“All

Calkins family dairying on farm established in 1864

“All

Continued learning leads to more questions on H5N1 in dairy cattleBy Danielle Nauman danielle.n@dairystar.com

Since the initial detection and identication of H5N1 in dairy cattle in March, all facets of the dairy industry have been working diligently to learn more about the disease, how it is spreading and the impact it is having on dairy cattle.

As of April 22, the bovine inuenza A virus has been identied on 33 dairy premises in eight states: Texas, 12; Michigan, 6; New Mexico, 6; Kansas, 4; Idaho, 2; and one case each in North Carolina, Ohio and South Dakota.

“This is rapidly changing and evolving; information is coming in by the day, by the hour,” said Dr. Mark Lyons, director of ruminant health for the U.S. Department of Agriculture’s Animal and Plant Health Inspection Services, in a webinar hosted by the National Milk Producers Federation April 17.

According to Lyons, the genome sequences show the strain of the virus present in dairy cattle in all affected states is similar to what has been found in wild birds.

The initial introduction of the disease from wild migratory birds into dairy cattle likely took place somewhere in the Texas panhandle, Lyons said, adding the virus appears to be transmitting laterally between cattle, but that exact transmission route remains unclear.

“This is inuenza,” Lyons said. “It is very unpredictable. It is important for us to keep monitoring it.”

Because of those unknowns regarding transmission of the disease, biosecurity is the best defense dairy farmers have, said Dr. Keith Poulsen, director of the Wisconsin Veterinary Diagnostic Laboratory.

BLUE EARTH, Minn. — Pioneering travels and tragedy cloak four 161-year-old trunks resting from their adventures in the attic of the Calkin family.

Bob and Lori Calkins own a sesquicentennial dairy farm near Blue Earth. Their 300 acres encompass the family’s original homestead claim from 1864.

“It’s a cool thing to know that four, ve generations of my ancestors have been here on this farm and started it,” Bob said.

Today, the Calkin family’s dairy farm has its building site a little way from the original home’s foundations, which are still in the woods.

Turn to CALKINS | Page 6

NEW LONDON, Minn. — One year ago, Tom Kampsen and Becky Heinz set a plan to build a parlor on Kampsen’s dairy farm near New London. They decided to utilize the existing structure of their tiestall barn.

Milking took four hours each time, turning the barn over twice with 48 cows in each group and using six units.

Poulsen said when H5N1 makes its way into a dairy herd, the virus peaks in the rst 4-6 days, tapering off by days 10-12. He said most dairies are reporting a recovery of approximately 30-45 days.

Poulsen urged producers not to wait too long before reaching out if they suspect the virus is in their herd.

320-352-6303 (ofce) 320-248-3196 (cell) 320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Maria Bichler - Assistant

Stacey Smart - Assistant Editor 262-442-6666 • stacey.s@dairystar.com

Danielle Nauman - Staff Writer 608-487-1101 • danielle.n@dairystar.com

Abby Wiedmeyer - Staff Writer

608-487-4812 • abby.w@dairystar.com

Tiffany Klaphake - Staff Writer 320-352-6303 • tiffany.k@dairystar.com

Jan Lefebvre - Staff Writer jan.l@star-pub.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Emily Breth - Staff Writer emily.b@star-pub.com Consultant

Jerry Jennissen 320-346-2292

920-979-5284 • kati.s@dairystar.com

Jerry Nelson (SW MN, NW Iowa, South Dakota) 605-690-6260 • jerry.n@dairystar.com

Mike Schafer (Central, South Central MN) 320-894-7825 • mike.s@dairystar.com

Megan Stuessel (Western Wisconsin) 608-387-1202 • megan.s@dairystar.com

Julia Merten (Southeast MN and Northeast IA) 507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell)

bob.l@star-pub.com

Mark Klaphake (Western MN)

320-352-6303 (ofce) • 320-248-3196 (cell) Published

“Very active observational surveillance is important,” Poulsen said. “The best way to respond to this is with strong communication. If you see something, call your veterinarian, ask questions. It’s OK to be wrong; it’s OK to have a negative test. I’d much rather have a negative test than not test at all and miss something.”

Polymerase chain reaction testing of raw milk is the best indicator of the presence of the virus, Poulsen said. Serology testing is not a measure of an acute infection but of an immune response, Poulsen said, adding that cows and mammals in general do not respond to inuenza well with antibodies. Poulsen said work is being done to develop diagnostic options.

Because H5N1 is a virus, Poulsen said antibiotics are only recommended in the presence of a secondary infection, suggesting farmers facing the virus work with their veterinarian to develop protocols for supportive therapies.

Poulsen said all milk from cows with clinical symptoms should be discarded and not used for feeding calves.

Turn to H5N1 | Page 5

started with

He also recommends that all calf milk be pasteurized.

“Pasteurization is always the gold standard,” Poulsen said. “There is no data out there that makes us think pasteurization is not 100% effective in killing the virus.”

Dr. Jason Lombard, an associate professor and dairy systems specialist at Colorado State University, addressed ways dairy farmers can implement biosecurity measures on their farms to help mitigate risk.

“Enhanced biosecurity is implementing management practices to protect cattle and people from exposure,” Lombard said.

The rst thing to consider is how disease enters a farm, Lombard said. This could be by animals and animal products; airborne; rodents, birds, ies and wildlife; vehicles and equipment; people; and through feed, water and bedding.

Lombard said biosecurity starts by monitoring sick animals and minimizing cattle movement as much as possible.

“We know that movement of cattle is what introduced the virus to some states,” Lombard said. “If we have to move cattle, then premovement testing is recommended along with quarantining new arrivals for at least 21 days.”

Recommendations for premovement testing include testing of milk samples taken from lactating cows and nasal swabs taken from non-lactating animals.

“If possible, delay or stop incoming or returning animals

Jersey cows eat a total mixed ra on on a Wisconsin dairy farm. One of the

the bovine inuenza A virus is reduced

from herds with unknown or suspect health status,” Lombard said. “Be sure to separate all new or incoming animals. Work closely with your veterinarian on how to best do this for your herd.”

When faced with sick animals, Lombard encourages dairy farmers to have a dedicated plan.

“Don’t have sick animals sharing air space, panels, fence lines, feed or water with others,” Lombard said. “Ideally, there would be dedicated caretakers and equipment for these animals. At the minimum, workers should be wearing (personal protective equipment) that is changed. Look to your veterinarian for advice on testing and

decreased

criteria for when sick animals can be returned to the herd.”

Cattle movement considerations include the use of equipment such as cattle trailers, Lombard said.

“Livestock trucks and trailers are an unknown risk since we don’t know how the virus is transmitted from cow to cow,” Lombard said. “We should try to limit the use of trailers to a single source — one herd. We should be cleaning and disinfecting the interior of the trailer between each load of cattle.”

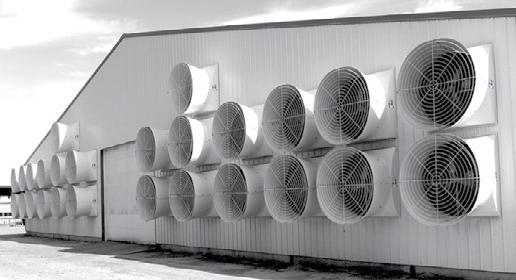

The presence of other animals on the farm, particularly birds, is one of the more daunting arms of implementing enhanced biosecurity measures, Lombard said.

“Birds are probably the most difcult thing to keep off a dairy operation in terms of biosecurity,” Lombard said. “We can manage a lot of things, but birds are really difcult. If they are playing a role in the continued spread of the disease, then that’s a concern.”

Disrupting the on-farm habitat such as taking away access to shelter, feed and water is critical but nearly impossible, Lombard said.

Limiting visitors and vehicles that come to the farm is another important step in creating an enhanced level of biosecurity, Lombard said.

“Limit visitors to essential personnel and keep a visitor log so you know who was on

the farm and when they were there,” Lombard said. “Visitors should stay away from the animal areas unless absolutely necessary. PPE should be worn by all visitors: coveralls, boots, gloves, masks and safety glasses or goggles.”

Lombard recommends keeping all parked vehicles in a clean area away from the cattle and where they move. He recommended having delivery drop-off areas located on the periphery of the premises.

With the concern that the virus can be spread through contact with raw milk, Lombard said milk truck biosecurity is paramount.

“Milk truck drivers should be wearing PPE and observing all biosecurity practices,” Lombard said. “Transfer hoses should be disinfected between farms, or ideally, there would be farm-dedicated transfer hoses.”

With so many unknown factors surrounding the transmission and long-term effects of the virus, enhanced biosecurity is the best tool dairy farmers have, according to Lyons.

Enhancing biosecurity in dairy, poultry and all industries is important, Lyons said. It is also paramount to be vigilant about monitoring sick animals and looking for disease in birds and ocks.

“Biosecurity is what we are emphasizing to get ahead of the spreading,” Lyons said. “This is something we’re going to have to face together, making sure we are identifying sick animals and getting samples to test.”

