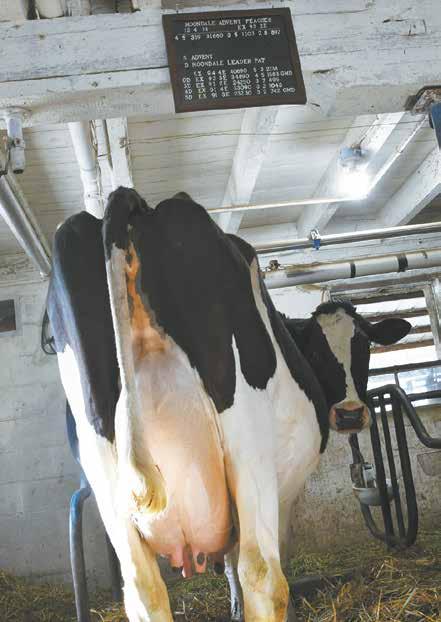

MONONA, Iowa — Detailed name boards hang in the whitewashed tiestall barn at Moondale Farm near Monona. Each board delineates a cow’s lineage and type.

“I always had a goal to breed good, high-type cows,” Dan Moon said. “(If your BAA) is up in the upper end, it must mean you’re doing pretty good.”

Dan and his wife, Nancy, own Moondale Farm where they are assisted full time by their son, Ryan. The Moons milk 50 Holsteins and raise most of their own feed on 350 acres.

“(Dairy farming is) all I’ve ever done, all I ever wanted to do,” Dan said.

High-type cows have always been a priority for Dan. He was named Premier Breeder at the Iowa State Holstein Show 19 times from 1991 to 2017 and has also shown three grand champions.

The Moons’ herd ranked among the best in the nation for BAA in the 1980s and 1990s. In 2023, their BAA ranked fourth in Region 6, which in-

cludes Minnesota, North Dakota, South Dakota, Nebraska and Iowa, and 69th nationally.

In 2007, Moondale Steffanie-TW was named reserve All-American after she placed second in the 5-year-old class at World Dairy Expo in Madison, Wisconsin.

In 2011, WDE honored Dan and his father, Vernice, with the Robert “Whitney” McKown Master Breeder Award.

The Moons do not show as many animals as they did in the past. They have taken as many as 10-16 to the Iowa State Holstein Show but now bring about six each year.

Before the Moons’ children grew up, they also showed in 4-H. Nancy said this is one of her favorite memories.

“(Teaching) them how to win and lose,” Nancy said. “You’re not always rst, and it’s OK because ... they’re yours.”

Dan has been dairying on the farm site his entire life. His rst memory with a tractor was his dad having him moldboard plow when it was chore time.

In 1977, Dan graduated from high school and started to farm full time. The farm was smaller then, with about 35 cows. In 1996, Dan and Nancy took over the farm after Dan’s parents retired.

Now, Ryan has been farming alongside his parents since

he graduated from high school in 2016.

Ryan said he has always enjoyed it.

“(I want to) keep it going as long as I can and as long as I have enough help,” Ryan said.

The Moons have taken a few steps toward transitioning

the farm, as Ryan receives a percentage of the milk check and has purchased equipment.

“I like being around the cows,” Ryan said.

For Dan, watching genetic progress is one of his favorite things about dairy farming.

“(I like) just seeing your cows, ... (the) matings you’ve made and if they turn out, especially when they turn out well,” Dan said.

The Moons focus on breeding for components over pounds of milk. In the winter, they average about 4.2%-4.3% butterfat and 3.2%-3.3% protein.

“A lot of times a cow with 22,000 (pounds with a) real high test will make way more pounds of fat than a 30,000 pounder with low test,” Dan said.

The Moons also consider udders, feet and legs, rumps and depth in their breeding program.

“I like big, deep-ribbed cows,” Dan said.

Currently, the Moons have cows that are 13, 11, 9 and 8 years of age. “With high type, they usually last longer,” Dan said.

The Moons give their cows free-choice dry hay and haylage but feed no corn silage. Part of the herd is housed in tie stalls and the rest are in a bedded pack barn. In the summer, the ration is supplemented with pasture.

Cows receive high-moisture corn, oats and protein allotments. Nancy joked about their system being high-tech.

“(Dan) has got a 5-gallon pail and a cup,” Nancy said. “He can dump on as much as he wants.”

Each day, the Moons begin milking around 5 a.m. Nancy and Ryan do the milking, while Dan switches cows and feeds. By 7:30 a.m., milking is done,

and by 9 a.m., chores are complete.

The Moons do not have hired help.

“(I like) being outside,” Nancy said. “I like that you do something different every day. ... You generally milk twice a day, but what you do in between is different every day. ... I wouldn’t want to sit in a chair all day or sit in front of a screen; that’s just not my thing.”

Outside the dairy farm, the Moons are active in their community.

The Moons’ farm is pen pals for a local kindergarten class. The class helps name a calf and comes for a tour of the farm where they watch a cow being milked.

Dan has served in various positions on the Iowa District 1 Holstein Association board. He also has served in various roles, including president of the Iowa Holstein Association.

“A lot of it is to get together with people,” Dan said. “People before you took their turn, so I guess you have to take your turn and do it too.”

Both Dan and Ryan are on the Clayton County Holstein Association board, and the whole family serves on the dairy promotion board.

“If you work for the better of things, you have to voice your input,” Nancy said. “It doesn’t always go the way you want it to, but at least you know you said what you think.”

stall Feb. 16 in the Moon family’s barn near Monona, Iowa. In 2011, World Dairy Expo honored Dan Moon and his father, Vernice, with the Robert “Whitney” McKown Master Breeder Award.

The U.S. Department of Agriculture February dairy supply and utilization report provided a look behind the markets.

Speaking in the April 22 “Dairy Radio Now” broadcast, HighGround Dairy economist Betty Berning said butter jumped out from it.

“We knew butter exports were down in February,” she said. “We heard reports of robust demand stateside as part of the narrative as to why butter prices were pushing $3 per pound. But, when looking at this report, we learned that domestic usage and exports were down.”

Butter usage totaled 161.2 million pounds, down 6.3%, as domestic usage fell 4.9%. No surprise that exports were down 35.2%. HGD said February inventories were healthy as well, indicating that neither high demand nor lack of supply were behind the elevated price.

Cheese consumption totaled 1.15 billion pounds, down 1.5% from February 2023, with domestic consumption down 3.5%. American style was down 7.3%.

Cheese exports totaled 95.5 million pounds, up 27.2%, led by the other-cheese variety, up 27.6%, and a new all-time high, according to HGD.

