WEST SALEM, Wis. — The Jandts thought their problems were over when they xed their stray voltage issues in 2017. Unfortunately, there was another problem lurking in their water supply.

“When we xed our stray voltage problems, feed intake increased, but the milk never did,” Joe Jandt said. “Components got better, but the pounds never went up. They were eating more feed, but they never came back (in milk production).”

Jandt milks

stanchion barn. A nutritionist tried to help the Jandts determine what could be preventing production from recovering. After adjusting the ration, testing feed and double-checking the electrical system, they resorted to a simple water sample. The results indicated there was a high level of iron in the water.

To be considered safe for cows, it is recommended that iron levels in water be under 0.3 parts per million. The iron in the Jandts’ water supply was 3.6 parts per million, which is 12 times higher than the threshold for concern.

“When they drink the water with the iron in it, it messes up the way they metabolize those minerals. A lot of times, when people don’t realize they have this problem, they end up overfeeding minerals in the diet.”JOE JANDT, DAIRY FARMER

160 cows with his wife, Jennifer, and their children, Gabe, Gibson and Ellison. Cows are housed in free stalls and milked in a

“There’s not a lot of help out there with how to x it,” Jandt said. “It kind of felt the same way as stray voltage.”

A high iron level in drinking water binds minerals and prevents proper absorption. The iron in treated water does not disappear; however, it transitions iron from a soluble mineral to an insoluble mineral, allowing the cows to absorb the other minerals in the water.

“When they drink the water with the iron in it, it messes up the way they metabolize those minerals,” Jandt

said. “A lot of times, when people don’t realize they have this problem, they end up overfeeding minerals in the diet.”

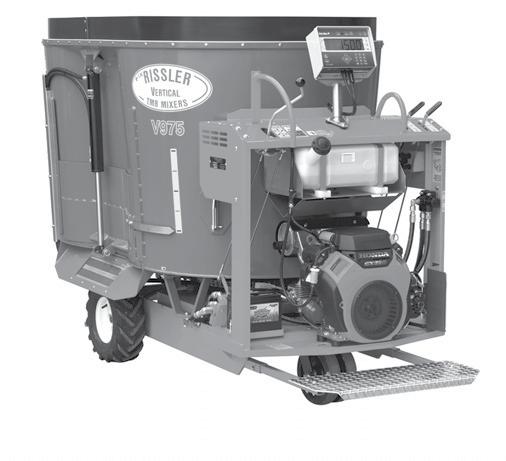

Their route supply company at the time helped the Jandts research ways to make the water safe. The mechanical iron separators they found were horribly expensive, Jandt said. Finally, they discovered that a peroxide injector could take care of the problem in the most cost-effective way.

A meter was installed on the pipe that supplies water to the cows. The meter measures the output of water from the well and then sends a signal to the controller mounted on the milkhouse wall. This prompts a pump to add chemicals. A 55-gallon barrel of 34.5% peroxide feeds the pump. Treated water then ows to the waterers.

Cows get a drink of water March 12 at Joe and Jennifer Jandt’s farm near West Salem, Wisconsin. The Jandts use a peroxide injector to treat the cows’ drinking water due to the high levels of iron that were causing herd health problems. They have used the system for three years.

The system includes a backow preventer, so treated water is unable to feed back into the well. Since it is illegal to treat a well, measures had to be taken to prevent the peroxide from reaching the main water supply. The preventer was about one-third of the cost of the project, and the Jandts pay to get it inspected every year.

Since the water that is going through the backow preventer is untreated, the high iron levels cause wear on the device. It has lasted three years, but Jandt expects to have to replace it before the next inspection.

The backow preventer was about $1,200, and the entire project cost around $3,600. The barrel of peroxide lasts about 3-4 months and costs $425. Their route supply company supplies the product.

When the system was rst installed, it took a few weeks for the Jandts to see results in the cows. When there is a high level of iron in the water for a long time, the level of peroxide going into the water is set at a higher rate to begin with. After a couple of weeks, the rate is dialed down. Eventually, it reaches a maintenance level.

Jandt said the automatic waterers are now cleaner, and all the iron bacteria that had built up in the waters disappeared after the peroxide treatment, resulting in healthier water for the cows.

Now that they have used the system for three years, the cows have developed a new standard, and they suffer tremendously if the peroxide barrel runs dry. When the system was initially used, the cows would drop 1,000 pounds of milk in a day if the barrel ran dry. When the peroxide barrel was replaced, production was back up the next day.

The Jandts recently ran out of peroxide again and did not realize it right away. They had three cows freshen, and the calves were born with their front legs curled under. They struggled to gure out why they were so weak. When their nutritionist mentioned a selenium deciency, they realized they had run out of peroxide.

“The peroxide was out, and the iron was back,” Jandt said. “It certainly affected the cows before we had the peroxide injector, but now that we’ve done it, they can’t be without it.”

The U.S. Department of Agriculture lowered its milk production forecast in its fth consecutive World Agriculture Supply and Demand Estimates report, citing a smaller dairy cow inventory and slower growth in output per cow.

2024 production and marketings were projected at 227.3 and 226.3 billion pounds, respectively, down 900,000 pounds on both from last month’s estimate. If realized, both would only be up 900,000 pounds, or 0.4%, from 2023.

Cheese is expected to average $1.71 per pound in 2024, up 2 cents from last month’s estimate, and compares to $1.7593 in 2023 and $2.1122 in 2022.

Butter was projected to average $2.80 per pound, up 3 cents from last month’s estimate, and compares to $2.6170 in 2023 and $2.8665 in 2022.

Nonfat dry milk will average $1.21 per pound in 2024, down 2.50 cents from a month ago, and compares to $1.1856 in 2023 and $1.6851 in 2022.

The dry whey average was projected at 45 cents per pound, down 3 cents from a month ago, and compares to 36.18 cents in 2023 and 60.57 cents in 2022.

Class III milk is expected to average $17.15 per hundredweight in 2024, up a nickel from last month’s estimate, and compares to $17.02 in 2023 and $21.96 in 2022. The Class IV average, at $20.10, is up a dime from a month ago, and compares to the 2023 average of $19.12 and $24.47 in 2022.

The WASDE lowered world ending stocks of corn and soybeans but left U.S. stocks unchanged. The corn outlook was unchanged, but the season-average corn price was lowered to $4.75 per bushel. Global coarse grain production was forecasted 2.7 million tons lower to 1.5 billion.

