DAIRY ST R

Volume 24, No. 21

Volume 24, No. 21

By Abby Wiedmeyer abby.w@dairystar.com

By Abby Wiedmeyer abby.w@dairystar.com

MONTICELLO, Wis. – When Johnna Blum learned she had won a heifer in Dairy Star’s Great Christmas Giveaway, she had only one question.

How soon could she retrieve the calf?

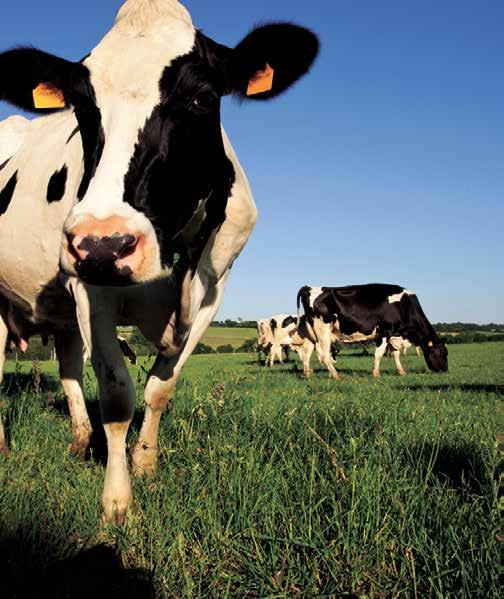

Johnna and her parents, John and Angie Blum, farm on their 60-cow dairy near Monticello. Their farm is home to mostly Holsteins, but two Brown Swiss cows stand out in the herd. They happen to be Johnna’s favorites.

“I just think they’re cute,” Johnna said.

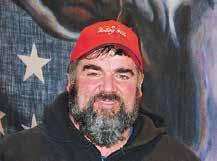

WHITEHALL, Wis. –The workload at the Pederson farm has been somewhat lightened since the fourth generation has joined the team.

Brothers Mark and Thane Pederson have been farming together since 1987 when Thane returned to the farm. Now, Mark’s youngest son, Austin, has joined his family as a full-time employee on the farm near Whitehall. The manpower he offers allows for progress to be made

The heifer calf, V B First Choice Zorah-TW, came from Voegeli Farms near Monticello. Bryan Voegeli and his son, Chris, and his brother, Jim, milk 135 registered Brown Swiss cows.

A former World Dairy Expo grand champion, several All-Americans and a Total Performance Award winner for the Brown Swiss breed are some of the cows that can be found within the pedigree of Zorah, who was born Sept. 6 and is sired by Brown Heaven C First Choice-ET. Zorah’s dam is V B Tequila Zah VG-87.

Winning the calf was a surprise because the New Glarus High School freshman had no idea her name was entered. John saw the ad in Dairy Star, and after reviewing the list of participating businesses, realized he did business at a few of those places.

“I had errands to run anyway, so I thought I’d put her name down,” John said. “We were surprised to

win.”

Johnna is most excited about taking her new calf to the fair this summer. As

December 24, 2022

on the continuous updates to facilities.

“I’ve worked a few other

jobs,” Austin said. “But I’d rather be here.”

Austin, 22, spent time af-

ter high school working jobs off the farm. When his grandfather, Kermit, began to slow

down, he decided to help his dad and uncle at home. The family milks 200 cows in a retrotted parlor. Cows are housed in a sand-bedded freestall barn.

The family updated its parlor and built a new milkhouse two years ago. They now milk in a swing-12 parlor, and Mark said there are opportunities to upgrade even further.

“We are set up to add activity collars if we want to,” Mark said. “We’ve got the sort gate and everything. We haven’t gured out exactly how we’re going to put it in.”

The upgraded parlor also offers potential for storing milk weights. For now, the guys rely on the digital read out in the parlor. They agreed it offers a point of reference while milking.

“Now you know when

ABBY WIEDMEYER/DAIRY STARwww.dairystar.com

ISSN Print: 2834-619X • Online: 2834-6203

522 Sinclair Lewis Ave. Sauk Centre, MN 56378

Phone: 320-352-6303 Fax: 320-352-5647

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com 320-352-6303 (ofce) 320-248-3196 (cell) 320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

The U.S. Department of Agriculture’s World Agricultural Supply and Demand Estimates report increased its 2023 milk production forecast slightly. Production is estimated at 229.5 billion pounds, up 300 million pounds from the previous forecast. Higher-than-expected cow numbers and more output per cow were factors. The 2023 price forecast for cheese and butter increased due to better-than-expected demand and recent price strength.

Karen Knoblach

• karen.k@star-pub.com Annika Gunderson • annika@star-pub.com

Editorial Staff

Tiffany Klaphake - Assistant Editor 320-352-6303

• tiffany.k@dairystar.com

Maria Bichler - Assistant Editor maria.b@dairystar.com • 320-352-6303

Danielle Nauman - Staff Writer 608-487-1101

• danielle.n@dairystar.com

Stacey Smart - Staff Writer 262-442-6666 • stacey.s@dairystar.com

Abby Wiedmeyer - Staff Writer 608-487-4812

• abby.w@dairystar.com

Grace Jeurissen - Staff Writer 320-352-6303

• grace.j@star-pub.com

Jan Lefebvre - Staff Writer 320-290-5980 • jan.l@star-pub.com

Consultant

Jerry Jennissen 320-346-2292

Main Ofce: 320-352-6303 Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication Sales Manager - Joyce Frericks 320-352-6303 • joyce@dairystar.com

Mark Klaphake (Western MN) 320-352-6303 (ofce) 320-248-3196 (cell)

Laura Seljan (National Advertising, SE MN) 507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com

Jerry Nelson (SW MN, NW Iowa, South Dakota) 605-690-6260 • jerry.n@dairystar.com

Mike Schafer (Central, South Central MN) 320-894-7825 • mike.s@dairystar.com

Amanda Hoeer (Eastern Iowa, Southwest Wisconsin) 320-250-2884 • amanda.h@dairystar.com

Megan Stuessel (Western Wisconsin) 608-387-1202 • megan.s@dairystar.com

Kati Kindschuh (Northeast WI and Upper MI) 920-979-5284

• kati.k@dairystar.com

Julia Mullenbach (Southeast MN and Northeast IA) 507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell) bob.l@star-pub.com

The deadline for news and advertising in the Dairy Star is 5 p.m. Friday the week before publication.

One year subscription $40.00, outside the U.S. $200.00. Send check along with mailing address to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378.

Our ad takers have no authority to bind this newspaper and only publication of an advertisement shall constitute nal acceptance of the advertiser's order.

Letters

Letters and articles of opinion are welcomed. Letters must be signed and include address and phone number. We reserve the right to edit lengthy letters. The views and opinions expressed by Dairy Star columnists and writers are not necessarily those of the Dairy Star / Star Publications LLC.

The Dairy Star is published semi-monthly by Star Publications LLC, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378-1246. Periodicals Postage Paid at Sauk Centre, MN and additional mailing ofces.

POSTMASTER: Send address changes to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378-1246.

High production costs, rising interest rates and weak demand will likely pressure farm margins in the year ahead. In its 2023 Year Ahead Report, CoBank said dairy farmers were able to pay down debt with record high milk prices earlier in 2022. Herd expansion was minimal this past year and that is expected to continue in 2023. Domestic dairy demand will be hurt as consumers try to reduce spending at the supermarket.

The International Dairy Foods Association wanted the Farm Workforce Modernization Act passed during the lame duck session. “Workforce is by far the No. 1 issue facing our IDFA members,” said Michael Dykes, CEO of IDFA. “Most of our members are short 10% to 20% of the workforce and are heavily reliant on temporary workers.”

ing on the Senate to pass the Farm Workforce Modernization Act during the lame duck session. Ford said the country is at a tipping point, and U.S. food security is threatened by inaction on the immigration issue.

H-2A visa changes sought

InsiderColorado Sen. Michael Bennett has introduced legislation to develop an agricultural visa system. The bill would revamp the H-2A visa program and give farm workers a path to permanent residency. At this point, there are no Republican cosponsors for the bill, limiting its chance for success.

By Don Wick Columnist

By Don Wick Columnist

According to USDA’s latest Dairy Markets Report, cheesemakers and butter makers are facing busy production schedules. Midwest cheese curd demand is described as soft. Food service sales are holding steady. Retail butter demand remains steady.

Education will be necessary for new ag committee

Agri-Pulse communications editor Sara Wyant said there will be a lot of new people writing the next farm

bill, and many of these lawmakers have no agricultural background. “A lot of them have not been involved in writing a farm bill in the past and may have joined the House Agriculture Committee not to work on farm policy but to work on food policy,” Wyant said.

