DAIRY ST R

Volume 24, No. 20

Volume 24, No. 20

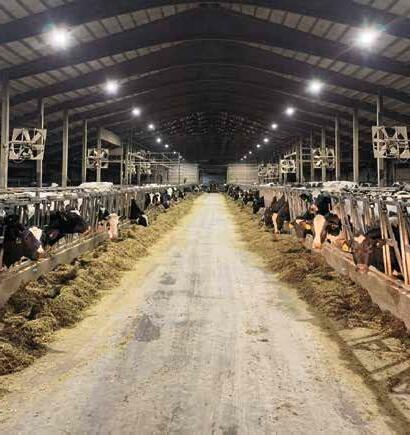

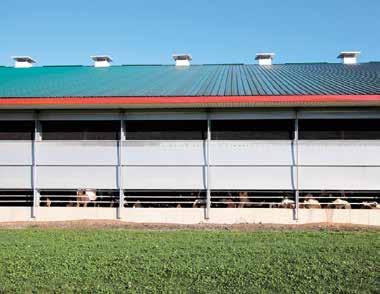

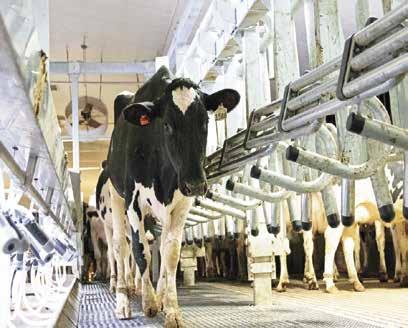

NEWTON, Wis. – More than 40 years ago, Jim and Sandie Fitzgerald began fullling a dream to farm when they purchased their own place and put up a barn. It was the rst of several barns they would build throughout the years as their farm grew from a 60-cow dairy to a 1,200-cow dairy. In time, their children latched onto the same dream as four of the ve Fitzgerald children joined the operation to make the farm their career.

Today, the Fitzgeralds own the farm with their daughters, Kelly Goehring, Julie Maurer and Stacy Klotz, and their son, Nick Fitzgerald, with each holding 20% ownership in the farm.

FARLEY, Iowa – Looking at photos of Doug Simon and Dan Hansen’s dairy farm, one may nd it hard to believe the farm is not real but instead a diorama display on a 1/64th scale.

In fact, the farm is so realistic that it won the national championship in its class Nov. 5 at the 45th annual National Farm Toy Show hosted by the National Farm Toy Museum in Dyersville.

Although it was a thrill to be named champions, both Simon and Hansen said they had an excellent chance of winning that day.

“We were both condant that we were going to come home with a trophy,” Hansen said.

Simon agreed.

“It was the amount of time we put into it,” he said. “When

Kelly and her parents were partners in the business when they established Soaring Eagle Dairy in 1997. Stacy and Julie joined the operation in 2003, and Nick joined in 2011. Stacy’s husband, Jeremy, also works on the farm.

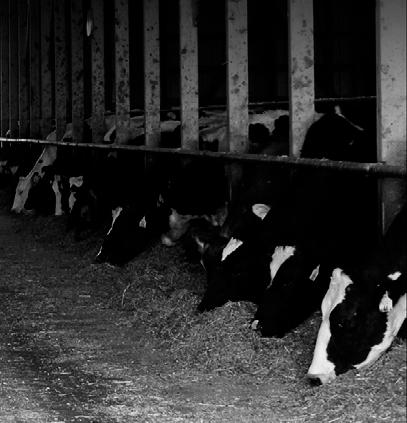

The family milks 1,150

cows and farms 2,200 acres near Newton with help from 20 full-time employees. Cows are milked three times a day in a double-16 parallel parlor. The farm’s rolling herd average is 30,856 pounds of milk, 4.2% butterfat and 3.2% protein.

Cows average 95 pounds of milk per day and maintain a somatic cell count under 150,000 on an annual basis. The Fitzgeralds ship their milk to Land O’Lakes.

Farming alongside their parents, the fourth generation is focused on continuous improve-

we were putting the whole display together, both of us kept saying that it was going to be really hard for somebody to beat this because it was pretty amazing seeing it all come together. What we ended up with was pretty cool.”

Simon and Hansen used weekends and any spare time for about a year and a half to create their masterpiece. Hansen worked from his home in Beaver Dam, Wisconsin, and Simon from his home in Farley.

“I built the equipment for the display,” Hansen said. “Doug did all the scenery and weathering stuff – putting manure in places, dirt and dust on the equipment and grass and gravel on the display board. We used each other’s talents within the hobby to do our own parts. Then a few parts we collaborated on and did together.”

Nothing on the display was simply purchased and placed. The farm equipment and some of the tractors were designed by Dan and then 3D printed by him.

A few tractors began as Ertl, a replica toy line, tractors but were sandblasted and deconstructed

down to the shell and then rebuilt and painted.

“Dairy cows in the barn are Ertl cows, but each one of them

has been custom painted (by Simon) with different markings because no two cows are alike,” Simon said. “Some of them are

December 10, 2022

ment of cows, crops, employees and the community, as is the generation before them.

“How do we get the next pound of milk or the next bushel of corn are questions we often like to ask ourselves,” Julie said. “How can we do better by the cow? The environment?”

Julie manages the parlor, is in charge of human resources and handles the Wisconsin Department of Natural Resources and Farm Service Agency regulations. Kelly and Stacy are the farm’s herd managers while Nick manages crops and does eldwork and maintenance with Jeremy. Julie’s daughter, Kelsey, also works on the farm. Jim and Sandie are semi-retired but active at Soaring Eagle Dairy.

“When there are six family members here on a daily basis, there are a lot of eyeballs on what’s going on,” Julie said.

One example of improvement was a tweak made to their milking system in 2016, which allowed the family to get more cows through the parlor. When

replicated off of show cows that my family shows competitively. The calves and the heifers, all the animals, were custom painted.”

For the contest, the display base had to be 8 feet by 8 feet, but materials used could be almost anything. Simon and Hansen were meticulous in their methods.

“Everything, even the littlest of things and accessories, we either weathered or detailed or made it custom,” Simon said.

Some of the feed in the display was made from actual feed.

“I would occasionally take a bag of distillers or soybean meal or corn gluten pellets, and Doug and I used a small coffee grinder to make it even ner,” Hansen said. “It still had the color and smell of real feed.”

They purchased additional materials from hobby stores.

“For the feed in the mangers and the alleyways, there’s a blended turf that they use in railroad hobbies that looks like a ground cover,” Simon said. “It

STACEY SMART/DAIRY STARwww.dairystar.com

• Online: 2834-6203

ISSN Print: 2834-619X

522 Sinclair Lewis Ave. Sauk Centre, MN 56378

Phone: 320-352-6303 Fax: 320-352-5647

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com 320-352-6303 (ofce) 320-248-3196 (cell) 320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Net U.S. cash farm income is forecast to be a record high $188 billion for 2022. That’s up 25.5% from 2021. Cash receipts for corn, soybeans, wheat and other crops are up 19%. Receipts from animal agriculture are expected to increase over 30% from last year.

The federal order Class III milk price was $21.01 per hundredweight. That’s 80 cents below October and $2.65 above November 2021. The Wisconsin all-milk price for October averaged $24.40 per hundredweight. That’s $2.30 above September and $4.70 more than October of last year.

Karen Knoblach

• karen.k@star-pub.com Annika Gunderson • annika@star-pub.com

Editorial Staff

Tiffany Klaphake - Assistant Editor 320-352-6303

• tiffany.k@dairystar.com

Maria Bichler - Assistant Editor maria.b@dairystar.com • 320-352-6303

Danielle Nauman - Staff Writer 608-487-1101 • danielle.n@dairystar.com

Stacey Smart - Staff Writer 262-442-6666 • stacey.s@dairystar.com

Abby Wiedmeyer - Staff Writer 608-487-4812 • abby.w@dairystar.com

Grace Jeurissen - Staff Writer 320-352-6303 • grace.j@star-pub.com

Jan Lefebvre - Staff Writer 320-290-5980 • jan.l@star-pub.com

Taylor Jerde - Staff Writer 507-403-1680 • taylor.j@star-pub.com

Consultant

Jerry Jennissen 320-346-2292

Main Ofce: 320-352-6303 Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication Sales Manager - Joyce Frericks 320-352-6303 • joyce@dairystar.com

Mark Klaphake (Western MN) 320-352-6303 (ofce) 320-248-3196 (cell)

Laura Seljan (National Advertising, SE MN) 507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com

Jerry Nelson (SW MN, NW Iowa, South Dakota) 605-690-6260 • jerry.n@dairystar.com

Mike Schafer (Central, South Central MN) 320-894-7825 • mike.s@dairystar.com

Amanda Hoeer (Eastern Iowa, Southwest Wisconsin) 320-250-2884 • amanda.h@dairystar.com

Megan Stuessel (Western Wisconsin) 608-387-1202 • megan.s@dairystar.com

Kati Kindschuh (Northeast WI and Upper MI) 920-979-5284 • kati.k@dairystar.com

Julia Mullenbach (Southeast MN and Northeast IA) 507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell) bob.l@star-pub.com

The deadline for news and advertising in the Dairy Star is 5 p.m. Friday the week before publication.

One year subscription $40.00, outside the U.S. $200.00. Send check along with mailing address to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378.

