WANT TO WIN $100 CASH?

See page 4 of second section for details!

See page 4 of second section for details!

Volume 25, No. 5

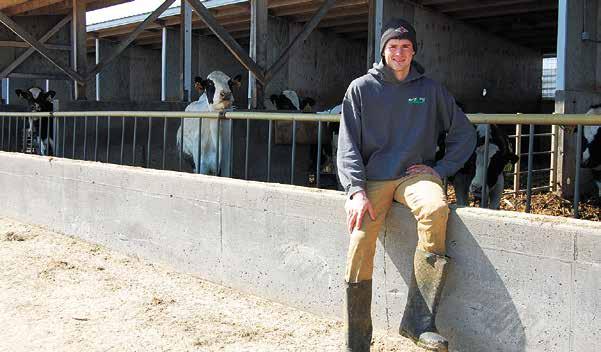

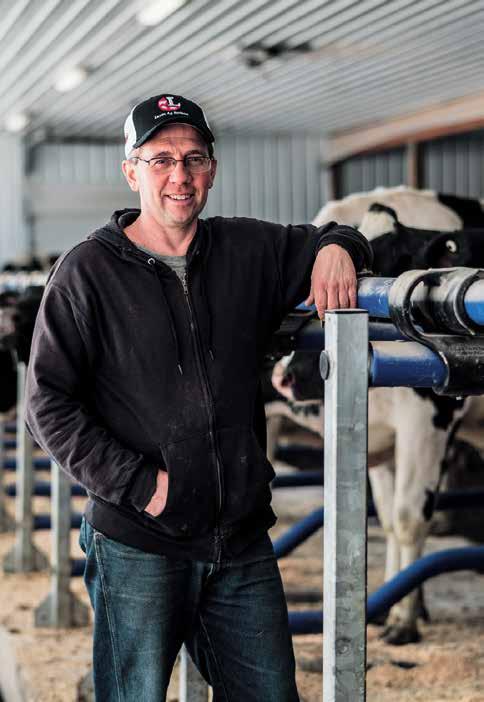

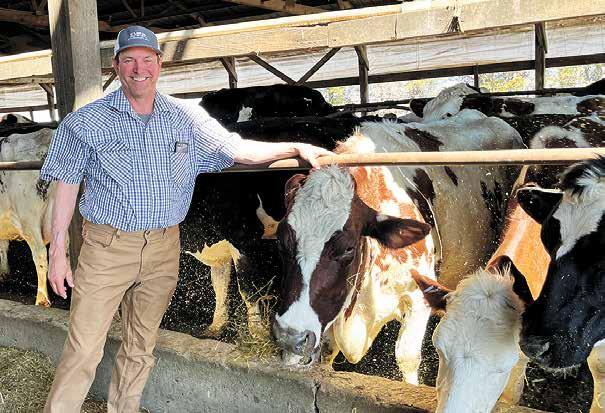

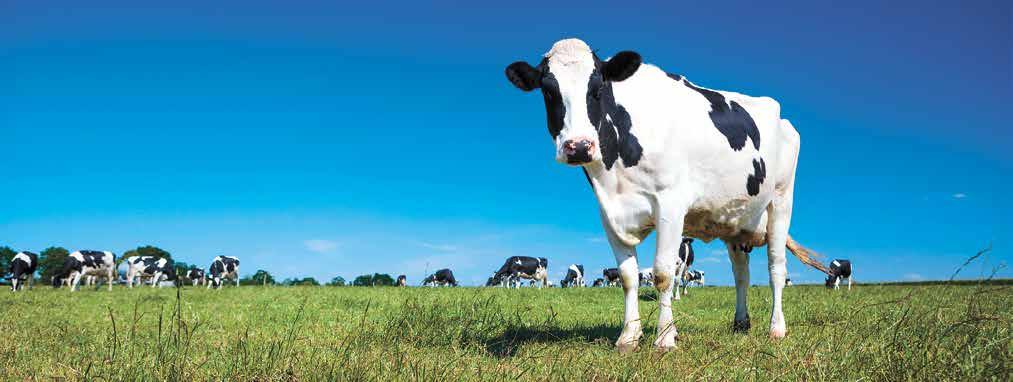

FARLEY, Iowa – The dairy where Virgil and Alvina Murphy, and later their son, Dan, and his wife, Christine, have farmed operates a little differently since the third generation came home from college. Gone are the herd bulls, hot iron dehorning and the old calf barn. Now, 25-yearold Owen Murphy, Dan and Christine’s son, is in charge of the cows, calves and breeding.

Owen’s return also relieves a good deal of the stress Dan had as the manager on the 200cow farm with 400 owned and 80 rented acres near Farley.

While Owen handles the animals, Dan manages the eldwork and does the feeding.

But, it remains a joint effort in many ways.

“I don’t bother with the stuff he’s in charge of, but we meet with the nutritionist together because that way we both hear the same thing,” Dan said.

The two men said they get along ne despite the new approaches Owen brought home with him after graduation from the University of WisconsinPlatteville in 2019.

Owen takes care of morning milking in the farm’s parabone double-8 parlor. Cows are milked and housed in free stalls with rubber mats and chopped straw.

One of the rst changes Owen made as he stepped in was a switch to A.I. The Murphys usually kept ve or six bulls on hand for breeding. That was not Owen’s preference.

“Two of those were breeding and three of them were usually hurt,” Owen said.

Plus, upon returning home a month before graduation, Owen was chased by a bull

with its head down and in an aggressive manner.

“That freaked me out,” he said.

So last winter, Owen

switched to A.I. but not without discomfort.

“It was denitely scary, going to preg check and not having any idea how things

April 22, 2023

would turn out,” Owen said. “Dad had a few sleepless nights.”

By Jan Lefebvre jan.l@star-pub.com

By Jan Lefebvre jan.l@star-pub.com

As a child growing up on a dairy farm in the 1970s and ‘80s, Minnesota Sen. Torrey Westrom helped his dad with morning chores before the school bus arrived. As his dad milked, Westrom fed the cows while his brother fed calves and youngstock.

“My brother and I would have to get up and do our part of the chores in enough time to get into the house, shower and get ready for school, and there were some mornings where that got cut pretty close,” Westrom said. “We knew we

were really short on time when we were running to the house and the bus was going past our house to pick up the neighbors beyond and then come back again to pick us up.”

Now, from his perspective as a senator, Westrom said he holds farmers in high regard.

“In the winter months especially, when it’s 20 below and blowing snow, an ofce job looks a lot nicer than out feeding cattle and milking cows,” Westrom said. “I have that great respect for any livestock farmer because it’s tough, it’s cold, it’s brutal, and it’s not always fun.”

Westrom said experiences he gained on the farm and in FFA prepared him for both

campaigning and legislative work.

“That gave me some core strengths that I can still use in the Senate and the Legislature,” Westrom said. “Parliamentary procedure, public speaking and salesmanship were all some competitions I was in for FFA, and I still use those skills today.”

Westrom’s family rst dairy farmed southwest of Willmar before moving in the early 1980s to the farm on which Westrom’s dad grew up near Elbow Lake. They milked anywhere from 30 to 50 Holsteins in a tiestall barn with a step saver and buckets.

“It was right at the era of needing to go to pipelines or a parlor or get out,” Westrom said.

“All dairy, all the time”™

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce)

320-248-3196 (cell)

320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Editorial Staff

Tiffany Klaphake - Assistant Editor

320-352-6303 • tiffany.k@dairystar.com

Maria Bichler - Assistant Editor

maria.b@dairystar.com • 320-352-6303

Danielle Nauman - Staff Writer

608-487-1101 • danielle.n@dairystar.com

Stacey Smart - Staff Writer

262-442-6666 • stacey.s@dairystar.com

Abby Wiedmeyer - Staff Writer

608-487-4812 • abby.w@dairystar.com

Grace Jeurissen - Staff Writer

320-352-6303 • grace.j@star-pub.com

Jan Lefebvre - Staff Writer

320-290-5980 • jan.l@star-pub.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Consultant

Jerry Jennissen 320-346-2292

Main Ofce: 320-352-6303

Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication

Sales Manager - Joyce Frericks

320-352-6303 • joyce@dairystar.com

Mark Klaphake (Western MN)

320-352-6303 (ofce) 320-248-3196 (cell)

Laura Seljan (National Advertising, SE MN)

507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com

Jerry Nelson (SW MN, NW Iowa, South Dakota)

605-690-6260 • jerry.n@dairystar.com

Mike Schafer (Central, South Central MN)

320-894-7825 • mike.s@dairystar.com

Amanda Hoeer (Eastern Iowa, Southwest Wisconsin)

320-250-2884 • amanda.h@dairystar.com

Megan Stuessel (Western Wisconsin)

608-387-1202 • megan.s@dairystar.com

Kati Kindschuh (Northeast WI and Upper MI)

920-979-5284 • kati.k@dairystar.com

Julia Mullenbach (Southeast MN and Northeast IA)

507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell) bob.l@star-pub.com

The dairy market remains wary about the spring ush and the destination for that volume of milk. In the Midwest, a lot of that milk supply ends up in a cheese vat. “The good news is the consumer has been relatively resilient,” said Mike North, principal, Ever.Ag. “Cheese production has been very elevated, but the buildup of inventory has not followed its seasonal norm; we’re actually keeping the inventory static or even depleting it a little bit depending on what category you’re looking at.” Nearby Class III prices have been in the $18 per hundredweight range, while deferred contracts are in the $19 territory. “When we lay that against feed prices right now, none of those prices are exciting, and what we’re going to need is some sort of relief on feed costs or an ongoing push in the milk market to carry those margins higher,” North said.

