DAIRY ST R

Volume 24, No. 20

“All dairy, all the time”™

December 10, 2022

Volume 24, No. 20

December 10, 2022

By Grace Jeurissen grace.j@star-pub.com

By Grace Jeurissen grace.j@star-pub.com

SAUK CENTRE, Minn. – Felling Dairy LLC was awarded the Dairy Cattle Reproductive Council’s highest award for excellence.

Six dairies received platinum recognition as part of the 2022 Excellence in Dairy Cattle Reproduction Awards from the council, which ranks dairies as platinum, gold, silver or bronze.

The winners were recognized Nov. 16 in Middleton, Wisconsin.

“I was surprised when they emailed and said we

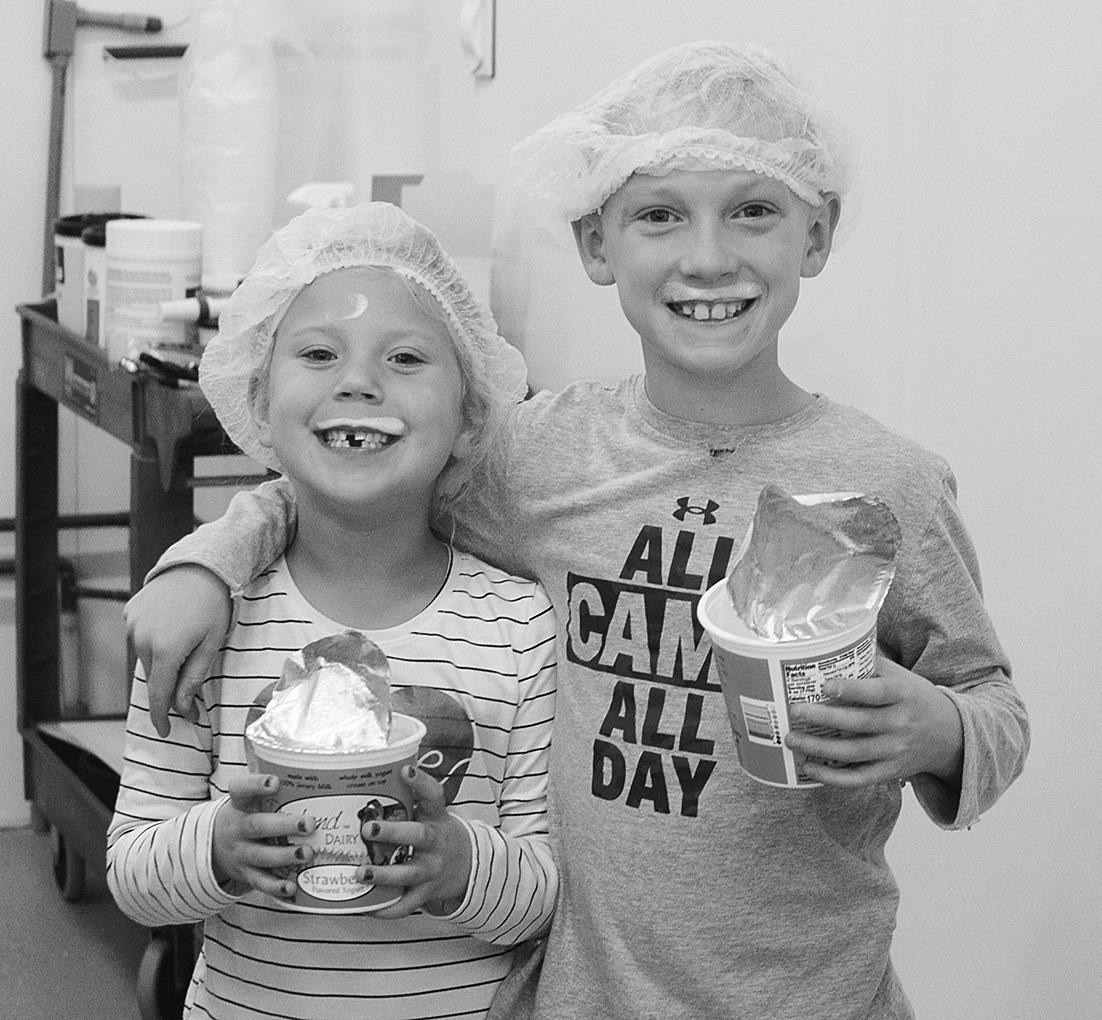

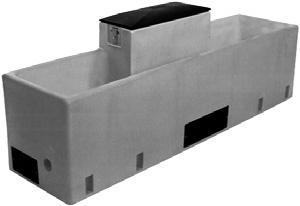

HUTCHINSON, Minn. – All students across the Hutchinson school district now have access to fresh milk straight from the farm.

On Oct. 25, Tiger and West elementary schools became the last schools in the district to roll out the bulk milk program that began in the high school and middle school last February. The feedback has been positive from students and staff.

Lesli Mueller, director of child nutrition for Hutchinson schools, was involved in getting the program up

“There’s a world of dif-

ference in the taste between coming out of a carton and coming out of the dispenser,” she said. “The milk is so fresh. It’s coming right off the farm. Kids are really excited about the taste.”

The improved taste of the milk has kids drinking more.

“I like that kids are drinking more milk,” Mueller said. “New kids are drinking milk. Once they gave it a try, they liked it; they just had to get past that rst taste.”

Mueller said she sees gains in both health and food knowledge through using dispensers.

“(Drinking more milk) is another way for kids to get nutrition as they are growing, another way to

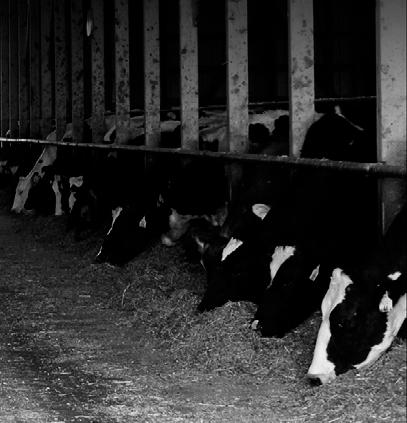

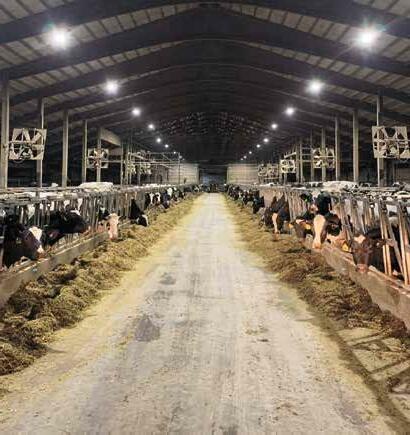

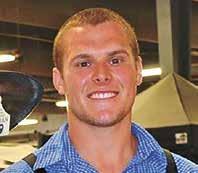

MARK KLAPHAKE/DAIRY STAR The Felling Dairy breeding team – Victor Ledsma (from le ), Hilarion Torres, Jason Felling, Saul Hernandez and Marcos Gomez – stand in the freestall barn Nov. 28 at Felling Dairy near Sauk Centre, Minnesota. Felling Dairy received the pla num 2022 Excellence in Dairy Ca le Reproduc on Award.www.dairystar.com

• Online: 2834-6203

ISSN Print: 2834-619X

522 Sinclair Lewis Ave. Sauk Centre, MN 56378

Phone: 320-352-6303 Fax: 320-352-5647

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com 320-352-6303 (ofce) 320-248-3196 (cell) 320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Net U.S. cash farm income is forecast to be a record high $188 billion for 2022. That’s up 25.5% from 2021. Cash receipts for corn, soybeans, wheat and other crops are up 19%. Receipts from animal agriculture are expected to increase over 30% from last year.

Karen Knoblach

• karen.k@star-pub.com Annika Gunderson • annika@star-pub.com

Editorial Staff

Tiffany Klaphake - Assistant Editor 320-352-6303

• tiffany.k@dairystar.com

Maria Bichler - Assistant Editor maria.b@dairystar.com • 320-352-6303

Danielle Nauman - Staff Writer 608-487-1101 • danielle.n@dairystar.com

Stacey Smart - Staff Writer 262-442-6666 • stacey.s@dairystar.com

Abby Wiedmeyer - Staff Writer 608-487-4812

• abby.w@dairystar.com

Grace Jeurissen - Staff Writer 320-352-6303 • grace.j@star-pub.com

Jan Lefebvre - Staff Writer 320-290-5980 • jan.l@star-pub.com

Taylor Jerde - Staff Writer 507-403-1680

• taylor.j@star-pub.com

Consultant

Jerry Jennissen 320-346-2292

Main Ofce: 320-352-6303 Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication Sales Manager - Joyce Frericks 320-352-6303 • joyce@dairystar.com

Mark Klaphake (Western MN) 320-352-6303 (ofce) 320-248-3196 (cell)

Laura Seljan (National Advertising, SE MN) 507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com

Jerry Nelson (SW MN, NW Iowa, South Dakota) 605-690-6260 • jerry.n@dairystar.com

Mike Schafer (Central, South Central MN) 320-894-7825 • mike.s@dairystar.com

Amanda Hoeer (Eastern Iowa, Southwest Wisconsin) 320-250-2884 • amanda.h@dairystar.com

Megan Stuessel (Western Wisconsin) 608-387-1202 • megan.s@dairystar.com

Kati Kindschuh (Northeast WI and Upper MI) 920-979-5284 • kati.k@dairystar.com

Julia Mullenbach (Southeast MN and Northeast IA) 507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell) bob.l@star-pub.com

The deadline for news and advertising in the Dairy Star is 5 p.m. Friday the week before publication.

One year subscription $40.00, outside the U.S. $200.00. Send check along with mailing address to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378.

