WANT TO WIN $100 CASH?

See page 20 of this section for details!

See page 20 of this section for details!

Volume 25, No. 1

PDPW Business Conference offers something for everyone

By Stacey Smart stacey.s@dairystar.com– Dairy farmers looking to deepen their arsenal of knowledge, and network with peers from near and far, will not want to miss the 2023 PDPW Business Conference. The two-day event will take place March 15-16 at the Kalahari Resort in Wisconsin Dells.

“If you have a stake in the conversation of the dairy industry, you need to be there,” said Cassandra Strupp, program manager at Professional Dairy Producers. “This is a chance to invest in yourself. The conference offers tools and information you can use to be better in your business and community.”

Forty-seven speakers will light up this year’s 30th annual business conference, the theme of which is “Empowering Success.” The conference promises to bring together the brightest minds in dairy to produce a premier educational event.

“What kind of tools and motivation do you need to be successful today, tomorrow or a year from now?” Strupp said. “The PDPW Business Conference offers the skillsets, awareness and education you can embody to be successful. Presenters come from both inside and outside of agriculture, which makes this event even more dynamic.”

This year’s conference will include sessions on water quality, carbon credits, business acuity, cover crops, udder health and much more. The conference caters to all types of learning styles – from longer listening sessions to hand-on hubs for those wanting to physically dive into a subject and learn a certain skillset.

The Nexus stage highlights product innovation, while the

February 25, 2023

MIDDLETON, Wis. –

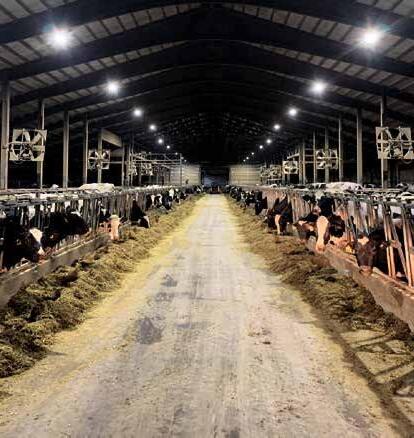

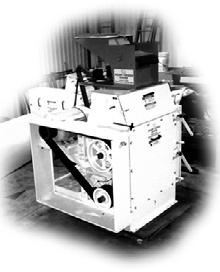

The Zieglers are better utilizing cows’ time in the parlor to complete tasks that previously kept the herd on their feet in the freestall barn. Instead of spending hours trying to nd cows that need reproductive shots, they now give shots on the rotary after having installed the ParlorBoss system in April 2021.

By giving shots in a more efcient manner, compliance improved by nearly 8% and the farm’s pregnancy rate climbed 9% all while reducing the amount of time cows spend in headlocks.

“It’s an awesome system,” Steve Ziegler said. “Anything we need to do with the cows,

we can now do while they’re milking.”

The Ziegler family milks

1,070 cows and farms 3,500 acres near Middleton. Three generations work side by side on Ziegler Dairy Farm, which was founded in 1862. Ziegler

and his four brothers – Andrew, Matt, Dan and Jon – are the fth generation on the farm they operate with their parents, Greg and Cheryl, and grandparents, Leo and Carol Ziegler. Cows are milked three times a day in the farm’s

48-stall rotary parlor that was installed in 2000. A 70-inch TV screen hangs on the wall near the exit of the parlor, clearly showing which cows need shots or need to be

Turn to ZIEGLERS | Page 8

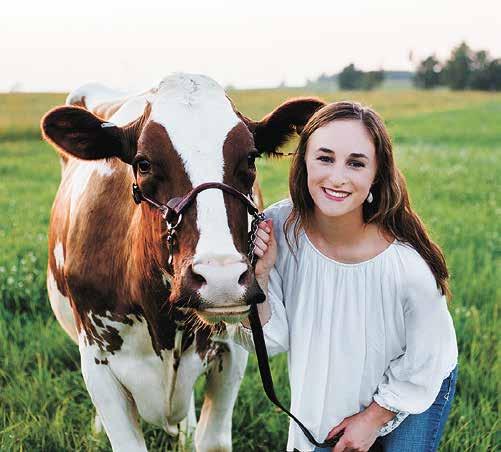

ROCKVILLE, Minn. –Before Hannah Molitor could accept an invitation to attend the State of the Union Feb. 7 in Washington, D.C., she needed to reschedule with area farmers.

“I had to do some checking around,” Molitor said. “I had some herds that I was already scheduled to test. I had to call all those guys.”

Molitor is a eld representative for Dairy Herd Improvement Association. She also helps at her family’s dairy farm, owned by her dad, Joe Molitor, and uncle, Tom Molitor. They milk 300 Holsteins near Rockville.

On the morning of Feb. 2, Molitor was in her coveralls and barn boots, doing some milk testing in a tiestall barn, when her cell phone rang.

received a call

ing me to the State of the Union,” Molitor said.

Molitor was expected to depart at 7 a.m. the following Tuesday. She said all of her clients were willing to reschedule their milk tests when they heard about Molitor’s unexpected invitation.

Emmer sponsored the Agriculture Skills Preparation for Industry Recruitment Efforts Act with Sen. Tina Smith, which was introduced this summer. The act would support workforce development in the agricultural sector by establishing a work-based agricultural training program within the U.S. Department of Agriculture’s Beginning Farmer and Rancher Development Program to fund apprenticeship and internship programs with local farms and agricultural businesses.

Molitor said the bill may be one of the reasons Emmer invited a young person in agriculture to attend the president’s speech. In a press release introducing his State of the Union guests, Emmer mentioned the bill. He also

Turn to

| Page 7

“All dairy, all the time”™

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce)

320-248-3196 (cell)

320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Editorial Staff

Tiffany Klaphake - Assistant Editor

320-352-6303 • tiffany.k@dairystar.com

Maria Bichler - Assistant Editor

maria.b@dairystar.com • 320-352-6303

Danielle Nauman - Staff Writer

608-487-1101 • danielle.n@dairystar.com

Stacey Smart - Staff Writer

262-442-6666 • stacey.s@dairystar.com

Abby Wiedmeyer - Staff Writer

608-487-4812 • abby.w@dairystar.com

Grace Jeurissen - Staff Writer

320-352-6303 • grace.j@star-pub.com

Jan Lefebvre - Staff Writer

320-290-5980 • jan.l@star-pub.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Consultant

Jerry Jennissen 320-346-2292

Main Ofce: 320-352-6303

Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication

Sales Manager - Joyce Frericks

320-352-6303 • joyce@dairystar.com

Mark Klaphake (Western MN)

320-352-6303 (ofce)

320-248-3196 (cell)

Laura Seljan (National Advertising, SE MN)

507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com

Jerry Nelson (SW MN, NW Iowa, South Dakota)

605-690-6260 • jerry.n@dairystar.com

Mike Schafer (Central, South Central MN)

320-894-7825 • mike.s@dairystar.com

Amanda Hoeer (Eastern Iowa, Southwest Wisconsin)

320-250-2884 • amanda.h@dairystar.com

Megan Stuessel (Western Wisconsin)

608-387-1202 • megan.s@dairystar.com

Kati Kindschuh (Northeast WI and Upper MI)

920-979-5284 • kati.k@dairystar.com

Julia Mullenbach (Southeast MN and Northeast IA)

507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell) bob.l@star-pub.com

year subscription $40.00, outside the U.S. $200.00. Send check along with mailing address to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378.

opinion

National Council of Farmer Cooperatives President and CEO Chuck Conner is optimistic about the upcoming farm bill debate but is concerned about the lack of activity. Conner said Congress is consumed with the debt ceiling issue. “It’s sort of taken all the oxygen out of the room,” Conner said. “By the time that’s resolved, I fear the clock may just be working too much against us to get the farm bill done this fall or even by the holidays.” Farm bill priorities for the farm cooperative organization include strong commodity and crop insurance titles. Climatesmart agriculture is also part of the discussion. “I’ve been working hard to really try and get agriculture out front of this climate debate in a way that is very, very pro-farmer,” Conner said. The NCFC annual meeting was held this past week. Labor shortages were a top issue at that meeting. Conner said labor is the reason many farm cooperatives have postponed plans for expansion.

Decit continues to grow

Without action to raise the debt ceiling, the nonpartisan Congressional Budget Ofce said the United States could default on its debt as soon as July. CBO Director Phillip Swagel also reported the U.S. decit totals $1.4 trillion. “The federal debt held by the public is projected to rise from 98% of GDP in 2023 to 118% in 2033,” Swagel said. “Over that period, the growth of interest costs and mandatory spending outpaces the growth of revenue. Those factors persist beyond 2033 pushing federal debt higher still to 195% of GDP in 2053.”

Seeking change in federal orders

New York Sen. Kirsten Gillibrand plans to reintroduce the Dairy Pricing Opportunity Act. This bill was rst introduced in 2021. It calls for the Secretary of Agriculture to initiate the process of Federal Milk Marketing Order

hearings within six months. American Dairy Coalition CEO Laurie Fischer praised this announcement, saying the Class I pricing formula needs to be modernized.