USDA considering FMMO petition

Federal order reform should go beyond ‘make allowances’

The American Dairy Coalition is asking Agriculture Secretary Tom Vilsack to deny the FMMO hearing petitions made by two dairy processor groups. ADC CEO Laurie Fischer said federal order reform is needed, but these petitions focus exclusively on “make allowances.”

“We do not support ‘make allowance’ updates based on processors having the ability to voluntarily participate in the cost surveys which undoubtedly would exclude essential relevant data,” Fischer said. “Farmers need transparency in order to understand how their net payment is calculated, and these ‘make allowances’ are not line items; they are embedded in pricing formulas.”

Farm bill politics

Ag Insider

TRACTORS

5525, FWA, cab, w/542 JD ldr & bkt, 6,100 hrs .. $39,000

JD 5065E, FWA, cab, w/loader & bucket, SS mount. $51,000

Allis Chalmers 180, gas................................................. $4,900

‘13 MF 8670, FWA, w/1,699 hrs. 2013 ................... $164,000

Massey Ferguson 20 Industrial, gas, 2WD

w/Lloader & Bucket ................................................ Coming In

COMBINES

Gleaner 9250-35 Draper Head....................... $37,000

‘09 Gleaner 8200-35 Flex Head w/Orbit Reel ...... $18,000

Gleaner 8200-35 Flex Head w/Crary Air Reel... Coming In

Gleaner 8200-30 Flex Head w/Crary Air Reel... Coming In

‘05 Harvestec 4306C 6 Row 30” Cutter Corn Head, Gleaner Mounts .................................................. $17,500

‘00 Geringhoff Rd630 Corn Head, Consigned, Gleaner Mounts .................................................. $14,000

Gleaner 313 Pick-Up Header .................................. $3,500

SKIDS, TRACK LOADERS, TELE-HANDLERS, & EXCAVATORS

‘07 Bobcat S185 Skid Steer, Cab, 4900 Hrs .... Coming In

‘14 Bobcat S570 Skid Steer, Cab, w/5,100 Hrs, H/F Control, 2 Sp. ............................................ Coming In

‘15 Bobcat S590, Skid Steer, 2330 Hrs, Single Spd........................................................ Coming In

Bobcat T595 Track Loader, Cab, Hvac, 1500 Hrs, H/F Control 2sp................................................... $46,000

‘16 Bobcat T770 Track Loader, Cab, Hvac, 3,000 Hrs, H/F Controls, Track Sus...................................... $45,000

Mustang 2032 Skid Steer, 3000 Hrs, 1-Owner, H/F Controls ..................................................... Coming In

‘14 NH L218 Skid Steer, H/F Ctrls, Single Spd, Cab Heat........................................................... Coming In

TILLAGE/FIELD CULTIVATORS

CIH 335 VT 25’ Vertical Tillage True Tandem ...... $51,000

WOTUS override vetoed

President Joe Biden delivered a veto rejecting a congressional effort that would have overturned the Waters of the United States rule. In a statement, Biden said the attempt to block WOTUS would increase uncertainty and threaten agriculture’s economic growth. The House and Senate used the Congressional Review Act to invalidate the controversial EPA rule. WOTUS is also being reviewed in the courts, including the U.S. Supreme Court.

Seeking checkoff reform

A coalition of 131 farm and food groups have sent a letter to congressional leaders, calling for checkoff reform in the 2023 farm bill. The groups claim the checkoff programs have “well-documented histories of waste, conicts of interest, misuse of funding, anti-competitive behavior and other related issues.” The signatories on the letter include the Environmental Working Group, National Farmers Union, Center for Food Safety and the Land Stewardship Project.

Culled cow numbers increase

Since the beginning of 2023, nearly 805,000 U.S. dairy cows have been culled. That’s up 27,000 head, or 3.5%, from the same time period last year.

Texas explosion kills 18,000 cows

An explosion and re at Southfork Dairy near Dimmitt, Texas, resulted in the loss of 18,000 dairy cows and the hospitalization of one employee. The cause of the explosion is being investigated. “This was the deadliest barn re for cattle in Texas history and the investigation and cleanup may take some time,” Texas Agriculture Commissioner Sid Miller said. “There are lessons to be learned, and the impact of this re may inuence the immediate area and the industry itself. Once we know the cause and the facts surrounding this tragedy, we will make sure the public is fully informed so tragedies like this can be avoided in the future.”

A helping hand after the long winter

Minnesota’s Rural Finance Authority has declared an emergency for the entire state. This makes zero-interest

disaster recovery loans available for farmers who suffered property damage or livestock losses this year. Eligible farmers will be able to work with their local lenders to secure the RFA loans.

Canada is looking for farmers

A new report indicates Canada is facing a signicant shortage of farmers. The report was commissioned by the Royal Bank of Canada, the Boston Consulting Group Centre and the University of Guelph. It said more than 40% of Canadian farmers will retire over the next 10 years. A policy analyst cited inationary concerns, land affordability and succession planning as the big issues. Sixty-six percent of Canadian farmers do not have a succession plan in place.

Krause leads Midwest Dairy Association

Buffalo, Minnesota, dairy farmer Charles Krause is the new chair of the Midwest Dairy Association. Krause also serves on the United Dairy Industry Association board.

Dorn, McCullough added to WDE Board

World Dairy Expo has welcomed Kami Dorn of the Wisconsin Guernsey Breeders’ Association and Annie McCullough of Farm Journal to its board.

Teacher receives ag literacy award Haley Madson is the Minnesota Agriculture in the Classroom Outstanding Teacher of the Year. Madson is a rst-grade teacher at St. Anne’s School in Le Sueur, Minnesota.

Trivia challenge

Gorgonzola is the popular blue cheese that originated in Italy. That answers our last trivia question. For this week’s trivia, what farm bill title represents the majority of the legislation’s nancial outlays? We will have the answer in our next edition of Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network, based in Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two adult sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

By 1986, his dad sold the dairy cows, but the family raised beef cattle and grew corn, alfalfa and soybeans.

“There was baling in summer,” Westrom said. “That’s a free exercise program. You don’t have to pay a gym membership for that.”

The Westroms stacked bales on a hay rack and unloaded them in a shed.

It was shortly after the cows had been sold that Westrom suffered a farmrelated car accident while he was coming back from checking a hayeld. The force of the accident caused a stroke in his optic nerve, which resulted in a complete loss of sight in both eyes.

“I went from 20/20 sight to zero,” said Westrom, who was 14 at the time.

About six weeks later, while recovering at home, Westrom’s dad needed help baling. Westrom was the only one at home.

“It wasn’t going to work well for me to drive the tractor, so my only option was to be on the hay rack,” Westrom said. “My dad said, ‘We’ll nd a way to make this work.’ Initially my job was to stand where the bale shoot was, get the bales pulled back until we had ve or six bunched up; then he’d stop and we’d stack them. That was my rst trip back to the hay rack.

Over the next few years, riding rack was my job and stacking the load.”

Westrom went back to doing other chores as well, guring out how to do things without sight.

“When you rst lose your sight, you’re not even familiar with where you would get a white cane,” Westrom said. “I remember the cane I initially used was a white cattle prod that happened to be long enough and actually worked pretty well because it was exible. If I ran into something, it wouldn’t break very easily.”

The routines of farm life helped.

“There was hay to bale and times when we had to feed the cattle, so I had to start learning my way around, which of course I knew because I had been in the barn most of my life, but it’s different when there’s always something sticking out or in the way … so it became a new challenge to make sure things were set up so I could nd them,” Westrom said.

Being able to adapt and work hard are lessons Westrom brought with him as an adult.

“Like life, you just transition with the skills you have and put in the hard work,” Westrom said. “If there’s one thing you learn on a dairy farm as an attribution for life, it’s hard work. The value of a hard day’s work is realized at the end of the day when you come in late for supper, get that shower and hit the bed, and you know you’ve done a day’s work.”

It was in college where Westrom’s career began to take shape. He was active with the young Republicans group that helped with county campaigns. The Republican party was looking for state candidates Westrom’s junior year.

“(I had) a growing interest by college for debate, problem solving and ultimately conservative, commonsense values that I didn’t always think were being exercised in government,” Westrom said. “As part of my education and interest in running for ofce someday, I decided to throw my hat in the ring.”

Westrom wanted to learn the process of getting on a ballot, whether it led to ofce or not. Five people vied for the spot, and he was not chosen to be the local candidate.

“It kind of put the bug in me, and the year after I graduated, they were looking for a Republican legislative

candidate in the area of Elbow Lake where I had moved back to.”

