ELLSWORTH, Wis. — The Webster family always farmed as a team.

Kim and her husband, Brian, raised three kids, Mitchell, Jennifer and Thomas, on the dairy and were making plans to transition the farm to the boys while Jennifer grew her career in grain marketing.

Kim and Brian’s wedding anniversary was only two weeks away, and retirement was just over the horizon for Kim when those plans came to a halt.

Brian took his own life Aug. 3, 2023, when he was just 58 years old.

“He was the love of my life,” Kim said. “I didn’t get to say goodbye.”

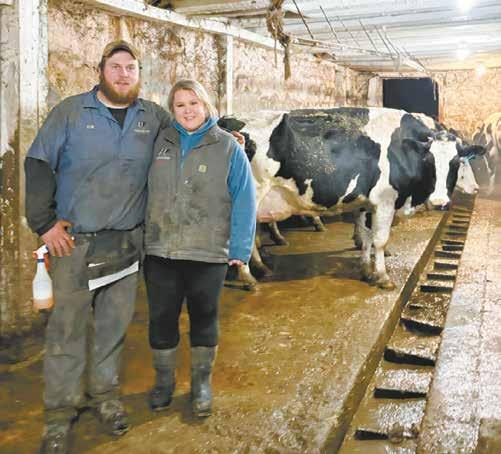

Thomas continued milking the herd of 75 Holsteins in Brian’s absence with the help of his girlfriend, Kylie Larsen.

Last Fall, Mitchell and Thomas harvested the last crop that Brian had planted. They farm around 1,100 acres and have an additional 200 acres of pasture. Mitchell and his wife, Taylor, manage a beef operation and raise pigs for an Iowa pork company as well.

Brian was a fourth-generation dairy farmer who loved to talk to everybody, Kim said. He was also a seed corn dealer and would not sell any seed that he had not already grown himself.

“He touched a lot of people’s lives in the community,” Kim said. “He was a popular guy.”

Jennifer learned a lot about the markets from Brian at a young age. Every Sunday morning, they watched “Market to Market” together on PBS. At the end of every day, she printed the market reports so the two could discuss them when he came in from milk-

ing. It led to her career at CHS Inc., where she continued to share her love of commodities with Brian.

“It’s really hard because I usually called Dad and told him what the markets were doing,” Jennifer said. “I cry on my way to work, and I feel like I’m supposed to call my dad, but I can’t because he’s not here.”

Kim said she feels compelled to share her husband’s story because it might help someone else who is struggling with suicidal thoughts.

Since Brian’s passing, she has worked with a counselor to cope with grief. She has also tried to learn as much as she can about mental illness to understand Brian’s struggle.

Brian had been on medication for mental illness but continued to have a difcult time. He was navigating the side effects of a change in medication which left him dizzy and lightheaded. Per the doctor’s instructions, Kim took Brian to the emergency room where he was given uids and sent home.

Kim said the emergency room experience left her wondering if there was more that she could have done and why her husband chose to end his life. She would like to advocate for more resources in the emergency room.

“I feel sometimes like I wasn’t paying attention like I should have,” Kim said. “But at the time, I wouldn’t have known that he would have done this. I wish he would have talked to me.”

Kim said it helps to talk about her loss with people, even though she does not want to burden anyone. She encourages people to stop in and see her and the boys on the farm. She especially worries about Thomas, who also struggles with mental illness.

“It’s different,” Thomas said. “He’s not here for advice so we just have to sink or swim on our own now.”

Turn to WEBSTER | Page 4

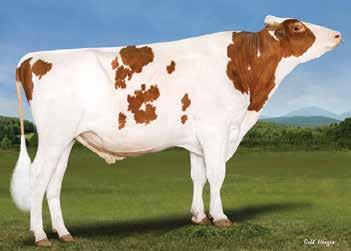

The #1 Red and Polled Bull in the breed for Type!

PTAT: +3.28

FUA: +3.28

RUH: +3.36

RUW: +3.22

Fat: +.18%

Pro: +.09%

Polled A2/A2

mpressive, well-balanced bull! 1st 8 dams average 4.6% fat! 1st 8 dams average 4.6% fat!

Impressive, well-balanced bull!

Available in SEXED semen!

Available in SEXED semen!

Since Brian always took care of the nances, Kim and the family are guring it out together. They were advised not to make any major decisions about the future of the farm for 18 months. Kim tells the boys to take it one day at a time and tries to do the same.

“Even though I knew he wasn’t coming back, I kept waiting for him to walk through the door,” Kim said. “Reality is hitting now.”

Since Brian’s death, Jennifer is working to expand the Farmer Angel Network, a support group that focuses on rural community outreach. A division called Farmer Angel Network of Western Wisconsin can be found on Facebook.

Kim and the family have made it a mission to celebrate Brian’s life and remember the good times. Even though it was hard to get away from the farm, the family enjoyed vacations to the Wisconsin Dells, South Dakota and Duluth, Minnesota, while the kids were growing up. After chores, Kim and Brian would often go for drives to spend time together, treating themselves to a meal or ice cream.

“God gave us a lot of memories,” Kim said. “I believe Brian is preparing a place for me, and someday, he’s going to come get me. But, I have to be here for the kids right now.”

Dairy product consumption continues to please, and butter was the big story in the U.S. Department of Agriculture’s latest supply and utilization report, according to HighGround Dairy’s Alyssa Badger.

Speaking in the Feb. 19 “Dairy Radio Now” broadcast, Badger reported that butter demand hit 220.9 million pounds, up a whopping 22.5%, the largest value ever for the month, and credited strong domestic utilization, which was up 25.3%. It gained 4.7% from November to December, she said, the rst increase in that period ever, versus the ve-year average of a decline of 22.6%.

Butter exports have been terrible, she said, down 41.3% from a year ago. But, the disappearance numbers “justify the prices we’ve been seeing, and we may even see a revision in the next cold storage report,” Badger said.

Nonfat dry milk utilization, at 199.6 million pounds, was down for the fth month in a row and down 12.1% from a year ago. Quite the opposite story of butter, according to Badger, as domestic usage was down 34.2% while exports were up 0.9%. Inventories were down 21% from a year ago, she said, an eight-year low, because production continues to be weak.

December cheese utilization totaled 1.2 billion pounds, up 1.9% from December 2022, and the third consecutive monthly gain. Total consumption for the year was up 0.3%, smallest annual gain since 2020, when disappearance actually fell, according to Badger. Interestingly, the December dairy products report showed 2023 cheese production was also only up 0.3% from 2022.

Dry whey disappearance, at 72.1 million pounds, was down 8% from a year ago, the smallest December value since 2012, according to HGD, as exports fell 15.6%. Exports were down on an annual basis from April to December 2023, said HGD, but domestic usage was stronger in 10 months of 2023, propping up the annual total, and resulted in an increase of 2.8% from 2022.

Meanwhile, the USDA’s latest livestock, dairy and poultry outlook stated that “domestic demand for dairy products in 2023 was year-over-year higher for most of them. On a milk-fat milk-equivalent basis, 2023 domestic use increased 1.8% over the previous year, in contrast to the 1.1% decrease in 2022. Domestic use on a skim-solids milk equivalent basis increased by 2.8% in 2023, compared to a 0.8% decrease in 2022.”