Dairy industry weighs in over school lunches

Ag Insider

‘19 S-450, Glass Cab & Heater, 2500 Hrs ....$24,500

‘18 Cat 236D, 775 Hours .............................$43,900

‘14 Toro 22321, 1251 Hours, Tracks Good, Gas ............................................................$15,900

‘17 MT-85, 1350 Hours................................$17,500

USED TILLAGE

‘16 W-R 13QX2 53’, 3 Bar Harrow

w/Rolling Baskets ......................................$69,500

‘12 W-R 13QX2 50’, 5 Bar Spike Harrow .....$28,500

‘12 W-R 13QX2 47’, 3 Bar Harrow

w/Rolling Baskets ......................................$34,500

‘04 W-R Excel 38’, 4 Bar Harrow .................$12,900

W-R 3400, 30’ 4 Bar Harrow .........................$4,500

(3) W-R 513 Soil Pro, 9 Shank ...Starting at $25,000

‘17 W-R 657, 13’ 3 Bar Mulcher ..................$17,500

‘11 W-R 5800 Chisel Plow, 39’ ....................$25,500

‘02 Case I-H 9300, 9 Shank Disc Ripper ......$16,900

DMI ET5 Ripper .............................................$7,500

J-D 2700 Plow, 4 Bottom, Vari Width ............$1,500

Kewanee 1020, 21’ Disk ................................$2,750

USED PLANTERS

White 6100, 12x30, Verticle Fold .................$10,900 White 6700, 12x30, Verticle Fold ...................$7,500

Case I-H 900, 12x30, 3 Point .........................$4,950

USED HAY EQUIPMENT

‘12 N-H H-7450, 13’ Discbine, Drawbar Swivel ..........................................$20,500

‘05 N-H 1431, 13’ Discbine, Std Hitch .........$14,900

‘95 N-H 499, 12’ Haybine...............................$4,250

‘97 N-H 1465, 9’ Haybine...............................$9,500

N-H 492, 9’ Haybine.................................$6,500

Idea 5209 ...............................................$6,500

Deere 260 Dsicmower...........................$3,500

790, 824 Cornhead, Hayhead .................$7,950

500TSS Forage Box ............................$7,500

N-H 460 Rd Baler, CropCutter ................$28,500

N-H 648 Rd Baler, Twine Only, Nice Shape$9,000

N-H 660 Rd Baler .....................................$4,950

N-H BC-5060 Baler w/thrower ...............$24,900

H&S HDX-17, 17 Wheel Rake ................$12,900

144 Invertor............................................$2,500

USED MISC (2) N-H 185 Spreader ...................Starting at $6,500

Evers delivers budget proposal

Wisconsin Gov. Tony Evers’ budget proposal includes nearly $16 million for the Dairy Innovation Hub, supporting the state’s dairy farmers and processors. There’s $2 million for the Wisconsin Initiative for Agricultural Exports and $1.6 million in biennial funding for the Dairy Processor Grant program through the Wisconsin Department of Agriculture, Trade and Consumer Protection. In his budget address, Evers emphasized the need to address climate change. At the same time, Evers said that doesn’t mean Wisconsin is abandoning “our farmers who’ve been the backbone of our state for generations.”

According to the USDA World Agricultural Supply and Demand Estimates, the forecast for milk production totals 228.3 billion pounds. That’s down 900 million pounds from the previous estimate. A downturn in the milk price is also inuencing the expected number of cows in the U.S. dairy herd.

Record dairy exports

U.S. dairy export sales were record high in both value and production in 2022. According to USDA, dairy exports totaled $9.5 billion in value last year. That beats the 2021 record by 25%. Sales totaled 2.8 million metric tons in volume, up 52% in the past 10 years. The U.S. dairy industry now exports 18% of all milk production.

The United States is challenging Canada’s use of dairy tariff-rate-quotas through the U.S.-Mexico-Canada dispute settlement panel. “We would expect to have a response and a nding from the panel in 2023,” said Doug McKalip, U.S. ag trade ambassador. “We think our dairy farmers are in a very solid position.

Torres Small nominated for deputy ag secretary post

President Joe Biden has nominated Xochitl Torres Small to be the next Deputy Secretary of Agriculture. Torres Small is currently the USDA Undersecretary for Rural Development and previously represented New Mexico in Congress. Torres Small succeeds Deputy Secretary Jewell Bronaugh, who is stepping down. USDA Animal Plant

Health Inspection Service Administrator Kevin Shea will serve as the acting deputy secretary in the interim.

From New Zealand to Wisconsin

GEA Farm Technologies is moving the manufacturing of its rotary parlor platforms to Galesville, Wisconsin. Before this change, many of the GEA rotary parlor components were made in New Zealand. Supply chain challenges made the move to Wisconsin more feasible.

Romanski to serve MASDA

Wisconsin Department of Agriculture, Trade and Consumer Protection Secretary Randy Romanski will serve as the secretary/treasurer of the Midwestern Association of State Departments of Agriculture. The election took place during the National Association of State Departments of Agriculture Winter Policy Meeting.

FarmFirst ofcers elected

John Rettler of Neosho, Wisconsin, was reelected president of the FarmFirst Dairy Cooperative. Steve Brock of Daggett, Michigan, will serve another term as vice president. Stephanie Hughes of Pittsville, Wisconsin, was elected secretary, and Bob Dieztel of East Dubuque, Illinois, was reelected treasurer.

Ag in the Classroom honors

The Wisconsin Agriculture in the Classroom Outstanding Educator of 2022 is Jessica Rettler. Rettler is a fourth grade teacher in Plaineld, Wisconsin, and will represent Wisconsin in USDA’s Excellence in Teaching About Agriculture Award Program.

Trivia challenge

In 1963, John Deere started producing and selling lawn and garden tractors. That answers our last trivia. For this week’s trivia, what snowmobile brand introduced the Pantera, Puma and Kitty Cat models? We will have the answer in our next edition of Dairy Star. Don Wick is owner/broadcaster for the Red River Farm Network, based in Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two adult sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

Learning Lounge offers practical information in 30-minute doses that dairy producers can apply to their farms. Attendees can also visit approximately 200 exhibitor booths in the Hall of Ideas.

“I don’t know how anyone could be bored,” Strupp said. “The conference has something for everyone. We strive to meet you where you’re at yet ll your cup at the same time.”

Enjoy a back-and-forth dialogue between Dan Basse and Jacob Shapiro as they talk markets and deglobalization and what that means for commodity products in a dueling piano-style platform. Their discussion of global politics and evolving markets will help dairy producers break down the effects this might have on their business.

The PDPW Business Conference will bring together university researchers and their graduate students to share current ndings in mastitis control, lameness and more on the Preview Stage.

“This is going to be an exciting area as there are many interesting things coming out of research right now,” Strupp said. “Hear from those with boots on the ground to learn about their projects and ask questions directly. Engage with those on the leading edge of research and learn what they are nding that affects dairy producers today.”

For the second year in a row, attendees can explore the Innovation Lane. This hallway located outside of the trade show includes the Nexus stage where ve companies will showcase cutting-edge technologies and research from the Dairy Innovation Hub.

Michael Hoffman, the emcee of the event, will lead the youth sessions March 15. By building up the social skills of youth attendees, Hoffman empowers these young people with the tools they need to partake in regular sessions as a fellow peer the following day.

On March 16, Hoffman will help farmers learn how to ll those help wanted ads. Asking the right questions is important in

attracting the right team members. Hoffman will have his audience rethinking their approach to writing job descriptions and evaluating qualities of potential candidates. In turn, attendees will discover foolproof strategies for attracting and retaining valuable employees.

Conference attendees can shift gears with Morgan Ekovich, a personal trainer, as she teaches farmers new stretching techniques and yoga poses. Ekovich will share simple methods for building endurance, strength and exibility while protecting the body.

“I’m really excited about this session,” Strupp said. “Keeping your body toned so you can do what you need it to do is really important – whether that be stepping up into a large tractor, pushing a wheelbarrow of feed or doing other repetitive movements.”

All sessions will be translated live for attendees who prefer to learn in Spanish.

“Simultaneous Spanish translation is an important element of the conference, and almost all programs include this feature,” Strupp said. “It does not slow down the caliber of the content and allows you to include more of your team. It doesn’t matter which language you learn in, just that we learn together.”

The conference is not all about business. On Wednesday evening, comedian Kvon Moezzi will provide a welcome break of entertainment and laughter.

“After you’ve taken in a whole day of intense learning, and you feel like your brain is ready to explode, this will be a time to just laugh,” Strupp said. “It won’t require any brain cells as we take the tempo down a notch and bring folks back together to decompress.”

The conference provides many opportunities for education and professional development.

“In addition to educational opportunities, the networking that happens at the business conference is invaluable,” Strupp said. “Here, you have the opportunity to engage with people from other states and countries and the ability to learn from someone else –someone who might have once been where you are now.”