Our ad takers have no authority to bind this newspaper and only publication of an advertisement shall constitute nal acceptance of the advertiser's order.

Letters and articles of opinion are welcomed. Letters must be signed and include address and phone number. We reserve the right to edit lengthy letters. The views and opinions expressed by Dairy Star columnists and writers are not necessarily those of the Dairy Star / Star Publications LLC.

The Dairy Star is published semi-monthly by Star Publications LLC, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378-1246. Periodicals Postage Paid at Sauk Centre, MN and additional mailing ofces.

POSTMASTER: Send address changes to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378-1246.

In the words of President Joe Biden, Congress’ action on the rail contract will spare the country “a Christmas catastrophe in our grocery stores, our workplaces and in our communities.” The House and Senate took action to force unions to accept a tentative contract agreement that was adopted in September. Biden later signed the legislation. The ve-year contract gives union railroad workers a 24% bump in wages but does not address the issue of paid sick leave.

The Republicans have a slim majority in the House and a very tight margin is in the Democrat’s favor in the Senate. Compeer Financial chief mission and marketing ofcer John Monson said that will inuence the farm bill debate. “I don’t sense that given the dynamics in place right now, that we’re going to see a major shift in policy perspective,” Monson told Red River Farm Network. “It just seems to me that the path of least resistance is more of an extension of the current farm bill at least for a year, if not longer.” Monson said there will be different dynamics at play during the upcoming session. “The nutrition title will cost 85% of this next farm bill of $1.3 trillion. That’s going to be a big task.”

Midterm elections are behind us, and there will be

many new legislators in St. Paul, Minnesota, for the upcoming session. Minnesota Farmers Union government relations director Stu Lourey said now is the time to build relationships with the 65 rstterm lawmakers. “Talk to legislators, invite them out to your farm,” he said. “I think folks are anxious to ask for their time, but they want to do a good job and represent their constituents well.”

The Minnesota DFL will control the governor’s ofce, House and Senate in the upcoming biennium. With the Democrats having a slim, one-vote majority in the Senate, incoming minority leader Mark Johnson believes the Republican caucus will need to be proactive. “We’ve got some really good ideas on ways to partner with them, but what that looks like at this point, I’m not exactly sure,” Johnson told Red River Farm Network. “We’ll have to see what their agenda is in agriculture.” Johnson, who is based in East Grand Forks, is worried about the potential regulatory impact on agriculture. “We’ve been able to ght back for six years and hold off a lot of those issues,” Johnson said. “Now the oodgates are kind of open; I’m really scared what that looks like for our ag industry.”

In an update on John Deere’s quarterly earnings, Reuters reported farm equipment and combines are virtually sold out for 2023. StoneX chief commodity economist Arlan Suderman said the high commodity prices in recent years have driven up demand. “Unfortunately, the same issues keeping us from getting new cars is also happening in the equipment industry,” Suderman said. The computer chip shortage is the missing link. “So much of our equipment is reliant on chips, and there is still a shortage,” he said. “The ability to manufacture and get products distributed has led to some long waiting lists for equipment.”

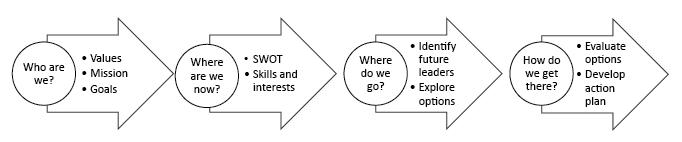

Strong management skills are a must for protable dairy farmers. “Most of the successful farmers have exible business plans and think about long- and short-range goals,” said Jim Salfer, University of Minnesota Extension dairy specialist. Salfer said the top dairies review their management plan on a regular basis. “They get together with their trusted advisors and say this is how we did this year,” Salfer said. “Based on our goals, what do you guys see coming down the road?” Record keeping skills and time management are also characteristics of successful dairy farms.

The National Milk Producers Federation is asking Congress to protect the domestic production of infant formula. When supplies tightened earlier this year, tariff waivers were granted to bring more baby formula into the United States. NMPF said the situation has improved and the preferential tariff benets should be allowed to expire at the end of the year.

Fed signals another half-point increase

Federal Reserve Board chairman Jerome Powell signaled the central bank is on track to raise interest rates by a half a percentage point at its next meeting. During a speech Wednesday, Powell said it would make sense to slow rate increases to give the economy time to adjust to previous rate hikes. A 75 basis point interest rate hike was seen for four straight months.

New Jersey Sen. Cory Booker has introduced a bill targeting large-scale livestock operations. The proposal would require packers, processors and farmers to register their businesses with USDA, submit a disaster preparedness plan and pay for disaster mitigation. The bill also calls for more humane treatment of downed animals or those being depopulated due to a disease.

Booker is a member of the Senate Agriculture Committee and has proposed similar bills in the past.

The Minnesota Department of Agriculture is funding three projects dealing with mental wellness in agriculture. The Minnesota FFA Foundation received $52,000 to support activities at the chapter level. Grants were also awarded to the Southern Minnesota Agricultural Center of Excellence and the Latino Economic Development Center.

Minnesota State Fair CEO Jerry Hammer plans to retire next spring. Hammer has been on the state fair staff for over 50 years, including 26 years as the CEO. The Minnesota State Fair Board of Managers has started the search process.

Farm broadcaster Joe Gill, who is with KASM-Albany, is taking over as president of the National Association of Farm Broadcasting in 2023.

Germany is credited with starting the tradition of putting up a Christmas tree. That answers our last trivia question. For this week’s trivia, how much eggnog is consumed by Americans each Christmas season? We will have the answer in the next edition of Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network, based in Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two adult sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

were nalists,” Jason Felling said. “To be considered for excellent performance in reproduction is humbling.”

Felling Dairy milks 1,200 cows in a 28-stall rotary parlor three times per day. The farm is owned in partnership between Felling, his wife, Marie, and Felling’s parents, Cyril and Deb Felling.

Also receiving a platinum award were the Davis Family Farm, Jayme and Brad Davis of Darlington, Wisconsin; Emerald Spring Dairy, Darrin Young of Plainview; Fetzer Farms of Elmwood, Wisconsin; High Noon Dairy LLC, Peter Bouma of Hereford, Texas; and Riddell Farms, Travis Riddell of Atwood, Ontario, Canada.

At Felling Dairy, all the breeding is done in-house which contributed to the recent achievement.

In 2018, the Fellings decided to train several employees who showed interest in learning how to articially inseminate. They provided those individuals with education, and now ve of their 30 employees are trained to do A.I., three of which are in charge of heat synchronization, heat detection and breeding on a daily basis.

The employees that A.I. for Felling Dairy have been dedicated to their job, and in turn, the results they receive in reproductive rates have gained the farm recognition.

“There is no way we would be achieving this level of reproduction in our herd without these guys,” Felling said. “They have been an asset to the farm, and I enjoy working with them.”

Felling likes to maintain a positive workplace and said he makes sure employees are heard; they work together as a team to change protocols on the farm.

“It’s important for me to listen to our employees because they are in places I’m not,” Felling said. “So, I have to build trust with them by being an open ear and taking their advice and considerations to heart.”

Felling will communicate with employees regularly to touch base on matings and synchronization. The farm uses double ovsynch around 70 days in milk and timed A.I. If a cow does not become pregnant at rst service, they watch for signs of heat until 30 days when the herd is pregnancy checked. If the cow shows up

open, they will re-synch her.

The farm uses all sexed Holstein semen on higher genomic cows and beef semen on the lower end. The heifers are bred with sexed Holstein semen.

Taking steps to get a cow bred back or a heifer pregnant for the rst time is a concise practice at Felling Dairy. They have implemented protocols that have worked for their operation.

“We are continuously adjusting things to improve,” Felling said. “This year, we adjusted our breeding age in heifers to around 415 days to give them more time to grow before freshening, and we extended our voluntary waiting period 14 days to not breed the cows too aggressively.”

Currently, Felling Dairy is achieving a pregnancy rate of 40%, a conception rate of 55% in cows and 58% in heifers.

Since 2018, Felling has been in charge of managing the breeding on the farm. When Felling started taking care of this aspect of the operation, he inquired about genomic testing. That became pivotal for the operation.

“I was skeptical of it at rst, but after doing it for several years now, I realize how valuable of a tool it is for herd improvement,” Felling said.

With the help of their STgenetics representative, Andrew Krause, the Fellings discovered the tools that took their breeding program to the next level.

“Andrew was the one that nominated us for the award,” Felling said. “He has been a key player in the success of our operation along with our great crew of employees.”

Genomic testing has made it possible for Felling to chromosomal mate his herd, helping mitigate the possibilities of inbreeding. He said they wrote sires in their systems before genomic testing and found that some of the cows had been misidentied. Genomic testing the herd allowed for the breeding team to x those inaccuracies and plan for a better next generation of producers.

Felling likes his cows to have moderate frames, good components and sturdy feet and legs. Production used to be highly sought, but after

reassessing their goals, the family agreed that utilizing more in-house forages for feeding and relaxing milk production was more protable for the farm and better for the cows.

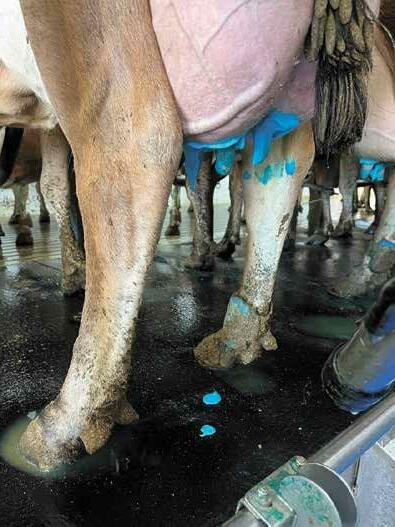

Cow comfort at Felling Dairy is a priority. The free stalls are bedded with sand. Employees groom stalls during every milking and scrape pens. Sand is added to the stalls twice a week to keep them 75%100% full for maximum cushion and comfort. Cows are also routinely hoof trimmed.

