By Danielle Nauman danielle.n@dairystar.com

Three generations of the Heeg family work together on the farm. Brothers Mark, Gary and Jay are partners in the operation. Their father, August, remains active on the farm, hauling tankers of milk from the farm to Mullins Cheese four days a week. The farm was established in 1999 when the herds owned by August and Mark were combined at one facility.

The Heegs farm 3,300 acres, growing all the forages needed to feed their milking herd and youngstock.

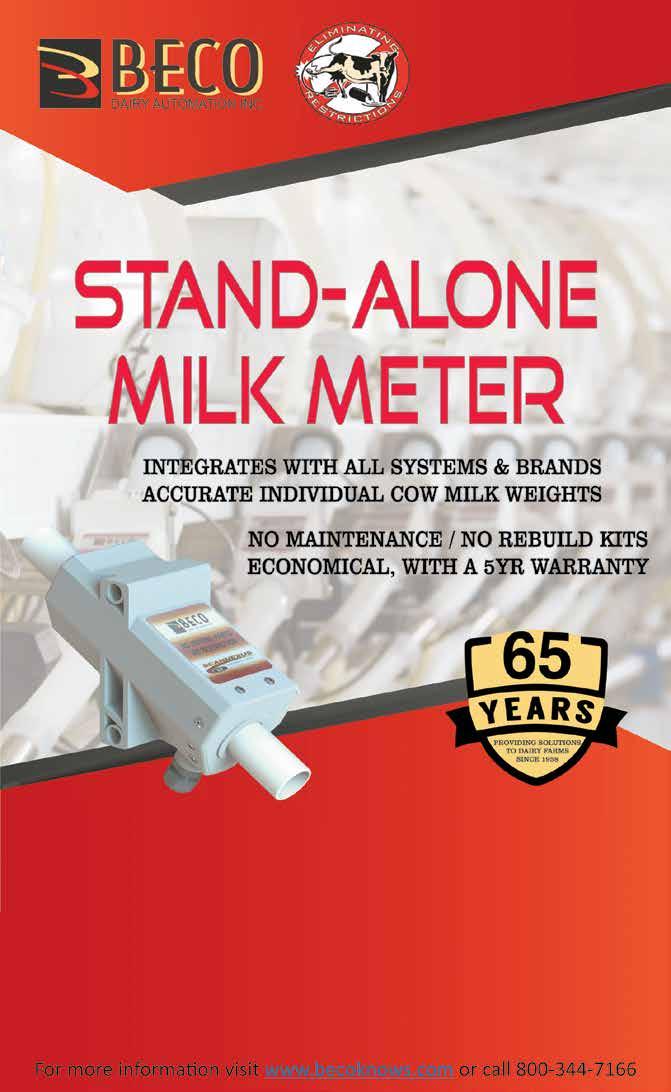

On Dec. 5, 2023, eight DeLaval VMS-300 robotic milking units in two pens were turned on for the rst time. The Heegs are milking 450 cows in the robotic facility and an additional 1,000 cows in their existing double-14 parallel parlor.

STACEY SMART/DAIRY STAR

Henschels’ sawmill, syrup businesses boost farm incomeBy Stacey Smart stacey.s@dairystar.com

STURGEON BAY, Wis.

In early March, a visitor to Cherryland Dairy Farm is greeted by the buzz of a saw cutting wood and maple syrup cooking to perfection.

In addition to dairy farming, for the last 38 years, the Henschel family has operated a sawmill and collected sap from their trees to make syrup. At the helm of Henschel Sawmill is Jamie Henschel, wood cutter extraordinaire.

“Jamie is the only female sawyer of a circular sawmill that we know of,” said her husband, Mike Henschel.

The Henschels milk 50 cows and farm 600 acres

The dairy barn built in 1908 is preserved in pristine red and white as the Henschels ensure their farm’s curb appeal with meticulous care and attention to detail.

Cherryland Dairy Farm is a family affair. Even Mike’s 83-year-old mom, Helen, helps with milking and eldwork. Mark’s wife, Kylie, helps milk cows and pick rock.

Phone:

Fax:

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce)

320-248-3196 (cell)

320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Editorial Staff

Maria Bichler - Assistant Editor maria.b@dairystar.com

Stacey Smart - Assistant Editor 262-442-6666 • stacey.s@dairystar.com

Danielle Nauman - Staff Writer

608-487-1101 • danielle.n@dairystar.com

Abby Wiedmeyer - Staff Writer 608-487-4812 • abby.w@dairystar.com

Tiffany Klaphake - Staff Writer 320-352-6303 • tiffany.k@dairystar.com

Jan Lefebvre - Staff Writer jan.l@star-pub.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Emily Breth - Staff Writer emily.b@star-pub.com

Consultant

Jerry Jennissen 320-346-2292

Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication

Sales Manager - Joyce Frericks

320-352-6303 • joyce@saukherald.com

National Sales Manager - Laura Seljan (National Advertising, SE MN)

507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com

Assistant Sales Manager - Kati Schafer (Northeast WI and Upper MI)

920-979-5284 • kati.s@dairystar.com

Jerry Nelson (SW MN, NW Iowa, South Dakota)

605-690-6260 • jerry.n@dairystar.com

Mike Schafer (Central, South Central MN)

320-894-7825 • mike.s@dairystar.com

Megan Stuessel (Western Wisconsin)

608-387-1202 • megan.s@dairystar.com

Julia Merten (Southeast MN and Northeast IA) 507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell) bob.l@star-pub.com

Kelsey Chrostowski (Eastern IA, SW WI & Northern IL)

608-576-6493 • kelsey.c@dairystar.com

Mark Klaphake (Western MN) 320-352-6303 (ofce) • 320-248-3196 (cell)

“We will keep milking in the parlor for the foreseeable future, but this gives us the capability that if we want to invest in something, it would be in robotics,” Jay Heeg said. “The robotics more closely meet the goals we have for our family down the road.”

The Heegs are opening their farm for visitors April 12 to share their experience of introducing robots.

“The future of the technology was interesting to us,” Heeg said. “It is a whole different philosophy for cow management.”

Driven by labor concerns and a desire to increase the use of technology, the Heegs began investigating their options over three years ago.

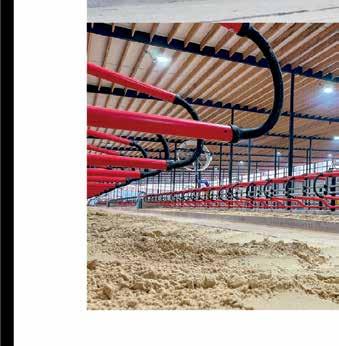

“We did a lot of touring, looking at both robot and rotary barns,” Heeg said. “We really liked the cow environment in the robot barns, the style of the life they live out there. They are on their own. They decide what they like to do. The cows are so calm and quiet.”

The Heegs determined that the DeLaval robots were the best t and spent the next year planning the future of their farm.

“We really liked the guided-ow system,” Heeg said. “The cow comfort we saw sold us, and we have a lot of condence in our relationship with Bob’s Dairy Supply.”

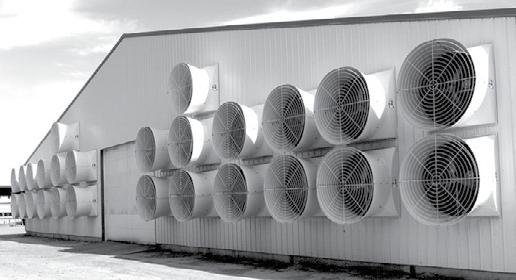

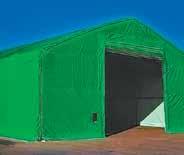

The Heegs chose to work with Fox Cities Builders to construct their tunnel-ventilated robotic barn.

This photo provides a bird’s-eye view as the cows go about their day March 15 in the newly built robo c facility at Heeg Brothers Dairy near Colby, Wisconsin. The facility is home to 450 cows that are milked with eight DeLaval VMS-300 robo c milking units.

“The planning process went really well,” Heeg said. “They were excellent in helping us lay out our robot barn. … The quality of the work was great. We are very happy with what they built. The process was seamless.”

Heeg described the planning process as intense but positive.

“It’s so important,” he said. “You

don’t want any surprises after. We met every week and went over every single detail, every doorknob, every window, everything.”

The robotic barn was built as the rst phase of a three-part plan.

Turn to HEEGS | Page 6

KNOWLTON, Wis. — Navigating the rough seas of the economy and commodity markets while keeping the ship sailing straight has become an extreme sport for dairy farmers. Knowledge of the industry and their own business is the best tool a dairy farmer has to steer the ship smoothly in rough water.

