WANT TO WIN $100 CASH?

See page 5 of the second section for details! !

See page 5 of the second section for details! !

Volume 25, No. 6

May 13, 2023

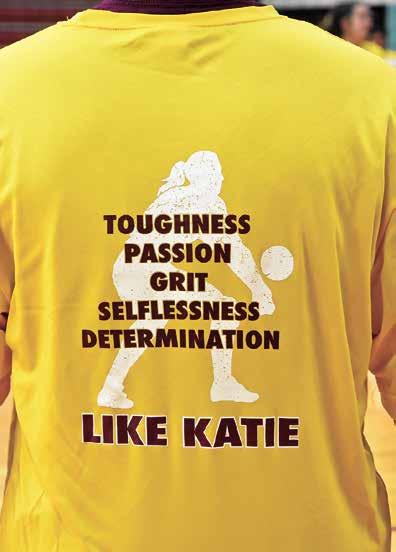

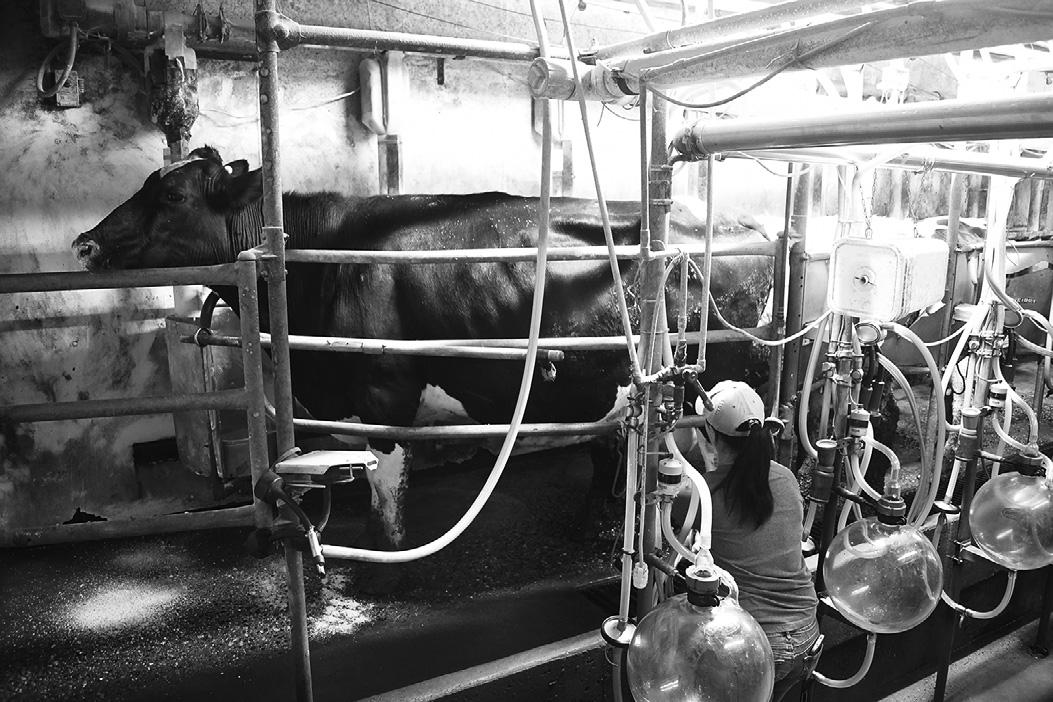

SAUK CENTRE, Minn. – Spring storms can bring strong, damaging winds, but Carolyn and Paul Reitsma have seen that faith, family, community and their daughter, Katie, are stronger.

One year after Katie suffered a massive brain injury when she was hit by ying debris during a storm that swept through her family’s dairy farm near Sauk Centre, she nally came home to continue her recovery.

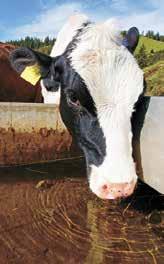

Katie and her parents, along with brothers, Joe and Mitchell, milk 280 cows with four DeLaval robotic milking systems at Reit-Way Dairy. Katie also works as a paraprofessional at Holy Family El-

By Jan Lefebvre jan.l@star-pub.com

By Jan Lefebvre jan.l@star-pub.com

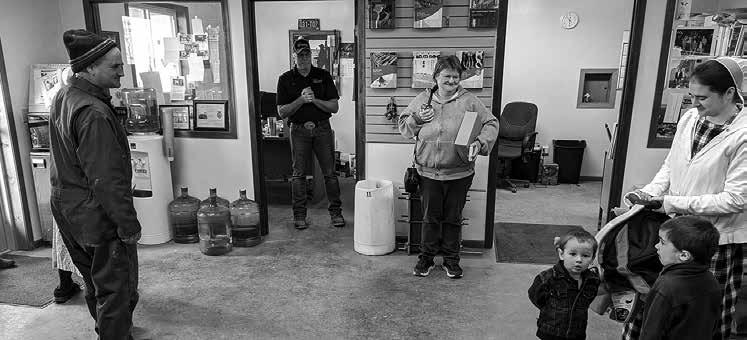

Although Gay Finn, head cook for Minnewaska Elementary School, was skeptical at rst, she said her school’s transition from milk cartons to a milk dispenser has been a success.

“There’s so much less waste now, and the kids can help themselves whereas before there were gallons of milk being thrown away,” Finn said. “Yes, there are a few kids who take too much, but the majority take just what they will drink. If they are only going to drink half a glass, they take half a glass.”

Now, only about half a gallon of milk is dumped during a complete lunch period at the

ementary School in Sauk Centre. She had been planning to begin taking evening courses to earn her teacher’s license.

When Katie ew home on a medical ight April 29, with her was her childhood neighbor and boyfriend Eugene Marthaler. The two began dating over two years ago. Marthaler stayed with Katie in Chicago since her rst being transferred there in early March to receive therapy at the Shirley Ryan AbilityLab.

“That poor guy slept on a couch that is not even comfortable to sit on, and it’s too short,” Paul said. “I think they (were) both ready to come home. It’s time.”

Katie will continue her recovery at Marthaler’s home in Sauk Centre. His house is

Turn to REITSMA | Page 6

only for the elementary school, but also for Minnewaska School District’s secondary school, which holds grades 4-12.

Bridget Gallagher is the director of food and nutrition services for the district. When she heard about the grant available for milk dispensers through the U.S. Department of Agriculture and administered through Midwest Dairy, she said she was immediately on board.

“Our superintendent had gotten an email about the grant available for the equipment and forwarded it on to me, and I thought, ‘Yep, we’re going to do this,’” Gallagher said. “I had just been in my position a couple of months.”

That was in January 2022. Gallagher needed to convince lunch staff the change was doable.

“Their big concerns were spills and swapping out the machine,” Gallagher said.

“All dairy, all the time”™

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce)

320-248-3196 (cell)

320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Editorial Staff

Tiffany Klaphake - Assistant Editor

320-352-6303 • tiffany.k@dairystar.com

Maria Bichler - Assistant Editor

320-352-6303 • maria.b@dairystar.com

Danielle Nauman - Staff Writer

608-487-1101 • danielle.n@dairystar.com

Stacey Smart - Staff Writer

262-442-6666 • stacey.s@dairystar.com

Abby Wiedmeyer - Staff Writer

608-487-4812 • abby.w@dairystar.com

Grace Jeurissen - Staff Writer

320-352-6303 • grace.j@star-pub.com

Jan Lefebvre - Staff Writer

320-290-5980 • jan.l@star-pub.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Hans Lammeman - Staff Writer hans.l@star-pub.com

Consultant: Jerry Jennissen 320-346-2292

Advertising Sales

Main Ofce: 320-352-6303

Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication

Sales Manager - Joyce Frericks

320-352-6303 • joyce@dairystar.com

Mark Klaphake (Western MN)

320-352-6303 (ofce)

320-248-3196 (cell)

Laura Seljan (National Advertising, SE MN)

507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com

Jerry Nelson (SW MN, NW Iowa, South Dakota)

605-690-6260 • jerry.n@dairystar.com

Mike Schafer (Central, South Central MN)

320-894-7825 • mike.s@dairystar.com

Amanda Hoeer (Eastern Iowa, Southwest Wisconsin)

320-250-2884 • amanda.h@dairystar.com

Megan Stuessel (Western Wisconsin)

608-387-1202 • megan.s@dairystar.com

Kati Kindschuh (Northeast WI and Upper MI)

920-979-5284 • kati.k@dairystar.com

Julia Mullenbach (Southeast MN and Northeast IA)

507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell) bob.l@star-pub.com

Klobuchar hosts Boozman in Minnesota

A bipartisan approach is often talked about in the agriculture committees. That was on display as Democratic Sen. Amy Klobuchar hosted Senate Agriculture Committee Ranking Member John Boozman for farm meetings in Rochester and the Twin Cities. “I am so honored to have Sen. Boozman here,” Klobuchar said. “We have worked together for years; he is the highest-ranking Republican on the Senate Agriculture Committee at a very important time, and we have always believed we are not going to get this done one party versus the other.” Boozman, who represents Arkansas, was able to hear from Minnesota farmers. “The farm bill really isn’t a Democratic or Republican thing; it is more about regions of the country with Southern agriculture different that the ‘I’ states,” Boozman said. With the makeup of the House and the Senate, Boozman said a farm bill won’t pass unless it is a bipartisan piece of legislation.

