“All

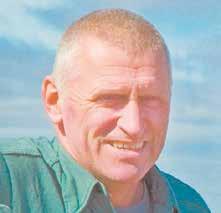

Community pays respects through tractor gathering

By Stacey Smart stacey.s@dairystar.com

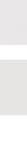

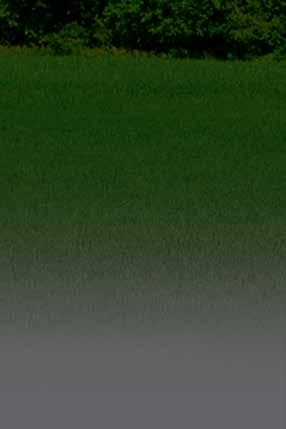

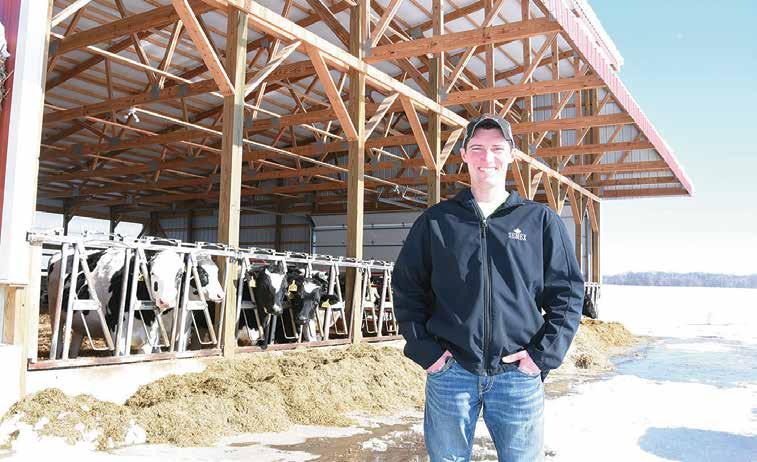

ALLENTON, Wis. — On Feb. 4, more than 350 people gathered at Farmers’ Implement in Allenton to remember and honor a special young man, Curtis Nehm. They came on tractors from ve counties to pay tribute to one of their own and support his family during a time of sorrow.

“The farming community is super supportive, and a lot of people came,” said Nehm’s sister, Cheryl Asmus. “It was awesome. It was what we needed.”

Nehm died in a farm accident Jan. 27 at the age of 27.

On the day of Nehm’s visitation and funeral, approximately 150 tractors, a combine, a chopper, a grain truck and several service trucks lined the road in front of the implement where Nehm had worked since he was 15. They

Powering sports nutrition with dairy Coming together for Nehm

Pederson, Johnson collaborate to get chocolate milk cooler for Fillmore Central High School

By Amy Kyllo amy.k@star-pub.com

HARMONY, Minn. — Music wafts through the halls of Fillmore Central High School, growing ever louder as one approaches the weight room. Inside, a dozen or so students work on strength conditioning using a squat rack, bench press and other equipment.

Bringing dairy back

Fernholzes named 2023 Douglas County Farm Family of the Year

By Emily Breth emily.b@star-pub.com

KENSINGTON, Minn. — Pete Fernholz and his wife, Nicole, play a leadership role in more than 10 community organizations. At the same time, they milk 500 registered Jerseys and farm 1,200 tillable acres of corn, soybeans, alfalfa and wheat at Little Brook Dairy Inc. near Kensington.

The Fernholz family was named the 2023 Douglas County Farm Family of the Year.

“That’s how you make a community, helping with other organizations besides just farming and not expanding your vision,” Pete Fernholz said. “It’s an honor to be named farm family because of all the people who were named before me. I have great respect for them, and they have done a great job in the community.”

February 24, 2024 Volume 26, No. 1

dairy, all the time”™

AMY KYLLO/DAIRY STAR

Turn to FILLMORE CENTRAL | Page 2

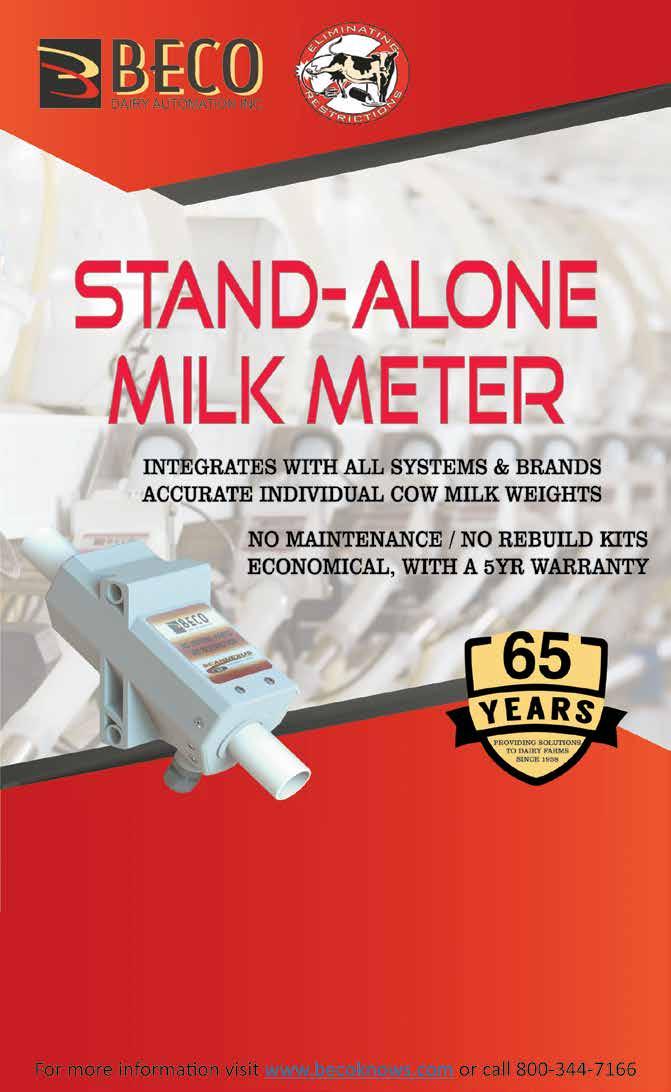

Margaret Johnson (from le ), Sawyer Johnson, Claira Johnson and Andrew Pederson hold milk in front of the chocolate milk cooler Jan. 31 at Fillmore Central High School in Harmony, Minnesota. Pederson and Johnson collaborated to get the cooler and its signage, which were primarily paid with grants from Undeniably Dairy.

PHOTO

SUBMITTED

Turn to FERNHOLZES | Page 7

Pete (from le ), Nicole, Garyvn, Tatum and Riley Fernholz stand together at Garvyn’s gradua on in 2023. The Fernholz family was named the 2023 Douglas County Farm Family of the Year.

PHOTO SUBMITTED

Turn to NEHM | Page 6 Sign up for our Newsletter up for our Dairy St r Milk Break Visit dairystar.com to sign up!

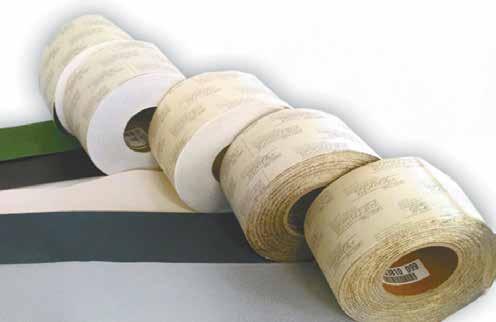

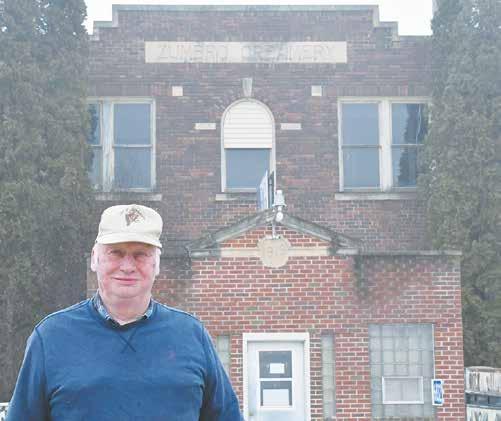

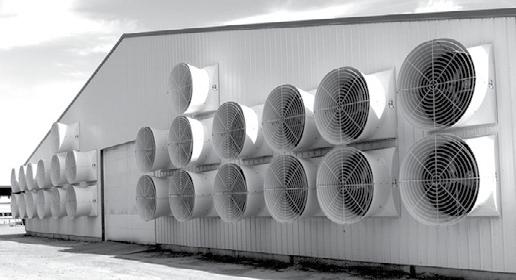

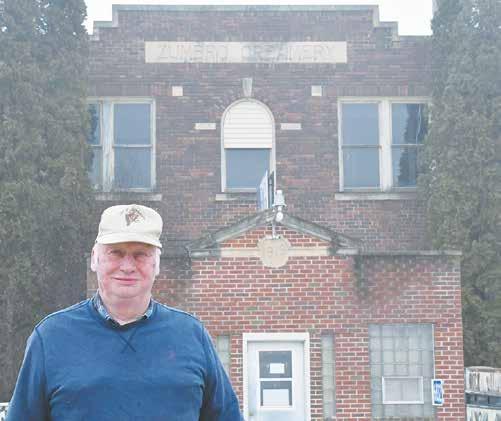

Tractors line the streets Feb. 4 in front of Farmers’ Implement in Allenton, Wisconsin. Farmers from ve coun es paid tribute to Cur s Nehm on the day of his visita on and funeral, riding in on approximately 150 tractors.

Published by Star Publications LLC General Manager/Editor

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce) 320-248-3196 (cell) 320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Editorial Staff

Maria Bichler - Assistant Editor maria.b@dairystar.com

Stacey Smart - Assistant Editor 262-442-6666 • stacey.s@dairystar.com

Danielle Nauman - Staff Writer 608-487-1101 • danielle.n@dairystar.com

Abby Wiedmeyer - Staff Writer 608-487-4812 • abby.w@dairystar.com

Tiffany Klaphake - Staff Writer 320-352-6303 • tiffany.k@dairystar.com

Jan Lefebvre - Staff Writer jan.l@star-pub.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Emily Breth - Staff Writer emily.b@star-pub.com

Consultant

Jerry Jennissen 320-346-2292

Main

ce: 320-352-6303

Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication Sales Manager - Joyce Frericks

320-352-6303 • joyce@saukherald.com

National Sales Manager - Laura Seljan (National Advertising, SE MN)

507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com

Assistant Sales Manager - Kati Schafer (Northeast WI and Upper MI)

920-979-5284 • kati.s@dairystar.com

Jerry Nelson (SW MN, NW Iowa, South Dakota)

605-690-6260 • jerry.n@dairystar.com

Mike Schafer (Central, South Central MN)

320-894-7825 • mike.s@dairystar.com

Megan Stuessel (Western Wisconsin)

608-387-1202 • megan.s@dairystar.com

Julia Merten (Southeast MN and Northeast IA) 507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell) bob.l@star-pub.com

Mark Klaphake (Western MN) 320-352-6303 (ofce) • 320-248-3196 (cell)

Coach Andrew Pederson moves among them, giving advice, spotting and helping them keep on task.