More than 1,200 people visited the conference last year, with attendees hailing from more than 20 states as well as Canada, France, Germany, Spain and Egypt.

“With the year we’re in, there’s a need to be resilient and stay in the now but also be prepping and bracing for the future,” Strupp said. “The PDPW Business Conference will give you the skillsets you need to make informed decisions.”

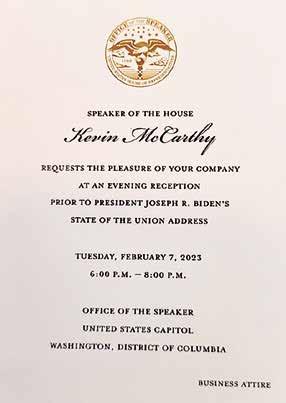

PHOTO SUBMITTED

Hannah Molitor received this invita�on to a recep�on she a�ended at the office of U.S. Speaker of the House, Kevin McCarthy, Feb. 7 in Washington, D.C. Molitor was at the Capitol as a guest of U.S. Rep. Tom Emmer for the State of the Union.

gave high praise to Molitor and his other guest, Blair Anderson, who retired as police chief of St. Cloud.

“Hannah and Blair have both dedicated their lives to service,” Emmer said. “They represent the best of the 6th District.”

As majority whip for the House of Representatives, Emmer was allowed three guests for the State of the Union. Other Congress members could invite only one guest. Besides Molitor and Anderson, Emmer invited his wife, Jacquie.

When Molitor arrived at Emmer’s ofce Feb. 7, she had the chance to visit with him in a small group.

“Emmer is a big advocate for young farmers, so he was really interested in hearing what is going on,” Molitor said.

After the meeting, Molitor and other guests were invited to attend the Speaker of the House Reception in the speaker’s ofce.

“That was really cool because I got to meet Kevin McCarthy,” Molitor said. “The reception was fun because I was rubbing shoulders with all of these Congress people and their guests. Being a guest at something like that really leveled the playing eld. Everyone was there for a

reason, and everyone was interested in what that reason was.”

Molitor said she was impressed with how authentic and down-toearth everyone seemed there.

When it was time to assemble for the president’s speech, Molitor and other guests gathered in the gallery, located in the upper level of the House of Representatives. From there, they could observe the event.

“Being in the House chamber itself was an honor,” Molitor said. “It’s not anywhere I ever expected to be. To be in the same room with all of the leaders of our nation, it was a really neat experience.”

The gallery’s design allowed for close viewing.

“The House chamber is smaller than one might think,” Molitor said.

“Looking down onto the senators and the representatives, you could see their facial expressions. You could denitely see people that you know about.”

Being there allowed her to experience the emotions of the atmosphere.

“You could tell there was energy in the room,” Molitor said.

“People were excited to be there.”

Although Molitor enjoyed being in the heart of the political arena, she said it does not make her want to pivot to a career in politics. However, she does see value in knowing one’s representatives in government.

“It does make me realize that your relationship with your elected ofcials does make an impact,” Molitor said. “For example, being on the Stearns County Farm Bureau Board, we host events on dairy farms called Farm Bureau Friends on the Farm, where we ask local ofcials to attend, and they meet with farmers for oneon-one conversations. I think events like these are important.”

Right after Molitor received the call from Emmer’s ofce, she called Dan Glessing, the president of Minnesota Farm Bureau.

“He told me I should do it, to not pass it up,” Molitor said. “I’m so glad I did it.”

Farm Bureau stepped in to help make Molitor’s trip easier. They sent someone to help Molitor navigate Washington D.C. and get to Emmer’s ofce.

“They were really generous,” Molitor said.

Back in Minnesota, Molitor said she is still processing her experience.

“It was a once in a lifetime opportunity,” Molitor said. “When would I ever get the chance to do something like this again?”

sorted for trimming or other activities.

The new parlor technology is helping the Zieglers manage their herd more efciently. A color-coded system makes it easy to identify groups of cows. For example, open cows are listed in red, fresh cows are light green, pregnant cows are dark green and trim cows are yellow.

“The system’s capabilities are endless,” Ziegler said. “Anything you want to do, you can add – somatic cell counts, milk weights, days in milk. If a cow has a high cell count, she’s going to stick out like a sore thumb, making decision making super easy.”

The system lists tasks for each cow, and shots are color coded as well with Lutalyse denoted as red and GnRH as blue, etc. Designed for rotary parlors, the technology works in cooperation with DairyComp herd management software.

Implementation of the system created a circle of success, touching many facets of the dairy operation. The family saved time and labor and increased its pregnancy rate. In addition, cow comfort improved when they reduced the amount of time cows are locked up

Steve

reproductive protocols. Ziegler said the system has saved 10 hours per week in lockups.

“It shaved off so much time,” he said. “I know we gained milk and have

less hoof issues because of that.”

With no way to efciently sort, pregnant cows were locked up as well.

“We had to walk ve pens to nd the cows that needed shots,” Ziegler

said. “It was a long time from the start of milking to the end – about three hours – and it took 45 minutes to give shots. All pens would be locked up this entire time. Pregnant cows shouldn’t have to be locked up because their neighbor needs a shot.”

A cow’s data is now displayed on the wall, making it painless to sort, Ziegler said.

“The process is efcient, and cow sorting became instantaneous,” he said. “You can see the last 18 cows at once of the 48-stall rotary. When you’re standing at the end, you know which cows are coming. The guy on the end post dips and gives shots.”

Pregnant cows are green; therefore, when glancing up at the screen, it is easy to tell if there is a cow that does not belong. The farm was able to eliminate one person in the parlor when it abandoned its manual sorting process.

“It’s really hard to keep groups separate on a rotary because it mixes cows so easily,” Ziegler said. “If a cow is not done milking when it’s time to get off, we’ll put a rope on her and let her go

Turn to ZIEGLERS | Page 9

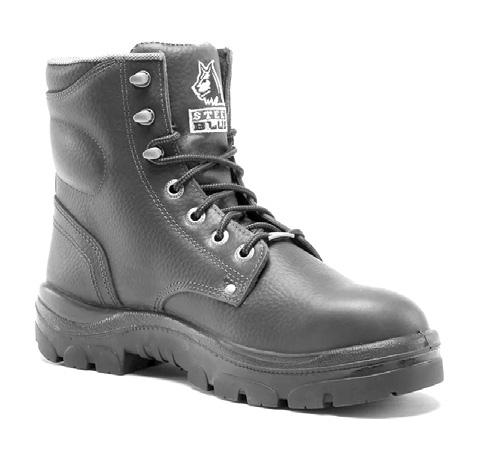

When the Zieglers installed ParlorBoss in April 2021, they put in this 70-inch TV screen at the exit of their rotary parlor to help iden fy cows through a colorcoded system. For example, open cows are listed in red, fresh cows are light green, pregnant cows are dark green and trim cows are yellow.

around again. She ends up in another group then.”

Previously, the Zieglers lived a data nightmare. Information about each cow was sent to 48 individual smart boxes, creating an intricate system prone to failure.

“There were lots of wires, and they were exposed to moisture,” Ziegler said. “On sort day, there could be up to six computers not working. The system was old and failing, and we didn’t want to put money into it. It was a headache. We were getting by, but we didn’t realize how bad it was until we got ParlorBoss.”

Now, one enclosed cable runs from Ziegler’s computer to the TV screen in the parlor. A hard-wired reader on each stall reads the cow’s RFID tag in her ear – a tag that has been with the animal since birth. The farm does not use an activity monitoring system.

“When we bought the technology, we just needed to add a TV in the parlor, so we took our mom’s from her living room and put all the data on one screen,” Ziegler said. “We did later replace Mom’s TV.”

Before installing the technology, the Zieglers’ pregnancy rate was around 25%.

“It was good, but we wanted it to be better,” Ziegler said.

Fifteen years ago, the farm’s pregnancy rate hovered at 17%. They switched breeding companies and it climbed to 25% but then sat stagnant until they changed their strategy for how repro shots were given. Now, their pregnancy rate is at 34%.

Due to the ease of giving shots in the parlor, the Zieglers improved shot compliance and were able to advance to a double ovsynch program – two important factors that helped increase their pregnancy rate. Prior to this, they did a presynch program with cherry picking. Ziegler and his brother, Jon, did the best they could when giving shots but inevitably missed 7% to 10% of cows due for repro shots. That number has since dropped to 1% or 2%.

“There was no system for us to go back and nd the cows we missed,” Ziegler said. “We could only allow so much time for two guys to do it with eldwork and other things we had to do. Timing was another factor. We probably were not giving shots at all the right times.”

Saturday is breeding day, and herd health is done every other Wednesday. Ziegler said those are the only days cows are locked up with 1.5 hours being the longest time any cow spends in a headlock.

“We did a minimum shot program before for repro because it reduced lockup time,” Ziegler said. “We were told we could up our breeding rate and increase our pregnancy rate if we increased the number of shots we were giving. We spend more money on shots now, but we’re breeding cows fewer times.”