The foreign grain outlook is for reduced production, larger trade and smaller ending stocks. Foreign corn production was lowered due to declines in South Africa, Ukraine, Mexico, Venezuela and Russia, partly offset by increases for Argentina and Syria. South Africa was down, reecting lower yield prospects. Mexico was cut based on expectations of lower winter corn area. Ukraine and Russia were reduced based on reported harvest results to-date, while Argentina was raised based on higher expected area.

The soybean outlook was also unchanged as were the season-average soybean and soybean meal price forecasts. Global soybean production was reduced 1.4 million tons on lower production in Brazil and South Africa. Global supply and demand forecasts included lower beginning stocks, lower production, lower crush, higher exports and lower ending stocks compared to last month, according to the WASDE.

The week ending March 2 saw 59,800 dairy cows go to slaughter, down 400 from the previous week and 7,100, or 10.6%, below a year ago. Year-to-date, 516,700 head have been culled, down 89,400, or 14.8%, from a year ago.

In an update from HighGround Dairy’s Betty Berning and her report two weeks ago on the wildre in Texas, Berning said, “Dairy farmers are reporting sick cattle in the Panhandle. Symptoms vary, but a consistent part of the reports is a drop in milk production ranging, on average, from 10-30 pounds per cow across the herd, according to Dr. Alexis Thompson with the Texas A&M Veterinary Medical Diagnostic Laboratory. A thick, gel-like milk, resembling mastitis, has been observed in the sick cows. Some bounce back after being sick, returning to normal milk output, but some do not come back fully, and some come back very marginally.

“The extent of the problem is still under evaluation. Not every farm in the area is affected, and even among the impacted herds, only a portion of the cows are showing signs of illness, estimated at around 5%20%. The cause of the ailment is under investigation by Texas A&M and the state veterinarian. Some in the industry have cited a common ailment, winter dysentery, as the likely disease, but tests have been negative.”

Cash cheese prices appeared to reverse direction the second week of March. The cheddar blocks, after losing 9 cents the previous week, fell to $1.4350 per pound Monday, lowest since Jan. 5, then jumped to $1.4725 Thursday, but closed Friday at $1.47, up a penny on the week, though 52.75 cents below a year ago when they gained almost 22 cents and hit $1.9975.

The barrels, after plunging 16.25 cents the previous week, fell to $1.42 Tuesday, also the lowest since Jan. 5, but reversed direction Wednesday after not seeing a gain in 11 consecutive sessions, and closed Friday at $1.4425. That’s down 4.50 cents on the week, 51.75 cents below a year ago and a typical 2.75 cents below the blocks. There were 13 loads of block traded on the week and 23 of barrel.

Dairy Market News reports that cheese demand is edging higher. Cheese plant contacts differ on what’s behind the bearish prices. Eastern region buyers have begun to add to their orders, for both retail and pizzeria cheese. Milk availability is growing. Mid-week spot milk prices ranged $3.50-under to 50 cents-over Class III; however, there were offers as low as $6-under Class. Last year, they ranged $12- to $4-under Class. Increased spot milk access was attributed to a number of factors, according to DMN, most notably: multiple cheese plants are on scheduled downtime, school districts’ current and upcoming spring break has Class I plants pulling less milk, and seasonal upticks in farm milk output.

Western cheese demand remains steady. Cream cheese demand is picking up. Export channels are steady to stronger, and second and third quarter shipments continue to be booked, DMN said. Class III milk is readily available, and vats are running strong to steady schedules, so there is plenty of cheese available.

StoneX blamed low demand for the falling cheese prices.

“Whether it’s a slowdown in mid-tier foodservice

restaurants (crippled by higher costs and fewer workers at that price point), general ination slowing retail demand for cheese, Ozempic (and similar weight loss drugs) killing appetites, hand-to-mouth buying at the wholesale level due to increased cost of money, or some combination of these and other factors, the demand side of the cheese equation remains lackluster,” StoneX said.

HighGround Dairy’s Eric Meyer warned in the March 8 Cheese Market News of the additional cheese capacity that came online in late 2023 with more to come through the rst half of 2025. That could invoke sustained pressure on price, he said.

“Recent estimates suggest this new production equates to around 6% of present annual cheese output,” Meyer said. “That’s a lot of product that will need to nd a home. Second, while the U.S. stock market and Bitcoin keep making all-time highs, cheese consumption trends this past year have not been bright.

“Dairy Management Inc.’s Total Dairy Retail Report stated that national retail cheese volume was virtually at in 2023 versus the prior year, with growth in reverse each year since 2020. The consumer’s return to restaurants post-COVID has contributed to a portion of that decline, but ination and, as a result, shrinkation (smaller package sizes) have also contributed to the retail struggles.”

January’s Dairy Supply and Utilization report added conrmation. Total cheese consumption, at 1.2 billion pounds, was down 2% from a year ago. Domestic disappearance was down 2.9% while exports, thankfully, were up 12.7%.

HighGround Dairy’s Alyssa Badger, speaking in the March 18 Dairy Radio Now broadcast, said cheese consumption was not only down from 2023 levels but from 2022 as well.

“That weak stateside demand kept the market under a bit of pressure,” Badger said, as CME prices were trading $1.40-$1.50 per pound then.

Butter usage, at 175.8 million pounds, was the exact opposite, Badger said, up 8.5%, driven by a 15.7 million pound, 10.5% increase in domestic demand and reminiscent of the demand bubble of 2022. It also accounted for 97% of total butter consumption, as butter exports were down 33.3% from a year ago.

“Butter stocks are not as aggressively thin as they were in January 2022, but the elevated use and general nervousness about tight milk and fat supplies have kept prices trending at similar levels for this time of year,” Badger said.

Nonfat dry milk utilization fell to 190.9 million pounds, down 7.7%, lowest January volume since 2020, according to Badger, who blamed struggling international demand. Exports dropped 14%, in large part due to a 22% decline in shipments to Mexico alone, which supported exports in 2023. Domestic use was up 9%.

Whey disappearance amounted to 79.8 million pounds, up 2.6%, with domestic use up 2.5% and exports up 2.8%. Whey protein concentrate disappearance was up for the 11th month over the last 12, according to Badger.

“Stocks narrowed in January, and prices continued climbing,” Badger said.

CME butter climbed to $2.8475 per pound Thursday but closed Friday at $2.8225, up 2 cents on the week and 42.25 cents above a year ago. There were eight sales reported on the week at the CME.

Butter production is somewhat steady with previous weeks, DMN said, but churning has slowed as more plants increase microxing (thawing 68-pound blocks and cutting them into 1 pound blocks or quarterpound sticks). Cream remains available, and most butter plants have cream intakes locked in for the month. Cream demand from other manufacturers is trending seasonally higher.

