By Abby Wiedmeyer abby.w@dairystar.com

By Abby Wiedmeyer abby.w@dairystar.com

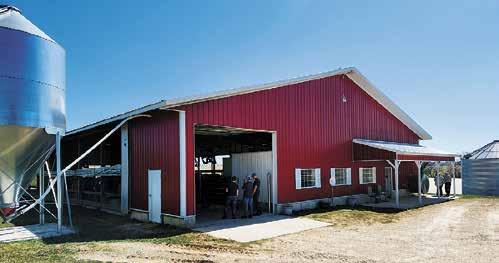

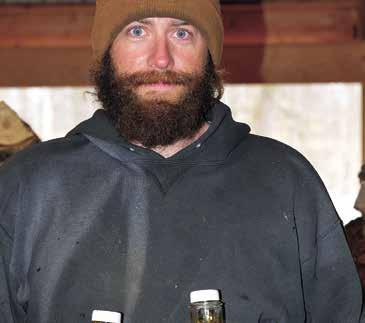

ARGYLE, Wis. – When Kevin Makos took over the farm from his dad, he knew he did not want to milk in a tiestall barn forever.

“We never wanted to expand to a big farm, and we never wanted employees,” Makos said. “When the robots came to my attention, it was the perfect t for me because now I can manage cows.”

Makos opened his farm to guests April 12 as part of a robotic tour hosted by Argall Dairy Systems. The tour also visited Voegeli farm near Monticello and Morton Farms near Evansville.

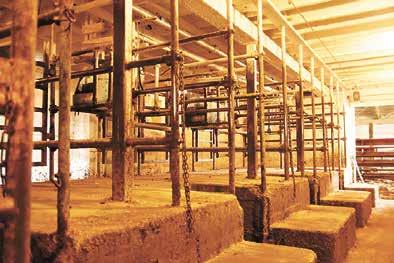

Makos milks 70 cows in a freestall barn with a Lely A5 robotic milking system. He bought the farm from his father in 2012 and installed his rst robot, a Lely A3, in 2014. When an upgrade became available in 2021, he took advantage of the cost discount and installed an A5.

The upgraded robot relies on electrical components in-

stead of air-driven parts, which results in a quieter system. There were also improvements made to the arm attachment which Makos said is more accurate.

Makos had close to 80 cows in the tiestall barn and downsized to milk 65-70 cows with the robot. He now averages between 100-105 pounds of milk per cow per day with an annual somatic cell count average of 150,000. Even with fewer cows, Makos is producing more milk than he ever did in the tie stalls.

The cows are milked an average of 3.1 times per day with the robot. Makos said it was an adjustment for the cows when they initially installed the robot, because the freestall system was new to the herd as well.

“The rst days can make you question a lot of things, but you have to just get through it,” Makos said. “This time of year, I start appreciating it more when there’s eldwork to be done, and I don’t have to be back here at a set schedule.”

Makos and his dad farm 275 acres. Cows are fed a total mixed ration with a high haylage diet. Feed is mixed once per day and fed by 8 a.m. Haylage, baleage, high-moisture shell corn, corn silage and mineral are fed in the ration, while

all the protein is fed through the robot while the cows are milked.

“When we rst started, our feed man came up with a pellet that he thought would work

with our feed,” Makos said. “We haven’t changed much since.”

The freestall barn is a 3-row barn with the robot on one end. Makos said he de-

cided to go with three rows because of the hill the barn sits on, and it was more cost effec-

tive to build longer instead of paying for more excavating. A special needs pen is right next to the robot for fresh or sick cows.

Makos said there are two things he wishes he could change with the layout. One is that he would have allowed more space in the area between the stalls and the robot, because right now, the area is easily congested.

The other change Makos suggests is to make the foot bath easier to utilize. His foot bath is on the far end of the barn, which he

said is inconvenient.

“I didn’t realize how big a deal hairy warts were going to be in a freestall barn,” Makos said. “If I had to do it over again, I would somehow design it so there’s a foot bath closer to the robot. Other than that, the rest of the barn I love.”

Makos said the cows eventually adapted to the design. He has had the best luck training fresh heifers. While every cow is

Turn

130-370 cu. ft. capacity

Two largest models will process whole round bales

Twin augers and nearly vertical sidewalls eliminate dead spots

All Stainless Steel mixing chamber for extremely long life

Input power options include electric motor or 540 PTO

“We never wanted to expand to a big farm, and we never wanted employees. When the robots came to my attention, it was the perfect t for me because now I can manage cows.”

KEVIN MAKOS, DAIRY FARMER

different, most animals are adapted within a month of freshening. Makos checks for fetch cows at 6 a.m. and 4 p.m., and any cow that has not been milked for 14 hours is sent to the robot.

“I’m not very good at just leaving them go,” Makos said. “I’d rather get her milked than take a chance on them not milking and getting mastitis.”

Free stalls are bedded with sand, which Makos said helps his SCC stay low and avoid having to treat cows. He said he maybe treats two to three cows for mastitis per year. When he does, he either treats them while they are in the robot, sorts them into the special needs pen or treats them in the freestall barn.

Then, he said, the important thing is to remember to update the computer so the robot knows to dispose of the milk.

“Make sure you do not leave the barn without entering that in,” Makos said. “I’ve caught myself walking out a few times.”

Makos also uses a Lely Juno feed pushing system and automatic barn scrapers. Manure is pushed into a twoday reception pit and then pumped to the main manure pit with a piston pump and underground plumbing.

“It’s been everything I wanted it for,” Makos said. “Between change in lifestyle and improved production, … it’s been more than worth the money and investment.”

By Amy Kyllo amy.k@star-pub.com

By Amy Kyllo amy.k@star-pub.com

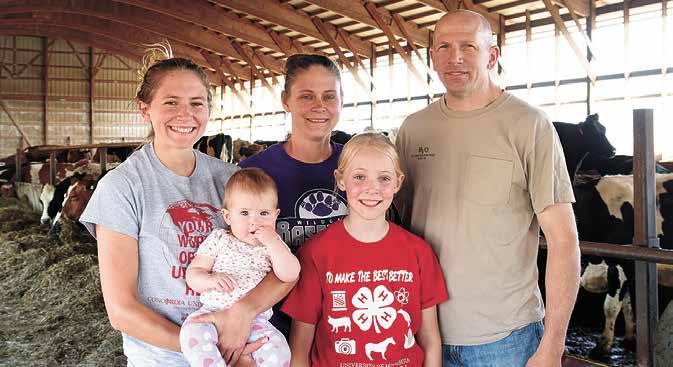

GOODHUE, Minn. – For Roger and Michelle Benrud, the variety and seasons on their dairy is part of what keeps them farming.

“I like not every day being the same,” Roger said.

The Benruds own an organic, semi-seasonal, grass-fed dairy with 115 cows near Goodhue.

“I do like the fact that we’re semi-seasonal because it does break things up a lot more,” Roger said.

Because of their calving scheme, the number

of cows they milk changes depending on the time of year.

Michelle said the rotating schedule welcomes slower seasons.

“When you’re only milking the half of them, it’s like, ‘Whoo, this is good,’” Michelle said.

However, when it is time for calves, Michelle is ready for them again.

As farmers on a grass-fed dairy, the seasons bring a level of variety to their daily work. Winter ushers the milking cows into the arched ceiling of the sawdust-compost barn where cows contentedly munch on bales spread outside their pen in the feed alley. Their heifers can be found outside grazing on bales in a sacrice pasture.

The Benruds transitioned to organic production in 2003. For Roger, it was a natural choice.

Con nued from BENRUDS | Page 6

“I always liked cattle on pasture,” he said.

During the summer, heifers and cows alike spend time amid the lush growth of the Benruds’ 180 acres of pasture. Cows eat meadow fescue, orchard grass and meadow brome. Pastures that need rejuvenation, perhaps after use for overwintering, bring further variety to the herd’s diet through annual crops such as sorghum sudan, oat, tillage radish and millet.

Their grazing ground is divided into large pastures which the Benruds subdivide twice a day for the milk cows for fresh grass. Subdividing versus more permanent fencing allows them to vary the grass area in correlation to their current cow numbers.

As grazers, one of their biggest focuses is feeding quality forage.

Though the Benruds have 60 acres of hay ground, they do buy forage for winter.

Michelle said Roger has a good eye for buying quality forage. Because they cannot use grain in their feed, they look for high-energy forage instead.

The Benruds said an important management aspect of their operation is using data and numbers such as Dairy Herd Improvement Association statistics to inform their decisions. Both of their college degrees – Roger in physics and Michelle in accounting and information systems – as-

sist in this.

“Numbers and spreadsheets and stuff, we do a lot of,” Michelle said.

After the Benruds married, they cash cropped with Roger’s sister for a few years. However, they wanted to nd a way to farm full time together, so they decided to dairy farm.

Their decision to graze was nancial-based. It provided a quick way to start dairy farming without many initial costs when they began on the farm in 2000.

Though Roger grew up on their current farm, the farm had not had dairy cows on it since the 1940s.

Because they did not own the land when they started farming, the couple decided to build an inexpensive parlor to mitigate investment in a property they did not own. They built a 14-stall step-up parlor.

Part of the Benruds’ persistence in farming was so their family could experience farm life. Roger said because both he and Michelle grew up on farms, they wanted to raise their kids on a farm too.