Animal rights group lobbies Congress

Animal rights activists were on Capitol Hill during the

522 Sinclair Lewis

Ag Insiderlast week of April, asking Congress to prioritize animal welfare in the new farm bill. The platform for this coalition includes a moratorium on new and expanded large livestock feeding operations and a complete ban by 2040. They are also seeking $100 billion for a buyout program to transition animal feeding operations to raising pasture-based livestock, growing specialty crops or organic commodity production.

Education needed

During a House Agriculture subcommittee hearing, Agriculture Committee Chair Glenn

“GT” Thompson asked farmers to educate members of Congress about the importance of the farm bill. “We’ve got a signicant number, over half of the members of Congress have not been here for a farm bill, and quite frankly, some folks who have been (in Congress for a farm bill vote), it wouldn’t hurt to do a little additional education with some of them,” he said.

NMPF submits federal order proposal

TurnEVEN

According to the monthly dairy report from the NMPF and the Dairy Checkoff, butter and cheese prices have reached their low point for the year. Class III milk prices have declined for four straight months. Feed costs have not followed milk prices lower, which will likely result in Dairy Margin Coverage payments until the fourth quarter.

A group of Republican senators has introduced a resolution of disapproval to overturn a U.S. Department of Labor rule dealing with H-2A workers. This rule increases the minimum wages for those working on an H-2A visa.

Climate collaboration

The U.S. Dairy Export Council and NMPF are partnering with similar organizations from Argentina, Brazil, Paraguay, Uruguay, Chile, Bolivia and Colombia on climate issues. The collaboration will work with governments and international organizations to promote policies that consider the unique needs of the livestock industry.

EU

An annual report from the U.S. Trade Representative’s Ofce outlines trade barriers from the European Union. In particular, the EU uses geographic indicators to control the use of common terms, such as Parmesan or mozzarella cheese. The U.S. Dairy Export Council and NMPF are asking the trade ofce to preserve export access for food with these common names.

APHIS outlines its strategic plan

USDA’s Animal and Plant Health Inspection Service has unveiled its new veyear strategic plan. It includes six goals, including the protection of agriculture from plant and animal disease, expanding safe trade, promoting animal welfare and addressing the agency’s workforce challenges. APHIS also focused on trends. That list ranges from threats to security, climate change and advances in science and technology.

Bongards year-end nancials

Bongards Creameries is reporting 2022 earnings of $35 million on sales of $942 million. Patronage earnings of $27 million resulted in a 20% cash payment to members of 36 cents per hundredweight. In addition, Bongards announced it will revolve half of the 2013 equity in the amount of just over $4 million. Patrons

will receive those payments in July.

Endless opportunities

At the Minnesota FFA Convention, students got a glimpse into their future at the Career Connections event. AgCentric Executive Director Keith Olander said this is a wonderful time to be in agriculture. “The opportunities are really endless for these kids with two, three, four jobs available to them,” Olander said. “On the other side, industry is here really seeking talent and courting these students; getting the talent and retaining talent, competition is high.” Parents often want their kids to get a four-year degree, but the prospects are also good for those getting a technical education. Olander cites less debt for the students coming out of a technical school, “and honestly, we’re seeing the earnings on the two-year side a little stronger than the four-year (degree) in a lot of cases.”

Nine selected for MN FFA Hall of Fame

Nine individuals are part of the Minnesota FFA Hall of Fame Class of 2023.

The inductees are T.J. Brown of Good Thunder, Dan Dylla of Wells, Mike Miron of Hugo, Brian Sather of Winona, Jon Yusten of Zumbrota, Leah Addington of Cannon Falls, Doris Mold of Cumberland, Sherry Newell-Opitz of Avon and James Tracy (deceased) of Dennison.

New state FFA ofcer team named The Minnesota FFA Convention capped off with the installation of the new state ofcer team. Katelyn Ketchum of Lewiston-Altura is the new president. Tyler Ratka of Rocori is vice president. The slate of ofcers also includes secretary Alison Murrell of Braham, treasurer Mason Grams of Buffalo Lake-Hector-Stewart, reporter Miriana Eiden of Buffalo and sentinel Mackenzie Kuschel of Sebeka.

Trivia challenge

The nutrition title accounts for 76% of mandatory spending in the farm bill. That answers our last trivia question. For this week’s trivia, who serves as USDA’s deputy agriculture secretary? We will have the answer in our next edition of Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network, based in Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two adult sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

one level and has easier access than the family’s house on the farm. They have purchased some equipment Katie will need as she keeps her therapy going at an intense pace along with outpatient therapy out of St. Cloud.

“I told Eugene that Shirley Ryan would hire him because he does so much,” Paul said. “Eugene’s aunt is an occupational therapist who advises him. He even has Katie doing pushups. They didn’t believe him (at Shirley Ryan), so Katie showed them.”

However, Marthaler said he did not see his efforts as above the ordinary for his relationship with Katie.

“If the roles were reversed, I know she’d do the same for me,” Marthaler said. … “You have to stick through the hard times to get to the good times.”

It was to Marthaler that Katie rst gave a sign that she was still Katie inside even though her brain was not cooperating. That sign came in early August 2022 in the form of the thumbs-up gesture.

“That was when I knew we’ve got this,” Marthaler said. “I knew then and there that Katie knew what was going on.”

At the time, Katie was at Regency Hospital in Golden Valley, the second facility she had been to. She would stay at two more during her year away from home. For her loved ones, the journey has gone from initial fear to hope and progress, and it all began with one storm.

Weather warnings were posted across Minnesota during evening chores May 12, 2022.

“Eugene had come over,” Carolyn said. “He said to me, ‘Something told me I needed to come help you get done before the storm.’”

Everyone was rushing to complete chores when the storm hit.

“The wind picked up the back end of a hutch, and the calf got out,” Carolyn said.

“I heard Katie say, ‘Mom, calf,’ and those were the last words she said to me.”

As Katie ran to address the loose calf, Carolyn nished up work with the skid loader.

“I was by the clothesline and saw all of these hutches ying up over the evergreens,” Carolyn said. “I didn’t know exactly where Katie was.”

Out of 66 calf hutches holding calves, only three stood in place when the storm ended. The rest were blown to elds and ditches around the farm. Calves roamed everywhere.

It was Marthaler who located Katie. She was lying on the ground close to the house. Thinking she had lost consciousness due to a concussion, he helped carry her inside the house. Paul called his sister, a retired nurse, who guided them in assessing Katie’s inju-

Carolyn Reitsma (le ) holds the hand of her daughter, Ka e Reitsma, May 7. at the family’s farm near Sauk Centre, Minnesota. A er a year of rehabilitaon for a trauma c brain injury, Ka e has returned home to con nue her recovery.

ries and then determined Katie needed emergency help. As Marthaler drove Katie to the Sauk Centre Hospital, the Reitsmas rounded up calves.

At the hospital, analysis was giving troubling results. Katie needed a ventilator and equipment the hospital was not set up with. She was transferred to the larger St. Cloud Hospital 40 miles away. Paul and Carolyn joined her and Marthaler.

“The rst diagnosis was that her brain stem was cut,” Paul said.

Katie also had multiple bleeds in her brain. Carolyn said they were told it was an injury similar to shaken baby syndrome.

“They said whatever hit her was heavy and blunt,” Carolyn said.

The family assumes it was a calf hutch that hit Katie, Carolyn said, but no one actually saw it happen. The type and location of her brain injury did not look promising.

“Everything initiates there – your walking, your talking, your coordination – everything stems from that spot in the brain,” Carolyn said.

As days passed, they began getting asked difcult questions.

“They kept asking us, because Katie was an athlete, if we could accept her in any other condition,” Paul said.

Katie played both high school and collegiate volleyball. She later helped coach her team at the University of Minnesota-Morris.

“We thought, ‘Katie’s much more than just an athlete,’” Paul said. “She has touched the lives of so many kids at Holy Family School. There’s more to

Turn to REITSMA | Page 7

her than just volleyball. She’s our daughter.”

The questions became even harder.

“They asked us if we wanted her to receive last rites,” Carolyn said.

The family agreed to have those rites performed.

“That’s when we realized it wasn’t good,” Paul said. “We were asked to make the decision between comfort death and giving her a chance.”

It was nearly 10 days after the storm. If they chose to keep trying, Katie needed to be taken off the ventilator and receive a tracheotomy to save her from permanent vocal cord damage. The hospital needed to know the family’s decision.

The Reitsmas and Marthaler needed a sign.

“The day we had to make the decision, that was the rst time she opened her eyes,” Paul said. “(The medical staff) didn’t look at that as being positive at all, but for us, it was.”

Then a staff member said something that Carolyn said was the right thing at the right time.

“A respiratory therapist said, ‘Well, let’s see what she can do,’” Carolyn said. “That helped us decide that we weren’t even going to think about comfort care because Katie could do this.”

Paul and Carolyn’s other daughters – Michelle, Renae and Christine – as well as neighbors and friends stepped in to help with the farm when

Paul and/or Carolyn were with Katie. After work each day, Marthaler, who is a carpenter, was by Katie’s side.

