DO YOU LIKE PUZZLES? DO YOU LIKE

Check out our puzzle book, Check out our book, inser ted into this edition! inserted

Volume 24, No. 24

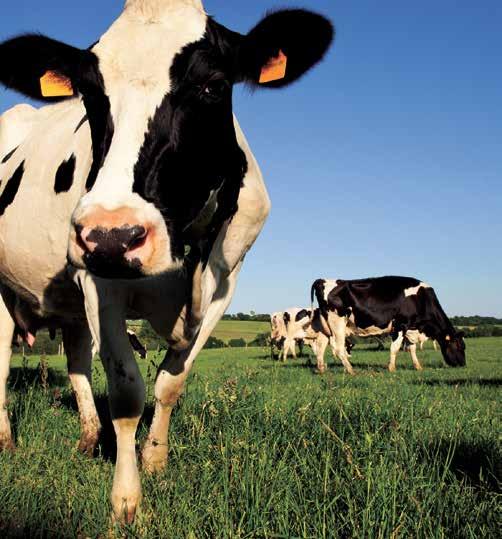

MAURICE, Iowa – A trio of northwestern Iowa dairy operations are teaming up to install a pair of anaerobic digesters that will make methane from their cows’ manure.

In a unique twist, the renewable natural gas produced by the dairies will be sold directly to the nearby town of Sioux Center.

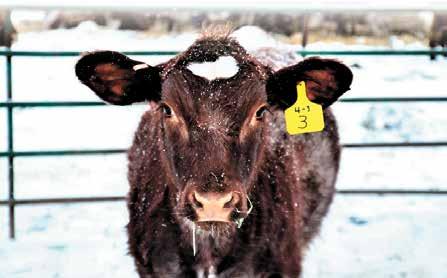

The three dairy farms include Maassen Dairy, which

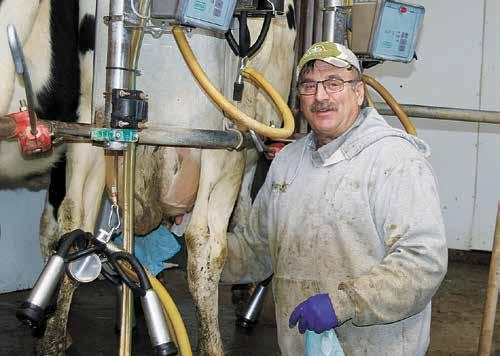

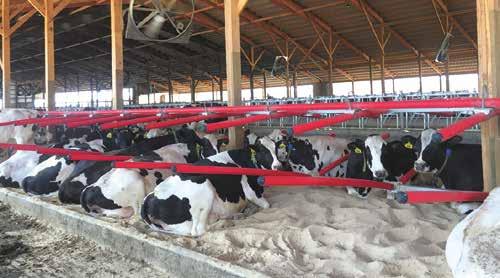

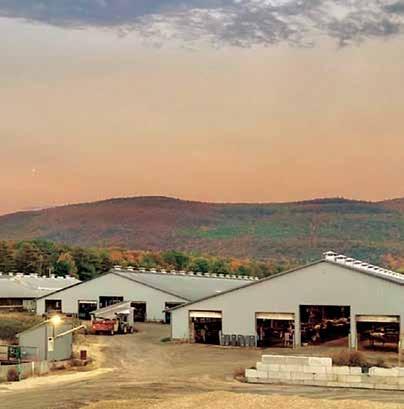

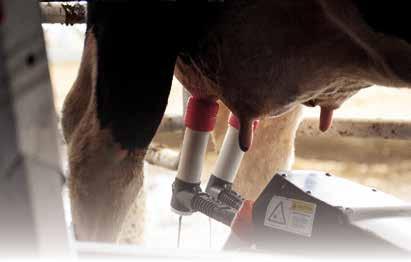

Aaron Maassen and his family milk 2,000 cows on their farm near Maurice, Iowa. The Maassens are installing a manure digester that will provide renewable natural gas to the nearby town of Sioux Center, Iowa.

is milking about 2,000 head; Brian Roorda Dairy, which is home to about 1,500 head; and Hoogland Dairy, an op-

eration that has about 3,000 head.

Construction of the two digesters will begin this spring. It is hoped they will start producing renewable natural gas by mid-2024.

“One digester will be built north of our manure lagoon and will handle the manure from our dairy and the manure from Brian Roorda Dairy, which is located a mile away,” said Aaron Maassen, a fth-generation farmer who, with his family, operates Maassen Dairy.

A pair of 6-inch pipes will be installed between Maassen Dairy and Brian Roorda Dairy. One pipeline will carry manure from Brian Roorda Dairy to the Maassens’ digester, while the other will carry the ap-

February 11, 2023

propriate amount of digestate back to Brian Roorda Dairy.

The second manure digester will be built at Hoogland Dairy. The Hoogland Dairy digester facility will also feature a renery that will remove impurities from the raw methane. The resulting product will be no different than the natural gas that is obtained from traditional sources.

“The renery is the most expensive part of producing renewable natural gas from manure, so it makes economic sense to have just one renery to serve all three farms,” Maassen said. “A

Turn to

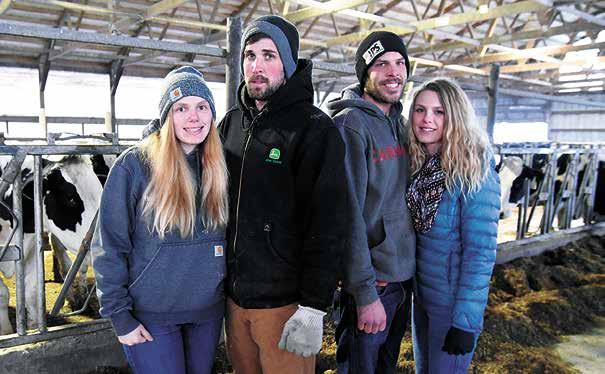

When Fritz Bushman and Alyssa (Nessa) Bushman locked their siblings Zack and Rachael in the mudroom together until they decided on a rst date, they sealed their fate of two brothers marrying two sisters.

Fritz and Alyssa Bushman and Zack and Rachael Bushman are organic dairy farmers in northeast Iowa. Fritz farms with his parents and another brother on their 160-cow dairy where they milk twice a day near Castalia. They also farm 700 acres

and raise 14,000 laying hens.

Zack and Rachael’s organic farm is located near Waukon, about half an hour away from the family’s home farm. They have 120 cows, 400 acres and milk three times a day.

The two farms collaborate together for eldwork.

The Bushman brothers met the Nessa sisters through church when the Nessas’ dad came to be the pastor where the Bushmans attended. Fritz and Alyssa were the rst two to fall in love.

The farm played a part in their love story.

“Our dating life revolved around milking and eldwork,” Fritz said.

Though unconventional, Alyssa said it did the trick.

“Our rst date was plowing together,” she said.

Fritz even let her drive the tractor, and Alyssa became confused in the dark and accidentally took a few tines off of a rake that was sitting at the end of the row. They were married less than a year later

in 2013.

Zack took a little more prodding to get a relationship going with Rachael.

| Page 6

“All dairy, all the time”™JERRY NELSON/DAIRY STAR

Published by Star Publications LLC

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce)

320-248-3196 (cell)

320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Editorial Staff

Tiffany Klaphake - Assistant Editor

320-352-6303 • tiffany.k@dairystar.com

Maria Bichler - Assistant Editor

maria.b@dairystar.com • 320-352-6303

Danielle Nauman - Staff Writer

608-487-1101 • danielle.n@dairystar.com

Stacey Smart - Staff Writer

262-442-6666 • stacey.s@dairystar.com

Abby Wiedmeyer - Staff Writer

608-487-4812 • abby.w@dairystar.com

Grace Jeurissen - Staff Writer

320-352-6303 • grace.j@star-pub.com

Jan Lefebvre - Staff Writer

320-290-5980 • jan.l@star-pub.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Consultant

Jerry Jennissen 320-346-2292

Main Ofce: 320-352-6303

Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication

Sales Manager - Joyce Frericks

320-352-6303 • joyce@dairystar.com

Mark Klaphake (Western MN)

320-352-6303 (ofce)

320-248-3196 (cell)

Laura Seljan (National Advertising, SE MN)

507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com

Jerry Nelson (SW MN, NW Iowa, South Dakota)

605-690-6260 • jerry.n@dairystar.com

Mike Schafer (Central, South Central MN)

320-894-7825 • mike.s@dairystar.com

Amanda Hoeer (Eastern Iowa, Southwest Wisconsin)

320-250-2884 • amanda.h@dairystar.com

Megan Stuessel (Western Wisconsin)

608-387-1202 • megan.s@dairystar.com

Kati Kindschuh (Northeast WI and Upper MI)

920-979-5284 • kati.k@dairystar.com

Julia Mullenbach (Southeast MN and Northeast IA)

507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell) bob.l@star-pub.com

The Ofce of the U.S. Trade Representative is moving forward and seeking a second dispute settlement panel against Canada and its dairy policy. The United States won its rst dispute panel over Canada’s unwillingness to obey the tariff-rate quota provisions of the U.S.-Mexico-Canada Agreement. Canada revised its approach to TRQs this past year, but the USTR contends the new policy also provides unfair advantages to Canadian dairy processors. “Canada’s TRQ allocation system is not only a violation of USMCA, it directly harms American dairy farmers, processors and other workers by unfairly restricting access to their market,” said Jim Mulher, president/CEO, National Milk Producers Federation.