Our ad takers have no authority to bind this newspaper and only publication of an advertisement shall constitute nal acceptance of the advertiser's order.

Letters and articles of opinion are welcomed. Letters must be signed and include address and phone number. We reserve the right to edit lengthy letters. The views and opinions expressed by Dairy Star columnists and writers are not necessarily those of the Dairy Star / Star Publications LLC.

The Dairy Star is published semi-monthly by Star Publications LLC, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378-1246. Periodicals Postage Paid at Sauk Centre, MN and additional mailing ofces.

POSTMASTER: Send address changes to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378-1246.

In the words of President Joe Biden, Congress’ action on the rail contract will spare the country “a Christmas catastrophe in our grocery stores, our workplaces and in our communities.” The House and Senate took action to force unions to accept a tentative contract agreement that was adopted in September. Biden later signed the legislation. The ve-year contract gives union railroad workers a 24% bump in wages but does not address the issue of paid sick leave.

The Republicans have a slim majority in the House and a very tight margin is in the Democrat’s favor in the Senate. Compeer Financial chief mission and marketing ofcer John Monson said that will inuence the farm bill debate. “I don’t sense that given the dynamics in place right now, that we’re going to see a

major shift in policy perspective,” Monson told Red River Farm Network. “It just seems to me that the path of least resistance is more of an extension of the current farm bill at least for a year, if not longer.” Monson said there will be different dynamics at play during the upcoming session. “The nutrition title will cost 85% of this next farm bill of $1.3 trillion. That’s going to be a big task.”

The World Trade Organization’s agriculture committee is working on a strategy to address hunger, especially in the least developed countries. Future discussions will center on market access, nancing food purchases and the strength of farm production worldwide. Specic policies were reviewed, including the U.S. Ination Reduction Act, the European Union’s new Common Agricultural Policy and Canada’s dairy supply/management program. Another meeting is planned in early December to continue the discussion.

In an update on John Deere’s quarterly earnings,

Reuters reported farm equipment and combines are virtually sold out for 2023. StoneX chief commodity economist Arlan Suderman said the high commodity prices in recent years have driven up demand. “Unfortunately, the same issues keeping us from getting new cars is also happening in the equipment industry,” Suderman said. The computer chip shortage is the missing link. “So much of our equipment is reliant on chips, and there is still a shortage,” he said. “The ability to manufacture and get products distributed has led to some long waiting lists for equipment.”

The National Milk Producers Federation is asking Congress to protect the domestic production of infant formula. When supplies tightened earlier this year, tariff waivers were granted to bring more baby formula into the United States. NMPF said the situation has improved and the preferential tariff benets should be allowed to expire at the end of the year.

Federal Reserve Board chairman Jerome Powell signaled the central bank is on track to raise interest rates by a half a percentage point at its next meeting. During a speech Wednesday, Powell said it would make sense to slow rate increases to give the economy time to adjust to previous rate hikes. A 75 basis point interest rate hike was seen for four straight months.

According to U.S. Department of Agriculture’s report on farm labor, farms in the Lake Region paid their hired workers an average of $18.83 per hour. That’s an increase of $2.62 per hour from one year ago. The Lake Region is made up of Wisconsin, Minnesota and Michigan.

New Jersey Sen. Cory Booker has introduced a bill targeting largescale livestock operations. The pro-

posal would require packers, processors and farmers to register their businesses with USDA, submit a disaster preparedness plan and pay for disaster mitigation. The bill also calls for more humane treatment of downed animals or those being depopulated due to a disease. Booker is a member of the Senate Agriculture Committee and has proposed similar bills in the past.

Former WFBF president passes

Former Wisconsin Farm Bureau president Donald Haldeman, 85, has passed away. Haldeman was elected in 1971 and served 20 years. Haldeman was a dairy farmer near Norwalk, Wisconsin.

Selz-Pralle honored

Dairy Girl Network presented its rst-ever Leading Impact Award to Pam Selz-Pralle of Humbird, Wisconsin. Selz-Pralle and her husband, Scott, have been recognized as Holstein USA Outstanding Young Breeders and Wisconsin Jaycee Outstanding Young Dairymen, and Pam has been honored as a Wisconsin Master Agriculturalist.

During the National Association of Farm Broadcasting Annual Meeting, Madison, Wisconsin-based farm broadcaster Pam Jahnke was inducted into the National Farm Broadcasting Hall of Fame. Jahnke leads the Midwest Farm Report.

Germany is credited with starting the tradition of putting up a Christmas tree. That answers our last trivia question. For this week’s trivia, how much eggnog is consumed by Americans each Christmas season? We will have the answer in the next edition of Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network, based in Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two adult sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

had the color variation of cattle feed. Within the hobby world, there’s a vast variety of products available to buy for making a display.”

Both Simon and Hansen have competed diorama display contests separately, but this was the rst Simon-Hansen collaboration. The partnership all began with a text.

“Doug sent me a text one day and asked if I had ever wanted to build a display for the national competition,” Hansen said. “I was hauling manure at the time, and I said yes. That was about a year and a half ago.”

Simon and Hansen grew up going to farm toy shows and became friends after meeting at one of them.

Simon now works for a trucking company, but he helps on a dairy farm, Farnear Holsteins, near Farley that is owned by his two uncles. The robotic dairy barn in the display is loosely based on their barn.

“My dad was a milk hauler for 35 years, so I grew up riding with him in the milk truck, going to all these different farms,” Simon said. “My mom worked for Ertl Toys nearby in Dyersville for a number of years. For birthdays or holidays, I would get toy tractors or farm and country playsets with everything you need to create a farm scene. That would get my imagination going.”

Because Dyersville was only a few miles away, Simon also had easy access to the national toy shows.

“I saw all the display contests, and I got ideas,” he said.

Simon started creating scenes of his own. It seems his whole childhood was a rehearsal for building diorama displays.

Meanwhile, Hansen was growing up in Beaver Dam, Wisconsin, with his own interest in farm toys and replicas being honed.

“I grew up on the farm here at home, but the majority of my life I’ve worked at Brossard Dairy, a 450-cow dairy down the road from me,” Hansen said. “This past year I started hauling cattle feed, mainly in the Midwest, so I’ve always had a connection to agriculture and farming since I was a little kid.”

Hansen’s dad owned a small equipment repair business and worked on tractors, various equipment and semis for farmers as well as hauled grain and hay .

“I’m more equipment focused from seeing tractors and equipment coming in

and out of the yard,” Hansen said. “On top of that, I never had video games. It was always just toy tractors.”

His parents liked the farm toy shows and brought him every year to local ones as well as the national show in Iowa.

“As I grew older, I got more into the hobby and wanted to change things,” Hansen said. “I’d take a tractor out of the package and, for example, if it didn’t have duals on it and I wanted more tires on it, I just glued more tires to it. From there, it progressed. If I wanted something that Ertl didn’t make, I would try to build it myself.”

As Simon and Hansen worked on their display, they received help from friends in the hobby world and beyond. Some helped build a few pieces, one friend loaned them shop space for putting the whole display together and another let them use his enclosed wagon to haul the main part of the display from the shop to the competition.

“We’ve had a few different people playing a hand in this,” Hansen said.

Family and friends came to the competition to cheer them on.

Simon and Hansen spent ve hours reassembling their display Nov. 4 for the judging that would take place by a panel later that day. They were competing against three other displays in their class. There were two other classes, a 1/16th class and a youth class.

The winners were not announced until Saturday, but the wait was worth it for Simon and Hansen as they heard themselves declared national champions.

“Doug and I looked at each other and gave each other a hug and a really hard high ve,” Hansen said.

Both felt a sense of accomplishment.

“We had been working on it for so long, basically calling each other about it or life in general every day,” Simon said. “It was pretty rewarding to see it come full circle.”

Hansen agreed.

“For two guys like us, who have gone to shows as long as we have and have seen so many winning displays, to actually leave with a win was awesome,” he said.

Simon and Hansen said they will now take a break from building displays, but neither is ready to say goodbye to the hobby.

“We’ve got some ideas in the works,” Simon said.

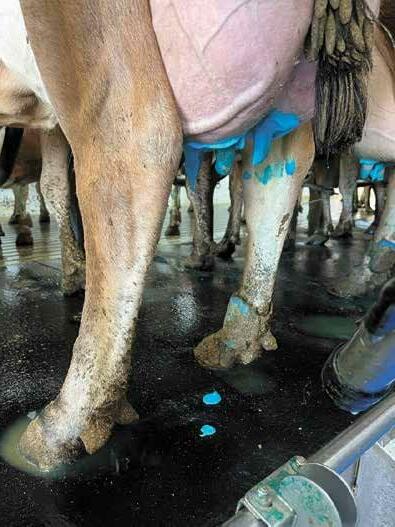

they switched from using dip and towels to using a scrubber to prep cows, the Fitzgeralds found that cows let down their milk more quickly. Faster milk outputs created a need to increase the capacity of the lines and meters to move milk away at a higher speed. Changing pipes allowed for the extra milk ow, and now the farm averages around 32 pounds of milk per cow per milking in under four minutes.

The farm does no till and plants cover crops on about 50% of the land and has also created buffer strips and grassed waterways to offer protection from nutrient contamination. A conversion to dry corn four years ago led to the Fitzgeralds building a grain drying and storage facility.