“We’ve found that building a moderate framed cow and not pushing production has helped build our reproductive rates as well,” Felling

said. “Our cows are comfortable and well fed which helps them settle.”

Felling said when they utilized a higher quality forage-based diet, their cows had less problems transitioning into the barn after freshening and stayed in the herd longer.

The key for Felling Dairy has been balancing the three key components of good people, quality cow comfort and good forages.

“We don’t do a good job on our farm to seek recognition,” Felling said. “Awards aren’t what give me the drive to do better. It’s knowing that we can provide top care for our cattle and a great place to work for our employees.”

get protein,” Mueller said. “They’re also learning about the farm and where their food is coming from. To me, that’s pretty exciting.”

Mueller said the district spent time preparing staff, students and parents for the change because there are reservations when attempting something new.

Linda Field has worked in the district’s lunch program for almost 30 years. She said it was unsettling at rst to think about the change.

“To be honest, I had my concerns, but the kids have proved me wrong,” she said. “They have done a wonderful job with the change.”

Field has seen positive results both in students drinking more milk and wasting less.

“This is denitely a lot better than kids taking just a few swallows from a carton and then throwing it in the garbage,” Field said.

Besides reusable glasses ending carton waste, students are throwing away less milk because of the principals, teachers and other staff taking time to explain and show how the dispensers should be used, encouraging students to take only the amount of milk they think

they will drink, knowing they can always return for more.

Although there is a bucket in each lunch room for students to dump any milk they do not drink before placing their used glass in the crate provided, the buckets now have little to no milk in them after lunch periods. The crates of used glasses can be placed directly in dishwashers.

Like Mueller, Joanie

Steinbach, a lead cook in the elementary schools, sees benets with the dispensers.

“The kids think it’s fun, so they are drinking more milk,” she said. “They love it. They’re also learning to be responsible and not to waste.”

Rob Richardson, a culinary coordinator in the elementary schools, agreed.

“Kids like the avor and the ability to go back for seconds,” he said. “It actu-

ally simplied things quite a bit.”

Richardson also said he appreciates both the reduction of waste and the cooler space they now have since they do not need room for carton storage.

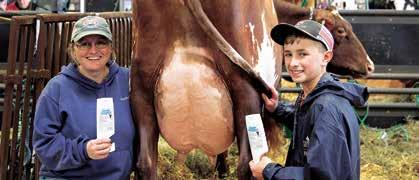

Milk is supplied to the district by Stoney Creek Dairy near Melrose. Nate Terres, who is in charge of sales and marketing for the dairy, said he is glad to be part of the district’s efforts to

offer a better milk product. Stoney Creek delivers milk once a week to Hutchinson schools and other schools that now have bulk tanks –Eden Valley-Watkins, Maple Lake, Litcheld, DasselCokato, McCray and West Central.

Terres said he knows of schools in the state that have made the switch, including schools in Minneapolis.

“It’s a great way to get students excited about dairy and to drink more milk,” he said. “The non-drinkers see how excited the other kids are and might give milk a try. We might make a milk drinker for life.”

Terres said he sees dispensers as being positive for both students and the dairy industry in general.

“It doesn’t matter which farm’s milk they drink, but it does mean a lot to us at Stoney Creek to be a part of it,” he said. “Healthwise, it’s benecial to these kids, and it helps grow the whole dairy industry.”

Mueller said she is grateful for others who rst got her thinking about adding the dispensers.

Barb Schank, nutritional services director in the Waconia district, had already implemented a bulk tank program several years ago. When a state meeting for directors was held at Waconia, Schank showed Mueller and the other directors how the program worked.

A few months later, Kevin Buss, who was on the Minnesota Dairy Promotion Council, contacted her about implementing a program.

“I thought, ‘Maybe I should be considering this,’” Mueller said. “I didn’t have to reinvent the wheel because I could always use Barb as a great resource.”

Mueller decided she wanted to take time to prepare everyone in Hutchinson before launching the program.

The district sent out information and materials to teachers a month ahead of time, helping them with what they could say to kids to help things run smoothly. Some even did a practice run with their students before their school’s launch date.

“We also put up posters and had announcements, just getting kids excited and really promoting it that month before starting,” Mueller said. “Things ran so much smoother that way, not that we didn’t have any hiccups, maybe some little spills, but surprisingly not as many as some thought there might be. I don’t think we even talk about spills anymore because there’s hardly been any.”

Elementary students wore cow-themed eye glasses on the rst day.

“They got a kick out of it,” Mueller said.

Kindergarteners Avalyn and Korbyn from West Elementary School approve of the new dispenser in their school.

“I like pulling up the levers,” Korbyn said. Avalyn mentioned the milk itself.

“I like when it tastes good like that,” she said.

Students have a choice between chocolate and white milk at each dispenser. Both Avalyn and Korbyn are fans of chocolate.

Mueller is also hearing approval from parents.

“Just like us, they were a little reluctant at rst, wondering if it was all going to work, but I’m denitely hearing good things, such as their kids coming home and saying how good the milk tastes,” she said. “They are probably hearing more comments now about school milk than they were before.”

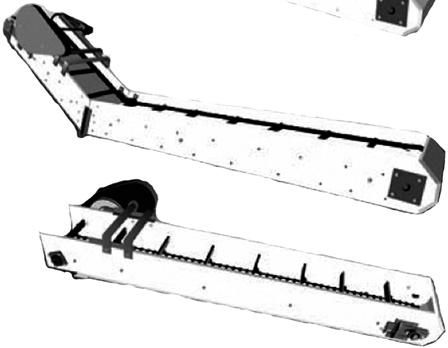

• Main drive wheels, directly under feed weight, increases stability

• Chain Choices, #55, 62, or 662 pintle, or SS T-Rod

• Honda Engine powered (6 or 9 hp)

• 33, 43, 60, 73 bushel sizes available

FREEPORT, Ill. – Paul Graybill grew up showing Jerseys and wanted to have his own herd. After seeing dairy setups across the country as a classier for the American Jersey Cattle Association, Graybill decided the only way to have a small dairy and remain protable was to diversify by processing their own products.

“It starts with really good milk from Jersey cows,” Graybill said.

Graybill and his parents, Doug and Kris, have been producing and selling Deerland Dairy yogurt since 2019 on their dairy farm near Freeport.

“Yogurt is one of the fastest growing products in the industry,” Graybill said. “It’s also one of the healthiest options so it’s an easy sell.”

The yogurt is made from 100% unhomogenized Jersey milk. Graybill said this adds to the avor and health benets of the product.

“The fewer processes that you run milk through the more natural it is,” he said. “Jerseys bring over 5% butterfat, and cream is all the value in yogurt. Yogurt is all about protein, and Jerseys typically run over 4% protein, so it adds to the quality.”

The process for Deerland Dairy’s yogurt begins with pasteurization. The raw milk is pasteurized and held at the pasteurization temperature for 30 minutes. It is then brought back to culture temperature. The cultures, avors and colors are added to the milk in the same vat that it is pasteurized in.

The product then runs through the pipeline to the ller machine. At this point, the product is as liquid as unprocessed milk. Cups are lled and foil tops are applied by a machine. Graybill then puts the lid on the container and sends the cup on a conveyor belt where the container is stamped with a sell-by date. It then slides down the ramp where cups are collected and put into

milk crates.

The crates of yogurt are placed in an incubating room where the product spends ve to six hours heating. The incubation process brings the pH below 4.6 and allows the product to set in the cup. After the incubation period is complete, the nished product is transferred to a cooler, where it is stored until being distributed.

Deerland Dairy products are sold in stores and restaurants throughout northern Illinois and southern Wisconsin. Kris also sells the products at a farmers market every week. Besides yogurt, the farm also produces sour cream and buttermilk. Many restaurants get their buttermilk and sour cream in 10-pound bags.

Yogurt is available in plain, strawberry, blueberry and vanilla avors. Graybill said their best-selling avor is plain, especially at the farmers market.

“People who want a high-end product like this want to add their own things to it,” Graybill said. “They like to buy plain yogurt and add berries or local honey from the market to avor it.”

Originally, the Graybills milked up to eight Jersey cows and processed all of the milk into their own products. Doug milked in the morning before going to work as a pipetter, and Graybill milked at night after working as a hoof trimmer during the day. When Doug had back surgery in 2020, however, the cows were rehomed to Kilgus Dairy in Fairbury. The Graybills now own 25 cows, all of which are housed elsewhere.

The move was bittersweet; the whole reason for making yogurt was to be able to have the cows. However, the partnership with Kilgus Dairy opened doors for the Graybill family. Because Kilgus Dairy processes all of their milk into products under their own label, they have been able to help distribute the Deerland Dairy products alongside their own.

Once a week, the Graybills deliver their products to Kilgus Dairy and bring milk back for their production. Kilgus Dairy milks all Jersey cows as well.

could work together as a family and raise kids on a farm,” Graybill said. “This is the way for small farmers.”

What counties or area do you cover? I have a lot of different counties that I have farms such as Swift, Kandiyohi, Cottonwood, Meeker and Stearns counties.

What do you enjoy about the farmers you work with? I love getting to know the farmers and how everything is going with them. Every farm is different, and it’s fun to see how different farmers do different things.

What do you like about your work for DHIA? I enjoy working around animals and people, so this job was a good t for me. I’m glad DHIA can help farmers in making their farm the best it can be. It’s a great company that’s centered on helping any farm big or small.