“Low prices on the CME spot market, which have been heavily discounted to Europe since November 2023, likely helped spur additional sales,” HGD said.

Nonfat dry milk utilization, at 182.3 million pounds, was up 2.4% but only because February 2023 was the weakest for the month since 2019, according to HGD. Berning said domestic consumption was down almost 3%, so exports carried the day despite reports of struggling international demand. She said it remains to be seen if those exports remain strong.

Dry whey utilization, at 66.8 million pounds, was down 3.2%. Exports were down 5.6%. HGD said dry whey exports have been down since March 2023, with the exception of this January. Domestic demand wasn’t great either, Berning said.

The USDA announced the May federal order Class I base milk price at $18.46 per hundredweight, down 72 cents from April and $1.11 below May 2023. It equates to $1.59 per gallon, down from $1.68 a year ago. The ve-month average is at $18.58, down from $20.12 a year ago and $22.81 in 2022.

The USDA’s latest livestock, dairy and poultry outlook reported, “Consumer price indexes for selected dairy products were year-over-year lower in March, while the indexes for overall prices and food prices show that the inationary pressures are lingering. Of note, the CPI for all dairy products has been year-over-year lower since September of last year.”

The latest “Margin Watch” from Chicago-based Commodity & Ingredient Hedging LLC reported,

“Dairy margins were mixed over the rst half of April, strengthening slightly in nearby periods following a price recovery in cheese and the Class 3 milk market while deferred periods held steady.

“The feed market was relatively at with USDA releasing the April World Agricultural Supply and Demand Estimates report, which did not cut corn ending stocks as much as expected despite increased projected usage. The cheese market caught a bid with block and barrel prices rallying to the highest level in six weeks at $1.61 per pound, and lower prices in the rst quarter may have renewed export interest.”

U.S. cheese remains the least expensive in the world, according to the MW.

“Mexico has been a bright spot for U.S. export demand,” the MW said. “February dairy product exports totaled 501.1 million pounds, up 5.5% from 2023 after adjusting for leap day and the rst time that February shipments have exceeded 500 million pounds, with cheese exports of 95.6 million pounds up 27.3% from last year including 36.6 million pounds to Mexico. Domestic demand has been more lackluster, as January demand was down 2.8% from 2023 while demand in February slumped by more than 4% after adjusting for leap year. U.S. demand for American-style cheese has been particularly weak, down nearly 6% in January and February compared to the rst two months of 2023. Butter demand by contrast has been robust, with the market hitting an all-time high for April at $2.97 per pound despite ample stocks and rising production from increased milkfat content, as buyers fear tighter supplies later in the year.”

The 40-pound cheddar blocks closed the third Friday of April at $1.68 per pound, up 14.50 cents on the week, fourth consecutive week of gain and the highest CME price since Nov. 7, 2023, but 7 cents below a year ago, as traders anticipated Monday’s March milk production report.

The 500-pound cheddar barrels nished Friday at $1.66, 8.75 cents higher, 10.75 cents above a year ago and 2 cents below the blocks. CME sales amounted to 23 loads of each on the week.

Dairy Market News reports the spring ush is here as milk levels near their peak in parts of the western U.S. and trend seasonally higher in the East and Midwest.

“As cheese market tones show further signals of life, the same is being said among contacts regarding demand,” DMN said. “Customers are trying to get ahead of increasing market price points.”

Cheese supplies are available in the Midwest but are not at levels of concern. Spot milk availability shifted lower, and mid-week prices ranged $3- to $1-under Class III. A year ago, they were $11- to $4-under Class, according to DMN.

Manufacturers note strong cheese production in

the West as plenty of milk is seasonally available. Cheese stocks are also readily available. Demand is steady to moderate, and international buying is steady to stronger, particularly from southern neighbor purchasers. Sources indicate immediate- to short-term sales continue to be more prevalent than sales for deliveries past second quarter. Some processors report that production is outpacing demand, DMN said.

CheeseExpo was held in Milwaukee, Wisconsin, and StoneX said that the takeaway from expo is that something around $1.60 per pound cheese is a good market clearing price today. Demand for fresh cheese is reportedly improved; however, “sustainability of demand is the key to holding prices up.”

“Further price strength for spot cheese will begin to usher in a change in the 2024 trend of modest pops in price that don’t last,” StoneX said.

CME butter climbed to $2.94 per pound Tuesday but backed off to close Friday at $2.92, unchanged on the week but 52 cents above a year ago, on eight sales.

Midwest butter makers report summer and fall inventories are in fair shape. Churning has been robust with plentiful cream. For the second consecutive week, spot cream multiples were below 1.00. Butter demand is steady. Interest remains for both unsalted and salted, but a number of customers say unsalted 82% butterfat availability (for export) is difcult to locate.

Western butter makers note strong to steady production as they work to build unsalted and salted butter inventories. Some processors convey unsalted butter availability is tight. Cream multiples were at or near those of last week. Cream remains readily available throughout most of the region. Domestic butter demand is mixed with some notes of lighter interest for retail and bulk butter. Export demand is steady to moderate, according to DMN.

Grade A nonfat dry milk closed at $1.12 per pound Friday, down 2.25 cents on the week and 4.50 cents below a year ago. There were 16 sales on the week.

A weaker than expected Global Dairy Trade this week may have provided the spot weakness.

Dry whey closed Friday at 39.25 cents per pound, up 3.25 cents on the week, highest in three weeks, and 3 cents above a year ago, on 28 sales.

Updating the avian or bovine inuenza outbreak, StoneX economists Nate Donnay and Dustin Winston said, “The detection of avian inuenza in the U.S. dairy herd has helped to rm market sentiment but hasn’t had a big impact on prices. As of April 16, the USDA conrmed infections on 26 farms, but we think the true number is closer to 100.

“Now that the mystery disease has been identied, and there isn’t any treatment for it, some farmers are choosing to handle it quietly. That means the conrmed number of cases from the USDA probably won’t be a good indicator for how widespread the problem is, and the impact will show up in prices rst and then eventually in the milk production data.”

They do not see a big impact on milk production and said only 10%-15% of the cows infected show signicant symptoms and most recover in about two weeks.

“Total production for the farm is down 15%-25% for a couple of weeks, which works out to about a 1% reduction for the course of a year,” they said. “With about 26,500 dairy farms in the U.S., we would need almost 3,000 farms infected to knock 0.1% off of annual production. That is certainly possible, but if it is spread out over a few months, even the short-term impact would be minimal.”

Dairy cow slaughter for the week ending April 6 totaled 57,400 head, up 700 from the previous week, but 4,300, or 7%, below a year ago. Year-to-date, 805,200 head have been culled, down 128,000, or 13.7%, from a year ago.