“Prior to that, we were feeding highmoisture corn, and I felt we lagged in components,” Julie said. “The drying center really allowed us to kick up our butterfat and protein levels.”

The Fitzgeralds have remained focused on their goals as they built, expanded and improved their operation. Through stages of growth and modernization, they grew at a pace compatible with their efcient and protable mindset.

It was in 1980 that Jim ventured out on his own after farming with his father and brothers for 14 years. He built a 60cow tiestall barn on the farm where he and Sandie raised a family. Prior to the expansion in 1997, the Fitzgeralds were milking 90 cows three times a day. Taking the farm in a direction of growth and prosperity for the future, they built a 400cow freestall barn and double-12 parallel parlor and grew to 500 cows. Two years later, a transition barn was added.

By 2000, the family was milking 650 cows and an addition was made to the freestall barn. Four years later, they added onto the barn once again when cow numbers reached 850. The transition barn was also expanded in 2004, adding 100 free stalls and a dedicated maternity area. In 2005, a second freestall barn was built, and the parlor was expanded to a dou-

ble-16, which allowed the milking herd to grow to 1,100. In 2016 and in 2020, two more barn additions were completed.

“We’ve been growing internally since 2000,” Stacy said. “That is the last time we purchased a cow, and we sell extra cows yearly.”

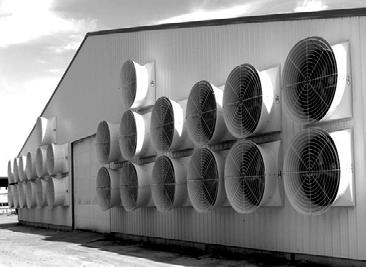

Cow comfort is critical to the Fitzgeralds who have invested in a mist cooling system, rubber ooring and longday lighting. In 2004, the Fitzgeralds switched from mattresses bedded with sawdust to sand bedding. Sand-settling lanes recover 90% of the sand, which is reused within four to six weeks. Two years ago, freestall barns were converted from natural ventilation to tunnel ventilation, which further enhanced cow comfort.

“We have seen a tremendous improvement in cow comfort as well as probably some gain in milk production since switching to sand,” Julie said.

Kelly agreed.

“We have fewer injured cows and fewer cull cows, along with more milk and a lower somatic cell count,” she said. “We thought sand would require a veto 10-year payback, but it ended up being

only a two-year payback.”

No youngstock reside at Soaring Eagle Dairy. Rather, heifers are raised in Colorado, taking advantage of open lots in a drier, warmer climate. In 2005, the farm formed a partnership called The Heifer Authority with four other northeast Wisconsin dairies, a nutritionist, a veterinarian and general manager. The Heifer Authority consists of two locations in Colorado where the partners raise about 15,000 head of dairy replacements – 45% of which come from the partnering farms.

“One of our partners who did consulting in Colorado suggested the area because it has a lot of sunshine, low moisture and not a lot of overhead,” Stacy said. “Animals are housed in dry lots instead of in expensive facilities.”

Heifer calves leave Soaring Eagle Dairy on day No. 1 and return to the farm six to eight weeks before calving. The average age at calving is 21 months.

“We’ve seen a lot of benets over the years of our heifers being raised on dirt lots,” Kelly said. “Calving ease is so much better as the heifers have improved muscle tone. They’re running around and getting exercise. It’s a great environ-

ment to raise heifers. We’ve saved a lot on labor too. We would have to hire three people to do calves for our size of dairy.”

The Fitzgeralds have been genomic testing for six years and use beef semen on the majority of their herd along with sexed semen. Sexed semen is used on 85% of their heifers in Colorado, while the bottom 15% are bred to beef. At Soaring Eagle Dairy, they use 40 units of sexed semen per month. All cows are bred by A.I. after an 80-day waiting period.

“We need 50 to 55 heifers born each month for replacements and are currently experiencing a 10%-15% buffer in heifer calf numbers,” Kelly said. “If beef prices are good, we might cull out the bottom cows. If dairy prices are good, we’ll sell fresh 2-year-olds.”

To help ensure success, the Fitzgeralds hold quarterly team meetings with their veterinarian, nutritionist, hoof trimmer, agronomist and Land O’Lakes representative. They use the meetings as an opportunity to ask team members what improvements could be made on the dairy.

In addition, an owners’ meeting is held once a month to discuss capital purchases and any hot topics on the table, review nancials and take time to plan while also deciding what other events in the industry they should attend. Once a year, the owners try to tour other dairy farms.

“We like to check out a farm that we feel has something of interest to our farm or one that we can gain value from,” Nick said.

Following in their parents’ footsteps with ambitious hearts, the Fitzgerald siblings are working in harmony to achieve the family’s goals.

“We are not necessarily looking to get bigger at this point, just better,” Julie said. “We are trying to milk the least amount of cows while getting the most amount of milk that we can from each one.”

ELMWOOD, Wis. –Frank Lastiri thought he was ready to retire when he sold his dairy farm in 2020. Six months and many miles later, the family moved to a Pierce County dairy near Elmwood Dec. 1, 2021, and began marketing their milk to Ellsworth Creamery.

“We moved tractors, feed wagons, cows and heifers,” Lastiri said. “I put 24,000 miles on my pickup, and ever since then, it’s been parked in my garage.”

The move was prompted by Lastiri’s daughter and son-in-law, Natalia Lastiri and Jose Perez, who wanted to return to the industry and found it difcult to nd a market in Oregon.

“In Oregon, once you quit the dairy, you’re out,” Lastiri said. “There is no way to get back in. We found this dairy with

the good creamery, so we came.”

After the family sold their dairy facilities in Oregon, they retained their youngstock. Their heifers were rst housed in Nebraska and later moved to a heifer grower in Minnesota.

Today, Lastiri milks 500 cows with Natalia and Jose. Lastiri mixes feed every morning while Jose milks the hospital cows. Natalia feeds calves and helps with other projects throughout the day. There are four additional employees who help with milking and various chores.

The herd consists of Holsteins, Jerseys and crossbred cows. Lastiri does not use A.I. and rather has breeding bulls.

“This is how we did it in Oregon, and it’s working here,” Lastiri said. “We use the best bulls that money can buy.”

Cows are averaging 72 pounds of milk per day with 3.48% protein and 4.15% fat. Recently, Lastiri said 65% of the cows were conrmed pregnant at 160 days in milk.

“A lot of guys want to brag about 100 pounds of milk per cow, but this

is what we always got,” Lastiri said. “The cows are healthy.”

Lastiri grew up in Spain and came to America when he was a young man. He began herding sheep in Chino, California. After ve years, Lastiri obtained legal residency and began

milking cows at a dairy farm in Idaho. He eventually became herdsman for the farm and worked there for 18 years.

Then, Lastiri managed another dairy farm in Idaho where they milked 2,500 cows in a 80-stall rotary parlor. He worked there for

two years before buying his own farm in Oregon in 2003 at the age of 50.

“I bought an old, beatup dairy after managing two beautiful big farms,” Lastiri said. “I had a beatup feed wagon, a beat-up

old loader and 150 cows. That was my start.”

Lastiri built up his dairy farm little by little. When he sold in 2020, the farm had a new parlor, and they were milking 1,200 cows.

Lastiri still owns the 800 acres of cropland in Oregon which is rented out.

Lastiri said one of the biggest challenges to overcome in managing the Wisconsin dairy was the shift in manure management.

In Oregon, Lastiri was composting manure. The dried compost was used for bedding and spread on the elds. In Wisconsin, sawdust is used for bedding, and Lastiri has had to learn how to utilize a manure pit.

“Last year, we paid guys to haul manure, and in two short days, it was $10,000,” Lastiri said. “I said I think we need to do this ourselves.”

They purchased a manure pump, a manure truck and a tanker to pull behind a tractor. After trial and error, Natalia, Jose and Lastiri emptied the pit themselves.

“We hauled like mad,” Lastiri said. “We’re going to try to do that every year.”

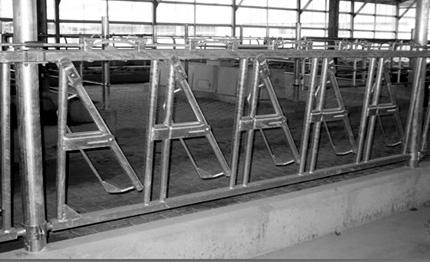

The family has spent the last year making updates to the facilities. A new double-18 parallel parlor was installed to replace the existing parlor. Headlocks and waterbeds were also installed in the freestall barn.

After a year of purchasing feed, Lastiri is looking forward to growing their own crops next year. They are working on securing more land and plan to farm 570 acres.

Lastiri said he can live anywhere, but he would not have had the opportunity to build the life he has anywhere but America.

“I like cows,” Lastiri said. “It’s been a part of my life since 1980. We worked very hard, and we made it. And now, we are here.”