What do you do in your free time? My husband and I have four teenagers so I keep busy with their sports and events. We also live on a hobby farm with horses, goats, chickens and a big garden.

Sauk Centre, MN Buffalo, MN 763.682.1091 www.mndhia.org

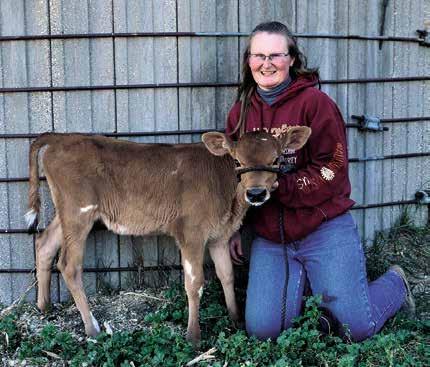

MILLVILLE, Minn. –

Over the last decade, Staci Sexton has spent her days growing and diversifying the genetics of her herd. She has sold nine bulls into the A.I. industry and shipped embryos across the U.S. and internationally; she has sold high genomic heifers and concentrates on polled genetics.

“I have always enjoyed genetics,” Sexton said. “I was in dairy judging, and I liked seeing how the animals look and also looking at their health and production traits while adding all that together. I enjoy seeing how one breeding from the next can change things and improve things.”

Sexton’s growth, combined with success, has resulted in her being named the 2022 Minnesota Farm Bureau Federation Young Farmers & Ranchers Achievement Award winner at the organization’s an-

nual meeting Nov. 17-19 in Bloomington, Minnesota.

The award winner is chosen based on their involvement in, and the nancial progress of, their farm and their contributions to the MFBF and their community.

Sexton spends her days working full time on the family dairy farm, Irish Ridge, where she also houses her herd, Schoene Kuh Dairy. She, her parents and brother, Lance, work together on the farm.

The family has a unique way of running the dairy farm. Animals are housed together and work is done in tandem, but family members have separate focuses on the farm. They have two bulk tanks, separate nances and different breeding programs.

Sexton decided this would work best for her and her family in order to focus on what she enjoys most –genetics.

“I like seeing my genetics grow,” Sexton said. “We keep everything separate but still work together to help

each other out.”

Along with growing her herd, Sexton is active in the Wabasha County 4-H program where she assists with the dairy show and previously coached the knowledge bowl team and the

dairy judging team. Sexton is the secretary of the Wabasha County Dairy Herd Improvement Association Board. She also served on the Wabasha County Fair Board from 2011-15 and helps with the fair as needed.

Sexton is also an active member of the Wabasha County Farm Bureau, where she served as a board member for two years. Through Farm Bureau, she attends many conferences and meetings.

“It’s a great thing for young farmers,” Sexton said. “It’s a great way to meet new people.”

After Sexton graduated from the University of Minnesota in 2010, she had a job with Land O’Lakes as a nutritionist. Sexton knew she wanted to return home to farm but wanted to go a different way with genetics.

At the age of 25, Sexton began her own herd of dairy cattle on her parents’ farm.

She started with 35 cows and bought the feed each day from her parents. She now has 60 cows – a mixture of Jersey, Holstein and Red and White Holstein –and rents 120 acres from her parents. They grow corn and alfalfa and use barley and pea as cover crops.

Sexton said she enjoys raising calves and seeing them reach their full potential. Previously, she raised

calves for another farmer with high genetic animals. She calved in his cows, and if she liked them once they calved, she had the opportunity to purchase them.

“That helped me grow my herd,” Sexton said.

Sexton said she is proud of the nine bulls she has raised and sold for use in the A.I. industry. Such success has allowed Sexton to purchase new equipment to enhance the farm.

In the last 10 years, Sexton and her family have invested into the farm. They built their newest calf shed in 2013, and in 2016, they built a heifer shed and also purchased heat detection collars.

Sexton also purchased a skid loader and bale chopper and most recently added weight readers in the parlor. Such advancements have allowed Sexton to become more efcient and focus her time on genetics.

Sexton said she enjoys being active in the agriculture industry through organizations such as Farm Bureau, which have allowed her to travel across the U.S. She said agriculture has taught her hard work and dedication.

“Agriculture has been a big part of my life,” Sexton said. “Agriculture is the backbone of the community.”

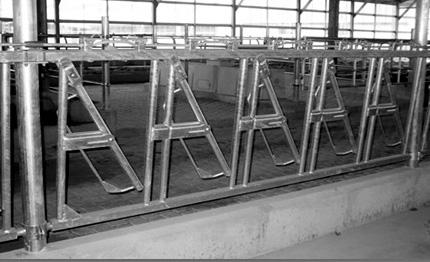

What is the size of your stalls and the depth of sand within them?

The head-tohead stalls are 48 inches wide and 14 feet long. The outside rows are 48 inches wide by 9.5 feet. Stalls are bedded with 8 inches of sand. We don’t have brisket boards.

What benets do you see from using sand bedding? We see less lameness, fewer injuries from slipping in the alleys and increased milk production.

How often do you replace sand or put sand in stalls and what is the method of adding sand? We add sand to the stalls twice a week using a skid loader and bucket.

How do you maintain and clean your stalls? Three times per day before the cows in that group get milked, we scrape out dirty or wet sand with a hand scraper.

How do you get rid of or recycle used bedding?

We have a ush ume that the sand and manure is scraped into when they clean the pens three times per day. The ume delivers that to the mechanical sand separator, which is located in a separate building. Our mechanical sand separator is a one-shot made by Daritech Inc. After 3-7 days, we move the sand with the payloader and pile it up next to the freestall barn to bed the stalls. We also have a vibrating slope screen to help clean the water to aid in sand separation.

What challenges can arise from using sand bedding?How did you solve those problems? There is a downside. Sand wears on equipment and concrete and everything. The production increase outweighs the extra expenses caused from sand. You can’t really solve those problems. Sand gets everywhere.

Tell us about your farm. The farm is owned by Eric and Chassidy Klein and Dean and Lois Klein near Lake City, Minnesota. We milk 700 cows and ship our milk to First District Association. We farm 2,000 acres. We also raise our heifer replacements and dairy crossbreds.

Greg Larson

Norwalk, Wisconsin Monroe County 310 cows

Twin Spruce Farms-North Perham, Minnesota Otter Tail County 1,350 cows

What is the size of your stalls and the depth of sand within them? The stalls are 48 inches wide and 17 feet curb to curb. Sand bedding is 8-10 inches deep.

What benets do you see from using sand bedding? Cow comfort is the main benet. We do not see any perching on the stalls. The hygiene scores are better, and we see more condence in the herd as far as mobility and traction.

How often do you replace sand or put sand in stalls and what is the method of adding sand? Stalls are raked three times a week and bedded once a week. We add sand with a sand shooter attachment on the skid loader.

How do you maintain and clean your stalls? We have a hoe that we use to scrape stalls as we collect cows at milking time. If there is any defecation or urine, we rake it out.

How do you get rid of or recycle used bedding? The sand gets scraped into the manure pit with the manure and then applied to elds when the pit is emptied.

What challenges can arise from using sand bedding? How did you solve those problems?

The manure pit needs to be managed. We bought a large enough pump and tractor to agitate everything so it could be hauled. Sometimes we use two pumps. Another challenge is that the cost of trucking has doubled in the last six months. We are looking into ways to haul our own to save on that cost. When sand is delivered on cold days, it tends to clump. We manage that by putting it in the stalls right when it is delivered.

Tell us about your farm. We are a cash crop farm and wanted to dairy. We farm 4,000 acres of corn, soybean, alfalfa and small grains. I have always been involved in the dairy because I love cows and the industry. Our milk is shipped to Foremost Farms. We have an excellent team and are excited about the future.

What is the size of your stalls and the depth of sand within them? The stalls are 48 inches wide and 6 feet long. The sand depth is 4-6 inches.

What benets do you see from using sand bedding? We have better cow comfort with more stall use as well as lower mastitis rates from bacteria not harboring in the sand.

How often do you replace sand or put sand in stalls and what is the method of adding sand? We add sand 2-3 times a week with a sand shooter or skid loader and bucket.

How do you maintain and clean your stalls? We hand scrape manure and wet sand out and work the stall level with a groomer on the tractor three times a day.

How do you get rid of or recycle used bedding? We scrape manure and sand into a ush ume and run it into a sand lane where we reclaim the sand. We stack the sand until it is dry enough to reuse.

What challenges can arise from using sand bedding?How did you solve those problems? You have to have an inventory of sand to allow the sand enough time to dry out before using again in the stalls. We have had the manure lagoon ll with sand over time from sand making its way through the settling lane. The increased agitation when pumping or hiring an excavator can be necessary for storage.

Tell us about your farm. We have two milking sites, one in Perham, Minnesota, and one in Richmond, Minnesota. We farm about 2,500 acres of land. This past year, we purchased a site near Sauk Centre, Minnesota, for our heifers. Our milk is sold to Bongards. Twin Spruce is run by Arnie and Kris with the help of three of seven children: Arnie Jr., Ashley and Andy. Some of the boys come home to help when they can.

Allamakee County

180 cows

What is the size of your stalls and the depth of sand within them? Our headto-head stalls are 4 feet by 8 feet. The outside stalls are 4 feet by 9 feet. They are all bedded with bluff sand approximately 12 inches deep.

What benets do you see from using sand bedding? Cow comfort is the No. 1 benet. Additional benets include a low somatic cell count. We just don't have to treat many cows for mastitis. We also have increased footing. We started using sand-bedded free stalls in 1998 when I started dairy farming on my parents’ farm. We tore out the old concrete stalls that were bedded with corn stalks. We went with sand because that’s what people where telling us is the best for cow comfort, and it was also more economical than mattresses and shavings.