Two colleagues with Nicolet National Bank, Brian Hoskens, vice president-agriculture banking senior lender, and Craig Rogan, vice president-agriculture banking ofcer, talked with members of the FarmFirst Dairy Cooperative Feb. 29 at its Young Cooperators event at Knowlton House Distillery in Knowlton.

“Being engaged and knowledgeable of the industry you’re in is important; cattle and crop production skills are extremely important in running your business,” Hoskens said. “As we look at the next decade or two

compared to the last decade or two, the business management side of running a farm business continues to become more and more important.”

Cultivating an understanding of farm business management involves developing an intimate understanding of the basics of the farm, Rogan said.

“Characteristics of a successful agricultural business include measures like working capital, cash ow and knowing your cost of production,” Rogan said. “It also includes having an open line of communication with the agribusiness professionals you work with on your farm, people like your banker, accountant, nutritionist, agronomist, veterinarian and consultants.”

When it comes to understanding the farm, the best tool available is a budget, Hoskens said. Knowing the cost of production goes hand-in-hand with the budgeting process.

“Putting together a budget is probably one of the hardest things, but it is very important to understand, based on milk prices, where you’re going to

end up for the year,” Hoskens said. “Then, track it. It gives you something to go back and look at. If you don’t have a budget, you have a sense of where things should be, but it’s a lot easier to go look at and monitor it when it’s in writing.”

Starting the process of developing a budget can be overwhelming, but Rogan said producers should start with themselves.

“I always tell my farmers to think about what they want to pay themselves; that is the rst thing,” Rogan said. “You can do this budget, but if there is only $20,000 left for your family to live on, is that enough? We need to start with what you want to pay yourself and go from there. How much revenue do you need to pay yourself what you want — not to just be satised with what is left over at the end of the day — and budget according to that.”

Hoskens said he often hears his colleagues tell farmers to hire a consultant and pay someone to do their budget for them, but he believes that is leaving a learning opportunity on the table for the individual farmer.

“I prefer anyone to do their own budget,” Hoskens said. “It might not be dialed in quite as close; although, some days it

might be closer. But, you will probably learn a lot more doing your own budget. “You will learn even more doing your own budget the year after it is off by a healthy margin; each year’s budget will be better and more accurate. Over the long time, that has denitely created more protable managers, when they are very engaged in their own numbers and running their own budgets.”

Once dairy farmers have a handle on those numbers, they can begin to assess other opportunities and challenges, such as risk mitigation options like Dairy Margin Coverage, Dairy Revenue Protection, Livestock Gross Margin and uctuations in interest rates.

“We should be aware of those options and have that knowledge on the business management side,” Hoskens said. “Today might not be the best day to go out and buy a bunch of DRP. That day might be next week, or it might have been last year. The time to learn how to do that isn’t the day milk has peaked, and we should be pulling the trigger to protect some of that.”

Ination and rising interest rates have made progress a double-edged sword for dairy farmers in recent years, but Ho-

skens and Rogan agreed that knowledge is the best weapon farmers have.

“Anyone that has priced anything, bought anything or built anything in the last couple of years has seen that things aren’t as cheap as they used to be, and doubling an interest rate on top of that has really made serious impacts on farm cash ows,” Hoskens said. “Interest rates the last two years have probably been even more unpredictable than the milk markets. Trying to manage the interest rate risk is something that is a real part of business.”

Whether managing risk mitigation, navigating interest rates or investing in technologies to improve efciency, Hoskens and Rogan agreed that their primary interest is the success of the farmers they work with.

“We want your business to work for you and for us,” Hoskens said. “It comes back to that budgeting, having a forecast that says we should be able to pay all the bills, pay the bank and have a little left over to live on at the end of the year. Things can change. Milk prices obviously go up and down, but that budget is the starting point for everything.”

“We designed the barn to be added on to so that it could have up to 24 robots,” Heeg said. “We’re at two pens of eight robots. We’re not even to the peak of the building yet.”

When the time came to start up, the Heegs were surprised at how smoothly their cows transitioned from the parlor to the robots. They started one pen with 160 cows and started the second pen two weeks later.

The cows sent to the robotic facility were selected based on udder scores, feet and legs, and milking speed. Cows from all stages of lactation were selected to create a herd dynamic. After a month, groups of 30 fresh cows were added every other week until each pen was full.

“I was nervous,” Heeg said. “I didn’t know how the cows would learn all the sort gates and robots, but they did really well. The cows learned faster than the people. The cows are settled in, but we’re still learning.”

“We don’t want to do anything to disrupt the ow out in the barn,” Heeg said.

In a short three months, Heeg said the investment in the robotic milking facility has exceeded their expectations. The cows have achieved a 95-pound milk average with a 4.2% butterfat test. Most impressive to Heeg was the somatic cell counts from the cows being milked in the robots. The cows are averaging 2.8 visits, with no pellets being fed in the robots.

“The rst load of milk we sent out had a SCC of 110,000,” Heeg said. “Within two weeks, it was down to 65,000. Now, we’re currently at 70,000, which is half of what the parlor is. That proves the milking process is very good and is important to udder health.”

Heeg said his family has no regrets about their decision to invest in robots and has been thrilled with the results.

Because of his admiration for the calmness of the cows milked by the robots, Heeg said they try to only work with the cows in the sort pens, staying out of the free stalls as much as possible. The exception is the addition of sand bedding once a week.

“Once the cows are trained, they do better without you out there in the pen,” Heeg said. “You just let them do their own thing. That has been the biggest learning curve for us — to have patience and let them be. We have had to change the way we think about managing the cows. We have to learn to rely on the data provided to us.”

Con nued from HENSCHELS

This diversied dairy in Door County has much to offer its community. Wood from its sawmill, maple syrup from its trees, honey from its bees, eggs from its chickens, beef from its steers and pork from its pigs are the goods the farm supplies to its neighbors and beyond.

“We’re into a little bit of everything, and there is always something to do,” Jamie said.

A large expansion occurred at the sawmill in 2023 when the family put up a building, growing their mill from 900 square feet to 5,000 square feet.

“It was a three-sided building before, but now it’s enclosed,” Mike said. “We can saw inside, which has made it a lot nicer.”

The Henschels sell 250,000-300,000 board feet of wood per year.

“We always called this our hobby, but now we call farming our hobby,” Mike said.

Mike and his dad, Roger, established Henschel Sawmill on Memorial Day 1986. Semi-loads of logs are delivered annually to the mill from the Northwoods of Wisconsin and Michigan’s Upper Peninsula.

“Cedar and white pine are the main types of wood we work with,” Mike said.

White ash and poplar are the next most common fol-

Page 1

lowed by local hardwoods like maple, birch, red oak, cherry and black walnut.

Henschel Sawmill supplies a variety of dimensional lumber for countless uses. From building decks, docks and fences to re-siding barns to providing wood ooring, tongue and groove paneling, and shiplap for houses, Jamie said there is a need for many proles.

“Everyone has different ideas about what they want to build, and we try to accommodate,” she said.

The Henschels do many custom jobs, cutting wood for trim work, ooring and shelves. They also offer design ideas if customers need assistance.

“Natural-edge countertops and replace mantels are hot items,” Mike said. “We make a lot of those.”

Most of the wood is sold locally to private property owners and contractors, but products from their sawmill also reach other states.

The before and after of their work can be seen in the piles of logs and stacks of nished wood that ll the yard in front of the sawmill, which is bustling yearround. Wintertime brings a push to stockpile wood when the family is not as busy on the farm. Projects like decks and Adirondack chairs make summer the busiest season at the sawmill.

“We’ll spend half the day at the sawmill and the other half baling or chopping,” Brian said. “We’re here pretty much every day except Sunday.” Located a mile from the farm, the sawmill is open to the public from 9:30 a.m. to 5 p.m. by appointment. Despite the summertime rush, Mike said crops always come rst.

The Henschels let no piece of wood go to waste. Scraps supply wood for sh boils — a popular Door County tradition — and slabs of wood are also used in the Henschels’ syrup-making process. Furthermore, wood scraps are turned into landscape mulch and sawdust for bedding animals, which is sold in horse and dairy mar-

kets.

Jamie took over the mill when Mike’s father passed away in 2002.

“I would’ve never thought of getting into it if it wasn’t for Mike and his family,” Jamie said. “I learned everything from my fatherin-law, and now it’s time to pass the torch to Brian.”

Turn

Henschel Sawmill was established in 1986 by Mike Henschel and his father, Roger, a mile from their farm near Sturgeon Bay, Wisconsin. Jamie Henschel took over opera on of the sawmill when her father-in-law passed away in 2002.

In 2019, the Henschels phased out their cherry orchard, which had been a part of the farm for 90 years.

“Harvesting cherries was very time-consuming,” Mike said. “The mill got bigger, and we can’t do it all.”