This was the closest to year-ago levels that it has been all year, according to StoneX.

“Total beef slaughter exceeded year-ago levels for the rst time this year, rising 1.57% above 2023 levels,” StoneX said. “This increase led to a tightening in the market share that dairy cows are holding in the beef market this week.”

The USDA’s latest crop progress report shows 6% of the U.S. corn crop had been planted, as of the week ending April 14, 1% behind a year ago but 1% ahead of the ve-year average. 3% of the soybeans are in the ground, dead even with a year ago and 2% ahead of the ve-year average.

The GDT weighted average inched up 0.1% Tuesday, following a 2.8% jump April 2.Traders brought 38.9 million pounds of product to market, down from 41.3 million April 2 and the lowest since Dec. 15, 2020. The average metric ton price inched to $3,590, from $3,558 April 2.

Anhydrous milkfat led the gains, up 1.7%, after gaining 2.3% April 2; however, butter was down 1.4% following a 3.1% rise. Whole milk powder was the only other product showing a gain, up just 0.4% after a 3.4% rise. Skim milk powder was unchanged following a 1.4% rise April 2.

Cheddar led the declines after leading the gains April 2 and dropped 8.5% following a 4.1% rise. Mozzarella was down 3.8%. Lactose was down 1.3% following a 3.1% drop April 2.

StoneX said the GDT 80% butterfat butter price equates to $2.8968 per pound, down 2 cents from April 2, and compares to CME butter which closed Friday at $2.92. GDT cheddar, at $1.8023, was down 16.6 cents, and compares to Friday’s CME block cheddar at a real bargain $1.68. GDT skim milk powder averaged $1.1524

per pound, down from $1.1568. Whole milk powder averaged $1.4830 per pound, up from $1.4726. CME Grade A nonfat dry milk closed Friday at $1.12 per pound.

North Asia purchases, which includes China, were weaker than both the previous GDT event and year-ago levels, said analyst Dustin Winston. Southeast Asia purchases increased from both the last event and last year’s levels. Increases in SMP purchases by Southeast Asia was a large part of the support in total purchase volume. Africa purchases were also stronger than the last event by more than double and outpaced last year by more than triple, Winston said.

Cooperatives Working Together member cooperatives accepted six offers of export assistance this week that helped capture sales contracts for 1.2 million pounds of American-type cheese and 176,000 pounds of whole milk powder. The product is going to customers in Asia, Central America, the Caribbean and Middle East-North Africa through June.

CWT-assisted exports now total 32 million pounds of American-type cheeses, 309,000 pounds of butter, 617,000 pounds of anhydrous milkfat, 8.1 million pounds of whole milk powder and 3.1 million pounds of cream cheese. The products are going to 25 countries and are the equivalent of 402.4 million pounds of milk on a milkfat basis.

Meanwhile, the U.S. Dairy Export Council, National Milk Producers Federation and Consortium for Common Food Names commended the House Committee on Ways and Means’ markup of a bill this week that would renew the Generalized System of Preferences trade program with new agriculturespecic eligibility criteria, giving U.S. dairy producers a fairer opportunity to sell products in key markets. GSP has not been in effect since it expired at the end of 2020.

The GSP trade program helps developing countries use trade to grow their economies by eliminating U.S. duties for a wide range of products. GSP-eligible countries must meet certain conditions. The bill will introduce provisions for the agriculture industry, including requirements that beneciary countries provide open and equitable market access to U.S. agriculture exports and protect the generic use of common food and beverage terms like Parmesan and feta.

“The U.S. dairy community is grateful for these expanded criteria, which will enable America’s dairy farmers and producers to compete on a level playing eld in these new and growing markets,” said Krysta Harden, USDEC president and CEO. “A special thank you to Reps. Adrian Smith, Jimmy Panetta and Michelle Fischbach, who continue to be champions for the U.S. dairy industry. Now more than ever, our members count on exports to succeed, and we look forward to supporting this bill through to the nish line.”

WISCONSIN DELLS, Wis. —

Getting one extra meal into a cow each day can directly impact production. Encouraging cows to make one more trip to the bunk and maximizing what they eat while at the bunk will increase dry matter intake and push pounds of milk higher.

This topic was the focus of Kathryn Elliott’s presentation, “Managing for more dry matter intake,” during the Professional Dairy Producers Business Conference March 13-14 in Wisconsin Dells.

Elliott is a dairy consultant and technical support specialist at ProAGtive Dairy Nutrition.

“Having cows eat more is a simple way to drive energy-corrected milk higher,” Elliott said. “Cows eat about 12 meals per day. Let’s try to get them to that 13th meal with one more visit to the bunk. Another few pounds of dry matter intake will result in more milk.”

When trying to increase DMI, Elliott said there are two things to watch for.

“If cows eat more, you don’t want the DMI to go wild and not see an increase in ECM, or you’re not going to be protable,” she said. “If cows are eating 61.5 pounds and are still not at 100 pounds of ECM, you need to dive in and see if this is a rate of passage issue and get that xed rst.”

Elliott said the cost per pound of dry matter also needs to be in line.

“As they eat more, that is also a cost, and we need to make sure it stays protable,” she said.

The rst step in promoting an additional trip to the bunk is to minimize time away from feed.

“Eating, drinking and lying time all help drive DMI higher,” Elliott said. “We need to pivot to activities that help a cow max out the ones that will help her eat the most.”

Elliott said top-production herds may spend two hours on milking and management; whereas, time away from the pen for lower-production herds is high, creating a bottleneck on eating and lying time.

Sometimes, a couple of pens are the main contributors to a high time away from feed, such as those furthest from the parlor or pens that are overstocked. To rectify the issue, Elliott said to begin by focusing on a couple of pens rather than the entire herd at once.

Feed to higher refusals to make sure bunks are never empty. Push up feed every hour to ensure cows always have feed in front of them. Limit the amount of time the bunk is empty between refusal and fresh feed drop.

“Cleaning refusal for two pens at once may result in a 30-minute timeframe of an empty bunk for one pen, and that’s 30 minutes those cows could have been eating,” Elliott said. “Try to time these things with when cows are at the parlor, and they’ll never know the bunk was empty.”

Another option is to push old feed to the end of the bunk, drop off new feed and have someone pick up the refusal later, Elliott said.

Elliott cautioned against continual regrouping of cows as it causes increased displacements from the feed bunk.

“Every time you regroup, there’s a bully cow that intimidates cows for three days,” she said. “That’s almost half a week that you could have cows getting pushed from the feed bunk. We want to try and limit the amount of regrouping, especially on high-stocked pens.”