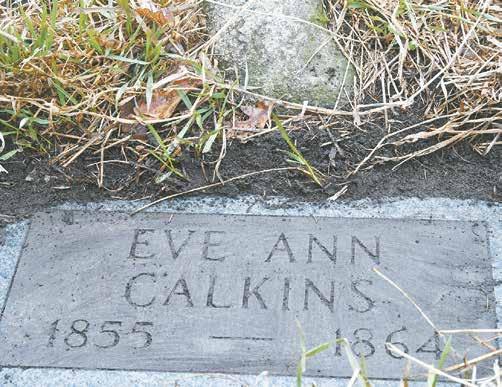

A gravestone marker for Eve Ann Calkins lies next to a stone April 2 on the Calkin family’s dairy farm near Blue Earth, Minnesota. Eve Ann passed away from diphtheria in 1864, the rst winter her family was on the farm. The stone next to the gravestone was the original marker for her grave.

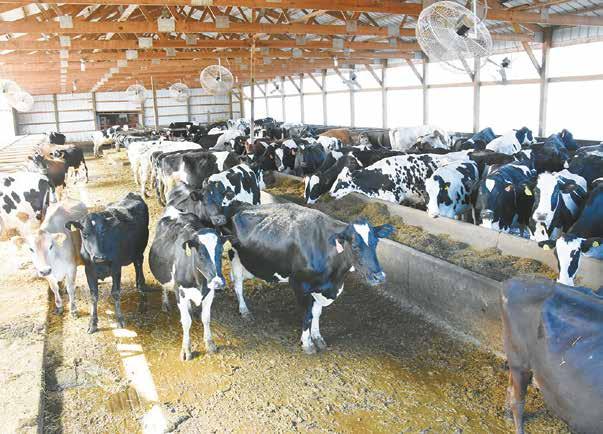

The Calkins milk their cows in a double-8 herringbone parlor they built in 2006.

“(Dairy farming is) a good t with our farm,” Bob said. “We don’t have a tremendous amount of acres here, and we’re able to utilize some manure and be efcient with the cropping.”

Bob and Lori are assisted by eight full- and part-time employees.

Cows are housed in a freestall barn built in 1999. Calves are housed in hutches inside a hoop barn during the winter and outside during the summer. Lori feeds the calves and likes the hoop house for the winter.

“I don’t have to be in the ice and the rain,” Lori said.

we bought,” Bob said. “I had a champagne taste on a beer budget.”

Today, they milk 240 cows. But their story begins in 1863, when Bob’s great-great-grandfather, David, and his wife, Mary, headed west. According to “Martin County, Minnesota History,” they traveled with four young children in an oxen-drawn, covered wagon. Accompanying them were two cows, two heifers, two calves and four trunks.

Bob and Lori moved to Bob’s family’s farm in 1988 after Lori nished her education at Iowa State University to become a veterinarian.

The Calkins took over the farm in 1993 and purchased it in 1997.

“I like farm life,” Lori said. “I like the independence; I don’t like the price. But, you have to take the good with the bad.”

When the Calkins moved back in the late ’80s, the farm was milking about 40 cows.

“We just gradually expanded from within, besides a few registered cows

According to “Martin County’s Heritage,” the Calkins’ ancestors crossed the mighty Mississippi via ferry because there was no bridge. They arrived on the prairies of Minnesota in November 1863 and chose a plot of wooded land on the east side of Lake Burnt Out.

Over the winter, their 9-year-old daughter, Eve Ann, died. According to “Martin County’s Heritage,” she succumbed to diphtheria, which was epidemic at the time. It said she was the rst recorded death in the township and that she was buried on the highest point of the farm. Bob said that her burial spot was her favorite vantage point to look over the lake.

Her grave was marked simply with a large stone, the tip of which is visible today. Bob’s parents placed a at engraved stone marker for her so her burial place would not be forgotten.

Bob’s great-grandfather, Amos, was a child when the family moved to Minnesota. The book tells the story of when a nearby settler decided to move to Sioux Falls, South Dakota. He had Amos help him herd his cattle for the 125-mile journey. It was fall, and when they arrived in South Dakota, 13-yearold Amos was sent back by himself on a poor-quality pony.

Amos made the journey across a prairie with no roads and few settlers. Most of the nights were spent camping on the prairie, fearing wolves and Native Americans. It said Amos thought he was not going to live through it.

The Calkins family has stories of Native Americans camping at their farmstead and other experiences. Care was taken to not disrupt the equilibrium.

Bob and Lori’s home was built in 1918 by Bob’s grandfather, John Calkins. Theirs was the rst rural home in Martin County to have electricity, according to “Martin County, Minnesota History.”

John was innovative. According to “Martin County, Minnesota History,” John was born in 1887 and graduated from the University of Minnesota in 1908. He purchased half of the Calkin’s farm from his father, Amos. On it, he created a “model farm,” with the building site in the middle of his land equidistant from his elds.

The Calkins have meticulous records and drawings done by John. They range from hand-drawn maps of their land’s tile ditches from 1908, including elevation, a crop rotation plan for the years 1914-19 and manure charts for the

Bob Calkins

same years.

The lake on the farm, which was quite shallow, was part of a chain of disintegrating lakes in the area. According to “Martin County, Minnesota History,” from 1904-12, Amos was part of a project to help drain the lakes, adding approximately 50 acres to the farm.

In 1946, the Calkins family was an early adopter of articial insemination. According to a journal article by W. Ombelet and J. Van Robays, the rst A.I. cooperative in the U.S. was started by a dairy farmer named E.J. Perry from New Jersey in 1938.

Today, after more than 160 years as a dairy farm, Bob said he does not know what the future will be.

“It’d be really cool to see somebody here using the parlor and the barn,” Bob said. “Frankly, it’s pretty hard to encourage children to do it, just because of what we’ve gone through over the years. ... I’m not saying we regret it.”

“That got old really fast,” Kampsen said. “It was a lot of labor. We were feeding cows in a freestall barn and feeding cows in a tiestall barn.”

Construction on the parlor began last July, and on Oct. 12, 2023, the couple began milking in their new facility. However, getting through the building process, they said, was a trial of perseverance as they continued to milk their cows in the barn while construction sights and sounds took place all around them.

“We were milking in 20 stalls on one end of the barn while the other end was ripped out, so the cows were spooked,” Kampsen said. “The last week, we milked in eight stalls and just had a pipeline hung from the ceiling with wire all the way to the milk room, and it took 5-6 hours for milking each time, because we could only use four units. It was a big pain in the butt during construction, but we got through it.”

Today, Kampsen and Heinz milk their herd of mostly Holsteins and some Jerseys in a double-7 herringbone parlor in their revamped facility. The parlor equipment is from Heinz’s farm near Brooten where she used to milk cows. Kampsen and Heinz are planning to grow the milking herd at Kampsen’s site to about 170.

“The parlor is way easier on the cows; they come in pretty much on their own,” Kampsen said. “Time savings is also big. The parlor cuts

Cows

and

milking time in half.”

A team of two can now milk the cows in two hours. Kampsen, who usually does the morning milking, can nish the job in three hours. Heinz handles most of the evening milkings with a part-time employee.

With the parlor completed, Kampsen and Heinz are looking toward their next project.

“Now we want to add on to the freestall barn this year and

(create) a bedding-pack barn so that we can put trouble cows and fresh cows on bed packs,” Kampsen said.

The freestall barn, built in 2021, is 50- by 120-feet. This summer, they will add 60 feet to the barn and increase from 70 stalls to 113.

The expansions on the farm are being done with the next generation in mind. Kampsen’s three sons are con-

sidering joining the operation.

Kampsen’s son, Dylan, was working with him full time when they built the existing freestall barn. Dylan then enlisted in the Marines, but he will likely come back to dairy farming in two years. Ayden will be 18 this fall. Kampsen said he intends to farm full time after high school. Tommy, 13, is already talking about possibly farming.

“(My sons) have plans and dreams, so we’ll see how it goes,” Kampsen said.

Heinz said building the parlor has been worth it for her and Kampsen, but they and their cows had to go through a learning curve.

“Even for us, just getting into a routine, and then for the cows to get into a routine, it took about six months before it came down to two hours for milking,” Heinz said. “Part of the issue was all the construction for several months in the cows’ environment.”

Kampsen agreed.

“They didn’t know if they were coming or going,” he said. “I’m glad that part is done. Production went down just because of the big transition, but it’s coming back.”

Heinz said they are noticing health benets to the herd as well.

“The somatic cell count has been cut in half,” she said. “When we rst started using the parlor, we had some areups. … But now, if we have one areup a week, that would be a lot.”

Kampsen and Heinz said they are happy with the costsaving measures they took while planning and building, which is making their expansion affordable. At rst, they thought about building everything new, but using the shell of the tiestall barn made nancial sense to them.

The pipes for the parlor were put in the tiestall barn’s gutters and cemented in, and now drainage from the parlor is pumped through the pipes to the pit. The parlor and concrete work were completed by D&D Agriculture Supply & Construction of Pennock. The other work was done by Kampsen and Heinz with help from family and friends.