Today, the entire Benrud family is involved on the farm. Their youngest child, Clara, helps with calf chores and milking. Their son, Calvin, helps when needed.

The Benruds’

oldest daughter Emily, who lives across the road with her husband, Dylan Mollenhauer, and baby Caroline, helps as she is able. Dylan pitches in to help give Roger and Michelle an occasional date night.

Roger focuses on the equipment, crops and manure. Michelle works with pasture management and bookkeeping. Together, they work on the milking and calf chores.

Calf care is another major focus on their farm. With the seasonality of their farm, they calve from mid-March to midMay, and again from midAugust to mid-October. Each season, they keep 16 calves. They keep 30 heifers and two bull calves. They sell the remaining calves.

Calves are housed individually and fed using nipple feeders. Roger said having their calf facilities empty throughout some of the year helps with disease. The Benruds feed their calves 2 gallons of milk a day. They also buy high-energy, high-quality grass hay to feed to their calves. As 100% grass-fed dairy farmers, they are not allowed to give their calves grain.

The Benruds use their homegrown bulls as part of their breeding program. They breed their milking herd using A.I. for six weeks then use a bull for any remaining open cows. Because their heifers are on pasture that is difcult to access, they are exclusively bull bred.

When breeding, they always use two bulls. This helps as insurance against infertility and helps keep them safer.

“If you have multiple

bulls, they’ll ght with each other rather than picking on you,” Roger said.

As the Benruds continue in their operation, Roger said they are making decisions on what improvements could look like, including manure storage and free stalls.

The

do not know what the next season of their farm is as they consider the next generation.

“What we came up with when we talk in detail is, ‘Well, for now, we’re going to keep doing what we’re doing,’” Michelle said.

near Goodhue, Minnesota. One of the

Cows eat hay April 11 on the

main focuses is feeding their cows quality forage.

There’s more milk coming. The U.S. Department of Agriculture raised its 2023 U.S. milk production estimate in the April 11 World Agricultural Supply and Demand Estimates report, again citing a “larger expected cow inventory.”

Production and marketing were estimated at 228.7 billion and 227.6 billion pounds, respectively, up 200 million pounds on production from a month ago and 100 million pounds more on marketing. If realized, 2023 production would be up 2.2 billion pounds, or 0.97% from 2022.

“Fat basis imports for 2023 were primarily raised on the strength of a number of dairy products during rst quarter,” WASDE said. “Imports of casein and milk protein concentrates are expected to remain rm, supporting higher skim-solids basis imports through the year. Expectations of increased competition in butter, cheese, nonfat dry milk and whey markets were reected in lower forecast exports on both a fat- and a skim-solids basis for 2023.”

Cheese and butter price forecasts were raised. Nonfat dry milk was lowered. Whey prices were raised on recent prices and stronger expected demand.

Cheese was projected to average $1.8550 per pound in 2023, up 4.50 cents from last month’s estimate, but compares to $2.1122 in 2022, $1.6755 in 2021 and $1.9236 in 2020.

Butter was projected to average $2.42 per pound, up 8.50 cents from a month ago, and compares to $2.8665 in 2022, $1.7325 in 2021 and $1.5808 in 2020.

Nonfat dry milk will average $1.1650, down 6.50 cents from last month’s estimate and compares to $1.6851 in 2022, $1.2693 in 2021 and $1.0417 in 2020.

Whey was projected at 42.50 cents per pound, up 3.50 cents from the March estimate, and compares to 60.35 cents in 2022, 57.44 cents in 2021 and 36.21 cents in 2020.

The 2023 Class III milk price average is now projected at $18.25 per hundredweight, up 70 cents from last month’s estimate, but compares to the $21.96 average in 2022, $17.08 in 2021 and $18.16 in 2020.

The Class IV was projected lower, at $18.10, down 20 cents from last month’s estimate, and compares to $24.47 in 2022, $16.09 in 2021 and $13.49 in 2020.

This month’s U.S. corn outlook is for reductions to imports and food, seed and industrial use, with unchanged ending stocks. Corn imports were lowered 10

million bushels. Feed and residual use was unchanged at 5.275 billion. FSI was lowered 10 million bushels. Ending stocks were unchanged at 1.342 billion bushels. The season-average farm price was unchanged at $6.60 per bushel. Global production was forecast at 1.44 billion metric tons, down over 7 million.

Soybean supply and use forecasts were also unchanged. The season-average soybean price forecast remained at $14.30 per bushel. Soybean meal was forecast at $465 per short ton, and soybean oil remained at 66 cents per pound. Global production, however, at 369.6 million metric tons, was down 5.5 million.

USDA’s rst Crop Progress report of the season shows 3% of the corn crop has been planted, as of the week ending April 9, in the top 18 states that produced 92% of 2022 acreage. That’s 1% ahead of this time a year ago and 1% ahead of the ve-year average.

Dairy product demand looked strong in February. The USDA’s latest U.S. Dairy Supply and Utilization report shows cheese utilization totaled 1.13 billion pounds, up 2.8% from February 2022, driven primarily by a 3% increase in domestic use. Exports were off 0.1%, a result of higher other-cheese varieties counteracted by a signicant drop in American cheese volume compared to February 2022, according to HighGround Dairy’s assessment.

Butter utilization, at 164.3 million pounds, was up 13.1% from a year ago, thanks to domestic usage being up 16.9%. Exports, however, were down 32.1%.

Nonfat dry milk-skim milk powder totaled 175 million pounds, up 1.5% from a year ago, with domestic use up 10.1%. Exports were off 0.5%, although year-to-date are up 6.5%. HGD cited the weak global economy and tepid demand and “while domestic utilization increased, February 2022’s domestic numbers were the weakest since 2002, making for a very easy comparison in 2023.”

Dry whey utilization amounted to 65.9 million pounds, up 3.3% from a year ago. Domestic usage was down 3.2%, but exports were up 9.5%.

The cheddar barrels rolled into Chicago big time this week, as 70 loads found new homes at the CME, highest weekly total since June 30, 2018. That took the price down to $1.5125 per pound, down 20.75 cents on the week, lowest CME price since Nov. 22, 2021, 92.75 cents below a year ago and 26.25 cents below the blocks.

The barrel lost 45 cents in three weeks.

The blocks closed the second Friday of April at $1.7750, down 5.50 cents on the week, lowest since

Sept. 6, 2022, and 59.75 cents below a year ago.

“Central cheesemakers are clearly viewing the bearishly veering market prices with interest,” said Dairy Market News, though demand is reportedly healthy.

Some of the concerns arise from a wait-and-see approach on the buyer side, as prices shift down. Lower prices are expected to entice more buying near-term. Some cheesemakers say orders are beyond what they can produce. Cheddar and Italian style cheesemakers say demand has been robust. Process producers say any extra loads are moving at slight overages to usual formulas, and most recently produced cheese is “spoken for.” Milk availability remains a constant, with spot prices as low as $11 under Class III. Prices have in fact been at $10 below or lower every week in 2023, according to DMN.

Western retail and food service cheese purchases are strong to steady, and some manufacturers have sold out inventories through April. Demand from contract purchasers is reported as strong to steady. Loads are available, and the large CME block-barrel spread is being watched. Export demand was mixed this week. Some report strong Asian demand, while others reported less interest due to lower-priced European offerings. Demand from Mexican, European and Oceanic purchasers is reported as steady to lighter and having more sporadic activity from week to week thus far this year. Cheesemakers are running maximum to strong schedules due to a plentiful to ample milk supply, according to DMN.

Butter climbed to $2.3750 per pound Wednesday but closed Friday at $2.3275, up a penny on the week but 42.75 cents below a year ago, with 11 sales.

Central butter makers say cream remains widely available and near-term availability is not expected to change. Churning is busy, and some plants ran churns throughout the holiday weekend. Bulk butter demand is lackluster, according to some contacts who say April has been somewhat quiet in sales in both retail and food service. Plant managers say they are churning for the potential of stronger demand in late summer-early fall, according to DMN.

Cream volumes are plentiful in the West, with cream demand strong to steady. Some butter manufacturers were taking additional cream, and demand is healthy from ice cream producers preparing for spring season demand. Butter output continues strong to steady, although some processing capacity was lessened due to

servicing. Still others report maximum capacity production. Demand is steady for retail and food service. Export demand is steady to lighter, with less competitive prices noted, compared to European and Asian markets.

Grade A nonfat dry milk climbed to $1.16 per pound Thursday but closed Friday at $1.13, a half-cent higher on the week but 69.25 cents below a year ago, with seven sales reported.

StoneX said the powder continues to feel the pressure from the lower GDTs as well as the higher than expected February stocks number which was up 7.5%.

Dry whey saw its Friday nish at 36.25 cents per pound, a quarter-cent lower on the week and 27.25 cents below a year ago. There were a whopping 47 sales reported on the week, highest weekly total since the week of Jan. 6, 2020.

The week ending April 1 saw 66,800 head of dairy cattle go to slaughter, up 600 from the previous week and 5,800 more than a year ago. Year-to-date, 871,500 cows have been culled, up 32,800 head, or 3.9%, from the same period in 2022.

Rising beef prices have incentivized cash strapped dairy producers to cull more or even shutter their operations. The April 12 Daily Dairy Report said, “Frontmonth cattle futures reached fresh all-time highs. The April contract settled at $174.275 per cwt., eclipsing the previous high set in October 2015.”

