Addition required to house collection

By Emily Breth emily.b@star-pub.comBERNADOTTE, Minn.

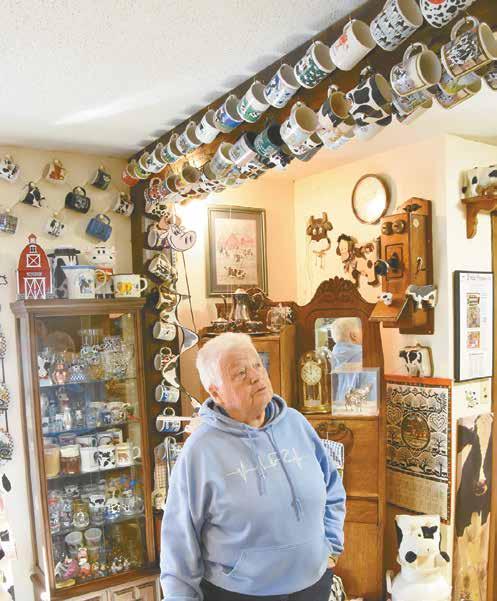

— Some dairy barns are home to 10,000 cows, but Ruth Klossner’s house is home to over 21,000.

Klossner was accepted into the Guinness World Records in summer 2015 when her cow collection was at 15,144 cows; however, it did not stop growing.

This year, Klossner built a 16- by 32-foot addition onto

her house in Bernadotte to better showcase her collection of cow paraphernalia as it continues to grow.

Before construction began, Klossner had a dozen people help her herd the cows into boxes and pack them safely away into a sh house until the remodeling was complete. Another dozen helped her move the collection back inside, and the cows were nally able to roam around the new space March 3.

The “herd count” sits at 21,165 pieces. Klossner collects anything she nds and likes and is cow related. Among the items are clothing, pins, stuffed animals, key chains, water bottles, mugs,

Shelves lled with cow items line the new addi�on to Ruth Klossner’s home May 3 in Bernado�e, Minnesota. Klossner recently added on to her house to gain more room for her collec�on.

cups, books, puzzles, clocks, candy, ornaments, wall hangings and more.

“I never intended to make it a collection,” Klossner said.

Klossner’s collection has attracted visitors from about 30 states and 30 foreign countries. Klossner has also been featured in newspapers from Denmark and Poland, which she has laminated.

Klossner has many collections within her collection. One

•

includes a group of around 500 Mary’s Moo Moos. These consist of cow knickknacks which take on the characteristics of humans. Each one is unique, hand-casted and hand-painted. Klossner also has a miniature version of collectibles based on CowParade. CowParade is an international exhibit consisting of life-size berglass cows that are placed in cities after being decorated by local artists.

When Klossner rst moved to her house in 1979, her collection t on the ledge in the stairwell. Her collection grew to take up the rest of the basement. It was not until 1992 that the rst cows started to wander out of the basement.

Lumber Company

Now, there is not a room that does not have a cow-themed item. The bathroom is even lled with cow collectables, as is the furnace room.

When it came to keeping track of how many pieces she had in her collection, Klossner gave each one a sticker and number and then put a description of the item into a spreadsheet. Her collection was at around 150 when she got her rst computer and started putting the list together in the mid-1980s.

The rst cow on the list is one she received in her 4-H days. She had other cow toys when she was a kid but had given them to nieces and nephews, and by the time they gave them back, the collection was in the thousands.

“The hunt is half of the fun, and sharing it with others is the other half,” Klossner said. “I love seeing the look on a retired dairy farmer’s face or when someone says they used to have something like (this piece) or when something reminds them of a story they then share.”

Klossner’s collection was started by a piece she found at a garage sale in the mid-1970s in Winthrop. The piece was made in the early 1900s in Germany. Klossner has many other international items as well, including Japan, Europe and Switzerland.

Klossner’s collection includes other unique items such as a framed auction bill from her family’s dairy auction in 1966 and gifts from the Nicollet High School sports teams. Klossner has photographed many games for the school, and the students sometimes gift her cow-related items.

“They gave me a football jersey with 00 for a number and included a small M in front of it,” Klossner said.

She has received posters, jerseys and shirts from the teams. Klossner also received a variety of items as gifts from family and friends and even from people she has never met.

The piece she considers the most valuable in her collection is a sterling silver cow-shaped cream pitcher from American actress Tippi Hedren, mother to Melanie Grifth, and star of Alfred

Hitchcock’s, “The Birds.”

“Tippi got it as a wedding gift when she married Peter Grifth,” Klossner said.

However, Klossner said she does not have a favorite piece. Well-wishers have left pieces on Klossner’s doorstep or mailed them to her. One piece was even left in the ofce of her church, just across the road.

Klossner said it is fun to see some of the things sent to her and hear from people she has never met.

“They may not know my name, but they know I’m the cow lady,” Klossner said.

Klossner welcomes guests by appointment and plans to hold an open house when landscaping and cement work are nished, possibly in July.

The U.S. Department of Agriculture announced the April federal order Class III benchmark milk price at $15.50 per hundredweight, down 84 cents from March and $3.02 below April 2023, brought down by falling prices in cheese, nonfat dry milk and whey. The four-month Class III average stands at $15.77, down from $18.46 at this time a year ago and $22.04 in 2022.

Late Friday morning Class III futures portended a May price at $18.36, June, $19.09 and July at $19.19, with a peak of $19.28 in September.

The April Class IV price is $20.11 per cwt, up 2 cents from March, $2.16 above a year ago and the highest Class IV since November 2023. Its four-month average is at $19.86, up from $18.80 a year ago and down from $24.31 in 2022.

CME butter and cheese prices continued to strengthen. Like a beach ball held under water, butter popped above $3 Wednesday and closed Friday at $3.0750 per pound, highest since Nov. 3, 2023, 10.50 cents higher on the week and 63 cents above a year ago. The record high is $3.5025 Oct. 6, 2023. There were 43 trades on the week and 90 for the month of April, up from 53 in March.

“Bulls continue to lead the charge on butter markets,” said Dairy Market News, which credited the moderate increases in year-over-year and monthly stocks in the March cold storage data. But, cream availability remains wide open. Central butter makers continue to say both regional cream and cream sourced from the West are holding in similar pricing patterns to recent weeks, at multiples below 1.20.

Western butter output is also strong as cream availability is “comfortable.” Some butter makers are securing additional loads for churning to build stocks for anticipated third and fourth quarter demand. Domestic demand is steady for salted butter and stronger for unsalted, though export demand is moderate.

Contacts at the American Dairy Products Institute annual meeting this week in Chicago were mostly bullish on butter, DMN said.

On May 2, StoneX said, “There was a modest change in perceptions of the (cheese) markets’ potential. As the bearish demand story we’ve dealt with all year subsides slightly, concerns around available milk supplies found a way into more conversations. Ultimately, this dynamic can best be characterized as skepticism around price strength.”