When Mike was a junior in high school, he built a shack to make maple syrup and bottled his rst batch in the fall of his senior year.

“I grew up helping my neighbors make syrup until someone suggested I build my own shack, and it took off from there,” Mike said. “It’s something to do in spring. Plus, I can’t stand the fake stuff on my pancakes.”

Mike started with 250 trees. Today, the family taps 1,500 trees. The syrup is made in February and March and sold at gas stations, feed mills and farmers markets. It is also available for purchase on the farm.

“This year was the earliest we ever tapped trees or cooked syrup,” Mike said. … “Mark is the main cooker now. It takes a lot of sap to make 1 gallon of syrup, but our equipment makes it easier.”

The tagline trademarked by the Henschels, Something Delicious from Door County!, appears on every

bottle of their syrup, which is primarily bottled in pints and quarts.

“We use glass bottles, which let the consumer see the product,” Mike said. “The bottle also features a iptop cap for convenient pouring.”

The Henschels also make 400-600 pounds of honey every year, which is sold directly to customers and carried by local businesses. Brian has been a beekeeper since age 12 and manages six to eight hives.

Mark manages the farm’s 40-sow farrow-to-nish hog operation. In addition, the Henschels have marketed beef for 40 years, raising every Holstein bull calf as a steer.

The family is a three-time host of the Door County Breakfast on the Farm and provides tours for third and fourth graders in the spring.

“This is our way to give back to the community,” Jamie said.

The Henschels have their hands in many facets of agriculture and thrive on producing quality products for others to enjoy. Their well-rounded farm relies on income from multiple sources, which has proved positive for protability.

With the current farm bill extended through September and no rm prospects for bringing new legislation up for a vote, National Farmers Union President Rob Larew is warning members not to be discouraged. “Even when there is a middle ground, unfortunately, there’s a small group of members that are blocking that,” Larew said. During his State of the Farmers Union address at the annual meeting, Larew encouraged members to stay engaged. “If farmers speak up, we can make the difference so that those that can nd a middle ground can get a farm bill wrapped up and through the halls of Congress,” Larew said.

NFU approves special orders of business

NFU delegates approved six special orders during its convention. The priorities include fairness for farmers, the farm bill, the farm safety net, conservation, dairy policy reform and support for the cooperative business model. The special order regarding dairy policy said the milk price only covers about 50% of the production costs, which has led to record Dairy Margin Coverage payments. The NFU is calling for an incentive-based plan to match milk supplies with demand, a reevaluation of the Federal Milk Marketing Order system, establishment of a national make allowance to reect the difference between milk prices and the cost of production, and the restoration of whole milk as an option in the school lunch program.

Dairy groups appeal DNR requirement

The Wisconsin Dairy Alliance and Venture Dairy Cooperative are appealing a decision made by the Wisconsin Department of Natural Resources to require large-scale farms to get a Wisconsin Pollutant Discharge Elimination System permit. The WMC Litigation Center is handling the case. “Larger-scale farms in Wisconsin are already some of the most regulated entities in our state and nationally, and this permit requirement simply creates additional burdens on our agricultural community,” said Scott Rosenow, ex-

ecutive director, WMC Litigation Center.

Emergency action sought

The American Dairy Coalition Inc. is urging the U.S. Department of Agriculture to grant the American Farm Bureau Federation’s ofcial request for an emergency decision to return the Class I skim price formula to the higher of. During the past ve years with the average of methodology, dairy farmers have experienced a net loss of $1.1 billion. Nearly 30 state, regional and national dairy organizations, state Farm Bureau organizations and cooperatives have signed the ADC letter.

By Don Wick Columnist

By Don Wick Columnist

GOP lawmakers press White House to address ag trade

Over 20 Senate Republicans have sent a joint letter to U.S. Secretary of Agriculture Tom Vilsack and U.S. Trade Representative Katherine Tai voicing concern about the sharp decline in ag exports. The letter said, “While the Biden administration continually refuses to pursue traditional free trade agreements, China, Canada, the European Union, the United Kingdom and others continue to ink trade pacts that diminish American export opportunities and global economic inuence.”

A difcult farm economy Margins will be tighter on the farm this year. Farmers Business Network Financial general manager Dan English cites the current economic environment. “This certainly isn’t going to be as protable of a year, unfortunately, as we saw a year or two ago,” English said. “The good news is we’re expecting to see a little bit of relief on interest rates here in the second part of this year, but there’s a lot more pressure on farmers this year with higher interest rates, higher input costs and lower prices.”

Despite the recent downturn in the dairy markets, Rabo AgriFinance LLC senior dairy analyst Lucas Fuess remains optimistic for the second half of 2024. “We’ve got to get through the spring ush period over the next few months, of course,” Fuess said. Fuess said several variables are at play. “Looking ahead, the U.S. is very well positioned, especially when considering other key dairy exporting places around the world, places like the European Union and New Zealand,” Fuess said. “We see milk production getting challenged in those regions and we still see growth in the U.S. over the long term.”

Midwest Dairy names CEO

The Midwest Dairy Association has named Corey Scott their new Chief Executive Ofcer. Scott began her duties March 13 and will be transitioning from retiring CEO Molly Pelzer. Scott previously served as vice president of sales and marketing for Athian Inc. and held several leadership positions over 15 years at Land O’Lakes.

Larew, Kippley return for another term

NFU delegates re-elected president Larew and vice president Jeff Kippley by unanimous ballot. Both will serve another two-year term. Larew has served as the NFU president since 2020. Kippley, who farms near Aberdeen, South Dakota, is beginning his second term as vice president.

Forrest earns leadership award

Professional Dairy Producers presented the Dean Strauss Leadership Award to Brian Forrest. Forrest is the owner and manager of Maple Ridge Dairy near Stratford, Wisconsin. Forrest has received dairy recognition at the state and national level, including Focus on Energy’s 2022 Energy Efciency Excellence Award and plat-

inum-level recognition in 2020 from the National Mastitis Council. Forrest was also named a 2021 Wisconsin Agriculturalist Master Agriculturalist.

Rosen receives meritorious service award

Former Wisconsin Farmers Union President Dennis Rosen received the Meritorious Service to Farmers Union and American Agriculture Award during the NFU Convention. Rosen was recognized for his 40-plus year dedication to the Wisconsin Farmers Union.

Farm Bureau establishes board of trustees

The Wisconsin Farm Bureau has created the Wisconsin Farm Bureau Foundation Board of Trustees, which is responsible for fundraising and program efforts. Bob Nash is the chair, and Andrew Dal Santo is vice chair. The board also includes Jim Renn, Ben Huber, Robert Nigh, Loren Wolfe, Roger Grade, Kaitlyn Kesler, Ken Harter, Sara Menard Huber, Isaac Christenson and Kristi Fiedler

Top Chef in Wisconsin

The “Top Chef” reality television show is on the air for its 21st season. The food competition show on the Bravo Media network was lmed in Wisconsin. America’s Dairyland and a plethora of dairy products will be on the menu.

Trivia challenge

The average American consumes 18 gallons of milk per year. That answers our last trivia question. For this week’s trivia, what was the average retail price for a gallon of whole milk last year? We will have the answer in the next edition of Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network of Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

MARSHFIELD, Wis. — Saving time and labor as well as money spent on equipment are key reasons farmers choose to hire a custom operator for eldwork. The speed at which crops can be harvested is another advantage of using a custom operator.

Rates for custom work vary, so farmers may wonder how custom operators determine what to charge. Knowing this information can eliminate shock when receiving a bill for custom work.

Equipment size and power can affect the rate charged. Larger pieces of machinery or equipment featuring advanced technology often garner a higher price tag. Many services are based on a per-acre cost, while other services, like chopping, are calculated by the hour.

Steve Salzmann operates Salzmann’s Custom Field Work near Marsheld, serving about 28 customers within a 50-mile radius, including 12 dairy farms. Salzmann is starting his fourth year of custom work, providing tillage, planting, chopping and combining services.

“Most of my customers hire me to do it all,” Salzmann said.

Salzmann charges $16 per acre for discing and soil nishing, $18 per

acre for chisel plowing, $21 per acre for planting, and $30 per acre for combining soybeans and small grains like barley and wheat. For corn, Salzmann charges $35 per acre because he runs a shredder head, which shreds cornstalks while he combines.

“My rate for corn can vary,” Salzmann said. “If I don’t run the shredder head, I charge a little less.”

Salzmann’s rate for cutting hay is $17 per acre. For merging, he charges $16 per acre. Rates for hauling and chopping are congured by the hour. Chopping runs $385 per hour while hauling a tractor with 24-foot wagons is $100 per hour.

“I run a used chopper, so my rate is a little lower than some people’s,” Salzmann said.