The outlook reported that “there were considerable increases in domestic use of whey protein concentrate, dry whey, butter, lactose and Americantype cheese in 2023, relative to 2022. However, do-

mestic use for other-than American-type cheese and dry skim milk products decreased.”

The 2024 dairy herd size forecast was revised up 5,000 head, totaling 9.355 million for the year, due to higher expected milk cow numbers in the second half. This small increase in the number of cows is attributed to higher than expected milk prices early in the year, as milk production usually responds to changes in milk and feed prices with a lag of several months.

Even with the higher forecast for milk cow numbers, they are expected to be lower than 2023. Recent slaughter trends, together with tight replacement heifer inventories and high reported prices for dairy heifers, suggest a year-over-year decline for the dairy herd in 2024 despite lower expected feed costs, improved milk prices and robust demand for dairy products. The forecast yield per cow was reduced by 20 pounds to 24,395 pounds based on recent data.

The week ending Feb. 3 saw 60,000 head go to slaughter, down 100 from the previous week, and 5,700, or 8.7%, below a year ago. Year-to-date, 275,700 head have been culled, down 62,900 head, or 18.6%, from a year ago.

The outlook pointed out that dairy cow slaughter for the rst three weeks of 2024 continued the downward trajectory from the second half of 2023, with the reported weekly slaughter rates among the lowest observed for this period of the year (lower than the 20-year average), but this may reect slaughter schedule reductions due to winter weather in late January.

The StoneX Feb. 15 update said, “Feed is getting cheaper, but it won’t help dairy producers with their xed costs, which continue to be a deterrent to any sort of on farm enthusiasm.”

The USDA estimated 2024 U.S. corn plantings at 91 million acres in their ag forum commodity outlook this week, down from 94.6 million in 2023. Yields are initially seen at 181 bushels per acre, with production at 15.040 billion bushels and carryout at 2.532 billion.

Soybean acreage came in at 87.5 million acres, up from 83.6 million last year. Yields are seen at 52 bushels per acre, with output at 4.505 billion bushels and carryout at 435 million.

Checking nances, the Feb. 9 “Daily Dairy Report” stated that USDA distributed record-level payments via the Dairy Margin Coverage and Dairy Revenue Protection programs in 2023.

“Smaller dairies have regularly used the DMC program, which has provided greater premium subsidies to farms producing 5 million pounds or less of milk, about 200-225 cows,” the DDR said. “Coverage levels have ranged from $4-$9.50 per cwt. However, any farm could have enrolled in DMC and re-

ceived catastrophic coverage ($4 per cwt) for a $100 administrative fee.”

Information on 2024 enrollment from the Farm Service Agency has yet to be released, according to the DDR.

CME block cheddar cheese, after dropping 8 cents the previous week, crept back to $1.5850 per pound Monday, but closed Valentine’s week at $1.48, losing another 9 cents, lowest since Jan. 19 and 40 cents below that week a year ago.

The cheddar barrels hit $1.60 Wednesday, then reversed direction, but closed Friday at $1.6075, up 3 cents on the week, 6 cents above a year ago and an inverted 12.75 cents above the blocks. Sales totaled 16 of block and eight of barrel.

HighGround Dairy’s “Monday Morning Huddle” warned, “Despite the U.S. price advantage to global markets, industry contacts report that future international sales are slow. Further, market participants continue to talk about the impact of the new capacity coming online later this year, with some concerned about an oversupply situation.”

Dairy Market News reported that cheese demand ranges from steady to seasonally quiet. Midwest cheesemakers are focused on building inventory as spring holiday demand draws closer. Some plants say milk availability is not where it would be expected in mid-February and spot prices under-Class had yet to be reported. Some do not expect them to return in the near-future, DMN said. Spot prices are holding in a tight range at or just over Class III, while last year during week seven, they were $10 to $2-under Class.

Western retail cheese demand is steady to light. Manufacturers and distributors note food service demand is strengthening and export demand is steady. Milk volumes are tighter, but spot loads are available. Plants report steady cheese production, and a few say near term inventories are tight, according to DMN.

StoneX said, “The July U.S. retail price of cheddar cheese was higher than expected at $5.72 per pound, up 18 cents from December, but down 22 cents from January last year. We should see some downward pressure on retail prices given the weakness we’ve seen in the spot cheese market. Comparing cheddar cheese to other food prices, it comes in dead last when looking at the percentage change since January 2021. Again, we should see a correction, and it is down signicantly from the highs in late 2022. But, consumers are still likely reconsidering buying the extra bag of cheese given the elevated retail prices from pre-pandemic levels.”

Cash butter closed Friday at $2.75 per pound, up 6 cents on the week and a hefty 37.50 cents above a year ago, with 17 sales reported on the week.

Midwest butter contacts continue to report bullish expectations, DMN said. Inventories are available but only if buyers are willing to pay premiums. Customers continue to say 82% milkfat (unsalted) loads are notably tight. Butter plants are focused on spring/fall demand inventory building. Plants are running at or near capacity as cream offers are abundant and expected to remain so the rest of the month, when Class II manufacturing moves into higher gear.

Cream is readily available throughout most of the west for butter makers, DMN said, and they are running busy schedules, working to ensure adequate inventories for spring holiday demands. Domestic demand is steady. Unsalted butter loads are tight but available. Distributors relay that inquiries from international buyers have been more frequent recently, and export demand is stronger, according to DMN.

Grade A nonfat dry milk fell to a Friday nish at $1.17 per pound 3 cents lower on the week, lowest CME price since Dec. 28, 2023, and 5 cents below a year ago. There were 16 CME sales on the week.

Comments around weak Mexico demand still persist, StoneX said, and that has likely been putting pressure on spot prices.

Dry whey held most of the week at the previous week’s close of 52 cents per pound. It gained a penny Thursday, only to give it back Friday and close at 52 cents, 7 cents above a year ago, with only one sale on the week at the CME.

Cooperatives Working Together member cooperatives accepted eight offers of export assistance this week from CWT that helped them capture sales contracts for 853,000 pounds of American-type cheese and 42,000 pounds of whole milk powder. The product is going to customers in Asia, Central America, the Caribbean and Middle East-North Africa, through June.

The sales raise CWT’s 2024 exports to 16.5 million pounds of American-type cheeses, 6.9 million pounds of whole milk powder and 842,000 pounds of cream cheese. The products are going to 13 countries in four regions and are the equivalent of 209.3 million pounds of milk on a milkfat basis. Over the last 12 months, CWT assisted sales were the equivalent of 914.6 million pounds of milk on a milkfat basis.

Tuesday’s GDT Pulse saw 4.35 million pounds of product sold, down from 4.4 million Jan. 30, with 98.8% of the total offered sold. There was 50,706 million pounds less instant WMP and 4,409 pounds less regular WMP sold versus the last Pulse. Prices were up from the last Pulse but were down from the last GDT.

Singapore Exchange futures Friday morning were pointing to the rst expected decline in GDT value in the last 11 events for the Feb. 20 event, according to StoneX.

In politics, the USDA is considering more than 12,000 pages of testimony, following the Federal Milk Marketing Order hearing and must now formulate its plan for FMMO modernization.

The National Milk Producers Federation said it is doing what it can to “ensure that proposal best reects the interest of dairy farmers and their cooperatives,” according to two NMPF economists in a recent “Dairy Dened” podcast.