How often do you replace sand or put sand in stalls and what is the method of adding sand? We add sand every 10-14 days by using a skid loader and

What is the size of your stalls and the depth of sand within them? We have three different-sized stalls in our 60-stall tiestall barn. All stalls are 76 inches long, or a little over 6 feet, and most are 56 inches wide. We have a 3-inch PVC bedding saver pipe in the back of the stalls and a 9-inch curb in the front of the stalls. Before adding sand, we ripped out the pasture mats and left the standard rubber mat beneath intact. It provides a nice, at cushion on top, and then I go as deep as I can with the sand which is about 9 inches initially and keep the stalls as full as I can. Half of our cows live in the tiestall barn and half live in our renovated freestall barn. We bed with sand in both barns.

What benets do you see from using sand bedding? The biggest benet we see is the quality of laying time. When I walk in the barn, all the cows are lying down. And if I walk through the barn, the cows won’t even get up. In the past, when I pushed in feed or cleaned up, cows would jump up left and right. We have no swollen hocks, and we went up a little in milk too. If you can improve cow comfort and efciency by putting sand in, it’s worth it. My mom was concerned about milking on sand, but she actually nds it more comfortable than the mats. I’ve had knee issues, and since putting sand in, my knees haven’t bothered me as much. We have more cushion now when stepping up and down in the stalls. Sand also saves me time as I don’t have to bed the cows every single day. I go through and rake and clean the stalls. It saves me a half hour every morning not having to shake straw. Putting sand in only takes 15 minutes.

We started using sand in our tiestall barn Oct. 28. The freestall barn has been bedded with sand since my parents bought the farm in 1991. It is benecial for these cows to be on sand. Previously, our cows were on pasture mats, and I didn’t like how hard the cows’ feet got. This made them more susceptible to getting a sore foot and didn’t allow for good foot growth. When we trimmed the cows, they hardly had any shedding or pad, just a at, hard sole wore down to nothing. Seeing the difference of cows’ feet in the free stalls versus the tie stalls and the amount of lameness the tiestall barn cows had over the freestall cows was a big push for putting sand in.

bucket. We also utilize a sand shooter at times.

How do you maintain and clean your stalls? We remove any manure or wet sand from the back of the stall each time we take the cows to the parlor and scrape the barn twice daily.

How do you get rid of or recycle used bedding? We currently don't reclaim any of the sand from the stalls. The sand goes into the manure pit.

What challenges can arise from using sand bedding? How did you solve those problems? The biggest challenge with using sand bedding is handling it once it's in the manure pit. We try to agitate well before pumping the pit. Whatever is left at the bottom of the pit is loaded with a loader and hauled out with slingers. Usually, we are able to remove 70% pumped and 30% needs to be hauled with the slingers.

Tell us about your farm. My wife, Michelle, and I along with our three teenage sons are very involved in the day-to-day operation of our 180-cow dairy. We also employ two high school students who help milk in the evening and on weekends. We have a 3-row freestall barn and milk in a double-8 parlor. Our milk goes to Foremost Farms. We raise our grain and forage to feed our herd and replacements.

How often do you replace sand or put sand in stalls and what is the method of adding sand? We add new sand in the tiestall barn once a week with a skid loader and sand shooter. If we didn’t switch cows in and out and have them tracking sand out every time, we could probably go every two weeks before adding new sand.

How do you maintain and clean your stalls? I have to be more aggressive initially with the trainers than I would like, but I don’t want cows making a mess under themselves. I don’t like to see manure, so I’m always cleaning under the cows. In the morning, I go through and groom the stalls with a garden rake and pull out any wet sand. I also do that at night before the cows come back in the barn.

How do you get rid of or recycle used bedding? We spread it on our elds. We’ve always had sand because of the free stalls. We spread a load every single day and have had no issues on the elds. We don’t recycle it; we use fresh sand all the time.

What challenges can arise from using sand bedding? How did you solve those problems? Wear and tear on the barn cleaner and putting sand on the land are challenges that can arise. We have a standard barn cleaner, and we recently put a plastic liner in the gutter so the barn cleaner chain and concrete at the oor of the gutter do not wear out as fast. Nobody wants barn cleaner troubles especially in the winter, but the barn cleaner doesn’t pay your bills. I don’t think the amount of sand we’re using will affect the land, but our agronomist will tell us next fall when he takes soil samples. The availability of sand long term is something I also wonder about.

Tell us about your farm. I farm with my parents, Jeff and Kate, and my wife, Riley. Our daughter, Adlee, is 1, and we have another child on the way. We milk between 110 and 115 registered cows at Jeffrey-Way Holsteins. We milk two groups of cows in our tiestall barn. We have 60 Excellent and 55 Very Good cows, none lower. Our average classication score is 90 points. We breed for type, production and longevity. Cows average 90 pounds of milk, 4.3% butterfat and 3.4% protein. We ship our milk to Klondike Cheese in Monroe, Wisconsin. We farm around 300 acres and make a lot of baleage which we top-dress with corn silage, haylage, high-moisture corn and protein when feeding cows. Genetics has always been the main goal for our farm, which has allowed us to milk fewer cows and have a successful operation.

Kevin and Ben Pearson Britannia Dairy Flandreau, South Dakota Moody County 1,100 cows

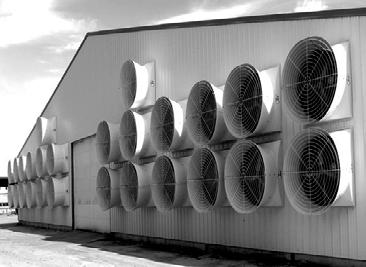

Describe your facilities and list your breeding management team. One of our freestall barns is naturally ventilated while the other is tunnel ventilated. We bed our free stalls with sand. All of our employees, including our milkers and our cow pushers, are part of our breeding management

team because they help keep our somatic cell count low. We have found that cows with a high SCC have lower conception rates. Ben does all of the breeding.

What is your current pregnancy rate? Our pregnancy rate is 42%.

What is your reproduction program? We use a double ovsynch on all of our rst services. We also give the animals two shots of luteinizing hormone 24 hours apart. We use activity monitors to catch animals that didn’t settle and perform pregnancy checks every two weeks.

How do you get animals pregnant? We have recently been giving a shot of GnRH at the start of estrus. This has increased our conception rate by 5%.

Describe your breeding philosophy. Our goal is to get more than 90% of our herd pregnant after three services.

He has an app on his smartphone that he uses to access this informaon from anywhere at any

What guidelines do you follow to reach the goals for your breeding program? We aim for strict

compliance regarding the shots that we give our animals and keep up on the activity transponders. A good transition program is critical to reproductive success. We have started giving a calcium binder to our transition animals.

What are the top traits you look for in breeding your

dairy herd and how has this changed since you started farming? We look for sires with sound health traits, good udder height and width, and a positive daughter pregnancy rate. Our herd is mostly Jerseys, and we recently started crossbreeding with Holstein sires. We monitor the stature of

our Holstein sires and only use bulls that are easy calving.

What are certain traits you try to avoid? We avoid a large stature and a low DPR. If a rst calf heifer isn’t performing well in the milking parlor, we

“Udder Comfort™ is like ketchup. We put it on everything, and it makes everything better! We have been using this product forever, especially on fresh cows for 4 to 5 days after calving. It also softens and heals flareups fast. Other products don’t do anything. Udder Comfort brings down swelling faster, so why use anything else?” says 4th generation dairywoman Ashley Olson. She works with cows every day at Jo-Al Acres, where she and Jeff milk 50 in a crops and grazing operation near Coon Valley, Wisconsin.

Their 14-year-old son Jed hopes to be the 5th generation in dairy. We met him checking feed and helping Jason and Leah James of Pine Valley Farm, Mineral Point get their Pine Valley Justice Carlin ready for the World Dairy Expo Milking Shorthorn show.

Leah and Ashley went to college together. They share a passion for cows and for moving dairy forward. They also share a pack at Expo and love the results they get with Udder Comfort at shows and for their respective herds at home.

won’t hesitate to ship her. Selecting sires is a balancing act.

Describe the ideal cow for your herd. She is an F1 Jersey-Holstein crossbred with high milk production, a welldeveloped udder and proper leg set.

What role does genetics have in reaching the goals of your farm? We hope that crossbreeding with Holstein sires will help us achieve our goal

of producing more energy-corrected milk. We use top sires whenever they are available.

What percentage of your herd is bred to sexed, conventional and beef semen?

All of our heifers are bred the rst two services with sexed semen; after that, they are bred with beef bulls. We use sexed semen for the rst two services on the cows that we want to produce replacements. The rest of our cows are bred to Charolais sires.

What is your conception rate? The conception rate for our rst service is 50% to 60%. We have seen little difference in the conception rates between sexed, beef and conventional semen.

What is the greatest lesson you have learned through your breeding program? Get the shots into the cows at the right time, and make sure your activity transponders are working. We know how the system works and are constantly trying to improve.

What is the age of your heifers at rst service? Our heifers receive their rst service at 12 months of age.

How does your heifer inventory affect your breeding program? We keep track of our heifer inventory and use more sexed semen if our numbers start to get low. Economics dictate that we keep our pool of heifers as small as possible. But, we also want to retain the ability to cull a rst calf heifer if she isn’t performing.

Tell us about your farm. We moved here from North Yorkshire, England, in 2007. We purchase all of our forages, and our heifers are raised by a heifer grower located in southwest Kansas. At 10 months of age, our heifers are taken to M & M Livestock at Chandler, Minnesota. Our heifers arrive back at

our

farm at three weeks prior to calving. Over the past few years, we have received

IOWA

Kramer Bros. Monticello, IA 319-465-5931

Prairie Land Ag Supply Inc. Rock Valley, IA 712-476-9290

United Dairy Systems, Inc. West Union, IA 563-422-5355

DeLaval Dairy Service Kaukauna, WI 866-335-2825

Joe’s Refrigeration Inc. Withee, WI 715-229-2321

Mlsna Dairy Supply Inc. Cashton, WI 608-654-5106

Professional Dairy Services Arlington, WI 608-635-0267

My dad was a big believer in cutting down our own Christmas tree out of our own woods. To go to the store and buy one would be a travesty in his mind.

