By Stacey Smart stacey.s@dairystar.com

By Stacey Smart stacey.s@dairystar.com

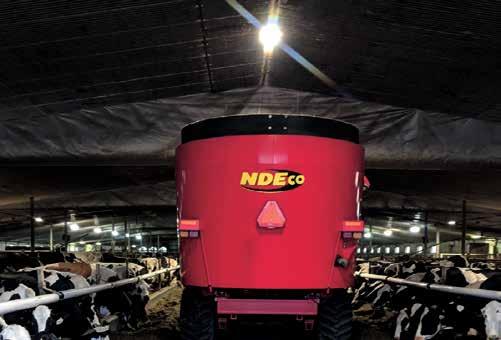

ALLENTON, Wis. – Before moving into new facilities last April, Justin and Samantha Krueger were milking 102 cows in a 42-stall stanchion barn.

“We were doing 2.5 switches,” Samantha said. “It was a little insane.”

The Kruegers had outgrown their buildings and were looking toward the future with plans of expansion on the farm near Allenton where Justin began working when he was 11 years old. It had always been more than a job to this farm-loving boy who wasted no time making his mark on the operation he would one day run.

“In July, I’ll be here 29 years,” Justin said.

Two years in, Justin began buying heifer calves, and when he graduated from high school, he owned 12.5% of the 60-cow herd. He and the farm’s owners, Jim and Carol Maul, set up a limited liability company and the farm became a partnership. Justin bought the rest of the herd in 2009.

Today, Justin and Samantha milk 180 cows and farm 700 acres. The couple nearly doubled the size of their herd when moving into their new facilities. Their goal is to get up to 200 head milking.

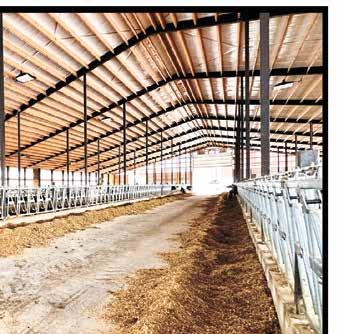

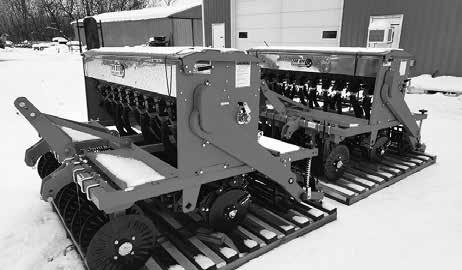

Building a farm of their own alongside the farm they rent, the Kruegers completed a building project last year that included a new freestall barn, special needs barn and milking parlor on land they purchased

on the farm in 2015. New facilities solved problems of overcrowding and relieved the stress of switching cows multiple times while creating a simplistic system for working with animals.

Within their modern setup, the Kruegers have discovered improvements in efciency, convenience and cow health. They have also seen an increase in milk components.

The new 160-stall, 4-row freestall

barn features a hybrid ventilation system with curtains on both sides and on the west end. The barn is set up for tunnel ventilation with the east end boxed out for tunnel-ventilated fans. The barn also features automatic scrapers, and cows use the automated brushes located on either side of the barn.

The special needs barn features dry cow, maternity and fresh cow housing. Connected to the main barn

by a breezeway, this building is situated close to the parlor and contains 40 free stalls for dry cows on one side and two bedding pack pens for maternity and one for fresh cows on the other side. Cows spend two weeks in the maternity pen prior to calving.

“We have a lot more room in these maternity pens,” Samantha said. “I keep fresh cows in the special needs barn until I feel comfortable they are

ready to move on. Once they hit a certain level of rumination for two to three days, we’ll move them out. We want to make sure they’re out of the woods for milk fever and ketosis.”

The Kruegers also appreciate the ease of transferring dry cows to the maternity side.

“We don’t have to move them across the yard anymore or deal with ice,” Justin said.

The special needs barn is a 4-row style that Justin said could easily be adapted for free stalls on the fresh cow side as well if they choose to in the future. Both barns feature headlocks which the Kruegers nd convenient for doing ovsynch protocols, breeding or working with fresh cows in the bedded pack.

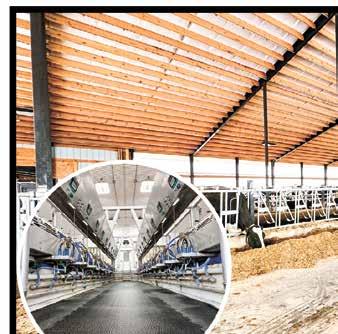

Cows are milked twice a day in the Kruegers’ double-10 parallel parlor. The parlor is a used model purchased from a farm that was switching to a rotary. The Kruegers upgraded to a rapid exit style and rebuilt the parlor with new equipment. A 3,000-gallon bulk tank also came with the parlor.

“It saved us quite a bit of money doing it this way,” Justin said. The parlor had been in operation for 20 years, but the fronts were 3 years old.

“We stripped the box clean and put all new equipment in, but we didn’t have to rewire or put in new air

lines,” Justin said.

The Kruegers also began using an activity monitoring system when they moved into their new barn, and additions to the parlor included waterjet cutouts for the readers. Monitoring milk, activity and rumination, Samantha said the system took animal health to a new level.

“I love it,” she said. “The monitoring system is the best investment out of this entire project. It’s denitely paid for itself already.”

Samantha said the system helps catch sick cows before she notices they are sick.

“I’ve tested it,” she said. “I noted which cows the system said were sick, but if a cow was chewing her cud and looked ne, I didn’t treat her. The next day, she was down. If you catch it right away and drench her once, she comes back up and never skips a beat.”

Having an extra set of eyes on the herd frees Samantha from having to be in the barn milking cows every day.

“It does everything that I could see when I would milk,” she said. “I come in the morning, sit down at my computer, and in 10 minutes, I know what I need to do. And, I know if something isn’t right.”

The parlor/holding area features push-button air-operated sort gates and a double return alley that enables easy sorting. An automated footbath in the return alley is lled twice a week for cows to step through as they exit the parlor.

The Kruegers receive help from three full-time and four part-time employees, and their new milking setup has benetted the labor situation.

“Milking shifts are a little longer now, which makes it easier to nd help as we can ll a day’s work between two shifts,” Samantha said.

The Kruegers also put in a 3.4-million-gallon manure pit last summer. A seven-to-10-day reception pit in the barn holds manure temporarily, and when full, the Kruegers open the gate and release it.

“We do a big ush at once so the sand doesn’t build up in one spot,” Justin said. “It works well.”

The Kruegers have bedded with sand for years, even in the stanchion barn.

“You can’t beat the cleanliness of sand,” Samantha said.

A prototype auger by Patz – which Justin said is the rst in the country –pushes manure from the special needs

cilities, enabling the Kruegers to move their heifers home in October. Since 2009, heifers 8 months old to springing were housed at a neighbor’s farm. The Kruegers’ former dairy cow freestall barn was transformed into housing for breeding-age heifers that includes an outdoor area with fence-line feeding. Every breedingage heifer wears a monitoring collar, eliminating the need to tail chalk.

The Kruegers also converted their old dry cow barn into bedded pack housing for heifers ages 6 to 12 months. In addition, they are planning to gut the stanchion barn this summer and put free stalls in.

“The new facilities turned out better than we could have imagined,” Samantha said.

barn toward the pit. Runoff from the heifer barn drains into the manure pit as well.

New facilities freed up older fa-

The couple has a son, Max, and is expecting their second child in June. With facilities to take the family far into the future, Justin and Samantha are hoping the next generation will share their desire to farm.

By Abby Wiedmeyer abby.w@dairystar.com

By Abby Wiedmeyer abby.w@dairystar.com

VIROQUA, Wis. – Cosette Henthorne joined her parents’ operation full time after college and worked alongside them and her grandfather until he passed away. Today, she continues to farm with her parents as a way to keep her late grandfather’s legacy alive.

“My grandpa Dwain is certainly one of the driving forces behind this farm,” Cosette said. “I believe that we all strive to work hard to make him proud.”

Cosette milks 90 cows in a swing-12 parlor near Viroqua with her parents, Philip and Jacinta Henden. Her husband, Eldon, works off the farm and helps on weekends. Cows are housed in two sand-bedded freestall barns. In warmer months, the cows have close to 150 acres of pasture to roam as well.

Dwain was diagnosed with fast-growing lymphoma in 2019. At that time, Cosette was due with her rst child, and Eldon was deployed in Afghanistan with the Air National Guard.

Cosette’s parents took her in to help her adjust to motherhood, and Dwain moved into their home as well to receive hospice care. Philip and Jacinta took care of them both and still ran the dairy farm.

Two weeks into hospice care, Dwain passed away. One of Dwain’s nal wishes was for Eldon to return home safely, which he did, to attend his funeral and meet his rst child, who is also named Dwain.