“The key to successful modernization is a comprehensive approach that addresses the complexity of federal orders in a way that respects the entire dairy industry while keeping in mind that orders most fundamentally must work for farmers,” said Dr. Peter Vitaliano, vice president for economic policy and market research, and Stephen Cain, senior director for economic research and analysis at NMPF. “That’s always been the bedrock principle behind NMPF proposals on areas ranging from returning to the ‘higher-of’ Class I mover to updating milk composition factors.”

“What separates National Milk’s proposals from processor groups is more of our holistic approach,” Cain said. “You can’t look at the federal order system having not been updated in 20 years and not address all facets of the industry, right? You can’t say in good faith that Class I differentials need to be updated because costs have gone up without also conceding the fact that make allowances need to go up for the same reason. So, we took that holistic approach. That is going to help move the industry forward together.”

U.S. milk production is steady in the Eastern region and steady to strong in the West, according to DMN’s weekly update. California handlers noted year-over-year production has been at or above 2023 levels. However, some manufacturers relayed limited ability to take additional spot loads. Midwest

Early Consignments Dairy Cattle

COMPLETE TIE STALL HERD DISPERSAL (40) Holsteins including (7) Springing heifers and (33) cows. Current bulk tank avg is 63 lbs milk, 4.9F, 3.4P, 200 scc. Included in the average is 25% Jerseys that will not be selling. Cows are all home raised, sired and bred AI through Select Sires. TMR fed, let out for exercise regularly, fully vaccinated. All throughout the herd are very good udders, feet, and legs!! Overall a young herd with a lot of cows in 1st and 2nd lactation!! Zimmerman, Riceville IA

Complete Dispersal #2

(15) Holstein & Jersey cows. All stages of lactation. Bred to Angus bull. Milked and housed in tie stalls, not pushed for production. Athens

Complete Dispersal #3

(10) Holstein dairy cows. 6 fresh in the last 90 days, 2 bred back and 2 dry cows. Outside daily, vaccinated, not pushed for production. Cashton

(8) Registered Jersey cows. All stages of lactation including several extreme fancy just fresh 3 year olds!! Milked and housed in tie stalls plus free stall adapted and let out every day. Westby Registered Guernsey springing heifer

New Lumber- Sells at 9:30

(49) 2x6x20 (61) 2x8x20 (26) 2x10x20 (3) 2x12x18 (36)

2x4x12 (23) 2x10x8 (24) 2x6x8 (13) 2x4x10 (3) 2x10x6 (12) 2x12x20 (44) 2x12x16 (121) 2x8x18 (37) 2x10x18 (70) 2x6x18 (23) 2x12x14 (84) 2x6x16 (53) 2x10x14 (90) 2x8x12 (70) 2x10x12 (94) 2x6x14 (92) 2x8x14 (54) 2x10x16 (144) 2x8x16 (81) 2x6x10 (146) 2x6x12 (38) 2x10x10 (69) 2x8x10 (220) 2x4x8 (5) 2x12x8 (36) 2x8x8 (36) 2x6x6 (11) 2x8x6 (218) 2x4x4. Lumber will be selling by the piece times whatever is in a bundle. All new lumber that doesn’t qualify for truss building specifications.

Semen Tank & Semen Sells at 11:00

Canister 1 (2) 7H291 Celebrity (2) 7H4211 Majic (2) 7H1128

Starfire (2) 7H235 Toystory; Canister 2 (5) 14H1160 Winken (4) 14H1224 Brock (1) 14H1928 Shallet (2) 198H0013 Juror Ford (2) 14H2586 Sailor (3) 14H1933 Mystery; Canister 3 (1) 7H2716

Glamour Bell (1) 7H3245 Quest (1) 7H3436 Kemper; Canister 4 (1) 7H3340 Choice (2) 7H4161 Rick (2) 7H4126 Saffron; Canister 5 (4) 1H6721 Hosea (1) 1H5045 Lynch (2) 9H1878

Windsor; Canister 6 (5) 566H1209 Add Up (5) 200H4779

Buckeye (4) 99H6145 Barry (10) 566H1261 Jo Dandy (4) 200H5378 Java (5) 200H Firestorm (2) 200H4754 Offroad; Tank is International Cryogenics IC20R

MARKET REPORT:

Big enough to make a difference, small enough to care!

today!

springing heifers selling mostly $2,000-2,400. (13) Holstein heifers bred 3-4 months @ $1,950 per head. Open Holstein heifers mostly $1.70 - 2.00/lb. Heifer calves $200-250 per head.

Breeding bulls $1,300-1,800. Top $2,375 and $2,200. Market bulls $1.07-1.25. Beef cross bull and hfr calves $600-765. Hol bull calves $450-600. Choice and prime Hol fed cattle $1.54-1.60. Top $1.62. Another large hay sale with close to 1000 bales. 3x4x8 Alfalfa $200-260/bale. 3x3x8 alfalfa $110-170. Rounds and squares 1st crop grass $70-90. 2nd and 3rd crop grass $90-130. 3x4x8 western orchard grass $170-210. All hay sold by the bale. Thank you all buyers, sellers, and truckers for your continued support!!

LA FARGE, Wis. — While consolidation continues to trend in the dairy industry, one dairy cooperative is sticking to the values it started with over three decades ago.

Organic Valley brought 84 farmers to the member-owner cooperative in 2023 and is looking to add more in 2024.

Offering a market for new members is part of a threelegged stool, according to Shawna Nelson, executive vice president of membership for Organic Valley. The ability to offer a market to new farmers is a collaborative effort between the membership, sales and marketing teams, supported by the operations team in the middle, which keeps the gears turning.

“It’s amazing work from one end of our supply chain to the other to be able to have a market for that milk,” Nelson said. “Our commitment and mission for the last 35 years has been around saving small family farms.”

Of the 84 farms that were onboarded with the cooperative in 2023, some were already shipping organic milk and simply switched markets. Others had been in the process of transitioning from conventional to organic dairying and their opportunity to get an organic market aligned with the certication timing.

Over 20 of the farms were not shipping milk at all and were able to either begin a start-up operation

or turn the lights back on after pushing the pause button for a while.

Brandon Probst became a member of the cooperative in 2023 after completing a transition from a retiring farmer. Probst and his wife, Philomena, have a 70-cow herd near Rib Lake. Probst took ownership of cattle 12 years ago and operated in partnership until 2023 when he became an ofcial member.

Probst took over the farm after participating in an apprenticeship program with support from Organic Valley as well.

“Not everyone is going to pass their family farm onto a family member,” Probst said. “There’s no other cooperative out there like Organic Valley.”

Though the age and situation of the coopera-

tive’s member-owners varies, the dedication to the small family farm remains consistent among members, Nelson said.

“We maintain an average of 80 cows per farm, so we’re talking about small, organic family farms,” Nelson said. “That’s important to us. When we’re onboarding a new farm, we’re talking about those pieces and making sure the value placed on a family farm happens with our new starts just like it has with our 1,600 farms that are part of our cooperative today.

We

The addition of producers is part of a trend that has been growing for a long time.

In 2022, a project in the Northeast, where a number of farms were losing their market, enabled Organic Valley to provide a market to farmers who would have otherwise had to close their doors.

Looking ahead, Nelson said they are seeing continued growth opportunities in the organic market.

The cooperative was structured to provide stability in pay price, supply management and a farmer voice for member-owners.

milk check because I already know what it’s going to say. If you can do the math, then you know what your check is going to be, which is great.”

