Poulsen urges biosecurity to protect herds

By Danielle Nauman danielle.n@dairystar.comMADISON, Wis. — Many Americans turned their attention toward March Madness last month.

The U.S. dairy industry found itself in the throes of its own version of madness as cows on dairy farms in Texas and Kansas began exhibiting symptoms of an illness later identied as highly pathogenic avian inuenza.

Dr. Keith Poulsen, director of the Wisconsin Veterinary Diagnostic Laboratory, spoke April 2 during a Professional Dairy Producer “The Dairy Signal.”

“The second week of March, farmers were dealing with an unknown morbidity event,” Poulsen said. “It was not acting like anything else we typically see on a dairy.”

Dr. Keith Poulsen Director, Wisconsin Veterinary Diagnostic Laboratory

Dr. Keith Poulsen Director, Wisconsin Veterinary Diagnostic Laboratory

As of April 9, the virus has been conrmed in 17 herds in six states: Texas, 9; Kansas, 3; New Mexico, 2; Idaho, 1; Michigan, 1; and Ohio, 1.

Farmers in the Texas panhandle began noticing a decrease in feed intake and reduced rumen motility as reported by rumination monitors. Cows suffering these symptoms were found to be second-lactation cows or older that were at least 150 days in milk.

The most unusual symptom was in the appearance of the milk of affected cows. While the cows did not

White family makes cost-effective upgrades

By Abby Wiedmeyer abby.w@dairystar.comREEDSBURG, Wis. —

Kinnamon Ridge Dairy has seen a lot of upgrades since the rst generation of Whites began dairying in the 1950s with 30 wooden stanchions.

Ryan and Nate White manage to continually make upgrades by being tech-savvy and penny-wise.

“I’ve always been a rm believer that we should be able to technically support the things we have,” Nate said. “(If you make) improvements 50 cents on the dollar

Creating their own progress

Handing down a herd of excellence

Vandertie

to take over farm, continue breeding for superior geneticsBy Stacey Smart stacey.s@dairystar.com

BRUSSELS, Wis. — On Jan. 1, 2025, Austin Vandertie will become the owner of Doorco Farms. Taking over the farm where he grew up, Austin looks forward to carrying on his family’s legacy of breeding registered Holsteins.

“I’ve known for quite a while that I wanted to come back to the farm, but college conrmed it,” Austin said.

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce)

320-248-3196 (cell) 320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com Editorial Staff

Maria Bichler - Assistant Editor maria.b@dairystar.com

Stacey Smart - Assistant Editor 262-442-6666 • stacey.s@dairystar.com

Danielle Nauman - Staff Writer 608-487-1101 • danielle.n@dairystar.com

Abby Wiedmeyer - Staff Writer 608-487-4812 • abby.w@dairystar.com

Tiffany Klaphake - Staff Writer 320-352-6303 • tiffany.k@dairystar.com

Jan Lefebvre - Staff Writer jan.l@star-pub.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Emily Breth - Staff Writer emily.b@star-pub.com Consultant

Jerry Jennissen 320-346-2292

or 30 cents on the dollar compared to dealer prices, you can do it 30% sooner, and payback is faster.”

Ryan agreed.

“You can push the envelope on size that way,” he said.

Ryan and Nate operate the 860-cow dairy near Reedsburg along with their parents, Jerry and Linda, and employees. Their milk is shipped to the Grande Cheese Company. Cows are milked three times a day in a parlor and housed in sand-bedded free stalls.

Jerry is the main herd manager and works with employees to complete herdsman tasks. Cows are monitored with activity leg bands and sort gate technology. Linda manages all business aspects and bookkeeping. Early in her career, she acquired herdsman skills, which she has passed on to her employees to save on veterinarian costs.

507-634-4413

920-979-5284

Jerry Nelson (SW MN, NW Iowa, South Dakota) 605-690-6260 • jerry.n@dairystar.com

Mike Schafer (Central, South Central MN) 320-894-7825 • mike.s@dairystar.com

Megan Stuessel (Western Wisconsin) 608-387-1202 • megan.s@dairystar.com

Julia Merten (Southeast MN and Northeast IA) 507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell)

bob.l@star-pub.com

Mark Klaphake (Western MN)

320-352-6303 (ofce) • 320-248-3196 (cell)

Nate oversees the crops, planting, a portion of the harvesting, part of the shop and employee management. Ryan is responsible for heavy repairs in the shop and feed management with the nutritionist. Ryan is also developing nancial planning skills and is doing risk management for incoming feed and milk sales.

The brothers are always considering their next upgrade, sometimes taking years to plan and acquire supplies for a project. Nate likes to hunt for bargains and credits Ryan for his technical skills.

One recent project includes a grain grinding facility built last year near the dairy.

It started when a local mill went out of business, and Ryan purchased the bins. The bins sat on the ground for two years while they pieced together the rest

of the supplies. Some items were new, and an electrician was hired to wire according to code. Ryan programmed all the electrical controls and programmed the programmable logic controller that runs the system.

“If we had to go out and set that system up with new bins and everything, we’re 50 cents on the dollar for cost,” Ryan said. “The big pieces we got used had a lot of life left in them.”

Upgrades to the manure-hauling equipment were done with similar attention to economic efciency.

The barns are cleaned using a ush system. Pens are cleaned with recycled manure liquid and gravity, to reduce the use of mechanical cleaning. Manure liquid is applied with a drag hose to minimize road trafc and eld compaction.

to Pine Country Bank! With our expertise and commitment to personalized assistance, we’re here to ensure that farmers have the resources they need to thrive in an ever-changing landscape. Contact us to learn more about our ag lending services:

The rst drag-line system was purchased in 2013. Last year, they invested in upgrades, which included high-wear pumps and a remote monitoring system that connects to their phones, allowing for mobile operation and monitoring of the pumps.

This investment also included adding mileage to their manure hoses, allowing them to cover up to 2.5 miles and essentially reach all of their contiguous owned and leased land.

“It’s been more effective than it’s ever been,” Ryan said. “We took our old pumps and put new parts on them.”

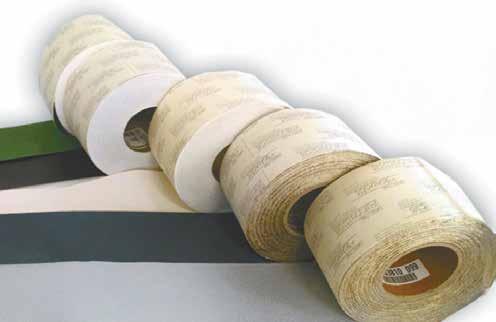

Cow comfort has not been overlooked while making upgrades. This year, a section of 20-year-old, metal free stalls was replaced with Easyx exible stalls.

They replaced about three dozen stalls in 2022 and had such success with them that they did another 116 this year. The stalls are constructed of half-inch

tubing with a quarter-inch neck rail. They are more exible than metal stalls and have memory. If they are bumped with equipment or a cow pushes them, they pop back to their original location.

The stalls were purchased from a dairy equipment dealer and installation was done in-house.

The brothers have spent the winter going through equipment to get ready for spring planting. As always, they are planning their projects so they can be on the hunt for bargains. They hope to increase feed storage and transition from sand bedding to ber-separated bedding. They believe that would bring a lot of efciencies.

Nate said it is important to have goals to be ready when opportunities arise.

“No plan is perfect, but knowing what moves you want to make and having an idea of what you’re trying to improve is important,” Nate said.

Farms near Brussels, Wisconsin. The family is focused on type and produc on, with a herd BAA of 112 and cows that average 108 pounds of milk per day.

twice-a-day milking.

“There aren’t many guys getting into farming, and very few are taking over a herd of this quality,” Dan said.

As the third generation steps into ownership, Austin is following in the genetic footsteps of his father and grandfather.

The Vanderties are known for breeding generations of high-scoring, high-producing cows, which has earned the family a Progressive Breeders’ Registry award from the Holstein Association USA for 49 consecutive years.

“This farm is a testament to what my parents and grandparents did,” Austin said. “What I do will be determined 20 years from now.”

The Vanderties have also received the Holstein Association USA’s Herd of Excellence Award six times.

