www.dairystar.com

ISSN Print: 2834-619X • Online: 2834-6203 522 Sinclair Lewis Ave. Sauk Centre, MN 56378

Phone: 320-352-6303

Fax: 320-352-5647

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce)

• 320-248-3196 (cell)

320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com Editorial Staff

Maria Bichler - Assistant Editor maria.b@dairystar.com

Stacey Smart - Assistant Editor

262-442-6666 • stacey.s@dairystar.com

Danielle Nauman - Staff Writer

608-487-1101

• danielle.n@dairystar.com

Abby Wiedmeyer - Staff Writer

608-487-4812 • abby.w@dairystar.com

Tiffany Klaphake - Staff Writer

320-352-6303 • tiffany.k@dairystar.com

Jan Lefebvre - Staff Writer • jan.l@star-pub.com

Amy Kyllo - Staff Writer • amy.k@star-pub.com

Emily Breth - Staff Writer • emily.b@star-pub.com

Advertising Sales

Main Ofce: 320-352-6303

Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication

Sales Manager - Joyce Frericks

320-352-6303

• joyce@saukherald.com

National Sales Manager - Laura Seljan (National Advertising, SE MN)

• fax: 507-634-4413

507-250-2217

laura.s@dairystar.com

Assistant Sales Manager - Kati Schafer (Northeast WI and Upper MI)

920-979-5284

• kati.s@dairystar.com

Jerry Nelson (SW MN, NW Iowa, South Dakota)

605-690-6260 • jerry.n@dairystar.com

Mike Schafer (Central, South Central MN)

320-894-7825

• mike.s@dairystar.com

Megan Stuessel (Western Wisconsin)

608-387-1202 • megan.s@dairystar.com

Julia Merten (Southeast MN and Northeast IA)

507-438-7739

• julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN)

320-260-1248 (cell) • bob.l@star-pub.com

Mark Klaphake (Western MN)

320-352-6303 (ofce) • 320-248-3196 (cell)

Deadlines

The deadline for news and advertising in the Dairy Star is 5 p.m. Friday the week before publication.

Subscriptions

One year subscription $42.00, outside the U.S. $200.00. Send check along with mailing address to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378.

Advertising

Our ad takers have no authority to bind this newspaper and only publication of an advertisement shall constitute nal acceptance of the advertiser's order.

OSSEO, Wis. — When the Otten family emigrated from the Netherlands to the United States in 2007, it was to nd a new dream in the dairy industry.

They dairy farmed back home, but the industry was too crowded and regulated, so they bought a dairy farm in Wisconsin. After farming for eight years, a buyer made them an attractive offer on their farm, so they sold it.

They moved less than an hour away to Osseo where they intended to raise a small beef herd and farm a few acres.

That is when opportunity knocked on their door in the form of heifer raising.

The Otten family answered. There was a void in the area for heifer raisers, so they decided to ll it and remodeled a horse barn on their property to accommodate calves.

“We still had a love for dairy cattle, and now, we have fun raising a good heifer for the dairy farmers,”

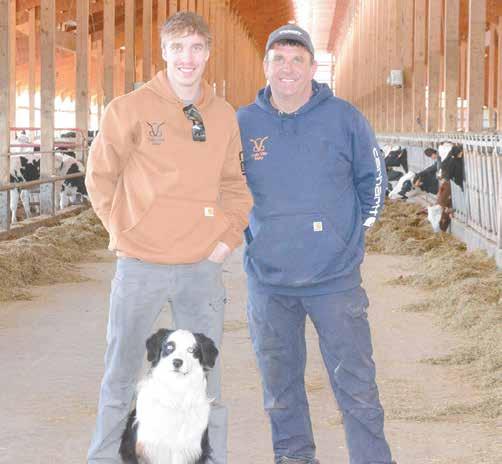

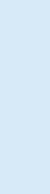

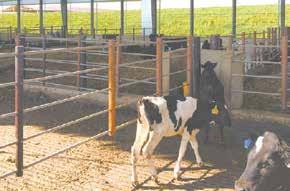

PHOTO SUBMITTED

This is the site of Calla Ville Dairy where the O en family custom raises heifers from 6 months old to 50 days pregnant near Osseo, Wisconsin. The heifers then spend me at a second loca on near Augusta, Wisconsin, before returning to their home farms.

Menno Otten said. “It’s really fun to work together now that Ruard wants to take over.”

Menno operates Calla Ville Dairy together with his wife, Kolinda, and son, Ruard.

Since custom raising their rst calves in 2015, they built a barn and expanded to a second site near Augusta. They now raise 1,500 animals on the two farms from ve Wisconsin dairy farms.

The calves begin at the Osseo site at 6 months old. They start on a bedding pack and rotate through the barn according to age.

The Ottens require all calves to be vaccinated with Bovi-Shield Gold before arrival and then follow each farm’s wishes for further vaccinations.