Improving their pregnancy rate also helped the Zieglers boost the beef side of their operation. The family raises about 500 steers and breeds many animals to Angus.

“We can either sell those calves between day 1 and 4 or raise them to ll our steer barn,” Ziegler said. “By keeping a higher, tighter pregnancy rate, we’re condent in getting calves, so the majority come out black. As a result, we have more overow calves to sell, which means more income.”

The ability to streamline tasks in the parlor has helped the Zieglers capture efciencies across the farm, resulting in an all-around win for the dairy.

“ParlorBoss solved an important problem we had with data,” Ziegler said. “Now, you can see the data, and everyone is happy. There is no downside to the system. It’s super simple to use, and everything lines up perfectly. I love it.”

UNITY, Wis. – Michelle Popp spent several years exploring options to add value to the milk produced by her small herd of Jersey cows before nding the one she felt might work for her.

Popp milks 26 Jerseys on her Clark County dairy farm near Unity.

“I started out thinking I wanted to bottle A2A2 milk, but anyway I looked at that, the capital investment required made it cost prohibitive for me,” Popp said.

Not giving up on her desire to create a value-added product to diversify her farm, Popp continued her search until she found the idea that worked for her.

“I just woke up one morning with the idea that I would explore making lotion from milk produced by my cows,” Popp said. “It turned out to be the perfect answer for me. It requires less labor, minimal investment and has a longer shelf life than food products would. And, it has turned out to be protable for me.”

Popp shared her story of creating a value-added business with oth-

er women in agriculture

Feb. 14 at the University of Wisconsin-Extension’s VITAL program in Milladore.

After about six months of research, experimentation and sharing samples of her lotion to gain feedback, Popp launched Jersey Girls Lotion February 2022, placing her lotions in small, local businesses and attending craft shows. To market her lotion, she needed only to obtain a Wisconsin seller’s permit through the Wisconsin Department of Revenue.

“Milk is the main ingredient in my lotions, and they are all natural,” Popp said. “That was very important to me; I messed around with the recipes until I came up with one I liked that was primarily milk.”

As a matter of choice, Popp pasteurizes the milk she uses for the lotions using an Instant Pot.

Popp produces lotions of seven scent varieties, including one that is unscented. Popp scents her lotions using essential oils.

Popp makes her lotions on an asneeded basis and has been working to discern trends in the demand. In

between milking, Popp said she can make up to four varieties of lotion.

“I have two sets of equipment to make the lotion,” Popp said. “One set can be in the dishwasher while I’m making the next batch. I use clean equipment between every batch to keep the scents pure.”

One batch of lotion yields about 7 quarts, and each 7-quart batch uses 88 ounces of milk. Popp packages her lotions in four sizes: 8-ounce tubs, 8-ounce pumps, 4-ounce bottles and 2-ounce bottles.

Once she found a recipe she was happy with, Popp started thinking about the marketing and branding of her product. She solicited name ideas from her family, and the suggestion of Jersey Girls was the one that most appealed to her.

“The lotion is about my cows, so this name really says it all,” Popp said.

Throughout her rst year in business, Popp has learned much about marketing her product.

“I have been able to experiment

and just try new things to see what works,” Popp said. “Because of the limited scope and investment, I am able to take those chances. I’m not relying on this for a primary income.”

In her marketing journey thus far, Popp has relied on both social media and word-of-mouth promotion.

“I’ve given away a lot of lotion this past year, just getting people familiar with it and being able to get their feedback,” Popp said. “I’ve donated quite a few baskets for fundraisers. I like to do that because I can. It’s a way I can give back.” Popp has also connected with customers at craft and vendor fairs and other events.

“I didn’t think I’d love spending my Saturdays at craft fairs, but I learned that I actually do,” Popp said. “It’s a great way to connect with the public to educate them about agriculture and the story of

my own dairy farm.”

In addition to her lotions, Popp offers canvas prints and notecards made from the photos she has taken around her farm. While Popp said she does not sell many photographs, they serve as a way to open conversations about her farm with consumers.

With a rst year of experience and learning under her belt, Popp is looking forward to the future with the protable business she has created. To increase her market share, Popp said she would like to venture

Michelle Popp lls an 8-ounce pump bo le with newly made Jersey Girls Lo on. Popp pasteurizes the milk she uses for her lo ons using an Instant Pot.

into the world of online sales and is considering opening an Etsy store for that purpose.

From a product development standpoint, Popp said she is exploring other non-food products made with milk, such as shampoos and lip balms.

Popp said others who want to nd a value-added product for their farm should adopt an open-minded attitude and persevere to nd the path that best ts the situation.

“I never thought this would become something I would love so much,” Popp said. “Having a positive attitude is so important in going after the things you want in life. I believe your current thoughts become your future life.”

What counties or area do you cover? Most herds are in Morrison county, but I also test herds in Crow Wing, Todd and Otter Tail counties.

What do you enjoy about the farmers you work with?

since 1995

I have great respect for all the work and dedication that dairy farmers, their families, and employees have for their animals. I enjoy seeing the results of all they do. I also enjoy the fact that a lot of dairies I am working with are the second generation. I’ve watched them grow up and take over.

What do you like about your work for DHIA? Every day is a new day. I have been in barns in many counties. Every one is different, but they make it work.

What do you do in your free time? I enjoy spending time with my grandchildren in Minnesota and Nebraska. I enjoy gardening and cutting rewood. I am also active in American Legion Post 136 in Flensburg.

Sauk Centre, MN Buffalo, MN 763.682.1091

www.mndhia.org

“I enjoy seeing the results of all that farmers do.”PHOTO SUBMITTED

STRATFORD, Wis. – A fondness for competition and the animals is what drew both Joe Carey and Jamie Perry to sled dog racing and eventually to each other.

The pair live near Stratford where Carey manages a small herd of dairy goats, and Perry works as a dairy nutritionist.

Carey rst started racing sled dogs 13 years ago, while Perry began 27 years ago as a middle school student.

“My dad was selling dairy chemicals, and a dealer he worked with had sled dogs and was looking for someone to race an extra team he had,” Carey said. “I ran his dogs that rst year and was hooked. The next year, I bought four dogs from him and a puppy.”

Perry’s story started following a unit about sled dog racing taught in her English class.

“I talked my mom into letting me get a Siberian husky,” Perry said. “Little did she know, when we went to pick that dog up, two would be coming home. By the time I graduated from high school, I had 21 dogs.”

The two connected through sled dog racing, and between their two kennels, the pair own about 40 dogs.

Most of the dogs Carey and Perry race are a performance crossbreed known as Eurohounds, which vary from the dog most people envision when they think of sled dog racing. Only about one-third of their dogs are Siberian husky.

“Eurohounds can have a variety of different breeds behind them,” Perry said. “There is some husky but also usually some pointer-type blood behind them too. They are bred for particular traits that make them excel at racing, and they are smaller dogs than a husky.”

Most of the races Carey and Perry run are short-distance sprints, which typically range from 4 to 12 miles. They run teams of 8-10 dogs. Perry’s daughter, Riley, an avid youth musher herself, runs a four-dog team. They have an extra six-dog team available that friends also sometimes race for them.

“When we go to races, we usually travel with 26 or 28 dogs,” Carey said. “We take our racing teams, but we’ll also take puppies with us for the socialization and the experience.”

The dogs usually run in pairs

within the team. The lead dogs are the front pair, while the second pair are referred to as the point. The dogs closest to the sled are called the wheel dogs and are typically the largest dogs on the team. Any pairs between the point and wheel dogs are referred to as team dogs.

“The lead dogs take all of the commands,” Perry said. “The point dogs are kind of like co-pilots and often become lead dogs. The wheel dogs are the ones that turn the sled, while the team dogs provide power.”

The dogs learn from each other and can develop into good lead dogs, but both Carey and Perry agreed it is fun to watch when they have a dog that emerges as a natural leader.

“There really isn’t an alpha dog,” Carey said. “There are some that are a bit bossier, but we won’t keep a dog that is aggressive toward other dogs. They can cause problems when the team is hitched.”

A sled dog is typically in their rac-

ing prime for only a couple years. Training begins just before a dog turns 1 year old.

“The average dog is at their peak from about 3 to 5 years old,” Carey said. “By the time they are 6 years old, you can see them start to slow a bit. By the time they are 8 or 10 years old, they’ll move down to what we call our Bteam. They still love what they’re doing, they just aren’t as competitive.”

Close attention is paid to the dogs’ diets to help them

reach the desired level of performance. They are fed a high-quality kibble that is 20% fat and 32% protein, which was developed by a fellow musher.

“The protein is higher than the average commercial dog food, but a sled dog’s nutritional requirements are higher too,” Perry said. “They don’t need to eat as much of this food, either, to meet their needs.”

Both Carey and Perry have high standards when it comes to choosing the dogs for their teams, and both have made key purchases from across the U.S. and Europe that they are looking forward to developing.