When they received the award in 2022, their average classication score was 88.7 with 36,491 pounds of mature equivalent milk, 1,425 pounds of butterfat and 1,117 pounds of protein on

Dan and Julie bought the farm in 1987 from Dan’s parents. Many animals trace back to the rst two registered heifers Dan’s dad purchased in the early 1940s. Like his father, Dan made smart breeding decisions. The homebred herd has a BAA of 112.

“We haven’t brought an outside cow into the herd in 35-40 years,” Dan said.

Tall, wide and strong describe the Holsteins that ll their barn that includes 17 Excellent cows. In the last six years, the Vanderties have had ve cows score 94 points.

“Our next goal is to get a cow to 95 points,” Austin said. “I don’t think Door County has had one yet, and we’re hoping to be the rst.”

Focused on type, production and longevity, the Vanderties look at linear traits and cow families when choosing bulls.

Dan said they like to see a stack of Gold Medal Dams behind the sires they choose. Dams and sires backing a bull must also have a classication score.

“We breed for strength,” Dan said. “A big, strong cow with a wide chest is what we strive for. We like them wide from the muzzle to the back end. Then, you know she can milk. That’s how you make money.”

Cows at Doorco Farms average 108 pounds of milk per day and 7.5-8 pounds of combined fat and protein. Cows peak at 170 pounds of milk and 12 pounds of combined fat and protein. To attain this level of production, the Vanderties place precedence on everything from feed to cow comfort.

“The cows always have feed in front of them,” Dan said. “We push up feed every couple hours. We top-dress the mix, too, and give extra corn to topproducing cows. We feed (a total mixed ration) in the outside bunk as well. Clean water, good bedding and good ventilation are also important.”

Every member of the Vandertie family has an eye for the details, ensuring cows reach their potential.

“It’s not just the big things that make a difference,” Julie said. “It’s the little things too.”

Dan agreed.

“We always challenge the cows,” he said. “From cow comfort to feed to genetics, we do the right things to get milk. Genetics is a big part of that.”

For the last three years, Austin has selected bulls, and Dan and Julie said they can already see the results of his breeding decisions.

“My dad was probably better at it than I was, and Austin

works for several years.

“Sometimes, farmers are concerned about treating all their kids the same when it comes to a succession plan,” Dan said. “Austin has two older sisters, and I told my kids long ago we are not going to split this farm up. I’ve worked too hard to put this together. Whoever takes over the farm gets the biggest piece of the pie.”

When starting out, the Vanderties gathered ideas from other farmers who had been through a transition. They then put a team of experts together, and Austin is in the process of applying for a Farm Service Agency loan.

“We have four people working on this transition for us,” Dan said. “It might cost more, but I can expect it to be good. I can sleep at night.”

Making it economically possible for Austin to take over is important to his parents.

from the Holstein Associa on USA for 49 consecu ve years. does a better job than I ever did,” Dan said. “Austin has raised our herd average by 3,000-4,000 pounds through ideas he implemented that he brought back from school.”

Austin is making his mark on the farm and has made changes in the areas of reproduction and conservation.

For example, he implemented ovsynch protocols to get cows bred back on time, and for the last few years, he has integrated cover crops and striptilling.

“Over 75% of our land is green year-round,” Austin said. The Vanderties continue to make improvements and are

building a heifer barn and manure storage this year. Austin sees a robotic milking system as an option.

“I’ve done a lot of research into robots and visited a lot of farms,” Austin said.

The Vanderties are entering the next phase of their succession plan, which has been in the

“We’re willing to help him out and willing to make a sacrice as long as we can be comfortable nancially,” Dan said. “I would rather see the farm carry on to the next generation. I’ve always kept my debt to a minimum; therefore, Austin is not taking over a lot of debt.”

Doorco Farms is at the cusp of a new owner, and Dan and Julie are condent the farm will be in good hands as they prepare to pass it on to their son.

“Next year, it will be ofcial,” Dan said. “The farm is going in Austin’s name, and I want to give him free rein.”

have mastitis, the milk took on a colostrum-like consistency. When milk conductivity caused the affected cows to be pulled out for examination, fevers ranging from 103-106 degrees were noted.

Farms saw nearly 10% of their herds being affected, Poulsen said, causing a signicant drop in overall production, with the production of affected cows dropping up to 30%.

The rate of incidence was fast, Poulsen said, with most cows exhibiting symptoms within four to six days of the initial cow. New cases in the herds typically tailed off by days 1012.

As common ailments were ruled out, farmers and their teams of animal health specialists began searching to nd answers.

Concurrently, the Minnesota Board of Animal Health announced March 20 that a young goat had tested positive for HPAI, the rst instance of a U.S. domestic ruminant contracting the virus. That goat resided on a property where a backyard poultry ock had been depopulated due to HPAI in February. The goats and poultry shared access to the same water source.

Meanwhile, affected farms in the Southwest began reporting dead birds on their properties. Additional testing commenced March 22. The U.S. Department of Agriculture’s Animal and Plant Health Inspection Service issued a press release March 25 conrming that cows on dairies in Texas and Kansas had tested positive for HPAI.

Based on those tests, wild mi-

gratory birds were believed to be the source of the HPAI infection in dairy cattle.

“Cows aren’t dying,” Poulsen said. “We are not seeing the same thing we see in domesticated poultry. They are getting sick, decreasing in their milk production. Like any disease, though, as the affected cows have returned to milk, their lactation curves are typically muted.”

Poulsen said it is important to remember that so far, the incidence of disease is limited in the population of dairy cattle being affected.

“We don’t see it in transition cows or fresh heifers, replacement youngstock or steers,” Poulsen said. “We haven’t noted it in any of our beef or cow-calf populations in any state. So, what is different about those cows?

Why are we seeing clinical signs in those cows that go off feed and drop in milk? That is yet to be determined. It is odd, because typically when you talk about disease incidence and prevention, we focus on transition cows and youngstock.”

The Centers for Disease Control and USDA continue to assure people the health risk to the general public remains low. However, the CDC conrmed April 1 that a dairy farm worker in Texas exhibited symptoms of conjunctivitis, testing positive for HPAI after having contact with infected cows.

Poulsen reiterated that the risk to public health is low.

“All dairy producers need to know this: All pasteurized milk and cooked meat are safe for consump-

tion,” Poulsen said. “There is no reason for the consuming public not to trust the safety and wholesomeness of their food supply.”

Poulsen said that the biology of this strain of inuenza is not new.

“This is the circulating strain of inuenza we watched in Europe in early 2020,” he said. “In 2022, it made its way through the migratory bird population through North America, down into South America and back. We’re still seeing this in our wildlife population. So far, it’s been the worst foreign animal disease in U.S. history, because we have depopulated close to 100 million birds.”

This is not the rst time mammals have been affected by HPAI. Over 130 different mammalian species have been affected.

“Most of our affected mammalian species are what we consider mesocarnivores, or scavenging carnivores,” Poulsen said. “They are eating dead birds, animals like cats and some hunting dogs in Nebraska. Right now, we’re talking about affected sea mammal populations that are scavenging dead birds in Washington. It’s a little different than our ruminant species; this is a new manifestation of the virus.”

Poulsen said the question to be answered is how the cows became affected and how the virus is transmitted.

“Cows don’t scavenge dead birds; they are herbivores,” Poulsen said. “It made us wonder if birds were the primary source. The topography in the panhandle of Texas is quite different than Wisconsin. It’s a desert, and the water sources are often shared by migratory birds.”

Following the movement of lactating dairy cattle from Texas and Kansas to herds in Michigan and Idaho, cow-to-cow transmission was noted.

“We’re still working (on) how that happened,” Poulsen said. “We know testing milk samples is a good way to identify it. We’re looking at if it could have been manure or urine, but the jury is still out. In people, we tend to spread u by aerosolization or coughing, but we know most animals don’t have respiratory disease.”

Poulsen said that in Wisconsin, migratory bird populations are monitored. The virus has been detected both last fall and this spring. He said that the virus is referred to as an enveloped ribonucleic acid virus, meaning it thrives in cold, wet weather.

The warm, dry weather in February and early March caused most of the migratory birds to move through the area quickly, although the migration is not yet over.

“Last fall was different,” Poulsen said. “It was warm, and due to the drought, the harvest was late. So, we saw migratory birds staying and comingling, because there was a lot of food available for them. We saw domestic poultry affected last fall, and we just nished the cleaning and sanitation earlier this year.”

As of April 2, Poulsen conrmed that no known cases of HPAI are present in Wisconsin. He urged farmers to be vigilant and bring concerns to their herd veterinarians immediately.