“My dad, Tom, did most of the carpenter work, and he also did most of the plumbing besides in the parlor,” Kampsen said.

Tom also did most of the steelwork, with Kampsen assisting. Kampsen’s cousin took a week off from his job to help with welding. Friends and other family came to help when they could.

While planning the parlor, Kampsen and Heinz considered various options.

“Becky had seen a lot of parlors when she worked in nutrition, and she saw some of what worked and what didn’t,” Kampsen said.

For the project, the couple was able to use parlor equipment from Heinz’s farm. They had thought about installing a robotic milking system but put that off for now.

“It came down to that we’d have to redo all the electrical for the farm (for robots),” Heinz said. “All those things would add a lot more expense.”

Kampsen agreed.

“The way we did it was very affordable,” he said. “At the end of the day, you can spend a million dollars on new equipment and such, but milk is still worth 15 bucks.”

Construction of the parlor involved a whirlwind of activity for the couple each day.

“There were many nights when I would go inside in my work clothes and

sit in my chair at 1 or 2 in the morning,” Kampsen said. “Then, I’d get right back up at 3 or 4 in the morning to go back out to work.”

Already, the parlor is allowing them to grow their herd while simultaneously giving them more time off and freedom.

Since the parlor is easier for employees to manage, Kampsen and Heinz have been able to schedule date nights and more family time. Heinz said she is nding a better balance and is able to give more time to her two daughters, Hailee and Evalyn, who come to Kampsen’s farm almost every day. Hailee has begun helping with milking and calf chores.

“This is the rst time I’ve been able to be a full-time dairy farmer,” Heinz said. … “Timewise, I had two kids who were getting the short end of the stick, and now I can be there. I can be there in the mornings and get them on the bus.”

Kampsen is nding more time for relaxation.

“I’ve always wanted to go to the (Central Plains) Dairy Expo, and I’ve never been able to do that,” Kampsen said. “This year, we went. It was fun.”

Mostly, Kampsen said he likes working with his family, and the expansion is making room for that.

“I like the family together, working together … side by side,” Kampsen said.

Weathering the construction storm has given the couple a sense of accomplishment.

“It was nice just to be able to breathe and be thankful for what we have and all the help we had,” Heinz said. “Now that we’ve had the winter to settle down and get some sleep, and with chores taking so much less time so that we can be done by 7:30 most nights, it’s nice to get in the house and make a good meal and enjoy the fruits of our labor.”

In the April 13 edition of Dairy Star, in the article, “A family of milk haulers: Swart passes love of job to next generation,” Tanner Rohner was incorrectly stated as being a stepson of Darren Swart. Rohner is a son of Swart. Dairy Star staff regrets this error.

“We like that the grooming brushes remove the winter hair and it keeps the cows cleaner and our parlor cleaner. The brushes are also easy to repair if necessary. Cows love them.”

The U.S. Department of Agriculture is working with state animal health ofcials to collect data about the spread of bovine inuenza A virus in dairy cattle. USDA chief veterinary ofcer Dr. Rosemary Sifford stresses the importance of this information. “It is important to us at this time to receive samples from these herds so we can get a more clear picture of what is going on,” Sifford said. “So far, it appears that the cattle can recover after a couple of weeks.”

Document your losses

As of publication, bovine inuenza A virus has been conrmed in dairy cattle in eight states. That list includes one dairy herd from South Dakota. “I suspect we will (see) some (cases),” said Thom Petersen, Minnesota Department of Agriculture Commissioner. “We may have it already.” Indemnity payments are made to poultry farms impacted by highly pathogenic avian inuenza. We asked Petersen if dairy farmers can expect similar assistance. “Document your losses, just like we do for other disasters, and if the USDA comes with an indemnity-type plan, we would be able to hopefully help those farmers out,” Petersen said. “People are saying the cow doesn’t die, but it doesn’t give milk. There is a loss of production.”

The current farm bill extension expires at the end of September, and there’s no apparent timeline for a vote in either chamber. U.S. Sen. Tina Smith, who is a member of the Senate agriculture committee, is anxious to move forward with the farm bill. “I just had a long meeting with Chair Debbie Stabenow from Michigan, and I know many of us on the committee and Sen. Stabenow are really eager to get this done,” Smith said. “It’s no secret we’ve been having a couple of big disagreements (over budget priorities) on the farm bill.” Stabenow will retire at the end of this year and wants to get the farm bill done on her watch. However, Smith

emphasized Stabenow will only support legislation that is good for farmers and consumers. “It’s pretty likely that our very own Minnesota (Sen.) Amy Klobuchar will be the next chair or ranking member of the agriculture committee, so that’ll be really great for us in Minnesota,” Smith said.

Congress, common food names

The House Committee on Ways and Means has approved the renewal of the Generalized Systems of Preferences trade program for agriculture-specic products. This bill protects the generic use of common food and beverage terminology, such as Parmesan and feta. The European Union has been trying to impose restrictions on these terms based on geography. Minnesota Rep. Michelle Fischbach is one of three lawmakers who were behind this bill. The NMPF, U.S. Dairy Export Council and the Consortium for Common Food Names praised this action.

Ford named to TIME 100

By Don Wick Columnist Ag Insider

By Don Wick Columnist Ag Insider

The environment policy bill includes technical provisions tweaking Minnesota’s 2015 buffer law. That includes language giving the Minnesota Board of Water & Soil Resources regulatory authority over buffer zones. “There may be a local entity that is not doing the implementation,” Rep. Rick Hansen said. “This actually provides a procedure for the Board of Water & Soil Resources to make sure that there’s a process if they are revoking that authority.” Rep. Jeff Backer of Browns Valley spoke in opposition, saying this is a “top-down” approach. “This could be interpreted as if BWSR does not like what the local soil water conservation district is doing, they will be forced to become the bad cop even though they have worked over the last 10 years to help get the landowners into compliance,” Backer said. The amendment to maintain local control was rejected.

TIME magazine has named Land O’Lakes Inc. President and CEO Beth Ford to its annual list of the 100 most inuential people in the world. Ford has been in her current role since 2018. Ford is also part of the President’s Export Council.

Midwest Dairy CEO takes the job at a unique time for the industry

Corey Scott is in her early days as the new executive director of Midwest Dairy. Scott spent the last 15 years of her career with Land O’Lakes and its sustainability division, Truterra. “It’s a unique time to be coming into a checkoff role given what the economics look like,” Scott said. “With my background in risk management, it forces me to take a very critical business look at how we’re deploying checkoff dollars. We don’t have the luxury to be using checkoff dollars in such a way that we can’t quantify the impact.”

Sawatzke, Hawkins reelected

Proposal impacts animal agriculture expansion

Minnesota Rep. John Burkel, of Badger, who serves on both the agriculture and environment committees, is disappointed in the efforts to increase the regulatory pressure on farmers. That includes a proposal to require an environmental impact statement for any farm with more than 10,000 animal units. “It would probably eliminate anybody’s ability to expand and, once again, opens the door to the conversation about dropping that threshold to 5,000 or 1,000 animal units in the future,” Burkel said. “It puts the brakes on any expansion of animal agriculture in Minnesota.” Burkel hopes this language won’t survive the conference committee process.

At the end of March, dairy cow slaughter nationwide was down 14.2% from one year ago. Beef cow slaughter is down 11.3%. The demand for ground beef has kept slaughter cow prices high. The value of the 90% lean beef trimmings used for hamburger meat is record high.

Dave Peterson is the new board chairman for Associated Milk Producers Inc. Peterson, who farms near Boyd, Wisconsin, succeeds Steve Schlangen, of Albany, Minnesota. Schlangen served as AMPI’s board chairman since 2011. The vice chairman is Dennis Hawkins of Chippewa Falls, Wisconsin. Steve Hoffman of New Ulm, Minnesota, returns as secretary. Schlangen now takes over as treasurer.

The Minnesota Board of Animal Health has reelected Erica Sawatzke as president and Peggy Anne Hawkins as vice president. Sawatzke is a turkey farmer near Kensington, Minnesota. Hawkins is a veterinarian in Northeld, Minnesota. The BOAH is a seven-member citizen board appointed by the governor.

Trivia challenge

National Blue and Corn Gold are the ofcial colors of the National FFA Organization. That answers our last trivia question. For this week’s trivia, which common dairy breed originated in Scotland? We will have the answer in our next edition of Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network of Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

How long have you been testing with DHIA?

We have been testing with DHIA since the early 70’s when my grandpa, Fred, started testing with DHIA.

What tests do you use and what do you like about those tests? We just do the milk analysis test and like to look at butterfat, protein, and somatic cell count. Our nutritionist likes to look at the sheets to see if he needs to make changes to our ration to boost protein or butterfat.