To minimize social stress, limit additions to each group to once a week maximum, and separate rst-lactation cows into their own group.

DMI in the rst few weeks of lactation is connected to higher peak milk; therefore, pay special attention to the post-fresh pen.

“The post-fresh pen is extremely important to manage in order to max out DMIs,” Elliott said. “Every time we have a spike of cows calving in, we may see a limit on dry matter intake unless managing for that. Make sure feed is always available to these cows, and try to move cows out of those pens as quickly as possible to make room for the next ones calving in.”

Making sure cows have plenty to drink is critical.

“Water is extremely important,” Elliott said. “Poor water quality and poor access to water will limit dry matter intake.”

Lameness is another factor that impacts the number of eating bouts. One herd Elliott worked with bedded once a week and had cows suffering from swollen hocks and knees. When they began bedding twice a week and putting in more sand, lameness issues signicantly declined.

“There are simple things you can do to help cows make that extra trip to the bunk,” Elliott said.

Pests, such as ies, can also limit how often cows eat.

“Flies are a small nuisance but can have a big economic impact,” Elliott said. “Cows bunch with high y populations, and in this situation, they won’t make an extra trip to the bunk.”

The use of y control can help reduce this risk. Lay out insecticides, put chitin inhibitors in feed to disrupt the development of y larvae and ensure proper wind speed in the barn.

Once a cow gets to the bunk for that extra meal, make sure she is being rewarded with a meal she can fully utilize. For example, too much ber or poorly digestible ber limits DMI.

“We create rumen ll as ber goes up, and then we see DMI go down,” Elliott said. “There is a portion of neutral detergent ber that’s digestible and a portion that’s undigestible. If we make more of it digestible, that automatically allows a cow to eat more.”

Elliott said a one-unit increase in NDF digestibility is associated with a 0.37-pound increase in DMI. Adding 10 points of relative forage quality to haylage often results in a gain of more than one point of NDF digestibility. As digestibility increases, indigestibility decreases and the percentage of total ber decreases.

“You can feed more of this digestible haylage, and cows will eat more and make more milk,” Elliott said. “The same thing goes for corn silage. As the plant be-

comes more digestible, the undigestible portion goes down, and you can feed more of this feed. How we process these forages also helps how the cow eats.”

Elliott said chopping forages to a shorter particle length reduces chewing time and increases intake. This strategy also works on a slightly mature forage to salvage quality.

“You can get more milk out of a higher uNDF (undigestible neutral detergent ber) forage by chopping it shorter,” Elliott said. “You can’t reverse high uNDF forage, but you can minimize the negative impact on the cow by pre-processing to a shorter length.”

When looking at starch sources, Elliott said not all starch is the same.

“High-moisture shell corn is mainly digested in the rumen, while dry corn is mainly digested in the intestine,” she said. “You don’t want to provide a starch that goes straight to her rumen and is digested in one hour. Instead, you want to provide a blend that gets digested in the rumen and intestine throughout the day.”

Important considerations when analyzing the blend of high-moisture corn are length of fermentation, digestibility, particle size and moisture.

“When moving from a dry cow ration to a postfresh ration, the starch level is going to change a lot,” Elliott said. “Too much fermentable starch in early lactation can cause satiety. I’m not saying we can’t feed high-moisture corn; we just need to be aware of how much fermented starch is in the post-fresh ration. This can be an opportunity to help DMI during the post-fresh period.”

Elliott recommends feeding higher metabolizable protein in the pre-fresh ration of rst-lactation animals to drive them to eat more in the post-fresh ration. During lactation, rumen degradable protein drives DMI.

“Make sure you have enough rumen degradable protein early on in lactation and during peak milk production,” Elliott said. “That helps keep rumen bugs going and keeps the rumen healthy.”

Enticing cows to the bunk for an additional meal and ensuring that meal is full of everything they need will have positive results on both DMI and ECM yield.

“From where you are today, if you can carry out some or all of these opportunities on your farm to manage for more DMI, you will see more energycorrected milk,” Elliott said.

April 17, 42 loads

April 18, 59 loads

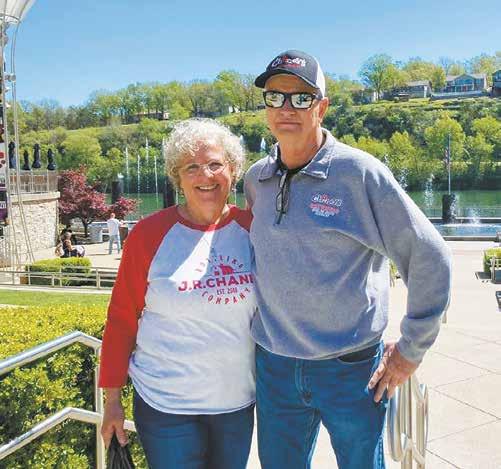

BOWLING GREEN, Ky. — Last year, 14,500 guests toured Chaney’s Dairy Barn.

People can watch the process of their ice cream being made all the way from milking to milk being processed, Carl Chaney said. Then, they can buy it in the store.

Chaney’s Dairy Barn is located on a 54-acre farm near Bowling Green. The Chaney family’s 60 Jersey cows are housed in a compost-bedded pack barn and milked with a robotic milking system.

The Chaneys churn premium ice cream and bottle milk. A 10,000-squarefoot restaurant, gift shop and ice cream shop with a playground outside provide a place for guests to relax and enjoy.

Guests can also take self-guided or guided tours of the dairy, making the Chaneys’ farm an agricultural tourism destination.

“The majority of the people appreciate the opportunity to see what a dairy farm does, how it operates,” Chaney said. “A lot of people are like, ‘Well, we read so much stuff, and it’s so great to see that it’s not true.’”

The Chaneys have been offering

tours for over 20 years. Self-guided tour participants can sit on bleachers in a viewing area to watch the robot milk the cows. An overview area gives guests a view of the compost barn. They also can watch the milk being processed through windows.

“I love the interaction of the people who come to the farm,” Chaney said.

Chaney’s Dairy Barn has a comment book. Chaney said it is seldom they get a negative comment. Many people express amazement or thank them for showing them a dairy farm.

Chaney said they use signage to direct people. They also have collaborated with The Dairy Alliance to put up signage that teaches about the nutrients in milk.

In 2019, the Chaneys started processing milk. They began processing ice cream in October 2003.

They processed their own product over concerns with milk pricing, Chaney said.

“I didn’t know that we’d ever be able to be condent that we would always be able to have cash ow,” Chaney said. “It just felt like we had to do something if we were going to continue.”