“If you see animals that present the symptoms of decreased feed intake and rumination, production drops, change in the appearance of milk or fevers, contact your veterinarian,” Poulsen said. “Those animals can be reviewed to see if they meet the criteria for testing.”

Poulsen said if a farm has animals that meet the case denition, the USDA will pay for testing up to 20 animals. That testing can be done by any accredited veterinarian.

“While HPAI is reportable, in Wisconsin and many other states, it is not actionable,” Poulsen said. “We shouldn’t be concerned about any quarantine, control zones or depopulation on these farms at this time. There is no indication for that at this time.”

Implementing biosecurity plays a vital role in protecting a dairy farm, Poulsen said.

“Many dairy producers ship calves to warm, dry climates because it is more efcient and cost-effective for health and productivity reasons,” Poulsen said. “We move cattle all over the country to be more efcient. That does institute risk, but we have a signicant infrastructure to diagnose and manage that risk. It’s not perfect, but it is pretty good.”

Poulsen recommends dairy farmers use the American Association of Bovine Practitioner’s guidelines for implementing biosecurity measures. That includes simple measures such as boot washes and increased sanitation. Others, such as quarantining new animals on the farm for 14-21 days, can be challenging.

“That is really hard to do on dairies, having facilities dedicated only to quarantining animals,” Poulsen said. “Dairy farmers should ask their veterinarians to go through those biosecurity protocols with them to see what they can do to safeguard and mitigate risk for any disease. Some things are going to be long-term plans. We need to think of the return on investment and the cost for biosecurity essentially as an insurance plan.”

The GEA RoboRebel refuses to conform to the past and is pushing a new path forward.

The RoboRebel rotating belt can handle a variety of feed piles. The smart sensor determines the load on the belt and adjusts the path of the robot automatically. When a large pile is detected, it turns into the pile and forces the feed towards the animal.

Working around the barn 24/7, you can be sure it is doing its job of providing your cows with optimal access to feed any time of the day and night.

Improved work efficiency

Better access to the feed

Efficient feed push-up can contribute to the reduction of refusals.

Improved animal health

Frequent feed pushing is beneficial on hoof health. Keeping feed within reach lowers the pressure on their front hooves and necks.

Improved milk production

Better bottom line

By keeping feed pushed towards the feed fence animals have access to feed and can increase dry matter intake.

Human case of HPAI reported

A dairy worker in Texas has tested positive for highly pathogenic avian inuenza. The Centers for Disease Control and Prevention said the case is relatively mild with the only symptom being a case of pink eye. The patient was treated with u medication and told to isolate. This is only the second person to be diagnosed with this subset of avian inuenza, with the rst case being in Colorado two years ago. This would be the rst time HPAI jumped from birds to cattle to people. According to an agency news release, “This infection does not change the H5N1 bird u human health risk assessment for the U.S. general public, which the CDC considers to be low.”

No impact to human health or the milk supply

of Cameron and Rep. Treig Pronchinske of Mondovi in response to the action taken by California to regulate housing standards for pregnant sows, veal calves and laying hens. “I object to removing control over animal welfare standards from local authorities and preempting their ability to pass ordinances with the interests of their community in mind,” Evers said.

HSUS will mobilize to protect Prop 12

By Don Wick Columnist

After the U.S. Department of Agriculture conrmed the presence of HPAI in a small number of dairy herds, the National Milk Producers Federation executive vice president of communications and industry relations Alan Bjerga was quick to assure the dairy industry. “We’re not seeing disruptions in milk supply or an animal health crisis, but we’re keeping an eye on it because it’s something new,” Bjerga said.

No long-term impact on dairy cattle

The HPAI cases in Texas and Kansas dairy herds will not have a signicant impact on milk prices. “If you look at the numbers, we look at this maybe impacting milk production by 1%-1.5% over some period of time,” said Mike North, principle, Ever.Ag. “There’s not going to be this big lightning bolt; it’s not going to be like the stories we heard about large chicken ocks with avian u euthanized.” North, who is also a past president of the Dairy Business Association, said dairy cows may exhibit u-like symptoms for two or three weeks. Once it’s done, production returns to normal. “Milk quality returns to normal and safety is never a problem through that entire period,” North said.

Adjustments sought in DMC calculation

USDA’s Dairy Margin Coverage triggers a payment for participating farmers when the difference between the all-milk price and the average feed price falls below a certain level. DMC was triggered in 11 of the 12 months in 2023. Associated Milk Producers Inc. vice president of marketing Sarah Schmidt said the risk management program was working as intended. “That said, the calculation for that program uses a national milk price,” Schmidt said. “Because the vast majority of our milk goes to cheese and cheese is the low market price right now, our average milk price in the Midwest is not close to the national average milk price. Our dairy farmers are telling us DMC isn’t providing the support that they had typically come to expect.” DMC payments kick in when margins are at $9.50 per hundredweight or less. Due to increased costs, Schmidt said that the margin should increase to $10 cwt. AMPI would like to see changes to the DMC program when the farm bill is completed. Schmidt remains hopeful that a farm bill will pass this year, but her optimism is cooling with it being an election year.

USDA reviewing federal order proposals

The deadline is now past for dairy industry stakeholders to submit legal briefs for the modernization of Federal Milk Marketing Orders. The USDA has until July 1 to review this information. This lengthy process began with a hearing near Indianapolis, Indiana, that began in late August 2023 and lasted until late January. This is the rst comprehensive review of the milk pricing system in nearly 25 years.

Evers vetoes

animal welfare bill

Gov. Tony Evers vetoed legislation that would have prevented local units of government from imposing regulations on animal housing facilities. The bill was introduced by Sen. Romaine Quinn

The Humane Society of the United States is challenging the comments made by House Committee on Agriculture Chair Glenn “GT” Thompson this past week. Thompson said he is determined to “x” California’s Proposition 12 through the farm bill. The activist group said this is one of the biggest ghts in its history, and it will mobilize its supporters to defeat any attempts to change this policy.

Baldwin visits Dairy Business Alliance

Wisconsin Sen. Tammy Baldwin toured the Center for Dairy Research at the University of Wisconsin-Madison. The center oversees the Dairy Business Innovation Alliance which supports new and expanding dairy businesses. “I’m proud to have secured funding so that farmers, cheesemakers and dairy processors can continue to innovate, support jobs and provide world-famous dairy products,” Baldwin said.

Alfalfa variety selection should not be ignored

Insects and diseases continue to evolve. According to Land O’Lakes Inc. alfalfa and forage specialist Jeff Jackson, seed treatments and new chemistries can help, but variety selection also has a role. “If you’re not paying attention to variety selection and nding the varieties that will work best in your soil type, it can be a pitfall to getting a stand established,” Jackson said.

WDE recognition announced

World Dairy Expo has announced its 2024 award winners. Jim Barmore, Marty Faldet and King Hickman of GPS Dairy Consulting LLC in Lakewood, Minnesota, are being recognized as the Industry People of the Year. Former Semex CEO Paul Larmer, of Guelph, Ontario, is being honored as the International Person of the Year. Larson Acres Inc., which milk 2,800 cows at Evansville, Wisconsin, is home to the Dairy Producers of the Year. The award ceremony will be Oct. 2.

Vet school dean selected

The new dean of the UW-Madison School of Veterinary Medicine is Jonathan Levine. Levine is a professor and head of small animal clinical sciences at Texas A&M University and will take on his new role Aug. 1. Levine succeeds Mark Markel, who will return to the faculty as a professor of large animal surgery.

Trivia challenge

The average retail price for a gallon of whole milk was $4.01 in 2023. That answers our last trivia question. For this week’s trivia, what are the ofcial colors of FFA? We will have the answer in our next edition of Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network of Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

Sign-up for Dairy Margin Coverage ends April 29

Polzin encourages producers to protect against market surprises

By Stacey Smart stacey.s@dairystar.comMADISON, Wis. — Enrollment in the Dairy Margin Coverage program typically takes place in the fall.

Without the passing of a farm bill last year, DMC received an extension and enrollment was pushed back to the new year.

April 29 is the last day that farmers can sign up for the DMC program at a Farm Service Agency ofce.

“When you enroll for 2024, it will retroactively go back to January,” said Leonard Polzin, dairy markets and policy outreach specialist at the University of Wisconsin-Madison Extension. “We did trigger a payment in January and February, and you would receive that.”