With the bloodlines they are developing, Carey and Perry produce a litter of puppies every other year and market their genetics to other mushers and breeders.

“We typically have people lined up for puppies before the mating even occurs,” Carey said.

vember. This fall, the dryland race saw 162 teams competing, making it the largest dryland race in the Midwest, according to Carey and Perry.

Joe

and Siberian huskies.

In addition to snow racing, they also participate in dryland racing. The couple hosts an annual dryland race the rst weekend of No-

During a typical racing season, Carey and Perry travel to ve to seven race events, and have taken in as many as nine in one season. They have traveled into Canada to race in Manitoba, eastern Ontario and Quebec, and have raced in New Hampshire. Carey has qualied for, and

competed in, the world championship races for both snow and dryland racing. Only 100 teams, from around the globe, are invited to participate in the championship races each year, Carey said.

“Sled dog racing is really becoming more and more popular,” Perry said. “The state of Wisconsin has the largest racing club outside of Alaska. There has been a huge insurgence of one- and two-dog events, and you see

all kinds of breeds running.” Races are timed events; each team has a set start time and are clocked as they cross the nish line to determine placings.

“The people we meet and race with are a big part of why I love racing, but it is really about the dogs,” Carey said. “It is truly a sport. You really work with the dogs. It is a joint effort. You pedal, push and run with them.”

Steve Endres Waunakee, Wisconsin Dane County

Steve Endres Waunakee, Wisconsin Dane County

700 cows

What is your current somatic cell count? Our current SCC is 90,000.

What does your milking procedure consist of? Dry wiping, stripping (three or four squirts per teat) and predipping with Valiant which contains the germicide, chlorine dioxide. We then come back and wipe the teats dry and apply the milking machine. We milk in a double-13 parlor and will prep a group of seven cows followed by a group of six. After milking, we post dip with another version of the Valiant product. We have been using Valiant for a long time.

Throughout your years of dairying, what were the biggest changes you made to decrease your SCC? Culling for it and being stricter on our milking routine. We are constantly striving to keep that as consistent as possible. We have found that is as big a driver as there is in maintaining cell count. Paying good attention to how stalls are manicured is another area we have continued to improve upon. We have almost completed a conversion from sand to solids and have seen a little uctuation in cell count because of that. Solids are more challenging than sand, and our SCC is currently 20,000 to 30,000 higher than it was before switching from sand. However, we have gured out a process to keep our cell count at a desirable level.

Kris Weber Elroy, Wisconsin Juneau County70 cows

What is your current somatic cell count? It is generally well under 100,000. Our last average was about 80,000. What does your milking procedure consist of? We try to stay on a 12-hour interval. We strip before predipping with a peroxide-based dip. Then, we wipe with a cloth towel and attach the unit. We post dip with an iodinebased dip. We try to prep 10-15 seconds before the milker is attached. We run eight units in a tiestall barn.

Throughout your years of dairying, what were the biggest changes you made to decrease your SCC? I guess we haven’t made any big changes. It's always been pretty low. One year, we experienced stray voltage and had a challenge until that was diagnosed. We were running a million cell count without a ake on the lter. It turned out to be a faulty neutral line in the breaker box.

What preventative measures are critical to keep your SCC low? We keep them dry and bedded up good and clean. We try to have everyone milk the same. We also wear milking gloves.

When your SCC starts to rise, what are the rst things you do to keep it in check? We try to monitor and gure out what cow has the high SCC and what quarter. We don’t use much for treatment. We'll strip them out more often and maybe use a little oxytocin. The chronic ones end up getting culled.

What advice do you have for someone who is trying to lower their SCC? Test milk. That’s the rst thing. You have to know what cow is the problem. Then, gure out the quarter. We will use a quarter milker now and again.

Tell us about your farm. We farm about 400 acres and sell some corn. We have 80 cows and try to keep 70 milking. We feed out about 80 dairy steers a year. Our milk is shipped to Grassland Dairy. My wife, Lori, daughter, Samantha, and her children, Hunter, Weston, Hazel and Trevor, are all involved on the farm with me.

What preventative measures are critical to keep your SCC low? Dry cow treating. We treat everyone. Most mastitis occurs in the early part of a cow’s lactation with calving time being a great risk. Therefore, a clean calving pen is also important as well as maintaining dry cow and pre-fresh cow stalls. Also, scheduled service and maintenance on milking equipment, including observing the washing and sanitizing of equipment, is critical.

When your SCC starts to rise, what are the rst things you do to keep it in check?

We culture cows that have clinical signs. We also make sure our milking routine is being maintained properly and that our bedding is dry enough. Our milk plant does a whole-tank culture every week which shows levels of strep, staph and E. coli. We look at that to see if there is a rise in any of those bacteria. We also check the chart recorder to verify correct water temperature as well as checking water softness level.

What advice do you have for someone who is trying to lower their SCC? Consistency is so important in a routine and so is stall management. Cleanliness of everything, such as equipment, is the rst place to look to see if you can improve. Also, culture your clinical mastitis cases to get a handle on what bacterias you may be dealing with.

Tell us about your farm. Endres Berryridge Farms LLC is a family farm where my wife, Kathy, and I farm with my brothers and their wives, Jeff and Jenny, and Randy and Karen. Jeff’s daughter, Sarah, and my son, Zach, also farm with us along with numerous employees. My son and niece are the fourth generation on the farm, which was established in 1915. Our farm is home to registered Holsteins, and we ship our milk to Grande Milk Marketing. We farm close to 1,300 acres of primarily corn, alfalfa and some grass acres.

Henry Soldner (second from left) pictured with William (from left) and sons, Simon & Luke H&W Soldner Farm Turtle Lake, Wisconsin Polk County

60 cows

What is your current somatic cell count? The somatic cell count from Feb. 1-13 is at 37,000.

What does your milking procedure consist of? We wash the cows with Monodine and Sepko with water. When they are done, we use a chlorohexidine spray in a bottle.

Throughout your years of dairying, what were the biggest changes you made to decrease your SCC? We focus on keeping the cows clean. We set a goal about 15 years ago to keep our somatic around 100,000. When we achieved that, we thought we could do better and set our next goal at 80,000. About 10 years ago, we achieved that, and thought we could keep doing better.

What preventative measures are critical to keep your SCC low? We dry treat and use a teat sealant and an exterior teat sealant.

When your SCC starts to rise, what are the rst things you do to keep it in check? We check cows for rm quarters.

What advice do you have for someone who is trying to lower their SCC? The best advice is to keep the cows clean.

Tell us about your farm. I farm with my brother, William, and my sons, Luke and Simon, are involved in the farm as well. We farm around 400 acres of cropland and plant corn, oats, soybeans, alfalfa and grass hay. We ship our milk to Burnett Dairy Cooperative. They consistently encourage their farmers to produce the highest quality milk possible.

Turn to OUR SIDE |

Star Blends has been helping Midwest farm families by providing, high-quality feed, dairy nutrition, and commodity contracting for more than 20 years.

Our state of the art mill can accuratelyblend anything from a custom pre-mix to complete feed,

in balancing diets, or work with your private nutritionist or dairy consultant.

Feeding your animals like they’re our own

Contact Star Blends at: 800-462-4125 or StarBlends.com

500 cows

What is your current somatic cell count? Our current SCC is 78,000.

What does your milking procedure consist of? We begin prepping by wiping off each cow with individual cloth towels to remove dirt and other debris. We then predip with chlorine dioxide and strip out each teat three times to check for abnormal milk. We then dip again with chlorine dioxide. We milk in a double-9 parlor and prep a set of ve cows and then a set of four. We rst dry wipe all the cows in one group and then come back to predip, strip and dip. We then go back again and use cloth microber towels to dry the front teats rst and then the back teats. After that, we ip the towel over and wipe each teat end before going back and attaching the machines. We have auto takeoffs and will come through and reattach if a cow didn’t milk through. We post dip with chlorine dioxide or iodine. We rotate back and forth depending on the weather and if we’re seeing mastitis. If it’s cool and damp out, we’ll stay on chlorine dioxide. If we see mastitis cases rising, we’ll go back to iodine. If we have singledigit or below-zero temperatures, we use a winter dip that has lots of emollients. However, it offers no bacterial kill which is its downfall, but it helps prevent teats from freezing.

Throughout your years of dairying, what were the biggest changes you made to decrease your SCC? Going to cloth towels that we clean in a washer and dryer. Also, removing sand and debris as the rst step in our prepping procedure helped a lot in lowering somatic cell count. In 2007, we bought a herd of cows, and our cell count exploded. We implemented culturing to see what microbes were present on the farm and became more proactive on culturing when staph aureus and microplasma popped up. We cleaned out both, and now we ght environmental factors sometimes. We also found that putting in dryer sand helped tremendously. We cover sand piles with tarps when rain or snow is coming, and we try not to put it in sand on a wet day or after it rains as that can spike everything. We always try to put in dry sand.