Block cheddar saw its Friday nish at $1.79 per pound, up 4 cents on the week, for a sixth week of gain, highest since Oct. 19, 2023, and 17.75 cents above a year ago. The barrels nished 10.75 cents higher at $1.88, 35 cents above a year ago. Sales totaled two cars of block on the week and 113 for April, up from 83 in March. Barrels totaled nine for the week and 82 for the month, up from 62 in March.

Cheese demand continues to strengthen, according to Midwest cheesemakers who are beginning to

turn away customers and tell current customers that requests for extra volumes will not be possible. Barrel makers say any extra is spoken for. Production is somewhat steady in the region however, as more processing comes online. Milk availability has begun to tighten, and last week’s low spot price of $5-under Class III had yet to be reported at mid-week.

Cheese production also remains strong in the West. Milk is ample but may soon tighten. Stocks remain comfortably available. Demand from domestic purchasers is stronger and is steady from international buyers, according to DMN.

Grade A nonfat dry milk closed Friday at $1.13 per pound, up 2 cents on the week but 6.75 cents below a year ago. Sales totaled 12 on the week and 49 for April, one more than the month before.

Dry whey saw its Friday close at 39.50 cents per pound, 1.25 cents higher and 6.75 cents above a year ago. There were 11 sales on the week and 66 for April, highest monthly total since October 2023’s 195 and up from eight in March.

March U.S. dairy exports took a hit following an increase in February. Sailings totaled 527 million pounds valued at about $740 million, down 4.5% in volume and down 9.2% in value, according to the May 2 Daily Dairy Report.

HighGround Dairy economist Betty Berning reported in the May 8 Dairy Radio Now broadcast that this was the smallest March total since 2020. Volumes to the top three markets dropped signicantly, down 22% to Mexico, down 27% to China and 4.9% less to Japan. But, exports to Canada and South Korea saw notable increases of 27% and 74%, respectively, and exports to Southeast Asia grew for a second month, up 4%.

Nonfat dry milk exports tumbled 18.4% as shipments to Mexico were down 37%. Nonfat dry milk is “languishing,” Berning said, “as there’s not a lot of demand out there and prices have traded in a tight band since January 2023.”

Dry whey exports were down 22.3%, as China continues to restrain purchases. Butter exports were down 42.4%, no surprise there considering U.S. prices.

The bright spot was record cheese exports, with 110.3 million pounds leaving our shores, up 20.5% from March 2023. Berning said that March bested the previous record set in June 2022, thanks to increased sales to Mexico, South Korea and Japan. Cheddar exports were up 24.7%, as lower U.S. prices in fall 2023 persisted into 2024.

Back on the farm, a higher all-milk price and lower soybean and hay prices nudged the March milk feed price ratio higher for a second month. The latest ag prices report shows the ratio at 2.17, up from 2.13 in February and compares to 1.55 in March 2023.

The all-milk price averaged $20.70 per cwt with a 4.28% butterfat test, up a dime from February but 30 cents below March 2023, which had a 4.19% test. California’s average at $20.20 per cwt was unchanged from

February but 10 cents below a year ago. Wisconsin’s, at $19.10, was up a dime from February but $1.60 below a year ago.

The national corn price averaged $4.36 per bushel, unchanged from February but $2.31 below a year ago. Soybeans averaged $11.80 per bushel, down a dime from February and $3.10 per bushel below a year ago. Alfalfa hay slipped to $195 per ton, down $5 per ton from February and $71 below a year ago.

Looking at the cow side of the ledger, the February average cull price for beef and dairy combined jumped to $119 per cwt, up $10 from February, $23.30 above March 2023 and $47.40 above the 2011 base average.

Quarterly milk cow replacements averaged $2,120 per head in April, up $230 from January and $400 above April 2023. Cows averaged $1,900 in California, up $150 from January and $245 above a year ago. Wisconsin’s at $2,380 per head was up $320 from January and $540 per head above April 2023.

Milk production margins moved above $11 per cwt for the rst time since November 2023 and were 22 cents per cwt above February, according to dairy economist Bill Brooks, of Stoneheart Consulting in Dearborn, Missouri.

“Income over feed costs in March were above the $8 per cwt level needed for steady to higher milk production for the seventh month in a row,” Brooks said. “Input prices were mostly lower, but all three input commodities remained in the top nine for March all time. Feed costs were the eighth highest ever for the month of March and the 82nd highest of all time. The ratio was also above the ve-year average for the second month in a row.

“Higher protability levels along with fewer available replacement heifers expected to calve in 2024 pushed quarterly prices received for milk cows to the highest level since October 2014.

“Dairy producer protability for 2022 in the form of milk income over feed costs was $11.91 per cwt. The protability was $4.12 above 2021 and $2.50 higher than the 2017-21 average. In 2022, the increase in milk income over feed costs was a result of the milk price increasing more than feed prices rose. Income over feed in 2022 was above the level needed to maintain or grow milk production.”

Brooks said milk income over feed costs for 2023 came in at $8.13 per cwt and were near the level needed to maintain or grow milk production. Protability was down $3.78 per cwt from 2022’s level and $1.59 lower than the 2018-22 average.

“Milk income over feed costs for 2024, using April 30 CME settling futures prices for milk, corn and soybeans plus the Stoneheart forecast for alfalfa hay, are expected to be $14.30 per cwt, a gain of $6.17 versus 2023,” Brooks said. “Income over feed in 2024 is $1.57 per cwt higher than last month and would be above the level needed to maintain or grow milk production.”

Meanwhile, the latest Margin Watch from Chicago-based Commodity & Ingredient Hedging LLC said, “Dairy margins improved over the second half of April as a rally in milk more than offset strength in the feed markets. A continued decline in milk production is helping to support the market with strong demand for dairy products keeping a rm tone across the complex.”

The U.S. corn crop was 27% planted as of the week ending April 26, according to the latest crop progress report, and was up from 12% the previous week, 4% ahead of a year ago and 5% ahead of the ve-year average. For corn, 7% was emerged, 2% ahead of a year ago. For soybeans, 18% were in the ground, 2% ahead of a year ago and 8% ahead of the ve-year average.

Dairy cow slaughter for the week ending April 20 totaled 55,100 head, down 5,700, or 9.4%, from a year ago. Year-to-date, 1,055,200 have been culled, down 139,800, or 13.2%, from 2023. Culling has lagged by double digits since January.

The bovine inuenza outbreak is a continuing challenge to the dairy industry and has been conrmed in nine states. Dairy cows moving across state lines must be tested rst. The USDA is testing ground beef at retail stores in states with the outbreak, and restrictions on imports of dairy cattle from the U.S. have begun to pop up. Reuters reported that a World Health Organization ofcial warned of the virus spreading to cows in other countries through migratory birds. At this point, there are perhaps more questions than answers, but one of the best sources of information is www.nmpf.org.