That was 1996, and at 23 years old, Westrom won the seat in the Minnesota House of Representatives with only 228 votes to spare.

“But again, the shoe leather, the hard work of door knocking all stems back to the hard work on a dairy farm,” he said. “We pounded the pavement and knocked on thousands and thousands of doors.”

Before knocking on doors, however, Westrom had to open an important one. Westrom needed an answer from the local party as to whether or not they would pay a driver to take him around the district for campaigning. The decision determined the cost for such assistance should not come from a candidate’s campaign budget.

“(That decision) is used yet today so that any assistance for a candidate who is disabled is not a campaign expense,” Westrom said. “That was one of the initial things I had to do to gure out how I could compete. It had not been a question posed or answered before.”

After serving several terms as a representative, Westrom was elected to the Minnesota Senate in 2012. He also served as the agricultural chair in the Senate from 2017 through 2022.

“One of the big things we looked at was the technology that has changed and improved dairy farming operations, but it’s expensive, so that’s always the trick,” Westrom said. “We helped open things up so that some of the (Rural Finance Authority) loans for beginning farmers could be used for technology and robots and doing anything to help promote innovative or new dairy facilities that might be more efcient and adaptive to technology.”

Westrom saw rsthand how technology could add quality of life to dairy farmers in 2021, when he and other legislators visited a dairy farm in Stearns County where they milked 120 cows with two robotic milking systems. A few months later, Westrom was at a middle school basketball game in Melrose where his son was playing. It was around 5:30 p.m., during halftime, when the referee came over to say hello. He was the same dairy farmer Westrom had met at the farm visit.

“I said, ‘Dennis, this is interesting because I know as a dairy farmer right now is about when you should be home milking cows, so this is pretty enlightening for me … You can be out doing a ref job – something you love and helping out the community,’” Westrom said.

It was a real-life example, Westrom said, of what technology could provide for dairy farmers.

“That technology is what is going to free up dairy farms and dairy farmers and the labor and really improve the life options that people have growing up and living on a dairy farm,” Westrom said. “Technology is something we can continue to embrace and nd ways to make it more affordable and adaptable for dairy farmers to help them stay strong into this century.”

Westrom’s family – wife, Anna, and their three children – recently had a scare when Westrom suffered another accident, this time being thrown from a snowmobile in February and suffering three broken ribs. He said he is almost healed and excited to be back to work, in part to keep advocating for dairy farmers.

“I appreciate being able to champion for farmers,” Westrom said. “My life experience puts me in a good spot to be a strong advocate for agriculture and the rural way of life.”

Along with the disappearance of the bulls, Owen began breeding heifers twice to sexed semen then to beef if not settled. The same protocol is applied to the top 20% of the herd. Everything else is bred to beef, reducing the number of replacements on the farm.

“We have half the number (of heifers) that we used to have,” Owen said.

His father was quick to agree.

“It’s a great thing,” Dan said.

The Murphys added CowManager tags to support heat detection under the new protocols. Owen averages two ser-

vices per conception now.

“I give minimal shots, … maybe one or two a week,” Owen said. “I don’t think we’re going to be giving shots forever. I think it can give dairy a black eye; the consumer doesn’t really want us to be doing that.”

With no headlocks on the farm, breeding is done in stalls. Owen said he thinks that contributes to calmer cows, although he hopes installing heifer headlocks will be the next investment.

Calf care has also undergone changes at the Murphys’. Last October, they installed a pasteurizer and bottle washer, saving money on milk replacer and improving calf health.

“The calves are doing so much better,” Owen said. “Getting milk at the same temperature every day with no bacteria makes a difference.”

Under Owen’s management, calf care also includes paste dehorning rather than the hot irons used previously.

Owen said the farm has been using 70% fewer drugs since the change in breeding and calf feeding.

Weaned calves have been moved from an older calf barn where manure had to be pitched manually. A year ago, the Murphys installed a pad with super hutches for post weaning. The calves stay in the super hutches for two months, then move to groups of eight in an open-front heifer barn, continuing to move through the system until 21 days before calving.

“Pitchforks are a thing of the past,” Dan said.

Dan agreed.

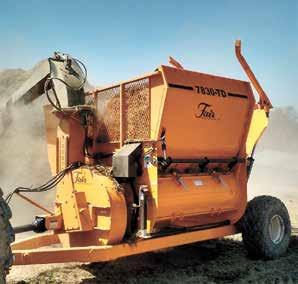

“You’ll get people to disagree when you say uprights are best,” he said. “But if it’s just us when we’re chopping, it’s easier, and we think the quality of the feed is better.”

Owen’s near-term goals include getting the rolling herd average higher, and by breeding for components, structure and longevity, he hopes to create a better-looking herd.

To Dan, Owen’s ideas have made sense, even if they are different from his previous practices.

“We just did things the way we always did,” Dan said. “It was kind of impressive what (Owen) said he had learned every time he came home (from college).”

Owen said some of what he learned was in class, but he also took many of his ideas from what other people were doing. And, he is pleased to be using his knowledge at home.

“A lot of people I graduated with didn’t come back to the farm,” Owen said. “I can’t even imagine that.”

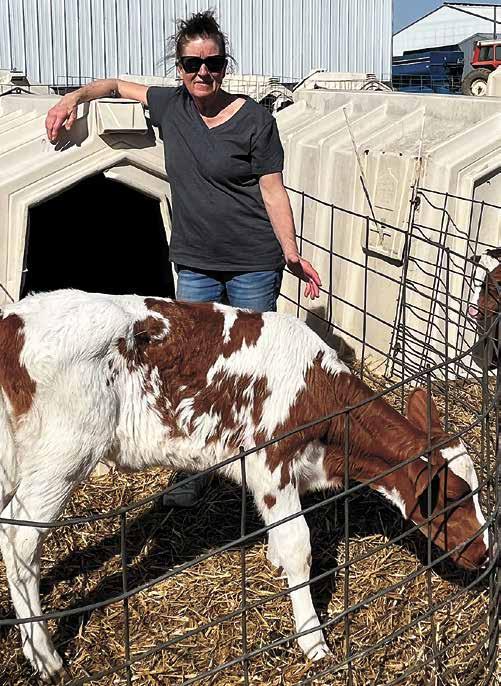

SHERRY NEWELL/DAIRY STAR

Dan Murphy and his son, Owen, stand together March 28 on their farm near Farley, Iowa. Owen returned to the dairy and began making herd management decisions a er college, while Dan con nued to manage crops and feeding.

Another thing on which father and son agreed is the upright storage of silage, a feedstuff they are using more of now and utilizing a vertical mixer.

“When you’re doing bags by yourself, you have to get on and off the tractor, make sure it’s packed right, and then if you leave for chores, everything stops,” Owen said.

By Danielle Nauman danielle.n@dairystar.com

By Danielle Nauman danielle.n@dairystar.com

Triplets are not typically an everyday occurrence on a dairy farm.

To have heifer calves, all born healthy and thriving, is an even more rare occurrence.

That is exactly what happened on two Wisconsin dairy farms in a 24-hour time period.

Triplet Brown Swiss heifers were born April 4 at the farm owned by Morgan and Sandy Long, where Nathan Campshure works as the herd manager, near Brillion, Wisconsin.

Campshure milks 105 cows in a tiestall barn with the Longs. Most of the herd consists of Holsteins.

Campshure and the Longs are in the planning stages of a farm transition. They purchased two Brown Swiss cows – including a cow named Skyler – from Campshure’s brother-in-law, Mitch Kappelman, who operates Meadow Brook Dairy in Manitowoc, Wisconsin, with his family.

“Skyler was my pick of Mitch’s 2-yearold group of Brown Swiss,” Campshure said. “He had her on shots to breed, so he bred her to Cozy Nook Doboy Tank before she came over to our place.”

calves rest together April 5 on Chris and Rikki Van Dyk’s dairy farm near New Richmond, Wisconsin. The Van Dyks milk 70 cows in a estall barn.

That service led to the triplets that were born earlier this month at the Longs’ farm. Campshure said he had no idea Skyler was carrying triplets.

“A time or two, I wondered if she could be carrying twins, but triplets never crossed my mind,” Campshure said. “As she got closer, I started to doubt that, because she was actually three days overdue when she calved.”

Campshure said that as Skyler began the early stages of labor, he left to go feed steers at a second farm. When he came back, rear feet of the rst calf had presented.

“I pulled that calf and checked to see if there was another,” Campshure said. “Sure enough, there was another set of rear feet coming, so I pulled

that calf. I checked once more and found front feet of the third calf.”

The third calf presented correctly, but Campshure said he had to work with her to get her breathing well.

“I had to rub and stimulate her chest, but once she got going, she was great,” Campshure said. “She was actually the rst one to get up on her feet.”

The triplets’ birth marks the beginning of Skyler’s second lactation, and Campshure said she has been doing well following the delivery.

“It took her a bit to clean, but she did,” he said. “When

she calved, I gave her warm water with dextrose in it, and I gave her IVs, polypropylene glycol and some rumen pills for a couple of days and nursed her along with some calf grain. But, she’s doing great now.”