If they want a recovery drink, students can walk over to the milk cooler and grab a low-fat chocolate milk for free.

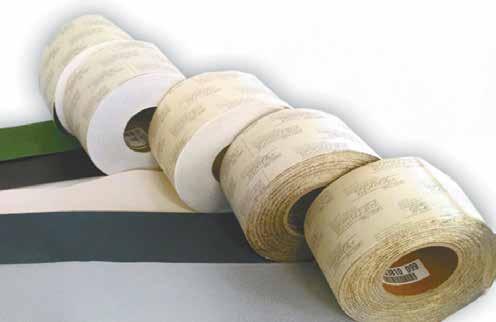

The chocolate milk cooler, which was installed in 2022, is a project funded by Undeniably Dairy grants. Pederson and dairy farmer Margaret Johnson, of Trailside Holsteins LLC, and her husband, Michael, and their children, Sawyer, Levi, Claira, Jacob and Royal, collaborated on the project.

Inspiration for the project started after Pederson attended a clinic for strength coaches. There, he said one of the presenters “raved” about the benets of chocolate milk.

“I just knew I wanted to nd a way to get our kids chocolate milk,” Pederson said.

Pederson said he researched chocolate milk and its benets for student athletes. He said that chocolate milk has the fats, protein and carbohydrates athletes need.

“Research has shown that student athletes ... that are drinking chocolate milk as a recovery method actually gain more strength compared to sports drinks,” Pederson said.

Johnson said the main importance

Kotek

low stand in the weight room Jan. 31 at Fillmore Central High School in Harmony, Minnesota. Pederson said chocolate milk has the fats, protein and carbohydrates that athletes need.

of the project is that it is creating future milk drinkers. She said this project gives kids accessible, high-quality milk that makes them feel good.

“Not only are they drinking it now, which is great, ... but in the future, it’s going to become part of their routine,” Johnson said. “They’re developing really great nutrition habits because milk is just the full package for people.”

Pederson and Johnson, who attend church together, discussed the idea of chocolate milk and came up

with the idea of a milk cooler using an Undeniably Dairy grant.

Pederson said the administration was on board immediately. From there, Johnson applied for the grant, and Pederson worked to nd a place for it at the school.

“Having that as a recovery method, and these kids are able to feel healthy,” Pederson said. “It was an easy sell to the coaching staff and to administration.”

Turn to FILLMORE CENTRAL | Page 5

Page 2 • Dairy Star • Saturday, February 24, 2024 DAIRY ST R ISSN Print: 2834-619X • Online: 2834-6203 522 Sinclair Lewis Ave. Sauk Centre, MN 56378 Phone: 320-352-6303 Fax: 320-352-5647 www.dairystar.com Deadlines The deadline for news and advertising in the Dairy Star is 5 p.m. Friday the week before publication. Subscriptions One year subscription $40.00, outside the U.S. $200.00. Send check along with mailing address to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378. Advertising Our ad takers have no authority to bind this newspaper and only publication of an advertisement shall constitute nal acceptance of the advertiser's order. Letters Letters and articles of opinion are welcomed. Letters must be signed and include address and phone number. We reserve the right to edit lengthy letters. The views and opinions expressed by Dairy Star columnists and writers are not necessarily those of the Dairy Star / Star Publications LLC. The Dairy Star is published semi-monthly by Star Publications LLC, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378-1246. Periodicals Postage Paid at Sauk Centre, MN and additional mailing ofces. POSTMASTER: Send address changes to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378-1246. © 2023 Star Publications LLC Advertising Sales

Of

Invest in Quality ® www.kuhn.com Visit your local KUHN Manure Spreader dealer today! SL 100 SERIES PROTWIN ® SLINGER ® | Manure Spreaders 1,000 – 2,400 gallon capacities • trailer models FAST. CONSISTENT. VERSATILE. Hammell Equipment Chatfield, MN Eitzen, MN Rushford, MN Harmony, MN Adkins Equipment Detroit Lakes, MN Isaacson Sales & Service Lafayette, MN Blue Hilltop Lake Wilson, MN Northland Farm Systems Owatonna, MN Lake Henry Implement Paynesville, MN Dairyland Supply Sauk Centre, MN Woller Equipment Swanville, MN Kunau Implement Preston, IA Bodensteiner Implement Elkader, IA Rexco Equipment Farley, IA Burco Sales Independence, IA

of Waukon

DeeImplement

Waukon, IA

Helmuth

Repair Kalona, IA

Con nued from FILLMORE CENTRAL | Page 1

AMY KYLLO/DAIRY STAR

Jacob

(from le ), Joey Ristau, Connor Hovey, Jackson Hildebrandt, coach Andrew Pederson, Davis Penhollow, Cody Sering, Ella Dahly and Lydia Penhol-

How did your involvement in FFA benet you in your dairy career? First Section: Pages 15 -16, 18 FROM OUR SIDE OF THE FENCE: For additional stories from our other zone, log on to www.dairystar.com Dairy Star • Saturday, February 24, 2024 • Page 3 Herkenhoffs shut down the use of silo Second Section: Pages 10, 15 Albany, MN Zone 2 Zone 1 Miller’s path goes from farm to food in Iowa Third Section: Pages 8 - 9 Dyersville, IA Kids Corner: The Palmers Third Section: Pages 12 - 13 Waukon, IA Historic Rock Dell Cooperative Creamery continues to contract milk, operate store First Section: Pages 25 - 26 Rock Dell, MN Dairy Prole: Jake Mehr First Section: Pages 32 - 33 Farming, MN Columnists Ag Insider Page 10 First Section F Dear County Agent Guy Page 36 First Section Dea Ag P Firs The “Mielke” Market Weekly Pages 6 - 7 Second Section Just Thinking Out Loud Page 38 First Section Ju F Something to Ruminate On Page 37 First Section S Fi Dairy Good Life Page 39 First Section D Fir FFA: Behind the Emblem Third Section: Pages 10 - 11 Howard Lake, MN UMN dairy club visits California farms First Section: Pages 8 - 9 St. Paul, MN Harmony, MN Pederson, Johnson collaborate to get chocolate milk cooler for Fillmore Central High School First Section: Pages 1, 6 Fernholzes named 2023 Douglas County Farm Family of the Year First Section: Pages 1, 7 Kensington, MN