We would bundle up, drive over to what we called the pines, which was a part of the farm that had a big stand of pine trees, and trudge through the snow (usually) to nd the best tree we could.

Dad would describe these trees we brought home each year as full of character. Most people would probably think they were a second cousin to Charlie Brown’s Christmas tree.

WISCONSIN

Advanced Dairy Spring Valley, WI 715-772-3201

Ederer Dairy Supply Plain, WI 608-546-3713

Redeker Dairy Equipment Brandon, WI 920-346-5579

The Scharine Group Inc. Whitewater, WI 800 472-2880 Mt Horeb, WI 800-872-3470

MINNESOTA & SOUTH DAKOTA

Farm Systems Melrose, MN 320-256-3276 Brookings, SD 800-636-5581

Advanced Dairy Mora, MN 320-679-1029 Pierz, MN 320-468-2494 St. Charles, MN 507-932-4288 Wadena, MN 218-632-5416

Several times, my dad would collect extra branches, and he would use those branches to make pine bough swags that he would tie up on the posts in the barn, decorating the barn for the holiday too. We used kiln-dried shavings as bedding in the barn, so the barn always had a slightly piney smell, but the smell from those pine boughs was so much different – better and more alive.

By Danielle Nauman Staff Writer

When we would get the tree home, there would usually be some sort of engineering required to convince the tree to cooperate. Some years, the trunks were slightly crooked. Sometimes, the tree had to be tied to the curtain rod.

One year, the best we could nd had some rather large gaps. Not to be deterred, my dad drilled holes in the trunk of the tree and inserted additional branches to ll in the blank spaces.

My mom often recounts the tree Dad brought home for their rst Christmas. When it stood alongside the old brick farmhouse they lived in, the top of the tree bypassed the tops of the upstairs windows. That one required quite a bit of engineering.

We never had trouble with needles falling off our fresh-from-the-woods trees, except for in 1988, which had been an incredibly hot and dry summer. That year, needles were falling off as we drug the tree home. The vacuum cleaner got plugged up a couple of times that year.

Once the tree was up and (hopefully) secured, Mom would dig out the boxes of ornaments, all which had a story behind them.

When I was a kid, my grandma Nauman would give us ornaments every Christmas. My favorites were the ones she made when her and my mom would go to ceramics classes at a lady named Etta’s house, near Wilton, Wisconsin. I used to go along and paint small simple things myself. I always loved going to Etta’s, so those ornaments bring back many good memories. As I grew older, I started collecting cow ornaments and probably have enough of those for at least one entire tree.

As we grew, once in a while, Dad would cave and would pick up a tree from the local grocery store, but they were never quite the same as the ones that came from the pines. I am grateful that my own son was able to experience the tradition of going out into the pines with Grandpa to nd a Christmas tree.

I hate to admit that I haven’t put up a Christmas tree in several years now. Dad died the day after Christmas in 2010, and honestly, the holiday has never been the same for me. Once Austin grew older and December became a busy month with hockey and other activities, it seemed more of a chore than something delightful to do.

There have been several years, around late October, when I think this will be the year I’ll get another Christmas tree. I usually think about all the ornaments packed away in totes full of newspaper and paper towels and about going to pick out all those trees with Dad. Those memories take over and spark an interest and desire. But by the time December rolls around, any enthusiasm I may have had has usually blown out the door with the cold wind, as I have been thrust into the rigorous routine of trying to balance winter chores with work.

By Jan Lefebvre jan.l@star-pub.com

By Jan Lefebvre jan.l@star-pub.com

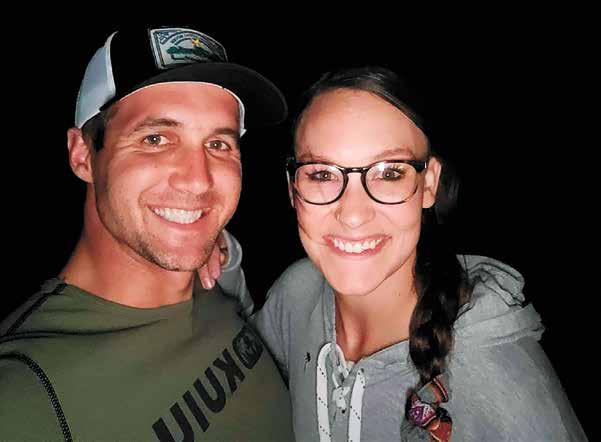

BRICELYN, Minn. – Innovation and leadership in farming earned Nathan and Loy Sahr recognition.

By expanding their dairy operation through raising heifers on-site and also by serving in leadership roles for the Minnesota Farm Bureau in Faribault County, the Sahrs became nalists for the 2022 Minnesota Young Farmers & Ranchers Achievement Award.

The other two nalists were Staci Sexton of Wabasha County and David and Michaela Ehlers of Grant County. The nalists were recognized at the Minnesota Farm Bureau Federation Annual Meeting Nov. 17-19 in Bloomington, with Sexton receiving the award.

The Sahrs are the fth generation to farm at Sahrside Dairy near Bricelyn, where they milk 1,450 Holsteins three times per day in a double-16 parallel parlor. They also farm 1,840 acres. The farm was established in 1898.

“Our main goals for the farm in the future are to continue to be protable and also to be able to produce all of our own feed for the dairy cows so that we have more control over our cost of production,” Nathan Sahr said.

According to the Minnesota Farm Bureau, the annual achievement award highlights efforts in production farming and leadership achievement. Contestants are evaluated on their farming operation growth, nancial progress of operation and leadership.

“More specically, the judges look for excellence in management, growth and scope of the enterprise and self-initiative that have been displayed throughout the operation,” Sahr said.

These are goals the Sahrs have worked toward.

“My dad and I farm together at Sahrside Dairy,” Sahr said. “While neither of my brothers or sister are involved in the operation, we do have about 25 employees that help with milking, feeding, cleaning and maintenance.”

Sahr’s parents live on the farm site, and he and Loy live about 4 miles away.

The Sahrs are putting their own stamp on the progression of the farm by raising replacement heifers and steers.

“We add leftover feed from the dairy’s milk cows to the heifer rations to save on feed costs,” Sahr said. “We

can raise our own heifers way cheaper than we can in having somebody else do it for us; while simultaneously, we can make sure they’re kept as clean and healthy as possible.”

Other plans at Sahrside Dairy include building a calf barn to get calves out of huts and building a sand storage area.

Combining operation growth with nancial sense is one reason they were nalists for the achievement award, but the Sahr family has valued this principle for generations.

“After realizing we could truck our own milk a lot cheaper than it was being trucked for us, we decided to haul our own milk,” Sahr said. “Our trucks

haul out milk two to three times a day to Agropur, where the majority of the milk from our cows is made into Parmesan cheese.”

The Sahrs also became nalists due to their commitment to Minnesota Farm Bureau efforts.