The Reitsmas also had 50 heifers due that month.

“You have to keep everything going,” Carolyn said. “Nothing stops.”

Kindness and support surrounded them.

“We were sent a video of the kids from Holy Family; they formed a rosary, praying for Miss Katie,” Paul said. “The school would cover a day each week the whole summer where two staff members would sit with Katie (at Regency Hospital) because we couldn’t always get down there.”

Once Katie woke up and was weaned from her tracheotomy, she was transferred Aug. 17, 2022, to Melrose Hospital near Sauk Centre. Katie received physical, occupational and speech therapy there with good results.

“There you go with that small town thing,” Paul said.

“Everyone knew her and treated her like family, and when you left there at night, you felt good because you knew she was going to be taken care of.

That’s when Katie really started responding to therapy.”

Meanwhile, Katie’s high school and college teams did fundraisers as did the FFA chapter and other groups. People keep bringing food. Prayer groups far and wide wrote, saying they were praying for Katie, one card coming from a

group in Rome.

“It’s working,” Carolyn said.

Meanwhile, Katie continued therapy to reconnect her

brain to muscle control because it was no longer automatic.

It was from the Melrose Hospital that Marthaler sent a video to the Reitsmas of Katie

singing three words – I love you – the words mufed and taking effort to be formed, but that did not matter.

“It was a thrill,” Carolyn said.

Katie was also able to the visit the farm a few times, the rst being in October 2022 when she arrived on a minibus with four residents from the nursing home. They drove through the barn. Both Paul and Carolyn said Katie lit up when she saw the cows again.

On March 9, the next phase of Katie’s recovery began, which required more equipment, and she and Marthaler prepared to move to Chicago.

“The staff and residents (at Melrose Hospital) lined the halls,” Paul said. “They clapped and were in tears.”

They even blew bubbles.

In Marthaler’s care, Katie worked on core strength in Chicago and continued with other therapy with the goal of Katie walking independently again.

Now, with Katie nally home, the next year of her recovery begins.

“We don’t know what the plan is in the end, but we still have her,” Paul said.

Carolyn said they never lost hope, and community helped them maintain that hope.

“One day, Katie will walk into Holy Family School,” she said.

Mark Klaphake contributed to this article.

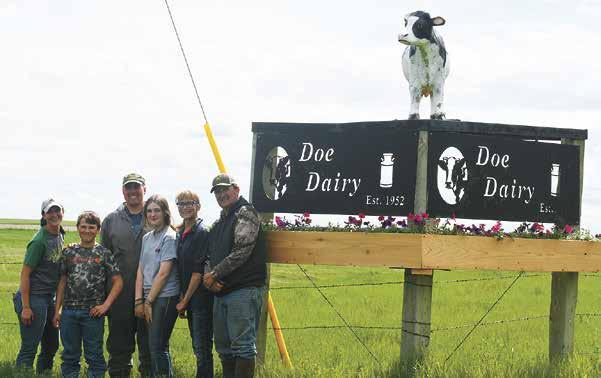

tween New England and Regent. The farm’s milk is picked up twice a week to be processed by Dairy Concepts, 169 miles away in Pollock, South Dakota.

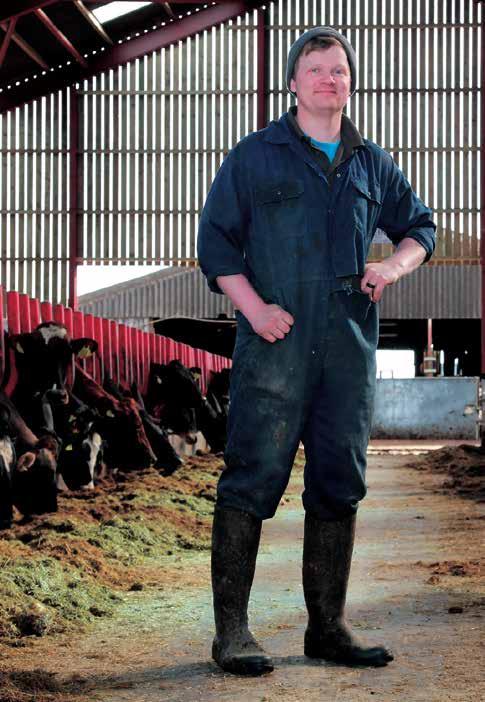

NEW ENGLAND, N.D. – When the last dairyfarming family in Hettinger County makes plans for the day, western North Dakota weather is the big factor.

“We had a blizzard last year in the beginning of April, and we weren’t able to get back into the eld until late,” Warren Doe said. “The weather is the most challenging thing with the extreme cold and wind and no trees to protect us. We had 55-below windchill for three, four days in a row this winter.”

Doe and his family milk 250 cows in both a double-8 and a single-12 parlor be-

Doe, his wife Gail, son Kory and daughter Ariann run the farm together. Warren and Gail’s grandchildren are now old enough to help as well. All three families live on the farm in separate houses. Doe said he appreciates being able to work with his family.

“Not many people get to do that, and we get along very well,” Doe said.

Even though the winters in Hettinger County are tough, this past winter marking a record snowfall, summer weather has been more of a problem with a drought lasting already more than two years. The family grows 640 acres of mixed grass, 240 acres of oats, 160 acres of barley, 2,100 acres of durum, 600 acres of silage corn and 150 acres of grain corn. They also have 1,000 acres of pasture.

“How do you scrape enough feed together when you are constantly ghting drought?” Doe said. “The

snow disappeared, and it’s dry. We’re praying for rain every day even though we have to get the crop in.”

However, after 75 years and three generations of dairy farming, drought is unlikely to stop the Doe family.

“It’s determination,”

Doe said. “I guess you have to work hard when you’re on a southwestern North Dakota dairy. It’s also being selfsufcient since there’s no service. It’s getting tough.”

The closest dairy to Doe Dairy is over 40 miles north.

“It’s really sad,” Doe said. “When I was grow-

ing up, there were at least 50 dairy farms (in Hettinger County). It seems like every small farm had dairy cows. It went from a slow decline to a rapid decline.”

However, Gallagher said neither have become a problem. At the secondary school, two dispensers were placed at the front of the food line.

“Spills are not any more of an issue than they were with the cartons,” Gallagher said. “At the high school, a lot of kids have learned to ll their glass and set it on the table before going through (the food) line. We have some who will stand there and drink one glass while they’re waiting in line and rell it right away.”

The elementary school’s one dispenser is placed at the end of the food line.

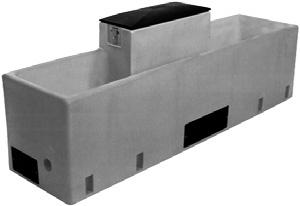

Containers that hold 5-gallon bags of bulk milk sit in the dispenser May 2 at Minnewaska Elementary School in Glenwood, Minnesota. Due to school dietary regula ons, the dispenser serves 1% and skim milk Mondays through Thursdays but also serves chocolate milk on Fridays.

Finn said even the youngest students have gured out the best method for handling both milk glasses and food trays.

“With kindergarten, they set their trays down rst, then they come get their milk. At the elementary level, paraprofessionals pick up the glasses afterward.” One reason Minnewaska schools experienced a smooth transition is they put in effort at the start of the school year to ready students. During student orientations last fall, students and parents had a chance to try the dispensers.

“We had the dispensers up and running and fully stocked, so we were encouraging families and kids to come in and get a feel for what was going to take place,” Gallagher said. “We had that benet of being able to prep everything to kick off the program rst thing.”

Help also came from the Vold family that owns and operates Dorrich Dairy near Glenwood. Suzanne and Brad Vold, along with Brad’s brother, Greg Vold, milk 450 cows with seven robotic milking units. Suzanne is also a Minnesota division board member for Midwest Dairy.

“The Volds spent a couple of weeks at each of the schools, helping the kids acclimate to the dispensers,” Gallagher said. “They were very instrumental in helping out and getting everything to run smoothly, especially for the kids who weren’t at orientation. They also helped with the grant process itself.”

Due to mandated school lunch guidelines with overall fat and sugar limits, Minnewaska dispensers offer 1% and skim milk Mondays through Thursdays. On Fridays, they also offer chocolate milk.

Nash Rassmussen, a rst grader, said he likes milk from the dispenser.

“It’s cold, and there’s other kinds,” he said. “I would say 1% white milk is my favorite. I drink any kind of milk unless it’s skim.”

He also said he chooses chocolate milk on Fridays and prefers glasses to cartons.

“(Cartons) get dents in them and stuff,” he said.

Gretta Gremmels, a kindergartener, said the dispenser is easy to use.

“I like it because you just have to pull up,” she said. “It tastes normal. It’s good.”

The positive student reaction, Finn and Gallhager said, has led to an uptick in milk consumption. Chocolate milk is by far the most popular. On days it is not offered, 1% milk tops skim milk.

The elementary school has around 350 students, kindergarten through third grade.

“I can go through eight of (the 1%

bags) during the week to every one bag of skim,” Gallagher said. “(On Fridays,) I can go through four of the 5-gallon bags of chocolate just at this school.”