Today, the dairy continues with Dwain remaining among everyone’s hearts.

“Grandpa was a pretty special person to all of us,” Cosette said. “I know we are all proud to carry on his legacy.”

Daily chores are handled between Cosette and her parents. Jacinta cares for the Henthornes’ two children, Dwain and Emmett, and manages the business

Certified Organic by USDA!

A solution to help control Hypocalcemia (Milk Fever) by utilizing anions derived from natural organic sources that are more palatable than straight mineral salts, which helps increase DMI during this critical time of Transition. It also regulates the metabolic pH of the cow’s blood and urine to increase the absorption of calcium.

FEATURES

Helps decrease Milk Fever (Hypocalcemia)

Helps increase DRY MATTER INTAKE

Helps increase feed consumption

Helps decrease displaced abomasum

Helps increase milk production

Helps decrease Ketosis

Helps decrease retained placenta

tasks for the farm. She also steps in to milk when the part-time hired help is not available.

The farm has seen many changes in the 75 years it has been in the family.

The legacy began in 1948 when Cosette’s great-grandfather bought the original 132 acres. Her grandfather Dwain was the second generation, and in 1990, Philip became the third generation to own the farm.

At that time, Dwain moved to a neighboring farm and milked his own herd of cows, Philip and Jacinta milked at the home farm, and Philip’s sister milked at another neighboring farm. The three families worked together to complete eldwork.

When Phillip’s sister got out of dairying in 1994, her herd was auctioned, and the remaining two herds were combined. It was a total of about 60 cows, and they were all milked at the home farm. Philip and Jacinta purchased 120 acres from his sister’s farm on a land contract.

“It was a nice way to keep it in the family and not lose the land,” Jacinta said.

A few years later, in 1999, conventional milk prices fell to less than $9 per hundredweight. Philip and Jacinta had a growing family and were feeling the nancial strain. Jacinta thought they should consider a different career path, and Phillip was tempted to agree with her until he consulted his father.

“I said something to my dad that maybe I should get a job somewhere,” Phillip said. “I could just see it in his face – the disappointment. So, I didn’t pursue it any more after that.”

Instead, they decided to transition to organic farming to capture a better milk price. Jacinta also worked off the farm as a teacher.

Jacinta said transitioning to organic was easier with Dwain’s guidance. Before consolidating the three herds, Dwain had farmed organically. Philip

had helped his father his whole life, so he drew on his prior experience when implementing organic practices with the cows and in the elds.

“It was hard for a couple years, and then once we got into organic, there was hope,” Jacinta said. “It was a lot easier, and it made sense.”

They took three years to transition the land, which is one thing Philip said could have been done differently.

“We could have bought organic feed and started right away,” Philip said. “That was one thing that would have been helpful to have a mentor tell us; that there are other ways to do it.”

The herd consisted of 60 cows at transition. Two years later, a freestall barn was built, and two years after that, a parlor was retrotted into the tiestall barn. The comfort of the sand bedding and efcient milking system helped the herd grow internally. In 2011, a second freestall barn was built to accommodate the growing herd.

“When we put the freestall barn in, the cows’ health was better as far as sand bedding,” Philip said. “Now, we’ve got so many heifers. We grew the herd from 60 to 140 without buying anything.”

Labor was difcult to nd to help with chores, so the herd was scaled back to around 100 cows. Cosette graduated from the University of Wisconsin-Platteville in 2014 and returned to the farm full time.

Now, the Henden and Henthorne families are looking toward the future.

Solar panels have been installed and are in the process of becoming operational. The hope is the energy produced from the panels will pay for any electricity the farm uses.

Further plans include implementing a robotic milking system. Philip said he is going to leave that decision to the fourth and fth generations to manage.

By Lee Mielke

By Lee Mielke

The U.S. Department of Agriculture’s latest supply and utilization data shows dairy’s commercial disappearance in 2022 was strong, up 1.6%, according to StoneX broker Dave Kurzawski in the Feb. 20 “Dairy Radio Now” broadcast.

Total cheese usage was up 2.1%, according to Kurzawski, buoyed by exports, which were up 12% from 2021. American cheese exports were up 38%.

The story on butter was not as good. Disappearance was down 4.6% for the year. Exports, however, were up 47.6%, indicating domestic demand was lagging, Kurzawski said, down 7%, prompting the question, “Why is butter at $2.40 per pound?”

The simple answer, according to Kurzawski, is that “the demand for fat is not down. Demand for butter at retail is down and demand for butter at restaurants is down, but demand for fat is probably as strong as it’s been for quite some time.”

Total nonfat dry milk utilization turned positive in December 2022 following six consecutive months below 2021 levels. Domestic usage rose above a year ago in August, and powder exports saw their biggest volume since December 2019.

Cheddar block cheese at the Chicago Mercantile Exchange climbed to $1.89 per pound Tuesday but closed Friday at $1.88, up 1.75 cents on the week but 10.75 cents below a year ago.

The barrels ended the week at $1.5475, 2.75 cents lower, 38.75 cents below a year ago and 33.25 cents below the blocks. Sales totaled six cars of block and 45 of barrel for the week, highest barrel total since the week of May 17, 2021.

Midwest barrel processors tell Dairy Market News that larger contractual based customers have cut back purchases, which affected production schedules this week and moved milk into other varieties when possible. Some retail cheddar-Italian style cheesemakers said sales were “hearty.” Milk remains notably available, and spot loads at $10 under Class III were reported for the eighth consecutive week but prices varied throughout the region. Some cheesemakers were not seeing offers that low but found milk closer to $4 and $5 under Class. Eyes are still on the large price gap between blocks and barrels.

While marketers expect an eventual convergence of the two, there is a bit of instability; however, market tones are not necessarily bearish but viewed more as mixed, DMN said.

Western cheese demand continues mixed domestically. Both steady and softer sales into retail and food service markets were noted. Contract sales were steady with some reports of inventories being sold out through rst quarter and almost sold out for most of second quarter. Export sales saw an uptick. Some cheesemakers are shifting from blocks to barrels. Ample regional milk volumes are available, and cheese production is steady to strong, DMN said. The abundance of barrel cheese is said to be contributing to the large block-barrel price spread at the CME.

CME butter climbed to $2.4575 per pound Tuesday, highest since Dec. 22, 2022, but closed Friday at $2.3750, down 3.75 cents on the week and 31.50 cents below a year ago, on 10 sales for the week.

Midwest butter sales are reportedly “meeting expectations,” DMN said; however, “expectations in mid-February represent a somewhat low bar when compared to the spring and late summer/early fall months.” Butter contacts say sales could be worse. Cream continues to ow to butter plants and at favorable pricing for churning. Butter market tones are rmer, according to DMN.

Cream volumes are also readily available in the West, and cream demand is steady to light. Less than fully staffed production schedules has been a challenge to some operations, but strong butter production continues. “Stakeholders look to assure mid-year demand coverage, but demand is light ahead of the expected increase related to the spring holidays,” DMN said. Retail demand is light, and some report sales are below seasonal forecasts. Spot market demand is mixed as some contacts note light demand, while others note no spot market activity taking place. Second quarter contract sales had a slight uptick from the previous week, but export sales are light, reports DMN, due to “uncompetitive prices compared to the world stage.”

Grade A nonfat dry milk dropped 3.75 cents Tuesday, following the GDT Pulse, and fell to a

Friday nish at $1.22 per pound, 4.50 cents lower on the week and 63 cents per pound below a year ago, with nine sales reported for the week.

Dry whey gained a penny Monday and closed Friday at 45 cents per pound, up 2.50 cents but 36 cents below a year ago, with only one sale recorded on the week.

USDA’s monthly Livestock, Dairy and Poultry Outlook, issued Feb. 14, mirrored milk price and production projections in the Feb. 8 World Agricultural Supply and Demand Estimates report.

The Outlook also warned, “Based on the latest information of lower inventory of heifers for replacement, active dairy cow culling, relatively high forecast for feed costs and weaker expected milk prices, the average number of milk cows is projected lower in 2023 at 9,380 million head, down 25,000 from last month’s estimate. Average milk yield was lowered 25 pounds to 24,345 pounds per cow.”

While dairy cow culling shot higher in December, it was slightly below December 2021; however, 2023 is looking like increased retirement from the dairy business is in the works, as culling helps stressed cash ows on the farm. Cull prices remain at decent levels.

The week ending Feb. 4 saw 65,700 dairy cows go to slaughter, down 2,800 from the previous week, but 2,800, or 4.5%, above a year ago. The year-to-date count is at 338,600 head, up 24,100, or 7.7%, from the same period in 2022.