During summer months, heifers are turned out to pasture once they are conrmed pregnant. At the 350-acre Osseo site, pregnant heifers are rotated through 20-acre paddocks every few days and supplemented with minerals. Once they are 150 days pregnant, they are moved to the Augusta location, where they are housed in the freestall barn and put on a total mixed ration. They are returned to their owners approximately 6-8 weeks before calving.

Ruard said pasture time is good for the animals.

“We’ve found it to be really good for hoof health to be on pasture for a few months,” Ruard said. “Then, when they get back, they’re back on TMR and trained in headlocks and for stalls, so they are ready for the condition they’re going to be in.”

Both facilities have free stalls,

headlocks and manure scrapers. A nutritionist is on-site once or twice a month to offer advice and get another pair of eyes on the animals. The breeding-age heifers are checked by a veterinarian every two weeks. Animals are also dewormed every six months. A footbath is run weekly in the barn. Animals are weighed upon arrival and departure, so they can analyze average daily gain.

The Ottens have seen trends in dairying since raising heifers, such as the use of more beef semen. This has caused a decrease in the number of heifers that need to be raised which directly impacts their business.

Menno said they had enough room in the barns to take on another account last year.

Turn to OTTENS | Page 5

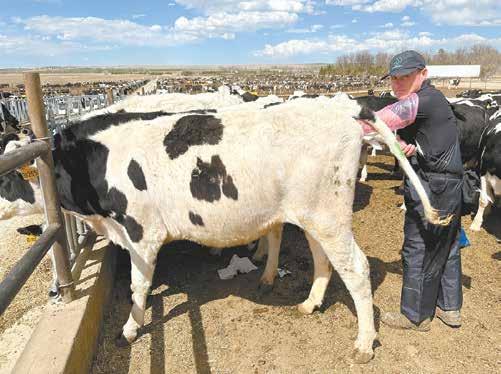

PHOTO SUBMITTED

The O en family’s freestall

“We didn’t have our barn completely full, and the margins are really small for heifer raising,” Menno said. “Right now, heifers are expensive, because (farmers) are keeping more. It will stay there for a couple of years before we have enough springers back.”

The Augusta facility was previously a freestall barn for dairy cows, so it was redesigned to t heifers. The Ottens kept the existing tunnel ventilation in the building and added solar panels to the roof with grant money. The facility uses a lot of electricity with a manure separator and tunnel ventilation. The Ottens said the upgrade has cut their electricity bill in half, especially for the tunnel ventilation.

at a trailer load of heifers,” Menno said. “It’s a big commitment for a dairy farmer to bring their cattle to somebody else to take care of. We try to do the best for them, and they trust us to raise their animals.”

“You cannot only love animals. You need to make business decisions also. It’s just great to work now with Ruard together. I am really proud of him that he wants to be a farmer and how he takes care of things as a businessman. It’s a complete thing.”

MENNO OTTEN, HEIFER RAISER

The pair believes it is important to stay efcient to keep labor costs down and be able to take time away from the farm. They have one full-time employee at the Augusta location.

They lean on their background as dairy farmers to do their best at custom-raising heifers. It translates well, Menno said.

“Instead of looking to see if your bulk tank is full, we are now looking

Ruard agreed. “There’s still a lot of work involved in it, but this is our main focus,” he said. “We specialize in dairy heifers, and we have all day to keep an eye on them. Whereas when you have your own dairy heifers, your main focus is your milking herd.”

Ruard plans to take over the operation in the next ve years. Menno said his father gave him the opportunity to take over a farm at a young age and believes Ruard is on the path to do the same. He said they both enjoy the lifestyle.

“You cannot only love animals,” Menno said. “You need to make business decisions also. It’s just great to work now with Ruard together. I am really proud of him that he wants to be a farmer and how he takes care of things as a businessman. It’s a complete thing.”

WOODVILLE, Wis. — Ensuring that calves get off to their best start is a priority for dairy farmers like Luckwaldt Agriculture Inc.

Luckwaldt Agriculture is operated by Dan and Mary Luckwaldt and their herdsmen, Patrick Kusilek and Derek Fenner. The farm is home to 1,550 cows and 100120 calves near Woodville.

“Patrick and Derek have put a lot of work into improving the genetics in our herd through genomic testing,” Dan Luckwaldt said. “These calves represent the best of our herd.”

The Luckwaldts genomically test every calf and use that data to determine which heifers to keep as breeding stock. The top 20% of the herd is bred with sexed semen while the balance is bred to beef bulls.

Calves on the Luckwaldts’ farm are housed in a calf barn built in 2017 until they are weaned at 60 days.

After weaning, calves are moved into groups of six. They are gradually transitioned to groups of 24 and then sent to a heifer raiser in southwest Kansas.

The Luckwaldts have been using caustic paste to disbud their calves for several years and now use Banamine transdermal to mitigate pain as well.