The DDR said, “Beef producers are scrambling to nd animals to nish, and they are willing to pay higher prices for dairy calves. A growing share of U.S. dairy producers have been crossbreeding with beef genetics and producing fewer pure dairy calves. This has slowly reduced the supply of U.S. dairy heifers ready to enter the milking herd.”

StoneX broker Dave Kurzawski said dairy beef is making up a bigger percentage of the beef supply than a year ago. Speaking in the April 17 Dairy Radio Now broadcast, he reported culling the past 12 weeks was up 3.5% from a year ago.

He said farmers are doing what they can to “cheapen the ration, to cut costs,” as evidenced in components. Both protein and butterfat were down for the past 12 months, he said. “Dairy farmers want to milk cows,” Kurzawski said. “That’s what they do for a living. They don’t want to cull animals unless they’re going out of business. Margins will be tough, and those with a little extra, with beef prices being what they are, will be culling a little extra. But the price of milk has a bigger impact on their margin than that of the beef price.”

Tuesday’s Global Dairy Trade Pulse saw 2 million pounds of Fonterra whole milk powder sold, down 200,000 pounds from the March 28 Pulse, and at just $3,005 per metric ton, down $15 from the April 4 GDT event.

HighGround Dairy said, “Whole milk prices fell further in this event to set a new GDT Pulse auction low as weak demand and a poor global macroeconomic environment keep sentiment bearish.”

In other dairy trade news, Cooperatives Working Together member cooperatives accepted eight offers of export assistance this week that helped them capture sales contracts for 908,000 pounds of American-type cheese, 2,000 pounds of anhydrous milkfat and 132,000 pounds of whole milk powder.

The product is going to customers in Asia, the Caribbean and Oceania through October and raised CWT’s 2023 exports to 13.5 million pounds of American-type cheeses, 550,000 pounds of butter, 2,000 pounds of anhydrous milkfat, 17.9 million pounds of whole milk powder and 2.5 million pounds of cream cheese. The products are going to 18 countries and are the equivalent of 287.7 million pounds of milk on a milkfat basis, according to CWT.

In politics, the International Dairy Foods Association gave a thumbs up to the U.S. Food and Drug Administration’s nal order announced Thursday to modify the yogurt standard of identity nal rule, published June 9, 2021.

Joseph Scimeca, Ph.D., senior vice president of regulatory and scientic affairs for the IDFA, said, “Following more than four decades of advocacy from IDFA and formal objections led by IDFA in July 2021, the FDA announced changes to the 2021 Yogurt Standard of Identity nal rule on Dec. 14 that largely aligned with IDFA’s requested changes and objections. Today, FDA issued additional clarity on the nal rule. IDFA considers the nal rule a win for consumers and yogurt makers.” Complete details are posted on the IDFA’s website.

The American Dairy Coalition, in a letter this week to Agriculture Secretary Tom Vilsack, urged him to deny two recent Federal Milk Marketing Order hearing petitions, which ask for increased payments from farmers’ pockets to processors in order to offset higher input costs.

Holding a federal milk pricing hearing on only make allowances without the opportunity to look at additional concerns facing dairy farmers is misaligned, ADC said.

“As a grassroots dairy farmer organization, ADC believes a comprehensive FMMO hearing is needed,” said ADC CEO Laurie Fischer. “We also do not support ‘make allowance’ updates based on processors saving the ability to voluntarily participate in the cost surveys, which undoubtedly would exclude essential relevant data. Farmers need transparency in order to understand how their net payment is calculated, and these ‘make allowances’ are not line items. They are embedded in pricing formulas.”

The ADC said the milk component pricing that is credited with make allowances only captures the value of about 10% of milk sales today. The specic products that are included in the circular end-product pricing formulas are: block and barrel cheddar cheese, salted butter, nonfat dry milk and dry whey.

“This means 90% of total milk sales do not have their end-product prices captured, not even for informational purposes or market transparency,” Fischer said. “USDA only surveys the prices of the specic products that are used in the FMMO formulas.

The ADC said processors have the exibility to offset costs from additional sales opportunities the nonformula products represent without having the increased value they extract from consumers captured and used in the FMMO formulas that establish the minimum prices paid to farmers.

Lastly, our prayers go out to South Fork Dairy which suffered a huge explosion April 10 in Dimmitt, Texas. Some 18,000 cows were reported to be lost in the resulting re, and one farm worker was hurt and hospitalized. The cause of the explosion is being investigated.

We’ll

joining our team, please stop in at Dairyland Supply for an application or contact Gordon or Roxane at 320-352-3987.

This morning going through the news channels made me realize that it is becoming difficult to find quality news information about what is happening in the world. It is getting to the point to where most news is becoming increasingly politically focused or pushing some sort of a social agenda. You have to wonder why news media feels it is more important to talk about social lifestyles and indoctrinations that go against the conservative family values that this nation was founded on, while denying the listeners opportunities to hear about important happenings around the globe. What happened to the good old days when news reported on financial, political, and economic happenings from multiple perspectives to help the general population better understand the world we are living in.

My interest in international news at the moment is centered around increasing financial concerns and the root cause of it. The whole milk powder dairy trade between NZ and China can typically be a good leading indicator of the international dairy markets. Recent activity has NZ whole milk powder trading near $1.38 with U.S. near $2.10 and EU $1.70. Does China have some internal issues?

Oceania dairy prices continue to fade. This just keeps lowering the international price ceiling for U.S. dairy product prices. The only value items remaining for U.S. dairy product offerings are cheddar blocks and barrels at $1.77 and $1.51 respectively. These prices should keep domestic and international buyers active. If cheese prices don’t improve soon, Class III futures will start to price in the low $16’s. That will be a tough pill to swallow.

There has been a lot of talk that is becoming a reality with the BRICS countries (Brazil, Russia, India, China, and South Africa) creating a new bank. BRICS partners are trying to develop cross-border alternatives to the U.S. dominated SWIFT payment system. The goal with this initiative is to create a non-dollar payment system that would not be vulnerable to U.S. government sanctions. It is my opinion that over time this could create more headwinds for the U.S. dollar as the newly created system becomes more dominate. Agriculture will likely start to see more exposure to this type of global structural changes in the financial system. It is

Ft. Atkinson, Iowa • 563-534-7513

April 12, 100 loads

April 13, 86 loads

“Thank you for helping when I was gone from the farm.”

With over 40 years experience, Wisconsin Silos is the most complete builder of concrete silos in the United States.

From pouring the footing, to xing the accessories, unloaders, feeders, conveyors, silo pipes, silo distributors & silo chutes.

By Amy Kyllo amy.k@star-pub.com

By Amy Kyllo amy.k@star-pub.com

Editor’s note: The interview with José Gallegos Timbi was conducted via interpreters: Paul Pillman, Carolyn Pillman and Jeremy Romero.

TARQUI, Ecuador –At 9,000 feet in the Andes mountains, cows graze on the slopes of the farm of José Gallegos Timbi and his family. The farm is eternally green as a combination of the altitude and living at the equator traps the farm in an everlasting spring.

Gallegos and his family milk two cows and have two calves on their almost 5-acre farm. Their cows are staked outside on pasture 24/7 and

are never in a barn. Their diet of grass is supplemented occasionally by a grain mix. Their pasture is a mix of kikuyu grass and clover which, because of their close proximity to the equator, grows yearround.

Milking happens in the open air. Amid the grass, the cows stand with a rope hobble around their back legs and tail to keep the Gallegos family safe during milking.

Gallegos sells his milk to a plant that processes a variety of dairy products. Their milk is picked up every day around 7 a.m., right after morning milking. At night, they cool and preserve their milk by putting it into a container with cold water surrounding it.

Gallegos has runa cows; runa roughly translates to “of the country.” The runa cows are inexpensive and have

lived in the mountains for generations so they are hardy for the climate and altitude.

Most runa milk around 6 liters a day. A runa cow has a longevity of ve to six lactations. The Gallegoses are currently getting about 4 liters of milk per day from each of their cows.

The family sells its milk by the liter. They said the current milk price range in Ecuador is $0.35 to $0.42 per liter. This converts to a milk price of approximately $15.41 to $18.49 per hundredweight. However, because the buying power of a dollar is approximately double in Ecuador compared to the Unites States, the milk price adjusted for U.S. ination is approximately $30.22 to $36.25 per hundredweight.

In addition to farming, Gallegos has a job in Cuenca, where he works as a marble craftsman. Cuenca has an urban population of 400,000, plus a wider metropolitan area with an additional 700,000 according to World Population Review. Gallegos also has a shop for working with marble on his farm. Among the pieces he crafts are animal gures of bulls and horses sculpted out of marble. Gallegos said his primary income is from the marble. Between the two careers, he makes enough money to sustain his family.

Turn to GALLEGOS | Page 13

Gallegos said one of the biggest challenges to farming in Ecuador is food, land and cow prices. There is a constant problem with high costs.

The family raises corn and beans – the bean variety is similar to a navy bean – and they also have sheep, pigs, ducks, chickens, rabbits and guinea pigs.

Farms like the one the Gallegos family owns are common in Ecuador where the majority of dairy farmers have a handful of cows. Dairy farming in Ecuador is split into two types, larger farms with more automation, which are less common, and a large number of small farms like theirs.