DMC enrollment period extended USDA has extended the deadline for farmers to enroll in the Dairy Margin Coverage and Supplemental Dairy Margin Coverage programs for 2023. The National Milk Producers Federation praised the news and encouraged dairy farmers to consider USDA’s complete array of risk management options. The new enrollment deadline is Jan. 31, 2023.

A new national poll determined 60% of adults in rural areas are more aware of the opioid crisis than they were ve years ago. Of those surveyed, 42% said they know someone who is or has been addicted to opioids or prescription painkillers. The American Farm Bureau Federation and National Farmers Union continue to work together on this issue. Both groups support more ed-ucation about mental health and opioid use in rural America.

The 2024 Wisconsin Farm Technology Days will be held at the Country Fest grounds near Cadott, Wisconsin. The show will be cohosted by Close Farms. Meanwhile, the 2023 Wisconsin Farm Technology Days will be in Sauk County near Baraboo, Wisconsin.

State Rep. Travis Tranel of Cuba City, Wisconsin, will chair the Assembly Committee on Agriculture in the upcoming legislative session. Tranel has been in ofce for six terms.

Darin Von Ruden of Westby, Wisconsin, has been reelected as president of the Wisconsin Farmers Union. Tim Hinchley of Cambridge, Wisconsin, is the vice president. Linda Ceylor

of Catawba, Wisconsin, is secretary, and Ed Gorell of Eleva, Wisconsin, is the treasurer. Paul Adams of Eleva, Wisconsin, and Dylan Bruce of Ferryville, Wisconsin, will serve as delegates to the National FFA Convention in March.

Kevin Krentz of Berlin, Wisconsin, will serve another term as president of the Wisconsin Farm Bureau. Joe Bragger of Independence, Wisconsin, is the new vice president.

The Wisconsin Farm Bureau has named Bradley Uken as its chief administrative ofcer. Uken has spent his career with Illinois Farm Bureau, most recently managing the Champaign County Farm Bureau.

The Dairy Business Association and Edge Dairy Farmer Cooperative has hired Karen Gefvert as its director of public affairs. Gefvert spent the past 11 years with the Wisconsin Farm Bureau.

Cheese alternative comes to a supermarket near you

The Bel Group is marketing its rst selection of cheese alternative products. The Nurishh Incredible Dairy brand will sell animal-free cream cheese spread alternatives in plain, strawberry and chive and onion avors. The Bel Group is partnering with a California-based precision fermentation company called Perfect Day for this new food option

A total of 135 million pounds of eggnog is consumed by Americans each Christmas. That answers our last trivia question. For this week’s trivia, a person described as a turophile is known for what? We will have the answer in the next edition of Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network, based in Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two adult sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

they’re milking what they’re giving,” Mark said. “It’s just nice to be able to see it.”

The new milkers also feature automatic takeoffs, which Mark said speeds up the chore process.

“It seems like it makes a difference,” Mark said. “One guy can manage better with the takeoffs.”

Most of the time, there are two people in the parlor; however, the brothers said there have been plenty of times during the busy harvest season that Austin managed by himself.

Around the same time they upgraded their parlor, they tore off a lean-to and used the space to create a bigger milkhouse with a bigger bulk tank. This has allowed the farm to go to having milk picked up every other day. It also gives them room to grow as Austin becomes more involved.

“We talk about expanding up to 300 cows,” Mark said. “That way there would be about 100 cows per family between Thane, Austin and I.”

Ideas to expand are not currently on the forefront, as it would involve moving heifers off-site to make room for more milk cows.

In addition to the three of them, Mark, Austin and Thane rely on the help of Mark’s daughter Mercedes and other part-time help.

Since joining the team full time, Austin has taken over managing the calves. Calves are housed individu-

ally in hutches during the winter months. In warmer temperatures, calves are housed in super huts. Austin said weather is one of the biggest challenges in raising calves. With uctuating Wisconsin temperatures, it is a daily battle to keep them comfortable and healthy.

“One of our goals is to get waterers set up,” Austin said. “Then we can rely more on the super hutches.”

Mark is the main feeder for the cows, while Thane takes care of paperwork for the cows and most of the breeding. While the herd consists of mostly Holstein cows, there is a scattering of Fleckvieh, Jersey, Ayrshire and Brown Swiss.

“We really kind of like the Fleckvieh breed,” Thane said. “They’re bigboned and overall hearty cows. We’ve had some that milk really good.”

The family has found ways to work together to continue the family farm.

“When you’ve got three people with three different ideas, it can be hard to come to one decision,” Mark said. “But Thane has good ideas, and we usually nd a way to agree.”

One thing they agreed on is doing most of the updates themselves.

“It saves a lot on cost, but a lot of things get put on hold,” Mark said. “We just keep plugging along and roll with it.”

shown pigs and entered crops in the past. This year, she had planned to show a beef steer as well. The Brown Swiss heifer will join the string.

At home, Johnna helps her parents with chores. The cows are housed in a sand-bedded freestall barn that was built in 2015.

“I mostly help with milking,” Johnna said.

Milking is done in the original 40-stall stanchion barn.

Johnna also holds interests in equine and enjoys attending rodeos. She hopes to expand on this hobby in the future.

The Blums only had a 10-minute drive to pick the calf up.

“We were all surprised it was a local winner,” John said.

John had Brown Swiss cows as a young man and said they require patience.

“They can be stubborn,” John said. “They’re a different breed. But I’ve always liked them.”

The calf seemed as smitten with Johnna as she was with the calf.

With the new calf already following Johnna closely, it seems the only trouble she will have is in deciding what to call the calf.

“I’m not sure what to name it,” Johnna said. “I’ll have to think of something.”

Dawn Haag was almost certain she did not win the $1,000 cash prize as part of Dairy Star’s Great Christmas Giveaway.

Haag $1,000 Winner“I registered at the last minute,” Haag said. “And when I didn’t get a phone call on Tuesday, I thought for sure I did not win.”

Haag registered at Argall Dairy Systems in Belleville. She and her husband milk 170 cows in a modied atbarn parlor and are in the process of building a barn that will eventually house four robotic milking units.

“I had to go to town for parts, and my husband told me not to forget to register,” Haag said. “I gured why not throw my name in?”

Haag said with building a barn, she is sure it will not be hard to nd a use for the money.

“Maybe I can get a nice desk for the new ofce when it’s built,” Haag said. “That way I don’t have to use boxes and boards.”

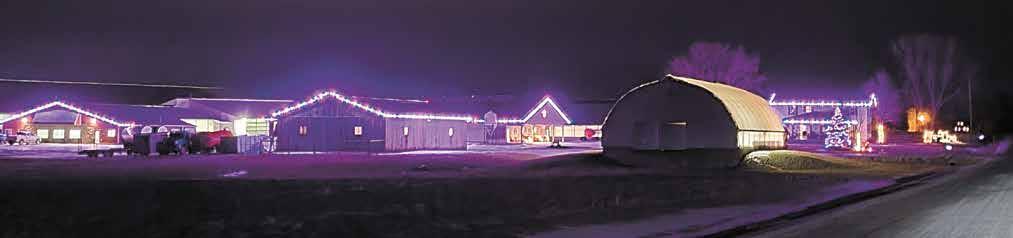

THORP, Wis. – When the sunlight of winter days fades away, Sander and Amy Penterman turn their attention toward bringing light to the world around them.

The Pentermans spread Christmas cheer throughout their neighborhood by decorating their dairy farm in Christmas lights.

“The lights bring joy to people, ourselves included,” Amy Penterman said. “It is so much nicer to drive up the road and see the farm all lit up and bright.”

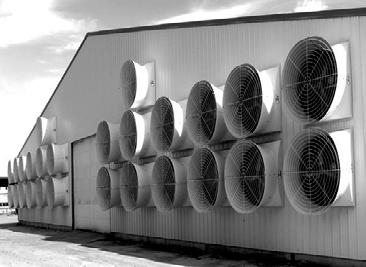

The Pentermans milk 850 cows in a double-12 parallel parlor at Dutch Dairy in Clark County near Thorp. For the past eight years, they have been celebrating the holidays by decking their farm in festive lights; each year, they add a little more to the display.

This year, the Pentermans purchased new lights to bring a whole new level to their display.

“We have always had lights on the barns, but we struggled with the little clips, putting them on and then keeping them up in bad weather,” Penterman said. “And when we would buy lights from the stores, we would always be disappointed that they weren’t very bright.”

The Pentermans learned of lights that could be attached to the structures using magnets. They purchased a small section of magnetic

lights to test last year. Pleased with how they performed, they ordered 1,000 feet to put around the farm this year.