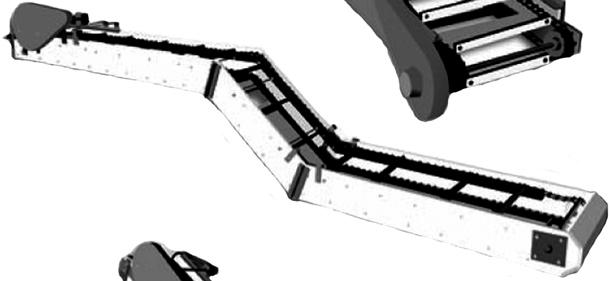

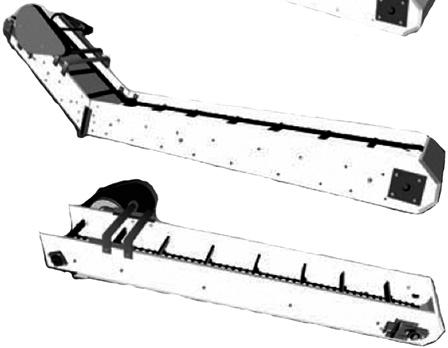

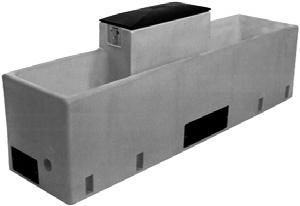

• Stainless steel feed box • Heavy-duty drive

• Wheels mounted directly to wheel motors

• Main drive wheels, directly under feed weight, increases stability

• Chain Choices, #55, 62, or 662 pintle, or SS T-Rod

• Honda Engine powered (6 or 9 hp)

• 33, 43, 60, 73 bushel sizes available

FREEPORT, Ill. – Paul Graybill grew up showing Jerseys and wanted to have his own herd. After seeing dairy setups across the country as a classier for the American Jersey Cattle Association, Graybill decided the only way to have a small dairy and remain protable was to diversify by processing their own products.

“It starts with really good milk from Jersey cows,” Graybill said.

Graybill and his parents, Doug and Kris, have been producing and selling Deerland Dairy yogurt since 2019 on their dairy farm near Freeport.

“Yogurt is one of the fastest growing products in the industry,” Graybill said. “It’s also one of the healthiest options so it’s an easy sell.”

The yogurt is made from 100% unhomogenized Jersey milk. Graybill said this adds to the avor and health benets of the product.

“The fewer processes that you run milk through the more natural it is,” he said. “Jerseys bring over 5% butterfat, and cream is all the value in yogurt. Yogurt is all about protein, and Jerseys typically run over 4% protein, so it adds to the quality.”

The process for Deerland Dairy’s yogurt begins with pasteurization. The raw milk is pasteurized and held at the pasteurization temperature for 30 minutes. It is then brought back to culture temperature. The cultures, avors and colors are added to the milk in the same vat that it is pasteurized in.

The product then runs through the pipeline to the ller machine. At this point, the product is as liquid as unprocessed milk. Cups are lled and foil tops are applied by a machine. Graybill then puts the lid on the container and sends the cup on a conveyor belt where the container is stamped with a sell-by date. It then slides down the ramp where cups are collected and put into

milk crates.

The crates of yogurt are placed in an incubating room where the product spends ve to six hours heating. The incubation process brings the pH below 4.6 and allows the product to set in the cup. After the incubation period is complete, the nished product is transferred to a cooler, where it is stored until being distributed.

Deerland Dairy products are sold in stores and restaurants throughout northern Illinois and southern Wisconsin. Kris also sells the products at a farmers market every week. Besides yogurt, the farm also produces sour cream and buttermilk. Many restaurants get their buttermilk and sour cream in 10-pound bags.

Yogurt is available in plain, strawberry, blueberry and vanilla avors. Graybill said their best-selling avor is plain, especially at the farmers market.

“People who want a high-end product like this want to add their own things to it,” Graybill said. “They like to buy plain yogurt and add berries or local honey from the market to avor it.”

Originally, the Graybills milked up to eight Jersey cows and processed all of the milk into their own products. Doug milked in the morning before going to work as a pipetter, and Graybill milked at night after working as a hoof trimmer during the day. When Doug had back surgery in 2020, however, the cows were rehomed to Kilgus Dairy in Fairbury. The Graybills now own 25 cows, all of which are housed elsewhere.

The move was bittersweet; the whole reason for making yogurt was to be able to have the cows. However, the partnership with Kilgus Dairy opened doors for the Graybill family. Because Kilgus Dairy processes all of their milk into products under their own label, they have been able to help distribute the Deerland Dairy products alongside their own.

Once a week, the Graybills deliver their products to Kilgus Dairy and bring milk back for their production. Kilgus Dairy milks all Jersey cows as well.

could work together as a family and raise kids on a farm,” Graybill said. “This is the way for small farmers.”

What counties or area do you cover? I have a lot of different counties that I have farms such as Swift, Kandiyohi, Cottonwood, Meeker and Stearns counties.

What do you enjoy about the farmers you work with? I love getting to know the farmers and how everything is going with them. Every farm is different, and it’s fun to see how different farmers do different things.

What do you like about your work for DHIA? I enjoy working around animals and people, so this job was a good t for me. I’m glad DHIA can help farmers in making their farm the best it can be. It’s a great company that’s centered on helping any farm big or small.

What do you do in your free time? My husband and I have four teenagers so I keep busy with their sports and events. We also live on a hobby farm with horses, goats, chickens and a big garden.

Sauk Centre, MN Buffalo, MN 763.682.1091 www.mndhia.org

MEDFORD, Wis. – For Joe and Christy Tomandl, organic dairy production is not necessarily the easiest path.

But, the path they have trodden is the right one for their family.

While holding steadfast to their beliefs, the Tomandls, of Medford, were given the 2022 Wisconsin Leopold Conservation Award Nov. 17 in Madison.

“Organic production is a tough business to be in,” Joe Tomandl said. “It can sometimes be hard to nd the value added with the increased costs of organic inputs. But if you work hard at managing those costs and maintaining your margins, the benets are worth it.”

With their three children Joe Jr., Abigail and Carlissa – the Tomandls operate Tomandl Farms.

Tomandl Farms is comprised of three organic dairies straddling the lines of

Taylor and Marathon counties.

The Tomandls milk about 500 cows between the three sites and farm 1,200 acres; 750 of those are devoted to pasture for grazing, while grass hay is raised on the remainder and harvested as baleage or haylage.

All of the corn and concentrates are purchased. The Tomandls have 12 employees who work on the three farms.

“Grazing is all I have ever really known,” Tomandl said.

Tomandl was raised on a small dairy farm that relied heavily on grazing, and in 1998, he began to forge his own career as a dairy farmer by purchasing what would become the rst of the three farms.

He set out on a path similar to that of his parents: A conventional dairy farm where the cattle are grazed.

“There was a grazing plan in place for this farm; the lanes and the fences were all there,” Tomandl said. “I understood the mod-

el, and it was a good way to get started.”

The Tomandls began grazing and milking 40 Jersey cows in a tiestall barn.

The original grazing plan was written by long-

time Marathon County conservationist Paul Daigle, who nominated the Tomandls for the Leopold Conservation Award after working with the couple throughout their career.

After nearly 20 years of operating much like an organic dairy but without the certication, the Tomandls decided to make it ofcial in 2017 and began the process of certifying their farms and their herd.

“With the dairy markets the way they were, we began looking at ways to continue to stay viable and relevant,” Tomandl said. “We looked at getting certied. It represented a fairly stable market, knowing where your price would be at for the year. The land was already basically organic. All there was to do was go through the process for the cows to become certied.”

Being willing to change, adapt and try new things to bolster their prot margins has been a hallmark of how the Tomandls choose to operate their business. For two years, they removed all grain and concentrates from the ration and procured a spot on an all-grass-based milk route. In 2020, they added grain and concentrates back into the ration.

With an eye toward improving both the environment and their farm, the Tomandls maintain their pastures by no tilling or interseeding into one-third of their existing pasture stands. They place a focus on trying new grasses, blends or improved varieties.

“We try to utilize as much grass as possible to cut back on our feed costs as much as we can,” Tomandl said. “At rst we thought it better to supplement (a total mixed ration) with managed grazing, but now we’ve moved to the philosophy that it is better to supplement managed grazing with TMR.”

The Tomandls try to appropriate up to 75% of the herd’s dry matter intake from grass for at least six to seven months of the year and an average of 55% throughout the year in order to keep feed costs in check.

In an effort to achieve the maximum results from the pastures, Tomandl has taken part in a paddock tracking program to more efciently manage his grazing program.

“We have a sonar mounted to the front of a four-wheeler and drive that through the paddocks,” Tomandl said. “That maps the paddocks and can tell us about the tonnage that is available for grazing and helps us determine if we need to be switching more frequently or grazing a bit longer to get the best utilization of

the grass that is available to us.”

As he worked to keep his farms running efciently, Tomandl witnessed what he considered to be a void in the dairy industry, and he set about nding a way to ll it.

“It was hard to nd key people to work on the farm,” Tomandl said. “Farming is tough to learn in a classroom. That is how the Dairy Grazing Apprenticeship was created, to bring those key people into the industry through structured work training. It is geared to create that pathway into dairy farming.”

The two-year program requires a total of 4,000 hours to be invested by the apprentice, 300 in the classroom and the remaining 3,700 on the farm. Since its inception in 2010, there have been more than 60 graduates of the program.

Because he sees dairy farming as a constantly changing and evolving endeavor, being recognized with the Wisconsin Leopold Conservation Award is an experience Tomandl said is humbling.

“Just to be named a nalist was such an amazing honor, and to be recognized as the winner is something I cannot even dene,” Tomandl said. “The nalists this year were such an accomplished group. It was just a privilege to be recognized among that group.”

What is the size of your stalls and the depth of sand within them?