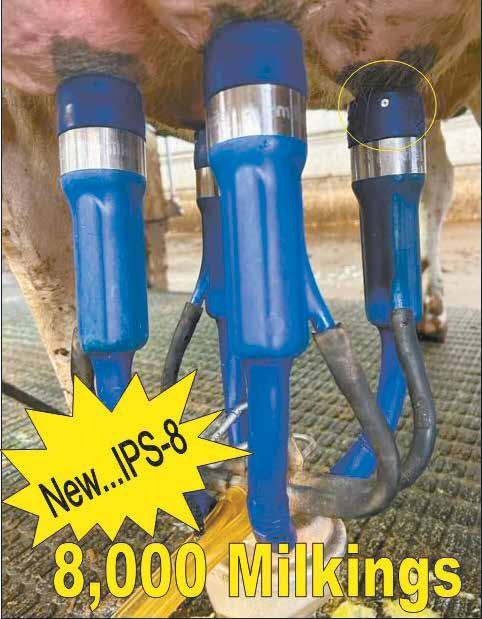

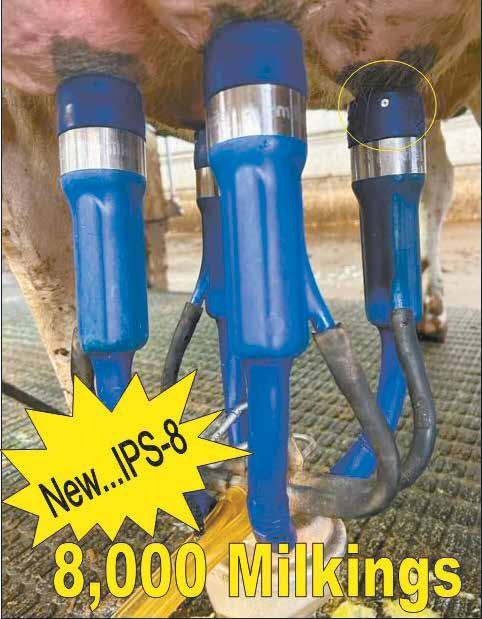

Page 4 • Dairy Star • Saturday, February 24, 2024 FOR MORE INFO - CONTACT ONE OF THESE DEALERS... Lang’s Dairy Equipment, Inc. 2337 Millennium Rd. • Decorah, IA 52101 (563) 382-8722 295 East Main Street • Lewiston, MN 55952 (507) 452-5532 Precision Dairy Equipment 24548 IA-13 • Elkader, IA 52043 (563) 245-2560 Tri-County Dairy Supply, Inc. 4107 N US HWY 51 • Janesville. WI 53545 608-757-2697 Bob’s Dairy Supply 540 E. County Rd. A • Dorchester, WI 54425 (715) 654-5252 Eastern Iowa Dairy Systems 105 3rd Ave. NW • Epworth, IA 52045 (563) 876-3087 Farm Systems 58 Interstate Drive • Melrose, MN 56352 Brookings SD • (320) 256-3276 Leedstone 222 E Co Rd 173 SE, Melrose, MN 56352 (877) 608-3877 24260 Cty. Rd. 27 • Plainview, MN 55964 (800) 548-2540 1720 Freitag Dr. • Menomonie, WI 54751 (866) 467-4717 2580 9th St. E. • Glencoe, MN 55336 (877) 864-5575 Fuller’s Milker Center, LLC 423 U.S. 61 • Lancaster, WI 53813 900 US Hwy. 14 West • Richland Center, WI 53581 (800) 887-4634 Gorter’s Clay & Dairy Equipment 1400- 7th St. SE • Pipestone, MN 56164 (507) 825-3271 Redeker Dairy Equipment W12287 Liner Rd. • Brandon, WI 53919 (920) 346-5576 United Dairy Systems 210 N. Industrial Pkwy • West Union, IA 52175 (563) 422-5355 132 W 11th St. • Monticell, IA 52310 (319) 465-5931 Advanced Dairy LLC 9 State Rd. 29 • Spring Valley, WI 54767 (715) 772-3201 913 W. Main St. • Mondovi, WI 54755 (715) 926-5777 967 West Ave. N • West Salem, WI 54669 (608) 633-6690 2195 Hwy. 23 • Mora, MN 55051 (715) 772-3201 117 West Circle Dr. • St. Charles, MN 55972 (507) 932-4288 1449 Homecrest Ave SE • Wadena, MN 56482 (218) 632-5416 Ask us about our Farm Services EXCHANGE Programs… Liner, Claw, Pulsator and Activity Exchanges. Economical ways to keep your equipment updated and running optimally! IPS-8 NC VENTED SILICONE LINER! NEW 8,000 Milkings! It’s nally here! • Durable and extended life • Cow comfort and speed of milking • Better teat health and higher quality milk • Extended life “The IPS-8 NC liner has completed 8,000 milkings with no issues. We cannot say that about any other liner we have used. It’s a one-piece liner made of a simple design, it cleans well and stays clean throughout the milking process.” - Eric Van Nurden, Van Nurden Farm LLC, Rice, MN FAST, SAFE, CLEAN MILKING FOCUS ON ENERGY SAVINGS Richland Center Lancaster Improving your dairy farm’s energy efficiency can lead to energy and financial savings. Fuller’s Milker Center, Inc. is partnering with FOCUS ON ENERGY® to help reduce your energy costs and improve your bottom line. Visit focusonenergy.com/agribusiness for a complete list of incentive offerings. “Since first purchasing LED barn lights in 2018, we have continued to update our existing barn lighting and seen even more savings on our energy bills.” -Steven Ziegler, Ziegler Dairy Farms, Middleton, WI Focus on saving energy today! ® 20-DFESGF-0086 P g D y US H P Ch 5 Ad 4 66 6 5 dd 1 1 30 20 5 41 PM ©2022 Wisconsin Focus on Energy REDUCING ENERGY WASTE ACROSS WISCONSIN fullersmilkercenter.com 608.647.4488 800.887.4634 Financial incentives are available for: LED lighting for livestock buildings VFDs for vacuum and milk pumps Free heaters Plate cooler s coolers And much more! 800.887.4634 Plate cooler s And much more! fullersmilkercenter.com Plate cooler s And much more! ® 20-DFESGF-0086 P ogress ve Da yman US H Pe Ch 5 Ad 4 66x6 5 ndd 1 1 30 20 5 41 PM Plate cooler s And much more! Dairy Supply Online: www.dairysupplyonline.com etalP relooc s dnA hcum !erom

Con nued from FILLMORE CENTRAL | Page 2

The milk cooler had to be lugged by hand to the basement weight room because there was no elevator.

“Once we got it down there, it wasn’t moving,” Pederson said.

The main challenge to installation was that they needed to wire a new outlet for the cooler.

Johnson said applying for the Undeniably Dairy grant was a simple process.

“I always encourage dairy farmers to do it,” Johnson said. “It’s a way to give back to their community in a way that isn’t going to cost them anything nancially, potentially.”

They decided to add self-feeding shelving inside which was an additional cost. Johnson’s farm covered this expense. These shelves hold more product and keep the cooler organized and appearing to be fully stocked.

“I wanted it to look like a vending machine or if they took it out of a shelf at the grocery store, Kwik Trip or wherever,” Johnson said. “I wanted it to look good.”

As part of a different Undeniably Dairy grant, Johnson also procured funds for custom signage on the cooler. The signage reads, “Falcon Strong Powered By Milk.”

The sign is in teal and black — two of the school’s colors — and also features the school’s falcon head logo. The bottom edge of the sign features a tide of white milk rolling up into a wave on the right side which includes the Undeniably Dairy logo.

“Wherever the cooler may end up someday, ... they know ultimately it came from dairy farmers,” Johnson said. “It looks cool too.”

The cooler is lled with chocolate milk using money from donations and sports fees. The Preston Fire Depart-

ment donated enough chocolate milk to cover the strength and conditioning program for the past two summers. Pederson said they keep the cooler stocked each year until available money runs out.

At Fillmore Central High School, Pederson is the head strength and conditioning coach, an assistant football coach and the health and physical education teacher.

In his role, Pederson shares nutrition information with his students. He said social media has been important for this. He posts on Instagram and X as well as a group texting app.

“On top of just milk, we just preach animal products,” Pederson said.

Pederson said another way he shares about nutrition is through an elective class called sport science. This class has a unit on sports nutrition, including a lab day devoted to smoothies.

Johnson said the chocolate milk project is a great way to advertise milk.

“They’re having a respected, role model adult encourage it,” Johnson said. “Coaches ... have huge potential. ... In Fillmore Central’s case, they’re very respected and great role models for the kids.”

Johnson said that it is great that coaches are emphasizing nutrition. She said this is a change from when Michael attended Fillmore Central High School. Then, they worked out with weights but did not learn about nutrition.

“It’s so cool that they’re joining them together,” Johnson said. “They’re both very important to meet your goals, and it’s pretty cool that dairy can be a part of that.”

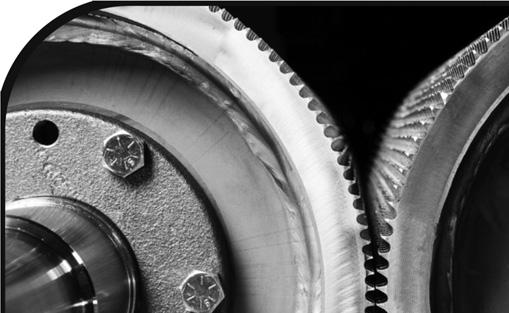

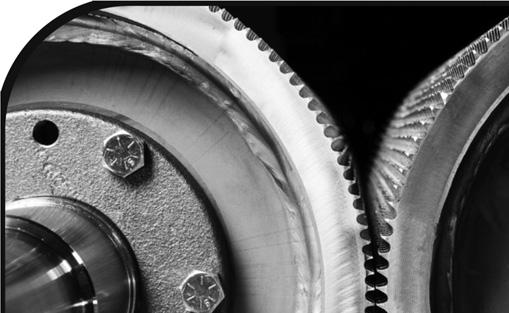

ExclusiveStraight-ThroughDesign ShearProcessingwith S

•Newelectrohydrauliccontrols•50%fastersharpeningprocedure •Newcontrolbox•Newmetaldetector•Newheavy-dutyspout •RedesignedKernelProcessorthatiseasiertoremoveandreinstall

NewDionScorpion300 harvestersinstock

NewDionF64,F61,&F63 rotaryheadsinstock

NewDion860&860HO forageblowersinstock Formoreinfoorpricingpleasecontactoursalesdepartment

W4927 Clearview Rd. Waldo, WI 53093

920-528-1436

920-528-1436

WWW.GIBBSVILLEIMPLEMENT.COM

See us at WPS Farm Show in North Tent #0137

W4927ClearviewRd.,Waldo,WI53093

WWW.GIBBSVILLEIMPLEMENT.COM

Dairy Star • Saturday, February 24, 2024 • Page 5

DionScorpionForageHarvesters ...Thenextgeneration!

TheUniqueStingerSpout UnmatchedCapacity

came in all kinds of brands and colors — from Case IH, John Deere, New Holland, and International to Ford, Massey Ferguson, Oliver, Challenger and Versatile.

“It really meant a lot to our family to see that many people who cared about Curtis,” said Nehm’s brother, Scott. “People looked up to him and appreciated what he did for everybody. He wasn’t just someone they went to from 8 to 5. He answered the phone late at night and on weekends. He was not just an employee at the dealership; he was more than that to a lot of people.”

Nehm could be found behind the parts counter at Farmers’ Implement. His knowledge of machinery parts and people-pleasing mentality made him a sought-after guru for any farmer needing to x something.

“Curtis was the kind of person who would do anything for anyone,” Asmus said. “He went above and beyond to help people nd parts and x stuff. That’s just how he was. People drove a distance to get parts from him because they knew he would get it right.”

Nehm, the son of Bill and Susan Nehm, grew up dairy farming. His family milked 70 cows on their farm near Slinger until 2022. Nehm’s favorite type of tractor was a Case IH, the red tractors he grew up with.

In addition to working full time at Farmers’ Implement, Nehm and his brother owned S&C Ag Services, a custom eldwork business. When the dairy cows left, the brothers remodeled the barn and began buying wet calves and raising steers as well, with about 60 calves on milk. The pair also opened a Dairyland Seed dealership and were planning to start selling seed this spring.

“We spent all day, every day together when he wasn’t at work,” Scott said. “We worked side by side every night, weekend and vacation day. Curtis never forgot anybody — what they needed or were looking for — whether in our business or the parts business. He made it a point to go the extra mile and people knew that.”

Scott Schrefer, agricultural sales representative at Farmers’ Implement, helped organize the event for Nehm, born from an idea of Nehm’s customer and friend, Matthew Beck.

“The amount of support from coworkers, friends, family, customers, the local re department and even past employees of the implement was amazing,” Schrefer said. “Curtis helped

everyone no matter what you were looking for, and he always did it with a smile. Even if customers were having a bad day, he would do his best to make it better.”

Jake Gehring, dairy farmer and longtime friend to Nehm, drove three John Deere tractors to Allenton that day with help from his wife, brother and hired hand. Gehring and his family milk 190 cows near Hartford.

“This was a nice event for the whole community to be a part of,” Gehring said. “It was tough but good to get together and start to heal. His family realized that day how big of an inuence Curtis had on the community and what big shoes he left to ll. He was denitely my go-to guy for parts, as he was for many people.”

Gehring said the event brought a lot of emotions.

“It was a good sendoff and a good way to pay our respects,” he said. “There’s not many of us left in the ag community, and we lost one of the good ones.”

Farmers’ Implement served lunch, and farmers ate together while celebrating Nehm’s life.

“It was a lot of planning and work on the implement’s part,” Asmus said. “We’re very lucky for all the support, and we couldn’t thank anyone enough.”

Farmers’ Implement is also setting up an Honours Inc. scholarship in Nehm’s name at Slinger High School.

“His employer has been fantastic,” Asmus said.

Asmus said her brother’s pleasant personality and witty commentary was what he was known for.

“He was always smiling and laughing,” she said. “He had the kind of laugh you don’t forget.”

Asmus wants people to remember her brother’s helpfulness and positive attitude toward life.