There are times I don’t even have to open the milk check because I already know what it’s going to say. If you can do the math, then you know what your check is going to be, which is great.”

“Pay price and stability of the pay price was one of the reasons this cooperative was founded,” Nelson said. “Being able to know what you are going to expect throughout the course of the year is a challenge that farmers face and something we have a specic mechanism in place to address.”

Supply management programs are also in place to help the cooperative accurately predict supply so it can ensure market demand for products. The other piece of the cooperative structure that Nelson said is important is giving their members a voice. The farmers served on the board of directors and are tackling challenges they face with the committees tasked with those challenges.

BRANDON PROBST, DAIRY FARMER“To me, one way to solve challenges is to have farmers at the table talking about what those challenges are and tackling them together,” Nelson said.

While Probst does not always have time to attend meetings, the value of his options is not lost on him.

Having a reliable pay price has been important to Probst, he said.

“If we kind of know our production, then we can sit down and pretty much determine our milk check for the year,” Probst said. “There are times I don’t even have to open the

“Being a member, you can see the meeting minutes and what they were discussing two months ago,” Probst. “Who else is offering that? Now that we’re full members, I have voting power too.”

• Average SCC 89,000

• Production 27,630# M

• % Fat 4.4

• Fat 1,210# F

• % Protein 3.3.

• Protein 932# P

• All AI breeding and AI sired with low SCC bull producers

• Closed herd since 1977

• Regular hoof trims

• Vaccinations up to date

If you’re looking for some really nice cows that are registered also, be sure to attend the sale. Rockin Conrad has daughters in the herd +.23% Dvation Butter – high butter fat producing daughters. For more information, please call Brad at 320-266-0724 or the barn at 320-732-2255

ALBANY, Minn. — Every year, Luke Herkenhoff and his family are faced with a recurring issue. Their silo that stores the farm’s silage freezes, causing extra work for the family.

“Every year we run into this trouble,” Herkenhoff said. “We look for more preventive measures, because if you run the silo through the cold, it seems like something always breaks that costs more than just feeding out of the silage bag. Plus, it’s never fun to be up there in the cold.”

Herkenhoff farms with his two sons, Tony and Sam, and his parents, Duane and Linda, who help on the farm. Together, they milk 44 cows in tie stalls and crop 220 tillable acres to grow corn, alfalfa and small grains.

SUBMITTED PHOTO

This year, the silage froze during the cold weather around Jan. 21. The silo was out of commission for about a week, which is normal for every time it freezes over.

“We quit feeding out of the

silo and fed out of the bag,” Herkenhoff said. “It’s a lot more labor intensive. Sometimes I will push the unloader, and other years, I’ll say we just have to quit using the silo.”

Since all feed for the milk-

ing cows is run through a mixer, they take silage from the bag — after picking through it and taking the less frozen siTurn to

Ft. Atkinson, Iowa • 563-534-7513

Small Squares

2nd crop $150-290/ton 2 loads

Large Squares

1st crop $135-165/ton 5 loads

2nd crop $155-175/ton 2 loads

3rd crop $150-185/ton 4 loads

4th crop $150-170/ton 2 loads

Straw $155/ton 1 load

Rounds

1st crop $130-195/ton 11 loads

2nd crop $130-190/ton 14 loads

3rd crop $110-175/ton

4th crop $130-190/ton

Small Squares

1st crop $220/ton

Grass $255/ton

Large Squares

2nd crop $150-155/ton

3rd crop $137.50-230/ton

Grass $130-137.50/ton

Mixed $140-142.50/ton

Straw $75-130/ton

Large Rounds

1st crop $135-165/ton

loads

loads

Grass $125-185/ton 9 loads

Rye $80/ton 1 load

CRP $30-80/ton 5 loads

Corn stalks $45-70 3 loads

2nd crop $140-177.50/ton

3rd crop $150-192.50/ton

Grass $82.50-235/ton

Mixed $140-175/ton

Straw $160/ton

Corn stalks $30-57.50/ton

From the stress of the lockdowns that were in place during the coronavirus pandemic in 2020 was born an idea that has enabled one English dairy farm to ourish.

Katherine Jenkinson, along with her parents, Andrew and Rebecca, and brother, Tom, operate Fordsyke Farm in Carlisle, a town in northern England just 10 minutes from the Scottish border.

Fordsyke Farm is home to 160 head of both pedigreed and crossbred cows. Included in that group is Katherine’s herd of 30 purebred Jerseys. Cows are milked in a swing-12 herringbone parlor and average 40 pounds of milk per day with tests of 6.1% butterfat and 4.04% protein. The farm consists of 206 acres of grassland.

“We have a low input, low output system,” Jenkinson said. “The cows have a grassbased diet from April through October, depending on weather. Throughout the winter, the cows get silage, wholecrop barley and an 18% protein parlor cake.”

The idea for on-farm milk sales rst came to Jenkinson in March 2019.

“I was working as a tutor and assessor at Newton Rigg College in Penrith,” Jenkinson said. “One of the rst things we did with the students was look at farm diversications. One of the student’s family had put in a vending machine on their farm, and I started thinking maybe I could do this at home.”

A year later, Jenkinson returned home and found herself struggling as the rst lockdown commenced.

“I was feeling down about everything,” she said. “We were in lockdown. Mum had the coronavirus, so I could not go to work, so I wasn’t earning any money. But that vending machine idea had been in the back of my mind. It just felt like the time was right to do it.”

Jenkinson said she quickly realized that nancing the idea would be difcult on her own. She developed a business plan, applied for a loan from a small business lender and was awarded the money to move forward.

The necessary machines — one for dispensing glass

bottles and one for dispensing milk — were ordered in August, and by November, Jenkinson was selling pasteurized, non-homogenized Jersey milk from her on-farm vending machine.

In addition to selling uid milk, Jenkinson operates an on-farm store that features four avors of milkshakes and a rotation of 30 avors of ice cream as well as soap made from milk produced on the farm. Jenkinson outsources the processing of the ice cream.

In the early days, the vending machines were successful, but Jenkinson has noticed a slowdown since the lifting of restrictions. Jenkinson said that in the last year, they have sold an average of 50 liters per day during the summer months, with the highest days selling as many as 100 liters. Milk produced by Katherines Jerseys is A2A2, making it a popular choice for people with lactose intolerance.

“The vending machines were a way for people to get out of the house and socialize while staying within the guidelines of the lockdown,” Jenkinson said. “However, now that things have resumed as normal, we have noticed a decrease in demand for people supporting small and local businesses.”

Turn to DAW | Page 13

Jenkinson said she is considering how to mobilize her milk sales, taking a vending machine to shows, fairs and parks, giving more people the opportunity to discover fresh Jersey milk.

The weather has presented a challenge with sales this winter, Jenkinson said, with gale-like winds and freezing temperatures.

The northern part of England is known for being wet and cold but has been unpredictable recently, Jenkinson said.

“The weather is one of our main challenges,” she said. “Once it starts raining, it sometimes forgets how to stop. Last year, we had a wet spring and just wanted some sunshine. Then, we had eight weeks of no rain, and the silage grass burnt off.”

The area around Carlisle is heavily populated with dairy farms, roughly 150 ranging from herds as small as 60 cows to as large as 1,200 cows. The management styles of the neighboring farms are diverse, Jenkinson said, ranging from highly intensive models to those practicing New Zealand-style grazing.