During a webinar March 22, Polzin shared details of the program and reasons producers should consider signing up.

“This is a continuation of the previous program that was in place last year, and except for some small tweaks, the program remains the same,” he said. “Coverage levels and premiums have not changed and will continue for another 12-month period. Once a different farm bill goes through, we would

look at changes at that time.”

Polzin said the ease and simplicity of the DMC program makes it compelling to consider.

“It’s not something you have to actively monitor like futures and options,” he said. “The FSA ofce takes care of knowing when payments are triggered and sending off the payments, etc.”

Following the same mechanics as last year, the program is based on the national average milk price, also known as the all-milk price, minus the value of the feed ration, which is the estimated price to produce 100 pounds of milk.

“There is no ration that perfectly ts everybody’s farm,” Polzin said. “The program tries to take the feed equivalent of fat, protein, carbohydrates and energy, and calculate them to nd that ration for 100 pounds of milk.”

When enrolling in the program, Polzin said there are two things to consider: percentage of coverage and coverage level. Farms can insure 5%-95% of their historic production level. Polzin said most people choose the maximum amount. The coverage level ranges from $4-$9.50 per hundredweight of margin coverage, with most people selecting coverage on the higher end.

The rst 5 million pounds of annual production is covered in Tier 1 of the program, and everything greater

Turn to DMC | Page 12

“Troubleshoot issues and analyze all aspects of the dairy.”

What do you like about the Dart program?

ability to customize reports to help analyze the trends on the farm.

Why did you decide to use Dart and how long have you been using it on your dairy? I’ve been using Dart for 13 years. It’s a very user friendly program that we could not only input and manage our cow information but also build reports, graphs, and lists to help troubleshoot issues and analyze all aspects of the dairy.

Which Dart features do you use the most? I use Dart for all my animal records, ID, treatments, matings and genetic data, but I probably use the pocket dairy on my phone the most. I can take all the info with my anywhere I go.

What are some other DHIA tests you use? We also use DHIA for Leukosis and Johnes testing.

Tell us about your farm. My wife Robyn and I milk 180 cows with my sister Jocelyn and dad Jim. We raise our own heifers, have a commercial ock of sheep and farm around 350 acres primarily for feeding the livestock.

6,700 hrs. .....................$65,000

CIH 8920, 2WD, 7,900 hrs. .....................$59,000

CIH 8920, 2WD, 4,100 hrs ......................$72,000

CIH 8920, FWA, 2,600 hrs ....................$110,000

CIH MX240, 4,700 hrs .............................$85,000

CIH MX220, FWA, 3,600 hrs. ..................$88,000

CIH MX120, 2WD, 3,800 hrs. ..................$72,000

CIH MX120 w/loader ...............................$75,000

CI 7220 w/6500 hrs., 2W ......................Coming In

CIH C90, 4,000 hrs. ..............................Coming In IH 5088, 7,100 hrs. ..................................$26,000

IH 1466 restored, new 20.4x38

Firestones ..............................................$38,000

IH 1486, 6000 hrs. ................................Coming In IH 1456, cab ............................................$22,000

IH 1086, 9,700 hrs. w/ldr. ........................$23,000

IH 1066, no cab .......................................$13,500

IH 1086, 5,000 hrs. ..................................$24,000

IH 686 ......................................................$14,000

TILLAGE

CIH Tigermate II, 26’ ...............................$28,000

CIH Tigermate II 26’ w/rolling basket.......$32,000

CIH Tigermate 200 w/basket, 34’ ............$42,500

CIH

CIH

CIH

CIH

than that is covered in Tier 2. The margin coverage level for Tier 1 ranges from $4-$9.50 cwt, while Tier 2 ranges from $4-$8. Premiums are 0-15 cents cwt for Tier 1 and $0-$1.813 for Tier 2.

“The price is a fairly good deal for producers,” Polzin said. “When you compare the cost per hundredweight of DMC versus other products, it is quite cost competitive, especially in that rst 5 million pounds of production.”

Polzin encouraged dairy farmers to use the DMC decision tool at dmc.dairymarkets.org to determine premiums and payments.

“Make sure you select the appropriate year, 2024, in the top left corner when using this site,” Polzin said.

The most signicant change to the DMC program is the way that historic production is stated in sign-ups. Prior to this year, previous production history and supplemental production history were both listed. This year, the two have been combined and are being called DMC production history.

FSA has revised regulations to allow eligible operations to make a one-time adjustment to established production history. This adjustment combines previously established supplemental production history with DMC production history for farms participating in Supplemental DMC during a prior coverage year.

“It’s possible to include new supplemental history that you have not previously included by talking to someone at your FSA ofce,” Polzin said.

About 75%, or 17,000, of dairy operations in the U.S. enrolled in the DMC program in 2023 and received nearly $1.3 billion in payments, averaging $75,753 per operation.

“We’re probably going to hit that again this

year,” Polzin said. “We’re very close to 100% participation in Wisconsin for dairies with established production history if you take out farmers who don’t sign up based on religious reasons. There is big utilization of the program, and we’re seeing quite a bit of benet to producers when we come across years that are not so positive in margin.”

Polzin said Wisconsin, New York, Pennsylvania and California are major utilizers of Tier 1 coverage with substantial pounds enrolled in the program.

The all-milk price is hovering around the $20 mark, but feed costs have come down quite a bit, Polzin said. Corn has dropped off recently, and soybean meal is coming down as well, bringing relief to feed costs.

The current forecasted period is not showing any DMC payment triggers, and farmers have asked Polzin why they should sign up in 2024.

“We’ve seen corn prices fairly low in the past, but there is no guarantee they’re going to keep going down,” Polzin said. “They could very well come back up again too. If milk prices continue to have additional down pressure, then it’s not unrealistic to have payments triggered over the next 12 months.”

When looking at the forecast in recent enrollment periods, Polzin said it was not uncommon for a portion of the year to look like it would not generate many payments, but as time went along, a lot of payments were made. This happened in 2023.

“It’s really hard to be bullish on price when we have so much production capacity coming online in the U.S. at the moment,” Polzin said.

Between now and the rst part of 2026, over $7 billion in production is slated to come online in dairy processing capacity. Tight demand and less-

than-favorable exports give Polzin reason to believe the industry could see price pressure that will weigh negatively on milk prices.

“The price has been holding fairly steady recently, and while it’s better than 2023, it is not a resoundingly strong milk price,” Polzin said. “To say that we’re out of the bottom for the dairy price cycle with only good news going forward is a tough claim to make.”

Polzin said the market response has been on the supply side, as production remains strong despite shrinking cow numbers.

“Until we see a response on the demand side come back fairly strong, it is a big ask of the market to deliver high prices, especially at Class III to hold us at good margins for a period of time,” Polzin said. “There are enough unknowns at the moment to warrant signing up for DMC.”

CONVENTIONAL SEED CORN SALE

Great price on worlds top hybrids. Non GMO grain is earning market premiums (up to $2 over CBOT). We offer proven, complete weed control programs for less than technology cost!

Maximize returns and IMPROVE YOUR BOTTOM LINE!

ORDER EARLY AND SAVE MORE!

Dairy farmers are under attack by the National Milk Producers Federation

Thomas L. Olson, Black River Falls, WisconsinThe National Milk Producers Federation has a National Dairy FARM Environmental Stewardship program.

This program is designed to lower greenhouse gas emissions from dairy cattle. This program is the height of hypocrisy.

According to the Dairy Management Inc. website, the U.S. dairy herd produces 1.3% of the nation’s greenhouse gas emissions. (NMPF provides a link to this information on their website.) The transportation industry produces 28%, according to the U.S. Environmental Protection Agency.

According to a study conducted by Virginia Tech and the U.S. Department of Agriculture, if the U.S. dairy herd was somehow removed, it would only lower greenhouse gas emissions by 0.7%.

If you are confused, you are not alone.

The NMPF website contains many pages about their different programs, so it is easy to research their ideas.

As dairy farmers, we have survived the FARM program because we had to. Dairy product buyers demanded that we abide by these rules. I am afraid that this National Dairy FARM Environmental Stewardship program will add a very costly economic burden on already struggling dairy farmers.