They were approached by University of Wisconsin-River Falls animal and food science professor Dr. Sylvia Kehoe, who wanted to use their herd as a research project to develop methods for applying caustic paste to newborn calves.

“I was teaching a student how to apply paste, and we stayed and watched the calf a little,” Kehoe said. “We were both surprised by how painful the caustic paste was for the calf.”

Shortly after that experience, Kehoe visited other dairy farms in other parts of

the country as a coach of the university’s dairy challenge team.

“I was seeing these caustic paste wounds on calves — how big and deep they can be,” Kehoe said. “Later, I was talking with a colleague (and said) that someone should

come up with some sort of standardized applicator or method. A student heard us and said, ‘Yes, you should.’ And, now, I have been working on this project for almost six years.”

In her study at the Luckwaldts’ farm, Kehoe and her

colleague Dr. Kate Creutzinger conducted a study using two brands of caustic paste: Dr. Naylor and Dr. Larson’s.

They compared the results of different amounts of paste applied to determine differences in terms of wound size and healing.

“It is really hard for people to determine how much paste they are really using,” Kehoe said. “We asked dairy people to estimate how much volume they’re putting on, and it was coming out to be quite a bit — 0.5-1 mL.”

The product packaging of each recommends the use of a “quarter-sized amount,” Kehoe said. “That’s big to go around the horn bud, but it also depends on how thick it is,” Kehoe said.

ing pasting. Kehoe said she and her students are beginning to analyze that footage to monitor the pain behaviors that might have been exhibited by calves after the lidocaine block wore off.

Kehoe’s research and work on developing a standardized applicator has been funded through the Dairy Innovation Hub. She is now working with WiSys, which facilitates projects that could lead to patents.

Kehoe and her students used standardized amounts of 0.2 mL and 0.4 mL. Kehoe said 0.4 mL is about the size of a green pea. Calves were given a lidocaine block before the paste was applied.

“We found that the brand didn’t make a difference,” Kehoe said. “All the groups healed the same. Both volumes did a really good job of taking horn tissue off. It’s common sense that the wound size was bigger with 0.4 mL than with 0.2 mL.”

Calves were monitored with video cameras follow-

In her quest to create an applicator, Kehoe connected with Dr. John Obielodan, an associate professor of mechanical engineering at the University of Wisconsin-Platteville.

“Dr. Obielodan and I worked together and came up with version after version of an applicator,” Kehoe said. “He could 3D print them and send them to me. I would try them out and make suggestions for changes. We nally have developed what we think is a pretty ready-to-go version of the applicator.”

Minimizing pain during disbudding can potentially allow calves to stay healthy during the crucial newborn period, Kehoe said.

“We know when calves

are feeling pain, they tend to be more susceptible to illness,” Kehoe said. “If we can reduce pain, that helps the immune system stay stronger, especially in the rst two weeks of life when calves are pasted. That is when their colostral antibodies are decreasing, and they are trying to build their own antibodies. That is when they are most likely to get sick.”

The Luckwaldts appreciate the value research such as Kehoe’s brings to not only their dairy farm but the industry in general.

“Having UW-River Falls right here is a great resource for us,” Mary Luckwaldt said.

“We get so much information and learn so much from working with faculty like Dr. Kehoe.”

From an on-farm perspec-

tive, Fenner said he appreciates seeing calves bounce back faster from the process of disbudding with the smaller wound size.

“For me, it is all about consistency, keeping everything as consistent for the calves as I can,” Fenner said. “Calves that are healthy and content eat better, grow better and ultimately will become better cows.”

Heavy duty, extremely efficient fan for quiet dairy barn ventilation Comfort and versatility... Designed for today’s cows

• Durable and innovative 6-blade design

• Heavy duty galvanized frame

• Heavy duty and easy to install

• Unique and flexible mounting systems

• Supreme versatility • Patented design

IPS-8 NC liner has completed 8,000 milkings with no issues. We cannot say that about any other liner we have used. It’s a one-piece liner made of a simple design, it cleans well and stays clean throughout the milking process.”

- Eric Van Nurden, Van Nurden Farm LLC, Rice, MN

Entire panel made of heavy duty 10 gauge tubing

• Heavy duty 6 gauge swing arms with hardened bushings inserted and 7/16” grade 8 bolts

(563) 534-7963

• Compact drive is easy to hide

• Low profile corner wheels

• Alleys of differing lengths are no problem

• Choice of on-floor or in-floor

The Buzz-Off System comes with a spray arm that applies a broad spray pattern of product through a photo-eye. The sensitivity of the photo eye controls the amount of product sprayed. The Buzz-Off System comes with an automatic 7 day / 24 hour timer…it also can be manually programmed to dispense product up to several times per week and different times of the day! • Oil based formulation

use with

Insecticide 1% Permethrin 1% Piperonyl Butoxide (for resistance control)