Salzmann’s rates do not include fuel as the farmer is expected to supply that.

When determining rates, Salzmann consults with other custom operators in his area each year to get an idea of what they are charging.

“If they’re getting a new chopper, their rate goes up a little because of the price of the equipment and the technology that goes with it,” Salzmann said. “Since I have a used chopper, my monthly payments are less, so I can charge less than some of the other guys. I try to be more competitive and give the farmer a better price in the long run.”

“Troubleshoot issues and analyze all aspects of the dairy.”

What do you like about the Dart program?

I like the ability to customize reports to help analyze the trends on the farm.

Why did you decide to use Dart and how long have you been using it on your dairy? I’ve been using Dart for 13 years. It’s a very user friendly program that we could not only input and manage our cow information but also build reports, graphs, and lists to help troubleshoot issues and analyze all aspects of the dairy.

Which Dart features do you use the most? I use Dart for all my animal records, ID, treatments, matings and genetic data, but I probably use the pocket dairy on my phone the most. I can take all the info with my anywhere I go.

What are some other DHIA tests you use?

We also use DHIA for Leukosis and Johnes testing.

Tell us about your farm. My wife Robyn and I milk 180 cows with my sister Jocelyn and dad Jim. We raise our own heifers, have a commercial ock of sheep and farm around 350 acres primarily for feeding the livestock.

Sauk Centre, MN Buffalo, MN

763.682.1091

Salzmann said some custom operators will calculate chopping and hauling rates according to tonnage. To do this, he said one must have a scale on their wagons and/or have a scale on hand for weighing.

“Newer choppers sometimes tell you the tonnage coming out,” Salzmann said. “Tonnage is hard to charge because you have to have a scale.”

Field conditions can affect pricing as well. Salzmann has raised rates a couple of times when he found rock in the ground during tillage and planting.

“Rocky ground beats the heck out of my equipment, and I could lose money on the job,” he said. “In those cases, I might charge more to cover myself if I have breakdowns.”

Salzmann occasionally offers discounts to farmers who use multiple services and pay their bill upon completion of the work, or soon thereafter.

is and the quantity of hay. If I’ve never chopped at that farm before, I would not know the answer.”

Custom operator Mike Maass, of Maass Farms, provides a variety of custom services, from planting and spraying to harvesting of forages and combining as well as installing eld tile. Based in Seymour, Maass has been doing custom work for 14 years and serves about 18 customers in a 20-mile radius. Maass said the dairy farms he services milk anywhere from 50-350 cows.

“If it’s a hefty bill with multiple services, and I get paid within a week or two, I usually give a 5%-10% discount,” he said. “At one farm, I do all the tillage, planting, and combining and also go back in the fall to chisel plow so it’s ready for springtime. It’s a big expense, so I give him a discount because he pays me within two weeks.”

Before deciding which custom operator to go with, Salzmann recommends asking what kind of equipment the operator has.

“This gives the farmer a better understanding of why rates are what they are,” Salzmann said. “A question that is not fair to ask is, ‘How many tons per hour can you do?’ A lot of factors go into that, such as how far the haul

“We charge mostly by the hour, and rates depend on machine size, etc.,” Maass said. “We have two self-propelled choppers.”

Last year, Maass charged $500 per hour to chop corn silage and haylage using his smaller, 600 horsepower chopper and $650 per hour when running his 800-plus horsepower chopper. His rate for planting is $22 per acre. Combining rates are $38 per acre for soybeans and $40 per acre for corn. Maass charges $8 per acre for spraying. Prices do not include fuel, as fuel is provided by the farmer.

Maass may raise prices this year to compensate for increased business costs.

“I’ve been eating some of the costs the last couple years with higher insurance rates and expensive parts,” Maass said. “Overall, everything is going up. The ination rate went up so high that insurance is raising their rates 15%20% this spring. The price of parts has also skyrocketed, putting us in a pinch.”

Things he used to be able to swap out, like a set of knives, have increased drastically, Maass said. Knives used

to cost $3,500 but now cost $4,500$5,000.

“Things are really getting out of control, and we haven’t changed our prices as needed,” Maass said. “We have to try to nd a happy medium. As equipment gets bigger, faster and more efcient, we can put more things through, but that comes with a cost.”

Field size, driveways and access to the farm are other factors that can affect rates, Maass said.

“I have to charge some customers by the hour because getting on and off highways takes longer,” he said.

Brad Wichman, of Wichman Farms, uses a custom operator for harvesting hay and corn silage. Wichman and his family milk about 250 cows and farm 680 acres near Appleton.

“We use a custom harvester for time savings, efciency and more consistent feed,” Wichman said.

Every year, Wisconsin Custom Operators conducts a survey on rates charged by its members. The following data was gathered from the 2022 growing season.

The average combining rate was $38 per acre, planting was $24 per acre, and tillage was $17 per acre.

The average rate for crop preparation using a merger or mower conditioner was $16 per acre.

For nine years, Wichman has called on Maass Farms to chop his corn silage. Last summer, he also began using their custom services for cutting, merging and chopping hay. The Wichmans do their own planting. The Wichmans have 140-150 acres of hay and 120-130 acres of corn harvested by Maass and his crew.

“The rest of the corn we combine, and we plant soybeans also,” Wichman said.

To help decide which custom operator to go with, Wichman said to rst ask the following questions: What are they capable of doing? How much are they capable of handling? How much time do they have? What are they willing to do regarding harvest?

Average forage harvesting or chopping rates were as follows: corn silage with a 500-800 horsepower chopper was $570 per hour; corn silage with a chopper greater than 800 horsepower was $845 per hour; haylage with a 500-800 horsepower chopper was $487 per hour; and haylage harvested with a chopper greater than 800 horsepower was $720 per hour. All rates reect the customer providing fuel.

Hauling rates were normalized to a 30-foot length to compare machine types. A semi came out at $96 per hour; a straight vehicle such as a chopper box on a truck was $118 per hour; and a tractor was $134 per hour.

Bagging rates averaged $8 per foot for a 10-foot diameter bag and $12 per foot for a

12-foot diameter bag. Pack tractor rates averaged $138 per hour when fuel was not included and $133 per hour when fuel was included.

Regardless of size or management philosophy, farmers can always use help in the elds. With a better understanding of how custom rates are determined and the average rates for services, farmers can make informed decisions in selecting a custom operator.

How do you see the large animal veterinarian industry changing in the next 5-10 years?

Dr. Mike DuporUniversity of Wisconsin-Madison School of Veterinary Medicine

Valley Veterinary Clinic in Seymour, Wisconsin 4 years of experience

Tell us about your normal workweek. Most days, I’m on-farm anywhere from 4:30-8 a.m. Usually, my mornings are spent doing pregnancy checks on cows or doing lung scans on calves. During the afternoons, I respond to sick cow calls and try to catch up on work at the ofce.

What kind of health issues did the warmer than average winter pose for your dairy animals? This winter, we’ve seen such wide swings in temperature and weather conditions. Many of our dairies are seeing high rates of respiratory disease, particularly in young calves. We’ve helped clients adjust their calf care programs, emphasizing getting calves off to the right start. Many clients now have us do regular ultrasound scans on calf lungs to detect pneumonia early and treat it before it becomes a chronic issue.

What other challenges are dairy farmers facing this winter and leading into spring? It’s not exactly a new challenge, but margins remain stubbornly thin as the cost of most farm inputs rise. The supply of cows and heifers is very tight right now, which creates challenges for some dairies and opportunities for others.

Dr. Lindley ReillyUniversity of Wisconsin-Madison School of Veterinary Medicine

Cedar Grove Veterinary Services in Cedar Grove, Wisconsin 10 years of experience

Tell us about your normal workweek. I am a mixed animal veterinarian and owner of the veterinary clinic. My weeks can include examining up to eight species of animals. About half of my time is spent working with dairy farmers. I have particular interest in calf care, milk quality and aiding in protocols/management that help a dairy farm run efciently. I also work with large goat dairy farms. The other half of my time is split between small animals and a variety of hobby animals including goats, sheep, pigs, alpacas, llamas, honeybees and reindeer. In addition, I manage a staff of 20 and enjoy the business aspect of running a veterinary clinic.

What kind of health issues did the warmer than average winter pose for your dairy animals? It presented many challenges. The chief among them was managing pneumonia and respiratory issues. The weather has uctuated so much, requiring labor for farmers to properly manage ventilation. During the day when the sun is out, curtains or barn doors should be open in order to provide good airow and keep humidity down. However, it is getting cold at night, so these should be closed again to keep animals from getting chilled or experiencing a draft. On any given day, employees could move the curtains up and down 3-6 times. Additionally, calves should be wearing jackets at night to stay warm, but some days are getting to the point of being too warm and may cause calves to sweat and be damp. Animals may need a jacket for 1-2 days and then may need to take it off for 2-3 days. With these uctuations, we are treating for pneumonia early to prevent future, chronic problems. Focus for my farmers has been on proper management, solid vaccine programs, colostrum management, good nutrition and training of staff to identify symptoms of pneumonia early.