“These magnetic lights have been a total game changer,” Penterman said. “They go up so much easier, and they are surprisingly strong, staying up through some pretty nasty weather. The only downside was the bulbs came separate from the strings, so we had to screw in all the light bulbs in the color pattern we wanted.”

The Pentermans attach the lights around the barns under the overhangs. Their home has metal roofing, and Penterman said that although the lights are more exposed, they have had no issues with them being affected by weather.

The Pentermans have an array of red, orange, yellow, green, blue and purple lights. It took them about four hours to screw in all the bulbs and four full days of putting lights up around the farm.

“Thorp FFA holds a worker auction as a fundraiser each year, and we purchased the time of two students,” Penterman said. “One came out and spent a day helping put the bulbs in the strings and preparing everything, and the other one spent a day helping Sander hang the lights around the barns.”

The goal at Dutch Dairy is to have all the lights up by Thanksgiving, but the decorating typically takes a backseat to harvest, fall tillage and the day-to-day happenings on the farm.

“It’s usually the rst weekend in December before we get them all up and turned on,” Penterman said. “We keep them on through the rst week in January.”

The new lights are much brighter, and problems with one bulb do not affect an entire section, Penterman said.

“You can see the lights from about 2.5 miles away,” Penterman said. “From a distance, they look purple, and I tease Sander that is intentional because I am a Viking fan; he is a Packer fan. But once you get closer, you can see all the colors.”

As their children have grown, they have become more involved in helping with the farm decorating, and the Pentermans are enjoying the time they spend together as a family partaking in their annual tradition.

In the future, Penterman said she would like to do more things to

decorate their yard.

“It’s something we always think of wanting to do, but there never seems to be a lot of time to work on it throughout the year,” Penterman said. “Then December rolls around, and we realize we didn’t get it done. One year we tried writing ‘Merry Christmas’ with rope lights on hog panel, but it just looked like a glob of lights when we lit it up. That is one of the things I would like to get done for another year.”

The Pentermans enjoy hearing from their neighbors and others in their community about the enjoyment they derive from driving by the farm on a dark December evening.

“This is a way we can continually keep agriculture and dairy farming in the forefront of our community,” Penterman said. “It really puts agriculture in a positive light.”

willfully ignore the significant studies. 60 years ago, Dr. Derek Forbes published research proving that liner action forces the staph up the teat canal. 22 years ago, Cornell published research proving CoPulsationtm prevents new Staph infections with CoPulsationtm fixing the problem Forbes identified. 18 years ago, at the NMC annual meeting Univ. of Madison and others reported milk is “pumped” back up into the udder by the closing liner, and the list goes on and on with you losing cows and money.

Will 2023 be the year they admit your pulsation is causing staph infections?PHOTO SUBMITTED The Penterman family decks out their Clark County dairy farm in more than 2,500 lights as part of their annual tradi on. The lights are visible from 2.5 miles away.

GREELEY, Iowa – Jason Sperfslage’s schedule is full. Not only is he a full-time dairy farmer, Sperfslage is also a part-time milk truck driver.

“Truck driving funded all of it,” said Sperfslage of purchasing his grandfather’s farm. “The only thing I had to take out was a loan for the land.”

Sperfslage milks 40 cows in a stanchion barn and farms 80 acres on his farm near Greeley. He drives a milk route every other day.

The money to purchase a farm was not the only benet to hauling milk.

“It helped me get my start by letting me see different options and helped me decide how I want to do it,” Sperfslage said. “Seeing the different ways of doing it gives me new ideas of things to try. I like to experiment and try new things.”

Sperfslage bought his grandfather’s farm in 2015 after his grandpa died.

“There hadn’t been any cows on the farm since 1986, and so there were a lot of upgrades that needed to be done to the barn,” Sperfslage said.

The biggest challenge for Sperfslage was getting a loan from the bank to buy the land.

“I had it all gured out how I was going to make it work, but the bank was very hesitant to give me a loan,” Sperfslage said. “I paid for everything up front as I went except the land.”

At the time, Sperfslage was working for a local well and plumbing company as well as working for a neighboring dairy farmer.

“I knew my neighbors’ milk hauler pretty well, and I got to talking to him one day,” Sperf-

slage said. “He said they are always looking for good drivers and that I should ride along one day to see what it was like.”

Sperfslage obtained his commercial driver’s license and started hauling milk in June 2017 on weekends while doing the well and plumbing work during the week.

“It didn’t take long for me to notice I was making more money hauling milk on the weekends,” Sperfslage said. “It became a no brainer to start hauling milk full time.”

Sperfslage hauled milk and farmed until 2020 when he had saved up enough money to x up his grandpa’s old barn and purchase seven cows.

The barn did not have a pipeline or a bulk tank and needed new wiring, leaving a lot of work for Sperfslage to do.

“Buying the pipeline and bulk tank was cheap compared to getting them installed,” Sperfslage said.

Sperfslage milked his own cows for the rst time July 13, 2020.

Sperfslage knew he wanted to milk cows from a young age. Sperfslage’s parents sold their 60 dairy cows in 2015 and bought beef cattle and continued to farm the land.

“My best memories growing up always revolve around the farm and the cows,” Sperfslage said. “That always stuck with me, that and I never could sit still for very long.”

Sperfslage said young farmers looking to start a farm of their own should not take on unnecessary debt.

“I had a lot of people tell me it’s not worth it to be small and to start dairy farming, but it is doable as long as you don’t bury yourself in debt,” he said.

Sperfslage raises his own feed which consists of baleage and ground corn with salt and minerals mixed in. In the summer, the cows are on pasture.

“I get really good components, and it pays

better to get higher components,” Sperfslage said.

Someday, Sperfslage plans on getting a mixer but is content with his current setup.

Sperfslage’s parents live about 10 miles away and help during the busy times of the year. His brother also helps when needed.

Looking ahead, Sperfslage would like to buy another 80 acres and increase his herd to 50-60 cows.

Sperfslage said part-time haul-

ing allows him to farm.

“Driving milk truck seven days a week was never my thing,” he said. “But it is nice to see other farms and talk to other farmers.”

Sperfslage plans to continue his working arrangement of farming while also hauling.

“I don’t feel like I’m missing out when I hear my friends going out on nights and weekends,” Sperfslage said. “Milking cows isn’t work to me. It’s what I want to do.

CHIPPEWA FALLS, Wis. –

Growing up as a part of his family’s restaurant business, the original Josef’s, Nicholas Wiener knew becoming a chef was his calling. What he did not predict is that cheesecake would become his life.

“I have worked as a chef for over 30 years all around the world in highend Michelin-rated resorts,” Wiener said. “I had never previously worked as a pastry chef, but it has become something I have fallen in love with.”

Wiener and his wife, Kristen, operate Josef’s Cheesecake in memory of his father and mother, Joseph and Mary Ann. Wiener launched the business in December 2019 in Chippewa Falls.

Today, more than 1,000 cheesecakes are sold at Josef’s Cheesecake on a daily basis. In addition to the cheesecakes, which are sold as full cheesecakes and as cupcakes, the shop also sells macarons made by Kristen, hot chocolate bombs, breads and a variety of pastries.

Wiener said vast amounts of dairy products are needed to churn out the many delicacies the store sells.

“We use a lot of cream cheese, heavy cream and butter,” Wiener said.

On an average basis, Wiener

said he goes through well over 1,000 pounds of cream cheese and over 500 gallons of heavy cream each week.

Wiener began the business when he struggled to nd the kind of work he was accustomed to.

“When my father became ill, I came back to this area to spend time with him and give him time with his grandkids,” Wiener said.

Wiener worked at a few local establishments, including a stint where he created a cheesecake recipe that was so well received he could barely keep up with demand. That was when Wiener made the decision to follow his newfound passion.

Wiener began selling cheesecakes from a food truck prior to opening the storefront.

“I gured out how many cheesecakes I would need to sell to make a living running a cheesecake shop,” Wiener said. “That magic number was 57 cheesecakes a day to get by. To say the least, I have been blown away by the response.”

Wiener has a repertoire that consists of more than 450 avors of cheesecake, all of which he has created his own unique recipes for. From traditional avors to specialty varieties, Wiener has made it all. On any given day, there are usually 12 to 30 avors available at Josef’s Cheesecake, envisioned and crafted by Weiner with the perfect avor.

“It is really a God-given talent,” Wiener said. “I get my inspiration from everywhere. Sometimes, I’ll just walk through the grocery store and dream up ideas.”

An example of Wiener’s more unique cheesecake avors include Dr. Pepper, Mountain Dew, chai tea, taco, dill pickle, chicken and wafes, and brandy old fashioned. Heading into the holiday season, specialty avors include hot chocolate, eggnog and sugar cookie.