Western butter makers are running strong to steady production, DMN said. Some are working to make inventory goals ahead of summer maintenance projects along with meeting remaining rst quarter demand. Processors say cream yields in milk and cream demand are strengthening. Cream availability is tighter, but there are no shortages. Domestic butter usage is strong, and earlier spring holidays are encouraging more consistent demand, although food service demand is weakening. Canadian purchasers are showing stronger interest, but demand is more moderate elsewhere, according to DMN.

Grade A nonfat dry milk saw its Friday nish at $1.1625 per pound, down 0.75 cents on the week and a quarter-cent below a year ago, with 11 sales reported.

Dry whey climbed to a Friday close at 44.50 cents per pound, up 3.50 cents on the week on unlled bids, but that’s 2.25 cents below a year ago.

Tuesday’s GDT Pulse saw 4.4 million pounds of product sold, up from 4.28 million Feb. 27, with 100%

of the total offered sold. There was 544,536 pounds more instant whole milk powder and 105,820 pounds more regular whole milk powder sold versus the last Pulse, with 22,000 more pounds of skim milk powder on offer sold in this auction.

The Consortium for Common Food Names reports that U.S cheesemakers did well at this year’s World Championship Cheese Contest, winning 84 best in class nishes in Madison, Wisconsin. A total of 25 countries participated in what is billed as the world’s premier cheese, butter and yogurt competition. The Wisconsin Cheese Makers Association has hosted the biennial contest since 1957.

Schuman Cheese’s Lake Country Dairy processors in Turtle Lake, Wisconsin, won both best of class and second award in the parmesan division, beating out an Italian competitor, and won top billing for its Cello Artisan extra aged asiago, ahead of a Danish entry. Additionally, Lactalis Belmont from Belmont, Wisconsin, won top brie over a French processor, and U.S. cheesemakers swept the Havarti category, beating two Danish contestants.

“The results are especially notable due to the European Union’s ongoing campaign to conscate these cheese terms as geographical indications that can only be used by European producers,” said Jaime Castaneda, executive director of the consortium. “While the EU would like to think that its producers own the exclusive right to make and sell parmesan, Havarti, asiago and other types of cheeses, it’s clear that U.S. and other cheesemakers can match their quality and then some.

“Just like in 2017, in the United Kingdom, when an American parmesan won out over all other parmesan entries, including every Parmigiano Reggiano contestant, this year’s World Cheese Awards showed the strength of U.S. cheeses when unleashed to compete on a level playing eld. We’re thrilled to see American cheesemakers get the recognition that they deserve, and we look forward to continuing to ght for them

and their rights to sell their award-winning cheeses all around the world.”

In politics, Green Bay-based American Dairy Coalition called on U.S. Secretary of Agriculture Tom Vilsack and AMS Dairy Programs Deputy Administrator Dana Coale this week to grant the American Farm Bureau Federation’s ofcial request for an emergency decision to return the Class I skim price formula to the higher of.

“The AFBF request was read into the record on the last day of the Federal Milk Marketing Order hearing Jan. 30 by Farm Bureau economist Danny Munch,” ADC said. “Nearly ve years of the ‘average of’ method has resulted in net losses to farmers of $1.1 billion in Class I revenue, alone, which is predicted to exceed $1.6 billion by the end of 2024.”

More than 30 state, regional and national dairy organizations, state farm bureaus and cooperatives as well as nearly 200 individual dairy producers and allied industry service providers have signed the ADC letter along with ADC president Walt Moore, a Pennsylvania dairy farmer. Signatories cover 33 states from coast to coast.

“This is an emergency,” ADC said. “The 2022 Ag Census showed a staggering 40% drop in the number of U.S. dairy farms in ve years. The move away from the higher of is contributing to dairy margin losses and negatively impacting dairy farm families and the rural communities that rely on them.”

LA CROSSE, Wis. — The effort to reduce methane emissions continues, and feed additives can be a practical approach. Recent research studied the effects of a seaweed product on the reduction of methane emissions in dairy cows.

The study took place under the supervision of Dr. Brad Heins, a professor of organic dairy production at the University of Minnesota.

The research was conducted at the West Central Research and Outreach

Center’s organic farm in Morris, Minnesota. The project was part of Organic Valley’s carbon insetting program. The seaweed product was provided by Symbrosia, of Hawaii.

“Most of the previous studies were done in just a month or two and saw great reductions in methane, so we wanted to nd out what happens after six months,” Heins said. “There was one study that found that the rumen microbiome returns to the same as what it did before that, so we wanted to know what happened.”

Heins presented ndings at the Marbleseed Organic Farming Conference Feb. 23 in La Crosse.

Methane was measured with a GreenFeed system. The pasture-based system includes a head box that cows enter freely to receive a bait of feed. After two minutes, the box will have measured 3-5 methane emissions. Heins said a cow

releases methane about every 45 seconds while eating.

“Contrary to what the world probably thinks, a cow is not releasing methane 24 hours a day,” Heins said. “It is being released in big bursts every minute or so.”

Methane also is released when a cow is digesting feed. Studies have shown that methane emissions are low in the morning and high at night because most dairy farmers put fresh feed down in the morning, and by the end of the day, a cow has a full rumen that is busy digesting feed.

average of 30 pounds per day, with tests of about 4.1% fat and 3.1% protein. Somatic cell count, milk urea nitrogen and dry matter intake all stayed relatively unchanged throughout the study.

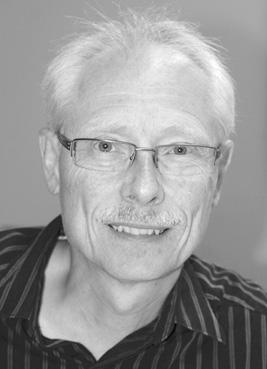

Dr. Brad Heins

University of Minnesota

Dr. Brad Heins

University of Minnesota

Heins began feeding the seaweed product in July 2023. The product was made from a variety of red seaweed that is high in bromoform, which is a component that reduces methane.

The study included 40 dairy cows that were fed 1 ounce per cow per day. Because this was the company’s rst controlled study, they were not sure where to start with intakes. The product was fed in the total mixed ration, and their rst discovery was that the cows did not like it. Feed intake was reduced by 60%, even at a rate of 1 ounce per day.

It took two weeks for the cows to adjust to their regular intake. Once their feed intake was adjusted, it took about 3-4 weeks for the rumen microbes to adjust and to see a methane reduction.

At that point, cows were on pasture and receiving the TMR with the seaweed additive. There was a 30%-40% reduction in methane emissions. This stayed relatively consistent throughout the study until the sixth month when it tapered off. Methane emissions eventually returned to their original levels, while still being fed the seaweed product.