Each container with a milk bag placed in it weighs about 40 pounds. On a usual day, Finn needs to change out a container once or twice per lunch except on chocolate-milk Fridays when she changes about four bags. She said the task has not been difcult.

“I’ve been doing it the whole year, and it doesn’t bother me,” Finn said.

“If I feel a need, I could ask somebody to help me out. Before, we had coolers sitting outside each door, and we’d have to load all that milk in for breakfast and for lunch. Now, we are just located to one spot.”

Since the dispensers stay plugged in and cold, the bags can stay in the dispensers until empty without having to move them to a cooler at night. When there is a longer break during the year, such as over the holidays, the machines get a deep clean.

The dispensers were delivered from Hubert, a food merchandising company out of Harrison, Ohio.

“Once we were selected for the grant, everything got shipped to us,” Gallagher said.

That included the glasses in their crates, dollies for moving them, the dispensers themselves with their wheeled bases and containers that hold the 5-gallon milk bags.

Minnewaska schools bought extra, smaller glasses for the elementary school as well as a few more dollies. They also bought disposable plastic lids that t the elementary school’s glasses, used only for the few times students carry glasses of milk to their classrooms for various events. For ease and speed when switching out bags during lunches, the district also bought a few extra milk bag holders so they could be ready to go when switching.

The bags of milk are delivered by Cass Clay, owned by Kemps, which also made for a smooth transition because Cass Clay had previously been supplying the district’s cartons of milk.

“It’s actually a little bit of a cost savings,” Gallagher said. “We get it delivered here once a week, twice at the high school.”

However, Gallagher said she especially likes the savings on waste.

“It’s good just having less waste going into the dump with cartons being a nonissue and less waste in product,” Gallagher said.

She also hears and sees good reports from both students and staff.

“Some kids were put off by drinking out of a paper carton – that alone turned them off to drinking milk – so having an actual glass, they say, gives a fresher taste,” Gallagher said. “We have kids who recognize the benets of the colder, better-tasting milk, so they are drinking more.”

2650 bale grinder

‘14 NDE 2906 twin screw TMR

Tubeline 5500 inline wrapper

JD 146 Loader w/bucket

‘98 Agco Allis 8875, 2WD, CAH w/ Westendorf loader

‘20

JD 5045E, 2WD, only 200 hrs.

‘21 MF 1725, ldr., snowblower, Curtis Hard Cab, only 127 hrs.!

‘21 MF GC1723, ldr., mower, 180 hrs.

MF GC1705 w/60” deck

‘18 MF 1705, 60” deck, 200 hrs.

‘18 MF 1705, 60” deck, 300 hrs.

‘16 MF GC1705, 60” deck, 500 hrs.

‘97 Kinze 2600, 31R15”

Sunflower 4211-9, disc chisel w/ buster bar

DMI 530B Disc Ripper

JD 712 9 shank disc chisel

CIH MRX690, 5 shank disc ripper disc.

JD 980 Field Cult., 44’ w/harrow

CIH 4800 30’ Field Cult, w/3 bar coil tine harrow

The biggest decline, Doe said, came around 40 years ago.

“What really hurt was in the 1980s when they had the dairy buyout,” Doe said. “That totally destroyed North Dakota dairy. We lost probably 70% of the dairies because of that.”

The Whole Herd Buyout Program of 1986 was a government plan to decrease milk supplies and raise dairy prots. Farmers signing up for the plan would slaughter or export their entire herds and get out of dairying for ve years in return for payments from the U.S. Department of Agriculture.

Other factors, Doe said, led to dairy decline in his area as well.

do not add bedding to the mattresses. Their calf barn is heated.

“In this country, everything has to be heated,” Doe said.

Some dairy supplies come from a dealer in Mandan.

“He’s the last dairy supplier in the state,” Doe said.

Other dairy equipment, supplies and parts come on a route from Leedstone out of Melrose, Minnesota, 450 miles away. Doe said his son has become skilled in repairing milking equipment, and they keep extra parts at the farm.

With a late start this spring, they are growing 73-day corn for grain, but they are using 88- to 95-day corn for silage as is usual.

Loftness 20’ Stalk Shredder, NICE!! ‘08 Agco 3000 Corn Head, 8R30, poly

Gehl 100 Feed Mill

SKID LOADERS

‘21 Bobcat T770, 407 hrs.

‘20 Bobcat T770, 215 hrs.

‘20 Bobcat T770, SJC, 300 hrs. ‘20 Bobcat T770, high flow, 1,000 hrs.

‘12 Brent 782 Cart, w/tarp & scale

“Then, with the high fuel prices and low milk prices, (dairy farmers) just couldn’t hang on,” Doe said. “Before that, if you worked hard, you could always make it, but now it didn’t pay the bills.”

Cash crops have helped Doe Dairy survive.

“If we weren’t diversied out here where we are, it wouldn’t be possible to sustain a dairy by itself,” Doe said.

It also helped that his wife ran her own hair salon business for the rst 25 years they were married. Slowly, they expanded the dairy farm.

“If you step back and look 50 years ago to where we are now, our aerial farm photos have changed drastically since 1952,” Doe said.

Doe said his parents rst milked around 10 cows in a hip roof barn. He and Gail expanded to 25 cows in a stanchion barn. In 1973, the Does built a double-4 parlor. But, 10 years later, they expanded the parlor to a double-8.

Later, as their children joined in running the farm, they added the second parlor, the single-12.

“It just kept growing and growing,” Doe said. “I don’t know what the next step will be with the way things are going, if we’ll expand or if we’ll just tie another knot in the rope and hang on.”

Cows on the farm are housed in a freestall barn with mattresses. The Does

“Our growing season is short, but the new varieties usually make it,” Doe said. “We raise all our own forage.”

The durum, one of their cash crops, is used to make pasta.

“It’s kind of considered a specialty crop,” Doe said. “It’s seeded just like spring wheat.”

Because most farms nearby are crop farms, the Does have another way to earn money – manure.

“We have that value commodity that all the grain farmers want to have,” Doe said.

“It’s not a real fun thing to do, but it’s really valuable.”

The soil and terrain on his farm, Doe said, varies. Parts have heavy loam, but others have sandy soil. Some places have rolling hills, but others are at.

Doe said he enjoys farming there.

“I guess I just like to work,” Doe said. “A great day is if I can get 300 acres seeded. I love making hay, a good day of baling.”

He said he does not even mind the lack of a vacation.

“We have a motorcycle,” Doe said. “When the work’s all done, which is rare, (Gail and I) like to jump on that bike and take a ride.”

Now 68 years old, Doe said he would like to keep working into his later years like his own parents did. His father quit milking at 62 years old but helped with eldwork for many years after. He lived to be 90. Doe’s mother milked cows until she was 75 years old.

“I nally had to kick her out of the barn because, if she fell and got hurt, I’d be blamed for it,” Doe said. “She loved to milk cows.”

However, the future, like the weather, is subject to variables.

“My knees are starting to go bad; the cold, damp cement is catching up with me,” Doe said. “Now I’m the old guy on the farm.”

As he looks to the next generations, he said he wonders how the dairy with fare.

“I’d hate to see my kids have to work that hard and not succeed,”

Doe said. “Once Gail and I aren’t able to help, it will make it that much tougher. Help is such an issue; you can’t get help here.”

For now, the Doe family will keep dairy farming.

“It’s what I was born into and grew up with, and it rubbed off on the kids, unfortunately,” Doe said. “If my kids weren’t here, there wouldn’t be a dairy here either, but they wanted to do it. It’s going to be tougher for them than it was for me.”

We are grateful to dairy farmer Directors who share their time, their ideas, and their common sense to help keep DHIA services relevant. From time to time we will use this space to recognize these leaders and to say thank you. We will start with our current president, Dave Scapanski. He started as a local DHIA leader in Benton County, serving on the Board and as President.In 2002 Dave was elected to the Minnesota Board, and has been our President for the past 10 years. He was elected to the National DHIA Board 10 years ago as well, and currently serves as Treasurer there.

What are some of your duties as director? Making sure that we are nancially sound, competitive and ef cient. We work to keep DHIA affordable, accurate, and timely for management decisions for your farm.

What do you like about this role? As president of the board, I enjoy working with good board members who all give a lot of insight into the future of DHIA. Also working with Bruce and the staff make my role as president an easier job.

Why is DHIA important to you? DHIA is a very important management tool to us and our consultants for making good decisions. We use PCDART software to keep track of herd information on our farm. Nutritionists look at it monthly or more depending on ration changes. PCDART also works with our activity monitoring system. We are a big user of the milk pregnancy test. Preg tests are taken every test day and in between tests. It is a big labor saver. The somatic cell count list is watched closely. We either cull or treat high cows. The treated waste milk is pasteurized for calves.

Tell us a about your farm. The farm – Scapanski Farms LLC – is a partnership with my two sons, Chad and Brad. We are a diversi ed farm. In addition to the dairy herd, we raise all of our heifers, feed our steers and farm 1,100 acres for feed and to sell. We also do custom chopping, planting and combining.

By Danielle Nauman danielle.n@dairystar.com

By Danielle Nauman danielle.n@dairystar.com

PITTSVILLE, Wis. – A few family road trips led to a question that began to churn in the minds of Mike Hobbs and Kim Baas: Could an ice cream shop be protable in a town like Pittsville?