“I just try and do different things; it is really just a creative process,” Wiener said. “I love cheesecake, and I try every single one of my batters.”

During the summer months, Wiener makes a cheesecake avored ice cream.

People are not the only creatures to enjoy the fruits of Wiener’s creativity. He has developed a recipe to make cheesecakes for dogs.

“I use honey instead of sugar in those, and the crust is made of crushed Milk Bones instead of graham crackers,” Wiener said. “Pumpkin is good for dogs, so that is the avor. We actually sell a ton of dog cheesecakes.”

Besides daily sales from the store, Wiener completes many special orders for events like company parties, weddings, graduations and an array of gatherings. Wiener utilizes the original food truck to stage catering desserts for events.

Wiener said the colder months, from Thanksgiving through the Easter holiday, are his busiest while the late spring and summer wedding season comes as a close second.

Wiener keeps his business local rather than branching out into offering shipping.

“I have been asked to ship cheesecakes frequently, but it is really cost prohibitive,” Wiener said. “The cheesecakes freeze well, but that is not the product I want to provide. I

pride myself on my cheesecakes being fresh every single day.”

Despite being anchored to the physical store, Wiener has customers who travel to purchase from Josef’s Cheesecake.

“I have customers that drive quite a distance and buy a few dozen cheesecakes to take home and freeze themselves,” Wiener said.

After witnessing the success Wiener had in opening Josef’s Cheesecake, his brother, Greg, approached Wiener about opening a Josef’s Cheesecake in Easton, Maryland.

“They are really two different businesses, but we do collaborate some on recipes and ideas,” Wiener said.

While Wiener never would have expected to become a master of the cheesecake four years ago, he said he has truly found his calling.

“I spent 30 years doing something I loved, working as an executive chef,” Wiener said. “But I never would have expected just how much I would truly love and enjoy making cheesecakes for a living.”

Levi Riebe

5 years old

Parents: Mark and Tanya Riebe Cumberland, Wisconsin Barron County 100 cows

How do you help on the farm? I love to help my dad with whatever I can with the cows, tractors or in the shop xing stuff. I help combine a lot too.

Tell us about your favorite animal. Mimi is my favorite heifer. I showed her this summer. I love her. She has a heart on her head. I call her Mimi Heart.

What is your favorite Christmas treat? Christmas cookies.

What do you want for Christmas? Spiderman toys and a small pitch fork.

What is your favorite activity to do during Christmas break? I like to feed the cows with Grandpa Roger, shovel snow and make a snow fort with my sister, Tani.

Do you think you are on the naughty or nice list? Nice list because I have been doing my chores and getting work done with my mommy and daddy.

If you could ride with Santa on his sleigh, where would you want to go and what song would you sing on the way there? I would want to go to the North Pole, and I would be singing, “You’re a Mean One, Mr. Grinch.”

What do you want to be when you grow up? I want to be a farmer with my daddy.

9 years old

Parents: David and Katy Lammers Fond du Lac, Wisconsin Fond du Lac County 42 cows

you help on the farm? I help with milking the cows, feeding the calves and petting the kit-ties.

Tell us about your favorite animal. My favorite animal is a cow named Melanie. She’s mostly white, and she has a good memory. She’s a young cow. She just had her rst calf in August.

What is your favorite Christmas treat? Turtle cookies.

What do you want for Christmas? Fuzzy slippers.

What is your favorite activity to do during Christmas break? Go sledding with my snow tube.

Do you think you are on the naughty or nice list? I’m on the nice list for sure because I’m always helpful and don’t start ghts with my sisters.

If you could ride with Santa on his sleigh, where would you want to go and what song would you sing on the way there? I would want to go to Hawaii because it’s warm and I could go swimming. We would sing “Joy to the World.”

What do you want to be when you grow up? A teacher or a doctor.

Ezra Vanden Wymelenberg 4 years old Parents: Adam and Marie Vanden Wymelenberg Shirley, Wisconsin Brown County 155 cows

How do you help on the farm? I help Daddy spread manure in the tractor.

Tell us about your favorite animal. The chickens.

What is your favorite Christmas treat? Cookies.

What do you want for Christmas? A sprayer and bucket tractor.

What is your favorite activity to do during Christmas break? Open presents.

Do you think you are on the naughty or nice list? Nice list because I pick up my toys and listen.

If you could ride with Santa on his sleigh, where would you want to go and what song would you sing on the way there? Chuck E. Cheese and “Tractorstuck.”

What do you want to be when you grow up? A farmer.

5 years old

Parents: Troy and Aimee Schomburg Bangor, Wisconsin La Crosse County 120 cows

How do you help on the farm? I put lime in the parlor, help Mom bed calves, ll waters, feed starter grain, check on calves and push snow every day.

Tell us about your favorite animal. Linebacker the cat. He is called Linebacker because he has lines on his back. He is my favorite because he snuggles me, and I made him

Brayden Karow

5 years old

Parents: Mark and Terri Karow

Augusta, Wisconsin

Eau Claire County 70 cows

How do you help on the farm? I help with pushing feed up for the cows, scraping the barn, checking on baby calves and holding bottles. I also like to ride with my dad in the tractor or combine.

Tell us about your favorite animal. My favorite animals are two Jersey cows named Itty Bitty and Sunshine. They let me brush them with the curry comb, and they like getting hugs from me. My other favorite animal is my brother's show calf, Kokobomb, that I got to show at the Eau Claire County Fair for the president's class.

my buddy.

What is your favorite Christmas treat? Cookies.

What do you want for Christmas? A bale trailer.

What is your favorite activity to do during Christmas break? Play with the snow.

Do you think you are on the naughty or nice list? The nice list because I have been nice.

If you could ride with Santa on his sleigh, where would you want to go and what song would you sing on the way there? I would go to the North Pole, and I would make up my own song.

What do you want to be when you grow up? I want to be like my dad. I want to be a farmer.

What is your favorite Christmas treat? Anything with frosting, especially my grandma's sugar cookies.

What do you want for Christmas? A football so I can be like Aaron Rodgers.

What is your favorite activity to do during Christmas break? Play outside in the snow making snowmen and forts.

Do you think you are on the naughty or nice list? The nice list because I help with chores and scrape the walk.

If you could ride with Santa on his sleigh, where would you want to go and what song would you sing on the way there? If I could ride with Santa, I would go where Peppa Pig lives and sing the song “Red and Green” that I am singing at my school Christmas program.

What do you want to be when you grow up? A tractor driver.

Describe your farm and facilities. We have a 3-row, sand-bedded and drive-thru freestall barn. We use a double-9 herringbone parlor for milking.

What forages do you harvest? We harvest alfalfa, corn silage and rye grass. We cut all the ditches and waterways and make grass hay out of that as well.

How many acres of crops do you raise? It’s around 470 acres tillable.

Describe the rations for your livestock. The milk cows right now are at an 80% corn silage and 20% haylage for forage along with the base concentrates. The dry cows are getting straw, corn silage and a little haylage. The pre-fresh

group gets a lot of straw and corn silage. Heifers clean house; they’ll get whatever refusal the dairy cows have from the day before plus a lot of straw, corn silage and haylage.

What quality and quantity do you harvest of each crop? I chop an earlier variety of corn silage, and we are at about 22 ton an acre. For my haylage, I’ve just done a three-crop program the last couple of years. It’s a low-lignin alfalfa variety. I’m feeding dry corn that gets powdered. It’s around 15 pounds of dry corn per cow.

Describe your harvesting techniques for alfalfa and corn silage. John Speltz, a dairy farmer by Altura, Minnesota, has a harvest crew, chopper, trucks and packing tractor. We coordinate with him for chopping the haylage and harvesting the corn silage. We also have a hay cutter and cut some of the

hay ourselves.

What techniques do you

use to store, manage and feed your forages? All the silages are on drive-over

piles/bunkers. We’ll do some baleage for hay and sometimes rye.

Describe a challenge you overcame in reaching your forage quality goals. The last few years, I’ve gotten more comfortable feeding rye to the milk cows. We planted rye after the corn silage, and we’ve been harvesting that and then planting soybeans on that ground the next season. It looks like you’re putting in straw sometimes, but somehow, the cows milk great on it. I’m learning to go after the rye early enough to make good quality feed. The rye can go from milk cow feed to dry cow feed really fast, within a period of four or ve days, so the harvest window for rye for milk cows was a challenge. Turn to

of the product.