Ready to complete the farm bill this year

House Agriculture Committee Chairman Glenn “GT” Thompson is committed to passing a new farm bill this year. “An extension is not what I prefer; I want to get the job done,” Thompson said. “I’m condent that if we lean in together and we do this in a bipartisan way and a bicameral way, we get this done before it expires at the end of September.” A divided government often brings fear of gridlock. Thompson said the thin margin will keep Congress more realistic and thwart unreasonable amendments. “This is probably the most important bill for people that eat,” he said. “Oh, that would be every American.”

Federal order reform coming Federal Milk Marketing Order reform will be part of the farm bill debate. “You can’t keep doing what you’ve always done and expect different results,” Thompson said. “We’ve been bleeding dairy farms; (Without change,) we will get to the point where we will be buy-

ing uid milk and dairy products from other countries and that is food insecurity.”

Thompson said Dairy Margin Coverage has worked well, but his committee will learn more during the hearings and regional farm bill listening sessions.

An opportunity for legislation that everybody needs

KuhnNorthAmerica.com rthAm Visit your local KUHN Hay and Forage Dealer today! INVEST IN QUALITY ® www.kuhn.com Van-Wall Equipment Albia, IA Indianola, IA Knoxville, IA Woodbine, IA Roeder Bros. Bellevue, IA Maquoketa, IA Vetter Equipment Clarinda, IA Denison, IA Indianola, IA Mt. Ayr, IA Shenandoah, IA Kunau Implement DeWitt, IA Preston, IA Diagonal Truck & Tractor Diagonal, IA Bodensteiner Implement Elkader, IA J P Scherrman Farley, IA Burco Sales Independence, IA Helmuth Repair Kalona, IA Graber Services Lockridge, IA Carroll Implement LuVerne, IA Greiner Implement Ottumwa, IA Engel Agri-Sales Sac City, IA Dee Implement of Waukon Waukon, IA Lindell Sales & Service Cannon Falls, MN Beck Implement Elgin, MN St. Joseph Equipment Eyota, MN Arnold's Glencoe, MN Kimball, MN Sauk Rapids, MN St. Martin, MN Dave’s Repair Hills, MN Isaacson Sales & Service Lafayette, MN Fluegge’s Ag Mora, MN Northland Farm Systems Owatonna, MN Lake Henry Implement Paynesville, MN Miller-Sellner-Slayton Slayton, MN Woller Equipment Swanville, MN A & P Service Wells, MN Jaycox Implement Worthington, MN Pfeifer Implement Sioux Falls, SD Grossenburg Implement Winner, SD Mark's Machinery Yankton, SD THE HAY AND FORAGE TOOL SPECIALISTS Mowers Mergers Rotary Rakes Wheel Rakes Tedders Harvesting high-quality hay and forage is the focus of KUHN's hay tool innovation. Our commitment is to help you gain a maximum return on investment by providing products known for performance, reliability, and longevity. THE MOST COMPLETE HAY LINE Cut Dry Harvest Save time, money and improve hay quality with KUHN.

of the powerful Ways and Means Committee, which has jurisdiction on everything from taxes to trade.

House ag committee passes RFA funding bill

The Minnesota House Agriculture Finance and Policy Committee approved two identical bills that would appropriate $50 million from state bond proceeds for the Rural Finance Authority. HF103 is sponsored by Badger, Minnesota, Republican John Burkel, and HF463 is sponsored by Brooklyn Center, Minnesota, DFL’er Samantha Vang. RFA funds can be used for beginning farmer loans, loan restructuring, ag improvement and livestock expansion loans. The House Capital Investment Committee is the next step for these bills.

Bill guarantees paid family leave

The beginning of the legislative session typically happens at a slow, methodical pace. That has not been the case this year in St. Paul, Minnesota. One of the bills on a fast track would require Minnesota businesses to provide up to 12 weeks of paid family leave and up to an additional 12 weeks of paid sick leave. Cory Bennett, of Bennett Government Consulting, said this proposal would impact farmers. “That’s certainly something that employers are going to have to provide if they’re not providing it already at a certain level; the same with sick time as well,” Bennett said. “After 80 hours, employees can start to accrue hours (for paid family leave), and they will start to have to provide that sick time as well.”

The Environmental Working Group is out with its latest farm subsidy database. Rather than releasing the names of farmers receiving government payments, the U.S. Department of Agriculture is now releasing the name of the bank or nancial institution nancing the farm’s operating loan. EWG said the Price Loss Coverage program paid out the most money to lenders, accounting for 6% of farm subsidies from 2019 to 2021. The Farm Service Agency received the most payments in 2021 at $87 million. AgriFund, which does business as Ag Resource Management, received nearly $35 million. AgCountry Farm Credit Services is ranked third at $18 million.

EWG database described as ‘misleading’

The Environmental Working Group’s so-called Farm Subsidy Data-

base has been highlighting farm program payments since 1995. Rather than releasing the names of all farmers receiving payments, USDA now lists the lender. AgCountry Farm Credit Services President and CEO Marc Knisely said the EWG information is misleading. “The only time a lender is listed as having received this support payment is when the farmer actually makes an assignment to a lender,” Knisely said.

“This money does not come to the lender for the lender’s benet. It is provided on behalf of the farmers and ranchers as a payment to be applied to their loan.”

Knisely also takes issue with the EWG characterizing farm program payments as a subsidy. “It is just unfortunate; causing a rift by using terminology like that is disappointing,” he said.

IDFA names chief economist

Mike Brown is the new chief economist for the International Dairy Foods Association. Previously, Brown was the director of the dairy supply chain for the Kroger supermarket chain.

Peterson to consult for IDFA

The International Dairy Foods Association has added three dairy policy consultants. The trio includes former House Agriculture Committee Chairman Collin Peterson, who now leads The Peterson Group. In addition, Chip English of the Davis Wright Tremaine LLP law rm and Steven Rosenbaum of the Covington law rm have signed on with IDFA. Both have experience with federal milk marketing orders.

AgriGrowth executive committee elected

The 2023 AgriGrowth ofcer team is in place. Associated Milk Producers Inc. CEO Sheryl Meshke succeeds Rod Hebrink of Compeer Financial as AgriGrowth’s chair. Jake Hamlin of CHS is vice chair.

Trivia challenge

Poutine is a classic Canadian dish featuring fries, cheese curds and gravy. That answers our last trivia question. For this week’s trivia, what year did John Deere start producing and selling lawn and garden tractors? We will have the answer in the next edition of Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network, based in Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two adult sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

the most demanding hydraulic attachments. When you need to attack your toughest jobs with pure Bobcat performance, the M2-Series 700 and 800 platform loaders deliver. This rugged lineup delivers the size, machine weight, lift capacities and horsepower to do more, while maintaining the exibility and versatility of a compact machine.

pipeline will carry raw biogas from our farm to Hoogland Dairy, which is located about 3 miles away. The puried renewable natural gas will then be piped to Sioux Center.”

Ypsilanti, Michigan-based Novilla RNG will build the manure digesters at Maassen Dairy and at Hoogland Dairy. Novilla RNG has formed a separate entity called West Branch LLC that will manage the operation of the digesters and market the dairies’ natural gas.

“We were referred to Hoogland, Maassen and Brian Roorda dairies as great dairies that did not have an RNG project,” said Jared Williams, co-CEO of Novilla RNG. “When we were looking for a natural gas pipeline to inject the gas into, we saw that Sioux Center was nearby and had the capacity to handle the gas injection. Once we started working with Sioux Center, we were impressed by their speed and forward thinking and decided that’s where we wanted to inject our product.”

The dairies received a down payment after signing letters of intent with Novilla RNG. The dairy operators will receive a second payment when construction of the digesters reaches approximately the sixmonth mark and another payment when the digesters are completed. Participating dairy farmers will receive their rst royalties a year after gas production begins.

“The majority of the revenue for this project comes from being able to sell negative carbon intensity gas to end customers,” Williams said. “A CI score is a measure of how much greenhouse gas emissions are released to create a unit of energy. As a reference, the CI of gasoline is +92, geological natural gas +67, solar and wind, near zero. The gas being generated at these dairies is expected to have a CI score in the negative 200s. This is an energy equivalent to roughly 1,025,000 gallons of gasoline per year.”

Adam Fedders is the assistant utilities manager for the city of Sioux Center, a growing town with a population of 8,583.

“During the summertime, the dairies will be capable of suppling

100% of Sioux Center’s natural gas needs,” Fedders said. “There hasn’t been any pushback against this project. People are happy to have a local, dependable source of renewable energy. It benets our local economy and increases Sioux Center’s natural gas capacity.”

Sioux Center’s utilities department will break ground this spring on a 6-inch natural gas pipeline that will run from Sioux Center to Hoogland Dairy. It is hoped that the pipeline project will be completed by this fall. The estimated $5.2 million cost for constructing the 8-mile pipeline will be covered by Novilla RNG.

“During the wintertime, the dairies will supply only a portion of the natural gas used by the people of Sioux Center,” Fedders said. “This is not only due to higher demand during the colder months, but also because the dairies will need to burn more of their gas to heat the digesters.”

Maassen said there will be three or four West Branch employees onsite at all times to manage the digesters and the renery.