U.S. cheese production totaled 14.2 billion pounds in 2023, according to the USDA’s annual dairy products summary, up 0.9% from 2022. The month with the biggest production was March, with 1.224 billion pounds. February had the smallest output at 1.116 billion pounds.

Wisconsin remains the leading cheese producer, at 3.5 billion pounds, or 24.7% of total production. California was No. 2, with 2.49 billion pounds, and No. 3 Idaho produced 1 billion pounds. New Mexico, New York and Minnesota followed.

Italian varieties totaled 5.85 billion pounds, down 0.8% from 2022, and accounted for 41.2% of the cheese total in 2023. Mozzarella accounted for 78.7% of the Italian production followed by Parmesan with 8.3% and provolone at 6.4%.

Wisconsin was the leading state in Italian cheese, with 28.6% of the total. American type, at 5.84 billion pounds, was up 3% and accounted for 41.1% of the cheese total. Wisconsin again was the leading state

with 18.8% of the total.

Butter production totaled 2.12 billion pounds, up 2.7%. California was the leading butter producer, with 680.2 million pounds, or 32.2% of the total output. Pennsylvania was a distant second with 86.9 million pounds.

Nonfat dry milk for human consumption totaled 1.87 billion pounds, down 4.4% from 2022. Skim milk powders, at 695 million pounds, were up 5.6%, and dry whey totaled 938 million pounds, up 2.5%.

The Global Dairy Trade held its 50th Pulse auction Tuesday with 3.79 million pounds of product sold, down from 3.85 million March 23. 98.2% of the total offered was sold. There was 559,968 more pounds of instant whole milk powder and 559,968 pounds less of regular WMP sold versus the previous week’s Pulse. 93.8% of the total skim milk powder on offer was sold. Prices continued to slip.

Cooperatives Working Together member cooperatives accepted 10 offers of export assistance this week that helped capture sales of 101,000 pounds of American-type cheese, 150,000 pounds of anhydrous milkfat, 66,000 pounds of whole milk powder and 604,000 pounds of cream cheese.

The product is going to customers in Asia, Central America, the Caribbean, Middle East-North Africa and South America through July and raised CWT’s 2024 sales to 37.8 million pounds of American-type cheeses, 309,000 pounds of butter, 767,000 pounds of anhydrous milkfat, 8.5 million pounds of whole milk powder and 3.9 million pounds of cream cheese. The products are going to 27 countries and the equivalent of 469.1 million pounds of milk on a milkfat basis.

Milk output is steady to stronger throughout the East and much of the West, according to DMN’s weekly update, though contacts in the mountain states of Idaho, Utah and Colorado say production varies from slightly weaker to strengthening. Midwest contacts report milk component levels are somewhat enriched currently.

Looking down under, DMN reports that March New Zealand milk output was down on a tonnage basis.

“An analyst group in the country stated March output in New Zealand was the weakest since 2020 in terms of milk solids and on a tonnage basis,” DMN

said. “El Niño contributed to drier than normal weather conditions in the country, and many farmers experienced drought-like conditions as well as irrigation restrictions due to low water table levels.”

We’ll whitewash with the cows in the barn! FLY CONTROL Pipeline, Windows and Light Bulbs cleaned at

16 Month old Holstein bull. Lithium x Archie Red. A2/A2, Proven. aAa264. Very nice bull out of a fancy uddered cow family!! Lamar Weaver, Unity

15 Month old Red & White Holstein Bull. Revmeup Red out of a 93pt Flirt Red,Registered and Proven. Photos available.Daniel Weaver,Lancaster

16 Month Red & White Holstein Bull. Redneck Red out of a 93pt Ammo-P, Registered, Proven. Photos available. Daniel Weaver, Lancaster

5 yearling bulls coming from Dorchester Holsteins. aAa analyzed,some with registration papers.

16 month old Holstein, Polled and A2A2 parents.Proven breeder. Rex dam. ADVANCE NOTICE

BLAIR, Wis. — The Killian family will never forget the day one of their beloved Jersey cows, Lemondrop, fell in the manure pit.

Steve and Amanda milk 75 Jerseys and Holsteins on their farm near Blair. One morning several years ago, the couple started chores like usual. It was a day in late winter that was too cold for barn fans but warm enough to keep the door to the tiestall barn cracked.

Steve discovered an empty stall when he went to milk the switch cows and determined Lemondrop was missing. He milked the rest of the cows and then looked for the missing Jersey. That is when he heard something near the manure pit and discovered Lemondrop in the pit. Just a sliver of her back was visible, and she was on the far side of the pit.

The manure pit is a short storage pit positioned so the barn cleaner empties into it. The cover is a foot-thick slab of concrete with a 3- by 4-foot hole for the manure to fall into. Inside, the pit is about 20 feet by 30 feet.

Steve alerted Amanda, who had nished feeding calves by then. The pit was almost full, and all Amanda could see as she peered into the opening was Lemondrop standing in the pit, with her nose just barely above the surface, facing away from her.

“I got a spotlight, laid down on my belly and had one of the kids hold my legs as I dangled upside down trying to see if I heard what I thought I heard,” Amanda said. “Our rst thought was that she was certainly going to die in there and we were going to have to gure out how to get a dead cow out of a covered manure pit. Then, God gave me an idea.”

With help from Steve and the kids, Amanda attached an old lariat to the end of a 15-foot piece of PVC pipe. She guided the apparatus over to the corner of the pit where Lemondrop stood. After several attempts, Amanda got the lariat over Lemondrop’s head.

With Lemondrop roped, the family guided her slowly to the opening of the pit. They then hooked a chain and a hook around Lemondrop’s collar and pulled her out of

Killian takes a

with

on her dairy near Blair, Wisconsin. Amanda and her husband, Steve, milk 75 Jerseys and Holsteins with their children in Trempealeau County.

the pit with the skid loader. They thought they would pull her partially out by the collar and then attach a strap to her body, but she was coming easily so they continued with the collar. She immediately stood once she was on solid ground and ran into the barn, directly to her stall. Amanda washed her down and treated her with antibiotics.

“I thought she was certainly going to get a horrible case of pneumonia,” Amanda said. “She never got sick. In fact, she came into heat the next week and settled on the rst service.”

Amanda said that when they discovered Lemondrop in the manure pit that morning, she did not think the situation would have a good ending. Instead, Lemondrop is in the barn to this day. She has had two calves since then and remains a productive member of the herd.

Large

1st

$102.50-150/ton 2nd

$120-190/ton 3rd

$142.50-172.50/ton

$260-157.50/ton

WISCONSIN DELLS, Wis. — Having a source of high-quality replacement heifers dictates the future of dairy farms. Many variables come into play when a producer considers the source of these females.