Dairy farms are also calling it quits. The Daily Dairy Report’s Sarina Sharp wrote in the Feb. 10 Milk Producers Council newsletter, “Livestock auctions have a growing line-up of dairy herds on the docket. … The combination of high slaughter volumes and low heifer supplies could speed contraction in the milk cow herd, but the shift from today’s surplus to tighter milk supplies will take some time. And if markets bounce back prematurely, the painful process will drag on even longer.”

Tuesday’s Global Dairy Trade Pulse saw the largest number of winning bidders since the Pulse began Aug. 9, 2022, but was the shortest session since then. There was 2.2 million pounds of Fonterra whole milk powder sold, up 30 million pounds from Jan. 31,

but at $3,285 per metric ton, down $10 from the Feb. 7 GDT.

HighGround Dairy warned, “This was a bearish outcome. There were plenty of buyers willing to procure small amounts of whole milk powder at a perceived value, but there was no effort to drive prices higher either or for bidders to push others out with larger quantity bids. Bull markets need fuel to keep momentum going, and this was a lackluster result.”

HGD also reported, “Widespread power cuts following Cyclone Gabrielle are impacting dairy farmers in some of the hardest hit areas of New Zealand’s North Island, according to the Ministry for Primary Industries.

“New Zealand’s government has declared a national state of emergency for only the third time in its history, and it has pledged an initial NZ $4 million for recovery efforts in rural communities. The hardest hit areas were Northland, Southern Auckland, parts of the Waikato, Bay of Plenty, Gisborne and Hawke’s Bay. Flooding has ruined orchards, vines, crops and livelihoods in the hardest hit regions, and has also drowned pastures and feed crops for winter.”

Cooperatives Working Together member co-ops accepted 23 offers of export assistance this week that helped them capture sales contracts for 1.4 million pounds of American-type cheese, 50,000 pounds of butter, 4.9 million pounds of whole milk powder and 333,000 pounds of cream cheese. The product is going to customers in Asia, Central America, the Caribbean, Middle East-North Africa and South America through August.

CWT’s 2023 exports now total 8.3 million pounds of American-type cheeses, 50,000 pounds of butter, 17.8 million pounds of whole milk powder and 1.2 million pounds of cream cheese. The products are going to 15 countries in ve regions and are the equivalent of 216.8 million pounds of milk on a milkfat basis.

In politics, the Green Bay-based American Dairy Coalitio gave a thumbs up to Sen. Kirsten Gillibrand (D-NY) for “the dairy priorities she has announced ahead of the upcoming 2023 farm bill negotiations, especially her plan to reintroduce the Dairy Pricing Opportunity Act.”

An ADC press release stated that Gillibrand rst introduced the legislation in 2021 with Sens. Leahy (D-VT) and Collins (R-ME).

“The introduction of this bill was a direct result of Sen. Gillibrand’s 2021 Senate Agriculture Subcommittee hearing on modernizing milk pricing and the FMMO system and has paved the way for critical discussions surrounding FMMO reform in not just Class I pricing, but potentially other areas as well,” the ADC said. “Specically, the Dairy Pricing Opportunity Act requires the Secretary of Agriculture to initiate the process of holding FMMO hearings within six months on the views and proposals of producers and the dairy industry on Class I skim milk price, including the ‘higher of’ formula … and any other views and proposals on the Class I skim milk price, and such other matters as the Secretary of Agriculture considers appropriate.”

“We are grateful to Sen. Gillibrand for her leadership on this important bipartisan legislation to open the Federal Milk Marketing Order hearing process which will empower dairy farmers to be at the table. There is consensus among major dairy organizations to see the Class I skim milk price formula returned to the ‘higher of’ instead of the ‘averaging’ formula implemented in May 2019,” said

The wholesomeness of dairy needs to be defended and the latest salvo is a book, No. 5 on a New York Times list of “10 Nutrition Myths Experts Wish Would Die.” “Plant Milk is healthier than dairy milk.”

“It’s just not true,” said Kathleen Merrigan, professor of sustainable food systems at Arizona State University and a deputy secretary of agriculture under President Barack Obama, in the article. “Indeed, the myth persists despite how plant-based beverages have much lower protein, numerous additives of dubious value and a lack of uniform quality that should give anyone pause.”

A press release from the National Milk Producers Federation states, “It’s also not shocking that the misinformation continues. Money talks, and the plant-based sector is well-funded with plenty of media allies and a ready-made base of support in a vegan community that insists a diet that’s impossibly difcult to follow and prone to malnourishment should be adopted by everyone.

“It also comes down to the names of the products themselves. If (whatever substance of the moment) is put in front of the word ‘milk,’ then a false impression of nutritional equivalence, if not superiority, is easy to create. If that weren’t the intention, the plant-based beverage peddlers wouldn’t be doing it.

“The good news is nutrition experts are seeing through it, hence endorsement of integrity in dairy labeling from the American Academy of Pediatrics and others. And consumers are seeing through it, which is why we’re seeing data like this, in which after years of gains, the plant-based tide is starting to

recede.”

Back on the farm, Midwest and Eastern milk output is steady, according to DMN’s weekly update Areas in the Northeast and Midwest experienced extreme cold temperatures and wind chills, though production was largely unaffected while some hauling obstacles and delays were noted because of ice and precipitation accumulation.

Milk output in certain locales in the West is steady to higher, but certain areas in northern California are reeling from the effects of recent extreme rainfall and milk output is mixed. Mud has persisted, therefore impeding cow comfort. Overall, Class I sales are steady in all regions as school orders are strong.

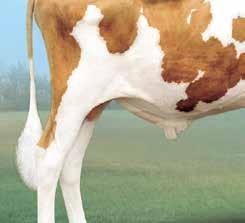

COMPLETE DISPERSAL DAIRY CATTLE

(70) High grade Holsteins. 50 Holstein cows including 44 milking cows averaging 89 lbs. milk with 85 scc. Ai breeding for many years and a lot of really fancy udders!! Cows are housed in sand bedded free stalls and milked 2x in robotic milkers that are manually operated. Fully vaccinated, on a regular hoof trimming schedule, and monthly herd health. Also selling 20 heifers mostly bred 6 months to calving. Coming from Malta IL.

AT OUR THORP LOCATION IN HEATED SHED

Tuesday, February 28th

CALL MARK AT 715-773-2240 TO CONSIGN

ADVANCE NOTICE

Tuesday, March 9th • 11 a.m.

EARLY CONSIGNMENTS BEEF COWS

(45) Beef cows bred for spring and summer calving. 70% black cows balance Red and Char cows. Housed outside on dirt lot. Fed a TMR with corn silage, peas and triticale, mineral, and 2 lbs dry corn. Nice set of gentle cows. Will be preg checked at the barn morning of the sale; (7) Black beef cows. Will be preg checked on sale day

EARLY CONSIGNMENTS FEEDER CATTLE

(78) Angus and Charolais steers and Heifers. Bovisheild 1 Shot, Covexin 8, Ivermec injectable, banded. All work done early January. Weaned last fall. 450- 600 lbs. Green and outside, Fancy!!; (22) Holstein steers. 2x vaccinated. Cold housing, on corn and pellets; (30) Holstein and Hol x Ang steers. 2x vacc, running outside, light flesh condition. 750- 950 lbs.; (70) Hol and Hol x Ang feeder hfrs. 2x vacc, outside, nice cattle. 750- 1000 lbs.; (13) Ang fdr strs and hfrs. 1x vacc. Not weaned, 550- 700 lbs.; (20) Ang x Hol strs and Hfrs. Vaccinated, cold housing, light flesh. 600 lbs. Reputation seller!!; (10) Holstein steers Vaccinated, green, outside cattle. 600 lbs.

Formerly Turenne Livestock

SALE EVERY MONDAY AND WEDNESDAY 5:00 PM

Selling Baby Calves, Hogs, Sheep, Goats, Feeder Cattle, Fat Cattle, Market Cows and Bulls

VERY COMPETITIVE MARKET PRICES

Call 712-432-5500 for daily market report

JWO NOTES & MARKET REPORT:

Big enough to make a difference, small enough to care!

A man said there’s no point in complaining about your lot in life, half the people don’t care and the other half probably figure you had it coming

Dairy cows sold lower today. Top $2,100 Jason Brubaker, Thorp. $2,000 Jason Nolt, Boyd. Many good cows $1,400-1,950.

Springing Holstein heifers $1,300-1,750. Opens $95-120 per pound. Single birth Holstein heifers calves $35-80.

Breeding Bulls $850-1,300. Market Bulls $70-90NT

Choice Holstein steers $138-145 cross breds up to $146. Holstein feeder steers $105-135. Crossbreds up to $170. Holstein bull Calves $95-160. Cross bred bull and heifer calves $200300. Wednesday crossbred calves $300-425.

20% of Market cows sold $79- 90. Top $92 Jamin Hess, Athens. 50% sold $62-78. Butcher hogs $70-80. Sows $59-66. Boars $24.