They contract with a veterinarian for vet services, and the family aims for their heifers to calve in at about 2 years old. Calves are separated from their mothers at birth and are fed their mother’s milk until they are weaned at 3 months. The Gallegoses often use a bull from a neighbor to service their animals, but A.I. is used as well to improve genetics. Each of their cows has a name.

Gallegos said he likes dairy farming because it is a family tradition that he learned when he was young. He also appreciates having animals so they can sell them when they need money.

The family rents a tractor to help plant their crops, but much of the work is done using non-automated hand tools. When it comes time to plow, the family rents a tractor, uses a yoke of oxen or can be found swinging pick axes to break up the ground depend-

ing on the eld. Harvest is also done by hand.

Gallegos said they do not use a lot of chemicals or manure on their crop ground which helps with runoff concerns on their mountainous farm. Because land is scarce in their area, the best way to obtain land is to get it from family. Gallegos received his land from his parents.

The family farm sits in relation to many other farms of relatives who also live in the area. The Gallegos family has ve children who help on the farm, and the family lives in an adobe house. Part of their culture includes collaborating together on the farms. The Tarqui area, where the Gallegos family lives, is populated predominantly by Quichua families who are indigenous to Ecuador.

The weather in the mountains of Ecuador is mild and cool. Cuenca, which is half an hour away from Tarqui, has an average annual rainfall of 63.5 inches per year and average temperature of 56.2 degrees for the month of November, which is their warmest month, and an average of 51.5 degrees in July, which is their coldest month, according to the Climate Data website. Cuenca, however, is approximately 1,000 feet lower in elevation than Tarqui which means Tarqui is generally 5-10 degrees cooler than Cuenca.

Gallegos said he would like to improve the quality of his pasture and the quality of his cows and the milk they produce to continue his family’s dairy farming way of life.

MENAHGA, Minn. – Anthony Peeters works along with his brothers, Eric and Ryan, and their parents, Terry and Tony, to operate Peeters Dairy near Menahga. Eric has taken over the role of main herdsman. Anthony is in charge of feeding and bedding the animals as well as eldwork. Ryan helps milk and drives tractor. He also has a beef herd at his place. Terry is still one of the main milkers, and Tony helps with driving tractor and is great for advice. Together, they milk 150 cows in a double-3 parlor and farm 30 acres of soybeans, 250 acres of hay and 150 acres of corn.

PHOTOS BY TIFFANY KLAPHAKE/DAIRY STAR

(Top) Anthony Peeters adds feedstuffs to the total mixed ra�on April 15 at Peeters Dairy near Menahga, Minnesota. The Peeters family milks 150 cows in a double-3 parlor.

(Le�) Anthony Peeters gets sawdust with a skid loader to add to the bedding pack. His main du�es at the dairy include bedding and feeding. He also is in charge of most of the eldwork.

Anthony Peeters has hooked up an old milkhouse vacuum pump to help pull the sap from the trees into a holding tank. He has two sec ons of trees set up with a vacuum pump, and a third sec on uses gravity ow to move the sap from tree to tank.

Peeters checks tubing April 15 in the woods by his family’s dairy farm near Menahga, Minnesota. He has 2,000 taps placed and gets about 500 to 600 gallons of syrup each year. This me of the year, he is usually nishing the job of cooking down the syrup, but this year, he is just ge ng started due to the cold weather this spring.

“With the sugar maples, you get higher yields, the sugar content is better and just the quality is that much better.”

ANTHONY PEETERS

checks on sap as it is cooking down in his homemade cooker. All of the equipment Peeters uses he built himself, including the cooker, the holding tanks, the ltering system and the shed where it is all housed, which he calls the sugar shack.

Anthony Peeters checks the temperature of the sap. He uses a refractometer to check the sugar content of each batch of sap. Peeters said it depends on the sugar content of the sap for how long it will take to cook the sap into syrup. On average, it takes Peeters 28 gallons of sap to make a gallon of syrup.

“Trees are a lot like cattle in that if you take care of them, they will take care of you. To this day, I am amazed by it.”

ANTHONY PEETERS

CAMP DOUGLAS, Wis. – One typical July afternoon morphed into the worst day on their farm for siblings Tammy and Jonathon “Skeeter” McCullough of Camp Douglas.

The two were starting evening chores the afternoon of July 2, 2006, while their parents were away at a family function. Tammy had gotten the cows into the tiestall barn, and Skeeter was running high-moisture corn out of the roller mill. Suddenly, the roller mill plugged and the power died.

“I was trying to get that unplugged, and she comes out screaming and hollering,” Skeeter said. “There were already ames coming down the hay mow chute maybe a minute and a half after the power had died. Within minutes, it was out of control.”

Tammy said the ames were already within 2 feet of the cows’ backs. The electric pole went up along the hay mow on the outside of the barn and then straight down into a breaker box. The hay mow was three-quarter lled with chopped corn stalks and dry baled hay. An electric arc from the power line started the entire haymow on re.

The McCulloughs were milking 45 cows at the time in a tiestall barn. All the youngstock were housed in nearby buildings, and it was a scramble to get all the animals out of harm’s way.

Tammy called 911 while Skeeter started letting cows outside. He had about a quarter of them unchained when he realized the gate outside that led to the pasture was shut. Once that was opened, Skeeter continued to struggle to get the cows out because they kept trying to get back in the barn for milking time.

Skeeter said the only thing that nally prevented the cows from coming back in the barn was a heifer who had recently calved in. She had been living on pasture and was a little wild.

“She was one of the rst ones out of the barn,” Skeeter said. “The rest of

the cows were going nuts in the cow lot, but she went through two gates and three hot single-wire gates to get back down to the pasture. The whole herd followed her.”

Six re departments responded to the scene. The re department of New Lisbon was largely staffed by volunteers who were all at a Fourth of July celebration. Tammy said many of them came straight to the scene.

“Half of them showed up with no socks on and ip ops and shorts,” Tammy said. “They had their reghter suits but no socks, so they went in the house in Mom and Dad’s bedroom grabbing socks and handing them out to people.”

Meanwhile, Tammy went into a shed that adjoined the barn where she had a group of calves housed to let them loose.

“I was grabbing calves and chucking them down the road,” Tammy said. “The neighbors were on fourwheelers on the road and were football tackling them to grab them.”

After those calves were rescued and the re departments were hard at work, Tammy went in a different calf barn where the younger animals were. She had the gates tied with baler twine for extra security because there was one calf that would always get out. She ripped the gate open and had all but the last calf out when she saw Skeeter outside the building, scream-

ing at her to get out because the roof was on re.

“I looked up and saw ames coming down close to my head, and I knew I had to get out of there,” Tammy said. “I went underneath the gate and ran through the re to get out. It was so hot.”

When Skeeter went to move the skid loader out of the way, he sat down and realized quickly that the seat was too hot to stay seated on. He

managed to drive the machine while sitting with one foot on the seat and using the hand controls. They later noticed that a perfect imprint of Skeeter’s jeans was melted into the seat, Wrangler emblem and all.

“We kept that seat as a souvenir,” Tammy said.

With the help of the neighbors and the re departments, no people were harmed and all but two calves were saved. At the time, there were 45 cows, 30 heifers and approximately 10 bottle calves.

They ended up losing the dairy barn, a cow shed and two calf barns to the re. They discovered ve silo doors’ worth of ashes built up in the silo closest to the barn. Two months later, when they took the silo down, it was still smoldering.

The cows were moved to a neighbor’s farm and housed outside their freestall barn on a sand-bedded pack. Between the summer heat and overcrowded conditions, the cows were not adapting well. So, a month after the re, the herd was sold. They kept the dry cows and springing heifers.

In November of that year, they started rebuilding the dairy barn. They purchased a new herd of cows from their cousin’s in-laws who were selling their herd at the time, and started milking in their new facility April 2, 2007.

“It’s been interesting to say the least,” Skeeter said. “As bad as it was, it could’ve been worse.”

Vacuum stability, teat condition, milking performance are all effected by pulsator design. 60 years ago, the industry was sold a story about alternating pulsation. The result has been a steady increase in replacement rates while milking performance has suffered. Dairy farmers got sold a costly flawed story.

Visit TridentPulsation.com/articles to see an article in the current issue of International Dairy Topics. After reading it ask yourself if you have been lied to for the past few decades.

Want a paper copy? Call and we will mail it to you.

SELLING

By Amy Kyllo amy.k@star-pub.com

By Amy Kyllo amy.k@star-pub.com

SIOUX FALLS, S.D. – Several key priorities affecting dairy farmers for the upcoming farm bill were part of a recent discussion March 29 at Central Plains Dairy Expo in Sioux Falls.

The session began with Rep. Brad Finstad, R-MN, joining virtually to present his priorities for the bill and answer audience questions. Finstad, a crop farmer from south central Minnesota, serves on the House Committee on Agriculture, which plays a large part in drafting the farm bill.

The current bill, which was passed in 2018, is set to expire in September.

Finstad shared three core priorities for the upcoming farm bill: risk management tools, conservation programs and the Conservation Reserve Program.

“First and foremost is to make sure that we are taking a strong look at protecting the risk management tools, that they really do afford the opportunity for us to plan against some tough times,” Finstad said.

Finstad said risk management tools like crop insurance provide the means to strengthen relationships with lenders.

Finstad wants to make sure that

the Dairy Margin Coverage program is looked at as well.

After Finstad presented, the session continued with a panel of nine staff members of eight congressional ofces from across the Midwest, answering questions and presenting priorities for the bill.