ALLAMAKEE COUNTY

• K & R Feed and Grain

Dorchester

• 563-568-4513

BREMER COUNTY

• Via eld

Sumner • 563-578-3214

DELAWARE COUNTY

• Del-Clay Farm Equipment

Edgewood • 563-928-6445

• Edgewood Feed Mill Edgewood • 563-928-6405

DUBUQUE COUNTY

• Brunkan Equipment

Worthington • 563-855-2434

• CJ Beeps Equipment Farley • 563-744-5010

• Eastern Iowa Dairy Epworth • 563-876-3087

• Helle Farm Equipment Dyersville • 563-875-7154

• New Vienna Ag Automation New Vienna • 563-921-2896

• Roeder Implement

Dubuque • 563-557-1184

• Scherrmann’s Implement Dyersville • 563-875-2426

• Skip Breitbach Feeds Balltown • 563-552-2393

• Ungs Shopping Center (IAS) Luxemburg • 563-853-2455

FAYETTE COUNTY

• Via eld

Elgin • 563-426-5566 Maynard • 563-637-2285

FLOYD COUNTY

• Livestock Systems

Charles City • 641-220-5257

HOWARD COUNTY

• Farmers Win Co-op Cresco West • 563-547-3660

SIOUX COUNTY

• Sioux Dairy Equipment, Inc. Rock Valley • 712-476-5608

WINNESHIEK COUNTY

• Brynsaas Sales & Service Decorah • 563-382-4484

• Franzen Sales & Service Fort Atkinson • 563-534-2724

• Lang’s Dairy Service Decorah • 563-382-8722

BECKER COUNTY

• Adkins Equipment Inc. Detroit Lakes • 218-847-3131

BENTON COUNTY

• Farm-Rite Equipment St. Cloud • 844-262-2281

• First National Bank of MilacaGilman Of ce • 320-387-2233

• Gilman Co-op Creamery Gilman • 320-387-2770

• Midwest Machinery Sauk Rapids • 320-259-6222

BROWN COUNTY

• New Ulm Regional Vet Clinic New Ulm • 507-233-2500

CARVER COUNTY

• Bongards’ Cologne • 952-466-5521

• Lano Equipment of Norwood Norwood/Young America 952-467-2181

• Storms Welding Cologne • 952-466-3343

DAKOTA COUNTY

• Midwest Machinery North eld • 507-645-4886

• Werner Implement Vermillion • 651-437-4435

DOUGLAS COUNTY

• Midwest Machinery

Alexandria • 320-763-4220

• Nelson Creamery Nelson • 320-762-0115

• Osakis Creamery Assn. 320-859-2146

• Pro Ag Farmers Co-op Gar eld • 320-834-2271

• Farmers Win Co-op

Rushford • 507-864-2161

• First Southeast Bank Harmony • 507-886-6922

• Hammell Equipment Harmony • 507-886-2255 Rushford • 507-864-2845

• Midwest Machinery Grand Meadow • 507-754-1100

GOODHUE COUNTY

• Ag Partners Farm Store

Goodhue • 651-923-4496

• Midwest Livestock Systems, LLC Zumbrota • 507-732-4673

• Midwest Machinery Cannon Falls • 507-263-4238 Wanamingo • 507-824-2256

• Midwest Machinery Elbow Lake • 218-685-4438

• Caledonia Haulers

Caledonia • 507-725-9000

• ESB Bank

Caledonia • 507-725-3329 Eitzen • 507-495-3321

La Crescent • 507-895-2227

• Farmers Win Co-op Caledonia • 507-725-3306 Houston • 507-896-3147

• Hammell Equipment Eitzen • 507-495-3326

• Midwest Machinery Caledonia • 507-725-7000

• Midwest Machinery Princeton • 763-263-6000

KANDIYOHI COUNTY

• D&D Ag Supply & Construction Pennock • 320-599-4466

• Farm-Rite Equipment Willmar • 877-484-3211

• Midwest Machinery Stewart • 320-562-2630

MCLEOD COUNTY

• Leedstone Glencoe • 877-864-5575

• Midwest Machinery Glencoe • 320-864-5571

• Mueller Sales & Service Dairy Equipment Glencoe • 888-205-0974

• Farm-Rite Equipment

Dassel • 888-679-4857

• Schlauderaff Implement Co. Litch eld • 320-693-7277

MILLE LACS COUNTY

• First National Bank of Milaca

Milaca • 320-983-3101

• Foreston Farmer’s Co-op Creamery Foreston • 320-294-5711

MORRISON COUNTY

• Central MN Credit Union Little Falls • 888-330-8482

• Lash’s Auto Pierz • 320-232-0537

• Litke’s Veterinary Service Pierz • 320-468-6666

• Midwest Machinery Little Falls • 320-632-5469

• Modern Farm Equipment Pierz • 320-468-2161

• Pierz Co-op Pierz • 320-468-6655

• Sunrise Ag Cooperative Buckman • 320-468-6433 Lastrup • 320-468-2543 Little Rock • 320-584-5147

OLMSTED COUNTY

• Ag Partners Stewartville • 507-533-4222 Lewiston • 507-523-2188

• Hammell Equipment Chat eld • 507-867-4910

OTTER TAIL COUNTY

• Bongards’ Perham • 218-346-4680

• Farmers Elevator of Fergus Falls & Henning 218-736-3301

• PCCA-Country Store Perham • 218-346-7075

• Perham Stockyards Perham • 218-346-3415

• Pro Ag Farmers Co-op in Henning 218-583-2947

• Pro Ag Farmers Co-op in Urbank 218-267-2401

PIPESTONE COUNTY

• Gorter’s Clay & Dairy Equipment Pipestone • 507-825-3271

POPE COUNTY

• Midwest Machinery Glenwood • 320-634-5151

RICE COUNTY

• Ag Partners - Agronomy Le Center • 507-357-6868

STEARNS COUNTY

• A&C Farm Service

Paynesville • 320-243-3736

• Albany Chrysler Dodge Jeep Ram Albany • 320-845-2801

• Arnold’s of Kimball Kimball • 320-398-3800

• Arnold’s of St. Martin St. Martin • 320-548-3285

• Arnzen Construction/St. Rosa Lumber Freeport, In St. Rosa 320-836-2284 or 1-888-276-1751

• Magni Financial Albany • 888-330-8482 Avon • 888-330-8482 Belgrade • 888-330-8482 Cold Spring • 888-330-8482 Freeport • 888-330-8482 Melrose • 888-330-8482 Paynesville • 888-330-8482 Sauk Centre • 888-330-8482

• Centre Dairy Equipment & Supply Inc. Sauk Centre • 320-352-5762 or 1-800-342-2697

• Dairyland Supply Sauk Centre 320-352-3987 or 1-800-338-6455

• Ecker Feed Service, LLC New Munich • 320-837-5800

• Elrosa Grain & Feed Elrosa • 320-697-5515

• Elrosa Lumber Elrosa • 320-697-5591

• Farm Systems Melrose 1-800-636-5581 • 1-800-247-0012

• Feed Co.

Paynesville • 320-243-3938

• Freeport State Bank Freeport • 1-800-252-9856 320-836-2126

Greenwald • 320-987-2265 New Munich • 320-837-5297 Melrose • 320-256-7208

• Hartung Sales & Service, Inc. Freeport • 320-836-2697

• Lake Henry Implement Lake Henry • 320-243-7411

• Leedstone Melrose • 800-996-3303

• Melrose Implement Inc. Melrose • 320-256-4253

• Midwest Machinery Paynesville • 320-243-7474 Sauk Centre • 320-352-6511

• Modern Farm Equipment Sauk Centre • 320-352-6543

• Nutrien Ag Solutions 320-352-6564

• Northland Farm Systems Owatonna • 507-451-3131

SWIFT

• Midwest Machinery Benson • 320-843-2610 Madison • 320-598-7575 Morris • 320-589-2011

TODD

• Magni Financial Grey Eagle • 888-330-8482 Long Prairie • 888-330-8482

• Farm-Rite Long Prairie • 866-514-0982

• Olson’s Custom Farm Service Staples • 218-894-2474

• Pro-Ag Farmers Co-op in Browerville Browerville • 320-594-2711

• Pro-Ag Farmers Co-op in Clarissa Clarissa • 218-756-2112

• Pro-Ag Farmers Co-op in Eagle Bend Eagle Bend • 218-738-2552

WABASHA

• Ag Partners Farm Store Plainview • 507-534-2531

• Beck Implement Elgin • 507-876-2122

• Leedstone Plainview • 800-548-2540

• Midwest Machinery Plainview • 507-534-3116

• Wingert Sales & Service Plainview • 507-534-2285

WADENA COUNTY

• Dairyland Equipment of Menahga Menahga • 218-564-4958

• Midwest Machinery Wadena • 218-631-2311

• Olson’s Custom Farm Service Verndale • 218-445-5500 Sebeka • 218-837-5749

WINONA COUNTY

• Elba Co-op Creamery Elba • 507-796-6571

• Lang’s Dairy Equipment Lewiston • 507-452-5532

• Lewiston Rentals and Repairs Lewiston • 507-523-3564

• Midwest Machinery St. Charles • 507-932-4030

WRIGHT COUNTY

• Hobert Sales Inc. Cokato • 320-286-6284, 1-800-820-6455

• Midwest Machinery Howard Lake • 320-543-2170

BROOKINGS COUNTY

• W.W. Tire Brookings • 605-696-7400

CODINGTON COUNTY

• Glacial Lakes Livestock Watertown • 605-886-5052

MINNEHAHA COUNTY

• Central Valley Dairy Supply Garretson • 605-467-0812

• Midwest Livestock Systems Renner • 605-274-3656

ROBERTS COUNTY

• Valley Dairy Supply Corona • 605-432-5224

“We understand the benets of being involved with Minnesota Farm Bureau,” Sahr said.

He and Loy have attended many Farm Bureau Leadership, Education, Advocacy and Promotion conferences, and Sahr has served for eight years as a young farmers and ranchers chair for the Faribault County Farm Bureau.

“We have enjoyed networking with, and learning from, other farmers as well as learning more about how politics affect agriculture,” Sahr said.

The Sahrs have four young children.

“Never a dull moment here,” Sahr said. “Our kids also love helping with heifer chores, and we love that they’re learning valuable life lessons in the process. We would love nothing more than to see one of our kids be the sixth (generation to farm).”

The children were with the Sahrs in Bloomington when the award winner

was announced. Since both Sahr and Loy grew up in families that were involved in the Minnesota Farm Bureau, having their family there was extra special.

The Sahrs had to leap one more hurdle at the event before the award decision was made.

“Minnesota Farm Bureau notied us that we would be interviewed at the annual meeting as nalists,” Sahr said.

After the interviews were completed, the judges selected the winner.

Even though the Sahrs did not receive the top award, they appreciate the wins in life they have already received through dairy farming.

“We believe raising our kids on a dairy farm is one of the greatest gifts we can give them,” Sahr said. “They are learning the value of hard work, common sense and empathy while simultaneously making lifelong memories together as a family.”

By Jan Lefebvre jan.l@star-pub.com

By Jan Lefebvre jan.l@star-pub.com

Throughout state tournaments this fall, dairy farm youth have contributed their skills and talents to their teams’ efforts. Dairy Star asked several of these students about their successful seasons.

When Minneota High School took rst place in the football Class A state tournament, two brothers and their cousin, all dairy youth, were on the Vikings team.

Zack Fier plays running back and corner back, and his brother, Brock Fier, plays running back and linebacker. Their parents are Kevin and Mindy Fier. Zack and Brock’s cousin Destin Fier is the son of Kurt and Julie Fier. Together the families milk 450 Holsteins, Red and White Holsteins and Milking Shorthorns with a robotic milker at Fierview Dairy near Taunton, Minnesota. All three boys said they also value teamwork on the football eld.

“Our team has the ability to work together and get along really well,” Brock said.

Destin said the farm has taught him life lessons.

“It has helped me learn to work hard and get things I earn,” he said.

After placing second in the state tournament last year, the Fiers said winning this year was extra rewarding.

“After playing last year and being as good as we were but falling short, I did not know how we were going to rebound,” Zack said. “I am super proud of all the young kids that stepped up and how the whole team handled the adversity to get us to where we are.”