3x3x8 Alfalfa grass mix $85-115. Grass rounds and squares $55-70. Older first crop grass $2535. Baleage $40-75. Small squares grass $3.75-5.50. 3x4x8 wheat straw $90-100. As always, we really appreciate your business!

Dairy & Hay sale EVERY Thursday starting with hay @ 10:00 followed by Dairy Cows @ 11:00 sharp, then bred heifers, open heifers and feeders followed by calves, market bulls, fat cattle and cull cows. Special feeder sale 2nd & 4th Thursday.

As I sit here pondering my thoughts on what to write I can’t help but feel some empathy for the producers that are going to feel financial pain in the coming months. It appears that dairy markets around the globe are sending the signal that less milk growth is needed to meet current consumer needs. That means more financial pain is required to disincentivize production.

It is truly amazing at how efficient world milk production is at ramping up and slowing down based on price movement. One positive about the current situation is there remains limited U.S. plant capacity to handle more milk. This may limit the amount of financial pain the industry will need to feel in this supply rebalancing cycle. That will all start to change as new plant expansion projects begin to ramp up new capacity. I am aware of at least 12 projects that are planned to come online over the next several years.

Spot CME Group trade continues to remain doggy with a few products trading values only seen in bear markets. Barrel cheddar is back in the mid $1.50’s with block cheddar trading in the upper $1.80’s. Based on current whey prices and DVi formula guesses this equates to a Class III price near $17.00. At that value

there will be many herds going negative cashflow for their March milk check. Futures remain more optimistic than this with March trading near $17.60. Pay prices like this don’t work with $500 meal and $7.00 corn.

Butter prices remain mildly supported in the U.S. and international markets due to tight stocks. Although supply fundamentals remain positive yet, prices are 77 cents off of their September 2022 high trading in the upper $2.30’s. This represents a $3.23/cwt change in Class IV prices just from this butter move. Nonfat dry milk prices seem to be struggling around the globe as supplies are building and offerings overwhelming buyers. Like butter, nonfat dry milk has seen a significant 60 cent price decline since the fall of 2022. This represents a $5.16 cent adjustment to the Class IV price. Combined, Class IV has taken a $7.49 cent hit over the prior 4 months.

All eyes are on the EU dairy markets. If EU prices hold, world markets may be putting in a seasonal low. If EU prices continue to fade, look for more milk price erosion in the U.S. and international markets.

SAN PEDRO DE LOS MILAGROS, Colombia – Sustainability and protability have gone hand in hand for Andres Felipe Gallego Elejalde as he has built his dairy farm in the South American country of Colombia over the past 20 years.

Gallego created his dairy farm near San Pedro de los Milagros, an hour and a half from the city of Medellin, in 2002. Today, he has a herd of 60 head, typically milking about 40 cows twice a day. The herd produces an average of 41 pounds of milk per cow per day. Gallego’s herd is primarily grass fed, using rotational grazing, and calves year-round.

Colombia is one of the most biodiverse countries in the world, Gallego said.

“We have different climates and topographies, and we are privileged for having great weather that allows us to grow grass the whole year in most of the country,” Gallego said.

Gallego, who holds a degree in animal husbandry, manages his farm with the help a full-time employee whom he charges with the day-to-day operations. Gallego oversees the farm and makes the management decisions while working off the farm as a consultant.

“The salaries here are lower than in

the U.S., so for me, it is more protable to pay an employee and provide technical assistance to other farmers than it is to run the farm by myself,” Gallego said. “Labor is about 12% of my total cost of production.”

Growing the farm has been a hurdle for Gallego but one he appreciates.

“When we established the farm, it was in bad shape; some of the pad-

docks were degraded because it had been mined, looking for gold,” Gallego said. “We had to x them by adding organic matter and planting stolons of kikuyu that we took from the paddocks in the best shape. It all had to be done by hand. Very few farms in the area have a tractor. The topography is quite steep, and having a tractor here is quite expensive. It is better to rent one from a

potato grower when it is needed.”

The 28.8-acre farm is divided into 30 paddocks of varying size dependent on the topography. Gallego’s grazing management includes moving his cows three times per day to give each paddock a resting period of 32 to 40 days.

All of the paddocks are planted with kikuyu, which grows well in the Colombian climate, Gallego said.

“We are located in the tropics and have only two seasons: winter and summer,” Gallego said. “The only difference is the rain we get. The winter months are the wet months, and we don’t get frost. During the summer, we get very little rain. Kikuyu is the predominant grass in the area.”

Gallego said kikuyu produces large volumes of grass, but the quality is poor, requiring him to supplement with a grain mix that consists of corn, soybean and minerals.

“Supplemental feeding is especially important during peak lactation, where they can produce over 90 pounds of milk,” Gallego said. “During this time, I offer extruded corn to fresh cows at the paddock. Each cow has a name, so I make a small paddock with electric net fence and set some feeders in it. Each cow is called by name; they come eat the corn and then go back to graze.”

When the rst cows came to the farm, Gallego said the cows were fed their supplemental feed and milked in the elds by hand. A horse was used to haul milk cans back to the farm, where it was picked up by the buyer. Gallego said for a few months, the milk was

picked up without being refrigerated before a holding tank was installed so the milk could be chilled.

After two years of milking by hand, Gallego purchased mechanical milking equipment.

“We still had to move from paddock to paddock to milk, but it had two units and it ran by a fuel engine, which helped reduce milking time and improved the quality of the product,” Gallego said.

The farm has continued to advance its technology. Eight years ago, a milking shed was built. The new facility included four milking units with a pump to send milk directly to the tank.

“This shed greatly improved the quality of life for the worker and the quality of the milk we sell,” Gallego said.

Gallego said one of the greatest benets of grazing is the longevity of the cows.

“Being on pasture all the time, our cows can last up to 10 years,” Gallego said. “The third or fourth lactation is typically the best for our cows. I only keep 20% of the heifer calves for replacements.”

Those heifers are raised on raw milk with supplemented grain and bred with conventional semen at 17 or 18 months of age.

The emphasis on grazing dictates the breeding decisions Gallego makes.

“I want a cow suitable for grazing: smaller frame, better hoof and legs, more gut capacity,” Gallego said.

The herd has been inuenced by U.S. genetics, which Gallego said has boosted production but has decreased grazing efciency.

“Most U.S. dairy cows are conned and fed (a total mixed ration),” Gallego said. “They are tall cows that demand

a lot of energy only to keep the metabolism going. In the U.S., there is better feed quality to meet the nutritional needs of this type of cow. Here, we need to supplement that type of cow heavily, and it is not easy to make a prot as we do not have any type of subsidy from the government.”

Those factors led Gallego to begin crossbreeding his Holsteins with Jerseys to reduce size and energy demands while improving milk solids. Gallego said that while he is paid for his milk based on volume, there are bonuses for butterfat and protein. In the past two years, he has started using New Zealand genetics to continue working toward the most efcient grazing animal he can create.

“We reduced a bit of production but get a better price, and we can meet the cows’ nutritional requirements with less supplementation,” Gallego said.

Gallego said marketing milk in Colombia is informal, with over half of the country’s 3 billion pounds of production being sold as raw product with few sanitary controls. There is great demand throughout the country for artisanal cheese, Gallego said.

Like his peers around the globe, Gallego has witnessed sky-rocketing input costs, and protecting his margins has become a focus; Gallego has found his answer in regenerative agriculture.

“Since 2018, I have been studying and implementing regenerative strategies in my production system,” Gallego said. “I want to combine genetics with improved grazing management, reducing the need for external inputs, so that I can produce better quality, more profitable milk. I hope to someday direct market my products to well-informed consumers.”

By Sherry Newell

Contributing writer

By Sherry Newell

Contributing writer

Siemers-Peterman of Cleveland, Wisconsin, was the Distinguished Service

recipient, while the Daningers, of Forest Lake, were named Golden Graduates.

For Siemers-Peterman, it was an award from a different school and state than the one that nurtured her background in dairy. The University of Wisconsin-Madison graduate is a former Badger Dairy Club president and Master Wisconsin Agriculturalist Award winner but said she became a University of Minnesota enthusiast in 2013 when her daughter, Crystal, was a student on the St. Paul campus.

“Things do change,” Siemers-Peterman said. “I might be the most vocal Wisconsin recruiter and cheerleader for the Gophers. You have

something truly wonderful here; treasure it.”

An alumnus of collegiate dairy judging herself, Siemers-Peterman has assisted in coordinating judging practices for the Gopher teams. She has mentored dozens of youth throughout her career at Siemers Holsteins Inc. and Cupid Cattle Company. With her daughter and mother Marlene, she has bred, acquired, managed and developed heifers and cows that have earned 75 All-American and Junior AllAmerican nominees.

The Gopher Dairy Club singled out Siemers-Peterman for her work coaching and hosting judging teams, serving on committees and hosting international students all the while promoting the University of Minnesota. In accepting the award, she explained her reasons for being a Gopher advocate.