After extensive market research, the couple felt the small town, located at the center of the state of Wisconsin with a population just under 900 people, might indeed be a good place to open a specialty ice cream shop.

“We really felt that if it was done right, an ice cream shop could be a good t for the community,” Hobbs said. “This feels like what an ice cream shop is supposed to be.”

Hobbs and Baas share an entrepreneurial streak and own another small business called Event City Designs, which shares building space with the ice cream shop. They relished the idea of creating a new business from scratch despite nei-

ther having a background in either food service or the dairy industry.

“We began researching the idea of stocking a premium ice cream brand, but that meant dealing with minimum orders and needing a crazy amount of freezer space,” Baas said. “Then, I came across a company that makes batch freezers, and I started playing around with the idea of making our own ice cream.”

For about four months after the arrival of the batch freezer, Hobbs taught himself to make ice cream, largely using tutorial videos put out by the freezer manufacturer.

“It really came pretty easily,” Hobbs said. “I just felt like I knew what I was doing.”

After all the planning, The Cranberry Creamery opened its doors to the public for the rst time over Memorial Day weekend last year and was

open through September. The success of the shop exceeded Hobbs’ and Baas’ expectations.

“We really thought we could staff this with just our own family,” Baas said. “We were blown away by the response, and we quickly learned that we needed more staff than just our own family. We were both working 80-hour weeks most of the summer.”

Hobbs and Baas turned to

the young people of Pittsville to staff their ice cream venture.

“We have been lucky to have such a great group of kids want to come work for us,” Baas said. “They are so happy and work together well; there is no drama. All of the kids who worked for us last season are coming back to join us again this year.”

The top two sale days last summer both came in July –National Ice Cream Day July 17 and the Fourth of July.

“We didn’t even know National Ice Cream Day was a thing, but it was great,” Hobbs said. “One of the local radio stations kept talking about it, and people came in steady all day.”

Baas said more than 20,000 customers were served during their inaugural year, and sales exceeded their expectations by over 50%

The Cranberry Creamery opened for business this season in early April, and the ice cream season in Pittsville runs through the later part of September.

What sets The Cranberry Creamery apart from other central Wisconsin locales is the ice cream itself. Hobbs makes all of the store’s ice cream in

A ight of four ar�san ice cream avors – Co�on Candy, White Chocolate Raspberry, Cookies and Cream, and All The Chocolate – is served with a piece of homemade waffle cone May 4 at The Cranberry Creamery in Pi�sville, Wisconsin. The shop is open from April to September.

small artisan batches of 5-6 quarts.

“We wanted this to become a destination and an experience,” Hobbs said. “We want the ice cream to be the main focus not just dessert after a meal. We purposely avoid having food on the menu. We don’t even have sundaes or any toppings; it is just about the ice cream.”

Hobbs and Baas have developed more than 130 recipes, and they typically have 15 on their avor board each day and up to 24 avors in their ice cream case.

“Some are rather basic standards, and some are pretty unique,” Hobbs said. “Some we make frequently, and there are others we have made once and might not make again.”

One of the most popular avors is Apple Pie. Contrary to what people might think, cranberry being in the name is not necessarily related to the ice cream itself.

“Cranberry is actually a really hard fruit to make ice cream with, because the dairy hides the tartness of the berry,” Hobbs said. “We do have several recipes that include cranberries, but we chose the name because the cranberry is the Wisconsin state fruit. We are in the heart of cranberry country in Wood County.”

Hobbs and Baas purchase the base mix for their ice cream from the Galloway Company Classic Mix Partners in Neenah.

“We tried nding a way to have it

made locally, but it wasn’t feasible,” Hobbs said. “We even considered making our own, but that meant more equipment, required more space and more things we had to learn to do. We decided to focus on doing one thing, rst, and doing it well.”

Keeping with the idea of making their shop a unique experience, Hobbs and Baas make the wafe cones for their ice cream on-site.

“We had planned to make the wafe cones in the back room, but we didn’t have enough counter space,” Baas said. “So, we were making them out here behind the ice cream case. People, especially kids, loved to watch them being made.”

That realization led them to rearrange their seating area to make room for a wafe-making station where customers could have a vantage point to watch the cones being made.

“It makes the place smell amazing, and it wafts down the street,” Baas said. “People will come in and say, ‘We knew you were making cones today.’”

For Hobbs and Baas, supporting the community that has supported them played a role in their desire to bring another small business to the downtown area of Pittsville.

“We hope others will see that small businesses can thrive in a small town like this,” Hobbs said. “People want a memorable experience, and providing that is our goal.”

Kirsten Udermann

(pictured holding Zoey and with husband Alex holding Kallie)

Sartell, Minnesota

Stearns County 80 cows

Tell us about your family and farm. Our farm is Meadowbrook Dairy Inc., and it consists of my husband, Alex, and I along with our two children, Kallie and Zoey. We farm with Alex’s parents, John and Mary Lou, and his brother, Jake. We farm 1,100 acres of corn, soybean, rye, alfalfa and grass hay. We milk 80 cows and raise 275 steers. We are a fth-generation farm. We no till plant our crops and plant cover crops for soil health and forage. We also custom haul liquid and solid manure and do custom no till planting.

What are some of the best aspects of being a mother and dairy farmer? The best aspects are getting to raise our children on the farm. It has been fun to watch their bonds with the animals and their love for farming grow. The girls get to learn many lessons they wouldn’t necessarily be exposed to off the farm. The girls also love to pitch in and help where they can, and they do so without being asked to. They are very observant, and it doesn’t take them long to pick up on a task.

What are the biggest challenges with your dual role? A big challenge especially this time of year is the balance of farm life and family life. 0ur family time is spent the most in the barn on our busy days, and the rest of the day is a constant run to get everything done while the weather is nice. The girls have learned to have patience on the busiest days and have adapted well to going with the ow. Having the girls around with us farming helps us to slow down and appreciate the little things throughout the day. They are denitely the bright spot in our busy days.

What are three traits you want to pass on to your children?

I’d like to pass on a strong work ethic, integrity and a strong dedication to nish what they start.

What has been a highlight of your dairy career as a mother? A highlight has been being able to watch the girls grow with the animals and watching their love for the farm ourish. It also has been fun to watch the girls pick up on our everyday routines and start to pitch in with chores. Kallie has taken an interest to helping me feed calves and bottle feed our new calves. She loves to help in any way she can. Zoey is starting to want to help also but is a little small, but she loves to play with the cows, cats and our dog any chance she can.

If you had an afternoon all to yourself, what would you do? I would spend it with my husband either going out for lunch or nding a new park or place to explore.

Who do you admire? I admire my mom and my mother-inlaw because they both raised their families on the farm and both of them have strong faith. They both have been extremely helpful during our busy times and have helped us tremendously with taking care of the girls.

Kristine Heinrichs Browerville, Minnesota Todd County 75 cowsTell us about your family and farm. We have a mix of Jerseys, Brown Swiss and Holsteins on our farm. It’s just me, my husband, Josh, and our son, Bo. We milk 75 cows in a tiestall barn and ship our milk to First District Association. We are rst-generation farmers, and we bought our farm in October 2020. We farm 220 acres of corn and alfalfa. We own 160 of those acres. What are some of the best aspects of being a mother and dairy farmer? What I love about it is being able to raise our son on the farm and teach him the same values we have, how to have a work ethic and take care of things. It’s priceless to be able to farm with my family every day. I love being able to work beside my husband and be able to stay home to raise my family. I get to work with the people I love.

What are the biggest challenges with your dual role? Some days there are not enough hours in the day to get everything done. We pick up and drop off our son at school, and I have to drop what I am doing when it is time to bring him in and be there to pick him up. Shortly after we get home, it is chore time, and whatever house work I didn’t get done has to wait until he goes to bed.

What are three traits you want to pass on to your children? A good work ethic, have respect for what you have and take nothing for granted.

What has been a highlight of your dairy career as a mother? I have learned so much. I still am learning. The whole process has been interesting, but my favorite part is farming alongside my husband and raising my son on the farm.

If you had an afternoon all to yourself, what would you do? Spend the day with my mother. She is one of my best friends, and we would do whatever she wants to do.

Who do you admire? My grandmother. She was so awesome. She did it all and was a stay-at-home mom of nine kids. She canned, cooked, gardened, sewed, made her own soap and milked cows every morning and night. All of those things were not as easy as they are today. She taught me so much, and now, I am following in her footsteps. I am a stay-at-home mom; I cook, garden, can, take care of our chickens and milk cows every morning and night with my husband. I think of her every day, and she had a huge impact on my life.

Erica Elsenpeter Maple Lake, Minnesota Wright County 180 cowsTell us about your family and farm. My husband, Dan, and I run our organic dairy in partnership with Dan’s brother and his wife. We farm about 600 acres. We have eight kids ranging in age from 17 to 2.

What are some of the best aspects of being a mother and dairy farmer? The farm is absolutely one of the best places to raise kids. Both Dan and I are here most of the time, and that provides both security and accountability for our kids. Beyond that, being able to have room for them to explore, get dirty, learn about living and growing things while also learning responsibility is invaluable.