I urge each and every one of you to get ahead of this mess and tell your raw milk handler that we, the dairy producer, do not want this mandated on our dairy farm. The raw milk handler needs to make clear to the nished product buyer that they will not mandate this program on dairy farms. The nished product buyer needs to go to the NMPF website so they can see for themselves the hypocrisy.

from our side our side OF THE FENCE THE

How have you increased your role on the farm?

Anthony Seelow Chaseburg, Wisconsin Vernon County64 cows

When did you know you wanted to be a farmer, and why are you considering a career in dairy?

Dairy farming as a career was always in the back of my mind, but I wanted to try something else for a bit. I got a degree for machining and worked at a computer numerical control machine shop for about a year. I got sick of staring at a machine all day, and when it was nice out, I wanted to be outside. So, I decided to come back to the farm.

How have you continued to increase your role on the farm? I do all the feeding for all the animals. I took over that role in 2018. I’ve been doing more of the managing hired help by coordinating schedules and making sure to line up help if we’re gone. I have slowly been taking over eld maps and dealing with crop planning. Last year, I planted all of our corn. That was the rst year I planted everything.

What is the most enjoyable chore to do on the farm? I like mixing feed. That’s the most enjoyable. I like mixing the total mixed ration for the cows and feed for the heifers, because it feels like you’re getting a lot accomplished. I’ve worked with the nutritionist, and I’ve got the rations dialed in. I know where it needs to be. It feels good to do a job well.

What excites you about the future of the dairy industry? The automation coming in is exciting because it could free up a lot of labor concerns and constraints. I am particularly interested in robots, which I hope to one day install with an expansion.

What challenges do you have as you embark on your career? Farm transition is the rst hurdle. We sort of have a plan in mind, but it starts with my sister buying land for her own operation. From there, the challenge would be land prices and how we’re going to acquire more land to give ourselves the option of expanding or diversifying.

Tell us about your farm and your plans for the dairy this year. We milk 16 cows at a time in a at parlor with eight units. Since there is no quota with Organic Valley, we will probably try to increase production this year. Even with the drought last year, we were able to push our milk a little bit. So, if the weather cooperates, we should do even better this year. We manage the farm with my parents and three high school students throughout the week. On the weekends, it’s me and my wife, Megan, and my parents.

Ben Kindschuh Brownsville, Wisconsin Dodge County 84 cows

When did you know you wanted to be a farmer, and why are you considering a career in dairy? I don’t think there was a time I ever thought about doing anything else but farming. I love being a dairy farmer, because you can see the quality outcome of your work when you put in the effort.

How have you continued to increase your role on the farm? I carry more of a leadership role when quick decisions must be made. My day involves managing what needs to get done that day and what can be done when time allows. My main role is focusing on the feeding and health of the herd.

What is the most enjoyable chore to do on the farm? My favorite chore on the farm is feeding cattle. I love the smell of the feed and seeing the cattle dig in and enjoy it.

What excites you about the future of the dairy industry? The most exciting part is new technology. The monitoring systems and infrastructure for herd health and production are always improving.

What challenges do you have as you embark on your career? There are always ideas for ways to make improvements on the farm, and the biggest challenge is where to start rst. Another big challenge is succession planning to ensure the farm can continue to be successful.

Tell us about your farm and your plans for the dairy this year. My mom, dad and I milk 84 cows in a 54-stall stanchion barn. We farm 500 acres of land. Our milk is shipped to BelGioioso Cheese Inc. Our plan for this summer is to put down a gravel pad for ag bags. We also plan to remodel our heifer barn to be more efcient with herd checks and breeding. This includes new gates to make sorting animals easier and headlocks to reduce stress of heifers during herd checks.

Rachel Hefel Epworth, Iowa Dubuque County 175 cows

When did you know you wanted to be a farmer, and why are you considering a career in dairy? I started milking cows when I was 6 or 7 years old when my mom tore her rotator cuff. I have done it my entire life since. It is a good lifestyle. I enjoy being around animals, especially cows.

How have you continued to increase your role on the farm? I have increased genetics with showing. I now manage all the breeding and calving. I have handled operating more equipment as well. I started by hauling bales with the skid loader and then went to hauling silage. Now, I am involved in all aspects of eldwork.

What is the most enjoyable chore to do on the farm? I enjoy feeding calves, because I like to watch them grow and develop.

What excites you about the future of the dairy industry? Genetics and the future of genetics. I am excited to continue watching the breeds develop.

What challenges do you have as you embark on your career? The cost of everything is a challenge. It makes it hard to purchase or update things. Of course, the milk price is always a challenge too. It makes it difcult for young people to buy in.

Tell us about your farm and your plans for the dairy this year. The farm is managed by my parents, Mark and Rhonda, and I. We milk in a double-6 parlor, and our cows are housed in a freestall barn. We ship our milk to Prairie Farms Dairy. We have cattle of every breed. We plan to continue showing this year at the county fair, Iowa State fair and World Dairy Expo.

Cheyenne Schubert

Milladore, Wisconsin

Wood County

750 cows

When did you know you wanted to be a farmer, and why are you considering a career in dairy? At a young age, I had a love for the dairy industry, helping feed calves and standing on a bucket to help milk cows. I have always stayed involved with the farm throughout middle and high school. During senior year, I shadowed different occupations outside of the dairy industry to see what else interested me. I decided to continue my dairy education by attending the University of WisconsinMadison Farm and Industry Short Course. After I completed the two-year course, I came home to the family farm. Within a few short years, I knew I made the right decision.

How have you continued to increase your role on the farm? A year ago, a neighboring farm came up for sale with a bulk food store on it. We have always talked about opening a small store to sell homegrown beef. So, when this opportunity came up, we jumped on it. My mother runs the store full time, the Blueberry Bulk Store & More LLC. I took on more roles with bookkeeping and herd management. I manage the herd health. I work hand-in-hand with my father on the cow and youngstock part of our operation.

What is the most enjoyable chore to do on the farm? I enjoy the everyday tasks on the farm. Since returning from school, I set goals to increase our pregnancy rate and lower our days in milk. Herd health has become a task I enjoy, while working with our veterinarians, Cole An-

Kenneth Levzow Rio, Wisconsin Columbia County120 cows

When did you know you wanted to be a farmer, and why are you considering a career in dairy? I have wanted to be a farmer since I was 5 years old. I have always enjoyed working side by side with my family and working outdoors. My grandfather, Maurice Levzow, instilled in me the work ethic we need to get the job done. This is what I have always wanted to do and hope to continue.

How have you continued to increase your role on the farm? My parents gave me responsibilities at a young age. I started with feeding calves, tractor driving and helping in the parlor. I oversee feeding and calf care. I have learned how to IV cows for milk fever and breed cattle. I am responsible for all cleaning and the management of bedded pens and yards. I have taken on cutting alfalfa and planting soybeans and wheat. I have learned to calibrate equipment to ensure proper seeding rates and coverage. I received my commercial driver’s license in 2022 and haul the grain to market. I have also been purchasing machinery to assist with eldwork and chores. In 2021, I purchased tillable acres from a neighbor. Our farm is enrolled in the Feed in Focus Program as part of the U.S. Dairy Net Zero Initiative through Foremost Farms USA, The Nature Conservancy and Nestlé. I took on the challenge by researching air seeder machinery and built my own machine. When the corn is 2-3 feet tall, I air seed radishes and rye into the corn rows. We found this to be benecial with our soil type to retain soil health and nutrients. By building my own seeder, I saved considerable costs. The rst year, I planted 70 acres. This year, I plan to plant 150 acres. Utilizing the air seeder allows us to establish cover crops earlier than if we were to plant post-harvest. This also saves time with our limited staff as we do not try to plant while trying to harvest.

What is the most enjoyable chore to do on the farm? My most enjoyable chore is cutting alfalfa. The smell of fresh-cut hay is one of the best scents there is. We cut four cuttings. I try to keep my Haybine prepared for the season and get frustrated if I break down. Quality forage is our No. 1 goal for the dairy herd. Our ration is based on forage, and I know I need to get out early and do a good job.

What excites you about the future of the dairy industry? The fact that there is a future if you work hard and are dedicated is what excites me most. I have found that being involved at the county and state level with Wisconsin Farm Bureau Federation allows me to network with like-minded individuals. I have gained knowledge about farming practices but also policy and

derson and Frankie Warzynski, to help better our herd in all aspects. Every Monday, after our herd check, we sit down and discuss the good and bad from the week and set goals on how we can keep moving forward.