The head-tohead stalls are 48 inches wide and 14 feet long. The outside rows are 48 inches wide by 9.5 feet. Stalls are bedded with 8 inches of sand. We don’t have brisket boards.

What benets do you see from using sand bedding? We see less lameness, fewer injuries from slipping in the alleys and increased milk production.

How often do you replace sand or put sand in stalls and what is the method of adding sand? We add sand to the stalls twice a week using a skid loader and bucket.

How do you maintain and clean your stalls? Three times per day before the cows in that group get milked, we scrape out dirty or wet sand with a hand scraper.

How do you get rid of or recycle used bedding?

We have a ush ume that the sand and manure is scraped into when they clean the pens three times per day. The ume delivers that to the mechanical sand separator, which is located in a separate building. Our mechanical sand separator is a one-shot made by Daritech Inc. After 3-7 days, we move the sand with the payloader and pile it up next to the freestall barn to bed the stalls. We also have a vibrating slope screen to help clean the water to aid in sand separation.

What challenges can arise from using sand bedding? How did you solve those problems? There is a downside. Sand wears on equipment and concrete and everything. The production increase outweighs the extra expenses caused from sand. You can’t really solve those problems. Sand gets everywhere.

Tell us about your farm. The farm is owned by Eric and Chassidy Klein and Dean and Lois Klein near Lake City, Minnesota. We milk 700 cows and ship our milk to First District Association. We farm 2,000 acres. We also raise our heifer replacements and dairy crossbreds.

What is the size of your stalls and the depth of sand within them? The stalls are 48 inches wide and 17 feet curb to curb. Sand bedding is 8-10 inches deep.

What benets do you see from using sand bedding? Cow comfort is the main benet. We do not see any perching on the stalls. The hygiene scores are better, and we see more condence in the herd as far as mobility and traction.

How often do you replace sand or put sand in stalls and what is the method of adding sand? Stalls are raked three times a week and bedded once a week. We add sand with a sand shooter attachment on the skid loader.

How do you maintain and clean your stalls? We have a hoe that we use to scrape stalls as we collect cows at milking time. If there is any defecation or urine, we rake it out.

How do you get rid of or recycle used bedding? The sand gets scraped into the manure pit with the manure and then applied to elds when the pit is emptied.

What challenges can arise from using sand bedding? How did you solve those problems?

The manure pit needs to be managed. We bought a large enough pump and tractor to agitate everything so it could be hauled. Sometimes we use two pumps. Another challenge is that the cost of trucking has doubled in the last six months. We are looking into ways to haul our own to save on that cost. When sand is delivered on cold days, it tends to clump. We manage that by putting it in the stalls right when it is delivered.

Tell us about your farm. We are a cash crop farm and wanted to dairy. We farm 4,000 acres of corn, soybean, alfalfa and small grains. I have always been involved in the dairy because I love cows and the industry. Our milk is shipped to Foremost Farms. We have an excellent team and are excited about the future.

What is the size of your stalls and the depth of sand within them? Stalls are 4 feet wide and 9 feet long, 70 inches to the brisket curb. Sand is about 4 inches deep. We have pack mats in so we only use about half of deep bedded sand.

What benets do you see from using sand bedding? Mainly just cow comfort. We don't deal with hock or leg issues, and typically, cows stay cleaner so the somatic cell count stays lower.

How often do you replace sand or put sand in stalls and what is the method of adding sand? We typically add sand every seven or eight days. We have a sand shooter on a skid loader to put it in.

How do you maintain and clean your stalls? Two or three times a day, we go through and scrape off manure and level off any stalls that need it.

How do you get rid of or recycle used bedding? Used sand goes into the manure pit. We don't reclaim sand.

What challenges can arise from using sand bedding? How did you solve those problems? We started using it when we built a new barn in 2014. We did it strictly for cow comfort, hoping it would improve cow health and milk production. Sand wears out my blades on ally scrapers and wears holes in the manure pump over time. Those have been my most common problems. It requires more maintenance on those pieces of equipment.

Tell us about your farm. We milk 65-70 cows with a Lely A5 robotic milking system. Our milk is sold to Chula Vista Cheese. We farm around 275 acres. It's a small family farm with just my wife and two sons and lots of tractor driving from my father.

Eric Klein Lake City, Minnesota Wabasha County 700 cows

Eric Klein Lake City, Minnesota Wabasha County 700 cows

What is the size of your stalls and the depth of sand within them? The outside row of stalls along the curtain are 4 feet by 9 feet. The inside row toward the feed alley are 4 feet by 8 feet. We run 10 to 12 inches of sand with a clay base.

What benets do you see from using sand bedding? We started using sand two years ago. The farm was setup for it when we bought it. All of the swollen hocks and legs have gone away. I really like the sand for traction; the cows have better footing. Our somatic cell count has gone down, but we also made some other changes at the same time. It is hard to tell if it is a benet of sand or not.

How often do you replace sand or put sand in stalls and what is the method of adding sand? We rell the stalls once a week. We use the skid loader with a dirt bucket and dump over the top. Eventually, the plan is to get a sand shooter.

How do you maintain and clean your stalls? We maintain them by hand right now. We scrape and level them twice a day when we go to push cows into the holding area.

Hendrickson Belleville, Wisconsin Green County 110 cowsWhat is the size of your stalls and the depth of sand within them? We have three different-sized stalls in our 60-stall tiestall barn. All stalls are 76 inches long, or a little over 6 feet, and most are 56 inches wide. We have a 3-inch PVC bedding saver pipe in the back of the stalls and a 9-inch curb in the front of the stalls. Before adding sand, we ripped out the pasture mats and left the standard rubber mat beneath intact. It provides a nice, at cushion on top, and then I go as deep as I can with the sand which is about 9 inches initially and keep the stalls as full as I can. Half of our cows live in the tiestall barn and half live in our renovated freestall barn. We bed with sand in both barns.

What benets do you see from using sand bedding? The biggest benet we see is the quality of laying time. When I walk in the barn, all the cows are lying down. And if I walk through the barn, the cows won’t even get up. In the past, when I pushed in feed or cleaned up, cows would jump up left and right. We have no swollen hocks, and we went up a little in milk too. If you can improve cow comfort and efciency by putting sand in, it’s worth it. My mom was concerned about milking on sand, but she actually nds it more comfortable than the mats. I’ve had knee issues, and since putting sand in, my knees haven’t bothered me as much. We have more cushion now when stepping up and down in the stalls. Sand also saves me time as I don’t have to bed the cows every single day. I go through and rake and clean the stalls. It saves me a half hour every morning not having to shake straw. Putting sand in only takes 15 minutes.

We started using sand in our tiestall barn Oct. 28. The freestall barn has been bedded with sand since my parents bought the farm in 1991. It is benecial for these cows to be on sand. Previously, our cows were on pasture mats, and I didn’t like how hard the cows’ feet got. This made them more susceptible to getting a sore foot and didn’t allow for good foot growth. When we trimmed the cows, they hardly had any shedding or pad, just a at, hard sole wore down to nothing. Seeing the difference of cows’ feet in the free stalls versus the tie stalls and the amount of lameness

How do you get rid of or recycle used bedding? This has been the biggest problem. Sand is the best bedding until it leaves the stall. We have been slowly getting a system worked out over the last two years. The barn is scraped into a reception pit that holds about ve days. We can get about 30% of the sand settled out. Then it is pumped to the big pit, which has been the main source of our problems. We inherited a full pit of sand when we bought the place almost three years ago, so it has been a slow battle. Between what sand settles out in the reception pit, and with the boat in the big pit, we are managing it now. Currently, we are not reusing the sand. We've been told it's very hard to reclaim the ne sand that we use.

What challenges can arise from using sand bedding? How did you solve those problems? Sand is hard on everything it touches, so you need to pay attention to your manure system more. The biggest challenge is handling it once it leaves the stall. People want to sell you a hundred different things to handle it. We're still guring this out and trying to keep it as simple as possible. The more moving parts, the more headaches.

Tell us about your farm. I have been milking for ve years now. I started out by remodeling my parents’ tiestall barn and renting the land from them. My dad has helped since day No. 1 and is a huge help. Then, a farm with a freestall barn a mile down the road came up for sale three years ago, and my wife and I bought that. A year later, we moved into it and went from 50 to 80 cows. We ship our milk to Ellsworth Cooperative Creamery. Now, my wife is home full time and helping. Dad also has beef cattle, and we farm about 400 acres.

the tiestall barn cows had over the freestall cows was a big push for putting sand in.

How often do you replace sand or put sand in stalls and what is the method of adding sand? We add new sand in the tiestall barn once a week with a skid loader and sand shooter. If we didn’t switch cows in and out and have them tracking sand out every time, we could probably go every two weeks before adding new sand.

How do you maintain and clean your stalls? I have to be more aggressive initially with the trainers than I would like, but I don’t want cows making a mess under themselves. I don’t like to see manure, so I’m always cleaning under the cows. In the morning, I go through and groom the stalls with a garden rake and pull out any wet sand. I also do that at night before the cows come back in the barn.

How do you get rid of or recycle used bedding? We spread it on our elds. We’ve always had sand because of the free stalls. We spread a load every single day and have had no issues on the elds. We don’t recycle it; we use fresh sand all the time.

