s stage of life and needs going forward. The current owners need to consider their source of income after selling the farm, whether they will need long-term care and what kind of lifestyle they are going to maintain after they leave the farm.

For the next generation, the focus is

“That plan is going to have to adapt and change,” she said. “We want to make sure that our plan is still set up to allow some exibility.”

Beyond the members of the farm changing, if succession planning starts early on, needs and dreams can inevitably change as people age. In that case, exibility is just as important. Most times, farm successions take time to implement.

“These plans typically are not happening in the snap of a nger where we plan today, do it tomorrow and all move on with our lives,” Wilfert said. “They take a while to play out.”

In order to implement a transition, a series of tools can be used like a sale, trust, gift or a combination. Other tools, which Wilfert refers to as emergency tools, include a medical and nancial power of attorney.

“Agriculture is a high-risk industry, so we strongly encourage folks to set these up and revisit them regularly,” Wilfert said.

All of the documents involved with succession planning are what most commonly scare people away from the process, Wilfert said.