What excites you about the future of the dairy industry? Since starting a family, I enjoy having our children, Presley and Layton, with me doing the day-to-day tasks. Having them exposed to the dairy industry will hopefully make an impact on them. I hope they will have an interest in an agricultural eld or in taking over the family farm.

What challenges do you have as you embark on your career? Working with family is a reward but also can be a challenge by separating work from personal lives and feelings. My father and I work well together and respect each other’s opinions. At the end of the day, we both have common goals for our farm: to maintain a healthy work environment, keep an open mind and be protable.

Tell us about your farm and your plans for the dairy this year. Liquid Coin Dairy LLC is owned by my grandparents, LeRoy and Leiann Altmann; my parents, Scott and Joyce Karl; and my uncle and aunt, Patrick and Jill Altmann. My husband, Dylan, and I, along with my cousins, Dylan and Noah Altmann, hope to become the next generation to take over the family farm. My brother, Tyler Karl, helps after his off-farm job. We milk 750 cows three times a day in a double-20 parlor. We ship our milk to Wisconsin Dairy State Cheese Company. We work with United Veterinary Service. Dave Strebe is our nutritionist, and Ashley Voelz is our calf specialist from Nutrition Service Company. We are working on building a heifer facility with a completion date of mid-summer. We are planning to put sand savers in to help limit our sand cost and help with cow comfort.

how the government operates. Being involved in a grassroots organization brings a voice to the agricultural industry. I see the value of educating the consumer on our products, as too often misinformation is prevalent. We need to be proactive in educating the consumer. This also is important when local government works on land-use laws and policies, since there are so few farmers around. I decided to get involved at the local level by joining the Wyocena Township Board. I want to have a say in local issues and further educate others about agriculture. This allows me to work with my neighbors to keep our community growing and thriving in the new age.

What challenges do you have as you embark on your career? The size of our farm makes it difcult for one person to manage by themselves. We are not large enough to hire employees for a specic task. Any employee would need to be able to do multiple tasks on the farm. Another challenge is managing input costs to remain protable. My parents have instilled in me the value of watching costs versus buying things we might not necessarily need. Continuing education will be a constant part of the business. I will need to continue to learn more about marketing, nancial decisions and production.

Tell us about your farm and your plans for the dairy this year. I am the fourth generation on Levzow Dairy. I farm with my parents, Ralph and Becky Levzow, and part-time employees. We milk 120 registered Holstein and Jersey cows, raise all youngstock on the farm and market feed steers through Equity Cooperative Livestock Sales Association. Milk is marketed through Foremost Farms USA. The family owns 625 acres. Total crop land owned and rented is 900 acres, of which we raise alfalfa, corn, soybeans and wheat. We do market grain, but the bulk of the crops are utilized for feed. We have been utilizing more no-till and minimum-till practices. We are attempting to utilize regenerative practices to reduce our carbon footprint. We milk in a double-6 herringbone parlor and feed a total mixed ration. We hire a custom operator to chop and bag the corn silage. We work with Bob Hagenow and Brock Irwin, Vita Plus, for ration calibrations and Lodi Veterinary Care for our herd health needs. Insight FS Inc. provides soil testing and spraying. This team is invaluable to our success. Because of last year’s drought situation, we planted winter rye that will be utilized for forage, followed by no-till corn. This should help our feed inventory. We plan to add more acres to cover crops. My goal is transitioning the bookkeeping process of the farm over to me.

When did you know you wanted to be a farmer, and why are you considering a career in dairy? I knew I wanted to farm at a young age. I liked being outside and working with equipment. There is just something about not having to work for someone else and watching the work you put in show for itself.

How have you continued to increase your role on the farm? I’ve increased my role in the farm by not hiring out as much of the eldwork and doing more of our own. We used to hire out plowing, planting and spraying, pretty much everything. Now, we do most of it on our own. I’ve taken a bigger role on xing day-to-day things like maintenance on the robotic milking systems and farm equipment. I’ve become more involved in calf and cow care. I treat the sick calves, and I also do all the breeding on the farm.

What is the most enjoyable chore to do on the farm? Doing eldwork is one of the most enjoyable things to do on the farm. I really enjoy planting because of the pace and the peacefulness. I like watching what you put in the ground come out and develop into a plant. It’s a nice way to get out and relax most of the time.

What excites you about the future of the dairy industry? Seeing what new technology they come out with to help manage and care for the cows more.

What challenges do you have as you embark on your career? Learning about new ways to manage the animals and utilizing all the new technology that they come out with for milking systems.

Tell us about your farm and your plans for the dairy this year. I farm with my parents, Keith and Roxanne, and we milk around 130 cows with two Lely robotic milking units. Our milk is shipped to First District Association in Litcheld, Minnesota. In the years to come, I would like to expand our heifer facility and hopefully one day put up a calf barn to help keep their environment more controlled for calf health. We may add one or two more robots in the years to come.

Thank you to all of our customers for doing business with us! And thank you to all who came to our customer appreciation event!

TOP PERFORMERS

Trent, Kristan, Pete and Jeanne Opelt, of River Crest Dairy LLC | Greenwood, Wisconsin | Clark County | 250 cows

How many times a day do you milk, and what is your current herd average, butterfat and protein? Our cows are milked twice a day. The current herd average is 30,242 pounds of milk with a 4.4% butterfat and 3.4% protein.

Describe your housing and milking facility. All of the cows are housed under one roof in a naturally ventilated, sand-bedded freestall barn with two group calving packs. Cows are milked in a double-8 parallel parlor.

Who is part of your farm team, and what are their roles? The farm team includes the following family members: Trent, feeder; Kristan, herdsman/bookkeeping; Pete, crops/ maintenance; Jeanne, calves; Kyle Opelt, crops/maintenance; Lindsay Van Cuyk, calves; and Jerry Noeldner, heifers. We also have two Amish employees and one part-time high school student.

What is your herd health program? A veterinarian comes every other week for herd health. Cows are vaccinated with BoviShield one month after calving. They are vaccinated during the dry period for mastitis with Endovac and for salmonella.

What does your dry cow and transition program consist of? To dry cows off, we move them into the dry cow pen as

Lexie Opelt (front, from le ) and Maggie Van Cuyk; (back, from le ) Trent Opelt, Kristan Opelt, Pete Opelt, Jeanne Opelt, Kyle Opelt and Lindsay Van Cuyk stand April 8 in the freestall barn at River Crest Dairy LLC near Greenwood, Wisconsin. The farm is home to 250 milking cows.

they leave the parlor. We pull them out of the dry cow pen two days later to be milked out again. Then, two days later, they are milked out one more time and treated with a teat sealant.

We started doing this years ago, because it seems to be easier on the cows that are still milking heavy, and with our setup, it is easy to do. We use selective dry cow therapy, only using antibi-

otics on cows with high somatic cell counts. When we built our barn, we put all the cows under one roof, including dry cows. It eliminates the weekly task of trailering dry cows, and it makes

cow movements easy and stressfree through the entire lactation. The dry cow pen is identical to the milking pens, with deep sand-bedded free stalls and fans. Springing heifers are moved to the dry pen two months before calving, which allows time for vaccines, hoof trimming and adjustment to the barn. The group calving packs are located adjacent to the dry pen. Cows and springing heifers are moved to the packs two weeks before calving and remain on the calving packs at least 24 hours after calving before going to the fresh pen. They stay in the fresh pen about 30 days then move to a 2-year-old or mature cow pen for the rest of the lactation. Dry cows and close-ups are fed winter rye, corn silage and minimal haylage, depending on our rye inventory. X-Zelit is top-dressed and mixed in by hand to closeups to prevent milk fever.

What is the composition of your ration, and how has that changed in recent years? Milking cows are fed alfalfa, brown mid-rib corn silage, whey, dry corn and a protein/mineral mix. We have not made any major changes to the ration since adding whey. We tend to make minor adjustments based on forage quality and inventory.

Turn to TOP PERFORMERS | Page 20

Doug and Julie Martin, son Grant and wife Kim, daughter Jill and

“There’s nothing like the sight of fresh Jersey cows on green grass. We love Udder Comfort™ for those fresh cows. We spray udders 2x/day for 5 days after calving. We don’t do intramammary treatments while in the milking period, but we do dry treat a few. If we get flareups, we use Udder Comfort after milkings, and in most cases, they clear up within a week,” says Jill Wiser, dairy manager and partner in her family’s Pleasant Valley Jerseys, Chambersburg, Pa., a grazing dairy milking 300 Jerseys.