“Our only job is to send fresh manure to the digesters every day,” Maassen said. “They want the manure to be as fresh as possible to increase methane yields and to decrease the amount of gas that will need to be burned to maintain optimal operating temperatures in the digesters.”

The nutrient value and the volume of the digested manure will remain unchanged.

“The only difference is that the nutrients in the manure solids may be more available because they have been predigested,” Maassen said.

The amount of revenue the dairies will receive for their renewable natural gas will vary according to market conditions and the quantity of methane produced.

“We have entered into a 20-year contract with Novilla RNG, so it’s a long-term relationship,” Maassen said. “The digesters have been sized to allow for the future growth of our

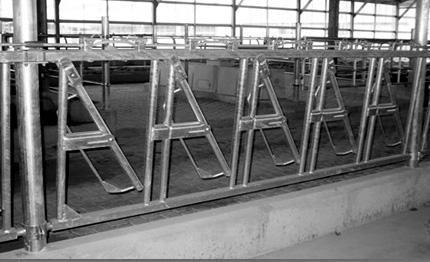

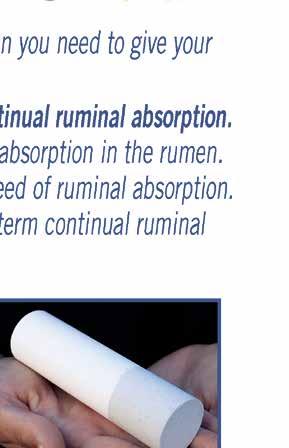

Construc on of the two digesters will begin this spring. Once completed, the digesters will look similar to the one above and produce renewable natural gas by mid-2024.

dairy herds. At peak capacity, the two digesters will be able to handle the manure from a total of 8,000 cows.”

Maassen Dairy beds their free stalls with sand. Preventing waste sand from entering the manure stream will create some managerial and technical challenges.

“Keeping sand out of the digesters is a big concern,” Maassen said. “We will be installing additional equipment, such as slope screens, to help us recover 100% of our waste sand. This will result in cost savings for us and better bedding for our cows.”

Brian Roorda is looking forward to the project.

“This project is good for us, good for the local community and good for the environment,” he said. “It became very exciting once I learned that the town of Sioux Center is going to be involved.”

Maassen agreed.

“Our focus is caring for our cows and our land,” Maassen said. “We are in the business of producing milk, not renewable natural gas. We were looking to partner with someone who knows the renewable natural gas business, and Novilla was a good t.”

Roorda said the digesters will help the three dairies remain protable well into the future.

“It just feels good to do something good,” he said.

Maassen said the amount of carbon-neutral energy the dairies will produce will be the equivalent of taking 8,800 cars off the road.

“The digesters will simply be capturing the gas that is naturally produced by the manure,” he said. “The development of new technology has now made that economically feasible.”

42,652 CFM 18.4 CFM/Watt @ 0.10” SP

“I knew that he was going to ask me out that day,” Rachel said. “So, I followed him around kind of like a puppy dog. … He never asked me out. He had all these opportunities.”

Thankfully, their already married respective siblings came to their rescue. When Rachael’s parents got ready to leave on Thanksgiving from the Bushmans’ house, Fritz and Alyssa offered to take Rachael home. They got both Zack and Rachael inside the mudroom, and Fritz guarded the outside door while Alyssa guarded the inside door.

“We thought, ‘They’re in there. They have no choice,’” Alyssa said.

The ploy worked. A year and a half later, they too were married.

Though they married brothers, the sisters have very different personalities and joke they married each other in male form. Rachael said their husbands each have a personality that seems to correspond to their respective sister-in-law.

“I’m similar to Fritz, and Alyssa is similar to Zack,” Rachael said.

All four of the Bushmans are involved on their respective farms.

Fritz and Zack farm full time. Fritz does morning milking and works with the calves. He also is the mechanic of the family since he

mes a day.

completed the John Deere training program at Northeast Iowa Community College in Calmar.

Alyssa is a stay-at-home mom. She takes care of their four children: Cyrus, Dulcy, Estelle and Gracia. She also helps with eldwork when they need an extra hand.

Rachael is also a stay-athome mom for their four children: Sophia, Briella, Joanna and Elliana. Rachael helps

with the bookwork, taxes and payroll for the farm. In the barn, she helps with one of their three milkings and also helps with calf feeding. Zack and Rachael have a full-time employee and one part-time high school student who helps. Zack takes care of everything else. He also does custom merging and manure hauling.

have found that raising their children with this lifestyle has provided its own unique experience.

“They learn a lot of responsibility,” Rachael said.

by the reality that Fritz cannot stop by for breakfast or lunch, and the kids do not get to go off with him in the tractor on a whim.

Alyssa and Rachael have broadened their understanding of dairy farming since their marriages. “I didn’t know that farmers never stopped working,” Rachael said.

Alyssa said she realizes now that some of her early conceptions of farming were incorrect.

“I didn’t realize how much technology has gone into farming,” Alyssa said.

Both couples have hopes and goals for their farming operations. Fritz and Alyssa hope to buy into the family farm and also build a house on the property. Zack has dreams of expanding the freestall barn. His current freestall capacity is 130 stalls spread throughout three buildings. He hopes to increase that to 150 stalls or more.

Both couples have marriage advice for other farming couples.

“When working cows, don’t take things seriously,” Fritz said.

With low equipment, operational and maintenance costs, Air King industrial air cleaners are an economical way to improve your overall air quality.

APPLICATIONS:

•Welding smoke/fumes

The Nessa sisters, who did not grow up on a farm,

Alyssa and her children have had a different experience living in town. Alyssa said living in town is the best of both worlds and the worst of both worlds. The opportunities to do things like walk to the library in town are offset

Zack said couples should milk cows together at least once a day, and Alyssa encourages couples to go to bed together. Rachael said it is important to work to understand each other and the issues that each may be experiencing. M-30

•Grinding dust •Bondo dust

•Oil mist •Diesel fumes

•Printing powder •Plastic dust

Air King industrial air cleaners are a valuable tool for capturing most airborne nuisance particulate. Our self-contained filtration units continuously pull contaminated air through multiple stages of highly efficient micro-glass filters. The filtered air is then re-circulated back into the working environment without the need for duct work. This results in a cleaner, healthier atmosphere for employees, while saving you money by keeping heated or air-conditioned air inside your facility.

•Other smoke/dust contaminants

1-800-669-4038

www.carlsonwholesale.net

Sauk Rapids, MN

Ritchie manufactures a complete line of livestock watering products with the highest specifications in the industry. From a single horse Stall Fount to a fountain that waters up to 500 head, Ritchie fountains are top quality. Plus, every Ritchie fountain is backed by our 10 year limited warranty. For more information contact us at:

Carlson Wholesale - 800-669-4038

www.carlsonwholesale.net

@carlsonwholesale

Editor’s note: This is the second story in a series highlighting families who are the last dairy farm to operate within their respective counties across our coverage area. Dairy Star hopes to shed light on the industry’s landscape surrounding these farms and how these isolated farms thrive.

In the Jan. 28 issue of Dairy Star, we featured Scott and Darlys Albrecht and their youngest son, Dallas, of Mizpah, Minnesota. They milk 90 cows in a double-10 parabone parlor in Koochiching County. Read their story at www.dairystar. com.

HANNOVER, N.D. – Randy Henke calls Oliver County home. His is the only dairy farm that does so.

Henke’s closest dairy farm neighbor hails from Morton County 10 miles away, but that farmer is

considering ending his dairy career.

“Oliver and Morton counties used to be big for dairy farming,” Henke said. “That’s why Morton County has Salem Sue, the big Holstein statue.”

Henke, and his wife, Sue, and their children, Wilton and Sigryn, milk 200 cows in a double-7 herringbone parlor near Hannover.

Once a hub of the dairy industry in southcentral North Dakota, the future of dairy in Oliver County

and the region, and North Dakota as a whole, is unclear; yet, the Henkes continue on.

The Henkes’ herd consists of Holsteins with a few Jerseys and Guernseys, and they raise 70 Hereford-Simmental cow-calf pairs. They farm 2,400 acres of corn, wheat, sunowers, soybeans and alfalfa. The Henkes also manage 800 acres of pasture.

“One thing I like about Oliver County is that land values aren’t

quite so crazy like they are other places,” Henke said. “Also, we can still raise pretty good crops up here. We don’t get 50-bushel beans every year. In fact, I only got that once. Most of the time, it’s 30-bushel beans, but it works out because our land values aren’t so high. But, that’s changing too.”

Henke said he struggles to nd needed supplies, repairs and employees for the farm and wonders whether there will continue to be a place to sell his milk. He is also concerned about how to transition the farm to the next generation.

When Wilton graduates from college this spring, he will farm with Henke full time with plans to take over the farm. However, decisions about the future are out of the Henkes’ hands.

“Our facilities are getting old,” Henke said. “We’re talking about robots or maybe a different parlor, but that’s going to be a very difcult decision to make because we have one processing plant, and we almost lost that a few years ago. We thought we were done (when it closed), but then Prairie Farms stepped in.”

Every other day, Land O’Lakes picks up the Henkes’ milk and hauls it to Prairie Farms Dairy in Bismarck. They also pick up milk for four dairy farms in nearby counties and a few more farms farther away. All is used for uid milk.