“Because I want to give back to the school that has been so important to Crystal and to me,” she said.

The Daningers were cited for similar support to the Gopher Dairy Club and its members. Both Pat and Sharlene were 1985 graduates of the university, where Sharlene was a founding member of the club. They operate a 110-cow registered Holstein dairy coupled with a micro-creamery, Au-

tumnwood Farm. Their four adult children are also alumni of both the university and club.

Sharlene credits Dr. Les Hanson, the club advisor, for his vision of an active dairy club.

“I have so many great memories,” Sharlene said.

The Daningers began dairying on Pat’s home farm, milking 38 cows in a tiestall barn. Sharlene worked rst in Extension and later for MidAmerica Dairymen Inc. They

began Autumnwood Farm in 2008 and now provide milk to 95 grocery stores, coffee shops and cafes. Six ice cream shops use their mix, and their on-farm store is a popular local business.

Their daughter, Mariah, works on the farm full time, and their son, Luke, works there part time.

Tuesday, February 28

Tuesday, March 14

Tuesday, March 28

Tuesday, April 11

Tuesday, April 25

Through Autumnwood Farm and the dairy herd, the Daningers provide hands-on experience to high school, college and veterinary students. Gopher Dairy Club members and other on-campus organizations have toured the farm, and open houses and local tours have provided connections between consumers and the dairy industry.

Pat said that when they received notication of the Golden Graduate award, he did not know what to make of it.

“We are in large part standing on the shoulders of those who came before us,” Pat said. “Pillars and pioneers of the industry are among the past winners of this award.”

In addition to the awards given to the Daningers and Siemers-Peterman, the Gopher Dairy Club recognized its current members with a host of scholarships and achievement awards. They also recognized dairy judging and Dairy Challenge participants.

Isaac Ro , of Elgin, Minnesota, stands with the University of Minnesota’s head of animal science, Dr. Michael Schutz, Feb. 19 in Roseville, Minnesota. Ro was the winner of the Gopher Dairy Club’s R.W. Touchberry Award. The award, in its 40th year, singles out the university’s outstanding junior in animal science and carries with it a $1,000 scholarship.

Ashley Hagenow of Poynette, Wisconsin, was named the Dr. Bill Mudge Outstanding Senior, while Isaac Rott of Elgin, Minnesota, received the R.W. Touchberry Outstanding Junior in Animal Science award. Haley Beukema of New Richmond, Wisconsin, received the Dylan Fulton Outstanding Rookie award. Keenan Thygesen of Tunbridge, Vermont, was the winner of the Douglas Siem Memorial Award for highest ranking new student.

SHERRY NEWELL/DAIRY STAR

Gopher Dairy Club secretary

Brenna Connelly (le ) presents the club’s annual Outstanding Rookie Award to Haley Beukema, of New Richmond, Wisconsin, Feb. 19 in Roseville, Minnesota. The award is named a er the late Dylan Fulton, who was a club member.

Ashley Hagenow, of Poyne e, Wisconsin, stands with Gopher Dairy Club member Isaac Ro Feb. 19 at the club’s annual banquet in Roseville, Minnesota. Hagenow was the 2023 Outstanding Senior of the University of Minnesota’s Gopher Dairy Club.

In the hopes of reaching carbon neutrality, on-farm manure digesters have grown in popularity.

Nature Energy, a biogas company founded in Denmark, and recently acquired by Shell Global, is hoping to bring its European model of co-digestion to farming communities in North America, beginning with towns in Minnesota and Wisconsin.

“Our rst two plants will be in Benson and Wilson (Minnesota),” said Alexis Glick, CEO of Nature Energy North America. “We are working around

the clock with the hope that we can put shovels in the ground as early as this year and have gas in the pipeline and connection to the grid by 2025.”

Glick said Nature Energy has the permits in place and is working with farmers and municipalities in those areas.

“There are many more (sites and plans) behind the scenes that we are working on building as well,” Glick said. “The reception from the farmers has been extraordinary; I hope we can get out and meet with many more.”

Although Shell Global expects to complete the transaction for acquiring Nature Energy by the end of March, Nature Energy will operate as a wholly owned subsidiary of Shell Global under its existing name.

“The Nature Energy team and our team members will deliver on our aggressive pipeline growth plans in Europe and North America,” Glick said.

Glick said Nature Energy has over 420 people in its organization, mostly in Europe and North America. Although the company was founded in Denmark 40 years ago as a traditional gas utility, 10 years ago it transitioned to become a biogas company. Today, Nature Energy has 12 plants in Denmark, which supply about 30% of the green gas that powers the electric grid there. Nature Energy is the largest biomethane producer in the world, according to Glick.

The company has three main goals in North America.

“One, how do we protect farmers’ freedom to operate, knowing that methane is one of the largest greenhouse gas emitters,” Glick said. “Secondly, with the passage of the Ination Reduction Act, how do we begin to adopt, grow and facilitate the growth of biogas facilities in North America while recognizing that we (the U.S.) are the

largest individual producer of waste in the world.”

Glick said this includes needing solutions for waste management, food insecurity and energy insecurity.

“The third goal is to address the increased pressure – not just on government but also on businesses – to report their emissions,” Glick said. “As a result of that, more and more companies are cracking down and making net-zero commitments. For farmers, if you’re supplying to (any number of businesses), you are being asked what your sustainability practices are, and this is something that is very front and center on the minds of farmers and is key to their freedom to operate every single day and sell their products.”

Nature Energy’s plan is to offer solutions through its codigestion system.

“The vast majority of digesters in the U.S. are on-farm

manure digesters that are taking the dairy manure and producing gas,” Glick said. “Many of those farmers are using that to power their operations and, in some cases, converting that gas to support the electricity grid in their local community.”

Glick said some farms are converting the gas into compressed natural gas that can be used for trucking milk to a local processor.

“In most cases, the manure is used in an on-farm digestion model where a limited amount of power is being created, but it’s creating a sustainable dairy, which is outstanding,” Glick said. “It has been fantastic to see those who have adopted on-farm digestors be successful with them.”

An issue, however, is cost. Most on-farm digestors are only

economically accessible to large operations, Glick said.

“Many dairy farmers do not have the capital to invest in what they need to meet net-zero goals,” Glick said. “Nature Energy can get them there because we are bringing the capital to the table to help them be a part of this energy transition.”

Glick said Nature Energy’s system is different in that it uses co-digestion plants to create green local economies – with farmers being important members.

“We are bringing together manure and other forms of organic waste, and we are combining the two to create a much higher density gas,” Glick said. “The amount of power we are producing in a Nature Energy biogas is 10 to 20 times (more than) the largest biogas facilities that exist in North America.”

In the co-digestion model, feedstocks are added to manure, which can be of a wide variety such as glycerin, sugar, beets, residues from cover crops and many others. Manure and feedstocks are trucked in separately to the facility. They each go into separate cargo bays with doors that immediately close after entry. A pipe connects to tanker trucks and extracts what is in those tankers, whether manure or feedstocks. Then, it takes it into the biogas facility.

As the manure and feedstocks are extracted, a few other tasks are completed simultaneously, which only take a few minutes. The rst is washing down the trucks so there is no detection of odor. Also, in the case of the manure, it is being measured for its makeup such as amounts of nitrogen, phosphorus and potassium. Part of what is being produced when combining the manure and feedstock is a higher quality gas and a higher quality of digestate, or fertilizer.

“When we use a co-digestion process, where we are putting lots of things together, we can help predict and control the outcome based on the types of things that go inside that co-digestion model,” Glick said.

The process extracts methane and puts the green gas into an existing pipeline with a local gas utility, using it to help supply power to local commercial customers. The methane gas can be compressed, liquied or used in various forms.

Through the process, Nature Energy also sequesters the carbon dioxide and cleans it.

“We’re creating what we call ‘Clean Green CO2,’” Glick said. “That is important because our goal is to reduce greenhouse gases in the environment, but we can also use that cleaned carbon for a number of purposes.”

Those purposes can include carbonation for beverages, refrigerants and other products.

“We are extracting the methane and the carbon, and when we combine it with excess hydrogen or excess wind power, we can produce even more gas,” Glick said. “What we are constantly looking at is the amount of output we can create in terms of how much energy can be produced, how that energy can be used and – very important for the farmer – the quality of the digestate that we are bringing back to the farmer.”

That digestate can be specically controlled to help the farmer who supplied the manure in the rst place. For example, digestates can be made to help farmers with nitrogen, phosphorus and potassium concerns.

“We are trying to give farmers back a more nutrient-rich digestate that will improve yields and quality to help, in some cases, displace the use of articial fertilizers,” Glick said.

Nature Energy designs, builds and operates its own facilities. In Denmark there are 12 Nature Energy plants running all day, every day within 25-30 miles of one another, so they can share biomasses to increase efciency while supporting local jobs, infrastructure, trucking and distribution.