“On our farm, we are wanting to improve our soil management each year, so we can get the most out of our grass, getting the best output from our cows,” Jenkinson said. “This includes soil sampling and reseeding elds as needed.”

Jenkinson said her family continues to look for ways to improve the herd to better meet their goals.

“We are wanting to increase the number of crossbreds for more milk production, and we are using Holstein bulls to breed those cows,” Jenkinson said. “We want to keep all of the Jerseys pedigreed, using the best genetics we can.”

In breeding Jerseys, Jenkinson said she utilizes the World Wide Sires mating program to select bulls that have plenty of milk and components behind them, while ensuring she is using bulls that sire strong, deep cows with good feet and legs.

The hardiness of the breed is a benet for the farm’s grazing program, Jenkinson said.

“I love working with cows that have very little foot problems,” Jenkinson said. “Our cows walk a half milk to a eld during the summer, and we

know we don’t have to worry about their feet.”

Much of the Jersey herd traces to Jenkinson’s original cow, Farlam Adas Gloria, and her 11 daughters. There are now 40 head in the herd that include Gloria in their lineage.

“My favorite cow is Katherines Elizabeth Excitation,” Jenkinson said. “She is a very special cow and the cow in my logo. She was the rstborn from Gloria and has given me a heifer every year, bar one when she had twins — a bull and heifer. She was born in 2007 and is happily retired, living her summers in a paddock with some show heifers. Her offspring make up my show team every year.”

Elizabeth’s daughter, Katherines Jenny Ontime, was a perennial show winner for Jenkinson.

“Jenny really put the Katherines prex on the map,” Jenkinson said. “Her daughter, Katherines Matt Amelia, and her granddaughter, Katherines Spanner Man Sophia, have started living up to her legacy, and I am excited to see what 2024 brings.”

Jenkinson’s love of the Jersey cow goes back as long as she can remember.

“My life has been all about Jersey cows,” she said. “There are photos of me as a little girl, feeding cows with Dad in the eld. If I’m having a bad day, I can walk into the cow shed and will be surrounded by cows instantly, making me feel much better.”

lage — and then dump it into the side door of their barn. After the silage is in the barn, they use a wheelbarrow to move it to the conveyer which then dumps it in the mixer.

This process adds an extra hour to both morning and evening chores versus a functioning silo.

However, not all news is bad when the silo freezes. The cows never seem to mind the switch. At times, Herkenhoff said it seems benecial to feed out of the bag because they can pick out more of the ice chunks that negatively affect the quality of the ration.

to the bag. Another perk is that they do not have to struggle to get a frozen bag open when the silo freezes since they feed silage out of the bag to youngstock.

“It’s the same corn silage, so it doesn’t affect the cows, so that’s a good thing,” Herkenhoff said. “We usually chop everything at the same time; otherwise, it would have disrupted the rations. Also, the mixer is able to break up some of the chunks of ice, but we still try to break it up and sort through it when we can.”

This year, Herkenhoff had his 20- by 90-foot silo half gone when the silage froze, and they switched

After the cold weather, it normally takes two days of warmer weather before they can run the silo again. Before starting the silo, Herkenhoff checks the unloader to ensure it will not become damaged when it is turned on.

“This year has been easy to deal with (the silo) because of the warmer weather,” Herkenhoff said.

After the weather warms for a couple of days and the unloader has been safely checked to ensure it is not frozen, Herkenhoff can turn on the unloader and resume use.

“I have learned to just look to prevent anything from breaking and not pushing the unloader,” Herkenhoff said. “Plus, hauling the silage is a good way to warm up if you’re cold.”

CUBA CITY, Wis.

Sam Schneider and his wife, Katie, are adjusting to a different lifestyle with the addition of a robotic milking system on their farm. It was a big leap from where they began their dairy story in 2008 with Sam milking 13 cows.

“I joke that when we started pushing cows through the robot, I gained 91 years of technology in an afternoon,” Sam said. “It’s more management than slinging milkers around.”

Today, the couple milks 90 cows in two Lely A5 robots. The herd is 65% Jersey cows and 35% Holstein cows. The robots began operation in July 2023.

Sam’s parents bought the farm in 1993 and sold their herd in 2006, one month after Sam’s father passed away. Sam attended Southwest Wis-

consin Technical College for two years and then brought cows to the farm with his own herd of 13 cows.

Sam gradually grew his herd and got the 40-stall stanchion barn equipped to milk again. In 2016, they built the freestall barn and added 20 cows. For the next seven years, cows were housed in the freestall barn and walked 800 feet one way down to the old stanchion barn to be milked.

“We walked them up and down that hill every day,” Sam said. “We milked two and a half barn fulls of 90-100 cows. It was getting old.”

When he constructed the freestall barn, Sam built it on a hill so he could capitalize on summer breezes and position it far enough from the road so a parlor could be added and then robots when the time came.

The decision to go with robots was largely due to labor concerns.

Being so close to the University of WisconsinPlatteville, most of his hired help came from college students. When the campus shut down due to the pandemic, all of those

students went home, and Sam and Katie were left with a labor void. Sam said they eliminated 90% of the labor force by adding robots.

Six months into milk-

ing with robots, production is up 8 pounds per cow per day, and cows are averaging 3.1-3.2 visits to the robots per day. Although Sam does not save many man-hours,

the work is different and more exible. Better than that, though, is how much time the cows are saving.

Turn to SCHNEIDERS | Page 17

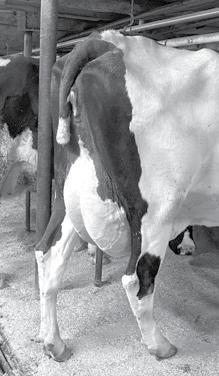

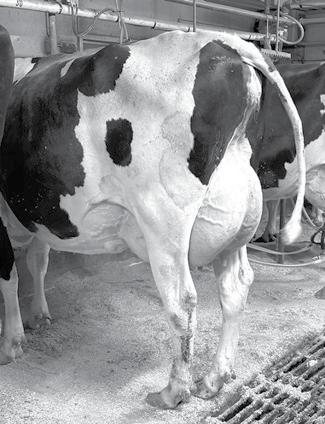

ABBY WIEDMEYER/DAIRY STAR

ABBY WIEDMEYER/DAIRY STAR

The 40-cow stanchion barn at Sam and Ka e Schneider’s farm was used to milk their 90-cow herd for seven years before the couple upgraded to a robo c milking system in 2023. The cows walked 800 feet each way from the freestall barn to the stanchion barn for milking before robots were installed in the freestall barn.

“For the cows, the time away from feed, water and bed was about 5-6 hours from the very rst cow to the last cow per day,” Katie said. “It was a very inefcient process.”

As a veterinarian, Katie does the herd health and foot trimming. Being able to monitor the cows from her phone at any time of day has been benecial, she said. At the end of the day, she and Sam can work together to tend cows that have been identied for care earlier in the day.

“It’s nice having all the information on the cows,” Katie said. “We didn’t have any reproduction monitoring on the cows before. That alone has improved us, because we went from no system to this. Now, we have a better pregnancy rate. Production is only going to get better as the repro gets better.”

“We didn’t have any reproduction monitoring on the cows before. That alone has improved us, because we went from no system to this. Now, we have a better pregnancy rate. Production is only going to get better as the repro gets better.”