Dr. Michael Overton spoke about those variables at the Professional Dairy Producers Business Conference March 14 in Wisconsin Dells.

“Heifers are a necessary investment,” Overton said. “We need to get the best return on that investment in terms of both future milk and beef production. These animals represent your future herd.”

Investing in replacement heifers allows farmers to upgrade their herd by keeping the most protable animals. Cows are typically replaced for two reasons: biologic failures such as death, chronic lameness, mastitis, reproductive failure or other health issues; and selective replacement, culling low-producing animals to improve production potential.

Current market trends have made it necessary for dairy farmers to continually reevaluate their approach to replacement animals to en-

sure growth and improvement. Overton pointed to the current market value of beef-on-dairy calves coupled with pressure from the beef side of the market, which brings competing dollars for dairy heifers.

“The inventory and prices of heifers is dramatically different right now than in recent history,” Overton said. “The inventory of heifers is going down. The replacement herd is down 14,000 head from 2023. Wisconsin has been identied as losing more animals from 2023 to 2024 than any other state, down about 50,000 animals.”

Looking at the average cost versus the marginal cost of raising heifers is important in determining the best path for a farm to follow, Overton said.

The average cost spreads the total cost over a set number of heifers, with an industry average of $2,300-$2,600. Adding in a few extra heifers, beyond that set number, represents what Overton calls marginal heifers.

Overton said farmers tend to focus solely on the cost of replacements with two goals in mind: lower the replacement rate as much as possible and raise heifers as cheaply as possible. Overton cautions against looking at cost simplistically.

“When cows need to be replaced, you should be improving your herd,” Overton said. “That improvement comes at a cost.”

Overton said that focusing solely on the tangible, explicit costs of replacements can result in a signicant lost opportunity cost because poorer quality animals — those that are poorly grown or have chronic health issues — might be kept in the milking herd longer.

“Raising 5% more heifers than what you plan for can be easily managed,” Overton said. “That 5% is the least expensive to raise because you have already allocated the xed expenses over the others. The average cost may be $2,500, but your marginal cost is $1,800. If we can raise a few more heifers without dramatically overcrowding, we can lower the cost per heifer and allow ourselves more exibility in decision making downstream.”

Overton reminded producers to not just consider acquisition cost but to factor in the salvage value of the animal being replaced.

“A higher replacement rate doesn’t always mean less protable, if done for the right reasons,” Overton said. “The salvage value of a cow is dramatically inuenced by how we manage our cows and when we make those decisions. The

longer a cow stays, the less salvage value she has. It is better to be more proactive in your replacement decisions. Don’t wait for cows to be thin, lame or run-down before culling. Selling at a more opportune time increases salvage value.”

How replacements are raised factors into their value as well. Overton said there are three options for providing those replacements: raising heifers on-farm, out-sourcing heifer raising to a grower, or selling all calves and purchasing replacements back from the market, a concept Overton termed “ying herds.”

Historically, raising replacements on-farm has been the most common approach. Overton said producers tend to want the control that direct oversight gives them, and some may have biosecurity concerns about animals leaving the property and returning. The perception has been that raising heifers on-farm is a lower cost, but Overton said that is likely not true because hidden or less tangible costs are often not factored in.

Factors that drive producers to choose off-site raising of their heifers include a lack of space and housing, along with issues surrounding manure management, ability to produce enough feed, access to water and potential labor issues.

“With the economic investment required to build heifer fa-

cilities, a grower might be able to do it cheaper,” Overton said. “There are certain efciencies of size and scale a heifer raiser growing 50,000 heifers that a 500-cow dairy does not have.”

Care is necessary when choosing a heifer grower.

Overton warns farmers not to incentivize the grower to underfeed calves in pursuit of cheap heifers, noting the cheapest heifer is not necessarily the best value.

Overton encourages producers to give a grower exibility in adjusting pricing with increased feed costs over a locked-in at rate or per diem. This allows the grower to keep their margins in line.

The ying herd was an attractive option when replacements could be purchased for $1,300 and market cows could be sold for $800 but is now a painful prospect with low heifer inventories driving up the price of replacements, which may potentially be of lower quality, Overton said.

Overton urges producers to consider all aspects of raising replacement heifers, focusing on prot over the cost of the transaction, and warns against limiting options by under-producing heifer calves.

“Raising fewer heifers improves cash ow now but can hurt long-term prots,” Overton said. “Keeping less productive cows in the herd in pursuit of greater lifetime milk ignores future lost opportunity costs.”

SIOUX FALLS, S.D. — As consolidation continues in the dairy industry and herd sizes grow larger, management practices are evolving to include more automation.

Producers lean on technology to monitor the performance and growth of their cows. One such evolution is 3D camera technology to measure body condition scores.

“Continuous monitoring is key to effective management,” Fernando Diaz said. “We cannot manage what we cannot measure. 3D cameras are an efcient, non-invasive monitoring solution.”

“There are dynamic changes in body condition score during critical periods, and 3D cameras allow us to measure this body condition uctuation,” Diaz said. “The camera is not very valuable to tell you that this cow today is a body condition score of 3. It is valuable to tell you that yesterday she was almost a 3, and, tomorrow, is she a 3 or a little over a 3.”

Because heifers continue developing into their third lactation, it is not accurate to measure health by milk production or weight alone, Diaz said. The cameras help to combine the weight of the animal with the body condition score. Weight itself is not a good representation of the body condition of the animal because of the contents of the rumen.

Diaz, CEO of Dellait — Animal Nutrition & Health, presented information about the 3D camera technology March 21 at the Central Plains Dairy Expo in Sioux Falls.

The cameras take measurements of cows as they walk by and predict a body condition score. The measurements and scores are saved in software that producers can access on their computers or smartphones.

Cows are identied with the use of RFID tags. Data can be analyzed for individual cows or groups. When looking at an individual, graphs can help determine changes in body condition score. Analyzing a group of cows can help nd trends or anomalies.

The camera shoots infrared rays at the cows, which then integrate to create a 3D image of the cow. It measures distances between the hips and pins. The system also provides the stature of the cow. Each 3D image can be viewed on a device and rotated for a 360-degree view of the animal.

The system is most effective when the camera can view one cow at a time and the cow is standing still for up to 30 seconds. Common places for cameras include return lanes from parlors, feed bunks or water troughs.

“It gives us a very powerful tool,” Diaz said. “You check the cows without being there but at the same time always being there from your computer or phone.”

Close monitoring of body condition scores enhances early detection of health issues such as ketosis. When cows are losing weight, they immobilize fat. Then, the ketones increase in the blood. Early detection is crucial for effective treatment. Substantial costs are associated with ketosis, and 3D cameras can mitigate economic losses, Diaz said.

One USDA study indicates that 31% of lactating cows suffer from ketosis.