Tell us about your farm. I farm with my mom, Nancy, and dad, Pat, we have 550 acres of corn and alfalfa and nish out our Holstein steers. We milk in an 85-stall tiestall barn. We also have three part-time high school kids that help. Accurate records that tell which cows

How does testing with DHIA bene t your dairy operation? DHIA bene ts our operation because of the accurate records and tells us which cows are more pro table and which cows it doesn’t pay to have in the herd. DHIA also helps with choosing which bulls to use on certain cows to improve components of the next generation of cows. I really enjoy the simplicity of getting the information. I can download the results of the tests through dairy comp to my computer to see the last test results.

Guess where your feed dollars are going?

Our soybeans have the energy, protein, amino acids and bypass protein for your cows!

Editor’s note: Dairy Star aims to provide our readers with a closer look into relevant topics to today’s dairy industry. Through this series, we intend to examine and educate on a variety of topics. If you have an idea for a topic to explore in a future issue, send Stacey an email.

MISHICOT, Wis. — When Steven Rahmlow received too many complaints for using an airplane to spray fungicide on his corn, he decided to use a drone instead.

acres, growing soybeans, winter wheat, alfalfa and corn, at Cedar Springs Dairy Farm near Mishicot.

“We always used an airplane to spray our corn,” Rahmlow said. “When people see planes ying around, it throws up a huge red ag, and you get complaints.”

“I absolutely loved it,” Rahmlow said. “The drone gets a lot closer and provides a lot better coverage than a plane.”

Rahmlow and his family milk 1,150 cows and farm 4,000

Rahmlow is going on his third year of hiring a drone operator to spray the fungicide. After spraying elds by drone the rst year, Rahmlow needed 1,674 acres sprayed the following year, and he had the drone applicator do it all.

“The drone is a lot smaller, and no one sees it,” Rahmlow said. “People don’t know there is someone out there spraying. We had zero complaints.”

When the need to spray a crop or plant cover crop seed arises, dairy farmers can turn to

drones to get the job done. They use drones to control insects, weeds and fungus, and to deliver nutrients to crops and seed for cover crops. Farmers might also use smaller camera drones to inspect elds and check crop health.

From cover crop aerial seeding and herbicide and fungicide application to doing test plots and crop scouting, drones have many uses in agriculture.

“A drone is such an awesome tool for someone with a growing operation,” said Jeramy

Williams, owner of American Drone. “Drones offer the benet of traditional aerial applicators but put the control in your hands. If you own the aircraft, you can do this yourself whenever you want. You don’t have to wait on a xed wing or have a lot of acres to justify one coming into your area.”

A drone can get onto a eld even when it is wet, ensuring timely application without leaving any evidence that it was there. When the ground is soft in spring, a ground applicator

can make ruts in the eld or get stuck, Williams said.

“You’re going to run over 3 bushels per acre just by driving the machine out there,” he said. “You are losing yield by pounding corn or soybean into the ground.”

American Drone provides liquid and dry aerial applications. It also runs a full-service dealership near Marsheld.

“We help them through the whole process, including all the legalities and regulations,” Williams said. “We train people and make sure they are safe, legal and condent in using drones. We are the only dealer of agricultural drones in Wisconsin that is also a custom applicator. We work with and service the two largest and most advanced drone brands: DJI and XAG.”

A drone can enter a eld at any stage in the plant’s life. Drones can also access hard-to-reach places like waterways, terraces, fence rows and tree lines. They can be used with success on rough, rocky or steep terrain and do applications near congested areas. When using a drone, the application stays on-site without drifting. In addition, drones target only those areas of a eld that require spraying.

set up with a drone applicator if they wish to go that route.

“Most of the dairy farmers I work with are using drones to apply fungicide on corn silage,” Verhulst said.

Verhulst said it is mainly bigger farms using a drone on their brown mid-rib corn silage, about 5%-10% of his clientele. As a service to his customers who buy fungicide from him, Verhulst lines up the drone application and ensures the farmer has the maps, water and other supplies needed for the operator.

“With a drone, you can be very specic about where you spray,” Williams said. “If you have a 100-acre eld with only 10 acres of weeds, you don’t need to put 100 acres’ worth of product out there. The precision inside of these drones allows them to be very accurate.”

Brooke Stewart, owner of AgriDrone LLC, is a custom applicator, certied crop adviser and agronomist. Operating out of Luxemburg, Stewart specializes in chemical and cover crop applications using a drone. She performs liquid and dry aerial applications, applying fungicide on corn, soybeans, winter wheat and alfalfa as well as planting cover crop seed.

“There are still quite a few farms with their own sprayer or they have the co-op do it,” Verhulst said. “If they don’t have their own sprayer, I recommend using a drone on the corn silage. I can help get the drone set up so the timing is correct. Timing is really critical for fungicide, and we can get the timing at the right stage with the drone.”

Rahmlow applies fungicide to prevent tar spots.

“We didn’t put it on one eld, and it was almost 30 bushels of a difference,” he said. “The plant died a lot sooner that year, and we lost tonnage.”

Rahmlow is considering trying the drone with soybeans this year.

“Pretty much anything you spray in agriculture can be done with a drone,” Stewart said. “From eld and vegetable crops to orchards, vineyards and forestry — all these industries can utilize drones.”

The drone ies 10 feet above the crop canopy with a swath of 30 feet at a rate of 25 acres per hour. Stewart said the cost for an application is about $20 per acre for an average-size eld.

“For a farm with a lot of small elds or higher rates of application, I would charge an hourly rate,” Stewart said.

Stewart sprays at a rate of 2 gallons per acre.

“That’s a typical rate we use to be efcient with the drone,” she said. “You can cover 25-40 acres per hour, depending on the type of drone you have.”

“We’re also thinking about getting our own drone in the future,” he said. “If I had a drone, I would maybe spread more cover crops instead of running equipment over the eld.”

Rahmlow said the only drawback of a drone is that it takes longer than an airplane.

“Airplanes are a little faster, but I’m getting better coverage with the drone, and the cost is about the same,” he said.

If a farmer is interested in purchasing a drone, Williams recommends working with a supplier that is also an applicator.

“Talk to a supplier who can work with you as a partner, train you and walk you through the process,” he said. “Make sure you’re not just buying a drone because they’re new and cool. … You need to be making that capital equipment purchase for a reason.”

Stewart ies a DJI Agras T30, which has a 30-liter tank or about 8-gallon payload capacity, which is equivalent to 50 pounds of seed or granular.

When planting cover crops, Stewart plants a winter rye mixture, clovers, brassicas and turnips at a rate of anywhere from 5-30 pounds per acre.

Last year, American Drone spread over 26,000 pounds of cover crop seed.

“Spreading cover crop seeds into standing corn that’s 8 feet tall can be done easily with a drone,” Williams said. “By the time you cut the corn, the cover crop is germinating already.”

Williams also applies foliar feed to crops via drone.

“Instead of dumping hundreds of pounds of nitrogen on the crop at once, the drone spoon feeds foliar feed to the crop 3-4 times throughout the plant’s life cycle,” he said. “It lands on the leaves, and the plant takes it in. People are seeing a big bump in yield from that.”

Williams also recommends using drones to spray pastures.

“If you have a pasture that’s hilly, rocky and full of thistles, and you want to take out the thistles, drones are awesome for that,” he said.

Williams said the investment for a drone, including training and all associated equipment, is about $60,000.

“The average return on investment is only 17 spray days or application days,” Williams said. “I’ve had many customers prove that.”

Many licenses are required to y a drone. These include Federal Aviation Administration Part 107 to y a basic drone, FAA Part 137 to operate a drone more than 55 pounds, a state aerial applicator license, a state chemical applicator license and a third class medical certicate.

Stewart said the operator must maintain a visual line of sight of the drone and avoid power lines, wood lines and other obstacles. A short battery life can be a drawback as batteries typically last 6-8 minutes or 4-5 acres.

Drones are proving benecial in helping farmers manage their crops, and Stewart said the demand for drone work is high.

“There are new crews and people getting into it this year,” she said. “It’s really taking off.”

Williams said American Drone is adding more capacity to the industry by setting up dealerships.

“A drone is an amazing tool, but you have to be able to use it legally, safely and effectively,” Williams said. “There are a lot of federal and state regulations to follow, and civil aviation safety is our top priority. We want to make sure that when people y these in the national airspace system, they’re doing it safely.”

When did you get started with spring fieldwork?

Neil Jaschen Tripoli, Iowa Bremer County 400cows

When will you get started with spring eldwork? Some of my neighbors started planting last weekend. We hope to start chopping winter rye silage the rst or second week of May. Then, we will apply liquid manure followed by no-till planting corn for silage.

What crops do you raise, and how many acres of each do you have? We raise 270 acres of silage corn, 230 acres of winter rye and 90 acres of established alfalfa. We harvest 100 acres of reed canary grass for dry cows and heifers.

How have planting decisions changed for you? We are doing more double cropping, winter rye and corn. We get more forage per acre that way. We notill the corn and rye, and that saves us a little time in the spring and fall.

What spring planting rules do you typically follow? We have no specic rules other than watching the calendar, weather and soil conditions.

What is the highlight of spring eldwork? Windrowing winter rye and chopping are my favorite eldwork in the spring.