“He was always happy and wanted to better himself,” she said. “He always tried to do new things and wasn’t scared to take a chance. It’s awful now, but you just have to try and keep going. He wouldn’t want us sitting around.”

Asmus said 1,200 people went through the visitation line prior to her brother’s funeral. Nehm will be missed by many in the community as his absence is felt by everyone he impacted.

“I don’t think we even realized how many people Curtis knew or helped,” Asmus said. “For only being 27, he touched a lot of lives.”

Page 6 • Dairy Star • Saturday, February 24, 2024 www.LangeAgSystems.com Specializing in Livestock Equipment and Construction, New and Used Bagging Machines, Silage Bags, Bunker Covers and Grain Storage! BULK OR BAG Wood Shavings S&S Wood Products 35335 Green Street | Independence, WI 54747 800-234-5893 | 715-985-3122 Call 320-352-6303 to place your classied or mail to: Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378. Pulaski Warehouse, Inc. 5777 Quarry Drive • Pulaski, WI 54162 Phone 920-822-3536 • Fax 920-822-5030 www.pulaskiwarehouse.com Your Complete Seed Dealer In Wisconsin BEST QUALITY • BEST PRICES! Alforex Hi-Gest, Low Lignin, Alfalfa Dealer. Brunner Seed, Corn & Soybeans, PWI Seed Corn • Alfalfas • Clovers • Grasses • Trefoil • Hay & Pasture Mixes • Inoculants • Seed Corn • Open Pollinated Seed Corn • Roundup Ready Seed Corn • Untreated Seed Corn • Forage Peas and Pea Mixtures • Seed Oats • Barley • Spring & Winter Wheat • Soybeans • Round Up Ready Soybeans • Rye Grain • Certi ed Organic Seed • Lawn Grasses • Huge Selection of Bulk Garden Seeds • Deer Plot Seeds • Ask for pricing on Conservation Mixes PULASKI WAREHOUSE, INC. 5777 Quarry Drive - Pulaski, WI 54162 2-1/2 Miles South of Pulaski on Hwy. 32 or 2 Miles North of Hwy. 29 on Hwy. 32, Then 1/2 Mile East of Hwy. 32 on Quarry Drive Phone: 920-822-3536 HOURS: Mon.-Fri. 8-5; Sat. 8-Noon SEED DAYS ARE COMING MARCH 27 - APRIL 1ST! Call for NRCS & CRP mixes!

nued from NEHM | Page 1

Con

PHOTO SUBMITTED

The Nehm family — Henry Asmus (front); Cur s Nehm (back, from le ), Sco Nehm, Marcus Asmus holding Leah, Cheryl Asmus, and Sue and Bill Nehm — gather for a photo October 2023 near Slinger, Wisconsin. Cur s died in a farm accident Jan. 27 at the age of 27.

The Fernholzes are active in a number of ways.

They showed cattle in 4-H as children, and now, they lease their own cattle to families who have kids who want to show.

Fernholz is on the Douglas County Agricultural Association board, is a representative for the Minnesota Dairy Herd Improvement Association board and an active member of the Lake Mary Township board.

Nicole works an off-thefarm job and is involved in her family’s church, the Alexandria Technical & Community College advisory board and the college’s foundation hall board, Alexandria Public School’s Champion Academy, the West Central Initiative board, the Lakes Area Professional Women and Andria Theatre.

They both have served as leaders in the University of Minnesota Extension’s Emerging Leadership Program. Along with their activities, the family gives back, donating beef to the local food shelf.

On the farm, Fernholz, and his brother, Mark, and Mark’s nephew, Caden, and eight employees manage the eldwork and milk in a double-10 parallel parlor twice a day. The brothers hired their employees when the Fernholzes’ children, Tatum, Riley and Gavryn, got jobs off the farm or went to college.

“When we rst bought the farm, we were sitting at about 200 milking,” Fernholz said. “Then, we added 60 shortly after and the other 240 about six years ago.”

Their milk is shipped through First District Associa-

The double-10 parallel parlor sits freshly washed a er the morning milking Feb. 13 at Li le Brook Dairy Inc. near Kensington, Minnesota. When the Fernholz brothers bought the farm, the parlor was set up for a double-10 but had a double-6 installed.

tion and is processed into butter and cheese through the Bongards, Fieldgate Cheese and Dinner Bell Creamery brands.

The herd is currently producing a 5.8% butterfat and 4.2% protein.

“Our butterfat is through the roof right now,” Fernholz said. “However, I’m most proud that we are having good luck with our calves. We have about 10 born every week.”

The work has not come without its challenges.

The biggest obstacle the family has faced is one many farmers do — the volatility of prices. Fernholz gave credit to Nicole for the farm being able to continue to cash ow everything more easily.

“Without her dedication and hard work, we probably wouldn’t be farming,” Fernholz said. “She has always been

driven. I could make a million dollars, and she’d still go work. She’s a people person.”

While being busy between work and their community, the couple nds and enjoys quality time with their family, even if it is going on the lake or taking a small vacation.

“In the past, it was harder because of all the different animals, but as we continued to grow (the dairy), we were able

to nd good help,” Fernholz said. “We still don’t get a lot of time away, but it helped.”

Through the years, the couple has been committed to spending time with their kids. The time on the farm and going to shows are things the kids will remember, Fernholz said.

“Stay involved in the community,” Fernholz said. “Make sure you take time to spend with your family even for the small things.”

Family and farming have always been important to Fernholz.

When Fernholz was younger, his father milked 52 registered Jerseys that were sold a week prior to his graduation from high school.

“After high school, I did a brief time in college then came back and started with hogs,” Fernholz said. “We started with 100 at the old farm.”

Soon, a new hog barn was built, and Fernholz was raising 700 sows from farrow to nish. Fernholz also raised elk for about 15 years.

Though the family’s farm site was purchased with plans for a beef feed lot, they continued the operation as a dairy farm. Fernholz said they were inspired to continue the Jersey lineage because their father had Jerseys. Before Fernholz and Nicole were named a farm family of the year, the award was also bestowed on Mark’s family in 2011 for their work with the dairy herd.

“One thing that sets us apart is the amount of Jerseys we have,” Fernholz said.

Dairy Star • Saturday, February 24, 2024 • Page 7

Con nued from FERNHOLZES | Page 1

SARA EISINGER/DAIRY STAR

UMN dairy club visits California farms

Annual trip expands skills, knowledge

By Jan Lefebvre jan.l@star-pub.com

ST. PAUL, Minn. — Nineteen University of Minnesota seniors broadened their experiences in the dairy industry Jan. 6-15 when they took part in this year’s annual Gopher Dairy Club trip to California. The event included visits to nine dairy farms as well as other agricultural sites.

Drs. Isaac Salfer and Isaac Haagen are the co-advisors of the Gopher Dairy Club and served as chaperones for the student-organized trip.

“The trip is really a co-curricular activity to provide educational experiences and leadership opportunities for the students outside of the experiences they would get in the classroom,” Salfer said. “A main reason why it exists is to expose students to the broader dairy industry outside of the Midwest.”

Kate Meyer, majoring in agricultural communication and marketing with a minor in agronomy, and Isaac Rott, majoring in animal science, are seniors in the dairy club who organized this year’s trip.

“As a planner, my goal was to expose the members to dairy and agriculture in California and show them around the cities to see as many attractions as possible,” Meyer said. “As an attendee, I was interested in learning about dairy farming in California, specically cow comfort, how they utilize byproducts in

The students took part in the club’s annual trip

their rations and what regulations they have.”

Rott said he was surprised by what California dairy farmers feed their cows.

“The highlight of the trip for me was visiting a 10,000-cow dairy that fed a variety of interesting food byproducts including pomegranates, bakery byproducts, citrus pulp and nacho cheese,” Rott said. “My biggest takeaway from the trip was that dairy farming throughout the country looks very different from the

6-15.

Midwest, but the passion for the dairy industry remains strong throughout the country.”

The choice of California as the yearly destination for the trip is purposeful, Salfer said.

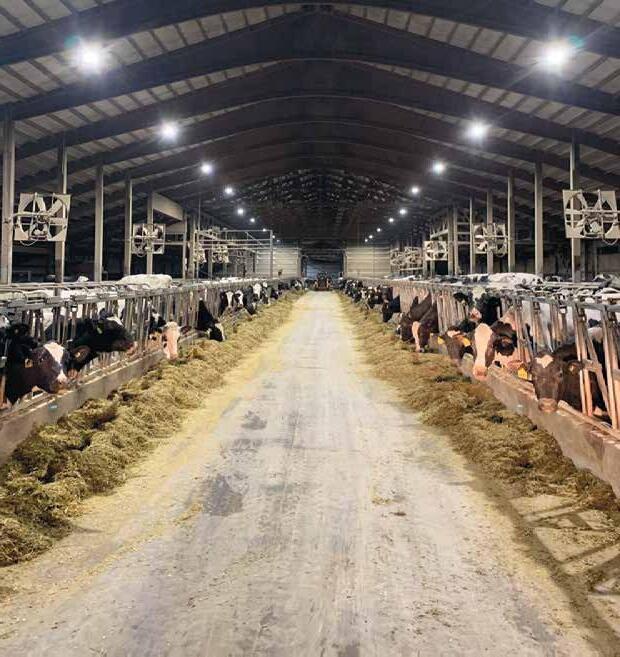

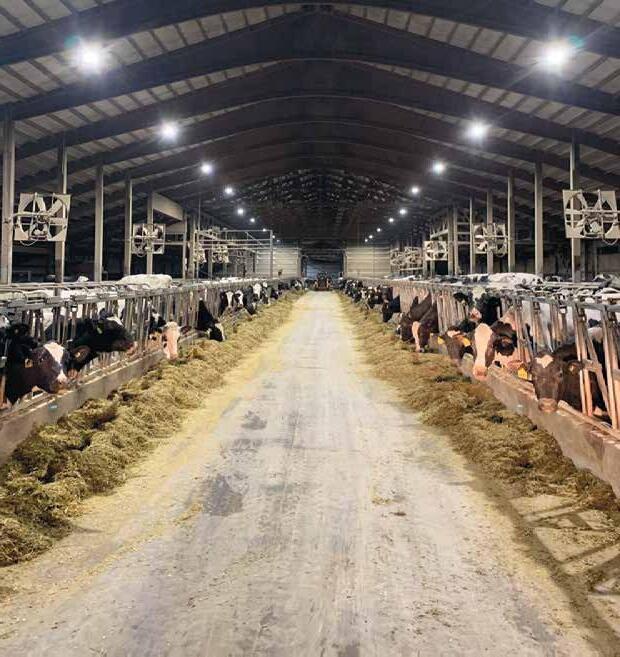

“California, for many years, has been the No. 1 dairy-cow and milk-producing state in the U.S., and there are many differences in how farms are managed there,” Salfer said. “In particular, students were exposed to western-style

dairies with cows housed on dry lots and saw much more variety in feed ingredients being used due to lower availability of corn silage and soybean meal. The club also has some highly active students who didn’t grow up on dairy farms, so for them, the trip was valuable just for gaining experience seeing a variety of types of farms.”