The couple is not running a footbath, so they keep a close eye on cows’ feet when they are doing herd health work. Katie trims 5-6 cows at a time in a manual chute as needed.

Because cows are fed a pellet in the robot, feed consumption is a big concern when making the transition. While training the cows, energy was pulled from the total mixed ration and put in the pellet to encourage cows to visit the robot. Six months in, the Schneiders are putting some of that energy back into the ration because most cows are visiting on their own.

KATIE SCHNEIDER, DAIRY FARMER

Sam has noticed the importance of healthy feet when utilizing a robotic milking system.

“If they have a sore foot, it just gives them one more excuse not to visit the robot,” Sam said. “So, foot health is huge.”

Daily life has improved for the couple as well. Sam can get calves fed early in the morning while Katie gets the kids ready for the day. Then, Sam and Katie trade off taking the kids to day care. If the calves are fed, Sam can take a break at 7 a.m. and then pick up where he left off when he gets home.

“It’s only going to get better as we calve more in,” Sam said.

JD 2700, 7 Shank ...............................................$14,500

DMI Tiger III, 3 Shank Ripper ...............................$3,300

Pepin Spike Harrow, 5 Section .............................$2,500

USED PLANTERS

White 6700, 12x30, Verticle Fold ..........................$7,500

USED HAY EQUIPMENT

‘00 N-H 1441 Disbine, 15’ Cut ............................$11,900

‘11 N-H H-7450 Discbine, 13’ Cut .......................$20,900

‘15 N-H H-7230 Discbine, 10’ Cut .......................$19,900

Toolcat, Cab, Hi Flow Aux, 202 hrs ..$64,500

‘20 T-870, Glass Cab with A/C, 2 Spd, 1475 hrs $69,500

‘19 T-770, Glass Cab with A/C, 2 Spd, 870 hrs ..$65,000

‘17 T-650, Glass Cab with A/C, 2 Spd, 2700 hrs $49,500

‘19 S-770, Glass Cab with A/C, 2 Spd, 3350 hrs $38,900

(2) ‘21 S-76, 2650 hrs and up ............Starting at $42,500

‘12 S-650, Glass Cab with A/C, 2 Spd, 2500 hrs $46,500

‘18 S-595, Glass Cab with A/C, 2 Spd, 3850 hrs $29,900

‘02 S-185, Glass Cab with A/C, 2 Spd, 3650 hrs $24,900

‘01 773, Glass Cab with A/C, 7000 hrs ...............$16,500

‘97 763, Glass Cab & Heater ..............................$12,000

‘21 Cat 259D3, Glass Cab with A/C, 2100 hrs ....$59,900

‘20 Kubota SVL75-2, Glass Cab w/A/C, 345 hrs $59,900

USED TILLAGE

‘04 W-R Quad X, 46’, 4 Bar Spring Tooth Harrow$19,300

‘04 W-R Excel 38’, 4 Bar Spring Tooth Harrow ...$12,900

WR 2500, 28’, 4 Bar Spring Tooth Harrow ...........$6,950

Case IH 4300, 25’ .................................................$7,500

Glencoe 26’, 3 Bar Spring Tooth Harrow ..............$1,800

‘13 W-R 513 Soil Pro, 7 Shank, Harrow..............$29,500

WR 957, 9 Shank, Harrow ..................................$12,900

(2) ‘03 N-H 1411 Discbine, 10’ Cut ......Starting at $9,900 ‘08 N-H 616 Discmower ........................................$5,500

AGCO 1326 Discmower........................................$3,250

‘20 N-H 560 Rd Baler, Specialty Crop, 4000 Bales$46,500

‘11 N-H BR-7090 Rd Baler, Cornstalk Special, Netwrap.............................................................$23,900

‘06 N-H BR-740A, Twine only ...............................$9,500

NH 688 Rd Baler ...................................................$5,900

JD 336 Baler .........................................................$2,950

‘22 N-H 3223 Rake .............................................$31,900

‘22 H&S AR-2112 Rake ........................................$8,500

‘05 H&S BC12HC, 12 Wheel Hi Cap Rake ...........$8,950

‘20 H&S 5200H Tedder, 4 Basket unit ..................$6,700

USED MISC

‘10 W-R 20’ Stalk Chopper, Nice Shape .............$10,900

‘07 Feterl 10x72 Auger, w/ Swing drive hopper .... $5,950

‘05 Feterl 8x60 Auger, Galivnized .....................$1,750

‘16 H&S S3131 Spreader ..................................$7,950

Gehl 325 Spreader ............................................$4,950

(2) JBM 7X20 Feeder Wagons................Each $4,000

THURSDAY, MARCH 21, 2024

DAIRY SALE RESULTS FROM January 15, 2024

Top Springing Heifer - $2,750

OUR COMMISSION IS ONLY 2.5%!

EVERY TUESDAY: 9 a.m. Slaughter Hogs • 11 a.m. Hay - Straw

These Minnesota DHIA cows are top lifetime production cows in 2023 ranked by dollar value, which is one measure of top herd management. Dollar value weights milk pounds, fat pounds, protein pounds and SCC by their respective economic value.

The dollar value formula is: (0.0197 x milk pounds)+(2.10 x fat pounds)+(2.39 x protein pounds)+[(350 - SCC/1000) x 0.00085 x (milk pounds/100)]

Pipestone Livestock Auction Market, Inc. PIPESTONE, MN

For more information phone: Office 507-825-3306 www.pipestonelivestock.com

As a dairyman, are you looking to improve the way your fresh cows transition, take off, peak and breed back? Looking to improve rumen health, rumen function, overall health, digestion, feed efficiency, and YOUR BOTTOM LINE???

The RECAL line of probio cs is NOT just another probio c on the market. RECAL is a probio c heavily weighted towards be er diges on and u liza on, primarily FIBER DIGESTION. There are a lot of nutrients in your forages that can be u lized by improving diges on.

RECAL is also a probio c that produces more B-vitamins in the rumen of that cow, mainly vitamin B12. B-vitamins are well known to aide in s mula ng appe te, stress, immune system, reproduc on and also very important in rumen diges on. Not all probio cs are the same. There are hundreds of various strains and combina ons.

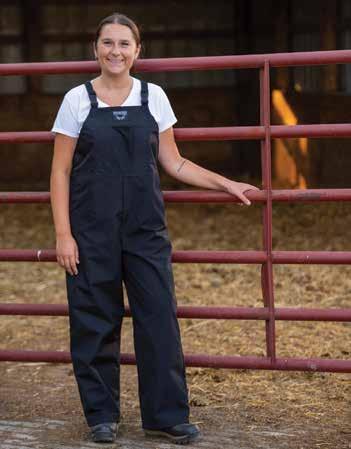

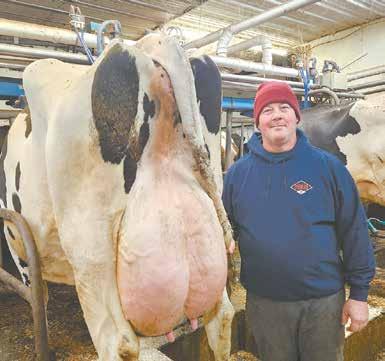

We all read magazine ads about how great products are and think yeah, right. Well, I have tried a lot of these products over the years and like many of you, never really saw any di erence in the cows. I had been watching the RECAL Microbials adver sing for some me and one day I was talking with my friend Je Core, who I knew had been feeding the RECAL for some years. He simply told me to try it and that I would like it. I was at the Keystone Farm Show in York, PA in January of 2023, and Jamie of RECAL had a booth there. Jamie and I talked about the RECAL and what he does to prove the product. I could tell he knew cows and wasn’t just a product pusher looking for a quick sale. So, with the o er he makes, I thought what do I have to lose and told him I wanted to try the RECAL Plus.