What challenges can arise from using sand bedding? How did you solve those problems? Wear and tear on the barn cleaner and putting sand on the land are challenges that can arise. We have a standard barn cleaner, and we recently put a plastic liner in the gutter so the barn cleaner chain and concrete at the oor of the gutter do not wear out as fast. Nobody wants barn cleaner troubles especially in the winter, but the barn cleaner doesn’t pay your bills. I don’t think the amount of sand we’re using will affect the land, but our agronomist will tell us next fall when he takes soil samples. The availability of sand long term is something I also wonder about.

Tell us about your farm. I farm with my parents, Jeff and Kate, and my wife, Riley. Our daughter, Adlee, is 1, and we have another child on the way. We milk between 110 and 115 registered cows at Jeffrey-Way Holsteins. We milk two groups of cows in our tiestall barn. We have 60 Excellent and 55 Very Good cows, none lower. Our average classication score is 90 points. We breed for type, production and longevity. Cows average 90 pounds of milk, 4.3% butterfat and 3.4% protein. We ship our milk to Klondike Cheese in Monroe, Wisconsin. We farm around 300 acres and make a lot of baleage which we top-dress with corn silage, haylage, high-moisture corn and protein when feeding cows. Genetics has always been the main goal for our farm, which has allowed us to milk fewer cows and have a successful operation.

Kevin and Ben Pearson Britannia Dairy Flandreau, South Dakota Moody County 1,100 cows

Describe your facilities and list your breeding management team. One of our freestall barns is naturally ventilated while the other is tunnel ventilated. We bed our free stalls with sand. All of our employees, including our milkers and our cow pushers, are part of our breeding management

team because they help keep our somatic cell count low. We have found that cows with a high SCC have lower conception rates. Ben does all of the breeding.

What is your current pregnancy rate? Our pregnancy rate is 42%.

What is your reproduction program? We use a double ovsynch on all of our rst services. We also give the animals two shots of luteinizing hormone 24 hours apart. We use activity monitors to catch animals that didn’t settle and perform pregnancy checks every two weeks.

How do you get animals pregnant? We have recently been giving a shot of GnRH at the start of estrus. This has increased our conception rate by 5%.

Describe your breeding philosophy. Our goal is to get more than 90% of our herd pregnant after three services.

He has an app on his smartphone that he uses to access this informaon from anywhere at any

What guidelines do you follow to reach the goals for your breeding program? We aim for strict

compliance regarding the shots that we give our animals and keep up on the activity transponders. A good transition program is critical to reproductive success. We have started giving a calcium binder to our transition animals.

What are the top traits you look for in breeding your

dairy herd and how has this changed since you started farming? We look for sires with sound health traits, good udder height and width, and a positive daughter pregnancy rate. Our herd is mostly Jerseys, and we recently started crossbreeding with Holstein sires. We monitor the stature of

our Holstein sires and only use bulls that are easy calving.

What are certain traits you try to avoid? We avoid a large stature and a low DPR. If a rst calf heifer isn’t performing well in the milking parlor, we

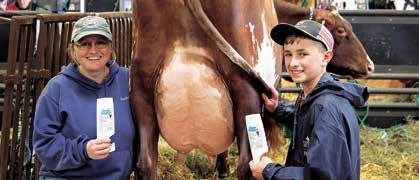

“Udder Comfort™ is like ketchup. We put it on everything, and it makes everything better! We have been using this product forever, especially on fresh cows for 4 to 5 days after calving. It also softens and heals flareups fast. Other products don’t do anything. Udder Comfort brings down swelling faster, so why use anything else?” says 4th generation dairywoman Ashley Olson. She works with cows every day at Jo-Al Acres, where she and Jeff milk 50 in a crops and grazing operation near Coon Valley, Wisconsin.

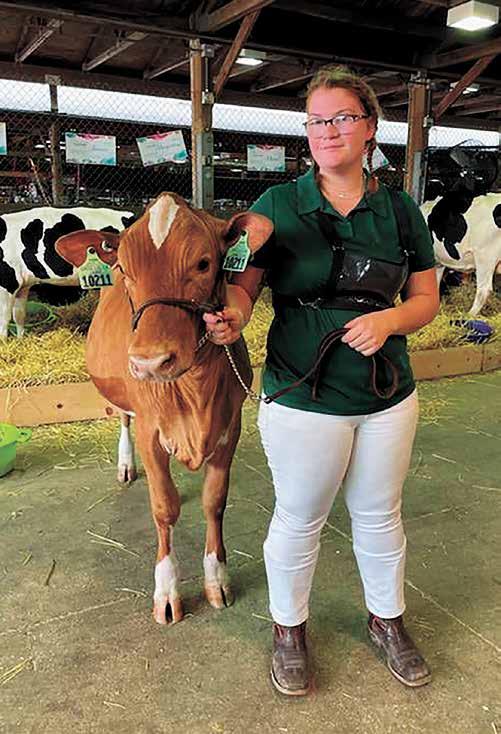

Their 14-year-old son Jed hopes to be the 5th generation in dairy. We met him checking feed and helping Jason and Leah James of Pine Valley Farm, Mineral Point get their Pine Valley Justice Carlin ready for the World Dairy Expo Milking Shorthorn show.

Leah and Ashley went to college together. They share a passion for cows and for moving dairy forward. They also share a pack at Expo and love the results they get with Udder Comfort at shows and for their respective herds at home.

won’t hesitate to ship her. Selecting sires is a balancing act.

Describe the ideal cow for your herd. She is an F1 Jersey-Holstein crossbred with high milk production, a welldeveloped udder and proper leg set.

What role does genetics have in reaching the goals of your farm? We hope that crossbreeding with Holstein sires will help us achieve our goal

of producing more energy-corrected milk. We use top sires whenever they are available.

What percentage of your herd is bred to sexed, conventional and beef semen?

All of our heifers are bred the rst two services with sexed semen; after that, they are bred with beef bulls. We use sexed semen for the rst two services on the cows that we want to produce replacements. The rest of our cows are bred to Charolais sires.

What is your conception rate? The conception rate for our rst service is 50% to 60%. We have seen little difference in the conception rates between sexed, beef and conventional semen.

What is the greatest lesson you have learned through your breeding program? Get the shots into the cows at the right time, and make sure your activity transponders are working. We know how the system works and are constantly trying to improve.

What is the age of your heifers at rst service? Our heifers receive their rst service at 12 months of age.

How does your heifer inventory affect your breeding program? We keep track of our heifer inventory and use more sexed semen if our numbers start to get low. Economics dictate that we keep our pool of heifers as small as possible. But, we also want to retain the ability to cull a rst calf heifer if she isn’t performing.

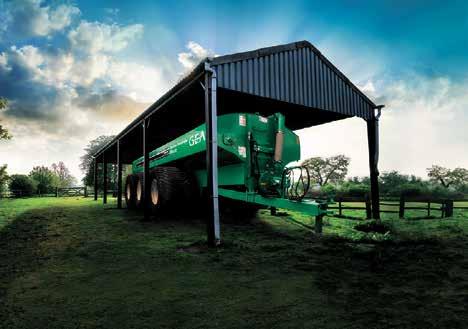

Tell us about your farm. We moved here from North Yorkshire, England, in 2007. We purchase all of our forages, and our heifers are raised by a heifer grower located in southwest Kansas. At 10 months of age, our heifers are taken to M & M Livestock at Chandler, Minnesota. Our heifers arrive back at

our

farm at three weeks prior to calving. Over the past few years, we have received

IOWA

Kramer Bros. Monticello, IA 319-465-5931

Prairie Land Ag Supply Inc. Rock Valley, IA 712-476-9290

United Dairy Systems, Inc. West Union, IA 563-422-5355

DeLaval Dairy Service Kaukauna, WI 866-335-2825

Joe’s Refrigeration Inc. Withee, WI 715-229-2321

Mlsna Dairy Supply Inc. Cashton, WI 608-654-5106

Professional Dairy Services Arlington, WI 608-635-0267

My dad was a big believer in cutting down our own Christmas tree out of our own woods. To go to the store and buy one would be a travesty in his mind.

We would bundle up, drive over to what we called the pines, which was a part of the farm that had a big stand of pine trees, and trudge through the snow (usually) to nd the best tree we could.

Dad would describe these trees we brought home each year as full of character. Most people would probably think they were a second cousin to Charlie Brown’s Christmas tree.

WISCONSIN

Advanced Dairy Spring Valley, WI 715-772-3201

Ederer Dairy Supply Plain, WI 608-546-3713

Redeker Dairy Equipment Brandon, WI 920-346-5579

The Scharine Group Inc. Whitewater, WI 800 472-2880 Mt Horeb, WI 800-872-3470

MINNESOTA & SOUTH DAKOTA

Farm Systems Melrose, MN 320-256-3276 Brookings, SD 800-636-5581

Advanced Dairy Mora, MN 320-679-1029 Pierz, MN 320-468-2494 St. Charles, MN 507-932-4288 Wadena, MN 218-632-5416

Several times, my dad would collect extra branches, and he would use those branches to make pine bough swags that he would tie up on the posts in the barn, decorating the barn for the holiday too. We used kiln-dried shavings as bedding in the barn, so the barn always had a slightly piney smell, but the smell from those pine boughs was so much different – better and more alive.

By Danielle Nauman Staff Writer

When we would get the tree home, there would usually be some sort of engineering required to convince the tree to cooperate. Some years, the trunks were slightly crooked. Sometimes, the tree had to be tied to the curtain rod.