Page 8 • Dairy Star • Saturday, February 24, 2024 You’re working hard today for a better tomorrow. We’re here to lend a hand. With over a century of personal service, we’re ready to help you and all you are working toward. Visit us today at StearnsBank.com/ag or call (800) 247-1922 Member FDIC | Equal Housing Lender Learn More Equipment finance Farm & land lending Full-service banking options Going to the Central MN Farm Show? Visit us at booth #A618

PHOTO SUBMITTED

Turn to UMN CALIFORNIA | Page 9

Nineteen seniors from the University of Minnesota Gopher Dairy Club — Kate Meyer (front, from le ), Ka e Biese, Madelyn Wehe, Elizabeth Manseld, Nicole Koziolek, Michael Moline, Karli Knopf, Kelsey Biel, Leah Transburg, Madeline Penoza and Abby Foss; (back, from le ) Isaac Ro , Nick Flom, Dane Haubenschild, Ma hew Gunst, Luke Borst, Timothy Magdall, Jacob Drummer and Aiden Musser — gather at McEvoy Ranch, an organic olive farm, Jan. 7 in Petaluma, California.

Jan.

That experience includes visiting some of the country’s largest dairies and observing unique challenges that dairy farmers and others in the agricultural industry face across their state.

“Overall production costs are much higher in California because of the $16.50 minimum wage, stricter overtime laws, more expensive input costs and regulations on water usage,” Salfer said. “Nearly all farmers we spoke to discussed the importance of managing water supply and recycling water because of California droughts in 2021 and 2022, which resulted in tight control over how much water from their aquifers can be used.”

Seeing what is happening in California’s agriculture industry can be benecial to farmers in other parts of the country or even globally, Salfer said.

“In some ways, including politically and environmentally, California can predict changes in the dairy industry that could happen in other parts of the country — for better or for worse,” Salfer said. “Some of the ways they have dealt with their state’s labor and environmental laws can be informative to students looking to enter the dairy industry who may experience these issues in the future. Furthermore, by visiting the largest and most diverse agricultural state in the U.S., the trip helped students develop a broader sense of the agricultural industry.”

Besides visiting nine dairy farms and a calf ranch, students also toured an almond processing plant, cheese plant, winery and olive oil farm.

“Seeing the production of commodities that are not grown in the Midwest was cool for the students,” Salfer said.

Students also bookended their farm visits with overnight stays in San Francisco at the beginning of the trip and Los Angeles at the end.

“The primary objective was learning about dairy farming and other forms of agriculture, but the trip is also structured to provide students with other experiences and opportunities for social development within San Francisco and Los Angeles,” Salfer said. “In San Francisco, students visited Fisherman’s Warf and Alcatraz prison, and in Los Angeles, they visited Universal Studios, went to an off-Broadway musical and toured Hollywood.”

During farm visits, students took time to hone their dairy skills.

“We did a lot of work practicing consulting-type skills on the farms,” Salfer said. “Being able to go to a farm that students had never seen before and being able to assess good management practices versus bad management practices also provided value.”

According to the UMN’s website, the Gopher Dairy Club is the largest student-run organization on the Twin Cities campus. The California trip is offered each year to seniors who have shown dedication to the club’s efforts.

“It’s a reward for the students who stay active in the club throughout their time at the university, including participation in our fundraiser and helping with youth contests and camps,” Salfer said.

In a typical year, around 75-80 students are in the club. The club’s biggest fundraiser is a malt stand outside the dairy barn on campus that is run by members during the Minnesota State Fair.

“The club’s activities include running various on-campus events such as the invitational FFA judging contest in fall, state FFA contest in spring, the Gopher Dairy Camp (in summer) for youth and other similar events,” Salfer said. “We also give students opportunities to develop skills in nancial management, agricultural marketing and promotions, and development of knowledge about the dairy industry. The club also puts on its own annual career networking event for livestock-focused students across the university called the Food Animal Networking Evening.”

The California trip is usually chaperoned by dairy club alumni, but as new advisors, Salfer and Haagen chaperoned the recent trip.

“I was a member of the dairy club when I was a student here at the University of Minnesota, and Isaac Haagen was very involved in the Penn State Dairy Science Club during his undergraduate studies,” Salfer said. “We both have a passion for dairy youth, and we chaperoned the trip this year because, as new advisors, we wanted to understand the trip experience for students.”

Some of the fun experiences that the trip afforded were accidental, such as what they saw while driving through San Francisco, Salfer said.

“The students got to see a self-driving car — which was exciting for me too because it is not something I had ever (witnessed) before,” Salfer said. “That was pretty crazy to see.”

Mostly, however, the trip expanded the students’ knowledge of agriculture. Meyer said she appreciated the chance to learn from others in the industry.

“We had a lot of time to sit down with some of the farmers and discuss their experience farming in California, and this was a great learning opportunity,” Meyer said. “Another highlight for me was seeing the reactions of our members who don’t have dairy backgrounds and getting to teach them some of the basics of the industry.”

Dairy Star • Saturday, February 24, 2024 • Page 9

Con nued from UMN CALIFORNIA | Page 8

PHOTO SUBMITTED

University of Minnesota Gopher Dairy Club students walk through the long line of calf hutches Jan. 11 at Maddox Dairy in Riverdale, California. The dairy was one of many agricultural sites visited by the students to gain broader experiences outside of the Midwest.

Call Us At (715) 223-3361 Or visit us on-line at www.cloverdaleequip.com N13835 County Rd. E - Curtiss, WI 54422 HOME OF THE CLOVERDALE MIXER Artex S200 CALL FOR PRICING New Hoosierland 1450 Spreader - CALL FOR PRICING Hoosierland 1300 spreaders $44,500 Artex SB600 CALL FOR PRICING New JBM Mfg T-1200DB Dirt Boss Dumper 12 ton dump wagon CALL FOR PRICE N ikki Bo Box ler | D FA A far mer -ow ner MEANS HAVING A SAY IN YOUR COOPERATIVE A TIVE M EAN S HA V I N G A S AY Y OU R CO O PER OWNERSHIP YOUR ADVT AD A D VT V NL2 NL23 N 23 2 3 0 00 0 06 6 dfamilk.com OWNED BY. GOVERNED BY. HERE FOR: DAIRY FARMERS

Trade enforcement is a priority

At the 100th annual Agricultural Outlook Forum, U.S. Trade Ambassador Katherine Tai briey touched on trade breakthroughs but spent more time on the enforcement of existing trade deals. The Mexican ban on biotech corn imports was at the top of that list. Tai also spoke about the market access concern for U.S. dairy products in Canada. “As trade representative and as a longtime trade negotiator and trade litigator, Canada dairy is personal for me,” Tai said. Tai went on to list the ongoing market access issues for U.S. dairy products in Canada dating back to the North American Free Trade Agreement.

Ag Insider

this Congress. However, we’d love for farmers to start reaching out to their elected ofcials now and making sure that they know that this needs to be top of mind so that when the new Congress is sworn in, we can hit the ground running and start working on legislation right away.” Agricultural groups are seeking H-2A reform and the ability to have a stable workforce.

Dwindling dairy heifer supplies

• 866-514-0982

More than 500,000 farms lost since 1981 Farm policy went through a noteworthy change in the 1970s. Rather than managing supply, the focus was put on maximizing productivity and exporting that production around the world. At the Agricultural Outlook Forum, U.S. Secretary of Agriculture Tom Vilsack shared a story about former U.S. Secretary of Agriculture Bob Bergland of Minnesota. When leaving the position in 1981, this Minnesotan voiced concerns about the societal impact of the sole focus on productivity. “He said we may lose farms, and when those farms are lost, we lose the farm families, and when those farm families are lost, we lose young people going to rural schools, and perhaps, that will have an impact on rural communities,” Vilsack said. Bergland’s prediction was realized with the U.S. losing over a half-million farmers since 1981. “You could take every farmer today in South Dakota and North Dakota, add them to every farmer in Minnesota and Wisconsin, every farmer in Illinois and Iowa, every farmer in Nebraska and Oklahoma, every farmer in Missouri and Colorado, and you’d have 536,000 farms,” Vilsack said. Vilsack said the Biden administration is focused on more new and better markets to give the farmer a bigger share of the food dollar.

By Don Wick Columnist

Despite downturn, farmers remain in good nancial position

Net farm income hit a high in 2022. It dropped off 26% this past year. Federal Reserve Bank of Kansas City Senior Vice President Nathan Kauffman said prots will also be thinner this year. “Despite this expected decline in farm income, I would argue many producers are still in a very, very strong nancial position,” Kauffman said. “Much of this has to do with storing up working capital in these past couple of years when incomes were very strong. We interact a lot with bankers and lenders, and in our conversations last year, we would have banks tell us they would have no borrowers on a ‘watch’ list; that’s not common to have no borrowers on a ‘watch’ list as it relates to potential risk.” If farm income declines again in 2025 with a similar decline in working capital, Kauffman said agriculture will be in a situation very similar to the period between 2016-19. “We know those were not strong years in ag,” Kauffman said.

Expanding trade

U.S. agriculture depends on market access and the development of new markets. “There are a number of different key markets that we should be focusing on,” said Matt Wohlman, vice president of government and industry relations, Land O’Lakes Inc. “Especially, as we look at the geopolitical shift that is going on, how do we build our relationship with markets that provide opportunities for our ag products but are also aligned with our security agreements around the world as well.”

Immigration standoff

A bipartisan immigration bill failed earlier this month. American Business Immigration Coalition director of legislative affairs Jim O’Neill sees this as a critical issue for agriculture. A resolution to this issue is not expected anytime soon. “We’re two months into an election year, and that tends to be a time when people are very wary of taking up issues that they see are controversial, so I don’t think that there’s many opportunities in this Congress, especially with such tight margins with both chambers being controlled by different parties,” O’Neill said. “I don’t see a pathway in

The number of dairy replacement heifers is at a 20-year low. According to a new report from the CoBank Knowledge Exchange, this situation could limit any meaningful growth in U.S. milk production. Due to tight numbers, dairy replacement prices are at an eight-year high. Despite that, heifer values have not kept pace with high production costs.