The calves – which Campshure named Eins, Zwei and Drei – are doing well too.

“They were all around 70 to 80 pounds each,” he said. “They were all in their own placenta. I think that is why they were all so big and healt hy.”

milk 105 cows on the Longs’ farm in Calumet County near Brillion, Wisconsin. The Longs, who recently had one of their dairy herd deliver triplet calves, are in the early stages of developing a farm transi on plan with Campshure.

Campshure said naming the calves

One, Two and Three in German is a nod to the German dialect spoken in Switzerland, the native homeland of the Brown Swiss breed.

“I nally was able to attend World Dairy Expo for the rst time last year,” Campshure said. “I went with Mitch, and we watched the Brown Swiss show, and I was so impressed with it and loved the yodelers.”

The next morning, as the Brown Swiss triplets were awakening to their second day of life, a set of polled Red and White triplets was entering the world at West Croix Holsteins and Jerseys on the other side of the state in St. Croix County near New Richmond, Wisconsin.

West Croix Holsteins and Jerseys is owned by Chris and Rikki Van Dyk and their family. The Van Dyks milk 70 cows in a tiestall barn that was rebuilt following a barn re that the Van Dyks suffered in 2015.

“Our vet had conrmed that Nevalina was carrying twins,” said Chris Van Dyk. “I was a little surprised to nd three calves, and even more so when I realized they were all three heifers.”

Van Dyk said Nevalina had the calves by herself and was up and licking them when they discovered she had calved.

“Both Nevalina and the babies are all doing well so far,” Van Dyk said. “I gave her an IV right away to help prevent any problems and babied her for a

few days to help her recover. The calves all drank well right away. They are very active and spunky.”

Van Dyk called the calves Jerseysized and said they weighed between 40 and 50 pounds each. He said there were at least two separate placentas.

Making the three little redheads –named Nellie, Nessie and Nettie – even more special was Van Dyk’s discovery that all three were polled.

The calves are sired by AvantGarde-I Latenite. Nevalina is a VG-85 Siemers Oct Apple-Crisp-ET daughter. Her mother, A Newbeginning, was the rst calf born in the new barn after the barn re. The Van Dyk family has been working with that particular cow family for over 25 yea rs.

In all his years dairy farming, Van Dyk said his family has never had triplets born much less triplet heifer calves.

“My vet said she has seen several sets, but there is almost always at least one bull calf in the mix,” Van Dyk said. “I don’t ever recall there even being twins in that particular cow family.”

Van Dyk said following the birth, he became interested in how often triplets are born to dairy cows.

“According to Google, only about one in every 105,000 bovine births are triplets,” Van Dyk said. “I feel pretty lucky, especially that all three are red, polled heifers, and that everyone is healthy and doing well.”

remove

hair and it keeps the cows cleaner and our parlor

The brushes are also easy to repair if necessary. Cows love them.”

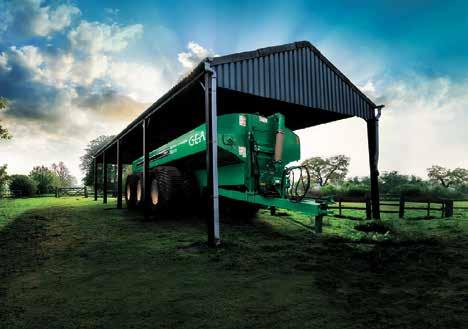

Your Mixer, Spreader, Hay Processor Headquarters

We carry:

Dana Berreau

507-879-3593 / 800-821-7092

Box 116, Lake Wilson, MN 56151

Teresa Hui did not grow up thinking of herself as an athlete. However, today at age 42, she is being featured in Milk Processor Education Program ads which spotlight women marathon runners.

“Through (MilkPEP), my biggest running dream came true: I was featured in “Runner’s World” magazine and appeared on a massive billboard in the heart of New York City,” Hui said. “I was overjoyed to bring my mom and husband to see it in person, and even my little sisters went to visit their big sister on the billboard by Penn Station, one of the busiest streets in the city.”

MilkPEP is funded by America’s dairy processors, which is governed by a nationally- represented processor board. MilkPEP is a consumer education program and the organization behind the Gonna Need Milk campaign – the 26.2 campaign is part of that campaign. The campaign aims to support and sponsor every woman running any marathon who signs up for #TeamMilk, but all current MilkPEP campaigns will feature women to boost attention on female athletes.

As part of the campaign, MilkPEP launched its Every Women Sponsored Fund in partnership with Girls on the Run International. Girls on the Run is an organization dedicated to empowering young girls through physical activity. For every woman who signs up for Team Milk, MilkPEP will pledge a donation to this fund with the goal of raising up to $1,000,000. This funding will enable the non-prot to enhance its curriculum to address the root causes of physical, social and emotional health inequities for girls and women.

“By actively supporting and empowering women, MilkPEP can play a crucial role in promoting gender equality and creating a more inclusive and equitable society,” said Yin Woon Rani, CEO for MilkPEP. “The pledge to feature only women across MilkPEP’s campaigns and partnership with

Girls on the Run is a step in the right direction to change the current narrative around women in sports.”

Only 5% of sports media coverage goes to women, Yin said.

“Over the past 30 years, there hasn’t been any signicant increase in women’s sports media coverage,” she said. “Everyone has a role to play in elevating the voices of women in sports.”

The campaign also celebrates the health benets of drinking milk.

“While this campaign focuses on women, dairy milk has performance and recovery benets for athletes and marathon runners, regardless of gender,” Yin said. “Not only does milk provide sustained energy to fuel your runs, the right 3:1 carb to protein ratio is ideal muscle refuel and recovery, and milk keeps you hydrated even better than water.”

For International Women’s Day, MilkPEP partnered with a diverse group of athletes, both current and retired, including Billie Jean King and Jordan Chiles. For 26.2 campaigns, female marathoners are specically highlighted.

Hui said she found out about the campaign from a fellow runner on Team Milk, Laurie Ann Sheppard.

“She knew how much I love running the New York City Marathon and that Marathon Sunday is my favorite day of the year,” Hui said. “She encouraged me to share my story with Milk, and it turned out to be a life-changing decision.”

After sponsoring women runners at the 2022 Marathon in New York City, MilkPEP will sponsor every woman running any marathon who signs up for Team Milk this year.

“The initiative will provide a spotlight for female runners’ journeys, along with female-centric training resources, nutritional advice, and mental and physical support from top sports experts,” Yin said. “(MilkPEP) aims to create a running community for women powered by women.”

The 26.2 campaign launched Nov. 6, 2022, at the New York City Marathon.

“When 26.2 launched in New York, over 3,500 women joining #TeamMilk … which raised an impressive $600,000 for Girls on the Run alone,” Yin said. “Women from 46 different states across the U.S. participated, showcasing the power of community and collective action.”

Hui is part of that community.

“When I started college, I decided to take up running as a way to lose weight,”

Hui said. “It was a tough challenge at rst. Running just half a block downhill left me out of breath and winded. But, I didn’t give up.”

She kept pushing herself, running a little further each time. Eventually, she was running miles.

“It was a major accomplishment for me, considering I used to think anyone who ran 2 miles a day was insane,” Hui said. “As I kept pushing myself, my mileage kept increasing until one Sunday I ran 18.54 miles on a long training run. My legs were sore, and I even got lost in a part of New Jersey I’d never heard of before.”

Hui ran her rst marathon, the NYC Marathon, in 2006.

“As I approached the last 3 miles of the race and saw the mile markers

in Central Park, I found myself crying tears,” Hui said. “It wasn’t because I was exhausted, but because I realized that the girl who once thought she could never run more than 2 miles was now nishing 26.2 miles in the largest marathon in the world.”

Besides now loving running and wanting to share her story through the campaign, Hui said she loves milk and feels good about promoting it.

“It was seriously the perfect campaign to be a part of and combined my favorite things in the world – marathons and milk,” Hui said. “When I was a kid, my grandma would take me to the bodega every week to get a half gallon of milk, and I would sometimes nish it so quickly she would have to go right back. We would go on long walks together and come back for a cold glass of milk. It hit the spot like nothing else. Today, I still drink milk to fuel my runs, and I look forward to my refreshing chocolate milk after a long run.”

Enthusiasm for running, the 26.2 campaign and drinking milk are helping to keep Hui in the race.

“Now that I’m 42, I’m a lot slower than I was when I was in my 20s, but I plan on continuing to run the New York City Marathon until I can no longer move my body,” Hui said. “I want to be that 100-year-old lady on the course that everyone cheers on. … And, after I take the subway back home from Central Park, there will be a glass of cold chocolate milk waiting for me to help my body recover.”

How many years have you been a director for DHIA?

We are grateful to dairy farmer Directors who share their time, their ideas, and their common sense to help keep DHIA services relevant. From time to time we will use this space to recognize these leaders and to say thank you.We will start with our current president, Dave Scapanski.He started as a local DHIA leader in Benton County, serving on the Board and as President.In 2002 Dave was elected to the Minnesota Board, and has been our President for the past 10 years.He was elected to the National DHIA Board 10 years ago as well, and currently serves as Treasurer there.