“That’s one-third of the cows in the U.S.,” Diaz said. “So, you better believe that you have cows that are suffering in your herd right now, subclinical or clinical.”

If changes in the body are monitored through body condition score, a producer can theoretically anticipate what might happen to a cow. Most illnesses are treated more effectively when treatment starts earlier.

The 3D camera system can aid in lameness problems as well. Diaz referenced a correlation between lameness and low body condition scores. Lameness affects 25% of U.S. herds, with an average treatment cost of $360.

“Visual observation is subjective and time consuming. If you have to pay an employee to do this, then you introduce the factor of human error. 3D imaging standardizes the way we are looking at that.”

FERNANDO DIAZ , CEO, DELLAIT

Diaz said herd health issues can be detected and solved by monitoring the body condition score of cows. He said statistics from the U.S. Department of Agriculture indicate that many cows leave the herd before their fourth lactation, for various reasons.

When measuring body condition score, Diaz stressed the importance of analyzing static versus dynamic body condition.

“Visual observation is subjective and time consuming,” Diaz said. “If you have to pay an employee to do this, then you introduce the factor of human error. 3D imaging standardizes the way we are looking at that.” A 3D camera system can also be useful for heifer and beef raisers. A custom heifer raiser can monitor growth more closely and adjust feed rations accordingly. Beef producers can better anticipate the value of their growing animal. All of this can be reviewed without physically pushing an animal through a chute and onto a scale.

“The key component of this is the less intrusion we have in the life of the animals,” Diaz said. “This is a technology that will shape the future. We need to change the way we see things.”

WATERTOWN, Wis.

The sun was shining, and the wind was blowing when James McManama took to the elds May 1 for the rst time this year.

Planting corn was the goal for McManama and his daughter, Rachel Schroeder. The pair milks 90 cows and farms 500

acres at Simply Crazy Farms near Watertown.

“We enjoy working together,” Schroeder said. “My dad is my best friend.”

The days get long for this father-daughter team, and May 1 was no exception. Work did not wrap up until about 9 p.m. for Schroeder and an hour later for McManama.

Schroeder does most of the milking and started at 6:30

a.m. while her dad mixed feed and fed the cows and heifers. Cows are milked in 17 stalls of the stanchion barn and housed in a freestall barn. Schroeder milks with eight units and said milking takes about two hours.

Schroeder is the third generation on the farm started by her grandpa in 1953. A mother of two, her 7-year-old daughter, Remington, and 4-year-old son, Colton, love being at the farm. Schroeder’s husband, Jesse, is a diesel technician and handy at xing farm equipment. Her mom, Sandy, works part time and also watches the grandchildren. A few part-time employees help with relief milking.

Schroeder has farmed with her dad for 12 years and been an owner of the farm for 10.

“It has taken us nine or 10 years to get the quality we were after,” Schroeder said. “It’s quality we thought we were never going to see. Our average somatic cell count is 50,000. Maybe once a year I treat a cow for mastitis.”

A healthy herd and attention to detail are key contributors to this success.

“A lot has to do with genetics,” Schroeder said. “We breed for the health of the animal and components.”

Schroeder said they re-

cently hit 100 pounds of milk per cow per day.

“It wasn’t even a goal of ours, so to see that is phenomenal,” she said. “We’re so thankful and blessed. I don’t like to push my cows too much. We have one group in the freestall barn, and everyone gets the same feed.”

Schroeder fed calves at 9

a.m. and then limed the stalls in the barn. When McManama returned from feeding heifers, he and Schroeder mixed another batch of feed to get a head start on evening chores.

Paul Mueller Company’s MAXXimizer™ L-40 package chiller, designed to ease the daily burdens of dairy farmers, has plug-and-play design and cloud connectivity, so you benefit from remote, real-time access to your refrigeration system data.

Central Ag Supply Juneau, WI; Baraboo, WI

Advanced Dairy Spring Valley, WI; Mondovi, WI; West Salem, WI; Mora, MN; Pierz, MN; Wadena, MN; St Charles, MN;

Ederer’s Dairy Supply Plain, WI; Blanchardville, WI; Dodgeville, WI

Central Ag Supply Juneau, WI; Baraboo, WI

J. Gile Dairy Equipment, Inc. Cuba City, WI

J. Gile Dairy Equipment, Inc. Cuba City, WI

Monroe Westfalia Surge Monroe, WI

Redeker Dairy Equipment Brandon, WI

Professional Dairy Services Arlington, WI

Stanley Schmitz Inc. Chilton, WI

Redeker Dairy Equipment Brandon, WI

Seehafer Refrigeration, Inc. Marshfield, WI; Sparta, WI

Tri-County Dairy Supply Janesville, WI

Stanley Schmitz Inc. Chilton, WI

Fuller’s Milker Center Lancaster, WI; Richland Center, WI

Total Dairy Services Kewaunee, WI

United Dairy Systems West Union, IA

Leedstone

Melrose, MN; Glencoe, MN; Plainview, MN; Menomonie, WI

Gorter’s Clay & Dairy Equipment Pipestone, MN

Monroe Westfalia Surge Monroe, WI

Leedstone

Eastern Iowa Dairy Systems Epworth, IA

Tri-County Dairy Supply Janesville, WI

Melrose, MN; Glencoe, MN; Plainview, MN; Menomonie, WI

Lely Center Monroe Monroe, WI

Sioux Dairy Equipment Rock Valley, IA; Colton, SD

Fuller’s Milker Center Lancaster, WI; Richland Center, WI

Eastern Iowa Dairy Systems Epworth, IA

United Dairy Systems West Union, IA; Monticello, IA

Gorter’s Clay & Dairy Equipment Pipestone, MN

Sioux Dairy Equipment Rock Valley, IA; Colton, SD

Midwest Livestock Systems Zumbrota, MN; Menomonie, WI; Renner, SD

Total Dairy Service Kewaunee, WI

Midwest Livestock Systems

S&S Dairy Systems St. Charles, MN

Zumbrota, MN; Renner, SD; Menomonie, WI; Kaukauna, WI; Weston, WI

Glencoe Co-Op Assn. Glencoe, MN

Cows enjoy a sunny day May 1 at Simply Crazy Farms near Watertown, Wisconsin. These dry cows were transferred to another area while Rachel

SMART/DAIRY STAR

Rachel Schroeder sprays the units May 1 a er the morning milking on her family’s farm near Watertown, Wisconsin. Schroeder does most of the milking with help from part- me employees.

James McManama watches as feed is mixed the morning of May 1 on his

Watertown, Wisconsin. McManama was ge ng a head start on evening chores as he knew he would be in the eld most of the day.

At 9:40 a.m., Schroeder cleaned the dry cow yard.

McManama hooked up the cultivator around 9:45 a.m., and at 10:30 a.m., he and his daughter lled the corn planter with seed.

“This is where it all starts,” McManama said. “We put the seed in the ground, but it’s up to the good Lord to give us the crops.”