“We remodeled

springing heifer barn and replaced the

steel stalls and switched to TORENNA 40” stalls, we were able to increase from 72 to 100 stalls. With the old steel stalls, a lot of heifers were laying in the alleyways but with the TORENNA stalls, that problem is solved. We like the TORENNA stall flexibility which allows the stalls to be narrower and larger cows can easily move the stalls to the width they need.”

BUILT TO KEEP GOING.

BECAUSE A FARM NEVER SLEEPS.

‘15 JCB 536-60 Telehandler, CAH, 3,200 hrs

IH 574 Diesel tractor, 2050 loader, 3,100 hrs.

‘12 Kinze 3000, 6RN, coulters, 2,200 acres

‘92 Kinze 2000, 7R19”, air planter

‘09 Kinze 3200, 12R30, LF

JD 7200 Conservation, 6R30 Dry

Tonutti 12 wheel Dominator rake

‘20 Vermeer VR1022 wheel rake

H&S 12 wheel rake

Gehl 420 10 wheel rake

‘15 Pottinger 762C rake

‘12 NH H7450 13’ discbine

MF TD1620, 2 rotor tedder

‘12 NH H7450 13’ discbine

NH 1499 SP haybine, 12’, CAH

‘94 Hesston 8200, 12’ head

‘22 Kinze 3505, 15R15, bulk fill, 1,400 acres

Sunflower 4211-9, disc chisel w/ buster bar

IH 6000 Consertill, 13 shank

DMI 530B Disc Ripper

JD 712 9 shank disc chisel

CIH MRX690, 5 shank disc ripper disc.

PEOPLE MOVING PRODUCT

Cheese as a love language

Noble Rind Cheese Company offers a unique buying experienceBy Abby Wiedmeyer abby.w@dairystar.com

– The rst time Sarah Clemens tasted artisanal cheese, she knew she could never go back to eating mild cheddar. When she began working in a specialty food shop in her early 20s and discovered the connection between local cheeses and the farms they came from, her perspective changed and an appreciation for quality cheese and dairy farming was formed.

“I’m not really sure what about it (dairy farming) pulled at my heart so much,” Clemens said. “But once I made the connection of where our dairy products come from, I was just fascinated by it.”

The St. Paul, Minnesota, native has made a home in Wisconsin’s Driftless Area as a cheesemonger. Her cheese shop, Noble Rind Cheese Company, celebrates its oneyear anniversary in February.

The cheese case takes center stage at Noble Rind Cheese Company, with a large variety of cut-to-order cheese options. There is everything from local raw milk cheese to elite cheeses imported from Europe. In between, there are classic cheddar and havarti cheeses, among others.

with milk and butter in the recipe. All of the dairy products used in the kitchen are sourced from Organic Valley, Westby Cooperative Creamery and Grassland Dairy.

While Clemens is not a licensed cheesemaker, she does make her own version of American cheese. The process involves shredding Organic Valley cheese and mixing it with butter, milk and a couple other ingredients. The mixture is then blended to create a creamy, melty texture. It is portioned out and used on sandwiches.

cheesecake.

While there is always a rotation of varieties of cheese, Clemens said that Widmer’s Cheese Cellars brick cheese, Pleasant Ridge Reserve and havarti are among the top sellers.

Vermeer 840, 10’3” disc mow. cond.

Gehl 2450, 15’ hydro swing disc mower

Haybuster 2650 bale grinder

‘22 JD 350C Center Pivot Mower, ONLY 300 ACRES! SKID LOADERS

JD 980 Field Cult., 44’ w/harrow

CIH 4800 30’ Field Cult, w/3 bar coil tine harrow

‘12 Brent 782, grain cart tarp scale, nice JD 7200, vac, 6 row, 30 dry Easy Trail 500 Grain Cart ‘06 NH BR780A, baler/wrap

‘04 Polaris 400 Sportsman

‘08 Agco 3000 Corn ‘21 Bobcat S76, 344 hrs. ‘19 Bobcat T595 ‘17 Bobcat T770, 1800 hrs. ‘18 Bobcat T770, 2400 hrs. ‘05 Bobcat T300, 4900 hrs. ‘19 Bobcat 3400 side-by-side, 4100 miles ‘19 Bobcat T595, SJC,CAH 1300 hrs.

Customers can taste cheeses before buying them. Once a selection is made, the order is hand cut from the wheel.

“I wanted to have the more interactive buying experience where people could taste cheeses before buying them,” Clemens said. “They could learn why one cheddar tastes so different than another cheddar, which

“You really have a personal connection to the product and the land where the product is coming from,” Clemens said. “I really love that.”

Along with the cheeses on hand, Noble Rind Cheese Company also offers a menu of soups and sandwiches where all the ingredients are made from scratch, including the bread. One popular bread is a white loaf

“Cooking is denitely my love language, and I have a real passion for cheese,” Clemens said. “I have been very fortunate that my passion and interests lined up with my work.”

Other dairy items used regularly in the kitchen include heavy cream, half-and-half, Westby Cooperative Creamery French onion dip and a local cream cheese that is used in the homemade

Clemens also uses her platform to educate customers about cheese. Some tips she offers include wrapping cheese in cheese paper instead of plastic, serving cheese at room temperature and that all rinds are edible except for wax or cloth rinds. Clemens offers demonstrations for how to build cheese or charcuterie boards as well.

Future plans for the shop include expanding the menu to include breakfast items.

Noble Rind Cheese Company is located within the larger Historic Fortney Hotel building with newly renovated boutique hotel rooms. Guests will be able to stay over-

night this spring.

Once that is up and running, hotel guests will be able to come downstairs to have a simple breakfast at Noble Rind Cheese Company.

“Though we’re not big enough to offer hash browns, eggs and a full farmer breakfast just yet, I’m excited to nd a good local yogurt to use in addition to offering pastries, fresh fruit, toast, and meat and cheese for breakfast,” Clemens said.

Clemens said she has seen the trend of dairy alternatives start to dwindle and believes it is a wave that will settle down. This is important to her because she values real dairy as a vital part of her business.

“I do think the trend will ease up especially as more and more education gets out there about how livestock and dairy operations are a vital part of our lifestyle and our environment,” Clemens said.

Clemens plans to promote dairy through her shop and her support of local cheese producers. She continues to be enamored with the romance of dairy farming and the quality cheese that comes from it.

“I think what fascinates me, too, is that milking animals is one of the most ancient traditions that we have in our civilization,” Clemens said. “That’s just really compelling to me. This is our survival, and this is life.”

What counties or area do you cover? I work for Wabasha and Olmsted counties, plus I test a few herds for the state. With a herd in LeRoy, Minnesota and 30 minutes north of Menomonie, Wisconsin, I get to see a lot of eastern Minnesota and western Wisconsin.

Don Heise

17 years with DHIA

What do you enjoy about the farmers you work with? Some of the farmers I deal with have become very good friends. There have been invitations to baptisms, graduations, weddings and, unfortunately, a few funerals.

What do you like about your work for DHIA? DHIA has given me the exibility to set my own schedule; If one of the grandkids has a ball game, I can usually schedule my day so I can go. DHIA, as an organization, has put together a great team for support. Support is just a phone call away.

What do you do in your free time? We have 30 beef cows. My wife raises a rare breed of horses (8) called Nokotas. 3 Border Collies, and the best hobby ever, 15 grandkids!

“Some

“Land O’Lakes called us and wanted our projections for the next three to ve years,” Henke said. “Our fuel provider asked us what our plans are down the road. Until they can tell me for sure that there will be a place for me to sell my milk, why would I want (to make plans) if I can’t move my milk in a month or a few years? We have no infrastructure up here anymore for dairy supplies.”

It makes dairy farming challenging.

“We’re not like the I-29 corridor in South Dakota where it seems like every other year a processing plant is expanding or they’re building a new one,” Henke said. “They have so many more options to sell their milk there.”

Infrastructure for the dairy industry has long been gone from Oliver County and the surrounding area.

Hannover used to have a creamery before it closed in 1970. Nearby Hazon had a cheese plant, and there were a number of businesses selling dairy farm equipment. But by the mid-1980s, a decline of the dairy industry was in motion. Now, it is difcult to nd parts or repairs. Henke said he twice dealt with fuel pump issues that affected his ability to milk cows because of his location.

“I had a milk pump go out and couldn’t get the new pump until that night,” he said. “I couldn’t milk (for the evening milking) until 2 a.m.”

Another time, a dream saved him from giving up on morning milking after already having to skip the eve-

ning milking when he could not nd someone to repair the pump.

“I dreamt about when someone had told me that the (pump’s) motor had a shaft that was a quarter inch too long, so I went out a few hours later, cut the shaft shorter and got it to work,” Henke said. “That was the rst time in my life that we skipped milking. If I would have been in Sauk Centre, (Minnesota), I could have had someone there in 20 minutes.”

Another obstacle for Henke is

nding employees.

“We live in coal country here, so

you can’t compete with wages people are getting at the coal mines and power plants,” Henke said. “Our local people can’t nd people to work at the convenience stores. Labor is a huge problem.”

The Henkes have two full-time employees and four part-time employees. Most of their part-time employees are from Mexico. They go to their home country in December and return to the Henkes’ farm in March; a few have kept this work schedule for more than 12 years.

“Right now, you could say we’re

shorthanded,” Henke said. Sue works on the farm with Henke. She does the bookwork and helps with eldwork including combining and chopping. The Henkes are looking forward to when Wilton will be an everyday presence on the farm. Henke said Sigryn prefers milking to eldwork, but she is busy with high school and sports.