What preventative measures are critical to keep your SCC low? Keeping cows clean and dry and putting in dry sand. Also, switching up the dips from chlorine dioxide to iodine whenever we see a spike is critical to keeping the SCC low.

When your SCC starts to rise, what are the rst things you do to keep it in check? We sample everything once a month, and if we see somebody that was low and now spiked up, I go through and culture to see what I am ghting. If there is something we can do treatment wise, we’ll do that. Otherwise, we have to gure out what’s going on. If we see a spike in SCC, we’ll watch the milkers and remind them we need clean, dry teats in the parlor and clean, dry units going on. We want to be mindful of what they’re doing too. We hold quarterly meetings for milkers to provide refreshers and get everyone back on the same page.

What advice do you have for someone who is trying to lower their SCC? Try to nd the problem cows. If you can treat them and try to get their SCC down, that’s great. If it’s some type of mastitis you can’t treat, sell the cow. Otherwise, she’s going to keep spreading it throughout the herd. Keep bedding dry. Cows need to be clean and dry; that’s the biggest thing. Also, try to be consistent. Cows like consistency. They want to be fed and milked at the same time every day and be able to lie down when they want. They don’t want to be bugged.

Tell us about your farm. My husband, Chet, and I own Dolph Dairy LLC with my in-laws, Don and Pat Dolph. We milk around 500 cows and farm about 1,000 acres with help from 13 employees. Our crops include 550 acres of corn and 450 acres of hay. We ship our milk to Grande Cheese Company. Grande makes a lot of cheese, like mozzarella and provolone, for the pizza industry and is focused on milk quality. Therefore, they try to help farms have good milk quality. We raise our animals onsite and focus on keeping them dry and clean. Heifers and cows are on sand bedding, while calves are in group housing on straw or cornstalk bedding.

Boyceville, Wisconsin

Dunn County

270 cows

What is your current somatic cell count? It is at 63,000.

What does your milking procedure consist of? We brush off excessive dirt, use an iodine predip, then wipe with an individual towel, strip and apply the milker. After milking, an iodine-based post dip is applied. During extreme cold weather, we use a powder dip.

Throughout your years of dairying, what were the biggest changes you made to decrease your SCC? Diligent use of a quarter milker or bucket to withhold suspect milk from the tank and routine systems checks on the vacuum line have been the biggest changes to decrease SCC. We are fortunate to have consistent hired help who know the cows well and keep the routines the same. When we started crossbreeding with Fleckvieh, we also experienced a notable drop in the SCC of the herd.

What preventative measures are critical to keep your SCC low? Keeping vacuum levels in check, routine ination changes, and cow comfort and cleanliness are important. Adjusting for the seasons with adequate y control in the summer and keeping good foot health help with overall health of the cow. We try to keep their dry period as stress-free as possible. We make sure udder health is good before dry off, and we minimize vaccines and extra movements during the dry period to keep stress levels low to prevent early lactation issues.

When your SCC starts to rise, what are the rst things you do to keep it in check? We begin doing more frequent California mastitis test sampling and examine teat ends for signs of vacuum level issues. We refer to the DHI reports for possible problem cows. A year ago, we implemented the use of smaXtec herd monitoring. Although we did not see a dramatic change in SCC levels, it has helped us determine where the problems may be. Temperature increases and graph changes help us look for cows to watch or sample more closely.

What advice do you have for someone who is trying to lower their SCC? Being consistent with routines, watching teat end health and stall cleanliness has helped us maintain our low levels. Keep things simple and nd what works for your farm.

Tell us about your farm. Over the years, our ve children have been involved in the dairy. Our son, Paul, and his wife, Catherine, are a major part of the day-to-day work and decision making. They also farm 45 acres of their own and have a custom business. We currently ship our milk to Burnett Dairy Cooperative.

Trevor Baier (pictured with his dad, Charles)

Baier Creek Farms

Elmwood, Wisconsin Dunn County

600 cows

What is your current somatic cell count? It is usually around 50,00060,000.

What does your milking procedure consist of? We predip with foamers, strip, wipe and then attach. Two guys milk in a double-12 parlor. We prep six cows at a time to achieve a two-minute letdown time. For a post dip, we use a 1% iodine solution. We have always liked spending a little more money on post dip.

Throughout your years of dairying, what were the biggest changes you made to decrease your SCC? Prior to 2009, we bedded with sawdust. With our new freestall barn, we went to sand bedding. Our SCC went from 150,000-200,000 down to under 100,000 in about three to six months. It goes to show the signicance of sand bedding.

What preventative measures are critical to keep your SCC low? We always rake the beds when cows go to get milked. We use fresh sand, not reclaimed, so we always get the nes. Cows are housed in a 4-row barn which helps keep manure managed.

When your SCC starts to rise, what are the rst things you do to keep it in check? We try to nd the cow with mastitis that caused the SCC to rise. Our employees get a $5 bonus for every cow they catch with mastitis which helps incentivize this.

What advice do you have for someone who is trying to lower their SCC? Everybody is so critical on parlor routine, but you need to walk around where the cows are spending their time – where they’re lying down, walking, eating. Manure management is key. It is important to keep the cows clean and comfortable.

Tell us about your farm. We farm about 1,200 acres of alfalfa, corn silage and grain corn. We ship our milk to Eau Galle Cheese in Durand, Wisconsin. The fth and sixth generation currently run the farm along with our employees. The fth generation is my uncle, Rodney, and my dad, Charles. The sixth generation is my cousin, Steve, and myself.

Mike and Lori Boesl (left) pictured with Catherine Boesl, holding Adaliene, and Paul Boesl, holding Waylon Cabin Hill Dairy Inc.

Mike and Lori Boesl (left) pictured with Catherine Boesl, holding Adaliene, and Paul Boesl, holding Waylon Cabin Hill Dairy Inc.

What were you doing 25 years ago?

One might think conjuring up details from a quarter century ago would be a difcult pursuit, but for me, vivid memories rise to the surface, making it feel much more recent. I was fortunate to be here 25 years ago when the rst issue of Dairy Star ew off the press. While I was a writer and salesperson for the local Sauk Centre Herald, an always thought-provoking dairy farmer, Jerry Jennissen, thought the area would benet from having a paper strictly geared toward dairy farmers.

because of the vastness of the challenge of operating a dairy farm. There are so many things that happen on a dairy farm every day; there are equally many thoughts from those same farmers on how they hope tomorrow can be a little easier.

Since day one, the stories we have featured are often informational and otherwise entertaining. Our story list covers the gamut of ideas.

By Mark Klaphake EditorAfter discussing the venture with Jeff Weyer, the then sales manager of the Sauk Centre Herald, and mentioning the idea to the then Sauk Centre Herald publisher Dave Simpkins, we decided to give Jennissen’s idea the go-ahead.

After working on the inaugural issue for several weeks, Dairy Star was born Feb. 27, 1999. Then and for many issues after, designer Janell Westerman and writer and assistant editor Andrea Borgerding and I crafted each issue along with Weyer and sales person Laura Seljan.

Our rst paper was delivered to mailboxes throughout Stearns County. Approximately 750 dairy farmers dotted the landscape in this dairy-rich county at that time.

In the inaugural issue, we highlighted Mennonite families that had moved to the Stearns County area. We published a column about the worst day on a farm and included relevant information for dairy farmers, like market updates.

Our mission then was to publish a newspaper about farmers for farmers. We wanted to be a median where farmers could share workings from their farms with other farmers.

And now, all these years later, our focus remains the same: We synchronize our efforts to craft a paper highlighting the dedicated, hard-working dairy farmers and the news happening in their farm yards.

I have a lot of family who milk cows, which includes ve brothers, two nephews and a brother-in-law. But when I think of my dairy family, I believe it stretches to everyone who milks cows. Whether you milk 50 or 1,000 cows, you are part of a unique family with one thing in common.

You work tirelessly to produce milk to feed a growing population. Our family numbers go down yearly, but the value or importance of being a dairy farmer only rises.

As a dairy newspaper, our job is to cover the farmer’s daily trials, whether good or, sometimes, not so good.

That scope can be pretty encompassing

We cover the broad technology boom we are within and dairy farmers receiving awards – from low somatic cell count to sustainable farming to tremendous farm families. We put pen to paper, highlighting farms handed down from generation to generation. We bring dairy-related news from our government and shine a light on dairy consumption and promotion. We share dairy farmers’ hobbies and pastimes. We journey through the tragedies that occur and rally among our dairy farming community.

The ideas are countless because of the incredible diversity of what it takes to be a dairy farmer.

The paper remains free thanks to the support of our advertisers. Without their belief in us, the paper could not exist.

Dairy Star is delivered to mailboxes on the second and fourth Saturdays of each month. While our sales team is visiting with dairy advertisers, our writers are heading up driveways to interview farmers about their thoughts and ideas.

Then, our ads are sent to our designers, and stories with photos are sent to our Sauk Centre, Minnesota, ofce. Within three to four days, we are ready to print.

As we embark on our 25th year, we have several signicant changes within Dairy Star.