Dustin VandeHoef is a staff member from the ofce of Sen. Joni Ernst, R-Iowa. DMC was a topic of discussion.

“(DMC) is going to be more evolutionary than revolutionary,” VandeHoef said.

Nick Lunnenborg, representing Rep. Michelle Fischbach, R-MN, agreed that there will not be revolutionary changes regarding DMC.

Lunnenborg said there have been people working on the 5-million-pound limit that is part of DMC, and there is interest in production history. However, Lunnenborg said that considering the budget constraints, any changes will have to be at the margins.

VandeHoef said they will work to make changes that are a better t for each operation.

“We’ll look at all changes that try to make the programs more user friendly,” VandeHoef said.

The panel also discussed the Federal Milk Marketing Order program.

Five dairy organizations have drafted a proposal for reforming the FMMO. The organizations are Dairy Business Association, Edge Dairy Farmer Cooperative, Minnesota Milk Producers Association, Nebraska State Dairy Association and South Dakota Dairy Producers.

Turn to FARM BILL | Page 21

Several staff members said there is interest in reforming the FMMO.

Lunnenborg said there are non-legislative xes for some of the issues the proposed reform seeks to address through the U.S. Department of Agriculture.

“To the extent that the industry can all get behind a singular x, there is already a process in place,” Lunneborg said. “To the extent that there needs to be some legislative pressure to make some changes, I’m all ears.”

Currently, the USDA has a formal, 12-step process for proposals for amending a FMMO. If a proposal successfully makes it through the rst steps of the process and is recommended by USDA, the nal step of the rule-making process is for it to be voted on by producers for approval of the amendment.

VandeHoef also shared his perspective on FMMOs.

“There is interest in doing something in the farm bill,” VandeHoef said. “Budget and everything else, it’s going to be challenging to make changes, but there is interest.”

Another topic of the session was conservation.

Finstad said he does not take a one-size-ts-all approach to conservation and gave support to making programs exible to make sure farmers have control.

“We need to make sure that those programs are strong and supportive and they remain voluntary,” Finstad said.

Working on the Conservation Reserve Program is another of Finstad’s priorities. He said he wants to make sure that CRP dollars go to vulnerable marginal land and that CRP does not become a retirement program older farmers use to make income off their land while simultaneously pushing other farmers out of the land marketplace.

“(We need) to make sure that we’re not tying up land that could and should be farmed by some of the greatest environmentalists that I know, and that’s our farmers,” Finstad said.

VandeHoef agreed that he does not want CRP to tie up good land from being in production.

“I think we’ll look to continue the ways that we ensure that CRP isn’t the one that makes it hard for young people to get access to grass,” he said. “A piece of that is to try to make CRP a bit more of a working land program rather than just a retirement program.”

Other priorities presented by the ofces represented included trade, bio security, foreign adversaries, supply chains, rural mental health, agricultural workforce development, meat processing, disaster assistance and response, reducing regulations to encourage rural investments and technology.

Finstad said farmers can expect to see movement on the farm bill from late spring and early summer going into the August recess.

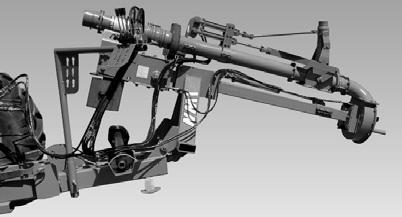

Nothing compares to the GEA liquid manure spreader. It gets the job done fast, easy, and with minimal maintenance required.

“We’ll look at all changes that try to make the programs more user friendly.”

DUSTIN VANDEHOEF OFFICE OF SEN. JONI ERNST, R IOWA.

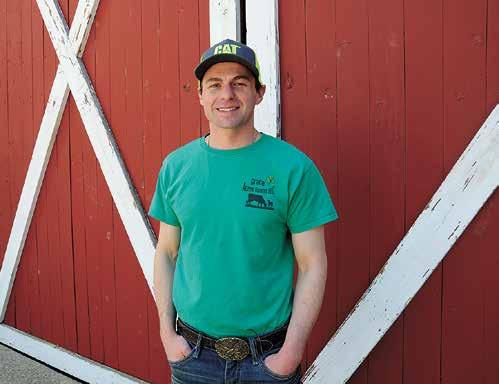

Wis. – Justin

“J.T.” Price is on a mission. His goal is to save a dying breed of Irish dairy cattle, known as the Celtic Kerry, from extinction.

Price is early in his endeavor but is already making an impact. Acquiring his rst Kerry in 2020, this large-animal veterinarian now has 30 head of registered Kerry cattle on his farm near DeForest. And this summer, Price plans to create the world’s rst Kerry embryos.

“There are only 45 registered Kerry cows remaining in all of North America,” Price said. “I felt a calling to preserve something so unique.”

Price found his rst Kerry cow July 31, 2020, in Ohio. She along with her bull calf, and two other pregnant Kerry cows, arrived at the farm that September. Price is now starting to freshen in animals that were born on his farm.

Price milks 29 cows with a Lely robotic milking system at Grace Acres Farms. His herd, which totals 40, is currently a mixture of Kerrys, Kerry crosses, Holsteins, one Jersey and one Normande. His goal is to be milking 40 pure Celtic Kerrys.

“It’s all about quality here not quantity,” Price said.

His herd of Kerrys is one of only two in North America. The other is located in Westminster, Massachusetts, and is owned by the secretary of the American Kerry Cattle Association. According to Price, the Kerrys’ home country of Ireland has 280 Kerrys remaining. Known to be one of the most ancient breeds in the world, the Kerry is now listed as critically endangered.

“The genetic pool is so limited, but there’s an element of diversity within the breed that I’m trying to hold onto,” Price said.

“The nucleus of the purity of the breed is important to protect to keep true genetics existing.”

Price participates in a program in which he sends his Kerry cattle’s DNA in for genotyping.

“I’m trying to help preserve a breed, and I don’t want to contribute to inbreeding,” he said.

“A lot of livestock/cattle breeds and companion animals are inbred.”

Price’s Irish heritage is what rst attracted him to the Kerry breed.

“I’m Irish on both sides of my family,” said Price, whose hometown is named Clover. “I’ve only been to Ireland once but would love to go back.”

The South Carolina native received his undergraduate degree from Clemson University and his degree in veterinary medicine from Mississippi State University. Price’s last year of clinicals brought him to Edgar,

Registered Kerry cows graze July 7, 2022, at Grace Acres Farms near DeForest, Wisconsin. At the farm, Jus n Price is growing a herd of the endangered breed.

Wisconsin. It was there he learned how to fetal sex pregnancies under Jill Colloton, DVM.

Price then worked at a vet clinic in Stevens Point before taking a job in STgenetics’ embryo/semen production and import/export program. It was a role that kickstarted Price’s love for genomics and genetics. His work with a geneticist

there led Price on a quest to nd the remaining Kerrys.

Angular and hardy, the allblack or mostly black animal is taller than a Jersey, Price said, but not as wide.

like an Angus with horns, and they kind of do, but they are a true dairy breed.”

Grace Acres Farms is a grass-fed dairy operation. Cattle are rotationally grazed May through November on 40 acres and consume a grass-fed diet during the winter.

“Kerrys are ne-boned, little, efcient, productive units,” he said. “They are a good longterm investment. And keeping them on grass keeps input costs low. People say the Kerry looks Turn to PRICE | Page 23

“Cows are built for grazing, and I built this farm around the needs of my cows,” Price said. “The cows are my family.”

Price said his Kerrys average 40 pounds of milk per day with 3.4% protein and 3.2% fat on a grazing schedule. The Kerry is known for having naturally homogenized milk containing small fat globules. During scheduled tours of Grace Acres Farms, milk is available for sampling.

“The milk is naturally blended and is a delicious treat,” Price said.

It takes three years for a Kerry to reach productive age; therefore, animals are usually not bred until age 2, Price said. Calves weigh about 40 to 45 pounds at birth, and a full-grown cow weighs about 900 pounds, but some can be as small as 650 pounds. According to Price, the Kerry has a long productive life.

“Kerrys lactate until their late teens or early 20s, and they start milking more the older they get,” he said. “They will last three to four times longer than a Holstein.”

The Kerry’s pleasant demeanor and desire to please are also characteristics Price nds appealing.

“Kerrys are very intelligent, and they really like people,” he said. “They’re kind of like a dog breed. They get attached to your voice and presence. They want to trust you and impress you. They are calm, easy to deal with and easy to care for.”

Price wants to help grow the Kerry breed and increase the number of herds in the country. Price collects semen on his bulls and recently began offering breeding stock but said he is careful about who he sells animals to.

“So many Kerrys were sent to slaughter or were underfed,” said Price of what led to the rapid decline of the breed. “I don’t want to put a Kerry in the wrong hands.”

Preservation and conservation of both land and cattle are a focus for Price, who uses organic practices. His goal is to one day be certied organic.

“I let the cows deposit manure on the elds, which helps offset time, labor and other costs,” Price said.

Price is working with the Natural Resources Conservation Service on projects, including building a cow lane in the pasture behind the barnyard.

“We have good soil quality here, which is perfect for a grazing operation,” Price said. “The grass practically grows overnight, and mowing at certain times helps the grass grow back faster and fuller.”

Price plants a blend of exotic grass strains, using Italian rye instead of standard rye, for example. His mix can also include orchardgrass, timothy grass, Florida black ryegrass, wheat and red clover mix, etc.