Supply, demand report released

According to the February USDA supply-demand report, 2024 milk production is expected to total 228.2 billion pounds, a decrease of 0.1 billion from the previous report. The prices for cheese, butter, nonfat dry milk and whey are all forecast to increase with strong domestic demand.

Dairy exports decline from record highs

USDA has released its 2023 agricultural export data. U.S. dairy export values declined $1.5 billion while volume dropped 7%. International Dairy Foods Association President and CEO Michael Dykes said this downturn underscores “a clear need for U.S. trade ofcials to focus on creating new, preferential market opportunities for American producers and food exporters while holding trade partners accountable to rules and agreements.”

Dairy consumption rises

In December 2023, domestic cheese consumption increased year-over-year. Consumption of American cheese rose 6.9 million pounds, and the other-thanAmerican cheese consumption increased 15.2 million pounds. USDA reports butter consumption was up 43.6 million pounds from December 2022. Usage of dry whey was up 82,000 pounds while nonfat dry milk and skim milk powder together declined 14.9 million pounds.

MLBA Hall of Fame inductees named

The Minnesota Livestock Breeders’ Association has announced the four latest inductees to the Minnesota Livestock Hall of Fame. Norb and Judy Sonnek, of Foreston, Minnesota, are being honored for the contributions made to the Holstein dairy business. Retired state veterinarian Dr. Bill Hartmann led the Minnesota Board of Animal Health from 2001-16 and will be recognized at the ceremony. The nal Hall of Fame honoree is Doris Mold, who has served as the superintendent of the milking parlor at the Minnesota State Fair since 1986 and helped create the Minnesota State Fair Moo Booth. The induction ceremony will be March 14 in Roseville, Minnesota.

MFBF names public policy specialist

Loren Dauer is the new public policy specialist for the Minnesota Farm Bureau Federation. Most recently, Dauer was a district outreach representative for Minnesota Congressman Brad Finstad. Previously, Dauer was a legislative assistant in the ofce of Sen. Gary Dahms

Trivia challenge

The pedal bone is the largest bone in a cow’s hoof. That answers our last trivia question. For this week’s trivia, how many slices of pizza does the average American eat every year? We will have the answer in our next edition of Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network of Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

Page 10 • Dairy Star • Saturday, February 24, 2024 717.844.9069 | New Holland, PA Meet the KP Rolls that redefine everything. Unique kernel tearing action with outstanding wear resistance. Premium caliber corn forage. A-1 dairy nutrition. Let’s roll. And roll. And roll. LESS WEAR. MORE TEAR. Call HIXWOOD for all of your Premium Roofing Material Needs! 26 Gauge Snap-Loc 40 yr. Warranty 2.12.24am N14685 Copenhaver Ave., Stanley Phone: (715) 644-0765 Fax: (715) 644-4931 SALES - SERVICERENTAL One Of The LargestLoaderSkid-Steer Dealers In The State Minnesota!Of INTEREST AS LOW AS 0% ON QUALIFYING EQUIPMENT Please see your Farm-Rite Sales Rep for more details FARM-RITE EQUIPMENT, INC. Visit our website: www.farmriteequip.com West Hwy. 12 • Dassel, MN 320-275-2737 • 888-679-4857 1515 West Litchfield Ave. • Willmar, MN 320-235-3672 • 877-484-3211 810 Mayhew Lake Rd. NE • St. Cloud, MN 320-240-2085 • 844-262-2281 19612 US-71 • Long Prairie, MN 320-732-3715

Her favorite place to be

Lake Mills, Wisconsin. Nielsen began buying Brown Swiss six years ago and now owns 12 head.

Nielsen fullls dream to farm while managing two herds

By Stacey Smart stacey.s@dairystar.com

LAKE MILLS, Wis. — Every morning, Madalyn Nielsen walks

down the stairs of her second-story apartment in her grandma’s red brick house to start the workday with her dog, Reed, at her side. The 22-yearold has a lot of responsibility on the farm, but she could not imagine doing anything else.

“I’ve known I wanted to be a farmer ever since I was 3 years old and saw a cow give birth,” Nielsen said.

Turn to NIELSEN | Page 12

“Accurate results, it’s safer and less stressful on the cow.”

What

do you like about the DHIA Pregnancy Tests?

We like the milk pregnancy test because it has accurate results, it’s safer and less stressful on the cow, it’s safer for us, and we have less vet bills.

How long have you been using the DHIA pregnancy test? Since it came out, maybe around 2013. We switched 100 percent to it and haven’t looked back.

Why did you choose to use it? We chose to use it because we didn’t like separating cows every month for pregnancy checks.

What are some other tests you use through DHIA? We do the normal monthly testing, and manure sampling yearly.

Why is testing with DHIA valuable to your dairy?

The value we get out of it is seeing the performance on a cow level, making culling decisions based on SCC, fat, protein etc. Also, the record keeping of cow and heifer events has helped better our management.

Charlie Dicke

Dicke Century Farm • Goodhue, MN • 200 cows

Tell us about your farm. I farm with my dad, Lyle, and mom, Shannon, on about 800 acres. We like trying new rotations of crops and utilize no-till practices. I have a sister in Buffalo, New York and a brother in Idaho dairy farming. We milk in a double-9 parallel parlor, with sandbedded free stalls. We raise our own replacements, utilize Cowmanager on all animals, and sell our milk to First District Association.

DHIA:

Dairy Star • Saturday, February 24, 2024 • Page 11 Sauk Centre, MN Buffalo, MN 763.682.1091 www.mndhia.org

Now MORE

than ever

STACEY SMART/DAIRY STAR Madalyn Nielsen poses with a favorite Brown Swiss cow Jan. 11 in the estall barn on her family’s farm near

CENTRE DAIRY EQUIPMENT AND SUPPLY INC. Henning Area 218-849-0211 Jon Stein 320-352-5762 • 1-800-342-2697 40625 State Hwy. 28 • Just West of Hwy. 71 • Sauk Centre, MN Seriously Comfortable Boots A boot that works as hard as you do is nearly impossible to fi nd - but your search is over! Backed by over 70 years of footwear manufa manufacturing cturing expertise, the Quatro Boot is hand-built specifically for the agribusiness industry and crafted with the highest level of comfort and durability in mind to provide you all-day comfort! One of the best boots available for hunters & farmers. Outdoor people NEED these boots! The World’s Most Comfortable Boots The I.R.S. is at KLC I Ideal R Roasted S Soybean! A great value for the money! The Ideal Roasted Soybean has what you need for your dairy ration: Energy Protein Amino Acids Bypass Protein Put the “I.R.S.” to work for you! Quality Consistency 320-352-3326 Visit www.roastedbeans.com KLC Farms 20352332 Roasting, Inc.

Nielsen farms with her dad, Christopher, and her grandma, Mary Ann. The Nielsens milk 145 cows and farm 530 acres near Lake Mills. Nielsen milks mornings and nights, feeds calves, does herd records, gives vaccinations, treats sick animals and more.

Nielsen manages two herds, splitting her duties between the two — farm A and farm B — named after the county road on which each is located.

Nielsen and Mary Ann live on farm A, the home farm, where she milks 65 cows with six units. She typically gets help from her dad or a part-time high school student. Five miles away at farm B, a hired hand milks 80 cows.

At farm A, cows are milked and housed in a 65-stall tiestall barn with access to pasture, where they spend nights in nice weather. At farm B, cows are housed in sand-bedded free stalls and milked in a 52-stall stanchion barn.

Keeping somatic cell count low is a focus for the Nielsens, who won a milk quality award from Dairy Farmers of America last year and have had a SCC as low as 32,000.

“We make sure cows are clean and that we keep everything clean to produce quality milk,” Nielsen said. “We also

The Nielsen family — Mary Ann (from le ), Madalyn and Christopher — pauses for a photo Jan. 11 on their farm near Lake Mills, Wisconsin. The Nielsens milk 145 cows in two herds and farm 530 acres.

test milk from fresh or treated cows before we ship it.”

Mary Ann and her late husband, Robert, purchased farm B in 1963. They rented farm A before buying it in 1976. They relocated to farm A but continued to milk cows at both places. Mary Ann owns both farms as well as half the cattle, while Nielsen’s dad owns the other half of the herd.

“Dad and I would like this farm to be ours eventually,” Nielsen said.

Nielsen owns 12 registered Brown Swiss which are housed at farm A. The Holstein, Red and White and Jersey herd owned by her dad and grandma is split between the farms.

“I love the Swiss,” said Nielsen, who bought her rst animal about six years ago. “Swiss have a stubborn and sassy personality — kind of like me. They are a challenge, but I like a challenge. The calves are hard to raise, but the cows are hardy and rarely

get sick.”

Nielsen started working on her grandma’s farm when she was 13 by caring for calves and, later, milking cows. When her aunt Nancy passed away, Nielsen took over naming the calves and managing their records.

Nielsen is responsible for the health of all cows and calves. She is present at every herd check and works with the farm’s nutritionist and veterinarian to make improvements.

“I work with our vet, Dr. Jen Brase of Cattle Creek Veterinary Clinic, a lot,” Nielsen said. “I ask her stuff all the time, and she’s helped me gain a lot of knowledge.”

Calf care is a priority for Nielsen, whose intuition keeps her on top of health issues.

“I just know if they’re not feeling good,” she said. “I don’t want to lose any calves, and I’m a critic with calf care from the moment a calf is born.”

All calves are raised at farm A in outdoor hutches. Nielsen has about 20 calves on milk. She cares for all newborns, including those born at farm B, ensuring they are promptly fed colostrum and receive preventative treatments.

Nielsen also cleans barns, beds calf hutches, does daily herd health checks and helps with eldwork.

Nielsen attended the University of Wisconsin Farm and Industry Short Course and was a member of the last class to graduate from the Madison campus in 2022. Nielsen said her heart is at home with the cows, and during her rst semester, she made the 45-minute drive back and forth each day, milking cows before and after classes.

Turn to NIELSEN | Page 13

Page 12 • Dairy Star • Saturday, February 24, 2024

Con nued from NIELSEN | Page 11

STACEY SMART/DAIRY STAR

PS 200 0 Ser e ies s Pr P oS oSpr p ead Re R ar ar-DDisischar a ge e Spreaders A SPREADER FOR EVERY OPERATION INVEST IN QUALITY www.kuhn.com Our innovative, high-quality spreaders provide superior performance with years of low-maintenance service. 60240 US HWY 12, Litchfield, MN 55355 Monday- Friday: 7:30am - 5:30pm 8 Saturday: 7:30am - 12:00pm www.schlauderaffimplement.com • (320) 693-7277 CAAug19-1B-NM ® SL 100 Series Pr oTwi n ® Sli nge r ® Side-DischargeSpreaders PXL 100 Series ProSpread Rear-Discharge Spreaders 1200 Series EasySpr ead ® Rear-DischargeSpreaders H P 160 Pr oPush® Rear-DischargeSpreaders

Madalyn Nielsen looks over her binder of records Jan. 11 during a daily heifer health check near Lake Mills, Wisconsin. Nielsen manages two herds and keeps paper records for every animal.