“At that point, their rumen microbes had adjusted back to what they were before we started feeding,” Heins said. “We didn’t see the reduction in methane like we had a few months prior to that.”

Throughout the study, there was no difference in milk production. The cows were in late lactation and producing an

Cows wore sensors to monitor rumination during the study. Cows fed the seaweed product ruminated about 30 minutes less per day than the control group.

“Maybe the rumen bugs were not as active,” Heins said. “We’re not sure why yet. Was the rumen more efcient at digesting feed? Certainly could be.”

The milk was tested to see if the seaweed product had any adverse effects on the milk and if it was safe for human consumption. They found that milk from a cow that was fed the seaweed product had higher bromide and iodine. They concluded that an adult male or female would have to consume 5 gallons of milk per day to experience adverse effects. A 1-year-old child would have to consume 1 gallon per day to experience negative effects. Because this is possible, consumption is not recommended for small children.

The milk was fed to calves throughout the study, and the calves showed no negative effects.

Rumen samples taken about once a month will be further analyzed by Heins and his students. Heins collected samples from the rumen, fat and liver of culled cows to determine if the seaweed product goes through the digestive system and is accumulated in the liver.

Additionally, milk was saved to be used in a taste-testing study, to see if adults could detect a difference of avor.

“There needs to be more studies done,” Heins said. “I would love to do another trial, especially at different feeding levels. We did it at a pretty low feeding level, but now, we could do some more with increased feeding levels to see if we could lower the emissions even more. Even at 1 ounce, we got 30%-40% (reduction).”

What is your background in the dairy industry?

I grew up working on my uncle’s dairy farm helping with chores. I did anything from milking in a rotary parlor to cleaning calf pens and pulling newborn calves and feeding them. I also did chores for a few local farms around the Albany, Minnesota, area. That included milking and feeding the cows and calves, to eventually to breeding cows.

How did you get started with A.I.? I was working as an assistant herdsman on an approximately 170-cow dairy, and they wanted to have me trained to breed the cattle. I took the training course through Select Sires Member Cooperative. I picked it up pretty quickly and got to practice and breed on the farm. My dad, Bernie Koltes, was a Select Sires technician at the time and asked if I would like to ride with him and have a little more training. Eventually, I started to give my dad a few extra days off a week to help him. Having had the chance to work for Select Sires part time, they eventually offered me a position full time. I’ve been there ever since in a few different positions.

Tell us more about your clients and the area you cover. I cover a wide range of farm sizes, from one cow to 300. Mostly, I deal with dairy cows on a daily basis. I have four herds that I go to six or seven days a week to tail chalk and heat detect on as well as around 10-15 other farms that call in for service. I travel approximately 1,200 miles a week to cover my customers that live anywhere from Holdingford to Avon, and the territory stretches to Melrose. I also travel to the Brooten area for a few dairies as well. I also work with about ve beef herds every year to help them achieve their breeding goals.

How many cows have you bred throughout your career? I passed the 30,000-cow mark about two years ago. I would guess my conception rate is around 40% overall. Each farm varies with different environments and protocols.

What is your favorite breed of cattle to work with? Working with Holstein cattle is my favorite. They have the widest variety of genetics and can produce some great-producing cattle.

What is your favorite bull in the industry? Parfect Siemers Rengd Parfect-ET offers some great benets. Ensenada Taboo Planet-ET was one of the most inuential bulls during my time working with dairy cattle.

CLASSIFIED Doesn’t Always Mean Top Secret! It’s no secret that a Dairy Star classied ad can help you buy or sell your farm items! Look for the classifieds and ad order form in 3rd section of this issue!

How do you set up your day? I like to start with my call-in herds and work my way across my area and then work back to my everyday herds of which I tail chalk and use active monitoring systems at. I try to make it to the same dairies daily about the same time when possible.

What do you enjoy about your role? The best part about my role is seeing what I can do to make a producer more successful. Plus, being in the country and working with farmers can be an enjoyable experience.

What is the most challenging aspect of your position? The most difcult parts for me are dealing with the weather and working in pens that get a little deep at times.

Tell us about a unique experience you had while at a farm. I started with one of my customers and created a plan to get them more pregnant cows. When I started, they had a pregnancy rate of 12%, and within the rst year, it was at a 24%. Today, it is much closer to 35%. On top of this, the relationship has become more of a friendship and makes my day more enjoyable. Watching their family grow is also amazing to see.

During your career, what has been the biggest change in the A.I. industry? There have been two major changes. First was genomic testing and the way we’re selecting for bulls. The second one is the use of beef-on-dairy cattle. The selection of bulls has been even more curtailed to meet the dairy and beef protability.

For your job, what tools or items could you not do without? A reliable vehicle and a good after-hours mechanic. Also, the support of my family as I end up missing certain events when I am busy. Also, the right pair of boots and a washable coverall make the day go a lot better.

2nd

March 13, 63 loads

Small Squares

Large Squares

1st crop $145-185

Rock Valley, Iowa • 712-476-5541

March 14, 67 loads

Large Squares

2nd crop $135-210/ton

3rd crop $137.50/ton

Grass $172.50-177.50/ton

Mixed $137.50-140/ton

Barley straw $132.50

Wheat straw $120/ton

Large Rounds

1st crop $137.50-150/ton

2nd crop $125-170/ton

3rd crop $125-165/ton

Grass $77.50-180/ton

Mixed $82.50-130/ton

Corn stalks $20-50/ton

Wheat Straw $125/ton

an island called Ringvassøy, Mariell Solli Sø-

is the fth generation of her family to farm in the northern Norwegian city of Tromsø.

Along with her parents, Sørensen milks a herd of 155 goats and raises 75 kids each year as the next generation of the family goat herd.

Sørensen’s family rst purchased the farm in 1924 primarily as a means of feeding themselves. Each generation has improved and invested in the farm.

Faced with an aging barn in disrepair, the Sørensens built a well-insulated barn in 2009. The barn gave them a larger and more efcient working environment, with every-

thing under one roof. At that time, the herd expanded from 100 goats to 250. The herd is milked in a double-24 parlor.

“We are usually pretty stable at about 240 goats, but something happened during our breeding season last year, and many goats, about 150, came up empty,” Sørensen said. “This made our immediate future as farmers uncertain, but with good help from an adviser, we managed to nd ways to keep going with a smaller herd. Now, six months later, we are doing very well and getting used to the number of goats and workload.”

Caring for their herd is a priority for the Sørensens.