“Sigryn likes to work with animals,” Henke said. “Both kids have enjoyed showing cattle. They both have some of their own cattle here on the farm.”

However, Sigryn is still deciding her future and has other careers beside dairy farming in mind.

Therefore, the dairy operation continues with the future being uncertain.

The Henke farm would not be located in Oliver County if it had not been for a decision Henke’s grandparents made more than a century ago. His grandfather emigrated from Germany and settled in Fairmont, Minnesota. There, he married Henke’s grandmother and started farming.

“For some strange reason, they decided to leave Fairmont and go to Oliver County,” Henke said. “We always have the joke, ‘Why did they ever leave Fairmont?’”

In 1907, Henke’s grandparents homesteaded the quarter of land where the farm is now. They ran the dairy farm until Henke’s father took over. Turn

“When I was a kid, we always had 21 cows in a tiestall barn that we milked,” Henke said. “By the time I was in high school, my parents built a freestall barn and then milked 40 to 50. As an adult, I always thought, ‘The more the merrier,’ so that’s when we really began increasing the herd.”

In 1978, the Henkes built their milking parlor, which has been expanded and remodeled through the years. In 2002, they built a larger freestall barn.

“I bought my rst heifer when I was in the eighth grade and knew then I wanted to be a dairy farmer, but I think even then my rst love was (crop) farming, and it probably still is,” Henke said. “When Sue and I got married, we thought as our acreage increased we would get out of dairy like everyone else has around here, but for whatever reason, that never happened. I am probably more of a dairy farmer now than I ever was.”

Henke is looking to the future. In 10 years, he will be 73 years old. By that time, Henke said he intends to be helping his kids on the farm or with their chosen career paths.

“When I was young, I almost (was required) to dairy farm because my dad didn’t have a lot of acres,” Henke said.

Henke wants to give Wilton the choice.

“If you wanted to make a liv-

ing on a farm then, the milk check is what paid everybody’s farm off, and that was ne because I liked the cows and milking,” he said. “I guess I thought Wilton should have that same opportunity to take over (a dairy operation) as I did, so it will be essentially his choice as to how long the cows are going to stay.”

Henke said among the challenges there is also pride in dairy farming, which he is reminded of when he travels to land the Henkes own near Hazen and stops by the Cenex store in town.

“They have an ice cream machine there, and I get such a kick in the summertime seeing all those kids that are so crazy about the ice cream; they all have ice cream cones and big smiles on their faces,” Henke said. “We do produce a very valuable product, and it kind of makes you proud that you’re part of providing that.”

Henke said he does not see himself moving from Oliver County any time soon.

“It’s home; you take what you were born into,” Henke said. “I always think about if (my grand-parents) would have stayed in Fairmont how much easier it would be to farm. Remember that show, “Back to the Future,” when one thing changes years ago and it changes the whole projection of your life? It’s where we’re at.”

750 cows

What is your favorite winter hobby? Restoring two-cylinder John Deere tractors. I’ve done four so far in the last 10 years. I just work on them mechanically to get them running. I don’t paint them to do the full restoration. My kids like to watch and help out so it is a fun activity to do with family.

How did you get introduced to this activity? About 10 years ago, I wanted to get my dad’s old tractors up and running because they were just sitting around. One was a John Deere B which was my dad’s rst tractor. He bought it brand new in 1990 when they started dairying. That one has all original parts.

How do you balance farm work and your hobby? I just make designated time for them in the winter because there is more down time in the winter. My good friend, who also works for us on the dairy, helps me out to x up the tractors.

What is the value of you having an activity away from the farm? It brings family and friends together. It is a good history lesson and helps teach the kids how things work.

Tell us your best story associated with this hobby. Restoring the John Deere B was a big highlight as that was my parents’ rst tractor, and I remember driving it when I was younger. It was a hand clutch so I could run the PTO for my dad when needed.

What else occupies your spare time during the winter? Taking care of our ve horses, snowmobiling and spending time with family and friends. We take the kids out snowmobiling around the yard and up north to my in-laws’ place.

Tell us about your farm. We milk 750 cows in a double-16 herringbone parlor. We farm 1,600 acres of corn, alfalfa, oat and sorghum. We ship our milk to First District Association. My mom, dad and brother, Kyle, help us daily along with my wife, Tessie. We also have 11 employees. Tessie and I have three young kids who also help as they are able. They like to feed calves and go for tractor rides with grandpa. My other brother, Shawn, and sister, Carrie, both live in the area and help when needed.

Roger Aldinger Winona, Minnesota Winona County

100

cows

cows

What is your favorite winter hobby? I collect coins. I collect mostly U.S. coins minted from the mid1800s to the mid-1900s.

How did you get introduced to this activity? When I was a kid and the bicentennial coins came out, I thought they were pretty cool and would save the quarters and half dollars when I got them for change. At that time some wheat pennies were in circulation, and I always saved any that I came across. Eventually, I started getting coin magazines and began buying coins through the mail.

How do you balance farm work and your hobby? Farm work always comes rst. Coin collecting is just something done on the side when there is free time.

What is the value of you having an activity away from the farm? Most people that dairy spend too much time on the farm. That's just the nature of the business. Everyone needs something to do away from the farm even if it's not very big. It's good for your overall attitude and mental health.

Tell us your best story associated with this hobby. Years ago, I got an opportunity to tour the Denver Mint. I found it quite fascinating to see how our coins are minted and to nd out some of the history behind U.S. coins.

What else occupies your spare time during the winter? I enjoy spending time with my family, especially our grandson, Lincoln.

Tell us about your farm. We raise corn and alfalfa on about 150 acres. Our milk is sold to Plainview Milk Products Cooperative and gets shipped directly to Kwik Trip. My son-in-law, Josh Herricks, works full time with me. We get part-time help from my daughter, Adriana, and from high school student Sam Koeller.

Star Blends has been helping Midwest farm families by providing, high-quality feed, dairy nutrition, and commodity contracting for more than 20 years.

Our state of the art mill can accuratelyblend anything from a custom pre-mix to complete feed,

in balancing diets, or work with your private nutritionist or dairy consultant.

Terry Popp Rice, Minnesota Benton County

200 cows

What is your favorite winter hobby? I like to go coyote hunting in the winter. I go out at my place at night with a call after chores are all done. It’s best to go when there is a full moon. There is a neighbor kid that comes with me sometimes too.

How did you get introduced to this activity? I always wanted to catch one because they can be so elusive, and they don’t make much noise. I was into trapshooting as a kid, and it evolved into this. I have been actively coyote hunting for about 10 years now.

How do you balance farm work and your hobby? Because I hunt coyote at night, it is easy to balance with dairy farming. As soon as I get evening chores done, I get all my white hunting gear on and go out. The next day, I am a little tired, but it’s worth it. What is the value of you having an activity away from the farm? It refreshes you. Just being out there gives you time for your mind to reset. When there is a full moon and everything is just so calm and still and peaceful; it’s a really cool feeling. It always amazes me how these animals can survive out there on these 20-below nights.

Tell us your best story associated with this hobby. One night, when I was walking out to go hunting, a big white owl came up and started hovering right above my head. I got kind of scared that he was going to attack me. I shooed him away, and thankfully, he ew away. There was another time a bald eagle came down and swooped at my electric call.

What else occupies your spare time during the winter? I also enjoy reloading bullets. I buy my own powder, primer and the empty bullet cases. I have been doing that for 15 years. It’s getting harder to nd the powder, so I might not get to do that one as much in the future.

Tell us about your farm. We farm 460 acres of corn and alfalfa. I farm with my brother, Russ, and together, we milk 200 cows in a New Zealand style swing parlor. We even had a guy from New Zealand come here and install it. My wife, Julie, and kids, Ingrid, Greta and Sam, help as needed. We have one full-time employee. We ship our milk to First District Association in Litcheld, Minnesota.

200 cows

What is your favorite winter hobby? I like to watch, play and coach football.

How did you get introduced to this activity? At a young age, I loved to watch my cousins play and watched the Vikings play on TV. When I entered the seventh grade, I started to play football myself.

How do you balance farm work and your hobby? During my free time on Sundays, my boys and I watch NFL Redzone in the house, and when we have to go milk cows, we will watch it on my phone. This way, we never miss out on how our fantasy team is doing. My employees help when I have to go to practice. I help coach the fourth, fth and sixth grade football program in Waverly, South Dakota. Usually, we are about done with chores, but our employees ll in if I do have to leave early, especially on a game day.

What is the value of you having an activity away from the farm? Having an activity like this helps get my mind off of the farm and gives my boys and

Mike and Linda Hanson

Goodridge, Minnesota Pennington County

175 cows

What is your favorite winter hobby? We have two winter hobbies, watching NASCAR and snowmobiling. It is funny how both involve motors and speed. One allows us to enjoy our cozy living room; the other the invigorating, beautiful Minnesota winters.

How did you get introduced to this activity? NASCAR grew slowly. We had a mild interest but started paying more attention and got hooked. We have followed it seriously for more than 20 years. Getting to races in person is rare, but we are excited to be attending the Daytona 500 Feb. 19. On the other hand, snowmobiling has been Mike’s passion since he was 13. He introduced me (Linda) to sleds when we met 35 years ago and have spent many days riding northwestern Minnesota trails between morning and evening milkings.