“Kerrys are highly efcient at converting grass into protein and thrive on high-quality hay,” Price said. “I feed good-quality hay made from a buffet of legumes and grasses. In the winter, I am super picky on the hay I feed. My cows’ health is No. 1.”

Price has a soft spot for animals of all kinds. In addition to dairy cattle, Grace Acres Farms is home to horses, turkeys, pigs and peacocks. Price’s farm, that he purchased in 2020, was a slice of paradise too good to pass up. Visitors bask in the tranquility of the farm’s historic charm as soon as they pull in the driveway. Although his farm is surrounded by development with houses lining his pastures, Price embraces the growing neighborhood.

Price is building an infrastructure around the Kerry breed to support an agritourism and education venture. It is a project Price is pouring his heart into.

Selling wholesome, preservativefree foods is part of that mission. Price offers premium farm food products, including frozen meat like grassfed beef, pork and poultry, as well as eggs, from his on-farm store and online. The store, which is located in Price’s house, is open daily from noon to 6 p.m.

“I would eventually like to do deliveries as well,” Price said.

Working with the Center for Dairy Research, Price has begun making cheese curds from his cows’ milk which are known as “Kerry curds.”

“A Kerry’s milk is rose gold in color, which comes from the grasses she eats,” Price said. “Genetically, they have unique milk. Their protein is higher than their fat content.”

Price is devoted to A2 genetics and is moving toward a 100% A2 herd. Price said most Kerrys are naturally A2.

“My twin sister and I have allergies to dairy, but I can consume dairy again because it’s A2,” Price said. “It’s not just lactose, but rather, the A1 protein that people are inammatory to.”

In October, Price was awarded a U.S. Department of Agriculture value-added producer’s grant to make A2 cheese and will be offering a variety of types and avors.

“We are at the cusp of making cheese, which will be available in the coming weeks,” he said.

The cheese will also be carried by Metcalfe’s Market, Woodman’s Market and Hy-Vee, among other stores.

Dairy product offerings at Grace Acres Farms are in their infancy as Price has ambitious plans to produce bottled milk, butter, yogurt and ice cream – all made from his herd of Kerry cows.

Price has also opened his farm up to educate youth – providing externships to high school students, pre-veterinary, agricultural and business-related undergrad

students, and veterinary students. This summer, he will be offering internships as well.

Price’s compassionate heart and helpful spirit also inspired him to set up a 501 c3 non-prot organization known as Grace Acres Ministries. Price is teaming up with other non-prots to provide a place of refuge and on-farm fellowship to people suffering from post-traumatic stress disorder.

Price does all the work on the farm with help from one employee and a couple volunteers who help run the on-farm store.

“I’m looking for more volunteers who can be long-term family to Grace Acres,” Price said.

Price continues to do relief and scheduled veterinary work while getting the farm established. He eventually hopes to expand his practice, Clover Leaf Veterinary Care, and would also like to offer reproductive services.

Grace Acres Farms is a destination built around one rare dairy breed – the Celtic Kerry. As Price works to revive a breed on the brink of extinction, he is also creating a special place to share the Kerry with the community. He wants to give others the opportunity to enjoy this uncommon breed’s company and the bounty they produce.

“It’s a miracle we got this far,” Price said. “It is truly a dream for me to be able to do this.”

175 cows, 600 acres

We are working on the tillage equipment. I think we could get in the field in a week or so. There are just snow piles. Everyone is getting ready to hit the field with manure; that should start in a week. We plant Cropland 3200 silage corn and Dairyland grain corn. Last year was one of the latest years we got in the field. The earliest was a couple years ago when we were in the field in early April. We are really sandy here, but it varies in the area. Some of the ground I rent is heavy, and some has light soil.

ARIANN DOE

250 cows, 5,530 acres

We have been cleaning out heifer pens. We have also been bringing hay home. We have some land farther away, and we couldn’t get to some of the bales. The 84-degree day last week melted a lot of snow. The only snow left is on the hills; most fields are open. Our goal is to get in the fields by May 1. April is the earliest we have gotten in the field. We had our durum cleaned. This year we plan to seed REA corn. Our soils vary from clay to sandy loam. We also have some flat land and some rolling hills.

ALAN VANNURDEN

600 cows, 1,400 acres

We are hauling manure now, and that will take us a week or so. We are hauling both pit and pack manure and applying it on our irrigated sand fields. There is a little snow by the tree lines; otherwise, the rest has melted. There could be a little frost in the fields yet. The earliest we have planted corn is April 25, and the latest is Memorial Day weekend. This year we plan to seed LG corn on all the acres. Our alfalfa is low lignin. Our soils range from heavy ground with rocks, sand and peat ground.

BENJAMIN SEIFERT

350 cows, 450 acres

We’ve been hauling pack manure on the days it has been dry. We had 3 inches of snow on Sunday (April 16). We plant LG corn and have been trying different varieties of alfalfa. I would say we are 2 weeks away from getting in the field. There were a few people out with their drills last week planting small grain. The earliest we have gotten in the field is around now and the latest was last year when we were planting corn around June 10. Hopefully we can get in sooner this year.

DENISE KURTH

40 cows, 250 acres

There isn’t much fieldwork going on yet in our area. The pastures are greening up nicely, but there is still a little snow left in the shelterbelts and in the ditches. This past Wednesday (April 12), we took a land roller over our oat ground. We followed that by no-till planting 60 acres of oats on Friday. We raise oats mostly for the straw. We received just a trace of moisture over the past two weeks.

CHARLIE DICKE

200 cows, 850 acres

The remaining snow is mostly gone following the snow storm April 16. We have done some seeding on our cover crop oats that go in before sweetcorn. Our manure is hauled. We hope to plant corn in the last days of April. Our hay ground is greening up, and the rye cover crops are taking off. We did not experience winterkill. North of our farm, about 10 to 20 miles, corn is planted in sandier ground. Snow total: 3-4 inches.

LANE HETTINGA

130 cows, 75 acres

We had a quick turnaround from winter to spring last week with a couple of really warm days. The last of our snow has finally melted. We have made good progress on hauling out the bedding pack from our barns and spreading it on our fields. I have seen a few farmers in the neighborhood doing some tillage and spreading fertilizer. I’m sure it won’t be long before we see corn planters rolling.

RICH HOUZNER

54 cows, 600 acres

Last week everyone scrambled to make stalks, haul manure and even do a little field work. Now, we’re doing cattle work. Nobody near us that we know of has put any corn in the ground. Some oats and seeding have been done, but we have not started that yet. We have some of the tillage done for that. Everyone is kind of in hold pattern, waiting for the ground conditions to improve. Snow total: 6.5 inches.

DOUG FAIRBANKS

380 cows, 600 acres

We received a snowstorm April 16, but the snow quickly disappeared. Temperatures were in the 80s April 9-15. We hauled all our manure, and our oats are planted. We put nitrogen on the cover crops we plan to harvest, and the remaining cover crops were terminated. The first yards are being mowed, and alfalfa is starting to green up. In the neighborhood, anhydrous is being applied, dirt leveling is occurring, and corn and soybeans are being planted by crop farmers. We hope to plant corn in a week to 10 days. Our neighborhood is nervous about drought. Snow total: 3 inches.

MITCHELL SCHAEFER

230 cows, 400 acres

We received 1 inch of rain. There was so much water left in the fields from all the rain we had – it’s taking a while to dry out. We got one field of cover crops (winter rye) sprayed so we can do new alfalfa seeding. We have to wait for that to kill off first. The weather was wet again this week, so we’re just patiently waiting to get out there. A few people are planting some new alfalfa, seeding on higher, drier fields. We use Dairyland 4400 alfalfa seed and Dairyland 4999Q corn seed, which is silage specific.

MATT REDETZKE

250 cows, 450 acres

We had about 10 inches of snow yesterday (April 17) and about 1 inch of rain on Sunday (April 16). We had had some pretty nice, dry weather the week before that, and everything was just about dried up. We are looking at a bunch more precipitation later this week. We haven’t done anything in the fields yet; we’ve just been getting equipment ready.

TIM VOSBERG

140 cows, 380 acres

We’ve had 3.4 inches of rain so far this month. One rain was 3 inches in one night. It all soaked in. We had 2 inches of snow on top of that. We had 80-degree temperatures last week before the snow this week. Everybody’s got their seeding in as far as I know, including me. We had perfect conditions for that, and I’ve been working on getting my compost on. I’m applying compost and chicken pellets on the corn and bean ground, so that’s all done and ready. There are a couple guys that are done planting corn, but many are holding off. I’m organic, so I’m going to hold off.

100 cows.

1,400 acres

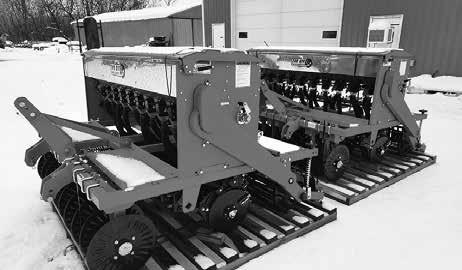

We had about a half inch of rain on Sunday and about 4 inches of snow on Monday. Before that, we had some really good drying weather. We haven’t been in the fields yet, but around the Seymour area, some guys have been doing some seeding. We’ve been continuing to get equipment ready, and everything is pretty much ready to roll when the weather is. We got a new planter and have been getting it set up to work with the tractor.