What other challenges are dairy farmers facing this winter and leading into spring? Internal and external parasites can be a problem with the mild winter. Winter provides a nice kill and break from these creatures; however, in a year like this, farmers may see more challenges with lice or mange. While neither are deadly, they may cause loss of production and thriftiness that cannot be afforded in a year with less-than-ideal milk prices. The other challenge dairy farmers may face is guring out how to move forward in the next year. This can range from breeding beef to dairy to take advantage of the demand for beef calves. This has to be balanced with raising enough replacements or having a strategy for purchasing milking animals if a farm chooses to move away from raising replacements. Other farms are considering building creameries or establishing a farm store. Some farmers want to keep doing the same but be more efcient.

Has a shortage in large animal veterinarians impacted your practice? No, because it has been balanced by a loss of dairy farmers in the last ve years in our practice area. Even though my practice has fewer large animal veterinarians than ve years ago, fewer farmers have balanced

Has a shortage in large animal veterinarians impacted your practice? We’ve been blessed to be able to continue to attract talented young veterinarians to join our practice, but that doesn’t mean the shortage hasn’t affected us. Our practice area continues to expand as solo vets retire and many mixed animal clinics shift to focus on pets. Fifteen years ago, our furthest dairies were 30-40 miles away. Today, we have dairies more than 80 miles from our ofce. In much of the area we cover, we are the only veterinarians willing to work with cattle.

How do you see the large animal veterinarian industry changing in the next 5-10 years? As a dairy-focused practice, we continue to adapt to the changing needs of our dairy farmers. Especially on larger dairies, we are watching our role evolve. In addition to traditional services such as pregnancy checks, delivering calves and treating sick cows, we offer services such as bilingual employee training, milking parlor audits, in-vitro fertilization, calf lung ultrasound and data management. We expect demand for these services to grow.

Tell us about the most unique call you have ever been on. My most memorable call happened about a month after I started working as a vet. One of our dairies had a calf born with an extra leg sticking off its shoulder blades. It was an otherwise healthy heifer calf out of a really good cow, and they wanted to keep her. I went out with another veterinarian. We anesthetized the calf and took off her spare leg. I remember thinking, “We didn’t cover this in vet school.” The other veterinarian saw her a little over a year later, growing well, happy and healthy.

What do you nd most rewarding about your work? I love building relationships with dairy farmers. I like getting to know them and their dairies well enough that I can help them improve and solve problems not just for individual cows but on the scale of the entire farm.

our workload. As for growth, my practice faces a unique challenge of being boxed in by Lake Michigan to the east and large urban areas such as Grafton, Mequon and Milwaukee to the south. Therefore, we can only grow with producers in two directions. We know there are deciencies in large animal vets in areas west of us, but we are trying to balance that with the amount of distance we can cover with staff. We have expanded to more hobby and specialty animal work. I also have been seeing small animal patients a few days a week since there is also a shortage of small animal veterinarians.

How do you see the large animal veterinarian industry changing in the next 5-10 years? Change is going to be based around work-life balance. Attracting veterinarians to the large animal industry is going to be a challenge when they see their small animal counterparts work 30-hour work weeks with no holidays, on-call time or weekends for more money. There are people with a passion for the ag industry who would rather work with farmers for less money every day of the week than talk about why Fluffy the dog isn’t doing well, but they are few and far between. Many going into the industry may try to nd ways to balance the input of hours. This may feel insulting to farmers who put in countless hours. I understand this sentiment as a farm girl myself who has found working as a veterinarian a much better schedule than when I farmed for 14 hours a day, seven days a week, 365 days per year. However, it is a change that may be on the horizon for the industry in order to keep talented veterinarians in agriculture.

Tell us about the most unique call you have ever been on. I have been on calls for a goat vasectomy, reindeer calvings and a rabbit pregnancy ultrasound. In the dairy industry, the most unique call occurred when a farmer said his cow was due to calve and hadn’t yet. He had also induced to calve two days prior. When I did a rectal exam, I found there was no calf, and she felt like she had calved already. The farmer looked at me and asked, “Well, where did the calf go?” I said, “I don’t know, the calf did not leave a note.” After we stopped laughing, I asked him if he had any twins born recently, and he did have a set born a few days prior. I explained it was likely not twins. While this scenario happens to many vets, the hilarity of the interaction has always stuck with me. It highlights the bond you can establish with farm clients even in the most confusing of scenarios.

What do you nd most rewarding about your work? The most rewarding part of my job is working with farmers. Coming from a farm, I wanted to give back to the community that gave me so much. I like planning a future with the farm and seeing them grow and develop. When rst working with one farm, they were bull-bred, had lower production and were doing a decent job but could do better. Over the last decade, they have improved reproduction through using A.I., heat detection and synchronization programs. We have increased milk production through management and nutrition-related changes. They do a great job with youngstock and use automatic calf feeders. It has been amazing to work with this farm since they are willing to discuss changes. It truly feels like we are a team working toward a common goal of running a better dairy farm. That is what I love: working with amazing dairy producers so we can all do better by the cows and industry each and every day.

University of Wisconsin-Madison School of Veterinary Medicine

Lodi Veterinary Care in Lodi, Wisconsin 36 years of experience

Tell us about your normal workweek. Mondays and Tuesdays tend to be our busiest days, heavily scheduled with herd health visits because almost all of our dairy herds use a version of the ovsynch protocol. We check cows on Monday or Tuesday so they can be scheduled for breeding Thursday or Friday. My Wednesday mornings alternate between herd health visits and open call time, with Wednesday afternoon being my half day off. We get a half day off each week to make up for our on-call time. Our livestock doctors all share on-call nights and weekends. We are available 24/7 on an emergency basis. Thursdays and Fridays are also shared between herd health visits and open calls. Open calls are often off-feed cows that need help, sick youngstock or routine events such as dehorning. We have a cattle handling facility and hospital stalls with a surgical facility at our clinic. Cattle handling appointments and in-house surgeries tend to be scheduled later in the week. We do a lot of fresh pen checks. These are once or twice a week regularly scheduled appointments where we work in the fresh pen trying to diagnose fresh cow problems early when cows can respond well to treatment. All fresh pen cows get their temperature taken and a BHBA blood test run for ketosis detection. These screening tests help identify cows needing more attention. While every cow in the fresh pen gets eyes on them by the veterinarian, the identied cows will get a more complete physical. These fresh pen visits cut down on emergency and sick cow calls from these herds.

What kind of health issues did the warmer than average winter pose for your dairy animals? The warmer than normal weather led to more days of high humidity. Dry air is healthy for cattle. These damp, moist days are good for transmission of mastitis and especially respiratory disease. Viruses and bacteria thrive in moist environments, so a warm winter is great for bacteria and viruses that cause disease. The younger doctors in our practice are doing a lot of lung ultrasounds of calves. This has been a transformational development for youngstock health. The calves receive a lung ultrasound weekly to identify pneumonia early when treatment can be very effective. Having the veterinarian in the calf barn on a weekly basis provides a great resource for your calf care team. The veterinarian is a coach for caretakers and monitors protocol compliance in the calf barn. Herds that use lung ultrasounds on their calves have less post-weaning disease and death loss, and have growing, thriving calves.

What other challenges are dairy farmers facing this winter and leading into spring? The price of milk sucks. There is concern the warm winter and spring could lead to crop challenges. They are especially worried about alfalfa. The popularity of manure digesters is leading to a new set of problems for dairy cows bedded with manure solids. Keeping clinical and subclinical mastitis at bay when bedding with manure solids is a challenge.

Has a shortage in large animal veterinarians impacted your practice? We are fortunate to be fully staffed with livestock veterinarians. We do not take this for granted as we know that many practices have difculty hiring veterinarians. We are able to attract livestock veterinarians because we are located in a strong dairy area. We have excellent, progressive dairy farmers as clients. We are in a picturesque rural setting yet close to the Madison/Dane County metropolitan area that offers cultural amenities and has a great economy, providing career opportunities for spouses. We have a nice, new facility that is enjoyable to work in and a kinder on-call schedule that comes with a larger practice.