“Our goal has always been to breed healthy animals,” Sørensen said. “We focus on breeding goats with good milk quality and high production, but we also pay attention to the exterior and the temperament of the animals. A lot of thought goes into matching the goat with the right male.”

The Sørensens dehorn their entire herd to prevent damage to the facilities and reduce injuries.

“After we started dehorning all the animals, we see that our herd is much more calm and harmonic with each other,” Sørensen said. “There is less ghting, fewer repairs and happier goats.”

The topography of the Sørensens’ farm lends itself to grazing the herd in the temperate months but makes harvesting stored feed for the long winter challenging.

The farm consists of about 130 acres of cultivated land, 10 owned and 120 acres rented, on which they raise all forages for the herd.

“Late springs and wet, short summers put a lot of pressure on farmers to produce enough hay and silage to last throughout the winter,” Sørensen said. “Buying feed from other areas costs a lot due to distance. With high diesel prices, shipping feed is more expensive than the feed itself.”

The cold, wet summers affect Norwegian farmers well beyond the connes of summer.

“Owning such little cultivated land, it is both expensive and time-consuming to harvest all the grass we need,” Sørensen said. “We rent elds in four different villages on the island. Some are separated from us by mountains, so driving to these elds 25-30 kilometers away can take 50 minutes.”

With increasing costs, the Sørensens are thinking of discontinuing the rental of the elds furthest from their farm.

“We live in the middle of both the mountains and the at area, which is perfect for our goats,” Sørensen said. “Our winters are harsh with a lot of snow, and temperatures down to 35 degrees below zero Celsius. Our summers are either warm or cold and wet; it is always one or the other and never in between. The weather can be very different from year to year, so we never know what we are going to get, but we have learned to prepare for the worst and appreciate the good years.”

Farmers in northern Norway have few choices when it comes to marketing their milk, Sørensen said.

“Unless you want to sell your milk yourself, you are limited to only one factory that will buy your milk,” Sørensen said.

The Sørensens market their milk through a company called TINE.

“There are very strict rules and regulations in Norway regarding the production and sale of food and drinks you produce yourself,” Sørensen said. “So, it is most common to sell our milk to a company that facilitates the production, marketing and distribution of products to different stores.”

According to Sørensen, most of the milk consumed in Norway is produced by dairy cows rather than goats.

“In my county, there are only three dairy farmers left, and we are all goat

farmers,” Sørensen said. “In total, there are only 230 dairy goat farms left in Norway, and on average, about 10 quit each year. It’s a sad statistic. Goat milk is more or less never marketed any way other than by farmers themselves at farmers markets or on social media platforms.”

Governmental and societal pressures felt by farmers around the globe plague Norwegian farmers too, Sørensen said.

“Farmers in Norway are not taken seriously by our government and some consumers or appreciated for the work we put into the food we put on everyone’s tables,” Sørensen said. “There is a lot of tension in Europe. Farmers are sick and tired of the workload with little pay. That tension has reached Norway, and farmers are putting pressure back on our government to do something about these problems. Many farmers are on the edge of just letting go and shutting down their farms, because they can no longer afford to keep going.”

Ination and rising input costs create the same issues for Norwegian farmers as their global counterparts.

“The ination of essential things farmers need to provide for our animals and take care of our equipment and running our farms is not in balance with the prices paid to farmers,” Sørensen said.

Despite the challenges, Sørensen said the goal for the future is to simply continue farming.

“Focusing on the quality of our production and living good lives ourselves keeps us going,” Sørensen said. “We hope that we can keep investing in our farm with newer equipment and new solutions to lighting, and improving the workload more for our own physical health. We hope that the pay will eventually start to go up, but we don’t have high expectations.”

any.k@dairystar.com

GILMAN, Minn. — Drier-than-normal conditions made for the ideal situation for Ron Bemboom to clean up a section of pasture that goes through a swamp — or so he thought.

Bemboom and his son, Shawn, milk 70 cows near Gilman.

They have been renting pasture ground for Shawn’s herd of beef cattle and farming the land that surrounds the pasture. A section of fence in the pasture needed to be replaced.

With the warmer temperatures, March 11 seemed like an ideal day to tackle the project.

“We gured since it is dry and the ground should be frozen, it should work to push out the old fence and clear room for a new fence,” Bemboom said.

To increase their chances of success, the duo borrowed a skid loader with tracks from Shawn’s father-in-law. Bemboom drove the skid loader to the rented ground 1 mile down the road and started the job by cleaning up the pasture ground.

“Everything was going just ne,” Bemboom said. “Then, I noticed some standing water I thought should be frozen. So, I did another big push, and I slid into the water. I tried to back out, but the skid loader just dug deeper in the rut.”

The skid loader started to tip to the side as it got hung up on the uneven ground. The sensors kicked in and automatically turned the skid loader off. With the bucket of the skid loader halfway in the air, the door could not be opened, locking Bemboom inside.

“Luckily, I had my cell phone with me, and I called Shawn,” Bemboom said. “He brought a tractor and chain. He was able to tip me back upright but had to go back home and get another tow strap to pull me out.”

With Bemboom still in the skid loader and Shawn in the CASE IH 2294 about 80 feet away, the duo tried for an hour to get the skid loader unstuck. The ground where the skid loader and Bemboom sat was rough, but where Shawn and the tractor sat was smooth and frozen, making it hard for Shawn to get traction and enough force to pull the skid loader out.

“We nally got it unstuck, but when we were pulling it out, the track started to fall

off,” Bemboom said. “It was completely full of mud.”

With little track skid loader experience, the father-son team called a friend, Charlie Lentener, to help them with the track.

“It took a couple of hours to get the skid loader track back on and cleaned up to be able to present to the father-

in-law once again,” Bemboom said. “It wasn’t my skid loader, and it was one of those situations where everything happened just right so everything that could go wrong did go wrong.”

Bemboom’s eventful day was not over yet. Once everything was cleaned and ad-

dressed, Bemboom went home for supper. As soon as he walked in the house, his wife, Amy, said she had bad news. Their 6-month-old puppy had broken his leash and run away.

Turn to BEMBOOMS | Page 15

With

The Bembooms put down their old farm dog a year ago, and last summer, a family friend gave them a puppy, Bear. The young Bear is still learning about farm boundaries.

“We looked in all the sheds, barns and calf huts,” Bemboom said. “We were about ready to give up and say we will have to just wait for him to come home when Amy said she was going to drive around town to look for him. I didn’t think he would go that far.”

The Bembooms farm is on the edge of town, and after driving a few blocks down the road, Amy found Bear sitting in front of the liquor store. She opened the car door, Bear jumped in, and the two went home.