What do you enjoy doing in your spare time in the spring? In my spare time, I do yard work, building maintenance and enjoy playing with the grandkids.

Tell us about your farm and your plans for the dairy this year. I have no specic plans for the dairy. My wife, Nancy, and I milk 400 cows in our 200-stall tiestall and freestall barns. Our youngest son, Nicholas, and his wife, Lexie, have a tanker and semi that they use to haul our milk to Associated Milk Producers Inc. They also help us in their spare time.

Jeff TeKrony Castlewood, South Dakota Hamlin County 500 cows

Jeff TeKrony Castlewood, South Dakota Hamlin County 500 cows

When did you get started with spring eldwork? We planted our oats and alfalfa April 9. Depending on eld conditions, we might get started with corn and soybeans in the last week of April.

What crops do you raise, and how many acres of each do you have? We raise 500 acres of alfalfa, 100 acres of oats, 600 acres of corn, 200 acres of sorghum and 200 acres of soybeans. This hasn’t changed in recent years.

How have planting decisions changed for you? We haven’t made any changes in our planting decisions. After a couple of dry years, we are focused on rebuilding our feed inventory. Our corn silage yields were down 25% last year.

What spring planting rules do you typically follow? This changes from year to year. We plant our small grains as early as possible. We generally don’t start planting corn or soybeans until the last week of April at the earliest.

What is the highlight of spring eldwork? Watching someone else pick rocks. Also, knowing that the weather will continue to get better.

What do you enjoy doing in your spare time in the spring? I enjoy working on our eld equipment and getting it ready to go.

Tell us about your farm and your plans for the dairy this year. I farm with my wife, Kim, along with my sister, April Brouwer, and her husband, Jared. We milk 500 cows and sell our milk to Valley Queen Cheese in Milbank, South Dakota. We have ve employees who help us with the milking and keeping the barn clean. We raise our own replacement animals and feed out all of our steers.

cows

When will you get started with spring eldwork? We will get started when the eld is not muddy. We will have to wait and see.

What crops do you raise, and how many acres of each do you have? We raise 750 acres of corn, 370 acres of existing alfalfa, 30 acres of new-seeding alfalfa under-seeded with barley and 100 acres of soybeans. We farm 1,200 acres total.

How have planting decisions changed for you? Using a stronger insecticide for rootworm issues. This is our rst year with a new product. We’ll see if there’s a benet.

What spring planting rules do you typically follow? With limited opportunity, as soon as the elds are dry enough and no freezing is predicted long term, we go for it.

What is the highlight of spring eldwork? The smell of freshly turned soil and the opportunity to plant another year.

What do you enjoy doing in your spare time in the spring? Spending time with my wife and two boys, and completing home projects together.

Tell us about your farm and your plans for the dairy this year. I farm with my brothers, Ken and Don. We milk in a double-12 parallel parlor. Our milk is shipped to First District Association in Litcheld, Minnesota. Cows are housed in crossor tunnel-ventilated freestall barns. We employ six full-time and ve part-time workers. We raise our heifers on-site and feed out steers and cross-bred heifers as well.

Tony Schwalbe Avon, Minnesota

Stearns County

120 cows

When did you get started with spring eldwork? On April 5, we planted our oat and alfalfa mix. We planted 31 acres. Then, we nished hauling our liquid manure April 19. By May 1, we are going to be planting corn, if not earlier.

What crops do you raise, and how many acres of each do you have? We don’t plant anything else besides corn, oats and alfalfa. We have about 450 acres. Nothing has changed in recent years.

How have planting decisions changed for you? The planting decisions are always the same for the most part, but people say the ground should be 70 degrees for corn. It seems like some guys have had luck with planting and it getting snowed on, so we aren’t too worried if the ground isn’t quite there when we plant. The alfalfa goes for three years, maybe four. The oats are just a cover crop with the alfalfa, so rotation is only between alfalfa and corn.

What spring planting rules do you typically follow? It’s pretty much the weather and keeping up with the technology we can afford. We plant 14 pounds of alfalfa per acre. For corn, I’ve been going 2.5 inches for a planting depth. This year, I’m going to try going a little shallower.

What is the highlight of spring eldwork? When the days are 65 degrees with no humidity, it’s nice to be in the eld. It’s pretty exciting getting the crops in the ground. Planting is my favorite part of spring eldwork.

What do you enjoy doing in your spare time in the spring? We were just out turkey hunting the last couple of days. That’s always fun to do. Pretty soon I will get out shing as well.

Tell us about your farm and your plans for the dairy this year. We are hoping to get a new system for raking hay. We milk 120 cows with two robotic milking units and ship our milk to Land O’Lakes Inc. in the Twin Cities. My wife, Nancy, and I farm with my brother, George, and his wife, Jenny, as well as their two sons, Kevin and Eli. George has been farming all his life. I started in 2006.

Ron Pagel Eyota, MinnesotaOlmsted County

130 cows

When did you get started with spring eldwork? We seeded oats March 12-13. They are about 4-5 inches tall right now.

What crops do you raise, and how many acres of each do you have? We raise 65 acres of food-grade oats, 110 acres of corn, 30 acres of soybeans and 100 acres of alfalfa. We have been growing oats for three years. It has worked well in our operation. We use the straw for feed, and we no till the alfalfa in the fall. In the oat acres, we don’t seed down to alfalfa. It allows us to seed down a second crop for additional forage. With the drought last year, we used a lot of excess forage inventory, so we need to rebuild our inventory. We are raising more alfalfa and corn, which will all go to silage. We can buy our grain for our cows cheaper than we can grow it. We usually put up corn silage and earlage, but last year, with the drought, we put it all up as silage.

How have planting decisions changed for you? We have been pretty much no till for eight years. We grow a lot of cover crops. We use some of those acres for

When did you get started with spring eldwork? We planted wheat April 6 and soybeans April 14-15. We thought we would experiment with beans since it was early.

What crops do you raise, and how many acres of each do you have?

We have 80 acres of spring wheat, 225 acres of alfalfa, 500 acres of corn and 500 acres of soybeans. We are a little bit more soybean heavy this year because of how the rotations worked out.

How have planting decisions changed for you? The weather forecast is a little better these days with knowing how much rain is coming and whether we should or shouldn’t plant since we can look out two weeks more condently.

What spring planting rules do you typically follow? Everything is based on if the eld is t and the soil and air are a little warm. If it is, we are going.

What is the highlight of spring eldwork? Watching the crops emerge after you put all the work into it. Once it’s up, you feel like you can sleep at night, because it’s out of the ground and you can visually see it.

What do you enjoy doing in your spare time in the spring? Having a bonre with the family and sitting around eating supper enjoying the moonlight.

Tell us about your farm and your plans for the dairy this year. The farm is owned by my mom, Janet, my brother, Chris, and myself. We ship our milk to First District Association. We milk in a double-10 parlor and nish all our steers. We don’t have any plans besides to keep going. My wife, Lisa, and our kids, Lydia, Madelynn, Kellen and Sylvia, are also active on the farm.

forage. Some of our corn has to wait until we remove the winter rye, and then we no till right into it behind the baler. We make baleage out of the winter rye.

What spring planting rules do you typically follow? I’m a rm believer in having patience to wait until the conditions are right. So, when I put the seed in the ground, it comes up. I don’t wait a month or six weeks fretting about germination. Part of that is driven by the fact that if we are waiting to pull cover crops off for feed, we can’t plant it yet anyway. Three years ago, we had corn emerge in four days. It was a gorgeous stand and tremendous yields, and that goes to show if you have moisture, heat and the right conditions, it’s up and going.

What is the highlight of spring eldwork? Seeing stuff grow, things greening up and the smell of fresh hay.

What do you enjoy doing in your spare time in the spring? Getting equipment ready and playing with the grandkids.

Tell us about your farm and your plans for the dairy this year. I farm with my wife, Lori, our two sons, Jeff and Tim, and their spouses. We milk in a double-8 parallel parlor. We use loose housing and compost barn for housing. We raise our heifers. We ship our milk through Land O’Lakes Inc. On the farm, there’s always things to x. We need to upgrade some stuff with our calf and heifer raising facilities. That’s probably the No. 1 on our to-do list. We are hoping for a better milk price.

How many times a day do you milk, and what is your current herd average, butterfat and protein? We milk three times a day with a yearly rolling herd average of 33,839 pounds. Our butterfat is 4.4% and our protein is 3.1%.

Describe your housing and milking facility. Cows are housed in a 4-row freestall barn with sand bedding, fans, sprinkler systems for the summer and long-day lighting for the winter. Our double-8 parallel BouMatic parlor is in the retrotted stanchion barn. Our calves are raised in calf barns with automatic feeders.

Who is part of your farm team, and what are their roles? I manage all aspects of the farm with the help of feeder Jeff Troester, herdsman Dan Busch and four parlor employees.