How do you see the large animal veterinarian industry changing in the next 5-10 years? Consolidation of dairy herds will continue with fewer, larger herds. Veterinarians will need to be able to offer the kinds of services larger herds need. Similarly, the trend will continue in the livestock veterinary industry of fewer, larger clinics. While livestock veterinarians tend to be passionate about the dairy industry, we need to be aware there are other areas of veterinary medicine, such as small animal practice, that can offer better salaries with less or even no on-call obligations. Young livestock veterinarians need to be supported with a proper salary and on-call schedule that will

provide the work-life balance they and their family desire. Dairy farmers benet when they have a successful, well-run veterinary practice they can count on as a business partner. For a practice to be successful, it needs to offer competitive wages. This can feel like being stuck between a rock and a hard place when our source of income is the fees we charge dairy farmers who are dealing with consistently low milk prices. Basically, it is hard to raise fees (even though you know you need to) when you also know your farmers are struggling economically.

Tell us about the most unique call you have ever been on. Several years ago, I was treating a cow in a tiestall barn during milking when the farmer asked if I could take a look at another cow that was acting strangely. She looked like a normal, healthy cow when suddenly she balled in terror, jumped and shook in her stall. This lasted a few seconds, then she returned to acting normally. In a short time, the same thing happened again. My rst thought was that she was receiving an intermittent electrical shock. While I searched for a bare wire, it happened again. The loud, full force, terried vocalization reverberated through the barn. While I could not nd the source of an electric shock, I noted a small mouse that crawled out from between the stones of the barn wall in front of the cow. As the cow bellowed and shook in fear, the mouse would retreat to its hiding place between the stones, and the cow’s agony would end until the mouse reappeared. I believe this was my one and only case in my long career when I prescribed a mouse trap while treating a cow.

What do you nd most rewarding about your work? The most rewarding part of my career has been the long-term relationships with farmers. I enjoy feeling that I am part of their team and a part of their success. I also enjoy seeing young people (veterinarians, staff members and farmers) grow, develop and become successful in their careers.

Dr. John Laukant

University of Wisconsin-Madison

Sunrise Veterinary Services in Reedsburg, Wisconsin 25 years of experience

Tell us about your normal workweek. I work Monday through Friday from 7 a.m. to 4 p.m. usually. I am on call every other night. I have herd health usually 3-4 days a week with sick cows and chute work.

What kind of health issues did the warmer than average winter pose for your dairy animals? There has been a higher risk of pneumonia due to high humidity in barns. Increased use of intranasal and pasteurella/ Mannheimia vaccines have helped.

What other challenges are dairy farmers facing this winter and leading into spring? Low milk prices and increasing costs from processors, i.e. trucking and market adjustments.

Has a shortage in large animal veterinarians impacted your practice? Yes and no. Farmers are aging out of dairy. There is no recruitment of new dairy farmers because prot margins are so small, so large animal veterinarians will be ghting over a smaller pie of farmers.

How do you see the large animal veterinarian industry changing in the next 5-10 years? We are already doing more work with beef cattle and small ruminants and less with dairy cattle. New veterinarians will be traveling farther and covering much larger areas to have a similar workload and income potential. Large online pharmacies are eroding one income stream for the independent clinic.

Tell us about the most unique call you have ever been on. I treated conjoined twins at the hips. I was able to correctly diagnose them and corrected it with only one cut.

What do you nd most rewarding about your work? Being my own boss, working with the absolute best co-workers in the world and enjoying all four seasons outside in Wisconsin.

miss congeniality and was one of the scholarship winners. Woitalla won the other scholarship.

Ambassadors are Chloe Hoppe, the daughter of Travis and Amy of Albany, Emily Peters, the daughter of Jeff and Melanie of Sauk Centre, and Haddie and Lanna Walter, the daughters of David and Cathy Walter of Sauk Centre.

Con nued from OUR SIDE | Page 16

Dr. Amy Dahlke

University of Minnesota College of Veterinary Medicine

Anderson Veterinary Service in Zumbrota, Minnesota

10 years of experience

Tell us about your normal workweek. Most of the early part of my workdays start with routine, scheduled dairy herd health visits. Afternoons vary depending on the week. After the herd health visits are complete, I help cover any sick animal calls or emergencies that have called into the clinic for the day. I also may have a scheduled afternoon of pregnancy checking or vaccinating beef cattle or small ruminants. I typically have one weeknight on call for the week, and I am on call every sixth weekend.

The biggest impact on our practice has been the number of solo large animal veterinarians retiring in the area, resulting in a large expansion of the area we cover. To be honest, we are still guring out how to best manage this within our practice. It is a hard balance to make sure we are taking care of our longtime clients in a reasonable and timely manner while still offering services to clients further away. Along with doing this, making sure we have time to make it home at night to be with our families. It is a controversial topic because many of the areas that are facing a veterinary shortage do not have enough consistent veterinary work to support a fulltime veterinarian.

What kind of health issues did the warmer than average winter pose for your dairy animals? The warmer than average temperatures were not necessarily harmful alone, but it was the temperature swings that contributed to health issues. It was a challenge to manage keeping barn curtains open on warm days but having to close them back up the next day for a drop in temperatures. Earlier in the winter, when we had a few more rainy and humid days, it was harder to keep bedding clean and dry, which did contribute to health challenges. To try and combat these issues, I had discussions with producers about frequent bedding changes and keeping things as clean and dry as possible. Keeping stocking density low — especially in youngstock pens — is also important to improve cattle health.

What other challenges are dairy farmers facing this winter and leading into spring? The low milk prices are the biggest challenge for our dairy farmers this spring. The potential for drought-like weather will also have an impact on the ability to produce quality, affordable feedstuffs.

Has a shortage in large animal veterinarians impacted your practice? We are very lucky to be fully staffed.

How do you see the large animal veterinarian industry changing in the next 5-10 years? As large animal veterinarians, we continue to change and adapt as the demands of our clients change. An increasing number of our clients are able to handle basic sick cow care and are instead looking to their veterinarian for more of a consulting role to analyze facets of the dairy.

Tell us about the most unique call you have ever been on. Looking back, most of the story-worthy recollections I have involve a dangerous situation that could have been avoided with good facilities. There are a couple of instances in which I have rode on the back of a four-wheeler into the woods to nd a beef cow tied to a tree trying to calve. It makes for a good story, but I hope to never encounter it again.

What do you nd most rewarding about your work? The most rewarding thing about my job is helping to come up with solutions that can improve efciency and protability on the farms I work with. As a large animal veterinarian, I get to know my clients when I visit them on a routine basis. I thoroughly enjoy developing those relationships.

How many times a day do you milk, and what is your current herd average, butterfat, and protein? We milk the main herd twice a day, and we milk the fresh group four times a day. Our rolling herd average is 30,909 pounds of milk with 4.7% butterfat and 3.48% protein. Our herd is averaging 96 pounds of milk per head per day.

Describe your housing and milking facility. We have conventional freestall barns that have curtain sidewalls. One of our barns has free stalls that are equipped with waterbeds while the other has free stalls that are bedded with sand.

Who is part of your farm team, and what are their roles? Our team includes Cal and Char Lubben, their son, Chad, and his wife, Morgan. Cal is in charge of overall herd health, fresh cows, breeding and chopping silage. Char takes care of the calves and is the farm’s bookkeeper. Chad does the feeding, and Morgan is the herdswoman. Morgan also helps with the calves, breeding, herd records and fresh cows.

What is your herd health program? Our vet performs herd health checks every other

Cal Lubben, of Lubben Dairy | Edgerton, Minnesota | Rock County | 400 cows

JERRY NELSON/DAIRY STAR

JERRY NELSON/DAIRY STAR

Madelyn (from le ), Morgan, Cal and Char Lubben stand in their freestall barn Feb. 13 on their family’s farm near Edgerton, Minnesota. The Lubben family milks 400 Holsteins. Cal and Char’s son, Chad, is not pictured.

week. We give the cows a J-5 vaccine at dry-off. They are vaccinated with SRP salmonella and ScourGuard two weeks later and are boosted throughout their dry period. Calves are given Nasalgen at birth. Close-

up cows also receive a dose of Nasalgen.

What does your dry cow and transition program consist of? Our cows are given a dry period of 60 days. At dry off,

we move them to free stalls that are bedded with sand. Three weeks prior to calving, they are moved into a pen that has a bedding pack. Our dry cow ration consists of straw, grass hay, rye silage, sorghum silage

and corn silage. After calving, the animals are moved to our fresh cow pen where they remain for the next three weeks and get milked four times per day. They are then moved to either the heifer group or the mature cow group.

What is the composition of your ration, and how has that changed in recent years? Our total mixed ration contains haylage, cottonseed, liquid molasses, soybean meal, corn silage, nely ground corn and a protein/mineral mix. Adding nely ground corn and amino acid balancing has helped us achieve higher milk production and has increased milk components.