One year, the best we could nd had some rather large gaps. Not to be deterred, my dad drilled holes in the trunk of the tree and inserted additional branches to ll in the blank spaces.

My mom often recounts the tree Dad brought home for their rst Christmas. When it stood alongside the old brick farmhouse they lived in, the top of the tree bypassed the tops of the upstairs windows. That one required quite a bit of engineering.

We never had trouble with needles falling off our fresh-from-the-woods trees, except for in 1988, which had been an incredibly hot and dry summer. That year, needles were falling off as we drug the tree home. The vacuum cleaner got plugged up a couple of times that year.

Once the tree was up and (hopefully) secured, Mom would dig out the boxes of ornaments, all which had a story behind them.

When I was a kid, my grandma Nauman would give us ornaments every Christmas. My favorites were the ones she made when her and my mom would go to ceramics classes at a lady named Etta’s house, near Wilton, Wisconsin. I used to go along and paint small simple things myself. I always loved going to Etta’s, so those ornaments bring back many good memories. As I grew older, I started collecting cow ornaments and probably have enough of those for at least one entire tree.

As we grew, once in a while, Dad would cave and would pick up a tree from the local grocery store, but they were never quite the same as the ones that came from the pines. I am grateful that my own son was able to experience the tradition of going out into the pines with Grandpa to nd a Christmas tree.

I hate to admit that I haven’t put up a Christmas tree in several years now. Dad died the day after Christmas in 2010, and honestly, the holiday has never been the same for me. Once Austin grew older and December became a busy month with hockey and other activities, it seemed more of a chore than something delightful to do.

There have been several years, around late October, when I think this will be the year I’ll get another Christmas tree. I usually think about all the ornaments packed away in totes full of newspaper and paper towels and about going to pick out all those trees with Dad. Those memories take over and spark an interest and desire. But by the time December rolls around, any enthusiasm I may have had has usually blown out the door with the cold wind, as I have been thrust into the rigorous routine of trying to balance winter chores with work.

By Danielle Nauman danielle.n@dairystar.com

By Danielle Nauman danielle.n@dairystar.com

LADYSMITH, Wis. –

Baking soothes Janet Hetke’s soul and takes her back to a simpler time when a homemade pie could improve nearly any situation.

“I grew up making pies all my life and learned to make them at my mother’s side,” Hetke said. “A homemade pie could turn any event or gathering into a special occasion.”

As an adult, Hetke continued the traditions of her grandmother and mother and took pies to family gatherings and church socials. About ve years ago, Hetke donated a homemade pie to be sold in a silent auction fundraiser at the county fair. That pie sold for what Hetke considered to be an astounding price of $50. With that interest, Hetke began the tradition of donating pies to various fundraisers. Each donation seemed to bring a little more money, with a pie selling for $150 at the Wisconsin Ayrshire Breeders’ Association annual meeting last spring.

Hetke and her husband, Paul, milk 50 registered Ayr-

shires on their Rusk County CloverKey Farm near Ladysmith.

Through a friend, Hetke learned of legislation that had been passed for the food-based cottage industry. The 2017 Senate Bill 271, commonly known as the Wisconsin Cookie Bill, allowed for the sale of homemade low-contaminant ourbased baked goods.

“That legislation opened the door for a home bakery business,” Hetke said. “There are a lot of particulars, but it created an avenue for the sale of those items.”

The timing of that bill coincided with an ample supply of lard, which, based on what she learned from her mother and grandmother, is an ingredient Hetke considers essential to baking pies.

“My daughter and son-inlaw opened a small butcher shop, and she asked me if I would be interested in lard to render,” Hetke said. “I now have access to all the lard I could ever need and then some. “

Like adding ingredients to a mixing bowl, Hetke began putting together the pieces of her own pie-making business which

she coined CloverKey Kitchen after her family’s dairy farm.

“I really agonized over pricing,” Hetke said. “Once you factor in ingredients and time, pies are not cheap to make.”

After polling friends, relatives and neighbors, Hetke set-

tled on charging $25 per pie, or a special of $45 for two pies.

Hetke began searching opportunities to sell her baked goods and was able to procure a spot at the Ladysmith Farmers Market beginning in early June.

The rst week, Hetke took 10

pies to the market and sold out.

“There is something about taking a pretty pie out of the oven and admiring it,” Hetke said. “To have other people ap-

CALUMET COUNTY

• D&D Equipment

Chilton • 920-849-9304

• Stanley Schmitz Inc Appliance & Dairy Center Chilton • 920-849-4209

CHIPPEWA COUNTY

• Chippewa Farm Service, LLC Chippewa Falls • 715-382-5400

• Chippewa Valley Dairy Supply Stanley • 715-644-2350

CLARK COUNTY

• Cloverdale Equipment Curtiss • 715-223-3361

• Premier Livestock Withee • 715-229-2500

• Silver Star Metals Withee • 715-229-4879

COLUMBIA COUNTY

• Central Ag Supply Baraboo • 608-356-8384

DANE COUNTY

• Argall Dairy Systems Belleville • 608-424-6110

DODGE COUNTY

• Central Ag Supply Juneau • 920-386-2611

• Knowles Produce & Trading Co. Knowles • 920-583-3747

DUNN COUNTY

• Leedstone Menomonie • 866-467-4717

• Midwest Livestock Systems Menomonie • 715-235-5144

FOND DU LAC COUNTY

• Redeker Dairy Equipment Inc. Brandon • 920-346-5576

• Argall Dairy Systems, West Platteville • 608-348-3385

• Dickeyville Feed Dickeyville • 608-568-7982

• Fuller’s Milker Center, LLC Lancaster • 608-723-4634

• J. Gile Dairy Equipment Inc. Cuba City • 608-744-2661

• Premier Co-op Lancaster • 608-723-7023

• Scott Implement Platteville • 608-348-6565

GREEN COUNTY

• Monroe WestfaliaSurge/Koehn, Inc. Monroe • 608-325-2772

• Top Notch Feed & Supply New Glarus • 608-527-3333

IOWA COUNTY

• Farmer’s Implement Store

Mineral Point • 608-987-3331

• Premier Co-op Mineral Point • 608-987-3100

JACKSON COUNTY

• W.H. Lien, Inc. Hixton • 715-963-4211

KEWAUNEE COUNTY

• Luxemburg Motor Company Luxemburg • 920-845-2011

• Spartan Construction Luxemburg • 920-845-9892

LAFAYETTE COUNTY

• Center Hill Veterinary Clinic Darlington • 608-776-4083

MANITOWOC COUNTY

• EIS Implement

Two Rivers • 920-684-0301

MARATHON COUNTY

• Brubacker Ag Equipment, LLC Edgar • 715-613-7308

MONROE COUNTY

• Preston Dairy Equipment Sparta • 608-269-3830

PEPIN COUNTY

• Anibas Silo & Repair Arkansaw • 715-285-5317

POLK COUNTY

• Midwest Machinery Osceola • 715-220-4256

RICHLAND COUNTY

• Fuller’s Milker Center, LLC Richland Center • 608-647-4488

• Premier Co-op Richland Center • 608-647-6171

ROCK COUNTY

• Tri-County Dairy Supply Janesville • 608-757-2697

SAUK COUNTY

• Central Ag Supply Baraboo • 608-356-8384

SHEBOYGAN COUNTY

• Perfect Circle Tire Co. Waldo • 920-528-7277

VERNON COUNTY

• Koon Kreek Feeds Coon Valley • 608-452-3838

• Premier Co-op Westby • 608-634-3184

ALLAMAKEE COUNTY

• K & R Feed and Grain Dorchester • 563-568-4513

DUBUQUE COUNTY

• Brunkan Equipment Worthington • 563-855-2434

• CJ Beeps Equipment Farley • 563-744-5010

• Eastern Iowa Dairy Epworth • 563-876-3087

• Helle Farm Equipment Dyersville • 563-875-7154

• New Vienna Ag Automation New Vienna • 563-921-2896

• Roeder Implement Dubuque • 563-557-1184

• Scherrmann’s Implement Dyersville • 563-875-2426

• Skip Breitbach Feeds Balltown • 563-552-2393

• Ungs Shopping Center (IAS) Luxemburg • 563-853-2455

HOWARD COUNTY

• Farmers Win Co-op Cresco West • 563-547-3660

WINNESHIEK COUNTY

• Brynsaas Sales & Service Decorah • 563-382-4484

• Franzen Sales & Service Fort Atkinson • 563-534-2724

• Lang’s Dairy Service Decorah • 563-382-8722

• Midwest Machinery North eld • 507-645-4886

• Werner Implement Vermillion • 651-437-4435

• Caledonia Haulers Caledonia • 507-725-9000

• ESB Bank Caledonia • 507-725-3329 Eitzen • 507-495-3321 La Crescent • 507-895-2227

• Farmers Win Co-op Caledonia • 507-725-3306 Houston • 507-896-3147

• Hammell Equipment Eitzen • 507-495-3326

• Midwest Machinery Caledonia • 507-725-7000

• Ag Partners Farm Store Goodhue • 651-923-4496

• Midwest Livestock Systems, LLC Zumbrota • 507-732-4673

• Midwest Machinery Cannon Falls • 507-263-4238 Wanamingo • 507-824-2256

WABASHA

• Ag Partners Farm Store Plainview • 507-534-2531

• Beck Implement Elgin • 507-876-2122

• Leedstone Plainview • 800-548-2540

• Midwest Machinery Plainview • 507-534-3116

• Wingert Sales & Service Plainview • 507-534-2285

• Elba Co-op Creamery Elba • 507-796-6571

• Lang’s Dairy Equipment Lewiston • 507-452-5532

• Lewiston Rentals and Repairs Lewiston • 507-523-3564

• Midwest Machinery St. Charles • 507-932-4030

*Enter as often as you like. One entry per store visit, please. Winners must be 18 years or older and a Grade A or B dairy farmer for adult prize, or 17 years or younger and a son or daughter of a Grade A or B dairy farmer for heifer calf. Winners must also live in the Dairy Star circulation area to be eligible and are responsible for transport of animal.

preciate

As the summer progressed, Hetke began attending the Bruce Farmers Market on occasion as well. She enjoyed increasing success at participating in those local markets and began to branch out, adding cookies and homemade breads to the inventory she loaded up each week.