“When Amy told me where she found him, I said, ‘With the day I had, I should be the one standing in front of the liquor store,’” Bemboom said.

At the end of the day, the skid loader was clean, in working condition and back with Shawn’s father-in-law, and Bear was home safe and sound.

Ron Bemboom and his dog, Bear, sit March 14 by their house near Gilman, Minnesota. On the same day Bemboom was stuck in a skid loader March 11, Bear also ran away from home.

“Thinking about it later, I don’t know what I would have done if I didn’t have my cell phone,” Bemboom said. “How long would I have had to sit there until someone found me?”

In the days since the incident, Bemboom learned why that spot in the pasture was always left alone.

“Now I know where not to drive,”

Bemboom said. “The people that own the pasture said they always meant to tell me to never go down in that spot because there is a natural spring, so the ground is always soft and doesn’t completely freeze over. They had gotten stuck there before too.”

ATTENTION DAIRYMEN!!!

OVER 1700 HEAD OF DAIRY CATTLE SELLING THIS WEEK!

3

Tuesday, March 26, 2024 at 11:00 am Over 1000 head of dairy heifers to sell!

FEATURE CONSIGNMENT #1 - Another outstanding group of REGISTERED Brown Swiss dairy heifers from Siegert Swiss!

65 Registered BROWN SWISS dairy heifers, extremely high quality heifers, newborn through yearlings! TOP END! Coming from Siegert Swiss, Iowa (see pictures & pedigrees on our website!

FEATURE CONSIGNMENT #2 - COMPLETE HEIFER DISPERSAL NEWBORN CALVES TO SPRINGERS!

400 Holstein Dairy Heifers! freestall/headlock adapted, AI sired & AI bred, mostly Semex sires used, extensive vaccination program, out of a 28,000#RHA! Excellent quality! Coming from Triangle Acres LLC

FEATURE CONSIGNMENT #3 - COMPLETE HEIFERS DISPERSAL NEWBORN CALVES TO SPRINGERS!

265 Holstein Dairy Heifers, headlock adapted, accustomed to outside housing, AI sired, using TOP sires through Select Sires and Accelerated Genetics, vaccination program. Selling their dairy herd on THURSDAY March 28th! Coming from Silvermound Dairy MANY MORE HEIFER CONSIGNMENTS ON OUR WEBSITE.

Wednesday, March 27, 2024 at 11:00 am

Expecting our usual run of dairy cows, springing heifers, short bred, open heifers and dairy bulls. See our website for updates! www.premierlivesockandauctions.com

COMPLETE DAIRY HERD DISPERSAL #1

46 CERTIFIED ORGANIC Dairy Cows. Herd includes Holstein, Red & Whites & (5)Guernseys. Tie stall milked, outside everyday. 55# 4.5BF 3.1P 85scc. Over 10 years of A2A2 bulls used, cows are not tested. Cows in all stages of lactation, including (4)springing dry cows (2)springing heifers. Over 30 years of AI breeding using Select Sires. Coming from Andrew Wissell, Gleason, WI

COMPLETE DAIRY HERD DISPERSAL #2

47 CERTIFIED ORGANIC JERSEY dairy cows. Milked in parlor, on bedded pack, rotationally grazed. No TMR fed, last tank components 5.0BF 3.6P scc85. Herd includes (35)cows (12)springing heifers. Cows are A2A2 tested, heifers are not A2A2 tested. Herd is 100% seasonal calving, so every cow/heifer is a close up springer. Cows bred to purebred Jersey bull, heifers bred Angus. 50% of herd is 2-3 year olds. Some older cows will sell as conventional. Coming from Iowa PENDING at ad deadline, 2 Certi ed Organic Dairy herds!

THURSDAY, March 28, 2024 at 10:00 am (note early start time)

• Holstein Dairy Cows

• All stages lactation, year round freshing

• Approximately 100 Springing Dry Cows and Springing Heifers

NO SHEEP, GOAT OR HOG SALE TODAY!

• Many years AI breeding, using Select Sires & Accelerated Genetics Also selling complete heifer dispersal of 265 baby calves through springing heifers ON Tuesday, March 26th! On our special monthly dairy heifer auction! Coming from Silvermound Dairy, MN ONE OWNER DISPERSAL! NOT ACCEPTING ADDITIONAL DAIRY CONSIGNMENTS!

SELLING CALVES & MARKET CATTLE AFTER THE DAIRY SALE!

NORWOOD YOUNG

AMERICA, Minn. — Bill Halfman, beef outreach specialist with the University of Wisconsin-Madison Extension, shared a presentation about nishing beef dairy-beef crossbred cattle Feb. 19 at the Carver County Dairy and Beef Expo in Norwood Young America.

“It’s very important that you get them off to a good start,” Halfman said. “The more you know about them, the better.”

When purchasing cattle from another farm, Halfman said it is good to know how the calves have been raised and what kind of feed they were eating.

“If you have calves that you don’t know what they were on, the best thing to start with is long-stem high-quality hay,

then have a very palatable concentrate to go with that,” Halfman said.

This background knowledge is helpful, Halfman said, so that rations and management decisions can get calves moving in the right direction.

“When you get a calf from somewhere else, the most important thing is getting them eating and drinking,” Halfman said. “It may take up to three weeks upon arrival for them to fully settle in.”

Bunk management is also an important aspect to consider. This includes rations, time of feeding, bunk space and the amount of feed.

in a slow, organized manner to prevent issues.

“A slow transition allows the microbes in the rumen to do their population shift,” Halfman said. “There are two types of microbes in the rumen: berdigesting microbes and starchdigesting microbes.”

“When you rst get the calves, they like to all go and eat at the same time,” Halfman said. “So, for the youngstock, it’s not bad to have 18-26 inches of bunk space. Once they gure out their social order, they won’t all come at the same time.”

Once the calves reach 750850 pounds, Halfman said to switch to a nishing ration. This transition should be done

While the concentrate amount is being increased, the population of the microbes in the rumen will slowly adjust to match the intake of the new ration. Watching the cattle during the transition can also help determine if the transition is taking place too quickly.

“The animals will actually learn how to eat within their rations,” Halfman said.

However, cattle will not gure this out immediately, which is the reason farmers must watch for digestive disruptions. The most common problem caused by a feed ration change is acidosis.

“Acidosis is a pH in the rumen below 5,” Halfman said. “It’s like a bad case of heartburn. If it’s bad enough for long enough, it can disrupt the integ-

rity of the rumen wall.”