Tell us about the forages you plant and detail your harvest strategies. Our forage crops include winter rye, alfalfa, sorghum and corn silage. When we harvest our alfalfa, we cut it one day and chop it the next day. We pay very close attention to moisture levels. We have our own chopper, so we can stop and wait for the hay to dry before continuing to chop. Highly digestible forages are the foundation of high milk production.

Turn to

What target?

How about your liner that remained open under the teat during the “rest”

How did milking go this morning with that target on the teat ends of your cows?

607-849-3880 • 607-352-0053

- Stephanie Hughes

- Stephanie Hughes

“We love cows and producing a nutritious quality product for consumers. That’s why we love Udder ComfortTM line of defense for 15 years. It’s our go-to for everything, and it’s wonderful for fresh cows, keeping udders supple during to protect the ligaments and get fresh cows going.

“Try it, you’ll love it. Nothing else compares,” says Stephanie Hughes. She and Alan started their Sunsett Dairy, Pittsville, Wisconsin in 2015 after building cow numbers since 2007. They worked and saved to make dreams reality.

They milk 60 cows in rotational grazing, with sons Bryce, Gavin, and Derek helping. Steph runs the herd, Alan the crops. He also serves as Wisconsin Air National Guard F-35 crew chief.

Steph says is good advice learned since starting their own dairy.

“That’s true for cows too. It’s good to have this versatile product for fresh cows, hard quarters, and it gets show cows ready quickly.”

Read their story at qrco.de/sunsett

or scan QR above

Con

nued from

What is your average somatic cell count, and how does that affect your production? Our current SCC is 118,000. Keeping our SCC low has helped us attain good milk production and components. We closely monitor our dairy facilities for stray voltage.

What change has created the biggest improvement in your herd average? The biggest improvement has been adding nely ground corn to the lactating ration. Doing this has increased our average daily milk production by 3-4 pounds. Grinding the corn down to 300 microns makes more of its starch available to the rumen yet doesn’t cause hemorrhagic bowel syndrome.

What technology do you use to monitor your herd? We monitor our herd with ID tags and track milk production with Dairy Herd Improvement Association and DairyComp.

List three management strategies that have helped you attain your production and component level. First was nely grinding our corn to 300 microns. Second was focusing more on our calves and making sure that they get the best possible start in life. We have also begun to pasteurize our colostrum and constantly monitor its quality, with the goal of it having a Brix score of 27-28. We make sure that all of our calves receive a gallon of high-quality colostrum within two hours of birth.

Tell us about your farm and your plans for the dairy in the next year. We are a multifamily, fourth-generation dairy farm. We have no big plans for the coming year. We just hope to keep getting better and, hopefully, be protable and pay down debt. It’s

possible that we will add tunnel ventilation to our freestall barns. There is no magic bullet to high production; it’s simply doing many little things right. High feed intakes means getting the cows to eat that extra mouthful of feed. We are averaging 58 pounds of dry matter intake per head per day. We have been with the same nutrition company for 40 years. I listen to podcasts and webinars and do a lot of reading, including the Dairy Star. Char and Morgan have implemented an excellent calf program with Purina and are getting 2 pounds of average daily gain in our calves. Because of that, we are beginning to see higher milk production from our rstcalf heifers. Our goal is to get 8 pounds per head per day of combined fat and protein.

JERRY NELSON/DAIRY STAR

2021

JD 2680H 2022, 40 ft., 3-Section Folding, #564729 ............................... $149,900

JD

JD

JD

Wil-Rich

DMI

Wil-Rich

Case IH 255 2021, 46 ft., 5-Section Folding, #578636 .............................

JD 2230 2021, 56 ft., 5-Section Folding, #574134 ..................................

JD 2230 2023,

JD

JD

JD DB66 2003, 36 Row, 22 in. Spacing, #577083 ...................................... $63,500

JD 1770NT 2012, 16 Row, 30 in. Spacing, #578120 .................................. $70,900

JD 1770NT CCS 2008, 24 Row, 30 in. Spacing, #574675 ........................... $89,900

JD 1775 2019, 12 Row, 30 in. Spacing, #578706 ...................................... $99,900

JD 1775 2018, 12 Row, 30 in. Spacing, #570817 ....................................

JD DB66 2011, 36 Row, 22 in. Spacing, #578691 .................................... $182,000

JD DB66 2012, 36 Row, 22 in. Spacing, #556901 .................................... $195,900

Case IH 2150 2021, 16 Row, 30 in. Spacing, #569307............................ $199,900

JD DB80 2012, 32 Row, 30 in. Spacing, #571885 .................................... $232,900

JD DB60 2017, 24 Row, 30 in. Spacing, #562192 .................................... $249,900

JD DB60 2018, 24 Row, 30 in. Spacing, #573437 .................................... $289,900

JD DB60 2019, 24 Row, 30 in. Spacing, #551039 .................................... $299,900

JD DB60 2017, 24 Row, 30 in. Spacing, #574768 .................................... $315,000

JD DB60 2020, 24 Row, 30 in. Spacing, #569113 .................................... $349,900

JD 1775NT 2023, 24 Row, 30 in. Spacing, #578635 ................................ $359,900

JD 1775NT 2023, 24 Row, 30 in. Spacing, #566196 ................................ $369,900

JD DB66 2019, 36 Row, 22 in. Spacing, #572188 .................................... $379,900

JD 1775NT 2022, 24 Row, 30 in. Spacing, #549842 ................................ $389,900

JD 1795 2023, 24 Row, 20 in. Spacing, #573347 .................................... $419,900

JD DB66 2022, 36 Row, 22 in. Spacing, #576258 .................................... $479,000

JD DB66 2023, 36 Row, 22 in. Spacing, #574902 .................................... $532,900

INTEGRAL PLANTERS

JD 1710 2000, 12 Row, 30 in. Spacing, #564510 ...................................... $15,500

Case

JD

Case

JD

Case

JD

Case

JD 2210 2014, 53 ft., 5-Section Folding, #575187

JD 2210 2014, 65 ft., 5-Section Folding, #578337

JD 2210 2017, 65 ft., 5-Section Folding, #574527

Moore Built 24R22 2000, 24 Row, 22 in. Spacing, #566760 ................... $25,000

Moore Built 24 22, 24 Row, 22 in. Spacing, #576259 ............................. $34,500

JD 1720 2003, 16 Row, 30 in. Spacing, #567177 ...................................... $37,000

JD 1720 2009, 16 Row, 30 in. Spacing, #569760 ...................................... $41,500

JD 1720 2005, 16 Row, 30 in. Spacing, #569419 ...................................... $41,500

JD 1720 CCS 2019, 12 Row, 30 in. Spacing, #569018 ............................... $79,900

JD 1720 CCS 2019, 12 Row, 30 in. Spacing, #569017 ............................... $89,900

JD 1725 CCS 2022, 16 Row, 30 in. Spacing, #572638 ............................. $154,900

JD 1725 CCS 2023, 16 Row, 30 in. Spacing, #564619 ............................. $184,900

BLANCHARDVILLE, Wis. — Dairy farm wrestler Aidan Gruenenfelder racked up 53 wins and one loss in the regular season and had an undefeated postseason to secure champion in the Division 3 106-pound weight category.

“It was a lot of mixed emotions,” Gruenenfelder said. “It was one of the best feelings I’ve ever felt. It was awesome. It was just all that hard work had nally paid off, and I was just super excited and grateful for the moment.”

The junior at Pecatonica High School placed second at state last year.

“I just love every part about wrestling and getting better every day,” Gruenenfelder said. “I like seeing myself progress and get better and beating guys that have beaten me.”

Gruenenfelder is the son of Farron and Jessica. The Gruenenfelders own a 140cow robotic dairy farm and 500-600 acres of crops.

Gruenenfelder has wrestled since he was in kindergarten.

“It just always has been a part of my family,” Gruenenfelder said. “I got into it early and loved it. It was competitive. It was a one-on-one sport.”

Personal tragedy is the biggest thing Gruenenfelder had to overcome this season. In December 2023, his grandfather died.

Gruenenfelder attends wrestling practice, lifts every day and participates in club wrestling 3-4 days a week year-round to stay conditioned for his sport. He also is active on his family’s farm.

Each day, Gruenenfelder gets early work release from school and goes home to haul and scrape manure.

Gruenenfelder said he has learned work ethic and determination on the farm.

“A lot of the other kids don’t have to do chores and get up early,” Gruenenfelder said. “It denitely helps separate you from other people.”

At New Richmond High School, dairy farm athlete Lane Van Dyk competed at

the state level in powerlifting.

The freshman placed 14th of 17 in the 114 weight class at state.

Van Dyk is the son of Chris and Rikki. They have a dairy farm near New Richmond where they milk 70 cows two times a day and

have 300 acres.

Van Dyk was named the most-improved male on the team. He increased his weightlifting by 41.9% over the season.