What are some of your duties as director? Making sure that we are nancially sound, competitive and ef cient. We work to keep DHIA affordable, accurate, and timely for management decisions for your farm.

What do you like about this role? As president of the board, I enjoy working with good board members who all give a lot of insight into the future of DHIA. Also working with Bruce and the staff make my role as president an easier job.

Why is DHIA important to you? DHIA is a very important management tool to us and our consultants for making good decisions. We use PCDART software to keep track of herd information on our farm. Nutritionists look at it monthly or more depending on ration changes. PCDART also works with our activity monitoring system. We are a big user of the milk pregnancy test. Preg tests are taken every test day and in between tests. It is a big labor saver. The somatic cell count list is watched closely. We either cull or treat high cows. The treated waste milk is pasteurized for calves.

Tell us a about your farm. The farm – Scapanski Farms LLC – is a partnership with my two sons, Chad and Brad. We are a diversi ed farm. In addition to the dairy herd, we raise all of our heifers, feed our steers and farm 1,100 acres for feed and to sell. We also do custom chopping, planting and combining.

Sauk Centre, MN Buffalo, MN 763.682.1091 www.mndhia.org

As I write this, a lot of family dairies have concern over how little National Milk Producers Federation and our processing plants care and do for the average small family dairy farm. Their focus seems to be more on the 1,000- to 10,000-cow factory farms and their ability to be sustainable and protable.

There is way too much concern over the FARM program and rewriting it every other year. They will soon make it impossible for the average family farm to survive. You will soon need a full-time employee to do all the paperwork involved to keep track of all the protocols and rules we now have to live with. If NMPF and our processing plants want to really help farmers, they would demand that our customers (Walmart and McDonald’s) and everyone else who seems to support so-called animal welfare pay for it.

They make millions off our products while dairy farmers can’t make our payments and build our business to the point we can bring the next generation into our business. It is wrong when family farms that have been around for generations can’t pay their family a living wage.

When we have nothing but huge mega dairies left that build their own milk plants and produce their own electricity and natural gas, the family farm will be gone. There will be no future for the next generation. How sad is it that the very farmers who built the dairy industry and helped build a strong country will no longer be able to afford to keep their way of life.

We shouldn’t have to hope for government program payments to make a decent living. Anyone who is a poor manager and abuses his animals won’t be in business long.

Think about it, please. Thank you.

Les Notz of Pelican Rapids, Minnesota

CIH

CIH 8950 1,600 hours ..........................$165,000

CIH 8910, 2WD, 4,100 hrs .........................$72,000

CIH 8920, FWA, 4,400 hrs. ....................$79,000

CIH 7240, 2,500 hours, coming in ...........$110,000

CIH 7230 Magnum, 5,000 hrs., sharp ....$85,000

CIH 7140, 5,900 hrs., FWA ....................$75,000

CIH 7120, FWA, 2800 hrs. .....................Coming In

CIH MX120 ............................................Coming In

IH 1466 restored, new 20.4x38 Firestones$38,000

IH 1456, cab ..............................................$22,000

IH 1086 w/no cab .......................................$18,000

IH 806 ....................................................$11,000

TILLAGE

CIH 527B ripper .....................................$13,500

CIH 6750, 4 shank, 3 twist w/lever.........$15,500

CIH 530B................................................$18,000

CIH 870 7-shank ....................................$38,000

CIH Tigermate II, 26’ ..............................$28,000

CIH Tigermate II, 26’ w/rolling basket ....$32,000

CIH Tigermate 200, 30’ ..........................$44,000

CIH Tigermate 200, 28’ w/rolling basket$40,000

CIH Tigermate 200, 32’, w/4 bar drag ....$33,000

CIH Tigermate 200, 32’ w/rolling basket$45,000

JD 714 11 shank chisel plow .................$14,000

CIH 5700 chisel plow, 23’ ...................Coming In

DMI 530 Ecolo-Tiger w/basket ...............$12,000

DMI 530 ripper w/leads..........................$14,000

CIH

$5,000

Many Sizes of Gravity Boxes ..................on Hand Brent 657 gravity box, green & black, fenders ................................................$23,000

(2) Brent 644 box .......................................$18,000

Brent 644 ...................................................$16,500

J&M 385 ......................................................$6,500

J&M 540 box .............................................$13,500

Parker 4800 box...........................................$8,500

Unverferth 7250 grain cart .........................$29,500

MISCELLANEOUS

New Red Devil & Agro Trend Snowblowers

Hagedorn 3290 Hydraspread spreader ..$36,000

USED SNOW BLOWERS

Schweis 8’................................................$1,000

By Tiffany Klaphake tiffany.k@dairystar.com

By Tiffany Klaphake tiffany.k@dairystar.com

– The smell of fresh cheesecake, crushed graham cracker and raspberry wafts in the air at Christine’s Cheesecake in Waite Park.

Over 30 varieties of cheesecake are set out at Christine Skoog’s display case for customers to bring home and enjoy on a daily basis.

“I have always made cheesecake for friends, family and potlucks,” Skoog said. “It’s always been a passion of mine.”

When Skoog rst started selling cheesecakes, she made them in a commercial kitchen and drove around in her minivan, stopping at various businesses to sell to the business or the people working there.

“I’m unique in this area because I only do cheesecake,” Skoog said. “When I rst opened, I had people ask me if I think I can sustain a business with only having cheesecake. I said, ‘If my cheesecake is re-

ally good, I can.’”

Skoog makes her creations in 9-inch and 19- by 11-inch pans. The larger pans are used to portion out mini cheesecakes.

Skoog buys cream cheese in 30-pound blocks and uses 15 pounds to make two sheetcake pans of cheesecake. The

oven at Skoog’s current location can hold six sheet-cake pans at one time. On days when Skoog bakes, she makes 18 sheet cakes or 20 9-inch round cheesecakes.

Skoog uses 360 pounds of cream cheese and a couple pallets of sugar every two weeks to craft her creations.

Making cheesecake was always a passion of Skoog’s but did not turn into a business until 2012. At the time, she was raising four children while working as a server at a restaurant. She offered to make the cheesecake for the staff Christmas party, which led to making cheesecake for the restaurant

itself.

“After a couple of months, they told me I really should start my own business,” Skoog said. “I said I didn’t know how to run a business, and they said, ‘You are a smart girl; you can gure it out.’”

The turning point for Skoog happened when she was waiting on one of the regular customers at the restaurant.

“I told her my dream as I did many other people,” Skoog said. “She just believed in me and wrote me a check to start my business. Dreams do come true.”

Skoog talked with her sister-in-law and came up with a name and color scheme. Skoog knew of a commercial kitchen available, and although it did not have a store front, it would work.

“Six weeks later, I was in full-edged business,” Skoog said. “God is great all the time; every stepping stone creates a path that guides us.”

Skoog has continued to pay back the woman who helped her, and just this month, she was able to write the nal check.

Skoog also likes paying it forward in her community. Later this spring, she will participate in a fundraiser to raise money for the Tanner’s Team Foundation.

Looking ahead, Skoog has lots of ideas, such as taking her cheesecake to the Minnesota State Fair, but she wants see the last of her children graduate from college rst and then hopes to expand to more locations.

“I would love to have many more of Christine’s Cheesecakes and for it to be all over the U.S., but that takes time,” Skoog said.

Turtle and white chocolate raspberry remain the best sellers at Christine’s Cheesecakes, but she has a list of over 200 types she can make. She uses the same recipe as her base that she used while she was growing up and baking with her mom and grandmother. Then, she uses various ingredients to make the avor combinations. Skoog said at rst it was a lot of trial and error, but now, it is much easier to create a new avor.

“Now that I am familiar with avors and different ingredients, I can get a pretty good idea what a avor will need,” Skoog said.

Special events such as weddings and showers as well as going to local fairs and festivals on top of the usual holidays keep Christine’s Cheesecakes busy year-round.

Skoog is not afraid to try something new and takes requests if there is a avor not on her list that a customer would like to have.

Chris�ne Skoog cuts into a 30-pound block of cream cheese April 12 in Waite Park, Minnesota. Skoog purchases 360 pounds of cream cheese every two weeks for her cheesecake business.

“I had a wedding one time that wanted black licorice cheesecake,” Skoog said. “I do not like black licorice, but they absolutely loved it and their whole family went crazy for it.”

Being a one-woman show, Skoog has learned how to run a business in the last 12 years. She has proven the skeptics wrong that it is possible to run a business selling only cheesecake.

“When you have a dream and it comes to fruition, it is just magical,” Skoog said. “It’s powerful.”