2018, PRWD, Duals, 1567 hrs., 1000 Sep. hrs., #552352............ $354,500 JD S780 2020, PRWD, Duals, 1487 hrs., 1145 Sep. hrs., #191082............ $358,600 JD S780 2020, PRWD, Duals, 1545 hrs., 1204 Sep. hrs., #531610............ $358,600 JD S780 2018, PRWD, Duals, 1202 hrs., 830 Sep. hrs., #523885.............. $359,600 JD S790 2018, PRWD, Singles, 1451 hrs., 1055 Sep. hrs., #549846 ......... $359,900

JD S780 2019, PRWD, Duals, 1015 hrs., 775 Sep. hrs., #549892.............. $379,000

JD S780 2020, PRWD, Duals, 1440 hrs., 941 Sep. hrs., #550187.............. $393,600

JD S790 2019, PRWD, Duals, 1219 hrs., 944 Sep. hrs., #550196.............. $396,500

JD S780 2020, PRWD, Floaters, 1018 hrs., 803 Sep. hrs., #553375 .......... $434,000

Case IH 8250 2021, 2WD, Tracks, 570 hrs., 400 Sep. hrs., #550253 ......$460,900

JD S790 2021, PRWD, Duals, 964 hrs., 724 Sep. hrs., #552457................ $479,900

JD S790 2020, PRWD, Floaters, 637 hrs., 484 Sep. hrs., #552993 ............ $489,900

JD S790 2021, PRWD, Duals, 664 hrs., 464 Sep. hrs., #276139................ $539,900

Christmas is the time of year when traditions are revisited. Most people have at least one special thing they celebrate at Christmas. Because I did not grow up on a farm, my Christmas traditions did not include waiting for chores to nish before opening presents or giving my favorite cow extra grain, as I have heard from others.

Growing up, my family always had family friends visit our house for Christmas Eve. We would stay up late playing games. I have three siblings, and our friends had four kids who came too, so it was a big crowd. Our favorite games were Spoons and Catch Phrase.

By Abby Wiedmeyer Staff WriterOn Christmas morning, we went to church and opened presents sometimes in that order, which was painful for a kid. I remember thinking as a young child that the church service might have had more of an impact if I had not spent the whole time wondering what was in all the boxes at home.

Every year, my dad’s side of the family gets together to celebrate. We alternate between my parents’ house and my aunt’s house. For a long time, it was not your usual serene Christmas dinner by the replace. My family tends to treat holidays as an excuse to party. Cousins and friends usually spread out across the house and into the garage. Libations ow and memories are made. With a large family, it was one of the few times we were all in the same place.

Now that I am grown with four kids of my own, it’s hard to make traditions. We do not live close to any of our families, so Christmas usually turns into a travel day for us. We generally have to leave my husband behind to run the farm while the kids and I make the two-hour drive to our hometown for an overnight visit.

My children now know the anticipation of waiting until chores are done to open presents. Our farm story has been so eventful with moving a handful of times and always trying to either build the herd up or milk three times a day, trying to increase productivity to make ends meet. It seems that every year has been different.

www.delaval.com

IOWA

Kramer Bros. Monticello, IA 319-465-5931

Prairie Land Ag Supply Inc. Rock Valley, IA 712-476-9290

United Dairy Systems, Inc. West Union, IA 563-422-5355

WISCONSIN

Advanced Dairy Spring Valley, WI 715-772-3201

Ederer Dairy Supply Plain, WI 608-546-3713

DeLaval Dairy Service Kaukauna, WI 866-335-2825

Joe’s Refrigeration Inc. Withee, WI 715-229-2321

Mlsna Dairy Supply Inc. Cashton, WI 608-654-5106

Professional Dairy Services Arlington, WI 608-635-0267

Redeker Dairy Equipment Brandon, WI 920-346-5579

The Scharine Group Inc. Whitewater, WI 800 472-2880 Mt Horeb, WI 800-872-3470

MINNESOTA & SOUTH

DAKOTA

Farm Systems Melrose, MN 320-256-3276 Brookings, SD 800-636-5581

Advanced Dairy Mora, MN 320-679-1029 Pierz, MN 320-468-2494 St. Charles, MN 507-932-4288 Wadena, MN 218-632-5416

One of our rst years at this farm was difcult because we had been having manure system troubles all week. In the tiestall barn, the barn cleaner chain kept breaking. It was one of those weeks where I hardly had a moment out of the barn, and I had not made it to the grocery store before Christmas. I was trying to think how to get creative to make a festive meal for my kids when my neighbors showed up with a huge bag of groceries. It had all the ingredients to make a luxurious breakfast of French toast and coffee and hot chocolate and so many other wonderful things. I do not know if she knew we were struggling or not, but I can’t think about that morning without getting choked up.

One year when we were renting a 40-stall barn and switching it to milk 80 cows, our youngest was about 9 months old. She had been woken up early to the other three kids’ delighted screams of Santa having visited, and she would not tolerate being put down so we could nish milking. At the time, the milkman would come and empty the tank while we switched the cows so there would be room for the second group’s milk. On that Christmas Day, he served as a surrogate grandpa and held on to our daughter so we could nish chores. I’ll always be grateful for his help that morning.

This year, my husband is serving as a milkman, and Christmas morning will nd him behind the wheel of the truck. I might remind him of that day just in case he sees any families struggling to get through chores this year.

Even though the situation seems to change every year, which makes traditions hard to maintain, I have fond memories to keep us warm this Christmas. Whatever we do, the important part is doing it together.

Your Mixer, Spreader,

Dana Berreau 507-879-3593 / 800-821-7092

Box 116, Lake Wilson, MN 56151

By Danielle Nauman danielle.n@dairystar.com

By Danielle Nauman danielle.n@dairystar.com

HUMBIRD, Wis. – For Pam Selz-Pralle, service leadership is a journey and one that grows exponentially as others are nurtured. That philosophy has been a cornerstone of Selz-Pralle’s life, the litmus test she uses to measure growth toward her goals.

“I have always told my kids, whatever you do, make it better for you being a part of it, whether it is a job, a relationship or any involvement in a committee,” Selz-Pralle said.

That philosophy is what earned Selz-Pralle the Dairy Girl Network’s inaugural Leading Impact award, which was presented Nov. 2 at the organization’s Forward TogetHER biennial national conference in Prior Lake, Minnesota.

Selz-Pralle and her husband, Scott Pralle, own and operate Selz-Pralle Dairy near Humbird where they milk 475 registered Holsteins.

Selz-Pralle credits her father with giving her advice as she left home for college that

has left its mark far beyond that day.

“My dad told me that there would be a lot of distractions at school but to always remember my purpose,” SelzPralle said. “He advised me that what they would be teaching me would be obsolete by the time I graduated, but that my real purpose of going to school was to learn how to learn. He said that college would teach me how to ask questions, nd resources and have discussions that would allow me to form my own opinions.”

After her college graduation, Selz-Pralle said she sat down to ponder what her purpose would become. Her father mandated she work off the farm for ve years before making the decision if coming home to farm was the direction she wanted.

“I thought about my life as a three-legged milking stool,” Selz-Pralle said. “First, I aimed to work in agribusiness and contribute to the business side of agriculture. Secondly, I wanted to work in production agriculture, improving the dairy industry through last-

ing genetics from our family farm. Finally, I wanted to repay the mentors in my life by being an active leader in the agricultural industry.”

From those facets, SelzPralle came to the conclusion that her true purpose was to help grow and develop others.

“The dairy industry needs people to carry the ag for the future of agriculture,” SelzPralle said. “We all need to be mentors for someone else and to give back.”

Through her own career and involvement in a variety of organizations, Selz-Pralle worked with mentors of her own and began to develop the voice and experience that would enable her to eventually serve that purpose for others.

“I was fortunate enough to come in contact with many people I admired for their knowledge or talent in certain areas,” Selz-Pralle said. “Alan Koepke was someone I respected and modeled myself after for his farm business management acumen. He was an early user of benchmark accounting. Linda Hodorff was another mentor for me, being a woman in agriculture. She just seemed to have so many connections and could always bring everyone together for a good purpose.”

After Selz-Pralle and her husband began taking over management of her family’s farm, she continued to priori-

tize involvement in the industry.

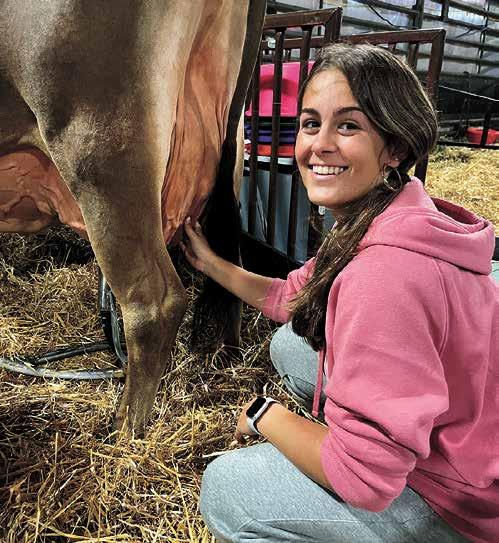

CHILTON, Wis. – This summer, the Meyer family opened up their home and farm to 15-year-old Iris Medina – a foreign exchange student from Madrid, Spain. Medina is having the time of her life learning about cows and helping with chores.