Adheres and endures

Cost Effective

Safe for cow & environment

Ready to use thick or thin

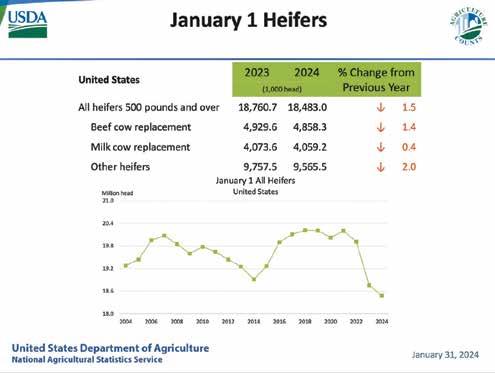

WASHINGTON — On Jan. 31, the U.S. Department of Agriculture adjusted its 2023 prediction for the number of 500-pound-and-over dairy heifers, decreasing it by 263,600 head. Farmers and others in the dairy industry took notice.

“The USDA came back a year later and said (they) were off on that number, and they revised it down,” said Corey Geiger, lead economist for dairy production and processing for CoBank in its Knowledge Exchange research division. “USDA doesn’t make revisions like this, and they did here.”

Overall, the USDA reported that the cattle inventory, which includes both beef and dairy, has been shrinking every year since 1999 and estimated the number of cattle and calves as of Jan. 1 to be at 87.2 million head.

That is 2% lower than one year prior and the lowest since 1951.

The beef cow herd was also reported to be in contraction, estimated to be at 28.2 million head, 2% smaller than 2023 and the lowest since 1961.

Specic to dairy, there are 4,059,000 heifers 500 pounds and greater, which is the lowest level since 2004.

Although the USDA’s revision may have been a surprise, the shortage of dairy calves and heifers had already been on the radar of many industry players.

“Last fall, some dairy farmers reached out to me and were looking for dairy replacements,” Geiger said. “These were really good dairy farmers who have deep networks, and I thought, ‘Wow, the replacements have gotten really tight.’”

In the past six years, this group has shrunk 17.5%, or 709,000 head.

In 2000, the USDA also began tracking the number of heifers expected to calve in the current year. In January, that number was at a record low of 2,593,000, and the number has fallen 14.6%, by 443,000 head, since 2018.

“Although dairy replacement numbers may be at a 20-year low, the big shift is really in the last six years, even more so in the last four years, that it’s really been profound,” Geiger said.

The factors contributing to cattle numbers and makeup are various, but the trend in recent years toward beefon-dairy has had an effect.

“There are between 3 and 3.25 million animals in the United States that came from a dairy female and a beef sire, but prior to 2017, that number

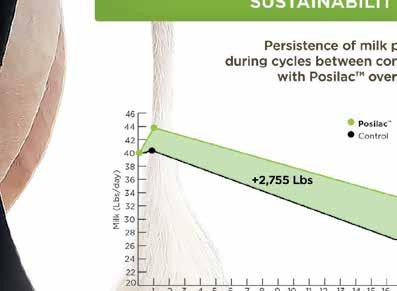

GRAPH SUBMITTED

The U.S. Department of Agriculture reported that there are 4,059,000 dairy heifers 500 pounds and greater as of Jan. 1, which is the lowest level since 2004. In the past six years, this group has shrunk 17.5%, or 709,000 head.

was almost nothing,” Geiger said. “So, you’ve got the milk story, and then, you’ve got the beef story.”

Beef prices have been at a record high, and milk prices have been low. Add high feed costs to the picture, and beef-on-dairy makes good economic sense.

“Dairy farmers are getting between

$800 and $950 for 3-day-old beef-ondairy calves, so they can sell them and make money without the risk of raising them,” Geiger said. “Five years ago, they would have been dancing with $200 for those calves.”

Turn to HEIFER REPLACEMENTS | Page 12

The economics are affecting cattle breeding decisions on dairy farms.

“Data has just come out showing that 54% of dairy semen sold last year in the U.S. was gender-sorted semen,” Geiger said. “That’s the biggest category, and it grew by 514,000 units.”

The next biggest category is beef semen sold to dairy farmers, followed by conventional dairy semen.

“We’re quickly coming to the place where we will be making two kinds of calves: the intentional dairy heifer calf and the intentional beef-on-dairy calf,” Geiger said.

Geiger said the dairy replacement decit will impact milk availability.

“It’s going to be a little more challenging to grow U.S. milk production based on the number of available replacements,” Geiger said.

With fewer replacements, farmers are holding on

to their cows.

“Dairy cow culling is down substantially this year from the same time last year,” Geiger said. “From Jan. 1 through the third week in March, U.S. dairy farmers have culled 113,800 fewer dairy cows this year.”

Geiger said cow longevity has become even more important.

“We need to try to get another lactation out of productive cows and foster their potential for additional production capacity,” Geiger said. “Cows are biological. Even if we make more heifer calves and started breeding cows today, it would be three years at a minimum to reverse the ship.”

The decline in cow slaughter is expected to continue this year, the USDA reported. But reductions likely could lead to improved forage conditions and even stronger calf prices, especially with the current lower numbers of beef cows.