“How do we help the farmer remove from their land the thing that they are being punished the most for, which is the manure that sits out on the land or is in a lagoon or being stockpiled?” Glick said. “How do we remove it so that we are taking away those greenhouse gases and provide back through our co-digestion process basically de-gassed manure that has higher nutrient density, the nutrients that the soil needs to produce better cover crops nearby or provide a really healthy bedding mechanism.”

To address what it takes to join in on Nature Energy’s process, the company partners with and assists farmers in changes they make, such as acquiring sand separators or building reception pits with agitators.

“We also have the ability to help farmers switch to straw pellets or digested manure solids to bed the cows,” Glick said. “We are removing the costs of taking away the manure as well.”

EPA regulations, federal and state guidelines, rising ination and consumer demands for green processes are some of the many farming pressures Nature Energy is aiming to address.

“The headwinds (for farmers) are enormous,” Glick said. “My fear is that we are not moving fast enough. The regulatory scrutiny is growing daily.”

Glick said she sees Nature Energy’s solution positively affecting all involved in the green communities it creates.

“If we do this right, we will protect our farmers, we will protect our food supply, we will protect our energy independence, and we will reduce the amount of fossil fuel use,” Glick said. “At the same time, we will engage a generation of kids who care deeply about protecting the planet and enable them to help lead the green transition with us.”

• Speci cally-selected bacteria that work together

• Added enzymes speci cally formulated to boost feed ef ciency

• Proprietary technology that lasts longer—our bacteria is grown and processed in order to remain stable over longer periods of time.

• Contains potassium sorbate, which starts to work immediately and does not have to compete with epiphytic microbes, and does not depend on acetic acid like Lactobacillus buchneri, a common ingredient in other silage inoculants.

By Tiffany Klaphake tiffany.k@dairystar.com

By Tiffany Klaphake tiffany.k@dairystar.com

ALBANY, Minn. – Brian Weyer has experienced many ways of milking cows in his career, but an investment he made three years ago will extend his career for years to come.

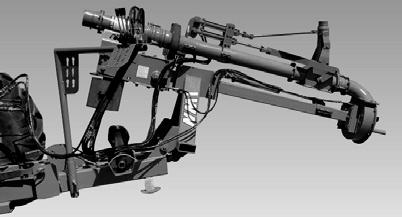

In March 2020, Weyer installed a guided-ow DeLaval VMS V300 robotic milking system at his farm near Albany.

“I’ve never been a fan of milking cows,” Weyer said. “Working with cows is ne, but when milking, (a cow) always has to kick you or knock a milker off.”

Since the installation, Weyer has more exibility with his schedule and has more time with family: his wife, Krissy, and children, Liam, Noah and Josy.

Weyer said he enjoys farming more.

“I get to see my kids at night now,” Weyer said. “That’s something I never used to do.”

Prior to milking with a robot, Weyer would milk the cows after supper. By the time he came back in, the kids would be in bed. With all three of their children active in sports, the Weyers stay busy attending events.

Weyer now has the time to do others things on the farm.

When there is eldwork to be done, Weyer goes out right away in the morning, and his dad, Mike, takes over after morning chores are complete to give him a break from the tractor.

“It helps split the day up so we both don’t have to work as hard,” Weyer said. “Especially in the spring when we haul out manure, that is a two-day project, and now, I can get started on that right away in the morning.”

The Weyers farm 200 acres of corn and alfalfa, and with so many farmers in the area, Weyer said land prices are very competitive; he has just enough land to produce forage for the herd.

The addition of the robot has also provided unexpected efciencies on the farm.

“During eldwork, I can just keep going,” Weyer said. “I don’t have to stop to milk the cows.”

Mike considers himself retired but helps on the farm daily.

“Dad likes the robot now, but at rst, he was skeptical,” Weyer said. “He learned more about the robot than he ever

thought he would.”

If Weyer is away from the farm and gets an alert that something is not working correctly with the robot, he can call Mike to walk him through how to x the problem.

Weyer’s robot was installed by Farm Systems in Melrose, and they schedule three maintenance checks a year to change inations, rub-

Protects the face of the bunker better than any other facer.

With the high feed prices it is more important than ever to use the Fritsch Forage Facer to preserve the face of the bunker

THE ONLY MATTRESS THAT RIVALS SAND BEDDING!

•About 1 3/4” of air cushioning

•100% waterproof

•#1 for hygiene

•No need for a top cover

For all your hydraulic connection applications, we provide a wide variety of hydraulic connection options, including Flat-Face couplers, Poppet-Style couplers, Screw-Type couplers, Volvo TEMA couplers, and Multi-Coupling units. With name brands like Faster, Stucchi, Parker, and Holmbury, we can provide custom hydraulic options to best t your needs!

ber valves, hoses or gaskets.

The robot has a cup that cleans the teats and uses a 3-D camera to nd the teat to then attach the milking unit. The system has a 25-minute wash cycle that runs twice a day.

“You can set it on a timed schedule, but I don’t have it set up that way,” Weyer said. “I want to make sure there aren’t a lot of cows waiting to get in when it runs.”

Weyer said he has been surprised by the robot’s reliability.

“It seems to work all the time,” Weyer said. “I only get a call once every couple of months.”

When Weyer does get a call from the robot, it is usually a cow-induced problem such as a cow kicking off one of the cups.

For Weyer, the robot transformed the decision to continue dairying.

Weyer came to the farm after high school. At that time, he was milking 50 cows in a stanchion barn with his dad. In 2009, Weyer and his dad put up the freestall barn and double-8 parabone parlor.

The freestall barn was renovated to accommodate the robot; cows were milked in the parlor up to the day the robot was ready.

Looking back at the transition, Weyer said he does not regret his decision.

“With the robot, it makes (chores) a one-person job instead of two like it was with the parlor,” Weyer said.

When Mike wanted to slow down with milking cows, Weyer debated other types of farming but ultimately decided dairy was for him.

“I wanted to stay in dairy to get that steady pay check, Weyer said. “I thought about other types of farming, but there doesn’t seem to be as much money in those.”

The robot was a way to make that happen and lessen the hands-on milking chores.

“When my dad wanted to retire and be done milking cows, it was either nd hired help or get a robot,” Weyer said. “For us, it just didn’t make sense to nd three or four part-time employees. I never liked milking cows.”

Now, Mike does the morning chores, and Weyer does the evening chores.

The technology that comes along with the robot has made it so Weyer and Mike cannot only take a step back from milking duties, but they can also learn more about each individual animal.

The cows wear activity collars and ear tags that record production levels,

robot visits and health, among other things.

Milk production has risen close to 10 pounds per cow, Weyer said.

“I mainly just watch the production levels,” Weyer said.

Weyer said he is more aware of how the weather affects the cows.

“If there is a change in weather, they are a lot more active,” Weyer said. “They seem to have more energy when the temp changes or a drastic weather change is coming. … Once it changes, they get lazy, and you’ll have more fetch cows.”

The data can be accessed on the computer or through an app on Weyer’s phone.

“Now it’s up to the cows if they want to push themselves in production,” Weyer said. “They can get milked more if they want, and some are just ne getting milked twice a day.”

To help with the transition from parlor to robot, Weyer pushed the cows through the robot after he milked in the parlor to show the cows the pellets and encourage them to enter the robot.

Weyer said they rarely have problems with cows not going into the robot.

“Our fetch rate is about 5%,” Weyer said. “The heifers we hardly have to train in. We push them through once maybe twice, and then, they are good to go.”

Weyer has a modied guide system for his robot. The system will automatically kick out cows that keep trying to get in just to get at the pellets, saving him time and money.

“Because of that, our pellet consumption is half of the free-ow system,” Weyer said.

The robot reads the ear tag of each cow as she enters and determines how much pellet that cow should receive. On Weyer’s farm, each cow gets 5-5.5 pounds of pellets a day. Because the cows receive pelleted feed in the robot, Weyer has adjusted the herd’s ration.

Fresh and treated cows are milked separately with a vacuum pump housed off the maternity pen.

“We have a hoof trimming shoot that we never really used and have that by the maternity pen to milk the fresh cows and treated cows in,” Weyer said.

Weyer visited a handful of robotic dairy farms in the area before deciding which style of robot to install.

“I like that I don’t have to milk cows; my time is exible now,” Weyer said. “I would say the robot has already paid for itself with the convenience. I don’t regret it at all.”

Planning Your Dairy Farm Future is a four-session, cohort-based program. Each class will include short lectures, follow-up activities and group discussion with other dairy farmers. Session one is on leadership and personal introspection. Session two is on positioning your farm and people for success. Session three is on identifying options for business success. Session four is on options to position your farm for the future. This program is a partnership between the University of Minnesota Extension and Minnesota Dairy Initiative. For more information and to register contact Jim Salfer at salfe001@umn.edu or Leah Bischof at 320-429-0611 or leahbischof@gmail.com.