“I just had to be here,” Nielsen said. “I don’t want to be away from the farm. When I’m not here, I feel like I’m missing something or that I could be doing something better.”

Nielsen has certicates in dairy farm management, management of soils and crops, and foundation of farm and agribusiness management. She is also certied to breed cattle.

“I want to start breeding our cows, but I need a little more training,” she said. “I put what I learned toward our farm and continue to learn more each day.”

Promoting wellness and identifying the rst signs of ketosis, milk fever or pneumonia are skills Nielsen learned in the short course that have proven of value in managing the herd.

“I brought a lot of that back and do all the treating of calves and heifers,” Nielsen said. “My dad helps with bigger heifers and cows.”

Nielsen makes culling and purchasing decisions, while her grandma and uncle make nancial decisions.

“I always want to do more things on the farm and would like to start getting into the nancial aspects too,” Nielsen said.

Nielsen is accustomed to being a leader. She served as president of her high school FFA chapter and received the American FFA Degree. She was a member of the track team and mentored younger students as well.

Nielsen’s short-term goal is to switch to an electronic program for storing all animal records. She would also like to build a dedicated dry cow and maternity pen at farm A with a goal to move all cows to this location. Two farms create twice the challenges, and Nielsen is hoping to consolidate the herds.

“It’s challenging to have two farms,” she said. “We have two of everything. It’s a lot of money and maintenance. I have to be in both places, and sometimes I’m just running around all day. It would be nice to have everything in one spot.”

She has also considered adding a freestall barn and milking parlor at farm A.

“I love the tiestall barn, but it might be easier on my knees,” Nielsen said. “I would retrot the parlor into the barn. I would also like to get a few really nice cows and sell embryos to earn a little more income beyond milking.”

Currently, other revenue streams for the farm are cash crops and steers.

Nielsen is hands-on, tackling all chores as she fullls her lifelong dream of being a dairy farmer.

“Even though it’s a hard business, farming is something I would love to do forever,” Nielsen said. “I love cows so much and have great connections with my animals. I wouldn’t want to do anything else.”

Dairy Star • Saturday, February 24, 2024 • Page 13 Easy as peel and stick! 3011 7th St. S. Waite Park, MN www.mntarpandliner.com • Available in 2in & 4in widths • Buy in bulk of 82ft per roll Or by the inch or foot. ilbli2i&4iid Specifications • Low cost • Time efficiency • Universal application • No down time • No hazardous chemicals • Permanent Benefits • Vinyl Tarps • Awnings • Tents • Vinyl Seats • Camper Canvas • Boat Covers • Boat Lift Covers • Sun Shades lT CC Applications And more! Step 1. Clean damaged fabric surface Step 2. Cut PETACKS to desired size Step 3. Peel & Stick PETACKS Patch is permanent and ready for immediate use! 3 Step Process 320-257-5535 UV Resistant Weather Resistant Temperature Resistant 80 lbs. Adhesion Strength Impermeable Bond R i t t Durability Awnings & Tents Covered Structures Boat & Boat Lift Covers Vinyl Coated Tarps Peel & Stick From Our Yard to Yours. AGRICULTURAL | RESIDENTIAL | LIGHT COMMERCIAL Decks | Barns | New Home Construction | Remodeling | Additions Industrial Buildings | Pole Sheds | Garages | So Much More! 320-243-7815 Paynesville, MN | BorkLumber.com Traditional Values. Continuing Excellence.

Con nued from NIELSEN | Page 12

STACEY SMART/DAIRY STAR

Page 14 • Dairy Star • Saturday, February 24, 2024 SAUK CENTRE, OFF I-94 ON THE CORNER OF HWY. 28 & 71 SOUTH WE ARE YOUR NEW TRIOLIET DEALER! In Stock Penta 6730 Parts in Stock! Many Different Sizes In Stock In Stock SPREADERS Call for availability Parts In Stock Central Minnesota Farm Show at the River’s Edge Convention Center Parts In Stock HYDRA-SPREAD In Stock Most Models In Stock. Service & Installation Available. Parts On Hand. In Stock The Woodchuck® is a side discharge bucket designed to apply bedding material with ease. It’s what you need to keep your cows clean and comfortable and to lower SCC by bedding more often, using less material at a time. n ock O M i n n e s o ta ’s LargestFeeding and ManureHandli n g D e a rel Ifyouhavea barn, we haveasolution. www.dairylandsupply.com Come see us February 27th & 28th In booths A612-A617 & A700-A705 It s Show Time!

from our side our side OF THE FENCE THE

How

Matt Schleske

Fergus Falls, Minnesota

Otter Tail County

did your involvement in FFA benefit you in your dairy career?

100 cows

What high school did you attend, and what years were you in FFA? I went to Fergus Falls High School. I was in FFA from 2005-09.

Why did you join

FFA? I always wanted to be in FFA. I enjoy agriculture, and that was the direction I wanted to go. I did have some friends in FFA, but I wanted to join before that.

What are your fond memories of being in FFA?

Going to the competitions. Crookston is where I competed in general livestock and took third as an individual one year. As a team, we made it to state one year for dairy judging. I also enjoyed all the agriculture classes with it.

Tell us about your involvement with your chapter. I was on the dairy judging team for two years and general livestock for two years. I was the ofcer atlarge my sophomore year, sentinel my junior year and student adviser my senior year. We sold fruit for a fundraiser and did a kindergarten farm day. We would head to a farm and bring a bunch of animals. We had all the kindergarteners from the district and surrounding districts come, and then, we would teach them farm safety, have a petting zoo and give hay rides. I also received a local scholarship from a family who gives $500 to one FFA member a year.

How did your involvement in FFA benet you in your dairy career? Dairy judging denitely helped. I know more things to look for in cows, such as teat placement and the structure of a good cow. I also met a lot of people in the agriculture industry. My old adviser used to raise Holstein heifers, and he is a great person to ask about calves. I wouldn’t have that connection without FFA.

What encouragement do you have for youth considering joining FFA? I would say go for it. You have nothing to lose, but everything to gain. Not all of FFA pertains to agriculture. You are able to go out and try new events. There are a lot of other opportunities to learn. It’s a good experience.

Tell us about your farm. I farm with my neighbor, Shawn Nelson. We have been in a partnership for about ve years now. We milk about 100 cows in a double-6 herringbone parlor, and the cows are housed in a freestall barn. Our cows are mostly Holstein with a few Jersey crosses. We ship our milk to the Perham Cooperative Creamery and don’t have any big changes planned for the dairy other than to keep going.

Natalie Barka Litcheld, Minnesota Meeker County 300 cows

What high school did you attend, and what years were you in FFA? I attended Litcheld High School and was in FFA from 2014-19.

Why did you join FFA? I joined FFA to continue family, community and agricultural traditions. Many of my family members were in FFA, and I was excited to follow in their footsteps.

What are your fond memories of being in FFA? Early morning parliamentary procedure practices come to mind rst. They were challenging, but I enjoyed growing close to my team and working toward a common goal. I also enjoyed being on the chapter and regional ofcer teams and traveling to different workshops and conferences. I was proud to always see family members and friends remaining active in FFA, as alumni and in the industry throughout my FFA career.

Tell us about your involvement with your chapter. My favorite contests were milk quality and products and parliamentary procedure. I enjoyed building my Supervised Agricultural Experience project for dairy production placement, which was focused on cow and calf health management. I had the honor of receiving the Minnesota Star in Production Placement award in 2018 with my work on my family’s dairy farm. I also held multiple ofces at the chapter and regional levels throughout my high school career.

How did your involvement in FFA benet you in your dairy career? FFA helped me develop leadership skills and lifelong relationships and further strengthened my passion for the agriculture community. The leadership experiences and network I built helped me become more involved in other areas in agriculture, such as the University of Minnesota, Midwest Dairy and Farm Bureau. Participating in the milk quality and products contest helped me nd my passion for creating safe and quality dairy foods and ingredients. I am fortunate to be able to fulll my passions by working at First District Association along with farming with my family.

What encouragement do you have for youth considering joining FFA? I would encourage youth to step out of their comfort zones and not be afraid to fail. FFA has a wide range of opportunities that can lead you to surprising places.

Tell us about your farm. My parents, Josh and Lynn, grandparents, Dan and Dianne, sister, Liz, and I are all part of the farm. We farm corn, alfalfa and rye and nish our dairy steers along with our dairy cows. We sell our milk to First District Association, where I also work as a quality assurance manager focused on whey products.

Karli Luehmann

Rollingstone, Minnesota

Winona County

120 cows

What high school did you attend, and what years were you in FFA? I attended Lewiston-Altura high school and was active in FFA from 2008-14.

Why did you join

FFA? I joined FFA to become more involved and to have the opportunity to participate in a variety of events. I was a very shy seventh grader when I joined, and I knew FFA would help me come out of my shell and develop leadership skills that could benet me later in life.

What are your fond memories of being in FFA?

My favorite memories were traveling to state and national conventions throughout the years. It was a time to bond with other FFA members from different chapters and to appreciate having the opportunity to travel.

Tell us about your involvement with your chapter. I was on the dairy judging team all throughout the years. We competed locally and at the state level. I held various ofcer positions such as historian and president. I kept busy year-round, helping with fundraising, petting zoos and working on my Supervised Agricultural Experience. My senior year I was awarded the Star in Production Placement award at the Minnesota State FFA Convention. Lastly, I was able to apply for my American FFA Degree at the end of my FFA involvement.

How did your involvement in FFA benet you in your dairy career? My FFA experience helped me to develop skills in dairy cattle evaluation and herd management.

What encouragement do you have for youth considering joining FFA? Be as involved as you can. FFA is not just for farm kids. There is something for everyone. Not only does your involvement look great on resumes, but also, it will teach you lifelong skills that will not go unnoticed.

Tell us about your farm. Since 2021, my husband and I are the fourth-generation dairy farmers on my family’s farm. We milk 120 cows twice daily in a double-6 herringbone parlor. We raise our youngstock on-site and grow our own crops. Our milk is sold to Plainview Milk Products Cooperative and shipped to Kwik Trip in La Crosse, Wisconsin.