Chaney’s family has been farming on the site since 1888. The farm has had chickens, pigs, mules and tobacco. In 1940, his father began the dairy with two Jersey cows. The rst full year of processing, the Chaneys made about 3,000 gallons of ice cream. Last year, they made about 30,000 gallons.

The cows give about 25,000 pounds of milk per week, and the

Chaneys purchase an additional 15,000 pounds a week from another dairy farm. They also purchase additional cream, because the fat content of their ice cream is almost 16%. They also add purchased nonfat dry milk in their ice

cream, something Chaney learned at Penn State’s Ice Cream Short Course.

They offer 32 regular avors and seasonal favorites. For milk, they offer whole, 2%, skim and chocolate. They also offer eggnog and strawberry milk seasonally.

The Chaneys’ dairy products have won awards. Last year at the Los Angeles International Dairy competition, their vanilla ice cream, Wow Now Brownie Cow and their chocolate milk earned perfect scores and gold medals.

In addition to its on-farm location, Chaney’s Dairy Barn also has two ice cream trailers that travel the area.

Chaney’s Dairy Barn is located in an increasingly suburban area. Just a half-mile away is a large high school. Across the road, what was once a 97acre corneld four years ago is now a subdivision for 315 homes.

Chaney double crops 22 acres of corn followed by rye and wheat. The rest of the acres are used for buildings, a 6-acre corn maze and pasture.

Chaney buys some of his alfalfa as baleage.

The dairy has changed over the years. In the 1980s, the Chaneys were milking over 100 cows. In the early ’80s, acres were sold off to what they are today.

Chaney’s father, James, worked to have excellent genetics on the farm.

“He just loved his Jerseys,” Chaney said. “He knew cow families.”

His father purchased a Jersey cow named Generators Topsy for $10,000. She was the rst Jersey cow to score Excellent 97. She achieved this honor in 1980. James was honored with the

American Jersey Cattle Association’s Master Breeder Award in 2003.

In 2001, the Chaneys sold part of the herd to milk just 60 cows. Chaney and his wife, Debra, began exploring options and settled on ice cream.

“I’m fourth generation,” Chaney said. “I didn’t want to be the one to screw it up and lose (the farm).”

Chaney and Debra are assisted on the cattle side of the business by their niece, Dore Baker, and two employees. Their daughter, Elizabeth Lunsford, is in charge of processing and is assisted by 7-8 employees.

Their daughter, Jessica, and son, James, both work off the farm but help when needed.

The restaurant, ice cream and gift shop are operated by about 50 employees, many of them teenagers. Chaney enjoys working with these young people.

“You’re working with 17-, 18-, 19-year-old kids,” Chaney said. “If that doesn’t keep you young, nothing will.”

The Chaneys are in the process of expanding their restaurant, ice cream and gift shop by adding another 10,000 square feet. They are also enlarging the parking lot and building a back porch.

“Not only are we already busy, but we’re getting to be continually busy,” Chaney said.

When other farmers want to learn how to do on-farm processing, Chaney said they try to be helpful.

“We were helped by so many people,” Chaney said. “We just feel that it’s our responsibility to reciprocate.”

AMES, Iowa — Raising healthy heifers through organic management practices can present challenges.

Larry Tranel, a dairy specialist with Iowa State University Extension and Outreach, has several do’s and don’ts for raising heifers from birth to rst calving.

To set a heifer up for success, Tranel said organic producers should give calves colostrum on time; double birth weight by 56 days; not feed calves too much energy while lacking protein from 3-9 months of age; and breed heifers at the proper body size and weight.

Tranel is a former dairy farmer and heifer raiser with experience in grazing. His family has been in the organic sector for almost 20 years.

Tranel said calves need to receive colostrum in the rst 4-6 hours after birth.

stay dry and clean. Caked manure or dampness on the ank and knee will make it harder for a heifer to stay warm.

“It just drains a lot of energy out,” Tranel said. “(They are) going to be that much colder and shivering.”

Cold and damp weather conditions force producers to feed additional grain or energy to maintain growth rates, Tranel said.

After weaning, the growth rate should be about 1.8-2 pounds per day. Heifers should be growing in both frame, stature and weight. Tranel said stature is more important than weight.

Two related problems occur during this period. Organic farmers may not feed enough energy, and farmers who feed extra energy without enough protein develop heifers with fat in their udders. This problem is more prevalent in heifers ages 3-9 months.

“I call those Doughboy or corn silage heifers,” Tranel said. “Sometimes producers don’t see that in their own herd.”

Larry Tranel Iowa State University Extension and Outreach

Larry Tranel Iowa State University Extension and Outreach

“There’s just so many things that the colostrum provides in (developing immunity to) help the calf stay healthy and not get sick,” Tranel said.

Organic farmers who have their calves with nurse cows may assume the calf is receiving its rst colostrum in that timeframe from their dam. However, especially with Holstein calves, Tranel said this might not be occurring in more than half the calves.

“Even though it’s more natural, it’s still important to get those cows milked and get that rst serving of colostrum into the calf and not just think that it’s going to happen automatically,” Tranel said.

Tranel said it also is important for calves to be clean and dry. During the winter, he said to have a warming box available for use after birth and use calf jackets.

Tranel said that good ventilation is especially important for early calf growth, especially since treatment options for respiratory disease can be limited.

“One episode of a respiratory disease will cut into milk production,” Tranel said.

Tranel said it is important that producers ensure calves are doubling their birth weight within the rst 56 days. Tranel said producers should weigh a few calves to track growth.

“There are a lot of different types of cells that grow whether in the udder or the milk-producing cells that ... if it doesn’t develop in the rst 45 days of life, it never will,” Tranel said.

For healthy rumen development, Tranel said to get calves on starter right away. He said the ber within the starter will develop the rumen.

“Get them to start nibbling on it and try to eat it, especially within the rst week,” Tranel said.

During winter, Tranel said it is important for pre-weaned calves to have deep bedding and to

The fat in the udder is there instead of milk-producing cells, leading to lower milk production.

Tranel said that research has shown that grazing heifers is benecial to milk production.

“Heifers that are rotationally grazed, or even just grazed, produce more milk than conventional counterparts,” Tranel said.

Tranel said that on well-managed pasture, his supplementation was as little as 1-1.5 pounds every other day. However, Tranel said heifers put on “the back 40” will not have the same rate of gain and need supplementation.

Heifers need to be moved regularly for their intake to be balanced. Tranel said he sometimes moved his heifers twice a day or three times a day on very hot summer days.

When it comes to pasture mixes, Tranel said to have at least 30%-40% legumes, such as alfalfa or clover. As far as grasses, Tranel said the species is less important than the variety within the species.