“We’ve been using Udder Comfort for 15 years. Nothing else we tried worked. We always have Udder Comfort here because it’s the only one that works. It gets swelling down fast and makes cows comfortable so they do better,” Jill explains and looks forward to trying the Udder Comfort BatteryOperated Backpack Sprayer to do large fresh groups quickly as their seasonal spring calving gets underway soon.

Tell us about the forages you plant and detail your harvest strategies. We plant alfalfa, BMR corn for milking cows, and conventional corn for heifer and dry cow silage. We also started planting winter rye for dry cow feed a few years ago. We plant peas and triticale with our newseeding alfalfa and harvest it for heifer forage. All forage is custom harvested.

What is your average somatic cell count, and how does that affect your production? Our SCC is around 100,000 according to Dairy Herd Improvement Association testing. It is lower in the tank, because we usually pasteurize milk from a few high SCC cows for calf milk. We used to try hard to keep our SCC lower, but when they stopped paying high premiums for a re-

ally low count, we backed off a little on culling and treating mastitis. Production didn’t seem to change.

What change has created the biggest improvement in your herd average? In 2018, we started feeding whey, and it was a game-changer. It’s a pain to work with and requires management, but our components immediately sky-rocketed. If we run into a supply problem with the whey, it causes issues with production.

What technology do you use to monitor your herd? We don’t have a heat detection system or anything fancy to monitor the cows. We use tail paint and walk the pens, which only takes about 15 minutes a day. The parlor is simple and shows milk weights

and temperatures, but nothing is recorded back to a computer. Milking employees write down high-temperature cows as they milk.

What is your breeding program, and what role does genetics play in your production level? Cows are bred rst service to a G6G program. Then, they are monitored for repeat heats. Beef semen is used on the bottom one-third of the cows, and we’ll probably increase that. The top 50% of heifers get sexed semen on the rst service. The remaining services are conventional semen. We are trying to nd the balance of how much beef semen to use. Our heifer facilities are sized to the number of heifers we need, so we regularly pick and choose extra heifers to sell after weaning to keep our

numbers where we need them. We don’t genomic test, but we know the important role genetics play. We try to be consistent in selecting bulls for pounds of fat and protein, daughter pregnancy rate, udders, feet and legs, and strength. We keep an eye on a number of other traits. We do not intentionally breed for big, tall cows but try to steer clear of bulls that sire shallow, narrow cows.

List three management strategies that have helped you attain your production and component level. Attention to detail in all areas of the farm. Our entire team of family members and employees try to do an exceptional job of taking care of the little things, day in and day out. Consistency with details is critical if you want consistent production.

The combination of dry corn and whey has boosted components and protability. BMR corn silage has helped increase intakes and, therefore, production.

Tell us about your farm and your plans for the dairy in the next year. River Crest Dairy LLC is owned by Pete and Jeanne Opelt, their son, Trent, and his wife, Kristan. The LLC was formed in 2015 when the freestall barn and parlor were built to combine the two tiestall herds. In 2017, a calf barn with automatic feeders was built. We raise our heifers and farm almost 700 acres, growing all of our own forage and grain corn. We do not have any major plans for the next year. We want to continue to try to get more production from the cows and the acres that we have.

$141,100

JD 2680H 2021, 35 ft., 3-Section Folding, #579164 ............................... $139,900

JD 2680H 2021, 35 ft., 3-Section Folding, #574929 ............................... $134,900

JD 637 2000, 29 ft., 3-Section Folding, 9” Spacing, #565358 .................... $23,900

JD 2680H 2022, 30 ft., 3-Section Folding, #556294 ............................... $129,900

DRAWN PLANTERS

JD 1775 2018, 12 Row, 30” Spacing, #570817 ........................................ $108,000

Case IH 2150 2021, 16 Row, 30” Spacing, #569307 ............................... $199,900

JD 1775NT 2022, 24 Row, 30” Spacing, #549842 ................................... $389,900

JD 1770NT 2013, 16 Row, 30” Spacing, #578120 ..................................... $70,900

JD 1795 2023, 24 Row, 20” Spacing, #573347 ........................................ $419,900

JD DB60 2017, 24 Row, 30” Spacing, #562192 ....................................... $249,900

JD DB60 2017, 24 Row, 30” Spacing, #574768 ....................................... $315,000

JD DB60 2013, 24 Row, 30” Spacing, #550243 ....................................... $149,900

JD 7200 1990, 12 Row, 30” Spacing, #577052 ............................................ $7,500

JD DB60 2018, 24 Row, 30” Spacing, #573437 ....................................... $289,900

JD 1760 2008, 12 Row, 30” Spacing, #568124 .......................................... $29,500

JD DB66 2012, 36 Row, 22” Spacing, #556901 ....................................... $195,900

JD DB66 2011, 36 Row, 22” Spacing, #578691 ....................................... $182,000

JD 1775 2022, 12 Row, 30” Spacing, #574581 ........................................ $139,000

JD 1770NT CCS 2013, 24 Row, 30” Spacing, #571367 ............................ $109,900

JD DB60 2010, 24 Row, 30” Spacing, #569759 ....................................... $151,500

JD 1770NT CCS 2009, 16 Row, 30” Spacing, #576764 ............................ $133,500

JD 1775NT 2023, 24 Row, 30” Spacing, #566196 ................................... $369,900

JD 1775NT 2020, 24 Row, 30” Spacing, #579102 ................................... $297,900

JD DB66 2022, 36 Row, 22” Spacing, #576258 ....................................... $479,000

JD DB60 2020, 24 Row, 30” Spacing, #569113 ....................................... $349,900

JD DB66 2007, 36 Row, 22” Spacing, #575704 ....................................... $129,900

JD 1770NT CCS 2008, 24 Row, 30” Spacing, #574675 .............................. $89,900

JD 1770NT CCS 2013, 24 Row, 30” Spacing, #578773 ............................ $119,900

JD 1775NT 2015, 24 Row, 30” Spacing, #577213 ................................... $159,900

JD 1775NT 2021, 12 Row, 30” Spacing, #579443 ................................... $215,000

Kinze 3500 2016, 8 Row, 30” Spacing, #578235 ...................................... $59,900

JD DB66 2023, 36 Row, 22” Spacing, #574902 ....................................... $532,900

JD 7200 1994, 12 Row, 30” Spacing, #576034 .......................................... $15,500

JD DB66 2003, 36 Row, 22” Spacing, #577083 ......................................... $63,500

JD 1775 2022, 12 Row, 30” Spacing, #578705 ........................................ $142,500

JD 1775 2019, 12 Row, 30” Spacing, #578706 .......................................... $99,900

JD 1770 2001, 12 Row, 30” Spacing, #578830 .......................................... $29,900

JD DB60 2013, 24 Row, 30” Spacing, #578708 ....................................... $139,900

JD DB60 2019, 24 Row, 30” Spacing, #551039 ....................................... $299,900

JD DB66 2019, 36 Row, 22” Spacing, #572188 ....................................... $379,900

JD DB80 2012, 32 Row, 30” Spacing, #571885 ....................................... $232,900

JD 7200 1995, 16 Row, 30” Spacing, #578819 .......................................... $13,900

JD R4030 2016, 120 ft. Boom, 20” Spacing, 1138 hrs., #568430

Bob’s Dairy Supply Dorchester, WI 715-654-5252

Ederer Dairy Supply Plain, WI 608-546-3713

DeLaval Dairy Service Kaukauna, WI 866-335-2825

Joe’s Refrigeration Inc. Withee, WI 715-229-2321

Mlsna Dairy Supply Inc. Cashton, WI 608-654-5106

Professional

A farm for a new generation

Wilterdinks begin renting family operation Jan. 1

By Stacey Smart stacey.s@dairystar.comSHEBOYGAN

FALLS, Wis. — A new chapter has begun at the Wilterdink farm, and it is a moment that Eli Wilterdink has been working toward for a long time.

To achieve his goals, Eli’s ever-increasing responsibilities were paired with decisionmaking capabilities to bring him closer to one day running the farm. He bought cattle and equipment but also saved his money.

Partway through this process, he met his wife, Natalie, who shared his dream to farm. On Jan. 1, the couple began renting the farm from Eli’s dad, David, to set their dream in motion.