McManama and Schroeder

plant 220-240 acres of corn. They plant Brevant seed for corn silage.

“This seed has a stronger stalk quality,” McManama said. “If we don’t need it for silage, we can leave it for highmoisture or dry corn.”

McManama has switched from planting with dry fertilizer to planting with liquid fertilizer.

“Dry fertilizer is more la-

bor intense,” he said. “With the pop-up fertilizer in the front of the tractor, I can apply a rst-pass herbicide in the furrow, and it removes one step in growing the crop. It also gives a stronger start to the plant.”

McManama and Schroeder grow 100-110 acres of alfalfa which they put up as baleage.

Turn to DAY IN THE LIFE | Page 15

About ve years ago, they decided to bring hay harvesting back in-house and purchased a vertical mixer and hay equipment.

“There is pride in making your own feed, and we’ve been so happy with the quality we’re getting,” Schroeder said. “Making round bales is probably one of my favorite jobs.”

They continue to use Ledgeview Custom Services to harvest silage.

“They are great to work with,” Schroeder said. “They put up our corn silage in about 8-10 hours.”

The farm also grows 150 acres of soybeans.

“We always grew beans for a cash crop, but last year, we began feeding it as well,” Schroeder said. “Our nutritionist suggested adding it into our ration as protein versus selling it at a loss and buying it back.”

As her dad took a rst pass over the eld with the cultivator at 10:45 a.m., Schroeder commented on the eld’s condition.

“I’m very happy with how the seed bed looks,” she said. “It’s nice and at. There are no big dirt balls. We’ll get really good seed depth.”

Schroeder took over cultivating for her dad around 11 a.m., while McManama went back to the farm to prep the planter. He began planting corn around 1 p.m. and planted 50 acres of corn that rst day in the elds.

One of Schroeder’s newest employees milked on her own for the rst time that night so that Schroeder could

remain in the eld. She nished cultivating at 8 p.m. Once she got back to the farm, Schroeder fed calves. Her husband was there to help nish milking. Then, Schroeder and her husband went to the heifer farm to breed a heifer before heading home.

“We run some late nights when trying to get corn planted, but I’m super happy with the progress we made,” Schroeder said.

ALBANY, Minn. — The sound of goats bleating while they roam his farm south of Albany is something that Tyler Gerads has heard for more than a year.

Milking is not a foreign concept to Gerads; however, milking goats is.

On the dairy, where Gerads farms about 150 acres and milks cows, he added over 160 milking goats to his work load, with plans to expand his goat herd. His herd is a mix of Alpines, Saanens, Lamanchas and a few Nubian mixes.

Along with the other chores found around the farm, Gerads also does custom hoof trimming. To make everything work, Gerads relies on the help of his three children: Kendra, Aleena and Kianna.

“The milking is just me in the morning,” Gerads said.

“The girls help with the evening milking. When it comes to the kidding, everyone helps.”

While most goat farmers would have dried up their goats over winter, Gerads did not. He freshens goats year-round and balances that with his hooftrimming business, spreading the workload throughout the entire year. However, it does lead to a challenge for him.

“It’s hard because all the goats I bought were always bred in the fall,” Gerads said.

“I need to get the gestation period on track for an all-year breeding season.”

To help the goats adjust to the new breeding schedule, Gerads had LED lights installed in the bedding pack area where the goats are housed. Gerads said this helps make the goats cycle more regularly so that they can be bred yearround.

Turn to GERADS | Page 17

“That helps me in winter so that I don’t have them all kidding at one time,” Gerads said.

Having kids throughout the year helps Gerads manage his time so he was able to add goats to his operation.

“(Milking goats) was something I was always interested in doing,” Gerads said. “Then, I just took the step and started the construction, such as knocking out walls, building the pit and pouring cement. I built the parlor and milk room myself.”

The road to begin milking goats was complicated. Gerads toured farms and did research before purchasing the goats. It took him a year, from concept to reality, to bring the goats to the farm.

Along the way, Gerads had help from his farm consulting team, including his nutritionist Kate McAndrews, Minnesota Goat Milk LLC eld representative Missy Isder and goat farmer Brad Donnay.

The mentors helped Gerads make decisions and showed Gerads ways to keep his goats healthy. He gured out the differences between caring for

goats versus cows. He also learned how to manage kidding.

Every day at 3:45 a.m., Gerads heads to the barn to get everything rinsed and set up for the goats. While Gerads is milking, the goats are also fed grain. Once the milking is done, the lines are washed and rinsed, and everything gets cleaned again. The goats are milked again at 3:45 p.m.

Gerads also milks cows twice each day at 5:30 a.m. and 5:30 p.m. Each of the four milkings takes about an hour.

Just like cows, Gerads knows goats can also suffer from mastitis and milk fever. He learned that the practices for identifying ailments and offering treatment is the same in both species, so the care is something he was already familiar with.

Gerads said having his idea come to fruition has been positive.

“The highlight for me was that I lucked out and ended up with a good herd of goats,” Gerads said. “For not knowing a thing about goats when I went to go look at them, I still managed to start with nice, healthy animals.”

Rensselaer

Buskirk, New York

this spring has been that the rains have been untimely and kept us out of the fields. There is not much corn planted here. We have 160 acres in the ground. Some of the corn went in earlier this week in eastern New York. When we see an opportunity, we plan to mow grass/alfalfa. We chop it all. The alfalfa hasn’t taken off yet.

It has been wet. The rain has fallen slowly; the most we’ve received at a time has been one-half inch. There has been very little drying weather. We finished seeding our oats and alfalfa but haven’t planted any corn or soybeans. One of our neighbors has planted some corn on his high ground. Our alfalfa is 6-8 inches tall and is ready to take off when the weather warms. I’m hauling manure on our high ground while waiting for our fields to dry. Next on my to-do list is working on the fences and getting ready for the grazing season.

We finished hauling the pit April 25. Then, it started raining, so we haven’t done anything in the field. The alfalfa looks good and stands around 8 inches tall. We are good with moisture right now. In the low ground, we have a little bit of standing water. I have seen a little small grain planted around here but nothing else. You couldn’t drive in the fields right now. I would say we are 5-6 days out. Everybody is hooked up and ready to go. We are ready, but we need a window. We plant mid-90-day grain corn and 107-day silage corn.

We have been so wet that we haven’t been able to do any fieldwork during the past two weeks. We’ve received 12 inches of rain since March 20. I heard that a neighbor who has some early-planted corn had to hire a drone to spray his field because it’s too soggy to go out there with a sprayer. Temperatures have remained cool. Corn that was planted two weeks ago still hasn’t emerged. You hate to wish rain away, but some of our flatter fields have big puddles. We have no idea when we’ll be able to get into those areas.