How do you balance farm work and your hobby? NASCAR is easy since we watch on TV and try to take Sunday afternoons off for viewing. In warm weather during busy times, we listen to the NASCAR radio channel. This year’s Daytona trip is possible because we have two sons farming with us and will leave with condence the cows are well cared for. Snowmobiling is usually a last-minute decision. We leave right from our front door, catch groomed trails within a mile and ride anywhere from 40 miles to 200 miles. We trade off riding opportunities, so someone is always home. Milking and feeding robots also allow exibility without rigid start times.

The easy and inexpensive way to maintain a broiler or turkey house

Manufacturing, Inc

• With more than 50 years’ experience.

• The Poultry Housekeeper removes feathers and caked or wet litter in less time than you ever dreamed possible.

• This simple one-man operation is the easy, cost-effective solution to litter management!

House Keepers DB4s In-stock.

me something to bond over.

Tell us your best story associated with this hobby. This last October, my wife, Emily, two oldest sons, Trent and Eli, and my oldest daughter, Mikayla, took a trip to Pittsburgh, Pennsylvania, to watch the Pittsburg Steelers play the Tampa Bay Buccaneers. Trent, my oldest, is a Steelers fan, so we gured it was a great opportunity to get away for a few days and make memories for a lifetime. Seeing the excitement on their faces from the moment when we took off to being at the game is something I will never forget.

What else occupies your spare time during the winter? I am on the volunteer Goodwin Fire Department and teach the conrmation class at Holy Rosary Parish in Kranzburg, South Dakota. We also do our own butchering so usually one week in January we are busy with that. It usually takes me two weeks once I do the curing and smoking. We did four beef and seven pigs this year.

Tell us about your farm. I farm roughly 1,000 acres. We raise corn, soybeans and alfalfa and have a little pasture ground. We sell our milk to Associated Milk Producers Inc., which is currently shipping our milk to Paynesville, Minnesota. The everyday work is being done by my dad, Gerald, brother Kennedy, uncle Rod and myself. My two oldest boys, Trent and Eli, help on weekends and in the summer when they are not in school.

What is the value of you having an activity away from the farm? Mostly putting the day-to-day worries and stressors away for a while. Farming, particularly dairy farming, can be fairly isolating so getting out and about with others is uplifting and usually relaxing. We love what we do but nd refreshment in not having the farm and cows be the topic of conversation all the time.

Tell us your best story associated with this hobby. In 2004, we attended the spring NASCAR race in Las Vegas, Nevada. We were following a new young driver, Kasey Kahne, at the time and saw him run and nearly win a terric race. Fast forward to summer 2021. Kahne, after a successful NASCAR career, retired from Cup but still runs Sprint cars. A close friend of Mike’s, a shing guide, guided a party that included a promoter of Sprint car racing. Long story short, the conversation revealed this promoter knew Kahne personally, and we got free tickets and pit passes to races in Fargo, North Dakota, and a personal meet and greet with Kahne. Not a Cup race but lots of fun anyway.

What else occupies your spare time during the winter? There really isn’t much spare time, but we enjoy movies, old TV shows, a good book and other sports on TV. We are active in our church and the snowmobile club. We are busy with responsibilities as a soil and water conservation district supervisor and local cooperative board member.

Tell us about your farm. We farm 2,800 acres of cash crop soybeans, spring wheat and oats. We raise corn silage and alfalfa to feed the dairy herd. We are a Land O’Lakes producer, but the milk is hauled to Bongards in Perham. In 2016, we built a new facility with robotic milking and feeding systems to accommodate our three sons desiring to farm. Two are here with us and fully engaged in the farm, Matthew with the dairy and Steven handling crop duties. David farms with his in-laws in southern Minnesota but participates in decision making, exhibits the show cattle, works on the farm as able and markets our genetics with Matthew. David’s wife, Ashley, does our embryo transfer/ in vitro fertilization work and straps the show cattle. Matthew’s wife, Malena, a teacher, helps if we are gone and readily lls in when needed. We have no hired labor.

• Stainless steel feed box

• Heavy-duty drive

• Wheels mounted directly to wheel motors

• Main drive wheels, directly under feed weight, increases stability

• Chain Choices, #55, 62, or 662 pintle, or SS T-Rod

• Honda Engine powered (6 or 9 hp)

• 33, 43, 60, 73 bushel sizes available Call

Towns Farms

Towns

Janesville, Wisconsin

540 cows total; 480 milking

Describe your facilities and list your breeding management team. Our milk cows are housed in a sand-bedded freestall barn and milked three times a day in a double-10 parallel parlor. We also have a special needs barn for close-up and early fresh cows that is located close to the parlor so these animals are easier to see and access. Dry cows are housed in our old tiestall barn which has been converted into free stalls. We raise heifer calves to 6 months of age. From 6 to 12 months old, they are sent to our neighbor who is a custom heifer raiser. They come home to be bred. We have a pack shed for heifers and a lane of headlocks outside. After they are conrmed pregnant, they are sent to a different neighbor and return home one to two months before calving. Our breeding management team consists of Marley Malkow from CentralStar Cooperative, our primary A.I. technician Alfonso Perdomo, our herdsman and relief breeder Dr. Haley Prohaska from Evansville Veterinary Service, and Mark and Pat Towns.

STACEY SMART/DAIRY STAR

Pat and Mark Towns own and operate Towns Farms near Janesville, Wisconsin, with Mark’s brother and sister-in-law, Sco and Nancy Towns. The Townses milk 480 cows.

What is your current pregnancy rate? The pregnancy rate of heifers is 47% and the cows are at 27%.

What is your reproduction program? We use a double ovsynch program on all cows after a 70-day voluntary waiting period. We have it set up so that

if a cow shows heat on the rst Lutalyse shot after 70 days, we will cherry pick and breed off that. This is our highest repro code. If she’s in heat, it saves on shots. Before we give the second Lutalayse shot, we do have the vet, during a normal herd check, to check those cows for a corpus luteum. Typically, 10% to 15%

of cows don’t have a corpus luteum, so we will use a CIDR on those animals – about one to two cows per week. This is why double ovsynch is probably better than single ovsynch because hormones get where they need to be. We do not do an ovsynch program with our heifers. We may give Lutalyse sometimes

but almost all are bred off natural heats which we use tail chalking to help determine.

Describe your breeding philosophy. We don’t individually mate our cows. We use the computer system the bull studs offer to help stay away from inbreeding. We like a moderatesize cow that ts our facilities and produces milk that is high in protein and fat. We’re using young genomic bulls. Are they as good as proven bulls? Probably not. But with genetic progress, generations turn over faster. I like our 2-year-olds; they are milking well. They look like cows that are going to last. I think average is good versus breeding for extremes which can create problems. A 1,400- to 1,500-pound cow is a nice size for us. I think it’s more important to have a wide cow than a tall cow. I used to be happy to have cows that were immature. We didn’t expect as much out of them as 2-year-olds; we just wanted them to milk well as they got older. We don’t have that luxury anymore. They have to come out of the chute milking.

“We have been using Udder ComfortTM a long time. Today, we use the Udder Comfort Battery-Operated Backpack Sprayer to apply it quickly and easily on all animals in our fresh groups daily,” says Britney Hill (above), herd manager and part of the next generation operating Four Hills Dairy, Bristol, Vermont.

They milk 2300 cows, calving 10 animals a day, applying Udder Comfort to fresh groups daily for a 5-day course. They also love Udder Comfort for their award-winning show cows.

“With the Udder Comfort Battery-Operated Sprayer, we can do all in our fresh groups without slowing our parlor throughput,” Britney reports.

“It’s convenient, efficient, easy to maneuver, and the battery charge lasts,” she says.

“With Udder Comfort, our fresh cows are more comfortable, and our fresh heifers adjust to milking much faster with better letdown. Doing all in our fresh groups helps keep our SCC around 130,000,” Britney explains.

What guidelines do you follow to reach the goals for your breeding program? Every time the new proofs come out, which happens three times a year, we change the group of genomic bulls we are using. That’s our safeguard in case we get a bull that is not that good. We stick within a certain price range and use bulls in the 80th percentile –not the highest bulls of the breed. We shoot for the best value. We use higher-priced genomic bulls on our heifers because heifers have better conception rates.

What are the top traits you look for in breeding your dairy herd and how has this changed since you started farming? It’s crazy how things have changed.

When I was in 4-H and showing cattle in the 1960s and ‘70s, we were all about pretty cows. We wanted milk too, but cows had to be so big. We went far away from that philosophy. If you’re making a living producing milk, you need to do it efciently. I think feet and legs are equally important to udders. I don’t like bad-uddered cows, but if we can get them through the parlor, we can milk them. If a cow has bad feet and legs and can’t get there, then we can’t milk her. I also breed for width so cows can gain capacity without getting so tall. If cows are not wide, they don’t have enough strength and don’t have as good of circulation. We also place emphasis on components. We are over 7% on combined fat and protein and use that as a metric to judge ourselves. Our cows average 91 pounds of milk, 4.4% butterfat and 3.3% protein. We used to average 100 pounds of milk but

Marley Malkow,

What is the greatest lesson you have learned through your breeding program? You can have the best of intentions genetically, but if a cow doesn’t settle, what good is that? We believe it’s best to start with conception. We used to struggle with conception. Days in milk would get long, and then you don’t get replacements. We had a young herd we were trying to grow, and if reproduction isn’t good, then it’s a battle.