The next week Jamie came to the farm and wanted to look at the diet, sta ng that he didn’t want to change the diet, that he just wanted to see the makeup of the diet as every farm is di erent. We walked the cows looking at manure and the forages all the while he was asking ques ons. Jamie told me more about the RECAL and what he thought I should see if I decided to try RECAL. He stated that every farm is di erent and that no product works the exact same way on every farm. There are so many di erences from farm to farm. But, since our herd is a split herd of about 50% Jerseys and 50% Holsteins which are grouped and fed that way, he advised to put only one group on the RECAL and wait on the other so we could see the changes. A er we saw changes, then add the other group to see if we saw the same changes. I liked that idea and so that’s what we did.

The forages we were feeding at the me weren’t the best and we knew that. But the manure consistency was all over the board and we were giving a lot of pink pills for upset stomachs. We started the Holsteins on the RECAL. Jamie told us what to watch for in the cows. Like he says, it is not all about ge ng more milk, it’s about ge ng the li le things. If you get the li le things, the bigger things will come. In three days me, we could see a big di erence in the manure which was more consistent with creamier texture while looking more digested. We were star ng to see stronger heats. So, a er we saw that we started feeding the RECAL to the Jerseys and saw the same results. We didn’t see much change in milk produc on but our components did climb some. As me went on our fresh cows were calving in be er and performing and breeding back be er. The overall cow health improved.

At the me we were feeding XP yeast and a clay binder. Jamie told me that we could pull the XP yeast out but he recommended keeping the clay binder in. He explained that clay binders do not work very well on vomitoxin but do work well on other toxins and that the RECAL Plus would take care of the vomitoxin as he had put it into a lot of herds that were having issues with vomitoxin and the RECAL Plus took care of it. So that’s what we did. He pulled a TMR sample and sent it to CVAS to get a toxin test as he was suspicious of having high levels. The test did come back at 1.8 ppm of vomitoxin. Not a real high level but high enough to cause issues.

We milk about 400 cows near Lawton, PA. We have been using the RECAL Plus now for about a year and we highly recommend it. Like I men oned before, I have tried a lot of products over the years, but RECAL Plus is the rst product that I can honestly say has made a di erence and gave me a bang for my buck. Like Jamie says, go by what the cows say, THEY DON’T LIE!!!!

From the kitchen of Holly LaPlant of Sturgeon Bay, Wisconsin

1 18-ounce roll refrigerated chocolate chip cookie dough

8 ounces cream cheese, softened

1/2 cup granulated sugar

1 egg room temperature

1/2 teaspoon vanilla extract

Preheat oven to 350 degrees. Line a 9-inch square baking dish with parchment paper or non-stick foil. Set aside. Spread a little more than half of the cookie dough onto the bottom of the baking dish and press down rmly, creating an even layer. Using a stand mixer or handheld mixer, beat the cream cheese until light and uffy. Add in the sugar and beat until combined. Beat in the egg and vanilla extract until smooth. Pour the cheesecake lling over the top of the cookie dough base. Crumble the remaining cookie dough over the top. Bake for 30-35 minutes. Let cool completely before cutting into bars. Store in an airtight container in the refrigerator.

From the kitchen of Jade Pinter-Brost of Medford, Wisconsin

1/2 cup nely chopped pistachio or walnuts, divided

1/2 cup butter, softened

1 cup our

1 tablespoon sugar

8 ounces cream cheese, softened

1 cup powdered sugar

1 liter Cool Whip topping, thawed, divided

2 packages Jell-O pistachio instant pudding, 4 servings each

2 1/2 cups cold milk

Heat oven to 325 degrees. Grease a 9-by-13 baking pan. Reserve 1 tablespoon nuts. Using a stand-up or hand-held mixer, combine the remaining nuts with butter, our and sugar. Press our mixture onto bottom of the prepared pan. Bake for 15 minutes and then set aside to cool completely. In a medium bowl, combine together cream cheese and icing sugar; whisk until well combined. Stir in 2 cups of Cool Whip. Spread cream cheese mixture over the cooled crust. Using a stand-up mixer, beat pudding mixes and milk with whisk on low speed for 3 minutes. Spread over cream cheese layer and let stand for 5 minutes or until thickened. Cover with the remaining Cool Whip. Refrigerate for 4 hours. Slice and sprinkle with remaining nuts just before serving.

SELLING 3000-3750 HEAD EACH WEEK, AND OVER 1000 CALVES!

Tuesday, February 27, 2024 • 10 a.m. Expecting 225 head! Feed Cattle to sell after the dairy heifers!

All 3-4

olds. This load of cows

105.8# 5.2BF, 3.66P, scc 140. All TOP cheese merit Jersey and Holstein bulls through Select Sires. Many A2A2 sires. Extensive vaccination program. Owner previously sold many top cows at Premier to very satis ed buyers! Well managed, overstocked dairy. Reputation consignor! Coming from Kemper Dairy, Mauston, WI 30 Holstein Dairy Cows, parlor/freestall, out of a 27,500#RHA. Majority are fresh and milking heavy, with balance bred back to Holstein and Angus bulls. Good framey cows. Well managed overstocked dairy! Coming from Ridgeline Farms, Buffalo County

Expecting our usual run of dairy cows, dairy bulls, springing heifers, short bred, and open heifers.

CALL WITH YOUR CONSIGNMENTS

Always a great selection of dairy cattle at Premier Livestock and Auctions!

DRIVE-INS ARE ALWAYS WELCOME!

PLEASE HAVE IN BY 10 AM TO BE INCLUDED IN THE DAIRY CATALOG

MACHINERY AUCTION

Friday, March 15, 2024

NOW ACCEPTING YOUR MACHINERY!

Bring in equipment by Feb, 28 to be included in advertising. Equipment intake

Weekly Highlights at Premier

Very busy week at Premier Livestock, selling 3,372 head. Full market report on website.

Wednesday sold 242 head of dairy cattle. Market strong, but not the highs we’ve seen the last few weeks, although quality was lower. Two tiestall herds sold. Top loads of dairy cows averaging $2,000 -2,600. Top load of fresh Holstein 2 year olds avg. $2,600. Top load of Jersey fresh two year olds avg $2.427. Top Jersey $2,600. Many other cows $1,700-1,975. Top quality Holstein springing heifers mostly $1,750-2,600. Tuesday 535 feeder cattle sold. Strong trade. Most beef calves $210-330 per #. Holstein strs mostly 140.-220. Bred beef cows up to $2,150. Beef breeding bulls up to $2,350. Newborn Holstein bull calves up to $665. Beef dairy cross calves up to $880 !!! Thank you to all of you who support us and our families!!

Feeding your fields can take a toll on your equipment. Manure is a heavy high stress inducing load that puts high strain on your spreader, not to mention it rusts whatever it touches. That’s why Penta’s Hagedorn spreaders use high strength poly boards, galvanized end and push gets, to stand up to the loads and fight rust.So you can feed your fields for years to come.