Van Dyk started his season lifting 130 pounds in the deadlift and nished lifting

270 pounds. For the squat, he started lifting 90 pounds and increased to 170 pounds at the end of the season. In the bench press, he started by lifting 70 pounds and nished at 95 pounds.

Van Dyk participated in four regular season meets. The last meet was for powerlifters who were within 10% of the amount of weight needed to qualify for state.

To qualify in his category, Van Dyk, who weighs 112 pounds, had to lift 515 pounds from the combined weights of his lifts in the deadlift, squat and bench press. Van Dyk qualied at the nal meet.

“Emotions matter,” Van Dyk said. “If I believe that I can get something, I’m more than likely going to get it.”

Self-doubt was the biggest obstacle Van Dyk said he encountered.

“I didn’t believe I could make state, and I almost didn’t,” Van Dyk said.

Van Dyk is active on his family’s farm where he helps bed, feed and milk cows. During the powerlifting season, he tries to get as much of his chores done as possible before practice.

Van Dyk said a lesson he has learned on the farm is to never give up and try his hardest.

Across the river in Minnesota, junior Keegan Kuball wrestles for the Grizzlies, a co-op team encompassing two districts, Waterville-Elysian-Morristown and Janesville-Waldorf-Pemberton. He won his second consecutive rst-place state champion title for heavyweight wrestling.

“I felt a lot of pressure

in New Richmond, Wisconsin. At state, Van Dyk, a freshman, placed 14th of 17 in the 114 weight class.

go off my shoulders,” Kuball said. “I had a lot of pressure to win it again, because I’m supposed to be the best one in the bracket. ... It was fun because I love doing it, and it’s pretty rewarding.”

Kuball is the son of Nate and Shannon, who milk 240 cows near Waterville, Minnesota. The Kuballs also farm

1,100 acres for feed and as cash crops.

Every day after practice, Kuball works in the shop. On weekends, he works as well, including milking on Sunday nights. In the summer, he helps with eldwork, milking, feeding and work in the shop.

The heavyweight cham-

pion was 40-4 in the regular season. Kuball has wrestled for 13 years.

“You’re the only one out on the mat,” Kuball said. “You’re the one winning, but you’re also the only one out there when you lose too. ... You have to put a little pressure on yourself to win, but you also don’t have to rely

on a whole team to be really good.”

In Willmar, Minnesota, wrestler Cavin Carlson won third place in the 133-pound weight category at the state tournament.

Carlson is the son of Carl and Kellie of Carlson Dairy near Pennock, Minnesota, which milks 2,000 cows. It was the sophomore’s third time competing at state but his rst time placing.

Carlson’s record was 39-4 in the regular season and 12-1 in the postseason.

“I love wrestling,” Cavin said. “It’s just something I really care about. ... I like to call it a legalized ght. ... You get to go out there and impose your will on another guy. ... There’s some fun about that and then going into a room every day with a team and having them behind your back.”

Cavin helps on the farm about two days a week. He helps his dad with whatever is needed, including sorting and nding cows, administering vaccinations, moving feed and moving tires.

“There’s always work that has to be done (on the farm), whether you do it now or you put it off,” Cavin said. ... “With wrestling, I’ve just made that a thing where ... I might as well put in the work now. ... This work will pay off eventually.”

ELDORADO, Wis. — With a schedule fuller than most kids his age, Keeton Grade begins his day long before school starts by working on his family’s dairy farm.

He loads and spreads manure, mixes feed and xes equipment in the shop, if needed. His schedule does not stop after classes, as Keeton is active in practices or games for three sports.

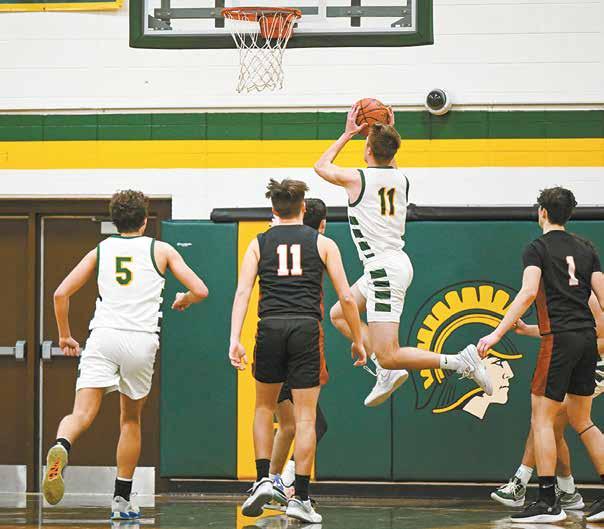

Keeton is a senior at Laconia High School in Rosendale and has been a three-sport athlete all four years, playing football, basketball and baseball. However, he nds time to work on his family’s dairy, Vision Aire Farms LLC, with his dad, David Grade, grandparents, Roger and Sandy Grade, and his aunt and uncle, Janet and Travis Clark.

The family milks 150 cows and farms 1,000 acres near Eldorado.

Keeton’s commitments are many, resulting in packed days, but lessons learned on the farm have helped contribute to his success as an athlete.

“Working on the farm helps with nding the drive to work harder at sports,” Keeton said. “You have to have a lot of discipline on the court

they milk 150 cows and farm 1,000 acres.

and on the eld.”

Keeton is accustomed to a busy routine as the seasons take him from one sport to the next, but he said it is challenging to balance both sports and work on the farm.

“They are long days, and it’s very tiring at times,” he said. “It’s hard to

nd time to hang out with my friends.”

David said Keeton’s work ethic is phenomenal.

“To balance school life and the farm is a struggle, especially with dairy farming,” David said. “The animals have to be milked, fed and cleaned every day. When Keeton is

scheduled to be here, he’s here. The things he’s learned on the farm have transitioned to the rest of his life, from being on time for practice to being respectful. He’s a great kid.”

Turn to GRADE | Page 26

Con

Playing a trifecta of sports, Keeton likes basketball the most. He is a forward on his team, a position he especially enjoys.

“I get to attack and play down low, which I like,” Keeton said.

One of Keeton’s most memorable moments in sports occurred this year during the basketball season.

“I’ll never forget when we knocked out the No. 2 seed in the regional semi-nals to make it to the regional nals,” Keeton said. “We were the No. 7 seed.”

Keeton also remembers making his rst dunk when he was a sophomore in the regional championship game. In addition, this farm kid holds the boys all-time rebounding record at his high school.

On the football team, Keeton is the quarterback and a linebacker.

“I like to throw the ball, and as the quarterback, I have the ball in my hands for almost every single possession,” he said.

Another memorable moment for the athlete was when the football team advanced to the second round of the playoffs last year.

In baseball, Keeton has multiple roles as a pitcher, shortstop and rst baseman.

PHOTO SUBMITTED

ketball. And by fth grade, he was playing football.

Keeton started with baseball around rst grade. A year later, he began playing bas-

David’s favorite sport to watch his son play is basketball.

“We’re a basketball family,” David said. “I’ve coached

Keeton since he was in third grade all the way through the youth program. When he got to high school, it was up to somebody else.”

David and his wife, Torrie, have three children. Da-

vid continues to coach his seventh-grade son.

“The last few months have been a little crazy with both of my sons and my daughter playing basketball,” David said. “Since Jan. 1, I’ve been in a gym almost every weekend. It’s fun, and there are a lot of good memories. You get to know the kids when you coach, and it’s good to build those relationships with other kids in the community. It’s neat to still have that connection when they grow up.”

Keeton is the captain on all three teams, a role that he said requires leadership.

“You have to keep yourself accountable because other guys look up to you,” Keeton said.

The demands of being an athlete do not give Keeton much time to work on the farm in the evenings. When he has time, he helps in the eld.

On the weekends, Keeton takes on more chores, working on the farm morning and night. In addition to his regular morning tasks, Keeton also milks cows on Saturday and Sunday evenings. Cows are milked twice a day in a double-8 herringbone parlor and housed in free stalls.

“We don’t give Keeton a lot of downtime,” David said.

Turn to GRADE | Page 27

“He works really hard. We probably don’t give him enough recognition.”

David expects his children to work on the farm, seeing it as an opportunity to learn important life skills.

“The things he’s learned on the farm have transitioned to the rest of his life, from being on time for practice to being respectful. He’s a great kid.”

ents of Keeton’s accomplishments, recognizing how the hours he puts in at the farm and the time spent playing sports are helping to shape their son into the man he is becoming.

“I told my kids they need to come to the farm and learn life’s lessons,” David said. “They need to learn how to do things, such as how to x a piece of equipment. That can transfer to xing something at your own house someday, like a lawn mower. Knowing how to do that stuff goes a long way.”

DAVID GRADE, DAIRY FARMER

David and Torrie are proud par-