You’ll notice our year-long theme celebrating 25 years. Starting with this issue and for the following 23 issues, we will give away $100 cash. All you have to do is nd the 25-year logo in each issue of Dairy Star and mail us the form or enter online at www. dairystar.com. We will draw one winner for each issue.

Secondly, we have content-driven changes starting with a shift in our Day in the Life feature being bolstered into a photo story feature. Day in the Life has been a popular feature for many years, and moving into the upcoming year, we plan to make this small but impactful change.

Another new feature we plan to highlight is introduced in this issue – The Day That Went Awry. Within this feature, we will visit with farmers about when things didn’t necessarily go according to plan. That might include equipment breaking down when traveling down the road or a cow putting herself into a position where words cannot explain how she got there nor how a farmer can get her out. Or, it could simply be when one breakdown leads to another, and by the end of the day, a cold drink is the answer.

We hope to continue to land on the top of your mail stack every two weeks. Between our feature stories, columns, and question-and-answer responses, know you are not the only one ghting the good ght. What you do really matters.

“Talking to veterinarian Doug Evans and the team at the Udder Comfort™ booth, we got more regimented in our use of Udder Comfort and saw SCC drop from 200,000 to 120,000. We started making sure we sprayed every fresh udder after each milking for the full 3 to 4 days after calving and watched our somatic cell counts respond. We saw SCC on our fresh cows drop right down collectively by 10 to 12 days in milk,” says Kyle Hirt, Mithva Farms, New Woodstock, New York.

“We were already using Udder Comfort for 4 years on swelling in fresh cows and mastitis. We knew it reduced edema faster and better than anything else,” Kyle adds.

“By getting more regimented on the full routine of Udder Comfort for every fresh animal, we saw even better results. It works,” he reports.

hrs., 1604 Sep hrs., #551147........... $165,000

JD S680 2014, PRWD, Duals, Chopper, 2317 hrs., 1575 Sep hrs., #555096........... $169,900

JD S680 2015, PRWD, Duals, Chopper, 2583 hrs., 1865 Sep hrs., #190078........... $174,500

JD S680 2014, PRWD, Duals, Chopper, 2260 hrs., 1355 Sep hrs., #554365........... $189,900

JD S680 2014, PRWD, Duals, Chopper, 2349 hrs., 1668 Sep hrs., #531966........... $195,000

JD S680 2017, PRWD, Duals, Chopper, 1516 hrs., 1053 Sep hrs., #273646........... $249,900

JD S690 2012, PRWD, Duals, Chopper, 2311 hrs., 1645 Sep hrs., #551148........... $149,000

JD S690 2015, PRWD, Duals, Spreader, 3600 hrs., 2565 Sep hrs., #552365 .......... $152,000

JD S690 2016, PRWD, Duals, Chopper, 2544 hrs., 1820 Sep hrs., #547267 .........$219,900

JD S690 2015, PRWD, Tracks, 2400 hrs., 1615 Sep hrs., #550872 ......................... $232,900

JD S690 2017, PRWD, Duals, 2102 hrs., 1461 Sep hrs., #552684 ......................... $249,900

JD S690 2017, PRWD, Duals, Chopper, 1433 hrs., 1028 Sep hrs., #549457........... $280,700

JD S770 2018, PRWD, Duals, Chopper, 2261 hrs., 1652 Sep hrs., #549678........... $259,900

JD S770 2021, PRWD, Duals, Chopper, 565 hrs., 486 Sep hrs., #554050............... $405,000

JD S770 2022, PRWD, Duals, Chopper, 270 hrs., 195 Sep hrs., #554014 .............. $560,000

JD S780 2018, PRWD, Duals, Chopper, 1521 hrs., 1130 Sep hrs., #551736........... $319,300

JD S780 2018, 2WD, Duals, Chopper, 1214 hrs., 826 Sep hrs., #555412 ............... $324,900

JD S780 2019, PRWD, Duals, Spreader, 1562 hrs., 1131 Sep hrs., #549680 .......... $328,800

JD S780 2018, PRWD, Duals, Spreader, 1620 hrs., 1131 Sep hrs., #276170 .......... $329,900

JD S780 2018, PRWD, Duals, Chopper, 1519 hrs., 1124 Sep hrs., #553584........... $333,900

JD S780 2019, PRWD,

PRWD, Duals, Spreader, 1072 hrs., 784 Sep hrs., #188458

2020, PRWD, Duals, Spreader, 953 hrs., 659 Sep hrs., #188459 .............. $428,400

JD S780 2020, PRWD, Floaters, Chopper, 1021 hrs., 803 Sep hrs., #553375 ......... $434,000

JD S780 2021, PRWD, Duals, Chopper, 798 hrs., 607 Sep hrs., #556191............... $479,900

JD S780 2021, PRWD, Duals, Spreader, 652 hrs., 469 Sep hrs., #191047 ...............$504,900

JD S780 2022, PRWD, Duals, Chopper, 449 hrs., 353 Sep hrs., #552362............... $549,000

JD S780 2022, PRWD, Floaters, Chopper, 395 hrs., 323 Sep hrs., #553546 ........... $549,900

JD S780 2022, PRWD, Duals, Chopper, 462 hrs., 345 Sep hrs., #553598............... $567,000

JD S780 2022, PRWD, Floaters, Chopper, 243 hrs., 177 Sep hrs., #554707 ........... $578,500

JD S780 2022, PRWD, Floaters, Chopper, 219 hrs., 169 Sep hrs., #554706 ........... $579,500

JD S780 2022, PRWD, Floaters, 182 hrs., 139 Sep hrs., #554710 .......................... $583,500

JD S780 2022, PRWD, Floaters, Chopper, 183 hrs., 131 Sep hrs., #554709 ........... $584,500

JD S780 2022, PRWD, Duals, Spreader, 240 hrs., 183 Sep hrs., #554094 .............. $587,500

JD S780 2022, PRWD, Floaters, Chopper, 140 hrs., 91 Sep hrs., #554708 ............. $589,500

JD S780 2022, PRWD, Floaters, Chopper, 236 hrs., 170 Sep hrs., #554623 ........... $599,000

JD S780 2022, PRWD, Duals, Chopper, 69 hrs., 39 Sep hrs., #190242................... $609,000

JD S780 2022, PRWD, Duals, Chopper, 5 hrs., 1 Sep hrs., #190724....................... $619,900

JD S780 2022, PRWD, Tracks, Chopper, 295 hrs., 238 Sep hrs., #554013 .............. $675,000

JD S790 2018, PRWD, Duals, 1847 hrs., 1407 Sep hrs., #549847 ......................... $303,900

JD S790 2019, PRWD, Duals, Chopper, 1770 hrs., 1426 Sep hrs., #532032........... $314,200

JD S790 2018, 2WD, Duals, Chopper, 1579 hrs., 1128 Sep hrs., #273973 ............. $319,300

JD S790 2018, PRWD, Duals, 1636 hrs., 1218 Sep hrs., #549845 ......................... $338,000

PRWD, Duals, Chopper, 1314 hrs., 940 Sep hrs., #554633............. $354,900

PRWD, Singles, Spreader, 1453 hrs., 1055 Sep hrs., #549846 ....... $359,900

727 hrs., 530 Sep hrs., #191075 ............. $569,700

JD S790 2022, PRWD, Duals, Chopper, 427 hrs., 302 Sep hrs., #552839............... $589,900

JD S790 2022, PRWD, Duals, Chopper, 334 hrs., 269 Sep hrs., #554381............... $610,000

JD S790 2022, PRWD, Duals, Spreader, 68 hrs., 24 Sep hrs., #274940 .................. $659,900

JD S790 2022, PRWD, Tracks, Chopper, 38 hrs., 21 Sep hrs., #553771 .................. $719,900

JD 980 2000, 44 ft., 5-Section Folding, #545689 ..................................................... $16,500

JD 980 2000, 44 ft., 3-Section Folding, #546434 ..................................................... $16,900

JD 2200 2003, 43 ft., 5-Section Folding, #555398 ................................................... $22,500

JD 2210 2005, 38 ft., 3-Section Folding, #191986 ................................................... $28,000

JD 2210 2004, 27 ft., 3-Section Folding, #531751 ................................................... $29,900

JD 2210 2006, 60.5 ft., 5-Section Folding, #553154 ................................................ $29,900

JD 2210 2005, 43 ft., 5-Section Folding, #551803 ................................................... $33,500

JD 2210 2009, 50.5 ft., 5-Section Folding, #535118 ................................................ $34,900

JD 2210 2008, 33 ft., 3-Section Folding, #554294 ................................................... $39,900

JD 2210 2014, 25 ft., 3-Section Folding, #554138 ................................................... $42,500

JD 2210 2011, 50.5 ft., 5-Section Folding, #556431 ................................................ $44,000

JD 2210 2014, 41 ft., 3-Section Folding, #554297 ................................................... $47,500

JD 2210 2010, 57 ft., 5-Section Folding, #542886 ................................................... $47,900