“We’re at a 60-year low on the beef cow herd,” Geiger said. “The beef-on-dairy has brought more beef, or a different quality of it, to the marketplace.”

Geiger said the trend will continue at least in the foreseeable future because beef-on-dairy makes economic sense for farmers. Just behind feed and labor costs, he said the cost of raising a dairy heifer is the third-highest expense on dairy farms.

“If I’m a dairy farmer and I’m getting that kind of revenue from a beef-on-dairy calf, I’m not going to make less of them, but what I’m going to do is make the right number of dairy replacements,” Geiger said. “For those who purchase their replacements and were planning to grow their dairy herds, they were penciling in $1,600, and you could have gotten about any good replacement a year ago at that price with no problem. Now, you might have to change that number to $2,800.”

When looking to buy 50-100 replacements, that $1,200 cost spread is substantial, especially given interest rates, Geiger said.

“It changes a lot of budgets,” Geiger said.

Although low milk prices could be contributing to the beef-on-dairy trend, Geiger said he does see it as the driving factor.

“In 2022, we had the highest milk price ever, and dairy farms were protable, but we made more beefon-dairy calves,” Geiger said. “So, milk prices are a reason, but not the reason for beef-on-dairy.”

Yet, Geiger said milk prices could benet from low dairy replacement numbers.

“We have $7 billion in dairy processing plant investment in the U.S. through 2026, and if I’m one of those plants, will I have enough milk to ll my plant?” Geiger said. “The near-term answer is yes,

“We need to try to get another lactation out of productive cows and foster their potential for additional production capacity. Cows are biological. Even if we make more heifer calves and started breeding cows today, it would be three years at a minimum to reverse the ship.”

COREY GEIGER, LEAD ECONOMIST IN DAIRY FOR COBANK

because there are a lot of base-excess plans that are in place that are really limiting what dairy farmers can ship. … But, if you are a dairy farmer, the limited number of replacements is certainly limiting expansion, and that limits the milk supply some and should theoretically boost the milk check.”

Your future is now. And it starts with her. Help her maintain normal digestive health and support a functioning immune system with First Arrival® total eubiotics. This easy-to-feed product is available in powder or paste. Kickstart tomorrow’s production today.

With calves at a premium, their health is more important than ever to a dairy farm’s bottom line.

Be proactive with calf

Scan for a free on-farm consultation with your local DBC representative.

“People who do a really good job of raising their calves and have a low death loss are going to fare a little better because they are going to have more animals to sell whether it’s a dairy replacement or a beef replacement,” Geiger said. “Right now, the incentive to take exceptionally good care of and invest more in calves and heifers is there.”

Within tight prot margins that dairy farmers must navigate, beef-on-dairy has been a winner.

“While the limited number of dairy replacements is concerning, the beef-on-dairy impact has been extremely positive for dairy farmers, and the near-term and mid-term forecast is that it should remain positive because beef prices are at record highs and the beef cow herds are at a 60-year low,” Geiger said. “Dairy farmers who are doing beef-on-dairy should continue to make some nice prots.”

For further information, Geiger and his colleague, Abby Prins, published a report Feb. 7 called “Dwindling Dairy Heifer Numbers May Inhibit New Milk Production.” It can be found at the CoBank website.

— In the eastern plains of Colorado, heifers at CK2 Cattle Company come in as calves and leave as pregnant heifers. Raised on western weather and feed, these heifers come home ready for a productive life.

“All the things that you need to grow a good heifer, we have right here in Colorado,” said Kirk Crone, one of the farm’s owners. “We’re in that sweet spot for heifer raising.”

Located one hour northeast of Denver near Fort Morgan, CK2 Cattle Company is home to 4,200 head housed on dry lots. The herd is 90% registered Holsteins and 10% crossbreds. All cattle come from two clients in Wisconsin and New York. Heifers arrive between 3-5 months of age and are sent home at 220-240 days pregnant. Every month, the farm receives 250-300 calves and ships out 120 bred heifers.

“We are small from a numbers standpoint and offer that personal touch, caring for animals on an individual basis,” Crone said. “We maintain

close relationships with our customers instead of treating them as another number in the lot. Communication is a priority, and we strive to continue that philosophy as we continue to grow with our current and future customers.”

The area’s dry conditions create an environment where heifers thrive, Crone said.

“We have the perfect climate for raising heifers,” he said. “Summers are typically drier than most places around us, but we still have enough moisture to produce good crops. It’s dry enough on the lots that we very seldom have a problem with moisture to where we have to mitigate foot rot.”

Heifers are housed on dirt and in pens large enough to give them the chance to exercise.

“Exercise makes them healthier and allows them to build a better rumen,” Crone said.

Milk production is on the rise for this grower’s clients. Crone credits the increased

production to the exercise heifers receive along with a robust diet.