“There’s not too many grasses that don’t work,” Tranel said. “Some are just more high yielding. ... There’s a lot of quality differences even within species.”

Breeding too early is also problematic, Tranel said. Producers may think they will save money on feed by breeding heifers to calve in at 22 months. However, if a heifer is not within 85% of the herds’ mature body weight at calving, the heifer will give 1,200-1,800 pounds less milk during her rst lactation and probably ensuing lactations as well, Tranel said.

“It’s what we call a Peter Pan problem,” he said. “These heifers are never going to get a chance to fully grow up.”

Tranel said to compute the average weight of 5-10 healthy cows that are in their third or fourth lactation and 100-plus days in milk. This will give farmers an understanding of their herds’ ideal mature body weight.

Tranel said he never recommends that a heifer be bred on age. Instead, he suggests breeding on stature or weight if a weight tape is used. Tranel said to put a post or marker within the heifer pen, so producers can see if the heifers have reached appropriate stature for breeding.

Dennis and Margie Schmidt take a break from making ice cream April 17 at Melody Gardens Restaurant and Skateland in Marsheld, Wisconsin. The Schmidts have managed Melody Gardens since 2012.

MARSHFIELD, Wis. — For nearly 50 years, Melody Gardens Restaurant and Skateland has entertained citizens of Marsheld.

Melody Gardens, owned by Margie and Dennis Schmidt, was opened in 1974 as a rollerskating rink by Margie’s parents, Alvin and Gladys Brock. The Schmidts purchased the business from Margie’s sister and brother-in-law, Deb and Dan Dietel, in 2012.

“We lived across the road,” Margie said. “I am one of 16 children in our family, and we all grew up working here at one time or another. Melody Gardens has always been a part of my life, and I love that I am able to run it. I love the skating, the restaurant and the ice cream.”

The Brocks added an ice cream parlor to the original rollerskating area in 1980 and an additional area for the restaurant in 1990. The family decided to begin making ice cream in 1996.

“My sister and my parents decided to give it a try,” Margie said. “They did the research and got set up to begin making ice cream. We’ve been doing it ever since.”

Dennis became schooled in ice cream making when the Schmidts purchased the establishment and is now the primary ice cream maker.

“It was on-the-job training,” said Dennis, who previously worked in construction. “I spent an entire summer learning how to make ice cream from Deb.”

Melody Gardens keeps its freezers full of ice cream year-round, serving 22 avors daily. In addition to cones, they serve a variety of other treats including shakes, malts and urries. They also sell quarts of ice cream.

“We have our staples that are always available and rotate other avors every time Dennis makes ice cream,” Margie said. “Chocolate peanut butter is probably our most popular. We also have popular kid’s avors like cotton candy, bubble gum, blue moon and Superman. The more traditional avors like maple nut and butter pecan are popular too.”

In all, there are over 80 recipes in the Schmidts’ repertoire.

“Some of the recipes are standard from the company, and others, we have created and developed over the years,” Margie said. “Our customers frequently make suggestions and requests for new avors.”

During the winter, Dennis typically makes ice cream once a week at a rate of 70 gallons each week. That ramps up to 120 gallons of ice cream during the summer, when Dennis spends several days making ice cream.

“It’s a 6-7 hour project when I make ice cream,” Dennis said. “Most of the recipes I have memorized by now.”

Some avors are simple to make while others are much more time consuming.

“When I make Superman, I make one avor and layer it in the bucket laying on its side,” Dennis said. “While that sets, I make the next and repeat the process. Then, I swirl it when all the layers are nished.”

For each batch of ice cream, Dennis begins with a 12% cream base made by Classic Mix Partners. From there, he adds whatever avorings and add-ins each recipe requires.

“I’m able to put all the liquid avorings and colorings into the mix in the machine,” Dennis said. “All of the solid add-ins are added and stirred by hand.”

Once each gallon of ice cream is completed, it spends 24 hours in a blast freezer to set before being moved to a walk-in freezer.

| 715-985-3122

The homemade ice cream has become a vital part of the Melody Gardens experience, the Schmidts said.

“People know we have ice cream all year, and the customers love that they can enjoy it year-round,” Margie said. “It really adds a lot of fun to the whole experience.”

Bill’s IBA Spring Valley, WI 715-505-2607

IBA Fahrney, Inc

Monroe, WI 608-325-4248

Innovative IBA Oconomowoc, WI 608-347-4948

Being in business for 50 years, Margie said one of her favorite parts of running the business is watching people bring their families, remember the avors they loved as a child and share those memories with their own children and grandchildren.

Those roots have led to the business being connected to the community in a variety of ways. They work with groups that serve their ice cream at events. Each year, Melody Gardens ice cream is on the menu at the June dairy breakfast sponsored by the Marsheld FFA Alumni.

In 2018, the Schmidts were asked to make cranberry ice cream for the Wood County Farm Technology Days.

“That was a really big thing for us, and it was an honor to be a part

of that,” Margie said. “We had never made cranberry ice cream, so it was quite a process developing the perfect recipe. We used a cranberry avoring and mixed in cranberries grown in Wood County. We still make the cranberry ice cream today, and people love it.”

What makes Melody Gardens special to the community is how the business embraces all age groups, the Schmidts said.

“We have the rollerskating for the younger generation, and our restaurant is popular with many older people,” Margie said. “Cooking for 1-2 people can be difcult. We keep our prices very reasonable, and many people come here daily — some even for two meals a day. Besides providing nutritious meals, we are also giving them opportunity for socializing.”

Melody Gardens has been part of the fabric of Margie’s life, and she said it is truly her calling.

“This is my passion,” she said. “Our customers are really more like family.”

Valley Dairy Supply Corona, SD 605-432-5224

our round bales of rye yesterday (April 23). It made 5-6 bales an acre. We’ve had corn planted for a week, and it’s barely spiking. We are planting more corn today. We don’t have much grass, because it’s been too cool. We have 40-degree nights and 60-degree days, and the wind is always blowing. We are super dry; it’s like a dust bowl around here. Our agronomist hasn’t planted, because it’s too dry. He’s worried about the loss.

SAMUEL FONDER

55 cows, 347 acres

We have been working on our small grains and are about 50% done with our small grain planting. We are using some of our small grain acres as a mother crop for a new seeding of alfalfa. I have heard that some early-seeded spring wheat in our area has emerged. There isn’t much fieldwork going on as of yet in our neighborhood. Some of our fields remain too wet to till. Our pastures and alfalfa are greening up nicely, but it will still be a while before we can turn our cows out onto the grass.