Persistent acidosis can also lead to liver abscess development. This can cause the hot carcass weight to drop along with a 20% decrease in an animal’s average daily gain. The pH of the rumen can often be managed with grain processing.

“If we are just cracking the corn, that’s the best way,” Halfman said. “When the corn is ne-ground, there is a lot of surface area that is exposed. The larger pieces with less surface area slow down fermentation.”

A fast rate of fermentation causes the pH in the rumen to drop. Increasing the amount of roughage in the ration can also help decrease the rate of feed consumption and increase rumination time.

“Be consistent with the ration put together, the time it’s fed and, ideally, have a good estimate of what the cattle are going to eat in a day,” Halfman said. “We like to see the bunk empty only about an hour or so. Otherwise, there are going to be hungry cattle that are going to eat too quickly or too much.”

Halfman also talked about three forms of bunk manage-

ment: ad libitum, which has a high feed waste and inconsistent daily dry matter intake; slick bunk, which has reduced feed waste and improves feedto-gain ratio and monitors average daily gain; and sustainable maximal intake, a form of bunk management that follows slick bunk 50%-70% of the time.

“Another positive of slick bunk and sustainable maximal intake is they help monitor cattle health,” Halfman said. “We want to observe how much feed is left in the bunk and how the cattle are behaving. If they are trying to eat at the same time, there is something wrong, whether it’s not getting fed on time or not having a big enough ration.”

Keeping the animals in a reduced stress situation is also going to lead to better performance.

“Implement feeding management practices that minimize risk of digestive upset and disorders,” Halfman said. “Good feeding management reduces stress that can lead to additional health problems, performance and quality of the end product.”

Hay sales starts at 12:30 p.m. and are the 1st and 3rd Thursdays of the months of September through May.

April 4, 2024 April 18, 2024

For more information, contact Kevin Winter 320-352-3803, (c) 320-760-1593 or Al Wessel at 320-547-2206, (c) 320-760-2979

www.mndhia.org

The Minnesota DHIA rolling herd average production in 2023 reached a new all-time high of 25,668 milk, 1,088 fat and 837 protein pounds with a SCC of 179,000. The dollar value is weighted by the pay prices for these four components and was also a new record of $5,219.

Below are the highest-ranking herds within each county afliate, alphabetically by county and herd owner. Congratulations to all!

Fillmore DHIA

DHIA

Hennepin

Con

Jackson/Nobles/Cottonwood

Early Consignments Dairy Cattle

HERD DISPERSAL #1: (34) Fully registered tie stall cows including 30 Holsteins & 4 Brown Swiss. Current bulk tank 75 lbs. milk 85 scc without being pushed for production. Herd BAA is 109.3 with a number of cows out of an EX94 dam. Top shelf quality and good enough to suit anybody!! Big frame rugged cows!! RHC Holsteins, Robert Jr, Nikki and Bryan Cramer, Juda WI

HERD DISPERSAL #2: (30) Holstein tie stall cows. Nice young herd that has been Ai for over 40 years. Bulk tank average is 72 lbs 4.2F, 3.2P and 40scc!! Individual cows milking over 100 lbs. Mid sized, younger herd that should adapt well to any setting. Coming from Rusk county.

HERD DISPERSAL #3: (30) Registered tie stall cows. Milking Shorthorn, Ayrshire, Blue Roan, Holstein, and crosses. Herd is averaging 60 lbs 4.3F, 3.4P. Not pushed for production and overall very nice herd!! Ossian, IA

Ask about our special, first Monday of the month, colored fat cattle sale!!

Tuesday April 2nd at our Thorp location

MARKET REPORT:

Big enough to make a difference, small enough to care!

493 @ $2.40. 3 Fleck strs 678 @ $2.25. 4 Hol strs 556 @ $2.05. 5 Hol strs 546 @ $2.05.

Choice Hol strs $1.59-1.63. Fleckvieh steers $1.61-1.66 . 1155 Angus bull $2,100. Market bulls, Hol 2305 @ $1.30. Fleckvieh 1665 @ $1.35.Angus 1715 @ $1.40. Hol 1300 @ $1.24.

Market cows mostly $1.09-1.20 .Top $1.28.

Beef cross bull calves $830-960 w/a top of $990. Beef cross hfr calves $720-845 w/top of $880/hd. Holstein bull calves 85 lb and up mostly $530-645 w/a top of $660. Hay sale was steady to strong. 3x4x8 alfalfa $170-235. 3x3x8 alfalfa $85-125. 3x4x8 grass $170. 1st and 2nd crop rds and sqrs grass $65-90. Alfalfa balage $75-100. 3x3 canadian wheat straw $70. 3x4 western wheat straw $75-85. Small squares straw $3.00. Small squares grass 3rd crop $7.00. Poor quality or moldy hay priced accordingly. Thank you again, buyers, sellers, and truckers!!

“Thank you for helping when

Con

from the kitchen of Suzie Menzer of Byron, Wisconsin

4 chicken breasts

2 cups Minute rice

2 cans cream of chicken soup

1 1/2 cans of milk, use empty soup cans

1 frozen package of broccoli

2 cups fresh, grated cheddar cheese or more Salt and pepper

Bake chicken breasts until done. While cooking, pour 2 cups of uncooked rice into an un-greased 9-by-13 pan. Mix 2 cans of soup with milk; salt and pepper and stir well. Pour mixture over rice and stir lightly. Sprinkle frozen broccoli on top of rice. Arrange cooked chicken over broccoli. Sprinkle with cheese and cover with foil. Bake at 375 degrees for 35-45 minutes. Take foil off for the last few minutes to completely melt cheese.

3 eggs

from the kitchen of Suzie Menzer of Byron, Wisconsin

Pinch of salt

1 cup milk

3/4 cup our

1/4 cup melted butter

1/2 cup low-fat diced ham

Canola oil, as needed

Whisk eggs, salt, milk and our. Stir in butter; let batter rest for 10 minutes. Spread 1/4 cup batter into a heated, oiled nonstick skillet. Move the skillet around to cover the bottom of the pan. Crepes should be as thin as possible. Cook for 2 minutes, until golden brown. Flip; cook the other side. Repeat with the rest of batter, stacking the crepes in between pieces of wax or parchment paper. Preheat oven to 350 degrees. Fill crepes with ham, tomatoes and cheese and roll. Bake on lightly oiled pan for about 5 minutes, until the cheese melts.

from the kitchen of Suzie Menzer of Byron, Wisconsin

1 pound sausage

2 cans crescent rolls

3 cups cheddar cheese, shredded 8 eggs, beaten

1 1/4 cups milk

1/2 teaspoon salt

1/8 teaspoon pepper

Onion and red bell pepper, optional

Preheat the oven to 375 degrees. Brown sausage and drain. If adding the onion and bell pepper, add them to the sausage while it is browning. Spray a 9-by-13 pan with cooking spray and line with crescent rolls. Layer sausage on top of crescent rolls. If onion and pepper were not added to sausage before, layer it on top now. In separate bowl, beat 8 eggs, salt and pepper. Top sausage mix with 3 cups of cheese and pour the egg evenly over the top. Bake at 375 degrees for 35-40 minutes or until cheese is brown/bubbly. Dish can always be made the night before and refrigerated. It is also great reheated.