‘20

Lift Cap, C&H, 2 Spd, 2,350 hrs ...........$32,500

‘00 Mustang 2050, H/F Ctrls, Dsl, 1550 Lift Cap, C&H, SS, 6,425 hrs ......................$16,000

‘21

Gehl V330, JS Ctls, Dsl, 3300 Lift Cap, C/H/A, 2 Spd, Hydra Glide, 1,224 hrs ....$53,900

‘21

Gehl V330, JS Ctrls, Dsl, 3300 Lift Cap, C/H/A, 2 Spd, Hydra Glide, 1224 hrs ...$53,900

‘18

Gehl RT165, JS Ctrls, 69HP Dsl, 15” Tracks, 2000 Lift Cap, C/H/A, 2 Spd, 950 hrs ..$44,900

‘19

Gehl RT165, ISO/JS Ctrls, Dsl, 15 1/2

All Season Tracks, Lift Cap 1800 @ 35% And 2400 @ 50%, C/H/A, 2 Spd, 1,720 hrs. $43,900

‘17

Gehl RT250, ISO/Dual H-Ctrls, Dsl, Camso

Tracks HXD 450x86x58, Both Standard And Hi-Flow Hyd, 2 Spd, Hydra Glide, 295 hrs, Warranty Till 6-30-26 Or 1000 Hrs .......$48,500

‘22

Gehl RT215, ISO/JS ctrls, dsl, square bar

17” tracks, 3000 lift cap at 50%, C/H/air, 2 spd, Hydra Glide, 1,375 hrs ..............$53,500

‘18

Gehl RT165, ISO JS Ctrls, Dsl, 1650

Lift Cap, C/H/A, 2 Spd, 990 hrs ...........$47,500

‘17 Gehl V270, ISO Ctrls, Dsl, 2700

Lift Cap, C&H, 2 Spd, 3,950 hrs ...........$40,500

‘18

Gehl R220, JS Ctrls, Dsl, 2200 Lift Cap, SS, 4,600 hrs ........................................$23,000

‘17 Gehl R220, H-Ctrl, Dsl, 2500 Lift Cap, C&H, 2 Spd, hrs ..........................$33,500

‘22 Gehl R220 T-Bar H-Ctrls, 2500 Lift Cap, C&H, 2 spd, 3890 hrs ..................$38,800

Gehl 4625SX, T-Bar Ctrls, Dsl, 1350

Lift Cap, SS, 3300 hrs .................$15,900

NH L225, ISO/Hand Switchable Ctrls, Dsl, Standard And Hi-Flow Hyd, 2500 Lift Cap, C&H, 2 Spd, 2,460 hrs..........................$29,800 ‘20 Deere 332G, ISO/Dual H-Ctrls, Dsl, 3600 Lift Cap, C/H/A, 2 Spd, 975 hrs ..$61,000 ‘06 Bobcat MT52, 20HP dsl, tipping load 1600 lbs, standard auxiliary hyd, 411 hrs......$22,500

‘13 Kuhn Knight 8124, 2400 Gal, 500 bu, Frt. & Rear Splash Guards .....................$16,500

‘17 Kuhn Knight 8124, 19L X 16.1 Flotation Tires, 2400 Gals, 500 Bu, Frt & Rear Splash Guards, Low Usage .........................$34,500

Kuhn Knight 8124, 500 Bu, 2400 Gal, Bushings Have Been Redone..........$10,500

MANURE

‘23 Kuhn Knight PS280, Accuspread Spinner Beater (Litter), Athne Scales-ISObus, Light Kit, Headland De ector, Auto Chain Oiler ...............................................$116,000

‘09 Kuhn Knight 8132, 425 Truck Tires, 3200 Gal ..........................................$25,500

‘15 Hagedorn Hydra-SpreadExtravert 5440, 684 Cu Ft Heaped, 440 Cu Ft Struck, Sequence Valve Flow Control, Wood Rails, Stone Guard, Endgate .......................$41,500

‘18 Hagedorn Hydra-Spread Extravert 5290, 425 Tires ............................................$36,900

‘12 H&S 370, 370 Bu, Endgate, Upper Beater, Hyd Drive Apro ..................................$13,700

NH 185, 170 Struck Cu Ft, 275 Bu, Upper Beater, T-Rod 67 Apron Chain, Poly Floor, End Gate .........................................$12,900

Jamesway Vacu-Pump, 6” transfer pump, 11L-15 Tires, 540 PTO ......................$3,400

‘19 Gehl AL750, Dsl, Full Turn 6127 Lift Capacity, C/H/A, 3 Spd, Power Q-Tach, Radio, Suspension Seat, Block Heater, 950 hrs.............................................$78,500

‘21 Manitou MLA5-60, C/H/A, 3 Spd w/ Speed Ctrl, Air Ride Suspension Seat, Back-Up Alarm, Bucket Not Included, 200 Hrs ............................................$69,500

‘22 Meyer F700, 693 Cu Ft, 36” LH Side Discharge Conv .......................$57,500

The LW1100 In-LineBale Wrapper features a new EFI engine for fuel savings, and an updated hydraulic system for faster wrapping!

‘89 NH 311, Model 170 Thrower, Small Square Baler ......................................$6,500

3 Point Wheel Rake ..............................$900

Tubeline TL1700SR, Square Bale 3’x3’ Up to 7’ Long, Rd Bale 4’x4’ To 5’x6’, Twin Bale Wrap Stretchers...............................$28,500

Kuhn SR300-12, 12 wheel, tandem axle .....................................$12,500

‘18 Mahindra EMAX 20S HST, 20HP Dsl, 4WD, Hydro, 198 hrs, King Kutter And 48” Tiller Included .........$14,700

MISCELLANEOUS

‘20 Kioti K9 2400, CVT Dsl, Canopy, Hyd Dump, Frt & Rear Windshield, 72 hrs, 245 miles .........................................$16,900

Lorenz 834, 540 PTO, 8 ft wide, 100 HP Tractor ..................................$5,600 ‘20

Edge/Manitou 50504442, 72” Width, 30”

Tall, Trip Bottom, Replaceable Steel Cutting Edge, Hyd Angle, Skid Ldr Universal Mount ................................................$3,800

Woods M5-4, 5’ Width, 3 point mount, Single Tail Wheel ...................$1,250

King Kutter L60-40-SC-FH, 540 RPM, 60”

Rotary Brush Cutter, 3PT Hitch, 40HP$2,350

Cabelas RC2072 Slip Clutch, 3 pt mt, 6’ Width, Frt & Rear Chains, Single Tail Wheel, Made By Woods ....................$2,900

Virnig Pallet Forks ................................$650

‘18 Grouser Tracks, 18 Pads, Fits JD 320G or Loader with a 44.2” Whl base, All new bushings and pins .............................$2,300

Grouser 12” Tracks, Fits Cat 246B ....$1,200 Tracks, Fits 2054, 10x16.5 Tires, Has Rubber Pads .............................$ 1,000

Westendorf 4300, Brush Cutter .........$1,200

TMG Industrial RT120 tiller, 540 PTO, 48”, 3 Pt.............................................$2,800

Steel Tracks 12” Tracks with Rubber Pads & Whl Spacers, Came O 2200R Mustang .. $700 Bale Spear .............................................$500

Pallet Fork .............................................$500