– March 2, 9, 16, 23 at Charlie’s Cafe in Freeport, Minnesota.

Registration is open for Practical Farmers of Iowa’s Midwest Covers & Grains Conference from 8 a.m. to 4 p.m. March 2 at The Hotel at Kirkwood Center, 7725 Kirkwood Boulevard SW, Cedar Rapids, Iowa. Attendees will have a chance to network with small grains and cover crop buyers and sellers, and the event will have sessions for cover crop beginners and experienced practitioners. PFI’s Midwestern small grains network extends across Illinois, Iowa, Minnesota, Nebraska and Wisconsin. Full conference details, including the list of sessions and speakers, are available at practicalfarmers.org/midwest-coversand-grains-conference. For questions, contact Taylor Hintch at 515-232-5661 or taylor. hintch@practicalfarmers.org.

To help farm families build relationships and set family goals, Iowa State University Extension and Outreach is offering a Farm Couple Getaway. The event is aimed at farmers wanting to take advantage of activities to improve farm family communication, work on farm or family goal setting, farm transitions or looking for a weekend away to discuss farm and family issues. There is no cost to attend the program as food, lodging and other expenses are covered by sponsorships. Registration will be on a rst-come, rst-served basis and will be limited to 10 couples per event. Registrations are due two weeks prior to each session. Registration brochures for the various sites can be obtained from Jennifer Bentley, dairy specialist with Iowa State University Extension and Outreach, at jbentley@ iastate.edu, or at the Iowa State University Extension and Outreach Winneshiek County ofce, 563-382-2949.

– March 3-4: Cobblestone Inn & Suites in Holstein, Iowa.

Irrigators, mark your calendars to attend the annual Irrigators Clinic. The event will be held March 6 at the Greenwald Pub, 310 First Ave N., Greenwald, Minnesota. This event will be of interest to anyone who is actively engaged in irrigation on agricultural lands and interested in soil health, farm economics and research.

For more information and to register, visit www.stearnscountyswcd.net/irrigatorsclinic.

A webinar series from the University of Wisconsin, the Badger Dairy Insight, will provide the latest research-based dairy information to improve animal welfare, breeding and genetic selection, automation and modernization, and nutritional decisions for producers, dairy workers and managers, ag professionals and educators. The webinars are Tuesdays from 1-2:30 p.m. Register at go.wisc.edu/farmreadyresearch.

– March 7, 14, 21

The I-29 Moo University Dairy Webinar Series continues from noon to 1 p.m. March 9 with a focus on new research for the complete management of the dairy cow at dry off. The program will be presented by Dr. Luciano Caixeta. There is no fee to participate in the webinar; however, preregistration is required at least one hour before the webinar. Preregister at https://go.iastate.edu/PEXNVY.

For more information, contact: in Iowa, Fred M. Hall at 712-737-4230; in Minnesota, Jim Salfer at 320-203-6093; or in South Dakota, Heidi Carroll at 605-688-6623.

Minnesota Dairy Initiative is sponsoring a Producer Night Out March 9 at Howard Lake American Legion from 8-9:30 p.m. This event will have industry professionals speak about current topics with dairy farmers. The featured speaker will be Jared Holt, from Ascent Financial, who will speak on farm transition as well as a producer panel discussion. For more information, contact Jill at 952-240-9993 or jzieroth@co.carver.mn.us.

Edge and Minnesota Milk are excited to host a dairy farmer social to engage with other dairy farmers from around the Midwest. The event will take place from 5-7 p.m. March 9 at Great Shots, an indoor golf experience, 2505 W. Benson Road, Sioux Falls, South Dakota. Edge and Minnesota Milk members will have two hours of unlimited play at the golf bays, and we will provide dinner. RSVP to Peter Scharpe at pscharpe@voiceofmilk.com or 507-317-9127.

The Wisconsin Ayrshire Breeders Association annual meeting will be at 11:30 a.m. March 11 at the Tundra lodge in Green Bay, Wisconsin. For more information, visit wisconsinayrshire.com.

Mid-State Technical College will host its annual Farm Tour from 9 a.m. to 3:30 p.m. March 15. The public is invited to the in-person event to explore the latest technology and agricultural practices designed to enhance farming operations.

This year’s tour includes a showcase of Marshland Dairy in Spencer, Wisconsin, owned and operated by Josh and Sarah Moga. Since taking over the dairy in 2015, the Mogas have modernized the farm through gradual budget-minded investments, including installation of automatic alley scrapers and a used robotic milker in repurposed existing buildings. They also converted to Jersey cows and began breeding and selling cattle to increase protability.

Participants will also tour Bells’ Runway Acres, a 1,250-acre corn and soybean farm in Marsheld, Wisconsin, co-owned by Josh and Ken Bell. Converted from a dairy farm in 2015, the Bells will be showcasing their move to a dedicated grain operation, with all aspects of the business performed in-house, including soil management, planting, harvesting, grain drying, storage and trucking.

The PDPW Business Conference will be March 15-16 at Kalahri Resort in Wisconsin Dells, Wisconsin. This event will offer best-in-class education and networking that strives to provide education and inspiration for a vibrant and thriving dairy infrastructure, leaving a positive legacy for generations to come. We bring together thousands of dairy farmers and agribusiness people from around the globe. Advance your capabilities through dozens of educational sessions. Discover new leadership paradigms; cultivate team building and elevate internal and external communications; strengthen your business strategy; and amplify your herd production, health, performance and beyond.

Winona County seeks dairy princess candidates

The American Dairy Association of Winona County seeks candidates to participate in this year’s dairy princess program. Dairy princesses and ambassadors serve as goodwill ambassadors for the dairy industry through appearances that help explain dairy farmers’ passion for taking care of their animals and land while providing nutritious food for people locally and throughout the world.

A princess candidate must be a high school graduate by July 1 but not yet 24 years old. A candidate must be a U.S. citizen or permanent resident. Additionally, she must have a connection to dairy farming through one of four ways: you or your family own and operate a dairy farm in Minnesota; you or your parents work on a dairy farm in Minnesota; you or your parents care for or custom raise dairy cattle for a farm in Minnesota; and either you or your parents own or lease a dairy animal(s) that are housed on another dairy farm in Minnesota.

Serving as a county dairy princess is also the rst step toward potentially becoming Princess Kay of the Milky Way. Ten nalists will be selected to compete for the Princess Kay title in August. At all levels of competition, contestants are judged on their communication skills, personality, enthusiasm for dairy promotion and general knowledge of the dairy industry.

Senior dairy ambassadors are also sought and must fulll all the above criteria with the exception of age. A senior ambassador must be between age 13 and a high school graduate.

Dairy producer bus to Central Plains Dairy Expo

Join the Stearns County Dairy Advisory Committee and central area Minnesota Dairy Initiative on a bus trip for dairy farmers to Central Plains Dairy Expo. Dairy farmers, and those involved in the dairy operation, are invited to join the bus trip to the Central Plains Dairy Expo event departing March 28 and returning March 29 in Sioux Falls, South Dakota. If attendees are interested in learning more about the CPDE event, visit https://www.centralplainsdairy.com.

Save the date for this bus trip for dairy farmers and employees of dairy farms to get out and about while getting professional development in the dairy eld at CPDE. A portion of the transportation cost will be covered by Stearns County DAC and central area Minnesota MDI. This bus trip to and from the event is an opportunity to network all while being transported to one of the most exciting ag events of the winter season. This trip will be for one overnight at the expo. Two pick up locations in Stearns County will be offered to attendees. This service provides participants an opportunity to network with other dairy producers in Stearns County that are riding on the bus to attend the CPDE Welcome Reception featuring a country singer concert, experience a full day of educational seminars and walk through the trade show.

Meals, hotel and conference expenses will be covered by attendees as well as a portion of the bus expense. The bus cost will depend on number of participants, but we anticipate approximately $50/person. If you have interest in using this bus service, communicate your interest by lling out the registration form here https://z. umn.edu/DACCentralPlains23. Sign up using the link as soon as possible due to limited space on the bus. Questions can be directed to Dana Adams at 320-2042968 or Leah Bischof at 320-429-0611. Residents of Stearns, Benton, Morrison and Sherburne counties can direct questions to adam1744@umn.edu or 320-2003135.

This remarkably productive group leads our dairies in USDA dollar value, which includes milk, butterfat and protein production plus milk quality. A lot of high quality dairy products resulted from the good work of these folks along with our other members. Congratulations and thank you.

• Provides calves with key nutrients while optimizing calf health.

• Contains a minimum of 150g of bovine globulin protein, up to 50% more than other products on the market.

• Free from all major colostral transmissible diseases.