What is the age of your heifers at rst service? 14 months.

herd. Our ideal cow is moderately sized with adequate depth and width, giving her the capacity to eat. We also like cows that get pregnant on the rst service and are aggressive eaters. They have to be in order to be a good cow. A cow with high components is another important quality we strive for.

25% sexed and 10%-15% beef.

Farms near Janesville, Wisconsin. Heifers are bred off natural heats star�ng at 14 months. had lower components. Our nancial consultant told us to focus on components. There was a change in emphasis from pretty type to functional type. We used to give registered cows a pass because they’re pretty, but we can’t afford that anymore. We used to try to get bulls into stud also. We had several that made it, with Townson Lindy being our most famous bull. Our No. 1 emphasis is now on production. Cows have to pay their way.

What are certain traits you try to avoid? Big cows; high pins; too straight legged or too set in the legs; meaty udders as cows carry edema then; and short back teats that cross because these cows squeak when milking.

Describe the ideal cow for your

What role does genetics have in reaching the goals of your farm? I think genetics are important. A cow cannot do something that is not in her. You have to do a good job with their environment too so they can reach their potential.

What percentage of your herd is bred to sexed, conventional and beef semen? Heifers: 60%-65% conventional,

Cows: 65%-70% conventional and 25%-30% beef. We have bred some 2-year-olds to sexed semen that showed a good heat after their rst Lutalyse shot. If cows are not pregnant after the third breeding, we breed them to beef semen for the fourth and fth breedings. If they are not pregnant after that, we usually let them go. We have not done any embryo transfer or in vitro fertilization since we’ve been in our current facilities except for a few beef embryos.

What is your conception rate? How does this differ with different types of semen? Heifers: 69%. Conventional 63%, beef 60% and sexed 50%. Cows: 45%. Conventional 49% and beef 40%.

How does your heifer inventory affect your breeding program? We only breed for how many heifers we need to calve every month and keep tight to a specic number. We shoot for 16. We would like to start with 18 in case we lose a calf or one does not settle. We like to have that wiggle room or cushion in there, but we don’t want more than 20. Our facilities can’t handle it.

Tell us about your farm. Our 495-acre farm became a sesquicentennial farm in 2001. We can’t raise enough feed, but we grow as many of our forages as we can. Half of our crops are corn and half are alfalfa, and we also grow a little bit of rye. We expanded in 1999, building a freestall barn and milking parlor. Prior to that, we were milking on two separate farms in tiestall barns. We ship our milk to Rolling Hills Dairy Producers Cooperative, and we love the people there. Switching to Rolling Hills was one of the best decisions we ever made on our farm.

$359,600

JD S680 2014, PRWD, Duals, Chopper , 2349 hrs., 1668 Sep hrs., #531966.......... $195,000

JD S790 2019, PRWD, Duals, Chopper, 1770 hrs., 1426 Sep hrs., #532032........... $314,200

JD S660 2014, PRWD, Duals, Chopper, 1727hrs., 1317 Sep hrs., #532082 ........... $189,500

JD 9500 1989, 2WD, Duals, Chopper, 6463 hrs., 4553 Sep hrs., #543952................$20,000

JD 9500 1990, 2WD, Singles, Chopper, 5984 hrs., 3564 Sep hrs., #547007 .............$27,900

JD S690 2016, PRWD, Duals, Chopper, 2544 hrs., 1820 Sep hrs., #547267........... $219,900

Case IH 1660 1987, 2WD, Singles, Spreader, 5259 hrs., #547901 ..........................$16,500

JD S680 2012, 2WD, Duals, 2631 hrs., 1790 Sep hrs., #548165............................ $147,500

Case IH 2388 1998, 2WD, Singles, 3876 hrs., 2943 Sep hrs., #549406 ...................$34,900

JD S690 2017, PRWD, Duals, Chopper , 1433 hrs., 1028 Sep hrs., #549457.......... $280,700

JD S780 2019, PRWD, Duals, Spreader, 1562 hrs., 1131 Sep hrs., #549680 .......... $328,800

JD S780 2019, PRWD, Duals, Spreader, 1559 hrs., 1058 Sep hrs., #549682 .......... $333,900

JD S780 2019, PRWD, Floaters, 1604 hrs., 1145 Sep hrs., #549684 ...................... $339,100

JD S790 2018, PRWD, Singles, Spreader, 1452 hrs., 1055 Sep hrs., #549846 ....... $359,900

JD 9760 STS 2007, 2WD, Duals, Chopper, 2943 hrs., 2141 Sep hrs., #550117 .........$63,900

JD S780 2020, PRWD, Duals, Chopper, 1440 hrs., 941 Sep hrs., #550187............. $393,600

JD S790 2019, PRWD, Duals, Chopper, 1220 hrs., 944 Sep hrs., #550196............. $396,500

JD S690 2015, PRWD, Tracks, 2400 hrs., 1615 Sep hrs., #550872 ......................... $232,900

JD S680 2013, PRWD, Duals, Chopper, 2485 hrs., 1604 Sep hrs., #551147........... $165,000

JD S690 2012, PRWD, Duals, Chopper, 2311 hrs., 1645 Sep hrs., #551148...........

JD S780 2018, PRWD, Duals, Chopper, 1521 hrs., 1130 Sep hrs., #551736...........

JD S680 2014, PRWD, Singles, Chopper, 2709 hrs., 2076 Sep hrs., #551975 ........

JD S660 2017, 2WD, Duals, Chopper, 1575 hrs., 1180 Sep hrs., #552261 ............. $219,900 JD S780 2022, PRWD, Duals, Chopper, 449

Duals, Chopper, 427 hrs., 302 Sep hrs., #552839............... $589,900

JD S780 2020, PRWD, Floaters, Chopper, 1018 hrs., 803 Sep hrs., #553375 ......... $434,000

JD S780 2022, PRWD, Floaters, Chopper, 392 hrs., 323 Sep hrs., #553546 ........... $549,900

JD 9500 1990, 2WD, Singles, Chopper, 3900 hrs., 2600 Sep hrs., #553583 .............$24,000

JD S780 2022, PRWD, Duals, Chopper, 462 hrs., 345 Sep hrs., #553598............... $567,000

JD S790 2022, PRWD, Tracks, Chopper, 38 hrs., 21 Sep hrs., #553771 .................. $719,900

JD S780 2022, PRWD, Tracks, Chopper, 295 hrs., 238 Sep hrs., #554013 .............. $675,000

JD S770 2022, PRWD, Duals, Chopper, 270 hrs., 195 Sep hrs., #554014............... $560,000

JD S770 2021, PRWD, Duals, Chopper, 565 hrs., 486 Sep hrs., #554050............... $405,000

JD S780 2022, PRWD, Duals, Spreader, 240 hrs., 183 Sep hrs., #554094 .............. $587,500

JD S660 2012, 2WD, Duals, Chopper, 1643 hrs., 1188 Sep hrs., #554132 ............. $179,900

JD S670 2012, 2WD, Duals, Chopper, 2774 hrs., 1883 Sep hrs., #554281 ............. $129,900

JD S680 2014, PRWD, Duals, Chopper, 2260 hrs., 1355 Sep hrs., #554365........... $189,900

JD S790 2022, PRWD, Duals, Chopper, 334 hrs., 269 Sep hrs., #554381............... $610,000

JD S780 2022, PRWD, Floaters, Chopper, 236 hrs., 170 Sep hrs., #554623 ........... $599,000

JD S790 2018, PRWD, Duals, Chopper, 1314 hrs., 940 Sep hrs., #554633............. $354,900

JD S780 2022, PRWD, Floaters, Chopper, 216 hrs., 169 Sep hrs., #554706 ........... $579,500

JD S780 2022, PRWD, Floaters, Chopper, 243 hrs., 177 Sep hrs., #554707 ........... $578,500

JD S780 2022, PRWD, Floaters, Chopper, 138 hrs., 91 Sep hrs., #554708 ............. $589,500

JD S780 2022, PRWD, Floaters, Chopper, 183 hrs., 131 Sep hrs., #554709 ........... $584,500

JD S780 2022, PRWD, Floaters, 182 hrs., 139 Sep hrs., #554710 .......................... $583,500

JD S790 2020, PRWD, Tracks, Chopper, 804 hrs., 584 Sep hrs., #554727 .............. $529,000

JD 9870 STS 2010, PRWD, Duals, Chopper, 3394 hrs., 2260 Sep hrs., #554931.... $118,900

JD S680 2012, PRWD, Duals, Chopper, 2500 hrs., 2000 Sep hrs., #554973........... $129,900

ft., 5-Section Folding, #190857 ................................................ $57,500

JD 2210 2005, 38 ft., 3-Section Folding, #191986 ................................................... $28,000

JD 2210 2009, 55.5 ft., 5-Section Folding, #531369 ................................................ $44,900

JD 2210 2004, 27 ft., 3-Section Folding, #531751 ................................................... $29,900

Case TM 14, 55 ft., 5-Section Folding, #532837 ...................................................... $23,000

JD 2210 2012, 58 ft., 5-Section Folding, #533062 ................................................... $57,500

JD 985 2000, 50.5 ft., 5-Section Folding, #535303 .................................................. $15,500

JD 2210 2010, 57 ft., 5-Section Folding, #542886 ................................................... $47,900

JD 980 2000, 44 ft., 5-Section Folding, #545689 ..................................................... $16,500

JD 2230 2021, 60.5 ft., 5-Section Folding, #545925 ..............................................$162,000