ALAN AINGER

300 cows, 1,100 acres

We received 2 inches of rain and 2 inches of snow. We planted our oats and peas with alfalfa (50) acres on April 13 and 14. We also did a little tillage on some manure ground. A few neighbors started planting soybeans and a couple fields of corn. As soon as it dries out, we will probably start planting corn – hopefully the week of April 24. We use AgVenture corn seed and KingFisher alfalfa seed.

Give Skip Breitbach Feeds a call today for seeding waterways and pastures!

SKIP BREITBACH FEEDS

Balltown, IA • (563) 552-2393

320-220-1342

320-339-1154

The Signature name says it all. The 504R Signature baler advances the Vermeer legacy by giving the working man a baler that is built upon the three signature pillars of Vermeer — convenience, ease of use and durability. Combine that with a camless wide pickup, rotor and a durable steel windguard roller for quiet and smooth operation — all while making bales at a quick pace Backed by a 3-year pickup warranty*, it’s clear the 504R Signature baler is truly one of a kind.

, desig iggn a n nd spe sp cifificat at a ion ions; s add d a improrovemvement e s s; or r dis d con co tin tinue ue manufufa u actuctturin n r g o gor d r ist st s ributi ut on at any ti t me e w witthoutn t n notiottice e or obl b igagation. n n. E Equ Eqquiipm pm ipment sh shown ow is s foor

YES EQUIPMENT & SERVICES, INC. Madison & Milwaukee, WI www.yesjcb.com

WOLLER EQUIPMENT Swanville, MN www.wollerequipment.com

A&C FARM SERVICE Paynesville, MN www.acfarmservice.com

HAMMELL EQUIPMENT Chatfield, Eitzen, Harmony, Rushford, MN www.hammellequipment.com R-EQUIPMENT Dodgeville, WI, Utica, IL, Sycamore, IL www.requipment.com

This list of herds by county includes dairies who have production above state average based on dollar value. They also have given permission to publish their data. Thank you to all DHIA dairies who choose to submit data to the Genetic Evaluation System that has served the industry so well over the years, beginning with sire summaries and cow genetic evaluations, and then resulting in the development and continuing calibration of genomics.

THURSDAY,

Hay 10:00 a.m. • Cattle 11:00 a.m.

Complete Herd Dispersal Complete

(40) HIGH QUALITY Registered Holstein cows!! Herd RHA is 25,600 milk with 4.1F, 3.2P, 90 scc.!! Cows are free stall and headlock adapted. Many years of Select Sires breeding resulting in an outstanding herd of cows!! Herd is fully vaccinated including Bangs vaccinated. Regular herd health and hoof trimming. Year round calving with 14 fresh in the last 90 days. Everything is genomic tested. Mikshowsky’s have placed 3 bulls in Ai over their years of farming!! A great opportunity to buy Registered cows with excellent pedigrees!! Contour Acres, (Randy & Sara Mikshowsky), Bangor, WI THESE COWS SELL

THURSDAY, May 4th

Hay 10:00 a.m. • Cattle 11:00 a.m.

Complete Herd Dispersal Herd

Herd consists of (22) Registered Jersey cows, (1) Registered Brown Swiss, (1) Registered Holstein, (9) Registered Jersey heifers due May & June. Cows are milked and housed in tie stalls and let out every day. Current bulk tank average is 50 lbs milk, 91 scc, 4.87F, 3.8P!! Cows are only fed dry hay and dry shelled corn. Cows have mostly been classified including a EX90 3 year old, and a VG86 2 year old. 12 cows fresh in the last 90 days. Some extreme high quality Jerseys in this herd!! Mark Ashmore, Boscobel

Complete Herd Dispersal #2 (45) Tiestall cows. Mostly registered Holsteins with several good Swiss. 22,000 RHA on official DHIA. Not pushed for production and let out daily. Top bulls used from several AI companies.

Formerly Turenne Livestock

SALE EVERY MONDAY AND WEDNESDAY 5:00 PM

Selling Baby Calves, Hogs, Sheep, Goats, Feeder Cattle, Fat Cattle, Market Cows and Bulls

VERY COMPETITIVE MARKET PRICES Call 712-432-5500 for daily market report

JWO NOTES & MARKET REPORT: Big enough to make a difference, small enough to care!

If anyone out there is interested in a part time office job in Loyal, please talk to me. Also need part time barn help in Loyal and Thorp. Let’s see, how do we make this sound like a good place to work?

Flexible schedule? Check. Nice working conditions? Check. (At least if you don’t mind rain, snow, heat and cold) Competitive wages? Check. (Hey I’m paying considerable more than I ever made working per hour) Great co-workers? Check. (For real) Great boss? (Meh..idk..)

534 head consigned today. No Supreme quality cows today. Good quality cows $1,2001,800. Top $2,100 Nelson Miller, Argyle. $2,000 Jonathan Horst, Loyal. Springing Holstein heifers $1,300-1,750. Brown Swiss $1,775 & 1,850. Open Holstein heifers $90-115. Single birth Holstein heifer calves $85-200. Breeding Bulls $1,100-1,700. Market Bulls $105-109.

Choice Holstein steers $136-147. Crossbreds $150-158. Top Crossbred hfr $158 Donald Rudolph, Athens. Holstein feeder steers $120-170. 5 head 439 lbs @ $170. 5 hd 782 lbs @ $140. 6 hd 603 lbs @ $138. 11 hd 635 lbs @ $136. 21 red & blk strs 533 lbs @ $225. 3 blk strs 550 lbs @ $204. 11 blk strs 620 lbs @ $197. 6 blk strs 623 lbs @ $180. 5 blk strs 898 lbs @ $163. 6 Fleckvieh hfrs 664 lbs @ $175. 10 Fleckvieh hfrs 697 lbs @ $170. 8 blk hfrs 732 lbs @ $169. 19 Fleckvieh hfrs 642 lbs @ $160.

Sold 115 calves. 60% of Holstein bull calves $200-300, top $305 J. Ervin Showalter, Spencer. Beef cross bull and heifer calves mostly $300-520, top $550 Laverne Lepak, Custer & $540 Linus Nolt, Willard.

20% of Market cows sold $94.50-99.50. 50% sold $85-93.50

3x4x8 Alfalfa $220-250. 3x3x8 Alfalfa grass mix $90-110. Grass rounds and squares $50-75. Older grass/smaller bales $27.50-40. Baleage $40-65. 3x4x8 wheat straw $75-85. Squares corn stalks $32.50.

As always, Thanks for your business!!

open heifers and feeders followed by calves, market bulls, fat cattle and cull cows. Special feeder sale 2nd & 4th Thursday. WATCH OUR SALE ONLINE AT WWW.CATTLEUSA.COM

SALE

May 6, 2023

10 a.m. - 2 p.m.

Departure at BBE HS at 10:20 am

Lunch served along the way

*All tractors must have SMV signs*

Call or text Teresa with any questions 320-292-9495

CLIP AND SAVE

THURSDAY, MAY 18, 2023

DAIRY SALE RESULTS FROM March 16, 2023

194 head sold

Top Springing Heifer (Swiss) - $2,300

OUR COMMISSION IS ONLY 2.5%!

EVERY TUESDAY: 9 a.m. Slaughter Hogs • 11 a.m. Hay - Straw

12 noon Slaughter Cattle

1ST & 3RD WEDNESDAYS: 1 p.m. all classes sheep & goats

2ND & 4TH THURSDAYS:11 a.m. Stock cows

Baby & Started calves

3RD THURSDAY: 9 a.m. Dairy Sale

• Feeder Cattle

• Springers, Bred & Open Heifers

• Breeding Bulls • Herd Dispersals

Pipestone Livestock Auction Market, Inc.

PIPESTONE, MN

For more information phone: Of ce 507-825-3306 www.pipestonelivestock.com

ATTENTION FARMERS...

Are rocks, re-rod or holes showing in your bunker silo?

WE CAN RESTORE YOUR BUNKER TO LIKE NEW CONDITION!

BUNKER SILO RESTORATION/ REPAIR WITH JETCRETE

Approximately 1” of steel reinforced material added to bunker walls.

• High pressure water blasting of walls for excellent bonding.

• 6 gage heavy duty wire mesh installed

• Jetcrete -phnuematically applied concrete.

SILO RELINING WITH “JETCRETE”

BARN WALL & BASEMENT RESTORATION WITH “JETCRETE” (Limestone, rock, block & concrete wall)

GUARENTEED BEST PRICING

SERVING IA, MN, WI, IL AND SD

CONTACT: 800-866-7327

Is Your Tractor Ready for Spring Field Work? Rea

We do general tractor repairs on most make or model tractors.

Doing your own repairs and need parts?

We can get parts for: John Deere New Holland

Case IH and many more

Call us for your tractor maintence, repairs and parts

Deere Tractor Salvage Stanley, WI • 715-773-0731

Hay sales starts at 12:30 p.m. and are the 1st and 3rd Thursdays of the months of September thru May.