‘20

‘18

‘15

Cap, C/H/ A, 2 Spd, Hydra Glide, 3,125 hrs .$36,250

‘21 Gehl V330, JS Ctrls, Dsl, 3300 Lift Cap, C/H/A, 2 Spd, Hydra Glide, 1224 hrs ...$53,900

‘18 Gehl RT165, JS Ctrls, 69HP Dsl, 15” Tracks, 2000 Lift Cap, C/H/A, 2 Spd, 950 hrs ..$44,900

‘19

Gehl RT165, ISO/JS Ctrls, Dsl, 15 1/2

All Season Tracks, Lift Cap 1800 @ 35% And 2400 @ 50%, C/H/A, 2 Spd, 1,720 hrs. $43,900

‘17

Gehl RT250, ISO/Dual H-Ctrls, Dsl, Camso

Tracks HXD 450x86x58, Both Standard And Hi-Flow Hyd, 2 Spd, Hydra Glide, 295 hrs, Warranty Till 6-30-26 Or 1000 Hrs .......$48,500

‘22

Gehl RT215, ISO/JS ctrls, dsl, square bar

17” tracks, 3000 lift cap at 50%, C/H/air, 2 spd, Hydra Glide, 1,375 hrs ..............$53,500

‘18

Gehl RT165, ISO JS Ctrls, Dsl, 1650

Lift Cap, C/H/A, 2 Spd, 990 hrs ...........$47,500

‘17 Gehl V270, ISO Ctrls, Dsl, 2700

Lift Cap, C&H, 2 Spd, 3,950 hrs ...........$40,500

‘18

Gehl R220, JS Ctrls, Dsl, 2200 Lift Cap, SS, 4,600 hrs ........................................$23,000

‘17 Gehl R220, H-Ctrl, Dsl, 2500 Lift Cap, C&H, 2 Spd, hrs ..........................$33,500

‘22

Gehl R220 T-Bar H-Ctrls, 2500 Lift Cap, C&H, 2 spd, 3890 hrs ..................$38,800

‘23

...............................................$116,000

‘11 H&S 5126, 2600 Gallons, 347 Cu Ft $8,900

‘15 Hagedorn Hydra-Spread Extravert 5440, 684 Cu Ft Heaped, 440 Cu Ft Struck, Sequence Valve Flow Control, Wood Rails, Stone Guard, Endgate .......................$41,500

‘12 Hagedorn Hydra-Spread Extravert 5440, 684 Cu Ft Heaped, 440 Cu Ft Struck, Sequence Valve Flow Control, Wood Rails, Stone Guard, Endgate .......................$41,500

NH 185, 170 Struck Cu Ft, 275 Bu, Upper Beater, T-Rod 67 Apron Chain, Poly Floor, End Gate .........................................$12,900

‘19 DODA AFI-35, 1 3/8 1000 PTO, 6” .$7,500

‘18

MISCELLANEOUS

‘20 Kioti K9 2400, CVT Dsl, Canopy, Hyd Dump, Frt & Rear Windshield, 72 hrs, 245 miles .........................................$16,900

Lorenz 834, 540 PTO, 8 ft wide, 100 HP Tractor ..................................$5,600

‘20 Edge/Manitou 50504442, 72” Width, 30”

Tall, Trip Bottom, Replaceable Steel Cutting

Edge, Hyd Angle, Skid Ldr Universal Mount ................................................$3,800

Woods M5-4, 5’ Width, 3 point mount, Single Tail Wheel ...................$1,250

King Kutter L60-40-SC-FH, 540 RPM, 60”

‘22 Manitou 1650RT, H/Ft Ctrls, Dsl, 12” Tracks, 1650

Lift Cap, C/H/A, 2 Spd, 169 hrs ..$56,500

‘21 Manitou 2700V NXT:2, H-Ctrls, Dsl, 3000

Lift Cap, Dsl, C/H/A, 2 Spd, Hydra Glide, 1,850 hrs...............................................$47,700

NH L225, ISO/Hand Switchable Ctrls, Dsl, Standard And Hi-Flow Hyd, 2500 Lift Cap, C&H, 2 Spd, 2,460 hrs..........................$29,800

‘20 Deere 332G, ISO/Dual H-Ctrls, Dsl, 3600 Lift Cap, C/H/A, 2 Spd, 975 hrs ..$61,000 ‘06 Bobcat MT52, 20HP dsl, tipping load 1600 lbs, standard auxiliary hyd, 411 hrs......$22,500

‘17 Kuhn Knight SLC132, 425 Tires, 3200 Gal ..........................................$36,500

‘17 Kuhn Knight 8124, 19L X 16.1 Flotation Tires, 2400 Gals, 500 Bu, Frt & Rear Splash Guards, Low Usage .........................$34,500

Kuhn Knight 8124, 500 Bu, 2400 Gal, Bushings Have Been Redone..........$10,500

‘09 Kuhn Knight 8132

425

Rotary Brush Cutter, 3PT Hitch, 40HP$2,350

Cabelas RC2072 Slip Clutch, 3 pt mt, 6’ Width, Frt & Rear Chains, Single Tail Wheel, Made By Woods ....................$2,900

Virnig Pallet Forks ................................$650

‘18 Grouser Tracks, 18 Pads, Fits JD 320G or Loader with a 44.2” Whl base, All new bushings and pins .............................$2,300

Grouser 12” Tracks, Fits Cat 246B ....$1,200 Tracks, Fits 2054, 10x16.5 Tires, Has Rubber Pads .............................$ 1,000

Westendorf 4300, Brush Cutter .........$1,200

TMG Industrial RT120 tiller, 540 PTO, 48”, 3 Pt.............................................$2,800

Steel Tracks 12” Tracks with Rubber Pads & Whl Spacers, Came O 2200R Mustang .. $700

Bale Spear .............................................$500

Pallet Fork .............................................$500

Snowblower ..........................................$900

Bucket ...................................................$850

‘19 Den Hartog