We planted about 110 acres of corn April 25. The oats that we planted are up. Our wheat is 4 inches tall, and the alfalfa is around 10 inches tall. The wheat where the water stood after we seeded is coming up, but it’s a little behind. If it doesn’t rain, we should be back in the field around Mother’s Day. I almost got stuck picking rock on the hills or tiled fields because it’s wet. Whatever fields we can work will be the next ones we plant. The new seeding alfalfa is coming up. Some of the neighbors that planted corn around a month ago haven’t had it emerge yet.

About 80% of the corn in our area has been planted, and quite a few farmers have started planting their soybeans. Most of the corn in the area was put in ahead of schedule. We strip-tilled and fertilized our corn ground last fall, so we were able to get all of our corn planted in one day. Because of this, we were able to help our neighbor with his planting and got his corn in before it rained. Our rye is 18 inches tall and is growing like crazy. Our alfalfa looks really nice.

We cut 22 of our 30 acres of rye and chopped one load yesterday. It was almost 4’ tall. We had an inch of rain overnight (May 7) otherwise yesterday was the first day we could get back in the field. I also saw a couple corn planters go yesterday. The oats, peas and alfalfa we planted are up. The oats is about an inch and a half tall. The alfalfa is at pre-bud stage and a week away from being cut. I will park the corn planter if I have to for first crop hay. The fields have some pooling at the ends and there are a few tile lines plugged.

We have not made progress for fieldwork because of the rain; it’s been coming almost every three days. We’d hope to get in the fields, and then, it would rain again. We got fertilizer spread, ground worked up and manure hauled, but otherwise, it has been slow. I know a couple of the big cash crop guys were done before this rain. But as far as dairy farmers who had to haul manure, we are not there. April rain makes our crop as much as June, July and August rain does. That subsoil moisture carries us through when we don’t get the late rains. If we can turn it loose for a couple weeks, then we’ll be caught up in no time, and everything will be fine.

We finished planting all of our new seeding alfalfa and also have 287 acres of soybeans and 650 acres of corn in. We started planting corn May 1. We planted soybeans from April 22-25. We have 160 acres of corn and 61 acres of soybeans left to plant. Last year, we didn’t start planting corn until May 7, so it’s pretty good to be 650 acres in. Even though we hadn’t gotten a lot of rain, we were still planting into good moisture, which is encouraging. Our wheat is looking really good, and the soybeans we planted April 15 are popping up.

We are definitely catching up on moisture, which is good. The top is good and moist. It has been raining a lot the last several weeks. We get a one- to two-day break, and then, it rains again. It has been hard to get stuff done. We have only been able to haul manure. All of our oats are up really nice now. The fields are nice and green, and you can hardly see the rows. The alfalfa is probably 13-14 inches tall and is also growing really nice. In the next weeks, weather permitting, hopefully, we can get corn in the ground. A few neighbors starting putting corn in May 6.

We have had about 5.75 inches of rain in the past two weeks. We are pretty wet and out of the drought. There are swamps and wetlands that are full that have not been full for maybe four years. We have been hauling manure on the lighter ground, and maybe tomorrow we can start corn on the lighter soil. I really don’t know how long it will be until we can get into the heavier ground. All of our alfalfa seeding is up. The alfalfa and the triticale look great. We are probably 2.5 weeks out on hay. We will probably be trying to do hay and corn at the same time.

We have had about 3.7 inches of rain in the past two weeks. We are wet, but with our sandier soil, we will be ready to be in the fields again — hopefully tomorrow if it doesn’t rain. Just north of us, in the Antigo Flats, they have not really even started. They are wet enough. We’ve got about 150 acres of corn left to plant. We are probably about two weeks out from doing hay. The hay looks phenomenal around here.

On May 1, we planted 22 acres of corn. We continued planting May 3 and had 90 acres in by May 6. We have at least 300 acres left to plant. One field behind my barn is going to be split between corn and soybeans. We’ll work up the ground and go in and work on both with soybeans on the far end and corn on the closer end. A lot of guys in the area started with soybeans instead of corn. We also have 18 acres to reseed with alfalfa. Our hay is growing fast, so we should be able to start pasturing cows pretty quick.

As a former Tri-County Beef Queen, it is my duty to continue to promote my favorite source of protein and iron: beef. As dairy farmers, we are fortunate to support two commodity check-offs with one single animal (milk and beef). I recently went on the Minnesota Beef Council website to nd new recipes for Beef Month. I was surprised with their recipe collections and ideas. I grabbed a few that I will be serving for Mother’s Day brunch with our family.

May is also the month of asparagus and rhubarb. I’ve included recipes using these fresh ingredients to add to our brunch. The rhubarb lemonade is going to be my new summer drink.

Beef breakfast sausage, cheese egg bake 1 recipe basic country beef breakfast sausage

1 pound frozen hash brown potatoes, thawed 8 eggs

1 teaspoon salt, divided 1/2 teaspoon pepper, divided 1 1/2 cups sour cream

1/2 cup milk

4 ounces crumbled cheese of choice

1/2 cup thinly sliced green onions

Preheat oven to 425 degrees. Spray a 9-inch springform pan with cooking spray. Squeeze excess moisture from potatoes. Combine potatoes, one egg, 1/2 teaspoon salt and 1/4 teaspoon pepper in medium bowl, tossing gently to coat. Press potato mixture onto bottom and up side of prepared pan. Do not place springform pan on baking sheet. Bake in a 425-degree oven 20-30 minutes until potatoes are crispy and brown. Remove pan from oven. Reduce oven temp to 375 degrees. Meanwhile, prepare sausage. Set aside.

Basic country beef breakfast sausage: Combine 1 pound ground beef, 2 teaspoons chopped fresh sage (or 1/2 teaspoon rubbed sage), 1 teaspoon garlic powder, 1 teaspoon onion powder, 1/2 teaspoon salt and ¼ teaspoon crushed red pepper in large bowl, mixing lightly and thoroughly. Heat large skillet over medium heat until hot. Add beef mixture; cook 8-12 minutes breaking into crumbles and stirring occasionally.

Whisk together remaining seven eggs, remaining 1/2 teaspoon salt and 1/4 teaspoon pepper, sour cream and milk in a large bowl. Stir in cheese, green onions and sausage; pour mixture into hashbrown crust. Bake in a 375-degree oven 40-50 minutes or until eggs are set. Cool 10-15 minutes. Remove from pan; cut into wedges.