May 4, 2023

May 18, 2023

For more information, contact Kevin Winter 320-352-3803, (c) 320-760-1593 or Al Wessel at 320-547-2206, (c) 320-760-2979

From the kitchen of: Kara Abraham of Plymouth, Wisconsin

1 cup butter

1 cup white sugar

1 teaspoon vanilla extract

1 egg

2 teaspoons baking powder

1/2 teaspoon salt

3 cups flour

Preheat oven to 350 degrees. In the bowl of your mixer, cream butter and sugar until smooth, at least 3 minutes. Beat in vanilla and egg. In a separate bowl, combine baking powder and salt with flour. Add dry mixture to wet mixture slowly. The dough will be very stiff. If it becomes too stiff for your mixer, turn the dough out onto a countertop surface and finish mixing by hand. Do not chill the dough. Divide into workable batches and roll out onto a floured surface and cut. You want these cookies to be on the thicker size, closer to 1/4-inch. Bake at 350 for 8-9 minutes. Let cool on the cookie sheet until firm enough to transfer to a cooling rack. Top with your favorite frosting and sprinkles.

From the kitchen of: Kara Abraham of Plymouth, Wisconsin

32-ounce bag frozen tater tots

3-ounce bag bacon pieces

1 pound boneless skinless chicken breast, diced

2 cups shredded cheddar cheese

3/4 cup milk

Salt and pepper to taste

Preheat oven to 350 degrees. Spray a 9-by-13 cooking dish with non-stick cooking spray. Layer half of the frozen tater tots on the bottom of the pan. Sprinkle with 1/3 of the bacon pieces. Now top with 1/3 of the shredded cheese. Add diced chicken on top and season the chicken with salt and pepper. Now add 1/3 of the bacon pieces and 1/3 shredded cheese. Put the rest of the frozen tater tots on top. Finish with the remaining 1/3 cheddar cheese and remaining 1/3 of bacon bits. Pour 3/4 cup milk all over the top. Bake for 50-60 minutes or until chicken is done

3x4

From the kitchen of: Kara Abraham of Plymouth, Wisconsin

1 pound butter

4 cups peanut butter, chunky

3 pounds powdered sugar

4 cups Rice Krispies

Mix together and shape into balls. Chill. Melt 24 ounces milk chocolate chips or almond bark and dip balls and place onto wax paper to cool.

FEEDER CATTLE AUCTION

Tuesday, April 25, 2023 at 11 a.m. EXPECTING 800-1,000 HEAD!!!

NEXT SPECIAL FEEDER CATTLE BRED BEEF COW AUCTION

Tuesday, May 2, 2023 at 11 a.m. Featuring Quality Beef Breeding Bulls! See our website for more details, pictures, and videos! EXPECTING 200 HEAD!!!

Tuesday, April 25, 2023 at 11:00 am Call with your consignments! Expecting 500 head!

Wednesday, April 26, 2023 at 11:00 am HERD DISPERSAL

100 Holstein Dairy Cows. Parlor/freestall, cows will sell on test., averaging 83# 4.9BF 3.1P 175scc. All 2 and 3 yr olds, majority just fresh, some bred back and milking heavy! Many many years of TOP sires used from ABS, majority AI bred Angus. Extensive vaccination program. Very nice gentle cows. *Note* Owner will be selling a big portion of his very large dairy herd, spread out over the next several months. Coming from Bonestroo Dairy COMPLETE REGISTERED JERSEY HERD DISPERSAL

60 JERSEY Dairy Cows and Dairy Heifers (33)cows (27)heifers, including (3)FANCY Red Holstein Dairy Cows. 5th generation family farm. Cows in all stages of lactation, milked in tiestall. Cows sell on test, averaging 55# 5.4BF 3.7P 170scc. Over 28 years of TOP AI sires used, polled genetics throughout. Regular herd health and hoof trimming. 60% are 1st & 2nd lactation. Many cattle have been shown at fairs and are halter broke. Heifers range from newborn calves through springers. Coming from THF Jerseys, Somerset, WI

12 Registered BROWN SWISS Dairy Cows. All springing dry cows. Bred to a registered polled Brown Swiss bull, due May. Tiestall milked, outside daily. Owners previously sold dairy herd at Premier, now selling springing cows as they get close. Coming from Brucedale Farms, Friendship, WI

35 REGISTERED Jersey Springing Heifers, mostly bred to Kid Rock son, freestall/headlock adapted, vaccination program. Owner sold his nice registered Jersey dairy herd at Premier last fall, now selling his springers as they get close. Coming from Mallery Jersey’s, Shafer MN

Always a great selection of dairy cattle at Premier Livestock and Auctions! DRIVE-INS ARE ALWAYS WELCOME! PLEASE HAVE IN BY 10:30 AM

Weekly Highlights at Premier

Another week at Premier, selling 2,540 head of livestock. Dairy Cattle Auction held Wednesday, 286 head of dairy cattle, 2 herds sold, strong market. Many loads of extreme top fresh cows averaging $2,2002,600 per load avg. Top fresh cows $2,2002,800. Many other good cows $1,500-2,175. Top springing heifers $1,400-1,850, light test. Full market report on our website and all major farm papers !! We are thankful for all of your business!!!

Scan

The Penta line of Dump Trailers are designed to get your crop from the field to your farm. Ranging in size from 1050 Cubic feet to 2475 Cubic feet there is one ready for you. Farmer focused features like better visibility in the box and the unique reverse tilt for better filling, all built as tough as you.

The best quality feed needs the best quality mix. Penta TMR Mixers are designed, tested and farm proven to deliver the best mix on the market. Our Hurricane Auger allows forage to circulate faster through the mix for quicker processing and mixing times.

The Penta (Hagedorn) line of Manure Spreaders allows you to make the best use of your organic nutrient resources. The Hagedorn Spreaders processes the manure finer with the best spread pattern. This lets your field make better use of this rich resource.

www.pentaequipment.com

‘18 Gehl RT165, JS Ctrls, 69HP Dsl, 15” Tracks, 2000 Lift Cap, C/H/A, 2 Spd, 950 hrs - $44,900

‘14 Gehl R260, T-Bar Ctrls, Dsl, 2600 Lift Cap, C/H/A, 2 Spd, 3,725 hrs ............................$31,900

‘17 Gehl R220, H-Ctrl, Dsl, 2500 Lift Cap, C&H, 2 Spd, 2660 hrs .$33,500

‘15 Gehl R220 T-Bar Ctrls, New 72HP

Yanmar Dsl Eng, 2500 Lift Cap, C&H, 2 spd, 4025 hrs .........$37,000

‘22 Gehl R220 T-Bar H-Ctrls, 2500 Lift Cap, C&H, 2 spd, 3890 hrs .............................$38,800

Gehl 5640, T-Bar Ctrls, 2500 Lift Cap, C&H, 2 Spd, 3,450 hrs ........$25,500 Gehl 4625, T-Bar Ctrls, 46HP Dsl, SS .......................................$11,900

Kuhn Knight PS150, 500 Bu Vert Beaters, New Apron Chains, New Beater Teeth ........................$35,250

H&S 310, 540PTO, 295/75-22.5 Tires .................$9,600

‘19 Hagedorn Hydra-Spread Extravert 5440, 540 Bu, Vert Beater, Hyd Push, Endgate, 4’ Rock Guard ............$46,000

Jamesway Vacu-Pump, 6” Transfer Pump, 11L-15 Tires, 540 PTO$3,400

Houle 13, 1 3/8, 1000PTO, 13’ Depth ..............................$4,900

‘09 Kuhn Knight 8132, 425 Truck

Tires, 3200 Gals ..................$25,500

Kuhn Knight 8132, Flotation Tires, 3200 Gal .............................$16,250

‘12 NH Duratank 3400S, 49x19.0-20 Tires, 3400 Gal ....................$16,500 NH S676, 540PTO, Selling As Is ..........................$1,700

‘15 SAC 6160 Turbo Max, 600 CuFt, Turbo Paddle Reel, 4 Auger Power Discharge ............................$32,500

‘12 Penta 6720HD, 540PTO, 670 CuFt, Flat Conveyor ......$19,500

‘15 Penta 4130, 450 Cubic Feet,

3’ Right Hand Conveyor ......$22,900

Kuhn SR110, 10 Whl Rake, Center Kicker, 21’ Raking Width .........$6,350 Hiniker 4000, 15’ Stalk Chopper, 9.50L-15 Tires.........................$5,500 Highline CFR650 ....................$18,500

8 Whl Rake, 3 pt ..........................$900

Lorenz 85 Mixer Mill, 540 PTO, 80 Bu ....................................$5,500 Oliver 550, 2 WD, 46 HP .......$4,900

JD 469 Premium, 4x5 Bales, Net, Twine, No Monitor, ISO Boss ..$27,500

JD 567, 5’x6’ Bales, Cover Edge Net, Twine, Bale Count 18,509........$12,870

‘19 McHale V6750, 4x5.5’ bales, surface wrap, auto wrap, bale kicker, cutter rotor, 900 bales .............$55,500

NH Roll-Belt 560, 2800 bales...$44,500

‘15 Anderson Hybrid X, Up To 6’ Rd & 6’ Sq Bales, GX630 20HP Honda Engine, 4 Stretchers, Hyd Push Extractors, Bale Row Guidance, Large Fuel Tank,Self Propelled ........$26,500

‘16 H&S BW1000, 11Lx15 Tires, 6’ Bales, 13,500 Bales On Counter ................................ $24,900

‘19 H&S LW1100 Linewrap, Wrap 6’ Bales, at 2,800 For Bale Count.............................$31,000

Tubeline TL1700SR, Square Bale

3’x3’ Up to 7’ Long, Rd Bale 4’x4’ To