What is your herd health program? A healthy herd begins with the calves. We vaccinate the calves with Inforce 3, C&D Antitoxin and First Defense at birth. At weaning, they are given Inforce 3. At 4 months, the calves receive the Bangs vaccine for brucellosis, BoviShield Gold and Ultrabac 7. At 5 months, they get Bovi-Shield Gold and Ultrabac 7. At 3.5 and 4.5 months of age, the calves get a pink eye vaccine. Heifers are given Bovi-Shield Gold and

Tom Kunkel

Dairy nutri onist Roger Hoppenjan (le ) and dairy farmer Tom Kunkel take a break April 17 at T Kunkel Dairy LLC near Cuba City, Wisconsin. Kunkel milks 250 cows and farms 550 acres in Grant County.

cess to pasture. Their ration is corn silage, rough hay and mineral. Thirty days before calving, they go to a pre-fresh pen. The pre-fresh ration is wheat straw, corn silage and a dry-cow concentrate that includes mineral. They are moved to a bedded pack one week prior to calving. Fresh cows are integrated with the rest of the herd shortly after calving.

What is the composition of your ration, and how has that changed in recent years? The milk cow ration consists of corn silage with 17 pounds of dry matter, two types of haylage that contribute 20.4 pounds of dry matter, nely ground highmoisture shell corn for 12.41 pounds of dry matter and protein that counts for 11.08 pounds of dry matter. As-fed pounds equal 123.25 with a dry matter weight of 61 pounds. We try not to make changes. We have a good base program that we make small tweaks to. Sometimes corn silage uctuates with the seasons or inventory, but the variation is in small amounts.

Tell us about the forages you plant and detail your harvest strategies. For alfalfa, we grow HarvXtra, which is a high-qual-

What does your dry cow and transition program consist of? The dry period is 60 days. They are housed in a freestall barn, and in the summer, they get ac-

Ultrabac 7 semi-annually. When bred heifers go to pasture, they receive LongRange, an extended release injectable parasiticide. Pre-fresh heifers get ScourGuard and J-5 at 65 days before calving and ScourGuard again six weeks pre-fresh and J-5 again 21 days pre-fresh. Mature cows receive Bovi-Shield Gold semi-annually. J-5 is administered 21 days pre-fresh and at fresh check. Dry cows are given ScourGuard and Ultrabac 7 at their dry check with the veterinarian. Two weeks after the dry check, they are given Vaxxon SRP Salmonella and Vaxxon SRP Klebsiella. At dry off, 60 days pre-fresh, the mature cows are given J-5 and ScourGuard.

Turn to TOP PERFORMERS

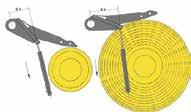

Mastitis is the most common and costly disease in the dairy industry. Veterinarians know that the liner when milking doesn’t totally close in the rest phase. This causes a large percent of mastitis in cows. With the liner open, Pre-dip doesn’t stop bacteria when being forced up the open teats in the rest phase. Mastitis shortens the life of the cow. TridentPulsation™ (winner of an ASABE award) is the only system that totally closes the liner in the rest phase when milking a cow. This stops bacteria being forced up the teats which causes a large percent of mastitis in dairy cows!

Which of these liners is your mastitis creator? Round, square, triangle…

“...the one that keeps quality milk in the tank.”

— Laura Rasmussen

“We got a sample of Udder Comfort™ at the Dairy Expo over a decade ago and have relied on it ever since,” say Corey and Laura Rasmussen. The family operates their 350-cow Udder Site Dairy near Harlan, Iowa.

“We see a response by the next milking with Udder Comfort. It’s a key part of managing healthy udders and quality milk, along with attention to details in nutrition, milking process, and cow comfort and cleanliness with sand-bedded freestalls,” says Corey.

“Udder Comfort is the one that takes swelling out of the udder and keeps quality milk in the tank,” says Laura as she visited our booth at Central Plains Dairy Expo in March, noting the key is to apply Udder Comfort consistently at the start of lactation.

“We apply Udder Comfort after each milking for 4 days on all fresh cows as well as for any type of edema, flakes or hardness. We find we just don’t need intra-mammary mastitis treatments anymore,” they explain.

JD 2680H 2021, 35 ft., 3-Section Folding, #579164 ............................... $139,900

JD 2623 2014, 37 ft., 5-Section Folding, 9” Spacing, #579549 .................. $39,900

JD 2680H 2021, 35 ft., 3-Section Folding, #580308 ................................. $94,900 DRAWN PLANTERS

JD 1775NT 2022, 24 Row, 30” Spacing, #549842 ................................... $389,900

JD DB60 2013, 24 Row, 30” Spacing, #550243 ....................................... $149,900

JD DB60 2019, 24 Row, 30” Spacing, #551039 ....................................... $299,900

JD DB66 2011, 36 Row, 22” Spacing, #556901 ....................................... $195,900

JD DB60 2018, 24 Row, 30” Spacing, #562192 ....................................... $249,900

JD 1775NT 2023, 24 Row, 30” Spacing, #566196 ................................... $369,900

JD 1760 2008, 12 Row, 30” Spacing, #568124 .......................................... $29,500

JD DB60 2020, 24 Row, 30” Spacing, #569113 ....................................... $349,900

Case IH 2150 2021, 16 Row, 30” Spacing, #569307 ............................... $199,900

JD DB60 2010, 24 Row, 30” Spacing, #569759 ....................................... $151,500

JD 1775 2018, 12 Row, 30” Spacing, #570817 ........................................ $108,000

JD 1770NT CCS 2013, 24 Row, 30” Spacing, #571367 ............................ $109,900

JD DB80 2012, 32 Row, 30” Spacing, #571885 ....................................... $232,900

JD DB66 2019, 36 Row, 22” Spacing, #572188 ....................................... $379,900

JD 1795 2023, 24 Row, 20” Spacing, #573347 ........................................ $419,900

JD DB60 2018, 24 Row, 30” Spacing, #573437 ....................................... $289,900

JD 1775 2022, 12 Row, 30” Spacing, #574581 ........................................ $139,000

JD 1770NT CCS 2008, 24 Row, 30” Spacing, #574675 .............................. $89,900

JD DB60 2017, 24 Row, 30” Spacing, #574768 ....................................... $315,000

JD DB66 2023, 36 Row, 22” Spacing, #574902 ....................................... $532,900

JD DB66 2022, 36 Row, 22” Spacing, #576258 ....................................... $479,000

JD 1770NT CCS 2009, 16 Row, 30” Spacing, #576764 ............................ $133,500

JD DB66 2003, 36 Row, 22” Spacing, #577083 ......................................... $63,500

JD 1775NT 2015, 24 Row, 30” Spacing, #577213 ................................... $159,900

Kinze 3500 2016, 8 Row, 30” Spacing, #578235 ...................................... $59,900

JD DB66 2011, 36 Row, 22” Spacing, #578691 ....................................... $182,000

JD 1775 2022, 12 Row, 30” Spacing, #578705 ........................................ $142,500

JD 1775 2019, 12 Row, 30” Spacing, #578706 .......................................... $99,900

JD DB60 2013, 24 Row, 30” Spacing, #578708 ....................................... $139,900

JD 1770 2001, 12 Row, 30” Spacing, #578830 .......................................... $29,900

JD 1775NT 2020, 24 Row, 30” Spacing, #579102 ................................... $297,900

JD 1775NT 2021, 12 Row, 30” Spacing, #579443 ................................... $215,000

JD 1760 1996, 12 Row, 30” Spacing, #579729 .......................................... $25,900

JD 1790 2003, 16/31 Row, 15/30” Spacing, #579847 ............................... $58,500

JD 1775NT 2023, 16 Row, 30” Spacing, #579850 ................................... $254,000

JD 1775NT 2023, 16 Row, 30” Spacing, #579851 ................................... $305,000

JD 1760 2011, 12 Row, 30” Spacing, #579953 .......................................... $44,900

JD 1725 CCS 2023, 16 Row, 30” Spacing, #564619 ................................. $184,900

Moore Built 24R22 2000, 24 Row, 22” Spacing, #566760 ....................... $25,000

JD 1720 2004, 16 Row, 30” Spacing, #567177 .......................................... $37,000

JD 1720 CCS 2019, 12 Row, 30” Spacing, #569017 ................................... $89,900

JD 1720 CCS 2019, 12 Row, 30” Spacing, #569018 ................................... $79,900

JD 1720 2005,

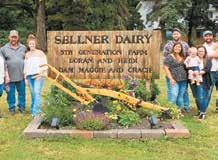

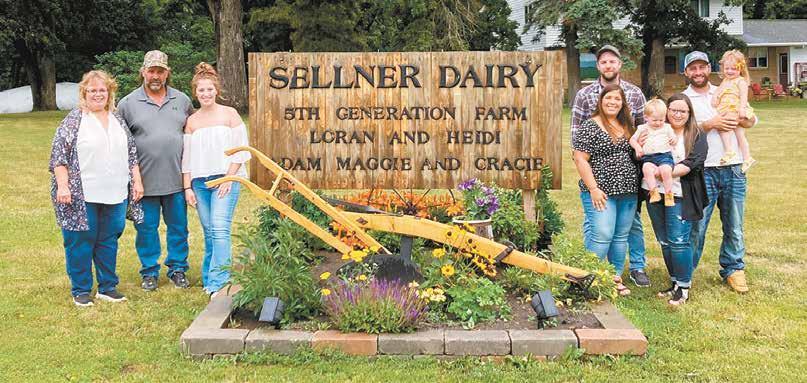

Loran and Heidi Sellner, who are active with many community programs, were recognized for their work by being named the 2023 Brown County Farm Family of the Year.