Spicy beef chorizo breakfast strata

1 recipe Mexican style beef sausage

12 cups chopped red bell pepper

2 cups packed fresh baby spinach

6 large eggs

1/2 teaspoon salt

2 cups milk

1/4 teaspoon black pepper

8 cups day-old French bread, cubed 1 1/2 cups shredded Monterey Jack cheese

Toppings: Salsa, chopped green onions, chopped tomatoes and sour cream

Preheat oven to 350 degrees. Prepare Mexican style beef sausage: Combine 1 pound ground beef, 2 tablespoons red wine vinegar, 1 1/2 teaspoons dried oregano leaves, 1 1/2 teaspoons smoked paprika, 1 1/2 teaspoons chili powder, 1 teaspoon garlic powder, 1/2 teaspoon salt and 1/2 teaspoon chipotle chili powder in large mixing bowl, mixing lightly but thoroughly. Heat large skillet over medium heat until hot. Add sausage mixture; cook 8-10 minutes, breaking into one-half inch crumbles, stirring occasionally. Meanwhile, beat eggs, milk, remaining 1/2 teaspoon salt and 1/4 teaspoon pepper in a large bowl until blended. Stir in bread, spinach and 1 cup cheese. Stir in sausage mixture.

Spray 3-quart shallow baking dish with cooking spray. Pour sausage mixture into dish. Top evenly with remaining 1/2 cup cheese. Cover with aluminum foil; bake in a 350 degree oven for 40 minutes. Remove foil; continue baking 10-15 minutes or until puffed and lightly browned. Let stand ve minutes before serving. Garnish with toppings if desired.

Rhubarb lemonade

4 cups chopped rhubarb

4 cups water

1 cup sugar

1 cup fresh lemon juice and pulp

4-6 cups ice cubes

Put rhubarb, water and sugar in a heavy bottom pan. Cook on medium heat until boiling. Boil for 15-20 minutes or until rhubarb is shapeless. Strain juice from pulp into big bowl. Let cool. Squeeze 4-6 lemons to equal a cup of juice. Add to cooled rhubarb syrup. Add ice cubes.

Beef, asparagus pasta toss

1 pound ground beef

3 cups uncooked bow tie pasta

1 pound fresh asparagus, cut into 1-inch

pieces

1 tablespoon olive oil

1/4 cup minced shallots (about two large)

1 tablespoon minced garlic

Salt and pepper

1/2 cup shredded Parmesan cheese, garnish

Cook pasta in salted boiling water 10 minutes or until almost tender. Add asparagus; continue cooking three to four minutes or until pasta and asparagus are tender. Drain well. Meanwhile, heat large skillet over medium heat until hot. Add ground beef; cook 8-10 minutes, breaking into three-fourth inch crumbles and stirring occasionally. Remove from skillet with slotted spoon; pour off drippings. Heat oil in same skillet over medium heat until hot. Add shallots; cook three minutes, add garlic and cook an additional minute until tender and fragrant. Remove from heat. Add beef; toss to mix. Season with salt and pepper as desired. Combine beef mixture with pasta and asparagus in large bowl; toss well. Sprinkle with cheese. Serve.

As their four children pursue dairy careers off the family farm, Natalie and Mark Schmitt started an adventure of milking registered Holsteins just because they like good cows on their farm north of Rice, Minnesota.

For decades, Calf-Tel® has set the standard for

calves, Calf-Tel promises – and delivers – a wise investment.

1 cup crunchy wheat and barley cereal

3 cups fat-free strawberry yogurt

1 bag (10-ounces) frozen unsweetened strawberries (about 2

1/2 cups)

1 cup fat-free sweetened condensed milk

1 cup light or fat-free whipped topping (optional)

Line an 8-by-8 baking pan with foil. Sprinkle cereal evenly on the bottom of the pan; set aside. Place yogurt, strawberries and condensed milk in a blender; cover and blend until smooth. Pour the mixture over top of cereal, gently smoothing yogurt mixture to edges of pan. Cover with foil (or plastic wrap) and freeze for 8 hours or until rm. Use edges of foil to loosen and remove from pan; let recipe thaw for 5-10 minutes. Cut into squares, top with whipped topping, if desired, and serve. Storage tip: Squares may be individually wrapped and frozen for single servings. Create your own variations by using other avor combinations of yogurt and fruit.

1 pound lean ground beef

1/2 cup onion, chopped

Whole-wheat elbow macaroni or penne or rotini pasta

1 medium tomato, chopped

8 ounces tomato sauce

1/2 teaspoon seasoned salt, optional

1/4 teaspoon black pepper

1 cup shredded cheddar cheese

Preheat oven to 350 degrees. Spray an 8-by-8 baking pan with nonstick cooking spray; set aside. In large skillet over medium heat, cook ground beef and onion until beef is brown and onion is soft; drain. Cook macaroni according to package directions; drain. Spoon macaroni into prepared pan. Spread beef mixture and chopped tomato over macaroni. Pour tomato sauce over beef. Sprinkle with seasoned salt, pepper and shredded cheese. Cover loosely with foil and bake for 35 minutes or until cheese is melted and edges of casserole are bubbling. To spice it up, use your favorite pizza or Italian-style tomato sauce instead of tomato sauce and seasoned salt. For a meal later, double the recipe and place the second casserole in the freezer for later use.

12 ounces cooked beef (such as steak, roast, pot roast or deli roast beef), thinly sliced

4 thin-style avored bagels or regular bagels, split 1/3 cup cream cheese

2 tablespoons nonpareil capers

8 thin slices tomato

4 thin slices red onion, separated into rings Nonpareil capers, optional

Holstein Organic Dairy Cows, herd includes some crossbreeds. Parlor/freestall, cows are averaging 65# 4.3BF 3.4P scc185, cows

**Cows are PENDING the HPAI/ H5N1 Avian In

Calmer

Coming from Bushman Moon Haven,

3 Holstein Dairy Cows and a springing heifer. SUPREME Fresh Holstein Dairy Cows! Parlor/freestall dairy cows. Out of a 32,000# RHA! Over 40 years of AI breeding through Select Sires, 25 years on a full mating program. Extensive vaccination program. Reputation consignor. Coming form Mark Chamberlain and Family, Pine Island, MN MANY CONSIGNMENTS PENDING AT AD DEADLINE, CHECK OUR WEBSITE FOR MORE UPDATED INFORMATION! Expecting our usual run of dairy cows, dairy bulls, springing heifers, short bred, and open heifers.

Spread cream cheese evenly on cut sides of each bagel half. Evenly sprinkle capers over cream cheese. Evenly top with tomato slices and onion rings; top with beef. Garnish with additional capers, if desired. Serve immediately or refrigerate until ready to eat.

Secure your tires and Secure Covers with us too!

“The Hanson Silo Bunker empowers us to control shrink loss. With our piles, we used to see lots of spoilage. But now we see very little, if any at all.”

Sako Vandermeer - White, South Dakota

• Engineered for strength and long-term durability

• DRY CAST formulation creates low porosity and slump

• Computerized batching for uniformity

• Robotic mold system provides consistency

• Quality nished for smooth edges and sure footing

• Manufactured in a controlled environment (Steam Beds) for faster curing

• Delivered, professionally leveled and installed

• Strength Compression Tests to exceed quality standards

• Modular design for easy installation