Roberts County Sobieski,

AJ WALDOCH

300 cows, 650 acres

We’ve been hauling manure the last four days and should be finished with that job this afternoon. We are hauling a 1.2-million-gallon pit. We also chisel plow behind the tanks. We will probably start on the alfalfa next week. The fields are pretty good, just a little wet in the low spots. The alfalfa looks good and is around 4 inches tall. There was discing done yesterday around here, and people have their oats in. When we finish hauling manure, we’ll pick rock and dig the corn planter out of the shed. The fields were soft for a day or two after the rain, but they have firmed up.

850 cows, 1,100 acres

It has been wet; we received 5.5 inches of rain over the past week. There have been a few acres planted in our neighborhood; although, everything is at a standstill for us. All of our equipment is ready, but we haven’t started planting. Our rye is looking great and is growing like crazy. We were able to haul a lot of manure before the wet weather hit, and our feedlots are in good shape. Our dairy cows are housed in a freestall barn, so the wet weather hasn’t affected them. For now, it’s hurry up and wait until fields dry out.

DOUG BENSON

225 cows, 1,300 acres

We finished planting oats April 14. Then, we did new seeding alfalfa, and we finished those 70 acres today (April 22). We are planning to get the planter going today or tomorrow and start with corn. The farms that we’ve been on were pattern tiles and ready to go. We’ve been waiting, not because we think we’ll get stuck but because of compacting the soil. The fields are damp, and there is a chance to freeze in the forecast. We have neighbors who have put in corn or soybeans in the last week. The alfalfa is coming along really quick and is 4 inches tall. The wheat we planted April 7 is uneven.

Heron Lake, MN

Cottonwood County

ETHAN JOHNSON

72 cows, 255 acres

We received an inch of rain last Tuesday (April 16). This was followed by several windy days, which quickly dried out the soil. People were back in the field by Thursday night. A lot of folks in our area have been planting soybeans. There is a rumor that some of the early-planted soybeans have emerged already and are vulnerable to frost. Our rye is 6 inches tall and has tripled in size since the rain. We haven’t planted any of our own corn yet but helped a neighbor plant his corn last week. We planted 120 acres in one day.

Earlville, IA

Delaware County

RAIN

Last 2 Weeks: Since April 1:

Wykoff, , MN

Fillmore County

BRIAN BOETTCHER

300 cows, 1,000 acres

We are definitely catching up a little bit on moisture. However, if you dig down very far, there is not much moisture, but the top is good. We have 130 acres of oats planted. They have sprouted but haven’t come up yet. We have had enough rainy, cool, cloudy days that they are a little slower. They will be coming through in the next few days. This week, we are working on getting the manure pit emptied. The alfalfa is coming up nice and greening. We will start planting corn in the next week or so. In the area, neighbors are getting corn in, and a few soybeans have been planted.

Last 2 Weeks: Since April 1:

DENNIS BURKLE

We had three mornings, April 19-21, where we’ve had frost. I got the oats, peas and alfalfa in yesterday (April 22), and then, I rolled the field down. The alfalfa came through the winter perfect. We plan to haul liquid manure and then prepare the corn and soybean fields. I went to Edgewood and Elkader today and only saw one planter in the field. There have been dry fertilizer and anhydrous applied. The pastures are greening up, but I don’t see a lot of cattle on them yet. In the next 10 days, I will be chopping 30 acres of rye that is knee-high.

Ellsworth, WI

Pierce County

Rosendale, WI

Fond du Lac County

140 cows, 450 acres

RAIN

Last 2 Weeks: Since April 1: 1.5”

JIM HAUSCHILDT

Spring is here. Large farms have started running corn planters. They’re putting corn on soybean ground where there’s no manure spread. Lots of manure hauling and biosolids are being spread along with fertilizer. Small grains are being put in. The ground seems to be working up well. We had two rains. The 1.8 inches goes a long way, but obviously, we’ll need more. We also had three-quarter inch of snow April 2. We are getting into the fields for the first time this week (April 21). We will put in spring triticale. My goal is to get that done before the next predicted rain at the end of the week.

BEN JULKA

120 cows, 300 acres

RAIN

Last 2 Weeks: Since April 1: 1.8”

Frederic, WI

Burnett County

JACE DEN HOED

DEN HOED DAIRY

500 cows, 1,250 acres

We have had 2.5 inches of rain in the last two weeks. We have planted about 150 acres of alfalfa. We’re about half finished with manure and have been doing tillage. We are probably about a week out on starting to plant corn, weather dependent.

Birnamwood, WI

Shawano County

Last 2 Weeks: Since April 1: 2.5”

DILLON BREYER

TOWNLINE ACRES

120 cows, 480 acres

We’ve had about 1.4 inches of rain in the last two weeks. We’ve been hauling manure and are just about have that completed. We’ve been working on new seeding alfalfa with peas and oats as a cover crop. I hope to be done seeding triticale for grain this week. We’ve been doing tillage, getting corn ground ready, but we’re probably about 10 days out from that.

On April 15, we planted 51 acres of soybeans and 33 acres of new seeding alfalfa — a peas and triticale mix. The soil temperature was in the 50s when we planted soybeans. The planting date matters a lot more for soybeans than corn in my experience, so we prefer to plant those first. The weather prevented us from doing anything again until April 22. We worked the ground and were hoping to have 200 acres of soybean ground ready to plant that week. We got in another 50 acres of the pea-triticale mix April 23. We also had an alfalfa plot going in April 23. We planted strips of three varieties on 50 acres. We will hopefully start corn the week of April 29.

Tues., April 30 Feeder & Slaughter Cattle Sale with hay/straw, baby calves, feeder cattle, replacement cattle, goats, sheep, hogs, fat and slaughter cattle

Fri., May 3 Dairy Sale - Noon

Tues., May 7 Feeder & Slaughter Cattle Sale with hay/straw, baby calves, feeder cattle, replacement cattle, goats, sheep, hogs, fat and slaughter cattle SALE DATES: Please consign your cattle as early as Thankpossible! You!!! a

RAIN

380 cows, 1,800 acres

RAIN

Last 2 Weeks: Since April 1: 0.7”

Fitchburg, WI

Dane County

For an on the farm estimate or current market info, call 320-732-2255 WE APPRECIATE YOUR BUSINESS! DAIRY SALES are held EVERY FRIDAY. Dairy cattle sell at noon EVERY FIRST SATURDAY is the EVERYTHING SALE starting at 9 a.m. EVERY THURSDAY we are in Belgrade - Misc. at 10am and cattle at 1:30 p.m.