JD 980 2000, 44 ft., 3-Section Folding, #546434 ..................................................... $16,900

JD 2210 2005, 43 ft., 5-Section Folding, #551803 ................................................... $33,500

JD 2200 2002, 60 ft., 5-Section Folding, #551815 ................................................... $29,500

Case IH TIGER MATE 200 2009, 54 ft., #552287..................................................... $43,500

Sunflower 5055-50 2012, 50.5 ft., 5-Section Folding, #552837 ............................ $39,900

JD 2210 2006, 60.5 ft., 5-Section Folding, #553154 ................................................ $29,900

Case IH Tigermate 2 2007, 44 ft., 5-Section Folding, #553875 ............................. $29,900

Case IH Tigermate 200 2009, 50 ft., 5-Section Folding, #554055 ......................... $39,900

JD 2210 2014, 25 ft., 3-Section Folding, #554138 ................................................... $42,500

Case IH 200 2014, 60 ft., 5-Section Folding, #554255 ............................................ $52,500

JD 2230FH 2019, 65 ft., 5-Section Folding, #554291 ............................................$152,000

JD 2210 2008, 33 ft., 3-Section Folding, #554294 ..........................................$39,900

JD 2210 2014, 41 ft., 3-Section Folding, #554297 ................................................... $47,500

JD 2210 2006, 45.5 ft., 5-Section Folding, #554617 ................................................ $29,900

Case IH

Advanced Dairy Spring Valley, WI 715-772-3201

Ederer Dairy Supply Plain, WI 608-546-3713

DeLaval Dairy Service

Kaukauna, WI 866-335-2825

Joe’s Refrigeration Inc. Withee, WI 715-229-2321

Mlsna Dairy Supply Inc. Cashton, WI 608-654-5106

Professional Dairy Services Arlington, WI 608-635-0267

Redeker Dairy Equipment Brandon, WI 920-346-5579

The Scharine Group Inc. Whitewater, WI 800 472-2880

Mt Horeb, WI 800-872-3470

Farm Systems

Melrose, MN 320-256-3276

Brookings, SD 800-636-5581

Advanced Dairy Mora, MN

320-679-1029

Pierz, MN

320-468-2494

St. Charles, MN

507-932-4288

Wadena, MN 218-632-5416

CLEAR LAKE, Minn. –Forty-ve years ago, the Person brothers’ father gave them an ultimatum.

“Dad said you guys need to be committed for 10 years, or I’m not going to switch the barn to cows,” Kris Person said. “We agreed, and 45 years later, here we are.”

The duo was in their 20s when their dad, Neil, who was a hog farmer and milk hauler, decided to venture into dairy farming and purchased cows in 1976.

With a combined 90 years of dairy farming to their names, Ray and Kris Person milk 43 cows twice a day in the original 24-stall tiestall barn built in 1919.

“Originally, we had 24 cows in the tiestall barn, but in our prime, we milked 70 cows,” Kris said.

The brothers agreed they are glad their dad bought a farm all those years ago.

“The farm is my life,” Kris said. “We lived to farm;

we didn’t farm to live.”

Ray agreed.

“It’s a way of life,” he said.

Out of all the types of farming the brothers have done, Kris said dairying is part of who they are.

“It’s a family affair,” Kris said. “There’s something about farming, especially dairy farming. The dairy barn is a gathering place, and it’s not worth much to anyone else. But, it’s the No. 1 place I want to be.”

The barn is the family’s meeting place, and during morning chores, family members discuss what they have going on during the week such as doctor appointments and school functions with children and grandchildren.

The Persons own 615 acres and raise corn, alfalfa, soybean and rye on 400 tillable acres. The farm site is nestled along the Mississippi River and includes many wooded acres.

The Persons, along with the help of neighbors, put up 2,000 small square bales of rye each summer. The neighbors have the equipment to harvest the grain, and the brothers make straw from the rye to use as bedding in the tiestall barn. The youngstock are bedded with corn stalks and soybean straw.

The brothers are not as young as they once were, and Kris’ son, Andy, farms full

time with his dad and uncle.

“Sometimes the cows get to be too much, but without them, I don’t know what I would do,” Kris said. “Andy wants to keep it in the family.”

Ray and Kris milk the cows at 7 a.m. every day. Andy comes later to help switch the cows. They repeat the task at 7 p.m. Kris’ wife, Diane, takes care of all the calves.

“We’d like to keep it go-

ing,” Kris said. “To have Andy helping out feels really good.”

Kris and Andy take care of the eldwork, and Andy also takes care of all the equipment maintenance.

“I used to work full time 80 hours a week for LG Seeds then come home and help on the farm,” Andy said. “Now, I farm full time and work part time as an agronomist.”

Andy also takes care of physical tasks such as gathering wood for the wood-burning stove, articially inseminating the cows, cleaning calf pens and scraping down sides in the silos.

Turn

Tyrel

Long

Dean

Chad

Yankton,

Mike Baczwaski • 800-445-0042

Gibbon,

Cody

Long Prairie, MN

Andy is raising his family on the farm and is instilling the same values that were instilled in him. Andy and his wife, Kristy, have three children. Andy said his daughter loves the cows and knows exactly which ones to bring in. She checks the barn daily for newborns.

Andy’s favorite memories of growing up on the farm are from the gatherings they used to host in the 1990s.

“We used to have a plowing bee and would have old antique tractors and plows come out,” Andy said. “We have 20 restored antique tractors in the shed of all kinds. Some are from my

grandpa.”

The farm has a unique history.

Ray and Kris, along with their sister and parents, were living in Big Lake until their parents purchased the farm in 1963. At the time, their dad worked as a milk hauler and hauled area farmers’ milk in cans.

The brothers said their parents wanted to raise their family on a farm.

At rst, they raised only crops and eventually added livestock when corn prices fell.

“Dad was told you’re a lot better off putting that corn in an animal, so we got hogs,” Kris said.

Four years after purchasing the farm, their dad quit driving milk truck to farm full time. He raised 500 hogs. Ray said his parents installed irrigation in 1969.

“We were one of the rst farmers to start,” Ray said. “There wouldn’t be any farming in Sherburne County if it wasn’t for irrigation. You couldn’t survive on this soil.”

They switched to dairy cows and added stalls to the barn in 1976. At the time, the brothers had their own jobs off the farm but worked around chores on the farm.

“We did it to get a steady paycheck so Ray and I could still farm,” Kris said.

After high school, Ray went to college and worked at a restaurant while helping on the farm.

“I never left the farm,” Ray said.

Kris drove school bus and worked for another farmer until their dad bought the cows. They also had beef cows. He continued driving bus and did so for 35 years for Becker School District. Kris eventually retired from driving so he could farm full time.

“I would get up and do chores till 6:30 a.m. then go drive bus,” Kris said. “I did that until 2007 when Dad wanted to retire from farming. He was 82.” Looking back, Ray and Kris agreed all their best memories revolve around the farm.

“I used to keep up with the cows, milk them and feed them, drive school bus, have 500 hogs and restore a tractor every year,” Kris said. “Now, I do eldwork and milk the cows.”

HUGO, Minn. – Kristy Miron’s involvement in the Minnesota Farm Bureau has had a ripple effect.

From engaging with consumers to advocating for the dairy industry, Miron sees the importance of the organization.

“As a farmer and as a person in industry, it gives me a lot of condence in the Farm Bureau with the level of rapport that Farm Bureau has on Capitol Hill with individuals to have inuence on key issues,” she said.

But now, Miron’s involvement has landed her the title of runner-up in the American Farm Bureau Federation Young Farmers and Ranchers Excellence in Ag competition Jan. 6-9 in San Juan, Puerto Rico.

To advance to the national competition, Miron, of Hugo, rst won the Minnesota Farm Bureau Federation competition during the MFBF 104th annual meeting Nov. 17-19, 2022, in Bloomington.

For the national competition, Miron completed an application and gave a presentation about challenges facing agriculture. She focused on the challenges of farming in a suburban area, generational transfer of the fam-

ily farm and sustainability.

“I identied three core issues,” Miron said. “One local, one state and one at the national level.”

According to Farm Bureau, participants are judged on their involvement in agriculture, leadership ability, and involvement in Farm Bureau and other organizations. The award is judged 80% on the application and 20% on the presentation.

“To me, it was a really big reection of my experiences and skill sets I have developed through Farm Bureau membership and other opportunities,” Miron said.

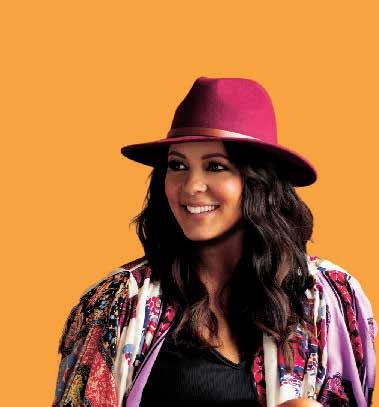

Miron’s second place win earned her $25,000 toward a Case IH product of her choice.

“I was pushed by our eld representative to apply for the award this year,” Miron said. “I am very grateful for the push and the encouragement and support.”

Miron’s family farm is located 25 miles northeast of downtown St. Paul. Miron’s experience of urban sprawl affecting agriculture gave her a clear message for her presentation. Miron said the circumstance also presents an opportunity to engage with consumers.

Miron said even their hometown of Hugo has grown from a population of about 5,000 20 years ago to a population of over 16,000 today.