• The first colostrum replacer on the market to contain

Feed: 320-468-6655

Toll Free: 877-468-6655

Agron./Petro: 320-468-2509 Toll Free: 877-438-3378

With over 40 years experience, Wisconsin Silos is the most complete builder of concrete silos in the United States. From pouring the footing, to xing the accessories, unloaders, feeders, conveyors, silo pipes, silo distributors & silo chutes.

WE

Meet

Bales • 1st, 2nd & 3rd Cutting Hay WE DELIVER

Also For

WE’RE

Target Your Customers!

CONTACT

Elsbernd IBA, Inc. Calmar, IA • 563-419-6757

River Divide IBA Epworth, IA • 563-543-7710

IBA Fahrney, Inc. Monroe, WI • 608-325-4248

Dairyland Equipment

Menahga, MN • 218-564-4958

Manitowoc IBA

Whitelaw, WI • 920-732-4680

LOCAL

Miller IBA Dairy Supply Goodhue, MN • 507-273-1026 Balzer IBA Owatonna, MN • 507-456-1617

Zumbro Ag Solutions Zumbrota, MN • 651-380-2856

Valley

Dairy Supply Corona, SD • 608-432-5224

HENNESSEY’S BEST

7,200

FT (2 Balls) ...........$2350

OIL AND DEF

HENNESSEY’S BEST

HYDRAULIC FLUID

5-GAL Bucket ..................$6295

55-GAL Drum ................$59795

15W-40 ENGINE OIL

5-GAL Bucket ..................$6895

55-GAL Drum ................$68830

10W-30 ENGINE OIL

5-GAL Bucket ..................$6895

55-GAL Drum ................$68795

#30 ENGINE OIL

5-GAL Bucket ..................$6995

55-GAL Drum ................$70780

DIESEL EXHAUST FLUID

2.5-GAL JUG ......................$1155

55-GAL DRUM ...............$17420

275-GAL TOTE ...............$68170

DRUM DEPOSIT ...............$9000

7,200 Ft & 9,000 Ft ..........$4850

16,000 FT ...........................$4680

HAY PRESERVATIVE

HENNESSEY HAY PRO

By Chemorse - 68% Propionic

Buffered W/ citric acid

450lb Drum ....................$39650

2400lb Tote ..................$210000

TILLAGE (Made in USA)

4” Twisted Shovels ..........$1995

7” Sweeps ..........................$1275

9” Sweeps ..........................$1375

11” Sweeps ........................$1475

TOTE DEPOSIT ...............$25000

BULK DEF - $2.10 /GAL IN YOUR CLEAN CONTAINER

COW TOWELS (4000 ct.)

1 Box....................................$3195

5+ Boxes ............................$3095

SHOP TOWELS 700 .......$2995

PALLET FORKS

WALK-THROUGH ..........$67500

TIRES SKIDLOADER

...........................$12795 12X16.5 ...........................$16395 14X17.5 ...........................$29696 TRACTOR FRONTS 6.00X16 ..............................$8795 6.50X16 ..............................$9895 7.50X16 ...........................$12095 11L-15 3-RIB ...................$17395 11L-15 4-RIB ...................$19175 10.00X16 3-RIB..............$19895 10.00X16 4-RIB..............$21295 11.00X16 3-RIB..............$23995 11.00X16 4-RIB..............$23475 14L-16.1 4-RIB ...............$37425 TRACTOR REARS 13.6-38 Bias ....................$51095 15.5-38 Bias ....................$61095 18.4-34 Bias ....................$73095 18.4-38 Bias ....................$82575 20.8-38 Bias ..................$119595 18.4-42 Radial .............$142575 WAGON TIRES 7.60-15 8PLY .....................$6995 9.5L-14 8PLY...................$10475 9.5L-15 8PLY......................$7850 11L-14 8PLY....................$11495 11L-15 12PLY ....................$8595 12L-15 12PLY .................$10595 12L-16 12PLY .................$15595 31X13.5-15 10PLY ........$22475 11L-15 Tire, tube, & rim $17095 12L-15 Tire, tube, & rim $19095 SILAGE BAGS Ag-Bag Brand Call for pricing and availability **PRICES GOOD FOR ON-HAND INVENTORY ONLY** WE SELL THE BEST, THE HELL WITH THE REST 2023 AUCTION DATES APRIL 20 JUNE 15 AUGUST 17 OCTOBER 19 DECEMBER 21 WWW.HENNESSEYIMPLEMENT.COM Dodgeville, WI • (608)935-3326 Fax (608) 935-5342 • nhparts@Mhtc.net Monroe, WI • (608)328-8331 Fax (608) 329-4329 • hennparts@Mhtc.net CONCRETE PRODUCTS 1-800-982-9263 Serving Minnesota, Iowa and Wisconsin Since 1965 www.alsconcreteproducts.com AL’S BUNKER SILOS AVAILABLE IN ONE OR MULTIPLE BAY DESIGN Height Available: 5’, 8.6’ & 12’ ALSO AVAILABLE: • Feed Bunks • Cattle Slats • Holding Tanks • Cattle Guards 29033 Co. Rd. 17 Freeport, MN In St. Rosa 320-836-2284 www.arnzenconstructioninc.com For All Your Ag & Robotic Barn Building Needs

Application open for MDA value-added grant program

The Minnesota Department of Agriculture is now accepting applications for the Agricultural Growth, Research and Innovation Value-Added Grant Program. Online applications are due March 15.

The program provides funding to help processors add value to Minnesota agricultural products by investing in production capacity, market diversication and market access for value-added products.

Applicants must be an individual (including farmers), business, agricultural cooperative, nonprot, educational institution or local unit of government (including tribal governments) engaged in the processing of Minnesota agricultural products. Applicants must currently reside in Minnesota or be authorized to conduct business in Minnesota. The MDA anticipates awarding approximately $1 million in this round of funding using a competitive review process. The maximum equipment award is $150,000, and the minimum award is $1,000. Grantees are responsible for at least 75% of the total project cost as a cash match.

The application must be received by 4 p.m. March 15 through the MDA’s online application system. Decisions are expected in early May.

Todd County seeks dairy princess candidates

The American Dairy Association of Todd County is seeking candidates to participate in this year’s dairy princess program. Dairy princesses and junior ambassadors serve as goodwill ambassadors for the dairy industry through appearances that help explain dairy farmers’ passion for taking care of their animals and land while providing nutritious food for people locally and throughout the world.

A princess candidate must be a high school graduate by July 1 but not yet 24 years old. Additionally, she must have a connection to dairy farming through one of four ways:

– You or your family own and operate a dairy farm in Minnesota.

– You or your parents work on a dairy farm in Minnesota.

– You or your parents care for or custom raise dairy cattle for a farm in Minnesota.

– Either you or your parents own or lease a dairy animal(s) that are housed on another dairy farm in Minnesota.

Junior dairy ambassadors are also sought and must fulll all the above criteria with the exception of age. A junior dairy ambassador must be between age 14 and 17.

Serving as a county dairy royalty is also the rst step toward potentially becoming Princess Kay of the Milky Way. At all levels of competition, contestants are judged on their communication skills, personality, enthusiasm for dairy promotion and general knowledge of the dairy industry. All interested canadiates should contact Shirley at 320-815-2500 or Amanda at 320-260-1533 by March 8.

Olmsted County seeks dairy princess candidates

Olmsted County American Dairy Association is searching for dairy princess candidates for the upcoming year. A dairy princess of Olmsted County is a goodwill ambassador representing the dairy farmers of Olmsted County. You will attend educational and social events promoting the dairy industry. You will expand your leadership abilities through this program. We plan events throughout the year where you get to interact with young children and adults. You will attend social events such as the Honkers game dairy night, breakfast on the farm and various other ice cream socials. With all of this, you will expand your communications skills along with connecting with customers to tell your dairy story. You have the opportunity to attend the Midwest Dairy leadership event along with competing for Princess Kay of the Milky Way.

Qualications:

– You are a female between the ages of 18-24. If you are a senior in high school but not yet 18, you are eligible.

– You or your family own and operate a dairy farm in Minnesota.

– You or your parents work on a dairy farm in Minnesota.

– You or your parents care for or custom raise daily cattle for a farm in Minnesota.

– Either you or your parents own or lease dairy animals that are housed on another dairy farm in Minnesota.

Contact Carrie Sachs at 507-951-8372 or DeeDee Hart at 507-208-1877 if interested and we can give you more information.

·

·

·

·

Hay sales starts at 12:30 p.m. and are the 1st and 3rd Thursdays of the months of September thru May.

March 2, 2023

March 16, 2023

For more information, contact Kevin Winter 320-352-3803, (c) 320-760-1593 or Al Wessel at 320-547-2206, (c) 320-760-2979

Cheddar cheese

Gouda cheese

Pepper jack cheese

Cornichons

Dried apricots

Pitted green olives

Miniature peppers, drained or chopped sweet red bell pepper

Sliced salami