Lydia Vatland is a sophomore at Mabel-Canton High School and a defensive specialist on the Cougars volleyball team, which earned third place at state. Her parents, Kevin and Joanie Vatland, own Vatland Dairy and Beef Farms near Mabel, Minnesota, where they milk 30 Holsteins and Jerseys in a tiestall barn.

Vatland said the small size of her team and school is a positive aspect.

“Considering how young and small our team was, many opponents would overlook us, but we used our small size to our advantage and gave it our all,” she said. “I enjoyed seeing how such a small community can come together to support the same thing.”

Growing up on a dairy farm also helped prepare Vatland for being a dedicated athlete.

“From a very young age, I learned what it means to always work hard and put all your effort into something you’re passionate about,” she said. “It also taught me about responsibility and learning to care for something other than yourself.”

Miles Mulhern is a junior on the Chateld High School football team. He

played on the defensive line and started at nose tackle. His team, the Gophers, took second place in the Class AA state football tournament. Miles, the son of Mitch and Jennifer Mulhern, works with his uncle, Cory, at Mulhern Dairy near Fountain, Minnesota, where they milk 1000 cows (Holsteins, Brown Swiss and Jerseys) in a herringbone parlor. Mulhern said that doing chores prepares him for football.

“Working around the farm helps a lot with strength,” he said.

Mulhern said that he enjoys his teammates, especially when they get together for meals. He thought his team was special from the beginning.

“Many people believed we would not make it to this point this season,” he said. “We proved them wrong.”

Paige Gruber represented Melrose High School at the state swim meet in two relays. The 200-yard medley team took fourth; the 200-yard freestyle placed eighth. Paige is the daughter of Conrad and Sandra Gruber. At Gruber Dairy near Spring Hill, Minnesota, they milk 60 Holsteins in a tiestall barn.

Gruber said she is proud of the cohesiveness her team creates.

“From the little seventh graders all the way up to the seniors on the team, everyone is so supportive of one another,” she said. “We want each other to succeed individually because we know it will help the team overall.”

Gruber said that growing up on a farm helped her value hard work.

“I understood that, for anything you want, you’re more than likely going to have to work for it, and a good majority of the time it is not going to be fun,” she said. “Anytime something would get hard (in swimming), I would remind myself that nothing is worse than picking rocks on a hot summer day.”

Ty Cleven played center for the Spring Grove football team in the state nine-man tournament. The Lions took 2nd place.

Cleven said he appreciates making it all the way to the nal game.

“I’m proud of how much we believed we could win and how far we got,” he said. “I enjoyed being able to play with my brothers for longer.”

Cleven is the son of Darci Cleven and works at Gerard Dairy near Spring Grove, Minnesota, helping to milk 250 cows in a step-up parlor. He also milks an Ayrshire and a Milking Shorthorn that he bought himself.

Two dairy youth competed for the Belgrade-Brooten-Elrosa Jaguars in the Minnesota Class A state volleyball tournament. The Jaguars made it to the seminals. Faith Radermacher is an outside hitter for the team. Her parents, Aaron and Jessica Radermacher, are owners of Radermacher Dairy LLC near Brooten, Minnesota, where they milk 240 Holsteins and Jerseys in a parabone parlor, but they are converting to a ro-

botic milking system.

“Growing up on a dairy farm helps me to stay active and in shape because I work daily,” Radermacher said. “It helps me with time management and improves strength.”

Her teammate, Harley Roering, is a defense specialist on the team. Roering milks cows at Jer-Lindy Farms, the site of Redhead Creamery near Brooten, Minnesota. Her parents are Alan and Lori Roering.

Roering said her team is what made going to state memorable.

“I am proud of how well our team connection is,” she said. “We can have a lot of fun and can also take things seriously when we need to. I think state really brought our team together because we spent so much time together; even after a long day of playing, we still visited each other in our hotel rooms.”

Radermacher also has respect for her teammates.

“I’m proud of my team for overcoming the setbacks that we experienced early on this season and for having come as far as we did,” she said.

Swimming at state for the Sauk Centre Mainstreeters, Stella Schirmers competed in two relay events along with the 100 buttery and the 100 backstroke. Stella’s best results came in the backstroke, placing 11th. Stella is the daughter of Dave and Missy Schirmers. The family milks 200 cows in a parallel parlor at Schirmers’ Dairy near Sauk Centre, Minnesota.

Stella remembers doing chores on the farm at a young age.

“I had to quickly learn how to keep up with my older cousins and siblings while working,” she said. “It has taught a good work ethic.”

Team togetherness is something Stella enjoys.

“After working hard to get to state, it was rewarding to spend time with all of my teammates at the hotel and restaurants,” she said.

Stella’s cousin, Nate Schirmers, competed at state. Nate played safety for the Mainstreeters football team, which made it to the quarternals in the Class AA tournament. He is the son of Tim and Jody Schirmers, who

also run Schirmers’ Dairy.

“I think the biggest thing that I learned by growing up on a dairy farm was work ethic,” Nate said. “Getting up early to milk, and seeing my dad do that every day, showed me what it takes to achieve something.”

Nate said he appreciates team camaraderie

“Just being able to keep playing games with this group of guys was what I enjoyed the most,” he said.

Both Porter Kuechle and Nicholas Becker played on the offensive and defensive lines for the Eden Valley-Watkins Eagles in the Class AA football state tournament, making it to the seminals. Kuechle milks cows with his parents, Perry and Sarah Kuechle, at Kuechle Dairy near Watkins, Minnesota, where they milk 220 Holsteins in a double-12 parallel parlor. Kuechle said that growing up on a dairy farm helped him in football.

“It taught me the value of hard work and dedication,” he said.

Becker agrees.

“Growing up on a dairy farm helped me because I was gaining strength from helping on the farm,” he said. “It also taught me that you get out of it what you put into it.”

Becker’s parents, Tom and Amanda Becker, own Becker Family Farm near Watkins and milk 65 Holsteins in a tiestall barn.

Both Becker and Kuechle said they enjoyed how their football team got along together so well.

“I’m most proud of the effort everyone puts in and what comes out of the effort,” Becker said.

“I’m proud that we never give up and are just one big family.”

When Samuel Jeurissen wasn’t doing chores on his parents’ farm this autumn, he was playing offensive guard and defensive end for the Lester Prairie Bulldogs, which made it to the Class A quarternals in foot-

ball.

Jeurissen’s parents, Rick and Mindy Jeurissen, own Jeurissen Family Farms near Lester Prairie, Minnesota, and milk 130 Holsteins in a double-12 parlor. Jeurissen said he enjoyed the football season in its entirety. The Bulldogs were undefeated in regular competition.

“We all came together at the beginning of the year and clicked,” he said. “Everyone knew what they were going to do, and it showed all the way through the season.”

Jeurissen said he was happy that the extended season gave more relatives a chance to see him play. He also said that working on the farm has always kept him physically strong.

“It helps a lot more when you are younger,” he said. “When I was in elementary school and middle school, I was stronger than most everyone. Being active (now) in the off season helps me stay in shape, so when two-a-days start, I don’t struggle as much as most people.”

Noah Thompson plays running back, linebacker and special teams for the Jackson County Central Huskies. Thompson works with his uncles at Hinkeldey Dairy Farm near Windom, Minnesota where they milk 115 Holsteins and a few crossbreds in a double-8 herringbone parlor. Thompson’s parents, Todd and Sarah Thompson, are connected to the farm in that Sarah grew up there.

Thompson said growing up around the farm taught him lessons he applies to athletics.

“Time management, dedication, work ethic and leadership – along with these lessons it also helps you to learn how to deal with struggles,” Thompson said. “For instance, you may struggle doing chores, breaking a show animal, clipping for show or washing it. Dealing with those struggles on the farm teaches you how to overcome struggles in sports such as when you make a bad play or are really exhausted but still have to give your all.”

Thompson said making the state tournament will stay with him forever.

“Getting to step onto the eld was just so surreal as many high school athletes don’t get that chance if their seasons are cut short,” he said. “Making it to the state football tournament and playing at US Bank Stadium will be a memory I won’t ever forget.”

Caring for a vital resource: Farmers’ hands

By Karen Johnson

A farmer’s hands are his or her lifeline. Every aspect of the day revolves around the ability to utilize their hands to get the job done. However, winter can be particularly hard on hands. Often farmers experience extremely dry, cracked and sometime painful hands during winter. The main cause is due to the lack of moisture. Cold air has a much lower moisture holding capacity than warmer air. Indoor heating systems dry out the inside air even further creating an environment that is difcult to keep skin healthy. Another factor to keep in mind is that during winter it is highly encouraged to increase hand washing due to the presence of seasonal respiratory illnesses.

The top layer of the skin, the epidermis, is the main protective barrier and where dry skin develops. When the epidermis dries out, the skin will not shed as rapidly as it normally does. This causes a buildup of thickened skin. Increased time in the cold, dry wind makes this situation worse. In addition, developing dry skin becomes more common as we age.Moreover, people who experience dry skin in previous winters are more likely to have it happen again.

– Start using moisturizers before you know that your dry skin typically starts. Moisturizing creams work well for mild dryness. Consider oils or ointment for moderate to severe dryness.

– Wear high quality, warm gloves to protect your hands when outside in the cold.

– If you don’t already have gloves as part of your milking procedures, wear gloves while milking to prevent excessive teat dip contact with hands.

– Establish an extra step in your hand washing routine. Use mild soap with warm water. Then, pat your hands dry and apply moisturizer. Moisturizing your hands several times a day combats skin dryness more effectively than one daily application.

– The best time to moisturize is immediately after a shower or right before bedtime.

– Contact a medical professional if your symptoms are more severe.