“Whether raising heifers at home or sending them out here, it’s not cheap,” Crone said. “But, our clients are seeing such better production results from heifers starting off. It’s enough of an increase to

offset the cost of sending them here. In some cases, they’re coming out ahead.”

CK2 Cattle Company was started by Crone, Travis Kroskob and Brandon Kroskob in 2021. Each partner farms his own land and operates a custom forage business. Facing ups and downs in feed inven-

tory due to uctuations in customer demand, the three men were sometimes left with more feed than they could use or sell, so they brainstormed options for consuming what they were producing.

Turn to CK2 | Page 14

Ask about the new “smart“ features!

“One of the biggest benefits to us of having the automatic calf feeder has been being able to eliminate a person bottle feeding 90-100 calves twice a day. We are also able to wean the calves earlier and still produce larger calves at weaning since switching to the automatic calf feeder. Additionally, we have received great support from Fuller’s Milker Center.”

Hardscrabble Farms LLC

Jerry Volenec Owner • Mike Spink Herdsman Montfort, WI • Calf Feeder installed April 2017

“We were passing a lot of feed through our hands and wanted to be the end user of that feed,” Crone said. “We were looking to do something that would be more sustainable year to year, and we wanted to do something in the dairy world. This helps ensure that we have a home for all the feed running through our custom operations now.”

With three years of custom heifer raising, this business is riding a path of growth and productivity. Crone and the Kroskob brothers manage the operation with help from a team of eight employees.

“We’re surrounded by the right people, which has helped us succeed,” Crone said. “It’s been a team effort. We’ve partnered with the right customers and the right team, and it’s all working very well.”

Manager Cari Vondy is a major part of the team, Crone said. Vondy is in charge of employees as well as dayto-day operations.

“Cari has been with us since almost the beginning and instrumental in getting things off the ground,” Crone said. “Most days, she is right in the mix with the rest of the guys. She knows the ins and outs of all that’s going on within the operation and plays a key role in the success of everything that takes place.”

Crone said what sets CK2 Cattle Company apart from other growers is their use of embryo transfer.

“Most grower yards in Colorado are all A.I.,” Crone said. “We are 95% embryo and 5% A.I. That’s what our expertise is.”

Heifers are bred at 13 months of age. The client ships fresh or frozen embryos of their choosing to CK2 Cat-

tle Company for implanting.

“We also use a lab an hour from here for our ushing program,” Crone said. “In the future, we have plans of having our own lab on-site, allowing us to ush here. Our conception rates have been very good, and this will improve our conception rates even more. Our embryologist and veterinarian are topnotch.”

Offering these services will benet the growth Crone sees on the horizon.

“When we rst started, our embryologist was transferring once every other week,” he said. “Now, he transfers 4-5 times a week. Eventually, he and his team will be transferring 6-7 days a week as we continue to grow.”

In addition to providing a genetic advantage through embryo transfer, CK2 Cattle Company also feeds a high-quality diet. Heifers receive a total mixed ration containing corn silage, alfalfa haylage, chopped triticale, wet distillers grain, alfalfa, baled oats and peas.

“We’ll also throw in other forages we can get our hands on, and we grind a lot of wheat straw and cornstalk too,” Crone said. “Our nutritionist is phenomenal and another major asset to our team. We couldn’t do this without him.”

The operation mixes about ve rations, which vary by the age of the group.

“We have a very good selection of roughages and are able to put up drier feed,” Crone said. “Our rations are a lot drier than Midwest rations. We’re in the 40s (percentage) for dry matter. The drier triticale and oats we mix in for scratch is helping to build production in heifers later in life.”

The average daily gain per heifer is around 2 pounds.

“Our goal is to get heifers to 850900 pounds before we put an embryo into them,” Crone said.

They follow the vaccine protocols provided by each of their clients, and Crone said the farm’s mortality rate is near zero.

“We’re getting healthy calves to start with, and that makes all the difference in the world,” Crone said. “We’re kind of picky about the clients we take on. Health of the animal is No. 1. Our

clients are extremely good about giving us healthy cattle, and we return a healthy animal to them.”

CK2 Cattle Company is focused on efciency and growing their team before growing their lot, Crone said. He predicts the farm will house over 20,000 head in the future.

“We will continue to grow until it’s no longer efcient to keep growing,” Crone said. “The benets our clients are getting here are helping them out big time.”

Ratherthancleaningbucketsandteats manually,automaticcalffeedingsystems handlethecleaningthemselves,thecleaner thesystem,thebetteritisforthecalves.

Nomorefillingmilkbuckets,liftingheavy buckets,ormanuallyfeedingcalves.Your workdayismoreflexible,leavingmore timeforotherthingsonthefarm.

Providingmultiplesmallerportionsduring theday,ratherthanabucketofmilk,can helpimprovemilkintakeanddigestion, resultinginbetteruseofnutrientsand higherdailyweightgain.