Dairy Star • Saturday, February 24, 2024 • Page 15 Turn to OUR SIDE | Page 16

www.norbco.com 67962 State Hwy 55, Watkins, MN 55389 • 320-764-5000 MA KING COW COMFORT OUR PRIORITY Curtain SystemsVentilation SystemsFreestall SystemsHeadlocks

Katherine Boelen

Brooklyn, Iowa

Poweshiek County

1,700 cows

What high school did you attend, and what years were you in FFA? I attended Kasson-Mantorville High School and was in the K-M FFA Chapter from 2009-13.

Why did you join FFA? I joined FFA because a friend persuaded me to join along with her. Initially, I didn't believe I had much to contribute or gain since I lacked a background in agriculture.

What are your fond memories of being in FFA? My time in FFA holds countless cherished memories. I treasure the deep friendships formed during those years, and we often reminisce about our FFA experiences together. Among the highlights was our unforgettable trip to the National FFA Convention & Expo in Indianapolis, a standout favorite for our group. Tell us about your involvement with your chapter. During my time with the chapter, I held positions as reporter, vice president and president, while also receiving numerous awards at the chapter level. Additionally, I participated in the dairy foods Career Development Event. Our chapter seized volunteering opportunities, including picking garden-fresh donations for the food shelf, participating in

Annie Achen Vannurden Buckman, Minnesota Morrison County

1,200 cows

What high school did you attend, and what years were you in FFA? I attended the school in Sauk Centre, Minnesota, from 2007-10 and Benton Central High school in Benton County, Indiana, from 2010-13. I participated in FFA from my freshman through senior years.

Why did you join FFA? I joined FFA because it was a family affair for me. I don’t think I had a choice. My mother, Cindy, and her siblings were members, and my older ve siblings were present and previous members. My sister, Emily, was a state ofcer at the time I started. It was expected of me, but I truly enjoyed every minute of it.

What are your fond memories of being in FFA? The fondest memories revolved around when the responsibilities were left in the members’ hands. I was a part of a chapter that relied on the students to make things happen. We worked as a team with the other members, normally without too much oversight, on auctions, food drives, dairy judging practices, ling prociencies and attending conventions, etc. This responsibility was when I felt most accomplished and motivated. FFA does a great job of empowering teenagers and pushing them to see what they are capable of.

Relay for Life, assisting with parking at Breakfast on the Farm, and engaging in activities like Food Check-Out Day and Farm Safety Day, among others.

How did your involvement in FFA benet you in your dairy career? My involvement in FFA has been transformative, guiding me from a non-agricultural background to a fullling life in dairy farming. Growing up in town, agriculture seemed distant. However, fate intervened when I accompanied a friend to their dairy farm job, where I unexpectedly developed a profound passion for dairy cows. FFA became my gateway to the dairy industry, offering me invaluable opportunities for growth and development. Despite my initial lack of farming experience, FFA provided me with the knowledge and skills necessary to thrive.

What encouragement do you have for youth considering joining FFA? Overall, joining FFA can open doors to endless opportunities, help you discover your passions and empower you to make a difference in the world of agriculture and beyond. So, if you're considering joining, go for it. You won't regret the experiences and connections you'll gain along the way.

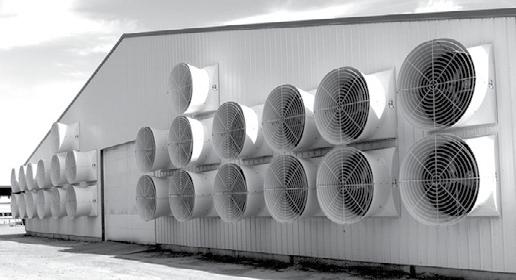

Tell us about your farm. In Brooklyn, Iowa, my husband, Joris, and his brother, Tuen, help run Bear Creek Dairy, a thriving operation their parents, Jan and Dorine Boelen, established after immigrating from the Netherlands in 2009. With 1,700 cows, our farm utilizes a double-24 parallel parlor with rapid exit for milking. The milk is sent to Prairie Farms Dairy Inc. for processing in Luana and Dubuque. Our cows reside in freestall barns, which we're upgrading to incorporate tunnel ventilation for improved comfort and productivity. While my main role is as a stay-at-home mom, I'm passionate about bringing dairy education and promotion to our community, on and off the farm, enriching the understanding and appreciation of dairy farming.

Tell us about your involvement with your chapter. While in Indiana, I received my State FFA Degree and American FFA Degree. I held the ofce of chapter president and regional treasurer my senior year of high school. I participated in dairy foods, dairy handling and dairy judging and was awarded as a national nalist for dairy prociency. I attended leadership camps, Minnesota and Indiana state conventions, and multiple national conventions. Volunteering revolved around community events, clean ups, petting zoos, and educating youth and the public about agriculture.

How did your involvement in FFA benet you in your dairy career? FFA gave me the opportunity to work with adults before becoming an adult. FFA and 4-H kids are bounds ahead of students once they get into adulthood because of that interaction. This has beneted me in my dairy career because I know how to hold people accountable and the importance of being held accountable myself. FFA has taught me how to be organized and set timelines for myself. When I am not qualied for a certain task, I know how to ask for help or guidance.

What encouragement do you have for youth considering joining FFA? FFA is for everyone, not just teens who grew up in agriculture. FFA has so much to offer in agriculture and plenty of areas outside of that realm. Students can be as involved as they can or want to be. You will get something positive from your time dedicated to this organization.

Tell us about your farm. I am a managing partner of Silverstreak Dairies LLC. We have dairy farms in Minnesota, South Dakota and Kansas. We are members of Dairy Farmers of America Inc. and Land O’Lakes Inc. I wouldn’t be anywhere or anything without the team that surrounds me. Our organization prides itself on PACE: people, animals, community and environment. We enjoy feeding our herd so that you can feed yours.

Page 16 • Dairy Star • Saturday, February 24, 2024 Con nued from OUR SIDE | Page 15 CALL FOR A QUOTE TODAY 605.368.5221 OR VISIT US AT equipmentblades.com Loader Edges Grader Blades Snow Plow Blades Custom Edges Skid Steer Blades Box Scraper Dozer Blades Wear Steel Turn to OUR SIDE | Page 18

Dairy Star • Saturday, February 24, 2024 • Page 17 JOIN OUR TEAM Now Hiring Service Technician Intern Apply Now! SCAN ME bit.ly/3fwYBl6 Paid Internship +1-800-636-5581 | Proudly serving you from Brookings, SD; St. Peter, MN; and Melrose, MN! DEALER Cutting-Edge Milking Equipment | Supply Delivery | Preventive Maintenance Herd Advisory & Software Support | Manure Management Services | Feed Management farm-systems.com © 2022 Farm Syststeems. All rig ts hts rese e rved. A-3386648395 Need Service? Keep your operation up and running with Farm Systems Your Local Milking, Manure and Feed Management Solutions & Service Provider

Gary Kregel

Guttenberg, Iowa

Clayton County

380 cows

What high school did you attend, and what years were you in FFA? I attended Guttenberg High School and was in FFA from 197075.

Why did you join FFA? Having been in 4-H and attending a rural school where every farm kid joined FFA, it was automatic to join. We also had an excellent instructor.

What are your fond memories of being in FFA? The contests, both livestock judging and leadership contests. In addition, there were many people I met beyond the local chapter level. This included two trips to Washington, D.C., multiple trips to the state FFA convention and attending the national FFA convention a number of times.

Tell us about your involvement with your chapter. I was a chapter ofcer, a district ofcer and eventually Iowa’s State FFA Secretary. I also received the State FFA Degree and the American FFA Degree, along with many judging contest awards. In addition, all three of our children received their degrees.

How did your involvement in FFA benet you in your dairy career? FFA’s inuence led me to Iowa State University and to joining the Alpha Gamma Rho agricultural fraternity, a relationship that keeps giving for a lifetime. There, and at the farm today, the leadership contests in high school paid huge dividends. The communication and parliamentary procedure skills I learned in FFA are used to this day in my many off-farm organizations and activities. Whether it has been school board, co-op board, Northeast Iowa Dairy & Agriculture Foundation, county conservation board or local political activities, I would use those skills when I became the chairman.

What encouragement do you have for youth considering joining FFA? FFA can teach you the life skills to speak and interact with others. Ditch the devices and talk. You will learn how to do a job interview or a radio interview to sell yourself or your business. FFA will give you the skills to be a leader rather than a follower. Today’s FFA is not just for agriculture; there is opportunity there for everyone.

Tell us about your farm. The farm is a family (sixth-generation) operation that has been in the family 150 years this year. Those involved are my wife, Darlene (met through 4-H and FFA), who manages the calves; our daughter, Maureen, who manages the cows; and our son, Travis, who works with crops and machinery as well as trucking. Travis also manages our custom cover crop business. Our daughter, Megan, is also involved in dairy in a neighboring county, having married a dairy farmer. She also has a popular social media presence. Our milk is shipped to Prairie Farms Dairy Inc. We just nished our 10th year with six Lely robotic milking units in a tunnel-ventilated barn. The farm also runs a cash grain business and has been using no-till and cover crops for 20-plus years.

Ytsje Andringa

Clear Lake, South Dakota

Deuel County 1,800 cows

What high school did you attend, and what years were you in FFA? I attended Great Plains Lutheran High School in Clear Lake, South Dakota. I was in FFA during my sophomore, junior and senior years.

Why did you join FFA? I like competition and think that agriculture is important. Being in FFA improved my speaking skills and enabled me to network with others. I also wanted to be involved in agricultural issues that are outside of dairy farming. I was able to start conversations with others that were specically about dairy. The speaking skills that I learned in FFA helped me when I served as South Dakota Dairy Princess.

What are your fond memories of being in FFA? Our chapter went to the National FFA Convention in Indianapolis in 2018. I made lots of new friends at the convention, and it broadened my view of FFA. In 2019, our dairy judging team placed second in the state dairy judging contest. We were just one point away from going to the nationals.

Tell us about your involvement with your chapter. I participated in ag sales and was on the dairy judging team. I served as treasurer for our chapter during my senior year. Our chapter did a color run to raise money for the family of Evie Kanke, a young lady from Florence, South Dakota, who died of leukemia at age 17.

How did your involvement in FFA benet you in your dairy career? I don’t hide anymore and now have the courage to speak. I network with everyone I meet. Networking is important because you never know when you will need help or you can help others. I am still in contact with connections I made in FFA. I am always promoting the dairy industry. The connection between farmers and consumers has been lost. If I can change the minds of just ve consumers, maybe they will change the minds of ve more and so on.