“The bread, especially, has

turned into something that has brought regular repeat customers,” Hetke said. “I have three pretty regular customers that will come out to the farm and pick up loaves of bread every week.”

Hetke developed a Facebook page to help promote her business but has found that the face-to-face contact she makes with customers at the farmers markets has been the best path-

way to growing her business.

“The farmers markets are a great way to have direct contact with the customer,” Hetke said. “That has been the best experience for me.”

CloverKey Kitchen kept Hetke busy and up to her elbows in our throughout the summer. Throughout the summer, she sold 153 pies, 86 baker’s dozens of cookies and 50 loaves of bread.

As the farmers market season wound down in late September, Hetke was left wondering how to shape her off-season marketing. She has looked into shipping her products.

“I sent some cookies to a friend who had surgery; I used an empty Pringles potato chip container for those and that worked well,” Hetke said. “A dozen cookies t the container pretty well, and the cookies made it to my friend in good shape.”

Shipping pies and breads are another story, Hetke said.

“It would be difcult to pack the pies in a fashion that they could make it through the transport in one piece,” Hetke said. “And by the time homemade bread spends a few days in the mail, you lose that freshness that makes homemade bread so good.”

Hetke has developed a pie of the month club for local customers to enjoy a variety of pies throughout the year. She also has punch cards, so a free dozen cookies or loaf of bread can be earned with the purchase of 10. With the slowing down of

the winter season, Hetke is turning her thoughts to what CloverKey Kitchen’s offerings might look like next spring.

“I am looking at starting to do some cake decorating,” Hetke said. “You can’t get a decorated graduation cake here in Ladysmith any longer, so there is maybe a need for that.”

Regardless of what direc-

tion CloverKey Kitchen will take in the spring, Hetke revels in what she is doing.

“Baking and selling my work, this is living my dream,” Hetke said. “I love being in this kitchen. I love what I am doing. I have always encouraged my children to nd what makes them happy in life. This is what makes me happy.”

By Stacey Smart stacey.s@dairystar.com

By Stacey Smart stacey.s@dairystar.com

CEDARBURG, Wis. What does the future of Wisconsin’s small family farm look like? This was the topic of discussion as members of the community gathered at the public library in Cedarburg Dec. 3 to get a glimpse into the daily lives of ve dairy farmers.

The panel entitled “Our Dairy Farms: Present and Future” featured Peggy Schoessow of Farmdale Farm in Mequon; Shelly Grosenick of Crimson Ridge Dairy in Lebanon; Bob Roden of Roden Echo Valley in West Bend; Jeffrey Dahm of Ja-Bon Dairy Farm in Belgium; Thelma Heidel-Baker of Bossie Cow Farm in Random Lake; and Elizabeth McMullen of Organic Valley Cooperative. The moderator was Judith Friebert whose artwork of dairy farms is on display at the Cedarburg Art Museum.

Schoessow farms with her husband, Dean, and her son, Michael.

“We are probably one of only three dairy farms left in the city of Mequon,” Schoessow said. “That is hard and does have its challenges.”

Michael is the seventh generation on the farm that has been in his family since

1839. The Schoessows milk 85 registered Holsteins and ship their milk to Family Dairies. Most of their milk is dedicated to uid use.

Over the years, the Schoessows have expanded and added new facilities. Cows are housed in a sand-bedded tiestall barn that was built in 1981 and added onto after Michael joined the operation. Ventilation was improved by adding multiple fans on the east side and garage doors on one side for better airow and circulation. New heifer facilities were also built with better ventilation in mind.

“My son and his wife have two little boys, and it would be nice if the eighth generation would be able to carry on our legacy in farming,” Schoessow said.

Schoessow also works off the farm, spending 40 years in corporate America. It is one of the ways she has helped her family’s small farm succeed.

“I think each and every one of us on this panel has some level of diversity,” Schoessow said. “You have to be exible and agile enough to know what’s going to work for you and your family.”

Heidel-Baker agreed.

“Think about what you’re good at and focus on that,” she said.

Three of the ve panelists have diversied into providing other avenues of income on their farm. In addition, McMullen said some Organic Valley farms diversify by offering an Airbnb rental.

At Bossie Cow Farm, Heidel-Baker and her husband, Ricky, milk 65 cows. She is the third generation on the dairy that her grandpa purchased in the 1950s. An entomologist by training, HeidelBaker came back to the farm in 2015.

Her parents were conventional farmers, but in the last 30 years, they switched to a grazing operation. The 80-acre farm has been all pasture since 2000 and certied organic since 2003. The Bakers practice adaptive managed grazing and move cows several times a day to provide new feed. Their animals are 100% grassfed.

“Our pastures are planted to a very specic, diverse mix of grasses,” HeidelBaker said. “We also feed our cows freechoice mineral. In the winter, we feed hay, and we also do a lot of baleage. We’re really self-sustaining.”

The Bakers, who ship their milk to Organic Valley, milked once a day for a period of time to give themselves a break but went back to milking twice a day this year when the farm became fully seasonal.

“Shipping to Organic Valley allows us to get a premium price for our milk,” Heidel-Baker said. “Because we’re grassfed, we push for quality of milk versus quantity.”

McMullen, who has worked in public relations at Organic Valley for four years, said the co-op has nearly 1,800 patron farms across the U.S. Making a future for the small family farm is its mission.

“Organic Valley was founded in the 1980s to save the small family farm,” McMullen said. “That’s why we’re here, and I will continue to ght for the small family farm.”

Heidel-Baker has an off-farm job, and to further support the farm when a milk check is not coming in, she direct markets grassfed beef as well as eggs. She also helped start local farmers markets to create communities that support

the direct market food business and local farms.

“Diversity is key to our farm not growing but still being successful,” Heidel-Baker said. “We are a grazing farm – that’s our primary feed source. It’s a different model and one we found works really well for us as a small farm.”

Grosenick and her husband, Jim, are the fourth generation on their farm where they milk 200 cows. The Grosenicks ship their milk to Dairy Farmers of America where most of it stays in the uid market.

“I have two degrees from (the University of Wisconsin)-Madison and was planning to do big things with international business and ended up going back home and marrying the boy next door,” Grosenick said. “We have three children, and they are probably the reason we’re still farming and milking cows.”

Grosenicks’ cows are housed in a sand-bedded freestall barn. The family grows most of its feed and purchases the remaining. Included in their total mixed ration is grocery store refusal, such as breads, fruits and vegetables.

“We’ve tried some really creative ways to stretch our budget and keep things out of landlls,” Grosenick said.

After falling ill from an autoimmune disease, Grosenick began experimenting with healthier food options that gave way to a value-added on-farm business – Crimson Kitchen and Gardens.

Grosenick makes jams, jellies, salsa and pickles as well as raw milk soap and lotion to sell at farmers markets. She also sells produce from her half-acre garden. Last year, Grosenick partnered with a local hemp grower to make raw milk CBD soap and raw milk CBD lotion.

Roden started milking 24 cows on a 40-acre farm in 1981. He gradually grew over the years and purchased his current operation in 1995 where he farms with his wife, Cindy, and their son, Rick. The

Rodens milk 850 cows and ship their milk to DFA. In March, they began milking in a new 40-stall rotary parlor. The Rodens were planning for the future when they built the facility which has capacity to milk up to 1,600 cows three times a day.

“This is the direction my son and I wanted to go,” Roden said. “We have some robotics in there and are hoping to develop more with the possibility of needing one less person for milking in the future.”

The facility includes a viewing room, which has been benecial for Roden’s daughter, Jacki, who branched off nine years ago with Roden Barnyard Adventures – an opportunity for the public to experience the farm through camps, tours and birthday parties. Jacki has also started offering sleigh rides in the winter.

Roden said that in 1978, 300 dairy permits were issued in Ozaukee County, but today, there are about 28 farms; however, cow numbers have not changed.

“I believe there are places for all sizes of dairy farms, but it’s sad to say I think the trend is toward larger farms,” Roden said. “I call myself a medium-size farm. I have 17 grandchildren and one on the way, and I’m hoping to continue this in the future.”

Dahm milks 50 cows in a 74-stall tiestall barn and ships his milk to Cedar Valley where it is made into mozzarella and provolone.

“We used to milk 120 cows, but as my kids grew up and went away, we downsized,” Dahm said. “My son, Lucas, is still on the farm and helps out, but possibly in two to four years, I might not milk cows anymore because I’m getting wore out.”