“I had never seen cows before I came here,” Medina said. “I’m learning so much about cows and all the work that goes into farming. I think it’s so cool.”

Larry and Jennifer Meyer milk 130 cows on their farm, Jenlar Holsteins and Brown Swiss, near Chilton with help from their children – Brianna, Austin and Abby. Hosting a foreign exchange student was Brianna’s idea.

“She wanted to pick someone from a Spanish-speaking country so she could learn about the culture and learn the language better,” Larry said. “When I was growing up, my family hosted a student from Sweden, so I was the rst one she convinced, and together, we encouraged the rest of the family that we should do it.”

Medina is an only child and is enjoying the company of sib-

lings and also likes the family’s two dogs.

“My parents thought it was so cool I was coming to a farm,” Medina said. “It is a new experience for me. I had no idea what farming was like, but I think I’m learning a lot.”

Medina helps clean up manure and feed the animals at the Meyers’ show barn that houses heifers and pigs. She has also fed milk to calves, helped cover the corn silage pile in the fall and helped Larry deliver a calf.

Medina enjoyed attending World Dairy Expo where she received an international badge and helped the Meyers care for their show string, which included nine homebred Brown Swiss head. She also learned how to milk a cow at Expo with a portable milking unit.

“I had no idea people show cows,” Medina said. “I could never imagine you do that with a cow; I thought you just milk them. I was amazed how they prepare the animals, like cleaning their hooves and spraying their hair.”

Medina has also taken a liking to the Meyers’ fair pigs.

“I love the pigs,” she said. “I liked helping them shine up the pigs for showing.”

Medina’s main reason for coming to the United States is to improve her English – a lan-

guage she learned around age 6.

“It’s also neat to experience another culture and see how people live,” she said. “I like being with another family and experiencing their traditions and spending time outside of Europe. I really like it here.”

Medina went from a bustling city of more than 3 million people to a quiet town of approximately 4,000. The two places are worlds apart.

“It’s very different here, but

I think it’s really cool where I ended up,” she said. “Chilton is a small place. It’s not a big city with shops and everything within walking distance like I’m used to. Here, you have to use a car to get everywhere. In Spain, we walk or take a bus or ride the subway.”

The cold weather has also been a big change for Medina.

“The coldest it gets in Spain is 32 degrees,” she said.

Medina did not get to choose

where in the U.S. she would go or what family she would stay with. Rather, the family chooses the student.

“We were reading through the applications and trying to nd someone who liked animals,” Jennifer said. “Iris mentioned her dog in her application so we thought she might be a good t.”

Medina attends Chilton High School – the same school as Brianna – where Medina was named homecoming queen this year. As a foreign exchange student, she is part of the senior class and can participate in the graduation ceremony next spring. She also joined the girls’ wrestling team.

“I’ve been doing fencing since I was 4 years old, and although wrestling is really different from fencing, it’s a little similar,” said Medina, whose dad was a three-time Olympian fencer. “I’ve never seen wrestling before, and I wanted to try something new. I’m liking it so far.”

Although this is her rst time in the United States, Medina is no stranger to traveling outside her native country. When she was 9 years old, she spent a month in England, and when she was 12, Medina traveled to Ireland for ve months.

“I love it,” she said. “Maybe when I’m a senior, I will travel abroad again.”

Medina arrived Aug. 10 and will be staying with the Meyers until June 26, 2023; therefore, Medina will be celebrating Christmas and ringing in the new year with her host family. The Meyers are planning to make this holiday season a special and memorable one for Medina.

On Christmas Eve, the Meyers attend church, prepare dinner at home and do chores. After chores, they eat, open presents and watch the movie, “It’s a Wonderful Life.” On Christmas Day, the family wakes up early to get chores done before traveling three hours to Monroe to celebrate Christmas with Jennifer’s family. The Meyers return home Christmas night to take care of the farm, show animals and dogs.

The Meyers like to make their house festive, spreading Christmas décor throughout the home. Every year, they get a tree the weekend after Thanksgiving and begin their Christmas shopping. The Meyers also like making cookies and other Christmas treats. Medina said Christ-

mas celebrations in Spain are similar.

“We put up lights and decorations, but there are not as many decorations outside,” she said. “Most of the Christmas trees are articial. We do a lot of baking, but we don’t send Christmas cards. Here, everyone goes shopping for presents, but in Spain, just the parents go buy presents, and we don’t see them until Christmas Day.”

In Spain, Medina opens presents Jan. 6 – the Feast of the Three Kings.

“We celebrate that more than Santa Claus,” she said. “On Christmas Day, we get one little present to open.”

On New Year’s Eve, Medina and her dad partake in a tradition of eating 12 grapes within 12 seconds before the next year arrives.

“My dad and I feed each other the grapes while a big clock in Spain counts down the seconds,” Medina said. “I’m going to miss doing that with him this year.”

To bring a bit of Spain into their festivities, the Meyers plan to incorporate the grape eating tradition into their New Year’s Eve plans.

“We try to stay awake until the ball drops in New York, but morning comes early, and Larry and I usually don’t make it,” Jennifer said. “But the kids usually do.”

When the time comes for Medina to return home, the Meyers are hoping she will take with her an appreciation for agriculture and where her food comes from.

“Now that Iris has seen a farm up close, she can appreciate how much work goes into making milk and other products for consumers to buy in the store,” Jennifer said.

Larry agreed.

“I would also hope Iris lets people know how much we care about what we do and how we care for our animals,” Larry said. “The animals come rst, and we almost take care of them better than we do ourselves.”

Medina is embracing farm life and looking forward to what the next six months have to offer.

“When I go back to Spain, I plan to tell people how much work dairy farming

is and that one cow gives a lot of milk,” Medina said. “There is so much to share with friends and family that they should know about farming.”

“It

be challenging to get off the farm and get involved,” Selz-Pralle said. “My golden rule was you have to have your ducks in order at home before you leave; but you need to leave the farm and get involved to grow yourself. Go to (Professional Dairy Producers) and other meetings. Don’t be shy, ask questions, talk to those you admire, learn how others think and why they do things.”

Selz-Pralle is a rm believer every single person has a talent or gift to share that others can benet from.

“God handed each of us a toolbox, a talent,” Selz-Pralle said. “He gave us the paintbrushes; it is up to us to add the colors. You need to intentionally grow yourself.”

Bolstering others, particularly young people, to help them achieve success is what Selz-Pralle considers to be a tool in her own toolbox, and she takes that to heart as the part she plays in ensuring the future of the dairy industry.

“It’s no different than building our herds,” Selz-Pralle said. “We have to raise our heifers to be good replacement cows. We are building a better industry when leaders raise strong replacements for the future.”

Selz-Pralle said part of that mentorship is sharing with others.

“More than just sharing our success stories, Scott and I try to share our struggles, our challenges and how we overcame those,” Selz-Pralle said. “Those honest experiences often help younger peers realize that success hasn’t come easy and they can do it too.”

Selz-Pralle related the story of a young dairyman who came to purchase a bull and had a conversation about calf raising, a topic SelzPralle not only considers near and dear to her heart but one she has struggled with. After sharing the story of her journey, Selz-Pralle was elated to hear that after making changes based on their conversation, the young dairyman had nearly eliminated his own troubles.

For Selz-Pralle, connections like that are where she nds her victories in each day.

just farm every day, and along the way, we have come to realize that

of agriculture is more than just

ourselves,” Selz-Pralle said.

“We

this industry

about

“There is a bigger cause and purpose in making a better agriculture for all of us.”PHOTO SUBMITTED Pam Selz-Pralle (far right) shares the story of how cows are milked in the parlor at Selz-Pralle Dairy in Humbird, Wisconsin. Her audience members were students from the Osseo-Fairchild School district

“We just farm every day, and along the way, we have come to realize that this industry of agriculture is more than just about ourselves. There is a bigger cause and purpose in making a better agriculture for all of us.”

PAM SELZ PRALLE, DAIRY FARM er

Family: My husband Michael, daughter Courtney, 22, and sons Zander, 20, and Keith, 18.

Tell us about your farm. We are the third generation on this farm. Keith has plans to be the fourth generation. The main farm was my father's and his mother's. My parents bought more land around the farm when they were farming. Currently, we own 300 acres and rent 80 acres. We milk about 80 cows plus raise our youngstock.