Each year, the University of Minnesota Farm Family Recognition Program honors families from across the state for contributions to their communities and the agriculture industry. The families are recognized each August during Farmfest.

“There are many deserving families in Brown County,” Heidi said.

The couple is and has been involved in organizations ranging from the American Dairy Association, 4-H, FFA, sports, coaching and Minnesota Dairy Initiative all

while managing their dairy farm near Sleepy Eye.

They have help from two employees to raise more than 240 acres of corn, soybeans and hay.

One of the main organizations Heidi is involved with is MDI.

“I love it,” Heidi said. “I’ve been a coordinator for

20 years now, and I get to work directly with farm families and help them nd a plan to achieve their goals.”

Heidi looks at records, brings in the farm’s key people to discuss the future and nds grants as well as offfarm experts to help move the farm forward.

She meets with the farm-

ers as often as they like, from monthly to biannually. Each meeting averages 1-2 hours. Covering southwest Minnesota, Heidi’s travel ranges from 10 minutes to two hours.

Loran is equally involved.

Recently, he was elected to the Springeld Co-op Creamery board. When their children, Adam, Maggie and

Gracie, were younger, he was a baseball coach. Together, the couple served on the ADA board. Heidi also served on the state dairy princess board and was active in 4-H with their children.

Achieving the pinnacle of efficiency with hay is now available at 0% financing for 48 months with a Hesston by Massey Ferguson® 2956 A round baler from Ziegler Ag Equipment. Purchase now through May 31, 2024, and get 10 free rolls of advanced net wrap with your Hesston® baler. Better bales are out there with the know-how and experience of Hesston. Lock in this offer now at your closest Ziegler Ag Equipment branch.

Their grown children return to the farm when needed and able. Their youngest, Gracie, is in her rst year of college at South Dakota State University, majoring in agricultural education and minoring in agricultural business.

“I helped on every committee with 4-H except the food stand,” Heidi said. “Our kids were involved in 4-H, FFA, sports, (including) summer sports at St. Mary’s (Catholic) School in Sleepy Eye.”

While being active in the community, the family never aimed to be in the spotlight. When they were rst named as a farm family, they said it was adjustment to be front and center.

“It was a change, but everything on the farm changes,” Loran said. “You have to adapt to it. It was a little more running around than we were used to but was a nice honor. There are other families that are just as deserving.”

The Sellners milk 200 Holsteins with three robotic milking units and ship milk to First District Association. Heifers are raised off the farm.

“I could never remember numbers, so all my cows got names,” Loran said. “Since we got the robots, everything is calm and gentle.”

Loran took the farm over from his parents in the 1980s. He uses A.I. and genomic

testing and tests for production and pregnancy through the Dairy Herd Improvement Association.

“(Genomic testing) is a nice tool to have,” Heidi said. “It can improve your herd quickly, and everything is right on your phone and computer.”

Loran is the fth generation on the farm. It was his mother’s family’s homestead, established in 1858.

“Adam is interested in coming back, but he is more interested in the crops and maybe diversifying the farm,” Heidi said.

They are hoping to make a slow generation change and pass more responsibility to Adam.

“You can’t take giant leaps,” Loran said. “It’s a generational farm. My life is here on the farm, and I like working with the cattle. There’s always something to do, and we are at the size we feel comfortable with.”

The family values the time they spent raising their family on the farm.

“You get all of life’s challenges you have to deal with; it teaches a kid everything,” Loran said.

Brad Herickhoff, Owner

320-351-4872

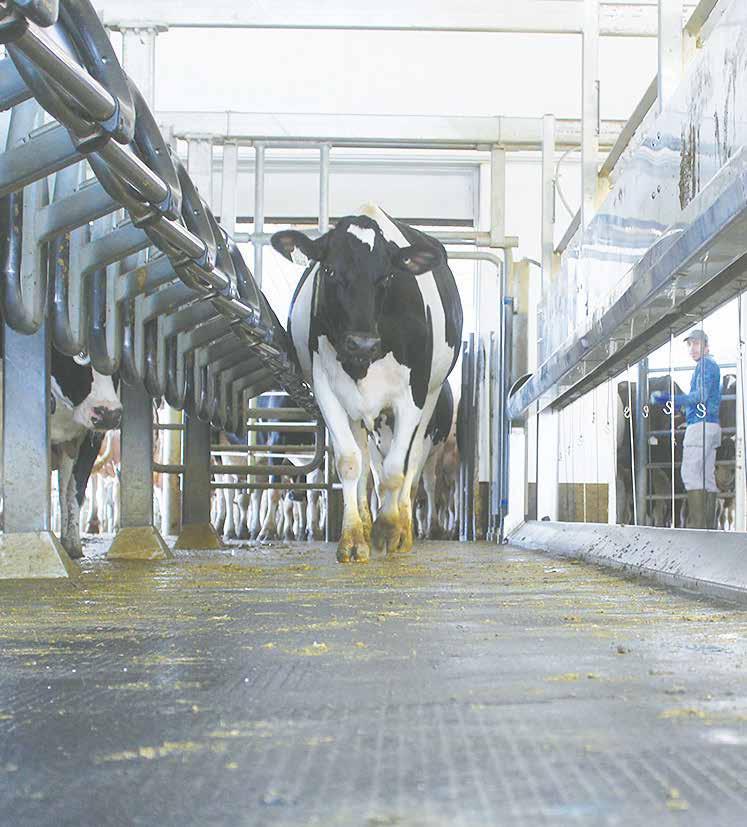

— Attendees at the Central Plains Dairy Expo March 20 took in a presentation called “Milking Their Way,” which featured three dairy farms from Iowa and Texas. All use DeLaval systems but manage their herds differently.

Richard Franta is the solution sales specialist for DeLaval North America and served as moderator for the panel.

“When we see people updating and changing their facilities, we see a lot of debate over how that family should decide what’s best for them,” Franta said. “There’s a real decision between how to manage the cows and how to manage the labor and everybody likes to do it a little differently.”

Franta was joined by producers Sam Schwartz of Rolinda Acres near Waterville,

Iowa, Aaron Titterington of Jones Family Farm near Spencer, Iowa, and Dr. Juan Velez, representing Ranch Pepper Dairy, near Dublin, Texas.

Schwartz’s farm consists of 950 cows that are milked with a double-12 parlor and 11 DeLaval VMS V300 robotic milking units. The parlor handles approximately 250 cows while the robots handle the remaining 700.

The robotic barn is designed with access to all 11 robots from a centralized room. There are three pens with three robots in each, with each robot accommodating 60 cows. This allows the cows in those pens to be milked three times a day. The fourth pen has two robots that hold 90 cows.

Schwartz said the robots perform well under the conditions.

“We couldn’t add a third robot in our fourth pen, so we run 90 cows per robot,” Schwartz said. “They hold about two-times-a-day milk-

ing and get 75 pounds per cow.”

To begin their lactation, 2-year-olds are milked in the parlor. They are milked here for about three weeks while

they recover from calving. Mature cows are moved to the robot right away.

Because the farm uses a guided-ow system, putting fresh cows with the robots too

early does not work for them, Schwartz said.

“If you do put them through a guided-ow system, make darn sure that you keep feed in front of them and keep them out of holding areas,” Schwartz said. “It’s why I like having that parlor.”

Schwartz said that putting a training robot in with heifers has made the transition easier. They can go through a basic robot box that only feeds them pellets.

“Anyone that tours our barn, I tell them to put in a training robot,” Schwartz said. “It’s the cheapest thing you’ll ever do, and it pays dividends.”

When the Titterington family of Jones Dairy was preparing for an upgrade, they considered robots for about six months. When they realized all the management changes they would have to make and the true cost of robots, they opted to upgrade to a 64-stall rotary milking parlor. They determined that the parlor route would also allow more room for growth in the future.

“The more we talked about it, it was a really easy decision after all those months,” Titterington said. “It took a couple of weeks, and it fell into place.”

Titterington’s family milks 1,800 Jerseys with a DeLaval rotary parlor installed in March 2023.

The family built a tunnel-ventilated barn at the same time and used the original facilities to house dry cows and heifers. Titterington said they like the tunnel-ventilated system. With automatic scrapers and a manureseparating system, they can bed all the cows and heifers with the recycled ber from the newest barn.

Cows were milked in a double-12 parlor before the rotary upgrade. All the shift workers remained through the transition. Milking times have been cut by almost half. This allows the workers to spend more time caring for youngstock.

“We’re doing a better job in some

of those areas, because we are milking cows more efciently and have more time,” Titterington said.