What are the biggest challenges with your dual role? Besides the mountains of laundry, the biggest challenge is time. Having time to give attention to all the kids as needed but also devoting attention to work is challenging. Striving to nd a balance between work and play is also a never-ending challenge.

What are three traits you want to pass on to your children? Faithfulness in God, loyalty and devotion to family, and a sense of humor.

What has been a highlight of your dairy career as a mother? These high points are different at various stages of motherhood and different ages of kids. Certainly, watching a joy-lled toddler ride with Dan in a tractor or a chopper is awesome. Later, when they drive a tractor or operate something on their own with pride, it is amazing. My 10-year old daughter once upon a time would run screaming in fright from a newborn calf and is now looking forward to her second year of showing “her” heifer at the county fair. I am proud of the kids when they work as a team to get a crop of hay up. I’m in a fairly unique situation where I get to witness some or most of these things on a continuous loop.

If you had an afternoon all to yourself, what would you do? First, I would go for a walk. Then, I would spend some time in quiet prayer, read a good book and putter in the garden. I’d also like a nap. It’s very possible I would need more than an afternoon.

Who do you admire? This may sound very uncool, but the one person I admire most is my husband, Dan. He’s a great dad, very smart and funny, and I’d be a terrible mom without him to support me.

Star Blends has been helping Midwest farm families by providing, high-quality feed, dairy nutrition, and commodity contracting for more than 20 years. Our state of the art mill can accuratelyblend anything from a custom pre-mix to complete feed, in balancing diets, or work with your private nutritionist or dairy consultant.

Meghan Palmer

Waukon, Iowa

Allamakee County

185 cows

Tell us about your family and farm. I farm with my husband, John, and our ve children. Our oldest is Faith who is graduating from Iowa State University with a degree in dairy science this month. She and her husband are expecting our rst grandchild very soon. At home are Ethan, Norah, Naomi and Roslyn. All the kids have always been active in the day-to-day operations, and the oldest kids help with eldwork. My husband and I grew up only a couple of miles from each other, and we are fortunate to have each of our family farms close and a part of our daily lives and farming operation. We own and milk cows on the farm I grew up on, and it means a lot to me to be able to raise my children here. We grow all our feed and raise our youngstock. We started a small cow-calf herd, and so far that has been a fun experience. What are some of the best aspects of being a mother and dairy farmer? I can’t think of another profession that enables the entire family to work together for a common goal while sharing in each other’s trials and successes. I appreciate seeing my kids grow up with the values I think are important to leading a successful life. I am fortunate I am able to be home to get the kids to school and am here when they get off the bus. I am also a registered nurse. I have been able to cut back to the level that I only pick up hours when I want to a couple times a month. The days I do work off the farm make me appreciate being able to be home on the farm that much more.

Kari Jungemann

(pictured with husband Lucas and children Vonn (front), Walker and Ava) Wolsey, South Dakota Beadle County

900 cows

Tell us about your family and farm. I have been married to Lucas Jungemann for eight years, and we have three children: Vonn, Walker and Ava. Vonn is about to nish kindergarten, and Walker and Ava keep us busy and are becoming a dynamic duo as they grow up. Lucas and I dairy alongside his parents, Russell and Janet, who started Lazy J Dairy in 1980. We milk 900 cows three times a day, raise our own heifers and grow our crops for feed. We have several employees who help us keep the dairy running 24 hours a day. My rst job is being kid wrangler, but other than that, I work alongside Janet with overseeing the nancial side of the dairy, managing our heifers and doing the recordkeeping for our herd. I also have been known to run a tractor and pack haylage or silage as needed.

What are some of the best aspects of being a mother and dairy farmer? Having a job that you can share with your kids. Before working full time on the farm, I worked as a CPA. While I loved it, that is a job a kid doesn’t understand. But kids completely understand working with animals, driving tractors and watching crops grow and are game to go along for the ride and help when asked. It is a job that can be done with your kids. It usually takes longer, but they can come along for the ride.

What are the biggest challenges with your dual role? Balance is always something we have to try hard to nd. Even though we work at home, that also means we are always at work. Planning time away from the farm can be a challenge, and there is always worry when you are away. I encourage my kids to be involved in school sports, 4-H, FFA and Holstein association activities, but it’s denitely hard to attend games, shows, contests, etc. Thankfully, the kids understand.

What are three traits you want to pass on to your children? In my living room, I have a sign that reads, “In a world where you can be anything, be kind.” That is something I hope my kids read and remember each day as they go about their lives. Otherwise, I want them to be curious and strive to never stop learning. The farm is the perfect place to teach hard work and resiliency.

What has been a highlight of your dairy career as a mother? Watching the kids enjoy life on the farm is what I enjoy most and a necessary reminder of why we do what we do on the harder days. I love watching them work together to get a job done and interact with the cows, calves and kitties.

If you had an afternoon all to yourself, what would you do? In the warm months, I would work in the ower garden and go on a long walk or go do a bike trail. In the winter, I would work on a quilt or just sit down and read a good book.

Who do you admire? I admire my mom and grandmothers. They were all farm wives. While my mom always worked full time off the farm, she was always supportive of my dad and proud of raising me and my siblings on the farm. My grandmothers and great-grandmother were integral parts of their farming operations while raising their families. They probably never got enough credit for that. I am fortunate that women are receiving recognition and respect as partners in their farming operations.

What are the biggest challenges with your dual role? Those times when you can’t do both things at once. There are some jobs that just don’t lend themselves to having kids along. Most of the time, I am the primary person who stays home with the kids when the hours get long, and the desire to be out working with everyone else is strong during planting and harvest. There are also times where I have to put the long hours in with everyone else and the kids spend time with our day care provider, grandparents, or aunts and uncles, and those times, you feel the guilt of shorter hours with your kids. That’s the normal guilt all moms can feel.

What are three traits you want to pass on to your children? Both my husband and I would like to raise our kids with a strong work ethic. We both saw that from our parents and appreciate how that has helped us, and we want to give that to our kids. We also hope to raise them to appreciate working with their hands, whether that is with plants, animals or machinery. It might not be the type of job they end up with, but hopefully, they will have an appreciation for it and how important it is. I hope they have compassion. Working with animals can develop that. Being able to care for another living being can soften your heart.

What has been a highlight of your dairy career as a mother? In a weird way, the summer of 2020. We typically send our kids to an in-home day care which was shut down during that summer. At the time, we only had Vonn, but he tagged along with us every day that summer. It makes you appreciate a job where it is OK to bring your kid to work every day if needed.

If you had an afternoon all to yourself, what would you do? The main thing would be relaxing. Take a hot bath, paint my nails, read a book, watch a show without cartoons in it and bake something I enjoy.

Who do you admire? My husband, Lucas. He works so hard every day whether it is on the farm keeping everything running, at home doing crazy building projects I suggest or being a great dad to our kids. It seems anything he tries to tackle he is amazing at, and I wish I had half of his knowhow.

Describe your farm and facilities. We have a 64-cow organic dairy with 64 head of replacements. This is a small family farm passed down from Pam’s parents. We purchased it in 1993, and now our son and his wife are working their way into ownership. They will be the fth generation. The milking barn is a converted stanchion barn to a at-barn parlor with free stalls and a manure pit. We have a small barn for the young babies and an open-sided shed for heifers with headlocks and drive-along feeding. For feed storage, we have a grain bin, two silage bunkers, an upright silo and a feed bin. What forages do you harvest? Forages consist of grain corn, silage corn and alfalfa, grain barley and/or wheat and alfalfa hay. We use a crop rotation of corn, corn, barley or wheat with a new seeding of alfalfa and three years of alfalfa hay.

How many acres of crops do you raise? We own and rent 300 tillable acres and have 130 acres of pasture land.

What quality and quantity do you harvest of each crop? We chop the rst cutting of alfalfa for optimum quality and bale the

remainder for dry hay. Then, we bale second and third cutting with high-moisture round bales with approximately 2,000 dry small

squares for calves. We chop about 40 acres of corn for silage; the remaining 40 acres are shelled for grain with an average of 120 bushels per acre of corn. We usually have surplus of hay which is sold to other farmers.

Describe the rations for your livestock. The cows get corn silage, haylage, baleage, ground corn, mineral, and soybean meal or roasted soybeans. Pasture is accounted for in the summer months into the ration. The dry cows get corn silage, baleage, ground corn, mineral, soybean meal or roasted soybeans, and pasture in the summer. The heifers get corn silage, haylage, baleage, ground corn, mineral and some soy if called for by a nutritionist. The summer ration for heifers is ground corn and mineral with most dry matter intake coming from pasture.

Has been a quality market for MN dairy farmers for over 100 years. MN producers provide one of the country’s most distinctive brands of cheese that is still made using the same Old World craftsmanship and has been combined with cutting-edge technology to produce cheese that delivers unforgettable taste with unparalleled quality. MN Dairy farmers and Bongards, quality that stands the test of time. We offer a competitive base price, premiums, and the best eld representatives in the industry.