JD 2210 2014, 60.5 ft., 5-Section Folding, #190857 ................................................ $57,500

JD 2210 2012, 58 ft., 5-Section Folding, #533062 ................................................... $57,500

JD 2230 2022, 55.5 ft., 5-Section Folding, #551187 ..............................................$141,900 Sunflower 5055-50 2012, 50.5 ft., 5-Section Folding, #552837 ............................ $39,900

Case IH TIGER MATE 200 2009, 54 ft., #552287..................................................... $43,500

Case IH Tigermate 2 2007, 44

IOWA

Rock Valley, IA 712-476-9290

United

Systems,

West Union, IA 563-422-5355

WISCONSIN

Advanced Dairy Spring Valley, WI 715-772-3201

Ederer Dairy Supply Plain, WI 608-546-3713

DeLaval Dairy Service Kaukauna, WI 866-335-2825

Joe’s Refrigeration Inc. Withee, WI 715-229-2321

Mlsna Dairy Supply Inc. Cashton, WI 608-654-5106

Professional Dairy Services Arlington, WI 608-635-0267

Redeker Dairy Equipment Brandon, WI 920-346-5579

The

Whitewater, WI 800 472-2880

Mt Horeb, WI 800-872-3470

Melrose, MN 320-256-3276

Brookings, SD 800-636-5581 Advanced

Mora, MN 320-679-1029

Pierz, MN 320-468-2494

Feb. 27, 1999 First issue of Stearns County Dairy Star is published.

September 1999

The paper expands into Otter Tail, Wadena, Todd, Morrison, Sherburne, Benton, Wright, Meeker, Kandiyohi, Pope and Douglas counties. It then becomes Minnesota Dairy Star.

Dairy farmers in the lower two-thirds of Minnesota are added to the newspaper’s mailing list.

The northern counties of Minnesota, as well as the larger dairy counties in South Dakota and Iowa are encompassed in the paper’s coverage area. Minnesota Dairy Star now becomes its current name, Dairy Star

Dairy Star expands into southwest Wisconsin, covering counties along the MinnesotaWisconsin border.

Dairy farmers in west central Wisconsin now receive the paper.

‘02 NEW HOLLAND FP230, Single axle, processor, low acres, hay and corn heads available! $18,900 (POTTER)

SEVERAL NEW NH FP240 IN STOCK! CALL TODAY!

2022 KWIK TILL AVAILABLE HIGH SPEED DISKS 24’ AND 25’ HD MODELS CALL NOW! (POTTER)

MILLER PRO 5100, 18 Ft. Unloading Box, EZ Trail 13 Ton Wagon, Good Condition, $9,000 (WAUPUN)

‘23 NEW HOLLAND

Dairy Star adds counties in northwest Wisconsin, providing dairy industry coverage to more than half the state.

Marathon, Wood, Adams, Juneau, Sauk, Columbia, Dodge, Fond du Lac, Jefferson and Rock counties are added to Dairy Star’s coverage in Wisconsin.

$5,500 (WATERTOWN)

Dairy Star is mailed to all the dairy farmers in ND, SD, WI, MN, IA and parts of Michigan and Illinois; encompassing 1/3 of the nation’s dairy farmers.

2013 CASE FARMALL 95U, 4,500 hrs, loader, $39,900 (POTTER)

2005 H&S HD7+4, 18 Ft. Unloading Box, H&S 16 Ton Wagon, VG Condition, $12,500 (WAUPUN)

2019 NEW HOLLAND TS6.140 Only 366 hrs, powershuttle, like new! $84,900 (POTTER)

NEW GREAT PLAINS TERRA-MAX, Brand New 20’ Terra-Max ON HAND, CALL NOW BEFORE IT’S GONE

VIROQUA, Wis. – Zach Hansen has responsibilities to juggle. Besides a full-time job, two small children and a wife expecting triplets, he also milks a herd of 30 organic cows on a farm near Viroqua.

Hansen and his wife, Stephany, bought the farm in November 2020. The road to farm ownership has not been a straight one, but Hansen is reveling in the journey.

“The biggest inspiration is I want my kids to grow up somewhat like I did,” Hansen said. “Just being able to run around and be around animals and learn how to work.”

Hansen grew up in the Viroqua area on a conventional farm with his parents. His grandparents were on a neighboring farm, and he and his siblings and cousins had the run of the land between the two farms.

Hansen said his grandparents taught him and his cous-

ins how to milk and take care of animals. They all have fond memories of milking, haying and raising tobacco, Hansen said. The families helped each other until Hansen’s parents exited the industry in the late 1990s. Then, when Hansen was 15, his grandfather died, and everything on his farm was sold.

At the time, Hansen was looking forward to taking over his grandfather’s operation with his cousin, but they were too young.

Hansen’s uncle purchased the farm instead and continues to operate it today. Hansen took jobs milking cows and worked for 10 years for Paul Buhr while nishing high school, attending college and getting married.

“Paul was a huge inspiration into how I operate my dairy today,” Hansen said. “I accredit him to his knowledge in many areas.”

In 2016, Stephany’s grandfather approached them about starting a dairy at a farm he owned, which is where the couple lives today. The barn was an old chicken barn. All the gutters were lled in, and there were no stalls.

While continuing to work at Buhr’s, Hansen gutted and renovated the entire barn. The

gutters were dug by hand, and concrete was poured with the help of friends. Hansen purchased all of the equipment used and brought it onto the farm, including tie stalls, a barn cleaner and chain, a bulk tank and milking equipment.

“We sourced all the stuff

and pieced it together,” Hansen said. “It was fun. It was kind of like a sense of ownership.”

After about a year of working with Stephany’s grandfather, they decided to go their separate ways. Hansen sold most of his cows,

and Stephany’s grandfather bought him out. Hansen’s brother-in-law stepped in at the farm, and Hansen and Stephany moved to town. After selling their house and buying another one on

Turn to HANSEN | Page 25

Con nued from HANSEN | Page 24

the edge of town, Hansen raised a heifer calf in the backyard using a dog kennel. The desire to farm was still strong.

“I just couldn’t get it out of my system,” Hansen said. “All I could think about was that I just wanted to milk cows.”

About a year later, Hansen’s brother-in-law went out on his own; the farm came up for sale. Hansen and Stephany decided to buy it outright and return to the farm they already loved.

It was actually the third time Stephany lived on the farm, because in the 1990s, her parents farmed the property for a couple of years before moving out of state.

“When she was a kid, this was her favorite place to be,” Hansen said. “She always had a dream of being back on this farm.”

The couple sourced an organic herd and brought cattle back to the farm. Hansen said it felt right to farm organically this time.

“I like organic for the crops because I just never really liked all the spraying and pesticides,” Hansen said. “I just think it’s safer for my family. It’s a more natural, old-time way to do it.”

Hansen also watched his parents and grandparents struggle with low milk prices when he was younger. The organic premium was an attractive point to consider, Hansen said.

The couple owns the buildings and 5.5 acres.

They rent the pasture ground from Stephany’s grandfather and purchase their feed. Cows are fed corn silage, baleage and a protein mix.

Hansen said it is not always easy to be at the mercy of the milk market and the feed market. His off-farm job helps to subsidize the family and sometimes the farm.

Hansen is working on raising replacements and ne tuning the organic techniques to get a higher milk production. With 35 stalls in the barn, his goal

is to milk a barn full.

While Hansen enjoys his off-farm job and spends time hunting, shing and playing sports when he can, he said his favorite place will always be in the barn with his family.

“My favorite part is milking together with my family,” Hansen said. “Everybody together in the barn, kids running down the walk while we’re milking, and no phones or TVs. Just the radio, the cows and the kids. I love that part of it.”

“My favorite part is milking together with my family. Everybody together in the barn, kids running down the walk while we’re milking, and no phones or TVs.”

ZACH HANSEN, DAIRY FARMER

By Abby Wiedmeyer abby.w@dairystar.com

By Abby Wiedmeyer abby.w@dairystar.com

MADISON, Wis. – Laura Paletta urges farmers to consider the value of manure and how intentional spreading can benet farm land. Instead of viewing manure as a waste to be disposed of, she encourages farmers to consider it a resource to be utilized.

“Here in Wisconsin, we see a lot of different weather throughout the year,” Paletta said. “We have four seasons, and our elds look vastly different throughout the year.”

Paletta is an outreach specialist at the University of Wisconsin-Madison Division of Extension’s Agriculture Water Quality Program. She spoke during a Jan. 31 webinar entitled, “Manure and water quality: Why looking at the calendar matters.”

With farm land in different stages throughout the year, Paletta said it is important to understand when elds suffer the most nutrient losses in order to carefully choose which manure management practice to utilize to avoid those losses.

Data from Discovery Farms, a research division of UW-Extension, shows that March is the month where the most runoff occurs due to snowmelt and

thawing of the soil. In May, June and July, when farmers are often tilling and planting, soil is most susceptible to loss. Roughly 77% of all soil loss occurs during those months, Paletta said.