What is a typical day like for you on the dairy? Not every day is the same. For sure, I milk and feed the cows with my husband twice a day and take care of the heifers. The rest of the day depends on what time of year it is. If I'm not tilling, planting or chopping crops, then I'm probably mowing lawn or doing yard work, doing bookwork for cows or nancials, keeping up the house, making meals or plowing snow.

What decision have you made in the last year that has beneted your farm? We decided to have my brother plant our corn. This took stress off of us so we weren't trying to seed new hay elds, plant corn and start chopping haylage all in a small timeframe. We don't have hilly land; it's a lot of low land with clay soil. In the spring, it doesn't dry out as fast as other elds a few miles north of us. So, if we have a wet spring, it can be a struggle for us.

Tell us about your most memorable experience working on the farm. I was chopping haylage on what we call the corner eld and one of my sons had given me a drink and a sandwich. As I sat in the tractor, I ate and watched that son take food to my husband who was cutting hay. I had switched chopper boxes, and my daughter was pulling the full box out of the eld. Then, coming from the farm, my other son was driving on the road with an empty box that he had put in the silo. I remember sitting there thinking, “Wow. I created this. A

mom, dad and three kids all working hard together for our farm.”

What have you enjoyed most about dairy farming or your tie to the dairy industry? I have enjoyed working with my husband and raising our kids on the farm. My family is very important to me, and the farm has made us closer as a family. We've gotten a couple of comments from people saying they were jealous of how Mike and I get to work with each other and how we work together so well.

What is your biggest accomplishment in your dairy career? My biggest accomplishment is becoming 99% free of Johne's disease. I'm not going to say 100% because there's always that slim chance. My dad used to truck cattle and would buy cows from different places and bring them back to the farm. This is how the disease had entered the herd and was not managed well. We lost a lot of cattle and money when we took over the farm in the beginning. I remember culling three breeding age heifers on the same day because they had Johne's. Usually a cow will show signs of the disease just after they have their second calf. We got very aggressive in ghting Johne's disease. If a cow tested positive, then I would check to see if she had any heifers. The next day, if possible, that cow and any of her offspring would be culled. Now, we try to keep a closed herd, and it has been a couple of years since we have had to cull for Johne’s.

What are things you do to promote your farm or the dairy industry? We focus on doing the best job we can, and we work hard at producing quality milk, much more than we focus on quantity. If someone comes to our farm, I love taking them around the farm, especially sharing the farm with kids. Their faces are priceless, especially if they have never been on a farm before. Even the adults are usually intrigued.

What advice would you give another woman in the dairy industry? The dairy industry is viewed as more of a male's career. I've had many encounters where I was treated disrespectfully because I am female. Don't let that discourage you. I once had a sales

guy come in the milkhouse and ask for Mike. I asked him if I could help him and he said, “No, looking for Mike.” So, I took him in the barn where my husband was struggling to turn an unborn calf's head back around in the birth canal so the cow could deliver the calf. I told my husband this guy was looking for him, and apparently, I couldn't help. I went back to the milkhouse to nish what I was doing. Minutes later, the sales guy came back through the milkhouse and very softly said, “Sorry,” and continued out the door to his car. I remember giggling on that one. My husband always has my back and says if you can't talk to my wife, then you don't need to talk to me.

When you get a spare moment, what do you do? I love spending time with my Rottweilers. Wherever I go, they go. My husband said that if he wants to know where I am and I can't hear him, he'll just look for the dogs. My oldest son asked me what I was going to do when he left for boot camp for the Marines because he knew that would break my heart. I told him I would get a puppy, and I did. Actually, that Rottweiler just had a litter of puppies, so I'm in heaven with all of the puppy kisses. My dogs are my stress reliever. It's true how petting a dog makes a person feel better.

By Dana Adams

By Dana Adams

Dairies are managed by a farm team, whether they have 1,000 cows or 100 cows. Common members of a dairy farm’s team include family, staff members and other professionals like agricultural lenders or veterinarians. This collaborative environment requires routine and effective communication between individuals. Now, just because something was verbalized does not mean that it was received and effective communication took place. Knowing the communication styles in a farm team can lead to more effective communication and less frustration from all involved.

Usually offered in the beginning of the calendar year, the University of Minnesota Extension program, “Planning Your Dairy Farm Future,” discusses how to set goals and a vision as well as communication and leadership styles. The program is targeted to farms expanding, transitioning and deciding how their farm ts into overall market trends. Visit z.umn.edu/dairy for times and locations near you.

During the class, farm teams are taught about the four primary ways individuals process information: action, process, people and ideas. Individuals are a mix of these four communication styles, having natural preferences for one or two of the four. All these communica-

tion styles have value on a farm team. Understanding their nuances can allow a farm to communicate better to take advantage of opportunities and prepare for challenges.

The best way to understand your style and the style of others on your team is to learn about each communication style.

Action-oriented people focus on results, practicality of solutions and value getting to the point quickly when communicating. Not only do they talk with action in mind, but they listen and expect actionable steps from co-workers and family. Some individuals can consider them terse, rude or hurtful. Actionoriented people view themselves as being efcient with everyone’s time and moving quickly toward goals. Many farm teams are composed of employees with an action communication style. When decisions need to be made, these are the team members to rely on for decisive action. To be heard when communicating with individuals with this style, get to the point quickly and emphasize practicality of proposed solutions. This approach will take practice but can pay off with increased clarity in communication.

Those with a process communication style take time to analyze the information given to them. For those with a co-worker with a process style of com-

munication, they can be viewed as taking too much time to evaluate options and getting hung up on the details. They thrive in situations when they are given all the information, it is presented in a logical manner, and they are not rushed. An asset that these individuals bring to the farm team, when they are supported, is sharing a carefully thought-out plan for the dairy.

Individuals with a people communication style value relationships. They frequently talk about values, motivation, teamwork and feelings. The challenge that people communicators present is focusing excessively on hearing everyone’s thoughts or job enjoyment. Outside of technical or physical tasks, people communicators want to know those on the dairy feel a sense of purpose and value. These individuals can be immensely valuable when teamwork, a focused vision or inclusion is needed on a farm. Steps that other team members can take are to offer small talk or discuss the farm’s mission and values. Building this connection with people communicators encourages them to connect with the operation, fostering an environment with increased motivation and teamwork.

The last communication style is referred to as an idea communication style. They can be perceived as innovative, exploring opportunities and looking for

Dana Adams, adam1744@umn.edu 320-204-2968

Joe Armstrong armst225@umn.edu 612.624.3610

Luciano Caixeta lcaixeta@umn.edu 612-625-3130

Gerard Cramer gcramer@umn.edu 612-625-8184

Marcia Endres miendres@umn.edu 612-624-5391

Joleen Hadrich jhadrich@umn.edu 612-626-5620

Les Hansen hanse009@umn.edu 612-624-2277

Brad Heins hein0106@umn.edu 320-589-1711

Nathan Hulinsky huli0013@umn.edu 320-203-6104

Kevin Janni kjanni@umn.edu 612-625-3108

improvements in the spheres they work in. Idea communicators on farm teams can be perceived as unrealistic in their ideas or even egocentric. A foundation for a successful relationship with these team members can be built by allowing time for discussion and vetting of possibilities. When these individuals are on your team, present ideas by connecting them to the big picture and the idea’s unique characteristics. Idea communicators, and the innovation they share, can be leveraged when new ideas or outsideof-the-box thinking is needed on dairies.

As mentioned earlier, people tend to use a combination of communication styles when they talk to their co-workers. This prompts the use of a combination of approaches when communicating. For example, herdsperson Jesse has an action and relationship communication style. When communicating with Jesse about the farm’s goal to lower somatic cell count in the milk, other farm team members can be brief with practical steps and restate the farm’s vision to produce high-quality milk.

With practice, and reinforcement from positive results, these types of mindful interactions can come naturally. Communicating to your audience rather than the way you would prefer allows your farm team to hear each other more effectively.

Karen Johnson ande9495@umn.edu 320-484-4334

Emily Krekelberg krek0033@umn.edu 507-280-2863

Claire LaCanne lacanne@umn.edu 507-332-6109

Brenda Miller nels4220@umn.edu 320-732-4435

Erin Royster royster@umn.edu

Isaac Salfer ijsalfer@umn.edu 320-296-1357

Jim Salfer salfe001@umn.edu 320-203-6093

Mike Schutz mschutz@umn.edu 612-624-1205

Emma Severns sever575@umn.edu 507-934-7828

Melissa Wison mlw@umn.edu 612-625-4276

two years ago, we started a virtual

some of the key areas mentioned:

By Marcia Endres U of M

event that focuses on robotic milking. I named it 30 Minutes: Robotic Milking Edition. This has been a very informal event that highlights a dairy producer guest giving a brief overview of their operation followed by a question and answer session with the live virtual audience. I co-host this webinar series with Jim Salfer, University of Minnesota Extension dairy educator. Events are attended live to include question and answer time, then I share the recorded episode on YouTube.