13200 Co. Rd. 51

Bongards, MN 55368

(952) 466-5521

Fax (952) 466-5556

110 3rd Ave. NE

Perham, MN 56573

(218) 346-4680

Fax (218) 346-4684

“Using the Udder ComfortTM Battery-Operated Backpack Sprayer every day has made us more compliant with our fresh cow protocol for better udder health. We’re getting our fresh cows sprayed more consistently with Udder Comfort 3x/day for a week after calving. In 3 months of getting fresh cows sprayed consistently, our SCC came down from 165 to 137,000. We run a really full freestall, and if we do get clinicals, they clear faster and don’t become repeat offenders,” says Scott family’s 750-cow Registered Holstein dairy near Maynard, Iowa.

“We notice a lot more udder texture and veination at 2 weeks in milk when sprayed consistently and right away after calving, compared with 3 to 4 weeks in, if they are not.

“The Udder Comfort Battery-Operated Backpack Sprayer is smooth. It puts a nice, even, effective coat of Udder Comfort on the udders. It gets under the udder, broadcasting over the ligament and around the teats, where you want it,” Scott explains.

“We have relied on Udder Comfort over 10 years as the best tool to get cows through transition and into milk faster with healthier udders,” he adds.

“We always talked about getting milkers to stick to the protocol. The Sprayer does that. It’s more convenient and user-friendly than I thought it would be. It holds a lot of product, charges fast, holds the charge well, so it’s always ready and easy to grab, turn on, and go,” Scott reports.

Describe your harvesting techniques for alfalfa and corn silage. We chop our own hay and corn with a pull-type chopper and custom hire a combine for corn, barley and wheat. We harvest hay three times a year, preferably every 30 to 40 days. Of course, corn is chopped in the fall.

What techniques do you use to store, manage and feed your forages? Haylage is stored in a bunker and covered with plastic and tires. Corn silage is stored in a bunker and covered the same as the haylage. The rest of the corn silage is in an upright silo for summer use. The animals are fed with a vertical mixer.

Throughout your career, have you changed the forages you plant, and how has that decision helped your operation? When we rst purchased the farm, there was cropland around the barn. We seeded in the corn ground with a pasture seed mix and left the hay, turning it into 50 acres of pasture on the farm utilizing rotational grazing with permanently fenced paddocks. Pasturing our cows made the switch from conventional to organic certication an easier transition. We also went from using oats to barley or wheat for nurse crops for alfalfa. The barley and wheat have less lodging, and the grain is used as a partial corn replacement in our cattle ration. We are experimenting with soybeans no tilled into crimped winter rye.

Cows eat a ra on May 3 at the Seelow family’s farm near Chaseburg, Wisconsin. Corn silage, haylage, baleage, ground corn, mineral, and soybean meal or roasted soybeans make up the total mixed ra on.

Describe a challenge you overcame in reaching your forage quality goals. Using our nutrient management plan as a guide in reaching optimum soil health which in turn gives a better long-term alfalfa stand. Soil testing tells us when we need to spread potash and lime.

How do quality forages play a part in the production goals for your herd? Quality hay reduced the need for added protein sources which lowers our cost of production.

What are management or harvesting techniques you have changed that have made a notable difference in forage quality? We have gone from hiring custom choppers to purchasing our own equipment which can make a difference in harvesting when the crop is ready.

6000 BC, #544396 .......................... $13,500

NH BR780 2005, 1000 PTO, 5 ft. bales, 7700 BC, #557075 ........................ $13,500

JD 568 2008, 540 PTO, 5 ft. bales, 17,649 BC, #550655 ............................. $14,500

NH BR780A 2007, 540 PTO, 5 ft. bales, 7350 BC, #542859 ....................... $14,750

JD 582 Silage Special 2009, 540 PTO, 4 ft. bales, 22,825 BC, #542349 ....

569 2014, 1000 PTO, 5 ft. bales, 10,100 BC, #553387 ...........................

569 2016, 1000 PTO, 5 ft. bales, 13,560 BC, #554379 ...........................

460R 2018, 1000 PTO, 4 ft. bales, 15,600 BC, #550251 ........................ $33,000 Case IH RB455 2018, 540 PTO, 4 ft. bales, 2091 BC, #543641 .................. $33,500 JD 569 2015, 1000 PTO, 5 ft. bales, 9200 BC, #545913 .............................. $33,900 Krone Comprima V 180XC 2019, 1000 PTO, 4 ft. bales, 13,573 BC, #550353 ....................................................................................................

Case IH RB565 2020, 1000 PTO, 5 ft. bales, 10,094 BC, #556680 ............. $34,900

JD 569 2014, 1000 PTO, 5 ft. bales, 6500 BC, #554698 .............................. $36,900

NH Rollbelt 460 2021, 540 PTO, 4 ft. bales, 687 BC, #553694 .................. $42,500

JD 560R 2018, 1000 PTO, 5 ft. bales, 8654 BC, #556060 ........................... $43,000

JD 560M 2019, 1000 PTO, 5 ft. bales, 7000 BC, #550210 .......................... $43,900

JD 560M 2019, 1000 PTO, 7300 BC, #555035............................................ $44,900

Vermeer 605N Cornstalk 2017, 1000 PTO, 5 ft. bales, 6768 BC, #548033 .................................................................................................... $46,500

JD 560M 2020, 1000 PTO, 5 ft. bales, 5491 BC, #552770 .......................... $46,500

JD 560M 2019, 1000 PTO, 5 ft. bales, 3576 BC, #531213 .......................... $46,900

JD 560M 2020, 1000 PTO, 5 ft. bales, 5500 BC, #544100 .......................... $47,900

JD 450M 2019, 1000 PTO, 4 ft. bales, 1918 BC, #531693 .......................... $48,500

JD 560M 2021, 1000 PTO, 5 ft. bales, 8233 BC, #557166 .......................... $51,500

JD 560M 2019, 1000 PTO, 5 ft. bales, 6000 BC, #554127 .......................... $51,900 JD 460M 2019, 1000 PTO, 4 ft. bales, 5898 BC, #557634 .......................... $53,500

JD 460M 2022, 1000 PTO, 4 ft. bales, 2600 BC, #557280 .......................... $57,900

540 PTO, 5 ft. bales, 1516 BC, #547391 ............................ $61,500

#555841 $289,000

Claas 970 2018, PRWD, 2257 hrs., 1639 CH hrs., #533174 ..................... $299,000

JD 8500 2017, PRWD, 1460 hrs., 1070 CH hrs., #553938 ........................ $299,000

JD 8700 2017, PRWD, 2544 hrs., 1835 CH hrs., #546919 ........................ $308,000

JD 8700 2016, PRWD, 1840 hrs., 1103 CH hrs., #525709 ........................ $324,000

JD 8700 2016, PRWD, 1469 hrs., 933 CH hrs., #532572 .......................... $339,000

JD 8800 2017, PRWD, 1728 hrs., 904 CH hrs., #544616 .......................... $339,900

JD 8600 2018, PRWD, 1652 hrs., 778 CH hrs., #188792 .......................... $342,000

JD 8700 2018, PRWD, 1702 hrs., 1069 CH hrs., #541389 ........................ $348,500

JD 9600 2019, PRWD, 1726 hrs., 1130 CH hrs., #553763 ........................ $349,900

JD 8800 2017, PRWD, 1558 hrs., 862 CH hrs., #524820 .......................... $355,000

JD 9800 2019, PRWD, 1893 hrs., 1368 CH hrs., #543355 ........................ $390,000

Claas 940 2020, PRWD, 650 hrs., 480 CH hrs., #532728 ......................... $399,900

JD 9600 2019, PRWD, 1224 hrs., 811 CH hrs., #532049 .......................... $409,900

JD 8300 2022, PRWD, 33 hrs., 9 CH hrs., #537501 .................................. $459,000

JD 9800 2020, PRWD, 1415 hrs., 942 CH hrs., #554135 .......................... $459,900

JD 9900 2019, PRWD, 1224 hrs., 884 CH hrs., #550177 .......................... $493,000

JD 9800 2020, PRWD, 1288 hrs., 833 CH hrs., #536344 .......................... $497,000

JD 9700 2020, PRWD, 1166 hrs., 835 CH hrs., #543646 .......................... $503,000

JD 9800 2019, PRWD, 899 hrs., 660 CH hrs., #550175 ............................ $503,000

JD 9900 2020, PRWD, 844 hrs., 661 CH hrs., #553436 ............................ $508,000

JD 9800 2021 PRWD, 416 hrs., 302 CH hrs., #550106 ............................. $518,000

JD 9900 2020 PRWD, 784 hrs., 455 CH hrs., #561177 ............................. $523,000

JD 9700 2020, PRWD, 961 hrs., 500 CH hrs., #552460 ............................ $524,900

JD 9800 2021, PRWD, 569 hrs., 369 CH hrs., #552624 ............................ $553,000

Ederer Dairy Supply Plain, WI 608-546-3713

DeLaval Dairy Service Kaukauna, WI 866-335-2825

Joe’s Refrigeration Inc. Withee, WI 715-229-2321

Mlsna Dairy Supply Inc. Cashton, WI 608-654-5106

Professional Dairy Services Arlington, WI 608-635-0268

Redeker Dairy Equipment Brandon, WI 920-346-5579

The Scharine Group Inc. Whitewater, WI 800 472-2880

Mt Horeb, WI 800-872-3470

Farm Systems

Melrose, MN 320-256-3276

Brookings, SD 800-636-5581

Advanced Dairy Mora, MN 320-679-1029

Pierz, MN 320-468-2494 St. Charles, MN 507-932-4288 Wadena, MN 218-632-5416

By Hans Lammeman hans.l@star-pub.com

By Hans Lammeman hans.l@star-pub.com

ST. PAUL, Minn. –Barry Visser stood in front of a crowd at his alma mater in late April, accepting an award recognizing his achievements in the dairy industry from the University of Minnesota.