120 cows, 800 acres

We’ve had 4-5 days with freezing temperatures at night. On April 13, we planted peas and oats on 22 acres. We’re running short on corn silage, so we put peas and oats in to make up the difference. We’ll feed it this summer, because we’re not going to make it to fall on our corn silage. Corn was way too short last year because of the drought. We were going to start planting corn, but the sensors on our corn planter were not working right. Daryl fixed them, and we’re planning to start planting April 24 if it doesn’t rain. I’ve seen people in the area putting in a few acres of corn silage in between the bad weather.

CLAYTON HAGEMAN

Last 2 Weeks: Since April 1: 1.4” RAIN

Last 2 Weeks: Since April 1: 1.5”

The Minnesota DHIA rolling herd average production in 2023 reached an all-time high of 25,668 pounds of milk, 1,088 fat and 837 protein with a somatic cell count of 179,000. The dollar value is weighted by the pay prices for these four components and was also a record of $5,219. Below are the highest-ranking herds within each county afliate, alphabetically by county and herd owner. Congratulations to all.

of every GSI product manufactured.

from the kitchen of Emma Borchardt of Watertown, Wisconsin

Strawberries

Banana Milk/yogurt

Spinach Ice

Your choice of protein powder

Add all ingredients to blender and mix until ingredients are blended together. Pour into a cup and enjoy.

1 roll Pillsbury sugar cookie dough

8 ounces cream cheese, softened

1/3 cup sugar

from the kitchen of Emma Borchardt of Watertown, Wisconsin

1 cup halved or quartered strawberries

1/2 teaspoon vanilla

1 cup fresh blueberries

2 kiwis, peeled, halved lengthwise and sliced

1 cup diced pineapple

1 cup mandarin oranges

Heat oven to 350 degrees. Spray 12-inch pizza pan with cooking spray. Break up cookie dough and press evenly in bottom of pan with 1/2inch edge. Bake 16-20 minutes or until golden brown. Cool completely, approximately 30 minutes. In a small bowl, beat cream cheese, sugar and vanilla with electric mixer on medium speed until uffy. Spread mixture over cooled crust. Arrange fruit over cream cheese. To serve, cut into squares or wedges.

from the kitchen of Emma Borchardt of Watertown, Wisconsin

2.5 cups shredded cheddar cheese

1 tablespoon corn our/cornstarch

1/2 tablespoon butter

1 garlic clove, minced

milk cows (25) dry springing cows (25) springing heifers. A very nice herd of cows!

Coming from 3-M Dairy, Glen May & Family Stacyville Iowa Owner phone number 641-220-4518

COMPLETE HERD DISPERSAL #2

44 Holstein and Colored Breed Dairy Cows, including (7) Jersey Crosses (3)Fleckveih (3)Milking Shorthorn (3)Blue Roan (1) Lineback (1)Guernsey. Cows milked in a step up parlor, housed in freestalls and on a bedded pack. on home grown feed, 55# 4.5BF 4.1P 150scc. Full vaccination program. Cows in all stages of lactation, mostly 2-3 year olds. Herd is all bred Angus. Coming from DR Farms, Eau

1/4 teaspoon onion powder

1/4 teaspoon garlic powder

13 ounces evaporated milk

1 small tomato, nely diced

1/4 small white onion, nely chopped

1/4 teaspoon cumin

4 ounces chopped green chiles

2-3 tablespoons milk

1/4 cup cilantro, nely chopped

Place cheese and corn our/cornstarch in a bowl, toss to coat. Melt butter over medium heat in a large saucepan. Add garlic and onion, cook slowly for 3 minutes or until onion is translucent but not browned. Add tomato and cook for 2 minutes until tomato is slightly softened. Add evaporated milk and cheese, stir, then add chiles and spices. Stir until cheese melts and becomes a silky sauce. Add salt to taste and stir. Stir in milk or water to adjust consistency. Remove from heat. Serve warm or room temperature. Store in refrigerator. Reheat in a microwave.

Farm Feeding The

From farm to field

The

‘21 Gehl V330, JS Ctrls, Dsl, 3300 Lift Cap, C/H/A, 2 Spd, Hydra Glide, 1224 hrs$53,900

‘18 Gehl RT165, JS Ctrls, 69HP Dsl, 15” Tracks, 2000 Lift Cap, C/H/A, 2 Spd, 950 hrs.............................................$44,900

‘19 Gehl RT165, ISO/JS Ctrls, Dsl, 15 1/2

All Season Tracks, Lift Cap 1800 @ 35% And 2400 @ 50%, C/H/A, 2 Spd, 1,720 hrs. .......................................$43,900

‘17 Gehl RT250, ISO/Dual H-Ctrls, Dsl, Camso Tracks HXD 450x86x58, Both Standard And Hi-Flow Hyd, 2 Spd, Hydra Glide, 295 hrs, Warranty Till 6-30-26 or 1000 Hrs ......................................$48,500

‘22 Gehl RT215, ISO/JS ctrls, dsl, square bar 17” tracks, 3000 lift cap at 50%, C/H/air, 2 spd, Hydra Glide, 1,375 hrs .........$53,500

‘18 Gehl RT165, ISO JS Ctrls, Dsl, 1650 Lift Cap, C/H/A, 2 Spd, 990 hrs ......$47,500

‘17 Gehl V270, ISO Ctrls, Dsl, 2700 Lift Cap, C&H, 2 Spd, 3,950 hrs ......$40,500

‘18 Gehl R220, JS Ctrls, Dsl, 2200 Lift Cap, SS, 4,600 hrs ...................................$23,000

‘17 Gehl R220, H-Ctrl, Dsl, 2500 Lift Cap, C&H, 2 Spd, 4635 hrs .............$38,500

‘22 Gehl R220 T-Bar H-Ctrls, 2500 Lift Cap, C&H, 2 spd, 3890 hrs .............$38,800

Gehl R190, Dual-H Ctrls, Dsl, 2150 Lift Cap, C&H, 2 Spd, 6,130 hrs.....................$22,500

‘22 Manitou 1650RT, H/Ft Ctrls, Dsl, 12” Tracks, 1650 Lift Cap, C/H/A, 2 Spd, 169 hrs.............................................$56,500

‘21 Manitou 2700V NXT:2, H-Ctrls, Dsl, 3000 Lift Cap, Dsl, C/H/A, 2 Spd, Hydra Glide, 1,850 hrs ...............................$47,700

NH L225, ISO/Hand Switchable Ctrls, Dsl, Standard And Hi-Flow Hyd, 2500 Lift Cap, C&H, 2 Spd, 2,460 hrs.....................$29,800

‘20 Deere 332G, ISO/Dual H-Ctrls, Dsl, 3600 Lift Cap, C/H/A,