The sort gate at the parlor exit directs cows to an area with headlocks, where they can be tended for herd health.

Rancho Pepper Dairy in Texas combines the concepts of parlors and robots with the use of batch milking. In this design, the cows are not given free access to the robots. Instead, the cows are brought to the robots in groups, or batches, and put in a holding area. Here, they work through 22 robots arranged in a double-11 parallel layout. This setup allows eight employees to manage 2,100 cows.

The cows are grass-fed and milked twice per day. They average 45 pounds of milk per cow per day. The decision to install robots was made due to a labor shortage and the desire to remain an organic, grazing herd.

“The combination of grazing more than one group of animals was one of the main drivers of us moving to batch milking,” Velez said. “The decision to go with robotic versus rotary was made due to the difculty of nding labor for milking cows in that part of the country nowadays.”

Two people manage the farm during the day, two manage it at night and two are relief milkers. For each shift, a cow mover keeps the robots clean, changes lters when needed, closes gates and observes cow behavior. The other person administers vaccinations, dries cows and takes care of cows that have been sorted after milking.

Verez said the parallel robotic system gives him the perfect blend of management.

“I really like the concept of managing the work on the cows in a rotary parlor with one herdsman doing the breeding and the vaccination in one exit lane,” Velez said. “And I like the idea of voluntary milking. To me, this is a combination of the best worlds.”

Kohl, Tranel, Hall present during eld day in Sioux Center

By Jerry Nelson jerry.n@dairystar.comSIOUX CENTER, Iowa — Iowa State University Extension and Outreach held a series of heifer eld days across the state in March.

The eld days took place March 26 in Kalona, March 27 in Postville and March 28 at the Dordt University Agriculture Stewardship Center near Sioux Center.

Presenters at the Sioux Center event included Dr. Larry Tranel, ISU Extension and Outreach dairy eld specialist; Kris Kohl, ISU eld agricultural engineer for northwestern Iowa; and Fred Hall, ISU Extension and Outreach dairy specialist.

tion.

“That is real money even with today’s milk prices,” Hall said. “One way or the other, you will pay for air quality. If you have a naturally ventilated calf facility, you will want the sidewall curtains to be at least halfway open in the spring, summer and fall.”

The Midwest is known for its unrelenting winds. This is something that producers can use to their advantage, Kohl said.

“A 10 mph wind is moving air at 880 feet per minute,” Kohl said. “This means that 1 square foot of opening can provide enough ventilation for up to 40 baby calves. One part of fresh air will entrain nine parts of room air. When it’s above 60 degrees, the goal is to actually create a windchill on the calves.”

Tranel talked about facility design and management for housing calves.

“Up until 2 weeks, baby calves do best in an environment that is between 50 and 78 degrees Fahrenheit,” Tranel said. “After that, they can tolerate temperatures between 32 and 78 degrees. Humans prefer temperatures that are between 72 and 86 degrees.”

Tranel stressed that it is important to keep calves dry and comfortable.

“You don’t want calves to have an environment that is dark, damp and dingy,” Tranel said. “They need to have deep, dry bedding. Straw is best for bedding for baby calves. Sawdust absorbs urine, and urine can be a big source of ammonia. Ammonia opens the lungs, and damaged lungs can affect the animal’s performance. If you detect a strong smell in a calf pen, there’s probably too much ammonia.”

Kohl said to avoid placing naturally ventilated barns that are in the wind shadow of other buildings, and the ease of cleaning a calf facility is important to consider.

“You should choose calfraising equipment that you love,” Kohl said. “Make dirty jobs as easy as possible so that they get done.”

Group housing for calves has become increasingly popular.

“One way to group house calves when using calf hutches is to create a common area between two hutches,” Tranel said. “The calves can interact with each other and use the common area as a playground. Studies have shown that 18 calves or less per pen is optimal.”

Tranel said to avoid using concrete as a base. Rather, he said a base of pea gravel with a tile line underneath it to carry away urine works well for housing calves and uses half as much bedding as a concrete oor.

Kohl said a calf should double its birth weight by weaning.

“Calves are adding a lot of cells during their rst 45 days,” Kohl said. “That is why calf comfort is so important.”

“They can’t look at it that way anymore,” Hall said. “It can cost more than $5 per head per day to grow wet heifer calves.”

There are several things that calf raisers can do to cut costs. Breeding heifers too young is not one of them.

“We might think that we are saving money by calving heifers at 22 months of age,” Tranel said. “But, that animal will never make up for the growth that she needed if she was bred too early. A heifer’s milk production will be reduced by 1,200 pounds in her rst lactation if she’s bred just one month too early.”

Grazing can result in substantial savings when growing heifers.

“Seeding land down to pasture isn’t feasible here in northwest Iowa where farmland is bringing upward of $20,000 per acre,” Tranel said. “If you can nd someplace to graze your heifers, it will bring advantages in both costs and milk production. Putting heifers on grass at 700 pounds can lower your costs by 12%-20%. The animals will have fewer health problems and will give 1,900 more pounds of milk on average during their rst lactations.”

since 1961. Dairy cows are currently producing over 30% of our beef calves. The use of beef breeding on our dairy cattle might result in a drought of dairy heifers in a few years.”

At the conclusion of the presentation, an audience member asked about the cases of highly pathogenic avian inuenza that have cropped up in some of the nation’s dairy herds.

“HPAI seems to be affecting mature cows that are in the early stages of their lactations,” Tranel said. “The infected animals tend to go off feed and suffer from reduced milk production for about 10 days. They appear to recover fully after that.”

The audience member asked if the affected animals would have immunity from HPAI after they recovered.

“I would guess so,” Tranel said. “That is what we see with most viral infections.”

Hall said a calf that is treated for pneumonia one time will give 8,000 pounds less milk during her rst lacta-

Hall said the days of dairy farmers viewing heifer raising as a form of recreation is in the past.

Using beef sires on lower-producing cows is rapidly becoming a standard practice for dairy operators, Hall said.

“Sexed semen and the use of beef sires has had a big effect on our nation’s dairy heifer supply,” Hall said. “Dairy beef has proven to be desirable to consumers. A quality dairy-beef crossbred calf can be worth up to $900. The nation’s beef herd is the lowest it has been

ISU has published a customizable spreadsheet that producers can use to track their costs for raising heifer calves. The worksheet can be viewed at: https://www. extension.iastate.edu/ dairyteam/calves-heifers

Often, efciency is correlated with speed. At times, this can be true, but that is not always the case. We want cows milked fast, but we also want a low somatic cell count, low bacteria counts, clean cows and as few mastitis issues as possible. It is a tough balance.

Parlor efciency refers to how many cows we can push through a parlor every hour. Often, this emphasizes speed, because the parlor is a choke point on the dairy. We want cows lying down, eating and drinking water rather than spending their time in the parlor, but we can’t sacrice milking preparation to achieve that goal.

There are two terms to refer to the same issue in the parlor when we sacrice milking preparation: bimodal milking and delayed milk ejection. They mean the same thing. They refer to putting a milking unit on, initially having some ow and then having no milk ow before returning to milk ow eventually.

When we see bimodal milking, it can be a clear indication that the cow did not receive enough stimulation right away or our lag time between stimulation was not long enough. Cows need oxytocin release to achieve milk letdown. Milk letdown takes 1-2 minutes after physical stimulation, but we need to actually have

the physical stimulation rst.

If you watch a rotary go by, especially large units, they go fast. The amount of time that an employee has, especially if they are standing in one place, to physically touch the cow, give good stimulation, check for mastitis and clean the teats can be difcult, if not impossible, to accomplish. Recently, we have focused on getting lag time to exactly 90 seconds. Lag time is important, but some of the data indicate it may not matter as much. As long as it is between 60 and 120 seconds, it is probably OK. We could even push it out to 180 seconds. What we need to focus on is can we actually get a minimum of 10 seconds of physical stimulation between all the different physical touching steps? If not, we are not engaging the feedback loop that starts the train rolling with oxytocin release.

So, what? To explain why this matters, we need our second big term: milking efciency. Milking efciency is the amount of time we have milk ow over the total time the unit is on the cow. In a good situation, if the milking unit is on the cow for 4 minutes and 45 seconds, we want that cow to have milk ow for as much of that time as possible, say 4 minutes and 30 seconds, or 95% of the total unit-on time. That is good milking efciency with a lack of bimodal milking. In contrast, poor milking efciency would be a unit-on time of 3 minutes with milk ow of only 2 minutes, or

67%. There is an entire minute where the teat is subject to high vacuum with no milk ow. We’re not getting milk because we didn’t stimulate everything correctly. The secondary issues caused by high vacuum can be teat damage, forming of keratin rings on the teat end, increased mastitis risk and more.

Now the comeback usually is, “Well, if she gets started a little bit late, it’s not that big a deal because she’ll just milk longer.” The data tells us that is false. Late-starting cows do not have longer milking times. The second argument is, “Well, she’ll just make it up at the next milking.” That is also false. This is the worst kind of lost milk because we have already paid for it. We fed her and paid to make the milk, but we failed to capture it.