The 2023 Golden Alumni Achievement in Industry Award marked the latest honor atop a long list of accomplishments on his resume.

During his April 27 acceptance speech at the university’s Animal Science Showcase, Visser maintained a humble tone, expressing gratitude for the mentors and opportunities that shaped his career.

“To me, the real reward in all of this is knowing that I have made an impact on enough people’s lives to be recognized with this award,” Visser said.

Visser reected on his life during the nomination process as he updated his resume – a task he had not done in two decades.

Growing up on a 70-cow dairy farm near Ada, a small town in northwest Minnesota, Visser developed a passion for working with livestock.

Visser credits his parents, Richard and Linda, with instilling the values of honesty, integrity, hard work and

relentless care for animals. Through multiple degrees and dairy experiences, Visser ultimately found his niche in the industry as a dairy nutritionist.

“What I knew from a very young age is that I wanted to be involved with the dairy industry,” Visser said. “To say that I knew I was going to be a nutritionist when I was 18 years old would have been an understatement, but it is a career that I have found rewarding and enjoyable for the past 25 years.”

While he originally planned to return to the farm in Ada after receiving associate degrees in dairy production and dairy science from the University of MinnesotaCrookston, Visser’s life course changed when professor and adviser Dr. Lyle Westrom challenged him to pursue a four-year degree.

In 1993, Visser moved south for a bachelor’s degree in animal science from the University of Minnesota-Twin Cities. As Visser was completing his undergraduate studies, Dr. Brian Crooker recruited him as a full-time site coordinator for a U.S. Food and Drug Administration trial at the St. Paul campus.

“Although I enjoyed this experience and it made me really appreciate research, it also made me realize that

I didn’t necessarily want to spend my career in the world of research,” Visser said.

Visser left the Twin Cities to work at a small feed mill in Byron for nearly four years. During his acceptance speech, Visser credited that time as a great introduction to the world of dairy nutrition consulting.

In the fall of 1999, Visser returned to the University of Minnesota-Twin Cities at the encouragement of Dr. Jim Linn to pursue a graduate degree in ruminant nutrition while working early mornings and late nights as an assistant herdsman for the university’s dairy herd.

Since graduating in the spring of 2003, Visser has recorded more than two decades of work with Vita Plus as a dairy nutrition consultant. Additionally, he holds a dairy superintendent position with the Minnesota State Fair, writes a monthly dairy nutrition column with Dairy Star and guest lectures dairy courses at several Midwest universities.

“I am very fortunate to work with many great dairy farms,” Visser said. “Some of them are successful because they achieve high production, high levels of protability or have effectively transitioned the farm to the next generation. Success can be dened in so many different ways on a

dairy farm, and knowing that I have been a small part of helping clients to achieve their goals is denitely the most rewarding.”

The emotional highlight of receiving the award for Visser was sharing the moment with his wife, Shannon. Although his daughters – Rachel, Kayla and Hannah – were unable to attend the award ceremony due to a dairy show in Wis-

consin, the family reunited the following morning at the livestock show.

“I am certainly appreciative of mentors along the way within the university system: Lyle Westrom at Crookston, Jim Linn at St. Paul and several others,” Visser said. “But, just like many people, it is the support from our spouse and family that allows us to be successful in what we do.”

Grapple buckets, bale spears, rock buckets etc.

Snow Buckets

By Hans Lammeman hans.l@star-pub.com

By Hans Lammeman hans.l@star-pub.com

SAUK CENTRE, Minn.

– Dozens of local dairy farmers turned out to Sauk Centre City Hall in force May 1 to learn about a promising green energy project that could help them increase prots and reduce their environmental impact.

The nearly two-hour informational meeting was lled with excitement and apprehension as farmers listened intently to the details of the proposed Nature Energy biogas plant for potential advantages and drawbacks.

Jesper A. K. Nielsen, Nature Energy vice president of business development, said tanker trucks would collect manure directly from participating farmers and return with nutrient-rich fertilizer after an anaerobic digestion process pulled methane from the waste. The presenters said the project would have a positive nancial impact on local producers and the Sauk Centre community.

Self-described as a leader in the green transition and

biogas pioneer, Nature Energy has ambitious goals to operate 15 plants in North America by 2027, beginning with agricultural communities in Wisconsin and Minnesota. Each plant is intended to produce renewable natural gas from local organic waste for more than 40 years.

Sauk Centre Economic Development Authority board members Jean Marthaler and Heidi Leach ew to Denmark in late March as part of the third group of Americans to tour the Nature Energy biogas facilities. After returning, Marthaler said road damage from trucks presented the primary apparent downside of the proposed plant in their community.

The Denmark-based biogas company opened its U.S. headquarters in St. Paul in February 2022. Shell Global acquired Nature Energy in March; the subsidiary continues to operate under the same brand name.

The proposed Sauk Centre plant would be the standardized design used in Nature Energy’s 14 large-scale renewable natural gas plants in Europe. City boards ap-

proved similar facilities in Benson and Wilson for the permitting process.

According to Nielsen, Nature Energy was exploring several sites in the Sauk Centre area to potentially house the biogas plant that requires at least 25 acres near an interconnect to a natural gas distribution system.

During the presentation, Nielsen said the project aims

to utilize manure from roughly 17,000 cows in nearby farms of all sizes within a 2030 mile radius of the facility. Nature Energy trucks would collect the manure from the storage site while it was still fresh – within seven days. The biogas company intends to compensate participating producers with an improved bottom line and higher-quality fertilizer.

According to Nature Energy data, the company transforms 4.4 million tons of waste into renewable natural gas annually, leading to about 5 million tons of soil health products and green fertilizer production each year. The company’s protability, however, relies heavily on selling carbon credits rather than biogas.

For the last 100 years, Ritchie has been manufacturing a complete line of livestock watering products with thehighest specifications in the industry.

From a single horse Stall Fount to a fountain that waters up to 500 head, Ritchie fountains are top quality. Plus,every Ritchie fountain is backed by our 10 year limited warranty.

“It is all about carbon credits at the end of the day,” Nielsen said. “The gas is sold off the same as natural gas. The green molecules go with the black molecules and travel (through) pipes around the U.S. The carbon credits are sold off to companies that need to lower their footprint.”

More than an hour into the meeting, one woman raised her hand with a question: “How does this model pay us?”

Bob Lefebvre, Nature Energy USA vice president of business development, said the annual rate per cow was dependent on several factors. The company’s payment model starts with a one-time upfront payment meant to cover initial investment costs for the farmer. That initial amount, and an annual payment, reect the amount of manure collected greater than 5% solids.

“Then there is prot sharing,” Lefebvre said. “The better we do, the better you’re going to do.”

Lefebvre said participating farmers, in many cases, could use savings and prots from the partnership to pay off the initial investment for the covered reception area within one to two years. However, this depends largely on the size of the storage site.

“The investment that Nature Energy makes with the farmer (impacts) the length of the contract,” Lefebvre said. “We would like to have 10-year contracts, and then we could work from there.”

Nielsen said one farmer increased their bottom line by 11% solely by participating; then, there were advantages of more efcient fertilizer and decreasing the carbon footprint.

“The (fertilizer) will come out (of the plant) with no gas in it, of course, but also with a lot less smell,” Nielsen said. “It does smell, but it does not hang in the air like natural manure, so there are a lot of neighbors that will be happy.”

While fertilizer returned to the producers from the biogas plant would have less volume than the manure collected, Nature Energy staff said the nutrient level would be equal to or greater than the initial input.

“That product that we’re bringing back (has) more nitrogen in part because of the turkey litter and in part because of the processing of the regular anaerobic digesting of it,” Lefeb-

vre said.

In addition to property taxes that would accrue on the state-of-the-art biogas facility worth tens of millions of dollars, the proposed plant would dramatically impact the Sauk Centre community in several ways.

Referencing data from Nature Energy’s European portfolio, Nielsen said one biogas plant would generate about $15 million in local revenue each year. Nielsen said through an email that the company was eager to partner with local government and had not yet discussed tax abatement plans.

The plant would bring an estimated 12 to 16 full-time jobs to the Sauk Centre community, with 65 to 75 additional full-time indirect positions. The company projects 650,000 man hours for facility construction.

The Shell subsidiary ensured it would be a corporate neighbor in Sauk Centre, supporting the community with initiatives like local scholarship funds. Nielsen said Nature Energy was open to working with local schools to provide educational opportunities for students.

The plant would operate from 6 a.m. until 8 p.m. on weekdays and 8

a.m. until 2 p.m. on Saturday. Trafc for the Benson plant was estimated to account for about 90 trucks daily during the week and roughly half that gure on Saturday.