The series has registrants from 46 countries. Much of the audience is comprised of dairy producers, but there are also industry professionals, those in academia and students. We planned the series with input received from a small sample of dairy producers in fall 2020. Producer feed-back helped us decide on the 11:30 a.m. time slot on the third Thursday of each month and the 30-minute duration. To register for the webinar series, visit z.umn. edu/30minRM. You will be sent a Zoom link. Once you register, you will receive automated reminders via email.

Over the last two years, we featured different brands of robots and various sized farms, from two to 72 robot-box dairies, two robotic rotary dairies and a grazing dairy. The audience includes producers who already have robots and those who are considering them. We are pleased to bring unbiased information directly from the end users to be shared with our audience. One easy conclusion from this series is that robotic milking systems are herd-size dependent and can work well in different barn layouts and congurations.

At the end of the session, we ask attendees to ll out a survey. One of the questions is what they have learned from attending the webinar. Here are

– Grouping rst lactation cows separately from older cows. Some of the producers indicated that by housing their heifers in a separate pen, milk production went up. This makes sense from a hierarchy perspective in a herd of cows, where the larger, more dominant cows can prevent access to resources; in this case, the robot box. Smaller dairies do not have the ability to create a separate group for heifers. It is then even more important to not overcrowd the pen, have enough space in front of the robot, avoid any design issues with dominant cows blocking entry or exit, and train heifers, etc.

– Training cows to visit the robot, especially rst lactation cows. Strategies mentioned by producers included installing a concentrate feeder in the dry cow pen or having a bedded pack area next to one of the robots to bring heifers through the robot box manually a couple of times a day. In addition, producers mentioned fetching those cows more often than twice a day in early lactation until they learn how to go voluntarily.

– Using a different liner in the milking units for those rst lactation cows housed in a separate group. Producers have seen increases in visits and milk production by doing this.

– Sand can be used as bedding on farms with robotic milking systems. It does increase maintenance costs, but producers like the cow comfort, low somatic cell counts and better traction. Sand can be used with all brands of robots.

– Free ow and milk-rst guided ow cow trafc, and how producers design the barns accordingly. Producers agreed that both systems can work well. Research shows the same. There are high-producing, healthy herds using either of these options. Older research indicated free ow had greater milk production, but this may have something to do with having feed-rst guided ow farms in those datasets. I would not recommend feed-rst cow trafc for U.S. dairy farms. Companies report they do not talk about feed-rst guided ow anymore.

– Learning more about different robot brands and the reason for choosing that particular brand. Producers mentioned having a competent supplier nearby or a prior relationship with them was a factor.

– Location and use of a footbath. Lame cows do not visit the robot box as often, so it is important to prevent lameness. Some farmers have the footbath at the end of the pen and manually walk cows through it a few times a week. Others automatically divert the cows at the robot exit to walk through the footbath.

– Feeding practices, especially what is fed in the robot box. Many guided ow farms in our webinar series are using corn gluten pellets instead of a formulated pellet to attract cows from the commitment pen to the robot box; this reduces cost. A farm reduced the average amount fed per day from 8 to 4 pounds without loss of production.

– Some free-ow farms are feeding more than one type of pellet, such as a high production and a low production pellet, or supplements specically for fresh cows. One of our research projects indicated that free-ow farms that intensively manage their feed tables by using more than one feed and more specic amounts by parity, stage of lactation and production level had greater milk production per cow and per robot.

By Abby Wiedmeyer abby.w@dairystar.com

By Abby Wiedmeyer abby.w@dairystar.com

OSSEO, Wis. – The Johnson family has discovered what works well for them in dairy farming. Tom Johnson harvested his 50th crop of cow feed this year with the help of his two sons, Brad and Ryan, on their farm near Osseo.

“We kind of stick with what we’ve been doing,” Ryan said. “Actually, that’s kind of unique because everybody our size has either been getting bigger or going out of business.”

The Johnsons milk 100 cows in a double-5 herringbone parlor. The parlor was installed in 1969, and the stalls were updated in 2013.

Tom has shipped milk to Foremost Farms for his entire career. He has utilized the buildings to be as efcient as he can with what is there.

“We kind of do the best we can,” Tom said. “It was actually an old chicken barn. We’re trying to squeeze every penny out of it that we can.”

When Ryan joined the operation in 2013, the family planned to transition everything over to him and Brad. The brothers have since purchased the cows from Tom, but that is as far as the transition process has gone.

“This way the farm has no payments,” Tom said. “If they tried to buy

me out, then there would be a big payment, and it probably wouldn’t work for any of us. We’ve made some money this way.”

The family manages the workload together. Brad takes care of the calves every morning. Ryan milks with the help of his oldest son who is almost 14. Tom helps on all fronts.

“We almost never lose a calf,” Tom said. “We always have a bunch of cattle around.”

One thing that has helped with cash ow over the years is raising steers alongside their heifers. They end up with about 50 steers and 50 heifers every year. They are fed a total mixed

ration that includes haylage.

“We feed them kind of like a Holstein cow,” Tom said. “Everything from a 600-pound heifer to a 1,700-pound steer are all in the same group. And, it works. You can’t skimp too much.”

The Johnsons aim to have their steers nished to 1,700 pounds within two years. The heifers are kept in the pen until they start to bag up and can be moved to a calving area.

The additional cattle provide ample amounts of manure which saves the family on fertilizer costs. With relatively high crop input costs this year, the Johnsons said the manure helped

them remain efcient with putting their crops in.

“We don’t buy much fertilizer,” Tom said. “We kind of know by now where we need the manure the most.”

All the feed for the cows, heifers and steers is grown on the farm. This year, 80 acres were chopped and put into a bunker silo and a pile. Additional chopped corn was put into a 20-by60 upright silo. High-moisture shelled corn was ground and put in two silos. The haylage crop for the year was put into bunker silos. Any corn that does not t in the silos is hauled to town.

“We hauled a lot for us this year,” Tom said. “Every cob I looked at has 20 rows around it, and I’ve hardly ever seen that.”

The family did deal with supply chain disruptions during the last year along with the rising cost of equipment. They usually purchase a new mixer every seven years.

“Everything is so crazy expensive,” Tom said. “I almost hate to buy anything now. We bought a new mixer last year, and we just got it yesterday.”

Ryan said that apart from their nutrition work, the family tries to handle everything else themselves. Between repairs, chores and eldwork, it is truly a family effort that has paid off in the long run.

Tom said the reliance on their family team has made a difference for the future.

“When I was young, we didn’t have any money,” Tom said. “Now we’ve made some money, and with our kids and grandkids, we can do stuff.”

Andy Buttles

Lancaster, Wisconsin

Grant County 1,200 cows

How did you get into farming? I grew up farming in Racine County south of Milwaukee, Wisconsin. It got to be too urban so we started looking at farms for sale and ended up here.

What are your thoughts and concerns about the dairy industry for the next year? I hope the milk price will stay competitive enough to offset all the increased costs.

What is a recent change you made on your farm and the reason for it? We have started to adjust our protocol to incorporate less antibiotic usage. It’s a combination of the right thing to do coupled with costs.

Tell us about a skill you possess that makes dairy farming easier for you. With our size, being able to manage people makes things easier for me.

What is the best decision you have made on your farm? Trying to put our

people rst. Being loyal and building people from within. I couldn’t do this without our people.

What are three things on the farm that you cannot live without? No. 1, our good people. No. 2, our computer management system. There is just too much information for me to keep track of without it. No. 3, our good cows. That’s what it is all about and what keeps it interesting. I wouldn’t want to do it otherwise.

What strategies do you use to withstand the volatile milk prices? We try to have a good milk marketing plan and stick to it. We also try to have a pricing strategy for buying inputs so we can have more control over the bigger costs.

How do you retain a good working relationship with your employees? We treat our people the way we would want to be treated.

What do you enjoy most about dairy farming? The cows. I like working with cows and genetics. I make breeding decisions with my herd manager, Levi.

What advice would you give other dairy farmers? You always have to keep trying to improve yourself. It’s not enough to just do things the way you’ve always done them.

What are your plans for your dairy in the next year and ve years? In one year, we’d like to continue to improve production. There are a few things to tweak. In ve years, I’d like to streamline replacement raising. It needs to be simplied.