The new MTX 4.0 featuring Smart Mix, Smart ID & the Calf Guide System will ramp your calves up to wean them off of milk just like an auto feeder, no matter who is feeding the calf! The Smart Mix knows how much milk, milk replacer, or combination, that you need to mix for the next feeding. No guess work.

Automatic calf feeders are an efficient and effective method to achieve intensive calf feeding. Automatic calf feeders, such as the DeLaval CF1000S, offer the ability to manage and track the feeding program of each animal. Significant labor savings are also a potential benefit of the CF1000S. Calves growing faster • Healthier calves Control over feeding cost and calf feeding operation

Lower mortality and morbidity rates

Earlier reproduction ng. he or 0S. on

Vienna, IA

“We know Roll-O-Matic curtains last because we have them on other buildings, so it was an easy decision to choose them again for our calf barn. We like having the motors on the curtains for raising/lowering because it has made it easy to keep the barn at the correct temperature and keep out the draft. The crew was also good to work with.”

Custom t to your new or existing building

Motorized or Manual Options

Highest UV inhibitor and lock stitch style sewing for longer curtain life Get the full value of air quality control curtains at the touch of a button

Bibbed overalls to

and built to be the longest lasting and most ef cient mixer on the market

• All Poly & Wooden Conveyors

• Taper Board Feeders

• All Poly Conversions for bottom unloader

The DairyFeed J C400+, V600+ and V640+ calf feeders are professionally designed to support calf rearing at your agricultural operation. The automated feeders are computerized, giving you targeted control over all relevant data and enabling you to optimize daily nutrition for your calves from the day they are born.

BENEFITS:

• Using the calf feeders reduces your workload

• Calves grow healthily

• Suitable for any herd size: one to four drinking boxes with teats designed for calves

• Variable portion sizes as either powder or all-milk blends

• Quick and easy: Link the calf feeders using DairyPlan 21 software

When the Reisinger family sold their cows in 2021, their goal was to keep the farm running in some way. They set out to raise steers but still had vacancy in their facilities.

That is when a local farm approached them about custom raising heifers. It seemed like just the thing to ll the void.

“I don’t like to put all my eggs in one basket,” Malia Reisinger said. “That’s why we have the custom animals and the steers. We can oat through the challenges of things that come up because you never know.”

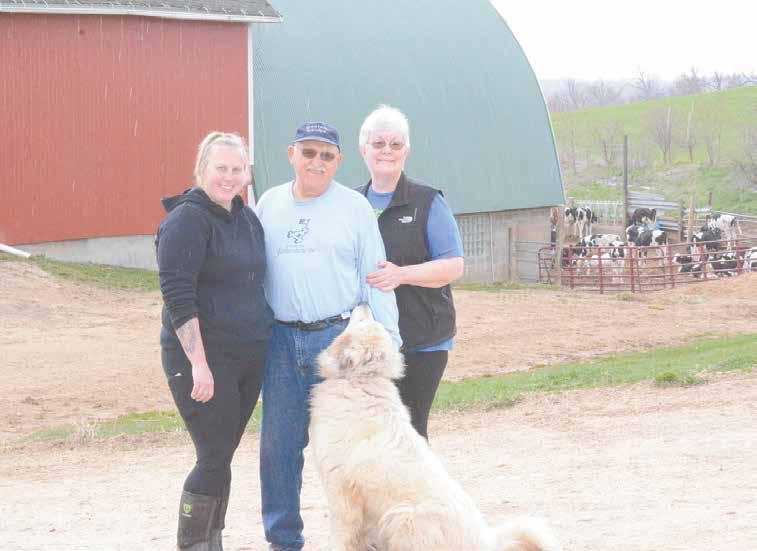

Malia manages the farm with the help of her parents, Jim and Jean.

When the family began heifer raising, they worked with various clients as the need in the area uctuated. Now, they focus on raising 120 heifers for one customer. In addition, they raise 80 steers up to 750 pounds for themselves.

The heifers come to the farm at 3-4 months old.

Originally, their customer was bringing a group of 60 animals twice a year. They have since adjusted the onboarding process. Now, the group of 60 heifers is divided into two batches.

A group of 30 animals comes to the farm, and once they are adjusted, another group comes about two weeks later. Then, six months down the road, the process is repeated.

Malia said smaller groups are more manageable.

“With 30, it’s easier to look through the group and pick out anybody who’s not quite where you want them to be,” Malia said.

The Reisinger family has changed

their facilities to accommodate smaller animals.

The freestall barn that used to house milk cows has been gutted and turned into a bedding pack. Headlocks have been installed in this area and the joining yard. Calves can be separated and quarantined when they arrive, and the Reisingers said the adjustments make cattle handling easier.

Turn to REISINGERS | Page 18

Fight Bac - the best disinfectant for post-milking, is also the best disinfectant for calf navels.