Art Stumpf Pierz, Minnesota Morrison County

Art Stumpf Pierz, Minnesota Morrison County

When did you start and nish your dairy career? I suppose I started my dairy career as soon as I could carry the stainless-steel surge bucket to the bulk tank, right about the age of 12. My wife, Jane, and I purchased the farm I was raised on from my parents soon after we married in 1975. Starting and ending our herd with around 50 head, we never found the need to expand our herd. After a 50-year career, in July 2017, all the dairy cows were sold. Although the barns are empty, save for a few cats and a dedicated but deaf dog, we still farm the land. Tell us about your farm when you milked cows. We had four children who helped greatly on the farm during many of those 42 years. In addition to working at the clinic in town, Jane also took over much of the calf feeding and care, and the kids helped with milking, feeding and eldwork. In the four decades of farming, there were many changes regarding our buildings, equipment and crop production. We moved away from grade Holstein to registered under the Grandair prex.

Who and when do you help on the farm? Since retiring from dairy, I’ve been helping some with eldwork with Kent and Stacy Happke and occasionally other neighbors.

What are some of your different duties? I do many different things including planting, tillage, rock picking, hauling liquid manure and chopping corn. During the haying season, I merge, chop and rake hay. While working for others, I don’t need to make decisions about what to plant, when and where. I don’t need to worry about the weather or planting conditions or the equipment. It’s freeing for sure.

What do you enjoy most about helping with eldwork? I enjoy harvesting a good crop no matter what it is. Listening to a Twins or local baseball game on the radio while operating in a modern tractor cab is always enjoyable. Most dairy farmers would say they have a preference for either the eldwork or the animal husbandry part of farming. I always liked the animal side of farming: the cows, the calving, and the feeling of accomplishment when everyone is fed, clean, healthy and happy at least for a little while. I do miss the smells of a stall barn and the aroma of fermented forage and grain.

What has been your best experience helping or your favorite time of year to help and your role within that? Any time during the growing season is enjoyable. What is a piece of equipment you operate now that you wish you had for your dairy career? After seeing a milking parlor in operation, that would have been a huge labor saver during my 50 years of milking cows. We always ran four units, just enough to keep one person busy for the entire milking.

When you look at the current state of the dairy industry, what are your thoughts and concerns? It seems technology is always changing the dairy industry, allowing the size of dairy operations to increase as well as the knowledge and skills of the operators. I see no change to that. It’s been interesting to see the increase of different so-called milk on the grocery store shelves: almond milk, cashew milk and oat milk, etc. I feel actual milk products will always be an essential part of the human diet.

What do you do in your spare time? I’m nding more time to visit grandchildren with some living in Minnesota, Wisconsin and Arkansas. I am also learning to relax at our lake cabin and have even started to nd my way around the kitchen thanks to the patience of my wife. I have more time for deer hunting and winter shing. I get to watch my grandson play baseball and basketball. Even though I’m not waking up at 4 a.m. every day to milk cows, I enjoy a good nap. Jane and I enjoy nding good, small-town restaurants and micro-breweries. We’ve always had horses, so we get to spend more time camping with our horses in state parks in the spring and fall. I’m always up for a game of cribbage or cornhole.

Arnold Keranen Wolf Lake, Minnesota Becker County

Arnold Keranen Wolf Lake, Minnesota Becker County

When did you start and nish your dairy career? I started Oct. 1, 1971, and we nished Oct. 1, 2001. It just happened to be the same date that I started and nished.

Tell us about your farm when you milked cows. My dad gave me 17 heifers, then I added 10 more on and increased it up to 60 on my own place. Then, I bought a different dairy with a double-6 parlor and more land, and we milked 180 cows. When I quit, I had 130 cows. A farmer from Denver, Colorado, bought all my cows. The heifers and calves were sold at an auction. I got stuck in a roller mill and had a hand injury and lost some ngers in 2000. That prompted me to quit. The prices were bad as well. My wife, Cynthia, and I have 13 kids, and they all helped on the farm.

Who and when do you help on the farm? I help my two sons, Andrew and Darren, on their farms. Their farms are 6 miles and one-quarter mile away, respectively. It is nice they are close.

What are some of your different duties? I do mechanical work, parts run, haul liquid manure, chop corn, rake hay, and do some spring and fall eldwork. I haul hay. I drive a lot of truck for them. In the spring, summer and fall, I am busy pretty much every day. In the winter, I usually have something I can help them with in the shop. I used to do all my own mechanical work. I taught my boys how to x a lot of their equipment.

What do you enjoy most about helping with eldwork? I like corn chopping; that’s the best. There are ve farmers who own the choppers and trucks, and we chop everybody’s corn. We go from place to place. It’s fun. I drive truck for the boys. I usually get started around 1 p.m. and go until dark. I like driving during the day and don’t like driving at night. Most of the time, they have to go milk cows when it’s dark anyway.

What has been your best experience helping or your favorite time of year to help and your role within that? Chopping is so fun. We have a good bunch of guys there. They are fun to work with. We stop for supper, and there is a lot of joking and laughing. It’s just a fun time. We have a lot of fun, but we get a lot of work done as well.

What is a piece of equipment you operate now that you wish you had for your dairy career? I would say the Discbine. I really like the Discbine. They are cheap to operate. You don’t have to monkey with changing sections on them. You can cut fast with them. My boys cut 200 acres in a day, and I just wonder how we are going to get it all up. But the next day, we put it all up. I get done raking about 7-8 p.m., and they nish up.

When you look at the current state of the dairy industry, what are your thoughts and concerns? When times are good, try not to spend too much because the lows are coming. It’s a very good place to raise a family. You teach kids how to work, and you have to reward the kids every once in a while with some fun.

What do you do in your spare time? I go visit the kids in four states. Every summer, my wife and I make the rounds to see all the kids. I can’t take more than 10 days off because I have to get home and see what the boys are up to.

Star Blends has been helping Midwest farm families by providing, high-quality feed, dairy nutrition, and commodity contracting for more than 20 years. Our state of the art mill can accuratelyblend anything from a custom pre-mix to complete feed, in balancing diets, or work with your private nutritionist or dairy consultant.

When did you start and nish your dairy career? I started milking with my dad, Marinus, and my brother, Marvin, when I was 12 years old.

Tell us about your farm when you milked cows. Back when we started, we milked 30 cows with buckets in a 10-stall stanchion barn. We separated the cream and put it into cans. We stored the cream in a refrigerated cabinet that sprayed ice-cold water on the cans.

Who and when do you help on the farm? I work with our sons, Virgil and Glen, on our family’s 250-cow dairy farm. I help with the eldwork and milking.

What are some of your different duties? I plant all of our corn in the spring and run the silage chopper when we put up haylage and corn silage. I also haul manure. The boys handle all of the tillage.

What do you enjoy most about helping with eldwork? I really enjoy it when spring has come and you can smell the fresh air and the warming soil. I also like chopping silage because you get to see the rewards of your efforts. Plus, I like the smell of silage. What has been your best experience helping or your favorite time of year to help and your role within that? Harvest is my favorite time of year. The harvest varies from year to year, which helps keep things interesting. One memorable harvest took place in 1976, right after my brother and I had taken over from Dad. We had a severe drought that summer, and it was a real nail-biter to see if we would be able to get enough feed for our cows. It was rewarding for us when we got through it. What is a piece of equipment you operate now that you wish you had for your dairy career? I wish we had a skid loader when I was young. We pitched way too much manure by hand back then. We used to do everything with a fork or a shovel. When you look at the current state of the dairy industry, what are your thoughts and concerns? It’s concerning that the milk price uctuates much more than it used to; it can move a lot in a short period of time. I worry that the big dairies that are moving in are forcing smaller dairies out. This might make it harder for young people to get started in the dairy business.

What do you do in your spare time? My wife, Kathy, and I have been married for 50 years and have 14 grandchildren. We like to attend our grandkids’ school programs. We have also been doing some traveling. We have been to Branson, Missouri, and Washington, D.C., among other places. This summer, we will be going on a bus tour to Kentucky.

Jerry Suhr Kasson, Minnesota Dodge CountyWhen did you start and nish your dairy career? I started helping with daily chores at around 9 or 10 years old. I graduated from high school in 1965. At that time, our family purchased my uncle’s farm just down the road. We started milking on that farm soon after. Other than my time in the U.S. Air Force, I continued to farm. I moved onto that second farm in 1972, and I milked cows and farmed there until 1990 when our barn burned down.

Tell us about your farm when you milked cows. We actually used 10-gallon milk cans until the late 1970s on our home farm. We did have a bulk tank on the second farm when we purchased it. In later years, we installed pipeline milking systems at both locations. After the barn burned, I rented barns for 2.5 years before selling the cows in 1993. After that, my kids and I did relief milking, and later, I was then employed full time on a local dairy farm.

Who and when do you help on the farm? After I sold my cows, I did relief milking for a few different farms in the area. I then began working full time for Curt and Marsha Oeltjenbruns for four years before then going to Bob and Diane Eustice’s farm in 1998. Bob and Diane sold their dairy herd in 2009, but I continued my employment there doing a variety of things from eldwork to feeding to cleaning and fencing. They continued doing embryo transfers and having dispersal sales for a number of years as well. Now, they are raising beef cattle and crops. I still help

LeRoy Moscho St. Martin, Minnesota Stearns County

When did you start and nish your dairy career? I came home from the Army in July 1964, and I sold the cows to my son, Mike, and his wife, Lisa, Sept. 1, 2014, exactly 50 years. I knew every cow in the barn, and I picked out all the bulls and did all the breeding myself. I farmed there with my wife, Geri, and we had eight children.