“We’ve been managing the farm for some time, but now it’s ofcial,” Eli said. “The nances changed hands, but decisionwise, I’ve been making those for a long time with my dad and sister.”

Taking over the nances and management of the farm, Eli and Natalie rent the equipment, buildings and land. They farm with Eli’s sister, Aimee Moehring, who owns two-thirds of the herd but does not rent any portion of the farm. Eli and Natalie

own the remainder of the herd. Their dad is on the farm full time but has let his children take control of day-to-day operations.

The family milks 85 cows and farms 250 acres near Sheboygan Falls. Cows are milked twice a day in a 37-stall stanchion barn and switched multiple times. The herd contains Holstein, Red and White Holstein, Jersey and Lineback breeds.

The Wilterdinks also raise beef crossbred cattle and sell beef to consumers.

Eli is the third generation on the farm his grandpa bought in 1956.

“We saved up money for quite a while in order to start renting,” Eli said.

Eli and his dad have been buying equipment together since Eli was 18.

“I slowly accumulated equipment for the past 10 years, and that was part of the process to get to where we are now,” Eli said.

The Wilterdinks set up a limited liability company last summer in preparation and had conversations with an accountant.

“We saved up as much money as we could, but it took a lot more than we thought it would to start,” Eli said. “We don’t have any debt, and I’m glad we

started out farming that way. Dad wanted to do this earlier versus some people who hold on for too long. He said whoever is doing the work should have the farm.”

Natalie started full time on the farm April 1, 2023. She can be found primarily in the barn.

“I’ve always worked with cows,” Natalie said.

Natalie has worked on various dairy farms. Previously, she spent seven years at Hickory Lawn Farm where she was a herdsman’s assistant. Here she met Eli, who volunteered to help with the farm’s robotic milking startup in 2019.

“Farming always found Natalie,” Eli said. “Then, she met a farmer.”

Natalie has milked in all kinds of setups and brings experience of various milking styles with her. Milking in a stanchion barn once again, Natalie has come full circle with milking methods.

Remote Monitoring Made Easy

Advanced Dairy Spring Valley, WI; Mondovi, WI; West Salem, WI; Mora, MN; Pierz, MN; Wadena, MN; St Charles, MN

Central Ag Supply Juneau, WI; Baraboo, WI

J. Gile Dairy Equipment, Inc. Cuba City, WI

Redeker Dairy Equipment Brandon, WI

Stanley Schmitz Inc. Chilton, WI

Paul Mueller Company’s MAXXimizer® L-40 package chiller has plugand-play design and cloud connectivity, so you benefit from remote, real-time access to your refrigeration system data and chilled milk temperature. 1-800-MUELLER

from Parlor to Processor…

Tri-County Dairy Supply Janesville, WI

Fuller’s Milker Center Lancaster, WI; Richland Center, WI

Eastern Iowa Dairy Systems Epworth, IA

Sioux Dairy Equipment Rock Valley, IA; Colton, SD

United Dairy Systems West Union, IA; Monticello, IA

Gorter’s Clay & Dairy Equipment Pipestone, MN

Leedstone Melrose, MN; Glencoe, MN; Plainview, MN; Menomonie, WI

Monroe Westfalia Surge Monroe, WI

Lely Center Monroe Monroe, WI

Total Dairy Service Kewaunee, WI

Midwest Livestock Systems Zumbrota, MN; Renner, SD; Menomonie, WI; Kaukauna, WI; Weston, WI

“I’ve learned a lot here and have learned more about managing than just doing jobs,” Natalie said. “I’ve learned why we do things a certain way. For example, Aimee has been teaching me why and how we treat cows and what to watch for or different ways that a cow might show she is in heat. Communication is key, and Aimee answers any question I have.”

Eli and Natalie are at the helm of a farm managed by a family with a give-and-take attitude that works together each day toward a similar set of goals.

“We have open communication here,” Eli said. “You have to be lenient with what everyone wants. Each person has to be happy with what you come up with.”

This will be the rst year Eli is trying winter rye for forage.

“We’re changing up cropping a little and experimenting in that area,” he said. “I’ve been taking care of crops for about eight years.”

Eli’s freedom to make decisions helped make for a seamless transition.

“Dad let me make a lot of decisions beforehand, and that helped with the transition,” Eli said. “Aimee has been making all the decisions with the cows for 20 years. Dad allowed us to make decisions and mistakes, which was really important.”

Eli said their goal is to improve the land and the cows but not necessarily to grow in size.

Building a heifer barn and a milking parlor are ideas he is considering.

The Wilterdinks switched to a compost bedding pack in

2008, which Eli said was a benet to cow comfort.

“It was a big improvement over the open cow yard we had before,” he said. “Cows last a lot longer than they used to. We have quite a few older cows in the herd, including one that is 13. Many make it past 8 years old.”

Having Natalie on the farm has been a help to the family, Eli said.

“We have more people on the farm now, and it’s given us more exibility with our schedule,” he said. “With Natalie on the milking crew, it frees a lot of time.”

Eli said the schedule has also been positive for Natalie, who has epilepsy.

“She gets seizures, but a consistent sleep schedule and

more time to relax has helped reduce those,” Eli said. “She doesn’t have to drive to work in the morning, which is better for her. This new arrangement is good for all of us.”

Eli and Natalie are enjoying the journey thus far and looking forward to what the future brings.

“We want to raise a family on the farm,” Eli said.

The young couple named the farm NEW Family Farm, an acronym for Natalie Eli Wilterdink.

“We plan to purchase the farm eventually, but there is no plan in place for that yet,” Eli said. “We’ve talked about doing some type of land contract, but we’re going to get through this rst year rst.”

Natalie Wilterdink dips a cow March 20 a er milking on the farm she and her husband, Eli, rent near Sheboygan Falls, Wisconsin. Wilterdink began working on the farm full me April 1, 2023.

Encouraging engagement

Clark County Holstein Breeders Association hosts competition

By Danielle Nauman danielle.n@dairystar.comMERRILLAN, Wis. —

With a desire to increase engagement in activities of the Clark County Holstein Breeders Association, Joe Meyer took a page from the book of his Canadian counterparts and spearheaded a herd competition for Holstein breeders.

“Our association is getting smaller as time goes on,” Meyer said. “To continue to keep that smaller membership engaged, increasing opportunities for involvement is vital.”

Meyer operates Badger Holsteins near Unity alongside his family.

Meyer became aware of several counties in Ontario that hosted on-farm herd competitions. That ignited an idea for Meyer. He began setting the wheels in motion to hold the county’s rstever Breeders Cup competition.

Members of the organization were invited to make a single entry in each of three classes of cows — rst lactation, second lactation and three or more lactations — for an entry fee of $10 per cow.

The rules stipulated that the cow must be owned by a member of the association and be

bred and housed within Clark County. Cows were not to have been exhibited at any show during 2023. Placings were based on conformation.

“There are a lot of good cows that never leave the farm for a variety of reasons,” Meyer said. “They deserve to be recognized, and their breeders deserve the recognition for those cows as well.”

The announcement of the contest caught the eye of Roger Turner, global sales and genetic manager of Jetstream Genetics, prompting the company to sponsor the contest.

“I’ve judged contests like this in Australia and nd them to be great things for the breeders who take part,” Turner said. “In every aspect, from encouraging participation in the local organization and keeping it vital to recognizing great cows, it’s a positive experience.”

Six breeders entered 14 cows in the inaugural contest. Participants included Badger Holsteins of Unity; Hornland Farms, Jeremiah Hagen and Kaiser Farms, all of Loyal; Echowood Holsteins of Neillsville; and SelzPralle Dairy of Humbird.

The judging took place Feb.

7. The Clark County Holstein Breeders Association invited fellow Wisconsin Holstein breeder

Mark Rueth, of Rosedale Genetics in Oxford, to evaluate their cows.

Rueth traveled to central Wisconsin and spent the day visiting the ve farms, evaluating the entrants. Although he was familiar with the competitions held in Ontario and abroad, Rueth said he had never been involved with one himself.

An accomplished dairy cattle breeder and judge, Rueth put a great deal of thought into

The World’s Best TMR Processor

approaching his rst experience judging a herd competition.

“I took a lot of notes about each cow — what I liked about her, what I might change about her — and took photos of each cow with my phone to help jog my memory,” Rueth said. “It’s been a great experience, judging the cows like this.”