Fight Bac’s antibacterial formula with chlorhexidine has been proven to be just as effective as 7% tincture of iodine, plus it’s more available and costs a lot less at only $0.08 per navel compared to $1.10 or more for navel dip. One can will treat 150 navels (spraying the navel generously). Fight Bac also is more convenient and less messy than using iodine in a dip cup (or paper cup). No gloves are needed, and there is no chance to spread infection.

For years now, hospitals have turned away from iodine and switched to chlorhexidine for treating umbilical cords in human babies. It simply is a better antibacterial.

Also, use Fight Bac on cuts, wounds, injection sites, udder rot (when nothing else works) and to cleanse a teat prior to intramammary infusion. Put a can in every corner of your dairy.

The customer does all their own vaccinations, in cooperation with the Reisingers. Malia and her dad get the animals locked up, and the owners administer vaccines.

Jim starts his day by mixing feed. He works with the nutritionist to achieve a minimum average daily gain of 2 pounds per day. Heifers are also weighed on the trailer on the way to the farm and then when they return to their owners around 13 months old. So far, they have averaged over their goal. Growing good feed helps achieve this, Jim said.

“We put up good hay,” Jim said. “He (the nutritionist) has a regular routine, so I have to follow that.”

The nutritionist provides batch lists for Jim to mix and is also on-site a few times a week during the onboarding process. All of the feed, except the mineral mix and distillers grain, is grown on the Reisingers’ 300 acres. The total mixed ration is a blend of corn silage, haylage, high-moisture corn, dry hay, distillers grain and mineral.

Jim and Malia work together to complete projects and eldwork.

Malia is in the process of transitioning into ownership of the farm. Malia’s brother, Brian, splits his time between northern California and the family farm but remains involved when he can.

Jim said communication is essential to keep everyone on the same page.

“We have a family meeting once a month,” Jim said. “Brian gets involved, Malia gets involved, and my wife gets involved. We talk it all over.”

Malia agreed that the meetings are helpful.

“Believe me, they’re not all glitter and rainbows,” Malia said. “But, we get out on the other side with things being talked about, even if they’re uncomfortable.”

The family plans to keep operating the farm as is for now, since they can manage it comfortably. Eventually, Malia would like to add more housing to expand their capacity. They already grow more feed than they can use and work with a neighbor to manage supply, so feed would not be an issue in expanding.

One of the biggest challenges for the family has been the transition to life without cows. For Jim, it was difcult after spending his whole life milking cows and then seeing the facilities change. For Malia, the challenge of taking on more responsibility at the farm while also growing her family has been a challenge and a blessing, she said.

“Our goal was to make this more manageable,” Malia said. “It’s the family farm. I don’t want to not have the family farm, but for my kids to grow up on the farm. You learn about life, death and how to work hard and get dirty.”

Fiberglass freestalls offer a heightened level of comfort which can lead to an increase in milk production!

New additive in our paint now prevents & protects against the growth of mold & mildew.

• All Solid Rail Fencing that has a 20 year UV coating to prevent slivers, colors available

• Show Fencing & Pasture fencing

• Cattle Panels & Continuous Fencing

• 1" & 1-1/4" Electric Fence Post UV Protected

•13% Chrome Post for Head Locks & Feed Rail

• Guard Rail and Fiberglass posts.

• Lifetime warranty on our fiberglass products from rusting and rotting

“ We installed freestalls and gates from TJ Fencing after seeing how reasonably priced they are compared to other options. I will never install a steel post again either after using their posts which will never rust. I really like the products I have from TJ Fencing and plan to put more of their freestalls in my next barn.”

- KG4 Farms, Ridgeway IA

“We installed our posts and 5 wire fencing in spring for our cattle receiving/training pen. Post and fencing were easy and quick to install & fiberglass is long lasting. We want to keep our farm natural looking so this product works well for us and the cattle.” Morris and Debra Weyers, Bethany, MO

“These gates are very simple to take apart, like calf huts, only bigger. We put 1-3 calves in a pen, which gets them accustomed to group housing. Ventilation is better for the calves having an open pen.We are very happy with our investment in the gates.”

Top Deck Holsteins-Westgate, IA, Jason, Derek, Justin Decker

“We decided to install freestalls from TJ’s Fencing after a friend recommended them. They were easy to install and the cows really like them. We only have about half of the stalls converted right now, but are eager to get the rest of our stalls converted to freestalls from TJ’s Fencing.“

- Bernard County Dairy, Richard Decker Installed in February 2020

“I have free stalls from TJ’s and love them! With my old steel stalls I was constantly repairing from the cows bending them. TJ’s stalls are very flexible and reasonably priced. I have saved a lot of time and money on repairs with TJ’s free stalls.”

Will Gerdes Caledonia, MN

“We have been supplying Glasfiber boxes for 10 years. Every customer is satisfied with this product and will definitely choose the glass fiber freestall again in the future. It is also a good fit for renovation projects. In addition, we also offer glass fiber fencing. The glass fiber is an excellent alternative to the iron barn equipment.”

Bertha Swaving, Holland, Netherlands