Tell us about your farm when you milked cows. We milked 75 cows in a tiestall barn. We al-ways milked between 75-80 cows. We raised out our steers, and we farmed 350 acres when I retired. Our farm is a century farm, and Mike and Lisa are the fth generation on the farm. Who and when do you help on the farm? I help Mike. I am always there at 7 a.m. to help feed. I run the tractor and the mixer, and Mike runs the skid loader. Then, I do all the feeding. Some-times I bring cows to market, pick up parts and am a gopher for whatever they need on the farm.

What are some of your different duties? I mix feed and help with eldwork. I get the elds ready in the spring, and Mike does the planting. In the fall, I do all the tillage. I also haul ma-nure whenever I need to.

What do you enjoy most about helping with eldwork? I enjoy the quietness, the scenery and the new equipment. The tractors are so quiet and comfortable. A lot of times when the grand-kids were 3-5 years old, they would spend some time in the tractor with me. I really enjoyed that.

What has been your best experience helping or your favorite time of year to help and your role within that? I like helping haul boxes in the fall when we start combining and chopping, and I get to see what kind of crops we have. Last fall was a really good year in the eld. It was so nice.

What is a piece of equipment you operate now that you wish you had for your dairy career? I wish I would have had the mixer. We used to feed every commodity separately, and now, we put it in the mixer and feed it with a feed cart.

When you look at the current state of the dairy industry, what are your thoughts and concerns? The number of farms has really decreased. On the road I drive into Freeport, there are only four left. It used to be that everyone milked cows.

What do you do in your spare time? We spend quite a bit of time visiting our eight children and 16 grandchildren. The youngest is 3 months old in Duluth, Minnesota. We also love to go out to eat. We also like to take trips. We have been to Hawaii, Switzerland and Alaska and short trips around the area.

when I can.

What are some of your different duties? Now, it is mainly eldwork and fencing when needed. Prior to the dairy herd being sold, I milked, fed animals, cleaned, scraped, did eldwork and fenced – most any jobs that needed to be done on a dairy farm. One of my favorite things to do is the fencing. Not everyone likes to do that, but for some reason, I just really enjoy it.

What do you enjoy most about helping with eldwork? I really enjoy being outdoors. I enjoy doing any and all kinds of eldwork.

What has been your best experience helping or your favorite time of year to help and your role within that? I enjoy the harvest season whether it be hay and forage harvest during the summer or grain or corn silage in the fall. Being outside and seeing the changes in the seasons and seeing the outcome of what was planted makes the hard work worth it.

What is a piece of equipment you operate now that you wish you had for your dairy career? I remember cutting hay with a 7-foot sickle mower with a Farmall M that did not have live power. The modern mower conditioners could run circles around the way it was back then. Also, the modern climate-controlled cabs are much, much more comfortable.

When you look at the current state of the dairy industry, what are your thoughts and concerns? I remember when almost all of our neighbors milked cows. That has dramatically changed over the years. Some townships in Dodge County no longer have a single dairy farm. I am concerned about the rate at which we are losing dairy farms. What do you do in your spare time? I have four children. Two of my daughters live out of state. I enjoy traveling to visit them as well as spending time with my son and daughter who live here. I also enjoy road trips both far and just around here.

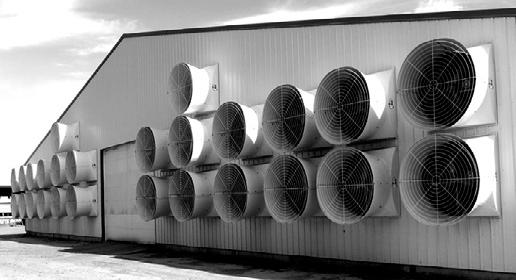

Describe your facilities and list your breeding management team. We have a crossventilated, 6-row robotic freestall barn with headlocks and a loose housing pole shed for the breeding age heifers. We have a small pen with a chute next to the heifer sheds.

Ben and I decide on the group of bulls we’re going to use with Ben doing most of the individual day-to-day breeding decisions. We use bulls from multiple studs.

What is your current pregnancy rate? It is usually around 35%.

What is your reproduction program? All the cows wear activity monitors and show up on the computer as a percentage of possible heat based on activity. Our voluntary waiting period is 70 days in milk. We use ovsynch on the cows that haven’t shown a heat by 90 DIM and cows that are conrmed open. All the heifers are caught in heat visually.

Describe your breeding philosophy. We’re trying to breed balanced cattle with good feet and legs and especially health traits and components. In more detail, we breed our virgin heif-

Steven and Julie Middendorf, and their son, Ben Sauk Centre, Minnesota | Stearns County | 200 cows

ers to sexed semen and about 25% of the top milking cows to sexed semen and the rest of the herd to beef bulls. We use mostly Angus and SimAngus.

What guidelines do you follow to reach the goals for your breeding program? Ben and I usually sit down and se-

lect a group of bulls that match our criteria and price. We usually do this after each proof run.

What are the top traits you look for in breeding your dairy herd and how has this changed since you started farming? Priorities certainly have changed over the years.

We’ve been selecting for high component bulls for the last 10 to 15 years, but since we went to the freestall barn, we’re watching feet and legs closer. With the robots, a few new Turn

“Udder Comfort™ is a product that has proven itself at our farm for at least 15 years. It is the one that works, so we make sure it’s always in the barn. My mom likes to rub it in and prefers the white lotion because it is thicker. When putting it on a hard quarter, it goes right down,” says Shelby Biasini. Shelby and Adele help their mom Debora milk 40 cows near Morrisville, Vermont. Their dad Stan makes the cheese. They show at Big E, Harrisburg, Madison and Louisville. During and after bagging, they use Udder Comfort.

“We also put Udder Comfort on udders and belly area daily for a week before calving and continue 2x/day as needed after calving. It takes edema out much faster than anything else,” she explains.

“Cows come into milk faster with softer udders. You can’t be random about it. Using it regularly, we don’t see mastitis issues, and our milk quality is always among the top herds in Vermont.

traits are being bred for like teat length, teat placement and milking speed.

What are certain traits you try to avoid? The traits we are avoiding are really short teats, close rear teat placement and slow milking speed. We also don’t like small cows, so we try to select bulls that are average size.

Describe the ideal cow for your herd. A 1,400-pound cow with a decent udder and feet and legs to handle the concrete. It’s a plus if they have a high IQ.

What role does genetics have in reaching the goals of your farm? We think genetics is very important, and we try to be diligent about the bulls we use. Everytime you breed a cow or heifer, there’s a good chance you’re getting a better cow than you have.

What percentage of your herd is bred to sexed, conventional and beef semen? We use sexed semen on all the heifers and the top 25% of the milking herd, and we use beef semen on the remaining of the milking herd.

The Middendorfs breed for teat length and placement as well as milking speed. They milk with three robo c milking systems.

What is your conception rate? How does this differ with different types of semen? Our conception rate is about 50%. In our experience, sexed semen settles as well as conventional Holstein semen, and beef semen lags behind just a little. That being said, we’re also breeding the harder settlers to beef semen.

What is the greatest lesson you have learned through your breeding program? My biggest lesson might be that

as much as I’ve tried to learn about breeding and genetics, my expertise is only scratching the surface of the vast array of information.

What is the age of your heifers at rst service? We aim for 15 months.

How does your heifer inventory affect your breeding program? Very little. We always seem to have enough heifers in the pens. We try not to raise extras because it’s too expensive.

Tell us about your farm. We have a 170-stall freestall barn with three robotic milking systems. Our son, Ben, is the herdsman and takes care of fetch cows, treating sick cows and most of the breeding. My wife, Julie, is the calf raiser, and I do most of the feeding and bedding and manure management. We have 500 acres of corn, alfalfa and soybeans.

.. $39,900

JD 2210 2010, 35.5 ft., 3-Section Folding, #559584 ...................... $40,000

Case IH TIGERMATE 200 2012, 60 ft., 5-Section Folding, #556196$45,900

JD 2210 2010, 57 ft., 5-Section Folding, #542886 ......................... $47,900

Case IH 200 2014, 60 ft., 5-Section Folding, #554255 ................... $52,500

JD 2210 LL 2014, 45.5 ft., 5-Section Folding, #559823 ................. $54,900

JD 2230FH 2021, 44 ft., 5-Section Folding, #554071................... $129,000

JD 2230 2019, 60.5 ft., 5-Section Folding, #558064 .................... $134,500

JD 2230 2019, 60.5 ft., 5-Section Folding, #558065 .................... $134,900

JD 2230 2022, 44 ft., 5-Section Folding, #559697 ....................... $151,000

JD 2230 2022, 60 ft., 5-Section Folding, #553589 ........................

PTO, 236 hrs., #547879 .... $89,700

JD 6430 2011, Cab, MFWD, 540/1000 PTO, 578 hrs., #549141 ........$89,900

JD 5115M 2022, Cab, MFWD, 540/1000 PTO, 48 hrs., #547523 ...... $98,300

JD 5115M 2022, Cab, MFWD, 540/1000 PTO, 4 hrs., #547343 ........ $98,300

JD 5125M 2022, Cab, MFWD, 540 PTO, 250 hrs., #273316 ........... $104,900

JD 5125R 2018, Cab, MFWD, 1000 PTO, 320 hrs., #559038 .......... $104,900

JD 5115R 2022, Cab, MFWD, 1000 PTO, 245 hrs., #547562 .......... $109,500

JD 6130M 2022, Cab, MFWD, 540/1000 PTO, 580 hrs., #554855 .. $134,900

JD 6130M 2022, Cab, MFWD, 540/1000 PTO, 169 hrs., #181603 .. $145,500

JD 6130M 2022, Cab, MFWD, 540/1000 PTO, 150 hrs., #273313 .. $148,500

JD 6120M 2021, Cab, MFWD w/ Suspension, 540/1000 PTO, 270 hrs., #272630 ........................................................................ $150,900

JD 6120M 2021, Cab, MFWD w/ Suspension, 540/1000 PTO, 150 hrs., #271072 ........................................................................ $152,200

JD 6120M 2022, Cab, MFWD w/ Suspension, 540/1000 PTO, 2 50 hrs., #273315 .......................................................................... $165,900

6120M 2022, Cab, MFWD w/ Suspension, 540/1000 PTO,

By Jan Lefebvre jan.l@star-pub.com

By Jan Lefebvre jan.l@star-pub.com

AURELIA, Iowa –

When David Fordyce graduated in 1977, two-thirds of his 46-member high school class chose careers in agriculture. However, he was the only one who picked dairy farming.

“It was an opportunity to do what my friends were doing, although they may have been raising pigs or beef cattle and I was milking cows,” Fordyce said. “Now this group is transitioning to slowing down. I’m looking to have more time to golf, go to meetings and spend time with family.”

Fordyce and his brother, Matt, own the last dairy farm in Buena Vista County in northwest Iowa where they milk 160 cows in a double-7 herringbone parlor. Most of their milk

is hauled 45 miles to the Dairy Farmers of America plant in Le Mars and the rest goes 43 miles to Associated Milk Producers Inc. in Sanborn.

The brothers’ site, near Aurelia, is also a crop farm. They grow 100 acres of alfalfa, 35 of oats seeded with alfalfa, 200 of corn and 60 of soybeans, which they roast themselves.

“We’re kind of self-sufcient,” Fordyce said. “We use up everything that we grow.”

Their herd consists of three-way crossbred cow –Holstein, Montbéliarde and Swedish Red. The Fordyces transitioned to crossbreds after discussions with Les Hanson from the University of Minnesota about his research with crossbred performance. The decision has worked well for the Fordyces, especially because of where they farm.

“We keep all females,” Fordyce said. “For a good percentage of the bulls, being they are cross-calves, we have cowcalf operators near us who want to buy them because they can put them on a beef cow, and they work really well.”

The brothers were willing to try new ideas throughout the years as the dairy industry in their area continued to change.

“There are 576 square miles in Buena Vista County, and 100 years ago, I think every section of land had at least one

dairy in it, so we may have had 800 to 1,000 dairies,” Fordyce said. “It was not out of the ordinary even in my lifetime to have another dairy one or two sections away.”

Eventually, those farms disappeared.

Fordyce and his brother

are the second generation to dairy farm at the site his parents bought over 60 years ago. They will be the last as well. Their children, as well as their nieces and nephews, have chosen other professions.

Wanting to slow down but not yet ready to give up the

dairy, the brothers looked for a solution. That is where Evan and Reena Hansen came in.

The Hansens had just begun launching a dairy operation when the coronavirus pandemic arrived. They had trouble getting anyone to come to the farm much less pick up their milk.

Turn

Summary: This proposal seeks to eliminate all undercutting in the marketplace by milk handlers and the resulting race to the bottom in farm milk pricing through “reblends”, “market adjustments”, pooling on distant Federal Milk Marketing Orders, and de-pooling. In return for this mandate on handlers, farmers will only supply the market with milk that is needed.

De nition of milk handler for this document: 1.Any party that is buying milk from any farm or collectively from a number of farms 2. Any party that is buying raw or un nished milk components that require additional processing before they are ready for retail from a dairy plant

This proposal will be implemented by the Federal Milk Marketing Order in which the milk is produced. If a milk handler is in a region not covered by a FMMO, rates will be set by the closest order to the plants location.

The Class I milk price will go back to the higher of the advanced Class 3 or Class 4 milk price.

All milk handlers shall pay all producers the Federal Order price on all milk components shipped by producer.

Any milk handler paying producers on a base price plus components are not allowed to deduct from components a higher rate than the federal order value of said component. The base price formula will be paid on 3.5% butter fat, 3.0% protein, and 5.6% other solids.

Make allowance for processors should be passed on to consumers and not deducted from farmers.

All milk handlers will pay federal order rates on milk or separated milk components purchased from any other milk handler. All separated milk component buyers will give 7 day notice to milk component sellers of an oversupply of component before lowering amounts of components purchased.

PPD must be paid at Federal Order rate. Handler may subtract any zone differential and fees charged by order.

All milk will be pooled in the Federal Order of where it was produced. No exceptions--Even on milk moved to and sold in an Order other than where it was produced.

Grade B milk shall be paid at Federal Order minimums with no PPD.

All milk handlers have the authority to balance their milk supply by disposing an equal percentage of milk on all of their farms. Farms will be noti ed by handler at least seven days prior to this action and at what percent of a baseline production needs to be reduced and for how long. Farmers must make this reduction by dumping (or not producing) raw milk at the farm. This milk may be used for animal feed or must be disposed of in a sanitary manner. Milk hauler will have the authority to release milk to accomplish desired production. Farmers are not allowed to turn off cooling tank and let milk separate and release only skim milk. Farmers lling directly into tankers will be responsible for the disposal of milk by obtaining scale or meter tickets when tanker is unloaded. Milk handler may let direct ship loads meet their disposal amount by extending the period for one week to allow for complications that may arise from not being able to be weighed on the farm.

Farmers’ milk production can be based off the previous month or the same month from the previous year in case of seasonal freshening, grazing or on farm event that signicantly lowered production for the previous month.

Dairy plants may allow for new producers and/or expansions as their market determine the need.

Milk hauling rates assessed by milk handler on producer will be assessed on a per hundred weight basis and may have a dollar amount cap per month. Hauling rates may not be used to discriminate against producers due to size or distance. Hauling rates may be adjusted from time to time due to increased cost of operating trucks. Hauling cost may not exceed actual cost by more than ten percent. Any hauling over charges must be refunded to producer as decided by the Order. Milk Marketing Order shall allow co-mingling of milk among handlers to make transportation as ef cient as possible.

Milk handler will notify Federal Order of this action so Federal Order may audit milk handlers’ farm records to ensure equal treatment of farms during their routine audits.

All milk handlers buying milk from another milk handler will give that milk handler a 45 day notice of changes to amount of milk they will accept during a Holiday schedule or a planned plant shut down.

In the event of an emergency plant shut down where milk cannot be processed and must be moved to another plant the Federal Order will oversee the transportation cost and may allow lower prices to be paid on this type distressed milk in the event that milk supply is long and milk is not needed at other plants.

“When they started their operation, they thought somebody would be interested, but suddenly the processors, the coops, didn’t want milk either,” Fordyce said. “Nobody wanted to take on more milk at the time, and it lasted for months. You just basically had to dump milk.”

The Hansens began looking for solutions.

The answer came for both the Fordyces and Hansens in a three-year, lease-to-own agreement for the Hansens to buy the Fordyces’ herd.

“We want to transition out of some of the normal day-today harvesting of milk and do more with managing while seeing this younger couple get a good start,” Fordyce said. “This is kind of a second chance for them.”

The three-year agreement suits both sides, but it does have unknowns, especially for the Hansens. Because they cannot roll into the milk contract the Fordyces have with AMPI, some things remain uncertain.

Evan said he realizes the ups and downs of the industry.

“My goal is to be able to continue dairy farming,” Evan said. “I know it sounds rough right now, but the dairy industry seems to be changing rapidly. Just in the few years that I have been involved, it went from the struggles with COVID-19, then to really no problem nding a market for milk to a real struggle to secure a milk contract.”

Reena said she sees advantages with their lease-to-own

agreement.

“The benet of being with Matt and Dave is being able to capture 90 years of dairy knowledge and experience,” Reena said. “Also, (we gain) the connections they have made and a way to get a herd of sound, crossbred cattle with good structure.”

Fordyce said the Hansens now take care of the majority of dairying on the farm while the brothers assist with feeding and take care of crop production. They all approach the future one day at a time because variables must be worked out as the answers become clearer.

“I’m not sure what will happen at the end of three years,” Fordyce said. “Evan and Reena don’t really have a milk contract right now, so if they decided to leave, they don’t really have any place where they can sell their milk to.”

However, there are signs the future is looking up for all parties involved.